Page 1

Power Distribution Unit

150/175 kVA

Operation

PDPM150G6F, PDPM150L6F, PDPM175G6H

12/2020

www.schneider-electric.com

Page 2

Legal Information

The Schneider Electric brand and any trademarks of Schneider Electric SE and its

subsidiaries referred to in this guide are the property of Schneider Electric SE or its

subsidiaries. All other brands may be trademarks of their respective owners.

This guide and its content are protected under applicable copyright laws and

furnished for informational use only. No part of this guide may be reproduced or

transmitted in any form or by any means (electronic, mechanical, photocopying,

recording, or otherwise), for any purpose, without the prior written permission of

Schneider Electric.

Schneider Electric does not grant any right or license for commercial use of the guide

or its content, except for a non-exclusive and personal license to consult it on an "as

is" basis. Schneider Electric products and equipment should be installed, operated,

serviced, and maintained only by qualified personnel.

As standards, specifications, and designs change from time to time, information

contained in this guide may be subject to change without notice.

To the extent permitted by applicable law, no responsibility or liability is assumed by

Schneider Electric and its subsidiaries for any errors or omissions in the informational

content of this material or consequences arising out of or resulting from the use of the

information contained herein.

Page 3

Table of Contents

Important Safety Instructions — SAVE THESE

150/175 kVA

INSTRUCTIONS

Safety Precautions .....................................................................................8

.........................................................................................7

Commissioning..........................................................................................10

Pre-Start Checklists ..................................................................................10

Initial Inspection Checklist ................................................................... 10

Electrical Inspection Checklist.............................................................. 10

User Interface Inspection Checklist ...................................................... 10

Final Inspection Checklist .................................................................... 10

Start-up Inspection Checklist ..................................................................... 11

Operation ................................................................................................... 13

Display Interface....................................................................................... 13

Navigate the Display Interface ............................................................. 13

Top Dynamic Display...........................................................................14

Main Menu Screen..............................................................................14

Menu Tree.......................................................................................... 15

Password Protection ........................................................................... 15

Modules Submenu....................................................................................16

View Module Status Information...........................................................16

View Power Distribution Module Information .........................................17

View Circuit Status Information ............................................................18

View or Reset Module Energy Usage ................................................... 19

Configure Individual Load Name, Location, and Alarm

Thresholds ......................................................................................... 20

Enable/Disable Alarm Thresholds for Individual Loads...........................20

Enable/Disable Module Breaker-Position Alarms................................... 21

Reset Module Alarm Settings to Default................................................21

Mass Configuration of Alarms .............................................................. 22

Reset Module Cable Settings to Their Default Values ............................ 23

Subfeeds Submenu .................................................................................. 24

View General Subfeed Information ....................................................... 24

View Subfeed Operational Status and Configure Name/Location............ 25

Configure Warning and Critical Alarm Thresholds for Subfeeds .............. 26

Enable or Disable Alarm Thresholds and Alarms for Subfeed

Breakers ............................................................................................ 27

Reset Subfeed Energy Usage..............................................................28

Totals Submenu ....................................................................................... 29

View Total Load Status ........................................................................29

Total Output Current by Phase ............................................................. 29

View or Reset Total Energy Usage by Phase......................................... 30

View Voltage and Frequency ...............................................................30

View Distribution Panel Settings........................................................... 30

Configure Critical and Warning Alarm Thresholds for Total Output

Current .............................................................................................. 31

Configure Critical and Warning Alarm Thresholds for Total Output

Voltage .............................................................................................. 32

Configure the Nominal Frequency Range to Affect Alarm

Conditions..........................................................................................32

990-4599F 3

Page 4

150/175 kVA

Environment Submenu .............................................................................33

View the Status or Configure Input Contact Settings ..............................33

Configure Output Relay Settings .......................................................... 34

Configure the Alarm Relay Map ........................................................... 35

View and Configure the Subfeed Menu.................................................36

Alarms Submenu...................................................................................... 37

View Alarms ....................................................................................... 37

Log Submenu........................................................................................... 39

View or Clear Log Items ...................................................................... 39

Admin Submenu....................................................................................... 40

Configure the Network Address Settings...............................................40

Upgrade Metering Board Firmware.......................................................40

Change the Password .........................................................................41

Change Display Interface Settings .......................................................41

Change the Date and Time on the Display Interface .............................. 42

Configure Device ID Settings ............................................................... 42

View System Component Information...................................................42

Set the Configuration to Factory Defaults..............................................43

Help Submenu .........................................................................................43

Use the Help Feature .......................................................................... 43

Modbus Configuration .............................................................................. 44

Configure Modbus Through the Display Interface........................................ 44

Modbus TCP Configuration.................................................................. 44

Modbus Serial Configuration................................................................ 44

Modbus Cable Connection ........................................................................ 45

Network Management Configuration ..................................................... 46

Overview .................................................................................................46

Initial Setup ........................................................................................ 46

Device IP Configuration Wizard............................................................ 46

Supported Web Browsers....................................................................47

Network Management Features ...........................................................47

Log On ....................................................................................................47

URL Address Formats......................................................................... 47

Security ...................................................................................................48

Access Priority for Logging On ............................................................. 48

User Accounts .................................................................................... 48

Watchdog Features .................................................................................. 48

Network Interface Watchdog Mechanism .............................................. 48

Resetting the Network Timer................................................................48

Recover from a Lost Password .................................................................. 49

Maintenance ..............................................................................................50

Parts Replacement ................................................................................... 50

Determine if you Need a Replacement Part........................................... 50

Return Parts ....................................................................................... 50

Power Distribution Modules ....................................................................... 51

Component Identification..................................................................... 51

Module Circuit Breaker Operation ........................................................52

Install a Power Distribution Module.......................................................53

Remove a Power Distribution Module ...................................................59

Troubleshooting ........................................................................................ 60

4 990-4599F

Page 5

150/175 kVA

LEDs on Power Distribution Modules ......................................................... 60

Status and Alarm Messages......................................................................60

990-4599F 5

Page 6

Page 7

Important Safety Instructions — SAVE THESE

INSTRUCTIONS 150/175 kVA

Important Safety Instructions — SAVE THESE INSTRUCTIONS

Read these instructions carefully and look at the equipment to become familiar

with it before trying to install, operate, service or maintain it. The following safety

messages may appear throughout this manual or on the equipment to warn of

potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a “Danger” or “Warning” safety

message indicates that an electrical hazard exists which will result in

personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages with this symbol

to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Failure to follow these instructions will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

Failure to follow these instructions can result in injury or equipment

damage.

NOTICE

NOTICE is used to address practices not related to physical injury. The safety

alert symbol shall not be used with this type of safety message.

Failure to follow these instructions can result in equipment damage.

Please Note

Electrical equipment should only be installed, operated, serviced, and maintained

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction,

installation, and operation of electrical equipment and has received safety training

to recognize and avoid the hazards involved.

990-4599F 7

Page 8

150/175 kVA

Safety Precautions

Important Safety Instructions — SAVE THESE

INSTRUCTIONS

This manual contains important instructions that must be followed during

installation, operation, and maintenance of the PDU. For safety reasons, only

trained users are allowed to operate the display interface and replace the Power

Distribution Modules (PDMs).

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Electrical equipment must be installed, operated, serviced, and maintained only

by qualified personnel.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

To remove a Power Distribution Module:

• Turn off all power supplying the equipment and perform appropriate lockout/

tagout procedures before installing or removing the Power Distribution

Module.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• The PDU must be installed in accordance with the National Electrical Code

or the Canadian Electrical Code and all applicable local codes

• Service access areas are locked with a Red Key. The Red Keys must remain

under the control of qualified service personnel.

• Wear appropriate personal protection equipment (PPE) when performing

maintenance on this PDU.

Failure to follow these instructions will result in death or serious injury.

WARNING

UNEXPECTED BEHAVIOR OF APPLICATION

Only trained users should operate the display and replace the Power

Distribution Modules.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

CAUTION

UNPROTECTED OUTPUTS

Apply circuit protection to all outputs.

Failure to follow these instructions can result in injury or equipment

damage.

Regulatory Agency Approval

This equipment has been tested and found to comply with the limits for a class A

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

8 990-4599F

Page 9

Important Safety Instructions — SAVE THESE

INSTRUCTIONS 150/175 kVA

radiate radio frequency energy and, if not installed and used in accordance with

the installation guide, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at

his own expense.

990-4599F 9

Page 10

150/175 kVA Commissioning

Commissioning

Pre-Start Checklists

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Procedures in this section should only be performed by qualified personnel.

• Equipment must be properly de-energized and locked-out prior to performing

service.

Failure to follow these instructions will result in death or serious injury.

After installation, verify that all components are working properly and that the

equipment is ready to begin operation.

Initial Inspection Checklist

Ensure the:

• Installation procedure is complete according to the installation manual.

• Equipment shows no signs of damage.

• Clearance around the equipment is in accordance with local and national

codes and regulations as well as the installation manual.

• Equipment is leveled and joined to the adjacent racks as specified in the

installation manual.

Electrical Inspection Checklist

Ensure the:

• Incoming voltages match the phase and voltage listing on the nameplate.

• Electrical wiring complies with local and national codes and regulations.

• Equipment is properly grounded.

• All field electrical connections are tight.

• Circuit breakers are correct.

User Interface Inspection Checklist

Ensure the:

• The building management system is connected correctly.

• The network port is connected correctly and an IP address has been

assigned to the equipment.

Final Inspection Checklist

Ensure the:

• System is clean and free from debris.

• Packaging materials are disposed off properly.

10 990-4599F

Page 11

Commissioning 150/175 kVA

Start-up Inspection Checklist

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Procedures in this section should only be performed by qualified personnel.

• Wear appropriate personal protective equipment (PPE) when checking

hazardous voltages.

Failure to follow these instructions will result in death or serious injury.

• Verify that the PDU is in Total Power OFF mode.

◦ The following circuit breakers are all set to OFF.

– UIB - Unit Input Breaker

– MOB - Main Output Breaker

– UOB1 - Unit Output Breaker 1

– UOB2 - Unit Output Breaker 2

◦ All modules are OFF.

• Power up the PDU:

◦ Make sure the circuit breaker for the Fan tray is set to ON.

◦ Set the following circuit breakers to ON.

– UIB - Unit Input Breaker

– MOB - Main Output Breaker

◦ If your system uses subfeeds, set the following circuit breakers to ON.

– UOB1 - Unit Output Breaker 1

– UOB2 - Unit Output Breaker 2

◦ Set all modules that will be used to ON.

• Verify that the display interface is working properly.

• Verify through the display interface that the PDU sees the correct number of

power modules.

• Using a phase rotation meter, verify phase rotation.

• Resolve any unexpected alarms.

• Configure the date and time through the display interface.

• Review the Event Log. Check for abnormalities in the log. Resolve any

abnormalities in the log. Clear the Event Log when you are finished.

990-4599F 11

Page 12

150/175 kVA Commissioning

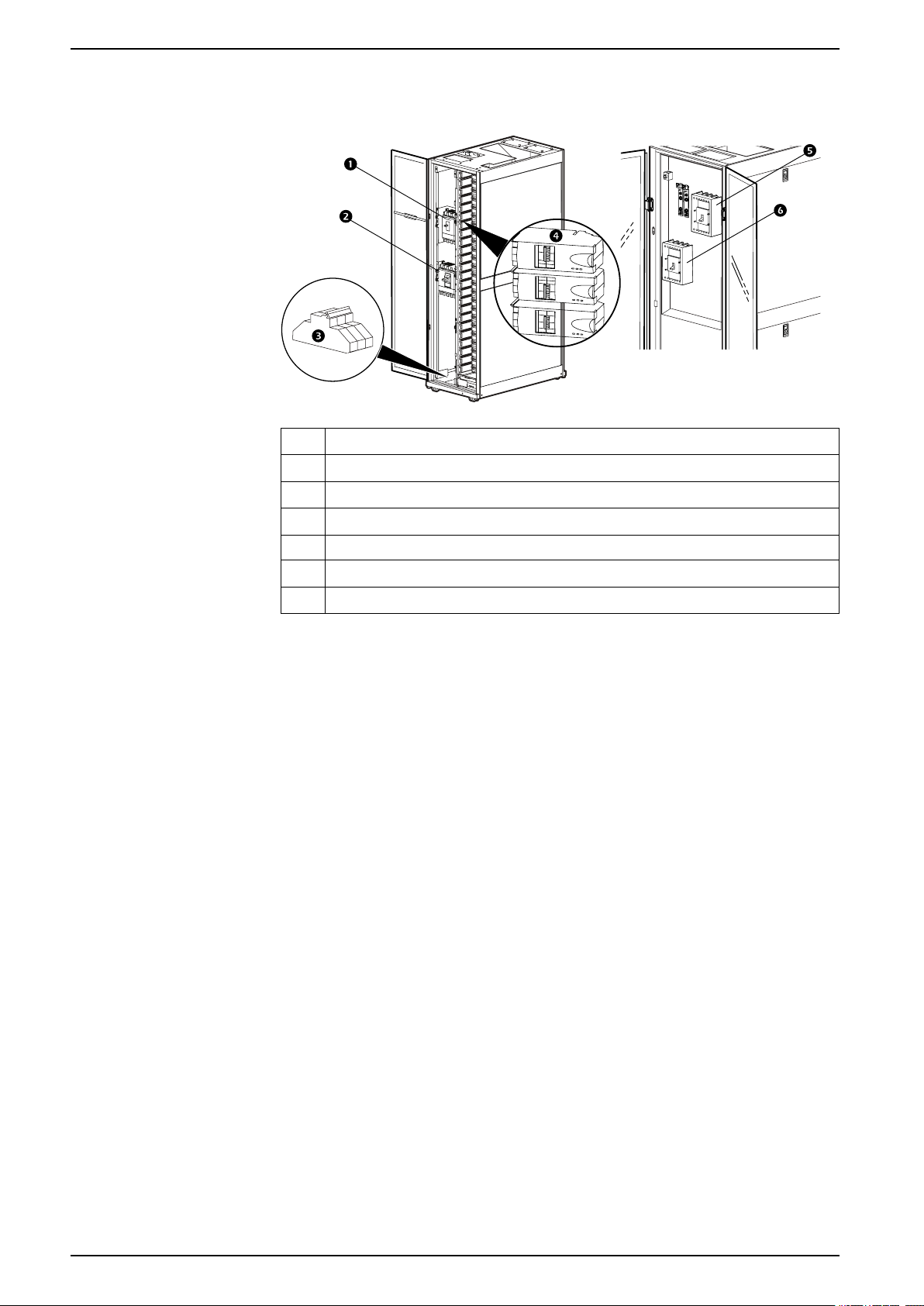

pdx0837a

pdx0928a

FRONT

REAR

INTERNAL PANELS REMOVED FOR CLARITY

Circuit Breaker Identification

Item Description

1 UIB - Unit Input Breaker

2 MOB - Main Output Breaker

3 Fan Tray Circuit Breaker

4 Module Circuit Breaker

5

UOB1 - Unit Output Breaker 1

6 UOB2 - Unit Output Breaker 2

12 990-4599F

Page 13

Operation 150/175 kVA

ESC

?

Normal

Check

Log

Warning

Critical

98765432

1

Operation

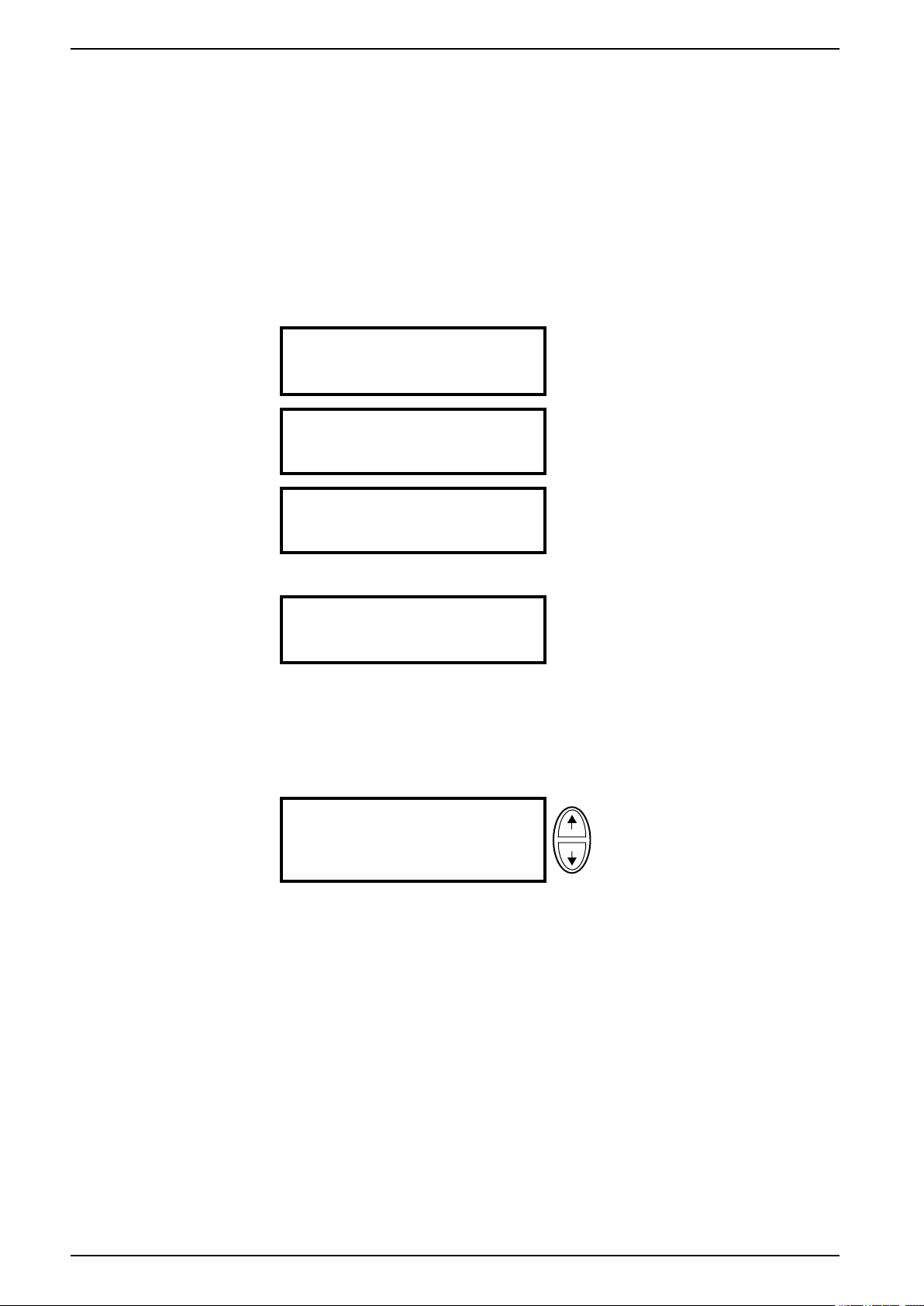

Display Interface

1 Normal LED Green = no alarms are present.

2 Check Log LED Green = a new event has been added to the

3 Warning LED Yellow = there are one or more active

4 Critical LED Red = there are one or more active critical

5

6 UP and DOWN keys Used to scroll through menu items.

7 ENTER Press to display new screens, open menu

8 ? - HELP Press to open content-sensitive help.

9 ESC Press to return to the previous screen.

Navigate the Display Interface

log.

warning alarms in the system.

alarms in the system.

LCD Screen Displays alarms, status data, instructional

help, and configuration items.

items, and finalize selections.

1. Selector arrow. Press the UP or DOWN arrow key 4 to move the selector

arrow to a menu option or setting. Press the ENTER key to view the selected

screen or modify the setting.

2. Continue arrows. Indicate that additional screens are available on a menu or

status screen. Press the UP or DOWN arrow key to view the additional items.

3. Input arrows. Input arrows next to a selected setting indicate that the setting

can be modified by pressing the UP or DOWN arrow key. Press the ENTER

key to save the change or the ESC key to cancel.

4. Press the UP or DOWN arrow key to:

a. navigate the selector arrow through the menu prompts

b. change the target item

c. edit a text string. Press the UP or DOWN arrow key to change the

character in the text string.

990-4599F 13

Press ENTER to confirm and advance to the next character.

Page 14

150/175 kVA Operation

Top Dynamic Display

When the system is running, the display interface will automatically scroll through

a series of screens showing general information about the PDU and any active

alarms on the system.

You can press the UP or DOWN arrow keys to manually scroll through these

screens.

Press ENTER at any time to go to the main menu screen.

If the display interface is inactive for the duration of a user-configured time-out

setting, it will return to the top dynamic display.

Overview Screens (No active alarms)

No Active Alarms

System Date/Time:

28-May-2012 10:37:01

Main Menu Screen

Out

L1:

L2:

L3:

Output Voltage

L1: 00V L1-2: 0V

L2: 00V L2-3: 0V

L3: 00V L3-1: 0V

Amps

0.0

0.0

0.0

kW

0.00

0.00

0.00

kVA

00.0

00.0

00.0

Overview Screen Alarm Shown

Active Alarms: 1 of 15

Communication Lost

With Metering Board

[1.6]

The main menu screen is the top-level screen on the display interface. The main

menu contains eight submenus that allow you to monitor and configure specific

aspects of the system.

Modules

Subfeeds

Totals

Environment

Alarms

Log

Admin

Help

NOTE: Pressing the UP arrow key when the first item in the main menu is

selected will result in the cursor moving to the last item on the screen, and vice

versa.

14 990-4599F

Page 15

Operation 150/175 kVA

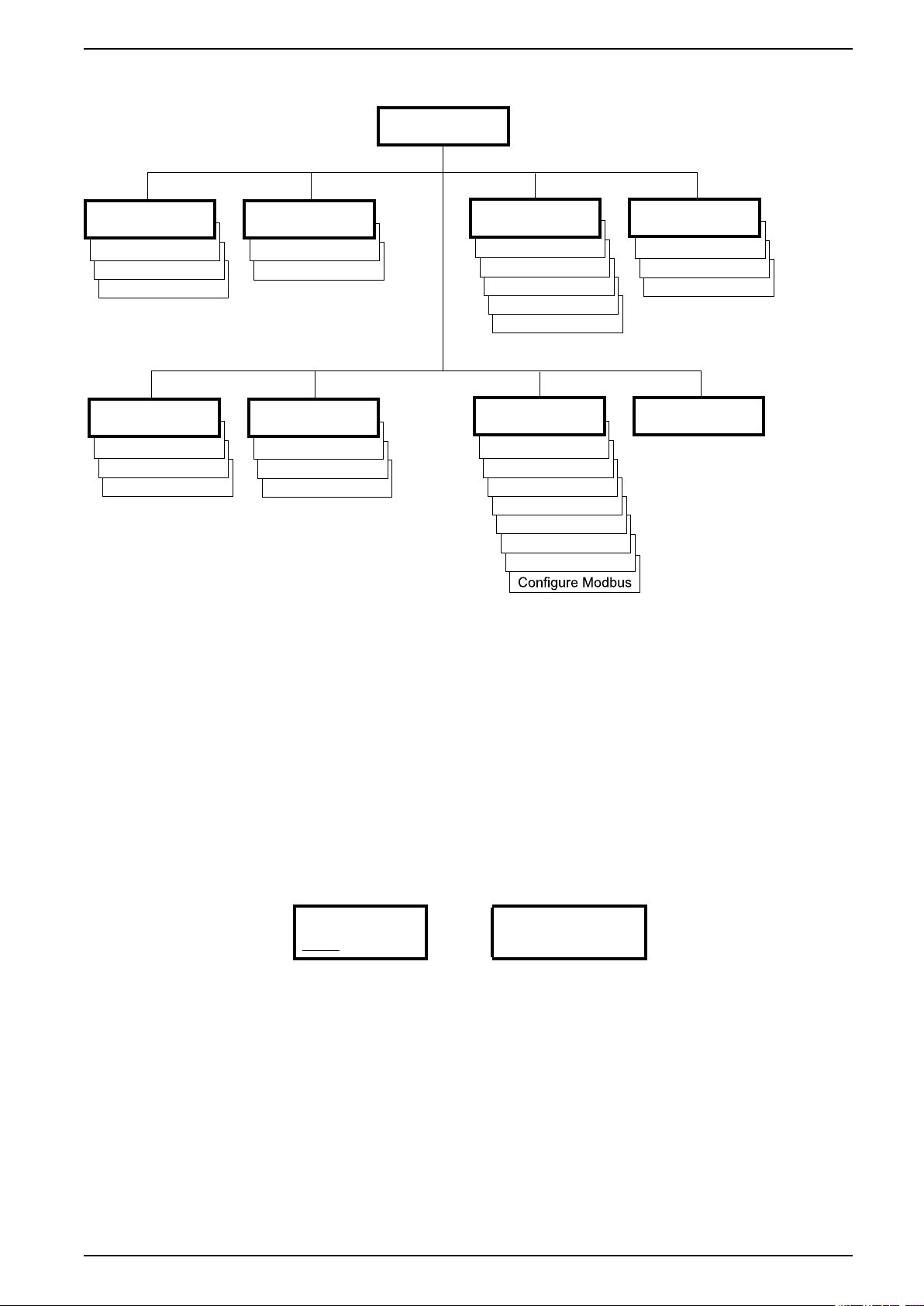

Input Contacts

Output Relays

Alarm Relay Map

Total Load Status

Total Load by Phase

Total Energy Usage

Status & Config

Factory

Main Menu

Modules

Subfeeds

Totals

Environment

Date/Time

Factory Defaults

Firmware Upgrade

Network Setup

Local Interface

Date/Time

Device ID

Manufacturer Data

New Logged Items

Entire Log

Clear Log

All Active Alarms

Active by Severity

Active by Type

Help

Admin

Log

Alarms

Module View

Load/Energy Meter

Circuit Config

Output Alarms Cfg

Volt-Meter

pdx0501a

Menu Tree

Password Protection

Certain screens can be configured to require a predefined password in order to

allow the user access to those screens. Pressing the ENTER key after selecting a

protected screen will result in the user being prompted for the password.

Passwords are case sensitive and can be up to eight characters in length. Use the

UP or DOWN arrow keys to scroll to different letters in the alphabet. Upper case

characters are shown first and then lower case characters. Press the ENTER key

to make a character selection. After you make your selection, the cursor will

automatically move to the location of the next character. At the end of the string,

select the underline (“_”) character and press ENTER.

Your system administrator may configure some screens to be passwordprotected. The input password will expire after a period of inactivity also

configured by the administrator.

Enter password:

*****

Incorrect Password:

Press any key to

Try again...

990-4599F 15

Page 16

150/175 kVA Operation

Modules Submenu

View Module Status Information

1. From the main menu screen, select Modules > Module View.

2. Press ENTER at the Module number. Scroll through the module list to the

specific module and press ENTER.

3. To view more information about the module, select Circuit Details and press

ENTER.

Module:↕00 of 00

Status: Critical

→ Circuit Details

About This Module

4. For 3-cable modules, select the relevant cable and press ENTER.

Module 00:

>Cable 1:

→>Cable 2:

>Cable 3:

Cable 0:

Normal

Critical

Normal

5. Scroll through the three status screens to view power level, amperage, and

alarm status of the selected module. Note the warning alarm on L2 in the

example below. An alarm status of High!, Low!, Min!, or Max! indicates a

reading above or below the threshold level.

Module 00,

Name

Circuit (Name)

Power: 00.0 kW

Mod 00, Breakers:

L1: Closed

L2: Open

L3: Closed

Mod 00, Cable 0:

L1: 0.0A 0.0%

L2: 0.0A 0.0% High!

L3: Closed

Cable 0:

Critical

↓

↑

↓

↑

16 990-4599F

Page 17

Operation 150/175 kVA

View Power Distribution Module Information

1. From the main menu screen, select Modules > Module View and press

ENTER.

2. Press ENTER at the Module number. Scroll through the module list to the

specific module and press ENTER.

3. Select About This Module and press ENTER.

Module:↕00 of 00

Status: Normal

Circuit Details

→ About This Module

4. The selected module is shown in this submenu.

Module: 00

Module Mfg Info a

Cable Details b

Breaker Ratings c

Select to view either:

a. Module Mfg Info

Module 00 Info:

Model: xxxxxxxxxx

S/N: xxxxxxxxxxxx

Mfg Date: dd/mm/yyyy

b. Cable Details

Mod 00, Cable: 0 of 0

Length: 0.0ft (0.0m)

Connector: IEC309-3W

Voltages 400V

c. Breaker Ratings

Mod 00, Cable: ↕0 of 0

Breaker Ratings:

L1:0.0A L2:0.0A L3:0.0A

990-4599F 17

Page 18

150/175 kVA Operation

View Circuit Status Information

The Load/Energy screens are used for status information on a circuit level and the

data is grouped by output cable. Scroll through the list to the specific circuit. The

circuit names are stated for identification.

1. From the main menu screen, select Modules > Load/Energy Meter.

2. Select from the Circuit Loading submenu:

Circuit Loading

→ Current & Power a

Percent Loading b

Energy Usage kWh c

a. Current & Power

Mod 00 Cable: 0 of 0

Circuit Name

L1:0A L2:0A L3:0A

Total Power: 0.00kW

b. Percent Loading

Mod 00, Cable: 0 of 0

L1: 0.0A 0.0%

L2: 0.0A 0.0%

L3: 0.0A 0.0%

c. Energy Usage (kWh)

Mod 00 Cable: 0 of 0

Circuit Name

Energy: 0000000.0 kWh

Reset: mm/dd/yyyy

18 990-4599F

Page 19

Operation 150/175 kVA

View or Reset Module Energy Usage

1. From the main menu screen, select Modules > Load/Energy Meter >

Energy Usage (kWh).

2. Press ENTER at the Module number. Scroll through the module list to the

specific module and press ENTER.

3. To reset energy usage, select Reset and press ENTER.

Mod 00 Cable: 0 of 0

Circuit (Name)

Energy: 0000000.0 kWh

→ Reset: mm/dd/yyyy

4. Select the scope of the reset: only the selected cable or module, or all

modules in the PDU.

Select kWh to Reset:

→ Mod: 00 Cable: 0

All of Module 00

All System Modules

5. Select YES, Reset kWh Now to authorize the reset, or NO. ABORT to abort.

Confirm kWh Reset

< type of reset >

NO. ABORT

→ YES, Reset kWh Now

6. The screen confirms that the reset has been completed. Press any key to

continue.

kWh Reset Complete

Press any key ...

990-4599F 19

Page 20

150/175 kVA Operation

Configure Individual Load Name, Location, and Alarm Thresholds

1. From the main menu screen, select Modules > Circuit Config > Individual

Load Cfg.

2. Scroll to the desired module and cable and press ENTER.

Mod: 00 Cable: 0 of 0

< Circuit Name >

→ Name/Location a

Alarm Configuration b

a. Move the selector arrow to Name/Location and press ENTER.

Specify the name and location.

→M 00 Cable: 0 of 0

Circuit Name

Location

Zone 0. Row 0. Rack 0

b. Select Alarm Configuration and press ENTER.

From the next screen, select Warning Thresholds or Critical

Thresholds. Press ENTER. Scroll to the desired High and Low

threshold. Enabled or Disabled the Alarm for each. Press ENTER.

M 00 Cable: 0 of 0

Alarms: Enabled

→ Alarm Thresholds

Reset to Defaults

M 00 Cable: 0 of 0

→ Warning Thresholds

Critical Thresholds

Position Alarms

M 00 Cable: 0 of 0

Warning Thresholds

→ High: 000% (00.0A)

Alarm: Enabled

Enable/Disable Alarm Thresholds for Individual Loads

1. From the main menu screen, select Modules > Circuit Config > Individual

Load Cfg > Module # > Alarm Configuration > Alarm Thresholds.

2. Select Alarms and press ENTER. The input arrow will be activated and you

can use the UP or DOWN arrow key to select Enabled or Disabled. Press

ENTER when finished to save the setting.

M 00 Cable: 0 of 0

→ Alarms:↕Enabled/Disabled

Alarm Thresholds

Reset to Defaults

20 990-4599F

Page 21

Operation 150/175 kVA

Enable/Disable Module Breaker-Position Alarms

1. From the main menu screen, select Modules > Circuit Config > Individual

Load Cfg > Module # > Alarm Configuration > Alarm Thresholds.

2. Move the selector arrow to the breaker you want. At the input arrow, use the

UP or DOWN arrow key to select Enabled or Disabled for the selected

breaker. Press ENTER to save the setting.

M 00, Brkr Alarms:

L1: Enabled

→ L2:↕Enabled

L3: Enabled

Reset Module Alarm Settings to Default

1. From the main menu screen, select Modules > Circuit Config > Individual

Load Cfg > Module # > Alarm Configuration > Reset to Defaults.

2. Select the module and cable you want or all modules and press ENTER.

What do you want to

reset to defaults

→ Mod: 00 Cable:↕ 00

All of Module 00

3. Select YES to reset, or NO to abort and press ENTER.

Confirm Reset:

Reset Type

NO, ABORT

→ YES, Reset kWh

990-4599F 21

Page 22

150/175 kVA Operation

Mass Configuration of Alarms

1. From the main menu screen, select Modules > Circuit Config > Mass

Configuration.

2. On the submenu, select from the list:

Mass Configuration

→ Threshold Values a

Threshold Enable b

Breaker Position c

a. Select Threshold Values and press ENTER.

Scroll to the desired High, Low, Min, andMax settings for alarm

thresholds. Select Apply to All and press ENTER.

Pick Alarm Limits:

→ Min:↕ 00% Hi: 00%

Low: 00% Max: 00%

Apply to All

Select YES, Apply Settings to apply settings, or NO, ABORT to abort

the process. Press ENTER to save your settings.

Confirm:

Mass Configure?

NO, ABORT

→ YES, Apply Settings

b. Select Threshold Enable and press ENTER. Set Alarms to On, Off, or *

(no change). Set High, Low, Min, and Max threshold alarms to On, Off,

or *(no change). Select Apply to All and press ENTER to save your

settings.

→ Alarms: *

Min:↕Off Hi: *

Low: * Max: Off

Apply to All

c. Select Breaker Position and press ENTER. Set Breaker Position

Alarms for Enabled or Disabled. Select Apply to All and press ENTER

to save your settings.

Breaker Position

→ Alarms:↕ Enabled

Apply to All

22 990-4599F

Page 23

Operation 150/175 kVA

Reset Module Cable Settings to Their Default Values

1. From the main menu, select Modules > Circuit Config.

2. Select Reset Ckt Defaults and press ENTER. The following screens are

typically password protected.

Individual Load Cfg

Mass Configuration

→ Reset Ckt Defaults

3. Select the scope of the reset: All Settings or Only Alarm Settings. Press

ENTER.

Reset Default Values

For Distr. Circuits:

→ All Settings

Only Alarm Settings

4. Select YES, Reset Now to apply the reset, or NO, ABORT to abort the reset.

Press ENTER.

Confirm Reset:

Reset Type

NO, ABORT

→ YES, Reset Now

990-4599F 23

Page 24

150/175 kVA Operation

Subfeeds Submenu

View information concerning the operational status of subfeeds, if installed. Also,

set and reset alarm thresholds for the subfeeds.

NOTE: If your PDU does not support subfeeds, ignore this section and all

references to subfeeds.

View General Subfeed Information

1. From the main menu, select Subfeeds.

Modules

→ Subfeeds

Totals

Environment

Alarms

Log

Admin

Help

a. If there are no subfeeds installed in your PDU, this screen will be

displayed after you select Subfeeds from the main menu.

Subfeeds not available with

this system

Press any key

b. To view general subfeed information, select Factory and press ENTER.

Subfeeds

Status & Config

→ Factory

Scroll to the desired Subfeed to view its installation status and breaker

rating.

→Subfeed:↕ 0 of 0

Installed: YES

Rating: 000A

24 990-4599F

Page 25

Operation 150/175 kVA

View Subfeed Operational Status and Configure Name/Location

1. From the main menu, select Subfeeds > Status & Config.

2. Scroll to the desired Subfeed. The Subfeed Name will reflect your selection.

Subfeed:↕ 0 of 0

< Subfeed Name >

→ Status: Normal a

Configuration b

a. Select Status. The status can be Normal, Warning, or Critical.

Subfeed 0 Current

L1: 000A 000%

L2: 000A 000%

L3: 000A 000% high!

Press ENTER to view the current, power, energy usage, and operational

status of the subfeed.

Subfeed 0

Power: 000.00 kW

Energy: 0000000 kWh

Breaker: Open - Alarm!

b. Select Configuration > Name/Location.

Subfeed: 0

Alarm Configuration

→ Name/Location

Reset kWh

Specify the Name and Location of the subfeed.

Scroll through the characters. Press ENTER to select the displayed

character and proceed to the next character. When you are finished

entering the characters, press ENTER to save.

Subfeed 0 Name

→ Subfeed Name

Location

Subfeed Location

990-4599F 25

Page 26

150/175 kVA Operation

Configure Warning and Critical Alarm Thresholds for Subfeeds

1. From the main menu, select Subfeeds > Status & Config .

2. Scroll to the desired Subfeed. Select Configuration > Alarm Configuration

> Alarm Thresholds and press ENTER.

Subfeed:↕ 0 of 0

< Subfeed Name >

Status: Normal

→ Configuration

3. Select Alarm Configuration and press ENTER.

Subfeed: 0

→ Alarm Configuration

Name/Location

Reset kWh

4. Select Alarm Thresholds and press ENTER.

Subfeed: 0

Alarms: Disabled

→ Alarm Thresholds

Position Alarms

5. Select Warning Thresholds or Critical Thresholds and press ENTER.

Subfeed 0

→ Warning Thresholds a

Critical Thresholds b

a. Scroll to the desired High and Low warning thresholds and set Alarm as

Enabled or Disabled for each of these thresholds. Press ENTER to save

the settings.

Subfeed 0

Warning Thresholds

→ High: 00% (000.0 A)

Alarm: Enabled

b. Scroll to the desired Min (minimum) and Max (maximum) critical

thresholds and set Alarm as Enabled or Disabled for each of these

thresholds. Press ENTER to save the settings.

Subfeed 0

Critical Thresholds

→ Max: 00% (000.0 A)

Alarm: Disabled

26 990-4599F

Page 27

Operation 150/175 kVA

Enable or Disable Alarm Thresholds and Alarms for Subfeed Breakers

1. From the main menu, select Subfeeds > Status & Config.

2. Scroll to the desired Subfeed. Select Configuration and press ENTER.

Subfeed:↕ 0 of 0

< Subfeed Name >

Status: Normal a

→ Configuration b

3. Select Alarm Configuration and press ENTER.

Subfeed: 0

→ Alarm Configuration

Name/Location

Reset kWh

4. Select from Alarms or Position Alarms.

Subfeed: 0

→ Alarms:↕ Disabled a

Alarm Thresholds

Position Alarms b

a. To configure alarm thresholds, select Alarms and set to Enabled or

Disabled. Press ENTER.

NOTE: When Disabled, this setting inhibits ALL alarms pertaining to

the selected subfeed.

b. To configure breaker position alarms, select Position Alarms and press

ENTER. Select Alarm and set to Enabled or Disabled.

Subfeed 0

Breaker Position

→ Alarm: ↕ Enabled

990-4599F 27

Page 28

150/175 kVA Operation

Reset Subfeed Energy Usage

1. From the main menu, select Subfeeds > Status & Config.

2. Scroll to the desired Subfeed. Select Configuration and press ENTER.

Subfeed:↕ 0 of 0

< Subfeed Name >

Status: Normal

→ Configuration

3. Select Reset kWh and press ENTER.

Subfeed: 0

Alarm Configuration

Name/Location

→ Reset kWh

4. Select YES, Reset Now to apply the reset, or NO, ABORT to abort. Press

ENTER.

Confirm Reset:

Subfeed 0 kWh

NO, ABORT

→ YES, Reset Now

5. The confirmation screen confirms the reset was successful. Press any key to

continue.

KiloWatt-Hours

now reset

Press any key . . .

28 990-4599F

Page 29

Operation 150/175 kVA

Totals Submenu

The Totals submenu allows you to view comprehensive information concerning

the operational status of the PDU. It also allows you to set and reset alarm

thresholds for the entire system.

View Total Load Status

1. From the main menu, select Totals > Total Load Status.

2. Status can be Normal, Warning, or Critical. View power factor and load (in

kW and kVA).

Total Load Summary

Status: Normal

kW: 000.0

kVA: 000.0 PF: 0.00

Total Output Current by Phase

1. From the main menu, select Totals > Total Load by Phase.

2. View Total Output Current and power factor for each phase. High!, Low!,

Min!, or Max! indicates a reading above or below the threshold level.

Total Output Current

L1: 000A 000%

L2: 000A 000% High!

L3: 000A 000%

KVA kW PF

L1: 00.0 00.0 0.00

L2: 00.0 00.0 0.00

L3: 00.0 00.0 0.00

990-4599F 29

Page 30

150/175 kVA Operation

View or Reset Total Energy Usage by Phase

1. From the main menu, select Totals > Total Energy Usage.

Total Energy Usage

Energy: 000000 kWh

→ Usage by Phase: a

Reset: mm/dd/yyyy: b

a. Select Usage by Phase and press ENTER to view total energy usage by

phase.

Energy Usage (kWh)

L1: 0000000

L2: 0000000

L3: 0000000

b. Select Reset and press ENTER to reset the total KiloWatt hours energy

usage to zero. The date of the last reset is shown.

Select YES, Reset Now to apply the reset, or NO, ABORT to abort.

Press ENTER.

The next screen confirms that the reset has been completed. Press any

key to continue.

View Voltage and Frequency

1. From the main menu, select Totals > Volt-Meter.

2. View frequency and voltage by phase.

Voltages Freq: 60.0

L1: 0.0 L1-2: 0.0

L2: 0.0 L2-3: 0.0

L3: 0.0 L3-1: 0.0

View Distribution Panel Settings

1. From the main menu, select Totals > Output Alarms Cfg > Nominal

Settings.

Confirm Reset:

Total Output: kWh

NO, ABORT

→ YES, Reset Now

KiloWatt-Hours

now reset

Press any key . . .

Total Load Thresh

Voltage Thresholds

Frequency Threshold

→Nominal Settings

2. View Voltage, Frequency, and Ampere Rating for the distribution panel.

Distribution Panel

Voltage (L-N): 000 V

Frequency: 00 Hz

Ampere Rating: 000 A

30 990-4599F

Page 31

Operation 150/175 kVA

Configure Critical and Warning Alarm Thresholds for Total Output Current

1. From the main menu, select Totals > Output Alarms Cfg > Total Load

Thresh.

2. Select the Total Current Alarm threshold you want to configure.

Total Current Alarm

→ Warning Thresholds a

Critical Thresholds b

a. Select Warning Thresholds and press ENTER.

Scroll to the desired High and Low warning thresholds and set Alarm as

Enabled or Disabled for each of these thresholds. Press ENTER.

Total Current

Warning Thresholds

→ High:↕ 00% (000.0 A)

Alarm:↕ Enabled

Total Current

Warning Thresholds

Low:↕ 00% (000.0 A)

Alarm:↕ Disabled

b. Select Critical Thresholds and press ENTER.

Scroll to the desired Max and Min critical thresholds and set Alarm as

Enabled or Disabled for each of these thresholds. Press ENTER to save

your settings.

Total Current

Critical Thresholds

→ Max:↕ 00% (000.0 A)

Alarm:↕ Enabled

Total Current

Critical Thresholds

Min:↕ 00% (000.0 A)

Alarm:↕ Disabled

990-4599F 31

Page 32

150/175 kVA Operation

Configure Critical and Warning Alarm Thresholds for Total Output Voltage

1. From the main menu, select Totals > Output Alarms Cfg > Voltage

Thresholds.

2. Select the Output Voltage Alarm threshold you want to configure.

Output Voltage Alarm

→ Warning Thresholds a

Critical Thresholds b

a. Select Warning Thresholds and press ENTER.

Scroll to the desired High and Low warning thresholds and set Alarm as

Enabled or Disabled for each of these thresholds. Press ENTER.

Output Voltage

Warning Thresholds

→ High:↕ 00% (000.0 A)

Alarm:↕ Enabled

Output Voltage

Warning Thresholds

Low:↕ 00% (000.0 A)

Alarm:↕ Disabled

b. Select Critical Thresholds and press ENTER.

Scroll to the desired Max and Min critical thresholds and set Alarm as

Enabled or Disabled for each of these thresholds. Press ENTER to save

your settings.

Output Voltage

Critical Thresholds

→ Max:↕ 00% (000.0 A)

Alarm:↕ Enabled

Output Voltage

Critical Thresholds

Min:↕ 00% (000.0 A)

Alarm:↕ Disabled

Configure the Nominal Frequency Range to Affect Alarm Conditions

1. From the main menu, select Totals > Output Alarms Cfg > Frequency

Threshold.

2. Set Range for +/- 9.0 Hz, +/- 5.0 Hz, +/- 4.0 Hz, +/- 3.0 Hz, +/- 2.0 Hz, +/- 1.5

Hz, +/- 1.0 Hz, +/- 0.5 Hz, +/- 0.2 or Disabled. Press ENTER.

Output Frequency

Critical Thresholds

Range: Disabled

32 990-4599F

Page 33

Operation 150/175 kVA

Environment Submenu

View the Status or Configure Input Contact Settings

1. From the main menu, select Environment > Input Contacts.

2. Scroll to the desired Input Contact. Up to 4 input contacts can be installed.

The contact name reflects your selection. Status can be Normal, Warning, or

Critical.

Input Contact:↕ 0 of 4

< contact name >

→ Status: Normal a

Configuration b

a. Select Status and press ENTER.

View the Normal condition (Open or Closed) of the contact and the

actual State of the contact (Open or Closed).

NOTE: When Normal and State are the same, the Status is

Normal. When Normal and State are different, an alarm condition

occurs.

< Contact name >

Status: Normal

Normal: Open

State: Open

b. Select Configuration and press ENTER.

Set Alarms as Enabled or Disabled.

Set Severity as Warning or Critical.

Set Normal state as Open or Closed.

Select Name/Location and press ENTER.

Specify the Name and Location of the input contact by scrolling through

the characters.

Press ENTER to select the displayed character and proceed to the next

character. To end the string, select the underline (“_”) character and

press ENTER.

→Name/Location X

Alarms: Enabled

Severity: Critical

Normal: Open

→Contact X Name:

User Contact X

Location:

Location: X

990-4599F 33

Page 34

150/175 kVA Operation

Configure Output Relay Settings

1. From the main menu, select Environment > Output Relays.

2. Scroll to the desired Output Relay. Up to 4 output relays can be installed.

The contact name reflects your selection. Status can be Open or Closed.

Select Configuration and press ENTER.

Output Relay:↕ 0 of 4

< contact name >

Status: Normal

→ Configuration

3. Specify the Name of the output relay by scrolling through alphabet

characters. Press ENTER to select the displayed character and proceed to

the next character. To end string, select underline (“_”) and press ENTER. Set

Normal state as Open or Closed. Press ENTER.

Relay X Name:

Output Relay X

Normal: Closed

34 990-4599F

Page 35

Operation 150/175 kVA

Configure the Alarm Relay Map

1. From the main menu, select Environment > Alarm Relay Map.

2. Select a category: Environment, System Output, or Breaker Modules.

Categories are system specific. Press ENTER.

Select an alarm condition for the selected category (a, b, or c). Press ENTER.

→ Environment a

System Output b

Breaker Modules c

Subfeed 1 d

a.

Environment

→ Contact 1

Contact 2

Contact 3

Contact 4

b.

System Output

→ Max Current

High Current

Low Current

Min Current

→ Max Voltage

High Voltage

Low Voltage

Min Voltage

Freq Alarm

c.

Breaker Modules

Max Current

High Current

→ Low Current

Min Current

Breaker Pos

3. Select the Relay or Relays (R1, R2, R3, and R4) that will be activated when

the specified alarm condition occurs. Press ENTER. Both category and alarm

condition can be changed from this screen to allow you to configure the entire

map using this screen.

System Output

Max Current

Relays:

R1 R2 R3 R4

990-4599F 35

Page 36

150/175 kVA Operation

View and Configure the Subfeed Menu

1. From the main menu, select Environment > Alarm Relay Map .

2. Select Subfeed 1 or Subfeed 2 .

Environment

System Output

Breaker Modules

→ Subfeed 1

→ Subfeed 2

3. Your selections from each Subfeed are:

Subfeed *

→ Max Current a

High Current b

Low Current c

Min Current d

Breaker Pos e

a. Max Current

Subfeed *

→ Max Current

Relays

√ R1 R2 R3 R4

b. High Current

Subfeed *

→ High Current

Relays

R1 R2 R3 R4

c. Low Current

Subfeed *

→ Low Current

Relays

R1 R2 R3 R4

d. Min Current

Subfeed *

→ Min Current

Relays

R1 R2 R3 R4

e. Breaker Position

Subfeed *

→ Breaker Position

Relays

R1 R2 R3 R4

NOTE: In the illustration above, at the display screen for Max Current, a

check has been placed in front of Relay R1. The check means an alarm will

signal for R1 if a Max Current condition exists.

36 990-4599F

Page 37

Operation 150/175 kVA

Alarms Submenu

View Alarms

1. From the main menu, select Alarms.

→All Active Alarms

Active by Severity

Active by Type

990-4599F 37

Page 38

150/175 kVA Operation

2. Select from the submenu:

a. Select All Active Alarms.

The most recent Active Alarm is displayed. Press the ENTER or UP

arrow key to go to the next alarm in sequence. Press the DOWN arrow

key to go to the previous alarm in sequence.

When there are no active alarms, the No Alarms screen displays.

Active Alarm: 00 of 00

< Description

No Active Alarms

System Date/Time:

01-Jan-2012 17:45:00

of active

alarm >

b. Select Active by Severity.

Select Warning or Critical.

0 is the number of active alarms of that type. Press ENTER.

The most recent Active Alarm of the severity you chose is displayed.

Press the ENTER or UP arrow key to go to the next alarm in sequence.

Press the DOWN arrow key to go to the previous alarm in sequence.

If there are no active alarms of the selected severity, the next screen will

inform you.

View Active Alarms

→ Warning (0)

Critical (0)

Active Alarm: 00 of 00

< Description

No Active Alarms

of Type Warning.

System Date/Time:

01-Jan-2012 17:45:00

of active

alarm >

c. Select Active by Type.

Select Distribution or Environment.

The most recent Active Alarm of the type you chose is displayed. Press

the ENTER or UP arrow key to go to the next alarm in sequence. Press

the DOWN arrow key to go to the previous alarm in sequence.

If there are no active alarms of the selected severity, the next screen will

inform you.

View Active Alarms

→ Distribution (0)

Environment (0)

Active Alarm: 00 of 00

< Description

of active

alarm >

No Active Alarms

of Type Warning.

System Date/Time:

01-Jan-2012 17:45:00

38 990-4599F

Page 39

Operation 150/175 kVA

Log Submenu

View or Clear Log Items

1. From the main menu, select Log.

→New Logged Items

Entire Log

Clear Log

2. Select from the submenu:

a. Select New Logged Items. All events logged since your last viewing will

display. The most recent item is displayed first.

NOTE: All logged items include a time stamp.

Press the ENTER or UP arrow key to go to the next alarm in sequence.

Press the DOWN arrow key to go to the previous alarm in sequence.

The No Logged Items screen displays when there are no new logged

items.

Logged Item: 00 of 00

< Description of

Most Recent Alarm >

dd/mm/yyy hh:mm:ss

No New Logged Item

System Date/Time:

21-Jan-2012 17:45:00

b. Select Entire Log. All events logged since the log was last cleared will

display.

The most recent item is displayed first. Press the ENTER or UP arrow

key to go to the next item in sequence.

Press the DOWN arrow key to go to the previous item in sequence.

The No Logged Items screen displays when there are no new logged

items.

c. Select Clear Entire Log.

The following screens are typically password protected. Select YES,

Clear Log to clear the log, or NO to cancel the process. If you press

YES, Clear Log, the next screen confirms that the log has been cleared.

Press any key to continue.

Confirm:

Clear Entire Log

Cancel

→ YES, Clear Log

Log cleared

Press any key to

return to previous menu.

990-4599F 39

Page 40

150/175 kVA Operation

Admin Submenu

Configure the Network Address Settings

1. From the main menu, select Admin > Network Setup.

2. View network address information. Select Mode and press ENTER.

Stat: +Up

→ Mode: DHCP & BOOTP

IP: 000.000.000.000

SM: 000.000.000.000

GW: 000.000.000.000

MAC Address:

[ 00 00 00 00 00 00 ]

3. Select the appropriate network configuration type.

→Fixed IP Addr a

DHCP Only b

BOOTP Only b

DHCP & BOOTP b

a. Select Fixed IP Address and press ENTER. Specify the IP, Subnet Mask

(SM), and Gateway (GW) addresses. Select Use Fixed Address and

press ENTER.

IP: 000.000.000.000

SM: 000.000.000.000

GW: 000.000.000.000

Use Fixed Address

b. Select DHCP Only, BOOTP Only, or DHCP & BOOTP. Select YES,

Restart Now to reboot with new address, or NO, Revert to revert to the

previous address.

Reboot needed for

this change, OK?

→ YES, Restart Now

Upgrade Metering Board Firmware

NOTE: Firmware versions 3.7.1 and later will auto-update.

1. From the main menu, select Admin > Firmware Upgrade.

2. Select YES. Download to download firmware, or NO. ABORT to abort the

process. Press ENTER.

NO, Revert

Update Meter PCB

FW to rev XX.XX?

NO. ABORT

→ YES. Download

3. If YES. Download is selected, this screen confirms that the firmware is being

upgraded. Wait for the process to conclude and then press any key to

continue.

Updating Meter PCBs

This will take

approximately XX min.

Press any key . . .

40 990-4599F

Page 41

Operation 150/175 kVA

Change the Password

1. From the main menu, select Admin > Local Interface > Local Password.

2. Specify the new Password by scrolling through alphabet characters using the

UP or DOWN arrow keys. Press ENTER. You can also change the Timeout

period. Scroll to your numerical selection and press ENTER.

Password: *********

Timeout: XX min.

Invalidate NOW

An Administrator User can cause a password timeout to expire using the

Invalidate NOW feature. This is useful if another user has logged in and

neglected to log out since only one user at a time may be logged in.

NOTE: Characters are presented in the following sequence: _, (space), A, B,

C, D, E, etc. Press the ENTER key to select the displayed character and

proceed to the next character. Passwords can be up to eight characters in

length. If your password is less than eight characters, end with the underline

(“_”) character.

Change Display Interface Settings

1. From the main menu, select Admin > Local Interface > Display Behavior.

2. Select the setting you want to change and press ENTER.

→Contrast: ↕ 0 a

Key Click: ↕ On b

Beeper Volume: ↕ Med c

Check Log Light d ↓

a. Contrast can be set between 1 (low) and 7 (high).

b. Key Click can be set to On or Off.

c. Beeper Volume can be Low, Med, High, or Off.

d. The Check Log Light option allows you to change the types of logged

items that cause the Check Log LED to illuminate. Select Check Log

Light and press ENTER.

Scroll to choose Info (informational), Warning, Critical, or Disabled and

press ENTER. Your selection represents the minimal type of event

monitored by the Check Log Light.

990-4599F 41

Page 42

150/175 kVA Operation

Change the Date and Time on the Display Interface

1. From the main menu, select Admin > Date/Time.

2. Select the setting you want to change and press ENTER.

Mode: Manual

→Format: dd/mm/yyyy a

Date: 21/01/2012 b

Time: 12:00:00 c

a. Format: You can change how the date is presented by scrolling through

the Format options.

b. Date: Scroll through the screen that opens to set the new Month, Day,

and Year. Select Apply New Date and press ENTER to save your

changes.

→Month: January

Day: 21

Year: 2012

Apply New Date

c. Time: Scroll through the screen that opens to set the new Time. Select

Apply New Time and press ENTER to save your changes.

→Time: 12:00:00

Apply New Time

Configure Device ID Settings

1. From the main menu, select Admin > Device ID.

2. Select the setting you want to change and press ENTER.

For Device Name, Product Contact, or Product Location, specify the

information for an external device by scrolling through alphabet characters.

Press ENTER to select displayed character and proceed to the next

character. To end the string, select underline “_” and press ENTER.

→Device Name

Product Contact

Product Location

→ < Field Name >

< User Defined Data

View System Component Information

1. From the main menu, select Admin > Manufacturer Data.

String >

2. Scroll to the desired system component. Up to 15 components can be

cataloged. Enter the information regarding the component. Press ENTER to

save your changes.

→Manuf. Data: 0 of 15

< Data Name >

< Factory Data >

42 990-4599F

Page 43

Operation 150/175 kVA

Set the Configuration to Factory Defaults

1. From the main menu, select Admin > Factory Defaults.

2. Select YES, Set Defaults to set to the configuration to factory defaults, or

NO, ABORT to abort the process. Press ENTER.

Set Configuration

to Factory Defaults?

NO, Abort

→ YES, Set Defaults

Help Submenu

Use the Help Feature

1. From the main menu, select Help.

2. Press the ? key on any line of any screen on the display interface to receive

context-sensitive help. Press the DOWN arrow key to view the rest of the help

screen. Press the UP arrow key to go back to the previous screen. Press ESC

to exit.

On any screen & any

line, press ‘?’ for

context sensitive

help. Try it now ...

990-4599F 43

Page 44

150/175 kVA Modbus Configuration

Modbus Configuration

Configure Modbus Through the Display Interface

Modbus TCP Configuration

1. From the main menu, select Admin > Configure Modbus > TCP.

2. Choose your selection and press ENTER to set or change:

Status: Disabled

Port: 502

a. Status: Enable or disable Modbus TCP to view the device through your

building management service’s interface.

b. Port: Each Modbus TCP must have a unique target TCP port number.

Enter a unique number, ranging from 502, 5000 to 32768.

3. Press ENTER. The display interfaces will navigate to the reboot page to save

your settings.

Modbus Serial Configuration

1. From the main menu, select Admin > Configure Modbus > Serial.

2. Choose your selection and press ENTER to set or change:

3. Press ENTER to save your settings.

Reboot needed for

this change. OK?

NO, Revert,

YES, Reboot Now

Access: Disabled

Target ID: 001

Baud Rate: 9600

a. Access: Enable or disable Modbus.

b. Target ID: Each Modbus device must have a unique target identification

number. Enter a unique number, ranging from 1 to 247, for this unit.

c. Baud Rate: Choose either 9600 bps or 19200 bps.

44 990-4599F

Page 45

Modbus Configuration 150/175 kVA

4-Wire

Unterminated

SW

1

2

SW

1

2

5

6

4-Wire

Terminated

Master Slave

2-Wire

Unterminated

2-Wire

Terminated

Modbus Cable Connection

The Modbus can be configured to accommodate 2-WIRE or 4-WIRE Building

Management Systems (BMS). Connect your Modbus cable to the port on the

Network Management Interface plate.

To configure for your BMS, remove the two screws holding the Network

Management Interface plate which is connected to the main printed circuit board.

The dip switches controlling Modbus configuration are located on the main board.

Check the dip switch positions and select from the following choices:

• Dip switch 1 and 2 are set to ON for 2 wire.

• Dip switch 1 and 2 are set to OFF for 4 wire.

• Dip switch 5 and 6 are set to ON for termination. Use termination when

connecting multiple PDUs in a chain. The last PDU in the chain is terminated.

• You should not have BIAS (dip switch 3 and 4) set to ON on a Modbus client.

NOTE: Modbus TCP is also supported.

990-4599F 45

Page 46

150/175 kVA Network Management Configuration

Network Management Configuration

Overview

NOTE: For complete Network Management Card setup instructions, see the

online User Guide at www.apc.com.

Initial Setup

You must configure the following three TCP/IP settings before the PDU can

operate on a network:

• IP address of the PDU

• Subnet mask

• Default gateway

If a default gateway is unavailable, use the IP address of a computer (that is

usually running) located on the same subnet as the NMC. The NMC uses the

default gateway to test the network when traffic is light.

NOTE: Do not use the loopback address as the default gateway address for

the Network Management Card. You will lose communication with the

equipment. Doing so will disable the card and require you to reset TCP/IP

settings to their defaults using a local serial login.

TCP/IP Configuration Methods

Use one of the following methods to define the basic TCP/IP settings needed by

the Network Management Card.

• Device IP Configuration Wizard

• BOOTP or DHCP server

• Networked computer

• Display interface

Device IP Configuration Wizard

The Wizard runs on Microsoft Windows 2000, Windows 2003, and Windows XP

operating systems. The Device IP Configuration Wizard configures the IP

address, subnet mask, and default gateway of one or more NMCs.

You can use the Wizard in either of the following ways:

• Remotely over your TCP/IP network to discover and configure unconfigured

NMCs on the same network segment as the computer running the Wizard.

• Through a direct connection from a serial port of your computer to the PDU to

configure or reconfigure it.

Installation

Install the Wizard from a downloaded executable file:

1. Go to www.apc.com.

2. Download the Device IP Configuration Wizard.

3. Run the executable file in the folder in which it was downloaded.

Launch the Wizard

The installation creates a shortcut link in the Start menu to launch the Wizard.

Most software firewalls must be temporarily disabled for the Wizard to discover

unconfigured NMCs.

46 990-4599F

Page 47

Network Management Configuration 150/175 kVA

Supported Web Browsers

Use Microsoft® Internet Explorer (IE) 7.x and higher (Windows operating

systems) or Mozilla Firefox 3.0.6 or higher (all operating systems) to access the

NMC through its Web interface. Other commonly available browsers may work but

have not been fully tested by Schneider Electric. The NMC cannot work with a

proxy server. Before using a Web browser to access its Web interface, do one of

the following:

• Configure the Web browser to disable the use of a proxy server for the NMC.

• Configure the proxy server so that it does not proxy the specific IP address of

the NMC.

Network Management Features

These applications and utilities work with a Modular PDU that connects to the

network through its Network Management Card:

• StruxureWare —Provide enterprise-level power management and

management of Schneider Electric agents, Modular PDUs, information

controllers, and environmental monitors

• PowerNet

browser—Perform SNMP SETs and GETs and to use SNMP traps

• APC Device IP Configuration Wizard—Configure the basic settings of one or

more NMCs over the network

• APC Security Wizard—Create the components needed for high security for

the NMC when using Secure Sockets Layer (SSL) and related protocols and

encryption routines

®

Management Information Base (MIB) with a standard MIB

Log On

URL Address Formats

Use the DNS name or System IP address of the NMC for the URL address of the

Web interface. The default user name differs by account type:

• apc for a Super User

• device for a Device user

• readonly for a Read-Only user

If you are using HTTPS (SSL/TSL) as your access protocol, your logon credentials

are compared with information in a server certificate. If the certificate was created

with the APC Security Wizard, and an IP address was specified as the common

name in the certificate, you must use an IP address to log on to the NMC. If a DNS

name was specified as the common name on the certificate, you must use a DNS

name to log on.

Type the DNS name or IP address of the NMC in the URL address field of the

Web browser and press ENTER. When you specify a non-default Web server port

in Internet Explorer, you must include http:// or https:// in the URL.

Common Browser Error Messages at Log-on.

Error Message Browser Cause of the Error

“This page cannot be

displayed.”

“Unable to connect.” Firefox

990-4599F 47

Internet Explorer Web access is disabled, or the

URL was not correct.

Page 48

150/175 kVA Network Management Configuration

Security

Access Priority for Logging On

Only one user at a time can log on to the Modular PDU.

• Local access from a computer with a direct serial connection to the Modular

PDU.

• Telnet or Secure SHell (SSH) access to the control console from a remote

computer.

• Web access, either directly or through StruxureWare Central.

User Accounts

The three levels of access are protected by user name and password

requirements. During authentication, the user's credentials are compared against

the Local User Database and/or are validated against a RADIUS server

(depending on configuration). If valid, access with appropriate permissions is

granted.

• An Administrator can use all the menus in the Web interface. The default user

name for the Administrator User is apc.

• A Device User can access only the menus on the Home, Power Distribution,

and Logs tabs in the Web interface. The default user name for the Device

User is device.

• A Read-Only User has only Web interface access. The same menus as

Device User are visible but no changes can be made. Links to configuration

options are visible but disabled. Event and data logs display no button to clear

the log. The default user name is readonly.

Watchdog Features

Watchdog mechanisms detect internal problems. After a restart, a System:

Warmstart event is recorded in the event log.

Network Interface Watchdog Mechanism

Watchdog mechanisms protect the NMC from becoming inaccessible over the

network. If it does not receive any network traffic for 9.5 minutes, it assumes there

is a problem with its interface and restarts.

Resetting the Network Timer

To ensure the NMC does not restart if the network is quiet for 9.5 minutes, it

attempts to contact the default gateway every 4.5 minutes. The gateway response

resets the 9.5-minute timer. If your application does not require or have a gateway,

specify the IP address of a computer that is running on the network most of the

time and is on the same subnet. The network traffic of that computer will restart

the 9.5-minute timer frequently enough to prevent the NMC from restarting.

48 990-4599F

Page 49

Network Management Configuration 150/175 kVA

Recover from a Lost Password

1. At the local computer, select a serial port, and disable any service that uses it.

2. Connect the provided serial cable to the computer and the port on the PDU.

3. Run a terminal program (such as HyperTerminal

9600 bps, 8 data bits, no parity, 1 stop bit, and no flow control.

4. Press ENTER, repeatedly if necessary, to display the User Name prompt. If

you are unable to display the User Name prompt, verify the following:

– The serial port is not in use by another application.

– The terminal settings are correct as specified in step 3.

– The correct cable is being used.

5. Press the reset button on the back of the unit. The status LED will flash. Press

the reset button a second time while the status LED is flashing to temporarily

reset both the user name and password to apc.

6. Press ENTER as many times as necessary until the User Name prompt

displays, then use the temporary user name and password apc. (If you take

longer than 30 seconds to log on after the User Name prompt is displayed,

you must repeat step 5 and log on again.)

®

) and configure the port for

7. At the command line interface, use the following commands to change the

Password setting, which is now temporarily apc:

user -n <user name> -pw <user password>

For example to change the a password to XYZ, type:

user -n apc -pw XYZ

The super user’s password must be specified when making any changes to

the user account. For more information, see the “user” section in the NMC

CLI Guide.

NOTE: For security reasons, it is possible to disable the super user

account. To verify that the super user account is enabled, type:

user -n <user name>

If Access: Disabled is returned, the super user account can be re-enabled by

typing:

user -n <user name> -e enable

8. Type quit or exit to log off, reconnect any serial cable you disconnected, and

restart any service you disabled.

990-4599F 49

Page 50

150/175 kVA Maintenance

Maintenance

Parts Replacement

Determine if you Need a Replacement Part

To determine if you need a replacement part, contact Schneider Electric Customer

Support and follow the procedure below so that a representative can assist you

promptly:

1. The display interface may show additional screens if module replacement is

necessary. Press any key to scroll through these lists, record the information,

and provide it to the representative.

2. Write down the serial number of the unit so that you will have it easily

accessible when you contact Customer Support.

3. If possible, call Customer Support from a telephone that is within reach of the

unit so that you can gather and report additional information to the

representative.

4. Be prepared to provide a detailed description of the problem. A representative

will attempt to help you over the telephone, if possible, or will assign a Return

Material Authorization (RMA) number to you. If a module is returned, this

RMA number must be clearly printed on the outside of the package.

Return Parts

5. If the unit is within the warranty period, repairs or replacements will be

performed free of charge. If it is not within the warranty period, there will be a

charge.

6. If the unit is covered by a service contract, have the contract available to

provide information to the representative.

Contact Customer Support to obtain an Returned Materials Authorization (RMA)

number.

To return a module, pack the module in the original shipping materials, and return

it by insured, prepaid carrier. The Customer Support representative will provide

the destination address. If you no longer have the original shipping materials, ask

the representative about obtaining a new set. Pack the module properly to avoid

damage in transit. Never use Styrofoam beads or other loose packaging materials

when shipping a module, as the module may settle in transit and become

damaged. Enclose a letter in the package with your name, RMA number, address,

a copy of the sales receipt, description of the problem, a phone number, and a

check as payment (if necessary).

NOTE: Damages sustained in transit are not covered under warranty.

50 990-4599F

Page 51

Maintenance 150/175 kVA

O

F

F

OFF

OFF

O

FF

OFF

OFF

pdx10

41a

5

6

4

3

2

1

Power Distribution Modules

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Electrical equipment must be installed, operated, serviced, and maintained only

by qualified personnel.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

To remove a Power Distribution Module:

• Turn off all power supplying the equipment and perform appropriate lockout/

tagout procedures before installing or removing the Power Distribution

Module.

Failure to follow these instructions will result in death or serious injury.

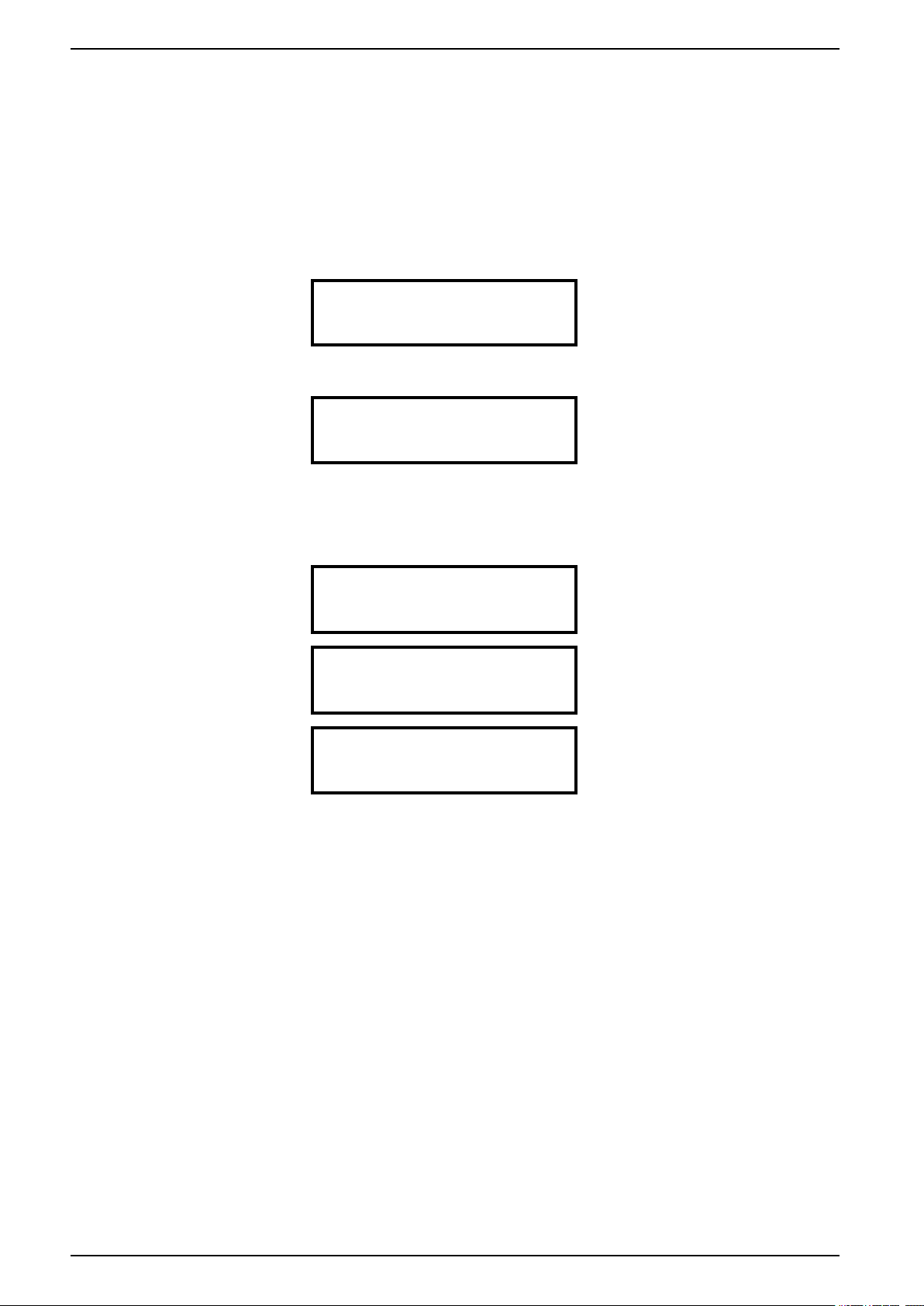

Component Identification

NOTICE

• Install only Schneider Electric PDMs with matching output voltage.

• Install PDMs starting from the bottom of the panel to avoid cable congestion.

• Save filler plates for future re-use. If a module is removed, a filler plate must

be installed to cover the open space.

Failure to follow these instructions can result in equipment damage.

Factory installed filler plates and slot locks cover each module position.

Before putting the unit into service, the backplane of each module position must

be covered with a filler plate or a Power Distribution Module (PDM). All positions

must be secured with a slot lock.

Item Description

1 Slot lock key

990-4599F 51

2 Slots (hold modules in place)

Page 52

150/175 kVA Maintenance

pdx104

3a

OFF

OFF

O

F

F

OF

F

OFF

OFF

O

FF

O

F

F

O

F

F

O

FF

O

FF

pdx0848b

OFF position

ON positions

Item Description

3 Bus bar

4 Filler plate

5 Module slot lock

6 Power distribution module

NOTE: Two slot locks are attached together as a pair.

The illustration shows the top lock removed from its slot but still attached to

the installed lock below it.

Module Circuit Breaker Operation

NOTE: The circuit breaker handle will pull all the breakers to the OFF position

together but can be flipped up to access the individual breakers separately.

52 990-4599F

Page 53

Maintenance 150/175 kVA

pdx1042a

O

F

F

O

F

F

OFF

OF

F

OF

F

O

F

F

c

b

a

Install a Power Distribution Module

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

To remove a Power Distribution Module:

• Turn off all power supplying the equipment and perform appropriate lockout/

tagout procedures before installing or removing the Power Distribution

Module.

Failure to follow these instructions will result in death or serious injury.

1. Open the front door of the PDU.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Electrical equipment must be installed, operated, serviced, and maintained

only by qualified personnel.

Failure to follow these instructions will result in death or serious

injury.

2. Remove the slot lock.

Use the key (provided) to remove the slot lock.

a. Insert the key in the slot lock as shown in the illustration.

b. Squeeze the sides of the key inward to grasp the slot lock firmly.

c. Pull the slot lock key out, while squeezing, to extract the lock from the

slot.

990-4599F 53

Page 54

150/175 kVA Maintenance

pdx1040a