Page 1

Presentation

Variable speed drives

for asynchronous motors

0

Altivar 11

561250

1

3

2

4

2

5

7

8

6

Schneider Electric

Page 2

Presentation (continued)

Variable speed drives

for asynchronous motors

Altivar 11

Applications

The Altivar 11 is a frequency inverter for 3-phase squirrel cage asynchronous motors

rated between 0. 18 kW and 2.2 kW.

There are three types of po wer supply:

# 100 V to 120 V single phase

# 200 V to 240 V single phase

# 200 V to 230 V 3-phase

The Altivar 11 incorporates specif ic features for loca l markets (Europe range,

America range, Asia range) and has functions suitable for the most common

applications, including:

# Horizontal materials hand ling (small conveyors, etc)

# Ventilation, pumping, access control, automatic doors

# Specia l machines (m i xer s, wa sh in g ma chines, cen trifuge s, et c )

Functions

The main functi ons incorporated in the Altivar 11 drive are:

# Starting and speed co ntrol

# Reversal of operation direction

# Accele ration, de ce le ra ti on , sto pp ing

# Motor and drive protection

# 2-wire/3-wire control

# 4 preset speeds

# Saving the configuration in the drive

# d.c. injection on stopping

# Ramp switching

# Catching a spinning load

# Local co ntrols (A sia range only)

Several functions can be assigned to one logic input.

Standard versions

The Altivar 11 offer consists of 3 ranges designed for 3 different markets:

# Europe range: ATV 11/U//M2E (items , )

5Single phase 240 V power supply

5Positive lo gic operation

5Inte gra ted class B EMC filter

# America range: ATV 11/U////U (items , , , )

5Power supplies: 120 V single phase, 240 V single phase or 230 V 3-phase

5Positive lo gic operation

5Meets current requirement in standard NEC 1999 208 V

# Asia range: ATV 11/U////A (items , )

5Power supplies: 120 V single phase, 240 V single phase or 230 V 3-phase

5Positive or negative logic op eration

5Local cont rols: Run and Stop keys, and poten tiometer

1 2

1 2 3 4

5 6

0

Characteristics:

pages 60251/2 to 60251/5

Schneider Electric

References:

pages 60252/2 to 60252/5

Altivar 11 driv es are supplied either with heatsink (ite ms ,,) for normal

environments and ventilated enclosures, or on a base plate (items , , ) for

mountin g o n a ma ch ine f r ame, when th e s ize of t he f ram e en ab le s diss ip at i on of th e

heat.

Electromagnetic compatibility EMC

The incorporation of EMC filters in AT V 1 1

machines and provides an economical means of meeting

ATV 11

/U////U and ATV 11 /U////A drives are available without EMC filter. Filters

are available as an option for customer assembly, if conformity to EMC standards is

required.

/U//M2E drives simplifies installation of

1 3 5

2 4 6

&marking requirements.

Options

The drive only communicates, in point-to-point mode, with the following tools and

software:

# PowerSuite advanced dialogue solution :

5PowerSuite software workshop for configuring the drive (item ),

5PowerSuite for Pocket PC (item ),

5Converter for connecting a PC or a Pocket PC

The following options can be used with the Altivar 11 drive:

# Braking module connected to the drive’s DC bus

# Braking resistors, for diss ipating the energy returned to th e drive when the motor

is operating as a generator

# EMC rad io interference input filters

# Plates for mounting on rail

# Adaptor plate for replacing an Al tivar 08 drive

# Plate for EMC mounting, earthing the cable shielding.

Dimensions:

pages 60253/2 and 60253/3

8

Schemes:

pages 60254/2 and 60254/3

7

3

Page 3

References

Variable speed drives

550483

ATV 11 HU18M2E

for asynchronous motors

Altivar 11

ATV 11//////E Europe range

Drives with heatsink (frequency range from 0 to 200 Hz)

Motor Line supply

Power

indicated

on

plate

kW A A A W kg

(1)

Max. line

current for

prospecti ve

Isc

1 kA

Single phase supply voltage: 200…240 V 50/60 Hz

0.18 2.9 1.1 1.6 12 ATV 11HU05M2E 0.900

0.37 5.3 2.1 3.1 20.5 ATV 11HU09M2E 1.000

0.55 6.3 3 4.5 29 ATV 11HU12M2E 1.100

0.75 8.6 3.6 5.4 37 ATV 11HU18M2E 1.100

Altivar 11

Permanent

output

current (2)

Max.

transient

current (3)

Power

dissipated

at nominal

load

Reference

(4)

Weight

0

550485

ATV 11 PU18M2E

550489

ATV 11 HU41M2E

1.5 14.8 6.8 10.2 72 ATV 11HU29M2E

2.2 20.8 9.6 14.4 96 ATV 11HU41M2E

(5)

(5)

1.800

1.800

Drives on base plate (frequency r ange from 0 to 200 Hz)

Motor Line supply

Power

indic ated

on

plate

kW A A A W kg

(1)

Max. line

current for

prospecti ve

Isc

1 kA

Single phase supply voltage: 200…240 V 50/60 Hz

0.37 5.3 2.1 3.1 20.5 ATV 11PU09M2E 0.900

0.55 6.3 3 4.5 29 ATV 11PU12M2E 0.900

0.75 8.6 3.6 5.4 37 ATV 11PU18M2E 0.900

(1) Line voltage 230 V.

(2) The current value is given for a 4 kHz switching frequency.

(3) For 60 seconds.

(4) Drive supplied with an integrated EMC filter which cannot be disconnected.

(5) With integrated fan.

Altivar 11

Permanent

output

current (2)

Max.

transient

current (3)

Power

dissipated

at nominal

load

Reference

(4)

Weight

4

Presentation:

pages 2 and3

Characteristics:

pages 8 to11

Dimensions:

pages 12 and 13

Schemes:

pages 14 and 15

Schneider Electric

Page 4

References

Variable speed drives

550484

ATV 11HU18M2U

550486

for asynchronous motors

Altivar 11

ATV 11//////U America range

Drives with heatsink (frequency range from 0 to 200 Hz)

Motor Line supply Altivar 11

Power

indicated

on

plate

kW/HP A A A W kg

Single phase supply voltage: 100…120 V 50/60 Hz

0.18/0.25 6 1.6 2.4 14.5 ATV 11HU05F1U 0.900

0.37/0.5 92.43.623ATV 11HU09F1U 1.000

0.75/1 18 4.6 6.3 43 ATV 11HU18F1U

Single phase supply voltage: 200…240 V 50/60 Hz

0.18/0.25 3.3 1.6 2.4 14.5 ATV 11HU05M2U 0.900

0.37/0.5 62.43.623ATV 11HU09M2U 1.000

0.75/1 9.9 4.6 6.3 43 ATV 11HU18M2U

1.5/2 17.1 7.5 11.2 77 ATV 11HU29M2U

2.2/3 24.1 10.6 15 101 ATV 11HU41M2U

3-phase supply voltage: 200…230 V 50/60 Hz

0.18/0.25 1.8 1.6 2.4 13.5 ATV 11HU05M3U 0.900

Max. line

current (1)

Permanent

output

current (2)

Max.

transient

current (3)

Power

dissipated

at nominal

load

Reference

(4)

(5)

(5)

(5)

(5)

Weight

1.800

1.100

1.800

1.800

0

ATV 11PU18M2U

550490

ATV 11HU41M2U

550491

0.37/0.5 3.6 2.4 3.6 24 ATV 11HU09M3U 1.000

0.75/1 6.3 4.6 6.3 38 ATV 11HU18M3U

1.5/2 11 7.5 11.2 75 ATV 11HU29M3U

2.2/3 15.2 10.6 15 94 ATV 11HU41M3U

(5)

(5)

(5)

1.100

1.800

1.800

Drives on base plate (frequency range from 0 to 200 Hz)

Motor Line supply Altivar 11

Power

indicated

on

plate

kW/HP A A A W kg

Single phase supply voltage: 100…120 V 50/60 Hz

0.37/0.5 92.43.623ATV 11PU09F1U 0.900

Single phase supply voltage: 200…240 V 50/60 Hz

0.37/0.5 62.43.623ATV 11PU09M2U 0.900

0.75/1 9.9 4.6 6.3 43 ATV 11PU18M2U 0.900

3-phase supply voltage: 200…230 V 50/60 Hz

0.37/0.5 3.6 2.4 3.6 24 ATV 11PU09M3U 0.900

0.75/1 6.3 4.6 6.3 38 ATV 1 1PU18M3U 0.900

(1) The line current value is given for the measurement conditions indicated in the table below.

Drive rating Prospective Isc Line voltage

ATV 11

ATV 11

ATV 11

(2) The current value is given for a 4 kHz switching frequency.

(3) For 60 seconds.

(4) Drive supplied without EMC filter. To order an EMC filter separately, see p age 60252/5.

(5) With integrated fan.

Max. line

current (1)

/UF1U 1 kA 100 V

/UM2U 1 kA 208 V

/UM3U 5 kA 208 V

Permanent

output

current (2)

Max.

transient

current (3)

Power

dissipated

at nominal

load

Reference

(4)

Weight

ATV 11HU41M3U

Presentation:

pages 2 and 3

Schneider Electric

Characteristics:

pages 8 to11

Dimensions:

pages 12 and 13

Schemes:

pages 14 and 15

5

Page 5

References

Variable speed drives

550488

ATV 11HU18M2A

550487

for asynchronous motors

Altivar 11

ATV 11//////A Asia range

Drives with heatsink (frequency range from 0 to 200 Hz)

Motor Line supply Altivar 11

Power

indicated

on

plate

kW A A A W kg

Single phase supply voltage: 100…120 V 50/60 Hz

0.18 6 1.4 2.1 14 ATV 11HU05F1A 0.900

0.37 9 2.4 3.6 25 ATV 11HU09F1A 1.000

0.75 18 4 6 40 ATV 11HU18F1A

Single phase supply voltage: 200…240 V 50/60 Hz

0.18 3.3 1.4 2.1 14 ATV 11HU05M2A 0.900

0.37 6 2.4 3.6 25 ATV 11HU09M2A 1.000

0.75 9.9 4 6 40 ATV 11HU18M2A 1.100

1.5 17.1 7.5 11.2 78 ATV 11HU29M2A

2.224.1101597ATV 11HU41M2A

3-phase supply voltage: 200…230 V 50/60 Hz

0.18 1.8 1.4 2.1 13.5 ATV 11HU05M3A 0.900

Max. line

current (1)

Permanent

output

current (2)

Max.

transient

current (3)

Power

dissipated

at nominal

load

Reference

(4)

(5)

(5)

(5)

Weight

1.800

1.800

1.800

0

ATV 11PU18M2A

550492

ATV 11HU41M2A

550493

0.37 3.6 2.4 3.6 24 ATV 11HU09M3A 1.000

0.75 6.3 4 6 38 ATV 11HU18M3A 1.100

1.5 11 7.5 11.2 75 ATV 11HU29M3A

2.215.2101594ATV 11HU41M3A

(5)

(5)

1.800

1.800

Drives on base plate (frequency r ange from 0 to 200 Hz)

Motor Line supply Altivar 11

Power

indic ated

on

plate

kW A A A W kg

Single phase supply voltage: 100…120 V 50/60 Hz

0.37 9 2.4 3.6 25 ATV 11PU09F1A 0.900

Single phase supply voltage: 200…240 V 50/60 Hz

0.37 6 2.4 3.6 25 ATV 11PU09M2A 0.900

0.75 9.9 4 6 40 ATV 11PU18M2A 0.900

3-phase supply voltage: 200…230 V 50/60 Hz

0.37 3.6 2.4 3.6 24 ATV 11PU09M3A 0.900

0.75 6.3 4 6 38 ATV 11PU18M3A 0.900

(1) The line current value is given for the measurement conditions indicated in the table below.

Drive rating Prospective Isc Line voltage

ATV 11

ATV 11

ATV 11

(2) The current value is given for a 4 kHz switching frequency.

(3) For 60 seconds.

(4) Drive supplied without EMC filter. To order an EMC filter separately, see page 60252/5.

(5) With integrated fan.

Max. line

current (1)

/UF1A 1 kA 100 V

/UM2A 1 kA 200 V

/UM3A 5 kA 200 V

Permanent

output

current (2)

Max.

transient

current (3)

Power

dissipated

at nominal

load

Reference

(4)

Weight

ATV 11HU41M3A

Presentation:

pages 2 and3

6

Characteristics:

pages 8 to11

Dimensions:

pages 12 and 13

Schemes:

pages 14 and 15

Schneider Electric

Page 6

References

Variable speed drives

550496

VW3 A5870

for asynchronous motors

0

Altivar 11

Options and accessories

Description For drives Reference Weight

Advanced dialogue solution

PowerSuite

Converter, for connecting a PC or

Pocket PC, equipped with PowerSuite

software

EMC input filters ATV 11HU05M2E

/

All ratings See page 60200/3 –

All ratin gs VW3 A11301 0.070

ATV 11HU09M2E

ATV 11HU12M2E

ATV 11HU18M2E

ATV 11HU05F1U/A

ATV 11HU09F1U/A

ATV 11HU05M2U/A

ATV 11HU09M2U/A

ATV 11HU18M2U/A

ATV 11HU29M2E

ATV 11HU41M2E

ATV 11HU18F1U/A

ATV 11HU29M2U/A

ATV 11HU41M2U/A

ATV 11HU05M3U/A

ATV 11HU09M3U/A

ATV 11HU18M3U/A

VW3 A11401 0.650

VW3 A11402 0.850

VW3 A11403 0.650

kg

550497

VW3 A5873

ATV 11HU29M3U/A

ATV 11HU41M3U/A

Braking module connected to the

DC bus

Braking resistors Not protected

Plates for mounting on

(width 35 mm)

(IP 00)

Protected

(IP 30)

rail

/

Adaptor plate for replacing Altivar 08 All ratin gs VW3 A11811 0.220

Earthing plate for EMC mounting All ratings VW3 A11831 0.100

All ratin gs VW3 A11701 0.250

ATV 11

/U05///(1)

ATV 11

/U09///(1)

ATV 11

/U12///(1)

ATV 11

/U18///(1)

ATV 11

/U29///(2)

ATV 11

/U41///(2) VW3 A58704 0.600

ATV 11

/U05///(1)

ATV 11

/U09///(1)

ATV 11

/U12///(1)

ATV 11

/U18///(1)

ATV 11

/U29///(2)

ATV 11

/U41///(2) VW3 A58733 2.000

ATV 11/U05///

ATV 11/U09///

ATV 11/U12///

ATV 11/U18M//

ATV 11HU18F1

ATV 11/U29///

ATV 11/U41///

VW3 A11404 0.850

VW3 A58702 0.600

VW3 A58732 2.000

VW3 A11851 0.220

/

VW3 A11852 0.300

550494

VW3 A11852

Presentation:

pages 2 and 3

Schneider Electric

Characteristics:

pages 8 to11

Ventilation kit (3) ATV 11HU18F1

(1) Minimum value of the resistor to be connected: 75 ohms.

(2) Minimum value of the resistor to be connected: 51 ohms.

(3) "Low noise" fan.

Dimensions:

pages 12 and 13

ATV 11HU18M/U

ATV 11HU29

ATV 11HU41///

Schemes:

pages 14 and 15

/

///

VW3 A11821 0.070

7

Page 7

Characteristics

Variable speed drives

for asynchronous motors

Altivar 11

Environment

Conformity to standards Altivar 11 drives have been developed to conform to the strictest international

EMC immunity

EMC conducted and radiated

emissions for drives:

All # IEC/EN 61800-3, environments: 2 (industrial supply) and 1 (public supply) restricted

ATV 11

/U05M2E to

ATV 11

/U18M2E

/U29M2E to

ATV 11

ATV 11

/U41M2E

ATV 11HU05M2E to

ATV 11HU41M2E

ATV 11HU05

ATV 11HU41

ATV 11HU05

& marking The drives bear & marking in accordance with the European low voltage directives

Produ ct certification

Degree of protection

Vibration resistance Drive without

Shock resistance

Ambient temperature

around the unit

Maximum operating altitude

Operating posit ion

Maximum permanent angle in relation to the normal vertical

mounting position

Storage

Operation

ATV 11HU41

rail option Conforming to IEC/EN 60068-2-6:

//U to

//U and

//A to

//A

standards and the recommendations relating to electrical industrial control devices

(IEC, EN), in particular:

EN 50178, EMC immunity and EMC conducted and radiated emissions.

# IEC/EN 61000-4-2 level 3

# IEC/EN 61000-4-3 level 3

# IEC/EN 61000-4-4 level 4

# IEC/EN 61000-4-5 level 3 (power access)

# IEC/EN 61800-3, environments 1 and 2

distribution

# EN 55011, EN 55022 class B, 2 to 12 kHz for motor cable lengths

65 m and class A (g roup 1), 2 to 16 kHz for lengths 6 10 m

# EN 55011, EN 55022 class B, 4 to 16 kHz for motor cable lengths

65 m and class A (g roup 1), 4 to 16 kHz for lengths 6 10 m

# With additional EMC filter: EN 55011, EN 55022 class B, 2 to 16 kHz for motor

cable lengths

# With additional EMC filter: EN 55011, EN 55022 class B, 2 to 16 kHz for motor

cable lengths

(73/23/EEC and 93/68/EEC) and EMC (89/336/EEC)

UL, CSA, NOM 117 and C-TICK

IP 20

- 1.5 mm peak from 3 to 13 Hz

- 1 gn from 13 to 200 Hz

15 gn for 11 ms conforming to IEC/EN 60068-2-27

5…93% without condensation or dripping water, conforming to IEC 60068-2-3

°C - 25…+ 65

°C - 10…+ 40,

- 10…+ 50 : removing the protective cover from the top of the drive

Up to + 60 with current derating of 2.2% per °C above 50 °C

m 1000 without derating (above this, derate the current by 1% per additional 100 m)

620 m and class A (group 1), 2 to 16 kHz for lengths 6 50 m

65 m and class A (group 1), 2 to 16 kHz for lengths 6 20 m

0

Drive characteristics

Output frequency range Hz 0…200

Switching frequency

Speed range

Transient overtorque

Braking torque

Maximum transient current

Voltage/frequency ratio

Frequency loop gain

Slip compensation

Presentation:

pages 2 and3

8

References:

pages 4 to 7

kHz 2…16

1…20

150% of the nominal motor torque

- 20% of the nominal motor torque without braking resistor at no-load with the

“deceleration ramp adaptation” function enabled

- 80% of the nominal motor torque with braking resistor (available as an option) at noload

- Up to 150% of the nominal motor torque with braking resistor (available as an option)

at high inertia

150% of the nominal drive current for 60 seconds

Sensorless flux vector control with PWM motor control signal (1)

Factory-set for most constant torque applications

Factory-set with the speed loop stability and gain

Possible correction for machines with high resistive torque or high inertia, or for

machines with fast cycles

(1) Pulse width modulation

Dimensions:

pages 12 and 13

Factory-set, according to the rating of the drive (adjustment possible)

Schemes:

pages 14 and 15

Schneider Electric

Page 8

Characteristics (continued)

Variable speed drives

for asynchronous motors

Altivar 11

Electrical characteristics

Power supply Voltage V 200 - 15% to 240 + 10% single phase for ATV 11/U//M2/

Frequency Hz 50 ± 5% or 60 ± 5%

Isc

Output voltage

Maximum connecti on capacity

of the power supply, the motor

and the braking module

Max. length of motor cables

Electrical isolation

Available internal supplies

Analog input AI1

Logic inputs LI

DO output

Relay outputs (RA-RC)

Maximum I/O connection capacity

Acceleration and deceleration ramps

Braking to a standstill

Main protection and safety features of the drive

Motor protection

Insulation resistance to earth

Frequency resolution

Time constant for reference change

Drive ATV 11

U12M

Drive ATV 11

U18F1/, U29///, U41///

Positive logic

Negative logic

/U05///, U09///,

//, U18M//

/

(1)Pulse width modulation

200 - 15% to 230 + 15% 3-phase pour ATV 11/U//M3/

100 - 15% to 120 + 10% single phase for ATV 11/U//F1/

A £ 1000 (prospective short-circuit current at the connection point) for single phase

power supply

£ 5000 (prospective short-circuit current at the connection point) for 3-phase power

supply

Maximum 3-phase voltage equal to:

- the line supply voltage for ATV 11

- double the line supply voltage for ATV 11/U//F1/

1.5 mm2 (AWG 14)

4 mm2 (AWG 10)

m - 50, shielded cable

- 100, non-shielded cable

Electrical isolation between power and control (inputs, outputs, power supplies)

Short-circuit and overload protection:

- One + 5 V (0/+ 5%) supply for the reference potentiometer (2.2 to 10 kW), maximum

current 10 mA

- One + 15 V (± 15%) supply for the control inputs, maximum current 100 mA

1 configurable analog input

Max. sampling time: 20 ms, resolution 0.4%, linearity ± 5%:

- voltage 0-5 V (internal power supply only) or 0-10 V, impedance 40 kW

- current 0-20 mA or 4-20 mA (without addition of a resistor), impedance 250 W

4 assignable logic inputs, impedance 5 kW

+ 15 V internal or 24 V external power supply (min. 11 V, max. 30 V).

Factory-set with 2-wire control in “transition” mode for machine safety, for Europe and

America ranges:

- LI1: forward

- LI2: reverse

- LI3/LI4: 4 preset speeds

- Local controls for the Asia range

Multiple assignment makes it possible to mix several functions on one input (example:

LI1 assigned to forward and preset speed 2

LI3 assigned to reverse and preset speed 3)

State 0 if < 5 V, state 1 if > 11 V

Max. sampling time: 20 ms

Available by programming on the Asia range only

State 0 if > 11 V or logic input not wired, state 1 if < 5 V

Max. sampling time: 20 ms

Factory setting:

- 2 kHz PWM (1) open collector output. Can be used for electromagnetic

galvanometer

- Max. current 10 mA

- Output impedance 1 kW, linearity ± 1%, max. sampling time 20 ms.

Assignable as logic output:

- Open collector logic output, output impedance 100 W, 50mA max

- Internal voltage (see above, available internal supplies)

- External voltage 30 V max: 50 mA

1 protected relay logic output (contact open on fault).

Minimum switching capacity: 10 mA for

Maximum switching capacity:

# On resistive load (cos j = 1 and L/R = 0 ms): 5 A for " 250 V or $ 30 V

# On inductive load (cos j = 0.4 and L/R = 7 ms): 2 A for " 250 V or $ 30 V

1.5 mm2 (AWG 14)

Ramp profiles: linear from 0.1 to 99.9 s.

Automatic adaptation of deceleration ramp time if braking capacities exceeded,

possible inhibition of this adaptation (use of braking module).

By d.c. injection: automatically to a standstill as soon as the frequency drops to zero.

Period adjustable from 0.1 to 30 s or continuous, current adjustable from 0 to 1.2 In

# Ther mal protect ion against overheating

# Protection against short-circuits between output phases

# Protection against overcurrent between output phases and earth, at power-up only

# Line supply overvoltage and undervoltage safety circuits

# Line supply phase loss safety function, for 3-phase supply.

Thermal protection integrated in the drive by continuous calculation of the l2t.

Thermal memory reset on p ower down.

MW > 500 (electrical isolation)

Display units: 0.1 Hz

Analog inputs: 0.1 Hz for 200 Hz max.

ms 5

/U//M//

$24 V.

0

Presentation:

pages 2 and3

Schneider Electric

References:

pages 4 to 7

Dimensions:

pages 12 and 13

Schemes:

pages 14 and 15

9

Page 9

Characteristics, Special

Variable speed drives

uses

for asynchronous motors

Altivar 11

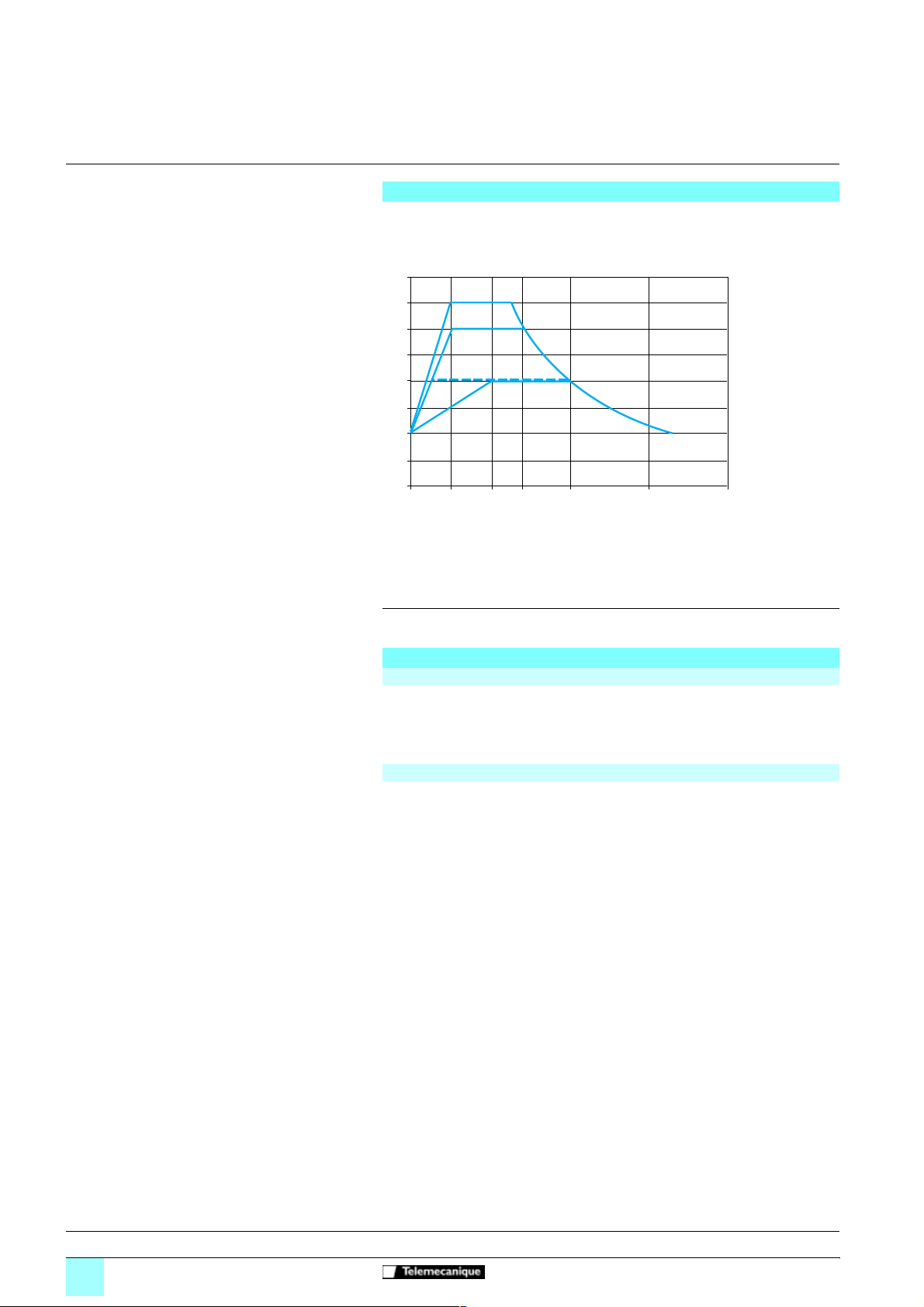

Torque characteristics (typical curves)

The curves be low defin e the avail able con tinuous to rque and tr ansien t overtorq ue for

both force-cooled and sel f-coole d motors. The only di fference is in the ab ility of the

motor to provide a high continuous torque at less than half the nominal speed.

T/Tn

1,7

1,5

1,25

0,75

0,5

0,25

2

1

0

0

0

4

3

2

1

121525

37

30

45

50

60

75

90

100

120

N (Hz)

0

1 Sel f- c oo le d mo tor: conti nu ous useful torque

2 Force-cooled motor: continuous useful torque

3 Transient overtorque in factory settings, when motor is warm.

4 Transient overtorque in optimised settings, when motor is war m .

Special uses

Use with a motor with a different rating to that of the drive

The device can su pp ly any mot or wh ic h ha s a pow e r ra tin g l owe r th an t h at fo r w hic h

it is designed.

For motor ratings slightly higher than that of the drive, check that the current

absorbed does not exceed the permanent output current of the drive.

Connecting motors in parallel

The rat in g of t he d riv e m us t be gre at er th an o r e qua l t o t h e sum of th e cur r ent s of the

motors t o be conn ect e d to t he dri ve . In t hi s cas e, p r ovid e e xt ern al t her mal p rot ec tio n

for each motor using thermal probes or relays.

If the nu mber of mot ors i n para lle l is g reate r than or equ al t o 3, i t is ad visa ble t o inst all

a 3-phas e choke between the drive and the motors.

Note: For the references of the chokes, please consult your Reg ional Sales Office.

Presentation:

pages 2 and3

10

References:

pages 4 to 7

Dimensions:

pages 12 and 13

Schemes:

pages 14 and 15

chneider Electric

S

Page 10

Combinations

Variable speed drives

for asynchronous motors

Altivar 11

Combinations for self-assembly

Function: to prote ct pers ons an d equi pment f rom an y level of over curr ent whi ch may

be encountered (overload or short-circuit).

Standard power

ratings of 3-phase

4-pole 50/60 Hz

motors

kW A kA

M1 A1 Q1 KM1

Single-phase supply voltage: 100…120 V 50/60 Hz

0.18 ATV 11HU05F1/ GV2 //14 6...10 > 100 LC1 D09

0.37 ATV 11

0.75 ATV 11HU18F1

Single-phase supply voltage: 200…240 V 50/60 Hz

0.18 ATV 11HU05M2/ GV 2 //08 2.5...4 > 100 LC1 D09

0.37 ATV 11

0.55 ATV 11

0.75 ATV 11

1.5 ATV 11HU29M2E GV2

1.5 ATV 11HU29M2U

2.2 ATV 11HU41M2

3-phase supply voltage: 200…230 V 50/60 Hz

0.18 ATV 11HU05M3/ GV 2 //07 1.6...2.5 > 100 LC1 D09

0.37 ATV 11

0.75 ATV 11

1.5 ATV 11HU29M3

2.2 ATV 11HU41M3

Speed drive

Reference (1)

/U09F1/ GV2 //14 6...10 > 100 LC1 D12

/U09M2/ GV2 //14 6...10 > 100 LC1 D09

/U12M2E GV2 //14 6...10 > 100 LC1 D09

/U18M2/ GV2 //16 9...14 > 100 LC1 D12

ATV 11HU29M2A

/U09M3/ GV2 //08 2.5...4 > 100 LC1 D09

/U18M3/ GV2 //14 6...10 > 100 LC1 D09

Circuit-breaker Contactor

Telemecanique

(2)

Merlin Gerin Rating

DT40 10 6 LC1 D09

DT40 16 6 LC1 D12

/ GV2 //21 17...23 50 LC1 D25

DT40 20 6 LC1 D25

DT40 66LC1 D09

DT40 10 6 LC1 D09

DT40 10 6 LC1 D09

DT40 16 6 LC1 D12

//20 13...18 50 LC1 D25

DT40 20 6 LC1 D25

//21 17...23 50 LC1 D25

GV2

DT40 20 6 LC1 D25

/ GV2 //22 20...25 50 LC1 D32

DT40 32 6 LC1 D32

DT40 66LC1 D09

DT40 66LC1 D09

DT40 10 6 LC1 D09

/ GV2 //16 9...14 > 100 LC1 D12

DT40 16 6 LC1 D12

/ GV2 //20 13...18 50 LC1 D25

DT40 20 6 LC1 D25

Adjustment

range

Max.

shortcircuit

current

Icu

Reference

0

Presentation:

pages 2 and 3

Schneider Electric

References:

pages 4 to7

Combinations of circuit-breakers and add-on modules

DT40 Vigi TG40

Rating (A) Rating (A) Type (3) Sensitivity

625A "si"30 mA

10 25 A "si" 30 mA

16 25 A "si" 30 mA

20 25 A "si" 30 mA

32 40 A "si" 30 mA

Recommendations for special uses:

# All RH10 / RH21 / RH99 / RHU residual current protection devices with separate sensors are

compatible as long as the type and sensitivity of the add-on modules given in the table above

are observed.

# It is advisable to connect one residual current differential safety device per drive. In this case

a type B dev ice mu s t not be loca ted do wns tr ea m of a typ e A or AC de vi ce .

(1) Replace the dots in the reference according to the type of drive required, see pages 60252/2

to 60252/4.

(2) Replace the dots with ME for pushbutton control or with P for control via rotating knob.

Type 2 coordination is provided by combining a GV2 circuit breaker with an LC1 D

contactor.

(3) For additional protection against direct contact, the add-on module must be type B with a

sensitivity of 30 mA, if the following conditions are met :

- 3-phase power supply, all neutral point connection systems and

- the braking resistor must be accessible.

Dimensions:

pages 12 and 13

Schemes:

pages 14 and 15

//

11

Page 11

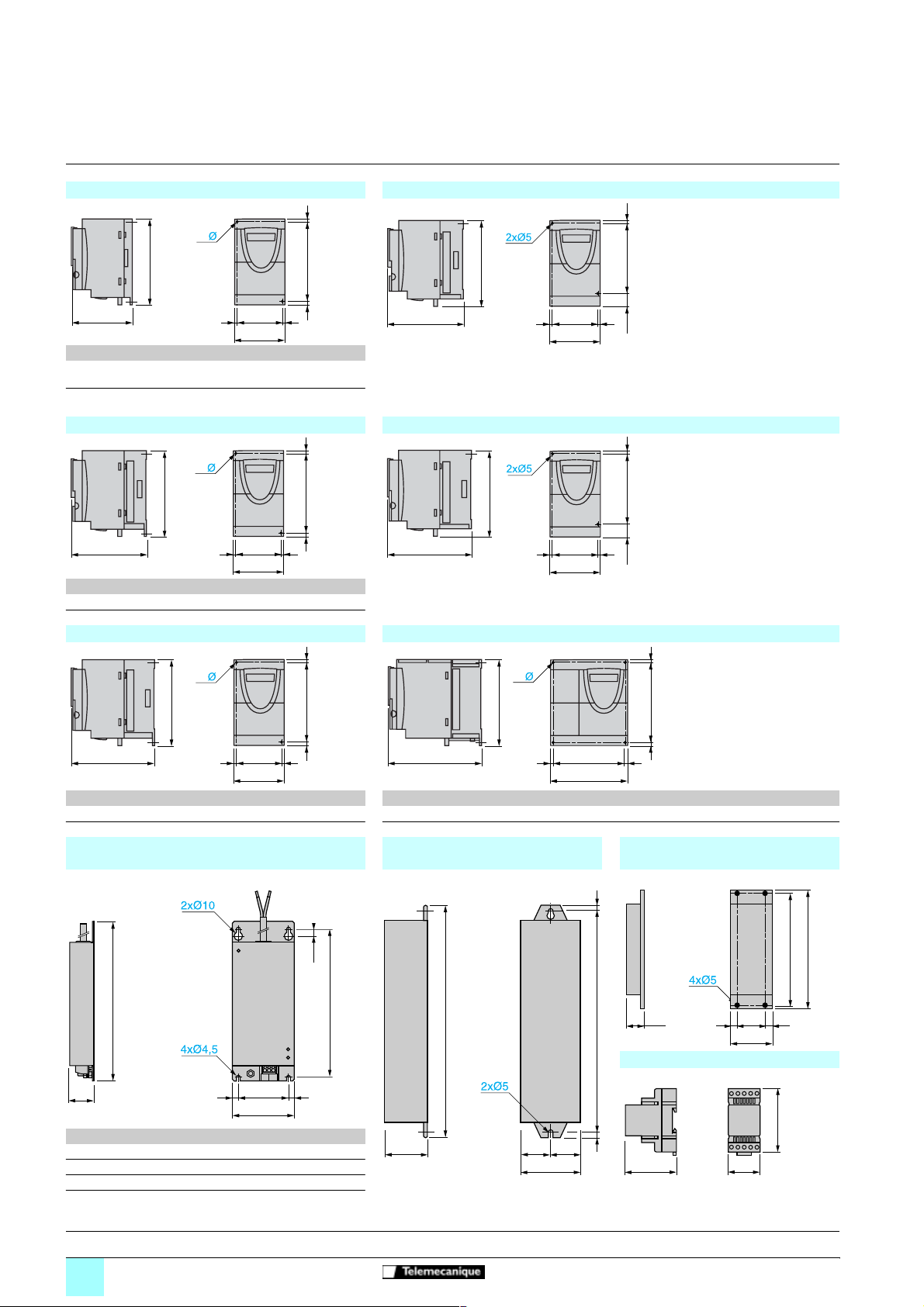

Dimensions

5

Variable speed drives

for asynchronous motors

Altivar 11

ATV 11HU05//E/U/A, ATV 11PU////E/U/A ATV 11HU09M2E

=

2x

b

c

ATV 11 a b c G H Ø

//E/U,

HU05

PU

HU05

PU

////E/U

//A,

////A

72 142 101 60±1 131±1 5

72 142 108 60±1 131±1 5

G

=

a

ATV 11HU09//U/A ATV 11HU12M2E, ATV 11HU18M2E

2x

b

H

=

=

=

H

125

142

60==

72

142

0

12016,5 5,5

12016,5 5,

c

ATV 11 a b c G H Ø

//U 72 142 125 60±1 131±1 5

HU09

//A 72 142 132 60±1 131±1 5

HU09

G

=

a

=

=

138

60==

72

ATV 11HU18M/U/A ATV 11HU18F1U/A, ATV 11HU29M/E/U/A, ATV 11HU41M/E/U/A

=

2x

b

c

ATV 11 a b c G H Ø ATV 11 a b c G H Ø

HU18M

/U 72 147 138 60±1 131±1 5 HU18F1U, HU29M/E/U, HU41M/E/U 117 142 156 106±0,5 131±1 5

/A 72 142 145 60±1 131±1 5 HU18F1A, HU29M/A, HU41M/A 117 142 163 106±0,5 131±1 5

HU18M

G

=

a

H

=

=

c

EMC input filters VW3 A11401 to A11404 Protected braking resistors

VW3 A58732 and A58733

8,5

4x

b

G==

a

H==

Non protected braking resistors VW3

A58702 and A58704

(2-wire output, length 0.5 m)

=

154

170

b

c

VW3 a b c G H

A11401 75 194 30 61 180

A11402 117 184 40 97 170

A11403 75 194 40 61 180

A11404 117 190 40 97 170

Presentation:

pages 2 and3

12

G==

a

Characteristics:

pages 8 to11

H

332

310

30

40 ==

60

Braking module VW3 A11701

(for mounting on AM1-ED rail)

90

61

References:

pages 4 to7

=

85

Schemes:

pages 14 and 15

=

=

73

45

Schneider Electric

Page 12

Dimensions,

mounting

Variable speed drives

for asynchronous motors

Altivar 11

ATV 08 adaptor plate VW3 A11811 Plates for mounting on rail VW3 A11851 and A11852

0

142

32,9 77,5

EMC earthing plate VW3 A11831 Ventilation kit VW3 A11821

(1)

(2)

61

15

(1) 2 screws supplied for fixing the earthing plate.

(2) 5 x Ø 4 mm screws for fixing EMC clamps.

67,6

143,6

37,9 77,5

59,9

23,3 59

143,6

39,9 122,8

Mounting recommendations

# Install the unit vertically, at ± 10°.

# Do not place it close to heating elements.

# Leave sufficient free space to ensure that the air required for cooling purposes can circulate, by natural convection or by ventilation, from the

botto m to the top of the unit.

# Free space in front of unit: 10 mm minimum.

-10 °C to 40 °C

d ³ 50 mm: no special precautions.

d = 0 (mounted side by side): remove the protective cover from the top of the drive

40 °C to 50 °C

d ³ 50 mm: remove the protective cover from the top of the drive

50 °C to 60 °C

d ³ 50 mm: remove the protective cover from the top of the drive, and derate the

nominal current of the drive by 2.2% per °C above 50 °C.

Recommendations for mounting on a machine frame (specific to ATV 11PU///// drives)

ATV 11P////// drives can be mounted on (or in) a steel or aluminium machi ne

(1)

(2)

(1) 2 x Ø M5 tapped holes.

(2) Minimum machined area

Presentation:

pages 2 and 3

Schneider Electric

Characteristics:

pages 8 to11

frame, observing the following conditio ns:

# Maximum ambient temperatur e: 40 °C

# Vertical mounting ± 10°

# The drive must be fixed at the centre of a support (frame) which is a minimum of

10 mm thick and with a minimum cooling area of 0.12 m

aluminium, exposed to the open air.

# Support area for the drive (142 x 72 min) machined on the frame with a surface

smoothness of 100 mm max and an unevenn ess of 3.2 mm max

# Mill the tapped holes lightly in order to remove any burrs.

# Coat the whole drive support area with thermal contact grease (or equivalent).

When the operating conditions are close to the ma ximum limits (power , cycle and

temperature), this type of use must be checked be forehand, by monitoring the

thermal state of the drive .

References:

pages 4 to7

Schemes:

pages 14 and 15

2

for steel and 0.09 m2 for

13

Page 13

Schemes

Variable speed drives

for asynchronous motors

Altivar 11

Schemes with contactor

3-phase power supply ATV 11////M3/ Single phase power supply ATV 11////F1/ and ATV

200…240 V 50/60 Hz

12

34

56

Q1

(4)

12

34

56

KM1

(1) (2) (3)

A1

L3

L1

L2

RA

RC

LI1

LI2

LI3

LI4

DO

+ 15 V

AI1

U

V

W

PA/+PC/

V1

U1

W1

A2

+

M1

3

Braking

resistor

PA

(5)

PB

Potentiometer

speed

reference

+ 5 V

0 V

0 -20 mA

or

4 -20 mA

0-10 V

(external power supply)

11

////M2/

100...120 V 50/60 Hz and 200...240 V 50/60 Hz

12

34

5

Q1

6

12

34

KM1

(1) (2) (3)

A1

L1

N/L2

U

V

V1

U1

M1

3

W

W1

Braking

resistor

A2

RA

PA/+PC/

+

PA

RC

(5)

PB

LI1

LI2

AI1

+ 5 V

Potentiometer

speed

reference

LI3

LI4

0 V

0 -20 mA

or

4 -20 mA

0-10 V

(external power supply)

0

(4)

DO

+ 15 V

2-wire control 3-wire control Analog voltage input Analog current input

External 10 V use 0-20 mA or 4-20 mA

ATV 11 control terminals

LI1

+ 15 V

LI1: Forward

LIx: Reverse

LIx

ATV 11 control terminals

LI1

+ 15 V

LI1: Stop

LI2: Forward

LIx: Reverse

LI2

ATV 11 control terminals

LIx

AI1

Speed

reference

potentiometer

2.2 to 10 kW

0 V

ATV 11 control terminals

AI1

Source

0 -20 mA

or

4 -20 mA

0 V

For combinations of KM1, Q1, etc, components (see the table on page 60251/5).

(1) Fault relay contact: for remo te signalling of drive status.

(2) Internal +15 V. If an external +24 V supply is used, connect the 0 V on th e external supply to the 0 V terminal, do not use the + 15 terminal on the drive, and

connect the common o f the LI inputs to the + 24 V of the external supply.

(3) DO output: can be configured as an analog or a logic output. Internal voltage + 15 V or external + 24 V.

(4) Galvanometer or low level relay.

(5) Braking module VW3 A11701, if braking resistor VW3 A587

//

is used.

Note: Fit interference suppressors to all inductive circuits near the drive or connected on the same circuit, such as relays, contactors, solenoid valves, fluorescent

lighting, etc.

Presentation:

pages 2 and3

14

Characteristics:

pages 8 to11

References:

pages 4 to7

Schemes:

pages 14 and 15

Schneider Electric

Page 14

Connections

Variable speed drives

for asynchronous motors

Altivar 11

Electromagnetic compatibility

Connections to meet the requirements of EMC standards

Principle

# Earths between the drive, the motor and the cable shielding must have "high frequency" equipotentiality.

# Use shielded cables with shielding connected to earth at 360° at both ends for the motor cables, and if necessary the braking module and

resistor and control-signalling cables. Conduit or metal ducting can be used for part of the shielding length provided that there is no break in

continuity.

# Ensure maximum separation between the power supply cable (line supply) and the motor cable.

Installation diagram for ATV 11/U////E/U/A

3

2

4

1

5

1 Earthing plate VW3 A 11831 to be fitted on the drive.

2 Altivar 11

3 Non-shielded power supply cabl e.

4 Non-shielded cable for fault relay contacts output.

5 Fix and earth the shielding of cables 6 and 7 as close as possible to the drive:

- strip the shielding

- use cable clamps of an appro priate size on the part s from which the shielding

has been stripped, to attach them to the earthing plate.

- the shielding must be clamped tightly enough to the earthi ng plate to ensure

good co ntact

- types of clamp: non-oxidizing metal

6 Shielded cable (1) for connecting the motor.

7 Shielded cable (1) for connectin g the control/signalling system. For applicat ions

which require a large number of conductors, small cross-sections must be used

2

(0.5 mm

8 PE ca ble.

(1) The shielding of cables (6, 7 and 8) must be connected to earth at both ends.

The shielding must be continuous and if intermediate terminals are used, they must be in EMC

metal boxes.

).

0

7

8

Note: If using an additional input filter, it must be mounted under the drive and connected directly to the line supply via a non-shielded cable. Link 3 on the drive is

then via the filter output cable.

Although there is an HF equipotential earth connection between the drive, the m otor and the cable shielding, it is still necessary to connect the PE protective

conductors (green-yellow) to the appropriate terminals on ea ch of the devices.

6

Presentation:

pages 2 and 3

Schneider Electric

Characteristics:

pages 8 to11

References:

pages 4to7

Schemes:

pages 14 and 15

15

Page 15

Presentation

510888

502945

PowerSuite advanced dialogue

solutions

The PowerSuite advanced dialogue solutions can be used for Schneider Electric

drives and starters. They enable communication with the product from a Pocket PC,

a PC or a dedicated terminal.

The solutions, with a Pocket PC or PC, enable f iles to be prepared for uploading to

the drives and the starters. The PowerSuite software creates its files ensuring

consistency between the configuration/a djustment functions of the product.

PowerSuite Pocket PC

The Pocket PC can be used during preparation, programming, setup and

maintenance.

It comprises a Pocket PC terminal and corresponding connection accessories.

The sof tw ar e is integra t ed i nt o a Wi nd ow s C E environmen t , fo r whi ch th e op er at i n g

system language can be selected on ordering (English, French, German, Spanish,

Italian).

The software i ncorp orates al l the fu nctions of int egrated an d remote t ermi nals (driv e or

starter configuration and adjustment, control, signalling, etc).

The Pocket PC can be used:

# alone to prepare and store configuration/adjustment files (integral battery or l ine

supply)

# connected to a PC for uploading configuration/adjustment files from the Pocket PC

to the PC or downloading from the PC to the Pocket PC

# connected to the drive or to the starter for configuration, adjustment or control

purposes or to upload a configuration/adjustment file from the Pocket PC to the

product or download a config uration/adjustment file from the product to the Pocket

PC.

510086

PowerSuite software workshop for PC

The PowerSuite software workshop is used to set up a drive or a starter from a PC

in a Microsoft Windows 95, 98, NT4 or 2000 env ironment.

The software incorporates all the functions of integrated and remote terminals (drive

or starter configuration and adjustment, control, signalling, etc.) with assisted, guided

operator dialogue in 5 languages (English, French, G erman, Spanish, Italian) in a

Windows environment.

It can be used:

# alone to prepare and store drive or starter configuration files on diskette, CD-ROM

or hard disk

The drive or starter configuration can be pr inted out on paper or can be exported to

office automation software.

# connected to the drive or starter for configuration, adjustment or control purposes,

or for uploading a configuration/adjustment file from the PC to the product or

downloading from the product to the PC.

Connection is via a link between the drive or starter connector and the serial port on

the PC.

Magelis display unit with matrix screen

The Magelis display unit with matrix screen can be used to monitor, diagnose and

adjust up to 8 Altivar 28, 38, 58 or 58F drives in 5 languages (English, French,

German, Spanish, Italian). It can display variables in alphanumeric format with

European, Cyrillic or Asian fonts in 4 sizes, or it can display icons or background

images in black and white as well as animations in barchart or gauge format. The

application is preloaded in the factory.

Compatibility

Compatibility of advanced dialogue solutions with drives and

starters

PowerSuite Pocket PC

Pocket PC VW3 A8108// 49 49 49 49

Setup kit VW3 A8 102 49 49 49 49

Connection kit VW3 A8111

PowerSuite software workshop for PC

CD-ROM VW3 A8104 1 4 V 1.0 4 V 1.40 49 4 V 1.30 4 V 1.40

Connection kit VW3 A8106

Magelis display unit with matrix screen

Display unit XBT HM017010A8

Accessories

CD-ROM VW3 A8105 1 4 V 1.0 4 V 1.40 49 4 V 1.30 4 V 1.40

Operator terminal VW3 A8103//

Incompatible products Compatible products and versions

1 V 1.40 software version available 2

QG

half 2002.

Drives Starter TeSys model U

ATV 28, ATV 58,

ATV 58F

ATV 38 ATV 11 ATS 4 8

controllerstarters

16

6FKQHLGHU(OHFWULF

Page 16

Reference

PowerSuite advanced dialogue

solutions

520962

VW3 A8103

//

PowerSuite Pocket PC

Several solutions are available to meet the needs of individual users:

- the complete Pocket PC

- the setup kit

- the connection kit for Pocket PC.

The complete Pocket PC comprises:

- 1 "Jordana 525" Pocket PC , with multilingual operating system (1), supplied with

PC synchronisation cable and mains power supply

- 1 CD-ROM containing the multilingual (1) setup software which can be ordered

separately

- 1 connection kit for Pocket PC

The setup kit comprises:

- 1 CD-ROM containing the multilingual (1) setup software which can be ordered

separately

- 1 connection kit for the Pocket PC

The connection kit for the Pocket PC comprises:

- 2 connection cables, length 0.6 m, with 2 RJ45 connectors

- 1 RJ45/9-way SUB-D adaptor for connecting ATV 58 and ATV 58F

- 1 converter marked “RS 232/RS 485 PPC” with one 9-way male SUB-D connector

and 1 RJ45 connector.

FRQYHUWHUIRU$79ZLWKRQHZD\PDOHFRQQHFWRUDQG5-FRQQHFWRU

Description Reference Weight

Complete Pocket PC VW3 A8108// (2) 1.000

Setup kit VW3 A8102 0.400

Connection kit for the Pocket PC VW3 A8111 0.300

kg

PowerSuite software workshop for PC

The PowerSuite software comprises:

- 1 CD-ROM containing the multilingual (1) setup software

- 1 connection kit for PC

The PC connection kit comprises:

- 2 connection cables, length 3 m, with 2 RJ45 connectors

- 1 RJ45/9-way SUB-D adaptor for connection of ATV-58 and ATV-58F drives

- 1 converter marked “RS 232/RS 485 PC” with one 9-way female SUB-D connector

and 1 RJ45 connector

FRQYHUWHUIRU$79ZLWKRQHZD\PDOHFRQQHFWRUDQG5-FRQQHFWRU

Description Reference Weight

1 CD-ROM containing the multilingual setup so ftware (1) VW3 A8104 1 0.100

kg

105080

XBT HM017010A8

Connection kit for PC VW3 A8106 0.350

Magelis display unit with matrix screen

The terminal has a backlit LCD with 8 lines of 40 charac ters.

The RS 458 connection kits for ATV 28 (VW3 A28301), ATV 38 and ATV 58

(VW3 A58306) drives, as w ell as other connection accessories, should be ordered

separately according to the number and type of drives connected. Please consu lt

your Regional Sales Office.

Description Reference Weight

Magelis display unit with matrix screen XBT HM017010A8 0.600

kg

Accessories

Description Reference Weight

1 upgrade CD-ROM for multilingual setup software VW3 A8105 1 0.100

“Jordana 525” Pocket PC terminal supplied with PC

synchronisation cable and mains power supply

[0%FRPSDFWIODVKFDUGFRQWDLQLQJWKH3RFNHW3&

VRIWZDUHIRUWKH-RUQDGD

(1) English, French, German, Spanish, Italian.

(2) To order the operating system in your chosen language, replace

French, DE for German, SP for Spanish and IT for Italian.

(3) To find out about the latest available version, please consult your Regional Sales Office.

(4) This card enables the software to be run immediately without synchronising with a PC.

1 V 1.40 software version available 2

QG

half 2002.

VW3 A8103// (2) 0.300

VW3 A8110 0.100

//

by EN for English, FR for

kg

6FKQHLGHU(OHFWULF

17

Page 17

Functions

Variable speed drives

for asynchronous motors

Altivar 11

Summary of functions

Operating speed range page 60255/3

Acceleration and deceleration ramp times page 60255/3

Second ramp page 60255/3

Deceleration ramp adaptation page 60255/3

Preset speeds page 60255/4

Configuration of analog input AI1 page 60255/4

Analog or logic output DO page 60255/4

Forward/reverse operation page 60255/4

2-wire control page 60255/5

3-wire control page 60255/5

Automatic d.c. injection page 60255/5

Switching frequency, noise reduction page 60255/5

Fault relay, unlocking page 60255/5

Fault reset page 60255/6

Automatic restart page 60255/6

Automatic catching a spinning load with speed detection page 60255/6

Controlled stop on loss of line supply page 60255/6

Drive thermal protection page 60255/6

Motor thermal protection page 60255/6

Monitoring page 60255/7

Incompatible functions page 60255/7

Functions specific to th e Asia ran ge page 60255/7

Drive factory setting

To facilitate the setting up of the drive, the functions have been programmed to the meet the

requirements of the most common applications.

0

Drive functions and I/O :

# 2-wire control on transition

5 Logic input LI1 : forward

5 Logic input LI2 : reverse

# Preset speeds:

5 Logic input LI3 : preset speeds

5 Logic input LI4 : preset speeds

# Analog input AI1 : 0-5 V speed reference

# Logic/analog output DO : motor frequency (analog)

# Dec eleration ramp adap tation

# Automatic d.c. current injection for 0.5 s to standstill.

Functions of the display and the keys

Altivar 11

1

3

ESC

5

RUN

ENT

STOP

4

2

6

7

18

1 Information is displayed in the form of codes or values in three "7-segment"

displays

2 Buttons for scrolling through the menus or modifying values

3 “ESC” : Button for exiting the menus (no confirmation).

4 “ENT” : Validation button for entering a menu or confirming th e new value selected

# Only on the Asia range:

5 “RUN” : Local control of motor operation.

6 “STOP” : Local control of motor stopping.

7 Speed reference potentiometer.

SchneiderElectric

Page 18

Functions (continued)

Variable speed drives

for asynchronous motors

Altivar 11

# Operating speed range

Used to determine 2 frequency limits which define the speed range permitted by the machine

under actual operating conditions.

f (Hz)

: low speed, from 0 to HSP, factory setting 0

HSP

LSP

0 V

0 V

0 mA

4 mA

# Acceleration and deceleration ramp times

Used to define acceleration and deceleration ramp times according to the application and the

machine dynamics

f (Hz)

5 V

10 V (external po wer supply)

20 mA

20 mA

LSP

: high speed, from LSP to 200 Hz, factory setting 50/60

HSP

Reference

f (Hz)

0

Adjustment of second ramp with

Pocket PC PowerSuite

50/60

t1

Linear acceleration ramp

Adjustm ent of t1 : 0.1 to 99.9 s

factory setting 3 s.

# Second ramp

Used to switch 2 acceleration or deceleration ramp times, which can be adjusted separately.

Enabled by means of 1 reassignable logic input.

It is suitable for machines with fast continuous speed correction and high speed lathes with

acceleration and deceleration limiting above certain speeds.

f(Hz)

HSP

Forward

or

reverse

1

0

Acc 2

Acc 1

50/60

t0

0t

Linear decelera tion ramp

Adjustment of t2 : 0.1 to 99.9 s

factory setting 3 s.

Dec 2

Dec 1

Acceleration 1 (Acc 1) and

deceleration 1 (Dec 1)

- adjustment 0.1 to 99.9 s

- factory setting 3 s

Acceleration 2 (Acc 2) and

deceleration 2 (Dec 2)

t

- adjustment 0.1 to 99.9 s

- factory setting 5 s

: high speed

HSP

t

t2

:

:

Schneider Electri c

1

LI4 0

Example of switching using logic input LI4

# Deceleration ramp adaptation

Used to automa tical ly incr ease th e dece lerat ion ramp ti me if the init ial set ting is too low w hen th e

load inertia is taken into account. This function prevents the drive locking if there is an

overvoltage on deceleration fault.

If this function is disabled, an appropriate braking module and resistor can be used.

t

19

Page 19

Functions (continued)

f(Hz)

Variable speed drives

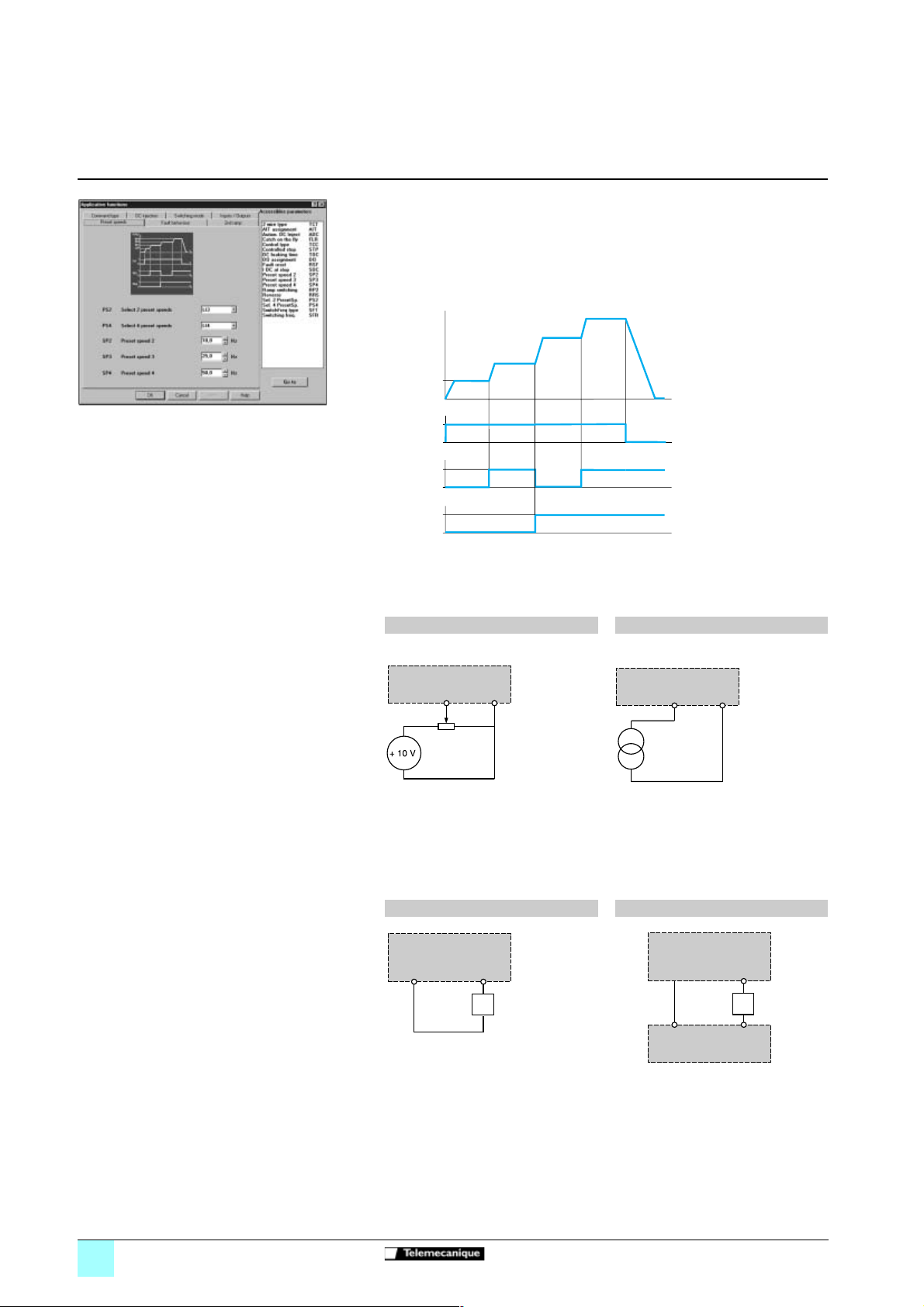

Adjusting the preset speeds with the PowerSuite

software workshop for PC

for asynchronous motors

Alti var 11

# Preset speeds

Used to switch preset speed references.

Choice between 2 or 4 preset speeds.

Enabled via 1 or 2 logic inputs.

The preset speeds can be adjusted in increments of 0.1 Hz from 0 Hz to 200 Hz.

They take priority over the reference given via the analog input or, for the Asia range, on the

drive’s potentiometer.

The spee d ob t a ined with inputs

LIx and LIy at state 0 is LSP or the

speed referenc e, depending on

the leve l of analog input AI 1.

LSP

1

LI1 0

1

LIx 0

1

LIy 0

Example of operation with 4 preset speeds.

# Configuration of analog input AI1

This is used to modify the specifications, for either voltage or current, of analog input AI1.

Factory setting : 0-5 V (internal power supply only).

Other possible values via external power supplies : 0-10 V, 0-20 mA, 4-20 mA.

Analog volt age input Analog current input

External 10 V use 0-20 mA or 4-20 mA use

Factory settings :

st

speed : LSP (low speed or

1

t

reference)

nd

speed : 10 Hz

2

rd

speed : 25 Hz

3

t

th

speed : 50 Hz

4

t

0

Altivar 11 control terminals

AI1

Speed

reference

potentiometer

2.2 to 10 kW

# Analog or logic output DO

Output DO can be programmed to be a logic output or an analog output. It enables remote

signalling of the following information as required :

5 Frequency threshold reached (logic output)

5 Reference reached (logic output)

5 Current threshold reached (logic output)

5 Current in the motor (analog output)

5 Motor frequency (analog output)

0 V

Altivar 11 control terminals

AI1

Supply

0-20 mA

or

4-20 mA

0 V

Diagram with internal power supply Diagram with external power supply

Altivar 11 control terminals

DO

+ 15 V

If it is a lo gic output: Z is a relay or a low level input.

If it is an analog output: Z can be, for example, a galvanometer.

For a ga lv anometer with resi s tance R, the maximum voltage supplied will be :

R W()

Ux

------------------------------------------- R W() 1000 W()+

Altivar 11 control terminals

0 V

DO

0 V

Power supply

+ U

20

# Direction of operation : forward/reverse

In 2-wire control, forward operation cannot be reassigned to any logic input other than LI1.

In 3-wire control, stopping cannot be reassigned to any logic input other than LI1, and forward

operation cannot be reassigned to any logic input other than LI2.

5HYHUVHRSHUDWLRQFDQEHGLVDEOHGIRUDSSOLFDWLRQVwith a single direction of motor rotation, by

not assigning any logic input to reverse operation.

SchneiderElectric

Page 20

Functions (continued)

Variable speed drives

Assignment of logic inputs with

Pocket PC PowerSuite

for asynchronous motors

Altivar 11

# 2-wire control

Used to control the direction of operation by means of a maintained contact.

Run (forward or reverse) and stop are controlled by the same logic input.

Enabled by means of 1 or 2 logic inputs (one or two directions).

This function is suitable for all non-reversing and reversing applications.

3 operating modes are possible :

5 detection of the state of the logic inputs

5 detection of a change in state of the logic inputs

5 detection of the state of the logic inputs with forward operation always having priority over

reverse

Altivar 11 control terminals

LI1

15 V

Wiring diagram for 2-wire control

# 3-wire control

Used to control the operating direction and stopping by means of pulsed contacts.

Run (forward or reverse) and stop are controlled by 2 different logic inputs.

Enabled by means of 2 or 3 logic inputs (non-reversing or reversing).

This function is suitable for all non-reversing and reversing applications.

f (Hz)

LIx

LI1

LIx

: forward

: reverse

0

Adjustment of the "d.c. injection" function using the

PowerSuite software workshop for PC

LI1

LI2

LIx

: Stop

: Forward

: Reverse

t

t

tt

t

0

Stop

1

0

Forward

1

0

1

Reverse

0

Example of operation with 3-wire control

Altivar 11 control terminals

LI1 LI2

15 V

Wiring d iagram fo r 3-wir e control

# Automatic d.c. injection

Enables d.c. injection to standstill, which is adjustable from 0 to 1.2 times the value of the drive

nominal current (preset at 0.7 In), as soon as oper ation is no longer controlled and the motor

speed is zero,

5 either for a period of time, which is adjustable from 0.1 to 30 s (preset at 0.5 s)

5 or continuously.

Factory setting : function active with d.c. injection for 0.5 s.

In 3-wire control, d.c. injection is only active if logic input LI1 is active (stop).

# Switching frequency, noise reduction

High frequency switching of the intermediate d.c. voltage can be used to supply the motor with

a current wave with low harmonic distortion.

There are 3 ranges of switching frequency :

5 Random switching frequency around 2 or 4 kHz (avoids resonance)

5 Fixed low frequen c y adjustable to 2 or 4 kHz

5 Fixed high frequency adjustable to 8, 12 or 16 kHz

Factory setting : Low frequency set at 4 kHz.

This function is suitable for all applications which require low motor noise.

# Fault relay, unlocking

The fault relay is energised when the drive is powered up and is not faulty.

It opens in the event of a fault or when the drive is powered down.

The drive can be unlocked after a fault in one of the following ways :

5 powering down the drive until the display disappears completely, then powering back up

5 activating the logic input associated w ith the “fault reset” function, i f the function is enabled

5 enabling the “automatic restart” function.

LIx

Schneider Electri c

21

Page 21

Functions (continued)

f(Hz)

Variable speed drives

for asynchronous motors

Alti var 11

# Fault reset

Used to clear the stored fault and restart the drive if the cause of the fault has disappeared.

The fault is cleared by a transition of the logic input LI which is assigned to this function.

Factory setting : function inactive.

The restart conditions after a reset to zero are the same as those of a nor mal power-up.

The following faults can be reset : drive thermal overload, motor thermal overload, line supply

overvoltage, over voltage on deceleration, overspeed, line phase loss (1), line supply

undervoltage (2).

# Automatic restart

Enables the drive to be restarted automatically after locking following a fault if this fault has

disappeared and if the other operating conditions permit a restart.

This restart is performed by a series of automatic attempts separated by increasingly longer

waiting periods: 1 s, 5 s, 10 s, then 1 minute for the following periods.

If the drive has not restarted af ter 6 minutes, the drive locks and the procedure is aband on ed

until the drive is powered down and back up again.

Factory setting : function inactive.

Restart autho rised w ith the fo llow ing fau lts : drive thermal ov erload, motor thermal overloa d, lin e

supply overvoltage, overvoltage on deceleration, line phase loss (1), line supply undervoltage

(2).

If the function is enabled, the drive’s safety relay remains activated until one of these faults

appears. This function requires the speed reference and the direction of operation to be

maintained, and is only compatible with 2-wire level control.

This function is suitable for machines or installations in continuous oper ation or without

monitoring, and where a restar t will not endanger equipment or personnel in any way.

# Automatic catching a spinning load with speed detection ("catch on the fly")

Used to restar t the motor smoothly after one of the following events:

5 loss of line supply or power down

5 fault reset or automatic restart

5 “freewheel stop” triggered by a fault.

On restarting, the effective speed of the motor is detected in order to restart on the ramp at this

speed and retur n to the re f er ence s pee d. Th e s peed detec ti on tim e can be up t o 1 s depen di ng

on the initial deviation.

Factory setting : function inactive.

This function requires the activation of 2-wire level control and is not compatible with the

continuous d.c . injection function.

This function is suitable for machines for which the loss of motor speed is negligible during the

line supply loss time (machines with high inertia).

0

Adjustment of the behaviour at a

fault with Pocket PC PowerSuite

Adjusting the thermal protection with the PowerSuite

software workshop for PC

# Controlled stop on loss of line supply

Used to define the drive stopping modes at a "loss of line supply" fault.

Three stopping modes are available for selection :

5 “Freewheel” stop : the drive is locked and the motor stops in accordance with the inertia and

the resistive torque

5 Normal stop : stop with valid deceleration ramp time (deceleration 1 or 2).

5 Fast stop : the stopping time depends on the inertia and the braking ability of the drive.

Factory setting : “Freewheel” stop.

1 Fast stop

2 Normal stop on deceleration ra mp

3 “Fre ewheel” st op

123

# Thermal protection of drive

Direct protection by thermistor, integrated in the drive’s power module. This protects the

components, even in the event of poor ventilation or excessive ambient temperature.

When the fault is detected, it lo cks t he d rive.

# Motor thermal protection

Motor thermal prote ction i s impl emented via co ntinuo us cal culati on of it s theor etical tempe ratur e

rise.

The drive is lock ed on a fault if thi s tempe ra tur e ri se ex ceeds 118% of the nomi nal t emp er atur e

rise.

This function is suitable for applications with self-cooled or force-cooled motors.

Note: The thermal state of the motor is not stored when the drive is powered down.

(1) The line supply phase loss fault is only accessible on drives with 3-phase power supply, if

monitoring of the fault has been enabled (Factory setting : enabled).

(2) The drive will restart as soon as the undervoltage fault disappears, whether or not the function

is active.

t

22

SchneiderElectric

Page 22

Functions (continued)

Variable speed drives

for asynchronous motors

Altivar 11

# Monitoring

The display shows the state of the drive or, if selected, one of the following values:

5 Frequency reference

5 Output frequency applied to the motor

5 Mot or current

5 Line voltage

5 Motor thermal state

5 Driv e thermal s tate

Incompatible functions

The choice of the last funct ion con figur ed is enab led, w hatev er the confi gura tion of t he pr evious

functions.

Application functions can be assigned to the same logic input, in which case one logic input

enables a number of functions (for example : direction of operation and 2nd ramp).

A check must be carried out to ensure that the functions are compatible.

# Direction of operation and 2-wire control : forward operation c an on ly be as si gn ed t o LI1 .

# Direction of operation and 3-wire control : forward operation c an on ly be as si gn ed t o LI2 .

# Automatic restart : requires the configuration of 2-wire level control. Changing the

configuration of the ty pe of control disables automatic restart.

# Automatic catching a spinning load with speed detection :

5 requires the configuration of 2-wire level control. Changing the configuration of the type of

control disables automatic catching a spinning load.

5 not compatible wit h continuous d. c. i nj ec ti on br aki ng to a standstil l . Co nfi gu rin g thi s f un ct io n

disa bles automatic catching a spinning load .

Functions specific to the Asia range

# Local control :

The keypad on the Asia range has 2 additional keys (RUN and STOP) and a potentiometer

(speed reference).

5 The keys and the potentiometer are active if local control is enabled.

The logic and analog inputs are inactive if local control is enabled.

Factory setting : function active.

5 Reverse : if local control is active, the reverse function is not visible.

# Logic inputs :

It is possible to choose the active level of the logic input.

Positive logic : the inputs are active if the signal is ³ 11 V.

Negative logic : the inputs are active if the signal is £ 5 V.

Factory setting : positive logic.

0

Schneider Electri c

23

Loading...

Loading...