Operator Manual

For printer model:

MB200i

www.satoamerica.com

PN: 9001144C

Read this Operator Manual before and during usage of the above product.

Keep this document handy for future reference.

SATO America, Inc.

10350A Nations Ford Road

Charlotte, NC 28273

Main Phone: (704) 644.1650

Technical Support: (704) 644.1660

Technical Support Fax: (704) 644.1661

E-Mail: satosales@satoamerica.com

techsupport@satoamerica.com

www.satoamerica.com

Copyright 2009 SATO America, Inc. All rights reserved

PN: 9001144C

Table of Contents

Technical Data ....................................................................................1 - 1

Basic Specifications.....................................................................................................1 - 2

Optional Accessories .............................................................................................................. 1 - 9

Power Items ............................................................................................................................ 1 - 9

Portability enhancements...................................................................................................... 1 - 11

Connectivity options.............................................................................................................. 1 - 13

Overview..............................................................................................2 - 1

Overview......................................................................................................................2 - 2

Product Features .................................................................................................................... 2 - 2

Bluetooth/Wireless Communication ........................................................................................ 2 - 2

Safety Precautions.................................................................................................................. 2 - 3

Setup....................................................................................................3 - 1

Setup ...........................................................................................................................3 - 2

Unpacking the printer.............................................................................................................. 3 - 2

Part Names ............................................................................................................................. 3 - 3

Functions of various parts....................................................................................................... 3 - 5

Charging the battery pack with a charger ............................................................................... 3 - 6

Charging the battery pack with the printer .............................................................................. 3 - 7

Using the battery pack ............................................................................................................ 3 - 8

Using the optional AC Adapter for power.............................................................................. 3 - 10

Loading the label roll (Continuous mode) ............................................................................. 3 - 11

Loading the label roll (Dispense mode) ................................................................................ 3 - 13

Operation and Configuration...............................................................4 - 1

Operation and Configuration .......................................................................................4 - 2

Turning the Printer On or Off .................................................................................................. 4 - 2

Turning the printer On............................................................................................................. 4 - 2

Turning the printer Off............................................................................................................. 4 - 2

Setting the DIP Switches ........................................................................................................ 4 - 3

Performing a Test Print ........................................................................................................... 4 - 4

Printing via the RS-232C Interface ......................................................................................... 4 - 6

Basic Specifications for RS-232C Interface ............................................................................ 4 - 6

Input and Output Signals ........................................................................................................ 4 - 7

Printing via the IrDA Interface ................................................................................................. 4 - 7

Printing via the Optional Wireless LAN Interface .................................................................... 4 - 8

Printing via the Optional Bluetooth Interface........................................................................... 4 - 8

Optional LCD screen............................................................................................................. 4 - 10

Adjusting Display Contrast.................................................................................................... 4 - 10

Printer Configuration ............................................................................................................. 4 - 11

Configuration Modes............................................................................................................. 4 - 13

Normal Mode ........................................................................................................................ 4 - 13

Label Sensor Selection ......................................................................................................... 4 - 14

Dispense Mode ..................................................................................................................... 4 - 15

Download Mode .................................................................................................................... 4 - 16

MB200i Operator Manual

Font Download Mode............................................................................................................ 4 - 18

Online Command Mode........................................................................................................ 4 - 20

CRC (Cyclic Redundancy Check) Mode............................................................................... 4 - 21

Sleep & Auto-Off Mode......................................................................................................... 4 - 22

Printing Procedure ................................................................................................................ 4 - 23

Adjusting printing for linerless labels .................................................................................... 4 - 24

Choosing the Label Dispensing Mode .................................................................................. 4 - 25

Configuring Dispense Mode ................................................................................................. 4 - 25

Other Printer Modes ............................................................................................................. 4 - 26

Normal Mode ........................................................................................................................ 4 - 27

Test Print Mode .................................................................................................................... 4 - 27

Head Check Setting Mode.................................................................................................... 4 - 29

Online Command Compatibility Mode .................................................................................. 4 - 29

Offset Configuration via Programming.................................................................................. 4 - 30

Operating Modes .................................................................................5 - 1

Operating Modes.........................................................................................................5 - 2

Enabling and Disabling Special Functions.............................................................................. 5 - 2

Cleaning and Maintenance..................................................................6 - 1

Cleaning and Maintenance..........................................................................................6 - 2

Cleaning the Print Head.......................................................................................................... 6 - 2

Cleaning the Platen and Dispenser Roller.............................................................................. 6 - 3

Troubleshooting .................................................................................. 7 - 1

Troubleshooting........................................................................................................... 7 - 2

What To Do In Case Of... ....................................................................................................... 7 - 2

Error Indicators ....................................................................................................................... 7 - 3

LCD Error Messages (WLAN Model Only) ............................................................................. 7 - 5

SATO Contacts .................................................................................... 8 - 1

SATO Group of Companies ........................................................................................8 - 2

MB200i Operator Manual

Unit 1: Technical Data

TECHNICAL DATA

• Basic Specifications

MB200i Operator Manual Page 1-1

Unit 1: Technical Data

BASIC SPECIFICATIONS

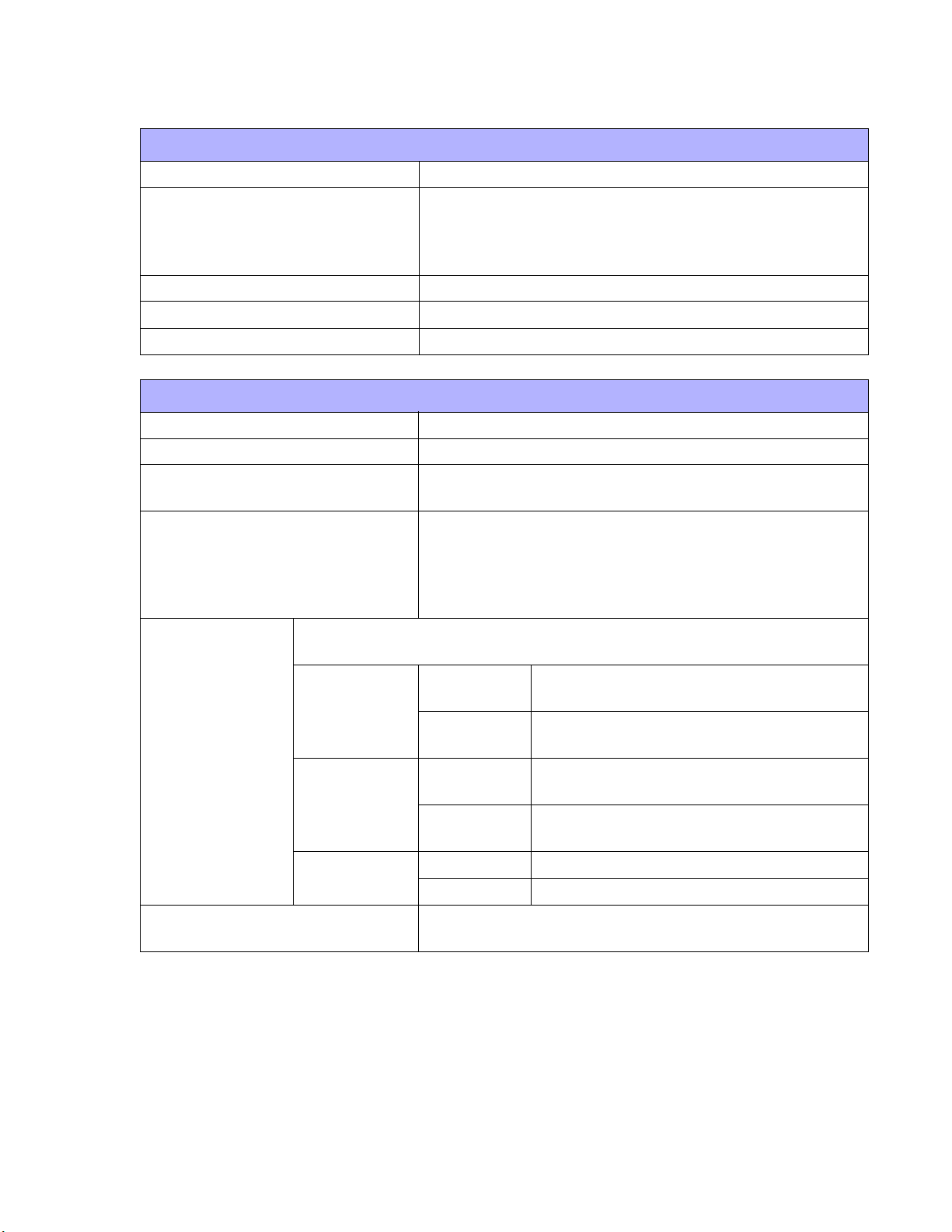

All technical data deemed pertinent has been tabulated below for quick reference. Find the

relative section header and then locate the specific type of technical data in the left column.

PHYSICAL CHARACTERISTICS

MB200i Printer Standard With optional boot installed

Width 5.1 Inches (129 mm) 6.2 Inches (158 mm)

Depth 2.9 Inches (73 mm) 3.7 Inches (94 mm)

Height 3.5 Inches (88 mm) 4.6 Inches (116 mm)

Weight 0.9 Pounds (410 g) 1.14 Pounds (515 g)

• The above dimensions are excluding the belt clip and weight is including the battery pack.

POWER

Adapter Voltage (optimal power

supply)

Battery Supply Lithium ion, 7.4VDC 2400mAh

Battery Capacity Battery continuously prints 4 rolls of thermal labels on a

Power Saving Auto power off after no operation for 5 minutes.

ENVIRONMENTAL

Does not apply to label media

Includes battery pack

Operating Temperature 5° to 122°Fahrenheit (-15° to 50°C)

Storage Temperature -13° to 140°Fahrenheit (-25° to 60°C)

Storage Humidity 20 to 80% RH, Non-Condensing

Input: Auto switching 100-240 VAC, 50/60 Hz

Output: DC 9V

full charge (equivalent to 48 m, print duty of 16%)

With Bluetooth or wireless LAN specifications, default is

no auto power off. Auto power off time can be changed

via the printer operation register command <PG>.

For details of the command, refer to the Programming

Guide.

WLAN model: 32° to 122° Fahrenheit (0° to 50°C)

Operating Humidity 20 to 80% RH, Non-Condensing

Page 1-2 MB200i Operator Manual

PRINT

Type Direct Thermal Only

Speed 4 Inches Per Second (103mm/s) in normal mode

3 Inches Per Second (75 mm/s) in dispenser mode

Dual color printing or high resolution modes reduce

speed

Resolution 203 Dots Per Inch (8 d/mm)

Maximum Print Width 1.9 Inches (48 mm)

Maximum Print Length or Pitch 6.3 Inches (160 mm)

MEDIA

Type Direct Thermal Roll media

Wind Direction Face out

Roll Diameter

MB200i: 2.63 inches (67 mm ±0.5 mm)

Maximum outer diameter:

Paper core inner diameter:

0.75 inch (19 mm), 1 inch (25 mm)

Core Diameter

Journal Coreless paper inner diameter: 0.3inch (8 mm)

Standard Linerless Coreless label inner diameter:

0.75 inch (19 mm)

• [Brackets indicate with liner sheet]

• Non-adhesive thermal paper follows the liner size.

Width

1 to 2.2 Inches (25.4 to 55 mm)

[1.1 to 2.3 Inches (28 to 58 mm)]

Standard

Length

Size

Width

0.5 to 6.3 Inches (13 to 160 mm)

[0.6 to 6.4 Inches (16 to 163mm)]

1 to 2.2 Inches (25.4 to 55 mm)

[1.1 to 2.3 Inches (28 to 58 mm)]

Dispenser

Length

0.5 to 6.3 Inches (13 to 160 mm)

[0.6 to 6.4 Inches (16 to 163mm)]

Width 1 to 2.2 Inches (25.4 to 55 mm)

Linerless

Length 0.8 to 4.7 Inches (20 to 120 mm)

Thickness

Label: 2.5 Mil to 7.5 Mil (0.064 ~ 0.190 mm)

Non-adhesive paper: 2.5 Mil (0.064 mm)

Unit 1: Technical Data

MB200i Operator Manual Page 1-3

Unit 1: Technical Data

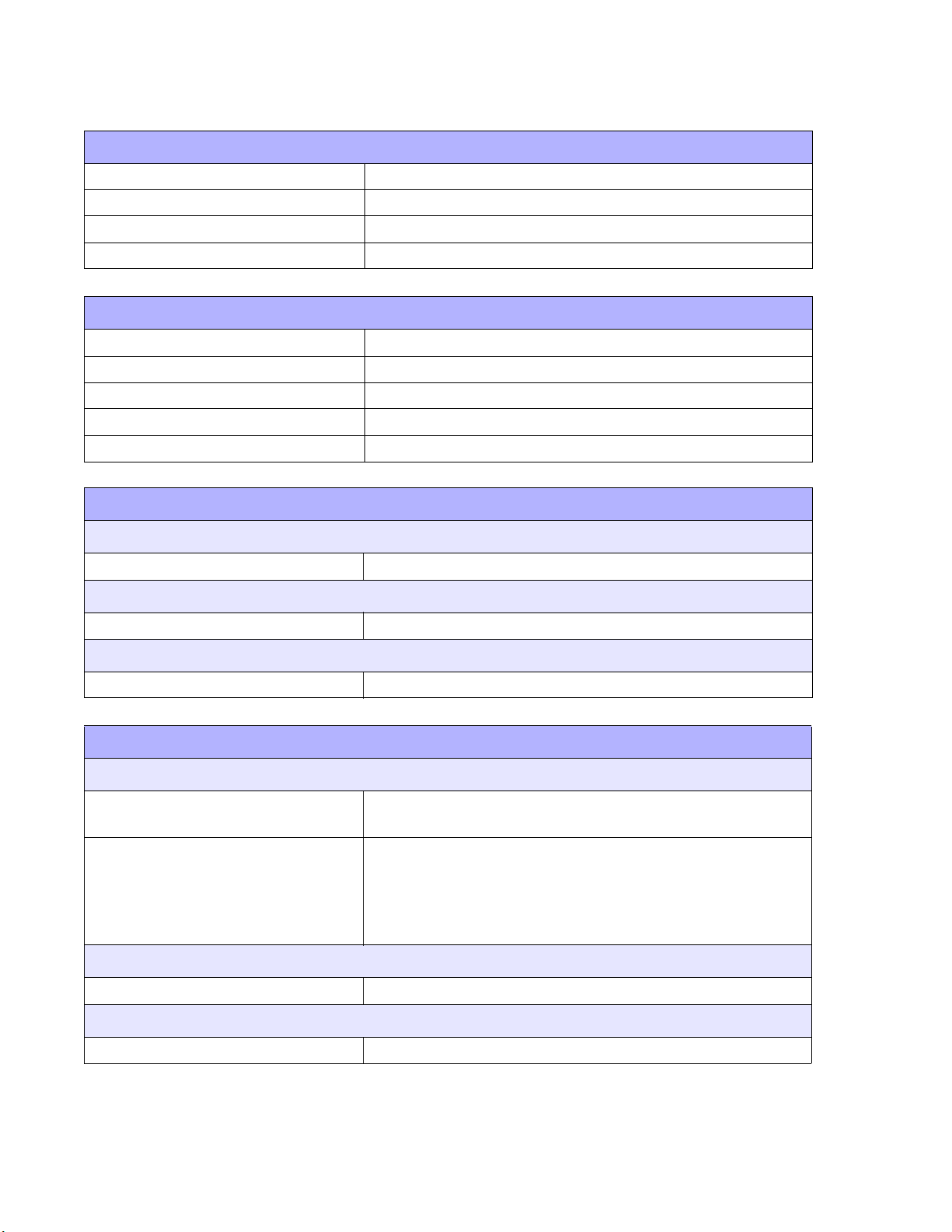

PROCESSING

CPU 32 Bit RISC

Flash ROM 4 Megabyte

RAM 256 Kilobyte

PRINTING LANGUAGE

INTERFACES

RS-232C Mini DIN (specified)

Optical Coupling 3-Wire Cooked Mode

Bluetooth Bluetooth Specification

SATO Barcode Printer Language (SBPL)

MB200 Compatible Command

Infrared communication (compliant with IrDA Standard

Ver 1.2)

Wireless LAN Wireless LAN interface (IEEE 802.11b/g)

TCP/IP (FTP, LPR, SOCKET)

RADIO FREQUENCY CHARACTERISTICS

2.4 FH1

Frequency Band Used 2.4GHz

Modulation System Frequency Hopped - Spread Spectrum System

Assumed Distance of Interference 10 mm Maximum

Availability of Frequency Change All area is used, and exclusion of the band for equipment

for mobile object identification is impossible

Note 1 Before using a wireless interface with this equipment,

make sure that any radio transmission/reception equip-

ment onsite does not share the same frequency range as

this product’s wireless setup.

Note 2 If any harmful radio interference should occur due to

operation of RF equipment that shares the same trans-

mission/reception characteristics, contact your nearest

dealer or service center to take appropriate measure to

prevent further interference (installing partitions).

SENSING

Gap (Transmissive) Fixed

I-Mark (Reflective) Fixed

Page 1-4 MB200i Operator Manual

SENSING

Unit 1: Technical Data

Dispenser sensor Fixed

MB200i Operator Manual Page 1-5

Unit 1: Technical Data

LABEL PRINTING MODES

SELF-DIAGNOSIS

CHARACTER FONT CAPABILITIES

Continuous Printing

Dispenser Printing

Journal Printing (no sensing)

Linerless Printing

Head Check

Cover Open

Paper End

Battery Check

Tes t Pr i nt

FONT TYPES

Bitmap Fonts XU, XS, XM, XB, XL, OCR-A, OCR-B, POP Character

CHARACTER MAGNIFICATION

Bitmap Fonts 1 to 6 Times

CHARACTER ROTATION

Rotation 0°, 90°, 180°, 270°

BARCODE CAPABILITIES

BARCODE SYMBOLOGIES

Linear Barcode EAN8/13, UPC-E/UPC-A, NW-7, CODE39, CODE93,

CODE128, INTERLEAVED 2 of 5, POSTNET, RSS-14

Two-Dimensional code PDF417 (ver 2.4) (Micro-PDF supported in SBPL v4.0)

QR code (ver 8.1 incl. micro QR)

Datamatrix code (ECC200) ver 2.0, MAXI code ver 3.0

Multi-row symbol (UPC-A/E, JAN/EAN, UCC/EAN-128.

RSS-14 is compatible with CC-A/B/C)

MAGNIFICATION

1 to 6 Times

ROTATION

0°, 90°, 180°, 270°

Page 1-6 MB200i Operator Manual

HARDWARE AND RELATED

Switches POWER, PRINT, FEED buttons, DIP switches

Indicators STATUS LED: One (lights in three colors: green, red and

Protective Features Overcharge/discharge protection

Water Resistance Optional case with rain-resistant cover (IPX3 JIS C0920-

Surface Treatment Antibacterial finishing for external cover and operative

Unit 1: Technical Data

orange).

Battery LED: Three

Built-in buzzer for audible alerts

Backlit 112 x 72 dot LCD screen on WLAN model

Print Head overheat protection

Non operable in Low Battery state

2003), only for printer without rubber boot installed

parts.

Complies with JIS Z 2801

STANDARD PACKAGE, STARTER KIT, AND OPTIONAL ITEMS

Standard Battery Pack

Quick Guide

Belt Clip

Standard Package with Starter Kit Battery Pack

AC Adaptor

Quick Guide

Belt Clip

Options Spare Battery Pack

AC Adapter

Battery Charger (Single-Socket)

Battery Charger (Five-Socket)

Belt Hook and Holder

Shoulder Strap

Case with Rain-resistant Cover

Holster-waist Case

Factory Installed Ruggedized Rubber Boot

REGULATORY COMPLIANCE

Safety regulation UL(UL 60950-1 (2001)), CSA (CSA22.2 No.60950-1-03),

CCC (GB4943-(2001)), TUV (EN60950-1), CE

EMC regulation FCC15B Class B, GB9254-1998, GB17625.1(2003),

EN55022, EN55024

Wireless regulation (Wireless

LAN/ Bluetooth)

FCC15C, GB4943, GB9254, GB17625.1, R&TTE

(EN300 328 V1.4:2003-04), (EN301 489 V1.4.1:2002-

08), IDATSSSS

MB200i Operator Manual Page 1-7

Unit 1: Technical Data

REGULATORY COMPLIANCE

Environment (RoHS) < 0.1% of Hexavalent chromium compounds, lead and its

compounds, mercury and its compounds, polybromi-

nated biphenyl (PBB) and polybrominated diphenyl ether

(PBDE) compounds

< 0.01% Cadmium and its compounds

Page 1-8 MB200i Operator Manual

Unit 1: Technical Data

OPTIONAL ACCESSORIES

The MB200i direct thermal printer is supported by a wide range of accessories to increase its

flexibility.

POWER ITEMS

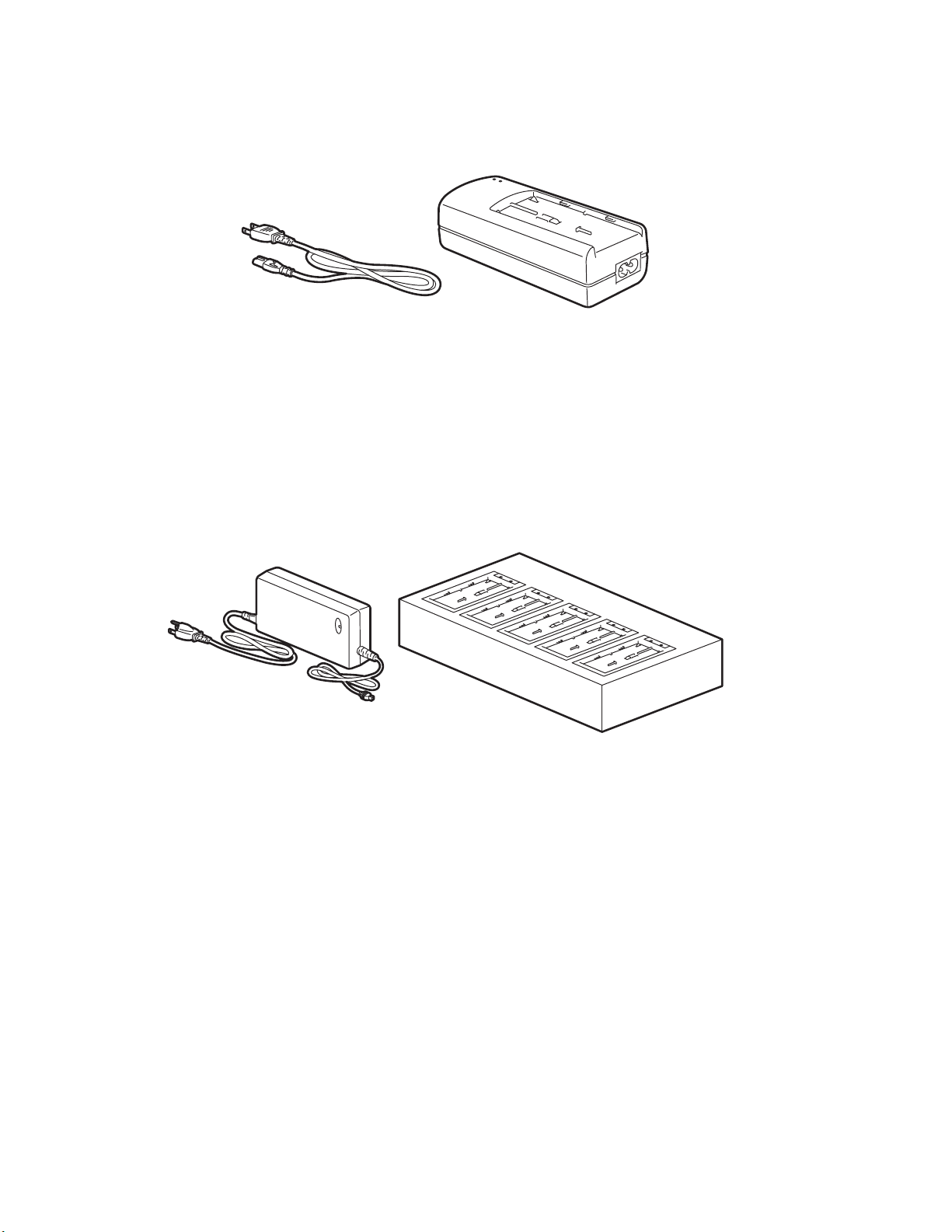

Figure 1-1, Spare battery pack

Spare battery pack—having a spare pack reduces interruption during extended periods of

printer operation.

Figure 1-2, AC adapter

AC Adapter—allows the printer to be operated via an AC outlet, and to charge a battery pack

loaded inside the printer.

Warning: Use only the specified AC Adapter designed for your printer.

MB200i Operator Manual Page 1-9

Unit 1: Technical Data

Figure 1-3, Single slot battery charger

Single-slot Battery Charger—use this to charge a battery pack without using the printer

connected to an AC outlet.

Figure 1-4, Five-slot battery charger

Five-slot Battery Charger—use this to charge multiple spare battery packs at the same time.

Page 1-10 MB200i Operator Manual

Unit 1: Technical Data

PORTABILITY ENHANCEMENTS

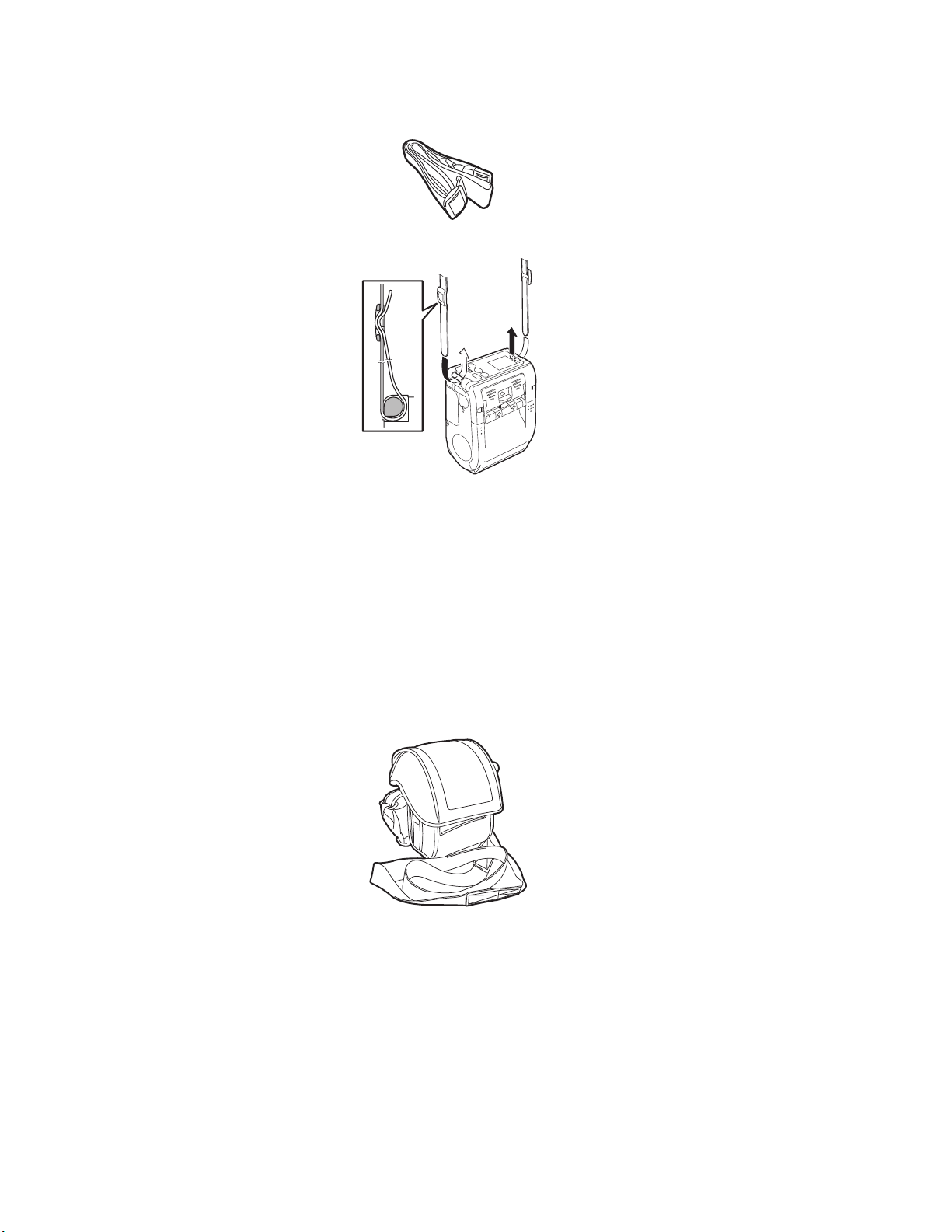

Figure 1-5, Belt Holder

Belt Hook and Belt Holder—allows users to attach or detach the printer for the waist belt easily.

Figure 1-6, Attach printer to the belt holder

Installation: Pass your belt through the belt holder. Insert the belt hook into the belt holder until it

clicks into place. If the belt hook is not inserted properly, the printer may fall off.

Figure 1-7, Detach printer from the belt holder

Detachment: Pull the printer sideways and upwards to remove it from the belt hook.

MB200i Operator Manual Page 1-11

Unit 1: Technical Data

Figure 1-8, Preparing the Shoulder Strap

Shoulder Strap—allows users to hang the printer from the shoulder.

Installation: Thread the shoulder strap through the strap holes on the printer, from the outside to

the inside. Then thread the end of the shoulder strap through the buckle, and adjust the length.

Note: If the strap is not routed correctly, the printer may drop off.

Figure 1-9, Rain-resistant shoulder case

Rain-resistant Shoulder Case — allows users to protect the printer when carry it around during

wet weather.

Installation: Pinch the Rain-resistant case with the belt clip of the printer. If the Rain-resistant

case is not pinched with the belt clip correctly, the printer may fall off.

Note: Shoulder case can be used only for the printer without rubber boot installed.

Page 1-12 MB200i Operator Manual

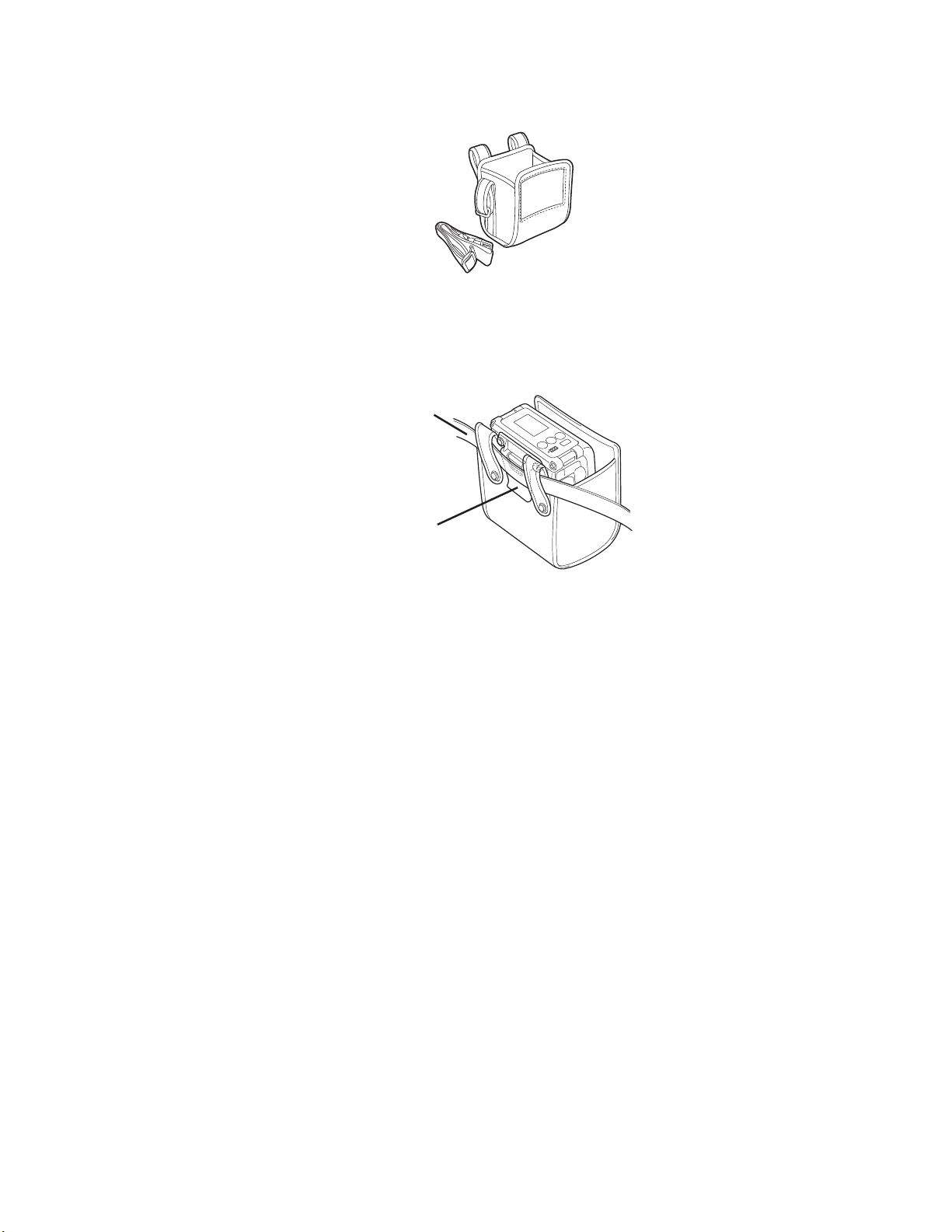

Unit 1: Technical Data

Waist belt

Belt Clip

Figure 1-10, Holster-waist case

Holster-waist case — a protective case that hangs from the waist for transporting the printer.

Figure 1-11, Pinch the Holster-waist case with the belt clip

Installation: Pinch the Holster-waist case with the belt clip of the printer. If the Holster-waist case

is not pinched by the belt clip correctly, the printer may fall off.

Note: The Holster-waist case can be used only for the printer without rubber boot installed.

CONNECTIVITY OPTIONS

RS-232C cable—allows connection of the printer to a PC or handy terminal.

ACTORY-INSTALLED OPTIONS

F

Wireless LAN Interface (with LCD)—allows printing via a WLAN network. The interface comes

with an LCD on the front panel to display the status of wireless communication.

Bluetooth Interface—allows printing via a Bluetooth connection.

For more details about the optional accessories, consult the Interfaces section of the Basic

Specifications table in this section of this manual, or consult your authorized SATO

representative.

MB200i Operator Manual Page 1-13

Unit 1: Technical Data

Page 1-14 MB200i Operator Manual

Unit 2: Overview

OVERVIEW

• Overview

MB200i Operator Manual Page 2-1

Unit 2: Overview

OVERVIEW

This manual is laid out consistent with the product discussed and provides all of the information

required for operation of the MB200i printer.

A comprehensive Table Of Contents provided at the front of this manual facilitates rapid

movement within. The contents identify the different Units, Chapters, and Sections. Each

references the page number of their commencement.

The pages of this manual have embedded headers and footers to assist the user in identifying

his or her exact position within the manual. The header provides the section number followed by

its name. The footer identifies the product on the left, and the page number to the right side of the

page.

Page enumeration is two-part with each separated by a hyphen. The first character set

references the Unit and the second identifies the page number. Page numbers begin with the

numeral (1) one at the commencement of a new unit and ascends sequentially.

This manual is intended to familiarize you with the basic features and operation of the MB200i

barcode printer in a short time.

PRODUCT FEATURES

Key features:

• High speed CPU and 103 mm/sec print speed (max)

• Long battery life

• Durable and rugged design

• Supports media up to 67 mm in width

• Built-in label dispenser

• Supports linerless media

• Available in IrDA, RS232C (standard), Bluetooth (optional), and IEEE802.11 b/g (optional)

interfaces

• Supports the MB200 compatible Programming Language or SATO Barcode Printer Language

Please read this manual carefully to make full use of this product. All information herein was

correct at the time of this document’s release. Revised versions of this document may be created

to match updates in firmware and procedures.

BLUETOOTH/WIRELESS COMMUNICATION

COMPLIANCE STATEMENT

This product has been certified for compliance with the relevant radio interference regulations of

your country or region. To ensure continued compliance, do not:

• Disassemble or modify this product

• Remove the certificate label (serial number seal) affixed to this product

Use of this product near microwave and/or other wireless LAN equipment, or where static

Page 2-2 MB200i Operator Manual

Unit 2: Overview

electricity or radio interference is present, may shorten the communication distance, or even

disable communication.

“Bluetooth” is a trademark of Bluetooth SIG, Inc., USA., and is used herein under license.

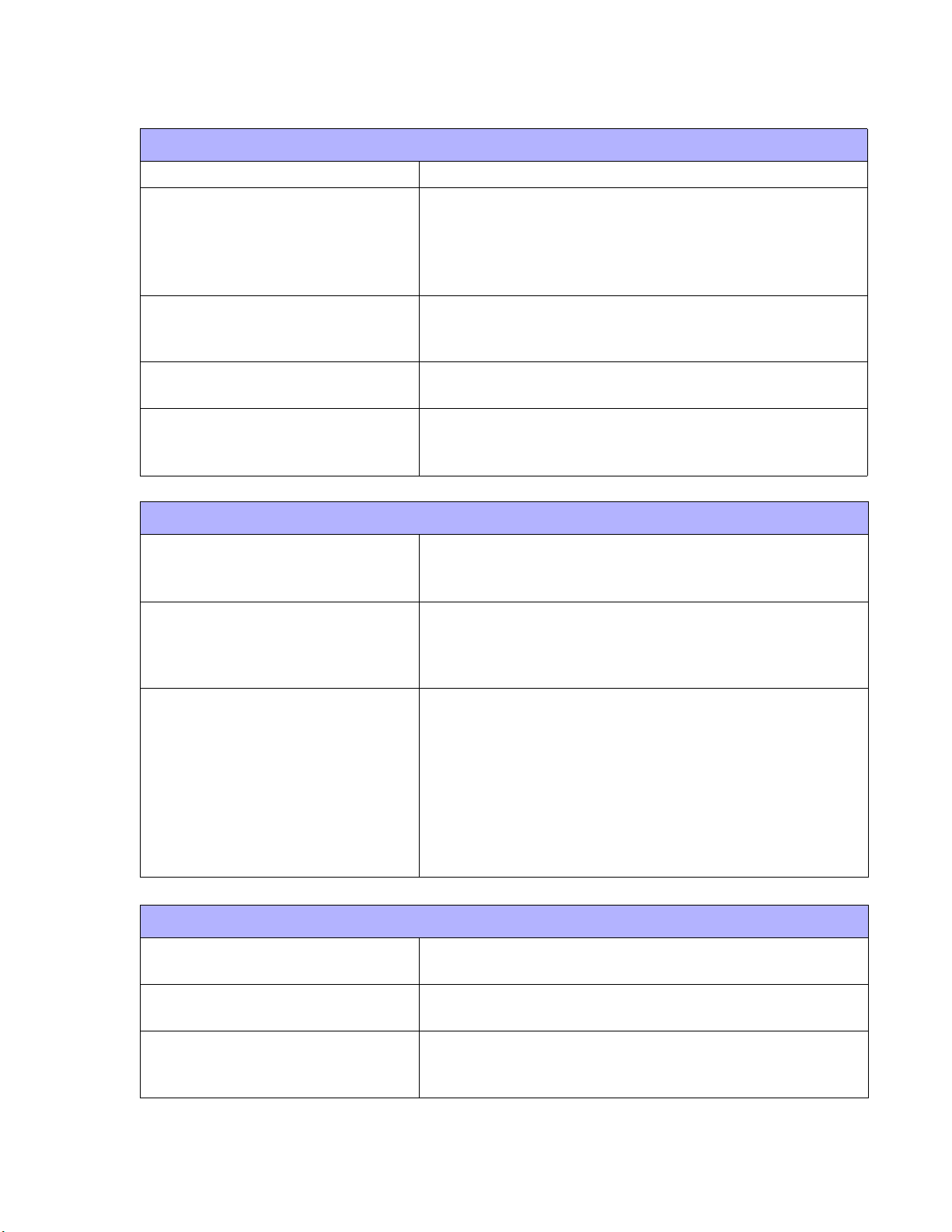

SAFETY PRECAUTIONS

This section outlines the safety precautions needed for safe operation of the printer. Make sure

to read the precautions carefully before using the printer.

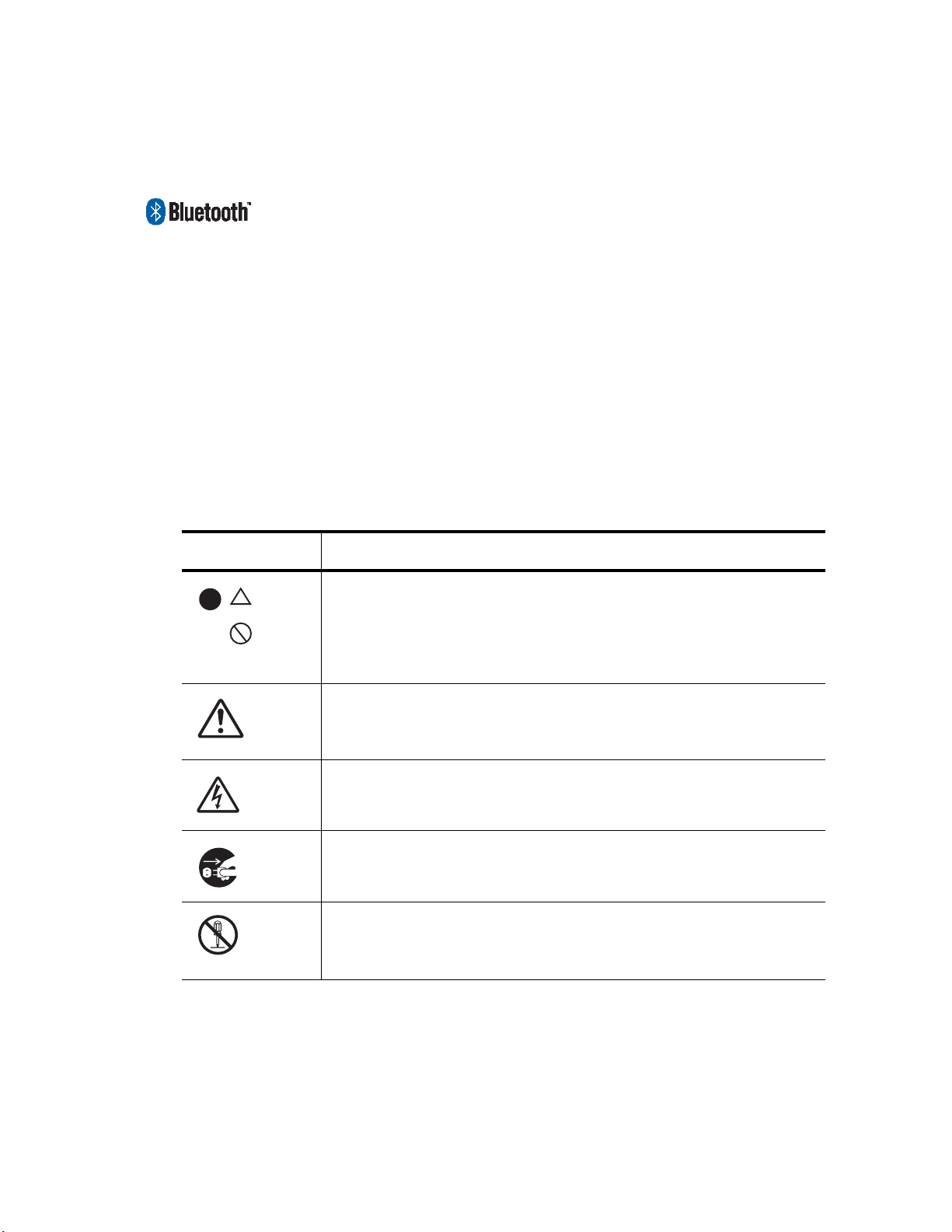

Symbols used in this manual:

The following symbols or markings are used in this manual and on the printer so that you can

properly use the printer, and to prevent any damage to property, harm or injury to yourself and

others.

Table 2-1, Symbols

SYMBOL MEANING

All safety symbols are enclosed by a circle or triangle. A black

circle is for an action you should do. A white circle with a bar

across it represents an action you should not do. A triangle

indicates that care is needed for that action, to avoid potential

hazards.

This symbol comes with the word Warning or Caution to alert

the user to be careful about an action to prevent (possible)

damage or injury.

This symbol alerts the user about the (possible) risk of electrical

shock if care is not observed when performing a certain action.

This symbol indicates that the user should remove the AC cord

by pulling the plug and not the cord.

This symbol indicates that the user should NOT attempt to dismantle or service the product.

MB200i Operator Manual Page 2-3

Unit 2: Overview

USAGE SAFETY

• Do not place the printer in a hot or cold place

The operation temperature range is -15°C to 50°C (for wireless LAN: 0 to 50°C) where humidity

is less than 80% and does not cause condensation. Do not place the printer in an area with high

humidity or at a temperature outside the specified range.

• Do not drop or apply undue shock to the printer

The printer is generally resistant to vibration possibly caused during normal transportation.

However, do not apply extreme vibration or shock by dropping the printer.

• Do not disassemble or modify the printer

The printer has high-precision components inside requiring fine adjustment.

• Connect the correct cables to the input terminals

Cables of the correct specifications are required for connection to the external equipment

through the external input terminals. Contact your nearest dealer or service center if necessary.

• Use the recommended accessories

Using optional equipment other than the specified equipment may cause a malfunction. Always

use the equipment specified in this guide.

• Use the correct media

Use the specified media. Otherwise, faulty printing or printer damage may occur.

SAGE WARNINGS

U

Table 2-2, Warnings

Do not place any container with water or chemicals, such as

flower vase or cup, as well as small metallic objects, near the

Liquids

printer. If any of these should drop into the printer, immediately

turn off the power and contact your nearest dealer or service

center. Continued use creates a danger of fire or electric shock.

Page 2-4 MB200i Operator Manual

Foreign Matter

Physical Shock

Abnormal Signs

Unit 2: Overview

Table 2-2, Warnings

Do not drop or insert metallic or flammable objects into the

openings on the printer (such as outlets for cables). If any of

these should fall into the printer,

immediately turn off the power and contact your nearest dealer

or service center. Continued use creates a danger of fire or

electric shock.

Should the printer ever be dropped or otherwise become

damaged, immediately turn off the power and contact your

nearest dealer or service center.

Continued use creates a danger of fire or electric shock.

Continued use of the printer while it is emitting smoke or strange

odors creates the danger of fire or electric shock. Immediately

turn off the power and contact your nearest dealer or service

center. Do not try to service the printer by yourself.

Never try to take the unit apart or modify it in any way. Doing so

creates the danger of fire or electric shock. Contact your nearest

dealer or service center for checking, adjustment, or repair.

Disassembly

Battery Pack

AC Adapter /

Battery Charger

(Option)

• Never try to take apart the battery pack or modify it in any

way such as with a solder iron.

• Never expose the battery to fire, or take any actions that may

lead to shorting.

• When charging the battery pack, make sure to use the

printer or the specified battery charger.

• Use only the specified voltage. Using a different voltage may

create the danger of fire or electric shock.

• Use only the specified AC adapter. Using a different adapter

unit may create the danger of fire or electric shock.

• Never use the battery charger with any other battery pack

except for the specified unit. Doing so can rupture the battery, cause leakage, or cause fire or an electric shock.

• Never cut, damage or modify the power cord. Also, never

place heavy objects on the power cord or heat or pull the

power cord. Doing so may damage the cord and create the

danger or fire or electric shocks.

• Should the power cord ever become seriously damaged

(internal wiring exposed or shorted), contact your nearest

dealer or service center for repair. Continued use of such a

cord creates the danger of fire or electric shock.

• Never modify, excessively bend, twist, or pull the power cord.

Doing so creates the danger of fire or electric shocks.

MB200i Operator Manual Page 2-5

Unit 2: Overview

USAGE PRECAUTIONS

Location

Power

Print Head

Table 2-3, Usage Precautions

Do not locate the printer in areas with high humidity or dew. If

dew forms inside the printer, immediately turn it off, and do not

use it until the dew has dried up. Otherwise, continued use

creates the danger of electric shocks or printer damage.

• Do not use wet hands to operate the power switch, replace

the battery pack or unplug the AC adapter or battery charger.

Doing so creates the danger of electric shocks.

• The AC adapter set provided for this printer is specific to this

printer. Do not use it for other electrical equipment.

• The print head gets very hot after printing. To avoid burns,

take care when replacing the label or cleaning the printer just

after printing.

• Touching the end of the print head with bare hands may

cause injury. Take care when replacing the label or cleaning

the printer.

• Do not try to replace the print head by yourself. Doing so creates the danger of injury, burns, or electric shocks.

Battery Pack

Storage

Maintenance

• When replacing the Battery Pack use only the specified

design.

• Make sure to install the pack in the correct orientation. Incorrectly replacing the battery creates the danger of injury or

damage to surrounding areas, if an explosion is caused.

• To dispose of a small rechargeable battery (Lithium ion battery), seal the metal contacts with tape, and ask our sales

representative or service center for the measures to be taken

to recycle the reusable materials. Do not place the battery

pack together with other batteries such as dry batteries.

If you have no plan to use the printer for a long time, remove the

battery pack from the printer and/or unplug the AC adapter from

the wall outlet before storing the printer (if you were using the AC

adapter as the power source).

For safe maintenance or cleaning of the printer, make sure to

remove the battery pack and the AC adapter from the printer.

Page 2-6 MB200i Operator Manual

Unit 3: Setup

SETUP

•Setup

MB200i Operator Manual Page 3-1

Unit 3: Setup

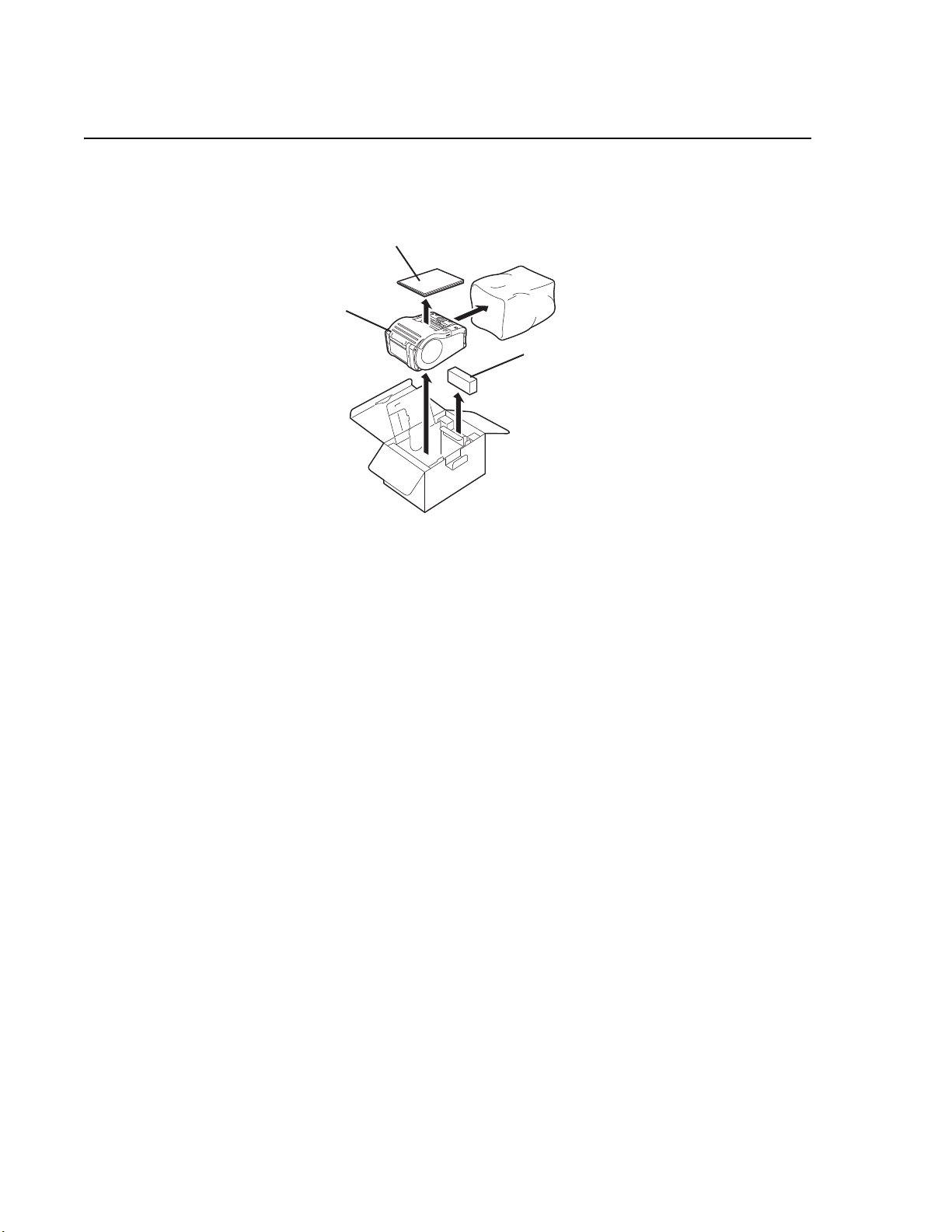

Quick Guide

Printer

Battery Pack

SETUP

UNPACKING THE PRINTER

Figure 3-1, Unpacking the printer

OTES:

N

If any component shown here is missing, contact your nearest dealer or service center.

The printer is shipped with an integrated belt clip and a battery pack.

Page 3-2 MB200i Operator Manual

Loading...

Loading...