Schneider ATV312H055M2, ATV312HU30N4, ATV312H037M2, ATV312HU15N4, ATV312H055N4 User Manual

...

Quick Start Guide - ATV312

ENGLISH

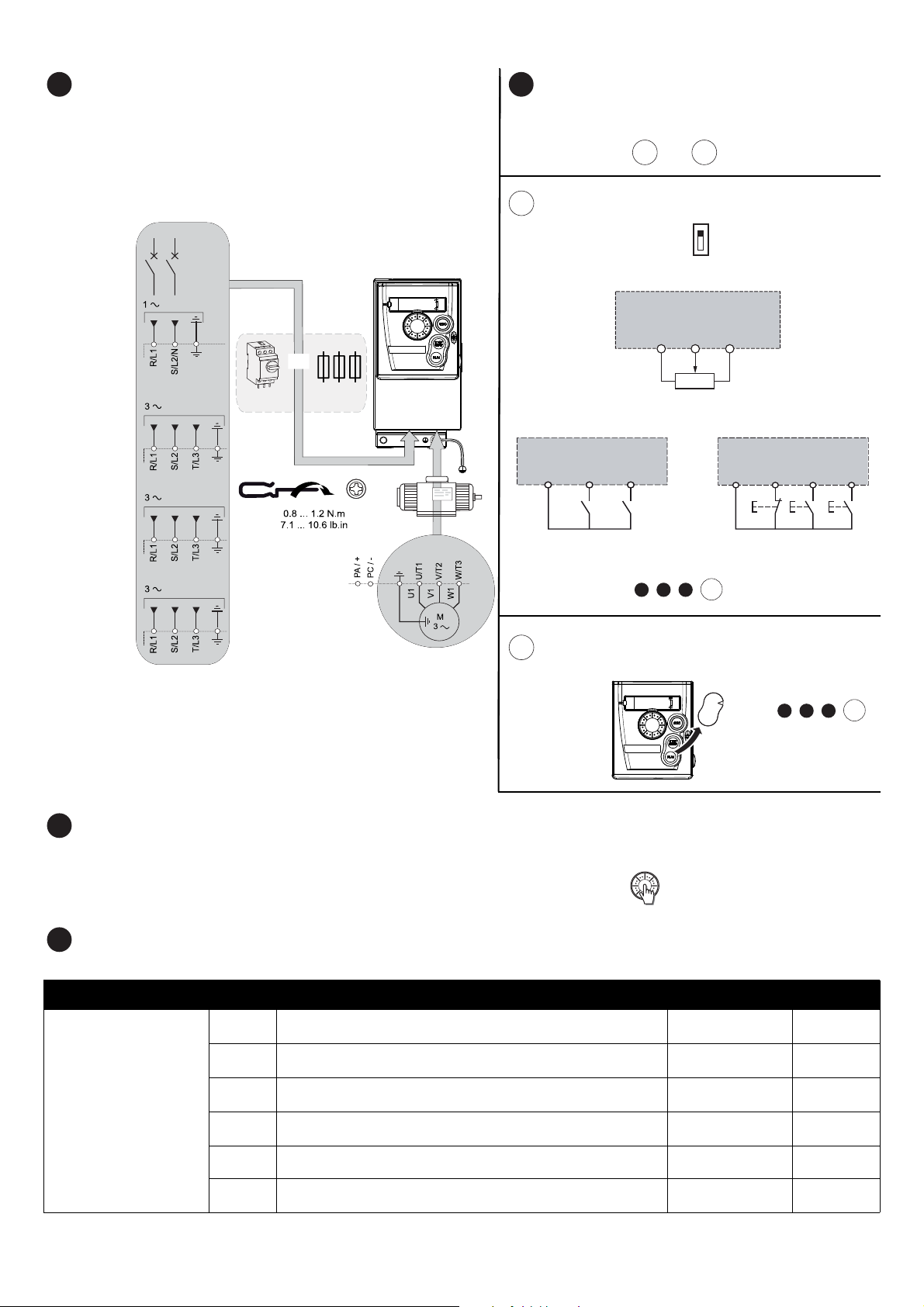

1

2

3

S1A1094203

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Only appropriately trained persons who are familiar with and understand the contents of this manual and all other pertinent product

documentation and who have received safety training to recognize and avoid hazards involved are authorized to work on and with this drive

system. Installation, adjustment, repair and maintenance must be performed by qualified personnel.

• The system integrator is responsible for compliance with all local and national electrical code requirements as well as all other applicable

regulations with respect to grounding of all equipment.

• Many components of the product, including the printed circuit boards, operate with mains voltage. Do not touch. Use only electrically

insulated tools.

• Do not touch unshielded components or terminals with voltage present.

• Motors can generate voltage when the shaft is rotated. Prior to performing any type of work on the drive system, block the motor shaft to

prevent rotation.

• AC voltage can couple voltage to unused conductors in the motor cable. Insulate both ends of unused conductors of the motor cable.

• Do not short across the DC bus terminals or the DC bus capacitors or the braking resistor terminals.

• Before performing work on the drive system:

- Disconnect all power, including external control power that may be present.

- Place a "Do Not Turn On" label on all power switches.

- Lock all power switches in the open position.

- Wait 15 minutes to allow the DC bus capacitors to discharge. The DC bus LED is not an indicator of the absence of DC bus voltage that

can exceed 800 Vdc.

- Measure the voltage on the DC bus between the DC bus terminals using a properly rated voltmeter to verify that the voltage is < 42 Vdc.

- If the DC bus capacitors do not discharge properly, contact your local Schneider Electric representative.

• Install and close all covers before applying voltage.

Failure to follow these instructions will result in death or serious injury.

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel. No responsibility is assumed by Schneider

Electric for any consequences arising out of the use of this product.

Information below is designed to use single drive connected to single motor with a motor cable length less than 50 meters (164 ft).

In any other case, consult the ATV312 installation manual (BBV46391) and programming manual (BBV46385) on www.schneider-electric.com.

Check the delivery of the drive

• Remove ATV312 from the packaging and check that it has not been damaged.

WARNING

DAMAGED DRIVE EQUIPMENT

Do not operate or install any drive or drive accessory that appears damaged.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

• Check that the drive reference printed on the label matches the delivery note and corresponding purchase order.

Write the drive Model Reference: _____________ ___________and Serial Number: ____________________________

Check the line voltage compatibility

• Check that the line voltage is compatible with the supply range of the drive.

Line voltage _______ Volts / Drive voltage range _______ Volts

Drive range: ATV312ppppM2 = 200/240 V single phase / ATV312ppppM3=200/240 V three-phase

ATV312ppppN4 = 380/500 V three-phase / ATV312ppppS6 = 525/600 V three-phase

Mount the drive vertically

For a surrounding air temperature up to 50 °C (122 °F)

8B0917121134

(a)

(a)

(a)

See installation manual (BBV46391) on www.schneider-electric.com for other thermal conditions.

www.schneider-electric.com 1/4 S1A10942 - 04/2014

(a)

(a) 50 mm (2 in.)

(b)

(b) 10 mm (0.4 in.)

4

ATV312 M2

ATV312 M3

ATV312 N4

ATV312 S6

200/240 V

380/500 V

525/600 V

REF

RUN

CAN

ERR

MON

CONF

200/240 V

or

See

SCCR annex

5

5.1

+10 v

AI 1

COM

2.2 KΩ

24 V

LI2

LI1

LIx

ATV 312

LI1: forward

LI2: reverse

LI1: stop

Control command 2-wire:

Control command 3-wire:

LI2: forward

LIx: reverse

OR

5.2

6

7

8

7

5.1

5.2

6

9.2

ENT

Connect power wiring

• Wire the drive to the ground.

• Check circuit breaker rating or fuse rating (see SCCR annex)

• Check that the motor voltage is compatible with the drive voltage.

Motor voltage ______Volts.

• Wire the drive to the motor.

• Wire the drive to the line supply.

Connect control wiring and select control configuration: or

[REMOTE configuration]

(Control by external reference)

Source

• Ensure SW1 = ‘’SOURCE’’

• Wire the speed reference:

• Wire the command:

ATV 312

LI1

24 V

LI2

CLI

SINK

•Next steps, do:

+ + +

6

9.1

[LOCAL configuration]

(control by internal reference)

CONF

RUN

REF

CAN

MON

ERR

.

Do: + + +

Apply power to the drive

• Ensure that Logic Inputs are not active (see Li1, Li2, Lix ).

• Apply power to the drive.

• At first power up, the drive displays nSt (3-wire control) or rdY(2 -wire control), after pushed drive displays bFr.

• On next start-ups, the drive displays nStor rdY .

Set motor parameters

• Refer to the motor nameplate for the following parameter settings.

[MOTOR CONTROL]

www.schneider-electric.com 2/4 S1A10942 - 04/2014

Menu Code Description Factory setting

drC-

[Standard mot. freq]:

bFr

UnS

FrS

nCr

nSP

COS

Standard motor frequency (Hz)

[Rated motor volt.]:

Nominal motor voltage on motor nameplate (V)

[Rated motor freq.]:

Nominal motor frequency on motor nameplate (Hz)

[Rated mot. current.]:

Nominal motor current on motor nameplate (A)

[Rated motor speed]:

Nominal motor speed on motor nameplate (rpm)

[Motor 1 Cosinus Phi.]:

Nominal motor cos

50.0

drive rating

50.0

drive rating

drive rating

ϕ on motor nameplate

drive rating

87

Customer

setting

Set motor parameters

7

8

9

9.1

9.2

10

LOC

35.1

rdY

3s

MODE

[Output frequency] (Hz)

• Set tUn parameter to YES.

Menu Code Description Factory setting

drC-

[MOTOR CONTROL]

tUn

DANGER DANGER

HAZARD OF ELECTRIC SHOCK OR ARC FLASH

• During auto-tuning, the motor operates at rated

current.

• Do not service the motor during auto-tuning.

Failure to follow these instructions will result in death

or serious injury.

Set basic parameters

Menu Code Description Factory setting

ACC

dEC

SEt-

[SETTINGS]

I-O-

[INPUTS / OUTPUTS CFG]

Fun-> PSS-

[PRESET SPEEDS]

Fun-> SAI-

[SUMMING INPUTS]

LSP

HSP

ItH

rrS

PS2

PS4

SA2

[Auto Tunning]:

Auto-Tunning for UnS, FrS, nCr, nSP and COS

[Acceleration]:

Acceleration time (s)

[Deceleration]:

Deceleration time (s)

[Low speed]:

Motor frequency at minimum reference (Hz)

[High speed]:

Motor frequency at maximum reference (Hz)

[Mot. therm. current]:

Nominal current on motor nameplate (A)

[Reverse assign.]:

Reverse assignment

[2 preset speeds]:

Preset speeds

[4 preset speeds]:

Preset speeds

[Summing ref. 2]

Analog input

(continued)

UNINTENDED EQUIPMENT OPERATION

•The Nominal Motor Parameters UnS, FrS, nCr, nSP and COS

• If one or more of these parameters is modified after auto-tuning has

Failure to follow these instructions will result in death or serious inju ry.

Customer

setting

nO

must be correctly configured before starting auto-tuning.

been performed, tUn will return to nOand the procedure must be

repeated.

Customer

setting

3.0

3.0

0.0

50.0

drive rating

LI2

LI3

LI4

AI2

Set control choice

Menu Code Description 5.1 [REMOTE configuration] 5.2 [LOCAL configuration] Customer Setting

CtL-

[COMMAND]

I-O-

[INPUTS / OUTPUTS CFG]

[REMOTE configuration]

(Factory setting)

Factory settings of parameters:

Fr1= AI1

tCC= 2C

Fr1

tCC

[Ref.1 channel]:

Reference control

[2/3 wire control]:

Command control

Al1 (factory setting),

Al2, Al3

2C: 2-wire (factory setting)

3C: 3-wire

[LOCAL configuration]

Factory settings of parameters:

Fr1= AIU1

tCC= LOC

= LI2

rrS

= LI3

PS2

= LI4

PS4

AlU1

LOC

Start the motor

www.schneider-electric.com 3/4 S1A10942 - 04/2014

Menus structure

SEt- ACC

dEC

26.

26.

15.

= ENT

SFr

ESC

ESC

ENT ENT

ENT

ESC

These 3 parameters are

only visible at first power up

of the drive.

Settings can be changed

subsequently in menu:

drC- for bFr

CtL- for Fr1

I-O- for tCC.

[SPEED REFERENCE]

[SETTINGS]

[MOTOR CONTROL]

[INPUTS / OUTPUTS CFG]

[COMMAND]

[APPLICATION FUNCT.]

[FAULT MANAGEMENT]

= ENT

bFr

Fr1

tCC

rEF-

SEt-

drC-

I-O-

CtL-

FUn-

FLt-

MODE

MODE

3s

LOC

rEN

MODE

3s

rdY

35.

ESC

2s

[Output frequency] (Hz)

rdY

ESC ENT

[COMMUNICATION]

[MONITORING]

COM-

SUP-

1 flash

(save)

Parameter selection

Refer to the programming manual (BBV46385) for comprehensive menu descriptions.

A dash appears after menu codes to differentiate them from parameter codes.

Example:

[SETTINGS] (SEt-), ACC parameter.

www.schneider-electric.com 4/4 S1A10942 - 04/2014

Loading...

Loading...