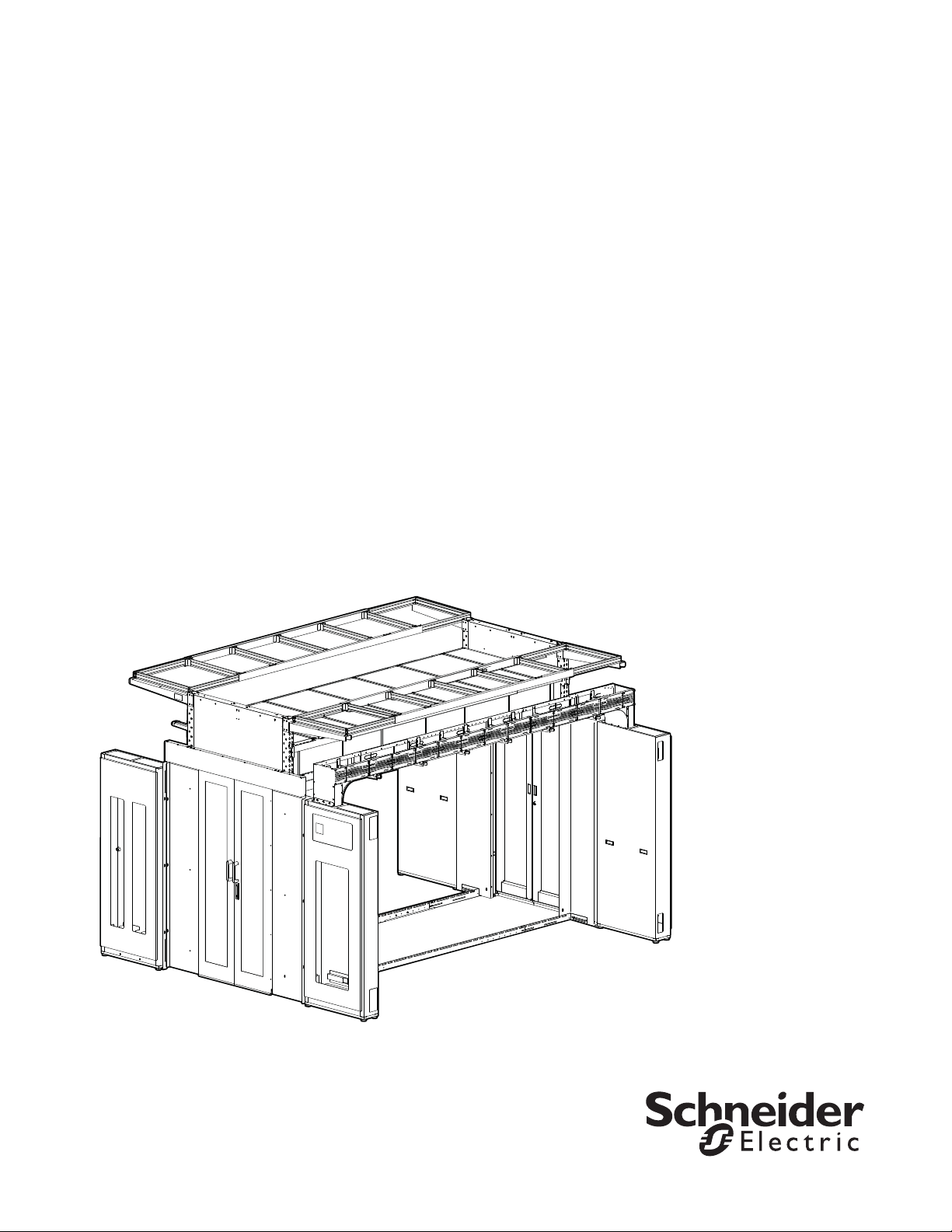

Page 1

Installation Manual

HyperPod™ System

990-5862B-001

Publication Date: October 2018

Page 2

Schneider Electric Legal Disclaimer

The information presented in this manual is not warranted by the Schneider Electric to be authoritative, error

free, or complete. This publication is not meant to be a substitute for a detailed operational and site specific

development plan. Therefore, Schneider Electric assumes no liability for damages, violations of codes,

improper installation, system failures, or any other problems that could arise based on the use of this

Publication.

The information contained in this Publication is provided as is and has been prepared solely for the purpose of

evaluating data center design and construction. This Publication has been compiled in good faith by Schneider

Electric. However, no representation is made or warranty given, either express or implied, as to the

completeness or accuracy of the information this Publication contains.

IN NO EVENT SHALL SCHNEIDER ELECTRIC, OR ANY PARENT, AFFILIATE OR SUBSIDIARY COMPANY

OF SCHNEIDER ELECTRIC OR THEIR RESPECTIVE OFFICERS, DIRECTORS, OR EMPLOYEES BE

LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL, OR INCIDENTAL

DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF BUSINESS, CONTRACT,

REVENUE, DATA, INFORMATION, OR BUSINESS INTERRUPTION) RESULTING FROM, ARISING OUT,

OR IN CONNECTION WITH THE USE OF, OR INABILITY TO USE THIS PUBLICATION OR THE CONTENT,

EVEN IF SCHNEIDER ELECTRIC HAS BEEN EXPRESSLY ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES. SCHNEIDER ELECTRIC RESERVES THE RIGHT TO MAKE CHANGES OR UPDATES WITH

RESPECT TO OR IN THE CONTENT OF THE PUBLICATION OR THE FORMAT THEREOF AT ANY TIME

WITHOUT NOTICE.

Copyright, intellectual, and all other proprietary rights in the content (including but not limited to software, audio,

video, text, and photographs) rests with Schneider Electric or its licensors. All rights in the content not expressly

granted herein are reserved. No rights of any kind are licensed or assigned or shall otherwise pass to persons

accessing this information.

This Publication shall not be for resale in whole or in part.

Page 3

Table of Contents

General Information ...............................................................................................1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Loading Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

HyperPod SKU List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Documentation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Unpacking and Inspecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Safety.....................................................................................................................5

Important Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety Recommendations for the HyperPod System . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Planning the Installation.........................................................................................7

General Guidelines for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Enclosures and Power Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Layout and Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

List of Recommended Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Systems Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Basic configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Component Identification .....................................................................................11

HyperPod System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Raised-floor Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

FS-FM-6001-B - Raised-floor Stand, 406 mm (16 in.)

FS-FM-6002-B - Raised-floor Stand, 610 mm (24 in.)

FS-FM-6003-B - Raised-floor Stand, 762 mm (30 in.)

FS-FM-6004-B - Raised-floor Stand, 914 mm (36 in.) . . . . . . . . . . . . . . . . . . . .12

Post Alignment Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

FS-FM-1011-U - 1.2 m (4 ft) Aisle Post Alignment Tool

FS-FM-1012-U - 1.9 m (6 ft) Aisle Post Alignment Tool . . . . . . . . . . . . . . . . . . .13

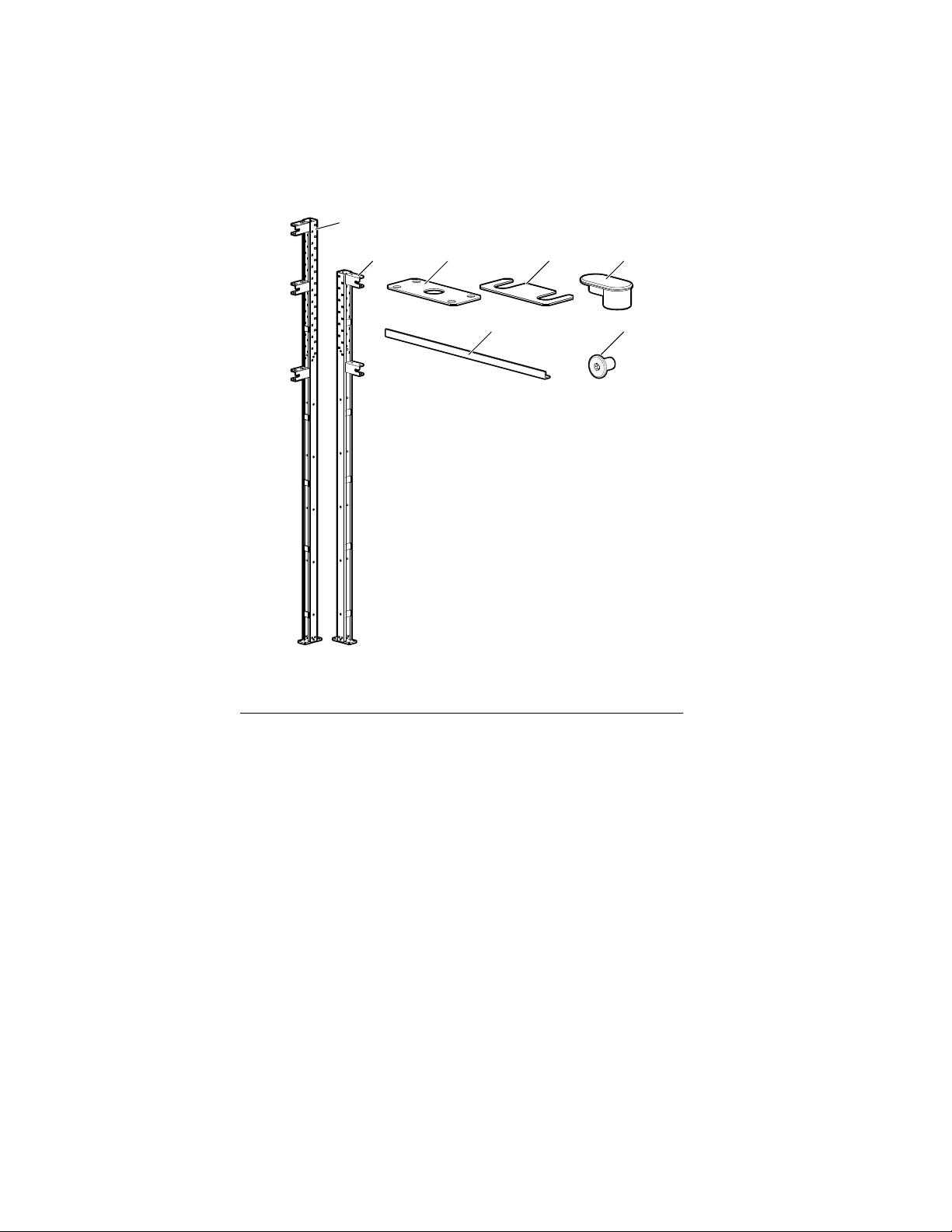

Vertical Posts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

FS-FM-1001-B - Vertical Post Assembly, 2750 mm (9 ft), Short

FS-FM-1002-B - Vertical Post Assembly, 3200 mm (10.5 ft), Tall . . . . . . . . . . .14

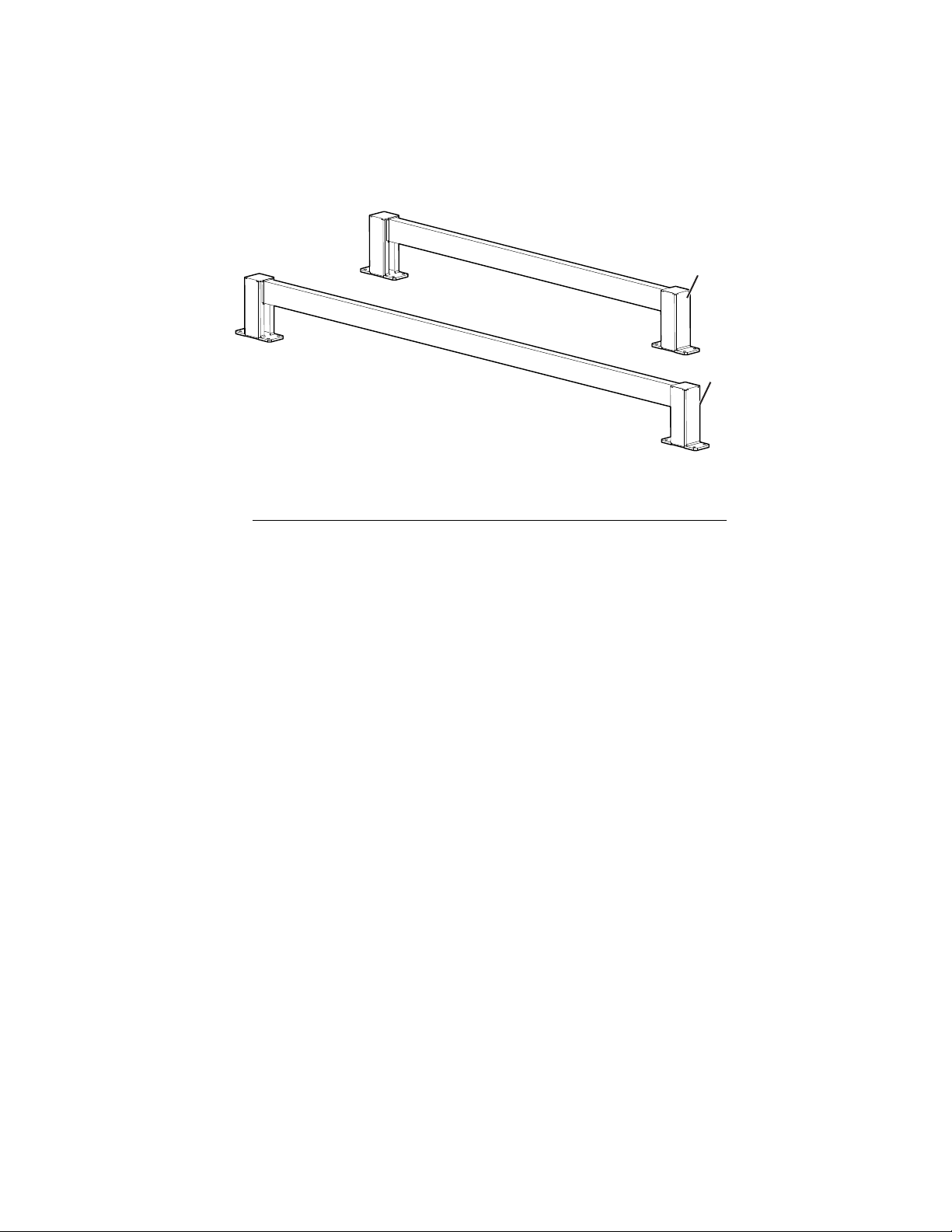

Width Beams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

FS-FM-2002-B - 1.9 m (6 ft) Aisle Width Beam Assembly

FS-FM-2003-B - 1.2 m (4 ft) Aisle Width Beam Assembly . . . . . . . . . . . . . . . . .15

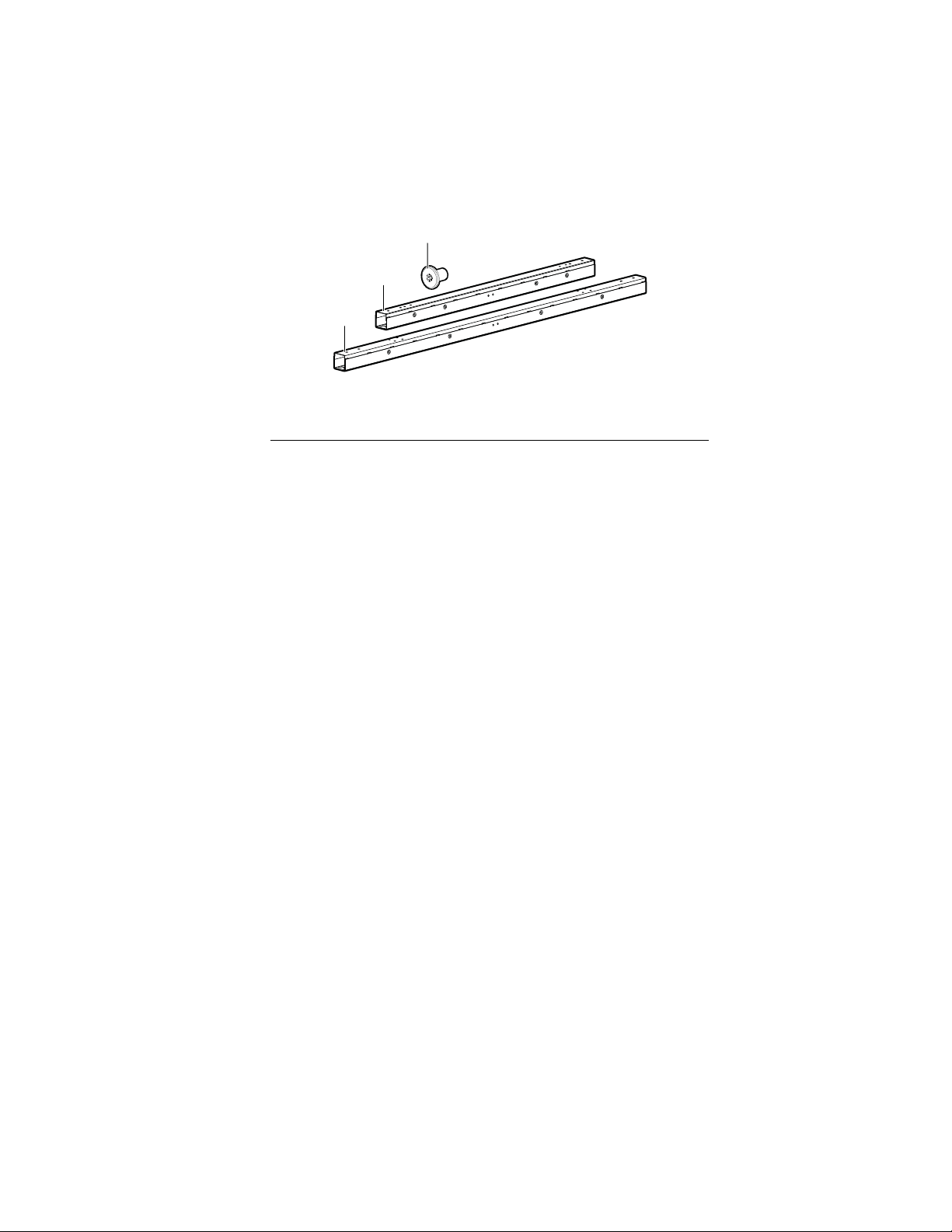

Length Beam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

FS-FM-3001-B - Length Beam Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

End Cap Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

FS-FM-4003-B - 1.9 m (6 ft) Aisle End Cap Assembly, Short

FS-FM-4004-B - 1.9 m (6 ft) Aisle End Cap Assembly, Tall . . . . . . . . . . . . . . . .17

FS-FM-4005-B - 1.2 m (4 ft) Aisle End Cap Assembly, Short

FS-FM-4006-B - 1.2 m (4 ft) Aisle End Cap Assembly, Tall . . . . . . . . . . . . . . . .17

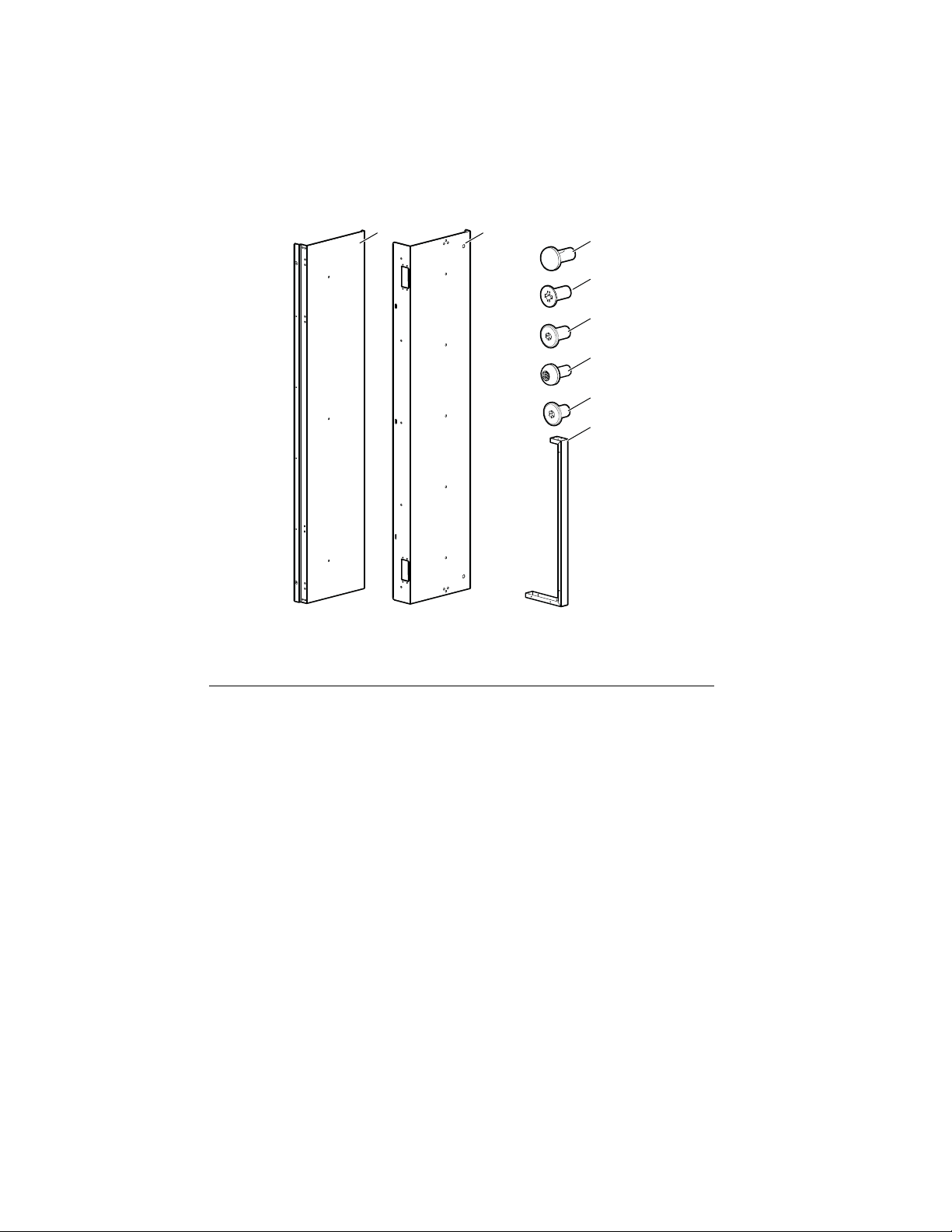

Door Frame Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

FS-DR-2002-B - 1.9 m (6 ft) Aisle Standard Door Frame

FS-DR-2003-B - 1.2 m (4 ft) Aisle Standard Door Frame . . . . . . . . . . . . . . . . . .18

HyperPod System Installation i

Page 4

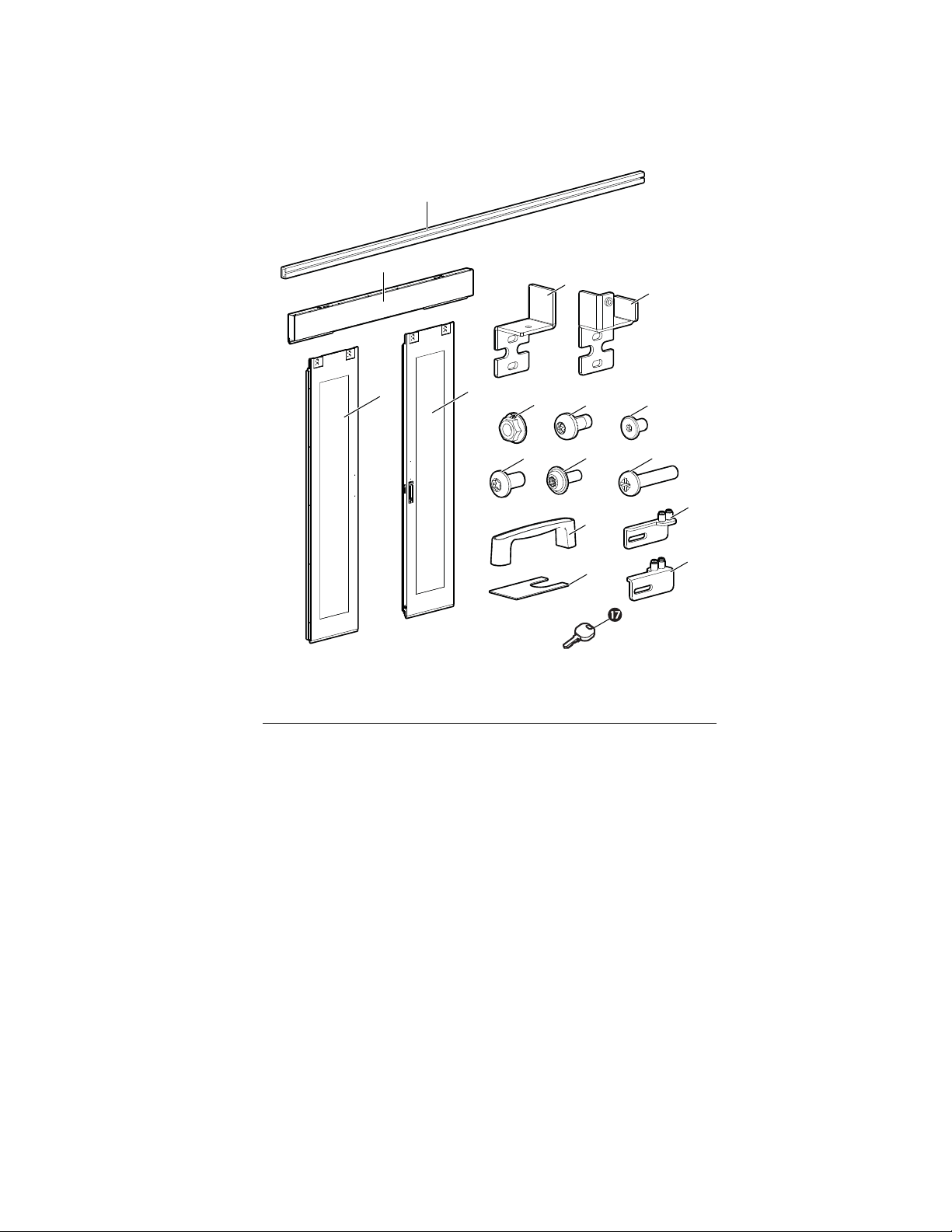

Door and Rail Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

FS-DR-1001-B - 1.2 m (4 ft) Aisle Door and rail assembly

FS-DR-1003-B - 1.9 m (6 ft) Aisle Door and rail assembly . . . . . . . . . . . . . . . 19

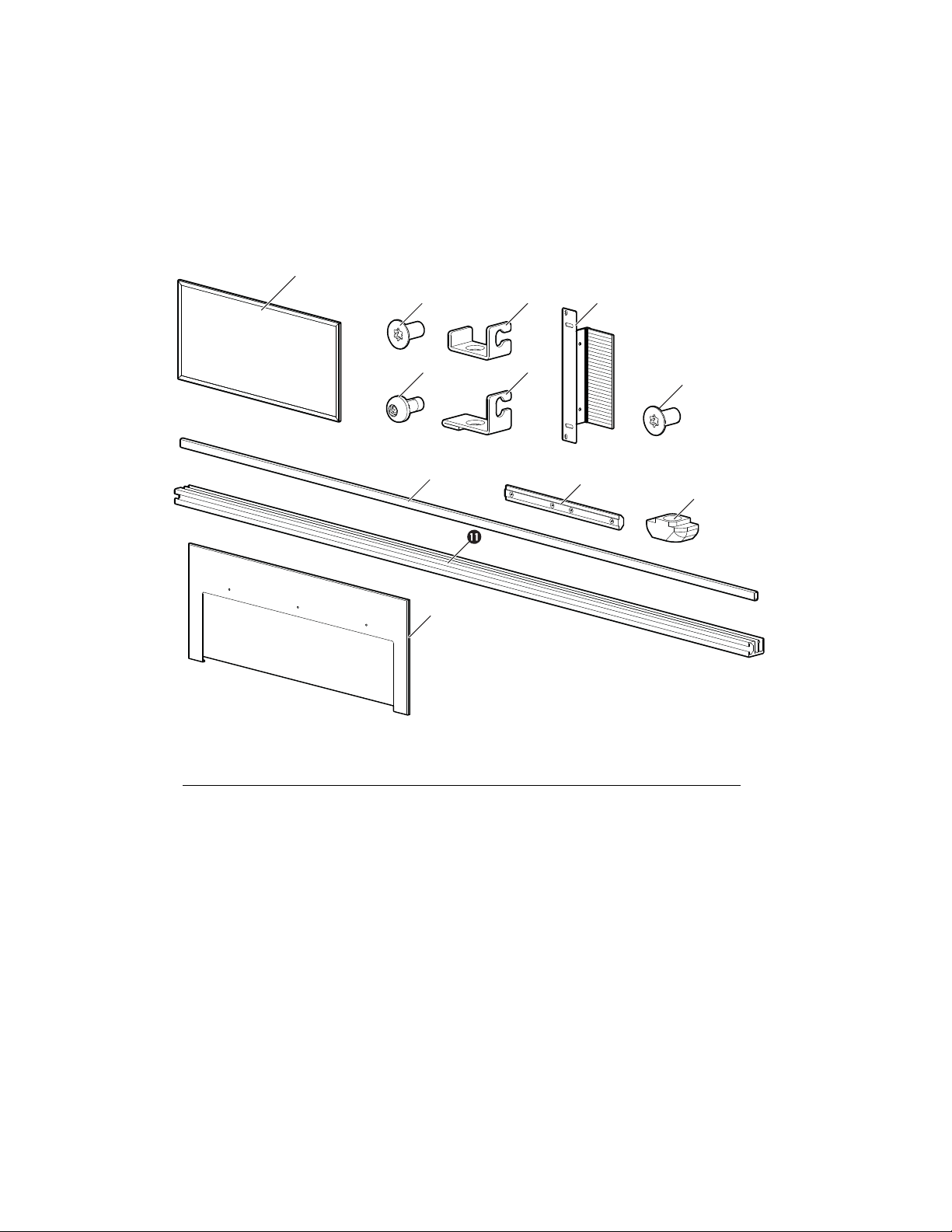

Windows, Rails, and Side Brushes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

FS-WI-1001-U - Window Panel 305 mm (2 ft)

FS-WI-1002-B - Window Rail Assembly

FS-WI-1003-B - Window Frame Brush Strips

FS-WI-1004-U - Window Brush Strip Pass-through . . . . . . . . . . . . . . . . . . . . . 20

Row Length Brush Strip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

FS-AC-2001-U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

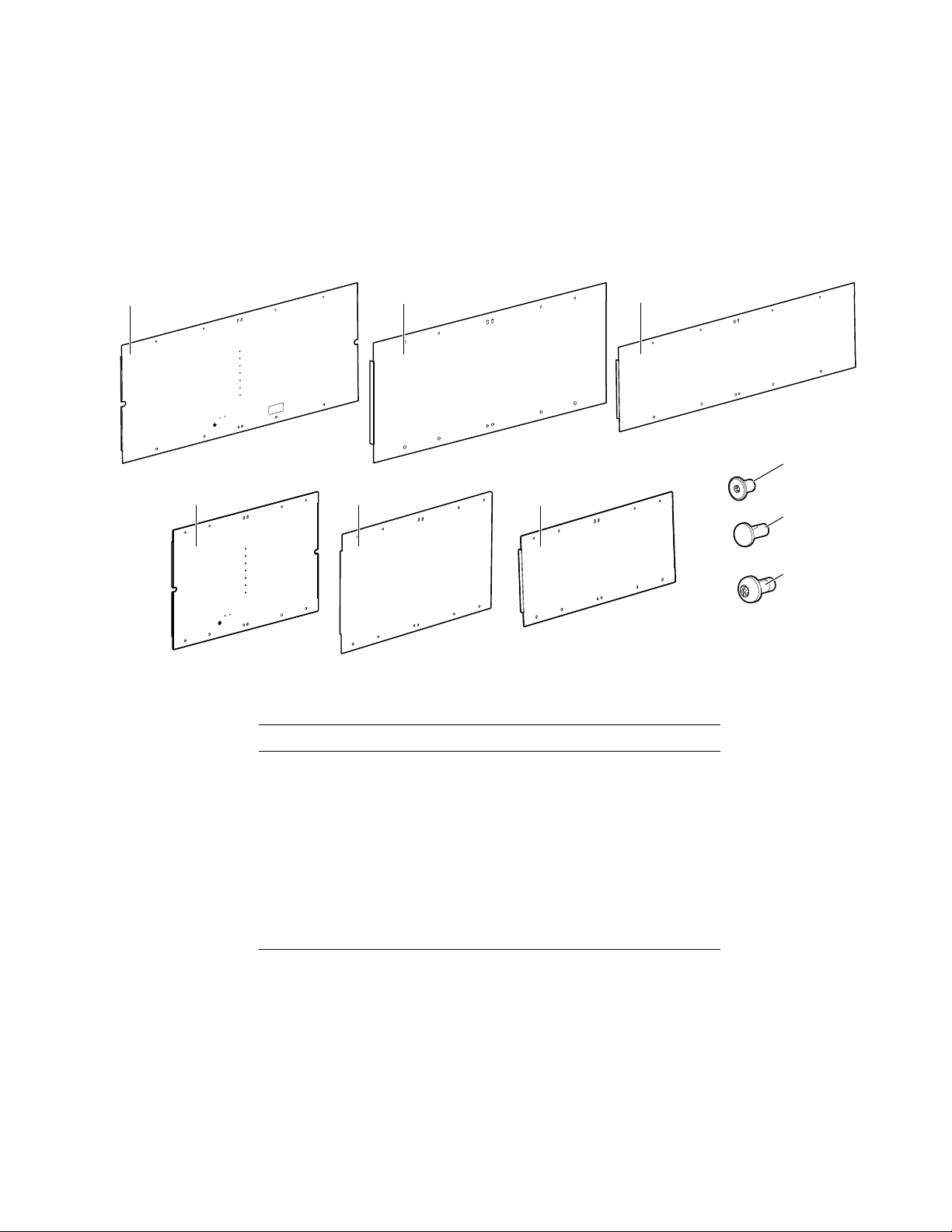

Roof Panel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

FS-RF-2004-U - 1.9 m (6 ft) Aisle Simple Roof Panel, 300 mm (12 in.)

FS-RF-2005-U - 1.9 m (6 ft) Aisle Simple Roof Panel, 600 mm (23.6 in.)

FS-RF-2006-U - 1.9 m (6 ft) Aisle Simple Roof Panel for Sprinkler Option, 600 mm (23.6

in.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

FS-RF-2007-U - 1.2 m (4 ft) Aisle Simple Roof Panel, 300 mm (12 in.)

FS-RF-2008-U - 1.2 m (4 ft) Aisle Simple Roof Panel, 600 mm (23.6 in.)

FS-RF-2009-U - 1.2 m (4 ft) Aisle Simple Roof Panel for Sprinkler Option, 600 mm (23.6

in.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Solid Roof Filler Panel Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

FS-RF-1002-B - 1.9 m (6 ft) Aisle

FS-RF-1003-B - 1.2 m (4 ft) Aisle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

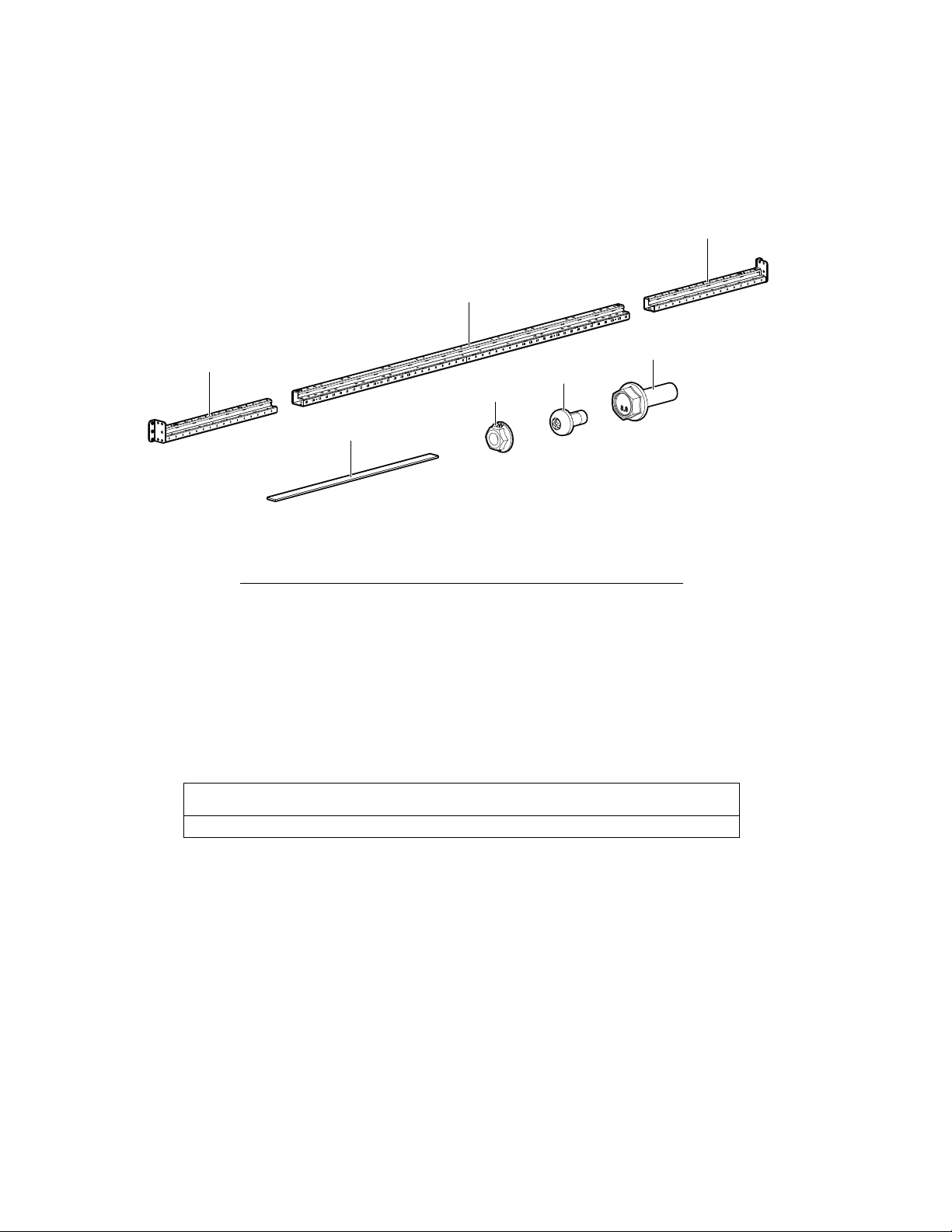

Stop Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

FS-FM-5001-B - Stop Rail Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Air Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

FS-AC-1001-U - Air Sealing Kit

FS-AC-1002-U - H Seal for Blanking Panels

FS-AC-1003-U - C Seal for Blanking Panels and Vertical Posts . . . . . . . . . . . 25

Blanking Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

FS-AC-5005-B - 300 mm (12 in.)

FS-AC-5006-B - 600 mm (23.6 in.)

FS-AC-5007-B - 750 mm (29.5 in.)

FS-AC-5008-B - 800 mm (31.5 in.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Installation Procedure Overview.......................................................................... 27

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Customizing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Installation locations for width beams and length beams . . . . . . . . . . . . . . . . . 28

Basic Frame Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Floor stands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Frame end configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Length beam assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Temporary frame support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Secure the frame to the floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

End caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Door frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Frame seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Window assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Row length brush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Roof panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Stop rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Blanking panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

C seals and H seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

HyperPod System Installationii

Page 5

Accessory Kits..................................................................................................... 61

End Row Transition Cabinets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

FS-AC-7001-B - Distribution Cabinet, MH50 . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

FS-AC-7002-B - Distribution Cabinet, Split . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

FS-AC-7003-B - Distribution Cabinet, Solid . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Drop Roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

FS-RF-3002-U - Drop Roof Mounting Rail, 300 mm (12 in.)

FS-RF-3004-U - Drop Roof Mounting Rail, 600 mm (23.6 in.)

FS-RF-3006-U - Drop Roof Mounting Rail, 750 mm (29.5 in.) . . . . . . . . . . . . . .62

FS-RF-3007-U - Drop Roof panel, 300 mm (12 in.)

FS-RF-3008-U - Drop Roof panel, 600 mm (23.6 in.)

FS-RF-3009-U - Drop Roof panel, 750 mm (29.5 in.) . . . . . . . . . . . . . . . . . . . . 62

Shrink Roof. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

FS-RF-6001-U - 1.2 m (4 ft) Aisle Shrink Roof panel, 610 mm (24 in.)

FS-RF-6002-U - 1.2 m (4 ft) Aisle Shrink Roof panel, 310 mm (12.2 in.) . . . . . . 63

FS-RF-6003-U - 1.9 m (6 ft) Aisle Shrink Roof panel, 610 mm (24 in.)

FS-RF-6004-U - 1.9 m (6 ft) Aisle Shrink Roof panel, 310 mm (12.2 in.) . . . . . . 63

Ceiling Panel Lock Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

ACDC2016 - Ceiling Panel Lock System, 100-120 V (with power supply) . . . . . 64

ACDC2017 - Ceiling Panel Lock System, 200-240 V (with power supply) . . . . . 64

ACDC2015 - Ceiling Panel Lock System, (without power supply) . . . . . . . . . . . 65

Rack Height Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

FS-AC-8001-U - Rack Height Adapter, 300 mm (12 in.)

FS-AC-8002-U - Rack Height Adapter, 600 mm (23.6 in.)

FS-AC-8003-U - Rack Height Adapter, 750 mm (29.5 in.)

FS-AC-8004-U - Rack Height Adapter, 800 mm (31.5 in.) . . . . . . . . . . . . . . . . . 66

Cantilever Support Arms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

FS-AC-3001-B - Large Cantilever Support Arms . . . . . . . . . . . . . . . . . . . . . . . . 67

FS-AC-3003-B - Mini Cantilever Arms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

FS-AC-3002-B - Overhead Support Frame, 2.4–3.6 m (8–12 ft) . . . . . . . . . . . 68

Power Raceway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

FS-AC-4001-B - Power Raceway End Module

FS-AC-4002-B - Power Raceway Main Module

FS-AC-4003-B - 300 mm (12 in.) Side Cover Pack

FS-AC-4004-B - 50/150 mm (2/6 in.) Side Cover Pack

FS-AC-4005-B - Power Raceway Extension Module . . . . . . . . . . . . . . . . . . . . . 69

Lighting kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

ACDC2018 - Lighting Kit with Power Supply

ACDC2019 - Lighting Kit without Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . 70

FS-AC-6001-B - Lighting Bracket Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Crossover Tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

FS-AC-4007-B - 1.9 m (6 ft) Aisle Crossover Tray

FS-AC-4008-B - 1.2 m (4 ft) Aisle Crossover Tray . . . . . . . . . . . . . . . . . . . . . . . 72

Single Swing Door Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

FS-DR-1002-U - Swing Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Installation of Optional Accessories .................................................................... 74

Transition Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Crossover Tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Mini Cantilever Arms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Power Raceway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Post Cantilevers and Suspension System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Possible configurations for Post Cantilevers: . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Standard configuration installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

HyperPod System Installation iii

Page 6

Shrink Roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Drop Roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Install the mounting rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Install the ceiling panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Solid Roof Filler Panel for Drop Roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Ceiling Panel Lock System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

System diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Power supply component identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Install the power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Install electromagnetic locks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Install the temperature switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Install electrical boxes and route cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Install the alarm beacon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Install the smoke detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Maintenance steps for dropout ceiling system: . . . . . . . . . . . . . . . . . . . . . . . . 105

Troubleshooting diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Lighting Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Lighting control unit installation options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Lighting brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Lighting System Setup and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Rack Height Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Single Swing Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

One-Year Factory Warranty ..............................................................................119

Terms of Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Non-transferable Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Exclusions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Warranty Claims . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

HyperPod System Installationiv

Page 7

General Information

Features

The HyperPod™ is a freestanding air containment system. Fully configured racks can be deployed or

removed from the HyperPod as necessary. Schneider Electric racks or other EIA-310-D racks can be

used in a HyperPod system.

The HyperPod system includes the following features:

• Telescoping length beams can extend the HyperPod length from 2.4 m (2421 mm or

about 8 ft) to 3.6 m (3621 mm or about 12 ft).

Additional length beams can be added to the vertical posts to extend the Pod up to another

3.6 m (12 ft).

• Two aisle widths are available: 1.2 m (1268 mm or about 4 ft) and 1.9 m (1877 mm or

about 6 ft).

• Two heights are available for vertical posts: Tall = 3.2 m (3200 mm or about 10.5 ft) and

Short = 2.8 m (2750 mm or about 9 ft).

F

acs0053c

E

Possible configurations:

Dimension 1.2 m aisle, tall 1.2 m aisle, short 1.9 m aisle, tall 1.9 m aisle, short

2421–3621 mm

(8–12 ft)

1268 mm (4 ft) 1268 mm (4 ft) 1877 mm (6 ft) 1877 mm (6 ft)

3200 mm (10.5 ft) 2750 mm (9 ft) 3200 mm (10.5 ft) 2750 mm (9 ft)

2421–3621 mm

(8–12 ft)

2421–3621 mm

(8–12 ft)

D

2421–3621 mm

(8–12 ft)

1HyperPod System Installation

Page 8

The basic HyperPod can be customized with the following accessories:

• Power Raceways

• Rack space blanking panels

• Cantilever support arms

• Overhead support frame

• Bi-parting and single swing doors

• Height adapters accommodate multiple rack heights

• LED aisle lighting with motion sensor

• End-of-row power transition cabinets

• Drop roof

• Shrink panels activated by heat

• End-of-aisle crossover tray

The HyperPod system provides a barrier between the hot exhaust and cold intake air streams in the IT

environment. The separation of the hot and cold air streams in the environment increases the efficiency

and effectiveness of the cooling system that supports the critical IT equipment. The separation will also

allow for an elevated supply-air temperature to be provided by the cooling system since the mixing of hot

and cold air is eliminated. The HyperPod system can be built using new or existing Schneider Electric

equipment. This containment system is compatible with row, room, or external cooling solutions and

available for cold or hot aisle containment.

This manual is a guide for the basic installation procedures for creating a HyperPod system

Loading Capacities

• End Frames (each): 249 kg (550 lbs.)

• Upper aisle length beams (each): 113 kg (250 lbs.)

• Large Cantilever (one side, system quantity is 2): 680 kg (1500 lbs.)

For balance, the load should be applied to both sides of the HyperPod. If Large Cantilevers are

installed on only one side, the max loading rating is 441 kg (974 lbs.)

• Mini Cantilever (one side, system quantity is 6): 90 kg (200 lbs.)

• Total System: 1814 kg (4000 lbs.)

HyperPod System Installation2

Page 9

HyperPod SKU List

This manual includes inventory and installation information for the following assemblies:

FS-AC-1001-U Air sealing kit FS-FM-4005-B 1.2 m aisle end panel, short

FS-AC-1002-U H-seal FS-FM-4006-B 1.2 m aisle end panel, tall

FS-AC-1003-U C-seal FS-FM-5001-B Stop rail

FS-AC-2001-U Row length brush strip FS-FM-6001-B Raised-floor stand, 406 mm

FS-AC-3001-B Large cantilever arms FS-FM-6002-B Raised-floor stand, 610 mm

FS-AC-3002-B Overhead support frame FS-FM-6003-B Raised-floor stand, 762 mm

FS-AC-3003-B Mini cantilever arms FS-FM-6004-B Raised-floor stand support, 914 mm

FS-AC-4001-B Power raceway end module FS-FM-1011-U 1.2 m aisle post alignment tool

FS-AC-4002-B Power raceway main module FS-FM-1012-U 1.9 m aisle post alignment tool

FS-AC-4003-B Power raceway 300 mm

side cover pack

FS-AC-4004-B Power raceway 50/150 mm

side cover pack

FS-AC-4005-B Power raceway extension module FS-RF-1003-B 1.2 m aisle solid roof filler panel set

FS-AC-4007-B 1.9 m aisle crossover tray FS-RF-2004-U 1.9 m aisle simple roof panel, 300 mm

FS-AC-4008-B 1.2 m aisle crossover tray FS-RF-2005-U 1.9 m aisle simple roof panel, 600 mm

FS-AC-5005-B Blanking panel, 300 mm FS-RF-2006-U 1.9 m aisle simple roof panel for sprinkler

FS-AC-5006-B Blanking panel, 600 mm FS-RF-2007-U 1.2 m aisle simple roof panel, 300 mm

FS-AC-5007-B Blanking panel, 750 mm FS-RF-2008-U 1.2 m aisle simple roof panel, 600 mm

FS-AC-5008-B Blanking panel, 800 mm FS-RF-2009-U 1.2 m aisle simple roof panel for sprinkler

FS-AC-6001-B Lighting bracket kit FS-RF-3002-U Drop roof mounting rail, 300 mm

FS-AC-7001-B Distribution cabinet, MH50 FS-RF-3004-U Drop roof mounting rail, 600 mm

FS-AC-7002-B Distribution cabinet, Split FS-RF-3006-U Drop roof mounting rail, 750 mm

FS-AC-7003-B Distribution cabinet, Solid FS-RF-3007-U Drop roof panel, 300 mm

FS-AC-8001-U Rack height adapter, 300 mm FS-RF-3008-U Drop roof panel, 600 mm

FS-AC-8002-U Rack height adapter, 600 mm FS-RF-3009-U Drop roof panel, 750 mm

FS-AC-8003-U Rack height adapter, 750 mm FS-RF-6001-U 1.2 m aisle shrink roof panel,

FS-AC-8004-U Rack height adapter, 800 mm FS-RF-6002-U 1.2 m aisle shrink roof panel,

FS-DR-1001-B 1.2 m aisle dual sliding doors FS-RF-6004-U 1.9 m aisle shrink roof panel,

FS-DR-1002-U Swing door

FS-DR-1003-B 1.9 m aisle dual sliding doors FS-WI-1001-U Window panel, 305 mm

FS-DR-2002-B 1.9 m aisle door frame FS-WI-1002-B Window rail assembly

FS-DR-2003-B 1.2 m aisle door frame FS-WI-1003-B Window frame brush strips

FS-FM-1001-B Vertical post, Short

FS-FM-1002-B Vertical post, Tall ACDC2015 Ceiling panel lock system

FS-FM-2002-B 1.9 m aisle width beam ACDC2016 Ceiling panel lock system 100-120 V

FS-FM-2003-B 1.2 m aisle width beam ACDC2017 Ceiling panel lock system 200-240 V

FS-FM-3001-B Length beam ACDC2018 Lighting kit with power supply

FS-FM-4003-B 1.9 m aisle end cap panel, short ACDC2019 Lighting kit without power supply

FS-FM-4004-B 1.9 m aisle end panel, tall

FS-RF-1002-B 1.9 m aisle solid roof filler panel set

610 mm

310 mm

FS-RF-6003-U 1.9 m aisle shrink roof panel,

610 mm

310 mm

FS-WI-1004-U Window Brush strip pass-through

(without power supply)

3HyperPod System Installation

Page 10

Documentation Information

All documentation is also available online at http://www.apc.com.

Check for updates to this manual on www.apc.com. Select Support > Resources & Tools > User

Guides. Then select Airflow Management in the Product Name drop-down list, or select the part

number for any HyperPod assembly in the Part Number drop-down list.

Unpacking and Inspecting

IMPORTANT: To avoid misplacing parts, do not leave boxes open following inspections. Reseal the

boxes until those parts are ready to be installed. Follow the order of procedures in this manual to ensure

proper installation.

If damage is noted to the shipping containers, inspect the contents for damage and notify the shipping

carrier and Schneider Electric.

After opening a box, check the components in the box against the list of items in “Component

Identification” beginning on page 11. If any components are missing, contact

http://www.apc.com/support.

The shipping materials are recyclable. Save them for later use or dispose of them

appropriately.

HyperPod System Installation4

Page 11

Safety

Important Safety Information

Read the instructions carefully to become familiar with the equipment before trying to install, operate,

service, or maintain it. The following special messages may appear throughout this manual or on the

equipment to warn of potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a Danger or Warning safety label indicates that an electrical

hazard exists which will result in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, can result in death

or serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, can result in minor

or moderate injury.

NOTICE

NOTICE addresses practices not related to physical injury including certain environmental

hazards, potential damage or loss of data.

5HyperPod System Installation

Page 12

Safety Recommendations for the HyperPod System

To reduce the possibility of injury or equipment damage, read and follow the safety recommendations.

Follow all local and agency safety requirements.

WARNING

TOOL USAGE HAZARD

Follow safety standards for all hand tools and power tools used. Read and follow the tool

manufacturer’s instructions. Follow the tool manufacturer’s recommendations and recognized

safety requirements for use of Personal Protection Equipment (PPE).

Failure to follow these instructions can result in death, serious injury, or equipment

damage.

CAUTION

WORKING HEIGHT HAZARD

The working height for the assembly process can exceed 2.3 m (7.5 ft). The use of stepladders or

scaffolding will be required during assembly.

Failure to follow these instructions can result in serious injury or equipment damage.

CAUTION

LIFTING HAZARD

At least two people are required to install this equipment. Some parts may be heavy and/or

excessive in size. For items weighing more than 12 kg (25 lbs), use more than one person.

Failure to follow these instructions can result in serious injury or equipment damage.

CAUTION

NO STEP HAZARD

Ceiling panels are not designed to support weight. Never lean or walk on the ceiling panels.

DO NOT use ceiling panels to support power or data cables.

Failure to follow these instructions can result serious injury or equipment damage.

HyperPod System Installation6

Page 13

Planning the Installation

NOTE: The data center floor must be within 0.075° from level for an 8-rack configuration, or within 0.035°

from level for a 16-rack configuration.

General Guidelines for Installation

Maintain a minimum clear space of 0.9 m (36 in.) required from the top of the frame to overhead

obstructions.

Maintain a minimum working space around the frame perimeter. Be sure to factor in the depth of the

racks you will install. Use your deepest rack when calculating the outside aisle space around the

HyperPod (finished size perimeter + 1.2 m [4 ft] around all sides).

Install this equipment directly on a concrete floor, or use floor stands to support a raised-floor system.

WARNING

HEAVY EQUIPMENT HAZARD

Raised-floor stands are required if the combined weight of the HyperPod system and all installed

equipment will exceed the structural capacity of your raised-floor system.

Failure to follow these instructions can result in death, serious injury, or equipment

damage.

See the documentation provided with each Schneider Electric product for additional

instructions on installation. All documentation is also available on www.apc.com.

Enclosures and Power Equipment

Refer to the instructions that come with your enclosures and power distribution equipment for

information on how to install them.

7HyperPod System Installation

Page 14

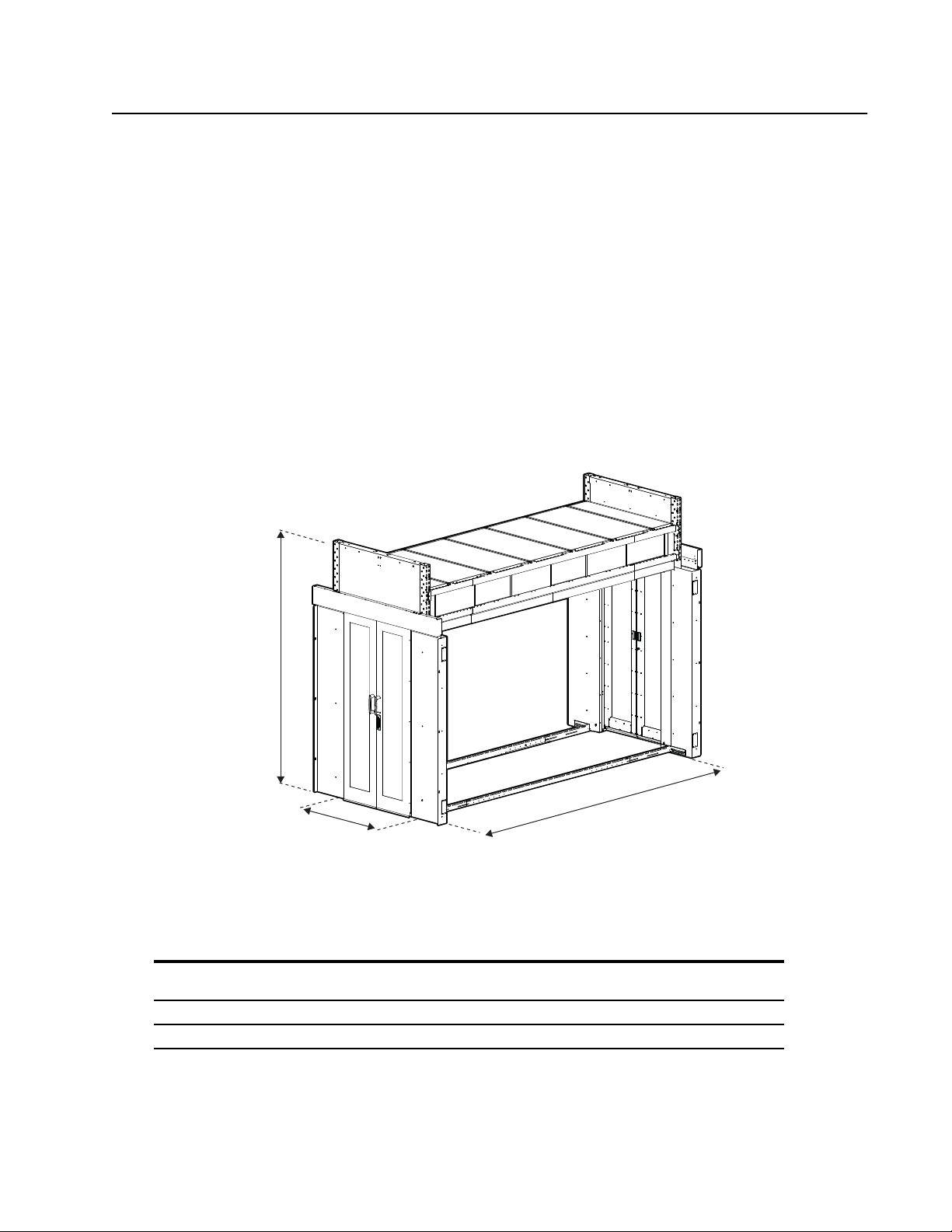

Layout and Positioning

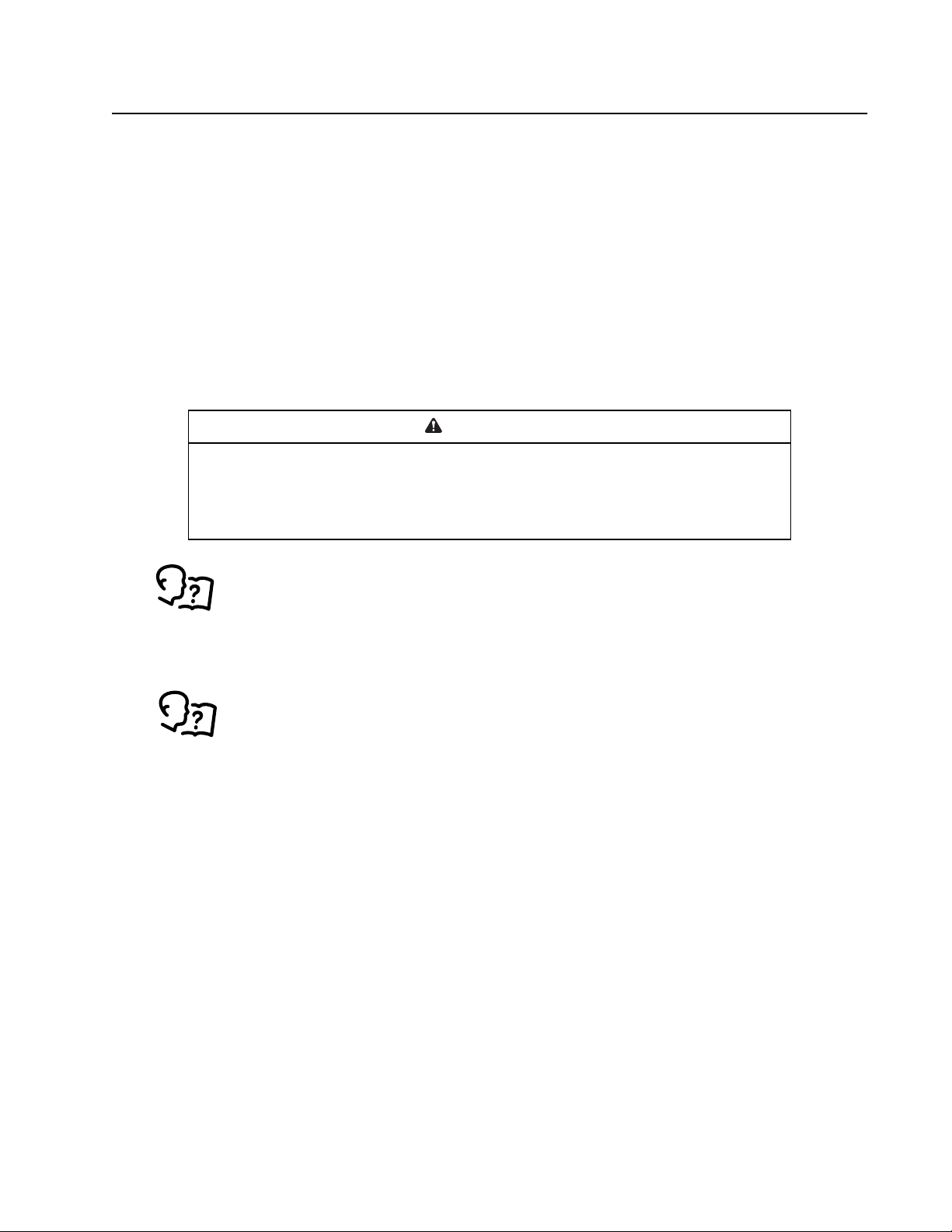

Referencing the ISX Designer report, determine the position of the main components, the total length of

the planned Aisle Containment System and the aisle width. Use a chalk line or similar tool to lay out the

perimeter making sure all corners are square.

A

B

C

90°

acs0020a

Dimension A will vary depending on the type and number of racks installed (2421–3621 mm or

8–12 ft). Dimension B is equal to 1268 mm for a 1.2 m (4 ft) aisle or 1877 mm for a 1.9 m (6 ft) aisle. Item

C notes the locations of the post feet provided in SKUs FS-FM-1001-B and FS-FM-1002-B.

Observe a 1.2 m (4 ft) perimeter around the outside so that racks can be moved in and out of the pod

NOTE: A template is provided to assist proper drilling of holes into the floor to secure the vertical post

feet.

HyperPod System Installation8

Page 15

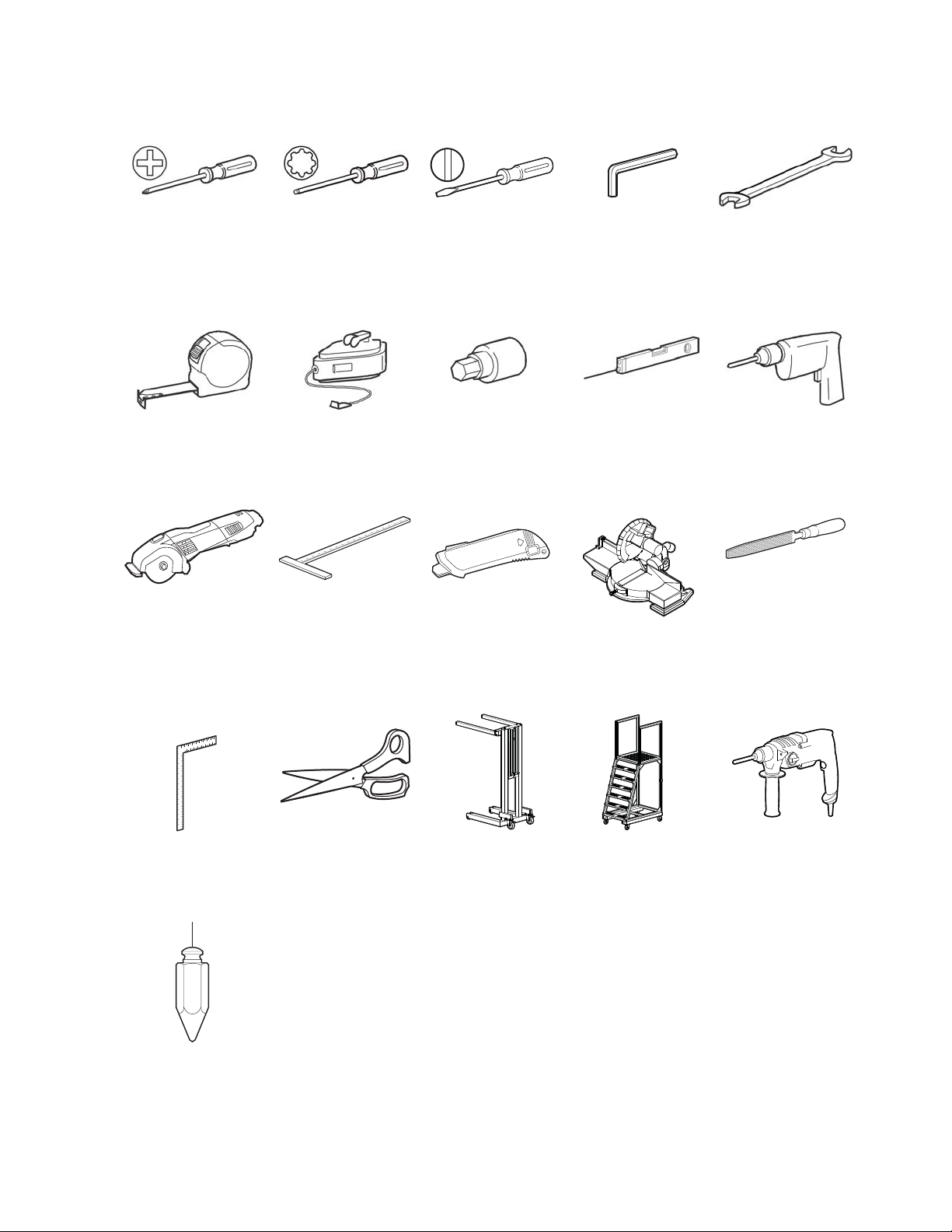

List of Recommended Tools

Screwdriver

P1 and

P2 Phillips

Tape measure Chalk line Hex socket

Rotary tool

(e.g. Dremel

®

)

Screwdriver

T-30, T-20, T-15

120 cm (48 in.)

®

TORX

T-square

minimum

Standard screwdriver Hex wrench

6.3 mm, 7 mm,

10 mm, 15 mm

Self-retracting knife Miter saw Metal files

3 mm, 4 mm, 6 mm

Level Drill with standard,

6, 7, 8, 10, 11,12

13,14, 18, 19, and

Phillips, TORX bits

Wrench

20 mm

T-square Scissors Lift Ladder Drill and concrete

bits

Plumb bob

9HyperPod System Installation

Page 16

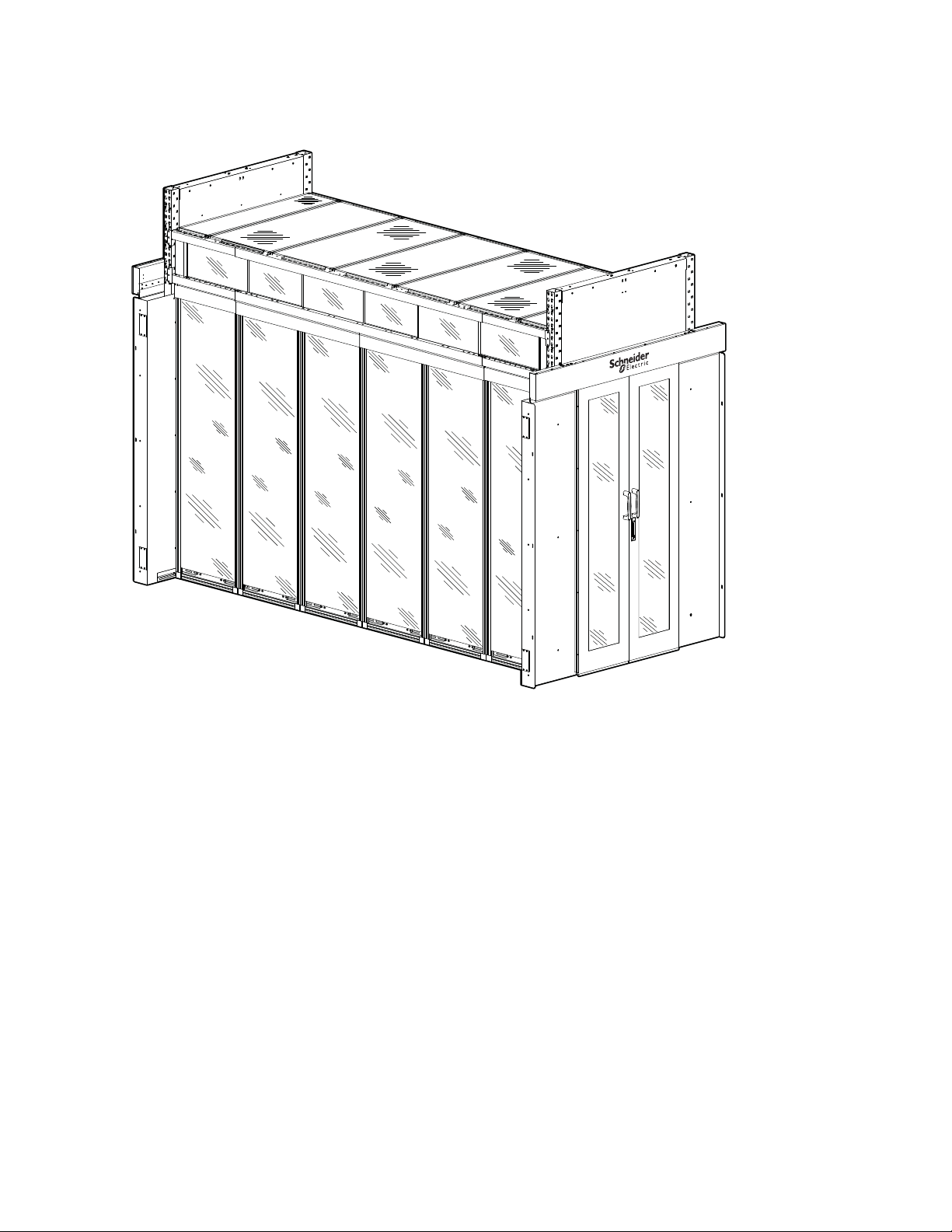

Systems Overview

Basic configuration

The HyperPod™ is a freestanding air containment system.

This manual is a guide for the basic installation procedures for assembling a HyperPod system.

Multiple configurations are possible depending on your requirements. Please contact Schneider Electric

at www.apc.com or your Schneider-Electric representative to explore your options.

HyperPod System Installation10

Page 17

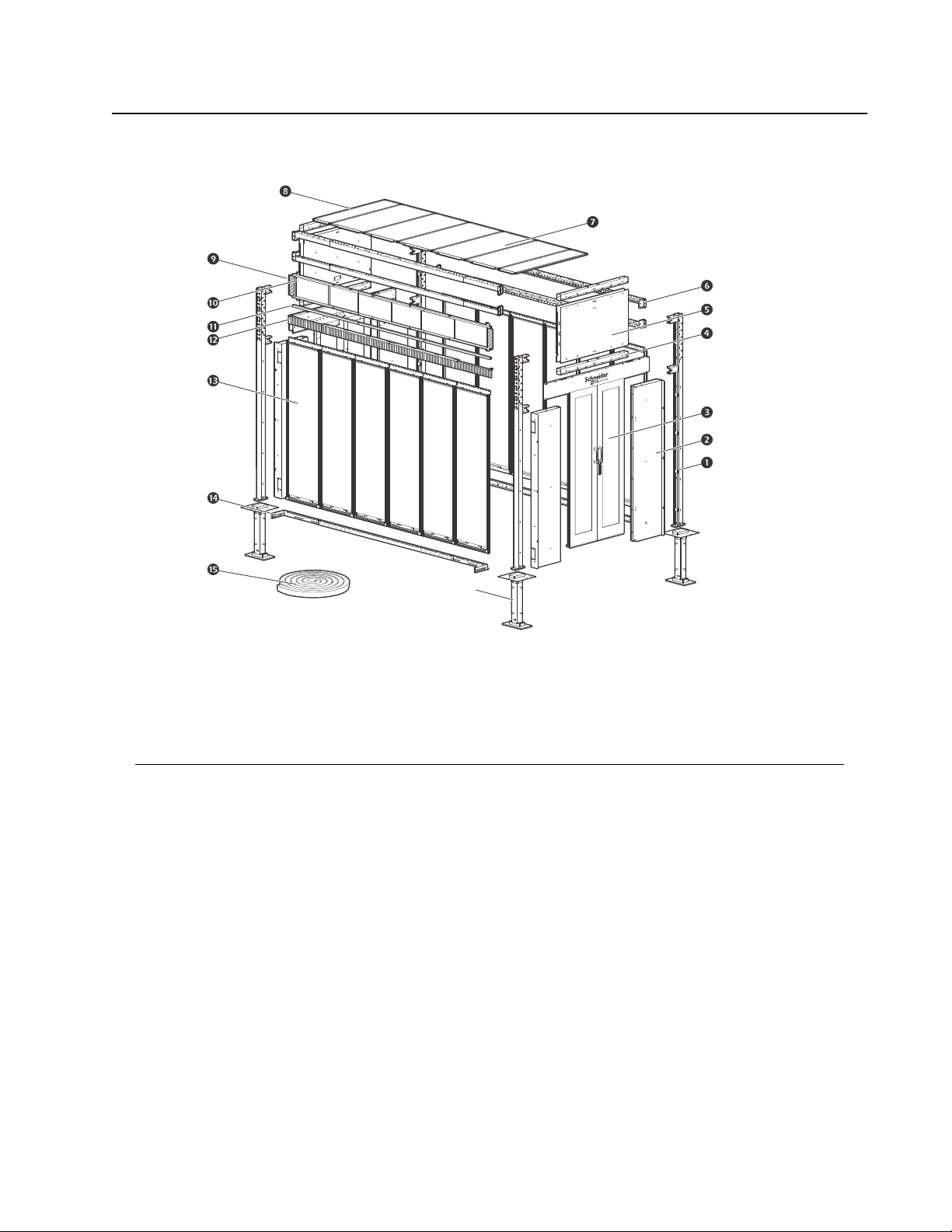

Component Identification

HyperPod System Components

acs0036b

#

Short version shown

Item Description Quantity Required

Vertical post 4

Door frame assembly 4

Dual sliding doors 2

Width beam, 1.2 m (4 ft) 4

Aisle end cap assembly 1.2 m (4 ft) 2

Telescoping length beam assembly, 2.4–3.6 m (8–12 ft) 4

Simple roof panel, 600 mm (23.6 in.), 1.2 m (4 ft) aisle 5

Simple roof panel, 300 mm (12 in.), 1.2 m (4 ft) aisle 2

Window frame brush strips 4

Window panels, 2 ft (contents, 2 panels) 6

Window rail assembly 2

Row length brush strip assembly 2

Blanking panel *

Stop rail assembly, 2.4–3.6 m (8–12 ft) 2

Air sealing kit 1

Raised-floor stands 4

*Quantity determined by number of spaces not inhabited by racks.

11HyperPod System Installation

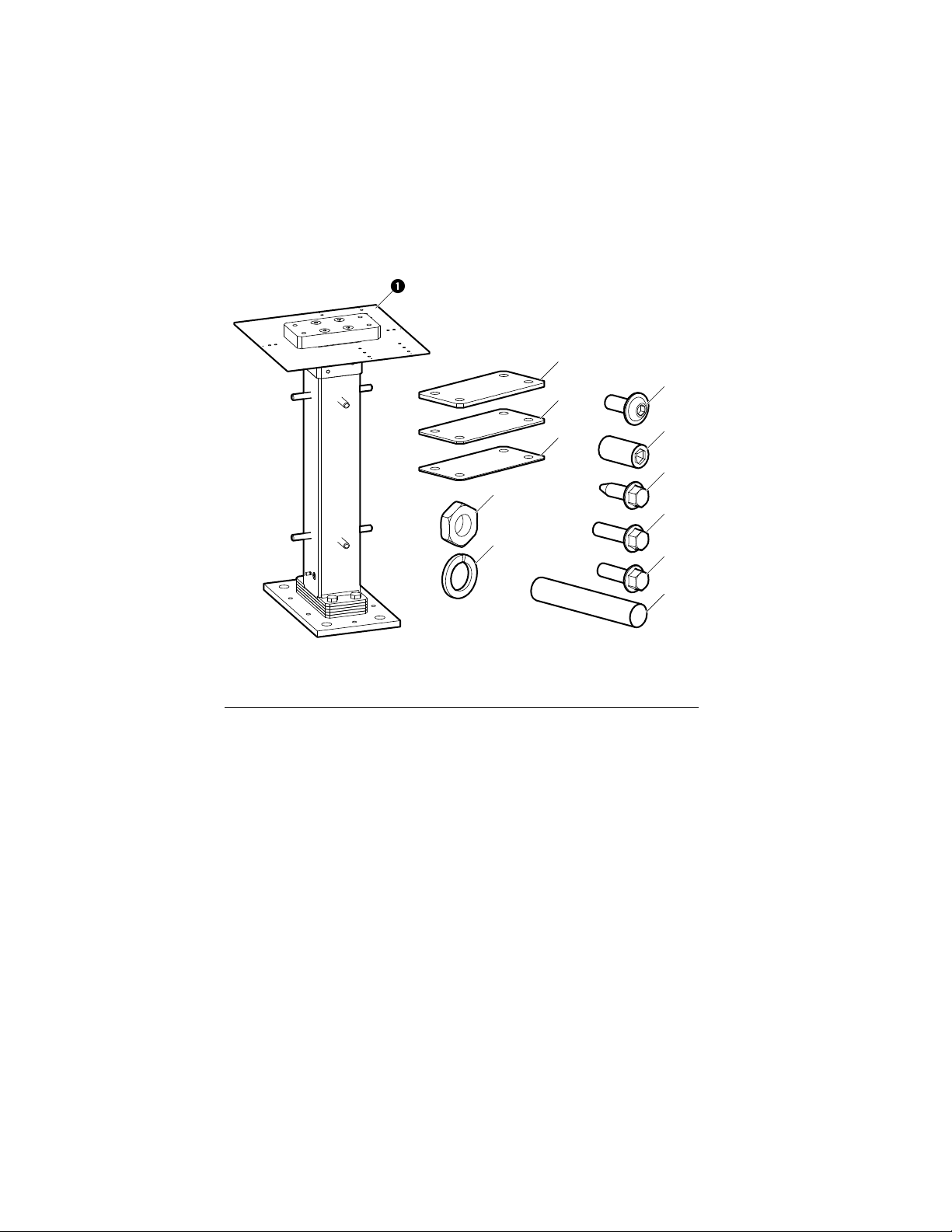

Page 18

Raised-floor Stand

FS-FM-6001-B - Raised-floor Stand, 406 mm (16 in.)

FS-FM-6002-B - Raised-floor Stand, 610 mm (24 in.)

FS-FM-6003-B - Raised-floor Stand, 762 mm (30 in.)

FS-FM-6004-B - Raised-floor Stand, 914 mm (36 in.)

acs0158a

Item Description Quantity

Raised-floor stand 406 mm (16 in.),

610 mm (24 in.), 762 mm (30 in.), 914 mm (36 in.)

Shim, 6 mm 4

Shim, 3 mm 2

Shim, 1.5 mm 2

Nut, M12 8

Spring ring 8

Button head cap screw, 30 mm, M10 x 1.5 8

Set cap screw, 20 mm, M10 x 1.5 12

Self drilling, flanged hex head screw, 22 mm 8

Flanged hex head screw, 25 mm, M12 x 1.75 8

Flanged hex head screw, 20 mm, M12 x 1.75 8

Rod, 100 mm, M12 8

2

HyperPod System Installation12

Page 19

Post Alignment Tool

FS-FM-1011-U - 1.2 m (4 ft) Aisle Post Alignment Tool

FS-FM-1012-U - 1.9 m (6 ft) Aisle Post Alignment Tool

Item Description Quantity

1.2 m (4 ft) Aisle Post Alignment Tool

FS-FM-1011-U

1.9 m (6 ft) Aisle Post Alignment Tool

FS-FM-1012-U

acs0159a

1

1

13HyperPod System Installation

Page 20

Vertical Posts

FS-FM-1001-B - Vertical Post Assembly, 2750 mm (9 ft), Short

FS-FM-1002-B - Vertical Post Assembly, 3200 mm (10.5 ft), Tall

acs0002a

Item Description Quantity

*Template for drilling holes into floor to secure vertical posts.

Vertical Post FS-FM-1002-B (Tall) 2

Vertical Post FS-FM-1001-B (Short) 2

Template* 1

Shim, 0.5 mm 2

Hole plug

FS-FM-1001-B (Short)

FS-FM-1002-B (Tall)

Temporary support 1

Screw, M8 x 12, T30 8

48

88

NOTE: Fasteners for securing the vertical posts to your floor are not included.

HyperPod System Installation14

Page 21

Width Beams

FS-FM-2002-B - 1.9 m (6 ft) Aisle Width Beam Assembly

FS-FM-2003-B - 1.2 m (4 ft) Aisle Width Beam Assembly

Item Description Quantity

Width Beam, 1.9 m (6 ft) aisle, FS-FM-2002-B 1

Width Beam, 1.2 m (4 ft) aisle,

FS-FM-2003-B

Screw, M8 x 12 T30 8

acs0003b

1

15HyperPod System Installation

Page 22

Length Beam

FS-FM-3001-B - Length Beam Assembly

Aisle length beams are attached to Front/Rear frame assemblies to form the basic frame.

Item Description Quantity

Length beam end section 2

Length beam center section 2

Length beam end section 2

Self-adhesive foam seal strip 4

M8 Hex nut 4

Pan head T30 screw, M6 x 12 8

Hex head bolt, M8 x 25 4

NOTICE

Aisle length beams are marked to note the 2.4 m (8 ft) and 3.6 m (12 ft) lengths.

acs0004a

HyperPod System Installation16

Page 23

End Cap Panels

FS-FM-4003-B - 1.9 m (6 ft) Aisle End Cap Assembly, Short

FS-FM-4004-B - 1.9 m (6 ft) Aisle End Cap Assembly, Tall

FS-FM-4005-B - 1.2 m (4 ft) Aisle End Cap Assembly, Short

FS-FM-4006-B - 1.2 m (4 ft) Aisle End Cap Assembly, Tall

Item Description Quantity

Short: FS-FM-4003-B, FS-FM-4005-B

Interior panel, 1.9 m (6 ft), FS-FM-4003-B 1

Exterior panel, 1.9 m, (6 ft), FS-FM-4003-B 1

Interior panel, 1.2 m (4 ft), FS-FM-4005-B 1

Exterior panel, 1.2 m (4 ft), FS-FM-4005-B 1

Low head Nylok® T30 screw, M8 x 12 16

Hole plug, 5 mm 1

Pan head T30 screw, M6 x 12 8

Tall: FS-FM-4004-B, FS-FM-4006-B

End cap panel, 1.9 m (6 ft), FS-FM-4004-B 2

End cap panel, 1.2 m (4 ft), FS-FM-4006-B 2

Low head Nylok T30 screw, M8 x 12 16

Pan head T30 screw, M6 x 12 8

acs004b

NOTE: For short vertical posts, two short end cap assemblies are required per HyperPod. For tall

vertical posts, two tall assemblies and two short assemblies are required per HyperPod. For example, for

a tall HyperPod with a 1.9 m (6 ft) aisle, you need two FS-FM-4003 assemblies, and two

FS-FM-4004 assemblies.

17HyperPod System Installation

Page 24

Door Frame Assembly

FS-DR-2002-B - 1.9 m (6 ft) Aisle Standard Door Frame

FS-DR-2003-B - 1.2 m (4 ft) Aisle Standard Door Frame

acs0039b

Item Description Quantity

Door frame front panel 4

Door frame rear panel cover 4

Hole plug, 5 mm diameter

FS-DR-2002-B

FS-DR-2003-B

M5 x 12 Flat under cut (U cut) flat head Phillips screw

FS-DR-2002-B

FS-DR-2003-B

Low head T30 screw, M8 x 12 33

Pan head T30 screw, M6 x 12 16

Low head screw, M5 x 10, FS-DR-2002-B 36

L Bracket, FS-DR-2002-B 4

25

2

55

8

HyperPod System Installation18

Page 25

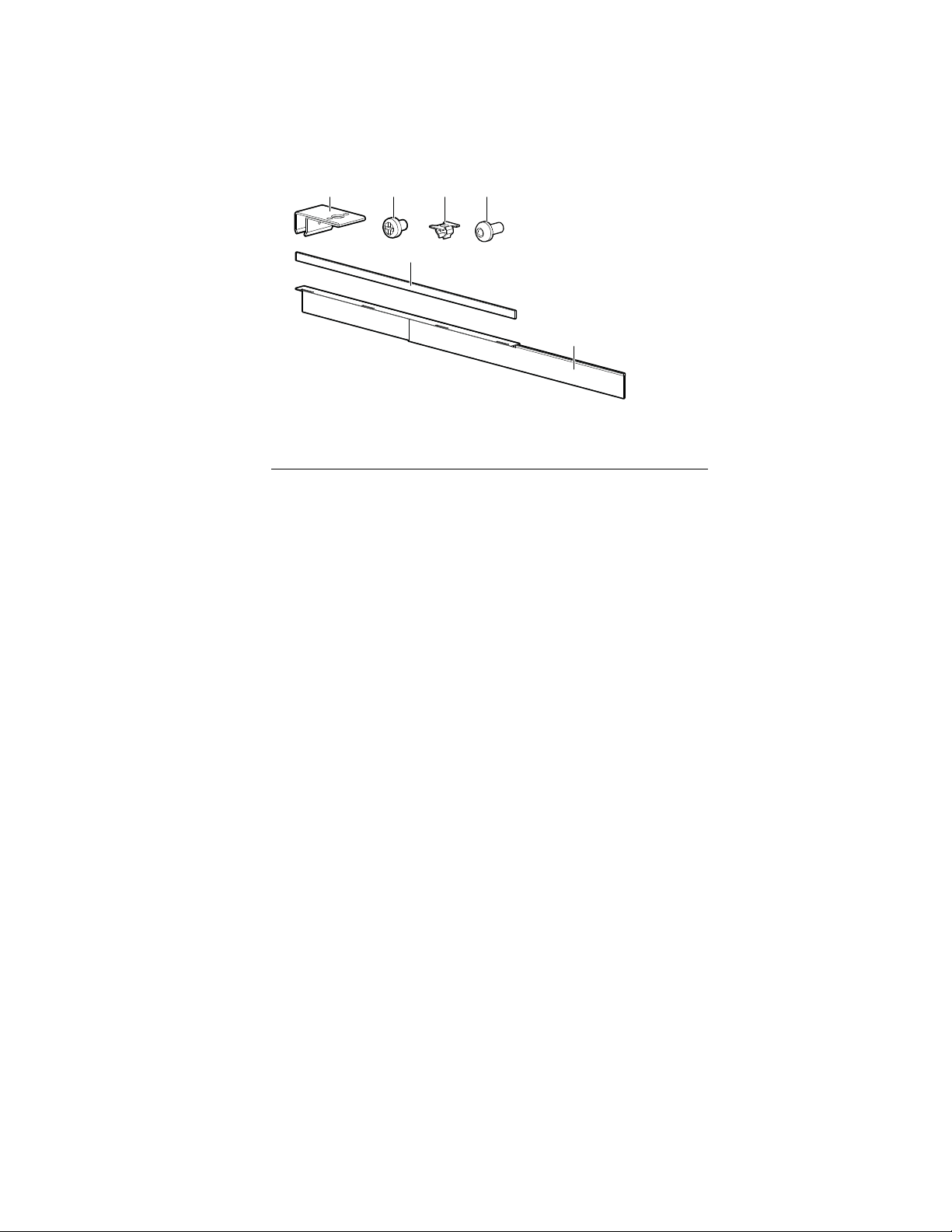

Door and Rail Assembly

FS-DR-1001-B - 1.2 m (4 ft) Aisle Door and rail assembly

FS-DR-1003-B - 1.9 m (6 ft) Aisle Door and rail assembly

!

#

"

acs0010a

Item Description Quantity

Door side brush, 36 x 4 x 1920 mm 2

Door hanging rail assembly 1

Bracket, Left door to reel 1

Bracket, Right door to dumper 1

Left door panel 1

Right door panel 1

Flanged hex nut, M6 9

Pan head T30 screw, M6 x 12 5

Low head T30 screw, M8 x 12 5

Button head TORX screw, M4 x 8 10

Flanged TORX screw, M3 x 8 10

Pan head #2 Phillips screw, M5 x 25 5

Outside door handle 2

Left door bottom rail 1

Door leveling shim 42 x 30 x 0.6 mm 4

Right door bottom rail 1

Key 1

19HyperPod System Installation

Page 26

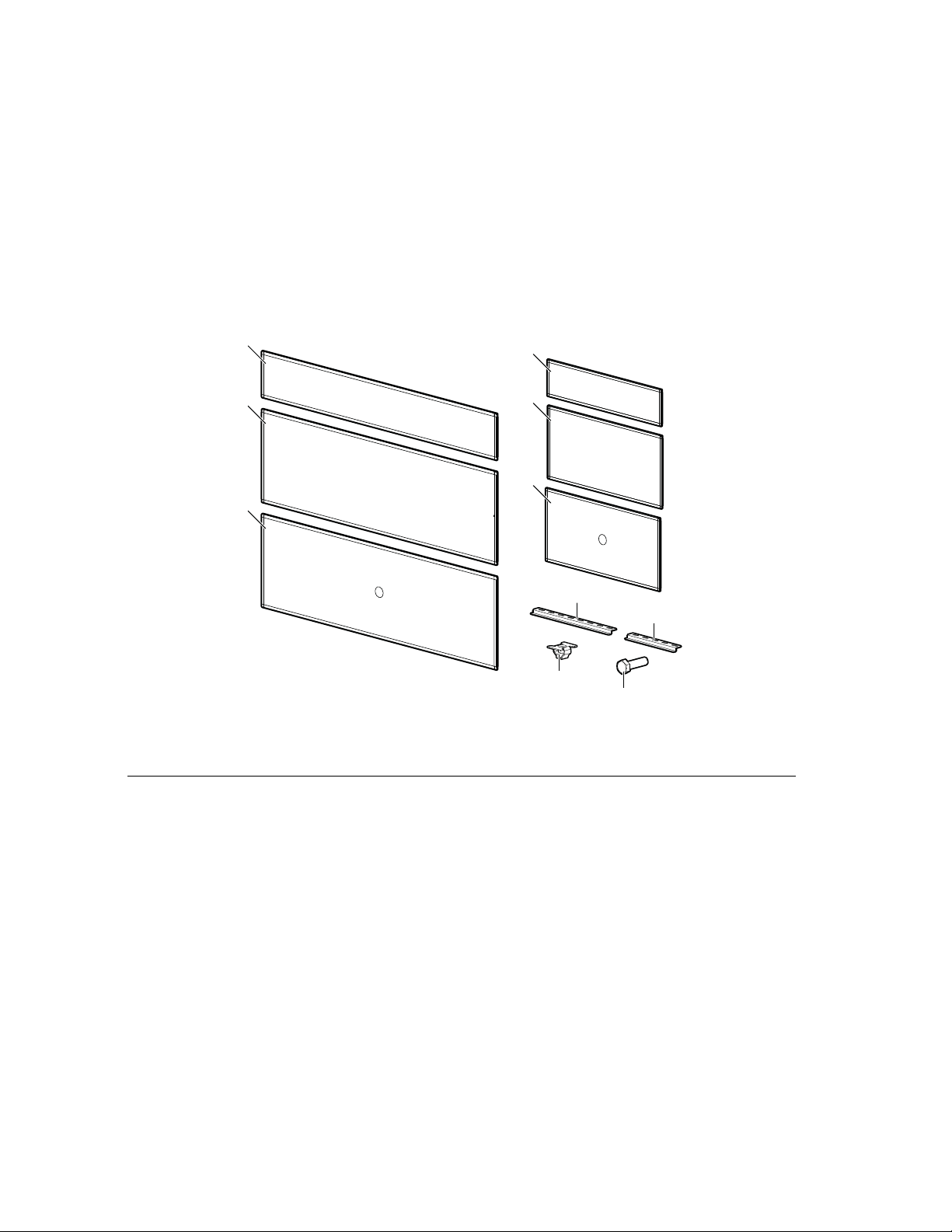

Windows, Rails, and Side Brushes

FS-WI-1001-U - Window Panel 305 mm (2 ft)

FS-WI-1002-B - Window Rail Assembly

FS-WI-1003-B - Window Frame Brush Strips

FS-WI-1004-U - Window Brush Strip Pass-through

acs0005b

Item Description Quantity

Ribbed 5 mm Lexan window, FS-WI-1001-U 2

Flat head T30 screw, M6 x 12, FS-WI-1002-B 18

Short rail bracket, FS-WI-1002-B 17

Side brush strip, FS-WI-1003-B 4

Pan head T30 screw, M6 x 10, FS-WI-1002-B 26

Long rail bracket, FS-WI-1002-B 9

Pan head T30 screw, M6 x 12, FS-WI-1003-B 8

Window rail block, FS-WI-1002-B 12

Connector with four M6 set screws, FS-WI-1002-B 8

Steel hammer head nut, M6, FS-WI-1002-B 26

Window rail, FS-WI-1002-B 12

Window Brush Strip Pass-through, FS-WI-1004-U 2

HyperPod System Installation20

Page 27

Row Length Brush Strip

FS-AC-2001-U

Item Description Quantity

Clip for brush 8

Pan head Phillips screw, M3 x 4 8

Insert nut, M6 5

Pan head T30 screw, M6 x 16 17

Self-adhesive foam seal strip 4

Brush strip 4

acs0008a

21HyperPod System Installation

Page 28

Roof Panel Assembly

FS-RF-2004-U - 1.9 m (6 ft) Aisle Simple Roof Panel, 300 mm (12 in.)

FS-RF-2005-U - 1.9 m (6 ft) Aisle Simple Roof Panel, 600 mm (23.6 in.)

FS-RF-2006-U - 1.9 m (6 ft) Aisle Simple Roof Panel for Sprinkler Option, 600 mm (23.6 in.)

FS-RF-2007-U - 1.2 m (4 ft) Aisle Simple Roof Panel, 300 mm (12 in.)

FS-RF-2008-U - 1.2 m (4 ft) Aisle Simple Roof Panel, 600 mm (23.6 in.)

FS-RF-2009-U - 1.2 m (4 ft) Aisle Simple Roof Panel for Sprinkler Option, 600 mm (23.6 in.)

acs0006b

Item Description Quantity

Roof panel 300 mm (12 in.), FS-RF-2004-U 1

Roof panel 600 mm (23.6 in.), FS-RF-2005-U 1

Roof panel for sprinkler option, FS-RF-2006-U 1

Roof panel 300 mm (12 in.), FS-RF-2007-U 1

Roof panel 600 mm (23.6 in.), FS-RF-2008-U 1

Roof panel for sprinkler option, FS-RF-2009-U 1

Long roof panel bracket

FS-RF-2005-U, FS-RF-2006-U, FS-RF-2008-U, FS-RF-2009-U

2

Short roof panel bracket, FS-RF-2004-U, FS-RF-2007-U 2

Insert nut, M6, all assemblies 4

Hex head screw, M6-1 x 16, all assemblies 4

HyperPod System Installation22

Page 29

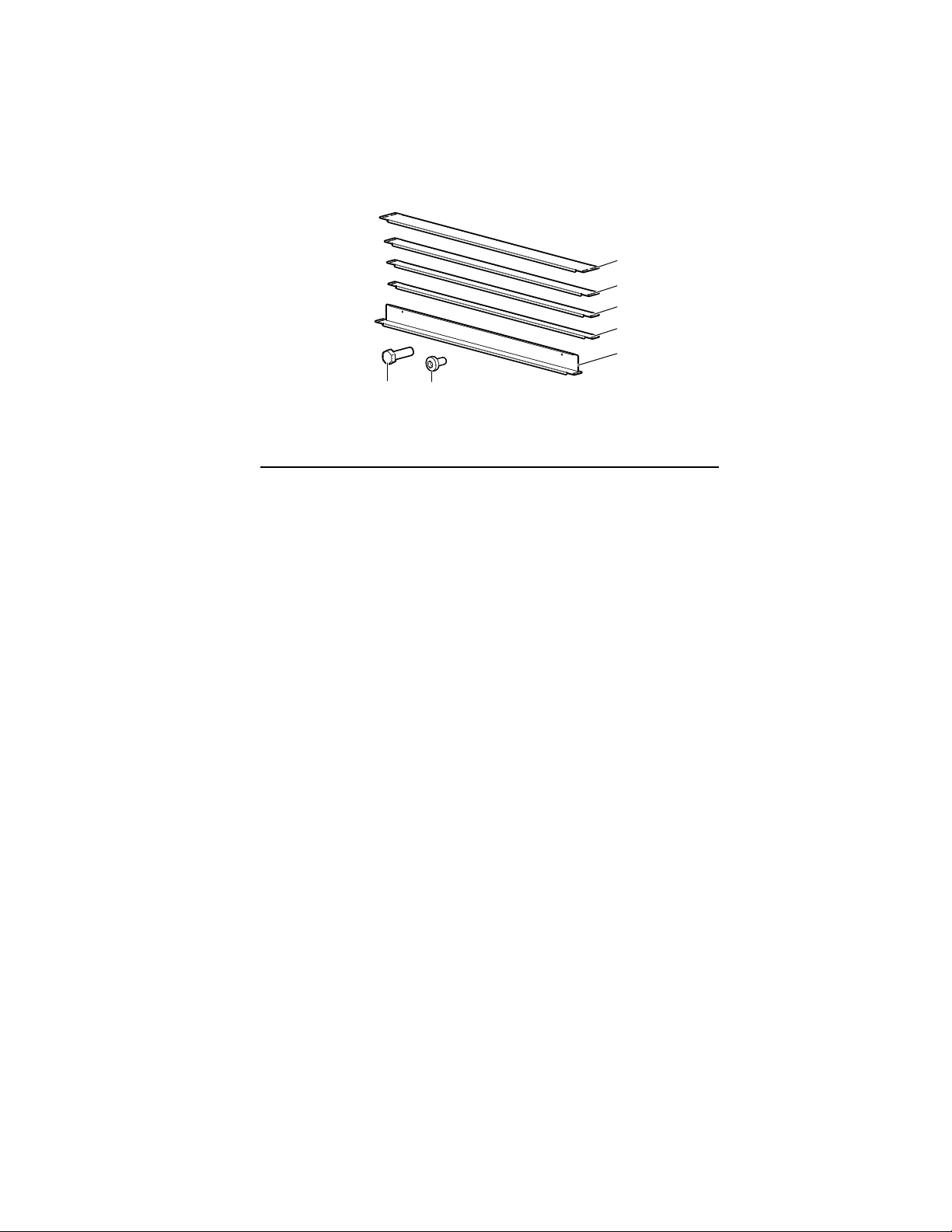

Solid Roof Filler Panel Set

FS-RF-1002-B - 1.9 m (6 ft) Aisle

FS-RF-1003-B - 1.2 m (4 ft) Aisle

acs0009b

Item Description Quantity

Solid roof panel, 100 mm 1

Solid roof panel, 60 mm 1

Solid roof panel, 50 mm 2

Solid roof panel, 40 mm 1

Solid roof panel (drop) 50 mm, FS-RF-1003-B* 1

Hex head screw, M6-1 x 16 mm

FS-RF-1002-B

FS-RF-1003-B

Pan head TORX screw, M4 x 8, FS-RF-1003B*

*Used for the drop roof option.

10

12

2

23HyperPod System Installation

Page 30

Stop Rail

FS-FM-5001-B - Stop Rail Assembly

acs0044a

Item Description Quantity

Left end rail 2

Pan head T30 screw, M6 x 10 8

Hex head screw, M8 x 20 9

Low head T30 screw, M8 x 12 9

Mylar electrical isolation plate 4

Right end rail 2

Stop rail middle plate 2

HyperPod System Installation24

Page 31

Air Seals

FS-AC-1001-U - Air Sealing Kit

FS-AC-1002-U - H Seal for Blanking Panels

FS-AC-1003-U - C Seal for Blanking Panels and Vertical Posts

acs0057b

Item Description Quantity

Self adhesive foam seal, 10 mm x 10 mm 12 M

H seal, FS-AC-1002-U 1

C seal, FS-AC-1003-U 1

25HyperPod System Installation

Page 32

Blanking Panels

FS-AC-5005-B - 300 mm (12 in.)

FS-AC-5006-B - 600 mm (23.6 in.)

FS-AC-5007-B - 750 mm (29.5 in.)

FS-AC-5008-B - 800 mm (31.5 in.)

acs0046b

Item Description Quantity

Blanking panel, 42–52 U

(300 mm, 600 mm, 750 mm, 800 mm)

Angle corner bracket 2

Ground wire 4 in. 2

Serrated lock washer, M6 2

Pan head T30 screw, M6 x 16 3

Insert nut, M6 3

Low head Nylok T30 screw, M8 x12 3

1

HyperPod System Installation26

Page 33

Installation Procedure Overview

Safety

Read and follow these safety instructions.

WARNING

TOOL USAGE HAZARD

Follow safety standards for all hand tools and power tools used. Read and follow the tool

manufacturer’s instructions. Follow the tool manufacturer’s recommendations and recognized

safety requirements for use of Personal Protection Equipment (PPE).

Failure to follow these instructions can result in death, serious injury, or equipment

damage.

WARNING

HEAVY EQUIPMENT HAZARD

Raised-floor stands are required if the combined weight of the HyperPod system and all installed

equipment will exceed the structural capacity of your raised-floor system.

Failure to follow these instructions can result in death, serious injury, or equipment

damage.

CAUTION

WORKING HEIGHT HAZARD

The working height for the assembly process can exceed 2.3 m (7.5 ft). The use of stepladders or

scaffolding will be required during assembly.

Failure to follow these instructions can result in serious injury or equipment damage.

CAUTION

LIFTING HAZARD

At least two (2) people are required to install this enclosure. Some parts may be heavy and/or

excessive in size. For items weighing more than 12 kg (25 lbs), use more than one person.

Failure to follow these instructions can result in serious injury or equipment damage.

CAUTION

NO STEP HAZARD

Ceiling panels are not designed to support weight. Never lean or walk on the ceiling panels.

DO NOT use ceiling panels to support power or data cables.

Failure to follow these instructions can result serious injury or equipment damage.

27HyperPod System Installation

Page 34

Customizing the Installation

Installation locations for width beams and length beams

acs0021a

NOTICE

• Vertical posts are marked with height notation . (The tall vertical post is shown in the

illustration above.)

• If 48 U or shorter racks are deployed in the tall HyperPod, 6 length beams are required. If

racks are taller than 48 U, use 4 length beams.

• Tall HyperPod frames support racks up to 52 U.

• Telescoping rails are marked to note 2.4 m (8 ft) and 3.6 m (12 ft) lengths .

Select the height of the length beams based on the height of the racks to be installed or your roof

and ducting needs. Determine these requirements prior to assembly of the frame. Once the

location of the lower length beam has been established, the (next) upper beam must be placed at

the correct height to allow for installation of the windows.

HyperPod System Installation28

Page 35

Basic Frame Assembly

Floor stands

Use the floor stands for raised-floor configurations. For the regular floor option, see “Secure the

frame to the floor” on page 38.

Configure the first two (2) floor stands.

1. Remove tiles (and pedestals, if necessary) from the raised floor in the proposed locations

for two (2) floor stands. Leave any stringers intact. If you remove any pedestals, save the

fasteners.

2. Attach two (2) floor stands to the alignment tool with the provided button head cap screws,

and place the floor stands in the desired locations.

acs0161a

3. If the floor is not even or horizontally level, use the provided M10 x 1.5 set cap screws and

a 4 mm Hex wrench to ensure that the floor stand is horizontally level.

acs0162a

29HyperPod System Installation

Page 36

4. Secure the floor stands to the floor according to local and national standards. (The holes in

the base of the floor stand will accommodate 20 mm fasteners). Remove the alignment tool.

5. Adjust the height of the control plates: use a 4 mm Hex wrench to loosen and tighten the set

screws .

NOTE: If the height of the floor stand is too tall for your raised-floor system, remove the

bottom shims . If the combined depth of the shims and vertical post foot is 25 mm (1 in.)

or less, use the 20 or 25 mm M12 x 1.75 25 flanged hex head screws to secure the shims.

If the combined depth of the shims and vertical post foot is 40 mm (1.6 in.) or more, use the

100 mm M12 rods, nuts, and spring rings to secure the shims.

– If no stringers are present, adjust the height of the control plates so that they rest against

the bottom of the raised-floor tiles .

– If stringers are present, adjust the height of the control plates so that they rest against the

bottom of the stringers .

– If stringers are present, but the floor tiles are thicker than the stringers, adjust the height

of the control plates so that they rest against the bottom of the tiles. Place shims (not

provided) between the stringers and the control plate so that the control plate supports

the stringers .

DE

FGH

acs0163a

HyperPod System Installation30

Page 37

6. Insert one 22 mm, self-drilling, flanged hex head screw on each side of the control plate

collar .

7. Attach the control plate to each stringer with one or two (2) screws. The tapped holes in the

control plate will accommodate M8 screws .

NOTE: Tighten the screws so that the heads are countersunk into the stringer, but the

stringer is not deformed.

E

D

acs0164a

8. Measure and cut the appropriate floor tiles so that the riser block can pass through them.

Replace the tile(s). If the riser block is lower than the tiles, place the provided shims on top

of the riser block until the top shim is flush with the surface of the tiles.

acs0165a

31HyperPod System Installation

Page 38

Configure subsequent floor stands.

1. Follow the instructions to configure the basic HyperPod frame (see “Frame end

configuration” on page 34 and “Length beam assembly” on page 35). Construct the frame

as close to the first set of floor stands as possible.

2. Secure two (2) vertical posts to the installed floor stands with 30 mm, M10 x 1.5 button

head-cap

screws.

acs0166a

HyperPod System Installation32

Page 39

3. Use a lift, or a rolling scaffold and a jack stand, to support the frame end that is not secured

to the floor stands.

acs0167a

4. Configure a second set of floor stands. Follow the procedure to “Configure the first two (2)

floor stands” on page 29 with one exception: use the HyperPod frame (instead of the

alignment tool) to determine placement for the second set of floor stands.

5. Check the frame and floor stands for proper alignment. Then secure the floor stands to the

floor according to local and national standards.

6. Secure the vertical posts to the floor stands with the 30 mm, M10 x 1.5 button head cap

screws.

Alternate method for floor stand configuration.

1. Follow the instructions to configure the basic HyperPod frame (see “Frame end

configuration” on page 34 and “Length beam assembly” on page 35). Ensure the frame is

level, plumb, and in the correct location. Use tape or a pencil to mark the floor tiles around

the vertical post feet (these markings can be used to cut the tiles).

2. Use a lift, or a rolling scaffold and a jack stand, to support one frame end (see “Configure

subsequent floor stands” , step 3 for an illustration).

3. Follow the procedure to “Configure the first two (2) floor stands” on page 29 with one

exception: use the HyperPod frame (instead of the alignment tool) to determine placement

for the floor stands.

4. Repeat steps 2 and 3 at the other end of the HyperPod frame.

33HyperPod System Installation

Page 40

Frame end configuration

Assemble vertical posts to width beams (2 width

beams for the Short HyperPod, 3 width beams

for the Tall Hyperpod) using the M8 x 12 T30

screws provided.

NOTICE

Hole plugs are included with this assembly. It is recommended

to wait until the accessories are installed before installing the

hole plugs.

Assemble a second set of vertical posts and

width beams.

NOTE: If needed, the temporary frame support

can be installed to the assembly at this time.

See “Temporary frame support” on page 37 for

more information.

acs0047a

.

Tall

Short

acs0160a

HyperPod System Installation34

Page 41

Length beam assembly

Install the telescoping horizontal beams to the vertical post assemblies.

1. Assemble the beam by sliding the end sections into the main beam. Make sure the bracket

on the end is in the correct position for attaching to the vertical post.

2. Slide the length beam to the desired length. The beam is marked at the 2.4 m (8 ft) and

3.6 m (12 ft) lengths. If the length of your HyperPod will be more than 2.4 m (8 ft) but less

than 3.6 m (12 ft), measure and mark the length beams so they can be secured at the

appropriate length.

NOTE: The left and right end inserts of the length beam can each be extended to add

600 mm (2 ft). When both end inserts are fully extended, the total length of the length beam

is 3.6 m (12 ft). When setting up the length beams to the calculated length of the aisle you

need in your HyperPod, make sure that the inserts on both ends of each length beam are

extended the same length. For example, if the left end insert is extended by 50 mm (2 in.),

then the right end insert should also be extended by 50 mm (2 in.).

acs0144a

acs0064b

=

acs0145a

35HyperPod System Installation

Page 42

3. Secure the small beam ends in place with M6 x 12 pan head T30 screws.

4. Secure the length beams to the vertical posts with four provided M8 x 25 hex head bolts and

M8 nuts.

The lower length beam should be placed in a position that will allow you to install your tallest

rack. The upper beam should be placed 3 U above the lower beam to provide space for the

window assembly.

acs0012a

5. The end inserts of the length beam are smaller than the main portion of the beam. Apply the

self-adhesive foam seal to the gap on the extensions of the length beam to fill the space.

acs0064b

HyperPod System Installation36

Page 43

Temporary frame support

If you are not going to secure the frame to the floor at this time, attach the temporary support to the

feet of the vertical posts with four M8 x 12 T30 screws per post to stabilize the frame while making

sure the frame is level and plumb. The temporary frame support helps maintain the placement of

the HyperPod system during assembly.

acs0105a

37HyperPod System Installation

Page 44

Secure the frame to the floor

This procedure is for the regular floor option. If you have a raised floor, see “Configure the first two

(2) floor stands” on page 29.

1. To prepare to secure the frame to the floor, adjust the frame until level and plumb. Use the

supplied shims as necessary. Use threaded screws (not provided) to raise the vertical post

foot plate from the floor.

acs0064a

2. Attach the vertical posts at one end to the floor. Do not attach both ends of the frame to the

floor until length is checked to accommodate the intended equipment and the frame is level

and plumb.

acs0048a

HyperPod System Installation38

Page 45

End caps

Install the end caps (exterior and interior panels) above the door area on the vertical posts.

Loosely mount (4) M6 x 12 pan head T30 screws on both sides of the topmost width beam, then

hang the interior and exterior end cap panels from the screws. Install four (4) more M6 x 12 pan

head T30 screws at the bottom of the panels.

acs0178a

Use eight (8) M8 x 12 low head Nylok T30 screws to secure the inner and exterior panels. Then

tighten the M6 x 12 pan head T30 screws.

acs0013b

NOTICE

Hole plugs are included with this assembly. It is recommended

to wait until the accessories are installed before installing the

hole plugs.

39HyperPod System Installation

Page 46

Door frames

1. If you have a 1.9 m (6 ft) aisle, secure the L bracket to the frame with M6 x 12 pan head T30

screws.

NOTICE

Vertical posts must be secured to the floor before installing the

door frames. The door frames enclose the vertical posts,

prohibiting access.

acs0169a

2. Place the front and back panels together around the vertical support post.

3. Secure the back panel to the vertical support post with the M8 x 12 T30 screws. For a

1.9 m (6 ft) aisle, also secure the back panel to the L bracket with four M5 x 10 low head

screws.

HyperPod System Installation40

Page 47

4. Secure the front panel to the back panel and vertical posts with the M8 x 12 T30 screws and

M5 x 12 flat U cut flat head Phillips screws. For a 1.9 m (6 ft) aisle, also secure the front

panel to the L bracket with four M5 x 10 low head screws.

NOTICE

Hole plugs are included with this assembly. It is recommended

to wait until the accessories are installed before installing the

hole plugs.

acs0014b

41HyperPod System Installation

Page 48

Doors

1. Remove the cover of the door hanging rail assembly. Save the cover and ten (10)

M4 x 8 mm button head TORX screws.

acs0175a

2. Remove the eight (8) M4 x 8 mm button head TORX screws and two (2) M6 Hex nuts

securing the shipping bracket. Discard the shipping bracket,

3. Remove the metal cover plate on the magnets.

acs0155a

acs0148b

HyperPod System Installation42

Page 49

4. Attach the door hanging case to the frame above the top of the door opening with four

M8 x 12 low head T30 screws.

acs0063a

5. Use the shims included with the door hanging case to ensure the hanging case is level,

plumb, and square to the door frame. The door hanging case must clear the door frame an

equal distance on both ends to ensure the doors will move without obstruction.

acs0063b

43HyperPod System Installation

Page 50

6. Hang the doors.

CAUTION

HEAVY EQUIPMENT HAZARD

At least two (2) people are required to perform this task.

Failure to follow these instructions can result in serious injury or equipment damage.

The two (2) locations on the doors for the brackets must be lined up with the sliding blocks.

The innermost brackets are already attached to the reel. The two (2) posts on the door fit

through the slotted holes on the bracket.

a. At least one person must hold a door up to the sliding blocks while another person

installs four M4 x 8 button head TORX screws to each of the two (2) blocks.

acs0154a

HyperPod System Installation44

Page 51

b. Install an M6 hex nut to each threaded post on the two (2) innermost brackets,

securing them to the doors.

acs0149a

c. Attach the bottom rails to the doors and secure them to the door frames with the

provided M6 x 12 pan head T30 screws.

acs0077a

45HyperPod System Installation

Page 52

d. Install the outermost left and right door hanging brackets to the threaded posts on the

doors with the M6 flanged hex nuts.

acs0079a

e. Pull the end of the cable and attach one end to each of the outermost brackets with

one M4 x 8 button head TORX screw.

acs0153a

HyperPod System Installation46

Page 53

f. Test how quickly the doors close. If the doors close quickly enough to slam into each

other, turn the adjustment screw to the right to slow the doors as they close.

acs0156a

g. Attach the door handles to the door with two (2) M5 x 25 pan head screws.

acs0106a

47HyperPod System Installation

Page 54

h. Install a brush to the outside edges of each door with four M3 x 8 mm flanged TORX

screws and adjust, using the slotted holes of the brush strip, to cover the gap between

the frame and the door.

Test how quickly the doors close again, and adjust if necessary.

acs0066b

i. Install the cover to the door rail assembly with ten (10) M4 x 8 button head TORX

screws.

acs0066a

HyperPod System Installation48

Page 55

Frame seals

Attach the self-adhesive foam seal strips from the seal kit to the backs of the door frame where they

will meet the rack or blanking panel and to the inside end caps where they will meet the roof panel.

acs0094a

NOTICE

You may want to wait until a rack, blanking panel, or roof panel is installed in order to place

the frame seals in the optimal locations.

49HyperPod System Installation

Page 56

Window assemblies

Window rails are installed to the underside of the top length beam and the top of the lower length

beam.

1. Starting at one end of the frame, install the window side brush to the length beams with two

(2) M6 x 12 screws to fill the area between the back of the door frame and the starting edge

of the window assembly .

2. Install two (2) rail brackets to the length beam with M6 x 10 screws for each four foot section

of rail . Use short rail brackets on the non-telescoping part of the length beams, and use

long rail brackets on the telescoping part of the length beams.

3. Join two (2) 1.2 m (4 ft) window rails using the connector with its four M6 set screws .

4. To secure the window rail to the window rail brackets, slide a hammer head nut into the rail

and behind the bracket. Once an M6 x 10 screw is inserted through the bracket to the nut,

rotate the nut 90 degrees to secure the nut in the rail .

5. Insert the rail blocks into the bottom rails .

6. Install the window panels or pass-throughs to the window rails by sliding the parts up into

the top rail and then allowing the bottom edge of the part to drop down into the bottom rail

.

acs0015b

NOTE: HyperPod frames that are 2.4 m (8 ft) long require two (2) 1.2 m (4 ft) rails along the length

of the length beam. Window rails may require cutting to size if the aisle length is longer than

2.4 m (8 ft) and shorter than 3.6 m (12 ft).

HyperPod System Installation50

Page 57

NOTE: There are two (2) tracks in the window rail. Alternate tracks when installing the windows.

acs0 50a

51HyperPod System Installation

Page 58

Row length brush

Each row length brush has a slide out extension brush on one end. Install the row length brush with

the extension brush end toward the vertical post. The left and right brushes with extension brushes

fully deployed measure 3.6 m (12 ft). With the end of each row length brush meeting at the center

of the length beam, slide out each end of the brush strip until it meets the end of the frame.

1. Install the brush extension clips at each end of the length beam with an M6 x 16 pan head

T30 screw.

acs0151a

2. Apply the self-adhesive foam strip to the bottom of the slide out extension of the length

beam.

acs0141a

HyperPod System Installation52

Page 59

3. Hold the row length brush up to the length beam and note the hole locations. Install the

insert nuts to the bottom of the length beams at the appropriate locations. Install the brush

strip to the bottom of the length beam with the provided M6 x 16 pan head T30 screws.

acs0016a

4. Insert the top edge of the brush extension into the clip. Secure the brush extension in the

clip with an M3 x 4 pan head Phillips screw.

acs0142a

53HyperPod System Installation

Page 60

Roof panels

1. Install the roof panels to the top of the horizontal length beams using the insert nuts,

brackets, and M6-1 x 16 hex head screws.

acs0022a

2. Use the roof filler panels and hex head screws to fill in the extra space at the end of the

aisle, if any. The roof filler panels have slotted holes to allow for adjustment.

NOTE: Do not use the drop panel for this configuration.

acs0012b

HyperPod System Installation54

Page 61

Stop rails

1. Measure from front to back of the aisle to make sure the stop rails are straight. Use a chalk

line to help install the HyperPod along a straight line.

acs0143a

55HyperPod System Installation

Page 62

2. Install the stop rails to the bottom of the door frames with the Mylar electrical isolation plate

between. Secure the stop rail to the door frame with two (2) M8 x 20 hex head screws at

each end. Use the slots to adjust the rail in or out. When the stop rails are in the correct

position, secure the extensions to the center rail with the M6 x 10 pan head T30 screws

along the sides of the rails and use anchor bolts (not provided) to secure the rail assembly

along the edge that sits flush to the floor.

acs0041a

HyperPod System Installation56

Page 63

Blanking panels

1. If the rack space is taller than 42 U, adjust the panel to fill the available space. Loosen the

screws as shown below and slide the 10 U panel to the necessary length.

acs0134c

57HyperPod System Installation

Page 64

2. Install insert nuts to the length beam. Attach the top blanking panel bracket to the horizontal

length beam with two (2) M6 x 16 pan head screws.

3. Attach the bottom blanking panel bracket to the stop rail. Attach the ground wire and

serrated washer.

NOTE: The blanking panels may also be attached to the floor with the provided angle

corner brackets.

acs0135a

HyperPod System Installation58

Page 65

C seals and H seals

You can install C seals and H seals before or after you install the blanking panels. If you install the

seals after the blanking panels, you may need to uninstall some blanking panels so that you have

enough space to install the seals.

Install C Seals. If there is extra space between the blanking panels and the end of the aisle, install

C seals on the blanking panels near the end of the aisle.

acs0170b

59HyperPod System Installation

Page 66

Install H seals. If there is extra space between the blanking panels, install H seals on the blanking

panels. You can install the seals directly on the side of the blanking panel . You can also pull the

two (2) pieces of the H seal apart, and slide them back together between two (2) blanking panels

.

NOTE: The second procedure may require one person to stand on either side of the blanking

panels to push the H seal together.

acs0170a

HyperPod System Installation60

Page 67

Accessory Kits

End Row Transition Cabinets

FS-AC-7001-B - Distribution Cabinet, MH50

FS-AC-7002-B - Distribution Cabinet, Split

FS-AC-7003-B - Distribution Cabinet, Solid

FS-AC-7001-B

FS-AC-7002-B

Item Description

Transition cabinet FS-AC-7001-B 1

Pan head T30 screw, M6 x 12 3

Transition cabinet FS-AC-7002-B 1

Pan head T30 screw, M6 x 12 3

Transition cabinet FS-AC-7003-B 1

Pan head T30 screw, M6 x 12 3

acs0078a

FS-AC-7003-B

Quantity

61HyperPod System Installation

Page 68

Drop Roof

FS-RF-3002-U - Drop Roof Mounting Rail, 300 mm (12 in.)

FS-RF-3004-U - Drop Roof Mounting Rail, 600 mm (23.6 in.)

FS-RF-3006-U - Drop Roof Mounting Rail, 750 mm (29.5 in.)

FS-RF-3007-U - Drop Roof panel, 300 mm (12 in.)

FS-RF-3008-U - Drop Roof panel, 600 mm (23.6 in.)

FS-RF-3009-U - Drop Roof panel, 750 mm (29.5 in.)

acs0007a

Item Description Quantity Item Description Quantity

Ceiling support assembly

300 mm (12 in.)

Ceiling support assembly

600 mm (23.6 in.)

Ceiling support assembly

750 mm (29.5 in.)

Bracket for 600 mm (23.6 in.) and

750 mm (29.5 in.) panel

Hammer head nut, M6 8

Baying hinge bracket 2

TORX pan head screw, M4 x 8 4

Insert nut, M6 4

1

1

1

1

Pan head T30 screw, M6 x10 8

Pan head T30 screw, M6 x16 4

Bracket for 300 mm (12 in.) panel 1

Roof panel, 750 mm (29.5 in.) 1

Roof panel, 300 mm (12 in.) 1

Connector 4

Roof panel, 600 mm (23.6 in.) 1

NOTE: The drop roof is only available for 1.2 m (4 ft) aisle configurations.

HyperPod System Installation62

Page 69

Shrink Roof

FS-RF-6001-U - 1.2 m (4 ft) Aisle Shrink Roof panel, 610 mm (24 in.)

FS-RF-6002-U - 1.2 m (4 ft) Aisle Shrink Roof panel, 310 mm (12.2 in.)

FS-RF-6003-U - 1.9 m (6 ft) Aisle Shrink Roof panel, 610 mm (24 in.)

FS-RF-6004-U - 1.9 m (6 ft) Aisle Shrink Roof panel, 310 mm (12.2 in.)

acs0157a

Item Description

1.2 m (4 ft) Aisle shrink roof panel, 310 mm (12.2 in.)

(FS-RF-6002-U)

1.2 m (4 ft) Aisle shrink roof panel, 610 mm (12.2 in.)

(FS-RF-6001-U)

1.9 m (6 ft) Aisle shrink roof panel, 310 mm (12.2 in.)

(FS-RF-6004-U)

1.9 m (6 ft) Aisle shrink roof panel, 610 mm (12.2 in.)

(FS-RF-6003-U)

Insert nut, M6 2

Pan head T30 screw, M6 x 12 6

Washer 2

EPDM foam 1

Quantity

1

1

1

1

63HyperPod System Installation

Page 70

Ceiling Panel Lock Systems

ACDC2016 - Ceiling Panel Lock System, 100-120 V (with power supply)

ACDC2017 - Ceiling Panel Lock System, 200-240 V (with power supply)

Power Status

Smoke

Detector

EM Lock &

Temperature Switch

Dropout

Alarm 2

Dropout

Primary Source

Secondary Source

Alarm 1

Item

Description

Quantity

Dropout power supply control box, 110 V (ACDC2016) 1

Dropout power supply control box, 220 V (ACDC2017) 1

Bracket for power supply box, left 1

Bracket for power supply box, right 1

Pan head Phillips screw, M6 x 16 4

Pan head T30 screw, M6 x 12 4

Button head T15 screw, M4 x 8 mm 6

Plastic cup washer, M6 4

Channel nut, M6 4

Caged nut, M6 4

Wire harness—power supply to wiring box, 3.6 m (12 ft) 1

Across aisle wiring assembly, 4 m (13.1 ft) 2

Alarm beacon 2

Wiring box cover 1

Terminal jumper 1

4-pin jumper 1

Wire tie 55

Cable holder 55

Power cord—CEE22 jump 2M 10A ROHS (ACDC2017) 2

Power cord—C13/15 DELL ROHS compliant (ACDC2016), 1.8 m (6 ft) 2

Smoke detector cable 1

na4051a

HyperPod System Installation64

Page 71

ACDC2015 - Ceiling Panel Lock System, (without power supply)

na5222-56

Item

Description

Flat head TORX screw, M5 x 8 8

Pan head TORX screw, M4 x 8 24

Flat head TORX screw, M5 x 10 4

Serrated hex flange nut, M4 8

Temperature switch, 135 ºF (57 ºC), 24 VDC 3 A 4

Electromechanical lock spacer 4

Electromechanical lock assembly, 24 V 50 MA 4

Wiring box 4

Box-to-box wire assembly 4

Quantity

65HyperPod System Installation

Page 72

Rack Height Adapters

FS-AC-8001-U - Rack Height Adapter, 300 mm (12 in.)

FS-AC-8002-U - Rack Height Adapter, 600 mm (23.6 in.)

FS-AC-8003-U - Rack Height Adapter, 750 mm (29.5 in.)

FS-AC-8004-U - Rack Height Adapter, 800 mm (31.5 in.)

acs0038a

Item Description

Bracket for brush/filler panel 1

Panel, 1 U, plastic, height filling, (length: 300, 600, 750, 800 mm) 6

Brush, short, height filling, (length: 300, 600, 750, 800 mm) 1

Pan head T30 screw, M6 x 16 4

Insert nut, M6 4

Pan head Phillips screw, 10-32 x 5/16 2

Quantity

HyperPod System Installation66

Page 73

Cantilever Support Arms

FS-AC-3001-B - Large Cantilever Support Arms

acs0023a

Item Description

Cantilever Arm 2

Hex head bolt, M12 x 100 4

Hex head nut, M12 4

FS-AC-3003-B - Mini Cantilever Arms

Item Description

Leveling pad 2

Mini Cantilever arm 2

Hex socket bolt, M4 x 10 4

Hex head bolt, M6 x 20 4

Insert nut, M6 4

Quantity

acs0027a

Quantity

67HyperPod System Installation

Page 74

FS-AC-3002-B - Overhead Support Frame, 2.4–3.6 m (8–12 ft)

Item Description Quantity

Aluminum frame 1

Pan head T30 screw, M6 x 12 17

Hammer head nut, M6 17

acs0069a

HyperPod System Installation68

Page 75

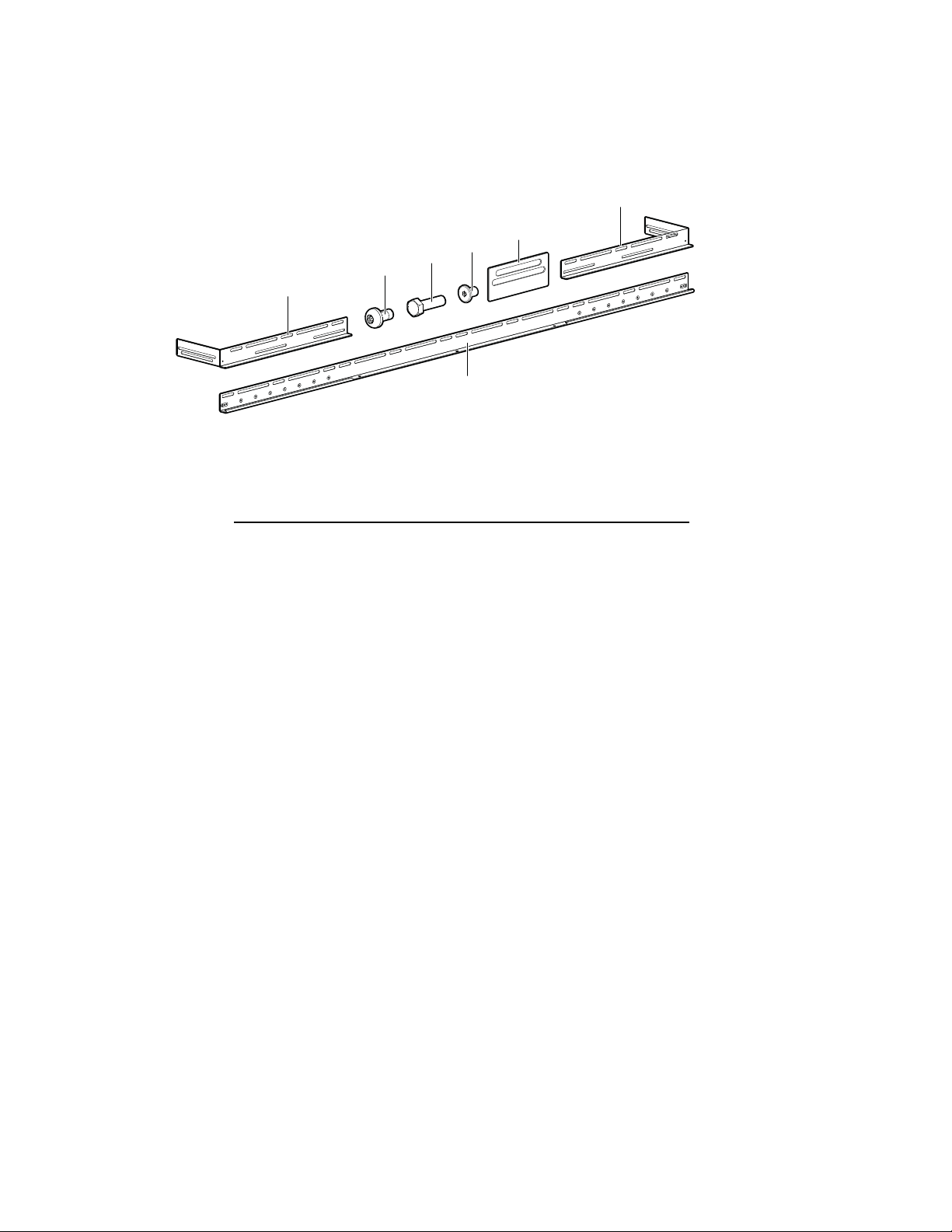

Power Raceway

FS-AC-4001-B - Power Raceway End Module

FS-AC-4002-B - Power Raceway Main Module

FS-AC-4003-B - 300 mm (12 in.) Side Cover Pack

FS-AC-4004-B - 50/150 mm (2/6 in.) Side Cover Pack

FS-AC-4005-B - Power Raceway Extension Module

acs0028a

Item Description

Quantity

Side cover 300 mm (12 in.) (FS-AC-4003-B)

Side cover 150 mm (6 in.) (FS-AC-4004-B)

Side cover pack 50 mm (2 in.) (FS-AC-4004-B)

Base tray (FS-AC-4002-B) 2

Extension module* (FS-AC-4005-B) 1

Rung of cable ladder (FS-AC-4002-B) 4

Main module (FS-AC-4002-B) 3

End module (FS-AC-4001-B) 1

Cover bracket 2

Chimney, 6 U (FS-AC-4001-B) 1

Chimney, 3 U (FS-AC-4001-B) 1

End cap (FS-AC-4001-B) 1

Pan head T30 screw, M6 x 12

(FS-AC-4005-B)

(FS-AC-4002-B)

Flat head screw, M5 x 12 8

Phillips head self-tapping screws, 10-32

(FS-AC-4003-B, FS-AC-4004-B)

4

2

2

13

29

16

* Extension module is used with double HyperPod.

69HyperPod System Installation

Page 76

Lighting kits

ACDC2018 - Lighting Kit with Power Supply

ACDC2019 - Lighting Kit without Power Supply

Motion

Motion

Sensor

Sensor

Motion

Sensor

Group Control

AC Line Inlet

Motion

Sensor

Manual

Switch

Manual

Switch

Power Status

Console Port

LED Lighting Power Outlet

Time Setting

na4052a

Item Description

Lighting control unit 1

Motion sensor mounting bracket 2

Motion sensor mounting bracket,

Quantity Item Description Quantity

Hook and loop fastener, manual switch 8

Wood screw - #6 x 3/4 - Phillips 4

2

Wall anchor 4

sliding door

TORX screw, thread forming, M4 x 8 mm 6

TORX screw, M4 x 8 mm 8

Motion sensor 2

Lighting control unit mounting bracket, left 1

Wire assembly, 24 V power 1

Wire tie cable holder 45

Wire tie 45

LED light assembly module, 6W

(ACDC2019)

Lighting control unit mounting bracket, right 1

Caged nut, M6 4

Phillips screw, M6 x 16 4

Power cord, 15A 250V, C13 to C14 1

console port to DB9F cable, 2.5 mm 1

Light-to-light wire assembly

(ACDC2019)

Cup washers 4

Light-to-light wire assembly, across

aisle

Magnets, manual switch 8

Manual switch 2 Light-to-light connector, end-to-end

Power Cord, 15A 125V, C13 to 5-15P 1

(ACDC2019)

NOTE: Items marked (ACDC2019) are included in both assemblies. All other items are only included in

ACDC2018.

6

5

1

5

HyperPod System Installation70

Page 77

FS-AC-6001-B - Lighting Bracket Kit

acs0073a

Item Description

Long bracket, left 2

Short bracket 8

Pan head T30 screw, M6 x 16 29

Long bracket, right 2

TORX pan head screw, M4 x 12 33

Wiring cover 16

Quantity

71HyperPod System Installation

Page 78

Crossover Tray

FS-AC-4007-B - 1.9 m (6 ft) Aisle Crossover Tray

FS-AC-4008-B - 1.2 m (4 ft) Aisle Crossover Tray

Item Description

Crossover tray 1

Flat head T30 screw, M6 x 12 8

acs0037a

Quantity

HyperPod System Installation72

Page 79

Single Swing Door Assembly

FS-DR-1002-U - Swing Door

acs0076b

Item Description

Door 1

EPDM foam 1

Door closer 3

Hex wrench 1

Key 1

Tension pin 4

Quantity

73HyperPod System Installation

Page 80

Installation of Optional Accessories

CAUTION

WORKING HEIGHT HAZARD