II 2GD T5

SERVICE & OPERATING MANUAL

Original Instructions

Model MSB1 Type 5

See pages 2, 18 & 19

for ATEX ratings

Model MSB25 Type 5

Table of Contents

Engineering Data, Temperature Limitations & Performance Curve ....................... 1

Explanation of Pump Nomenclatur ........................................................................ 2

Dimensions ............................................................................................................ 3

Principle of Operation ............................................................................................ 4

Installation and Start-Up ........................................................................................ 4

Air Supply .............................................................................................................. 4

Installation Guide ................................................................................................... 5

Air Inlet & Priming .................................................................................................. 6

Air Exhaust ............................................................................................................ 6

Between Uses ....................................................................................................... 6

Check Valve Servicing ........................................................................................... 6

Diaphragm Servicing ............................................................................................. 6

Air Valve Lubrication .............................................................................................. 6

®

:

ESADS+Plus

Externally Serviceable Air Distribution System ................................7

Pilot Valve .............................................................................................................. 7

Pilot Valve Actuator ................................................................................................ 8

Service Instructions: Troubleshooting ................................................................... 8

Warranty ................................................................................................................ 8

Recommended Accessories .................................................................................. 8

Important Safety Information ................................................................................. 9

Recycling ............................................................................................................... 9

Grounding The Pump .......................................................................................... 10

Material Codes .................................................................................................... 11

Composite Repair Parts List ........................................................................... 12-13

Composite Repair Drawing.................................................................................. 14

Composite Repair Parts List for:

Dual Port Suction/Single Port Discharge .................................................. 15

Dual Port Suction and Discharge.............................................................. 15

Composite Repair Drawing for Dual Port Options ............................................... 16

CE Declaration of Conformity - Machinery .......................................................... 17

CE Declaration fo Conformity - ATEX .................................................................. 18

Explanation of ATEX Certication ........................................................................ 19

Warren Rupp, Inc. • A Unit of IDEX Corporation • 800 N. Main St., Manseld, Ohio 44902 USA

Telephone (419) 524-8388 • Fax (419) 522-7867 • www.warrenrupp.com

msb1dl5sm-rev0813

©Copyright 2013 Warren Rupp, Inc. All rights reserved.

Quality System

II 2GD T5

ISO9001 Certied

Environmental

Management System

ISO14001 Certied

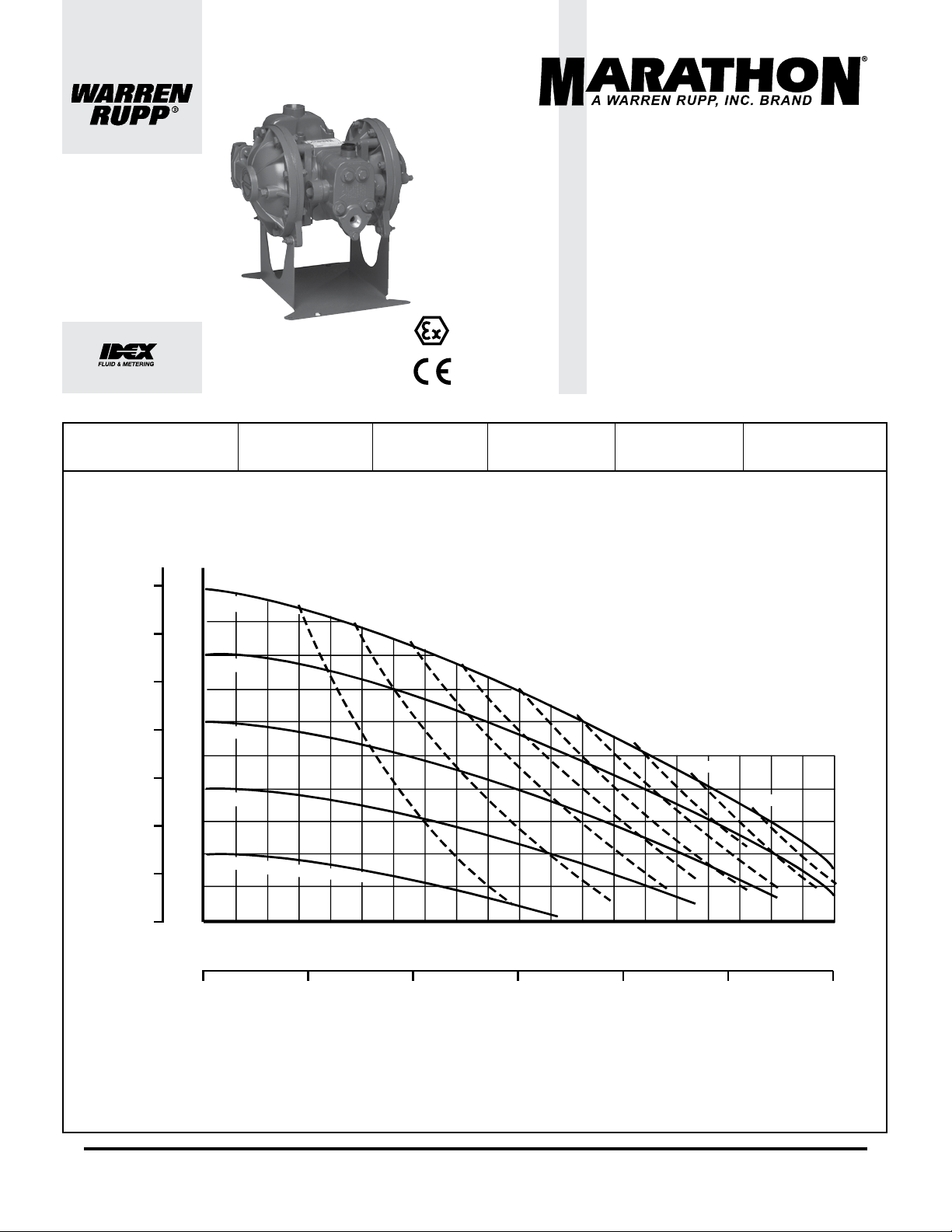

MSB1 Type 5

MSB25 Type 5

Heavy Duty

Ball Valve

INTAKE/DISCHARGE PIPE SIZE

MSB1: 1” NPT(F)

MSB25: 1” BSP Tapered

BAR

7

100

PSI

100 PSI

90

6

80

80 PSI

5

70

60

4

60 PSI

50

HEAD

3

40

40 PSI

30

2

CAPACITY

0 to 42 gallons per minute

(0 to 159 liters per minute)

AIR CONSUMPTION

SCFM (M

10(17)

15(25.5)

AIR VALVE

No-lube, no-stall

design

3

/hr)

20(34)

See page 2, 18 & 19

for ATEX ratings

SOLIDS-HANDLING

Up to nearly 1/4” (6.3mm)

Air-Operated

Double Diaphragm Pump

ENGINEERING, PERFORMANCE

& CONSTRUCTION DATA

HEADS UP TO

125 psi or 289 ft. of water

2

(8.8 Kg/cm

or 88 meters)

DISPLACEMENT/STROKE

.09 Gallon / .34 liter

MODEL SB1/SB25 Performance Curve

Performance based on the following: elastomer fitted pump, flooded suction,

water at ambient conditions. The use of other materials and varying hydraulic

25(42.5)

30(51)

conditions may result in deviations in excess of 5%.

35(59.5)

40(68)

45(76.5)

50(85)

20

1

20 PSI Air Inlet Pressure

10

0

0

0 4

8

12

16

20

24

28

32 36

U.S. Gallons per minute

0 50 75 100 125 150

25

Liters per minute

CAPACITY

MARATHON® pumps are designed to be powered only by compressed air.

msb1dl5sm-rev0813 Models MSB1 & MSB25 Page 1

40

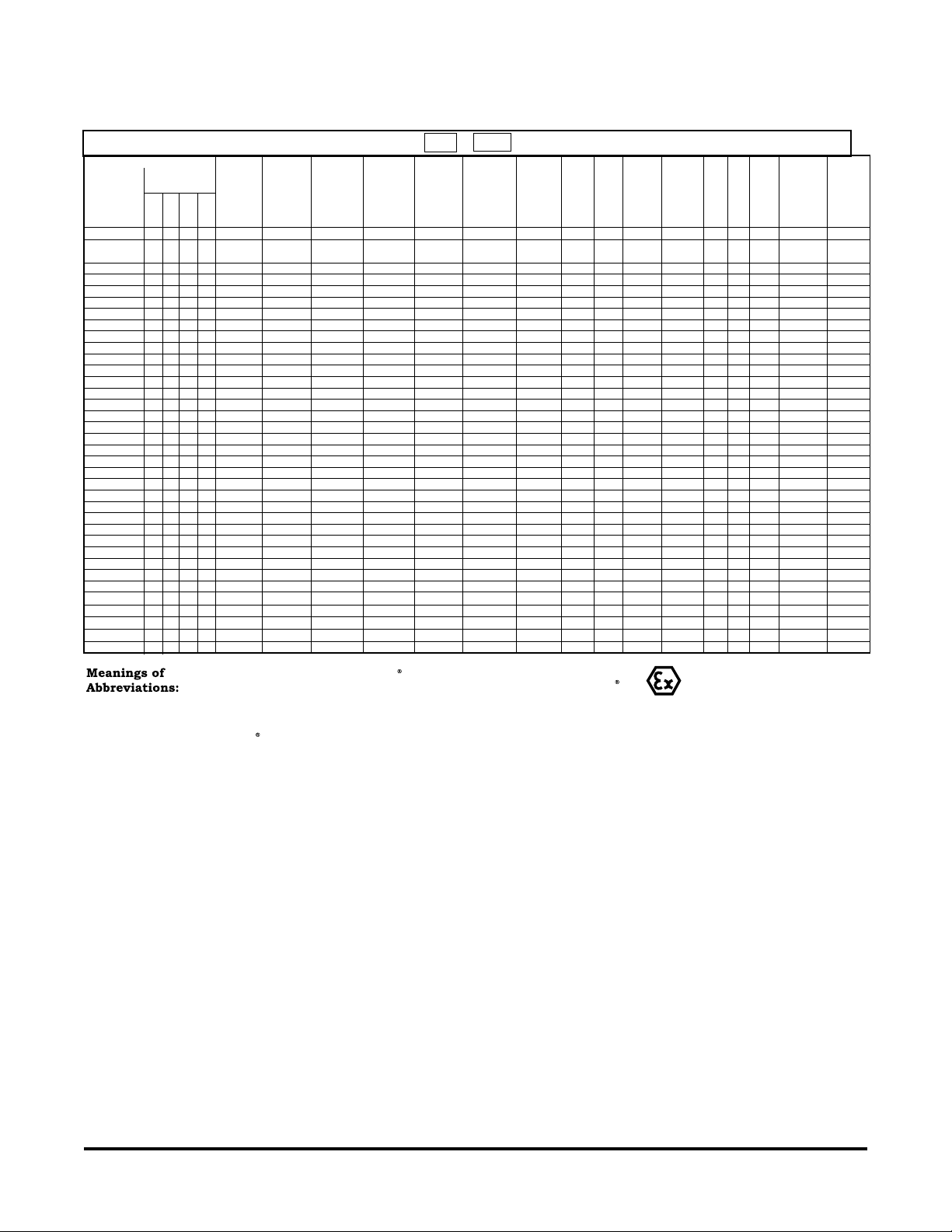

Explanation of Pump Nomenclature, MSB1 & MSB25

II 2GD T5

SR-4-HC XXAlloy C Alloy C AL380DC Alloy C PS AL380DC 416SS Alloy C PS H H A B PE AL380DC 50

SGR-4-HC XXAlloy C Alloy C AL380DC Alloy C PS AL380DC 416SS Alloy C PS H/T T T T PE AL380DC 50

ESC-4-S X Alloy C Alloy C

AL380DC

Alloy C PS AL380DC 416SS SS PS V T T T PE AL380DC 45

SGN-4-HI XXAlloy C Alloy C CI Alloy C PS CI 416SS Alloy C PS N/T T T T PE PE 65

*

SB1

SB25

Manifold

Shipping

Wt. (lbs)

Hard-

ware

Intermediate

Housing

Inner

Diaphragm

Plate

Outer

Diaphragm Diaphragm

Diaphragm

Plate

ChamberChamber

Rod

Valve

Seat

Ball

Valve

Material

Air

Valve

Air

Valve

Cap

Manifold

Porting

Dual

Bottom

Side

Manifold Gasket

Seat Gasket

MATERIALS OF CONSTRUCTION

To order a pump or replacement parts, rst enter the Model Number MSB1, or MSB25, followed by the Type Designation listed below in the far left column.

Manifold

Porting

Type

Designation

SB4A. 356-T6AL AL380DC AL380DC PS AL380DC 416SS R PS B B A B PE AL380DC 31

SC4A. 356-T6AL AL380DC AL380DC PS AL380DC 416SS SS PS V T T T PE AL380DC 31

SH4A. 356-T6AL AL380DC AL380DC PS AL380DC 416SS SS PS I T T T PE AL380DC 31

SN4A. 356-T6AL AL380DC AL380DC PS AL380DC 416SS R PS N N A N PE AL380DC 31

SR4A. 356-T6AL AL380DC AL380DC PS AL380DC 416SS R PS H H A B PE AL380DC 31

SS4A. 356-T6AL AL380DC AL380DC PS AL380DC 416SS SS PS S S T T PE AL380DC 31

SV4A. 356-T6AL AL380DC AL380DC

SGN4A. 356-T6AL AL380DC AL380DC SS PS AL380DC 416SS SS PS N/T T T T PE AL380DC 31

SGR4A. 356-T6AL AL380DC AL380DC SS PS AL380DC 416SS SS PS H/T T T T PE AL380DC 31

SB4SS. SS SS AL380DC SS PS AL380DC 416SS R PS B B A B PE AL380DC 45

SF4SS. SS SS AL380DC SS PS AL380DC 416SS SS PS F T T T PE AL380DC 45X

SC4SS. SS SS AL380DC SS PS AL380DC 416SS SS PS V T T T PE AL380DC 45

SH4SS. SS SS AL380DC SS PS AL380DC 416SS SS PS I T T T PE AL380DC 45

SJ4SS. SS SS AL380DC SS PS AL380DC 416SS SS PS B T A B PE AL380DC 45

SN4SS. SS SS AL380DC SS PS AL380DC 416SS R PS N N A N PE AL380DC 45

SR4SS.

SS4SS. X SS SS AL380DC SS PS AL380DC 416SS SS PS S S T T PE AL380DC 45

SV4SS. X SS SS AL380DC SS PS AL380DC 416SS R PS V V T T PE AL380DC 45

SGN4SS. X SS SS AL380DC SS PS AL380DC 416SS SS PS N/T T T T PE AL380DC 45

SGR4SS. X SS SS AL380DC SS PS AL380DC 416SS SS PS H/T T

SB4SI. X SS SS CI SS PS CI 416SS R PS B B A B PE PE 60

SC4SI. X SS SS CI SS PS CI 416SS SS PS V T T T PE PE 60

SH4SI. X SS SS CI SS PS CI 416SS SS PS I T T T PE PE 60

SJ4SI. X SS SS CI SS PS CI 416SS SS PS B T A B PE PE 60

SN4SI. X SS SS CI SS PS CI 416SS R PS N N A N PE PE 60

SR4SI. X SS SS CI SS PS CI 416SS R PS H H A B PE PE 60

SV4SI. X SS SS CI SS PS CI 416SS R PS V V T T PE PE 60

SGN4SI. X SS SS CI SS PS CI 416SS SS PS N/T T T T PE PE 60

SGR4SI. X SS SS CI SS PS CI 416SS SS PS H/T T T T PE PE 60

SC4HC. X Alloy C Alloy C AL380DC Alloy C PS AL380DC 416SS Alloy C PS V T T T PE AL380DC 50

SN4HC. X Alloy C Alloy C AL380DC Alloy C PS AL380DC 416SS Alloy C PS N N A N PE AL380DC 50

SV4HC. X Alloy C Alloy C AL380DC Alloy C PS AL380DC 416SS Alloy C PS V V T T PE AL380DC 50

SGN4HC. X Alloy C Alloy C AL380DC Alloy C PS AL380DC 416SS Alloy C PS N/T T T T PE AL380DC 50

SR4HC. X

SGR4HC. X

ESC4S. X Alloy C Alloy C

*

SGN4HI. X

Kit available to convert

to top porting

Most other types available in dual ported design. See price book or consult factory for details.

*

®

Viton

& Hytrel

Dual

Bottom

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

®

are registered tradenames of E.I. du Pont. Santoprene

Manifold

Side

Top

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Alloy C Alloy C AL380DC Alloy C PS AL380DC 416SS Alloy C PS H H A B PE AL380DC 50

X

Alloy C Alloy C AL380DC Alloy C PS AL380DC 416SS Alloy C PS H/T T T T PE AL380DC 50

X

XXAlloy C Alloy C CI Alloy C PS CI 416SS Alloy C PS N/T T T T PE PE 65

A = Compressed Fibre

AL = Aluminum

B = Nitrile

CI = Cast Iron

DC = Die Cast

F = FDA Nitrile/PTFE

H = Hytrel

Outer

Chamber

SS SS AL380DC SS PS AL380DC 416SS R PS H H A B PE AL380DC 45

Inner

Chamber

AL380DC

Outer

Diaphragm

Plate

AL380DC

AL380DC

AL380DC

AL380DC

AL380DC

AL380DC

AL380DC PS AL380DC 416SS R PS V V T T PE AL380DC 31

Alloy C PS AL380DC 416SS SS PS V T T T PE AL380DC 45

H/T = Hytrel Backup/ PTFE

I = EPDM

N = Neoprene

N/T = Neoprene Backup/PTFE Overlay

PE = Conductive HDPE

PS = Plated Steel

®

is a registered tradename of Exxon Mobil Corp.

Inner

Diaphragm

Plate

Intermediate

Housing

Overlay

Dia-

phragm

Valve

Rod

Seat

R = Ryton

S = Santoprene

SS = Stainless Steel

T = Virgin PTFE

V = FKM

Alloy C = Alloy C

Hard-

ware

Dia-

phragm

Ball

Valve

Material

Manifold Gasket

Seat Gasket

T T PE AL380DC 45

II 1 G c T5

II 3/1 G c T5

II 1 D c T100oC

I M1 c

I M2 c

Models equipped with

Stainless Steel or Alloy

C wetted parts, and Cast

Iron midsection parts.

See page 18 for ATEX

Explanation of EC-Type

Certicate

Air

Valve

Air

Shipping

Valve

Wt. (lbs)

Cap

II 2 G c T5

II 3/2 G c T5

II 2 D c T100oC

All models, including

pumps equipped with

Aluminum wetted and

midsection parts.

See page 18 for

ATEX Explanation

of Type Examination

Certicate.

msb1dl5sm-rev0813 Models MSB1 & MSB25 Page 2

Materials

Materials

Nitrile General purpose, oil-resistant. Shows good solvent, oil, water and hydraulic uid resistance. Should

not be used with highly polar solvents

like acetone and MEK, ozone, chlorinated hydrocarbons and nitro hydrocarbons.

EPDM Shows very good water and chemical resistance. Has poor resistance to oil and solvents, but is fair in

ketones and alcohols.

NEOPRENE All purpose. Resistant to vegetable oils. Generally not affected by moderate chemicals, fats,

greases and many oils and solvents. Generally

attacked by strong oxidizing acids, ketones, esters, nitro hydrocarbons and chlorinated aromatic hydrocarbons.

®

HYTREL

PTFE Chemically inert, virtually impervious. Very few chemicals are known to react chemically with

PTFE: molten alkali metals, turbulent liquid or gaseous uorine and a few uoro-chemicals such as

chlorine triuoride or oxygen diuoride which readily liberate free uorine at elevated temperatures.

FKM (Fluorocarbon) shows good resistance to a wide range of oils and solvents; especially all aliphatic,

aromatic and halogenated hydrocarbons, acids, animal

and vegetable oils. Hot water or hot aqueous solutions (over 70°F) will attack FKM.

Santoprene

lent abrasion resistance.

‡

Good on acids, bases, amines and glycols at room temperature.

®

Injection molded thermoplastic elastomer with no fabric layer. Long mechanical ex life. Excel-

CF-8M Stainless Steel equal to or exceeding ASTM specication A743 for corrosion resistant iron chro-

mium, iron chromium nickel, and nickel based alloy castings for general applications. Commonly referred

to as 316 Stainless Steel in the pump industry.

Maximum and Minimum Temperatures are the limits for which

these materials can be operated. Temperatures coupled with

pressure affect the longevity of diaphragm pump components.

Maximum life should not be expected at the extreme limits of

the temperature ranges.

Operating Temperatures

Maximum Minimum

190°F -10°F

88°C -23°C

280°F -40°F

138°C -40°C

200°F -10°F

93°C -23°C

220°F -20°F

104°C -29°C

220°F -35°F

104°C -37°C

350°F -40°F

177°C -40°C

275°F -40°F

135°C -40°C

ALLOY C CW-12MW equal to or exceeding ASTM A494 specication for nickel and nickel alloy castings.

For specic applications, always consult “Chemical Resistance Chart" Technical Bulletin

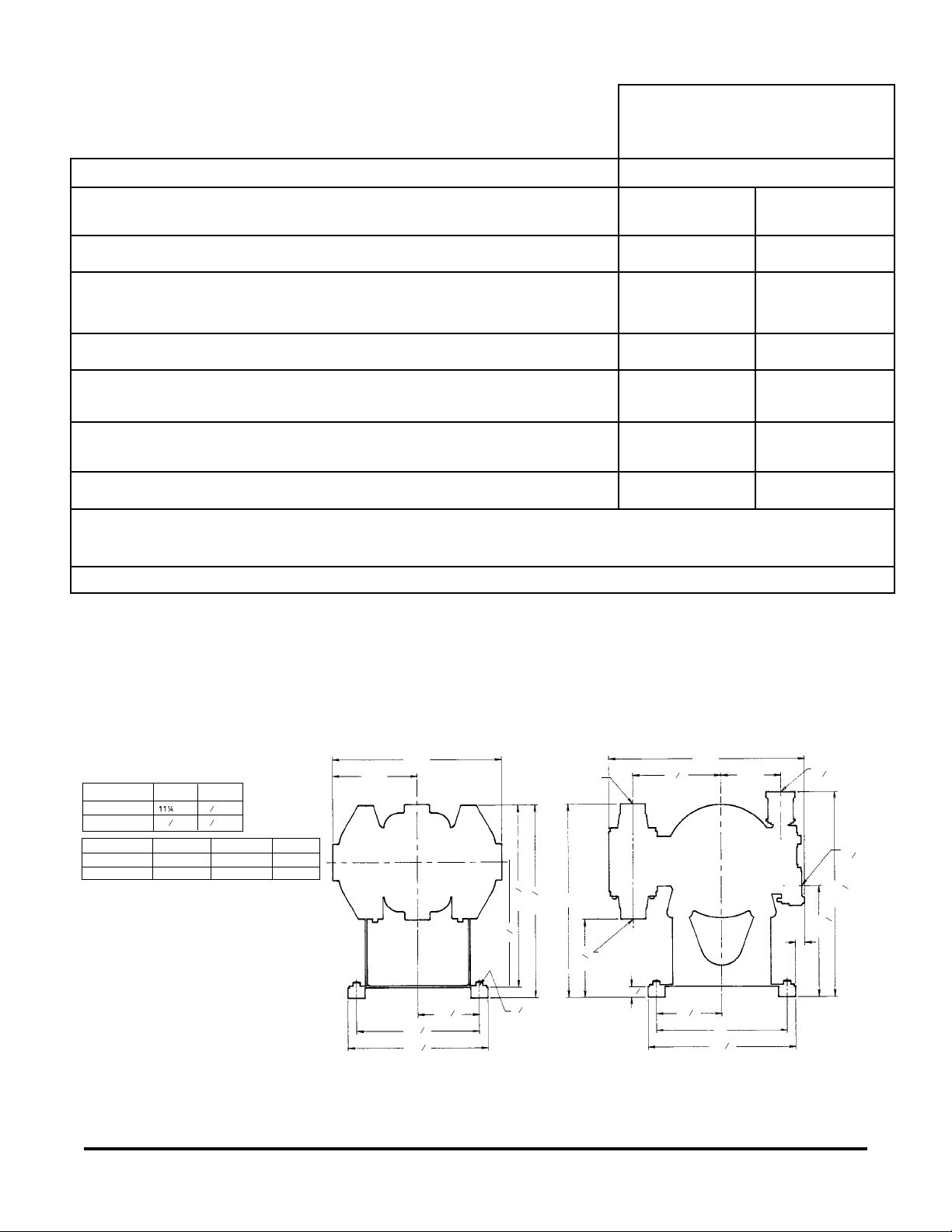

Dimensions: MSB1 & MSB25 Metallic

Dimensions are 1/8"

Figures in parenthesis = millimeters

Models "A" "B"

SST & Alloy "C"

All Others 11

Dimension C D E

Std. Pump 4.3/32" (104) 13.9/32" (337) 5/8" (16)

Pulse Output Kit 4.17/32" (115) 13.23/32" (348) 1.1/16" (27)

(286) 5

3

4

(298) 5

5

8

(143)

7

8

(149)

Model MSB1 features NPT threaded connections.

Model MSB25 features British Standard Pipe (BSP)

Tapered threaded connections

NOTE: UNIT FURNISHED WITH FEET

AS STANDARD. FOR STATIONARY

BOLT DOWN USE, RUBBER FEET CAN

BE REMOVED.

*16 7/16 With Metal Muffler

MSB1: 1" NPT(F) SUCTION AND DISCHARGE • ½" NPT(F) AIR INLET PORT • ¾" NPT(F) AIR EXHAUST PORT (NOT SHOWN)

MSB25: 1" BSP(F) TAPERED SUCTION AND DISCHARGE • ½" NPT(F) AIR INLET PORT • ¾" NPT(F) AIR EXHAUST PORT (NOT SHOWN)

"A"

"B"

(109)

9

32

4

(217)

9

16

8

(248)

3

9

4

(316)

(333)

16

8

7

1

12

13

(217)

16

9

8

9

" DIA.

32

MOUNTING HOLES

TYP. (4) PLACES

DISCHARGE PORT

1" NPT(F)

1" BSP(F) (25)

(330)

13

(133)

4

1

5

SUCTION PORT

1" NPT(F)

1" BSP(F) (25)

(17)

11

16

D

(149)

7

5

8

1

4

2

(114)

C

(229)

9

(260)

1

10

4

AIR EXHAUST

3

" NPT(M)

4

AIR INLET

1

" NPT(F)

2

(367)

16

7

14

*

(194)

8

5

7

E

msb1dl5sm-rev0813 Models MSB1 & MSB25 Page 3

II 2GD T5

SERVICE & OPERATING MANUAL

Model MSB1 Type 5

See pages 2, 18 & 19

for ATEX ratings

PLEASE NOTE!

The photos shown in this manual are for general instruction only. Your specic

model may not be shown. Always refer to the parts list and exploded view draw-

ing for your specic model when installing, disassembling or servicing your pump.

PRINCIPLE OF PUMP OPERATION

This ball valve pump is powered by compressed air and is a 1:1 pressure ratio

design. It alternately pressurizes the inner side of one diaphragm chamber, while

simultaneously exhausting the other inner chamber. This causes the diaphragms,

which are connected by a common rod, to move endwise. Air pressure is applied

over the entire surface of the diaphragm, while liquid is discharged from the opposite

side. The diaphragm operates under a balanced condition during the discharge

stroke, which allows the unit to be operated at discharge heads over 200 feet (61

meters) of water head.

Since the diaphragms are connected by a common rod, secured by plates to the

center of the diaphragms, one diaphragm performs the discharge stroke, while the

other is pulled to perform the suction stroke in the opposite chamber.

For maximum diaphragm life, keep the pump as close to the liquid being pumped

as possible. Positive suction head in excess of 10 feet of liquid (3.048 meters) is

not recommended. For applications with higher suction heads, consult the factory.

Alternate pressuring and exhausting of the diaphragm chamber is performed by

means of an externally mounted, pilot operated, four-way spool type air distribution

valve. When the spool shifts to one end of the valve body, inlet air pressure is applied to one diaphragm chamber and the other diaphragm chamber exhausts. When

the spool shifts to the opposite end of the valve body, the porting of chambers is

reversed. The air distribution valve spool is moved by an internal pilot valve which

alternately pressurizes one side of the air distribution valve spool, while exhausting

the other side. The pilot valve is shifted at each end of the diaphragm stroke by the

diaphragm plate coming in contact with the end of the pilot valve spool. This pushes

it into position for shifting of the air distribution valve.

The chambers are manifolded together with a suction and discharge check valve

for each chamber, maintaining ow in one direction through the pump.

Model MSB25 Type 5

Original Instructions

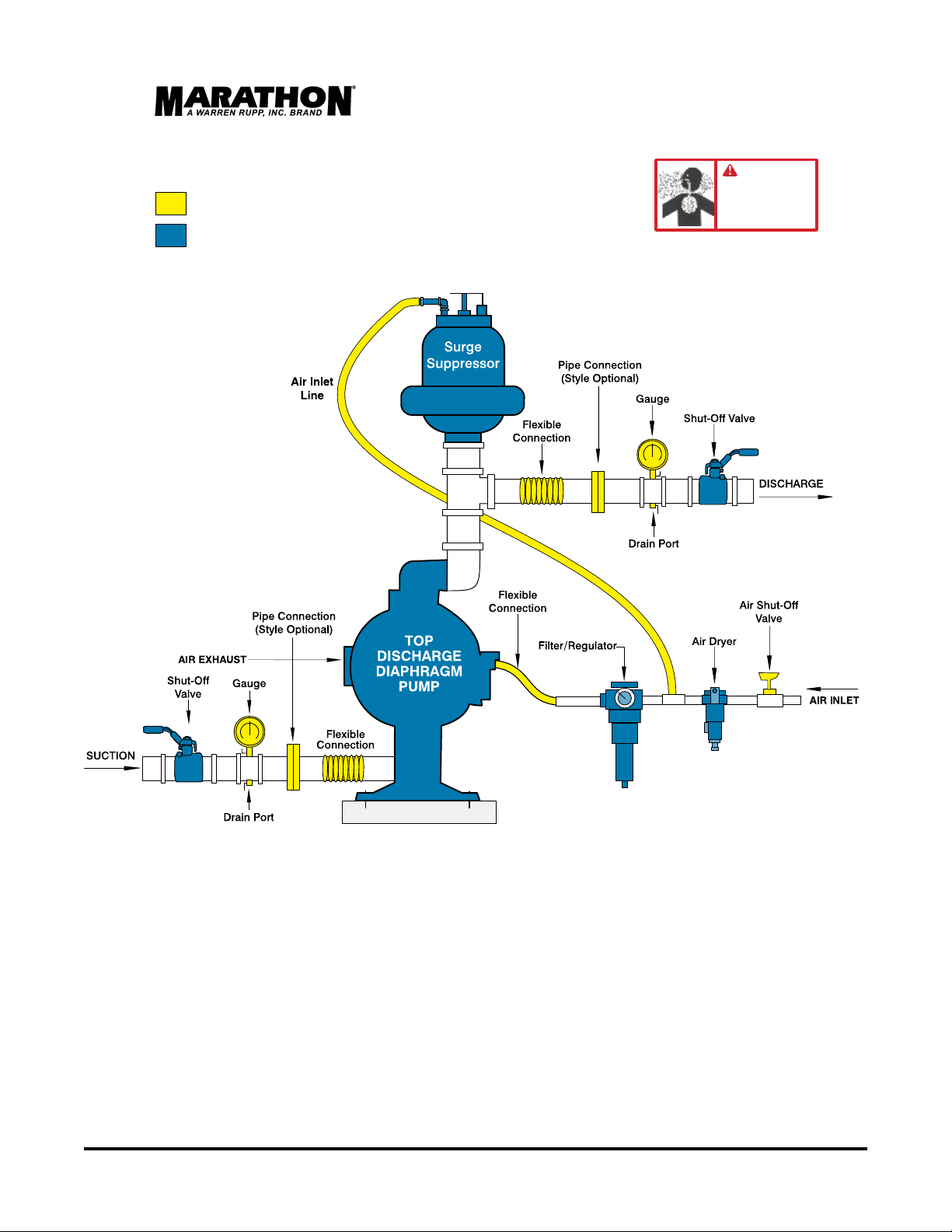

INSTALLATION & START-UP

Locate the pump as close to the product being pumped as possible, keeping

suction line length and number of ttings to a minimum. Do not reduce line size.

For installations of rigid piping, short exible sections of hose should be

installed between pump and piping. This reduces vibration and strain to the piping

system. A Warren Rupp Tranquilizer

reduce pulsation in ow. Tighten all fasteners before pump startup.

This pump was tested at the factory prior to shipment and is ready for operation.

It is completely self-priming from a dry start for suction lifts of 10-15 feet (3.05-4.57

meters) or less. For suction lifts exceeding 15 feet of liquid, ll the chambers with

liquid prior to priming.

®

surge suppressor is recommended to further

AIR SUPPLY

Air supply pressures cannot exceed 125 psi (8.61 bar). Connect the pump

air inlet to an air supply of sufcient capacity and pressure required for desired

performance. When the air line is solid piping, use a short length of exible hose

(not less than 3/4" (19mm) in diameter) between pump and piping to eliminate

strain to pipes.

msb1dl5sm-rev0813 Models MSB1 & MSB25 Page 4

Available from

Distributor

Available from

MARATHON

INSTALLATION GUIDE

Top Discharge Ball or Flap Valve Unit

CAUTION

The air exhaust should be

piped to an area for safe

disposition of the product

being pumped, in the event

of a diaphragm failure.

msb1dl5sm-rev0813 Models MSB1 & MSB25 Page 5

Loading...

Loading...