Page 1

Applications

For two-position operation of dampers or valves in

heating, ventilating and air-conditioning systems and

similar applications where return to normal position is

not required.

These unidirectional actuators (clockwise rotation)

require a three-wire control circuit; SPDT snap-acting

switch or its equivalent such as a thermostat, pressure

switch or relay. A built-in cam operated, snap-acting,

adjustable SPDT auxiliary switch is standard. It is

factory set to make at mid-stroke. One contact closes

at end of stroke; other contact closes at end of next

stroke.

MC-351, 421, 431, MC-4311

Three-Wire, Two Position Actuators

General Instructions

MC-xxx

(Standard Actuator)

Features

• 24, 120, and 240 Vac models

• Equipped with SPDT auxiliary switch

• Actuator has a rugged die cast aluminum housing

with two 1/2” conduit openings

• Hazardous location actuator housing has two 3/4"

pipe taped openings for rigid metal conduit

connection

• Oil immersed gear train

• Requires a three wire control circuit SPDT

snap-acting or equivalent

Options

Available 24, 120, 208, 240 Vac; 50 or 60 Hz. 50 Hz

specify MC5-xxx. For hazardous locations, specify

MC6-xxx (60 Hz), MC7-xxx (50 Hz). Actuators factory

assembled, UL Listed, cUL Listed.

MC6-3xx, MC6-4xx, MC7-4xx,

(Hazardous Location Actuator)

Applicable Literature

• AV-390 Series, Valve Linkage for Gear Train

Actuators, General Instructions, F-24376

• Electric/Electronic Products Catalog, F-27382

Printed in U.S.A. 6/12 © Copyright 2012 Schneider Electric All Rights Reserved. F-08366-15

• Apparatus for Hazardous Locations EN-56-2

F-18451

• AV-29x Series Hazardous Location Valve Linkage

for Geartrain Actuators General Instructions

F-27441

Page 2

SPECIFICATIONS

Control Circuit: Three Wire SPDT snap-acting switch or equivalent.

Shaft Rotation: Unidirectional clockwise 180° when power is applied.

Auxiliary Switch: Adjustable SPDT is standard. Factory set to make (or break) at mid stroke.

Running, 5.8A at 120 Vac, 2.9 at 240 Vac

Locked Rotor: 34.8 at 120 Vac, 17.4 at 240 Vac

Non-inductive, 12A at 120 Vac, 6 at 240 Vac.

Environment:

Ambient temperature limits: Shipping and storage -40 to 136 °F (-40 to 58 °C)

Operating -40 to 136 °F (-40 to 58 °C).

Humidity: 5 to 95% RH, non-co ndensing.

Locations: NEMA 1. Optional NEMA 4 with AM-363 gasket, or hazardous service locations

N.E.C., Class 1, Groups C and D, and Class 2, Groups E, F, and G.

Connections: Coded screw terminals.

Options: Hazardous locations specify MC6-351, 421, or 431 (60 hz), MC7-4311 (50 hz).

Agency Listing: UL File #E9429 standard models.

UL File #29291 Hazardous location models. Temperature code T6 for hazardous housing.

T able-1 Model Chart.

Input

No Load

Timing

(Sec./180

×)

Rated Torque

Lb.-in. (N-m)

d

Part No.

Hazardous

Location

MC7-4311

a b

Volts Hz Watts VA Rating

d

240 50 50 96 36 220 (25) 122 (11) 157 (15)

Part No.

Standard

Service

MC-351 MC6-351 24 60 28 53 70 220 (25) 122 (11) 157 (15)

MC-421 MC6-421 120 60 50 96 20 175 (20) 97 (9) 125 (12)

MC-431 MC6-431 120 60 50 96 30 220 (25) 122 (11) 157 (25)

MC-4311 — 240 60 50 96 30 220 (25) 122 (11) 157 (15)

MC5-4311

a

Class 1, Groups C & D, and Class 2, Groups E, F, and G hazardous locations; ref er to EN-56 -2, F-18451. Hazardou s locatio n valve actuato rs can also be used

for hazardous location damper applications.

b

Models for hazardous locations are only available as fa ctory-built enclosure/act uator asse mblies. See st a ndard actuat or p art n umber wiring di agrams f or wiring

terminations.

c

Damper ratings are nominal and based on standard (not low leakage) dampers at 1" (25.4 mm) W.C. static pressure and 2000 FPM (10 ml/S) velocity.

d

Not cUL approved.

Nominal Damper

Sq. Ft. (m2)

Parallel

Blade

Opposed

c

Area

Blade

ACCESSORIES

Damper Linkage Accessories (See Figure-1)

AM-111 Crank arm for 5/16" diameter damper shaft

AM-112 Crank arm for 3/8" diameter damper shaft

AM-113 Crank arm for actuator or 1/2" diameter damper shaft

AM-115 Crank arm for 7/16" diameter damper shaft

AM-116 Splined crank arm for actuator

AM-122 Linkage connector straight type

AM-123 Damper clip

AM-125 5/16" diameter x 20" damper rod

AM-125-048 5/16" diameter x 48" damper rod

AM-132 Ball joint connector

AM-161 Damper linkage kit

AM-161-1 Damper linkage kit

AM-301 90 degree mounting bracket

Valve Linkage Accessories (See Figure-4)

AV-330 Valve linkage for 2-1/2" & 3" VB-9323

AV-352 Valve linkage for 2-1/2" to 6" VB-9213 or VB-9313 valve bodies and 4" to 6" for VB-9323

AV-393 Valve linkage for 1/2" to 2" VB-7xxx and 1/2" to 1-1/4" VB-92x3 or VB-93x3

AV-394 Valve linkage for 1-1/2" & 2" VB-92x3 or VB-93x3 (discontinued)

AV-396 Valve linkage for 2-1/2" to 4" VB-9213 or VB-9313

Valve Linkage Hazardous Location Accessories (See Figure-5)

AV-293 Valve linkage for 1/2" to 2" VB-7xxx series for hazardous locations

AV-296 Valve linkage for 2-1/2" and 3" VB-9xxx (bronze) series for hazardous location

2 © Copyright 2012 Schneider Electric All Rights Reserved. F-08366-15

Page 3

Miscellaneous Actuator Accessories

Standard models only.

AM-321 Two step switch kit

AM-341 Four step switch kit

AM-363 NEMA 4 rated gasket kit

TYPICAL APPLICATION (Wiring Diagram)

Make all electrical connections in compliance with the job wiring diagram and the national and

local electric codes. Typical connections are shown in (Figure-2).

Figure-1 Damper Linkage Accessories.

Figure-2 External Wiring for Heating Application.

PRE-INSTALLATION

The MC actuators are shipped without mounting hardware or linkage. In damper applications,

crank arms (AM-113), connectors (AM-122 or AM-132), link rods (AM-125) and mounting

brackets (AM-301) will be required. In valve applications, a valve body and AV type linkage will

be required.

Before installing the actuator, check for bent or broken parts or oil leaks. Actuators may be

connected to power supply to check operation prior to installation.

F-08366-15 © Copyright 2012 Schneider Electric All Rights Reserved. 3

Page 4

INSTALLATION

Requirements Preferred mounting for the actuator is in the upright position, but other positions are acceptable.

Adjustable speed units should never be mounted upside down or with the output shaft pointing

upward. Allow six inches clearance above the actuator wiring compartment. If an AM type

mounting bracket is not used, the base of the actuator may be used as a template for marking

mounting holes.

Procedure Actuator may be used in damper and valve control applications. Figure-3 illustrates linkage

operating an arm through a 90° arc. To fasten damper linkage proceed as follows.

Figure-3 180° Actuator Rotation Driving a Damper

Rotation of 90°.

Damper Installation

1. Fasten linkage connector at end of damper crank arm.

2. Fasten linkage connector at punch mark on actuator crank arm (about .707 of the radius).

3. Move damper to normal position and clamp connecting link to connectors.

4. Check adjustment for proper operation by running actuator and driven shaft between limits

of travel.

Caution: If crank arm does no t provide proper travel, reset connecting link in linkage

connector. Never attempt to turn the actuator shaft with a wrench or a crank. This may damage

the gears.

Valve Installation Install all valves with pressure under seat. Refer to flow arrow on body or piping information on

valve body tag. Three way mixing valves should be installed with two inlets and one outlet. Three

way diverting valves should be installed with one inlet and two outlets.

To assemble an actuator to a valve, refer to detailed instructions on AV-3xx General Instruction

Sheet, F-19068 or AV-29x Series Hazardous Location Valve Linkage for Geartrain Actuators

General Instructions, F-27441.

4 © Copyright 2012 Schneider Electric All Rights Reserved. F-08366-15

Page 5

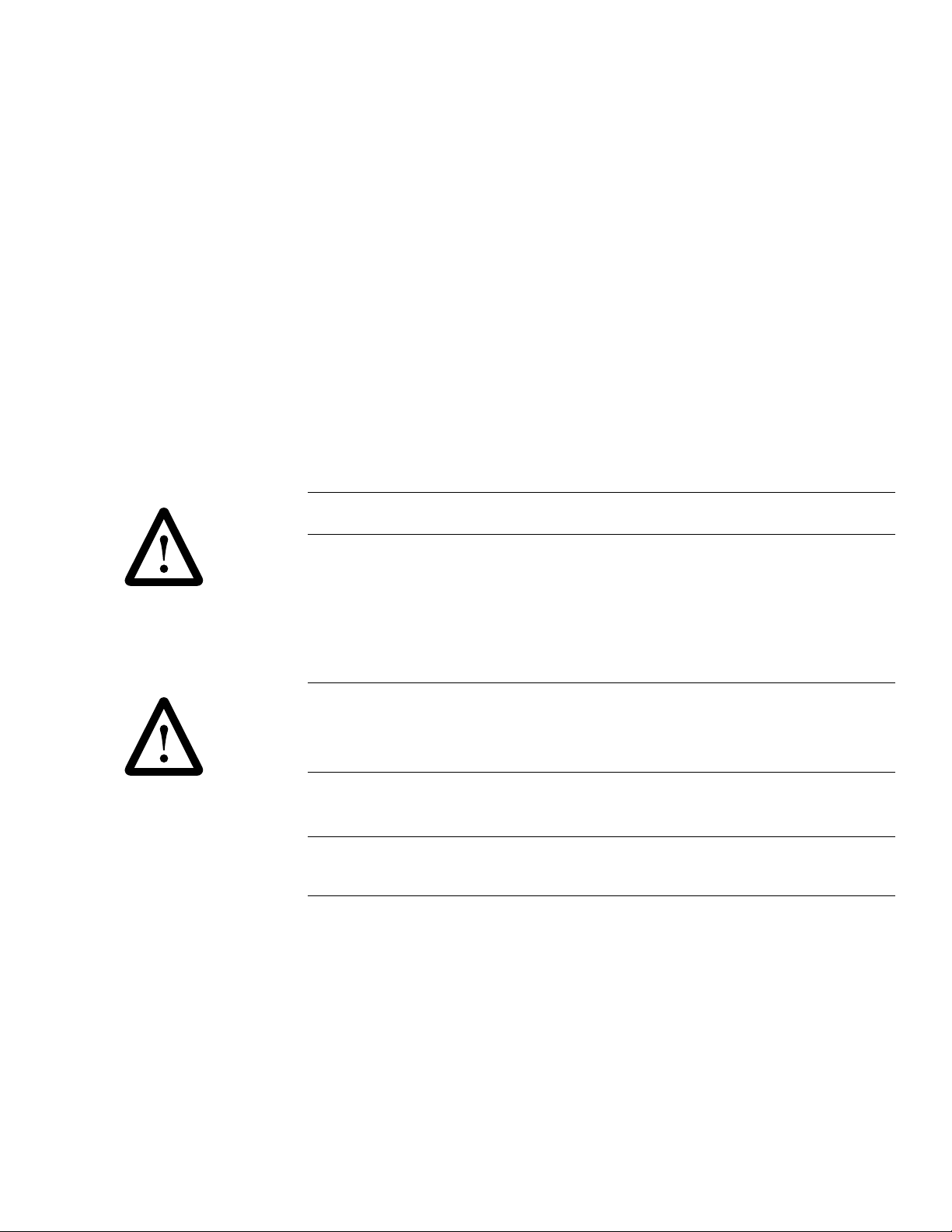

Figure-4 Co mponents for Valve Installation of Standard Actuator.

Indicator Screw

Front Cover

Nylon Bushing

Actuator

Mounting Screws (3)

Mounting Bracket

Valve Body

(VB-7XXX Shown)

Plunger Assembly

Connecting Pin

Stem Extension

Stem Locknut

Packing Nut

Mounting Nut

Cover Screws (2)

Indicator

Plunger Cam

1

1

1

1

"C" Ring

1 Not included in AV Kits.

2 Used with 1/2" through 2" valve bodies.

2

Note: See AV-390 Series, Valve Linkage for Gear Train Actuators, General

Instructions, F-24376 for detailed instructions when used as a valve actuator.

F-08366-15 © Copyright 2012 Schneider Electric All Rights Reserved. 5

Page 6

Indicator Screw

Front Cover

Nylon Bushing

Mxx-xxx Hazardous Location Actuator

Mounting Screws (3)

Mounting Bracket

Valve Body

Plunger Assembly

Connecting Pin

Stem Extension

Stem Locknut

Packing Nut

Mounting Nut

Cover Screws (2)

Indicator

Plunger Cam

1

1

1

1 Not included in AV kits.

1

Figure-5 Co mponents for Valve Installation 1/2” to 2” VB-7xxx and VB-9xxx-xxx-4-xx 2-1/2" and 3" Globe Valves

for Hazardous Location Actuators.

Note: See AV-29x Valve Linkage for Hazardous Location Gear Train Actuators

General Instructions, F-27441 for detailed instructions when used as a valve actuator.

6 © Copyright 2012 Schneider Electric All Rights Reserved. F-08366-15

Page 7

WIRING

For control and power wiring on low voltage actuators (H, G, R, B AND C terminals), use No. 14

wire on runs under 140 feet and No. 12 wire on longer runs. On line voltage units (L1, L2, R, B,

and C terminals), use No. 14 wire on runs up to 1300 feet.

Class I circuits must be used for connections to the control and power terminals (L1, L2, R, B,

and C terminals) on line voltage actuators. Class II circuits may be used for connections to the

control and power terminals (H, G, R, B, and C terminals) on 24 Vac actuators. Connections to

the auxiliary switch terminals (R1, B1, and C1) may be per Class II circuits except when the

switch is used on line voltage applications in which case Class I circuit must be used. When

powering actuators from a common transformer, the G terminals must all connect to the same

side to prevent transformer damage.

Hazardous Location Models

Make all electrical connections to the assembly in accordance with the job wiring diagram, the

National Electric Code Article 500, and in compliance with the local electrical codes.

Two 3/ 4" pipe tapped openings are provided in the housing for rigid conduit connections. It is

recommended to insert a chase nipple from inside of the housing to prevent threads from cutting

or damaging wiring.

When wiring, take care to lay all leads in the wiring channel located just under the housing cover

to protect the leads from any sharp edges which may be in the vicinity.

The housing and the edge of the cover are stamped with the letter "O." When replacing the cover,

the letters must be aligned with each other.

Warning: The cover-to-housing orientation must be maintained in order to preserve the

integrity of the seal. Failure to observe this warning can result in injury or death.

1. Remove twelve cover screws and cover. Place cover, machined surface up, in a protected

location to avoid damage to machined surfaces.

2. Make all wiring connections to actuator taking care to lay all leads in the wiring channel

provided.

3. Before enclosing the actuator, wipe machined surfaces of housing clean with a lint free cloth

and apply one of the UL approved compounds. See Note below.

Warning: Failure to observe these warnings can result in injury or death.

• Do not scrape, scratch, or use abrasives on the machined surfaces.

• Ensure the surfaces are clean.

• Use only the approved compounds listed below.

4. Secure cover tight against the enclosure in the same position before removal with the twelve

screws provided.

Note: Underwriters Laboratories has sanctioned the use of the following compounds on

hazardous location ground joints: Crouse-Hinds type OSL lubricant, Crouse-Hinds type STL

lubricant, or "No-OXID" oil, grade "D."

Two 1/ 2

Refer to Figure-6 for terminal locations.

" conduit knockouts are provided on the actuator case.

F-08366-15 © Copyright 2012 Schneider Electric All Rights Reserved. 7

Page 8

CHECKOUT

After the entire system has been installed, the following checks for proper operation must be

made.

1. Be sure that the system power is connected, and on.

2. Turn thermostat to call for cool. Actuator should rotate clockw ise from 0° t o 180°, tur ning of f

the heating media. (View actuator from output shaft end (front).)

3. Turn thermostat to call for heat. Actuator should rotate clockwise from 180° to 360° (also 0°),

and turn on heating media.

4. If the room temperature varies excessively, see System Repair.

Actuator Checkout Turn power off and connect terminals as follows:

1. Connect terminal C to B and actuator should run clockwise (when energized) to end of travel

(usually 180°).

2. Connect terminal C to R and actuator should run clockwise (when energized) from 180° to

360° (0°).

RUN/ADJUST

Theory of

Operation

Unidirectional

Three-Wire,

Two-Position

Actuators

The motor, gear-train assembly with limit switches to stop the movement (usually at the end of

180° CW travel) is built in two types. The damper actuator output shaft gives rotary motion. The

valve actuator has a cam-operated plunger which transforms rotary motion to linear motion to

operate the valve stem. Three-wire actuators require a SPDT switching action in the controller.

“R” contact of the thermostat is made on a call for heat; “B” contact is made on a call for less heat;

“C” terminal is common. “R” of the actuator (assume on valve) is a starting switch that starts to

open the valve; “B” starts to close the valve; and “C” is the limit switch. Auxiliary cam-operated

switches are available for the operation of additional valves, actuators, relays, etc.

Figure-6 Internal Wiring Diagram and Cam Chart.

8 © Copyright 2012 Schneider Electric All Rights Reserved. F-08366-15

Page 9

Auxiliary Switch Adjustment

The adjustable built-in SPDT auxiliary switch is actuated by the cam nearest to the back of the

actuator. Although it can be adjusted to operate at any point in the actuator rotation, it is factory

set to operate at approximately mid-stroke. This operating point may be changed by inserting a

screwdriver through the opening in the top plate directly behind the terminal block, and engaging

the screwdriver with the gear-like plastic disc. Turning the disc clockwise causes the switch to

operate nearer the counterclockwise end of actuator travel. Each click of the switch actuating

cam represents approximately 3 angular degrees change in operating point.

Figure-7 Cut-a-way of Actuator.

REPAIR

None. Replace an inoperable actuator with a functional unit.

F-08366-15 © Copyright 2012 Schneider Electric All Rights Reserved. 9

Page 10

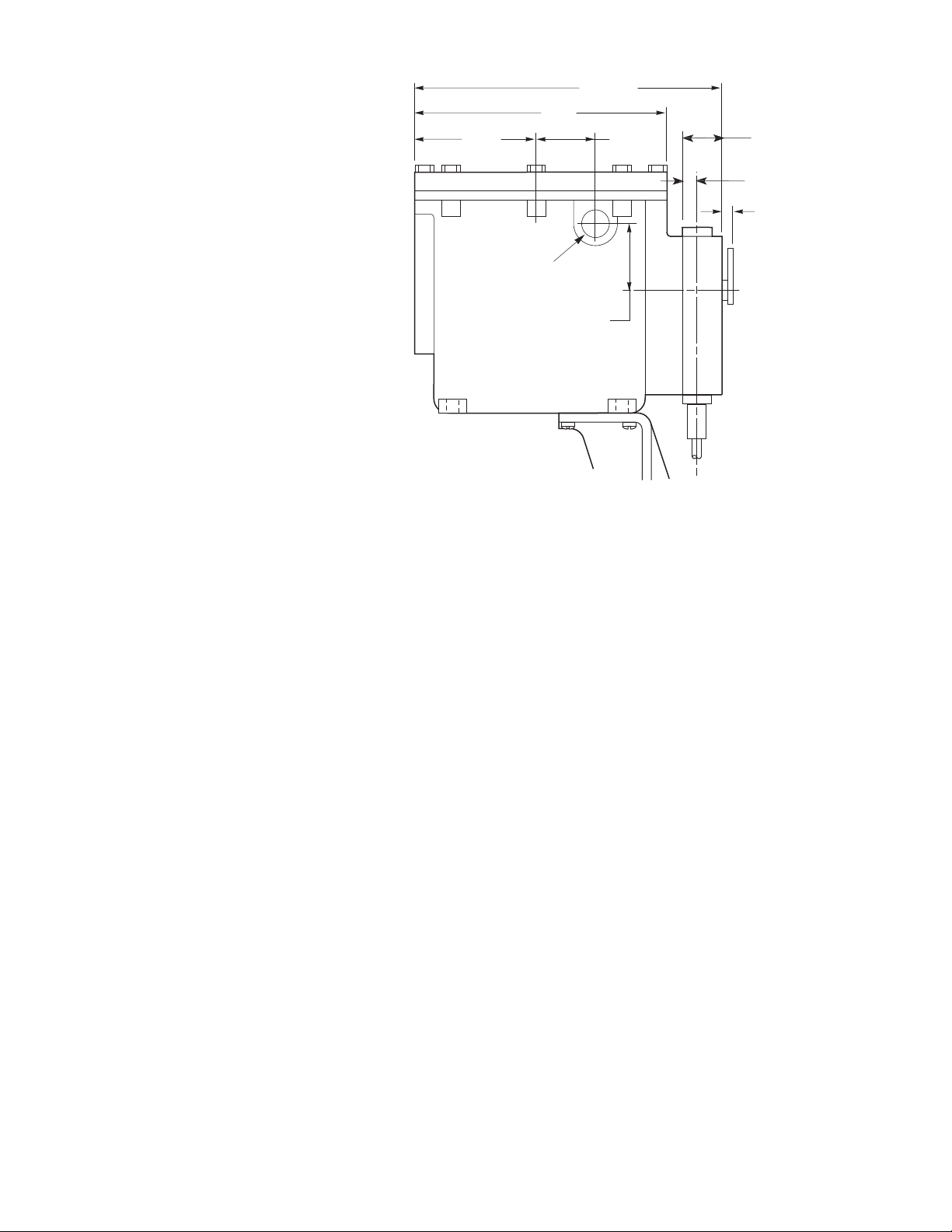

DIMENSIONAL DATA

Allow 12” (300 mm) minimum service clearance above the housing top.

O

P

E

N

C

L

O

S

E

D

8-1/4 (209)

4-1/8 (105)

4-1/2

(114)

7

(178)

9

(228)

Coupling Line

for Actuator

1/4

(6)

Dimensions shown

are in inches (mm).

4-1/4 (108)

Coupling Line

for Valve Body

5-7/16

(139)

7-7/8 (200)

Figure-8 Standard Actuator Dimensions.

Hazardous Location

Shown with valve linkage components. Mounting bracket, open/close cover, pointer, and plunger

are not included for damper applications.

10 © Copyright 2012 Schneider Electric All Rights Reserved. F-08366-15

Figure-9 Hazardous Location Actuator Front Dimensions.

Page 11

4-1/2

(114)

2-15/16

(51)

2-1/8

(54)

3/4 (19) Pipe Tap

On Each Side

9

(229)

10-13/16

(275)

1/8

(3)

1-1/4 (32)

5/8 (16)

Dimensions shown

are in inches (mm).

Figure-10 Hazardous Location Actuator Side Dimensions.

F-08366-15 © Copyright 2012 Schneider Electric All Rights Reserved. 11

Page 12

© Copyright 2012, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained within this

document is subject to change without notice.

F-08366-15

Loading...

Loading...