Page 1

BT-

Beacon

Exit Device

Installation Instructions

A7974C

02/13

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written permission

of Sargent Manufacturing Company is prohibited.

Page 2

Beacon Exit Device

Installation and Wiring Instructions

Table of Contents

Warning ...................................................................................2

Section I - Overview ................................................................3

Section II - Installation Instructions .......................................6

Section III - Beacon Wiring Examples ..................................10

Section IV - Alarm Mode Operation ......................................15

Section V - Test Mode Operation ..........................................15

Section VI - BEACON Modes of Operation ............................16

Trouble Conditions & Corrective Actions .............................17

Changes or modifications to this unit not expressly approved by ASSA ABLOY Inc.could void the user’s

Warning

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in

a residential installation.

This equipment generates, uses and can radiate radio frequency energy and if not installed and used in accordance

with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that

the interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected

• Consult the dealer or an experienced TV technician for help

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme avec la norme NMB-003 du Canada.

authority to operate the equipment.

Copyright © 2013 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

02/01/13

2 A7974C

Page 3

Beacon Exit Device

Installation and Wiring Instructions

SECTION I: OVERVIEW

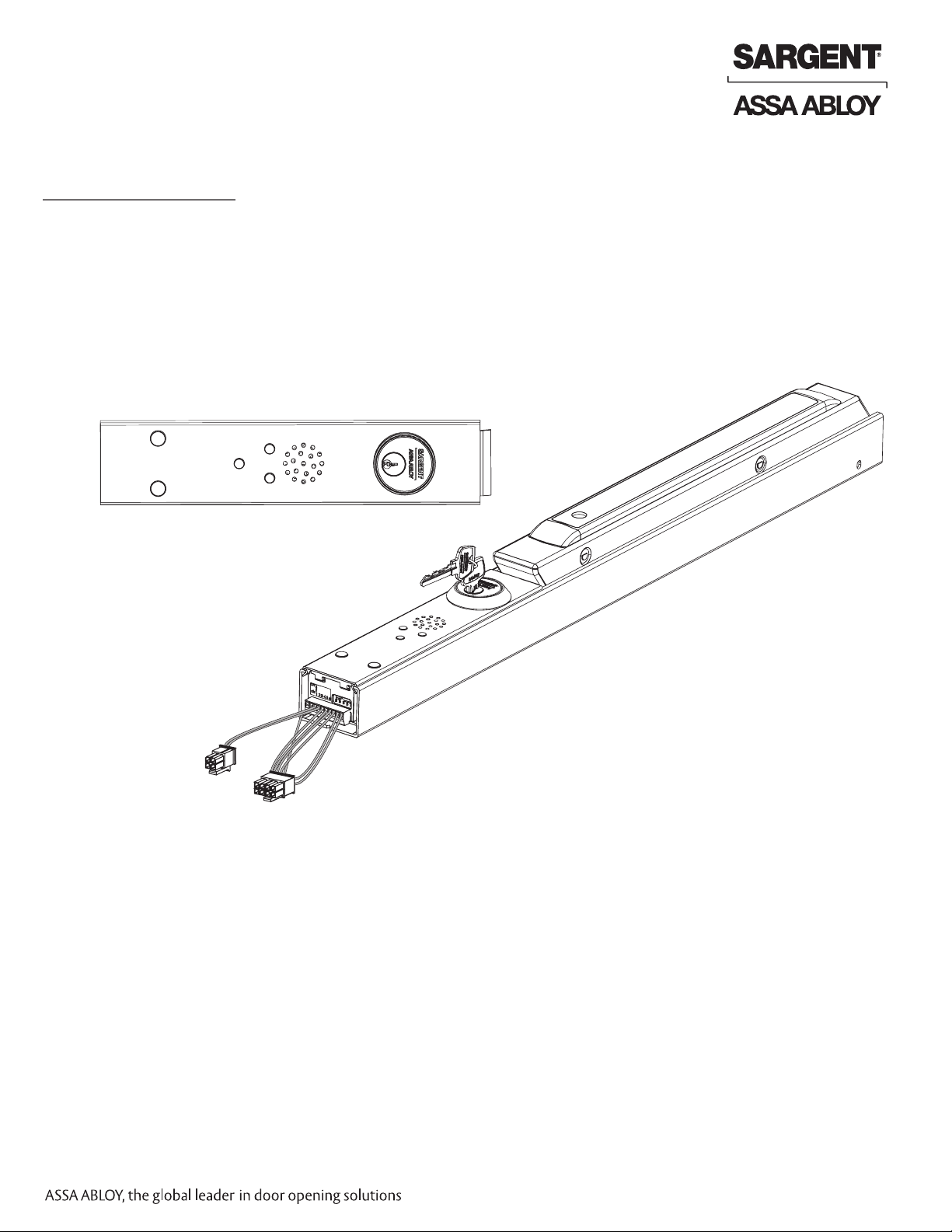

1. Description

Part of the ASSA ABLOY LiteGuide family of products, the Beacon exit device provides both

audible and visible alerts to enhance the visibility of exit locations in dark or smoke-filled

passages and is intended as a supplement to existing codes for emergency egress lighting

and direction.

Connected to the building’s alarm system, an activated Beacon emits pulsing light followed by

an audible message declaring “Exit located here” in single or multiple languages. A highly visible

green laser light cone combined with the pulsing LEDs draws people directly to the exit.

Amber

Diagnostic

LED

Green

Laser

Green

Ready-State

LED

Fig. 1 BEACON Exit Device

White

High-Intensity

LED

White

High-Intensity

LED

Speaker

Cylinder

Innovative design protected by

U.S. Patent Nos. 7,839,265 & 7,528,700

The SARGENT Beacon (BT-) Exit Device is compatible with the following prefix:

• TL- (SARGuide): Illuminated touchpad for 80 Series exit devices.

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

A7974C 3

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

02/01/13

Page 4

Installation and Wiring Instructions

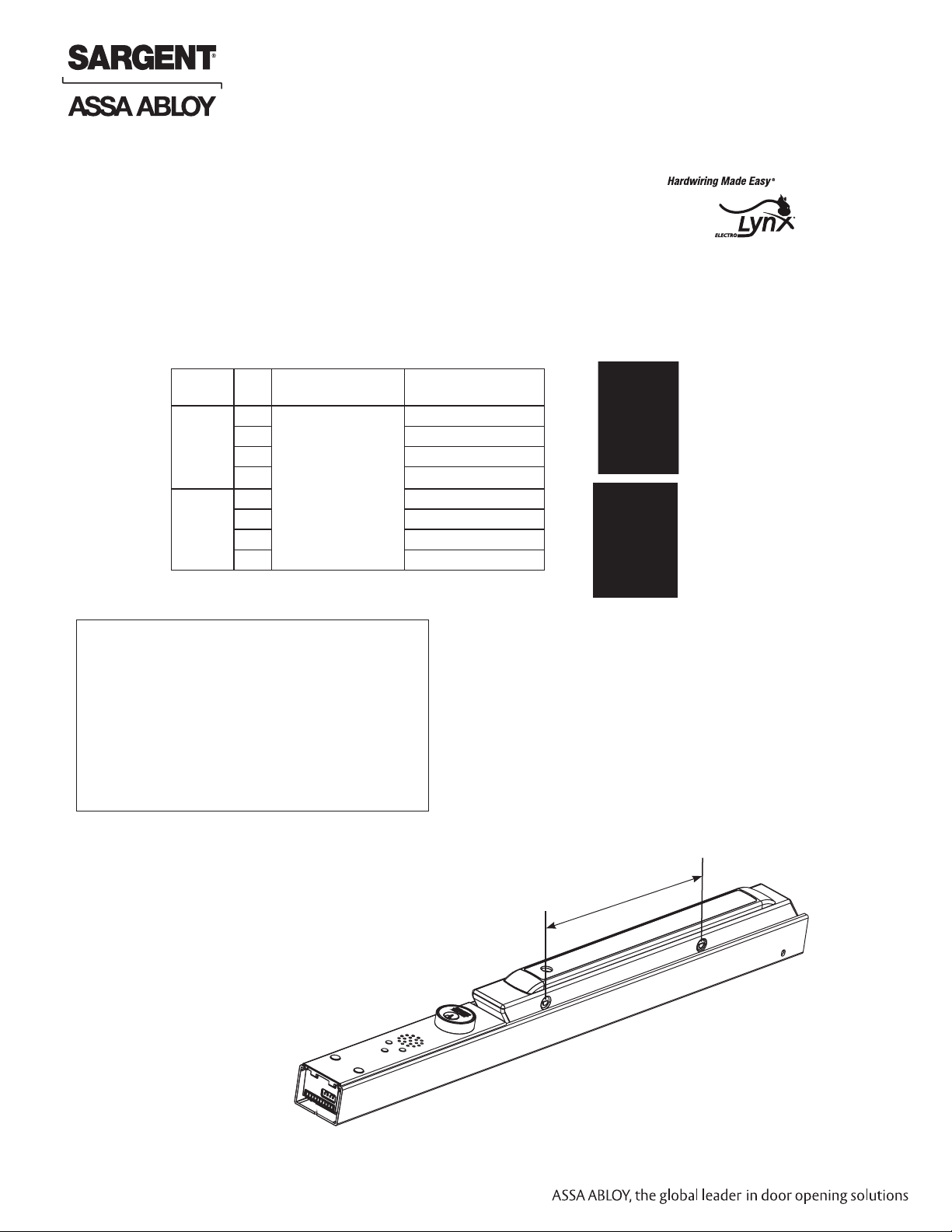

2. Hardware Specifications

• Easily installed within all 80 Series Exit Devices as either a retrofit kit or

as a factory installed option (consult catalog for exceptions).

• Order kit as 548-Kit (x door width x finish). See table below.

• Order factory installed option as BT- (e.g. BT-8813F x ETL x 32D x 36” door)

• Door Widths: Minimum Wide Stile Door 32”

• Convenient wiring installation with ElectroLynx 8-pin & 4-pin connectors*

*ElectroLynx door & frame wire harnesses and power transfer devices must be ordered separately.

Refer to McKinney Power Transfer Device Catalog for further information.

Beacon Exit Device

Stile Rail

Size

Wide E

F 35”- 36”

J 38”- 42”

G 44”- 48”

Narrow E 30”- 32”

F 33”- 36”

J 37”- 42”

G 43”- 48”

Type of

Exit Device

80 Series Exit

Devices

Note: The Beacon Retrofit Kits can NOT be

added to FM8700 Devices, Low Profile Exits

and devices with Cylinder Dogging (16-).

548- Retrofit Kits replace Beacon BT- ONLY

products (without other electrical prefixes).

For existing TL- BT-, consult factory.

The Retrofit Kits are based on rail design

(wide or narrow) and dimension from pivot

to pivot.

Size

Door

32” only

Wide Stile

Narrow Stile

Kit # Device Stile Rail Size Pivot to Pivot

548-1 Wide F 11-1/4”

548-2 Narrow F 11-1/4”

548-3 Wide G 20-1/2”

548-4 Narrow G 20-1/2”

548-5 Wide E 8-1/2”

548-6 Narrow E 8-1/2”

548-7 Wide J 14”

548-8 Narrow J 14”

*

Field-cut rail assemblies are not allowed.

The exit device must be ordered from

factory for specific door widths.

Copyright © 2013 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

02/01/13

4 A7974C

*Pivot-to-Pivot

Dimension

Fig. 2

Page 5

Beacon Exit Device

Installation and Wiring Instructions

3. Electrical Specifications

• Accepts alarm signal from either dry contact relay or 24VDC from the Notification Appliance Circuit

(NAC) of a Fire Alarm Control Panel (FACP)

• Low current draw 30mA @ 24VDC in Standby Mode, 900mA max @24VDC in Alarm Mode ensures long

operation time on back-up batteries. Power supply required; 24VDC, 1.0 amp, filtered and regulated.

• Test mode and diagnostic trouble reporting for ease of installation and periodic functional checks

• Customizable functionality through on-board adjustment of dip switch and NAC/CC slide switch settings

• Centralized control from fire alarm control panel (FACP) with silence and reset commands

• AHJ (Authority Having Jurisdiction) needs to authorize setup

Caution:

1. Disconnect all input power before beginning installation to prevent electrical shock and

equipment damage.

2. Installer must be a trained, qualified service person.

3. All wiring must comply with applicable local electrical codes, ordinances and regulations.

4. Beacon is equipped with a Class IIIa 5mW max output power (Green) laser.

Warning: Do NOT stare into laser beam.

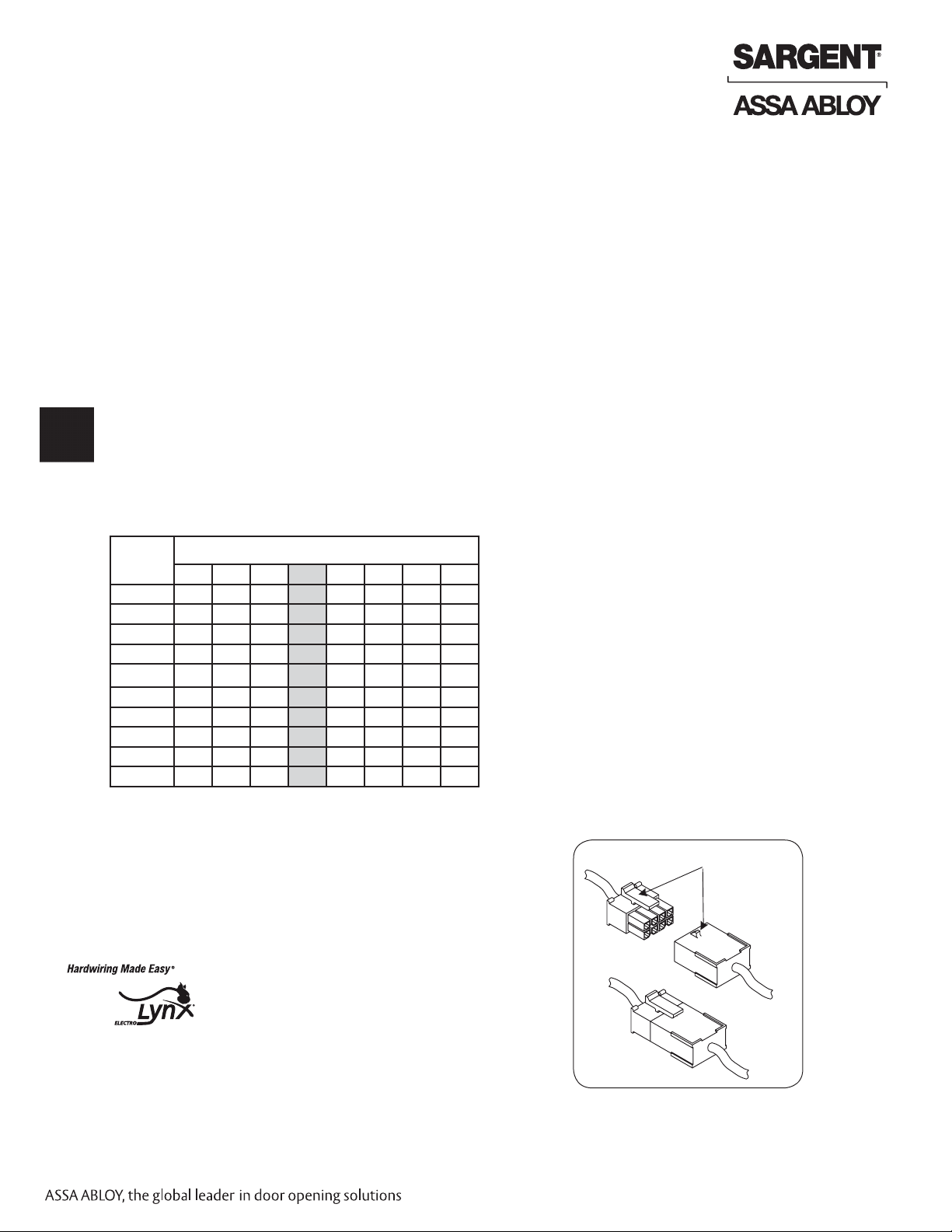

4. Wire Gauge Chart

Total

One-Way

Length of

Wire Run (ft)

1/4A 1/2A 3/4A *1A 1-1/4A 1-1/2A 2A 3A

100 24 20 18 18 16 16 14 12

150 22 18 16 16 14 14 12 10

200 20 18 16 14 14 12 12 10

250 18 16 14 14 12 12 12 10

300 18 16 14 12 12 12 10 —

400 18 14 12 12 10 10 — —

500 16 14 12 10 10 — — —

750 14 12 10 10 — — — —

1,000 14 10 10 — — — — —

1,500 12 10 — — — — — —

Load Current @ 24VDC

5. ElectroLynx Wiring System

BEACON exit devices are supplied with one 4-pin and one

8-pin Molex® connector harness, allowing simple installation

using the ASSA ABLOY ElectroLynx® system.

IMPORTANT: ElectroLynx connectors plug and

lock together in only one way.

Do NOT force connectors together.

*When calculating voltage drop, use 1A as the

recommended current draw for the BEACON

NOTE: For wire locations and positions, see

wiring examples later in this document.

Locking Mechanism

Plug

Receptacle

Fig. 3 ElectroLynx Connections

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

A7974C 5

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

02/01/13

Page 6

Installation and Wiring Instructions

SECTION II: Installation Instructions

1. New Installation

Rail assembly is shipped with cylinder installed.

A. If cylinder does not need to be replaced, verify proper switch settings for

your facility in Section II.4 - Alarm Mode Operation/Dip Switch Settings

and Section II.5 - Alarm Notification Switch Setting (NAC/CC).

B. If replacing cylinder, go to Section II.3 - Cylinder Installation/Replacement.

C. Complete wiring connections - refer to this manual’s example

wiring diagrams (Section III) for proper connections.

D. Refer to 80 Series installation instructions and complete

exit device installation.

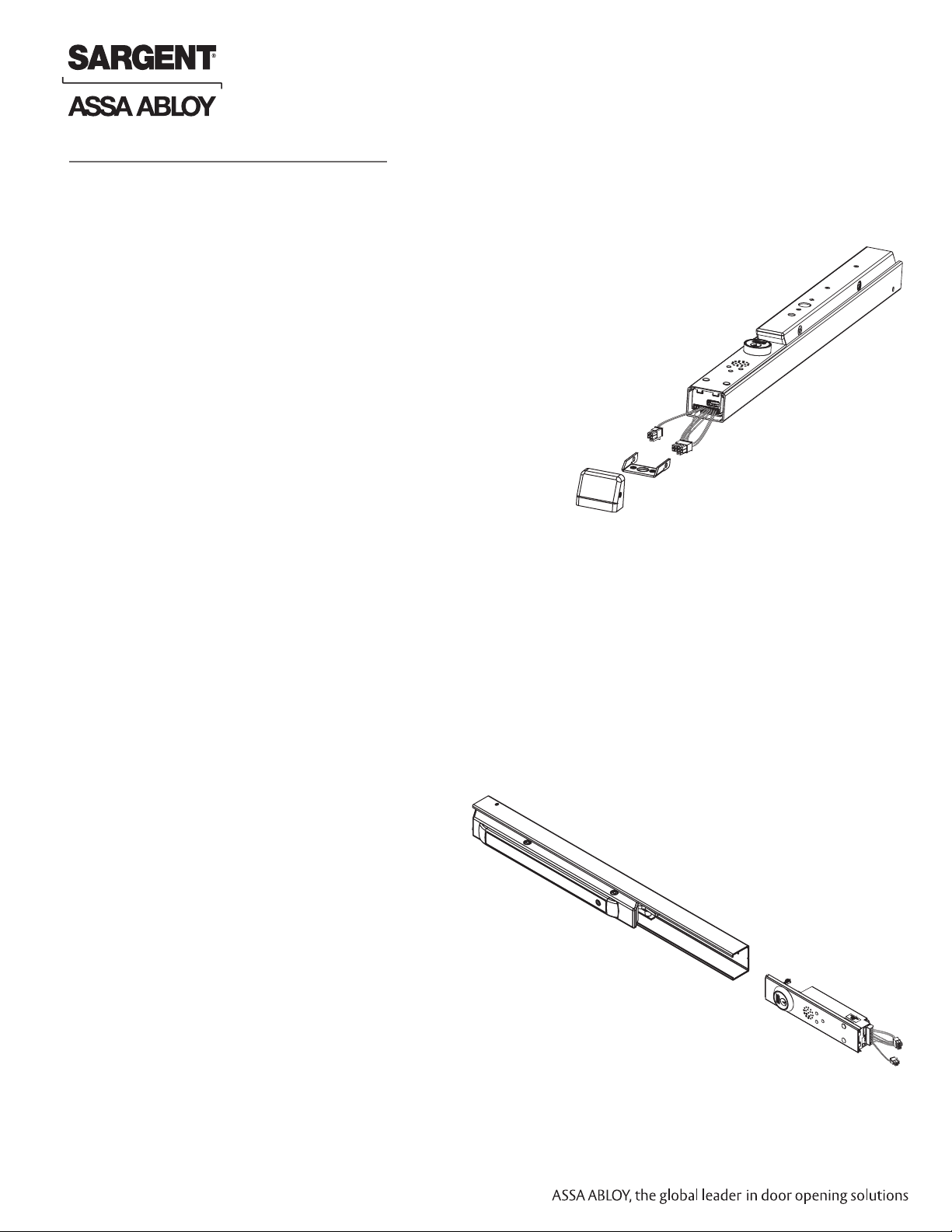

Beacon Exit Device

Mounting Bracket

End Cap

2. Kit Installation - Replacement/Servicing

If installing new Beacon insert assembly on existing mechanical rail:

A. Remove end cap and mounting bracket from rail assembly.

B. Remove insert plate by sliding out from rail assembly.

C. If replacing cylinder, go to Section II.3 - Cylinder Installation/Replacement.

D. Slide Beacon insert assembly into rail assembly (Fig. 5).

E. Complete wiring connections - refer to

this manual’s example wiring diagrams in

Section III for proper connections.

F. Reinstall mounting bracket and end cap.

Fig. 5

Rail Assembly

Fig. 4

Copyright © 2013 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

02/01/13

6 A7974C

Beacon Insert Assembly

Page 7

Beacon Exit Device

Installation and Wiring Instructions

2. Kit Installation - Replacement/Servicing (Continued)

If installing new Beacon insert assembly on existing Beacon (BT- only) electro-mechanical rail:

A. NOTE: Remove power from device.

B. Remove end cap and mounting bracket.

C. Slowly slide insert assembly (2 inches) away from push bar (Fig. 6), carefully checking for any

additional wires required for TL- prefix.

Fig. 6

D. Disconnect all wiring connectors before attempting to fully remove Beacon insert assembly.

E. Remove insert assembly by sliding out from rail assembly.

F. If replacing cylinder, go to Section II.3 - Cylinder Installation/Replacement.

NOTE: For TL-BT-, retain existing Beacon harness for reuse.

G. Slide new Beacon insert assembly into rail assembly.

H. Complete wiring connections - refer to this manual’s example wiring diagrams in Section III for

proper connections.

I. Reinstall mounting bracket and end cap.

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

A7974C 7

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

02/01/13

Page 8

3. Cylinder Installation/Replacement

To install or replace cylinder, Beacon insert assembly

must be removed from exit device.

NOTE: Remove power from device.

A. If necessary, remove end cap and mounting bracket.

B. Slowly slide insert assembly (partially) away from push

bar (Fig. 7), carefully checking for any additional wires

required for TL- prefix.

NOTE: Disconnect all wiring connectors before

attempting to fully remove insert assembly.

Beacon Exit Device

Installation and Wiring Instructions

Fig. 7

C. Remove insert assembly from exit device.

D. Rotate cylinder nut counter clockwise and remove (Fig. 8).

E. Remove cylinder and collar (Fig. 8).

NOTE: Use factory-supplied rings and collars.

F. Install cylinder with cylinder cam in proper

position. Cam must be positioned so that it makes

solid contact with plastic switch actuator when

rotated (Fig. 9).

Note: Cylinder must be installed as shown for

proper switch operation.

G. Complete wiring connections - refer to this

manual’s example wiring diagrams in Section III

for making the proper connections.

H. Install mounting bracket and end cap.

I. Refer to 80 Series installation instructions and

complete exit device installation.

Nut

Cylinder & Collar

Plastic Switch Actuator

Beacon

Insert Assembly

Fig. 8

Copyright © 2013 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

02/01/13

8 A7974C

Cam rotates to

Fig. 9

engage actuator

Page 9

Beacon Exit Device

Installation and Wiring Instructions

4. Alarm Mode Operation/Dip Switch Settings

A. Verify settings are correct for your facility’s

requirements.

NOTE: Device is shipped with factory default settings

(all switches ON - see Fig. 10 below).

Visual and audio (voice messages) will repeat sequence

in Alarm Mode.

If dip switch settings need to be changed from the factory

default, set according to chart (Fig. 11).

Two White

High-Intensity

LEDs

5 6

ON

English

Message

1 2

Fig. 10

Spanish

Message

French

Message

3 4

OFF

ON

Door

Surface

Not Used Green

1 2 3 4 5 6

Laser

Alarm Mode Operation Dip Switch Settings

• Two (2) WHITE LEDs flash continuously

• GREEN Laser ON 3 seconds

• ENGLISH message followed by

• GREEN Laser ON 3 seconds

• SPANISH message followed by

• GREEN Laser ON 3 seconds

• FRENCH message

• Two (2) WHITE LEDs flash continuously

• GREEN Laser ON 3 seconds

• ENGLISH message followed by

• GREEN Laser ON 3 seconds

• SPANISH message followed by

• Two (2) WHITE LEDs flash continuously

• GREEN Laser ON 3 seconds

• ENGLISH message only

• Two (2) WHITE LEDs flash continuously

• ENGLISH message followed by

• SPANISH message followed by

• FRENCH message

• (NO Green LASER)

• NO White LEDs

• GREEN Laser ON 3 seconds

• ENGLISH message followed by

• GREEN Laser ON 3 seconds

• SPANISH message followed by

• GREEN Laser ON 3 seconds

• FRENCH message

• NO White LEDs

• ENGLISH message followed by

• SPANISH message followed by

• FRENCH message

• (NO Green LASER)

• Trouble condition #4

• AMBER LED blinks 4 times and repeats

ON

1 2

Default Settings

ON

1 2

ON

1 2

ON

1 2

ON

1 2

ON

1 2

ON

1 2

3 4

3 4

3 4

3 4

3 4

3 4

3 4

5 6

5 6

5 6

5 6

5 6

5 6

5 6

5. Alarm Notification Switch Setting (NAC/CC)

Factory default for NAC/CC switch is set to

CC (closed contact).

To change Beacon to NAC Alarm Mode:

A. Flip unit; slide insert assembly out 2 inches (Fig. 12).

B. Set the device for NAC by moving the slide switch

to the left, as shown in Figure 12.

C. Once switch is in proper position, slide insert

assembly back into rail assembly.

D. Refer to Section III NAC wiring examples

for proper wiring of NAC (vs. CC).

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

Fig. 11

Fig. 12

A7974C 9

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

02/01/13

Page 10

Beacon Exit Device

Installation and Wiring Instructions

SECTION III: Beacon Wiring Examples

Wiring diagram examples reflect ElectroLynx system application.

For additional ElectroLynx product (door harnesses, power transfer devices, and frame harness) information and

requirements, refer to McKinney Power Transfer Device Catalog.

ElectroLynx power transfer device and harness requirement for all Beacon applications is QC12.

Beacon

TB1

1 + DC IN

2 -

3 + IN/CC

4 -

5 + RET

6 -

7 + SIL

8 -

Termination Description

Beacon Input Power: 24VDC (1.0 Amp minimum) from FACP (Fire Alarm Control Panel).

Beacon will operate from 16 to 33VDC.

Beacon Alarm input from FACP. Two choices: NAC IN (NAC) 24VDC (8 to 33VDC) or dry contact

closure (CC) sets Beacon into Alarm Mode. Set NAC/CC switch on Beacon module to NAC or CC

according FACP wiring application.

Additional Alarm signal connections for interconnectiing multiple Beacon rail assemblies

Beacon Silence input signal from FACP. Purpose is to stop Beacon audible (voice messages) during

a fire alarm so emergency personnel can listen to their radios. A valid silence condition occurs when

24vdc (8 to 33VDC) signal is present on the Silence Input for >= 500 msec, and is then removed for

>= 125 msec.

Simplified Diagram of an In-building Commercial Fire Alarm System

(excludes fire suppression and central station controls)

Copyright © 2013 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

02/01/13

10 A7974C

Page 11

Beacon Exit Device

Installation and Wiring Instructions

Example: NON-Addressable Fire Alarm System with BEACON

(Diagram ignores Initiating Devices)

NAC - Notification Appliance

Circuit

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

A7974C 11

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

02/01/13

Page 12

Beacon Exit Device

Installation and Wiring Instructions

Example: Addressable Fire Alarm System with BEACON

(Diagram ignores Initiating Devices)

NAC - Notification Appliance Circuit

SLC - Signalling Line Circuit

CC - (dry) Contact Closure

Copyright © 2013 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

02/01/13

12 A7974C

Page 13

Beacon Exit Device

Installation and Wiring Instructions

Example Wiring Diagram: BT- Beacon Exit Device

ElectroLynx Application

Must connect to Earth

Ground (EGND)

*

*

*

*

QC12

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

A7974C 13

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

02/01/13

Page 14

Example Wiring Diagram: TL- BT- (Beacon)

Exit Device ElectroLynx Application

Beacon Exit Device

Installation and Wiring Instructions

For TL- option, additional

External Power Supply

needed

Must connect to Earth

Ground (EGND)

*

*

QC12

Black,

Copyright © 2013 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

02/01/13

Red,

14 A7974C

Page 15

Beacon Exit Device

Installation and Wiring Instructions

SECTION IV: Alarm Mode Operation

Alarm Mode operates according to Dip Switch/Configuration Settings (Section II.4) and NAC/CC Switch

Setting (Section II.5)

1. Upon power up, the Green LED will light (Standby Mode).

2. When alarm is activated via a fire alarm, Beacon will activate.

3. Beacon will respond according to switch settings (see Section II.4) using:

• Flashing high intensity LEDs

• Audible message (Factory programmed)

• Laser (Green)

Amber

Diagnostic

LED

Green

Laser

Green

Ready-State

LED

White

High-Intensity

LED

White

High-Intensity

LED

Speaker

Cylinder

CAUTION: Do not stare into laser beam

4. Beacon will remain in Alarm Mode until manually reset by the cylinder (keyswitch rotated fully clockwise to

stop for >= two (2) seconds) or after power/alarm reset.

5. Upon reset, Beacon will return to Standby Mode/Ready State.

SECTION V: Test Mode Operation

Test Mode Features

Sequence of operation (from Standby Mode):

• Green LED is ON, key switch is operated by rotating fully clockwise (until stop) for >= 5 seconds.

Do NOT overtorque key switch. Green LED flashes 5 times then stays ON.

• Amber LED is OFF, flashes 6 times, ON

• Two high intensity LED’s are OFF, both flash 4 times, then OFF

• Green Laser is OFF, ON for 4 seconds, OFF

CAUTION: Do not stare into laser beam

• Voice messages play: English, Spanish, French

• Voice message: Test Mode Complete

• Green LED remains ON (back to Standby Mode)

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

A7974C 15

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

02/01/13

Page 16

Beacon Exit Device

Installation and Wiring Instructions

SECTION VI: BEACON Modes of Operation

Mode Description What Happens Initiated by: Deactivated by

Active/

Standby

Test

Alarm

Silence

Trouble

This mode can be

considered the idle state.

(Notification Alarms are shut

off in this mode)

A temporary state where the

Beacon will perform a selftest.

Beacon alarms in response

to fire alarm system outputs.

Overrides audible notification

during a fire alarm so that

emergency personnel can

listen to their radios.

Problem with operation,

setup or wiring

Green LED is ON. This is the default power on

Audio messaging will

play every message

once, followed by

“Test Mode Complete”

message.

All Visual Notification

including the high

brightness LEDs will

flash and laser cone

will illuminate for four

seconds.

Audio messaging will

play according to dip

switch settings.

High Brightness LEDs

and laser cone will

illuminate according to

dip switch settings.

state.

(Beacon is connected and

powered)

Rotating key switch clockwise

(to stop) for five seconds,

then releasing

Fire alarm system outputs Automatically returns to

Beacon comes out of

Active Mode whenever

another mode is triggered

Automatically returns to

Active Mode after cycling

Active Mode when:

• key switch is fully

rotated for two seconds, then released

• FACP alarm input is

inactive for two or

more seconds

See Silence Mode (below)

Audio messaging will

not play.

High Brightness LEDs

and laser cone will

illuminate according to

dip switch settings.

Blinking Amber LED Internal diagnostics See following section on

A silence condition can occur

only during ALARM MODE:

When Beacon’s Silence

input receives a valid

silence condition from FACP,

8-33VDC is present on the

Silence Input for >= 500ms,

and then removed for >=

125ms

Beacon alarm input is

inactive for two or more

seconds

NOTE: Audio messages

return if Silence input to

Beacon receives 8-33VDC

signal from FACP

When key switch is rotated

fully clockwise (to stop)

for two seconds, then

released, Alarm Mode is

turned off and unit returns

to Active state (Silence

Mode is turned off)

trouble conditions

Copyright © 2013 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

02/01/13

16 A7974C

Page 17

Beacon Exit Device

Installation and Wiring Instructions

Trouble Conditions and Corrective Actions

Fault Condition Fault Corrective Action

Blink Amber trouble LED

using repeating Blink *1

pattern.

*A 1 second blink with a 5

second pause.

Input power under

16VDC**

Correct input voltage to 24VDC (nominal);

(operates from 16-33VDC)

Blink Amber trouble LED

using repeating Blink 2*

pattern.

*Two 1 second blinks with a

5 second pause.

Blink Amber trouble LED

using repeating Blink 3*

pattern.

*Three 1 second blinks with

a 5 second pause.

Blink Amber trouble LED

using repeating Blink 4*

pattern.

*Four 1 second blinks with

a 5 second pause.

Blink Amber trouble LED

using repeating Blink 5*

pattern.

*Five 1 second blinks with a

5 second pause.

Laser over current

condition**

Motor over current

condition**

Invalid DIP switch

configuration

All DIP switches are OFF**

Key switch stuck error**

If key switch is detected as

turned for >= 30 seconds.

Replace Beacon Insert Assembly

Replace Beacon Insert Assembly

Refer to DIP Switch Setting/Configuration

Section II.4 for valid switch selections.

Inspect operation of cylinder cam with

Beacon plastic switch actuator.

Free possible obstruction or replace

Beacon Insert Assembly if inoperable.

**Disables all audible and visual notification alerts.

FOR INSTALLATION ASSISTANCE CONTACT SARGENT • 1-800-810-WIRE (9473) • www.sargentlock.com

A7974C 17

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

02/01/13

Page 18

SARGENT Manufacturing

100 Sargent Drive

New Haven, CT 06511 USA

800-810-WIRE (9473) • www.sargentlock.com

Founded in the early 1800s, SARGENT® is a market leader in locksets, cylinders, door closers, exit devices,

electro-mechanical products and access control systems for new construction, renovation, and replacement applications.

The company’s customer base includes commercial construction, institutional, and industrial markets.

Copyright © 2013, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

ASSA ABLOY is the global leader in door opening solutions, dedicated to

satisfying end-user needs for security, safety and convenience.

A7974C - 2/13

Loading...

Loading...