Scanwill

Scanwill

Fluid Power

ApS

The MP-Series of Hydraulic

Pressure Intensifiers

Applications:

Hydraulic Workholding on Machine Tools

Static and Impulse Testing Equipment

Hydraulic Power Packs

Stone Chrushing Machines

Subsea R.O.V.’s

Hydraulic Construction Tools

Press Applications

Demolition Tools

Pressure Die Casting Machines

Quick Die Changing Equipment

Scanwill

Scanwill

Fluid Pow er ApS

Application Examples

Page 11

Specials & Accessories

Page 10

2

The MP-T Series

In-Line Pressure In ten si fi er

Rating to 800 Bar /11,600 PSI

Multiple Intensifi cations

Reciprocating - Continous Flow

High Pressure Valves in te grat ed Page 4

The MP-C Series

Page 5

Cetop D03/NG6 Pressure In ten si fi er

Rating to 500 Bar / 7,000 PSI

Multiple Intensifi cations

Reciprocating - Continous Flow

High Pressure Valves in te grat ed

The MP-F Series

Flange-On Pressure In ten si fi er

Rating to 700 Bar / 10,000 PSI

Multiple Intensifi cations

Reciprocating - Continous Flow

High Pressure Valves in te grat ed Page 6

The MP-2000 Series

In-Line Pressure In ten si fi er

Rating to 2,000 Bar / 29,000 PSI

Multiple Intensifi cations

Reciprocating - Continous Flow

High Pressure Valves in te grat ed Page 7

The MP-M Series

In-Line Pressure Intensifi er for fl ows up to 35 LPM

Rating to 800 Bar / 11,600 PSI

Multiple Intensifi cations

Reciprocating - Continous Flow

High Pressure Valves in te grat ed Page 8

The MP-L Series

In-Line Pressure Intensifi er for fl ows up to 80 LPM

Rating to 800 Bar / 11,600 PSI

Multiple Intensifi cations

Reciprocating - Continous Flow

High Pressure Valves in te grat ed Page 9

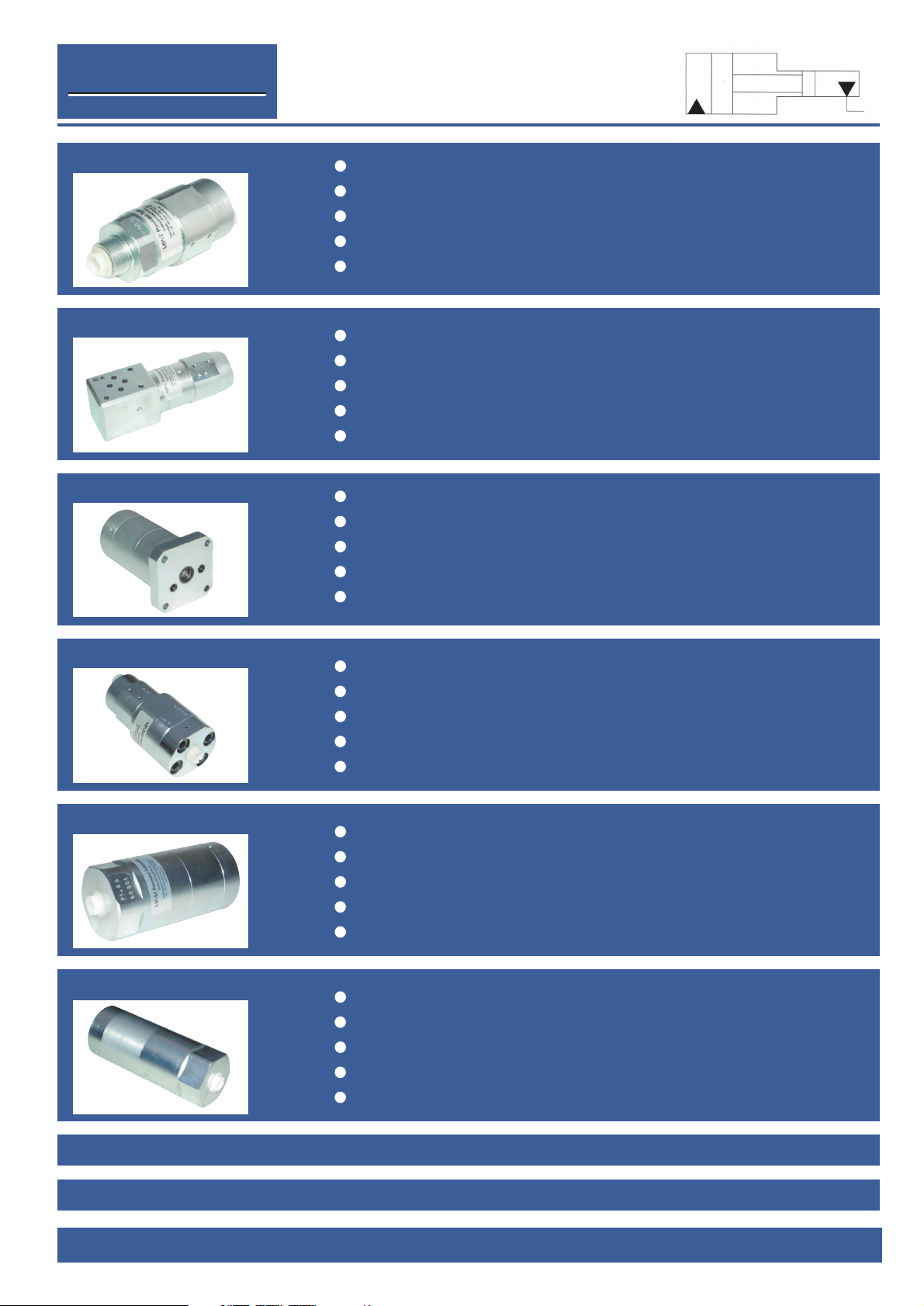

The MP-Series of hydraulic pressure intensifi ers are

reciprocating, and will automatically increase a supplied pressure to a higher end pressure. Fig. 1 shows

the basic principle of the intensifi ers, consisting of a

piston arrangement and a Piston Control Valve, PCV.

The position of the pistons will at the end of every stroke

prompt a signal S to the PCV, which makes this change

position, ensuring the pistons are moving in the opposite

direction. This cycle will continue until the end pressure

has been reached. At this point the pistons stop, and will

now only move to maintain the end pressure.

Function:

Fig. 1:

When a hydraulic fl uid is supplied to the P-connection of

the intensifi er and the T-connection is connected to tank,

the oil will be directed through the check valves CV1 and

CV2 to the high pressure connection HP. If the internal

pilot operated check valve POV is incorporated the oil will

go straight to the HP connection. In this situation all the

fl ow supplied goes to the high pres su re side ensuring a

fast fi lling of the system. When pump pressure has been

reached, the intensifi er pistons will deliver the fl ow to the

high pressure side, and continue to do so until the required

end pressure has been reached. The pistons then stop,

and will only move to make up for a pressure loss due to

leakage or consumption.

A general fl ow curve showing how the intensifi er works is

shown in Fig.2. For evacuating the high pressure side the

internal POV is used. This valve is opened by directing the

supplied pressure to the T-port and connecting the P-port

to tank. This allows the oil from the high pressure side to

fl ow directly back to tank.

The Cycle:

General Data:

3

Material: Body parts of cast iron or steel, pistons and valves of steel

Surface coating: Zinc-Chrome silver blue fi nish

Temperature range: -40° C to +120° C

Fluids: Recognised hydraulic fl uids and water glycol only.

For other fl uids contact factory or distriutor.

Filtration: 10 micron nominal, maximum 19/16 according to ISO 4406

Scanwill

Scanwill

Fluid Pow er ApS

Fig. 2:

)i(oitaR

wolFtelnI

)MPG/MPL(

1QwolFteltuO

)MPG/MPL(

2QwolFteltuO

)MPG/MPL(

erusserPtelnI

)isP/raB(

erusserPteltuO

)isP/raB(

5.1 1.2/0.8 12.0/8.0 80.0/3.0 009,2/002 053,4/003

0.2 1.2/0.8 12.0/8.0 80.0/2.0 009,2/002 008,5/004

4.3 0.4/0.51 85.0/2.2 31.0/5.0 009,2/002 068,9/086

0.4 7.3/0.41 74.0/8.1 01.0/4.0 009,2/002 006,11/008

0.5 7.3/0.41 73.0/4.1 80.0/3.0 023,2/061 006,11/008

0.7 4.3/0.31 92.0/1.1 50.0/2.0 356,1/411 006,11/008

0.9 4.3/0.31 91.0/7.0 30.0/1.0 092,1/98 006,11/008

4

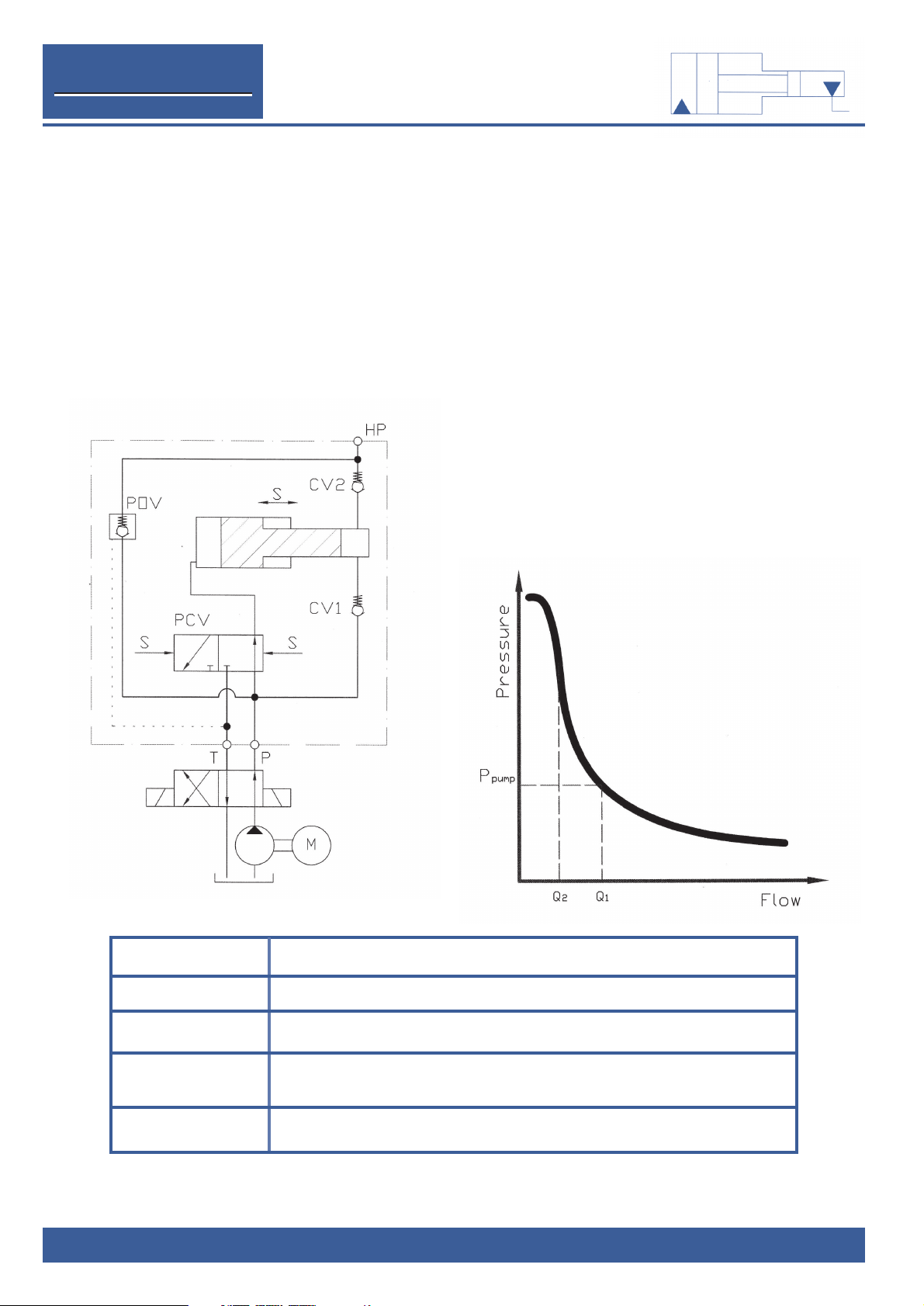

The MP-T is an in-line pressure intensifi er designed to be positioned in a

low pressure hydraulic system, and will provide higher pressure exactly

where needed (max. 800 bar). Having all the required high pressure valves

incorporated, the need for additional high pressure components is minimized

ensuring a cost effective system. Control of the high pressure side is achieved

by valves on the low pressure side through the intensifi er which adds to safety.

The intensifi ers are offered with 7 different intensifi cation ratios as standard

with additional ratios on request to meet most intensifi cation requirements. The

compact design ensures easy installation in new as well as existing hydraulic

circuits.

Flow & Pressure:

The supplied fl ow and pressure to the MP-T are dependant on the intensifi cation ratio chosen. The table shows the fl ow

and pressure for each model. Flow Q1 is when the pump pressure has been reached, and fl ow Q2 is moving up the vertical part of the curve (see graph on page 2). Please note fl ow values will vary with the viscosity of the fl uid. Inlet values

must not be exceeded.

Ordering Code:

First decide whether the pilot operated check valve,

POV, is required, then decide the intensifi cation ratio

(i), and fi nally decide the connections (BSP or UNF).

MP-T - - -

Example:

MP-T with POV, intensifi cation 5.0 and

BSP connections: MP-T-P-5.0-G

Dimensions in mm

The standard MP-T will provide pressure intensifi cation as required. As an

option a built in pilot operated check

valve, POV, allows the high pressure

side to be relieved through the intensifi er (see page 3).

The MP-T

The MP-T

Pressure In ten si fi er

edisylppuS ediserusserphgiH

G PSB"4/1 PSB"4/1

U FNU02-61/7 FNU02-61/9

VOP

ON S

SEY P

noitacifisnetnI

5.1 0.2 4.3 0.4 0.5 0.7 0.9

7/16"-20 UNF

9/16"-18 UNF

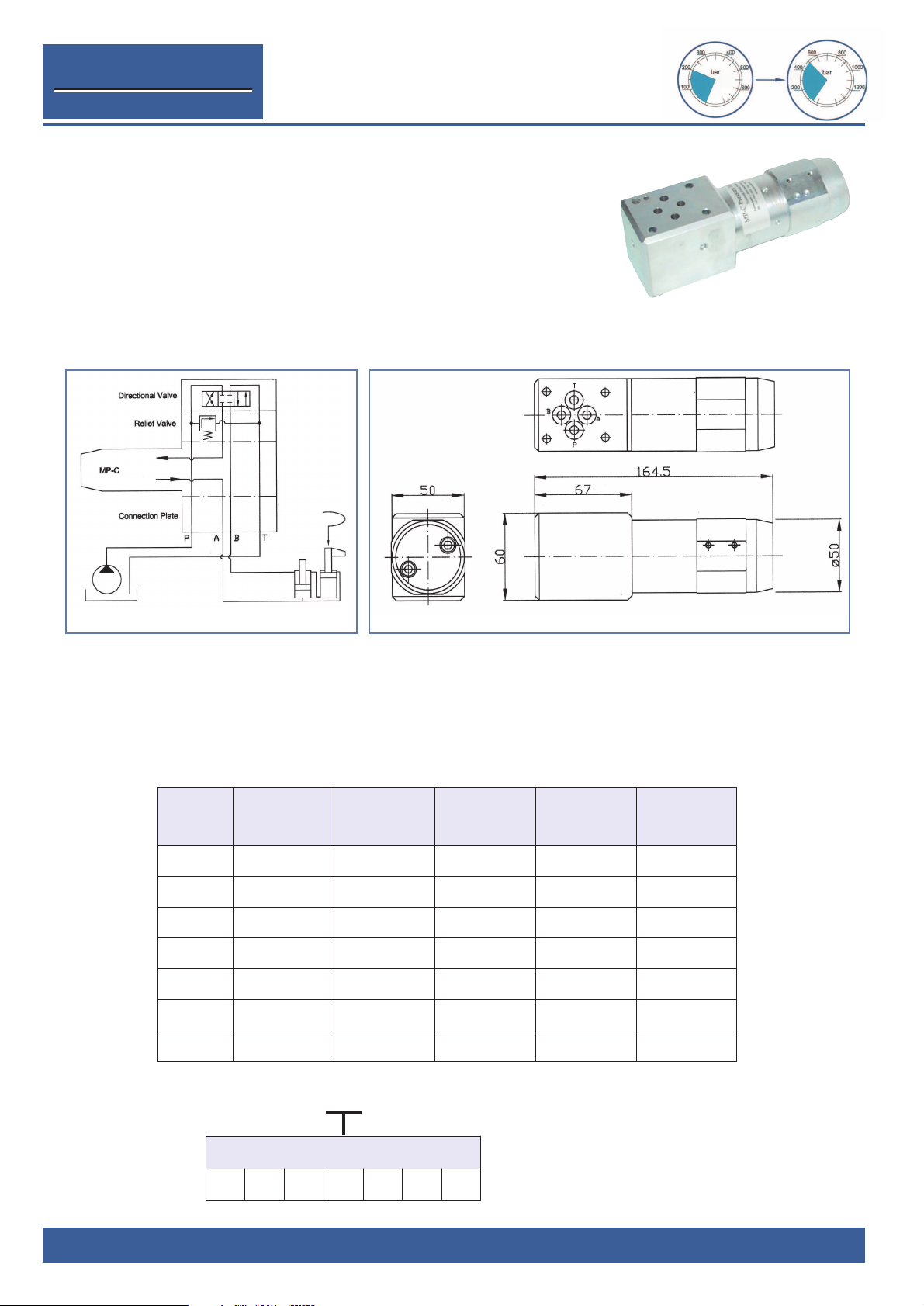

The MP-C pressure intensifi er is designed for the cetop-system (D03/NG6) and

will increase a supplied pressure to the higher end pressure required (max. 500

bar).Having high pressure valves incorporated, including the POV (see page 3),

a pilot operated check valve, for relieving the high pressure side, the MP-C offers

a cost effective solution for intensifi cation needs. Controlling the high pressure

side is achieved by valves on the low pressure side through the MP-C, allowing

the intensifi er to be installed in most existing as well as new hydraulic circuits.

The MP-C intensifi er is offered with 7 different intensifi cation ratios as standard

with additional ratios on request to meet most intensifi cation requirements.

Flow & Pressure:

The supplied fl ow and pressure to the MP-C are dependant on the intensifi cation ratio chosen. The table shows the fl ow

and pressure for each model. Flow Q1 is when the pump pressure has been reached, and fl ow Q2 is moving up the vertical part of the curve (see graph on page 2). Please note fl ow values will vary with the viscosity of the fl uid. Inlet values

must not be exceeded.

The MP-C in a system:

Ordering Code:

MP- C -

Example:

MP-C with intensifi cation 4.0: MP-C-4.0

5

Pressure Intensifi erPressure Intensifi er

The MP-C

The MP-C

Pressure In ten si fi er

noitacifisnetnI

5.1 0.2 4.3 0.4 0.5 0.7 0.9

Dimensions in mm

)i(oitaR

wolFtelnI

)MPG/MPL(

1QwolFteltuO

)MPG/MPL(

2QwolFteltuO

)MPG/MPL(

erusserPtelnI

)isP/raB(

erusserPteltuO

)isP/raB(

5.1 1.2/0.8 12.0/8.0 80.0/3.0 009,2/002 053,4/003

0.2 1.2/0.8 12.0/8.0 80.0/2.0 009,2/002 008,5/004

4.3 0.4/0.51 85.0/2.2 31.0/5.0 231,2/741 052,7/005

0.4 7.3/0.41 74.0/8.1 01.0/4.0 218,1/521 052,7/005

0.5 7.3/0.41 73.0/4.1 80.0/3.0 054,1/001 052,7/005

0.7 4.3/0.31 92.0/1.1 50.0/2.0 630,1/17 052,7/005

0.9 4.3/0.31 91.0/7.0 30.0/1.0 608/65 052,7/005

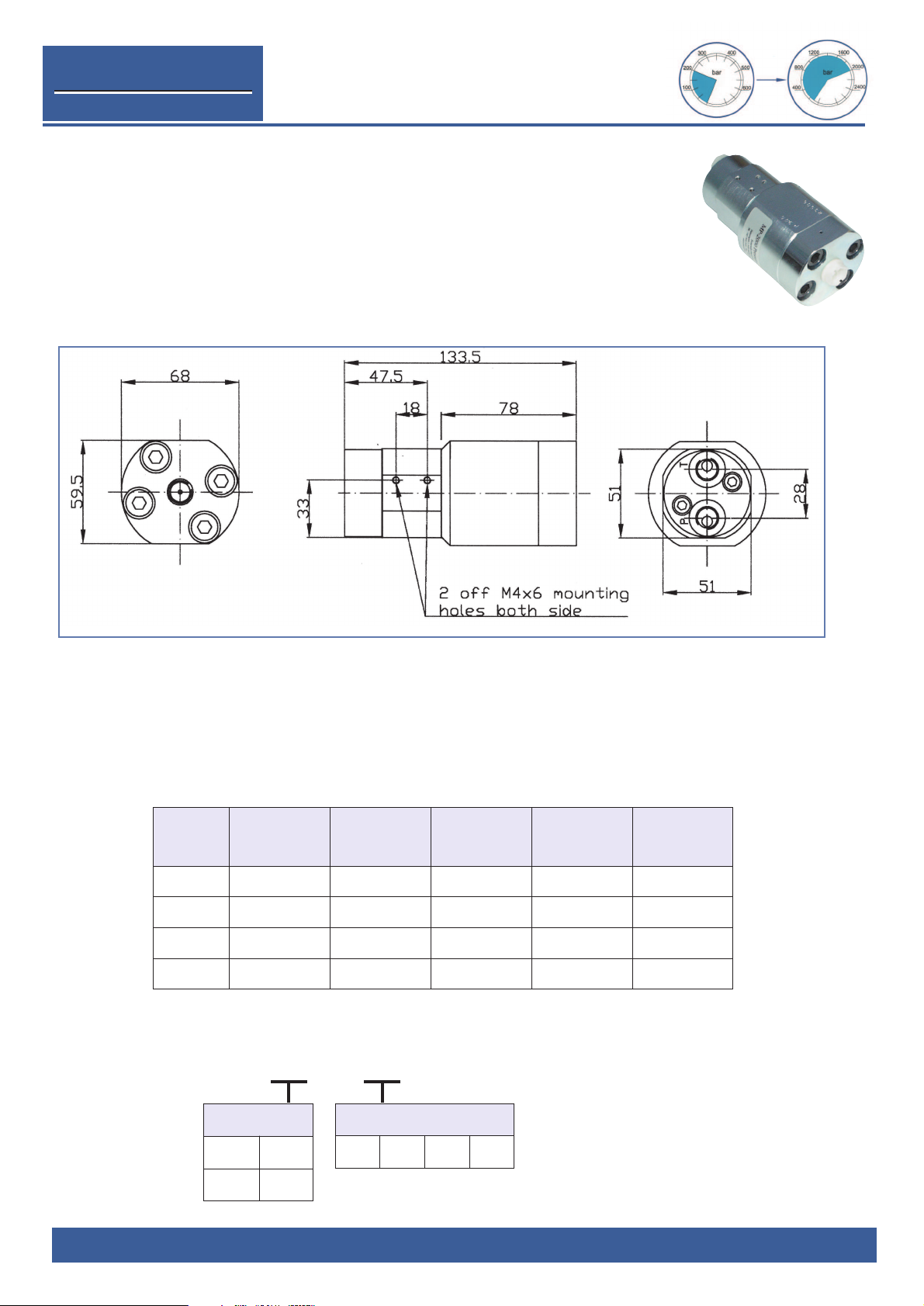

The MP-F pressure intensifi er is a fl ange-on model, designed to be mounted to a hydraulic

block. The MP-F will increase a supplied pressure to the higher end pressure required (max.

700 bar). Having high pressure valves incorporated, including the POV (see page 3), a pilot

operated check valve, for relieving the high pressure side, the MP-F offers a cost effective

solution for intensifi cation needs. Controlling the high pressure side is achieved by valves

on the low pressure side through the MP-F, allowing the intensifi er to be installed in most

existing as well as new hydraulic circuits. The MP-F intensifi er is offered with 5 different intensifi cation ratios as standard with additional ratios on request to meet most intensifi cation

requirements.

Flow & Pressure:

The supplied fl ow and pressure to the MP-F are dependant on the intensifi cation ratio chosen. The table shows the fl ow

and pressure for each model. Flow Q1 is when the pump pressure has been reached, and fl ow Q2 is moving up the vertical part of the curve (see graph on page 2). Please note fl ow values will vary with the viscosity of the fl uid. Inlet values

must not be exceeded.

Ordering Code:

MP- F -

Example:

MP-F with intensifi cation 4.0: MP-F-4.0

6

Dimensions in mm

The MP-F

The MP-F

Pressure In ten si fi er

noitacifisnetnI

0.2 4.3 0.4 0.5 0.7

)i(oitaR

wolFtelnI

)MPG/MPL(

1QwolFteltuO

)MPG/MPL(

2QwolFteltuO

)MPG/MPL(

erusserPtelnI

)isP/raB(

erusserPteltuO

)isP/raB(

0.2 1.2/0.8 12.0/8.0 80.0/2.0 009,2/002 008,5/004

4.3 0.4/0.51 85.0/2.2 31.0/5.0 009,2/002 068,9/086

0.4 7.3/0.41 74.0/8.1 01.0/4.0 835,2/571 051,01/007

0.5 7.3/0.41 73.0/4.1 80.0/3.0 030,2/041 051,01/007

0.7 4.3/0.31 92.0/1.1 50.0/2.0 054,1/001 051,01/007

Flow & Pressure:

The supplied fl ow and pressure to the MP-2000 are dependant on the intensifi cation ratio chosen. The table shows the

fl ow and pressure for each intensifi cation ratio. Flow Q1 is when the pump pressure has been reached, and fl ow Q2 is

moving up the vertical part of the curve (see graph on page 2). Please note fl ow values will vary with the viscosity of the

fl uid. Inlet values must not be exceeded.

Ordering Code:

MP- 2000 - -

Example:

MP-2000 with the POV integrated and

intensifi cation 7.0: MP-2000-P-7.0

7

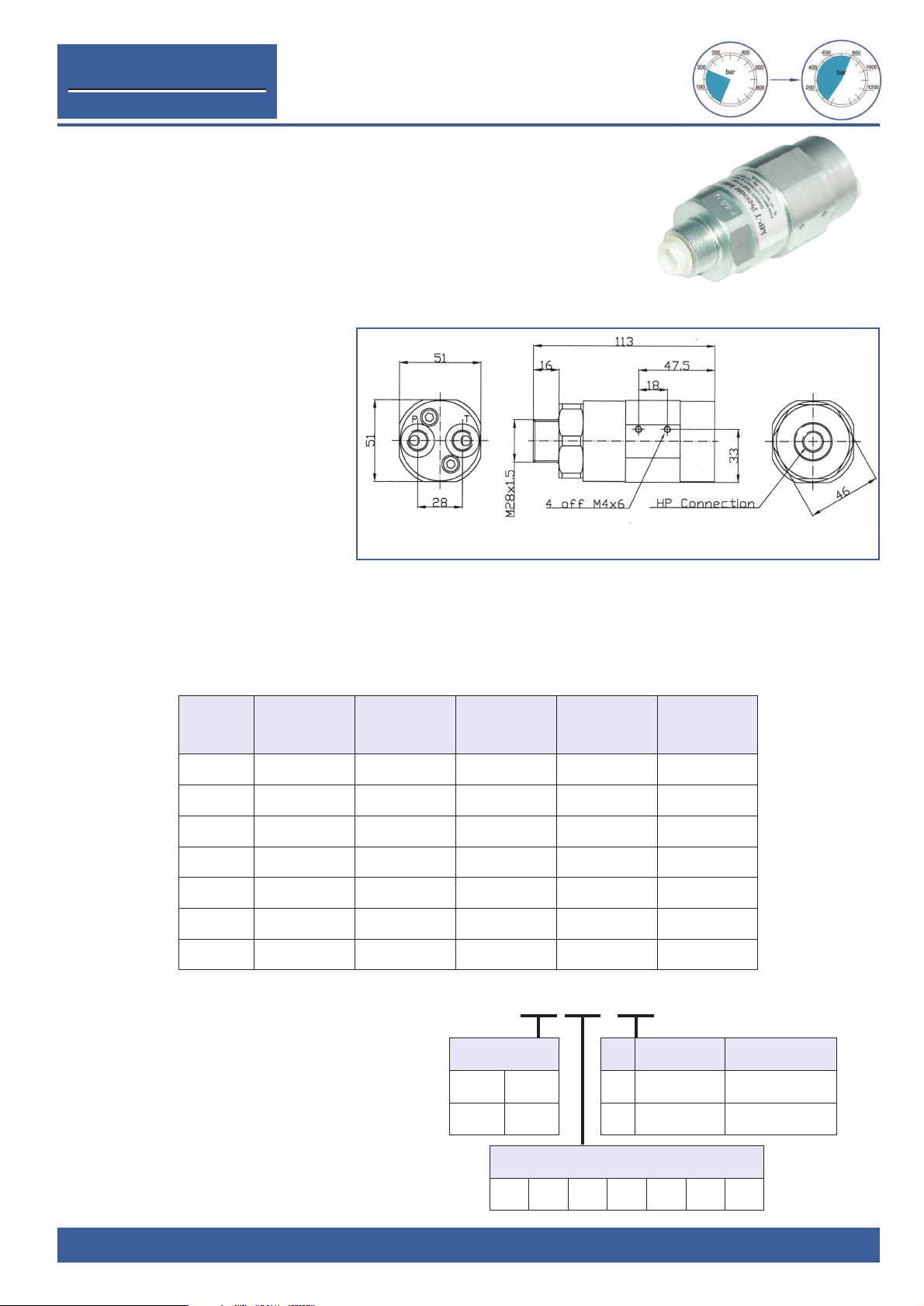

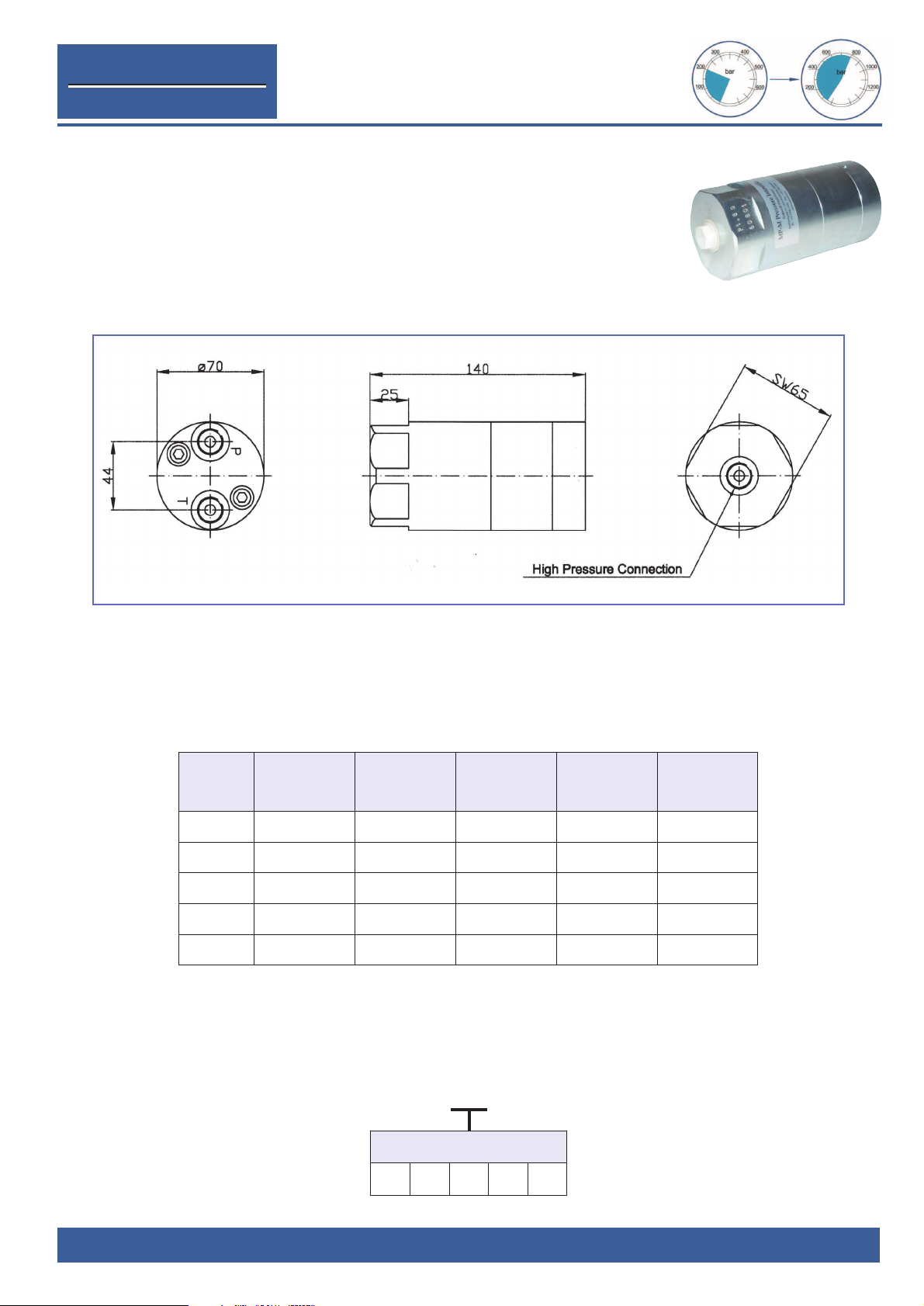

The MP-2000 is an in-line pressure intensifi er designed to be positioned in a low pressure

hydraulic system, and will provide higher pressure exactly where needed (max. 2.000 bar).

Having all the required high pressure valves incorporated, the need for additional high pressure components is minimized ensuring a cost effective system. Controlling the high pressure

side is achieved by valves on the low pressure side through the intensifi er adding to safety.

The intensifi ers are offered with 4 different intensifi cation ratios to meet most intensifi cation

requirements. The compact design ensures easy installation in new as well as existing hydraulic circuits.

The MP-2000 is offered with a pilot operated check valve (POV) integrated, which allows the

high pressure side to be relieved through the intensifi er (see page 3).

The MP-T

Pressure Intensifi er

The MP-2000

The MP-2000

Pressure In ten si fi er

VOP

ON S

SEY P

noitacifisnetnI

0.7 0.01 0.31 0.61

Dimensions in mm

P and T connections: 1/4“ BSP

)i(oitaR

wolFtelnI

)MPG/MPL(

1QwolFteltuO

)MPG/MPL(

2QwolFteltuO

)MPG/MPL(

erusserPtelnI

)isP/raB(

erusserPteltuO

)isP/raB(

0.7 71.3/0.21 92.0/1.1 50.0/2.0 009,2/002 003,02/004.1

0.01 71.3/0.21 81.0/7.0 50.0/2.0 009,2/002 000,92/000.2

0.31 46.2/0.01 31.0/5.0 20.0/1.0 332,2/451 000,92/000.2

0.61 46.2/0.41 01.0/4.0 20.0/1.0 218.1/521 000,92/000.2

10.0

The MP-M

The MP-M pressure intensifi er is an in-line model, designed to be positioned in a low pressure hydraulic system, and will provide high pressure exactly where needed. The MP-M will

automatically increase a supplied pressure to the higher end pressure required (max. 800 bar).

Having high pressure valves incorporated, including the POV (see page 3), a pilot operated

check valve for relieving the high pressure side, the MP-M offers a cost effective solution for

intensifi cation needs. Controlling the high pressure side is done by valves on the low pressure side through the MP-M, allowing the intensifi er to be installed in most existing as well

as new hydraulic circuits. The MP-M intensifi er is offered with 5 different intensifi cation ratios

as standard with additional ratios on request to meet most intensifi cation requirements.

Flow & Pressure:

The supplied fl ow and pressure to the MP-M are dependant on the intensifi cation ratio chosen. The table shows the fl ow

and pressure for each model. Flow Q1 is when the pump pressure has been reached, and fl ow Q2 is moving up the vertical part of the curve (see graph on page 2). Please note fl ow values will vary with the viscosity of the fl uid. Inlet values

must not be exceeded.

Ordering Code:

MP- M -

Example:

MP-M with intensifi cation 4.0: MP-M-4.0

8

The MP-M

Pressure In ten si fi er

noitacifisnetnI

8.1 4.3 0.4 0.5 0.7

All connections are 3/8“ BSP

All Dimensions in mm

)i(oitaR

wolFtelnI

)MPG/MPL(

1QwolFteltuO

)MPG/MPL(

2QwolFteltuO

)MPG/MPL(

erusserPtelnI

)isP/raB(

erusserPteltuO

)isP/raB(

8.1 6.6/0.52 23.1/0.5 93.0/5.1 009,2/002 022,5/063

4.3 3.9/0.53 23.1/0.5 47.0/8.2 009,2/002 068,9/086

0.4 3.9/0.53 60.1/0.4 36.0/4.2 009,2/002 006,11/008

0.5 3.9/0.53 39.0/5.3 05.0/9.1 023,2/061 006,11/008

0.7 3.9/0.53 08.0/0.3 43.0/3.1 356,1/411 006,11/008

The MP-L

The MP-L pressure intensifi er is an in-line model, designed for high fl ow applications,

where it will provide high pressure exactly where needed. The MP-L will automatically increase a supplied pressure to the higher end pressure required (max. 800

bar). Having high pressure valves incorporated, including the POV (see page 3),

a pilot operated check valve for relieving the high pressure side, the MP-L offers a

cost effective solution for intensifi cation needs. Controlling the high pressure side is

done by valves on the low pressure side through the MP-L, allowing the intensifi er

to be installed in most existing as well as new hydraulic circuits. The MP-L intensifi er

is offered with 5 different intensifi cation ratios as standard with additional ratios on

request to meet most intensifi cation requirements.

Flow & Pressure:

The supplied fl ow and pressure to the MP-L are dependant on the intensifi cation ratio chosen. The table shows the fl ow

and pressure for each model. Flow Q1 is when the pump pressure has been reached, and fl ow Q2 is moving up the vertical part of the curve (see graph on page 2). Please note fl ow values will vary with the viscosity of the fl uid. Inlet values

must not be exceeded.

Ordering Code:

MP- L - P -

Example:

MP-L with intensifi cation 4.0: MP-L-P-4.0

9

The MP-L

Pressure In ten si fi er

noitacifisnetnI

0.2 3.3 0.4 0.5 0.7

Dimensions in mm

)i(oitaR

wolFtelnI

)MPG/MPL(

1QwolFteltuO

)MPG/MPL(

2QwolFteltuO

)MPG/MPL(

erusserPtelnI

)isP/raB(

erusserPteltuO

)isP/raB(

0.2 22.31/0.05 23.1/0.5 93.0/0.2 009,2/002 008,5/004

4.3 61.12/0.08 17.4/8.71 44.3/0.31 009,2/002 068,9/086

0.4 61.12/0.08 98.3/7.41 19.2/0.11 009,2/002 006,11/008

0.5 61.12/0.08 60.3/6.11 33.2/8.8 023,2/061 006,11/008

0.7 61.12/0.08 22.2/4.8 76.1/3.6 356,1/411 006,11/008

0.52

Specials

Spe cials

& Accessories

The MP-L-2000 is based on the MP-L series, and is made for a

concrete bursting application (demolition), where a combination of

high fl ow and high pressure is needed. The MP-L-2000 is modifi ed

to deliver pressures up 2,500 Bar.

The MP-T-R pressure intensifi er is based on the MP-T series, but

modifi ed to be inserted in a rotating application, where it rotates

at 1,500 rpm, while intensifying a supplied pressure of 30 Bar to

210 Bar.

The M-Kit consists of two brackets

which can be used to fasten the MPIntensifi ers to a base plate.

The M-Nut is a nut M28 x 1.5 to be

used for mounting the MP-T pressure

intensifi er.

The NG-6 Top plate is offered to be

used with the MP-C pressure intensifi er, in situations where a closed top for

the Cetop / NG6 block is required.

10

Specials:

Accessories:

The MP-T series of hydraulic pressure intensifi ers is ideal for making specials, to meet the market demands. Below are

two examples on specials made for customers.

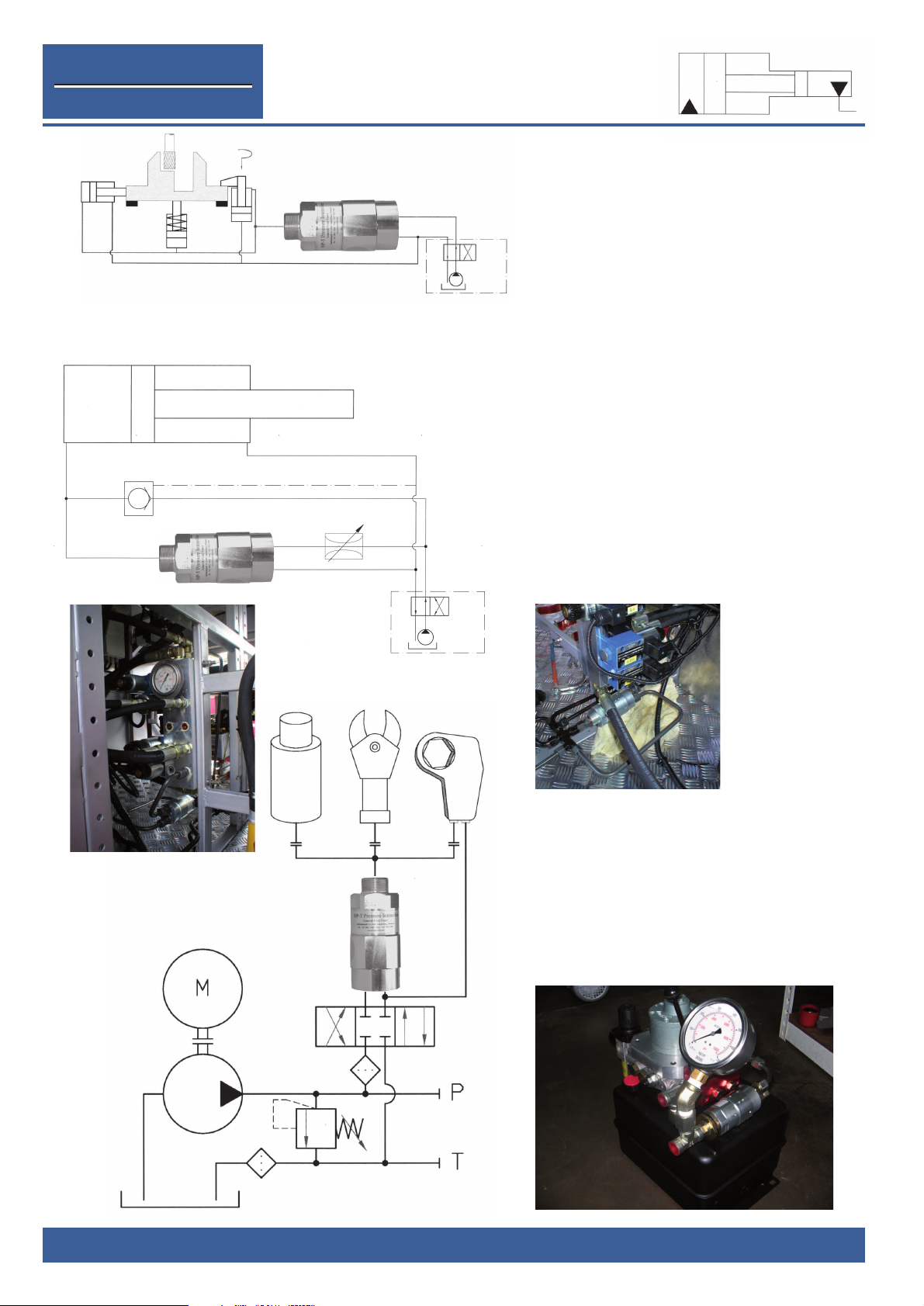

Application

Application

Examples

Hydraulic Workholding Circuits on machine

tools is a major application area for the MP-series

of hydraulic pressure intensifi ers. Inserting the

intensifi er between the hydraulic system already

on the machine tool and the hydraulic clamping

components allows the higher pressure to be

obtained and controlled from the supply side.

In High Flow Applications ( plastic injection

moulding machines, pressure die casting machines, demolition tools etc.) the MP-intensifi ers are

inserted parallel with a p.o. check valve, which is

designed to take the full fl ow and pressure. This

allows the full pump fl ow to be used to fi ll the

cylinder, and subsequently the end pressure is

delivered by the intensifi er. During retract mode

the external p.o.check valve allows the full fl ow to

go back to tank. This setup allows you to get high

pressure with a minimum of loss in cycle time.

In Hydraulic Power Packs, the MP-intensifi ers

are used to give a high pressure output. This is

achieved without changing the standard setup of

the standard power pack, and presents a fl exible

and economical way of obtaining high pressure.

Using the MP-Intensifi ers enables the operation

of high pressure tools directly from a low pressure

power pack.

11

Scanwill

Scanwill

Fluid Power

ApS

Scanwill

Scanwill

Fluid Power ApS

2008-10-GB1

Loading...

Loading...