Page 1

SERVICE & OPERATING MANUAL

II 2GD T5

RHDB2

Hazardous Duty

Heavy Duty Ball Valve

AirVantage Design Level 1

Table of Contents

SAFETY PRECAUTIONS

Engineering, Performance and Construciton Data ............................................................................ 1

Explanation of Pump Nomenclature .................................................................................................. 2

Performance Curve ........................................................................................................................... 3

Dimensions ........................................................................................................................................ 4

Important Installation Information ...................................................................................................... 5

Principle of Pump Operation .............................................................................................................. 7

Principle of AirVantage ...................................................................................................................... 7

Installation and Start-Up .................................................................................................................... 7

Air Supply .......................................................................................................................................... 7

Air Line Moisture ................................................................................................................................ 7

Air Valve Lubrication .......................................................................................................................... 7

Air Inlet and Priming .......................................................................................................................... 7

Between Uses ................................................................................................................................... 7

Pump Troubleshooting ....................................................................................................................... 9

AirVantage Troubleshooting ...................................................................................................... 10-11

Composite Repair Parts List ........................................................................................................... 12

Composite Repair Parts Kits ........................................................................................................... 13

Composite Repair Parts Drawing: Wetted Side ............................................................................... 14

Diaphragm and Check Valve Servicing ........................................................................................... 15

Composite Repair Parts Drawing: Air Side ...................................................................................... 16

BOTTOM PORTED

Intermediate and AirVantage Sensor Servicing ............................................................................... 17

Air Valve Servicing, Assembly Drawings and Parts List .................................................................. 18

Air Valve Servicing with Stroke Indicators, Assembly Drawings and Parts List .............................. 19

Pilot Valve and Actuator Plunger Servicing .................................................................................... 20

Pulse Output Kits and Drawing ....................................................................................................... 21

Composite Repair Parts Drawing - AirVantage Unit ........................................................................ 23

AirVantage Servicing - Pilot Valve and Pressure Regulator ............................................................ 24

AirVantage Servicing - Power Generation Module .......................................................................... 25

AirVantage Servicing - Control Module ........................................................................................... 26

AirVantage Servicing - Sensor Assembly ....................................................................................... 27

AirVantage Servicing - Poppet Valve Drawing ................................................................................. 28

AirVantage Servicing - Poppet Valve .............................................................................................. 29

AirVantage Servicing - Check Valve ............................................................................................... 30

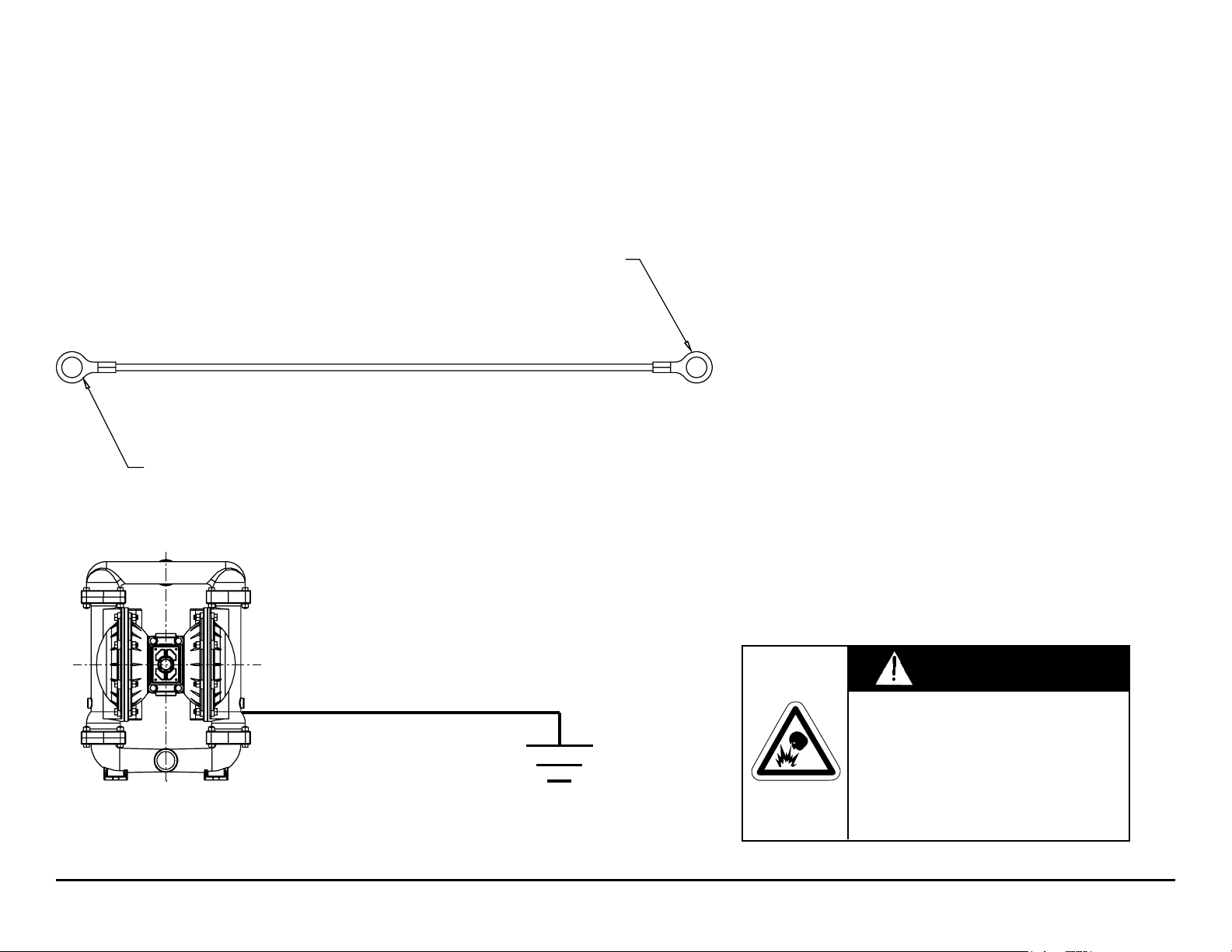

Grounding the Pump ...................................................................................................................... 31

Pumping Hazardous Liquids - Shutdown Procedure ...................................................................... 32

Converting the Pump for Piping Exhaust Air ................................................................................... 32

Material Codes for the Last 3 Digits of the Part Number ................................................................ 33

CE Declaration of Conformity - Machinery ...................................................................................... 34

CE Declaration of Conformity - ATEX .............................................................................................. 35

Declaration of Conformity - IECEx ................................................................................................... 36

US Patent # 6,241,487

US Patent # 7,521,921 Pending

TOP PORTED

II 2GD T4

Ex d ib IIB T4 Gb

Ex tb IIIC 135°C Db IP66

-20°C to +40°C

Sira 10ATEX1151X

IECEx SIR 10.0110X

2350863

Class I Div 1 - Groups C,D T4

Class II Div 1 - Groups F,G

Class I Zone 1, Ex d ib IIB T4

Class I Zone 1, AEx d ib IIB T4

Enclosure Type 4X

12 Volt (2 - 8) mA

rhdb2dl1sm_haz duty-rev0614

Warren Rupp, Inc.® • A Unit of IDEX Corporation • 800 N. Main St., Manseld, Ohio 44902 USA

Telephone (419) 524-8388 • Fax (419) 522-7867 • warrenrupp.com

©Copyright 2014 Warren Rupp, Inc. All rights reserved.

Page 2

Cautions - Read Operating and Safety Precautions First

IMPORTANT

Before installation and

start-up of the pump read

these safety warnings

and instructions in this

responsibility of the purchaser to retain this

manual for reference. Failure to comply with

the recommendations stated in this manual will

damage the pump, and void factory warranty.

manual completely. It is the

CAUTION

Before pump operation,

inspect all gasketed

fasteners for looseness

caused by gasket creep. Re-

prevent leakage. Follow recommended torques

torque loose fasteners to

stated in this manual.

CAUTION

Pump not designed,

tested or certified to be

powered by compressed

natural gas. Powering the

pump with natural gas will

void the warranty.

WARNING

Before maintenance

or repair, shut off the

compressed air line,

bleed the pressure, and

disconnect the air line from

the pump. The discharge

line may be pressurized and

must be bled of its pressure.

Recycling

Warren Rupp is committed to protecting the environment and preventing pollution

for the benet of our employees, as well as local and global communities, now

and in the future.

Many components of SANDPIPER® Metallic AODD pumps are made of recy-

clable materials (see chart on page 32 for material specications). We encourage

pump users to recycle worn out parts and pumps whenever possible. Follow all

applicable guidelines if hazardous material has been pumped.

WARNING

In the event of diaphragm

rupture, pumped material

may enter the air end of the

pump, and be discharged

into the atmosphere. If

is hazardous or toxic, the air exhaust must be

piped to an appropriate area for safe disposition.

pumping a product which

WARNING

Take action to prevent static

sparking. Fire or explosion

can result, especially when

handling ammable liquids.

The pump, piping, valves,

containers or other miscellaneous equipment

must be grounded. (See page 30)

WARNING

This pump is pressurized

internally with air during

operation. Always make

certain that all bolts are in

good condition and that

all of the correct bolts are

reinstalled during assembly. Do not open when

an explosive atmosphere may be present.

Users of electrical and electronic equipment (EEE) with the WEEE marking

per Annex IV of the WEEE Directive must not dispose of end of life EEE as

unsorted municipal waste, but use the collection framework available to them

for the return, recycle, recovery of WEEE and minimize any potential effects of

EEE on the environment and human health due to the presence of hazardous

substances. The WEEE marking applies only to countries within the European

Union (EU) and Norway. Appliances are labeled in accordance with European

Directive 2002/96/EC. Contact your local waste recovery agency for a

designated collection facility in your area.

None of the equipment supplied within the AirVantage unit either use

of exceed the amounts stated above hazardous substances. A signed

declaration from our supplier of the electronic/electrical portion of the

AirVantage unit will be held on le stating their adherence to the RoHS,

2002/95/EC regulation.

The enclosure is non-conducting and may generate an ignition-capable level

of electrostatic charges under certain extreme conditions. The user should

ensure that the equipment is not installed in a location where it may be subjected to external conditions (such as high-pressure steam) which might cause

a build-up of electrostatic charges on non-conducting surfaces. Additionally,

cleaning of the equipment should be done only with a damp cloth.”

WARNING

When used for toxic or

aggressive uids, the pump

should always be ushed

clean prior to disassembly.

WARNING

Before doing any

maintenance on the pump,

be certain all pressure is

completely vented from the

pump, suction, discharge,

piping, and all other openings

and connections. Be certain the air supply is locked

out or made non-operational, so that it cannot be

started while work is being done on the pump. Be

certain that approved eye protection and protective

clothing are worn at all times in the vicinity of the

pump. Failure to follow these recommendations

may result in serious injury or death.

WARNING

Airborne particles and

loud noise hazards.

Wear ear and eye

protection.

WARNING

Substitution of

components may impair

intrinsic safety.

WARNING

Use safe practices

when lifting

kg

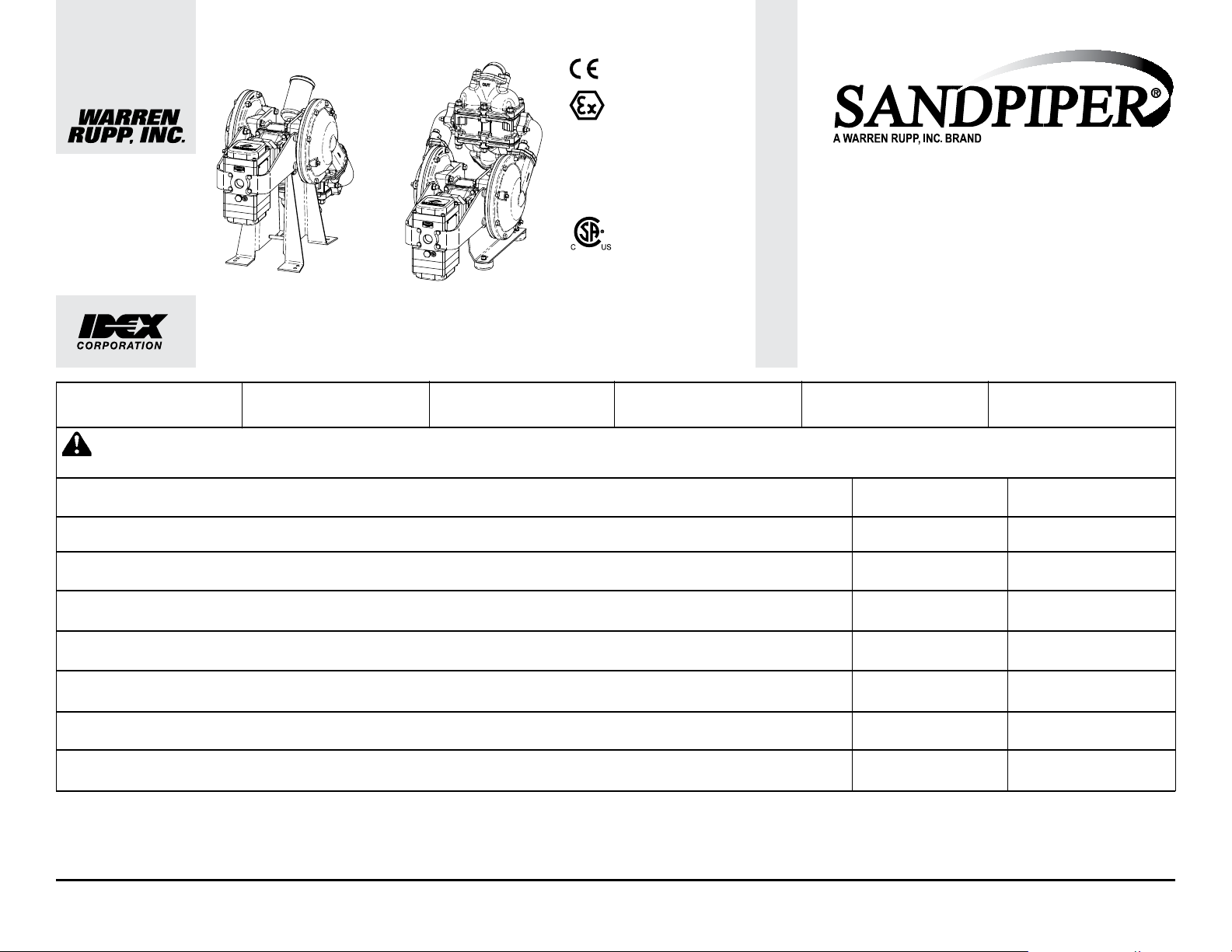

Page 3

Quality System

II 2GD T5

ISO9001 Certied

Environmental

Management System

ISO14001 Certied

BOTTOM PORTED

US Patent # 6,241,487

US Patent # 7,521,921 Pending

TOP PORTED

II 2GD T4

Ex d ib IIB T4 Gb

Ex tb IIIC 135°C Db IP66

-20°C to +40°C

Sira 10ATEX1151X

IECEx SIR 10.0110X

2350863

Class I Div 1 - Groups C,D T4

Class II Div 1 - Groups F,G

Class I Zone 1, Ex d ib IIB T4

Class I Zone 1, AEx d ib IIB T4

Enclosure Type 4X

12 Volt (2 - 8) mA

RHDB2

Hazardous Duty

AirVantage

Design Level 1

Heavy Duty Ball

Air-Operated

Double Diaphragm Pump

ENGINEERING, PERFORMANCE

& CONSTRUCTION DATA

INTAKE/DISCHARGE PIPE SIZE

2" NPT (internal)

CAUTION! Operating temperature limitations are as follows:

CAPACITY

0 to 130 gallons per minute

(0 to 492 liters per minute)

AIR VALVE

No-lube, no-stall

design

SOLIDS-HANDLING

Up to 3/8 in. (9mm)

HEADS UP TO

125 psi or 289 ft. of water

(125 psi or 8.6 bar inlet) (8.6 bar or 88 meters)

Operating Temperatures

DISPLACEMENT/STROKE

.47 Gallon / 1.77 liter

Materials Maximum Minimum

Nitrile: General purpose, oil-resistant. Shows good solvent, oil, water and hydraulic uid resistance. Should not be used with highly polar

solvents like acetone and MEK, ozone, chlorinated hydrocarbons and nitro hydrocarbons.

EPDM: Shows very good water and chemical resistance. Has poor resistance to oil and solvents, but is fair in ketones and alcohols.

Neoprene: All purpose. Resistant to vegetable oil. Generally not affected by moderate chemicals, fats, greases and many oils and solvents. Generally

attacked by strong oxidizing acids, ketones, esters, nitro hydrocarbons and chlorinated aromatic hydrocarbons.

Santoprene®:: Injection molded thermoplastic elastomer with no fabric layer. Long mechanical ex life.

Excellent abrasion resistance.

Virgin PTFE: Chemically inert, virtually impervious. Very few chemicals are known to react chemically with PTFE- molten alkali metals, turbulent liquid or

gaseous uorine and a few uoro-chemicals such as chlorine triuoride or oxygen diuoride which readily liberate free uorine at elevated temperatures.

FKM (Fluorocarbon): Shows good resistance to a wide range of oils and solvents; especially all aliphatic, aromatic and halogenated hydrocarbons,

acids, animal and vegetable oils. Hot water or hot aqueous solutions (over 70°F) will attack FKM.

Polypropylene:

UHMW Polyethylene:

For specic applications, always consult The Warren Rupp Chemical Resistance Chart

SANDPIPER® pumps are designed to be powered only by compressed air.

190° F

88° C

280° F

138° C

200° F

93° C

275° F

135° C

220° F

104° C

350° F

177° C

180° F

82° C

180° F

82° C

-10° F

-23° C

-40° F

-40° C

-10° F

-23° C

-40° F

-40° C

-35° F

-37° C

-40° F

-40° C

32° F

0° C

32° F

0° C

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 1

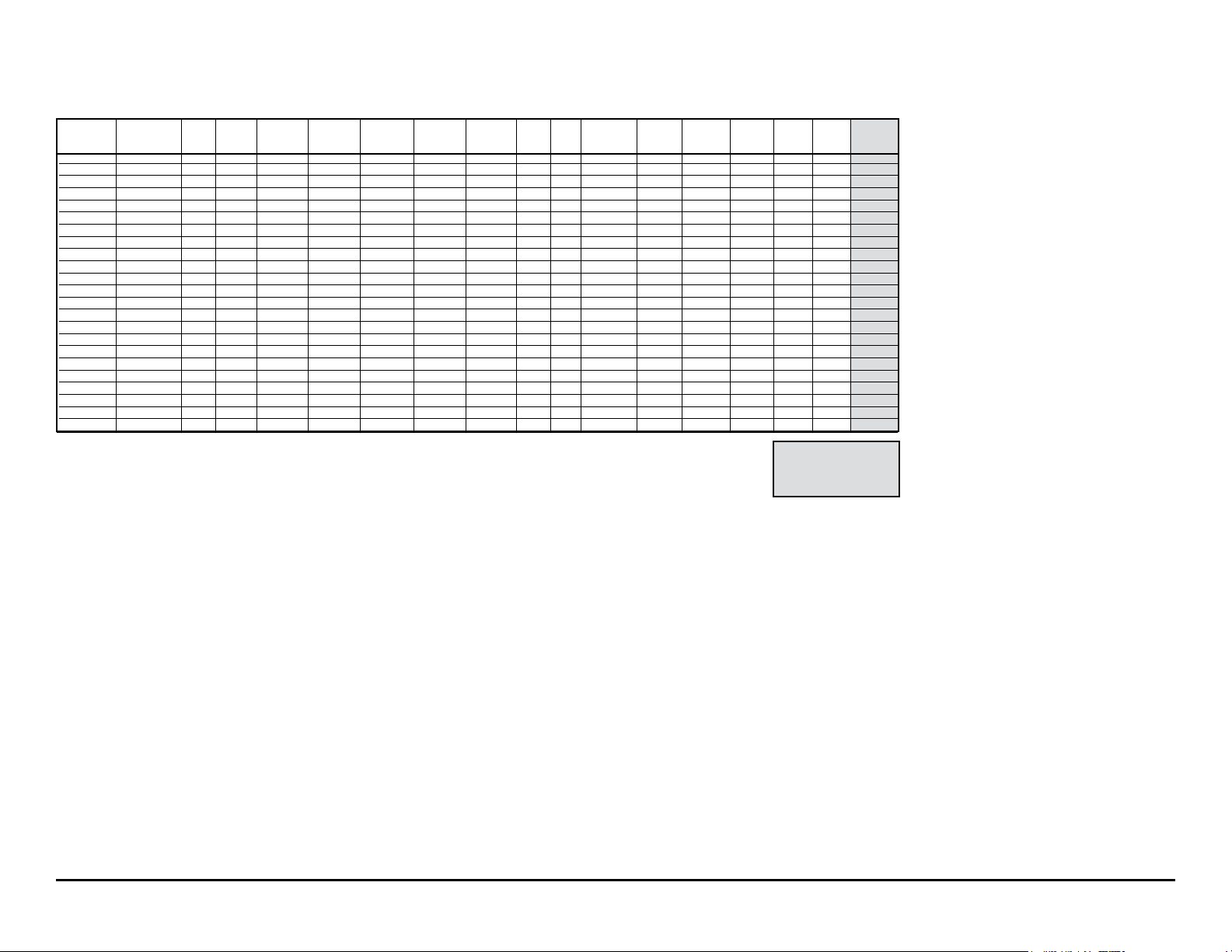

Page 4

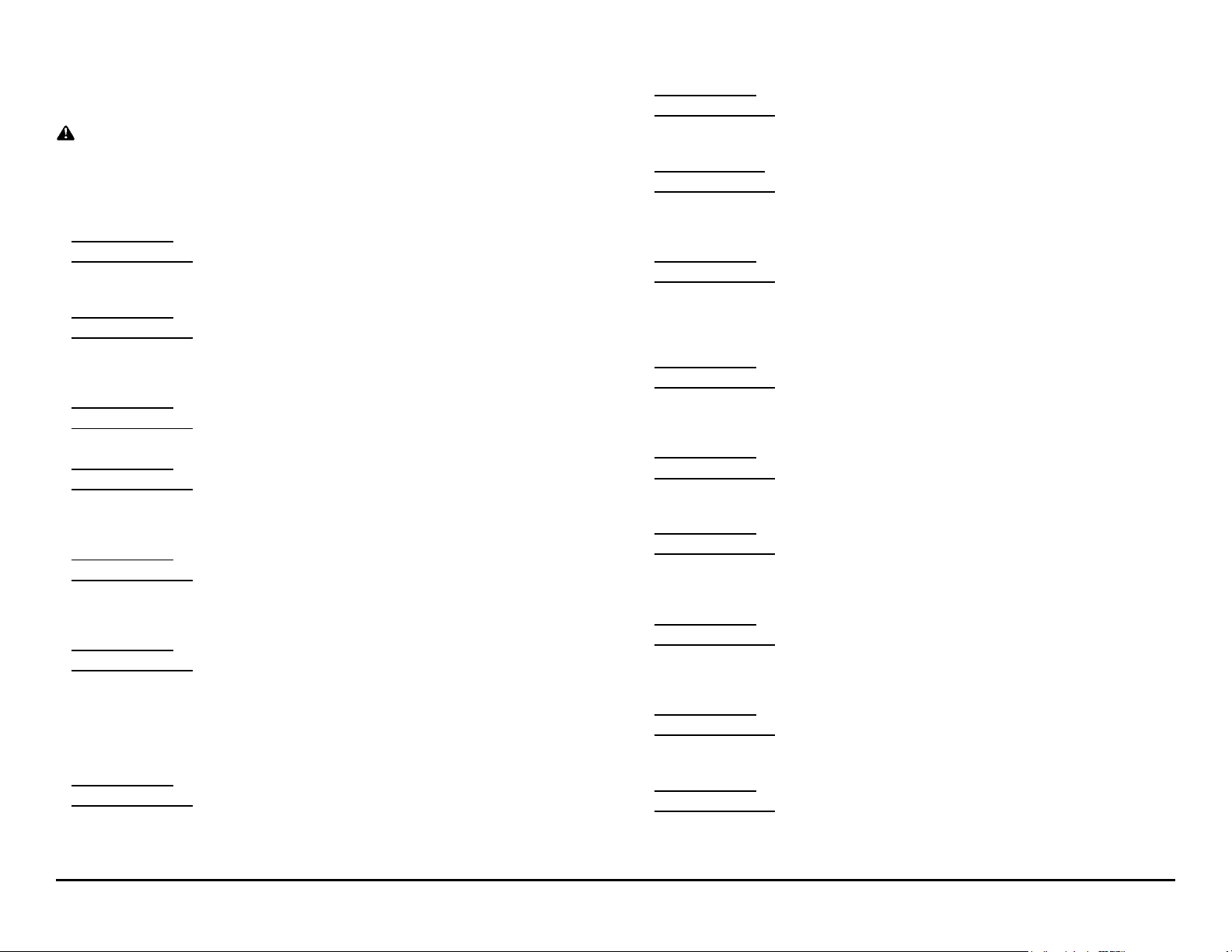

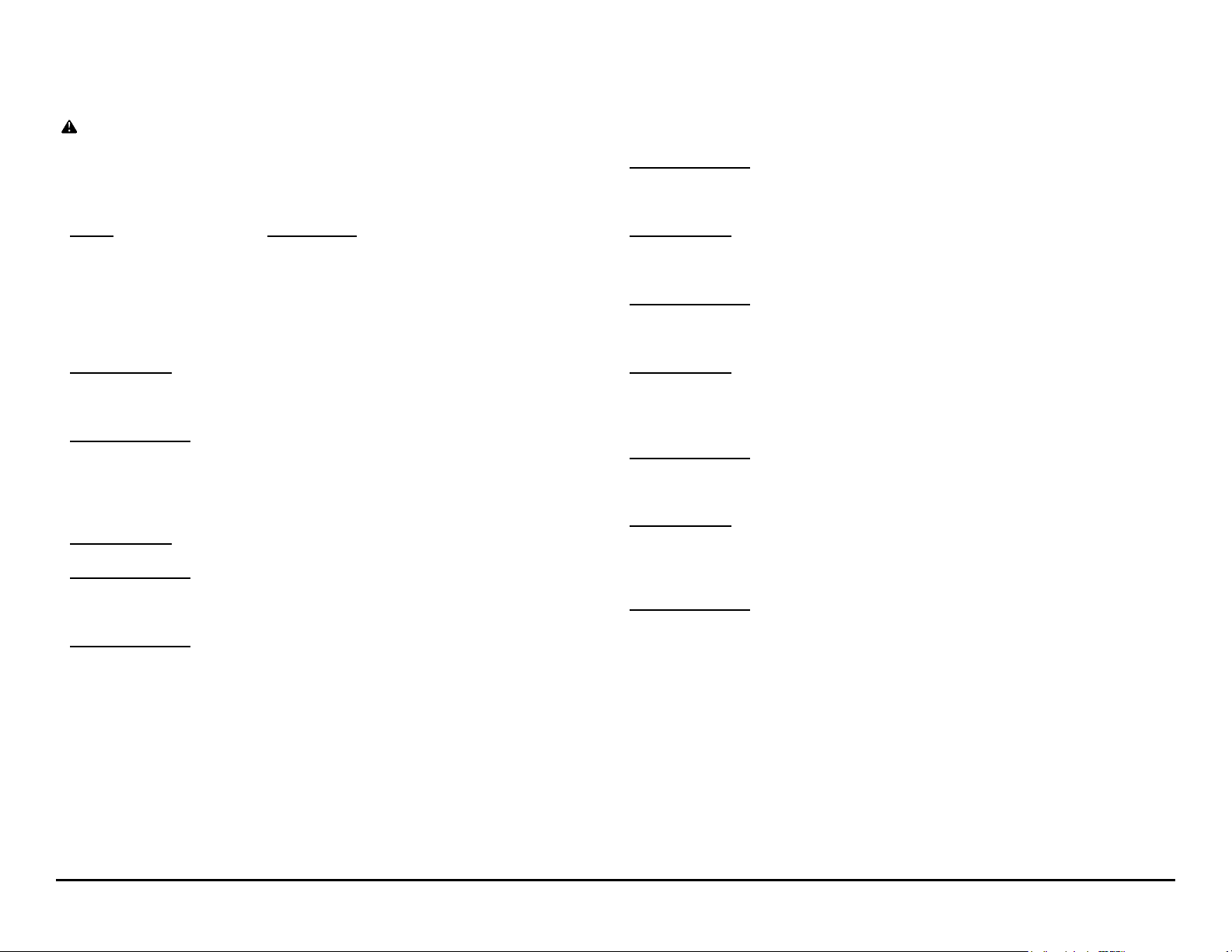

Explanation of Pump Nomenclature, RHDB2 Hazardous Duty Ball Valve

Outer Inner Ball Manifold Manifold Shipping Shipping

Top Bottom Manifold Outer Inner Diaphragm Diaphragm Intermediate Diaphragm Valve Hard- Diaphragm Valve Seat Sealing Wt. (lbs.) Wt. (lbs.) AirVantage

Porting Porting Chamber Chamber Plate Plate Housing Rod Seat ware Material Gasket Rings Top P Bottom P Options

TB-3-A DB-3-A AL AL AL CI PS AL SS SS PS B B CB B 105 112 Y

TC-3-A DC-3-A AL AL AL CI PS AL SS SS PS V T CT V 105 112 Y

TI-3-A DI-3-A AL AL AL CI PS AL SS SS PS I I CT I 105 112 Y

TN-3-A DN-3-A AL AL AL CI PS AL SS SS PS N N CN N 105 112 Y

TGI-3-A DGI-3-A AL AL AL CI PS AL SS SS PS I/T T CT V 105 112 Y

TGN-3-A DGN-3-A AL AL AL CI PS AL SS SS PS N/T T CT V 105 112 Y

TGR-3-A DGR-3-A AL AL AL CI PS AL SS SS PS H/T T CT V 105 112 Y

TS-3-A DS-3-A AL AL AL CI PS AL SS SS PS S S CT I 105 112 Y

TB-3-I DB-3-I CI CI AL CI PS AL SS SS PS B B CB B 151 161 Y

TC-3-I DC-3-I CI CI AL CI PS AL SS SS PS V T CT V 151 161 Y

TI-3-I DI-3-I CI CI AL CI PS AL SS SS PS I I CT I 151 161 Y

TN-3-I DN-3-I CI CI AL CI PS AL SS SS PS N N CN N 151 161 Y

TGI-3-I DGI-3-I CI CI AL CI PS AL SS SS PS I/T T CT V 151 161 Y

TGN-3-I DGN-3-I CI CI AL CI PS AL SS SS PS N/T T CT V 151 161 Y

TGR-3-I DGR-3-I CI CI AL CI PS AL SS SS PS H/T T CT V 151 161 Y

TS-3-I DS-3-I CI CI AL CI PS AL SS SS PS S S CT I 151 161 Y

TB-3-S DB-3-S

TC-3-S DC-3-S

TI-3-S DI-3-S

TN-3-S DN-3-S

TGN-3-S DGN-3-S

TGR-3-S DGR-3-S

TS-3-S DS-3-S

Meanings of

Abbreviations:

‡SS ‡SS AL SS PS AL SS SS PS B B CB B 166 173 Y

‡SS ‡SS AL SS PS AL SS SS PS V T CT V 166 173 Y

‡SS ‡SS AL SS PS AL SS SS PS I I CT I 166 173 Y

‡SS ‡SS AL SS PS AL SS SS PS N N CN N 166 173 Y

‡SS ‡SS AL SS PS AL SS SS PS N/T T CT V 166 173 Y

‡SS ‡SS AL SS PS AL SS SS PS H/T T CT V 166 173 Y

‡SS ‡SS AL SS PS AL SS SS PS S S CT I 166 173 Y

A = Compressed Fibre

AL = Aluminum

B = Nitrile

CB

= Conductive Nitrile

CI = Cast Iron

CN = Conductive Neoprene

CT = Conductive PTFE

DC = Die Cast

H/T

= Hytrel® Backup/PTFE

Overlay

I = EPDM

I/T = EPDM Backup/PTFE Overlay

N = Neoprene

N/T

= Neoprene Backup/

PTFE Overlay

PS = Plated Steel

S = Santoprene

SS = Stainless Steel

T = PTFE

V = FKM

®

X = AirVantage

ATEXCertied

Y = US Hazardous Duty

‡ CF-8M Stainless SteelequaltoorexceedingASTMspecicationA743forcorrosionresistantironchromium,ironchromiumnickel,andnickelbasedalloycastingsfor

generalapplications.Commonlyreferredtoas316StainlessSteelinthepumpindustry.

Santoprene is a registered tradename of Exxon Mobil Corp.

Hytrel is a registered tradename of E.I. du Pont.

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 2

Page 5

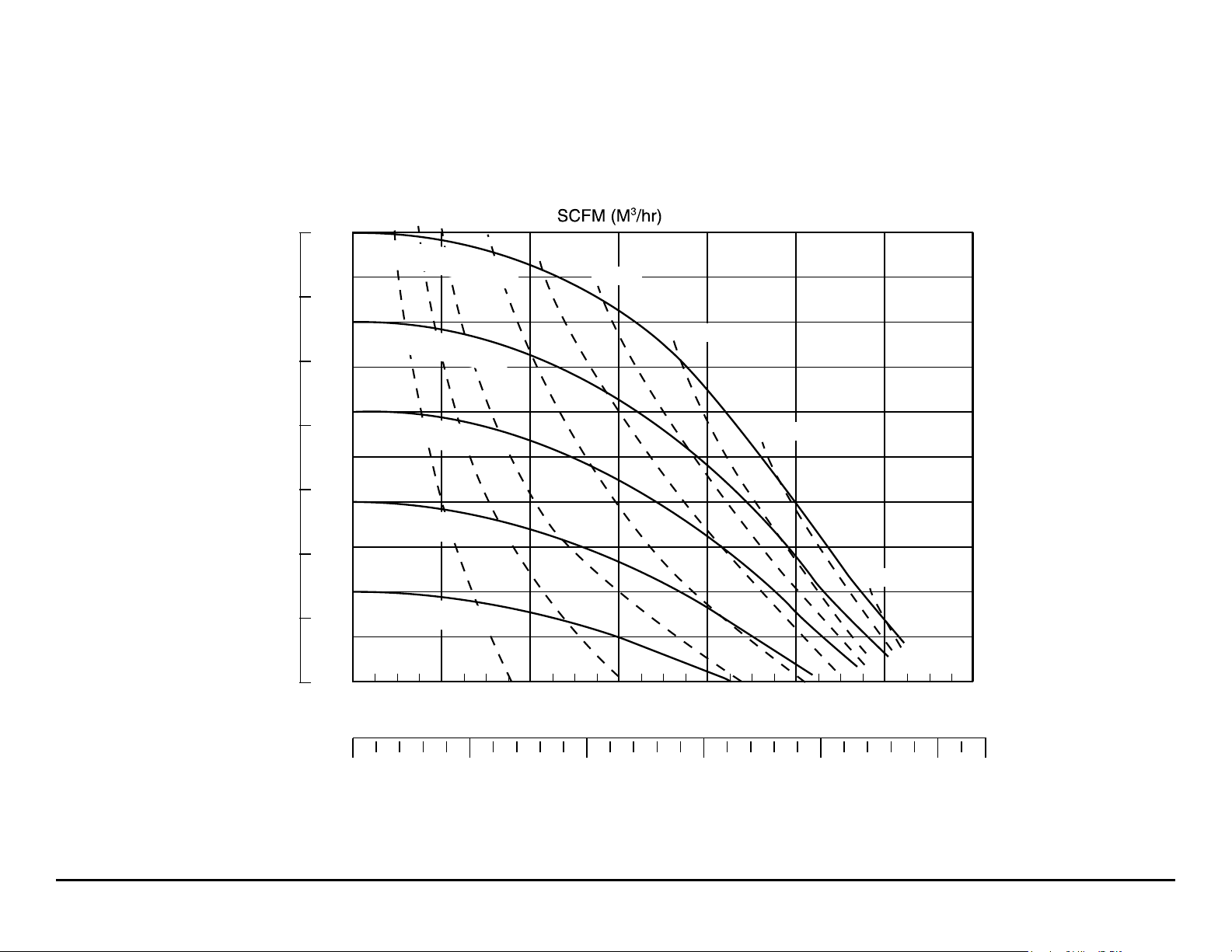

Performance Curve,

Model RHDB2 Performance Curve

Performace based on the following: elastomer fitted pump, flooded suction, water at ambient conditions.

BAR

100

7

6

5

4

HEAD

3

2

1

RHDB2 Hazardous Duty Ball Valve

The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%.

15

10

PSI

(17)

100 PSI (6.9 Bar)

90

80

80 PSI (5.5 Bar)

70

60

60 PSI (4.1 Bar)

50

40

40 PSI (2.8 Bar)

30

20

20 PSI (1.4 Bar)

10

(25)

20

(34)

30 (51)

40 (68)

50 (85)

60 (102)

70 (119)

80

(136)

0

0

0 20 40 60 80 100 120 140

U.S. Gallons per minute

500400300200100

Liters per minute

CAPACITY

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 3

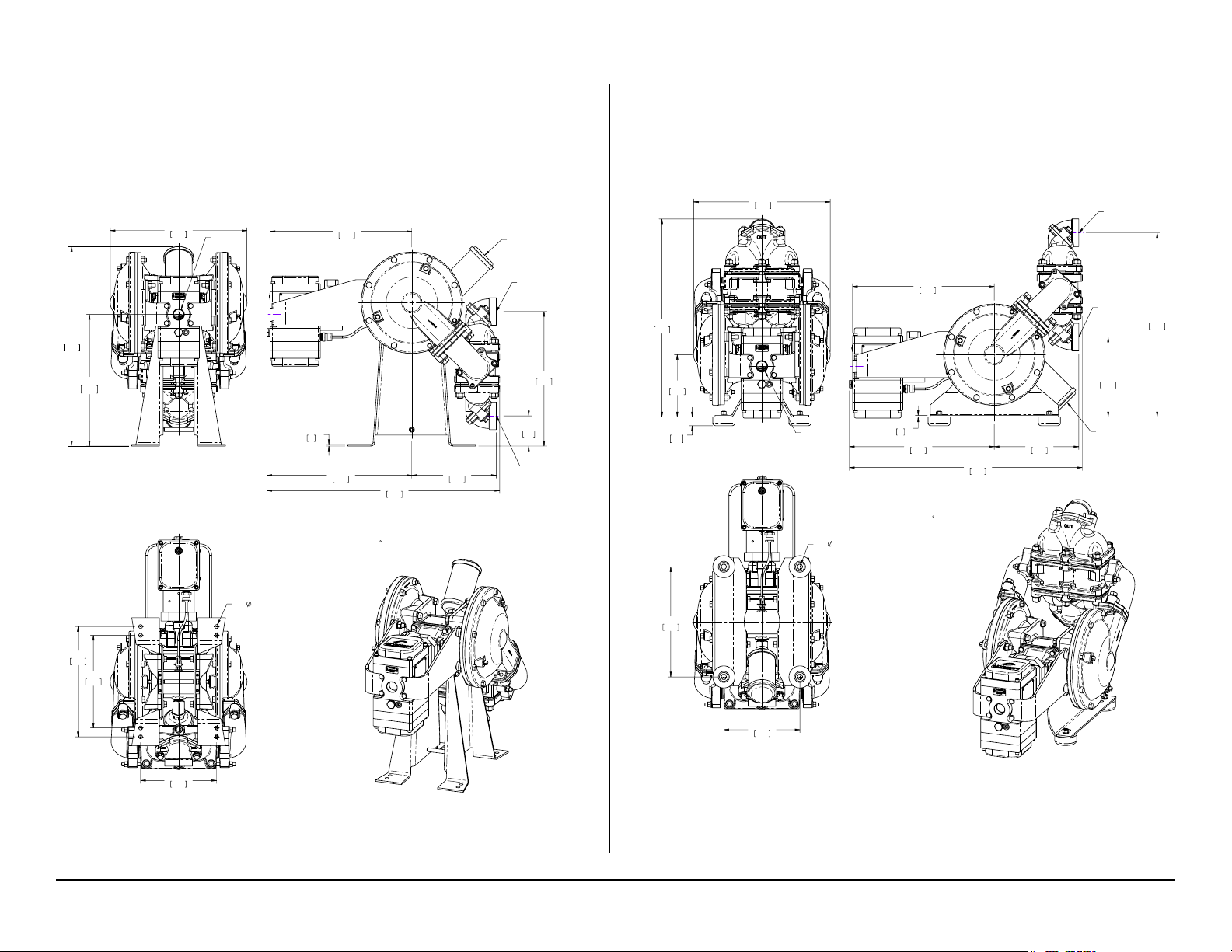

Page 6

Dimensions: RHDB2 Hazardous Duty

15.50

Dimensions: RHDB2 Hazardous Duty

Bottom Ported

Dimensions are ± 1/8"

Figuresinparenthesis=millimeters

394

AIR INLET

1" FNPT

22.63

575

14.93

379

16.07

408

.18

5

16.43

417

SUCTION AND DISCHARGE PORTS ARE

AVAILABLE WITH 2" BSP CONNECTIONS

SUCTION AND DISCHARGE PORTS CAN

BE ROTATED 90

26.40

671

FOR VERTICAL PORTING

9.59

Top Ported

Dimensions are ± 1/8"

Figuresinparenthesis=millimeters

15.50

394

3/4" NPT EXHAUST

DISCHARGE PORT

2" FNPT

22.45

570

15.27

388

3.43

87

SUCTION PORT

243

2" FNPT

7.06

179

4X

1.00

25

AIR INLET

1" NPT

8X

.44

[11] MTG.HOLE

16.07

408

.18

5

16.43

417

SUCTION AND DISCHARGE PORTS ARE

AVAILABLE WITH 2" BSP CONNECTIONS

SUCTION AND DISCHARGE PORTS CAN

BE ROTATED 90

26.40

670

FOR VERTICAL PORTING

9.59

243

DISCHARGE PORT

2" NPT

SUCTION PORT

2" NPT

9.05

230

3/4" NPT EXHAUST

20.89

531

8X

.44

[11] MTG. HOLE

12.50

318

12.50

318

10.50

267

8.63

219

8.63

219

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 4

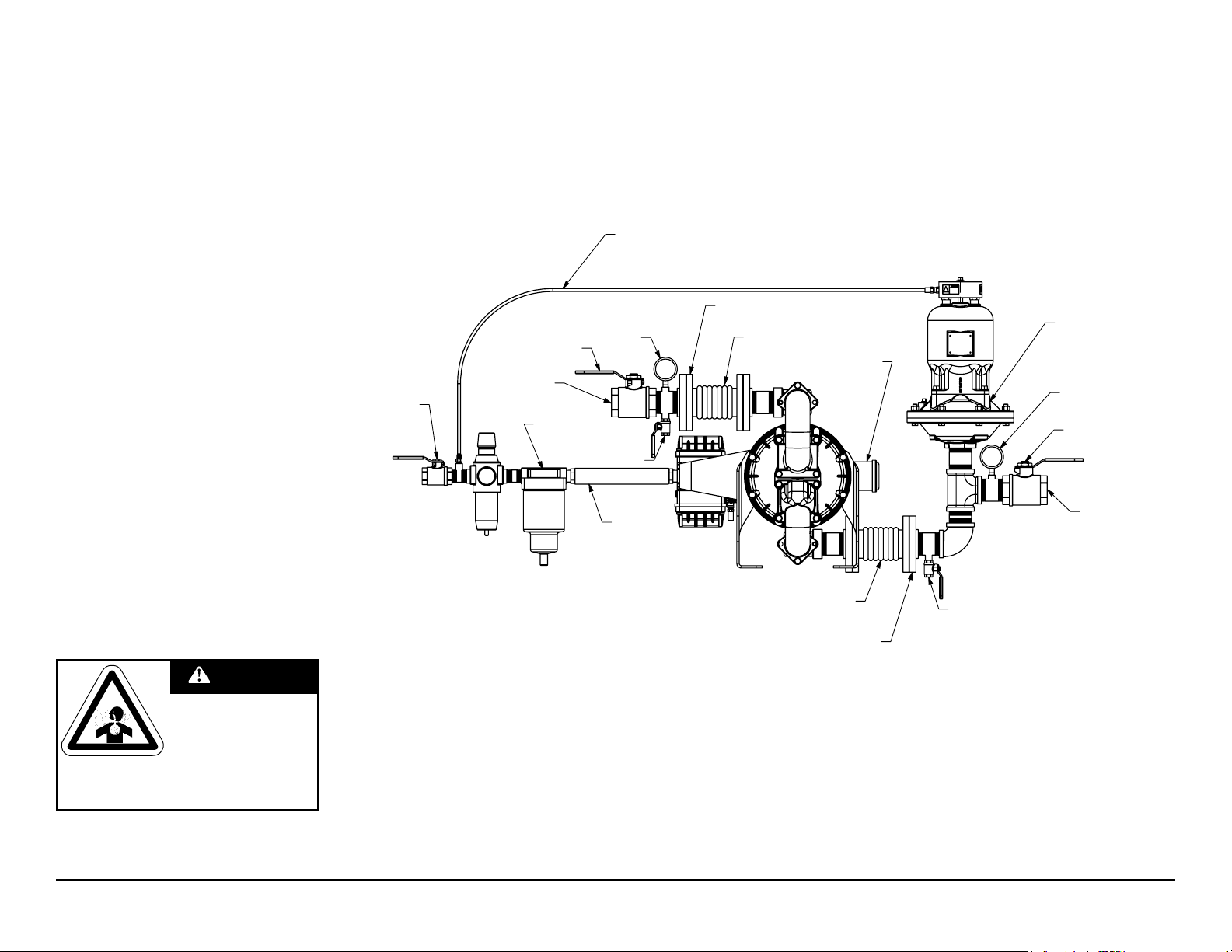

Page 7

Important Installation Information

Use of the standard AODD Installation Guide is recommended for pumps

tted with AirVantage technology. Install shut-off valves on both the suction and

discharge of the pump. (This will help limit the amount of product that enters the center section

of the pump in the event of a diaphragm failure.) Using shut-off valves in conjunction with a drain

port also provides a means of allowing the lines to be drained when maintenance needs to

be conducted.

When the supply liquid level is above the air inlet of the pump, and a

diaphragm fails, the pumped liquid or fumes can enter the air end through

the point of failure. When a diaphragm failure is detected, it is best to close

the shut-off valves and bleed the lines of product. This will limit the ability

of the material being pumped to enter the AirVantage. Failure to do so may

result in damage to the AirVantage and air distribution components.

If a diaphragm failure has been detected in pumps

tted with AirVantage, the following procedure for

shut-down must be used:

1. Close the suction shut-off valve

(this will limit any new product from

entering the pump)

2. Close the discharge shut-off valve

(this will stop any product from

reentering the pump)

3. Close the air supply shut-off valve

4. Drain the discharge line

5. Drain the suction line

6. Perform maintenance

Shut O

Valve

Shut-O Valve

Suction Port

Dessicant Dryer

(Optional)

Unregulated Air

Supply to Tranquilizer

Filter Regulator

PN: 020.107.000

Vacuum

Gauge

Drain Port

Flexible

Connection

Suggested Installation Guide

Pipe Connection

(Style Optional

Flexible Connector

(Optional Piped Exhaust)

Muer

Warren Rupp Tranquilizer

Limited to 125 psi

(Optional)

Pressure Gauge

Shut-O Valve

Discharge Port

Caution: When performing a direct spray washdown, a

plug must be installed in place of the AirVantage mufer.

Failure to do so may damage internal components.

(See page 23)

Flexible Connector

Pipe Connection

(Style Optional)

Drain Port

Note: Pipe weight should not be supported

by pump connections.

WARNING

In the event of diaphragm

rupture, pumped material

may enter the air end of the

pump, and be discharged

pumping a product which is hazardous or toxic,

the air exhaust must be piped to an appropriate

area for safe disposition.

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 5

into the atmosphere. If

Page 8

This Page Intentionally Blank

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 6

Page 9

PRINCIPLE OF PUMP OPERATION

This ball valve tted pump has been equipped with IDEX’s patented AirVantage equipment. To fully understand the

operation of the AirVantage, one must rst understand the basics of Air Operated Double Diaphragm (AODD) pumps.

AODD’s are powered by compressed air. The compressed air is directed behind each of the exible diaphragms by a

Main Air Valve. Once the diaphragm has reached the end of its stroke, a Pilot Valve is mechanically actuated, sending

an air signal back to the Main Air Valve which redirects air to the opposite diaphragm. This causes the diaphragm

assemblies, which are connected by a common Diaphragm Rod, to move in a reciprocating action.

Air is directed to the inboard side of the diaphragm, which is closest to the center of the pump. This is referred to

as the air side of the diaphragm. The opposite side is commonly called the uid side. Most AODD pumps have a 1:1

ratio design. This means, when the discharge of the pump is closed completely (dead headed), the maximum pressure

the pump will create will be equal to the air pressure being applied to the pump. At this point, and only at this point, the

diaphragm will be completely balanced. The air pressure is equivalent to the uid pressure and there will be no movement

of the diaphragm. If the pump is stroking, then the system is not balanced. There will be more pressure applied to the air

side than uid pressure on the uid side.

During each stroke of the pump there are two distinct operations that occur. One diaphragm is moving away from

the center of the pump, moving uid out of the Discharge Manifold, while the other diaphragm is moving toward the

center, bringing uid into the Suction Manifold. Considering that the pump has a common suction and discharge port,

these two operations are separated from each other through a series of Check Valves.

PRINCIPLE OF AIRVANTAGE

AirVantage is a special air side device which uses equipment that can accurately monitor the operation of the pump.

Based on the monitored information, air is metered to the correct amount to perform the work required, and

NOTHING MORE.

Once the pump starts up, and the AirVantage is turned on, the LED indicator light will go through a series of patterns.

Initially the light will be solid green. This indicates the AirVantage is allowing the pump to reach a steady state. Next,

the light will pulse at a very rapid rate. This is called the learn phase. Learn is where the AirVantage monitors the pump

in non-AirVantage mode. This will set the parameters for operation in AirVantage mode. In less than one minute, the

pump will change tones. The LED indicator light will start an uneven blink when optimization has started. Optimization

will be completed once the LED light is blinking in unison with the stroke rate of the pump. All this is completed without

sacricing a signicant amount of ow.

AIR LINE MOISTURE

Water in the compressed air supply can create problems such as icing and freezing of the exhaust air. The

formation of ice in the exhaust can cause the pump to cycle erratically, degrade efciency, or even stop the pump. Fitting

the pump with the AirVantage technology reduces the exhaust temperature. This is due to more energy being extracted

from every pulse of air. When more energy is extracted, the temperature of the air is reduced. Some method of air drying

will be necessary. Most refrigerant dryers installed on compressors can reduce the dewpoint to about 40° F. This is

normally adequate for most pumping applications. If further drying needs to occur due to internal ice build-up, a desiccant

dryer can be installed. These air line dryers can lower the dewpoint to around -40° F.

AIR VALVE LUBRICATION

The air valve and pilot valve are designed to operate without lubrication. There may be instances of personal

preference or when extremely dry air is being used (instrument quality or nitrogen) that a small amount of lubrication will

improve the life of the rubber components being used on the air side of the pump. The lubrication may be added using an

air line lubricator (¾” PN: 020.051.001 – 1” PN: 020.052.001). At the point of operation use SAE 10 weight, non detergent

oil at a maximum rate of 1 drop per hour for every 20 scfm (9.4 liters/sec) of air consumption. Consult the pump curve to

determine this value. The smallest amount needed is preferred.

AIR INLET AND PRIMING

To start the pump, make sure the AirVantage switch is in the off position. Increase the pressure until the pump starts

to cycle. The pump stroke rate should slow slightly when the pump is primed. Once the pump is fully primed, increase

the pressure at the regulator until the desired ow rate is achieved. Again, the pump curve can be used to derive this

value. If increasing the pressure to the pump does not generate a higher ow rate, then cavitation has occurred. Back the

regulator off slightly. To gain the most efciency from the pump, try to run the pump fully primed at all times.

BETWEEN USES

When the pump is being used to move materials that tend to settle out or solidify, the pump should be ushed to

prevent damage. The product that remains in the pump could dry and settle out. This could potentially cause damage

to the diaphragms and/or check valves during restart. In freezing temperatures the pump must be completely drained

between uses. Due to the addition of the new technology, it is recommended the air supply to the pump be shut off if the

pump is going to be shut down for an extended length of time.

INSTALLATION AND START-UP

The pump should be located near the product being pumped, in order to keep the suction line as short as possible.

Minimize the number of ttings between the product and the pump and maintain the line size, if possible. Better results

will always be realized if the line size of the suction line is increased by one size. It's not recommended to hook up

rigid pipe directly to the pump. Some method of expansion joint or vibration isolator should be used. A Warren Rupp

Tranquilizer

the level of the pump, a pressure regulating device may need to be added to the exhaust of the pump (Consult the factory

for recommendations).

AIR SUPPLY

The air supply pressure cannot exceed 125 psi (8.6 bar). The air line and associated components (lters,

regulators, solenoid valves, etc.) should not be less than ½” (13 mm). However, 3/4" (19mm) or greater is preferred. An

air line lter-regulator is necessary for the AirVantage installation. The required component (PN: 020.107.000) is available

through the distributor. Rigid pipe should not be hooked directly to the air inlet of the AirVantage. A exible hose should be

installed to reduce the strain. Do not let the weight of the air line components be supported by the air inlet of the pump.

Failure to provide a means of supporting the weight may result in damage to the pump. If the pump will be shut down for

any extended length of time, it is recommended that the air supply to the pump should be shut off.

SPECIAL CONDITIONS FOR SAFE USE

For the safe operation of the equipment, it is necessary for the air supply to come from a safe area, therefore,

the supplied air shall be clean.

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 7

®

is recommended to reduce the pulsation in the ow. If the uid level is more than 10 feet (3 meters) above

WARNING

Hazardous Duty Rating

This pump is certied to be

operated in the hazardous areas

listed on the front cover. To

maintain this certification, only genuine, approved

parts must be used and assembled in accordance to

the instructions detailed in this manual by a competent

person. Any deviation or modication to this will invalidate

certication and may result in serious injury or death.

Page 10

This Page Intentionally Blank

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 8

Page 11

PUMP TROUBLESHOOTING

CAUTION! WHENEVER TROUBLESHOOTING OR PERFORMING ANY

REPAIRS ON ANY WARREN RUPP, INC. EQUIPMENT, ALWAYS REMOVE

THE AIR SUPPLY LINE TO THE PUMP AND WEAR PROPER PERSONAL

PROTECTIVE EQUIPMENT.

PUMP WILL NOT CYCLE

What to Check: • The system head exceeds the air supply pressure to the pump.

Corrective Action: • Increase the air inlet pressure to the pump. Most diaphragm pumps are

designed for 1:1 pressure at zero ow.

What to Check:• Check ESADS+, including pilot valve assembly and main air valve assembly.

Corrective Action: • Disassemble and inspect the main air distribution valve, pilot valve, and

pilot valve actuator pins. Check for scores, wear, or damaged o-rings. Replace parts as necessary.

Refer to the exploded view drawing and air valve section (P.18 & 20).

What to Check: • Blocked discharge line.

Corrective Action: • Check for obstruction or closed discharge line.

What to Check: • Blocked pumping chamber.

Corrective Action: • Disassemble and inspect wetted chambers of the pump. Remove or ush

any obstructions. Refer to page 14 for disassembly.

PUMP CYCLES, BUT WILL NOT FLOW OR FLOW RATE IS UNSATISFACTORY

What to Check: • Restricted or undersized air line.

Corrective Action: • Make sure there are no obstructions or restrictions in the air inlet to the

pump. Install proper size air line and/or air line equipment. Refer to air supply section (p.7) air inlet

plumbing recommendations.

What to Check: • Restricted or undersized suction piping.

Corrective Action: • Make sure there are no obstructions or restrictions in the suction line or

related suction components such as screens or strainers. Install the proper size suction line and/

or equipment. It is recommended that any suction line components and pipe size be at least the

same size as the suction line thread size to the pump. Though best results will always be realized

if the line size of the suction line is increased by one size. Refer to the installation section (p.5) for

recommended suction plumbing recommendations.

What to Check: • Excessive Suction Lift.

Corrective Action: • For lifts exceeding 20 feet (6 meters), lling the pump chambers with liquid

will prime the pump in most cases. If not, place pump closer to uid level.

What to Check: • Suction line cavitation.

Corrective Action: • If no obstructions are in the suction line of the pump, decrease the inlet

air pressure and/or volume to the pump. This will slow down the diaphragm speed and reduce the

cavitation.

What to Check: • Partially blocked exhaust mufer.

Corrective Action: • Remove mufer and make sure that some of the material being pumped has

not migrated into the mufer element. If it has, replace the element or clean it and reinstall. If product

has made it to the mufer, then the diaphragm assembly will need to be inspected. Refer to the

Diaphragm Replacement section (p.15).

What to Check: • Suction side air leakage or air in the product.

Corrective Action: • Visually inspect all suction side gaskets, seals, as well as pipe and pipe

connections.

PUMP CYCLE SEEMS UNBALANCED OR PRODUCES EXCESSIVE VIBRATION

What to Check: • Excessive ooded suction in system.

Corrective Action: • Check height of uid above pump. For ooded conditions, exceeding 10 feet

(3 meters) of liquid, install a back pressure device in the exhaust side of the pump.

What to Check: • Worn or misaligned check valve or check valve seat.

Corrective Action: • Disassemble the wet end of the pump and inspect check valves and seats

for wear and proper seating. Replace them if necessary. Refer to the Check Valve section (p.15) for

disassembly instructions.

What to Check: • Obstructed check valves.

Corrective Action: • Disassemble the wet end of the pump and look for obstructions that may

prevent the check valve from seating on the seat. Look for damage on the valve and the seat. Replace

them as necessary. Refer to the Check Valve section for disassembly (p.15).

What to Check: • Rigid pipe connections.

Corrective Action: • Install exible pipe isolators or expansion joints between the plumbing and

the pump.

What to Check: • Blocked air exhaust mufer.

Corrective Action: • Remove mufer, clean or de-ice and reinstall.

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 9

What to Check: • Pulsation in the discharge line.

Corrective Action: • Excessive pulsation in the discharge line may be corrected by installing a

Warren Rupp Tranquilizer Surge Suppressor.

Page 12

AirVantage Troubleshooting

Caution! Whenever troubleshooting or performing any repairs on any

Warren Rupp, Inc. equipment, always remove air supply line to the pump

and wear proper personal protective equipment.

LED OUTPUT FOR AirVantage UNIT

STAT E LED OUTPUT

Startup/Settle/Deadhead Solid

Standby/Low Flow 1 Second ON / 1 Second OFF

Learn Mode 0.1 Seconds ON / 0.1 Seconds OFF

Seek/Optimize 1 Second ON / 0.1 Seconds OFF

Steady State/Air Savings OFF / ON in rhythm with Cycle Rate of Pump

AirVantage LED DOES NOT LIGHT UP AT ALL

What to Check:

• Make sure power switch on the control module is turned on, (depressed to the left)

• Make sure air is being supplied to pump or make sure 110 VAC unit has power

being supplied to it

Corrective Action:

• Cycle power switch off/on

• Unplug patch cable and cycle power switch off/on

• Consult Factory After Sales Support team

AirVantage LED LIGHTS UP AND STAYS ON SOLID

What to Check:

• Make sure patch cable is plugged in and locked

Corrective Action:

• Consult Factory After Sales Support team

VALVE FIRES ONCE AND IMMEDIATELY RESETS

Corrective Action:

• Consult Factory After Sales Support team

VALVE LED NEVER LEAVES SEEK MODE - AirVantage LED PULSING IN TIME TO

PUMP, BUT VALVE NOT ACTUATING AND THE PUMP IS NOT SAVING AIR

Corrective Action:

• Consult Factory After Sales Support team

UNEXPECTED OPERATING CONDITION (AIR SAVINGS OR FLOW RATE)

What to Check:

• Check for varying environmental pumping conditions (changing head or suction)

• Check ice buildup in exhaust area

• Inspect sleeve and spool set for damage

Corrective Action:

• Consult Factory After Sales Support team

PUMP CYCLING IS UNSTABLE OR ERRATIC

What to Check:

• Run pump without AirVantage and check pump operation

• Make sure pump has correct sleeve and spool set installed

• Make sure patch cable plug is connected and locked

• Make sure power wire connectors are tight

Corrective Action:

• Consult Factory After Sales Support team

PUMP RUNNING SLOWLY

What to Check:

• Run pump without AirVantage and check operation

• Cycle the power off/on to the control module to reset controller

• Check ice buildup in exhaust area

• Inspect sleeve and spool set for damage

Corrective Action:

• Consult Factory After Sales Support team

• Cycle the power switch on the control module off/on

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 10

Page 13

AirVantage Troubleshooting Continued

Page 28

ITEM NO.

PART NUMBER

DESCRIPTION

032.054.000

1 171.092.115

CAPSCREW, HEX SOC, M6 X 35mm

8

2 258.020.147

COVER, END, ATEX

1

3 720.071.360

SEAL, O-RING

4

4 765.004.000

VALVE, SOLENOID

1

5 893.104.000

VALVE, POPPET

1

6 171.091.115

CAPSCREW, HEX SOC, M6 X 25mm

8

7 031.202.000

POWER GENERATION MODULE, ATEX

1

8 258.022.147

COVER, END, ATEX

1

9 020.069.000

REGULATOR

1

10 560.200.360

O-RING

2

11 249.019.000

CONTROL MODULE, RS20 HAZ. DUTY

1

12 560.104.360

O-RING

1

13 165.135.330

CAP, SWITCH

1

14

B27.7M - 3BM1-25

RING, RETAINER

1

15 430.050.147

HOUSING, MUFFLER

1

16 720.073.365

SEAL, DUST VALVE

1

17

HX-SHCS 0.125-40x0.188x0.188-N

CAPSCREW, HEX SOC HD, 5-40 X .25

1

18

BSI 4518 0221-16

O-RING

1

19 530.045.115

MUFFLER, SPARK ARRESTOR

1

20 165.137.115

PLATE, PERFORATED

1

21 535.096.000

TAG, WARNING

1

22 710.010.115

SCREW, SELF TAPPING, 4-24 X .25 LG

6

23 901.051.115

WASHER, FLAT, M6

8

24 535.094.000

TAG, NAME

1

AirVantage RESETS AND ENTERS LEARN MODE TOO FREQUENTLY

What to Check:

• Check for excessive varying environmental pumping conditions

(changing head or suction)

• Check ice buildup in exhaust area

• Inspect sleeve and spool set for damage

• Make sure patch cable plug is connected and locked

Corrective Action:

• Consult Factory After Sales Support Team

PUMP STALLS, RESETS, LEARNS, SEEKS AND REPEATS

What to Check:

• Make sure patch cable plug is connected and locked

• Check ice buildup in exhaust area

Corrective Action:

• Consult Factory After Sales Support Team

PUMP MOVES OUT OF STEADY STATE AND NEVER

ATTEMPTS TO RELEARN (LED ON)

What to Check:

• Make sure patch cable plug is connected and locked

• Cycle the power off/on to the control module

Corrective Action:

• Consult Factory After Sales Support Team

• Cycle the power switch on the control module off/on

WHAT TO DO IN THE EVENT OF A DIAPHRAGM FAILURE

If a diaphragm failure has been detected in pumps tted with AirVantage,

see page 5 for shut-down procedure.

What to Check:

• Has product migrated to the sensor?

Corrective Action:

• If the sensor has been submerged in product, the sensor will need to be

replaced. Consult the AirVantage servicing section of the manual for detailed instructions.

What to Check:

• Has product contaminated the check valve cartridge?

Correct Action:

• If a signicant amount of product has made it into the check valve assembly, then the unit will need to

be disassembled for inspection. If the check valve assembly is damaged, then it will need to be replaced.

Consult parts list for information.

REGULATOR

O-RING

CONTROL MODULE

O-RING

CAP, SWITCH

O-RING

WASHER, FLAT, M6

CAPSCREW, HEX SOC, M6 X 35mm

WASHER, FLAT, M6

COVER

SEAL, O-RING

VALVE, SOLENOID

VALVE, POPPET

SEAL, O-RING

SEAL, O-RING

CAPSCREW, HEX SOC, M6 X 25mm

POWER GENERATOR MODULE

CAPSCREW, HEX SOC, M6 X 25mm

SEAL, O-RING

COVER

CAPSCREW, HEX SOC, M6 X 35mm

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 11

Page 14

Composite Repair Parts List

Item Part Number Description Qty

1 031.019.004 Ass’y - Air Valve 1

031.098.001 Ass’y - Air Valve (Pulse Output Application) 1

2 032.063.000 Ass’y - AirVantage 1

3 050.017.360W Ball, Check 4

050.017.364W Ball, Check 4

050.017.365W Ball, Check 4

050.017.354 Ball, Check 4

050.018.354 Ball, Check 4

4 070.006.170 Bearing 2

5 095.073.001 Pilot Valve Assembly 1

6 114.032.156 F Bracket, Intermediate 1

7 115.057.080 Bracket, Mounting, Bottom Port 2

115.176.080 Bracket, Mounting, Top Port 2

8 115.172.159 Bracket, Mounting, R.H. 1

9 115.173.159 Bracket, Mounting, L.H. 1

10 132.002.360 Bumper, Diaphragm 2

11 135.016.162 Bushing, Threaded, W/ O-Ring 560.001.360 2

12 165.138.150 Cap, End, Sensor, Hd Est 2

13 170.024.330 Capscrew, Hex Hd, 7/16-14 X 1 12

14 170.025.330 Capscrew, Hex Head 7/16-14 X 3.00 4

15 170.030.330 Capscrew, Hex Head 1/2-13 X 2.00 4

16 170.045.115 Capscrew, Hex Head 5/16-18 X 1 1/4 4

17 170.060.330 Capscrew, Hex Hd, 7/16-14 X 2.00 12

18 170.125.330 Capscrew, Hex Hd, 5/16-18 X 6 4

19 171.100.115 Capscrew, Hex Hd, 5/16-18 X 2.50 4

20 196.001.157 Chamber, Inner 2

21 196.035.156 Chamber, Outer 2

196.035.010 Chamber, Outer 2

196.035.110 Chamber, Outer 2

196.035.112 Chamber, Outer 2

22 258.023.147 Cover, Sensor 1

23 286.007.354 Diaphragm 2

286.007.356 Diaphragm 2

286.007.360 Diaphragm 2

286.007.363 Diaphragm 2

286.007.364 Diaphragm 2

286.007.365 Diaphragm 2

24 286.020.604 Diaphragm, Overlay 2

25 312.033.156 Elbow, Manifold 2

312.033.010 Elbow, Manifold 2

312.033.110 Elbow, Manifold 2

312.033.112 Elbow, Manifold 2

26 312.121.330 Elbow, Pipe, 45deg, 3/4 NPT 1

27 334.025.156 Flange, Threaded 2

334.025.010 Flange, Threaded 2

334.025.110 Flange, Threaded 2

334.025.112 Flange, Threaded 2

28 334.026.156 Flange, Porting, Suction 1

334.026.010 Flange, Porting, Suction 1

334.026.110 Flange, Porting, Suction 1

334.026.112 Flange, Porting, Suction 1

29 334.027.156 Flange, Porting, Discharge 1

334.027.010 Flange, Porting, Discharge 1

334.027.110 Flange, Porting, Discharge 1

334.027.112 Flange, Porting, Discharge 1

30 360.041.379 Gasket, Pilot Valve 1

31 360.048.425 Gasket, Main Air Valve 1

32 360.049.425 Gasket, Flange 2

360.049.603 Gasket, Flange 2

33 360.050.379 Gasket, Manifold 4

360.050.384 Gasket, Manifold 4

360.050.608 Gasket, Manifold 4

Item Part Number Description Qty

34 518.027.156 Manifold 1

518.027.010 Manifold 1

518.027.110 Manifold 1

518.027.112 Manifold 1

35 530.041.000 Mufer 1

36 538.108.110 Nipple, Pipe 1

37 545.004.330 Nut, Hex, 5/16-18 2

38 545.005.330 Nut, Hex, 3/8-16 4

39 545.007.330 Nut, Hex, 7/16-14 4

40 545.008.330 Nut, Hex, 1/2-13 12

41 560.001.360 O-Ring 2

42 560.011.360 O-Ring 2

43 560.022.360 O-Ring 2

44 560.033.360 O-Ring 2

45 560.047.360 O-Ring 2

46 560.200.360 O-Ring 1

47 560.201.360 O-Ring 2

48 560.203.360 O-Ring 2

49 570.009.360 Pad, Wear 2

570.009.363 Pad, Wear 2

570.009.364 Pad, Wear 2

570.009.365 Pad, Wear 2

50 612.047.330 Plate, Diaphragm 2

51 612.241.147 Plate, Adapter 1

52 612.039.157 Plate, Outer Diaphragm 2

612.039.010 Plate, Outer Diaphragm 2

612.097.110 Plate, Outer Diaphragm 2

612.097.112 Plate, Outer Diaphragm 2

53 618.003.330 Plug, Pipe, 1/4 2

54 618.003.330 Plug, Pipe, 1/4 4

618.003.110 Plug, Pipe, 1/4 4

55 620.011.114 Plunger, Actuator 2

56 675.013.360 Ring, Sealing 2

675.013.363 Ring, Sealing 2

675.013.364 Ring, Sealing 2

675.013.365 Ring, Sealing 2

675.013.600 Ring, Sealing 2

57 685.007.120 Rod, Diaphragm 1

58 685.032.080 Rod, Connecting 1

59 720.004.360 Seal, U-Cup 2

60 722.035.110 Seat, Check Valve (for use with PTFE balls only) 2

722.035.112 Seat, Check Valve (for use with PTFE balls only) 2

722.097.110 Seat, Check Valve 2

722.097.112 Seat, Check Valve 2

61 724.008.000 Sensor, Feed Back 1

62 770.074.159 Spacer 8

63 807.026.330 Stud, 5/8-11 X 2 2

64 807.038.330 Stud, 3/8-16 X 2.75 4

65 807.039.330 Stud, 1/2-13 X 2.50 12

66 846.001.167 Probe Tip 2

67 894.014.000 Valve, Check 1

67a 031.206.000 Cartridge, Check Valve 1

68 900.003.330 Washer, Lock, 1/2 20

69 900.004.330 Washer, Lock - 5/16 4

70 900.005.330 Washer, Lock, 3/8 4

71 900.006.330 Washer, Lock, 7/16 12

72 901.022.330 Washer, Flat, 7/16 8

73 902.003.000 Washer, Sealing 2

74 P126-0011 Foam, Sensor, Est 2

75 P126-0032 Capscrew, Soc Hd, 8-32 X 7/16 8

76 475.101.000 Rubber Foot Kit 1

Note: The only difference between this and RHDF2 Parts list is the change to item 2, and removing item 68 (920.028.000), bumping up the last 2 parts

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 12

Page 15

Composite Repair Parts Kits

Available Service And Conversion Kits

Air End Kit - 476.247.162

Seals, O-rings, Gaskets, Air Valve Sleeve and Spool Set, and Pilot Valve Assembly

Wet End Kit – 476.245.354 (RHDB2, HDB2)

Santoprene Diaphragms, Balls and EPDM Wear Pads, Sealing Rings, and PTFE Gasket

Wet End Kit – 476.245.360 (RHDB2, HDB2)

Nitrile Diaphragms, Balls, Wear Pads, Gasket, and Sealing Rings

Wet End Kit – 476.245.364 (RHDB2, HDB2)

EPDM Diaphragms, Balls, Wear Pads, and Sealing Ring, and PTFE Gasket

Wet End Kit – 476.245.365 (RHDB2, HDB2)

Neoprene Diaphragms, Balls, Wear Pads Gasket, and Sealing Ring

(Note: All Wetted End Kits listed above contain Fiber Gaskets, and Nitrile O-Rings

Wet End Kit – 476.245.633 (RHDB2, HDB2)

FKM Diaphragms, Wear Pads, and Sealing Rings, and PTFE Balls, O-Rings, & Gaskets

Wet End Kit – 476.043.635 (RHDB2, HDB2)

Neoprene Diaphragms, and PTFE Overlay Diaphragm, Balls, Sealing Rings, O-Rings, & Gaskets

Wet End Kit – 476.043.663 (RHDB2, HDB2)

Hytrel Diaphragms, and PTFE Overlay Diaphragm, Balls, Sealing Rings, O-Rings, & Gaskets

Sealing RingsSensor Kit - 476.307.000

(Sensor, Probe Tips and O-rings)

Poppet Valve Kit

(Poppet Valve Assembly, O-ring)

Poppet Valve Assembly Kit

(Poppet Valve Assembly, O-ring, Regulator and Pilot Valve)

Control Module Kit – 476.303.000 (Power Gen AirVantage Only)

(Control Module Assembly, Gaskets, Hardware and O-rings)

Power Gen Kit – 476.293.000 (Power Gen AirVantage Only)

(Power Gen, Gasket, Hardware and O-ring)

Seal Kit – 476.280.000

O-rings and Gaskets

Probe Tip Kit – 476.283.000

(Probe Tips and O-rings)

Midsection Upgrade Kit – 475.XXX.000 Consult Factory

(Replaces S20 Metallic Midsection with AirVantage Components)

Electronic Leak Detector Kits

032.037.000 100-120/220-240 VAC

032.045.000 12-32 VDC

GASKET, PILOT VAVLVE

PILOT VALVE

GASKET, MAIN AIR VALVE

BUMBER, AIR VALVE

GASKET, AIR VALVE

SEAL, U-CUP

O-RING

BUSHING

PLUNGER, ACTUATOR

O-RING

AIR END KIT

DIAPHRAGM

PAD, WEAR

O-RING

GASKET, MANIFOLD

DIAPHRAGM, OVERLAY

BALL, CHECK

WETTED END KIT

RING, SEALING

GASKET, MANIFOLD

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 13

Page 16

Composite Repair Parts Drawing: Wetted Side

MANIFOLD ASSEMBLY

BOTTOM PORTED CONFIGURATION

26

35

13

68

27

40

68

29

3

336033

65

34

65

3

60

33

33

28

68

40

27

68

13

39

17

1414

17

21

32

25

68

64

15

38

2

18

51

42

54

14

36

EST UNIT ASSEMBLY

TOP PORTED CONFIGURATION

Note: Refer to Composite Repair Parts List

on page 12 for part numbers

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 14

Page 17

DIAPHRAGM AND CHECK VALVE SERVICING

• To service the diaphragms, rst shut off and bleed the air being supplied to the pump. For safety

purposes the air supply line should be disconnected from the pump.

• Then shut off the suction and discharge lines to the pump.

• Bleed the pressure from the pump suction and discharge lines and remove the lines from the pump.

• Drain any remaining liquid from the pump.

• During the servicing of the diaphragms, consult the “Composite Repair Parts Drawing” (p.7).

Step #1: Removing the Manifolds

• Using a 9/16" wrench or socket, remove the 16 cap-screws, hex-nuts, and lockwashers that fasten the

manifolds to the outer chambers.

• Remove the manifolds.

Step #2: Inspect Check Valve Components

• Inspect the four check balls for wear, abrasion or cuts on the spherical surface. Also inspect the

four check valve seats for cuts, abrasive wear or embedded material around the area where the ball

contacts the seat.

• For maximum pump performance and efciency, the surface of the ball must seal against the seat

without any gaps.

• Replace worn or damaged parts as necessary. Consult the “Composite Repair Parts Drawing” for part

numbers and quantities.

Step #3: Removing the Outer Chambers

• Using an 11/16" and a 5/8" wrench or socket, remove the 16 cap-screws, and hexnuts that fasten the

outer chambers, diaphragms, and inner chambers.

Step #4: Removing the Diaphragm Assemblies

• Once the outer chambers are removed, use a 1-1/16” (27mm) wrench or six-pointed socket to remove

the diaphragm assemblies (outer plate, diaphragm, and inner plate) from the diaphragm rod by turning

counterclockwise.

• “AirVantage CAUTION” – When diaphragm assemblies are removed, watch for the brass probe

tips located on the end of the sensor rod. There is one brass probe tip and one o-ring per side.

Inspect the probe tips and o-rings for wear. For every diaphragm service, these parts should be

replaced and are available in kit form. Consult the “Composite Repair Parts Drawing” for part

numbers and quantities.

• The diaphragm connecting rod will usually stay with one of the diaphragm assemblies. Install the rod in

a vise tted with soft jaws and loosen the diaphragm assembly from the rod. Take care not to scar the

surface of the rod.

• Insert a 1/4-20 capscrew or set screw into the smaller tapped hole in the inner diaphragm plate.

• Insert the protruding stud and the 1/4-20 fastener loosely into a vise. Use the 1-1/16" wrench or socket

to remove the outer diaphragm plate by turning counter-clockwise.

Step #5: Inspect Diaphragms, Diaphragm Connecting Rod, U-cup Seals and

Bumpers

• Inspect the diaphragms for cuts and/or punctures in the exing area. Even the smallest hole or crack

can allow product to get to the air side of the pump. If there is product noticed on the air side of the

diaphragm, there is a good possibility the diaphragm needs to be replaced.

• “AirVantage CAUTION” – If product is observed on the air side of the diaphragm, refer to the

“AirVantage Servicing” section of the service manual.

• Abrasive wear of the diaphragm needs to be inspected at the point where the diaphragm contacts the

outer chamber or where the diaphragm plates contacts the diaphragm. Chemical attack of a diaphragm

will usually result in swelling or deformity. Replace the diaphragms if necessary. Inspect the diaphragm

connecting rod for scars, nicks or any imperfection that could cause damage to the u-cup seal. Inspect

the u-cup seal for imperfections on the sealing lip. Inspect the bumpers for damage on the face.

Replace components as necessary. Consult the “Composite Repair Parts Drawing” for part numbers

and quantities.

Step #6: Assemble the Diaphragms

• Push the threaded stud of the outer diaphragm plate through the center hole of the diaphragm. Thread

the inner plate clockwise onto the stud.

• Insert the loose assembly with the above 1/4-20 fastener back into the vise. Use a torque wrench and

1-1/16” socket (27 mm) to tighten the diaphragm assembly together to 480 in.-lbs. (54.23 Newton

meters).

• Allow a torqued assembly to set for 15-minutes. This will allow the diaphragm to relax. Re-torque the

assembly to compensate for stress relaxation in the clamped assembly.

Step #7: Installing the Diaphragm Assemblies to the Pump

• Make sure the bumper is installed over the diaphragm rod. Thread the stud of the one diaphragm

assembly clockwise into the tapped hole at the end of the diaphragm rod until the inner diaphragm plate

is ush to the end of the rod.

• “AirVantage CAUTION” – With the pump lying on one inner chamber, pull the sensor rod UP

the full length of its stroke. Insert the brass probe tip and o-ring into the sensor rod. Insert rod

and diaphragm assembly into pump, taking care not to damage the u-cup seal. Make sure the

diaphragm plate contacts the brass probe tip and stays in contact with it. This will help make

sure the probe tip does not fall out during reassembly.

• Align the bolt holes in the diaphragm with the bolt pattern in the inner chamber. Fasten the outer

chamber to the pump, using the cap screws, and hex nuts, but do not tighten. Flip the pump over so

that it is now setting on the outer chamber. Pull the diaphragm rod out as far as possible. Make sure the

bumper is installed over the diaphragm rod.

• “AirVantage CAUTION” – Install the second brass probe tip and o-ring on the sensor rod.

• Thread the stud of the remaining diaphragm assembly clockwise into the tapped hole at the

end of the diaphragm rod (item 34) until the diaphragm plate contacts the end surface of the

diaphragm rod. If the bolt holes in the diaphragm do not line up with the inner chamber, use a

1-1/16” (27 mm) socket or wrench to tighten the assembly until they line up.

• Fasten the remaining outer chamber to the pump, using the cap screws and hex nuts, and once again,

do not tighten at this point. Tip the pump 90° and set it on a at surface with the discharge side of the

chambers down. This will allow the outer chambers to be aligned with each other. Tighten the sixteen

fasteners. Make sure to use a cross tightening pattern to ensure an even sealing on the diaphragm.

Step #8: Re-install the Check Valve Components and Manifolds

• While the pump is setting on the discharge side, insert the check balls and seats on the suction side of

the pump. Make sure the seats t within the counter bore of the chambers. The suction manifold can

now be installed, using the eight cap screws,

hex nuts and lock washers.

• Flip the pump 180° and install the seats and

check balls on the discharge side.

• Now the discharge manifold can be installed

and fastened using the remaining cap screws,

hex nuts, and lock washers.

OVERLAY DIAPHRAGM SERVICING

The overlay diaphragm is a PTFE diaphragm

that ts over the exterior of the diaphragm. The

PTFE diaphragm is used to protect the standard

diaphragm from the chemicals being pumped.

Repeat step #6 when diaphragms need to be

serviced.

this manual for reference. Failure to

comply with the recommendations stated

in this manual will damage the pump, and

void factory warranty.

IMPORTANT

Read these instructions

completely, before

installation and start-up.

It is the responsibility of

the purchaser to retain

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 15

Page 18

Composite Repair Parts Drawing: Air Side

24

22

33

INTERMEDIATE ASSEMBLY

(SHOWN ROTATE 180

5

4

6

7

18

17

14

3

)

4

1

10

8

5

4

PTFE OVERLAY

CONFIGURATION

13

71

31

27

28

26

1

30

7

12

13

11

20

35

18

17

21

32

16

15

35

2

19

22

24

23

25

34

33

Note: Refer to Composite Parts List on

page 12 for part numbers

7676767676

36

37

38

BOTTOM PORTED CONFIGURATION

TOP PORTED CONFIGURATION

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 16

Page 19

A

BRACKET, INTERMEDIATE, ASSEMBLY

SENSOR, FEEDBACK

NUT

SEAL

DIAPHRAGM

PLATE,

OUTER DIAPHRAGM

PLATE,

INNER DIAPHRAGM

PROBE TIP

O-RING

SENSOR, FEEDBACK

BUMPER

DETAIL A

FLAT EDGE

INTERMEDIATE AND AirVantage SENSOR SERVICING

• To service the intermediate and AirVantage sensor, rst shut off and bleed the air being supplied to the

pump. For safety purposes, the air supply line should be disconnected from the pump. Shut off both the

suction and discharge lines to the pump. Consult the “Composite Repair Parts Drawing”.

Step #1: Remove the Patch Cable

• Twist the ribbed portion of the patch cable connector in a counterclockwise direction, until it unthreads

from the connector. The cable can either be removed from the intermediate or from the control module.

Step #2: Remove the AirVantage from the Pump

• Use a ½” socket and remove the four 5/16-18 x 5 ½ cap screws that hold the AirVantage to the pump.

Be sure to support the weight of the AirVantage while removing the last cap screw. After the AirVantage

is removed from the pump, set the unit down on the plastic cover located on the bottom.

Step #3: Remove the Manifolds, Chambers, and Diaphragms (See Diaphragm

Servicing Section)

Step#8: Reinstallation

• Slide the new sensor assembly in the intermediate.

• “AirVantage CAUTION” – Make sure the cable assembly ts into the groove machined in the

intermediate. Failure to do so may damage the cable during assembly.

• Feed the connector through the hole in the intermediate, making sure the gasket is on the connector

before installation. The at edge on the connector should line up with the inside of the intermediate.

Install the nut and hand tighten it using a 13/16" socket.

• The inner chambers and gaskets can now be reinstalled. Use blue thread locker on the inner chamber

bolts and torque them to 300 in-lbs.

• Refer to the “Diaphragm Servicing” section of the manual to nish the diaphragm installation procedure.

Step #4: Remove the Diaphragm Assemblies

• Refer to the “Diaphragm Servicing” section of the manual to remove diaphragm assembly from the

pump.

• “AirVantage CAUTION” – When the diaphragm assembly is removed, watch for the brass probe

tips located on the end of the sensor rod. There is one brass probe tip and one o-ring per

side. Inspect the probe tips and o-rings for wear. For every diaphragm service, these parts should be

replaced and are available in kit form. Consult the “Composite Repair Parts Drawing” for part numbers

and quantities.

• Note: For AirVantage sensor servicing, refer to page 27.

Step #5: Remove the End Caps

• Use an Allen wrench and remove the two screws from the End Caps on either side of the intermediate.

• Use two small at-head screw drivers to simultaneously pry the End Caps up at the ends.

• “AirVantage CAUTION” – Remove the End Caps from the intermediate with caution, taking care

not to damage the sensor. Inspect the gaskets and u-cup seals under each End Cap and replace

them as necessary.

Step #6: Accessing the Actuator Plunger Bushings and O-rings

• The actuator plunger pin bushings and o-rings can now be accessed. If it is determined that these parts

need to be replaced, use a small screwdriver and remove the retaining rings.

• NOTE: It is recommended that new retaining rings be installed after disassembly. The bushing

and o-ring can now be removed and inspected.

Step #7: Accessing the AirVantage Sensor

• If the sensor needs to be replaced, use a 13/16” socket and remove the plastic nut securing the

connector to the intermediate. Slide the connector out of the hole, taking care not to lose/misplace the

gasket on the connector.

• The sensor can now be removed from the intermediate assembly.

JAM NUT

O-RING

FOAM BUMPER

BEARING

SENSOR COVER

CAPSCREW

INTERMEDIATE

SEAL

FEED BACK SENSOR

O-RING

Note: Refer to Composite Repair Parts

List on page 12 for part numbers

END CAP

CAPSCREW

CAPSCREW

PLATE,

OUTER DIAPHRAGM

PAD, WEAR

DIAPHRAGM

PLATE, DIAPHRAGM

WASHER, SEALING

PROBE TIP

O-RING

SENSOR, FEED BACK

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 17

Page 17

Page 20

Air Valve Servicing, Assembly Drawing & Parts List

1.B

1.A1.A

1.C

1.F

1.D

1.E

1.F

1.C

1.F

1.D

Note to Trent: Do not paste this table in S/M. Only use to modify on

on page 18

ITEM

NO.

PART NUMBER DESCRIPTION

QTY.

1.A

031.012.162

SLEEVE & SPOOL SET

1

1.B

095.043.156

DESCRIPTION

1

1.C

132.014.358

BUMBER, AIR VALVE

2

1.D

165.011.157

CAP, END

2

1.E

170.032.330

CAPSCREW, HEX HEAD 1/4-20 X 3/4

8

1.F

360.010.427

BODY, AIR VALVE

2

1.F

560.020.360

O-RING

6

AIR VALVE ASSEMBLY PARTS LIST

Item Part Number Description Qty

1 031-183-003 Air Valve Assembly 1

1-A 031.012.162 Sleeve and Spool Set 1

1-B 095.043.156 Description 1

1-C 132-014.358 Bumper, Air Valve 2

1-D 165.011.157 Cap, End 2

1-E 170.032.330 Capscrew, Hex Head 1/4-20 x 3/4 8

1-F 360.010.427 Body, Air Valve 2

1-F 560.020.360 O-ring 6

AIR DISTRIBUTION VALVE SERVICING

STEP #1: Remove Air Valve

The main air valve sleeve and spool set is located in the valve body mounted on the pump with four

hex head cap-screws. The valve body assembly is removed from the pump by removing these four hex

head cap-screws.

STEP #2: Disassembly of the Air Valve

With the valve body assembly off the pump, access to the sleeve and spool set is made by removing four

hex head cap-screws (each end) on the end caps of the valve body assembly.

With the end caps removed, slide the spool back and forth in the sleeve. The spool is closely sized

to the sleeve and must move freely to allow for proper pump operation. An accumulation of oil, dirt or other

contaminants from the pump’s air supply, or from a failed diaphragm, may prevent the spool from moving

freely. This can cause the spool to stick in a position that prevents the pump from operating. If this is the

case, the sleeve and spool set should be removed from the valve body for cleaning and further inspection.

Remove the spool from the sleeve.

Using an arbor press or bench vise (with an improvised mandrel), press the sleeve from the valve

body. Take care not to damage the sleeve.

At this point, inspect the o-rings on the sleeve for nicks, tears or abrasions. Damage of this sort could

happen during assembly or servicing. A sheared or cut o-ring can allow the pump’s compressed air supply

to leak or bypass within the air valve assembly, causing the pump to leak compressed air from the pump

air exhaust or not cycle properly. This is most noticeable at pump dead head or high discharge pressure

conditions.

Replace any of these o-rings as required or set up a routine, preventive maintenance schedule to

do so on a regular basis. This practice should include cleaning the spool and sleeve components with a

safety solvent or equivalent, inspecting for signs of wear or damage, and replacing worn components.

Reassembly of the Air Valve

To re-install the sleeve and spool set, lightly lubricate the o-rings on the sleeve with an o-ring

assembly lubricant or lightweight oil (such as 10 wt. air line lubricant).

Re-install one end cap, gasket and bumper on the valve body.

Using the arbor press or bench vise that was used in disassembly, carefully press the sleeve back

into the valve body, without shearing the o-rings. You may have to clean the surfaces of the valve body

where the end caps mount. Material may remain from the old gasket. Old material not cleaned from this

area may cause air leakage after reassembly.

Take care that the bumper stays in place allowing the sleeve to press in all the way.

Reinstall the spool, opposite end cap, gasket and bumper on the valve body.

After inspecting and cleaning the gasket surfaces on the valve body and intermediate, reinstall the

valve body on the pump using new gaskets.

Tighten the four hex head cap-screws evenly and in an alternating cross pattern.

IMPORTANT

Read these instructions

completely, before

installation and

start-up. It is the

responsibility of the

purchaser to retain this

manual for reference. Failure to comply

with the recommendations stated in this

manual will damage the pump, and void

factory warranty.

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 18

Page 21

Air Valve with Stroke Indicator Assembly Drawing and Parts List

1.D

1.F

1.C

1.A1.A

1.F

1.B

1.G

1.D

1.E

1.H

Note to Trent: Do not paste this table in S/M. Only use to modify on

on page 19

AIR VALVE ASSEMBLY PARTS LIST

Item Part Number Description Qty

1 031-147-003 Air Valve Assembly 1

1-A 031-012.162 Sleeve and Spool Set 1

1-B 095-043.156 Description 1

1-C 132-014.358 Bumper, Air Valve 2

1-D 165-065.010 Cap, End 2

1-E 170.032.330 Capscrew, Hex Head 1/4-20 x 3/4 8

1-F 360.010.427 Body, Air Valve 2

1-F 560.020.360 O-Ring 6

1-G 210-008-330 Clip, Safety 1

1-H 560-029-360 O-Ring 2

Air Distribution Valve With Stroke Indicator Option Servicing

To service the air valve rst shut off the compressed air supply, bleed the pressure from the pump, and

disconnect the air supply line from the pump.

Step #1: See COMPOSITE REPAIR PARTS DRAWING.

• Using a 5/16" Allen wrench, remove the four hex socket capscrews and four at washers. Remove the

air valve assembly from the pump.

• Remove and inspect gasket for cracks or damage. Replace gasket if needed.

Step #2: Disassembly of the air valve.

• To access the internal air valve components rst remove the two retaining rings from each end of the air

valve assembly using clip ring pliers.

• Next remove the two end caps. Inspect the o-ring for cuts or wear. Replace the

o-rings if necessary.

• Remove the two bumpers. Inspect the bumpers for cuts, wear or abrasion. Replace if necessary.

• Remove the spool from the sleeve. Be careful not to scratch or damage the outer diameter of the spool.

Wipe spool with a soft cloth and inspect for scratches or wear.

• Inspect the inner diameter of the sleeve for dirt, scratches, or other contaminants. Remove the sleeve if

needed and replace with a new sleeve and spool set.

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 19

Step #3: Reassembly of the air valve.

• Install one bumper and one end cap with o-rings into one end of the air valve body. Install one retaining

ring, into the groove on the same end. Insert the safety clip through the smaller unthreaded hole in the

endcap.

• Remove the new sleeve and spool set from the plastic bag. Carefully remove the spool from the sleeve.

Install the six o-rings into the six grooves on the sleeve. Apply a light coating of grease to the o-rings

before installing the sleeve into the valve body.

Align the slots in the sleeve with the slots in

the valve body. Insert the spool into the sleeve.

Be careful not to scratch or damage the spool

IMPORTANT

during installation. Push the spool in until the

pin touches the safety clip on the opposite end.

• Install the remaining bumper, end cap with

o-rings and retaining ring.

• Fasten the air valve assembly

and gasket to the pump.

• Connect the compressed air line to the pump.

Remove the safety clip. The pump is now ready

for operation.

manual for reference. Failure to comply

with the recommendations stated in this

manual will damage the pump, and void

factory warranty.

Read these instructions

completely, before

installation and

start-up. It is the

responsibility of the

purchaser to retain this

Page 22

Pilot Valve and Actuator Plunger Servicing

Step #1: Remove the Patch Cable

• Twist the ribbed portion of the patch cable connector in a counterclockwise

direction, until it unthreads from the connector. The cable can either be removed from

the intermediate or from the control module.

Step #2: Remove the AirVantage from the Pump

• Use a ½” socket and remove the four 5/16-18 x 5½ cap screws that hold the AirVantage to the

pump. Be sure to support the weight of the AirVantage while removing the last cap screw. After the

AirVantage is removed from the pump, carefully set the unit down on the plastic cover located on the

bottom.

STEP #3: Remove the Pilot Valve

• Remove the main air distribution valve body from the pump.

• Lift the pilot valve body out of the intermediate housing. (Most problems with the pilot valve can be

corrected by replacing the o-rings.)

STEP #4: Dissasemble the Pilot Valve

• Remove the pilot spool and wipe it clean. Inspect the spool and o-rings for dirt, cuts or wear.

Replace parts if necessary.

• Use a set of outside snap ring pliers and remove the retaining ring holding the sleeve in the pilot

valve body.

• Gently push the sleeve from the body and wipe it clean. Inspect the sleeve and o-rings.

• Replace parts if necessary

STEP #5: Inspect the Actuator Plungers

• Remove the plungers by sliding them out of the bushings. It may be necessary to use a ne piece of

wire to pull them out.

STEP #6: Reassemble the Pilot Valve

• Generously lubricate the o-rings on the pilot sleeve with multipurpose grease (BP-LSEP-2 or

equivalent).

• Carefully insert the sleeve in the pilot valve body on the chamfered side, taking care not to shear any

of the o-rings.

• Securely insert the retaining ring around the sleeve.

• Generously lubricate the o-rings on the pilot spool. Carefully insert the spool in the sleeve.

• If the pilot valve does not t ush against the gasket, check to make sure the actuator plunger are pushed

all the way. Failure to do so may cause damage to the pilot valve or the actuators.

• Insert the pilot valve body onto the intermediate housing.

• Reinstall the main air distribution valve body onto the pump.

Step #8: Reassemble AirVantage and Cable

• Reinstall the AirVantage using the four 5/16-18 x 5½ cap screws and torque to 90 in-lbs.

• Reattach the patch cable connector that connects the AirVantage module to the intermediate.

Item Part Number Description Qty

4.A 095.070.558 BODY, Pilot VALVE 1

4.B 755.025.162 SLEEVE, Pilot VALVE 1

4.C 560.033.360 O-RING 4

4.D 775.026.115 SPOOL, Pilot VALVE 1

4.E 560.023.360 O-RING 2

4.F 675.037.080 RING, RETAINING 1

5

28

4.A

4.F

15

49

35

4.B

4.D

10

STEP #7: Reinstall the Pilot Valve

• Push both plungers (located inside the intermediate bracket) out of the path of the pilot valve spool

ends to avoid damage.

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 20

29

1

4.C

4.E

Note: Refer to Composite Repair

Parts List on page 12 for part

numbers

Page 23

Pulse Output Kit Drawing

PULSE OUTPUT KIT OPTION

This pump can be tted with a Pulse Output Kit. This converts the mechanical strokes of the

pump to an electrical signal which interfaces with the Stroke Counter/ Batch Controller or user

control devices such as a PLC.

The Pulse Output Kits mount directly onto the Mufer Cap on the Air Distribution Valve Assembly

or onto the air valve and senses each stroke of the main spool.

Consult the factory for further information and availability.

Pulse Output Kits

475-244-001 10-30 VDC

475-244-002 110/220 VAC

475-244-003 10-30VDC, 110VAC and 220 VAC

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 21

Page 24

This Page Intentionally Blank

rhdb2dl1sm_haz duty-rev0614 Model RHDB2 Hazardous Duty Page 22

Page 25

Composite Repair Parts Drawing: AirVantage Unit

Page 23

ITEM NO.

PART NUMBER

DESCRIPTION

032.054.000

1 171.092.115

CAPSCREW, HEX SOC, M6 X 35mm

8

2 258.020.147

COVER, END, ATEX

1

3 720.071.360

SEAL, O-RING

4

4 765.004.000

VALVE, SOLENOID

1

5 893.104.000

VALVE, POPPET

1

6 171.091.115

CAPSCREW, HEX SOC, M6 X 25mm

8

7 031.202.000

POWER GENERATION MODULE, ATEX

1

8 258.022.147

COVER, END, ATEX

1

9 020.069.000

REGULATOR

1

10 560.200.360

O-RING

2

11 249.019.000

CONTROL MODULE, RS20 HAZ. DUTY

1

12 560.104.360

O-RING

1

13 165.135.330

CAP, SWITCH

1

14

B27.7M - 3BM1-25

RING, RETAINER

1

15 430.050.147

HOUSING, MUFFLER

1

16 720.073.365

SEAL, DUST VALVE

1

17

HX-SHCS 0.125-40x0.188x0.188-N

CAPSCREW, HEX SOC HD, 5-40 X .25

1

18

BSI 4518 0221-16

O-RING

1

19 530.045.115

MUFFLER, SPARK ARRESTOR

1

20 165.137.115

PLATE, PERFORATED

1

21 901.051.115

WASHER, FLAT, M6

8

22 535.096.000

TAG, WARNING

1

23 710.010.115

SCREW, SELF TAPPING, 4-24 X .25 LG

6

24 535.094.000

TAG, NAME

1

1

21

2

3

9

10

11

12

13

10

14

15

16

17

18

19

20

4

5

3

3

6

7

6

3

8

21

1

ITEM No. PART NUMBER DESCRIPTION QTY.

3 720.004.360 SEAL, O-RING 4