Schneider Electric Erie VM PopTop Series Installation Instructions

SPECIFICATIONS

C A U T I O N

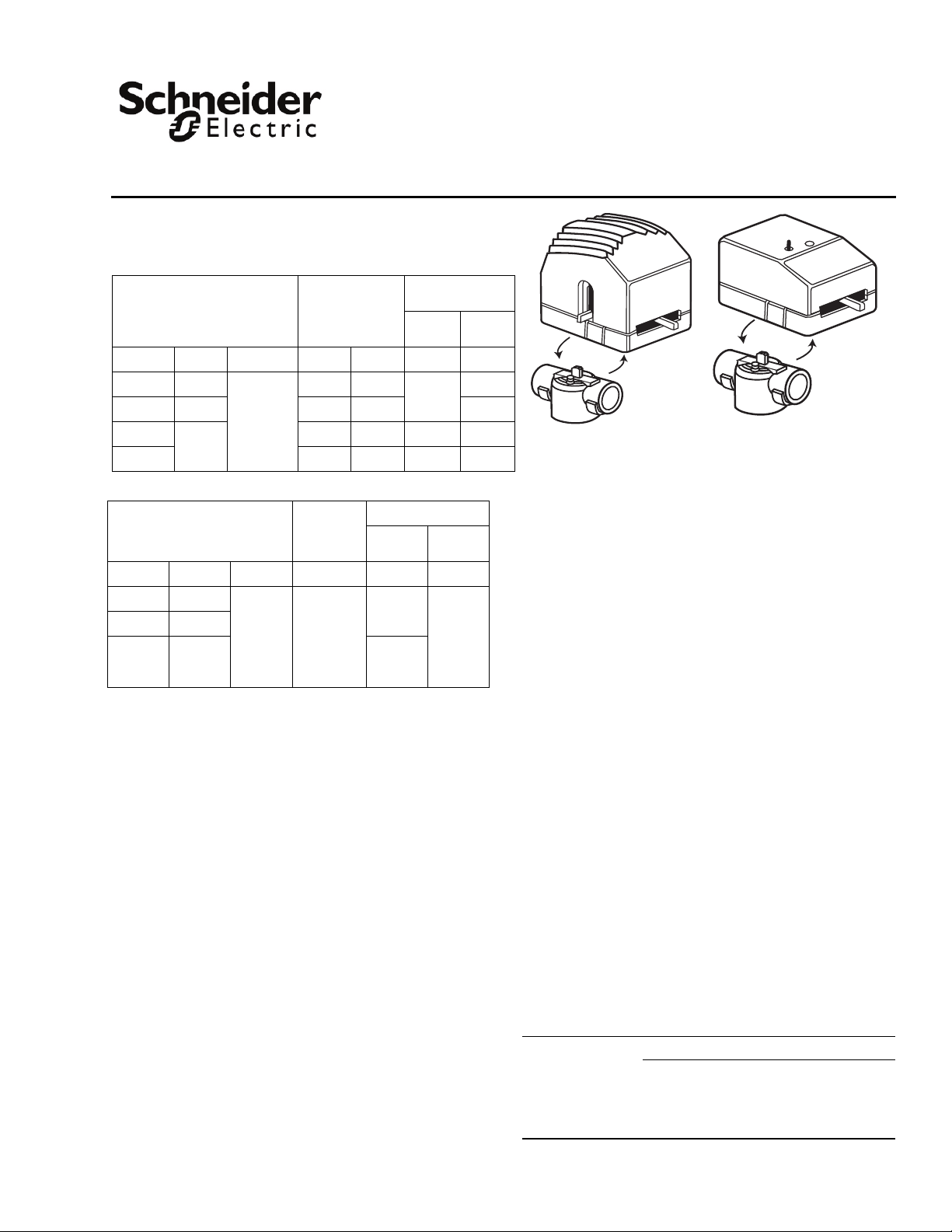

Spring Return Non-Spring Return

Inputs

Total A ctu ato r,

Powerup

Inrush

10

Running

a

Max.

a

1.7

Running

Floating Actuator

Series Action Vac mA VA VA VA

AT13A00T SR N.C.

AT23A00T SR N.O. 24 0.6 1.9

AT3 3A00 0

AT33A00T — — 1.2 1.2

a

Transformer must be sized for Powerup Inrush.

Series Action VAC Range (Rin) VA VA

AP13A000 SR N.C.

AP23A000 SR N.O.

AP33A000

Non-

spring

Return

Proportional Actuator

Nonspring

Return

a

Transformer must be sized for Powerup Inrush.

b

Factory supplied. Actual Range is 1-9 Vdc.

24 Vac

+25%/-15%

50/60 Hz

24 Vac

+25%/-

15%

50/60 Hz

Control Circuit,

Max.

24 0.6

——1.01.0

Control

Circuit, Max.

b

0-10Vdc

(>200K)or

0-5Vdc

(>200K) or

5-10 Vdc

(>200K) or

4-20 mA

(300)

Total Actuator, Max.

Powerup

Inrush

10

1.7

Outputs

Electrical:

Stroke, 60 Hz: 2 minutes 30 seconds.

50 Hz: 3 minutes.

Action, T series: Direct acting. P series: Direct acting (Valve

opens B port with increase in signal). Field selectable

reverse acting.

Mechanical:

Manual Override, Allows manual positioning.

Operating Pressure Limits, 400 psi (2758 kPa) static

pressure.

Material:

Actuator: High temperature plastic.

Va l v e : Body: forged brass; Stem: chrome-plated brass;

Seat: brass; Plug/paddle: high temperature thermoplastic/

rubber.

Flow Characteristic, 1.0 to 4.0 Cv: Equal percentage. 7.0/

8.0 Cv: Linear.

Environment

Ambient Temperature Limits:

Shipping & Storage, -40 to 158°F (-40 to 70°C)

Operating, 35 to 125°F (1.7 to 52°C).

Fluid, 32 to 200°F (0° to 93°C) (not steam rated).

Humidity: 5 to 95% RH, non-condensing.

Seat Leakage: ANSI class IV (0.01%)

Shipping Weight: 1.9 lbs (860 g), actuator and valve body.

Location: NEMA Type 1.

Erie™ VM PopTop™ Series

Modulating Valves

Floating "T" & Proportional "P"

Standard and Spring Return Modulating Valves

Installation Instructions

1.9

Agency Listings

UL 873: Underwriter Laboratories (File #E9429 Category

Temperature-Indicating and Regulating Equipment), Class 2.

CUL: UL Listed for use in Canada by Underwriters Laboratories.

Canadian Standards C22.2 No. 24.

European Community: EMC Directive (89/336/EEC)

Australia: This product meets requirements to bear the C-Tick

Mark according to the terms specified by the

Communications Authority under the Radiocommunications

Act 1992.

INSTALLATION

Inspection

Inspect package for damage. If damaged, notify the appropriate

carrier immediately. If undamaged, open package and inspect the

device for obvious damage. Return damaged products.

Requirements

• Tools (not provided):

— W

rench 1 to 1-5/8" (if threaded valve)

— Soldering equipment (if sweat fit)

— Pipe wrench according to pipe size (if threaded)

— #1 Phillips head screw driver

— Volt-ohm multimeter

• Training: Installer must be a qualified, experienced technician

• Other accessories as appropriate

Precautions

• Electrical shock hazard! Disconnect power before installation to

prevent electrical shock or equipment damage.

• Make all connections in accordance with the electrical wiring diagram and in accordance with national and local electrical co

Use copper conductors only.

• Avoid locations where excessive moisture, corrosive fumes,

explosive vapors, or vibration are present.

• Avoid electrical noise interference. Do not install near large conductors, electrical machinery, or welding equipment.

des.

Printed in U.S.A. 2-13 © Copyright 2013 Schneider Electric All Rights Reserved. F-26801-9

Mounting

N O T E

C A U T I O N

C A U T I O N

C A U T I O N

C A U T I O N

N O T E

N O T E

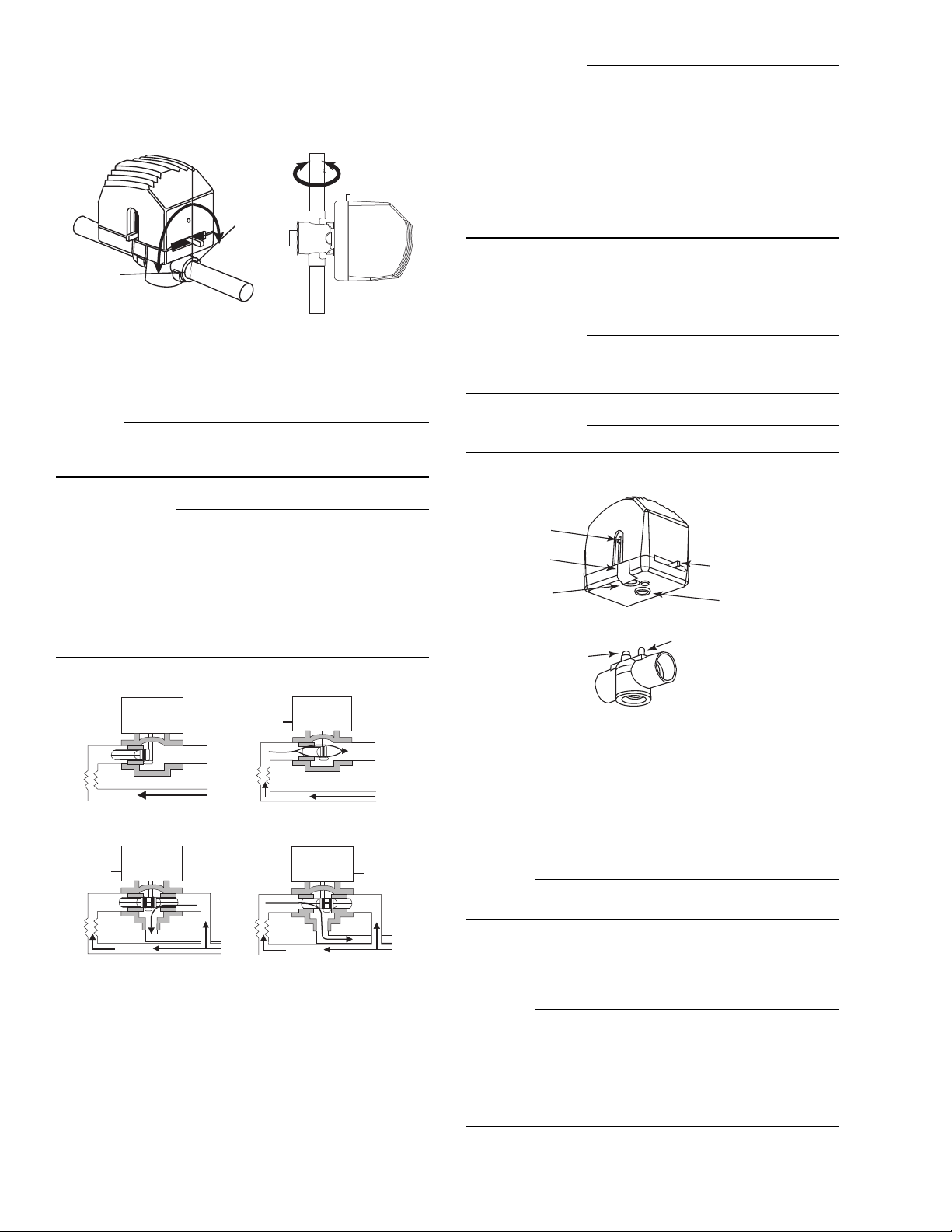

Figure-1 Mounting.

Power/Signal

Normally Closed

COIL

A

B

Power/Signal

Spring Return

Normally Closed

COIL

A

B

The valves can be mounted in horizontal or vertical piping. When

installed in horizontal piping, the actuator must be above the valve

body. Refer to Figure-1.

360

85

• The plug inside the valve is made of a plastic material. It may be

damaged by heat conducted through the valve body if it remains

seated against its port during soldering. Be sure to manually open

the valve to mid-position before soldering to prevent damage.

• If the manual operating lever does not move freely for manual

positioning, the solenoid may have latched during shipping. Do

not force the lever. Instead, first unlatch the solenoid by placing

the red manual solenoid lever (on the side of the actuator) in the

“Down” position, then place the manual operating lever in the

mid-position

2. With the valve in mid-position, latch the solenoid by placing the

manual solenoid latch lever in the “Up” position. Detach the actuator by depressing the release button and pulling it away from the

valve body (Figure-4).

Piping

Refer to the piping diagrams in Figure-2 for two-way valves. For

three-way valves refer to Figure-3.

The 3-way is only configured as B port normally closed. For normally

open configuration to the coil turn valve around. For proportional

valves, set the control action (direct or reverse) accordingly.

• The valve should be used in a closed loop system.

• All valves must be piped so the plug closes against the direction

of flow. For two-way valves, flow is from port B to port A. For

normally closed three-way valves, B is the service port and A is

the bypass port. For normally open three-way valves. A is the

service port and B is the bypass port.

• Three-way valves must be piped in a mixing configuration, not

diverting.

Power/Signal

Normally Open

B

COIL

Figure-2 Two-Way Spring Return Valves

Power/Signal

Spring Return

Normally Open

AB

COIL

A

• To avoid damage to the actuator and to ease the soldering process, be sure to remove the actuator from the valve body before

soldering.

• Use only solder with a melting point below 600°F (315°C).

Solenoid Latch

Lever

Release

Button

Pin Mating Hole

Pin

Stem

Manual Opening

Lever

Stem Mating Hole

Figure-4 Three-Way Spring Return Valves

3. Thoroughly clean the ends of the water supply tubing for a minimum distance of 1 inch (25 mm) from the end, so a good joint can

be made in the shortest time and without an excessively large

flame.

4. Solder the valve body in place, directing the flame tip away from

the valve and taking care not to overheat the joint area. When finished, cool the valve quickly with a wet cloth.

The valve body may be submerged in water, or pressurized for leak

testing before reattaching the actuator.

Sweat End Valves

1. To manually open the valve so the plug is not in contact with the

2 © Copyright 2013 Schneider Electric All Rights Reserved. F-26801-9

Figure-3 Three-Way Spring Return Valves

valve body, slowly position the actuator’s manual operating lever

(on front of the actuator) to mid-position.

5. Reinstall the actuator according to "Reattaching the Actuator to

the Valve Body" on the next page.

NPT and Rp Threaded Valve

When installing threaded valves, the actuator should be detached

from the valve body to ease installation. To do so, first slowly move

the actuator’s manual operating lever (on the front of the actuator) to

mid-position. Latch the solenoid by placing the red manual solenoid

latch lever on the side of the actuator to the “Up” position. Finally,

detach the actuator by depressing the release button and pulling the

actuator away from the valve (Figure-4).

Loading...

Loading...