Page 1

00:45-51

Issue 3

Dismantling information

Scania Touring

Scania - Higer A80, A30

Work description

en-GB

©

Scania CV AB 2013, Sweden

Page 2

General ...................................................................................................... 3

Draining and removing ........................................................................ 4

Climate system .............................................................................................. 4

Identification of materials for recycling ......................................... 7

General .......................................................................................................... 7

Polymeric materials ....................................................................................... 8

Glass fibre and glass ................................................................................... 11

Aluminium .................................................................................................. 12

Steel and copper .......................................................................................... 13

Colour codes ............................................................................................... 15

©

Scania CV AB 2013

Page 3

General

This information is aimed at everyone dealing

with reconditioning and scrapping of Scania

vehicles. The information applies to workshops

as well as companies specialising in dismantling and recycling.

The information is applicable to Scania Touring bus bodywork. However, not all parts are

covered in this information booklet. The information is by no means complete.

The first section describes how hazardous

waste is to be separated from the vehicle (environmental disposal).

The purpose of the second section is to facilitate identification and sorting of material for

recycling.

General

00:45-51 Issue 3

©

Scania CV AB 2013 3 (15)

Page 4

Draining and removing

WARNING!

WARNING!

Draining and

removing

Climate system

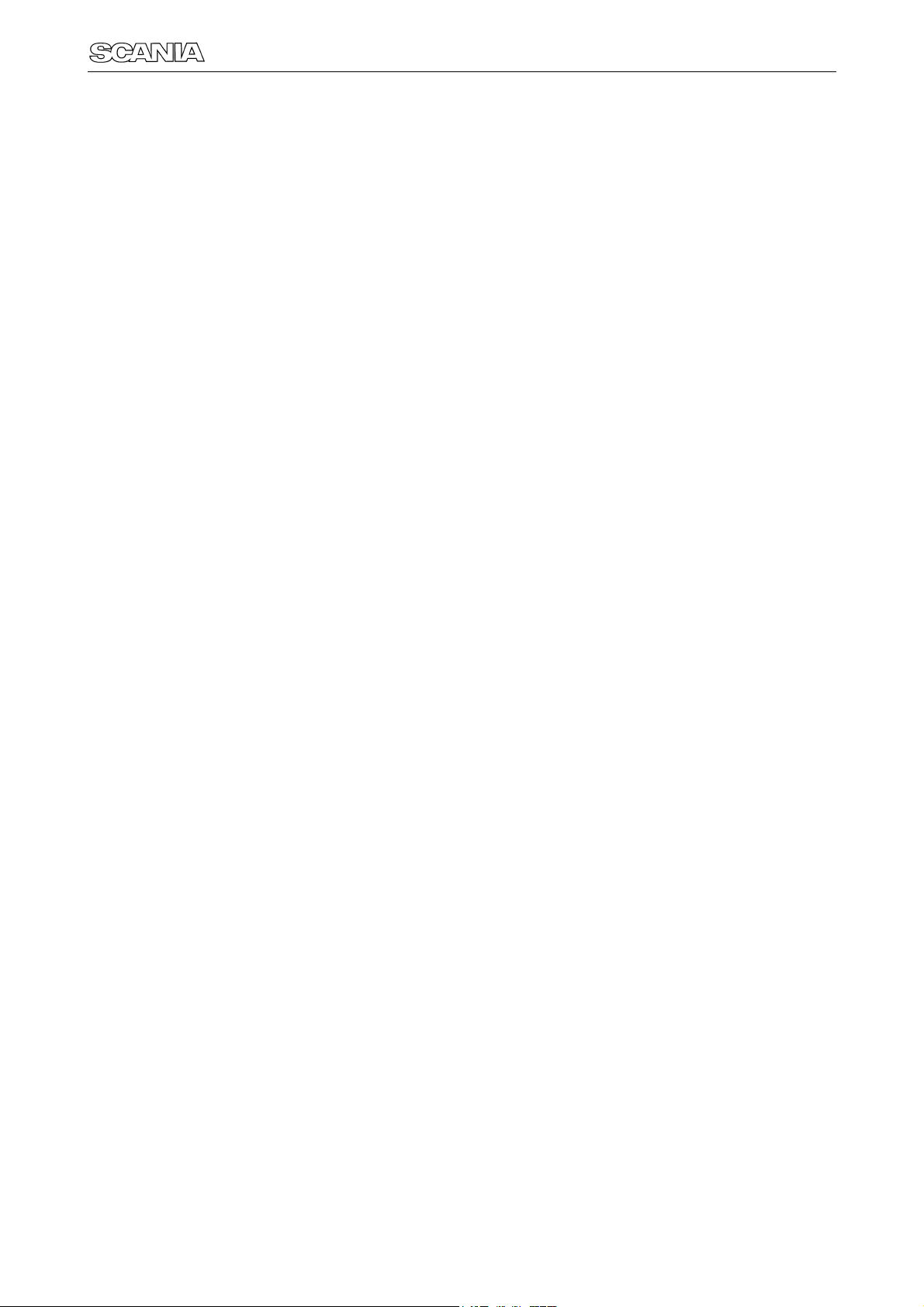

Tool

Number Designation Illustration Tool board

587 627 Recycling station -

Refrigerant R134a

Wear protective gloves and goggles.

Welding, smoking or heating are not allowed if

there is refrigerant in the air. Refrigerant generates a very toxic gas when heated.

4 (15)

©

Scania CV AB 2013 00:45-51 Issue 3

Page 5

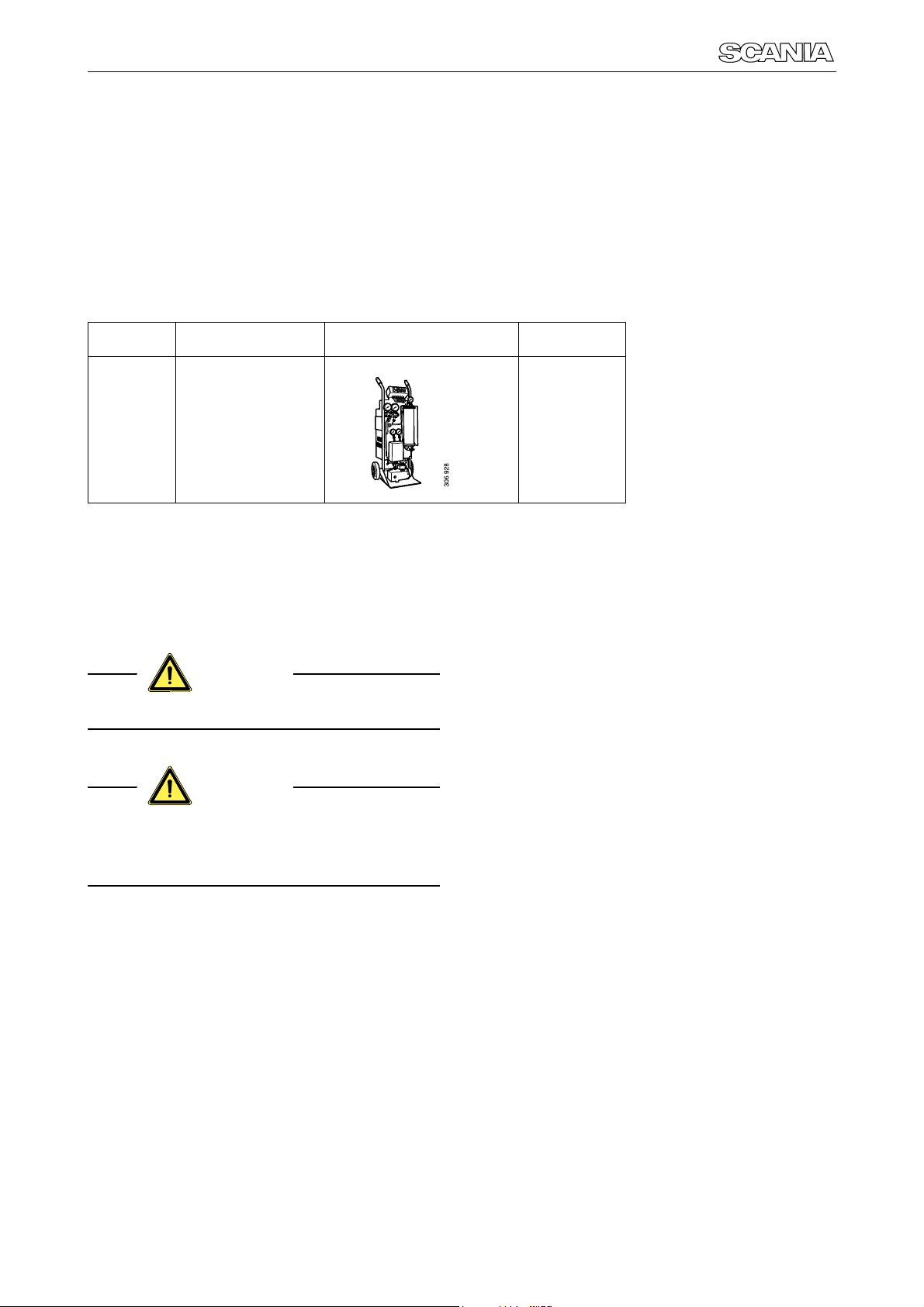

1. Connect the recycling station hoses to the

IMPORTANT!

1. Service valve, low-pressure

2. Service valve, high-pressure

low-pressure and high-pressure service

valves.

2. Drain the refrigerant slowly.

The refrigerant must not be released into the

atmosphere and must be recycled according to

local regulations.

Draining and removing

00:45-51 Issue 3

©

Scania CV AB 2013 5 (15)

Page 6

Draining and removing

Note:

Pipes and components where some coolant potentially remains

1. Return to the engine

2. From the engine

Coolant

There might be some coolant left in the system

after the coolant has been drained from the system.

6 (15)

©

Scania CV AB 2013 00:45-51 Issue 3

Page 7

Identification of materials for recycling

Identification of materials for recycling

General

The following pages illustrate parts of the vehicle that consist of polymeric materials (primarily plastics), glass fibre, glass, aluminium and

steel. The illustrations enable the identification

and sorting of these materials for recycling.

00:45-51 Issue 3

©

Scania CV AB 2013 7 (15)

Page 8

Identification of materials for recycling

1. PU (Q345A inside)

2. PVC (Glass fibre inside)

3. PU (wooden board and Q235 inside)

4. PU (HRB400 inside)

5. PVC together with non-woven fabric

6. ABS, frames and panels in the instrument

panel

Polymeric materials

8 (15)

©

Scania CV AB 2013 00:45-51 Issue 3

Page 9

Identification of materials for recycling

1. PVC

2. ABS

3. Felt together with PP

00:45-51 Issue 3

©

Scania CV AB 2013 9 (15)

Page 10

Identification of materials for recycling

1. ABS

2. Others

3. Others

4. Others

5. ABS

10 (15)

©

Scania CV AB 2013 00:45-51 Issue 3

Page 11

Glass fibre and glass

1. Glass

2. Glass fibre

Identification of materials for recycling

00:45-51 Issue 3

©

Scania CV AB 2013 11 (15)

Page 12

Identification of materials for recycling

Aluminium

Production of raw aluminium consumes a lot of

energy. Recycling aluminium consumes relatively little energy. From a life cycle perspective as much of the aluminium as possible

should be recycled. Therefore, Scania wants to

ensure that most of the aluminium used can be

recycled.

The illustration on this page shows the main

use of aluminium in the bus. Parts made of aluminium are marked in grey.

12 (15)

©

Scania CV AB 2013 00:45-51 Issue 3

Page 13

Steel and copper

Identification of materials for recycling

00:45-51 Issue 3

©

Scania CV AB 2013 13 (15)

Page 14

Identification of materials for recycling

1. Zinc-coated panel DC51D+Z, 1.2 mm

2. Q345

3. Zinc-coated panel DC51D+Z, 1.5 mm

4. Copper, some parts in the AC assembly

5. Zinc-coated panel DC51D+Z, 1.0 mm

6. Q235 or Q345

14 (15)

©

Scania CV AB 2013 00:45-51 Issue 3

Page 15

Colour codes

1. PU

2. PVC

3. ABS

4. Glass

5. Glass fibre

6. Aluminium

7. Steel

8. Zinc-coating

9. Copper

10. Others

Identification of materials for recycling

00:45-51 Issue 3

©

Scania CV AB 2013 15 (15)

Loading...

Loading...