Page 1

Altivar 31pppT

Variable speed drives

Programming manual

Traverse control

for asynchronous motors

Traverse control

Page 2

Page 3

Table of contents

Warnings____________________________________________________________________________________________________ 2

Using the traverse control programming manual _____________________________________________________________________ 3

Factory configuration __________________________________________________________________________________________ 4

Function compatibility __________________________________________________________________________________________ 5

List of functions which can be assigned to inputs/outputs ______________________________________________________________ 6

Settings menu SEt- and motor control menu drC- ____________________________________________________________________ 7

I/O menu I-O- ________________________________________________________________________________________________ 8

Control menu CtL- ____________________________________________________________________________________________ 9

Application functions menu FUn- ________________________________________________________________________________ 11

Display menu SUP- __________________________________________________________________________________________ 22

Configuration/Settings table ____________________________________________________________________________________ 23

Communication variables ______________________________________________________________________________________ 24

NOTE: Please also refer to the "Installation

Manual" and the "Altivar 31 Programming

Manual".

1

Page 4

Warnings

When the drive is powered up, the power components and some of the control

components are connected to the line supply. It is extremely dangerous to touch

them. The drive cover must be kept closed.

In general, the drive power supply must be disconnected before any operation on

either the electrical or mechanical parts of the installation or machine.

After the ALTIVAR has been switched off and the display has disappeared

completely, wait for 10 minutes before working on the equipment. This is the time

required for the capacitors to discharge.

The motor can be stopped during operation by inhibiting start commands or the

speed reference while the drive remains powered up. If personnel safety requires

prevention of sudden restarts, this electronic locking system is not sufficient: fit

a cut-off on the power circuit..

The drive is fitted with safety devices which, in the event of a fault, can shut down

the drive and consequently the motor. The motor itself may be stopped by a

mechanical blockage. Finally, voltage variations, especially line supply failures,

can also cause shutdowns.

If the cause of the shutdown disappears, there is a risk of restarting which may

endanger certain machines or installations, especially those which must

conform to safety regulations.

In this case the user must take precautions against the possibility of restarts, in

particular by using a low speed detector to cut off power to the drive if the motor

performs an unprogrammed shutdown.

The drive must be installed and set up in accordance with both IEC international

and national standards. Bringing the device into conformity is the responsibility

of the systems integrator who must observe the EMC directive among others

within the European Union.

The specifications contained in this document must be applied in order to

comply with the essential requirements of the EMC directive.

The Altivar 31 must be considered as a component: it is neither a machine nor a

device ready for use in accordance with European directives (machinery

directive and electromagnetic compatibility directive). It is the responsibility of

the end user to ensure that the machine meets these standards.

The drive must not be used as a safety device for machines posing a potential

risk of material damage or personal injury (lifting equipment, for example). In

such applications, overspeed checks and checks to ensure that the trajectory

remains under constant control must be made by separate devices which are

independent of the drive.

The products and equipment described in this document may be changed or

modified at any time, either from a technical point of view or in the way they are

operated. Their description can in no way be considered contractual.

2

Page 5

Using the traverse control programming manual

This document should be used in conjunction with the Altivar 31 programming manual.

It describes functions and parameters that are additional or different to the Altivar 31.

Differences from the Altivar 31

• The PowerSuite software workshop cannot be used with the Altivar31pppT

• Different factory configuration (see page 4

• Compatibility of the different functions (see page 5

• Assignments of the different analog/logic output and relays (see page 8

• Diagrams of the different reference channel (see pages 9

• Application functions menu FUn-:

- Addition of the Traverse control sub-menu: tCO- (see page 17

- Different PI Regulator sub-menu: PI- (see page 20

- Deletion of Brake control menu: bLC-

- Deletion of Management of limit switch menu: LSt-

• Display menu SUP

- Addition of parameters relating to the PI function and the traverse control function (see page 22

)

)

)

and 10)

)

)

)

3

Page 6

Factory configuration

Factory settings

Factory settings which are specific to the AltivarpppT are underlined.

The Altivar 31 is factory-set for the most common operating conditions:

• Display: Drive ready (rdY) with motor stopped, and motor frequency with motor running

• Motor frequency (bFr): 50 Hz

• Constant torque application (UFt = L)

• Suppression of the speed loop filter (SrF = YES)

• Normal stop mode on deceleration ramp (Stt = rMP).

• Stop mode in the event of a fault: Freewheel

• Linear ramps (ACC, dEC): 3 seconds

• Low speed (LSP): 0 Hz

• High speed (HSP): 50 Hz

• Motor thermal current (ItH) = Nominal motor current (value depending on drive rating)

• Standstill injection braking current (SdC1) = 0.7 x nominal drive current, for 0.5 seconds

• Automatic adaptation of the deceleration ramp in the event of overvoltage on braking

• No automatic restarting after a fault

• Switching frequency 4 kHz

• Logic inputs:

- LI1: Forward, 2-wire transition detection control, non-reversing, inactive on the ATV31

LI2: Inactive (not assigned)

-

- LI3: Traverse control command

- LI4: Inactive (not assigned)

- LI5 - LI6: Inactive (not assigned)

• Analog inputs:

- AI1: Speed reference 0-10 V, inactive on ATV 31

- AI2: Summed speed reference input 0±10 V

- AI3: 4-20 mA inactive (not assigned)

• Relay R1: The contact opens in the event of a fault (or drive off)

• Relay R2: Inactive (not assigned)

• Analog output AOC: 0-20 mA inactive (not assigned)

.

ppppppAT drives (not assigned)

ppppppAT.

ATV 31ppppppAT range

When they leave the factory, ATV 31ppppppAT drives are supplied with local control activated: the RUN, STOP buttons and the drive

potentiometer are active. Both logic input LI1 and analog input AI1 are inactive (not assigned).

If the above values are compatible with the application, the drive can be used without changing the settings.

4

Page 7

Function compatibility

Incompatible functions

The following functions will be inaccessible or deactivated in the cases described below:

Automatic restart

This is only possible for 2-wire level detection control (tCC = 2C and tCt = LEL or PFO).

Flying restart

This is only possible for 2-wire level detection control (tCC = 2C and tCt = LEL or PFO).

This function is locked if the automatic DC injection on stopping is configured as Continuous (AdC = Ct).

Reverse

On the ATV31pppAT range only, this function is locked if local control is active (tCC = LOC).

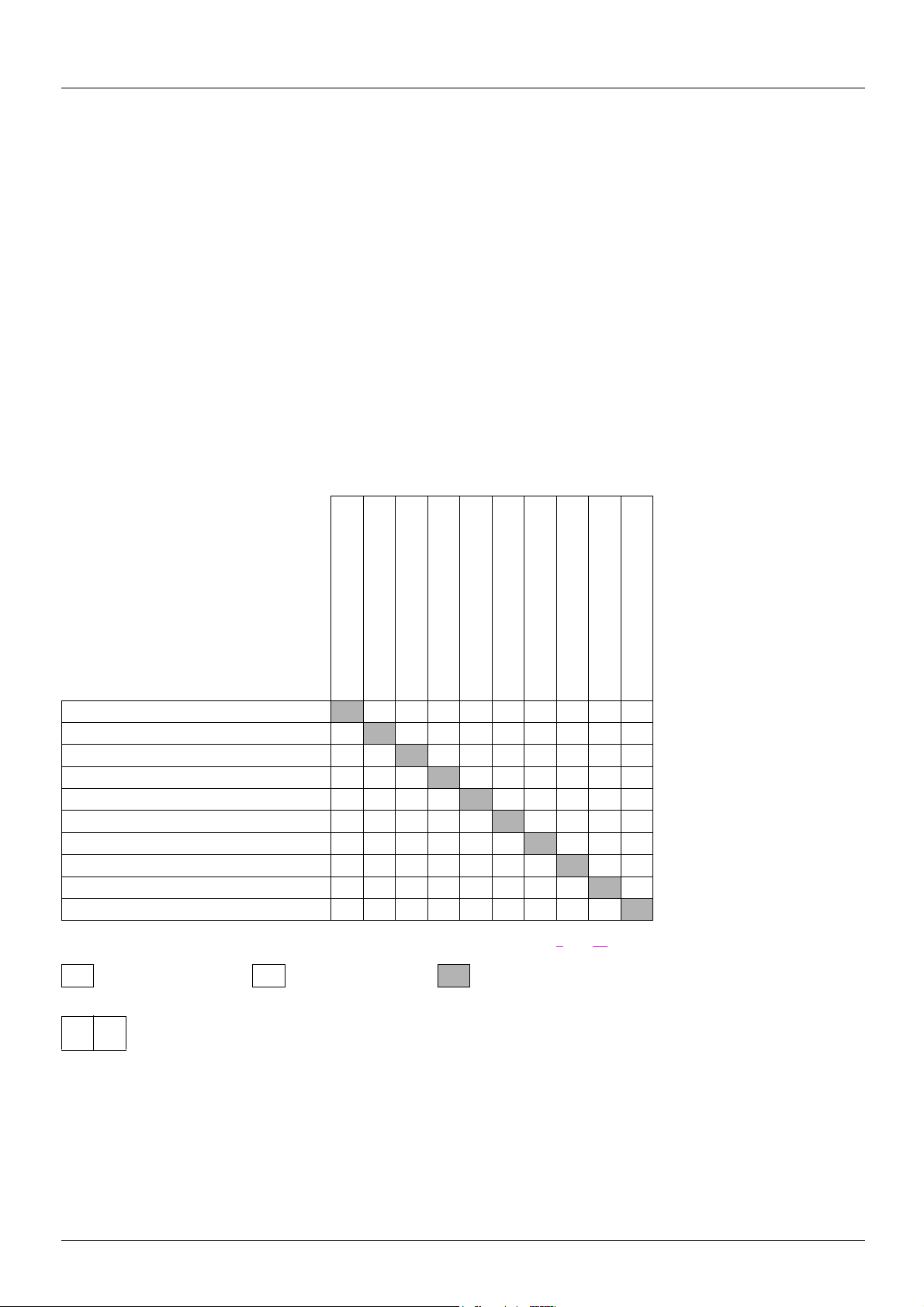

Function compatibility table

The choice of application functions may be limited by the number of I/O and by the fact that some functions are incompatible with one

another. Functions which are not listed in this table are fully compatible.

If there is an incompatibility between functions, the first function configured will prevent the remainder being configured.

To configure a function, first check that functions which are incompatible with it are unassigned, especially those which are

assigned in the factory setting.

Summed inputs (factory setting)

+/- speed (1)

Traverse control (factory setting)

Preset speeds

PI regulator

JOG operation

Summed inputs (factory setting)

+/- speed (1)

Traverse control (factory setting)

Preset speeds

PI regulator

JOG operation

Motor switching

DC injection stop

Quick stop

Freewheel stop

(1)Excluding special application with reference channel Fr2 (see diagrams on pages 9

Incompatible functions Compatible functions N/A

p

Priority functions (functions which cannot be active at the same time):

XA

Stop functions have priority over run commands.

Speed references via logic command have priority over analog references.

The function indicated by the arrow has priority over the

other.

pAA

p ppp

Xp pA

ppp

Xp Xp

X

Motor switching

A

p A

DC injection stop

Quick stop

p

XX

and 10)

Freewheel stop

A

5

Page 8

List of functions which can be assigned to inputs/outputs

Logic inputs

The assignments Limit switch forward LAF and Limit switch reverse LAr are not available on the ATV31pppT.

Addition of assignments to the "Traverse control" function.

Analog inputs

Unchanged.

Analog/logic output

Addition of assignments to the "Traverse control" function.

No "brake sequence" assignment.

Relay

Addition of assignments to the "Traverse control" function.

No "brake sequence" assignment.

6

Page 9

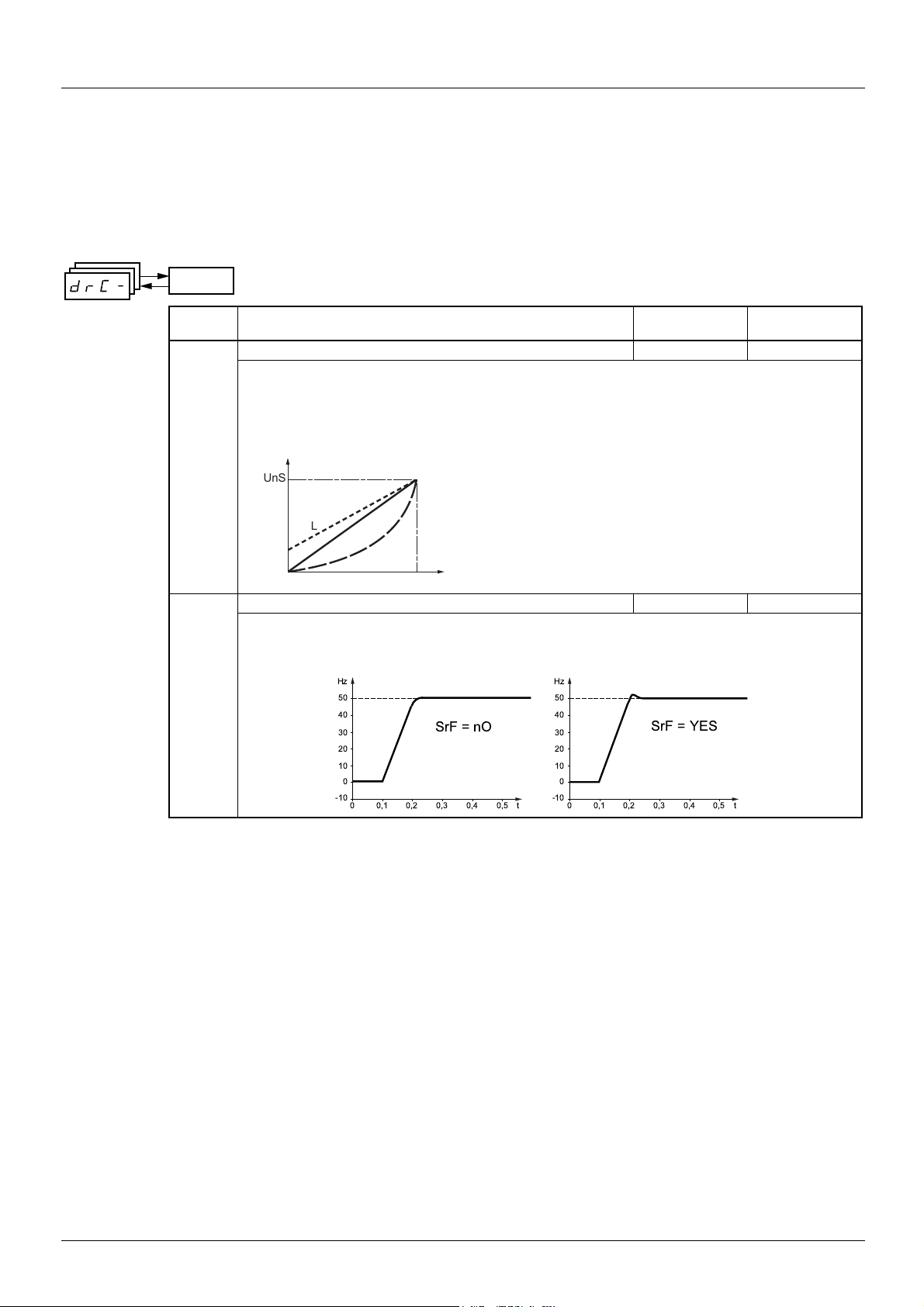

Settings menu SEt- and motor control menu drC-

Settings menu SET-

Unchanged.

Motor control menu drC-

Unchanged except for the factory setting of parameter UFt which is now "L" and the factory setting of parameter SrF which is now "YES".

drC-

Code Description Adjustment

Factory setting

range

UFt Selection of the type of voltage/frequency ratio L

L: Constant torque for motors connected in parallel or special motors

P: Variable torque: Pump and fan applications

n: Sensorless flux vector control for

constant torque applications

nLd: Energy saving, for variable torque applications not requiring high dynamics (behaves in a similar way

to the P ratio at no load and the n ratio on load).

Voltage

UnS

L

n

P

FrS

Frequency

SrF Suppression of the speed loop filter YES

nO: The speed loop filter is active (prevents the reference being exceeded).

YES: The speed loop filter is suppressed (in position control applications, this reduces the response time

and the reference may be exceeded).

7

Page 10

I/O menu I-O-

Unchanged except for the analog/logic output and relay assignments:

• No "brake sequence" assignment

• Addition of the "end of reel" assignment

• Addition of the "counter wobble synchronization" assignment

Code Description Factory setting

dO Analog/logic output AOC/AOV nO

nO: Not assigned

OCr: Motor current. 20 mA or 10 V corresponds to twice the nominal drive current

OFr: Motor frequency. 20 mA or 10 V corresponds to the maximum frequency tFr

Otr: Motor torque. 20 mA or 10 V corresponds to twice the nominal motor torque

OPr: Power supplied by the drive. 20 mA or 10 V corresponds to twice the nominal drive power.

Making the following assignments (1) will transform the analog output to a logic output (see the diagram in

the Installation Manual):

FLt: Drive fault

rUn: Drive running

FtA: Frequency threshold reached (Ftd parameter in the SEt- menu)

FLA: High speed (HSP) reached

CtA: Current threshold reached (Ctd parameter in the SEt- menu)

SrA: Frequency reference reached

tSA: Motor thermal threshold reached (ttd parameter in the SEt- menu)

APL: Loss of 4-20 mA signal, even if LFL = nO

: End of reel (parameter tbO, page 17)

EbO

: "Counter wobble" synchronization. To be configured on the thread guide drive (master) only. See

CLO

page 15

The logic output is at state 1 (24 V) when the selected assignment is active, with the exception of FLt (state

1 if the drive is not faulty).

(1) With these assignments, configure AO1t = 0A.

r1 Relay r1 FLt

nO: Not assigned

FLt: Drive fault

rUn: Drive running

FtA: Frequency threshold reached (Ftd parameter in the SEt- menu)

FLA: High speed (HSP) reached

CtA: Current threshold reached (Ctd parameter in the SEt- menu)

SrA: Frequency reference reached

tSA: Motor thermal threshold reached (ttd parameter in the SEt- menu)

APL: Loss of 4-20 mA signal, even if LFL = nO

: End of reel (parameter tbO, page 17)

EbO

: "Counter wobble" synchronization. To be configured on the thread guide drive (master) only. See

CLO

page 15

The relay is powered up when the selected assignment is active, with the exception of FLt (powered up if

the drive is not faulty).

r2 Relay r2 nO

nO: Not assigned

FLt: Drive fault

rUn: Drive running

FtA: Frequency threshold reached (Ftd parameter in the SEt- menu)

FLA: High speed (HSP) reached

CtA: Current threshold reached (Ctd parameter in the SEt- menu)

SrA: Frequency reference reached

tSA: Motor thermal threshold reached (ttd parameter in the SEt- menu)

APL: Loss of 4-20 mA signal, even if LFL = nO

: End of reel (parameter tbO, page 17)

EbO

: "Counter wobble" synchronization. To be configured on the thread guide drive (master) only. See

CLO

page 15

The relay is powered up when the selected assignment is active, with the exception of FLt (powered up if

the drive is not faulty).

8

Page 11

Control menu CtL-

Menu unchanged, but different diagrams: summed input placed after the PI

Reference channel for LAC = L1 or

Fr1

+

UPdt

UPdH

AI1

AI2

AI3

AIP

SA2

nO

AI1

AI2

AI3

AIP

SA3

speed

A

Function

page 18

speed

PI

see

Preset speeds

nO

(SP1)

SP2

SP16

LI

L2

Remote

display

terminal

LFr

LI

Jog

operation

Note: If the +/- speed command is

configured (Fr1 = UPdt or UPdH),

summed inputs SA2/SA3 are not active.

Ref: Traverse control function

base reference.

AI1

AI2

AI3

AIP

UPdt

UPdH

AI1

AI2

AI3

AIP

Key:

nO

nO

Fr2

+

speed

B

speed

Parameter:

The black square represents

the factory setting assignment

Channel 1Channel 2

rFC

YES

nO

nO nO

LCC

Modbus

Forced local mode

CANopen

Ref

FLO

"Modbus" or "CANopen" is selected online by

writing the appropriate control word (see the busspecific documentation).

Function accessible for LAC = L2

Traverse

control

see

page 12

HSP

LSP

FrH

Ramps

ACC DEC

rFr

AC2 DE2

tdntUP

9

Page 12

Control menu CtL-

Reference channel for LAC = L3

LFr

Remote

display

terminal

LFr

Remote

display

terminal

LFr

Remote

display

terminal

UPdt

UPdH

AI1

AI2

AI3

AIP

LCC

Mdb

CAn

nO

AI1

AI2

AI3

AIP

LCC

Mdb

CAn

nO

AI1

AI2

AI3

AIP

LCC

Mdb

CAn

UPdt

UPdH

Fr1

SA2

SA3

Fr2

Function

A

+

speed

speed

PI

see

page 18

+

speed

speed

Note: If the +/- speed command is configured (Fr1 = UPdt or UPdH), summed inputs

SA2/SA3 are not active.

FLOC

Preset

speeds

(SP1)

SP2

SP16

Remote

display

terminal

LFr

nO

LI

AI1

AI2

AI3

AIP

LCC

Jog

LI

Mdb

CAn

operation

Ref: Traverse control function

base reference.

Channel 1

nO

rFC

LI

Traverse

Ref

nO

FLO

Forced local mode

control

see

page

12

HSP

LSP

FrH

ACC DEC

AC2 DE2

tUP

tdn

Ramps

rFr

Channel 2

B

LFr

Remote

display

terminal

10

nO

AI1

AI2

AI3

AIP

LCC

Mdb

CAn

Key:

Parameter:

The black square represents

the factory setting assignment

Page 13

Application functions menu FUn-

FUn-

ENT

ESC

ESC

ESC

tCO-

rPC-

FCS

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

Traverse control additional

sub-menu

Sub-menu

The parameters can only be modified when the drive is stopped and no run command is present.

On the optional remote display terminal, this menu can be accessed with the switch in the position.

Some functions have numerous parameters. In order to clarify programming and avoid having to scroll through endless parameters, these

functions have been grouped in sub-menus.

Like menus, sub-menus are identified by a dash after their code: for example.

There may be an incompatibility between functions (see the incompatibility table page 5

PSS-

). In this case, the first function configured

will prevent the remainder being configured.

Additional sub-menu: Traverse control: tCO-

Modified sub-menu: PI regulator: PI-

Deleted sub-menus: Brake control: bLC-

Management of limit switches: LSt-

11

Page 14

Application functions menu FUn-

Traverse control

Function for winding reels of thread (in textile applications)

Traverse control

drive

Traverse control motor

Winding

drive

Winding motor

Gearbox

Gearbox

Reel of thread

Main shaft

Thread guide

Thread

Cam

The cam speed of rotation must follow a precise profile to ensure that the reel is steady, compact and linear:

Run command

Traverse control

Command bit or LI

Motor speed

ACC ramp

Base reference

ACC

ramp

start of function

Bit 15 of word LRS1

(traverse control active)

t

t

dEC ramp

t

end of function

t

The function starts when the drive has reached its base reference and the traverse control command has been enabled.

When the traverse control command is disabled, the drive returns to its base reference, following the drive ACC or dEC ramp. The function

then stops, as soon as it has returned to this reference.

Bit 15 of word LRS1 is at 1 while the function is active.

12

Page 15

Application functions menu FUn-

Function parameters:

They define the cycle of frequency variations around the base reference, as shown in the figure below:

Motor speed

Base

reference

0

• trC: Traverse control command: Assignment of the traverse control command to a logic input or to a communication bus control word bit

• tdn: Traverse control deceleration time, in seconds

• tUP: Traverse control acceleration time, in seconds

• trH: "traverse frequency high" in Hertz

• trL: "traverse frequency low" in Hertz

• qSH "quick step high" in Hertz

• qSL "quick step low" in Hertz

tdn

tUP

Frequency skip

Frequency skip

qSH

trH

trL

qSL

t

Reel parameters:

• tbO: Time taken to make a reel, in minutes.

This parameter is intended to signal the end of winding. When the traverse control operating time since command trC reaches

the value of tbO, the logic output or one of the relays changes to state 1, if the corresponding function EbO has been assigned

in menu I-O-.

The traverse control operating time EbOt can be monitored online by a communication bus and in the Display menu SUP-.

• dtF: Decrease in the base reference.

In certain cases, it is necessary to reduce the base reference as and when the reel increases in size. The value dtF corresponds

to the time tbO. Once this time has elapsed, the reference continues to fall, following the same ramp.

If low speed LSP is at 0, the speed reaches 0 Hz, the drive stops and must be reset by a new run command.

If low speed LSP is anything but 0, the traverse control function continues to operate above LSP.

Motor speed

Base reference

0

Motor speed

Base reference

tbO

dtF

dtF

With LSP = 0

t

With LSP > 0

LSP

0

tbO

t

13

Page 16

Application functions menu FUn-

• rtr: Traverse control reset

This command can be assigned to a logic input or to a communication bus control word bit. It resets the EbO alarm and the EbOt

operating time to zero and reinitializes the reference to the base reference. As long as rtr remains at 1 the traverse control function

is inhibited and the speed remains the same as the base reference.

This command is mainly used when changing reels.

Motor speed

Base reference

dtF

Run

trC

0

tbO

0

0

t

t

t

EbOt

tbO

bit 15 of LRS1

EbO

rtr

0

0

0

0

t

t

t

t

14

Page 17

Application functions menu FUn-

Counter wobble

Master drive Slave drive

CLO SnC

Synchronization

Gearbox

Reel of thread

Main shaft

Winding motor

Thread

guide

Thread

Gearbox

Thread guide motor

Cam

The "Counter wobble" function is used, in certain applications, to obtain a constant thread tension when the Traverse control function causes

significant variations in speed on the thread guide motor (trH and trL see page 13

).

Two special "Traverse control" drives must be used (a master and a slave).

The master controls the speed of the thread guide, the slave controls the winding speed. The function gives the slave a speed ratio in

anti-phase with that of the master. A synchronization operation is therefore necessary, using a master logic output and a slave logic input.

Run command

affecting master and

slave

t

Traverse control

command affecting

master and slave

Thread guide motor

speed

(master drive)

CLO/SnC synchronization

Winding motor speed

(slave drive)

t

trH

trL

t

t

trH

trL

t

15

Page 18

Application functions menu FUn-

Connecting the synchronization I/O

Master drive Slave drive

ATV31 ATV31

(CLO) AOV

COM

Preferably, logic output AOV should be used.

The starting conditions for the function are:

- Base speeds of both drives reached

- "Traverse control command" input trC activated

- Synchronization signal present

Note: On the slave drive, parameters qSH and qSL should usually be left at zero.

LIp (SnC)

COM

16

Page 19

Application functions menu FUn-

FUn-

Code Description Adjustment

tCO- Traverse control

trC Traverse control command LI3

trH Traverse frequency high (1) 0 to 10 Hz 4 Hz

trL Traverse frequency low (1) 0 to 10 Hz 4 Hz

qSH Quick step high (1) 0 to trH 0 Hz

qSL Quick step low (1) 0 to trL 0 Hz

tUP Traverse control acceleration time (1) 0.1 to 999.9 s 4 s

tdn Traverse control deceleration time (1) 0.1 to 999.9 s 4 s

tbO Time taken to make a reel (1) 0 to 9999 minutes 0

dtF Decrease in the base reference (1) 0 to 500 Hz 0

rtr Traverse control reset nO

Caution the "Traverse control" function may be incompatible with other functions (see

)

page 5

nO: Not assigned

LI1: Logic input LI1

LI2: Logic input LI2

LI3: Logic input LI3

LI4: Logic input LI4

LI5: Logic input LI5

LI6: Logic input LI6

If LAC = L3, the following assignments are possible:

Cd11: Bit 11 of the Modbus or CANopen control word

Cd12: Bit 12 of the Modbus or CANopen control word

Cd13: Bit 13 of the Modbus or CANopen control word

Cd14: Bit 14 of the Modbus or CANopen control word

Cd15: Bit 15 of the Modbus or CANopen control word

nO: Not assigned

LI1: Logic input LI1

LI2: Logic input LI2

LI3: Logic input LI3

LI4: Logic input LI4

LI5: Logic input LI5

LI6: Logic input LI6

range

Factory setting

SnC "Counter wobble" synchronization nO

(1)Parameter can be adjusted during operation.

These parameters only appear if the function has been enabled by assignment of trC.

If LAC = L3, the following assignments are possible:

Cd11: Bit 11 of the Modbus or CANopen control word

Cd12: Bit 12 of the Modbus or CANopen control word

Cd13: Bit 13 of the Modbus or CANopen control word

Cd14: Bit 14 of the Modbus or CANopen control word

Cd15: Bit 15 of the Modbus or CANopen control word

nO: Not assigned (function inactive)

LI1: Logic input LI1

LI2: Logic input LI2

LI3: Logic input LI3

LI4: Logic input LI4

LI5: Logic input LI5

LI6: Logic input LI6

To be configured on the winding drive (slave) only.

17

Page 20

Application functions menu FUn-

PI regulator

Diagram

The function is activated by assigning an analog input to the PI feedback (measurement).

Internal

reference

rPI

YES

nO

Reference A

Pages 9

and 10

PII

(rP1)

rP2

rP3

rP4

LI

Pr2

Pr4

nO

inversion

nO

YES

Error

x1

x(-1)

PIC

+

-

Reference A

pages 9

Restart error

threshold

(wake-up)

tLS

rSL

0

Gains

and 10

Preset PI

PIF

nO

PI

feedback

AI1

AI2

AI3

Reference B Pages 9

references

FbS

x FbS

and 10

PI feedback:

The PI feedback must be assigned to one of the analog inputs (AI1, AI2 or AI3).

PI reference:

The PI reference can be assigned to the following parameters in order of priority:

- Preset references via logic inputs (rP2, rP3, rP4)

- Internal reference (rPI)

- Reference Fr1

rPG

PIF

rIG

POH

POL

nO

AI1

AI2

AI3

(auto)

(manu)

rFC

Key:

Parameter:

The black square

represents the

factory setting

assignment

HSP

FrH

LSP

Ramps

ACC DEC

AC2 DE2

tdn

tUP

rFr

Combination table for preset PI references

LI (Pr4) LI (Pr2) Pr2 = nO Reference

rPI or Fr1

00 rPI or Fr1

01 rP2

10 rP3

11 rP4

Adjustment parameters:

• Internal reference (rPI)

• Preset references (rP2, rP3, rP4)

• Regulator proportional gain (rPG)

• Regulator integral gain (rIG)

• FbS parameter:

The FbS parameter can be used to scale the reference on the basis of the variation range of the PI feedback (sensor rating).

E.g.: Regulation of the thread tension

PI reference (process) 0-5 Newton (0-100%)

Rating of tension sensor 0-10 Newton

FbS = Max. sensor scale/Max. process

FbS = 10/5= 2

• rSL parameter:

Can be used to set the PI error threshold above which the PI regulator will be reactivated (wake-up) after a stop due to the max. time

threshold being exceeded at low speed (tLS).

• Reversal of the direction of correction (PIC): If PIC = nO, the speed of the motor will increase when the error is positive, for example:

pressure control with a compressor. If PIC = YES, the speed of the motor will decrease when the error is positive, for example:

temperature control via a cooling fan.

• PI regulator min. (OPL) and max. (OPH) outputs.

Parameter which can be accessed in the display menu SUP-:

• PI feedback (rPF).

18

Page 21

Application functions menu FUn-

"Manual - Automatic" operation with PI

This function combines the PI regulator and the switching of reference rFC. The speed reference is given by Fr2 or by the PI function,

depending on the state of the logic input.

Setting up the PI regulator

1 Configuration in PI mode

See the diagram on page 18

2 Perform a test in factory settings mode (in most cases, this will be sufficient).

To optimize the drive, adjust rPG or rIG gradually and independently and observe the effect on the PI feedback in relation to the reference.

3 If the factory settings are unstable or the reference is incorrect:

Perform a test with a speed reference in Manual mode (without PI regulator) and with the drive on load for the speed range of the system:

- In steady state, the speed must be stable and comply with the reference and the PI feedback signal must be stable.

- In transient state, the speed must follow the ramp and stabilize quickly and the PI feedback must follow the speed.

If this is not the case, see the settings for the drive and/or sensor signal and cabling.

Switch to PI mode.

Set brA to nO (no auto-adaptation of the ramp).

Set the speed ramps (ACC, dEC) to the minimum permitted by the mechanics without triggering an ObF fault.

Set the integral gain (rIG) to minimum.

Observe the PI feedback and the reference.

Switch the drive ON/OFF a number of times or vary the load or reference rapidly.

Set the proportional gain (rPG) in order to ascertain the ideal compromise between response time and stability in transient phases (slight

overshoot and 1 to 2 oscillations before stabilizing).

If the reference varies from the preset value in steady state, gradually increase the integral gain (rIG), reduce the proportional gain (rPG)

in the event of instability (pump applications), find a compromise between response time and static precision (see diagram).

Perform in-production tests throughout the reference range.

.

Regulated value

Proportional

gain

Integral

gain

Reference

Reference

Reference

Stabilization time

rPG high

Overshoot

Static error

rPG low

Rise time

time

rIG high

rIG low

time

rPG and rIG correct

The oscillation frequency depends on the system kinematics.

Parameter Rise time Overshoot

rPG

rIG

Stabilization

time

=

time

Static error

19

Page 22

Application functions menu FUn-

FUn-

Code Description Adjustment range Factory setting

PI- PI regulator

PIF PI regulator feedback nO

nO: Not assigned

AI1: Analog input AI1

AI2: Analog input AI2

AI3: Analog input AI3

rPG PI regulator proportional gain (1) 0.01 to 100 1

Contributes to dynamic performance during rapid changes in the PI feedback.

rIG PI regulator integral gain (1) 0.01 to 100 1

Contributes to static precision during slow changes in the PI feedback.

FbS PI feedback multiplication coefficient (1) 0.1 to 100 1

For process adaptation

PIC Reversal of the direction of correction of the PI

regulator (1)

nO: normal

YES: reverse

Pr2 2 preset PI references nO

Selecting the assigned logic input activates the function.

nO: Not assigned

LI1: Logic input LI1

LI2: Logic input LI2

LI3: Logic input LI3

LI4: Logic input LI4

LI5: Logic input LI5

LI6: Logic input LI6

nO

If LAC = L3, the following assignments are possible:

Cd11: Bit 11 of the Modbus or CANopen control word

Cd12: Bit 12 of the Modbus or CANopen control word

Cd13: Bit 13 of the Modbus or CANopen control word

Cd14: Bit 14 of the Modbus or CANopen control word

Cd15: Bit 15 of the Modbus or CANopen control word

Pr4 4 preset PI references nO

Selecting the assigned logic input activates the function.

Check that Pr2 has been assigned before assigning Pr4.

nO: Not assigned

LI1: Logic input LI1

LI2: Logic input LI2

LI3: Logic input LI3

LI4: Logic input LI4

LI5: Logic input LI5

LI6: Logic input LI6

If LAC = L3, the following assignments are possible:

Cd11: Bit 11 of the Modbus or CANopen control word

Cd12: Bit 12 of the Modbus or CANopen control word

Cd13: Bit 13 of the Modbus or CANopen control word

Cd14: Bit 14 of the Modbus or CANopen control word

Cd15: Bit 15 of the Modbus or CANopen control word

rP2 2

rP3 3

rP4 4

nd

preset PI reference (1) 0 to 100% 30%

Only appears if Pr2 has been enabled by selecting an input.

rd

preset PI reference (1) 0 to 100% 60%

Only appears if Pr4 has been enabled by selecting an input.

th

preset PI reference (1) 0 to 100% 90%

Only appears if Pr4 has been enabled by selecting an input.

(1)Parameter can also be accessed in the settings menu SEt-, and can be adjusted during operation.

These parameters only appear if the function has been enabled by assignment of PIF.

20

Page 23

Application functions menu FUn-

FUn-

Code Description Adjustment

PI-

(continued)

(1)Parameter can also be accessed in the settings menu SEt-, and can be adjusted during operation.

(2)Parameter can be adjusted during operation

These parameters only appear if the function has been enabled by assignment of PIF.

rSL Restart error threshold ("wake-up" threshold) 0 to 100% 0

If the "PI" and "Low speed operating time" tLS functions are configured at the same time,

the PI regulator may attempt to set a speed lower than LSP.

This results in unsatisfactory operation which consists of starting, operating at low speed

then stopping, and so on…

Parameter rSL (restart error threshold) can be used to set a minimum PI error threshold

for restarting after a stop at prolonged LSP.

The function is inactive if tLS = 0.

PII Internal PI regulator reference nO

nO: The PI regulator reference is Fr1, except for UPdH and UPdt (+/- speed cannot be

used as the PI regulator reference).

YES: The PI regulator reference is internal via parameter rPI.

rPI Internal PI regulator reference (1) 0 to 100% 0

POH PI regulator max. output (2) 0 to 500 Hz 50

Maximum value of the regulator output (deadband). The factory setting is 50 Hz, or 60 Hz

if bFr is set to 60 Hz.

POL PI regulator min. output (2) 0 to 500 Hz 0

Minimum value of the regulator output, even when there are no errors.

range

Factory setting

21

Page 24

Display menu SUP-

Additional parameters:

• PI feedback

• Traverse control operating time

SUP-

Code Description Variation range

LFr Unchanged

rPI

rPF PI feedback 0 to 100%

FrH

Unchanged

tHd

EbOt Traverse control operating time 0 to 9999 minutes

LFt

to Unchanged

AI3A

These parameters only appear if the function has been enabled.

22

Page 25

Configuration/Settings table

Application functions menu

Code Factory setting Customer

tCO- trC LI3 PSS-

trH 4 Hz Hz SP10 50 Hz Hz

trL 4 Hz Hz SP11 55 Hz Hz

qSH 0 Hz Hz SP12 60 Hz Hz

qSL 0 Hz Hz SP13 70 Hz Hz

tUP 4 s s SP14 80 Hz Hz

tdn 4 s s SP15 90 Hz Hz

tbO 0 min min SP16 100 Hz Hz

dtF 0 Hz Hz JOG- JOG If tCC = 2C: nO

rtr nO If tCC = 3C: LI4

SnC nO If tCC = LOC: nO

rPC- rPt LIn

tA1 10% % UPd- USP nO

tA2 10% % dSP nO

tA3 10% % Str nO

tA4 10% % PI- PIF nO

ACC 3 s s

dEC 3 s s

rPS nO

Frt 0Hz

AC2 5 s s Pr2 nO

dE2 5 s s Pr4 nO

brA YES

StC- Stt rMP

FSt nO

dCF 4 rSL 0

dCI nO

IdC 0.7 In A rPI 0% %

tdC 0.5 s s POH 50 Hz Hz

nSt nO

AdC- AdC YES LC2- LC2 nO

tdC1 0.5 s s CL2 1.5 In (1) A

SdC1 0.7 In (1) A CHP- CHP nO

tdC2 0 s s UnS2 According to drive rating V

SdC2 0.5 In (1) A FrS2 50 Hz Hz

SAI- SA2 AI2

SA3 nO

PSS- PS2 If tCC = 2C: LI3

If tCC = 3C: LI4

If tCC = LOC: LI3

PS4 If tCC = 2C: LI4

If tCC = 3C: nO

If tCC = LOC: LI4

PS8 nO

PS16 nO

SP2 10 Hz Hz (1) In corresponds to the nominal drive current indicated in the

SP3 15 Hz Hz

SP4 20 Hz Hz These parameters only appear if the corresponding

SP5 25 Hz Hz

SP6 30 Hz Hz

SP7 35 Hz Hz

SP8 40 Hz Hz

FUn-

Code Factory setting Customer

setting

SP9 45 Hz Hz

JGF 10 Hz Hz

rPG 1

rIG 1

FbS 1

PIC nO

rP2 30% %

rP3 60% %

rP4 90% %

PII nO

POL 0 Hz Hz

nCr2 According to drive rating A

nSP2 According to drive rating RPM

COS2 According to drive rating

UFt2 n

UFr2 20% %

FLG2 20% %

StA2 20% %

SLP2 100 Hz Hz

installation manual and on the drive rating plate

function has been enabled. They can be adjusted during

operation.

setting

23

Page 26

Communication variables

The communication variables user's manual should be used, filling in the following information for the different or additional parameters.

NOTE:

The communication variables are listed with:

• Their address •••• in decimal format for Modbus

• Their index and subindex address ••••/•• in hexadecimal format for CANopen

Read/write

Whether the parameters have read and/or write access is indicated in the "Read/Write" column with the following codes:

• R: read only, drive stopped or running

• R/WS: read access when drive stopped or running and write access only when drive stopped

• R/W: read and write access when drive stopped or running

The variables or values specific to the ATV31

pppT are underlined.

Monitoring variables

Modbus

address

3250 2002 / 33 LRS1 R Extended status word No. 1

11981 2059 / 52 rPF R PI feedback

12209 205C / A EbOt R Traverse control operating time

CANopen

address

Code

Read/

Write

Name/Description/Possible values

bit 0: Reserved

bit 1 = 0: No drive fault

bit 1 = 1: Drive fault

bit 2 = 0: Motor stopped

bit 2 = 1: Motor running

bit 3: Reserved

bit 4 = 0: Frequency threshold (Ftd) not reached

bit 4 = 1: Frequency threshold (Ftd) reached

bit 5 = 0: High speed not reached

bit 5 = 1: High speed reached

bit 6 = 0: Current threshold (Ctd) not reached

bit 6 = 1: Current threshold (Ctd) reached

bit 7 = 0: Speed reference not reached

bit 7 = 1: Speed reference reached

bit 8 = 0: No motor thermal overload alarm

bit 8 = 1: Motor thermal overload alarm

bit 9: Reserved

bits 10 and 11: Reserved

bit 12 = 0: No loss of 4-20 mA fault

bit 12 = 1: Loss of 4-20 mA fault

bit 13: Reserved

bit 14 = 0: No drive thermal overload alarm

bit 14 = 1: Drive thermal overload alarm

bit 15 = 0: No traverse control

bit 15 = 1: Traverse control active

Unit: 0.01%

Unit: 1 minute

This parameter is reset by command rtr.

24

Page 27

Communication variables

Configuration and adjustment variables

Modbus

address

9607 2042 / 8 UFt R/WS Selection of the type of voltage/frequency ratio

9101 203D / 2 SrF R/WS Suppression of the speed loop filter

5031 2014 / 20 dO R/WS Analog/logic output AOC/AOV

CANopen

address

Code

Read/

Write

Name/Description/Possible values

Factory setting: 0

0 = "L": Constant torque for motors connected in parallel or special motors

1 = "P": Variable torque: Pump and fan applications

2 = "n": Sensorless flux vector control for constant torque applications

3 = "nLd": Energy saving, for variable torque applications not requiring high dynamics (behaves

in a similar way to the P ratio at no load and the n ratio on load).

Factory setting: 1

0 = "nO": The speed loop filter is active (prevents the reference being exceeded).

1 = "YES": The speed loop filter is suppressed (in position control applications, this reduces the

response time and the reference may be exceeded).

Factory setting: 0

0 = "nO": Not assigned

For the following assignments the output is analog type:

129 = "OCr": Motor current. 20 mA or 10 V corresponds to twice the nominal drive current.

130 = "OFr": Motor frequency. 20 mA or 10 V corresponds to the maximum frequency tFr

132 = "Otr": Motor torque. 20 mA or 10 V corresponds to twice the nominal motor torque.

139 = "OPr": Power supplied by the drive. 20 mA or 10 V corresponds to twice the nominal drive

power

For the following assignments the output is logic type (see diagram in the Installation Manual):

1 = "FLt": Drive fault

2 = "rUn": Drive running

4 = "FtA": Frequency threshold reached (Ftd parameter)

5 = "FLA": High speed (HSP) reached

6 = "CtA": Current threshold reached (Ctd parameter)

7 = "SrA": Frequency reference reached

8 = "tSA": Motor thermal threshold reached (ttd parameter)

12 = "APL": Loss of 4-20 mA signal, even if LFL = nO

101 = "EbO": End of reel

102 = "CLO": "Counter wobble" synchronization

The logic output is at state 1 (24 V) when the selected assignment is active, with the exception

of FLt (state 1 if the drive is not faulty).

5001 2014 / 2 r1 R/WS Relay r1

Factory setting: 1

0 = "nO": Not assigned

1 = "FLt": Drive fault

2 = "rUn": Drive running

4= "FtA": Frequency threshold reached (Ftd parameter)

5 = "FLA": High speed (HSP) reached

6 = "CtA": Current threshold reached (Ctd parameter)

7 = "SrA": Frequency reference reached

8 = "tSA": Motor thermal threshold reached (ttd parameter)

12 = "APL": Loss of 4-20 mA signal, even if LFL = nO

101 = "EbO": End of reel

102 = "CLO": "Counter wobble" synchronization

The relay is powered up when the selected assignment is active, with the exception of FLt

(powered up if the drive is not faulty).

With these assignments, configure AO1t = 0A.

(parameter tbO page 17)

(parameter tbO page 17)

25

Page 28

Communication variables

Configuration and adjustment variables

Modbus

address

5002 2014 / 3 r2 R/WS Relay r2

11952 2059 / 35 POL R/W PI regulator min. output

11953 2059 / 36 POH R/W PI regulator max. output

12201 205C / 2 trC R/WS Traverse control command

CANopen

address

Code

Read/

Write

Factory setting: 0

0 = "nO": Not assigned

1 = "FLt": Drive fault

2 = "rUn": Drive running

4 = "FtA": Frequency threshold reached (Ftd parameter)

5 = "FLA": High speed (HSP) reached

6 = "CtA": Current threshold reached (Ctd parameter)

7 = "SrA": Frequency reference reached

8 = "tSA": Motor thermal threshold reached (ttd parameter)

12 = "APL": Loss of 4-20 mA signal, even if LFL = nO

101 = "EbO": End of reel

102 = "CLO": "Counter wobble" synchronization

The relay is powered up when the selected assignment is active, with the exception of FLt

(powered up if the drive is not faulty).

Unit: 0.1 Hz

Factory setting: 0

Adjustment range: 0 to 5000

Unit: 0.1 Hz

Factory setting: 500 if bFr = 50 Hz,

600 if bFr = 60 Hz

Adjustment range: 0 to 5000

Factory setting: 0

0 = "nO": Not assigned

129 = "LI1": Logic input LI1

130 = "LI2": Logic input LI2

131 = "LI3": Logic input LI3

132 = "LI4": Logic input LI4

133 = "LI5": Logic input LI5

134 = "LI6": Logic input LI6

(parameter tbO page 17)

Name/Description/Possible values

If LAC = L3, the following assignments are possible:

171 = "Cd11": bit 11 of the CMD control word written by Modbus or CANopen

172 = "Cd12": bit 12 of the CMD control word written by Modbus or CANopen

173 = "Cd13": bit 13 of the CMD control word written by Modbus or CANopen

174 = "Cd14": bit 14 of the CMD control word written by Modbus or CANopen

175 = "Cd15": bit 15 of the CMD control word written by Modbus or CANopen

The function is activated when the logic state of the input or control word bit is at 1.

12202 205C / 3 trH R/W Traverse frequency high

12203 205C / 4 trL R/W Traverse frequency low

12204 205C / 5 qSH R/W Quick step high

12205 205C / 6 qSL R/W Quick step low

12206 205C / 7 tUP R/W Traverse control acceleration time

Unit: 0.01 Hz

Factory setting: 400

Adjustment range: 0 to 1000

Unit: 0.01 Hz

Factory setting: 400

Adjustment range: 0 to 1000

Unit: 0.01 Hz

Factory setting: 0

Adjustment range: 0 to trH

Unit: 0.01 Hz

Factory setting: 0

Adjustment range: 0 to trL

Unit: 0.1 s

Factory setting: 40

Adjustment range: 1 to 9999

26

Page 29

Communication variables

Configuration and adjustment variables

Modbus

address

12207 205C / 8 tdn R/W Traverse control deceleration time

12208 205C / 9 tbO R/W Time taken to make a reel

12210 205C / B rtr R/WS Traverse control reset

12211 205C / C dtF R/W Decrease in the base reference

12212 205C / D SnC R/WS "Counter wobble" synchronization

CANopen

address

Code

Read/

Write

Name/Description/Possible values

Unit: 0.1 s

Factory setting: 40

Adjustment range: 1 to 9999

Unit: 1 minute

Factory setting: 0

Adjustment range: 0 to 9999

Factory setting: 0

0 = "nO": Not assigned

129 = "LI1": Logic input LI1

130 = "LI2": Logic input LI2

131 = "LI3": Logic input LI3

132 = "LI4": Logic input LI4

133 = "LI5": Logic input LI5

134 = "LI6": Logic input LI6

If LAC = L3, the following assignments are possible:

171 = "Cd11": bit 11 of the CMD control word written by Modbus or CANopen

172 = "Cd12": bit 12 of the CMD control word written by Modbus or CANopen

173 = "Cd13": bit 13 of the CMD control word written by Modbus or CANopen

174 = "Cd14": bit 14 of the CMD control word written by Modbus or CANopen

175 = "Cd15": bit 15 of the CMD control word written by Modbus or CANopen

The function is activated when the logic state of the input or control word bit is at 1.

Unit: 0.1 Hz

Factory setting: 0

Adjustment range: 0 to 5000

Factory setting: 0

0 = "nO": Not assigned

129 = "LI1": Logic input LI1

130 = "LI2": Logic input LI2

131 = "LI3": Logic input LI3

132 = "LI4": Logic input LI4

133 = "LI5": Logic input LI5

134 = "LI6": Logic input LI6

The function is activated when the logic state of the input is at 1.

27

Page 30

DIA2ED3040202 EN

atv31_traverse control_EN_V1

2004-05

Loading...

Loading...