Page 1

TeSys DFB Library V2 for Unity Pro

1672609EN-03 01/2020

TeSys DFB Library V2 for Unity

Pro

a SoCollaborative library

User Manual

01/2020

1672609EN-03

www.se.com

Page 2

The information provided in this documentation contains general descriptions and/or technical characteristics of the performance of the products contained herein. This documentation is not intended as a

substitute for and is not to be used for determining suitability or reliability of these products for specific user

applications. It is the duty of any such user or integrator to perform the appropriate and complete risk

analysis, evaluation and testing of the products with respect to the relevant specific application or use

thereof. Neither Schneider Electric nor any of its affiliates or subsidiaries shall be responsible or liable for

misuse of the information contained herein. If you have any suggestions for improvements or amendments

or have found errors in this publication, please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of this

document on any medium whatsoever without permission of Schneider Electric, given in writing. You also

agree not to establish any hypertext links to this document or its content. Schneider Electric does not grant

any right or license for the personal and noncommercial use of the document or its content, except for a

non-exclusive license to consult it on an "as is" basis, at your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and using this

product. For reasons of safety and to help ensure compliance with documented system data, only the

manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions must

be followed.

Failure to use Schneider Electric software or approved software with our hardware products may result in

injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2020 Schneider Electric. All rights reserved.

2 1672609EN-03 01/2020

Page 3

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TeSys DFB Library Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TeSys DFB Sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Modbus SL DFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Ctrl_cmd_mdb_u_••••: TeSys U Control/Command for Modbus SL. . . . . . . . . . . . . . . . . . . .

Comm_manager_u: TeSys U Communication Management for Modbus SL . . . . . . . . . . . .

Ctrl_cmd_mdb_t_••••: TeSys T Control/Command for Modbus SL . . . . . . . . . . . . . . . . . . . .

Comm_manager_t: TeSys T Communication Management for Modbus SL . . . . . . . . . . . . .

Chapter 3 Modbus SL and Modbus/TCP DFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Special_mdb_u_••••: TeSys U DFB for Modbus SL and Modbus/TCP . . . . . . . . . . . . . . . . .

Special_mdb_t_••••: TeSys T DFB for Modbus SL and Modbus/TCP . . . . . . . . . . . . . . . . . .

Custom_mdb_••••: Custom Read DFB for Modbus SL and Modbus/TCP . . . . . . . . . . . . . . .

Chapter 4 Modbus/TCP DFB for Quantum PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Special_mdb_u_addq: TeSys U DFB for Modbus/TCP for Quantum PLC . . . . . . . . . . . . . .

Special_mdb_t_addq: TeSys T DFB for Modbus/TCP for Quantum PLC . . . . . . . . . . . . . . .

Custom_mdb_addq: Custom Read DFB for Modbus/TCP for Quantum PLC . . . . . . . . . . . .

Chapter 5 Profibus DFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Ctrl_pfb_u_ms: TeSys U Control/Command for Profibus DP MS . . . . . . . . . . . . . . . . . . . . .

Ctrl_pfb_u_mms: TeSys U Control/Command for Profibus DP MMS . . . . . . . . . . . . . . . . . .

Ctrl_pfb_t_mms: TeSys T Control/Command for Profibus DP MMS . . . . . . . . . . . . . . . . . . .

Chapter 6 Cyclic Control/Command DFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Ctrl_cmd_u: TeSys U Cyclic Control/Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ctrl_cmd_t: TeSys T Cyclic Control/Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7 PKW Exchanges DFB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Special_pkw_u: TeSys U DFB for PKW Exchanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special_pkw_t: TeSys T DFB for PKW Exchanges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom_pkw: Custom Read DFB for PKW Exchanges. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8 Treatment DFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Scale: TeSys U DFB for Measurement Unit Conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timestamp_•: TeSys U DFB for Data Time-Stamping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

13

17

22

26

30

34

40

46

58

62

68

78

82

84

86

90

92

96

102

113

118

120

1672609EN-03 01/2020 3

Page 4

4 1672609EN-03 01/2020

Page 5

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before

trying to install, operate, service, or maintain it. The following special messages may appear throughout

this documentation or on the equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel.

No responsibility is assumed by Schneider Electric for any consequences arising out of the use of this

material.

A qualified person is one who has skills and knowledge related to the construction and operation of

electrical equipment and its installation, and has received safety training to recognize and avoid the

hazards involved.

BEFORE YOU BEGIN

Do not use this product on machinery lacking effective point-of-operation guarding. Lack of effective pointof-operation guarding on a machine can result in serious injury to the operator of that machine.

1672609EN-03 01/2020 5

Page 6

WARNING

UNGUARDED EQUIPMENT

Do not use this software and related automation equipment on equipment which does not have point-

of-operation protection.

Do not reach into machinery during operation.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

This automation equipment and related software is used to control a variety of industrial processes. The

type or model of automation equipment suitable for each application will vary depending on factors such

as the control function required, degree of protection required, production methods, unusual conditions,

government regulations, etc. In some applications, more than one processor may be required, as when

backup redundancy is needed.

Only you, the user, machine builder or system integrator can be aware of all the conditions and factors

present during setup, operation, and maintenance of the machine and, therefore, can determine the

automation equipment and the related safeties and interlocks which can be properly used. When selecting

automation and control equipment and related software for a particular application, you should refer to the

applicable local and national standards and regulations. The National Safety Council's Accident Prevention

Manual (nationally recognized in the United States of America) also provides much useful information.

In some applications, such as packaging machinery, additional operator protection such as point-ofoperation guarding must be provided. This is necessary if the operator's hands and other parts of the body

are free to enter the pinch points or other hazardous areas and serious injury can occur. Software products

alone cannot protect an operator from injury. For this reason the software cannot be substituted for or take

the place of point-of-operation protection.

Ensure that appropriate safeties and mechanical/electrical interlocks related to point-of-operation

protection have been installed and are operational before placing the equipment into service. All interlocks

and safeties related to point-of-operation protection must be coordinated with the related automation

equipment and software programming.

NOTE: Coordination of safeties and mechanical/electrical interlocks for point-of-operation protection is

outside the scope of the Function Block Library, System User Guide, or other implementation referenced

in this documentation.

START-UP AND TEST

Before using electrical control and automation equipment for regular operation after installation, the system

should be given a start-up test by qualified personnel to verify correct operation of the equipment. It is

important that arrangements for such a check be made and that enough time is allowed to perform

complete and satisfactory testing.

Follow all start-up tests recommended in the equipment documentation. Store all equipment

documentation for future references.

Software testing must be done in both simulated and real environments.

Verify that the completed system is free from all short circuits and temporary grounds that are not installed

according to local regulations (according to the National Electrical Code in the U.S.A, for instance). If highpotential voltage testing is necessary, follow recommendations in equipment documentation to prevent

accidental equipment damage.

Before energizing equipment:

Remove tools, meters, and debris from equipment.

Close the equipment enclosure door.

WARNING

EQUIPMENT OPERATION HAZARD

Verify that all installation and set up procedures have been completed.

Before operational tests are performed, remove all blocks or other temporary holding means used for

shipment from all component devices.

Remove tools, meters, and debris from equipment.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

6 1672609EN-03 01/2020

Page 7

Remove all temporary grounds from incoming power lines.

Perform all start-up tests recommended by the manufacturer.

OPERATION AND ADJUSTMENTS

The following precautions are from the NEMA Standards Publication ICS 7.1-1995 (English version

prevails):

Regardless of the care exercised in the design and manufacture of equipment or in the selection and

ratings of components, there are hazards that can be encountered if such equipment is improperly

operated.

It is sometimes possible to misadjust the equipment and thus produce unsatisfactory or unsafe

operation. Always use the manufacturer’s instructions as a guide for functional adjustments. Personnel

who have access to these adjustments should be familiar with the equipment manufacturer’s

instructions and the machinery used with the electrical equipment.

Only those operational adjustments actually required by the operator should be accessible to the

operator. Access to other controls should be restricted to prevent unauthorized changes in operating

characteristics.

1672609EN-03 01/2020 7

Page 8

8 1672609EN-03 01/2020

Page 9

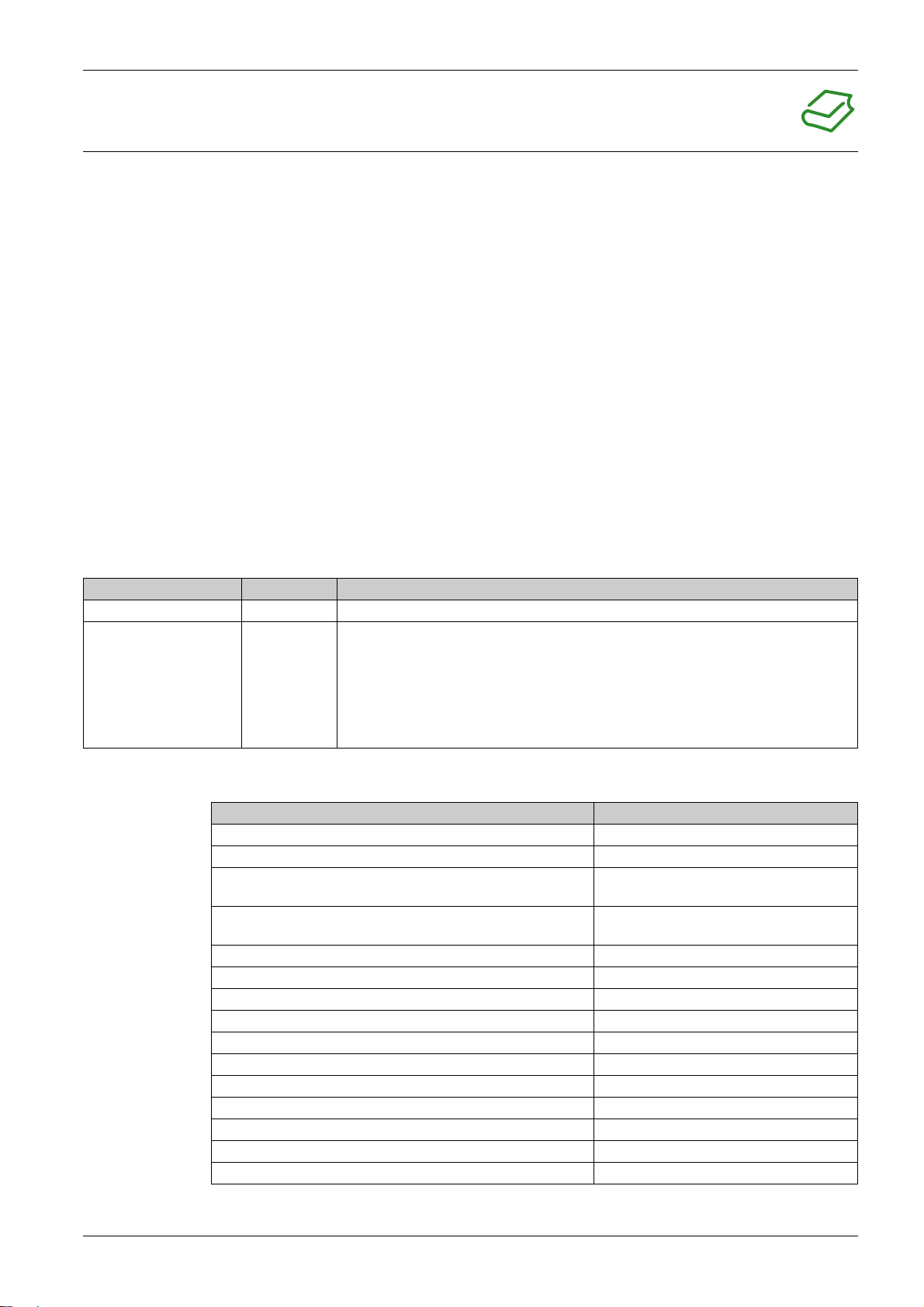

At a Glance

Document Scope

Validity Note

About the Book

This manual describes the DFB (Derived Function Block) library dedicated to TeSys U starter-controllers

and TeSys T motor management systems.

It is intended for design engineers and system integrators who have a good knowledge of Unity Pro PLC

programming platforms.

The purposes of this manual are to

describe the scope of the DFB library and platform compatibility,

describe the DFB characteristics and the download procedure from the Schneider Electric website,

explain how to implement the DFB in the PLC application.

This TeSys library is compatible and usable with the following versions of Unity Pro:

Unity Pro V2.3 SP2

Unity Pro V3.0

Unity Pro V3.1

Unity Pro V4.0 or later

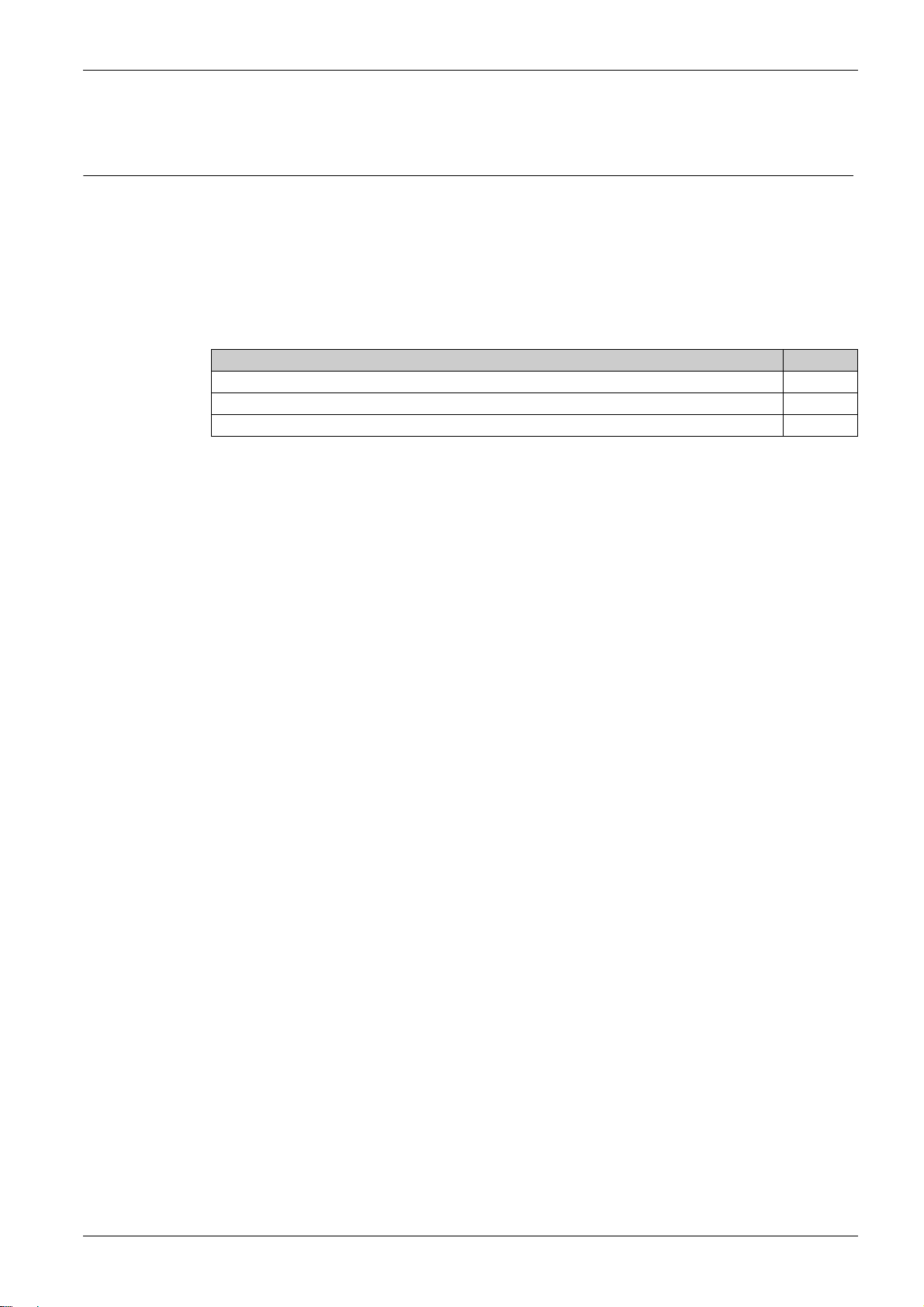

This manual is valid for all TeSys DFBs. The following table describes the differences between versions 1

and 2 of Unity Pro:

Library Version Date Evolution

V1 03/2009 Initial version

V2 09/2009 Addition of 3 new DFBs for Quantum PLC:

Special_mdb_u_addq

Special_mdb_t_addq

Custom_mdb_addq

Evolution of 2 existing DFBs to be compatible with Quantum PLC:

Ctrl_cmd_u

Ctrl_cmd_t

Related Documents

Title of Documentation Reference Number

TeSys U LUCM and LUCMT Multifunction Control Unit User Manual 1743237

TeSys U Communication Variables User Manual 1744082

TeSys U LULC032-033 Modbus Communication Module User M

anual

TeSys U LULC15 Advantys STB Communication Module User

Manual

TeSys U LULC08 CANopen Communication Module User Manual 1744084

TeSys U LULC07 Profibus DP Communication Module User Manual 1672610

TeSys T LTMR Motor Management Controller - User Guide DOCA0127

TeSys T LTMR Ethernet Communication Guide DOCA0129

TeSys T LTMR Modbus Communication Guide DOCA0130

TeSys T LTMR PROFIBUS DP Communication Guide DOCA0131

TeSys T LTMR CANopen Communication Guide DOCA0132

LAD9AP3•• Quickfit Instruction Sheet 1568984

LUFC00 Parallel Wiring Module Instruction Sheet 1743239

LU9G02 Splitter Box Instruction Sheet 1638822

LU9G03 Splitter Box Instruction Sheet AAV90641

1743234

1744083

1672609EN-03 01/2020 9

Page 10

You can download these technical publications and other technical information from our website at

https://www.se.com/ww/en/download/ .

10 1672609EN-03 01/2020

Page 11

TeSys DFB Library V2 for Unity Pro

Introduction

1672609EN-03 01/2020

Introduction

Chapter 1

Introduction

Introduction

This chapter gives an overview of the TeSys U and TeSys T DFB (Derived Function Block) library,

presents the DFB library download procedure from the Schneider Electric website, and describes the

sequencing system used to synchronize the treatment between DFBs.

What Is in This Chapter?

This chapter contains the following topics:

Presentation 12

TeSys DFB Library Overview 13

TeSys DFB Sequencing 17

Topic Page

1672609EN-03 01/2020 11

Page 12

Introduction

Presentation

Aim of the TeSys DFB Library

The TeSys DFB library has been developed to simplify and optimize the integration of TeSys U startercontrollers and TeSys T motor management systems in PLC applications, for both PLC programmers and

end users.

The TeSys DFB library for Unity Pro can be ordered with part number UNYLTSZFUWB.

Advantages for the PLC Programmer

The TeSys DFB library enables the PLC programmer to

simplify the program design: the program is split by functions (control, command, data treatment,...),

optimize the programming time: the DFB is tested and can be re-used for different applications,

increase the program understanding: the applications are coded in the same way using the common

DFB,

optimize the program size: the same code is used for each DFB instantiation,

simplify the TeSys U and TeSys T integration: the data mapping management is masked.

Advantages for the End User

The TeSys DFB library enables the end user to

optimize the communication response time:

the Modbus requests management is optimized,

the data exchange management is optimized,

the product performance is taken into account,

have a functional view of the motor-starter by providing direct access to common functions (Ready,

Alarm, Run, Stop,...),

group data related to a specific application (diagnostic, maintenance, measurement,...) through a

program number,

facilitate debugging: variables used by the DFB are identified on its interface.

PLC Platform Compatibility

The TeSys DFB library can be integrated in the Unity Pro programming platform with Quantum, Premium

and M340 PLC platforms.

TeSys Compatibility

The TeSys DFB library for Unity Pro is compatible with:

TeSys U starter-controllers (up to 38 A/18.5 kW or 25 hp),

TeSys T motor management system.

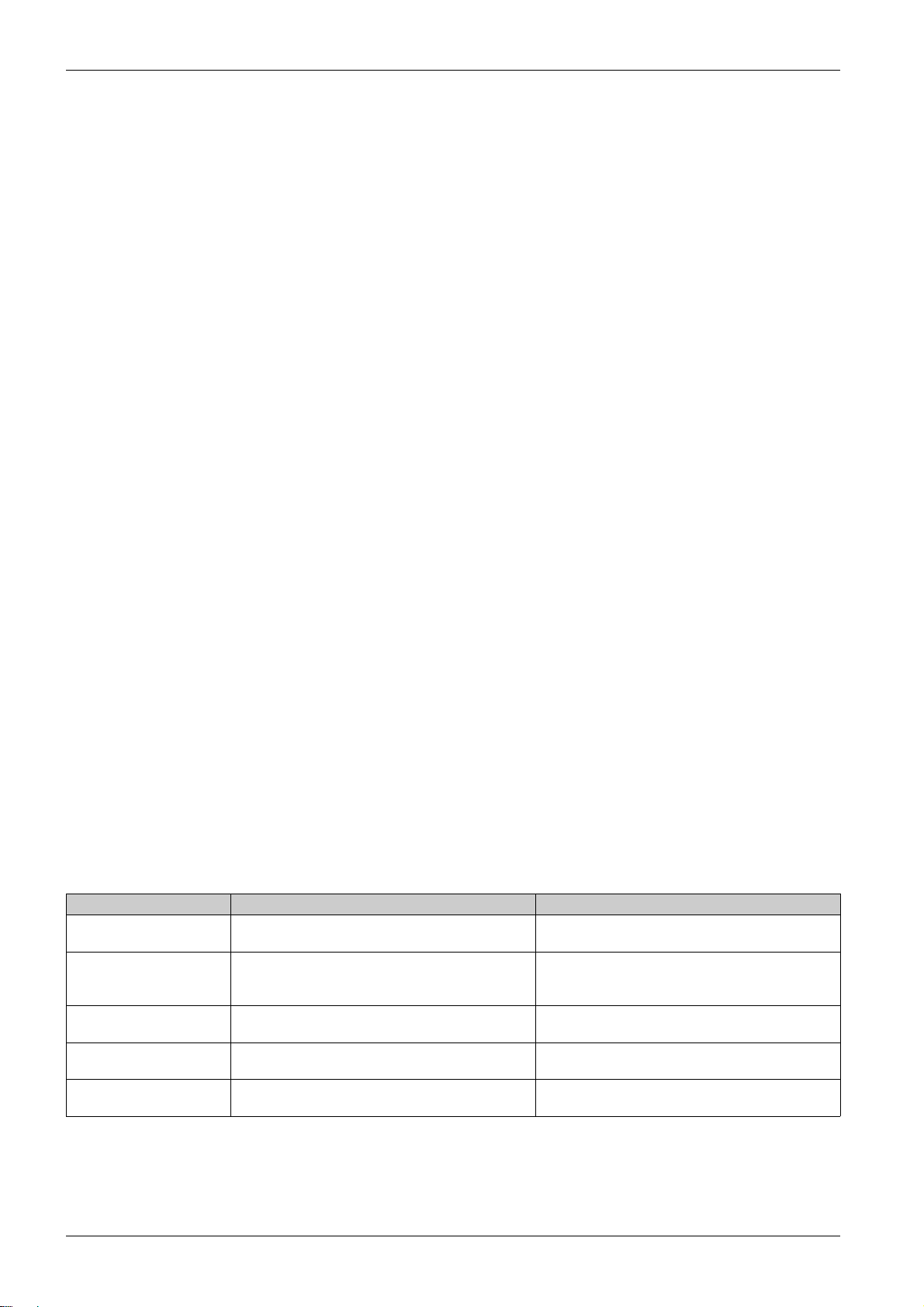

Communication Protocol Compatibility

The following table describes the TeSys DFB library compatibility with communication protocols and the

corresponding TeSys U and TeSys T assemblies.

Protocol TeSys U TeSys T

Modbus SL

(Serial Line)

Modbus/TCP Starter-controller with LULC033 Modbus

Profibus DP Starter-controller with LULC07 Profibus DP

CANopen Starter-controller with LULC08 CANopen

Advantys STB with

communication module

Starter-controller with LULC033 Modbus

communication module

communication module and Ethernet gateway

(TeSysPort, TSXETG100, TSXETG1000,...)

communication module

communication module

Starter-controller with LULC15 Advantys STB

communication module

LTMR••M•• Modbus SL controller with or without the

LTM E expansion module

LTMR••E•• Modbus/TCP controller with or without the

LTM E expansion module

LTMR••P•• Profibus DP controller with or without the

LTM E expansion module

LTMR••C•• CANopen controller with or without the

LTM E expansion module

–

12

1672609EN-03 01/2020

Page 13

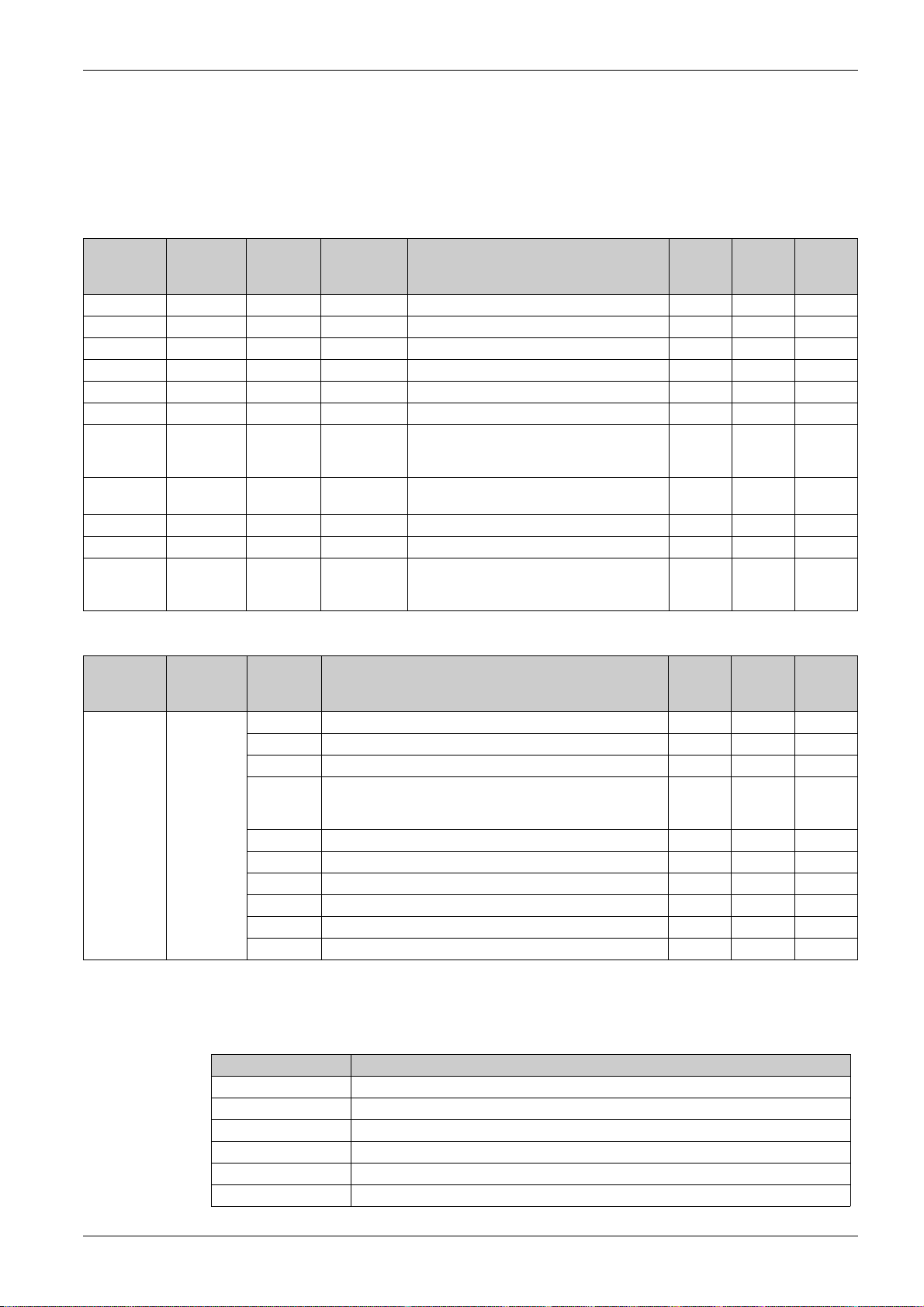

TeSys DFB Library Overview

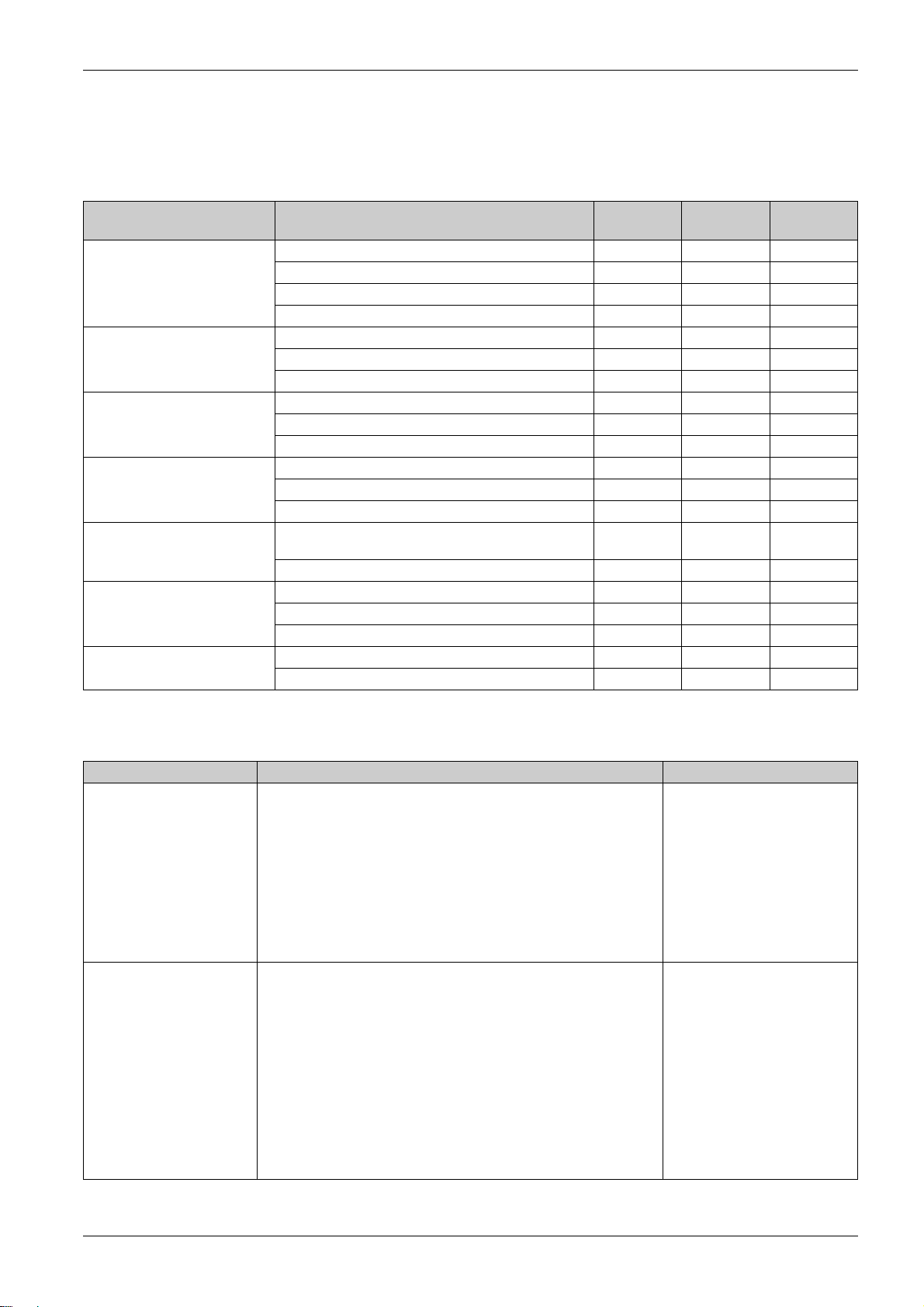

TeSys DFB Library Organization

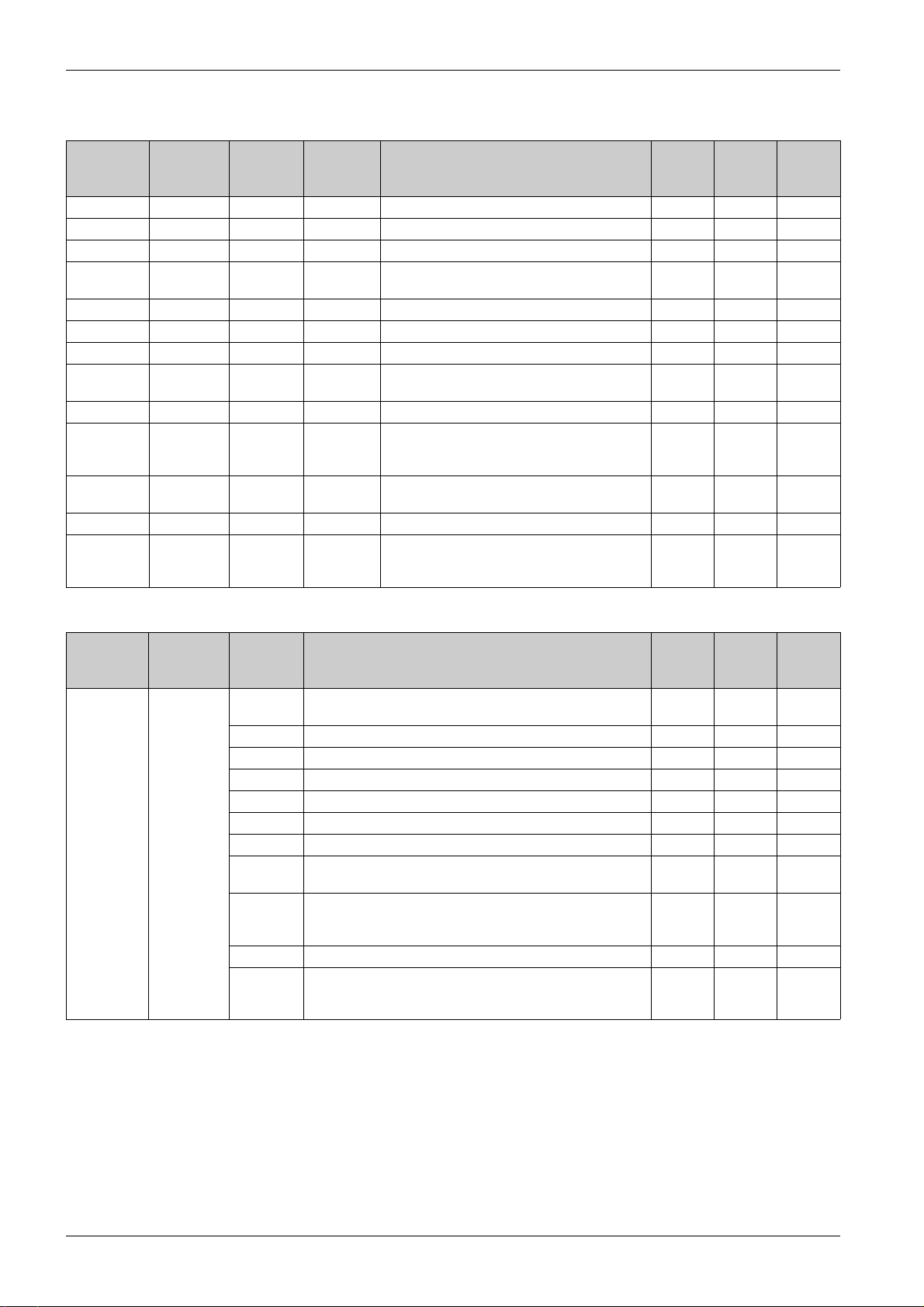

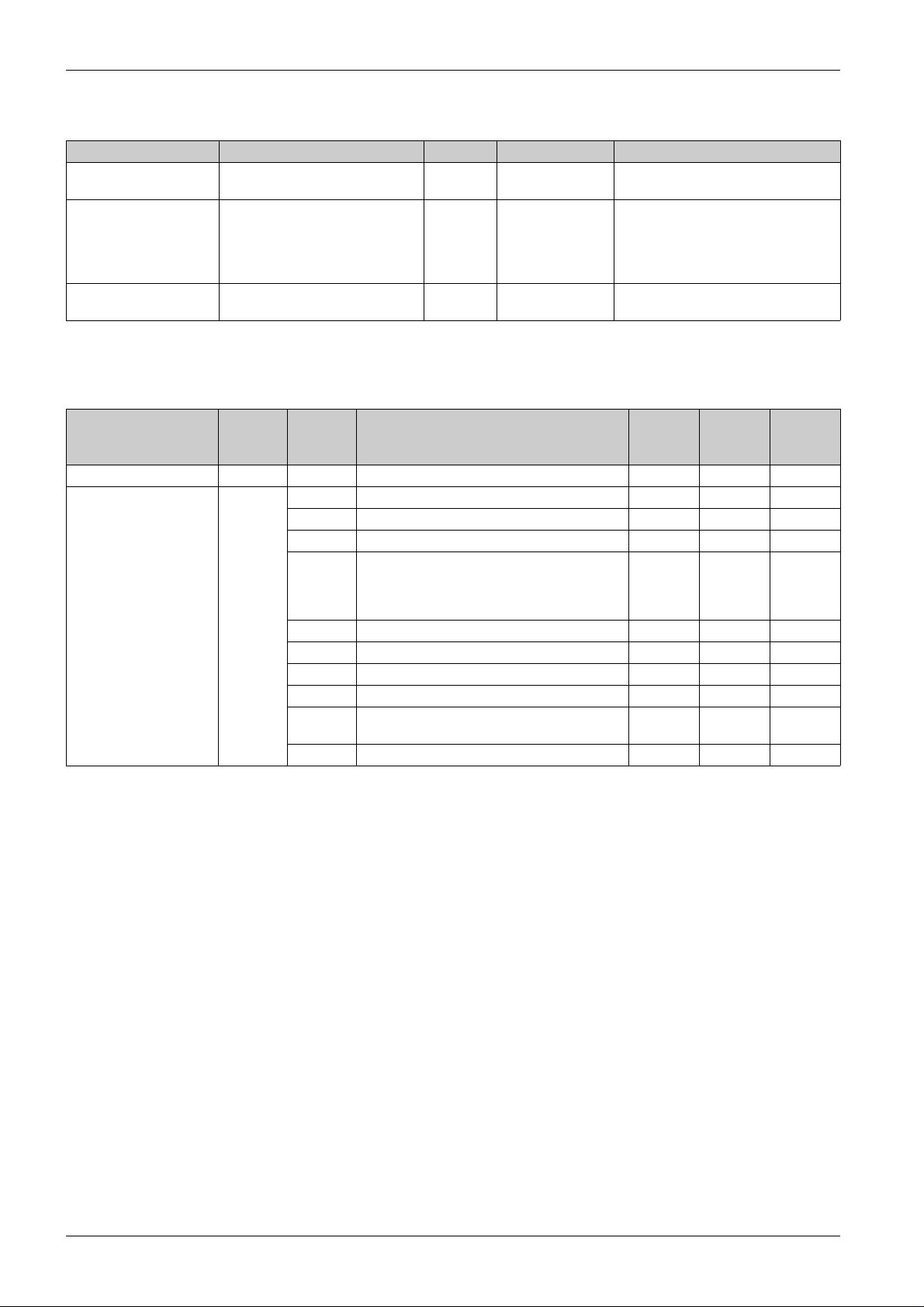

The following table lists the TeSys DFB library according to the communication protocol and service and

their availability according to the TeSys model:

Introduction

Communication Protocol /

Service

Modbus SL Ctrl_cmd_mdb_u_•••• √ √ –

Modbus SL and Modbus/TCP Custom_mdb_•••• √ – √

Modbus/TCP (for Quantum PLC) Custom_mdb_addq √ – √

Profibus DP Ctrl_pfb_u_ms √ √ –

Cyclic control/command

(Modbus/TCP (IO scanning),

CANopen, and Advantys STB)

PKW Special_pkw_u √ – –

Treatment Timestamp_• √ – –

DFB Name TeSys U up to

32 A

Comm_manager_u √ √ –

Ctrl_cmd_mdb_t_•••• – – √

Comm_manager_t – – √

Special_mdb_u_•••• √ – –

Special_mdb_t_•••• – – √

Special_mdb_u_addq √ – –

Special_mdb_t_addq – – √

Ctrl_pfb_u_mms √ – –

Ctrl_pfb_t_mms – – √

Ctrl_cmd_u (Modbus/TCP (IO scanning), CANopen, and

Advantys STB)

Ctrl_cmd_t (Modbus/TCP (IO scanning) and CANopen) – – √

Special_pkw_t – – √

Custom_pkw √ – √

Scale √ – –

√√–

TeSys U up to

38 A

TeSys T

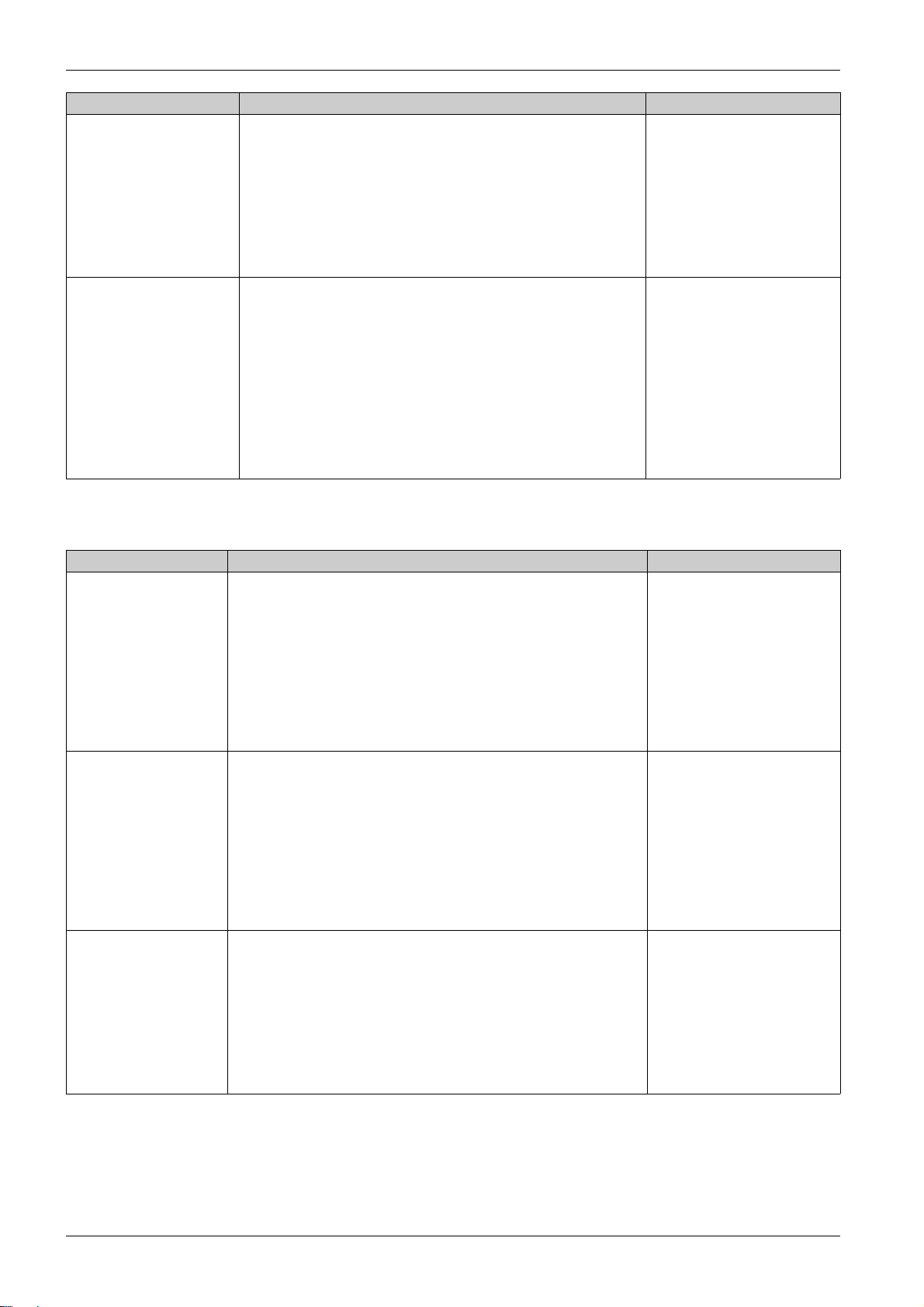

Modbus SL DFB Library

The following table describes the Modbus SL (Serial Line) DFB library:

DFB Description For More Information

Ctrl_cmd_mdb_u_addr

Ctrl_cmd_mdb_u_addm

Comm_manager_u This DFB is dedicated to the control and command of up to 31 TeSys U

These DFBs are dedicated to the control and command of a single TeS ys

U starter-controller with any control unit and a LULC033 Modbus

communication module.

Ctrl_cmd_mdb_u_addr is dedicated to Premium PLC.

Ctrl_cmd_mdb_u_addm is dedicated to M340 PLC.

These DFBs enable the user to

read status register 455,

write command register 704,

reset communication loss (register 703, bit 3).

The program number enables the user to select bit or word control.

starter-controllers with any control unit and a LULC033 Modbus

communication module.

It must be associated with the Ctrl_cmd_mdb_u_•••• DFBs to manage the

Modbus requests sequencing.

It enables the user to

optimize the response time by taking into account the response time

of the devices,

send write requests only when necessary,

manage the disconnection and reconnection of a TeSys U Modbus

slave.

The program number enables the user to select different Modbus request

sequences.

Ctrl_cmd_mdb_u_••••: TeSys U

Control/Command for Modbus

SL, page 22

Comm_manager_u: TeSys U

Communication Management for

Modbus SL, page 26

1672609EN-03 01/2020 13

Page 14

Introduction

DFB Description For More Information

Ctrl_cmd_mdb_t_addr

Ctrl_cmd_mdb_t_addm

These DFBs are dedicated to the control and command of a single TeSys

T LTMR••M•• Modbus SL controller with or without the LTM E expansion

module.

Ctrl_cmd_mdb_t_addr is dedicated to Premium PLC.

Ctrl_cmd_mdb_t_addm is dedicated to M340 PLC.

Ctrl_cmd_mdb_t_••••: TeSys T

Control/Command for Modbus

SL, page 30

These DFBs enable the user to

read status registers 455 and 456,

write command register 704.

The program number enables the user to select bit or word control.

Comm_manager_t This DFB is dedicated to the control and command of several TeSys T

LTMR••M•• Modbus SL controllers with or without the LTM E expansion

module. It must be associated with the Ctrl_cmd_mdb_t_•••• DFBs to

Comm_manager_t: TeSys T

Communication Management for

Modbus SL, page 34

manage the Modbus requests sequencing.

It enables the user to

optimize the response time by taking into account the response time

of the devices,

send write requests only when necessary,

manage the disconnection and reconnection of a TeSys U Modbus

slave.

The program number enables the user to select different Modbus

requests sequences.

Modbus SL and Modbus/TCP Library

The following table describes the Modbus SL and Modbus/TCP library:

DFB Description For More Information

Special_mdb_u_addr

Special_mdb_u_addm

Special_mdb_t_addr

Special_mdb_t_addm

Custom_mdb_addr

Custom_mdb_addm

These DFBs are dedicated to the reading of up to 16 predefined registers

(diagnostic, maintenance, measurement,...) of a TeSys U starter-controller

(up to 32 A/15 kW or 20 hp) with a LUCM multifunction control unit and a

LULC033 Modbus communication module.

The program number enables the user to select the predefined registers.

Special_mdb_u_addr is dedicated to Premium PLC and can be used with

a TeSys U starter-controller connected on Modbus Serial Line or through

a Modbus/TCP gateway.

Special_mdb_u_addm is dedicated to M340 PLC and can be used with

a TeSys U starter-controller connected on Modbus Serial Line or through

a Modbus/TCP gateway.

These DFBs are dedicated to the reading of up to 16 predefined registers

(diagnostic, maintenance, measurement,...) of a TeSys T Modbus SL

controller or TeSys T Modbus/TCP controller with or without the LTM E

expansion module.

The program number enables the user to select the predefined registers.

Special_mdb_t_addr is dedicated to Premium PLC and can be used with

a TeSys T controller LTMR••M•• connected through Modbus Serial Line

or a TeSys T controller LTMR••E•• through a Modbus/TCP network.

Special_mdb_t_addm is dedicated to M340 PLC and can be used with a

TeSys T controller LTMR••M•• connected through Modbus Serial Line or

a TeSys T controller LTMR••E•• through a Modbus/TCP network.

These DFBs are dedicated to the reading of up to 5 sets of registers in one

single TeSys device.

A set of registers is defined by the address of the first register to read and

the length of the set (up to 16 registers per set).

Custom_mdb_addr is dedicated to Premium PLC and can be used with

a TeSys connected through Modbus Serial Line or through a

Modbus/TCP network.

Custom_mdb_addm is dedicated to M340 PLC and can be used with a

TeSys connected through Modbus Serial Line or through a Modbus/TCP

network.

Special_mdb_u_••••: TeSys U

DFB for Modbus SL and

Modbus/TCP, page 40

Special_mdb_t_••••: TeSys T

DFB for Modbus SL and

Modbus/TCP, page 46

Custom_mdb_••••: Custom Read

DFB for Modbus SL and

Modbus/TCP, page 58

14

1672609EN-03 01/2020

Page 15

Modbus/TCP Quantum Library

The following table describes the Modbus/TCP DFB library dedicated to Quantum PLC:

DFB Description For More Information

Special_mdb_u_addq This DFB is dedicated to the reading of up to 16 predefined registers

(diagnostic, maintenance, measurement,...) in a TeSys U starter-controller

(up to 32 A/15 kW or 20 hp) with a LUCM multifunction control unit and a

LULC033 Modbus communication module through a Modbus/TCP gateway

connected to a Quantum PLC.

The program number enables the user to select the predefined registers.

Special_mdb_t_addq This DFB is dedicated to the reading of up to 16 predefined registers

(diagnostic, maintenance, measurement,...) in a TeSys T Modbus/TCP

LTMR••E•• controller with or without the LTM E expansion module

connected to a Quantum PLC.

The program number enables the user to select the predefined registers.

Custom_mdb_addq This DFB is dedicated to the reading of up to 5 sets of registers in one single

TeSys device connected through Modbus/TCP to a Quantum PLC.

A set of registers is defined by the address of the first register to read and

the length of the set (up to 16 registers per set).

Special_mdb_u_addq: TeSys U

DFB for Modbus/TCP for

Quantum PLC, page 62

Special_mdb_t_addq: TeSys T

DFB for Modbus/TCP for

Quantum PLC, page 68

Custom_mdb_addq: Custom

Read DFB for Modbus/TCP for

Quantum PLC, page 78

Profibus DP DFB Library

The following table describes the Profibus DP DFB library:

DFB Description For More Information

Ctrl_pfb_u_ms This DFB is dedicated to the control and command of a single TeSys U

starter-controller with any control unit and a LULC07 Profibus DP

communication module using the Motor Starter profile.

Ctrl_pfb_u_mms This DFB is dedicated to the control and command of a single TeSys U

starter-controller (up to 32 A/15 kW or 20 hp) with a LUCM multifunction

control unit and a LULC07 Profibus DP communication module using the

Motor Management Starter profile.

Ctrl_pfb_t_ms This DFB is dedicated to the control and command of a single TeSys T

LTMR••P•• Profibus controller with or without the LTM E expansion module.

Ctrl_pfb_u_ms: TeSys U

Control/Command for Profibus DP

MS, page 82

Ctrl_pfb_u_mms: TeSys U

Control/Command for Profibus DP

MMS, page 84

Ctrl_pfb_t_mms: TeSys T

Control/Command for Profibus DP

MMS, page 86

Introduction

Cyclic Control/Command DFB Library

The following table describes the cyclic control/command (Modbus/TCP (IO scanning), CANopen, and

Advantys STB) DFB library:

DFB Description For More Information

Ctrl_cmd_u This DFB is dedicated to the control and command of a single TeSys U

starter-controller with any control unit and a LULC08 CANopen, a LULC15

STB communication module, or a LULC033 Modbus communication

module with an Ethernet gateway.

Ctrl_cmd_t This DFB is dedicated to the control and command of a single TeSys T

LTMR••C•• CANopen controller or a TeSys T LTMR••E•• Modbus/TCP

controller, with or without the LTM E expansion module.

Ctrl_cmd_u: TeSys U Cyclic

Control/Command, page 90

Ctrl_cmd_t: TeSys T Cyclic

Control/Command, page 92

1672609EN-03 01/2020 15

Page 16

Introduction

PKW DFB Library

The following table describes the PKW DFB library:

DFB Description For More Information

Special_pkw_u This DFB is dedicated to the reading of up to 16 predefined registers

(diagnostic, maintenance, measurement,...) of a single TeSys U startercontroller (up to 32 A/15 kW or 20 hp) with a LUCM multifunction control

unit and one of the following communication modules that support PKW

exchanges:

LULC07 (Profibus DP)

LULC08 (CANopen)

LULC15 (Advantys STB)

The program number enables the user to select the predefined registers.

Special_pkw_t This DFB is dedicated to the reading of up to 16 predefined registers

(diagnostic, maintenance, measurement,...) of a single TeSys T LTMR••P••

Profibus controller or a LTMR••C•• CANopen controller with or without the

LTM E expansion module.

The program number enables the user to select the predefined registers.

Custom_pkw This DFB is dedicated to the reading of up to 5 sets of registers of a single

TeSys device supporting PKW exchanges.

A set of registers is defined by the address of the first register to read and

the length of the set (up to 16 registers per set).

Special_pkw_u: TeSys U DFB for

PKW Exchanges, page 96

Special_pkw_t: TeSys T DFB for

PKW Exchanges, page 102

Custom_pkw: Custom Read DFB

for PKW Exchanges, page 113

Treatment DFB Library

The following table describes the treatment DFB library:

DFB Description For More Information

Scale This DFB is dedicated to the conversion of current measurement unit from

Timestamp

Timestamp_q

relative value (% FLA) to Amps for a TeSys U starter-controller (up to

32 A/15 kW or 20 hp) with a LUCM multifunction control unit. It also enables

the user to select another unit in the A...mA range.

These DFBs are dedicated to the time-stamping of up to 8 input registers of

a TeSys U starter-controller (up to 32 A/15 kW or 20 hp) with a LUCM

multifunction control unit. It provides an output table of the 8 time-stamped

registers and 4 date and time registers.

Timestamp is dedicated to Premium and M340 PLCs

Timestamp_q is dedicated to Quantum PLC.

Scale: TeSys U DFB for

Measurement Unit Conversion,

page 118

Timestamp_•: TeSys U DFB for

Data Time-Stamping, page 120

16

1672609EN-03 01/2020

Page 17

TeSys DFB Sequencing

Introduction

Some of the TeSys DFBs use a sequencing system using dedicated inputs and outputs that enable the

sequencing and the synchronization of the treatment between DFBs.

The following derived function blocks use a sequencing system:

Ctrl_cmd_mdb_u_••••

Ctrl_cmd_mdb_t_••••

Special_mdb_u_••••

Special_mdb_t_••••

Custom_mdb_••••

Special_pkw_u

Special_pkw_t

Custom_pkw

Timestamp_•

Sequencing System Principle

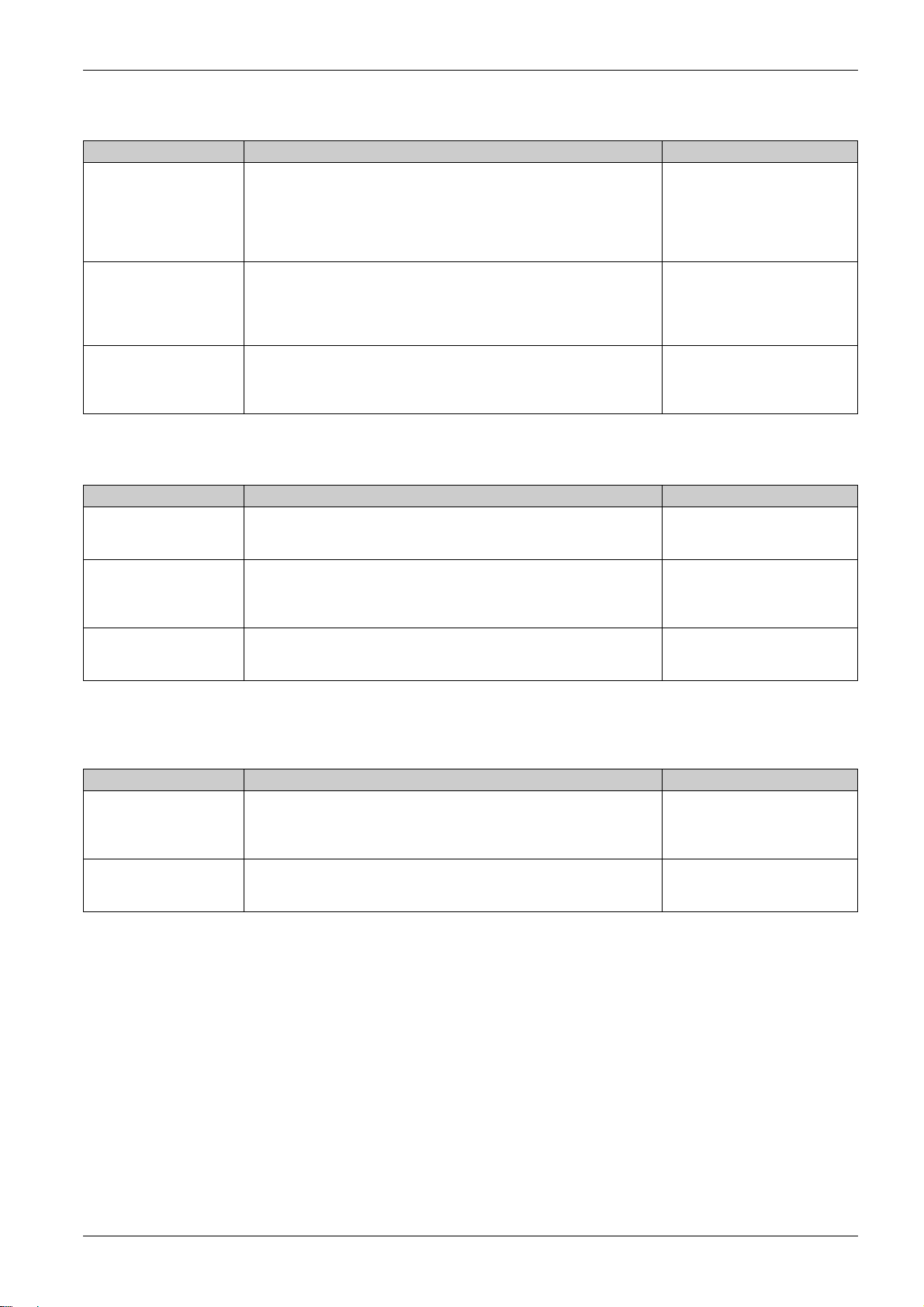

The sequencer has 2 boolean inputs and 3 boolean outputs:

Introduction

The _cmd suffix indicates a command dedicated to the DFB sequencer function.

The _st suffix indicates a status information concerning the DFB sequencer function.

The following table describes the sequencer inputs and outputs:

Input/Output Description

Rst_cmd This command resets the DFB and/or restarts the DFB treatment if Strt_cmd is set to 1.

Strt_cmd This command starts the DFB treatment.

Fault_st This status bit indicates

a parameterization error (value out of range),

a communication fault.

If a fault occurs, the applicative boolean outputs are reset to 0, and the output words are forced to –1.

Rst_st This status bit indicates

a reset in progress,

a treatment in progress.

End_st This status bit indicates the end of the DFB treatment.

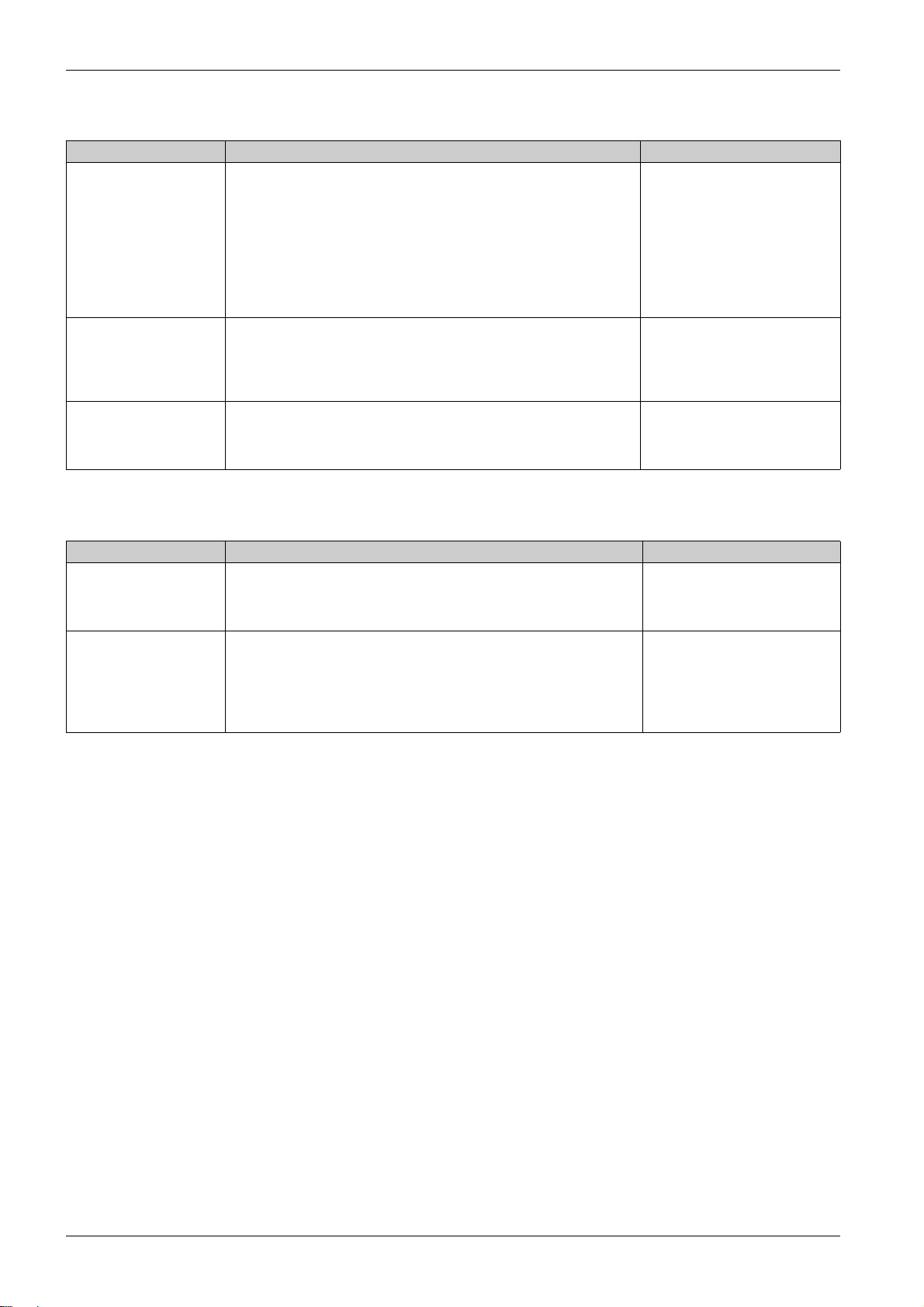

Stand-Alone with Manual Restart

In the stand-alone with manual restart configuration, the DFB is not linked to another DFB and it is activated

each time %M0 is set to 1:

1672609EN-03 01/2020 17

Page 18

Introduction

Stand-Alone with Automatic Restart

In the stand-alone with automatic restart configuration, the DFB is not linked to another DFB and it is

activated continuously when %M0 is set to 1:

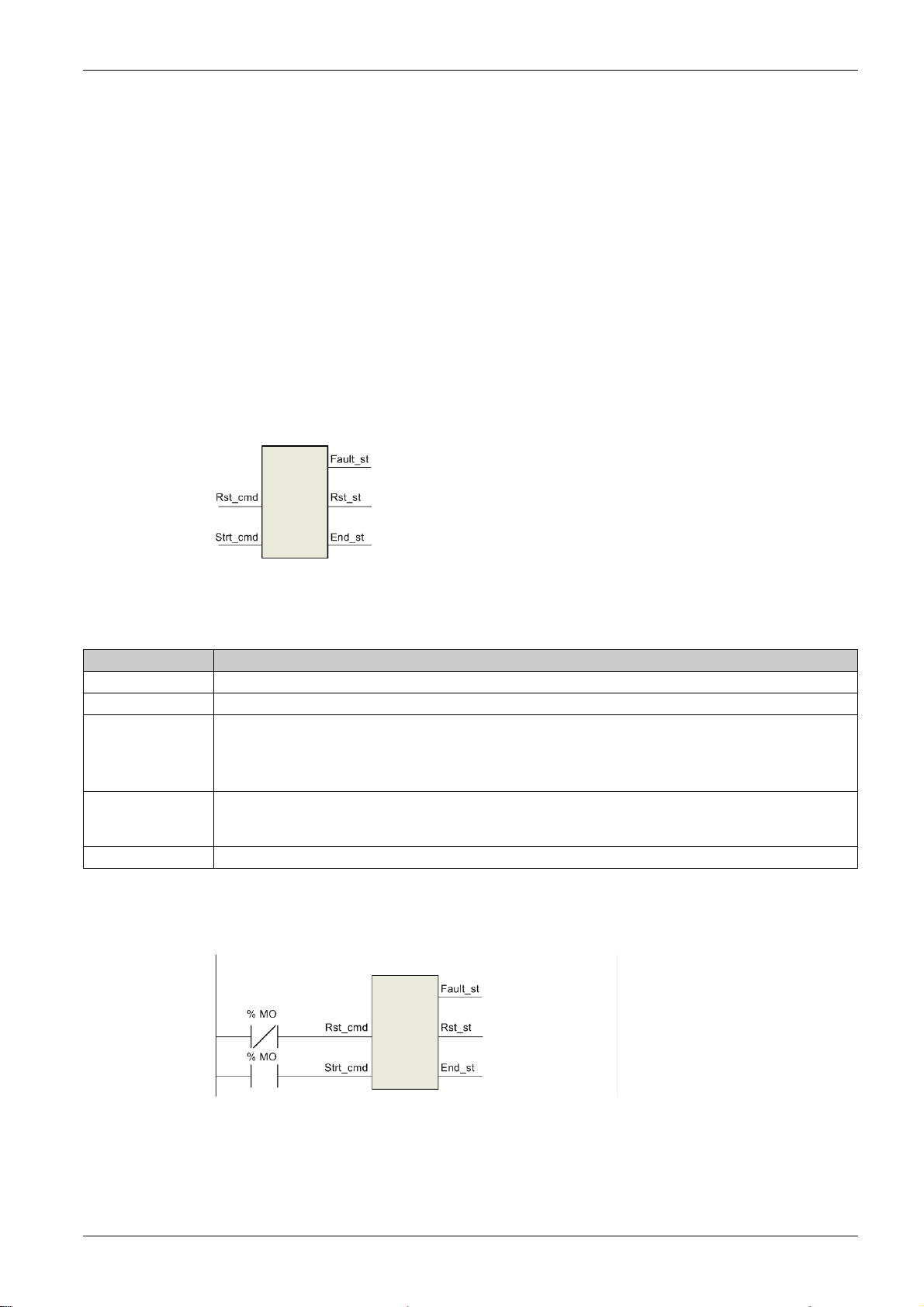

DFB Chaining with Manual Restart

In the DFB chaining with manual restart configuration, the DFB is linked to other DFBs and it is activated

each time %M0 is set to 1:

18

1672609EN-03 01/2020

Page 19

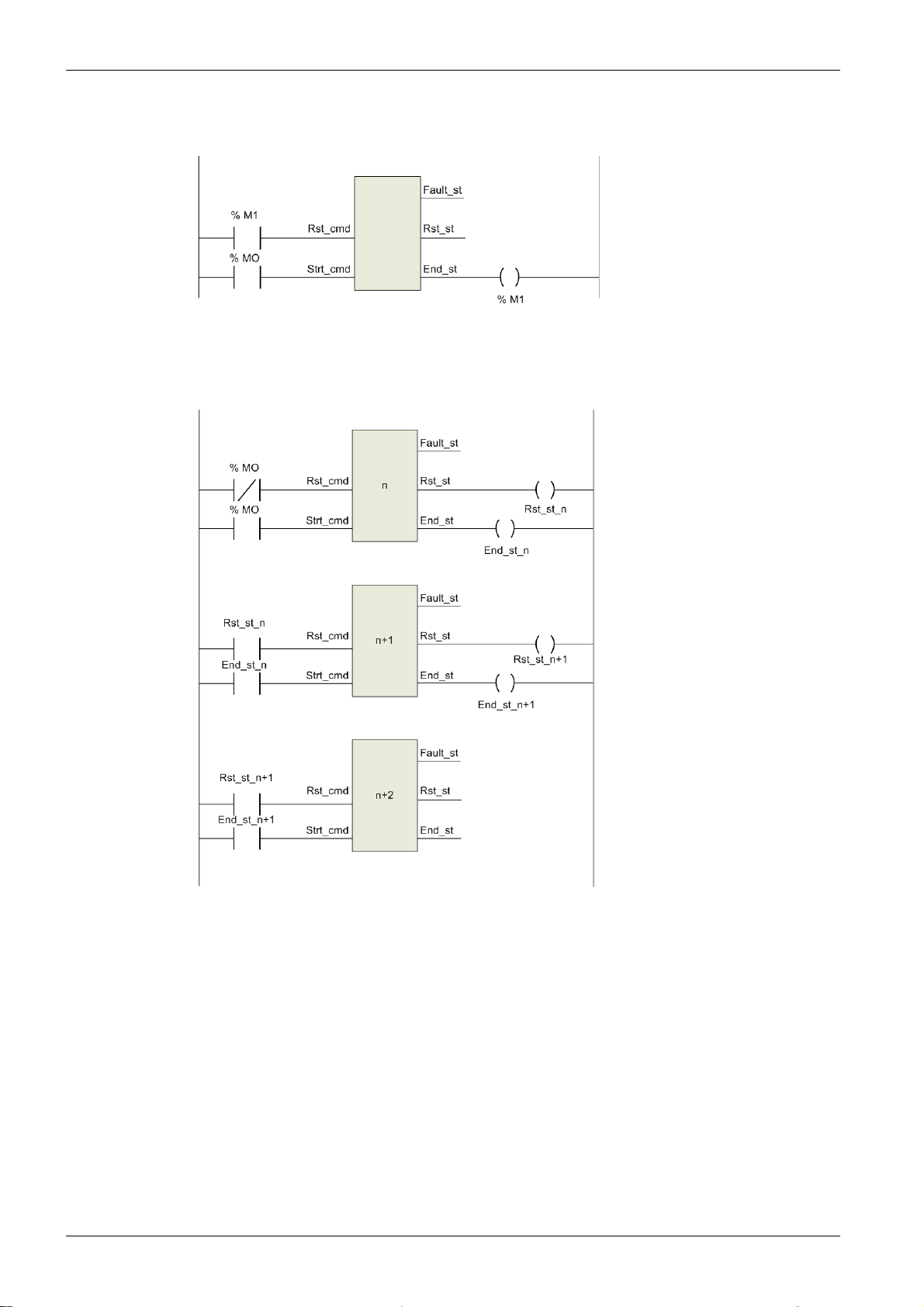

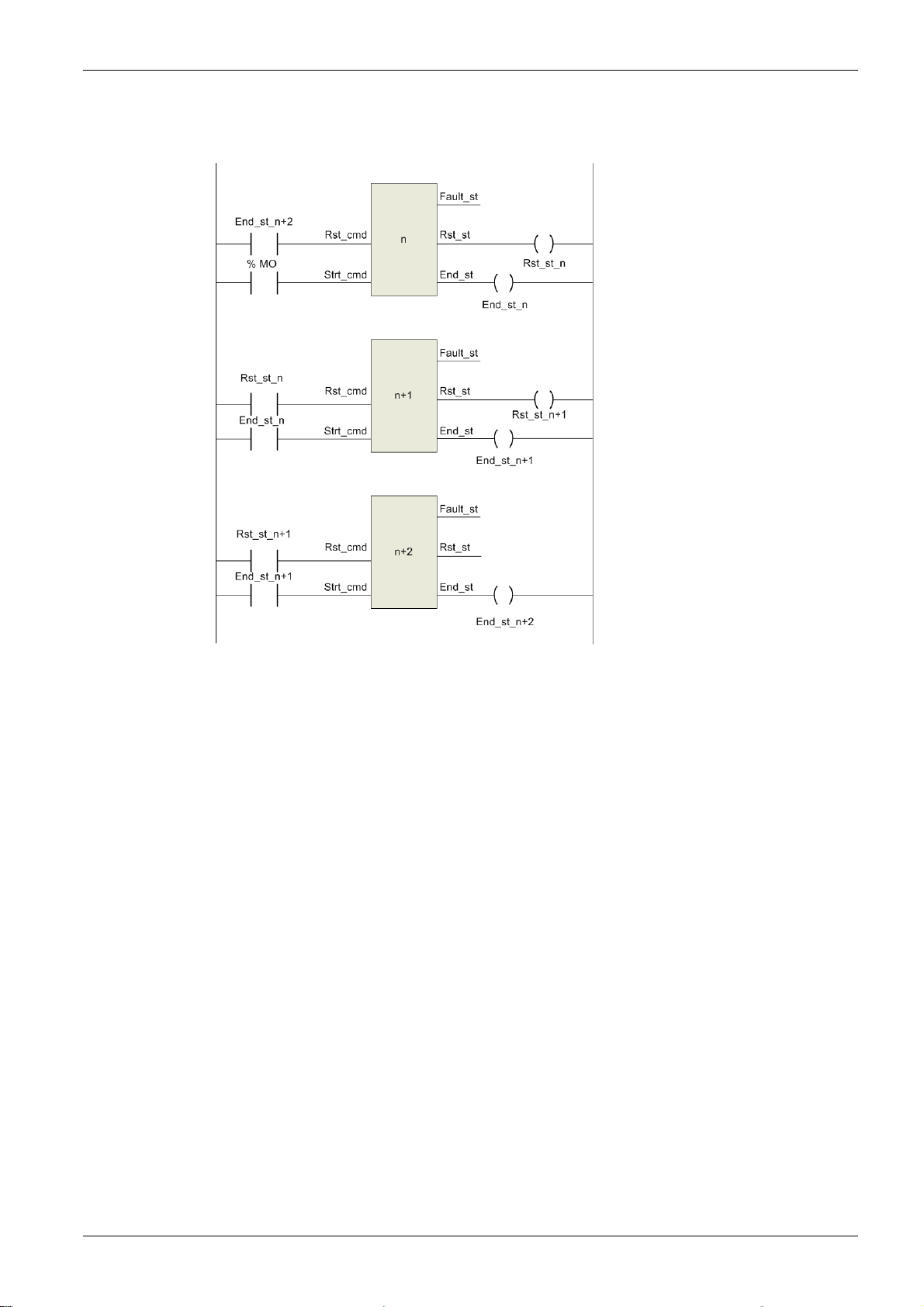

DFB Chaining with Automatic Restart

In the DFB chaining with automatic restart configuration, the DFB is linked to other DFBs and it is activated

continuously when %M0 is set to 1:

Introduction

1672609EN-03 01/2020 19

Page 20

Introduction

20

1672609EN-03 01/2020

Page 21

TeSys DFB Library V2 for Unity Pro

Modbus SL DFB

1672609EN-03 01/2020

Modbus SL DFB

Chapter 2

Modbus SL DFB

Introduction

This chapter describes the TeSys U and TeSys T Modbus SL (Serial Line) DFBs.

What Is in This Chapter?

This chapter contains the following topics:

Ctrl_cmd_mdb_u_••••: TeSys U Control/Command for Modbus SL 22

Comm_manager_u: TeSys U Communication Management for Modbus SL 26

Ctrl_cmd_mdb_t_••••: TeSys T Control/Command for Modbus SL 30

Comm_manager_t: TeSys T Communication Management for Modbus SL 34

Topic Page

1672609EN-03 01/2020 21

Page 22

Modbus SL DFB

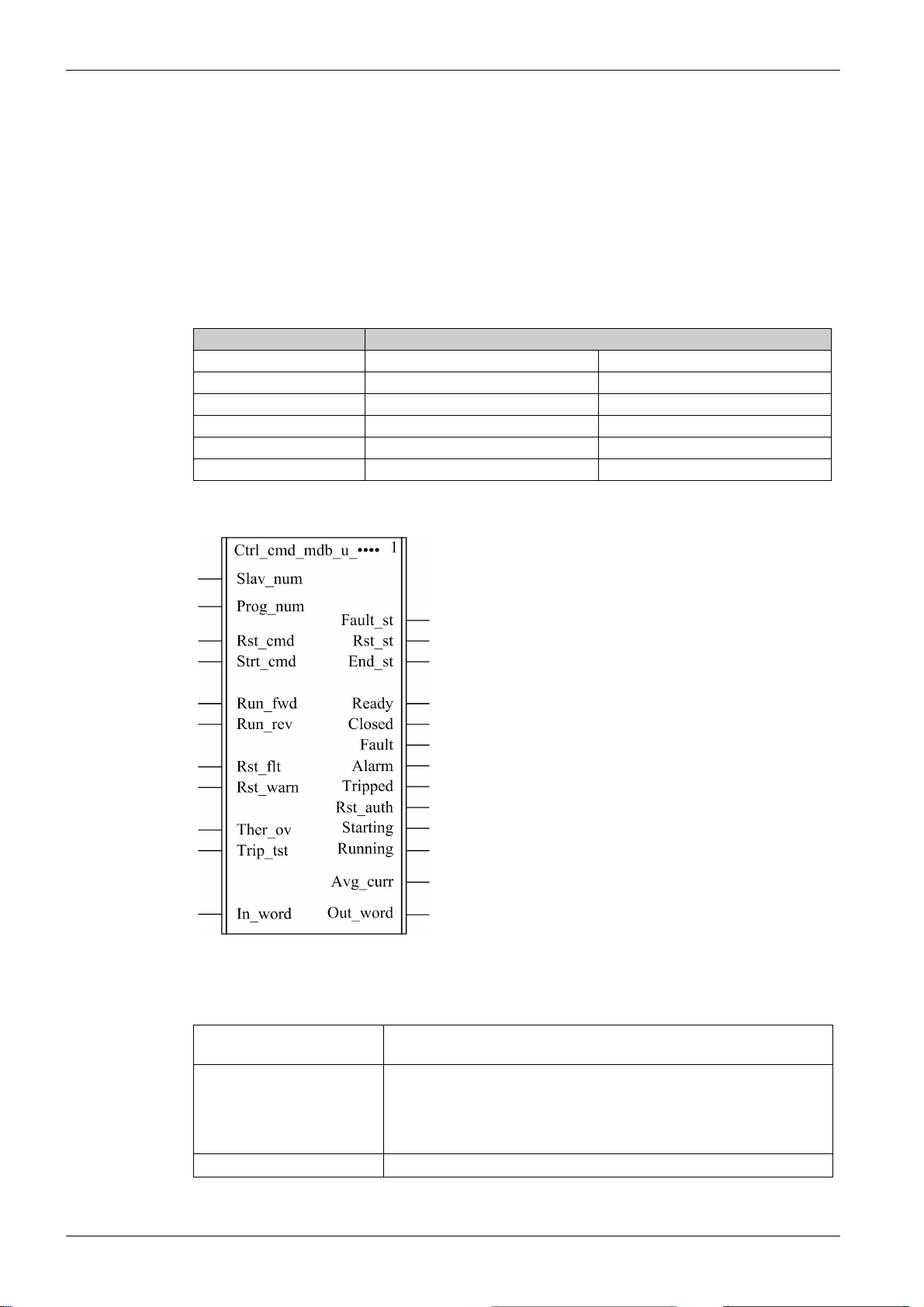

Ctrl_cmd_mdb_u_••••: TeSys U Control/Command for Modbus SL

Presentation

The Ctrl_cmd_mdb_u_•••• DFBs are dedicated to the control and command of a single TeSys U startercontroller with any control unit and a LULC033 Modbus communication module through the Modbus SL

(Serial Line) network.

Ctrl_cmd_mdb_u_addr uses XWAY addressing and is dedicated to Premium PLCs.

Ctrl_cmd_mdb_u_addm uses an addressing method dedicated to M340 PLCs.

For more information, see the

Characteristics

Characteristic Value

Name Ctrl_cmd_mdb_u_addr Ctrl_cmd_mdb_u_addm

Version 1.00 1.00

Input 11 11

Output 13 13

Input/Output 0 0

Public Variable 6 8

TeSys U LULC032-033 Modbus Communication Module User Manual

.

Graphical Representation

TeSys U Compliance

22

The Ctrl_cmd_mdb_u_•••• DFBs are compliant with the following TeSys U sub-assemblies:

Power base LUB•• non-reversing power base

LU2B•• reversing power base

Control unit

Communication module

LUCA standard control unit

LUCB and LUCD advanced control units

LUCC advanced control unit (up to 32 A/15 kW or 20 hp)

LUCL magnetic control unit

LUCM multifunction control unit (up to 32 A/15 kW or 20 hp)

LULC033 Modbus communication module

1672609EN-03 01/2020

Page 23

Software Implementation

The parameters and the inputs can only be changed if the End_st output variable is set to 1.

The output data is only valid if the End_st output variable is set to 1 and if there is no fault detected

Input Characteristics

The following table describes the DFB inputs and their availability according to the control unit:

Modbus SL DFB

(Fault_st = 0).

Input Type Range Default Value Description LUCA

LUCL

Slav_num INT 1...31 1 Modbus slave number √ √ √

Prog_num INT 1...30 – See

Rst_cmd EBOOL 0...1 0 Reset command √ √ √

Strt_cmd EBOOL 0...1 0 Start command √ √ √

Run_fwd EBOOL 0...1 0 Motor run forward command √ √ √

Run_rev EBOOL 0...1 0 Motor run reverse command √ √ √

Rst_flt EBOOL 0...1 0 Reset device (if register 451 = 102 or 104, fault

Rst_warn EBOOL 0...1 0 Reset warning (for example, communication

Ther_ov EBOOL 0...1 0 Automatic thermal overload fault test – – √

Trip_tst EBOOL 0...1 0 Overcurrent trip test via communication bus – –√

In_word INT – – This input is only used when program number

Program Number, page 23

acknowledgment causes a return to

communication module factory settings)

loss)

is 10, 20, or 30. See next table and program

number description.

√√√

√√√

√√√

–––

LUCB

LUCC

LUCD

LUCM

The following table describes the In_word input:

Input Type Bit Description LUCA

LUCL

In_word INT 0 Motor run forward command √ √ √

1 Motor run reverse command √ √ √

2 Reserved – – –

3 Reset device (if register 451 = 102 or 104, fault

acknowledgment causes a return to communication module

factory settings)

4 Reserved – – –

5 Automatic thermal overload fault test – – √

6 Overcurrent trip test via communication bus – – √

7 Reserved – – –

8 Reset warning (for example, communication loss) √ √ √

9...15 Reserved – – –

√√√

LUCB

LUCC

LUCD

LUCM

Program Number

The program number enables the user to select bit or word control.

The following table describes the programs of the DFB:

Program Number Description

1 Read registers 455 and 456, then write register 704 (systematic)

2 Read registers 455 and 456, then write register 704 (conditional)

3 Write register 704

10 Same as program 1 but using the In_word input and the Out_word output

20 Same as program 2 but using the In_word input and the Out_word output

30 Same as program 3 but using the In_word input and the Out_word output

1672609EN-03 01/2020 23

Page 24

Modbus SL DFB

Output Characteristics

The following table describes the DFB outputs and their availability according to the control unit:

Output Type Range Default

Value

Fault_st EBOOL 0...1 0 Fault detected √ √ √

Rst_st EBOOL 0...1 0 Reset state √ √ √

End_st EBOOL 0...1 0 End state √ √ √

Ready EBOOL 0...1 0 System ready: the rotary handle is turned to On

Closed EBOOL 0...1 0 Pole status: closed √ √ √

Fault EBOOL 0...1 0 All faults √ √ √

Alarm EBOOL 0...1 0 All warnings √ √ √

Tripped EBOOL 0...1 0 System tripped: the rotary handle is turned to

Rst_auth EBOOL 0...1 0 Fault reset authorized – √ √

Starting EBOOL 0...1 0 Start in progress:

Running EBOOL 0...1 0 Motor running with detection of current, if

Avg_curr INT 0...200 0 Average motor current (x 1% FLA) – √ √

Out_word INT – – This output is only used when program number

Description LUCA

LUCL

√√√

position and there is no fault

√√√

Trip position

–√√

0 = descending current is lower than 150% FLA

1 = ascending current is greater than 10% FLA

–√√

greater than 10% FLA

–––

is 10, 20, or 30. See next table and program

number description.

LUCB

LUCC

LUCD

LUCM

The following table describes the Out_word output:

Output Type Bit Description LUCA

LUCL

Out_word INT 0 System ready: the rotary handle is turned to On position and

there is no fault.

1 Pole status: closed √ √ √

2 All faults √ √ √

3 All warnings √ √ √

4 System tripped: the rotary handle is turned to Trip position. √ √√

5 Fault reset authorized – √ √

6 Reserved – – –

7 Motor running with detection of current, if greater than

10% FLA

8...13 Average motor current (% FLA)

32 = 100% FLA

63 = 200% FLA

14 Reserved – – –

15 Start in progress:

0 = descending current is lower than 150% FLA

1 = ascending current is greater than 10% FLA

√√√

–√√

–√√

–√√

LUCB

LUCC

LUCD

LUCM

24

1672609EN-03 01/2020

Page 25

Public Variables Characteristics

The following table describes the Ctrl_cmd_mdb_u_addr DFB public variables (using XWAY addressing)

and their availability according to the control unit:

Modbus SL DFB

Public Variable Type Range Default

Value

Net_num INT 0...255 0 Network address √ √ √

Stat_num INT 0...255 0 Station address √ √ √

Rack_num INT 0...7 0 Destination rack address √ √ √

Slot_num INT 0...10 0 Destination slot address √ √ √

Chan_num INT 0...1 0 Destination channel address √ √ √

Sq_princ INT 0...7 0 Reserved for support √ √ √

Description LUCA

LUCL

LUCB

LUCC

LUCD

The following table describes the Ctrl_cmd_mdb_u_addm DFB public variables (using M340 addressing)

and their availability according to the control unit:

Public Variable Type Range Default

Value

Rack_num INT 0...7 0 Destination rack address √ √ √

Slot_num INT 0...10 0 Destination slot address √ √ √

Chan_num INT 0...1 0 Destination channel address √ √ √

IP_addr1 INT 0...255 0 First byte of IP address √ √ √

IP_addr2 INT 0...255 0 Second byte of IP address √ √ √

IP_addr3 INT 0...255 0 Third byte of IP address √ √ √

IP_addr4 INT 0...255 0 Fourth byte of IP address √ √ √

Sq_princ INT 0...7 0 Reserved for support √ √ √

Description LUCA

LUCL

LUCB

LUCC

LUCD

LUCM

LUCM

1672609EN-03 01/2020 25

Page 26

Modbus SL DFB

Comm_manager_u: TeSys U Communication Management for Modbus SL

Presentation

The Comm_manager_u DFB is dedicated to the control and command of up to 31 TeSys U startercontrollers with any control unit and a LULC033 Modbus communication module though the Modbus SL

(Serial Line) network. It must be associated with the Ctrl_cmd_mdb_u_•••• DFBs to manage the Modbus

requests sequencing.

The number of TeSys U Modbus slaves is defined in the Slav_num variable (Slav_num = 1...31).

For more information, see the

Characteristics

Characteristic Value

Name Comm_manager_u

Version 1.00

Input 4

Output 4

Input/Output 0

Public Variable 3

TeSys U LULC032-033 Modbus Communication Module User Manual

.

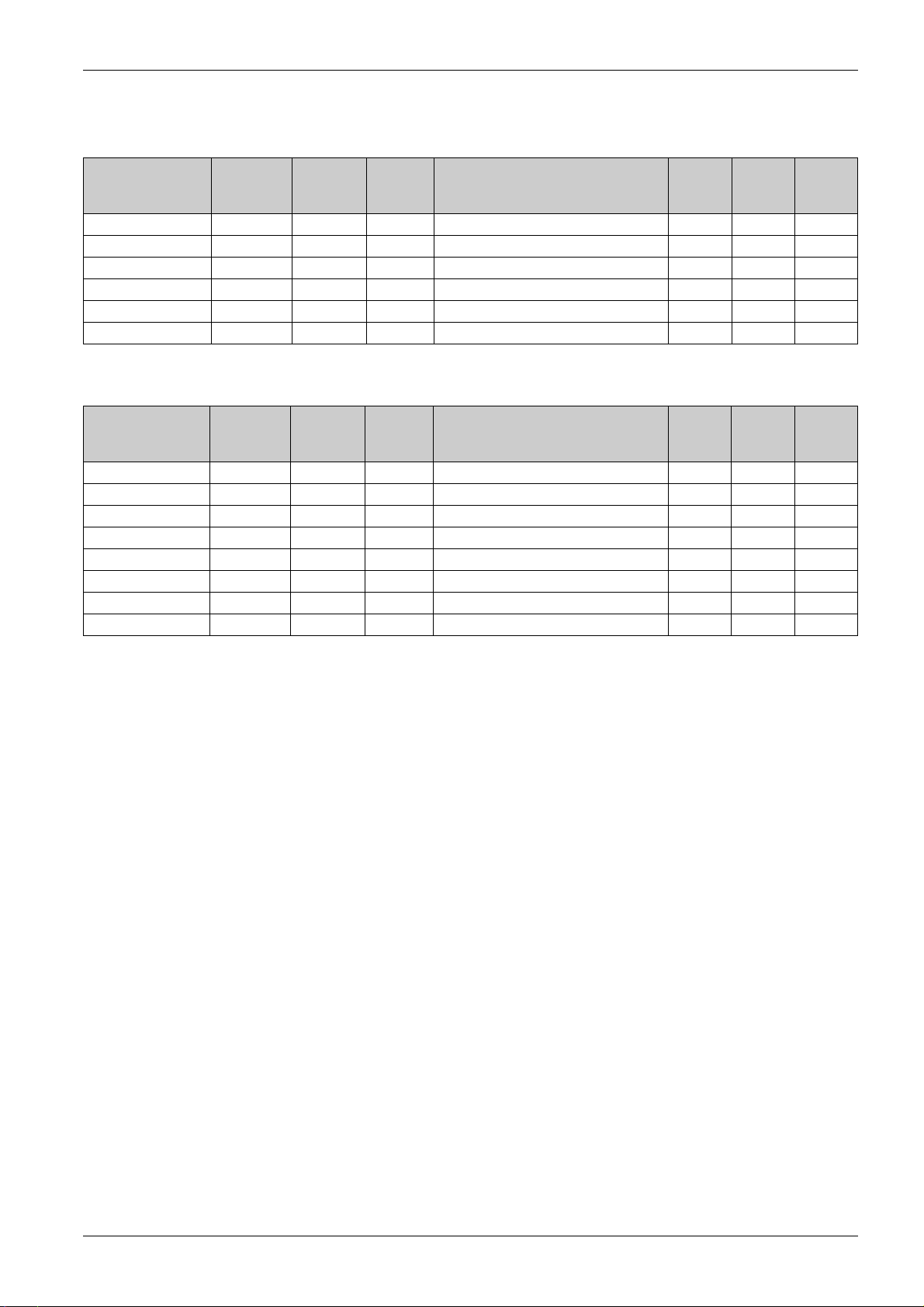

Graphical Representation

TeSys U Compliance

The Comm_manager_u DFB is compliant with the following TeSys U sub-assemblies:

Power base LUB•• non-reversing power base

Control unit

Communication module

LU2B•• reversing power base

LUCA standard control unit

LUCB and LUCD advanced control units

LUCC advanced control unit (up to 32 A/15 kW or 20 hp)

LUCL magnetic control unit

LUCM multifunction control unit (up to 32 A/15 kW or 20 hp)

LULC033 Modbus communication module

26

1672609EN-03 01/2020

Page 27

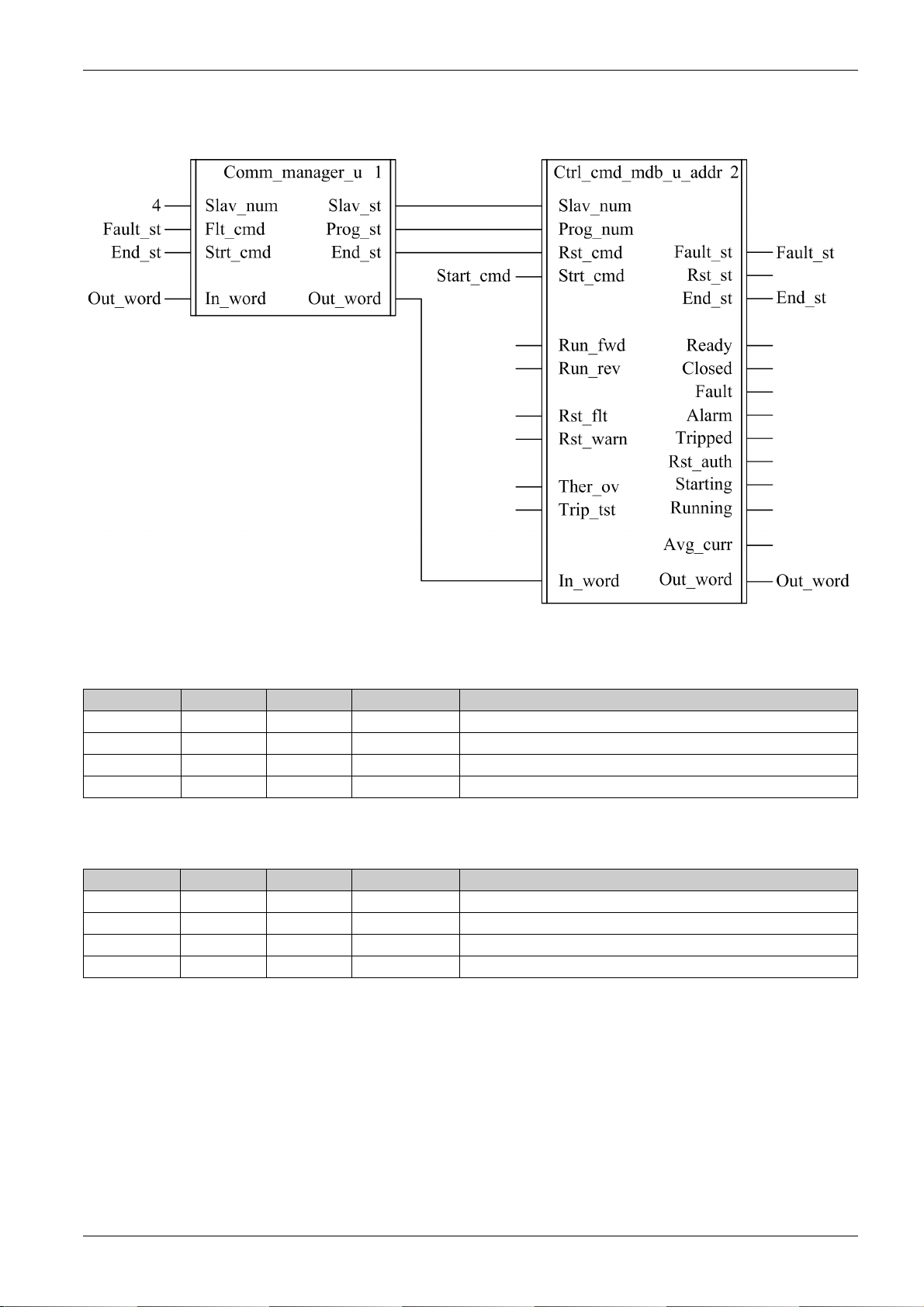

Software Implementation

The following figure shows a Unity Pro program extract in FBD language showing how to interconnect the

Ctrl_cmd_mdb_u_addr and the Comm_manager_u DFBs:

Modbus SL DFB

Input Characteristics

The following table describes the DFB inputs:

Input Type Range Default Value Description

Slav_num INT 1...31 1 Modbus slave number

Flt_cmd EBOOL 0...1 0 Reset command

Strt_cmd EBOOL 0...1 0 Start command

In_word INT – – To connect to the Out_word output of the Ctrl_cmd_mdb_u_•••• DFB

Output Characteristics

The following table describes the DFB outputs:

Output Type Range Default Value Description

Slav_st INT 1...31 1 Modbus slave number

Prog_st INT 20 or 30 – Program number of the Ctrl_cmd_mdb_u_•••• DFB

End_st EBOOL 0...1 0 End state

Out_word INT – – To connect to the In_word input of the Ctrl_cmd_mdb_u_•••• DFB

1672609EN-03 01/2020 27

Page 28

Modbus SL DFB

Public Variables Characteristics

The following table describes the DFB public variables:

Public Variable Type Range Default Value Description

In_cmd[0]...[31] ARRAY [0...31] of INT – – See

In_cmd[0]...[31] Public Variable,

page 28

Out_urg INT – – Priority level

Out_st[0]...[31] ARRAY [0...31] of INT – – See

Bit 0 = Pulling

Bit 1 = Writing priority

Bit 2 = Reading priority

Bit 3 = Fault priority

Out_st[0]...[31] Public Variable,

page 29

In_cmd[0]...[31] Public Variable

The In_cmd[0]...[31] public variable is a table of 32 words corresponding to the TeSys U Modbus slave

address. The following table describes the In_cmd[0]...[31] public variable:

Public Variable Type Bit Description Corresponding to the TeSys U

Slave 1...31

In_cmd[0] INT – Not significant – – –

In_cmd[1]...[31] INT 0 Motor run forward command √ √ √

1 Motor run reverse command √ √ √

2 Reserved – – –

3 Reset device

(if register 451 = 102 or 104, fault

acknowledgment causes a return to

communication module factory settings)

4 Reserved – – –

5 Automatic thermal overload fault test – – √

6 Overcurrent trip test via communication bus – – √

7 Reserved – – –

8 Reset warning (for example, communication

loss)

9...15 Reserved – – –

LUCA

LUCL

√√√

√√√

LUCB

LUCC

LUCD

LUCM

28

1672609EN-03 01/2020

Page 29

Out_st[0]...[31] Public Variable

The Out_st[0]...[31] public variable is a table of 32 words corresponding to the TeSys U Modbus slave

address.The following table describes the Out_st[0]....[31] public variable:

Modbus SL DFB

Public Variable Type Bit Description Corresponding to the TeSys U Slave

1...31

Out_st[0] INT – Not significant – – –

Out_st[1]...[31] INT 0 System ready: the rotary handle is turned to On

position and there is no fault.

1 Pole status: closed √ √ √

2 All faults √ √ √

3 All warnings √ √ √

4 System tripped: the rotary handle is turned to Trip

position.

5 Fault reset is authorized – √ √

6Reserved – – –

7 Motor running with detection of current, if greater

than 10% FLA

8...13 Average motor current (% FLA)

32 = 100% FLA

63 = 200% FLA

14 Reserved – – –

15 Start in progress:

1 = ascending current is greater than 10% FLA

0 = descending current is lower than 150% FLA

LUCA

LUCL

√√ √

√√ √

–√√

–√√

–√√

LUCB

LUCC

LUCD

LUCM

1672609EN-03 01/2020 29

Page 30

Modbus SL DFB

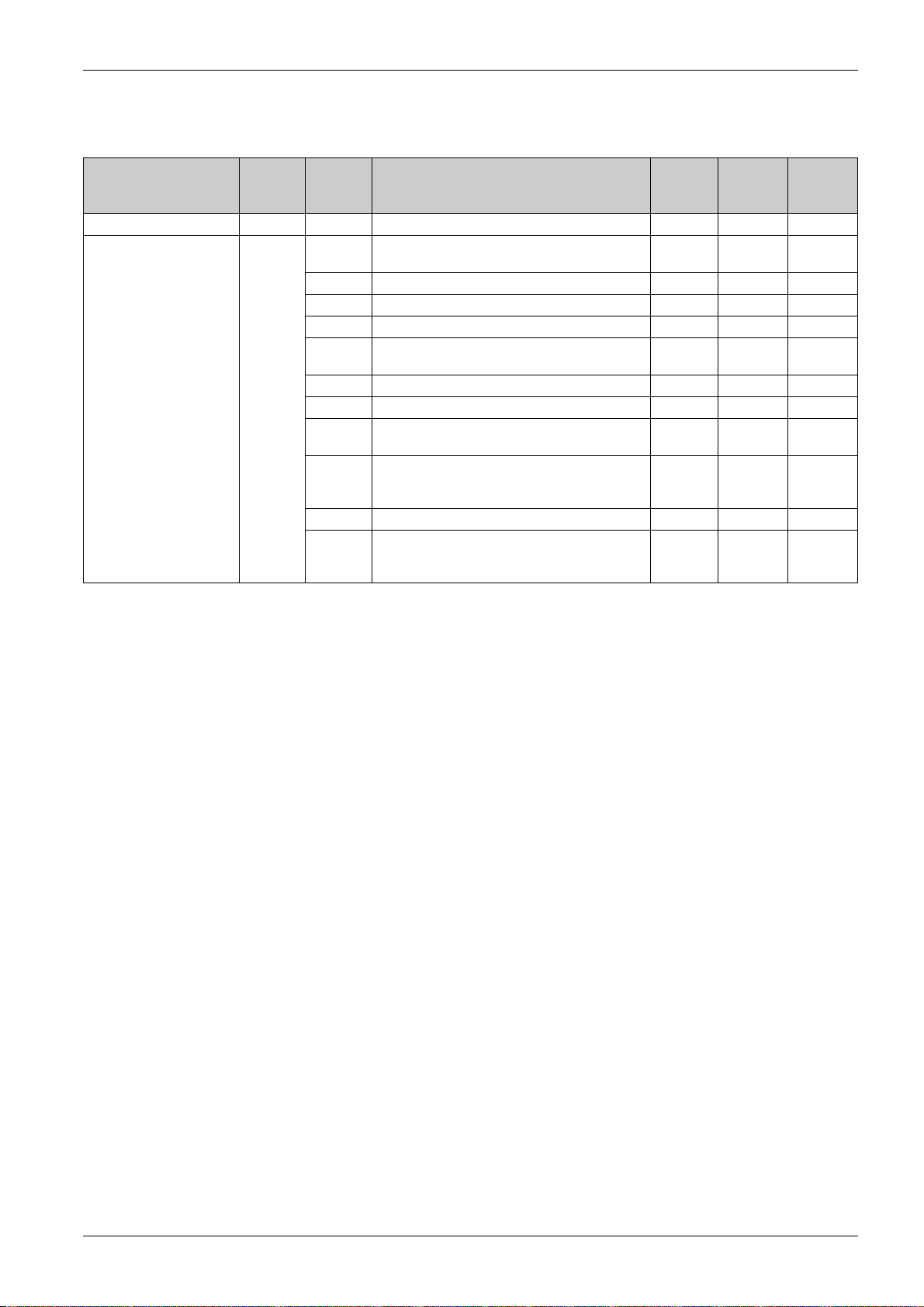

Ctrl_cmd_mdb_t_••••: TeSys T Control/Command for Modbus SL

Presentation

The Ctrl_cmd_mdb_t_•••• DFBs are dedicated to the control and command of a single TeSys T LTMR••M••

Modbus SL controller with or without the LTM E expansion module through the Modbus SL network.

Ctrl_cmd_mdb_t_addr uses XWAY addressing and is dedicated to Premium PLCs

Ctrl_cmd_mdb_t_addm uses an addressing method dedicated to M340 PLCs

For more information, see the

Characteristics

Characteristic Value

Name Ctrl_cmd_mdb_t_addr Ctrl_cmd_mdb_t_addm

Version 1.00 1.00

Input 10 10

Output 24 24

Input/Output 0 0

Public Variable 6 8

Graphical Representation

TeSys T LTMR Modbus Communication Guide

.

30

1672609EN-03 01/2020

Page 31

Modbus SL DFB

TeSys T Compliance

The Ctrl_cmd_mdb_t_•••• DFBs are compliant with all the TeSys T LTM R••M•• controller versions, with or

without the LTM E expansion module.

Software Implementation

The parameters and the inputs can only be changed if the End_st output variable is set to 1.

The output data is only valid if the End_st output variable is set to 1 and if there is no fault detected

(Fault_st = 0).

Input Characteristics

The following table describes the DFB inputs:

Input Type Range Default Value Description

Slav_num INT 1...31 1 Modbus slave number

Prog_num INT 1...30 – See

Rst_cmd EBOOL 0...1 0 Reset command

Strt_cmd EBOOL 0...1 0 Start command

Run_fwd EBOOL 0...1 0 Motor run forward command

Run_rev EBOOL 0...1 0 Motor run reverse command

Rst_flt EBOOL 0...1 0 Fault reset command

Autotest EBOOL 0...1 0 Self test command

Lo_speed EBOOL 0...1 0 Motor low speed command

In_word INT – – This input is only used when program number is 10, 20,

Program Number, page 31

or 30. See next table and program number description.

The following table describes the In_word input:

Input Type Bit Description

In_word INT 0 Motor run forward command

1 Motor run reverse command

2 Reserved

3 Fault reset command

4 Reserved

5 Self test command

6 Motor low speed command

7...15 Reserved

Program Number

The program number enables the user to select bit or word control.

The following table describes the programs of the DFB:

Program Number Description

1 Read registers 455 and 456, then write register 704 (systematic)

2 Read registers 455 and 456, then write register 704 (conditional)

3 Write register 704

10 Same as program 1 but using the In_word input and the Out_word output

20 Same as program 2 but using the In_word input and the Out_word output

30 Same as program 3 but using the In_word input and the Out_word output

1672609EN-03 01/2020 31

Page 32

Modbus SL DFB

Output Characteristics

The following table describes the DFB outputs:

Output Type Range Default Value Description

Fault_st EBOOL 0...1 0 Fault detected

Rst_st EBOOL 0...1 0 Reset state

End_st EBOOL 0...1 0 End state

Ready EBOOL 0...1 0 System ready

Syst_on EBOOL 0...1 0 System On

Fault EBOOL 0...1 0 System fault

Alarm EBOOL 0...1 0 System warning

Tripped EBOOL 0...1 0 System tripped

Rst_auth EBOOL 0...1 0 Fault reset authorized

Ctrl_pwr EBOOL 0...1 0 Controller power

Running EBOOL 0...1 0 Motor running (with detection of a current, if greater than 10% FLC)

Avg_curr INT 0...200 0 Motor average current ratio (x 1% FLC)

Starting EBOOL 0...1 0 Motor starting (start in progress)

0 = descending current is less than 150% FLC

1 = ascending current is greater than 10% FLC

Hi_speed EBOOL 0...1 0 Motor high speed

Hmi_ctrl EBOOL 0...1 0 Control through HMI

Auto_rst EBOOL 0...1 0 Auto-reset active

Pwr_rqst EBOOL 0...1 0 Power cycle requested

Rst_Time EBOOL 0...1 0 Motor restart time undefined

Rpd_cycl EBOOL 0...1 0 Rapid cycle lockout

Load_shd EBOOL 0...1 0 Load shedding

Hmi_loss EBOOL 0...1 0 HMI port communication loss

Net_loss EBOOL 0...1 0 Network port communication loss

Motor_tr EBOOL 0...1 0 Motor transition lockout

Out_word DINT – – This output is only used when program number is 10, 20, or 30. See

next table and program number description.

32

1672609EN-03 01/2020

Page 33

The following table describes the Out_word output:

Output Type Bit Description

Out_word DINT 0 System ready

1System On

2 System fault

3System warning

4 System tripped

5 Fault reset authorized

6 Controller power

7 Motor running (with detection of a current, if greater than 10%FLC)

8...13 Motor average current ratio

32 = 100% FLC

63 = 200% FLC

14 Control through HMI

15 Motor starting (start in progress)

0 = descending current is less than 150% FLC

1 = ascending current is greater than 10% FLC

16 Auto-reset active

17 Not significant

18 Power cycle requested

19 Motor restart time undefined

20 Rapid cycle lockout

21 Load shedding

22 Motor speed

0 = FLC1 setting is used

1 = FLC2 setting is used

23 HMI port communication loss

24 Network port communication loss

25 Motor transition lockout

26...31 Not significant

Modbus SL DFB

Public Variables Characteristics

The following table describes the Ctrl_cmd_mdb_t_addr DFB public variables (using XWAY addressing):

Public Variable Type Range Default Value Description

Net_num INT 0...255 0 Network address

Stat_num INT 0...255 0 Station address

Rack_num INT 0...7 0 Destination rack address

Slot_num INT 0...10 0 Destination slot address

Chan_num INT 0...1 0 Destination channel address

Sq_princ INT 0...7 0 Reserved for support

The following table describes the Ctrl_cmd_mdb_t_addm DFB public variables (using M340 addressing):

Public Variable Type Range Default Value Description

Rack_num INT 0...7 0 Destination rack address

Slot_num INT 0...10 0 Destination slot address

Chan_num INT 0...1 0 Destination channel address

IP_addr1 INT 0...255 0 First byte of IP address

IP_addr2 INT 0...255 0 Second byte of IP address

IP_addr3 INT 0...255 0 Third byte of IP address

IP_addr4 INT 0...255 0 Fourth byte of IP address

Sq_princ INT 0...7 0 Reserved for support

1672609EN-03 01/2020 33

Page 34

Modbus SL DFB

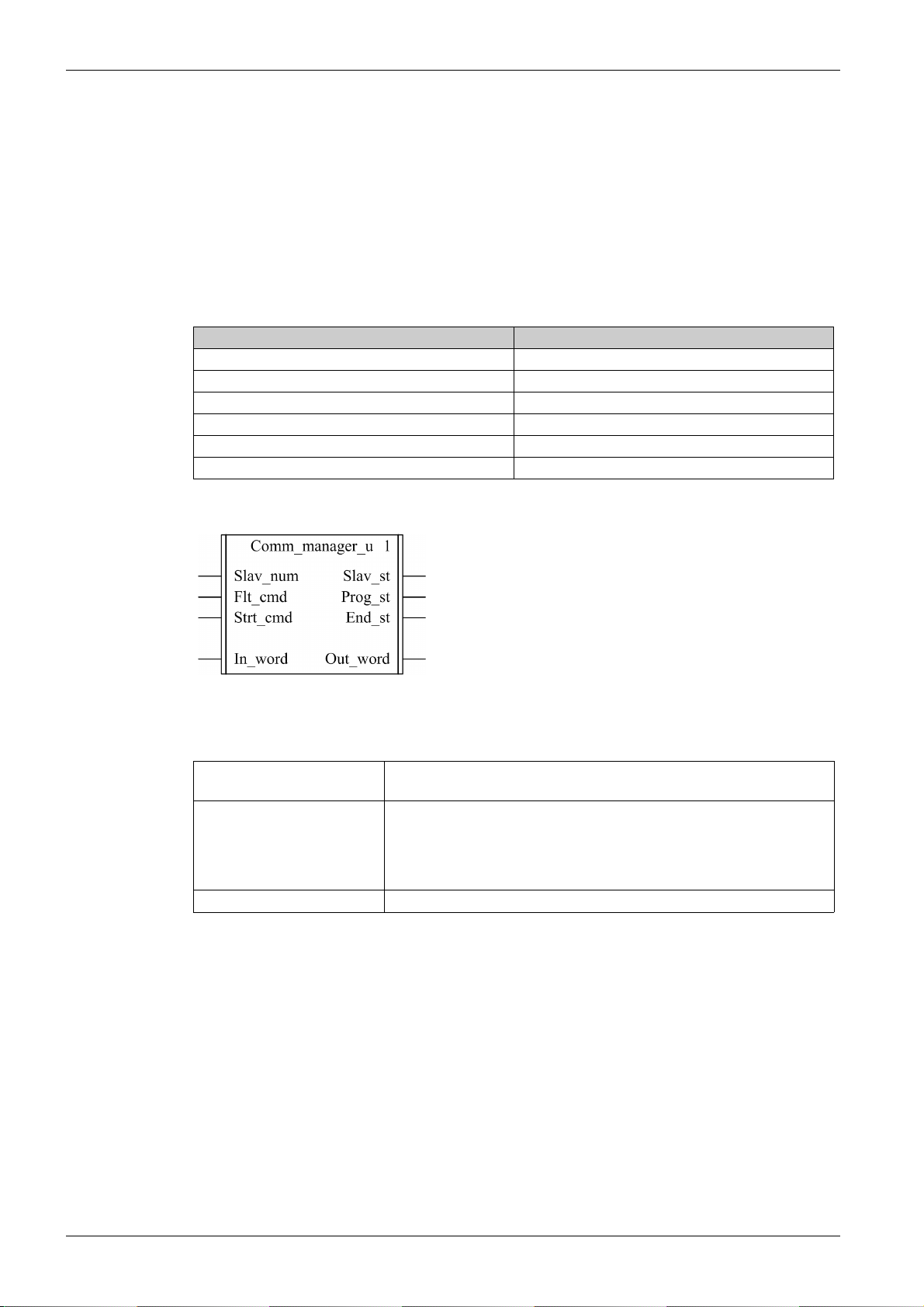

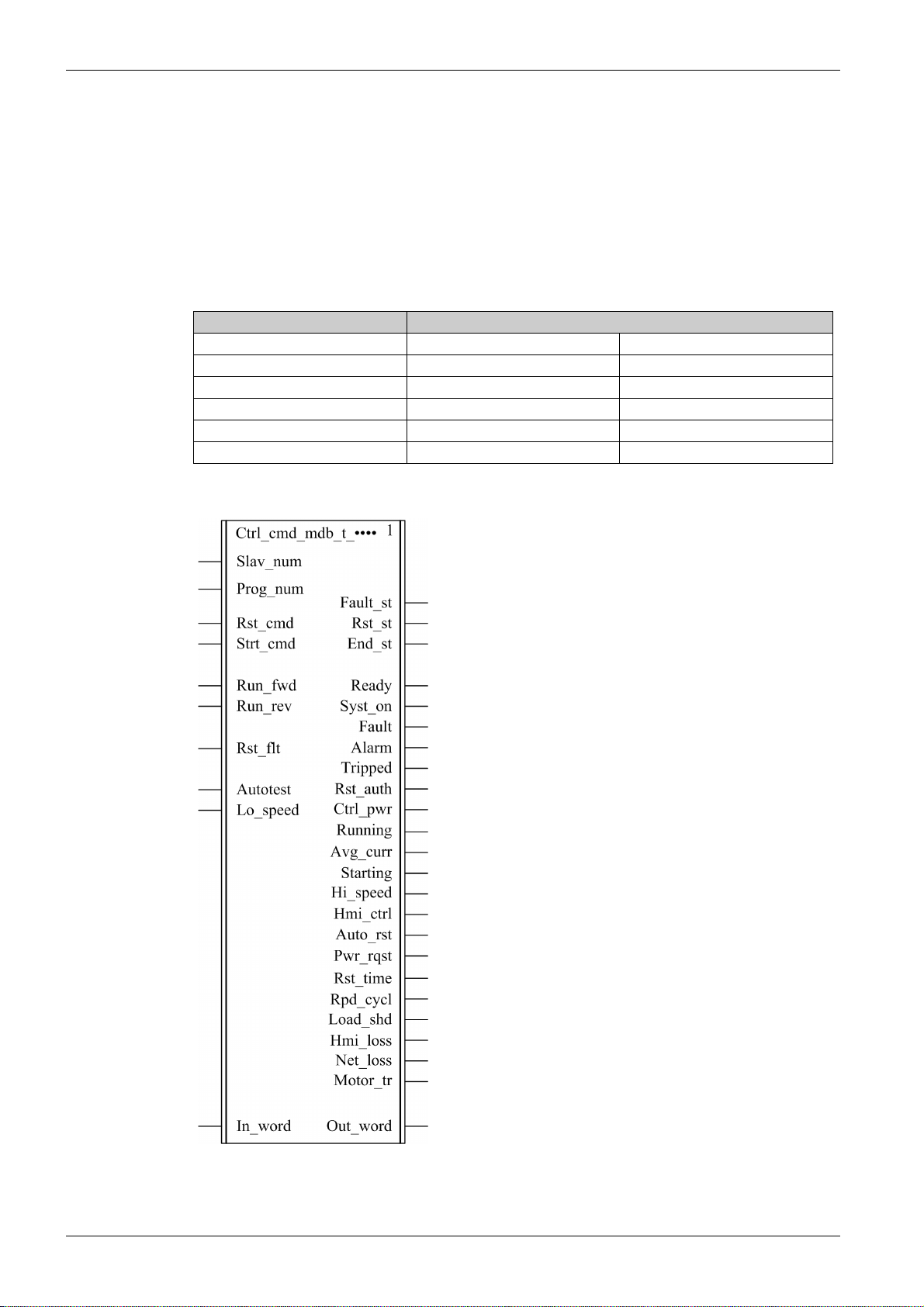

Comm_manager_t: TeSys T Communication Management for Modbus SL

Presentation

The Comm_manager_t DFB is dedicated to the control and command of up to 31 TeSys T LTMR••M••

Modbus SL controllers with or without the LTM E expansion module through the Modbus SL network. It

must be associated with the Ctrl_cmd_mdb_t_•••• DFB to manage the Modbus requests sequencing.

The number of TeSys T Modbus slaves is define din the Slav_num variable (Slav_num = 1...31).

For more information, see the

Characteristics

Characteristic Value

Name Comm_manager_t

Version 1.0

Input 4

Output 4

Input/Output 0

Public Variable 3

Graphical Representation

TeSys T LTMR Modbus Communication Guide

.

TeSys T Compliance

The Comm_manager_t DFB is compliant with all the TeSys T LTM R••M•• controller versions, with or

without the LTM E expansion module.

34

1672609EN-03 01/2020

Page 35

Software Implementation

The following figure shows a Unity Pro program extract in FBD language showing how to interconnect the

Ctrl_cmd_mdb_t and the Comm_manager_t DFBs:

Modbus SL DFB

The Comm_manager_t DFB can be used in case both TeSys U starter-controllers and TeSys T motor

management systems are present on the same Modbus SL network.

Input Characteristics

The following table describes the DFB inputs:

Input Type Range Default Value Description

Slav_num INT 1...31 1 Modbus slave number

Flt_cmd EBOOL 0...1 0 Reset command

Strt_cmd EBOOL 0...1 0 Start command

In_word DINT – – To connect to the Out_word output of the Ctrl_cmd_mdb_t_••••

1672609EN-03 01/2020 35

DFB

Page 36

Modbus SL DFB

Output Characteristics

The following table describes the DFB outputs:

Output Type Range Default Value Description

Slav_st INT 1...31 1 Modbus slave number

Prog_st INT 20 or 30 – Program number of the Ctrl_cmd_mdb_t_•••• DFB

End_st EBOOL 0...1 0 End state

Out_word INT – – To connect to the In_word input of the Ctrl_cmd_mdb_t_••••

DFB

Public Variables Characteristics

The following table describes the DFB public variables:

Public Variable Type Range Default Value Description

In_cmd[0]...[31] ARRAY [0...31] of INT – – See

Out_urg INT – – Priority level

Out_st[0]...[31] ARRAY [0...31] of DINT – – See

In_cmd[0]...[31] Public Variable, page 36

Bit 0 = Pulling

Bit 1 = Writing priority

Bit 2 = Reading priority

Bit 3 = Fault priority

Out_st[0]...[31] Public Variable, page 37

In_cmd[0]...[31] Public Variable

The In_cmd[0]...[31] public variable is a table of 32 words corresponding to the TeSys T Modbus slave

address. The following table describes the In_cmd[0]...[31] public variable:

Public Variable Type Bit Description Corresponding to the TeSys T Slave 1...31

In_cmd[0] INT – Not significant

In_cmd[1]...[31] INT 0 Motor run forward command

1 Motor run reverse command

2 Reserved

3 Fault reset command

4 Reserved

5 Self test command

6 Motor low speed command

7...31 Reserved

36

1672609EN-03 01/2020

Page 37

Out_st[0]...[31] Public Variable

The Out_st[0]...[31] public variable is a table of 32 words corresponding to the TeSys T Modbus slave

address.The following table describes the Out_st[0]....[31] public variable:

Public Variable Type Bit Description Corresponding to the TeSys T

Slave 1...31

Out_st[0] DINT – Not significant

Out_st[1]...[31] DINT 0 System ready

1System On

2 System fault

3System warning

4 System tripped

5 Fault reset authorized

6 Controller power

7 Motor running (with detection of a current, if greater than 10%FLC)

8...13 Motor average current ratio

32 = 100% FLC

63 = 200% FLC

14 Control through HMI

15 Motor starting (start in progress)

0 = descending current is less than 150% FLC

1 = ascending current is greater than 10% FLC

16 Auto-reset active

17 Not significant

18 Power cycle requested

19 Motor restart time undefined

20 Rapid cycle lockout

21 Load shedding

22 Motor speed

0 = FLC1 setting is used

1 = FLC2 setting is used

23 HMI port communication loss

24 Network port communication loss

25 Motor transition lockout

26...31 Not significant

Modbus SL DFB

1672609EN-03 01/2020 37

Page 38

Modbus SL DFB

The Out_st[0]...[31] public variable is a table of 32 words corresponding to the TeSys T Modbus slave

address.The following table describes the Out_st[0]....[31] public variable:

Public Variable Type Bit Description Corresponding to the TeSys T

Slave 1...31

Out_st[0] DINT – Not significant

Out_st[1]...[31] DINT 0 System ready

1System On

2 System fault

3System warning

4 System tripped

5 Fault reset authorized

6 Controller power

7 Motor running (with detection of a current, if greater than 10%FLC)

8...13 Motor average current ratio

32 = 100% FLC

63 = 200% FLC

14 Control through HMI

15 Motor starting (start in progress)

0 = descending current is less than 150% FLC

1 = ascending current is greater than 10% FLC

16 Auto-reset active

17 Not significant

18 Power cycle requested

19 Motor restart time undefined

20 Rapid cycle lockout

21 Load shedding

22 Motor speed

0 = FLC1 setting is used

1 = FLC2 setting is used

23 HMI port communication loss

24 Network port communication loss

25 Motor transition lockout

26...31 Not significant

38

1672609EN-03 01/2020

Page 39

TeSys DFB Library V2 for Unity Pro

Modbus SL and Modbus/T CP DFB

1672609EN-03 01/2020

Modbus SL and Modbus/TCP DFB

Chapter 3

Modbus SL and Modbus/TCP DFB

Introduction

This chapter describes the TeSys U and TeSys T Modbus SL and Modbus/TCP DFBs dedicated to

Premium and M340 PLCs.

What Is in This Chapter?

This chapter contains the following topics:

Special_mdb_u_••••: TeSys U DFB for Modbus SL and Modbus/TCP 40

Special_mdb_t_••••: TeSys T DFB for Modbus SL and Modbus/TCP 46

Custom_mdb_••••: Custom Read DFB for Modbus SL and Modbus/TCP 58

Topic Page

1672609EN-03 01/2020 39

Page 40

Modbus SL and Modbus/TCP DFB

Special_mdb_u_••••: TeSys U DFB for Modbus SL and Modbus/TCP

Presentation

The Special_mdb_u_•••• DFBs are dedicated to the reading of up to 16 predefined registers of a TeSys U

starter-controller (up to 32 A/15 kW or 20 hp) equipped with a LUCM multifunction control unit and a

LULC033 Modbus communication module directly through a Modbus SL network or through an Ethernet

gateway with a Modbus/TCP network.

Special_mdb_u_addr uses XWAY addressing and is dedicated to Premium PLCs and can be used with

a TeSys U starter-controller connected on Modbus Serial Line or through a Modbus/TCP gateway.

Special_mdb_u_addm uses an addressing method dedicated to M340 PLCs and can be used with a

TeSys U starter-controller connected on Modbus Serial Line or through a Modbus/TCP gateway.

For more information, see the

Characteristics

Characteristic Value

Name Special_mdb_u_addr Special_mdb_u_addm

Version 1.00 and 1.10 1.00 and 1.10

Input 4 4

Output 3 3

Input/Output 0 0

Public Variable 7 9

TeSys U LULC032-033 Modbus Communication Module User Manual

.

Graphical Representation

TeSys U Compliance

The Special_mdb_u_•••• DFBs are compliant with the following TeSys U sub-assemblies:

Power base LUB•• non-reversing power base (up to 32 A/15 kW or 20 hp)

Control unit

Communication module

Software Implementation

The parameters and the inputs can only be changed if the End_st output variable is set to 1.

With version 1.00:

The output data is only valid if the End_st output variable is set to 1 and if there is no fault detected

(Fault_st = 0).

With version 1.10:

The output data is only valid if there is no fault detected (Fault_st = 0).

Prog_num input can be modified on the fly.

LU2B•• reversing power base (up to 32 A/15 kW or 20 hp)

LUCM multifunction control unit

LULC033 Modbus communication module

40

1672609EN-03 01/2020

Page 41

Input Characteristics

The following table describes the DFB inputs:

Input Type Range Default Value Description

Slav_num INT 1...31 1 Modbus slave number

Prog_num INT 0...6 0 Program number

See

Program Number, page 41

Rst_cmd EBOOL 0...1 0 Reset command

Strt_cmd EBOOL 0...1 0 Start command

Output Characteristics

The following table describes the DFB outputs:

Output Type Range Default Value Description

Fault_st EBOOL 0...1 0 Fault detected

Rst_st EBOOL 0...1 0 Reset state

End_st EBOOL 0...1 0 End state

Program Number

The Prog_num input variable enables the user to define the public variables data depending on the

application type. Each program uses variables related to one application (diagnostic, maintenance,

measurement,...). The following table describes the programs of the DFB:

Modbus SL and Modbus/TCP DFB

Program Number Description

0 Bypass: no action

1 Diagnostic: faults monitoring variables, warnings monitoring variables, and communication monitoring variables

2 Maintenance: global statistics variables

3 Measurements: measurements monitoring variables

4 Statistics: last trip statistics and trip N–1 statistics

5 Statistics: trip N–2 statistics and trip N–3 statistics

6 Statistics: trip N–4 statistics

Public Variables Characteristics

The following table describes the Special_mdb_u_addr DFBs public variables (using XWAY addressing):

Public Variable Type Range Default Value Description

Net_num INT 0...255 0 Network address

Stat_num INT 0...255 0 Station address

Rack_num INT 0...7 0 Destination rack address

Slot_num INT 0...10 0 Destination slot address

Chan_num INT 0...1 0 Destination channel address

Sq_princ INT 0...7 0 Reserved for support

Out_data[0]...[15] ARRAY [0...15] of

INT

0...65535 0 The output data depends on the program number.

Out_data[0]...[15] Public Variable (Program

See

1), page 42

...

Out_data[0]...[15] Public Variable

(Program 6), page 45

The following table describes the Special_mdb_u_addm DFB public variables (using M340 addressing):

Public Variable Type Range Default Value Description

Rack_num INT 0...7 0 Destination rack address

Slot_num INT 0...10 0 Destination slot address

Chan_num INT 0...1 0 Destination channel address

IP_addr1 INT 0...255 0 First byte of IP address

IP_addr2 INT 0...255 0 Second byte of IP address

IP_addr3 INT 0...255 0 Third byte of IP address

1672609EN-03 01/2020 41

Page 42

Modbus SL and Modbus/TCP DFB

Public Variable Type Range Default Value Description

IP_addr4 INT 0...255 0 Fourth byte of IP address

Sq_princ INT 0...7 0 Reserved for support

Out_data[0]...[15] ARRAY [0...15] of INT 0...65535 0 The output data depends on the program number.

Out_data[0]...[15] Public Variable (Program 1),

See

page 42

...

Out_data[0]...[15] Public Variable

(Program 6), page 45

Out_data[0]...[15] Public Variable (Program 1)

The following table describes the Out_data[0]...[15] public variable in the case of the diagnostic program

(program number 1):

Public Variable Type Register Bit Description

Out_data[0] INT 452 0 Short-circuit fault

1 Magnetic fault

2 Ground fault

3 Thermal fault

4 Long start fault

5 Jam fault

6 Phase imbalance fault

7 Underload fault

8 Shunt trip fault

9 Test trip fault

10 Communication loss fault on LUCM Modbus port

11 Control unit internal fault

12 Module identification or internal communication fault

13 Module internal fault

14 Module trip fault

15 Module drop-out fault

Out_data[1] INT 461 0...1 Not significant

2 Ground fault warning

3 Thermal warning

4 Long start warning

5 Jam warning

6 Phase imbalance warning

7 Under-current warning

8...9 Not significant

10 Communication loss fault on LUCM Modbus port

11 Internal temperature warning

12 Module identification or internal communication warning

13...14 Not significant

15 Module warning

Out_data[2] INT 457 0 Button position On (0 = Off)

1 Button position Trip (0 = Not tripped)

2 Contactor state On

3 24 Vdc power supply present on outputs

4...15 Not significant

Out_data[3] INT 450 – Time to automatic reset on a thermal fault (s)

Out_data[4]

...Out_data[15]

– – – Not significant

42

1672609EN-03 01/2020

Page 43

Out_data[0]...[15] Public Variable (Program 2)

The following table describes the Out_data[0]...[15] public variable in the case of the maintenance program

(program number 2):

Public Variable Type Register Description

Out_data[0] INT 100 Short-circuit faults count

Out_data[1] INT 101 Magnetic faults count

Out_data[2] INT 102 Ground faults count

Out_data[3] INT 103 Thermal faults count

Out_data[4] INT 104 Long start faults count

Out_data[5] INT 105 Jam faults count

Out_data[6] INT 106 Phase imbalance faults count

Out_data[7] INT 108 Shunt trip faults count

Out_data[8] INT 115 Auto-resets count

Out_data[9] INT 116 Thermal warnings count

Out_data[10] INT 117 Starts count (LSB)

Out_data[11] INT 118 Starts count (MSB)

Out_data[12] INT 119 Operating time (LSB)

Out_data[13] INT 120 Operating time (MSB)

Out_data[14] INT 121 Maximum internal temperature (°C)

Out_data[15] – – Not significant

Modbus SL and Modbus/TCP DFB

Out_data[0]...[15] Public Variable (Program 3)

The following table describes the Out_data[0]...[15] public variable in the case of the measurements

program (program number 3):

Public Variable Type Register Description

Out_data[0] – – Not significant

Out_data[1] INT 465 Thermal capacity level (%)

Out_data[2] INT 466 Average motor current (x 0.1 % FLA)

Out_data[3] INT 467 L1 current (% FLA)

Out_data[4] INT 468 L2 current (% FLA)

Out_data[5] INT 469 L3 current (% FLA)

Out_data[6] INT 470 Ground current (% FLA min)

Out_data[7] INT 471 Current imbalance coefficient

Out_data[8] INT 472 Control unit internal temperature (°C)

Out_data[9]

...Out_data[13]

Out_data[14] INT 79 Control unit sensor maximum current (x 0.1 A):

Out_data[15] INT 652 Full load amps setting (% FLA max):

– – Not significant

6 = adjustment range 0.15–0.6 A

14 = adjustment range 0.35–.4 A

50 = adjustment range 1.25–5 A

120 = adjustment range 3–12 A

180 = adjustment range 4.5–18 A

320 = adjustment range 8–32 A

minimum = 25 (default value)

maximum = 100

1672609EN-03 01/2020 43

Page 44

Modbus SL and Modbus/TCP DFB

Out_data[0]...[15] Public Variable (Program 4)

The following table describes the Out_data[0]...[15] public variable in the case of the statistics program

(program number 4):

Public Variable Type Register Description

Out_data[0] INT 150 Last trip fault number

Out_data[1] INT 152 Last trip thermal capacity level (% trip level)

Out_data[2] INT 153 Last trip average current (% FLA)

Out_data[3] INT 154 Last trip L1 current (% FLA)

Out_data[4] INT 155 Last trip L2 current (% FLA)

Out_data[5] INT 156 Last trip L3 current (% FLA)

Out_data[6] INT 157 Last trip ground current (% FLA min)

Out_data[7] INT 180 N1 trip fault number

Out_data[8] INT 182 N–1 trip thermal capacity level (% trip level)

Out_data[9] INT 183 N–1 trip average current (% FLA)

Out_data[10] INT 184 N–1 trip L1 current (% FLA)

Out_data[11] INT 185 N–1 trip L2 current (%FLA)

Out_data[12] INT 186 N–1 trip L3 current (% FLA)

Out_data[13] INT 187 N–1 trip ground current (% FLA min)

Out_data[14] INT 79 Control unit sensor maximum current (x 0.1 A):

Out_data[15] INT 652 Full load amps setting (% FLA max):

6 = adjustment range 0.15–0.6 A

14 = adjustment range 0.35–1.4 A

50 = adjustment range 1.25–5 A

120 = adjustment range 3–12 A

180 = adjustment range 4.5–18 A

320 = adjustment range 8–32 A

minimum = 25 (default value)

maximum = 100

44

1672609EN-03 01/2020

Page 45

Out_data[0]...[15] Public Variable (Program 5)

The following table describes the Out_data[0]...[15] public variable in the case of the statistics program

(program number 5):

Public Variable Type Register Description

Out_data[0] INT 210 N–2 trip fault number

Out_data[1] INT 212 N–2 trip thermal capacity level (% trip level)

Out_data[2] INT 213 N–2 trip average current (% FLA)

Out_data[3] INT 214 N–2 trip L1 current (% FLA)

Out_data[4] INT 215 N–2 trip L2 current (% FLA)

Out_data[5] INT 216 N–2 trip L3 current (% FLA)

Out_data[6] INT 217 N–2 trip ground current (% FLA min)

Out_data[7] INT 240 N–3 trip fault number

Out_data[8] INT 242 N–3 trip thermal capacity level (% trip level)

Out_data[9] INT 243 N–3 trip average current (% FLA)

Out_data[10] INT 244 N–3 trip L1 current (% FLA)

Out_data[11] INT 245 N–3 trip L2 current (%FLA)

Out_data[12] INT 246 N–3 trip L3 current (% FLA)

Out_data[13] INT 247 N–3 trip ground current (% FLA min)

Out_data[14] INT 79 Control unit sensor maximum current (x 0.1 A):

6 = adjustment range 0.15–0.6 A

14 = adjustment range 0.35–1.4 A

50 = adjustment range 1.25–5 A

120 = adjustment range 3–12 A

180 = adjustment range 4.5–18 A

320 = adjustment range 8–32 A

Out_data[15] INT 652 Full load amps setting (% FLA max):

minimum = 25 (default value)

maximum = 100

Modbus SL and Modbus/TCP DFB

Out_data[0]...[15] Public Variable (Program 6)

The following table describes the Out_data[0]...[15] public variable in the case of the statistics program

(program number 6):

Public Variable Type Register Description

Out_data[0] INT 270 N–4 trip fault number

Out_data[1] INT 272 N–4 trip thermal capacity level (% trip level)

Out_data[2] INT 273 N–4 trip average current (% FLA)

Out_data[3] INT 274 N–4 trip L1 current (% FLA)

Out_data[4] INT 275 N–4 trip L2 current (% FLA)

Out_data[5] INT 276 N–4 trip L3 current (% FLA)

Out_data[6] INT 277 N–4 trip ground current (% FLA min)

Out_data[7]

...Out_data[13]

Out_data[14] INT 79 Control unit sensor maximum current (x 0.1 A):

Out_data[15] INT 652 Full load amps setting (% FLA max):

–– Reserved

6 = adjustment range 0.15–0.6 A

14 = adjustment range 0.35–1.4 A

50 = adjustment range 1.25–5 A

120 = adjustment range 3–12 A

180 = adjustment range 4.5–18 A

320 = adjustment range 8–32 A

minimum = 25 (default value)

maximum = 100

1672609EN-03 01/2020 45

Page 46

Modbus SL and Modbus/TCP DFB

Special_mdb_t_••••: TeSys T DFB for Modbus SL and Modbus/TCP

Presentation

The Special_mdb_t_•••• DFBs are dedicated to the reading of up to 16 predefined registers of a TeSys T

LTM R••M•• controller through the Modbus SL network or a TeSys T LTM R••E•• controller through the

Modbus/TCP network.

Special_mdb_t_addr uses XWAY addressing and is dedicated to Premium PLCs.

Special_mdb_t_addm uses an addressing method dedicated to M340 PLCs.

For more information, see:

TeSys T LTM R Modbus Communication Guide

TeSys T LTM R Ethernet Communication Guide

Characteristics

Characteristic Value

Name Special_mdb_t_addr Special_mdb_t_addm

Version 1.00 and 1.10 1.00 and 1.10

Input 4 4

Output 3 3

Input/Output 0 0

Public Variable 7 9

Graphical Representation

TeSys T Compliance

The Special_mdb_t_•••• DFBs are compliant with all the TeSys T LTM R••M•• and LTM R••E•• controller

versions, with or without the LTM E expansion module.

Software Implementation

The parameters and the inputs can only be changed if the End_st output variable is set to 1.

With version 1.00:

The output data is only valid if the End_st output variable is set to 1 and if there is no fault detected

(Fault_st = 0).

With version 1.10:

The output data is only valid if there is no fault detected (Fault_st = 0).

Prog_num input can be modified on the fly.

Input Characteristics

The following table describes the DFB inputs:

Input Type Range Default Value Description

Slav_num INT 1...31 1 Modbus slave number

Prog_num INT 0...6 0 Program number

Rst_cmd EBOOL 0...1 0 Reset command

Strt_cmd EBOOL 0...1 0 Start command

46

Program Number, page 47

See

1672609EN-03 01/2020

Page 47

Modbus SL and Modbus/TCP DFB

Output Characteristics

The following table describes the DFB outputs:

Output Type Range Default Value Description

Fault_st EBOOL 0...1 0 Fault detected

Rst_st EBOOL 0...1 0 Reset state

End_st EBOOL 0...1 0 End state

Program Number

The Prog_num input variable enables the user to define the public variables data depending on the

application type. Each program holds variables related to one application (diagnostic, maintenance,

measurement,...). The following table describes the programs of the DFB:

Program Number Description

0 Bypass: no action

10 Diagnostic: faults monitoring variables, warnings monitoring variables, and communication monitoring variables

20 Maintenance: global statistics variables

30 Measurements 1

31 Measurements 2

32 Measurements 3

40 Statistics: last fault statistics (N–0)

41 Statistics: last fault statistics with expansion module (N–0)

50 Statistics: N–1 fault statistics

51 Statistics: N–1 fault statistics (with expansion module)

60 Statistics: N–2 fault statistics

61 Statistics: N–2 fault statistics (with expansion module)

70 Statistics: N–3 fault statistics

71 Statistics: N–3 fault statistics (with expansion module)

80 Statistics: N–4 fault statistics

81 Statistics: N–4 fault statistics (with expansion module)

Public Variables Characteristics

The following table describes the Special_mdb_t_addr DFB public variables (using XWAY addressing):

Public Variable Type Range Default Value Description

Net_num INT 0...255 0 Network address

Stat_num INT 0...255 0 Station address

Rack_num INT 0...7 0 Destination rack address

Slot_num INT 0...10 0 Destination slot address

Chan_num INT 0...1 0 Destination channel address

Sq_princ INT 0...7 0 Reserved for support

Out_data[0]...[15] ARRAY [0...15] of INT 0...65535 0 The output data depends on the program number.

Out_data[0]...[15] Public Variable (Program

See

1), page 42

...

Out_data[0]...[15] Public Variable

(Program 6), page 45

The following table describes the Special_mdb_t_addm DFB public variables (using M340 addressing):