CL408e/412e Quick Guide

10350A Nations Ford Road, Charlotte, North Carolina 28273

declare under our sole responsibility that the product

complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

DECLARATION OF CONFORMITY

SATO America, Inc.

TEL (704) 644-1650

CL408e, CL412e

FCC COMPLIANCE

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged

to try and correct the interference by one or more of the following

measures:

— Reorient or locate the receiving antenna.

— Increase the separation between the equipment and receiver.

— Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

— Consult the dealer or an experienced radio/TV technician for help.

PN9001067 Rev B Page 1

CAUTION

Please maintain the distance at least 20 cm (7.9 in) in an uncontrolled

environment from the antenna's surface when using the device.

See FCC OET Bulletin 56 "Hazards of radio frequency and

electromagnetic fields" and Bulletin 65 "Human exposure to radio

frequency electromagnetic fields."

This device shall not be co-located with any other transmitting antenna.

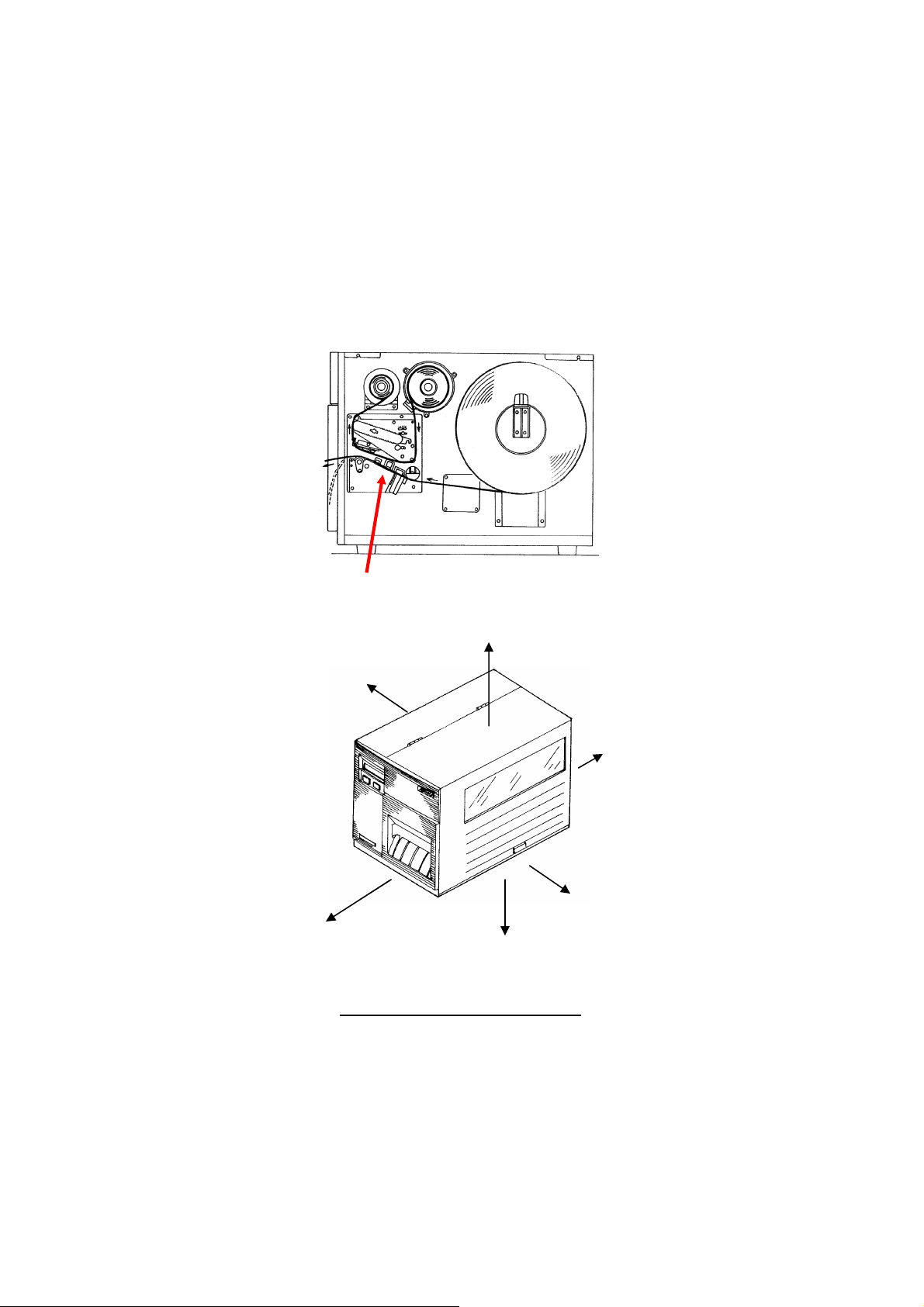

Antenna Position (Cover open view)

2cm

9cm

0cm (It leaves sufficiently)

18cm

12cm

6cm

The distance from outside the case

PN9001067 Rev B Page 1-1

CL408e/412e Quick Guide

Table of Contents

What You Get ................................................................................. 3

Controls and Indicators ................................................................... 4

Operator Panel ................................................................... 4

LED Indicators .................................................................... 4

Adjustments ........................................................................ 4

Keys ..................................................................................... 5

Rear Panel Connections ..................................................... 5

Initial Setup ..................................................................................... 6

Connecting the Printer ........................................................ 6

Printing a Test Label ........................................................... 7

Configuring the Printer ........................................................ 8

Computer Connections ....................................................... 8

CL408e/412e Software and Drivers ................................................. 10

Label Wizard SE ................................................................. 10

Windows Drivers ................................................................. 11

What to do if it will not print ........................................................... .... 11

CL408e/412e Specifications ............................................................ 15

Media and Supplies ......................................................................... 16

Options ............................................................................................ 16

Safety Considerations ...................................................................... 17

Safety Information ............................................................................ 18

This Quick Guide was prepared to get you up and running quickly. It will

enable you to get your new SATO CL408e/412e installed and printing

with a minimum of ef fort. H owev er, it is recomme nded th at yo u famili arize

yourself with the contents of the CL408e/412e Operator and Technical

Reference Manual for detailed descriptions so you will be able to

properly use the printer to its full potential.

PN9001067 Rev B Page 2

CL408e/412e Quic k Guide

What YouGet

TheCL408e/412eThermal Transfer printer comespackedin aprotective

carton. Includedinthecartonarethefollowingitems:

CL408e/412ePrinter

•

Quick Guide

•

Operator andTechnical ReferenceManual

•

HeadCleaningSheet

•

SampleRibbonsandRibbonTake-Up Core

•

Power Cable

•

TestPrintoutLabels

•

Label WizardSE CD-ROM

•

AftertakingtheCL408e/412efromthecartonandremovingtheprotective

plastic cover, it is ready for installation.

PN 9001067 Rev B Page 3

Controls and Indicators

Operator Panel

LED Indicators

CL408e/412e Quic k Guide

Status: Dark whenOff Line

Greenwhenprinter is OnLine.

Redwhenan error conditionexists.

LCD Display: Illuminatedwhenpower is applied.

Adjustments(controls behindfrontpanel)

Print: Adjustsprintdarkness.

Offset: Adjustsamountof back/forwardfeedfordis-

pense/cut/tear-off position.

Pitch: Adjustshomepositionof thelabel +/- 3.75 mm. Affects

stoppositionof label, printpositionanddispense/cutpo-

sition.

DSW2-3: Setsprinter configuration

Page 4 PN 9001067 Rev B

CL408e/412e Quic k Guide

Initial Set-Up

Connectingthe Printer

1. Locatea suitablespotfor theprinter. It shouldbewithin 6 ft. of the

hostif usinganIEEE1284 Parallel interfaceorwithin35 ft. if usinga

HighSpeedRS232interface. For other types of Plug-In interface

cards, seetheOperatorandTechnical ReferenceManual. Makesure

thereis adequateroomaboveandtotherightof theprinter for thelabel accessdoortoswingopen.

2. PlugtheAC cable providedintotheback of theprinter andconnect

toa suitable 115VAC outlet.

3. Opentheprintheadandloadtheribbonusingtheribbonrouting

guidelocatedontheinsideof thetopcover. Besuretopositionthe

ribbonroll correctly ontheRibbonSupply Spindleandplacethe

sparetake-upcoreontheTake-Up Spindle. Tapethefreeendof the

ribbontothetake-upcoreso thatit will take-upwhenrotatingin a

counterclockwisedirection.

4. Placethelabel roll ontheLabel Supply Spindleandpushthegreen

Label Roll Retaineronthespindleuntil itpushes thelabel roll all the

way to theinsideof theprinter. Thelabels should comeoff thebottomof theroll (labels woundface-in ontheroll).

5. Routethelabels as indicatedby thelabel routingdiagramontheinsideof thetopcover. Thelabels should gounder theplastic guide,

throughtheLabel Sensor Assembly, under theprintheadandoutthe

frontof theprinter. PositiontheLabel EdgeGuidetowardtheinside

of theprinteruntil itbarely contacts theoutsideedgeof thelabels.

6. ClosethePrintHeadLatchandthenthesideaccess door last.

7. Selecttheproper label sensingmethodusingthefrontpanel DIP

switches. TheDIP switchfunctionchartis locatedontheinsideof

thefrontcover. Theprinter comes fromthefactory setforlabel gap

detection(DSW2-2, DSW3-3 bothOFF). NotethattheOFF position

for theDSW switchesis downandtheON positionup.

8. Apply power by placingthefrontpanel Powerswitchinthe“1" position.

9. ThePower andOn-LineLEDs should beilluminatedandONLINE

should bedisplayedontheLCD.

10. PresstheLINE key once. TheOnLineLED shouldgooutand

OFFLINE shouldbedisplayedontheLCD.

11. PresstheFEED key once. Theprinter shouldfeedoutonelabel and

stop.

Page 6 PN 9001067 Rev B

CL408e/412e Quick Guide

Safety Information

PN9001067 Rev B Page 18

CL408e/412e Quick Guide

Safety Information

PN9001067 Rev B Page 19

CL408e/412e Quick Guide

Safety Information

PN9001067 Rev B Page 20

CL408e/412e Quick Guide

Safety Information

PN9001067 Rev B Page 21

Loading...

Loading...