Application

The AV-7600-1 valve linkage kit is used to field assemble MA-521x, MF-5x13, MP-521x, MP-541x, MP-551x, MPR-561x, and MPR-571x round hydraulic actuators to 1/2” through 2" VB-7xxx series valve bodies only.

Features

• Provides direct couple interface between MA, MF,

MP

, and MPR-5xxx actuators and valve bodies.

• Kit fits all VB-7xxx series valve bodies.

• Optimized linkage springs for maximum close off.

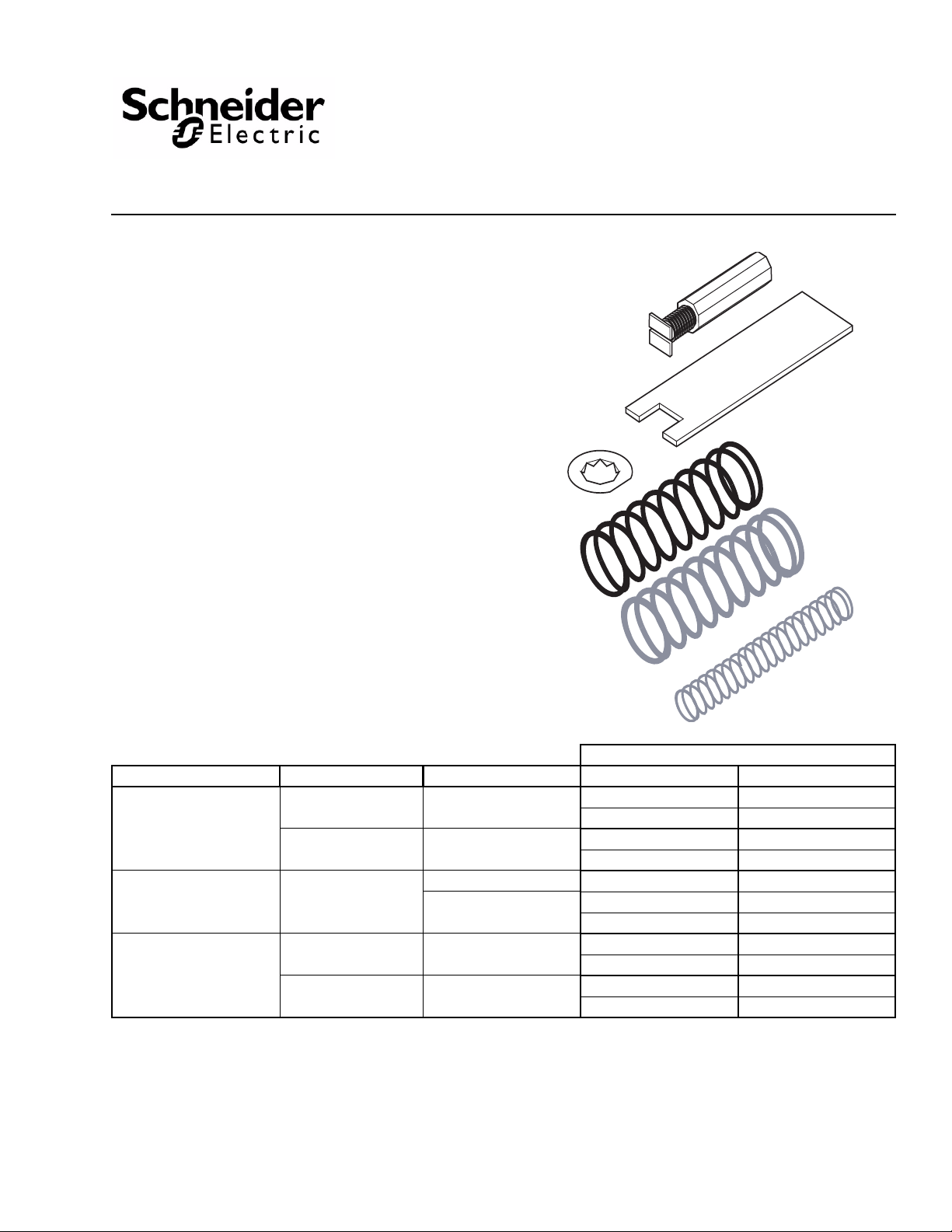

AV-7600-1

Hydraulic Actuator Valve Linkage Kit

for VB-7XXX Series Valves

General Instructions

Spring Selection and Calibration

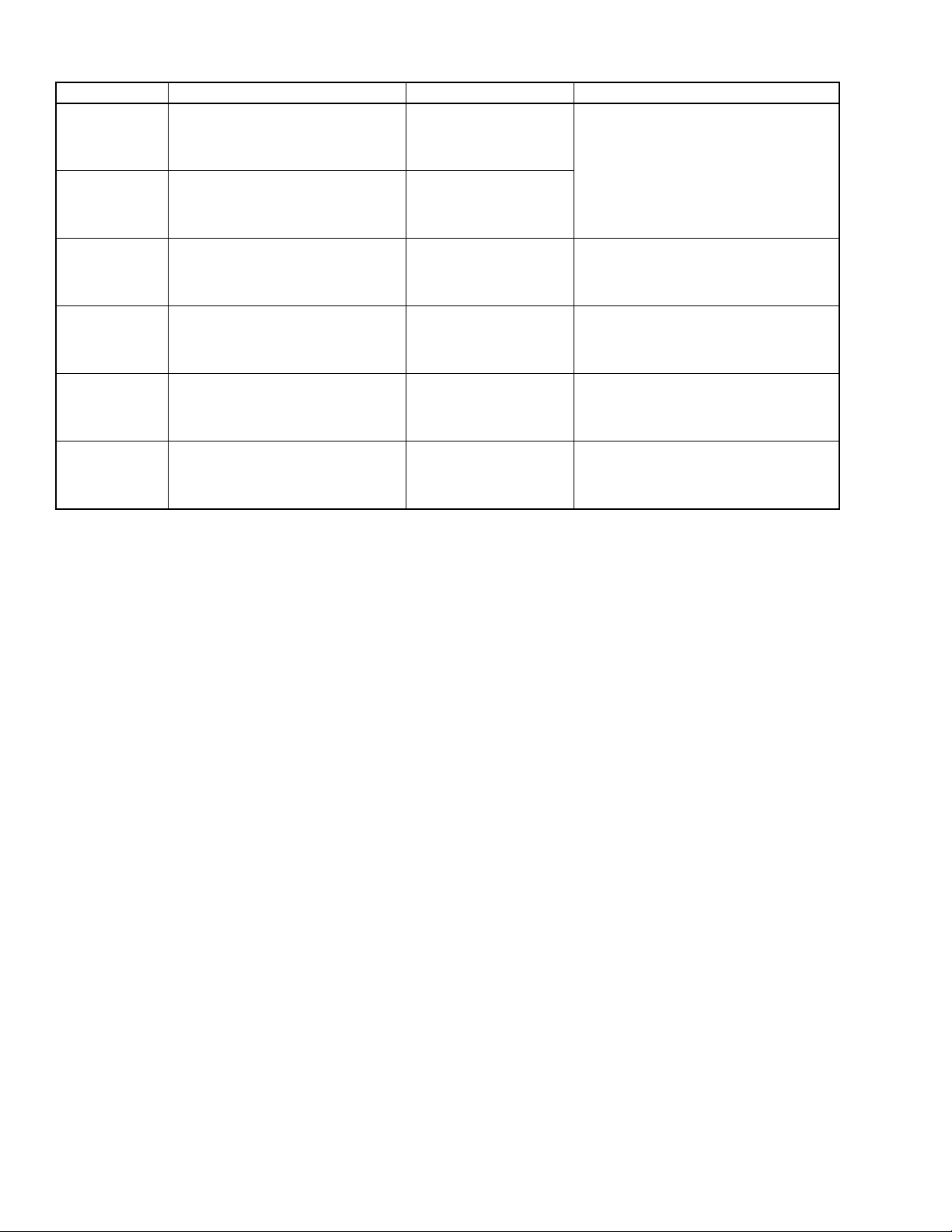

The springs in the AV -7600-1 kit are used with selected actuators for specific valves and/or valve sizes. Reference Table-1.

Table-1 Spring Usage for VB-7xxx Valves.

MP-521x Series

Valve Size Spring(s) Controller Calibration

VB-721x

VB-725x

VB-727x

Normally Open

VB-731x - Mixing

2x - Diverting

VB-73

VB-7332 - Sequencing

VB-722x, VB-726x

& VB-7

Normally Closed

a

MA, MF, MP-541x, and MP-55xx actuator positioning is independent of spring selected.

b

When using a Schneider Electric System 8000 controller or a 4 to 20 mA signal across a 500 Ohm resistor to get the proper voltage.

c

The black spring used on a normally open valves may eliminate the need for positive positioning actuators.

d

PNV-145-48 Blue spring is not part of this kit. It is only required for controllers limited to 10 volts or 20 mA maximums.

e

Used with signals limited to 10V such as 0 to 10 Vdc and 4 to 20 mA across a 500 Ohm resistor. Note a reduced control range.

f

The small unpainted spring may be added to provide addition close off.

28x

1/2” to 1-1/4”

(15 to 32 mm)

1/2” thru 2”

(15 to 50 mm)

1/2” thru 2”

(15 to 50 mm)

1/2” thru 1-1/4”

(15 to 32 mm)

1/2” thru 2”

(15 to 50 mm)

Large Unpainted

c

Black

(highest close off)

Large Unpainted 7.5 Volts 6 to 9 Volts

d

PNV-145-48

small unpainted booster

Large Unpainted

Large and small unpainted

ooster (highest close off)

b

Blue with

f

e

7.5 Volts 6 to 9 Volts

15 mA 12 to 18 mA

5.0 Volts 3.5 to 6.5 Volts

10 mA 7 to 13 mA

7.5 Volts 7to 8 Volts

15 mA 14 to 16 mA

7.5 Volts 6 to 9 Volts

15 mA 12 to 18 mA

7.5 Volts 6 to 9 Volts

15 mA 12 to 18 mA

a

b

Nominal Control Range

b

Printed in U.S.A. 4/10 © Copyright 2010 Schneider Electric All Rights Reserved. F-26235-5

Applicable Literature

F-Number Description Audience Purpose

– Sales Personnel

F-23638 Cross-Reference Guide

F-26789 Component Cross-Reference Guide

F-21683 Reference Manual

F-27383 Pneumatic Products Catalog

F-26080 EN-205 Water System Guidelines

F-26280

AV-601 Linkage Extension Kit General

Instructions

– Application Engineers

– Installers

– Service Personnel

– Sales Personnel

– Application Engineers

– Installers

– Service Personnel

– Sales Personnel

– Application Engineers

– Installers

– Service Personnel

– Sales Personnel

– Application Engineers

– Installers

– Service Personnel

– Application Engineers

– Installers

– Service Personnel

– Start-up Technicians

– Application Engineers

– Installers

– Service Personnel

– Start-up Technicians

Provides specifications and part number cross

referencing of phased out controls with the

new Schneider Electric controls.

Provides a collection of general and

installation instructions and other reference

documents

Provides descriptions and specifications for

the Schneider Electric components.

Describes Schneider Electric approved water

treatment practices.

Describes the linkage extension kit’s features,

specifications and possible applications.

Provides step-by-step installation instructions.

2 © Copyright 2010 Schneider Electric All Rights Reserved. F-26235-5

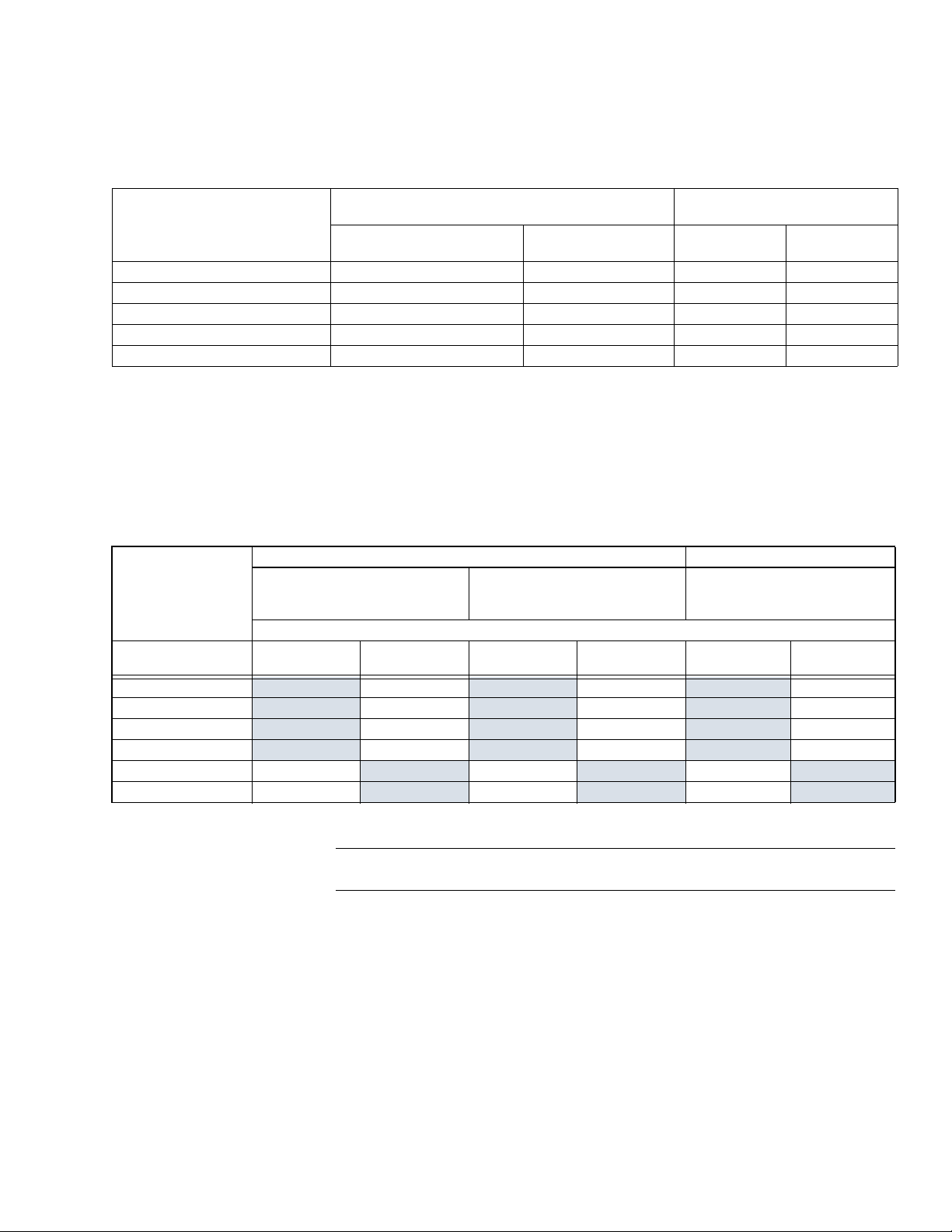

SPECIFICATIONS

Temperature Restrictions

Verify that temperature of the media in the valve versus the ambient temperature at the

actuator does not exceed the ratings shown in

Table-2 Restrictions on the Maximum Ambient Temperature for the Valve Actuator.

Max. Temperature of Media in °F

(°C)

in the Valve Body (Check Ratings

a

Maximum allowable ambient temperature of the actuator.

of the Valve)

366 (180) Do Not Use 88 (31) 90 (32) 90 (32)

340 (171) Do Not Use 93 (34) 100 (38) 100 (38)

281 (138) Do Not Use 103 (39) 115 (46) 140 (60)

181 (83) Do Not Use 120 (48) 140 (60)

80 (26) 140 (60)

Max. Ambient Temperature in °F (°C)

of MF-5x1x, MP-541x, or MP-551x

AV-7600-1 Only for Chilled

Water Applications Only

a

AV-7600-1

& AV-601

140 (60)

The AV-601 linkage extension provides thermal insulation between the valve and actuator.

It

is required for all heating valves with MF-5x13, MP-541x, MP-551x, MPR-561x,

MPR-571x, and MPR-581x actuators. It is recommended for cooling valves with MF-5x13,

MP-541x, MP-551x, MPR-561x, MPR-571x, and MPR-581x actuators. It is also used for

higher ambient and fluid temperatures with MA-521x and MP-521x actuators. Re fer to

AV-601 Linkage Extension Kit General Instructions, F-26280 for installation procedures.

Table-2.

a

Max. Ambient Temperature in °F (°C)

of MA-521x or MP-521x

AV-7600-1 Only

a

a

140 (60)

AV-7600-1

& AV-601

140 (60)

140 (60)

a

a

a

Table-3 Nominal Hydraulic Two-Way Valve Close Off Ratings. (See Table-1 for controller calibration.)

Spring Closes (Normally Closed) Spring Opens (Normally Open)

MP-5x1x Analog Actuators:

6 to 9, 0 to 10 Volt, and 4 to 20mA

Close Off Rating with Springs Shown Psi (kPa)

Valve Size Unpainted

1/2 inch (15mm) 130a (900)

3/4 inch (20 mm) 80 (550) 180 (1200) 130 (910) 200 (1300) 80 (550) 200 (1300)

1inch (25 mm) 40 (270) 60 (410) 50 (340) 90 (620) 40 (270) 150 (1000)

1-1/4 inch (32 mm) 25 (170) 40 (270) 35 (240) 60 (410) 25 (170) 90 (620)

1-1/2 inch (40 mm) 15 (100) 25 (170) 20 (140) 35 (240) 15 (100) 60 (410)

2 inch (50 mm) 6 (40) 14 (95) 10 (70) 20 (140) 6 (40) 35 (340)

a

Shaded area as shipped from factory.

Unpainted with

Booster

250 (1700) 200 (1300) 250 (1700) 130 (910) 250 (1700)

MA-521x & MF-521x

Digital Actuators:

2 Position and Floating

Unpainted

Unpainted with

Booster

All Actuators:

Analog, 2 Position, and Floating

Unpainted Black

Note: Close off ratings describe only the differential pressure which the actuator can close

off with adequate seating force. Consult valve body specifications for limitations.

F-26235-5 © Copyright 2010 Schneider Electric All Rights Reserved. 3

Table-4 Nominal Hydraulic Three-Way Valve Close Off Ratings. (See Table-1 for controller calibration.)

Close Off Rating Psi (kPa)a Differential pressure between A & B ports

Spring Closes “A” Port Actuator Closes “B” Port

Mx-521x Analog Actuators:

6 to 9 and 0 to 10 Volt, 4 to 20 mA

Valve Size

1/2 inch (15mm) 130 (900) 250 (1700) 200 (1300) 250 (1700) 130 (910) 250 (1700)

3/4 inch (20 mm) 80 (550) 250 (1700) 130 (910) 250 (1700) 80 (550) 250 (1700)

1inch (25 mm) 40 (270) 250 (1700) 50 (340) 250 (1700) 40 (270) 250 (1700)

1-1/4 inch (32 mm) 25 (170) 250 (1700) 35 (240) 250 (1700) 25 (170) 250 (1700)

1-1/2 inch (40 mm) 15 (100) 250 (1700) 20 (140) 250 (1700) 15 (100) 250 (1700)

2 inch (50 mm) 10 (70) 250 (1700) 14 (95) 250 (1700) 10 (70) 250 (1700)

a

VB-7332, 1/2 inch sequencing valves close off 35 Psi (240 kPa) on both ports.

b

Factory shipments have unpainted large springs. For 0 to 10 Volt and 4 to 20 mA controllers use blue and booster springs. (See Table-1.)

VB-731x

Mixing

VB-732x

Diverting

b

MA-521x & MF-521x

Digital Actuators:

2 Position and Floating

VB-731x

Mixing

VB-732x

Diverting

Analog, 2 Position, and Floating

All Actuators:

VB-731x

Mixing

VB-732x

Diverting

Note: Close off ratings describe only the differential pressure which the actuator can close

off with adequate seating force. Consult valve body specifications for limitations.

INSTALLATION

Inspection Inspect the package for damage. If damaged, notify the appropriate carrier immediately.

If undamaged, open the package and inspect the device for obvious damage. Return any

damaged products.

Requirements • Tools:

– Screwdriver appropriate for slotted spring compression screw (not provided)

– Linkage wrench (provided) or TOOL-20-1, packing and linkage wrench (not

provided)

• Installer must be a qualified, experienced technician

Caution:

• Avoid locations where excessive moisture, corrosive fumes, or vibration is present.

• Install all two-way valves so that they close against the flow. An arrow on the valve body

or a tag indicates the proper flow direction.

• Always install three-way mixing valves with two inlets and one outlet.

• The actuator must be above the center line of the valve. For steam applications mount

the actuators above the valve body at 45° from vertical.

Linkage Kit Installation

The AV-7600-1 linkage kit used on VB-7xxx series valve bodies requires no stem height setting.

Procedure

The linkage kit is assembled onto the VB-7xxx valve body with the stem in the up position.

1. Select the appropriate spring(s) as detailed in Figure-1.

2. Thread the hexagon coupler onto the valve stem all the way to the bottom of the stem thread, finger-tight (Figure-1). Pull the valve stem completely up.

4 © Copyright 2010 Schneider Electric All Rights Reserved. F-26235-5

Spring

Compresion

Screw

Hexagon Coupler

Spring Retainer

Valve Stem

1/16" (1.6 mm)

Max.

Figure-1 Installation of Hexagon Coupler and Spring Compression Screw.

Spring

Screwdriver

Linkage Wrench

(Hold to prevent turning.)

2-1/4" (57 mm)—VB-721X

2-3/16" (56 mm)—VB-722X & VB-73XX

Spring Retainer

(Turn 45 degrees to

lock in place.)

Turn until Spring Compression

Screw bottoms firmly on

valve stem.

Figure-2 Completing Linkage Kit Assembly to Valve.

Caution: The hexagon coupler must reach to within 1/16” (1.6 mm) of the smooth section

of the stem to assure proper seating. Do not use the Spring Compression Screw to run the

Hexagon Coupler down.

3. On normally closed valves (1-1/2” [40 mm] to 2” [50 mm] mandatory) slip the small unpainted booster spring over the stem.

4. Start the spring(s) compression screw one turn or more into the hexagon coupler.

5. Slip the spring over the coupler and the spring compression screw.

6. Place the retainer over the screw. Twist the retainer 45° to lock it in place.

7. Insert the linkage wrench (supplied with kit, also included on TOOL-20-1) through the spring coils about 3 coils from the bottom to hold hexagon coupler.

8. Hold the wrench from turning and tighten the spring compression screw. To establish

proper linkage height, run the spring compression screw down until the screw end

bottoms firmly on the stem top (

Figure-2).

F-26235-5 © Copyright 2010 Schneider Electric All Rights Reserved. 5

9. Confirm the stem height setting (Figure-2):

Spring Retainer

Mounting Nut

Spring

Compression

Screw

Hexagon Coupler

Actuator

(purchase separately)

Booster Spring

(Small Unpainted)

Spring

(Large)

Figure-3 Assembly of Linkage Kit onto VB-7xxx Series Valve.

• 2-5/16” (59 mm) maximum after installation on stem up open valves (VB-721x).

• 2-7/32” (56 mm) maximum on stem up closed valves (VB-722x) or three-way valves

(VB-73xx).

10. Center the spring on top and bottom to assure smooth actuator operation. See Figure-3 for total assembly components required.

MAINTENANCE

The actuator linkage requires no maintenance.

For linkage removal, insert wrench through springs and hold. Remove spring compression

screw and p

Regular maintenance of the total system is recommended to assure sustained, optimum

performance. Hard water leaves abrasive deposits and reduces component life. To

maximize valve life, consult EN-205 Water System Guidelines, F-26080.

arts.

6 © Copyright 2010 Schneider Electric All Rights Reserved. F-26235-5

FIELD REPAIR

1

2

5

6

3

4

Figure-4 AV-7600-1 Hydraulic Actuator Valve Linkage Kit.

Individual parts of the actuator linkage are not repairable. Replace an inoperative actuator

linkage with a functional unit or replace individual parts as necessary (

Table-5 AV-7600-1 Replacement Parts.

Item (See Figure-4) Part No. Description

1 P4-14 Large Unpainted Spring

2 P4-14-10-1

3 PNV-145-45 Large Black Spring

4 YBA-559 Spring Retainer

NYBA-80 Stem Coupler (hexagon)

5

6 NYBA-82 Linkage Wrench

NYBA-79

Table-5 and Figure-4).

Small Unpainted Booster

Spring

Spring Compression

Screw

F-26235-5 © Copyright 2010 Schneider Electric All Rights Reserved. 7

On October 1st, 2009, TAC became the Bui ldings business of its par ent c om pany Schneider El ectric. This document reflect s the visual identity of Schneider El ectric,

however there remains ref ere nces to TAC as a corporate brand in the body copy. As each document is updated, the body copy will be changed to reflect appropriate

corpo rate bra nd ch a nges.

Copyright 2010, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained within this

document is subject to change without notice.

F-26235-5

Loading...

Loading...