Installation Instructions

SmartX MF41-6043 and MS41-6043

Non-Spring Return Direct-Coupled Actuators

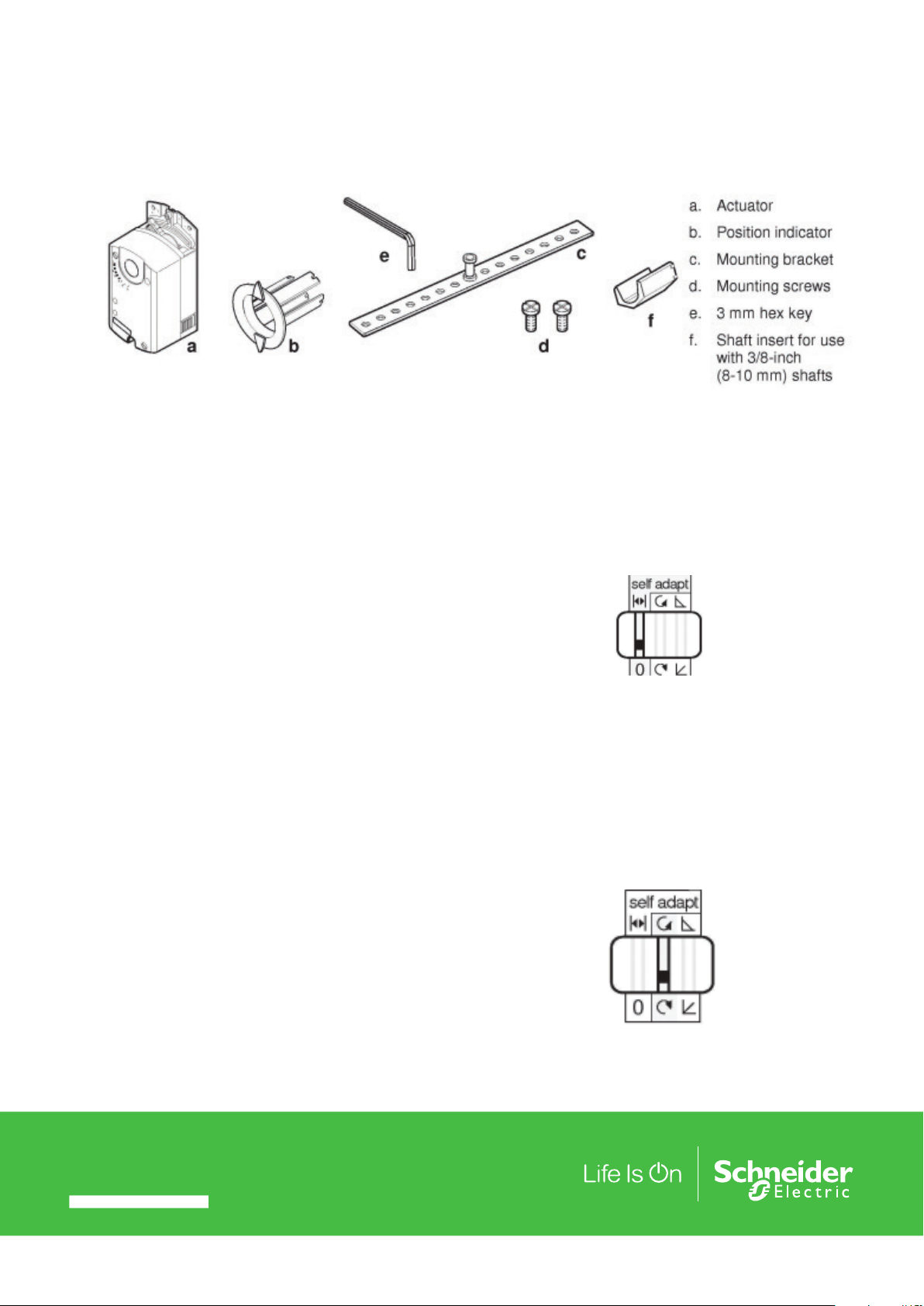

Figure-1 Parts of the Smar tX Rotary Actuator

Product Description

These installation instructions describe the steps for direct

coupled mounting of the following SmartX Actuators:

35 lb-in MF41-6043 and MS41-6043 non-spring return rotary

electronic damper models.

Product Numbers

• 3-position control: MF41-6043

• Modulating control: MS41-6043

Required Tools

• 3 mm hex wrench

• 4 mm (5/32-inch) drill bit and drill

• Phillips small flat-blade screwdrivers

• Marker or pencil

Installation Notes

• Equipment damage or data loss may occur if the user

does not follow a procedure as specified.

• Estimated installation time is 30 minutes.

• Do not open the actuator. Place the actuator on

the damper shaft so that the front of the actuator is

accessible. The label is on the front side.

Installation

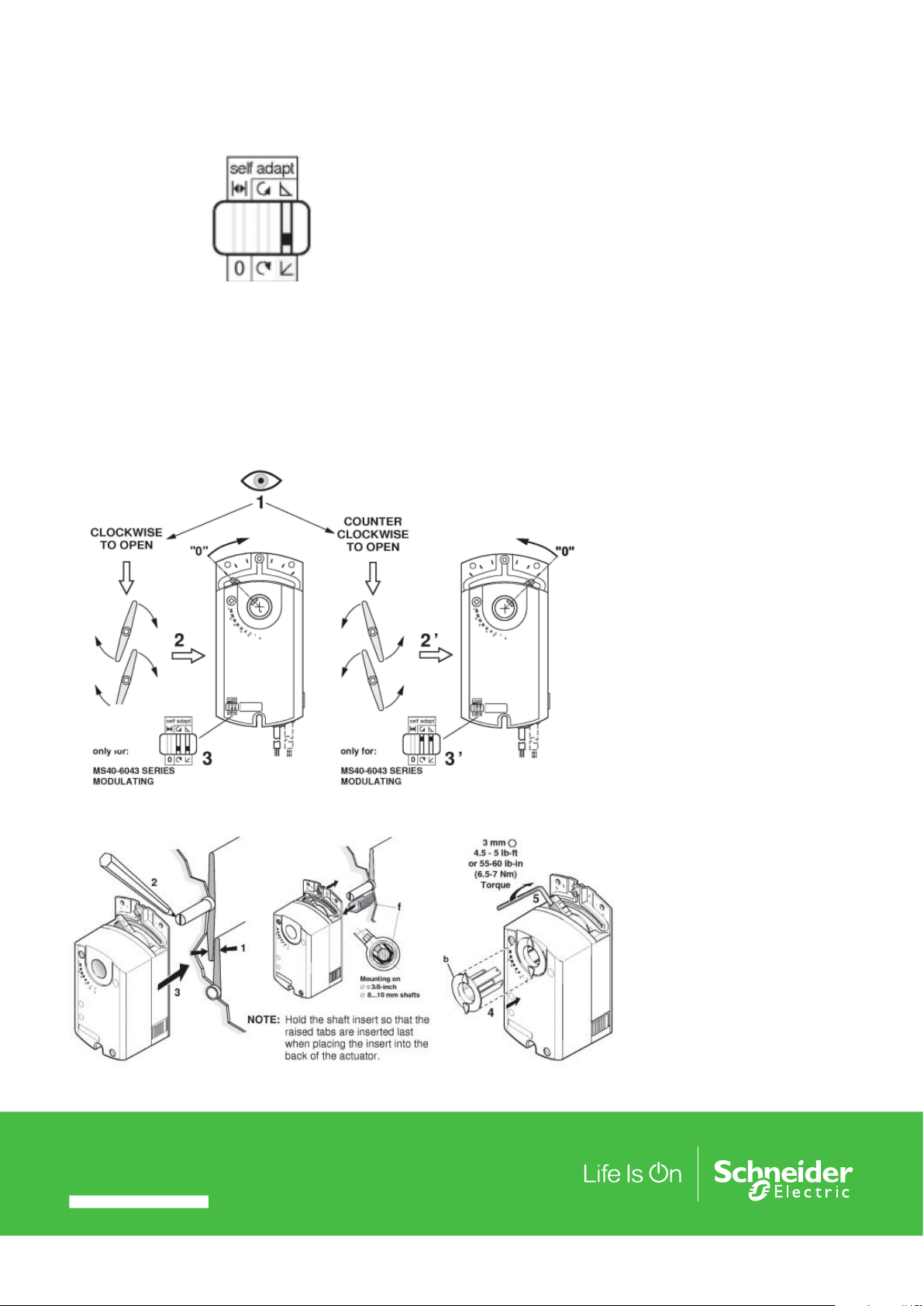

1. Determine whether the damper blades will rotate clockwise or counterclockwise to open. See Figure 7.

2. If the blades will rotate counterclockwise, slide the

manual override switch to manual, and move the adjustment lever to the right. Return the switch to automatic.

See Figure 10.

To wire an MF41-6043 actuator (three-position) for counterclockwise rotation, follow the Counterclockwise Damper Rotation instructions located in the Wiring Diagrams section when

wiring the actuator to the controller. If the actuator model

has any switches or adjustments, set them with the following

instructions.

DIP Switch Settings

For MS41-6043 only

1. To access the Dual In-line Package (DIP) switches, raise

the tab on the lower left side of the actuator.

See Figure 7.

Self-Adapt Switch (Factory setting = 0 or OFF)

Figure-2 Self-Adapt Switch.

2. When using the mechanical range stop screw to limit

the angle of damper blade rotation (see the Mechanical

Range Adjustment section for details), turn the selfadapt switch ON so that the adjusted range will become

the new 0…100% for the actuator logic. In this case,

0…100% is not equal to 1.

3. The position output signal U is not influenced by the

self-adapt function. The 0…10V feedback signal U is

always proportional to 0 to 1 (or 1 to 0).

Direction of Rotation Switch (Factory setting = Clock wise)

Figure-3 Direction of Rotation Switch.

Discolsure© 2016 Schne ider Ele ctric. All ri ghts reserved. All t radem arks ar e owned b y Schnei der Ele ctric I ndustr ies SA S or its affil iated co mpanie s. March, 2 016

Docume nt Number: F-26 736- 4

Installation Instructions

4. The direction of rotation switch should match the

damper rotation movement.

Output Signal Switch (Factory setting = Direct Acting)

Figure-4 Output Signal Switch.

5. As the clockwise angle of rotation increases, the output

voltage increases.

6. If the direction of rotation is counterclockwise, the output

signal switch should be set at reverse acting to match

the direction of the rotation switch.

7. Close the tab over the DIP switches.

Mounting

Figure-7 Setting the Direction Rotation.

Figure-8 Mounting the Actuator to the Damper Shaft.

Discolsure© 2016 Schne ider Ele ctric. All ri ghts reserved. All t radem arks ar e owned b y Schnei der Ele ctric I ndustr ies SA S or its affil iated co mpanie s. March, 2 016

Docume nt Number: F-26 736- 4

Loading...

Loading...