SARGENT HC8700 User Manual

INSTALLATION INSTRUCTIONS 8700, 12-8700, HC8700 & HC4-8700

SURFACE VERTICAL ROD EXIT DEVICE

U.S. Patent No. 268,003 Canadian Patent No. RD 1981

FOR ASSISTANCE, CONTACT SARGENT AT 800-727-5477 or www.sargentlock.com

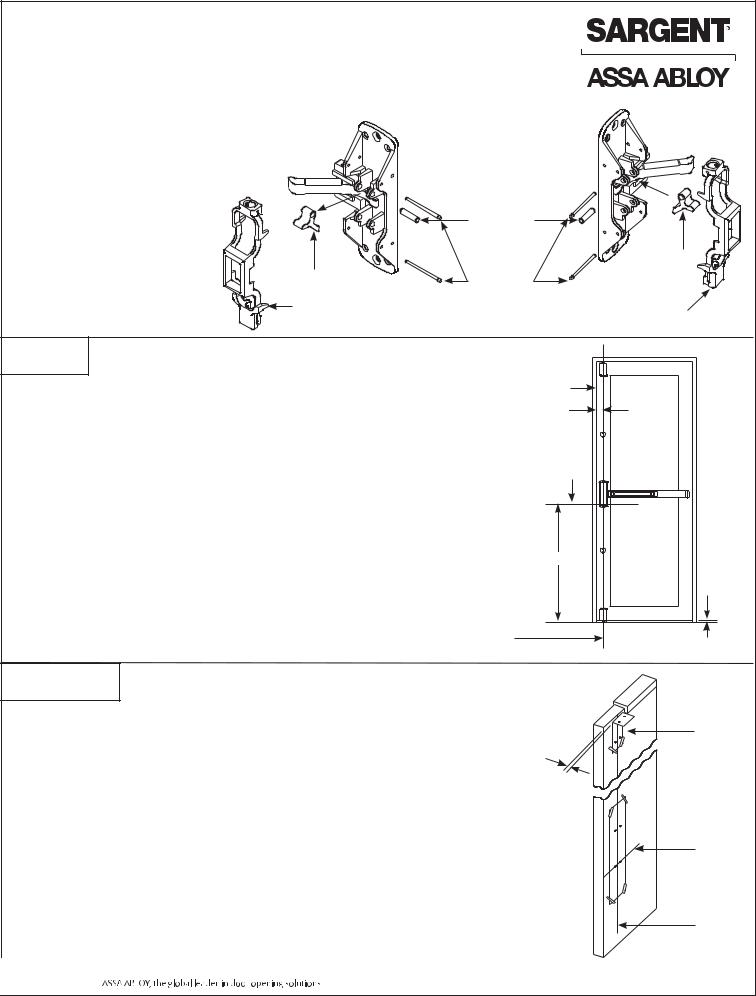

Top case

Top cover

Top cover

Top rod

Rod guide

Rod guide

Chassis

Chassis

Chassis

cover

Bottom rod

Bottom case

Standard 8700 Exit Shown

Copyright © 2009-2011, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved. Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

CYLINDER DOGGING (16PREFIX)

For complete assembly information see

Instruction Sheet A6848

Must be installed with opening in plastic cam

Slide mounting rail insert with cylinder dogging (16prefix) into mounting rail

TO OPERATE:

•Depress push rail

•Insert key and turn counterclockwise to lockdown

(dog) push rail

End cap bracket

End cap bracket

End cap

End cap

Push rail assembly

CAUTION: CHECK BEFORE STARTING DOOR PREP

Door should be fitted and hung.

Check box label for size of exit device, function, hand and design.

Surface of the door must |

THIS EXIT DEVICE IS HANDED |

|

|

|

|

be flush. Clear away any |

|

OUT |

raised projections to allow |

|

|

|

5 |

|

exit device to rest on flat |

|

|

surface of the door. |

Right hand |

Left hand |

|

||

AVAILABLE STOCK LENGTHS |

reverse bevel |

reverse bevel |

|

|

|

Length “E”: 32" door, no cut off required.

Can be cut to fit doors down to 24" wide.

Length “F”: 36" door, no cut off required.

Can be cut to fit doors down to 33" wide.

Length “J”: 42" door, no cut off required.

Can be cut to fit doors down to 37" wide.

Length “G”: 48" door, no cut off required.

Can be cut to fit doors down to 43" wide.

TOOLS REQUIRED

1. |

Measuring tape |

5. |

Hacksaw or any power cutter (to cut |

||

2. |

Power drill |

|

rail if necessary) |

|

|

3. |

Drill bits: #7, #16, #25, 3/32", 1/4", |

6. |

Screwdrivers: Phillips #2 and #3 |

|

|

|

11/32", 3/8", 25/64", and 3/4" |

7. |

Hex Wrenches: 3/16" and 3/8" |

|

|

4. |

Taps: #10-24, #12-24, 1/4"-20 and |

8. |

Level |

|

|

|

1 |

||||

|

7/16"-20 |

|

A6701L |

|

|

|

|

|

11-30-11 |

|

|

|

|

|

|

|

|

All 8700 series exit devices are handed except the 8710, which is field reversible.

The 8710 is shipped as LHR unless ordered as RHR.

TO CHANGE HAND OF 8710 EXIT DEVICE:

1.Remove both chassis pins and main slide.

2.Remove lift lever pin and lift lever.

3.Rotate chassis 180° and reposition lift lever and lift lever pin as shown.

4.Position main slide with large end of main slide at the bottom and retain with chassis pins.

Chassis

|

|

Lift lever pin |

|

|

|

|

|

Lift lever |

|

Lift lever |

|

Chassis pin |

|

|

|

|

|

||

Main slide |

Right Hand |

Left Hand |

Main Slide |

|

Large end |

||||

Large end |

Reverse |

Reverse |

||

|

FIRST MARK VERTICAL AND HORIZONTAL REFERENCE LINES ON DOOR

WITH DOOR CLOSED:

1.Determine dimension “A” to locate vertical reference line. If door stile is 4-1/2" wide or wider, “A” is 2-3/4".

If door stile is less than 4-1/2", “A” is 1/2 the exposed

width of the door stile when the door is closed against the stop.

2.Standard rail centerline height is 41" above the finished floor. Horizontal reference line is 37-5/8" standard.

(Location of lower chassis mounting holes)

Door |

|

|

Stop |

|

|

“A” |

|

|

|

Inside |

|

Horizontal |

face of |

|

door |

||

reference |

||

|

||

line |

|

37-5/8"

Vertical reference line |

Finished floor |

(C chassis, top and bottom case) |

|

L |

|

SECOND PREPARE DOOR

WITH DOOR CLOSED:

1.Tape template for Chassis/Trim on inside of door, along vertical and horizontal reference lines.

2.Fold top case template and tape on inside of door along vertical reference lines.

3.Spot and drill all holes from inside of door.

4.Mortise pockets for outside trim, if required. See trim installation instructions supplied with trim for details.

NOTE: Any holes drilled from the outside need pilot holes drilled from the inside to ensure good alignment.

NOTE: For electrical trim applications, ensure access to a raceway from the trim to the electric hinge or armored door loop.

Top case Stop template thickness

Chassis/Trim

Template Horizontal

reference

line

Tape (supplied)

Vertical reference line

2 |

A6701L |

11-30-11 |

|

|

|

Copyright © 2009-2011, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved. Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

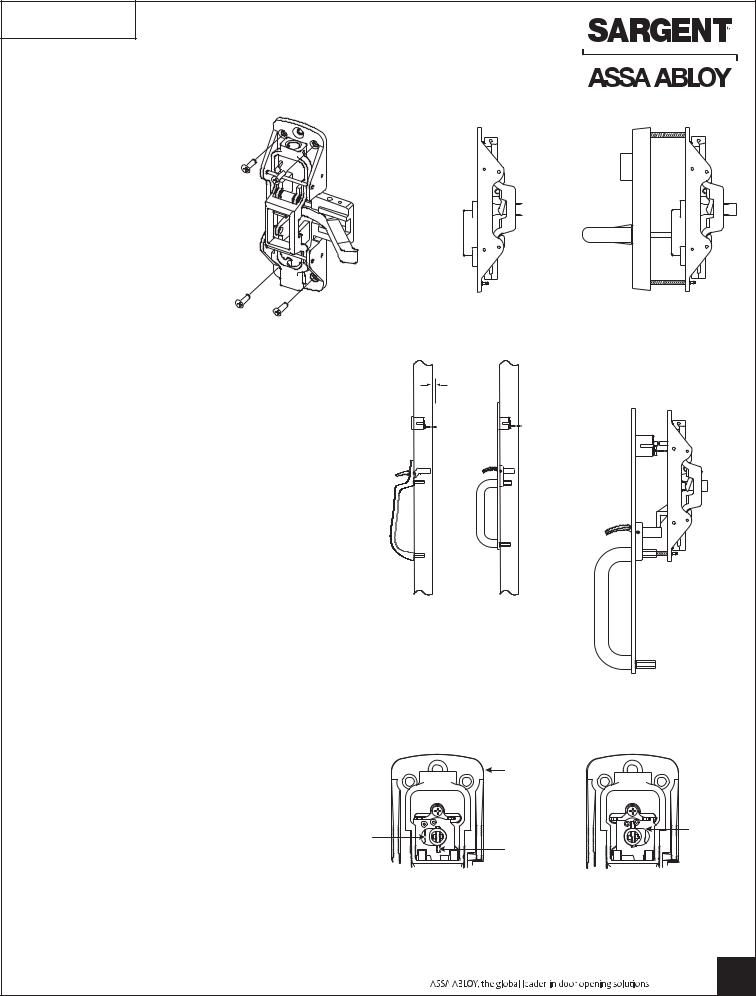

THIRD APPLY CENTER CHASSIS AND TRIM

700 SERIES ET TRIM:

1.Secure chassis to door with (4) #10 flat head screws using corner mounting holes.

NOTE: Electrical functions – see instruction sheet A6374 for wire connections.

2.Position ET trim on door, align spindle with bell housing.

3.Through-bolt chassis to ET trim with (2) 1/4-20 flat head screws.

Chassis

Chassis

Bell housing

8706 OR 8713 BY

ETJ CONTROL SHOWN

NOTE: Thumb Trim is not available for HC8700 |

|

Series Exit Devices |

5/16" |

800 SERIES THUMB PIECE TRIM:

Determining rim cylinder tail length

FOR FLL, FLW, MAL, STS OR PTB TRIM:

1.Position trim on door (except STS).

2.Insert rim cylinder through trim plate (or cylinder collar for STS trim).

3. Mark cylinder tail at 5/16” beyond inside door surface.

4. Remove cylinder and trim from door and cut tail |

|

|

piece as marked. |

STS TRIM |

FLL TRIM |

|

SHOWN |

SHOWN |

APPLY CHASSIS AND TRIM:

1.Hold trim plate to door.

2.Insert cylinder and secure using supplied back plate.

3.Position cylinder hub with in the chassis to correct position for desired function (see drawings).

4.Position chassis on door, align cylinder tail with hub

and secure chassis to door with (4) #10 flat head |

|

Chassis |

|

screws using the corner mounting holes. |

|

||

|

|

||

5. Through-bolt chassis to trim with 1/4-20 flat head |

|

|

|

screws and to door with cup washer and 1/4-20 |

Cylinder |

||

flat head screw. |

|||

hub |

Hub pin |

||

NOTE: |

|||

|

down for |

||

|

|

||

STS, FLL, FLW and MAL thru-bolt to chassis |

|

62 function |

|

|

For 8762 long end of pin |

||

with (1) 1/4-20 flat head screw. |

|

||

PTB trim through-bolts to chassis with (2) 1/4-20 |

|

faces down. Cylinder turns |

|

|

180° in both directions. |

||

flat head screws. |

|

|

|

8762 OR 8763 BY FLW SHOWN

For 8763 long end of pin faces up. Cylinder turns 360° to the left or right.

Copyright © 2009-2011, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved. Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

A6701L 3

11-30-11

Loading...

Loading...