Page 1

Samsung Electronics

3-1

3. Alignment and Adjustment

3-1 Mechanism Alignment

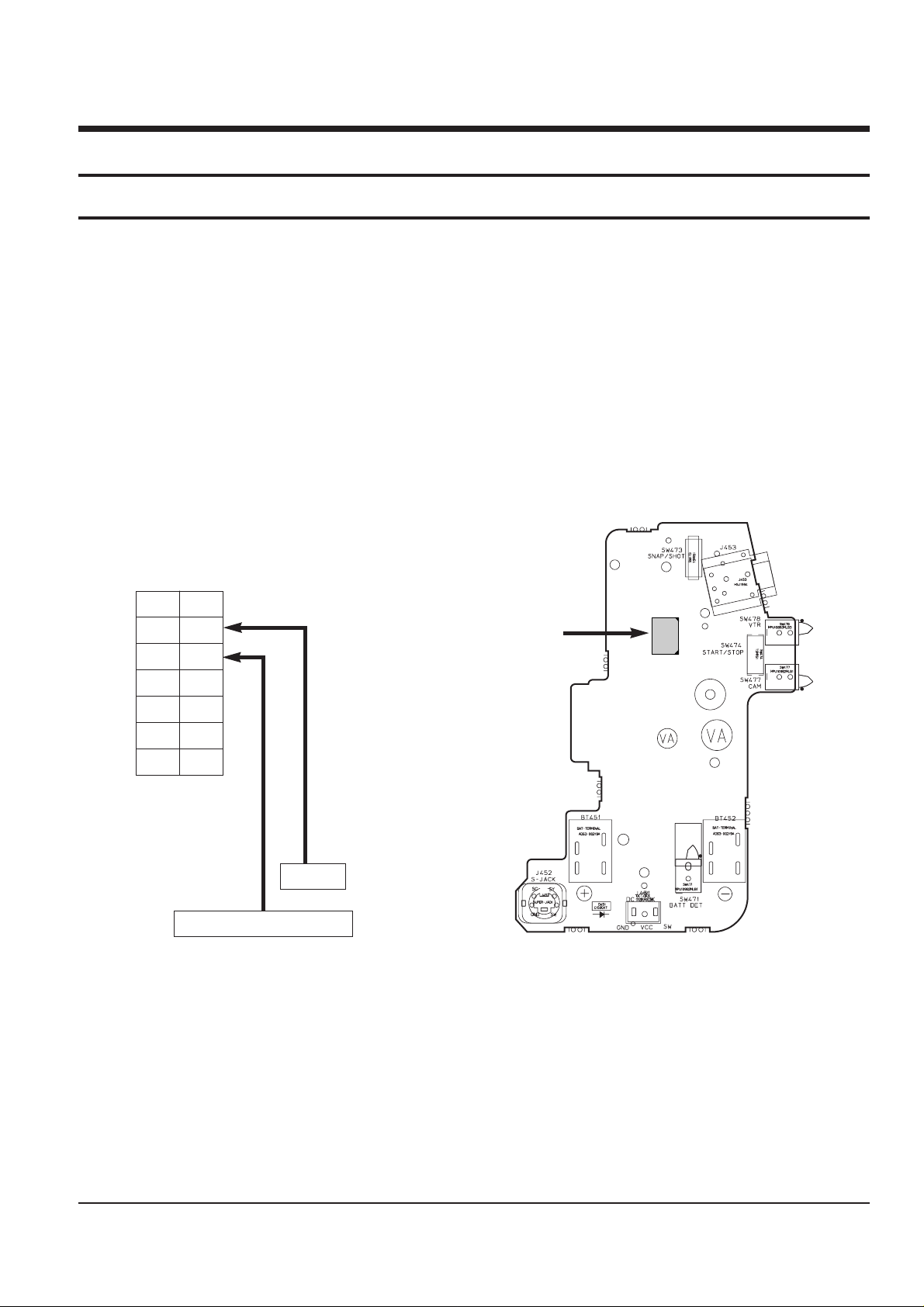

• The location of test point (See Fig.3-1)

Test Point:

PB RF - Pin 11 of CN452

Head Switching Trigger - Pin 9 of CN452

Fig. 3-2 Test location of test point (Rear Board)

Fig. 3-1 Test point

CN452

14

2

13

1

CN452

PB RF

Head Switching - Trigger

CN452

14 13

12 11

10 9

87

65

43

12

Page 2

3-2

Alignment and Adjustments

Samsung Electronics

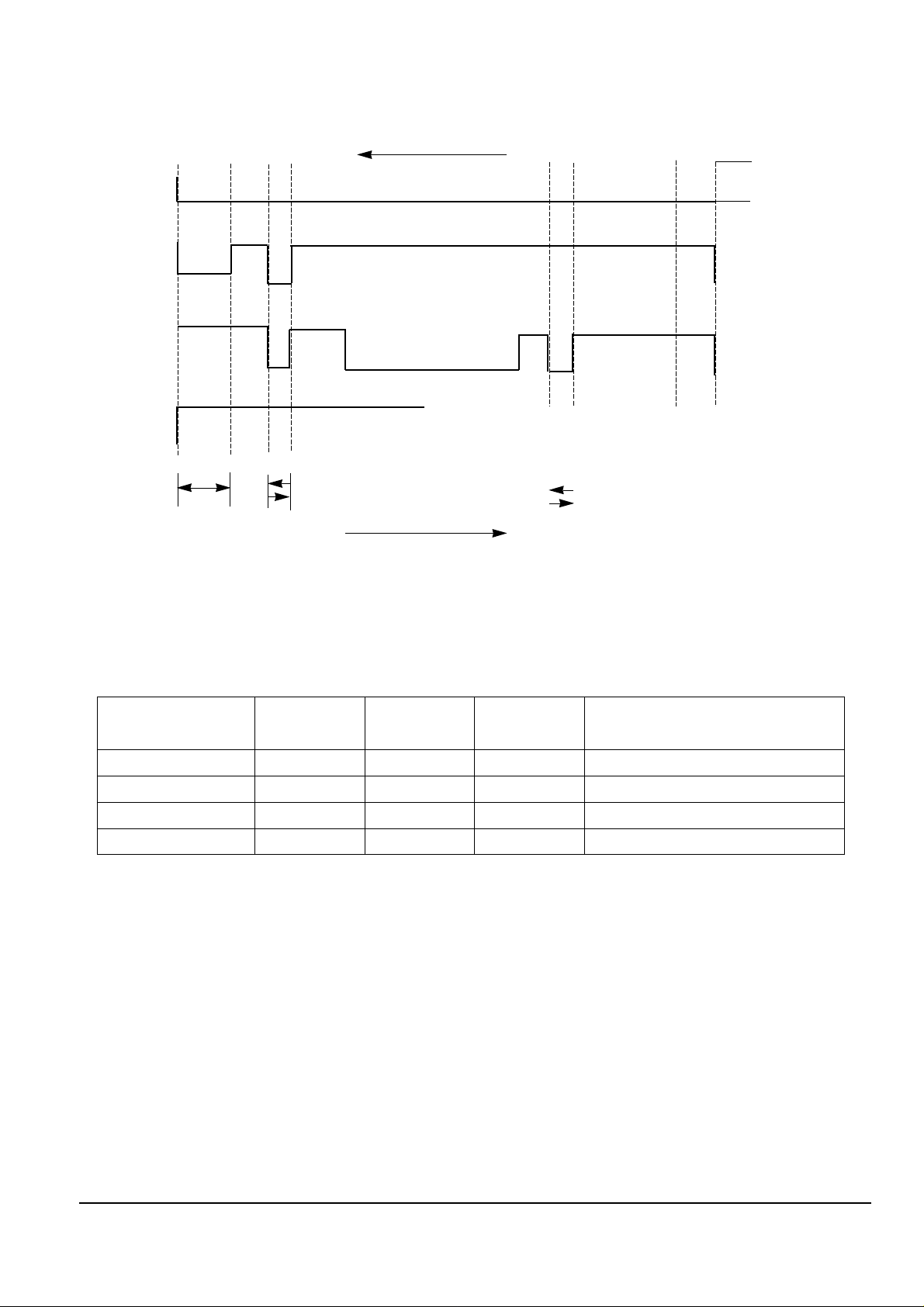

POSITION

IC601 IC601 IC601

ACTION MODE

157PIN 158PIN 159PIN

LHH EJECT

LLH UNLOADING STOP

HLL LOADING STOP

HHL PLAY, FF, REW, STILL....

EJECT

UNLOADING STOP

LOADING STOP

PB

IC601

158PIN

GROUND

IC601

159PIN

COMMON

IC601

157PIN

OPEN

EJECT

PLAY

LOADING STOP

UNLOADING

STOP

LOADING

UNLOADING

Fig. 3-3

Table. 3-1

Page 3

Alignment and Adjustments

3-3

Samsung Electronics

3-2 Camera Adjustment

Note :

1. This system has :

1) EEPROM to store the confirmed adjustment data.

2) DSP (Digital Signal Process ; ICP01 - Main board) chip to process the signal of camera parts.

3) The special mode for camera adjustment using the remote controller.

2. Keep in mind :

1) All adjustment steps should be performed using the remote controller.

3-2-1 Preparations

4. Remote control :

The following is a chart explaining the use of each button :

1. Equipment to be used :

1) DC Power supply

2) Oscilloscope

3) Frequency counter

4) Vectorscope

5) Waveform monitor

6) Color monitor or TV

7) Various charts

- Color bar chart

- Gray-scale chart, etc...

2. Composition of camera P.C.Boards :

1) Main PCB 2) CCD PCB

3) CVF PCB

3. Adjustment preparations :

1) Some buttons of set is used as a camera adjust tool.

2) Press the confirm button when each manual

adjustment step is completed to write the

adjustment data to the EEPROM.

3) After each adjustment step is completed, OSD

shows “OK!”.

4) To cancel the adjustment mode, remove the power

source.

Using Button

ENTER (CONFIRM)

P.AE (DATA UP)

DSE (DATA DOWN)

BLC (MODE UP)

FADE (MODE DOWN)

MANUAL FOCUS RING (NEAR/FAR)

ZOOM TELE

ZOOM WIDE

Adjustment

Data store after finishing adjustment by DATA UP/DOWN button.

When change data value of adjust state.

Mode change.(One step or 100 step)

Manual focus adjustment.

1) Move the zoom position of lens.

2) Semi-Auto lens adjustment.

MENU ON/OFF (MODE UP ‘100’)

Table. 3-2

Page 4

3-4

Alignment and Adjustments

Samsung Electronics

Note : In service adjustment mode, button names are different from those in customer camera function control

mode. EX) ENTER button is the same as confirm.

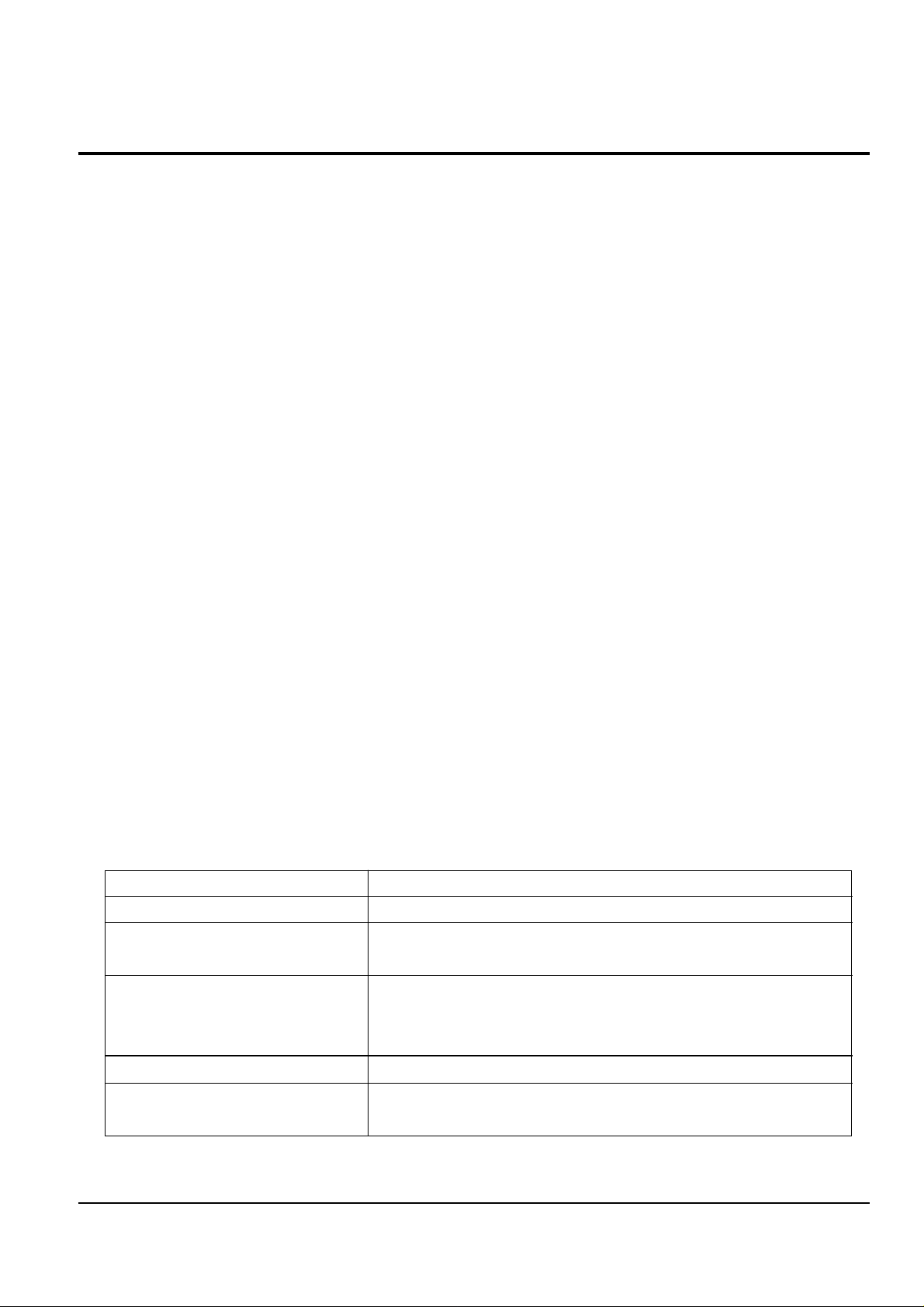

5. How to get into service “ADJUST” mode

1. Remove the lithium battery from the

camcorder.

2. Connect the power source (battery/

DC cable).

3. Eject the tape if it is in the unit.

4. Set the power switch of the

camcorder to “CAMERA” position.

STEP 1

1. Press and hold the “EJECT” button and

DATE/TIME button on the camcorder at the

same time for more than 5 seconds.

Then unit goes into service mode.

STEP 2

Note : When “XX XX” is shown in service adjustment procedures, this indicates variable values.

MENU

ON/OFF

ENTER

(MF)

UP/DOWN Dial

P

.AE

BLC

FADE

DSE

0DF.

ERR : A0 EVR : A0

STEP 3

Fig. 3-4

Page 5

Alignment and Adjustments

3-5

Samsung Electronics

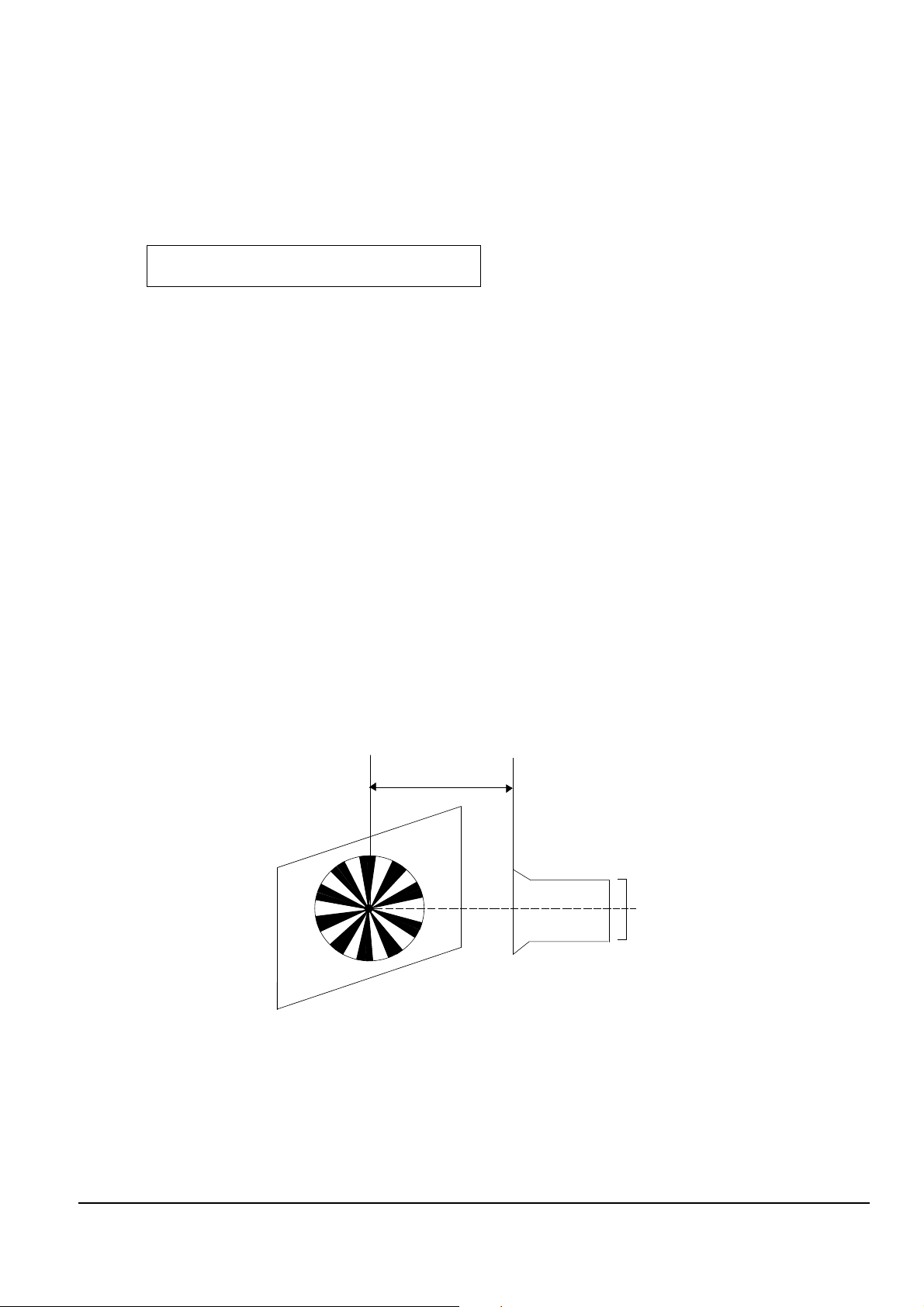

1. Focus to zoom tracking

Notes : To maintain proper focus throughout the zoom range, the focus lens position must be changed as the

zoom lens is moved.

During this adjustment the microprocessor will measure the focus positioning requirements at the wide

and telephoto position of the zoom lens.

1) Camera “E-E”.

2) Focus chart (Attached on the last page of this manual).

3) Aim the camera at the focus chart placed 3 meters away and perpendicular to the center of the lens.

The chart should be placed on the flat, gray or white wall.

4) Connect monitor TV jack to video output jack.

5) Press the “BLC(MODE UP)” and “FADE(MODE DOWN)” button, so that the OSD start is “0DE. 3M LENS XX

XX”.

6) Press “ENTER(CONFIRM)” button.

The camera will move both zoom and focus lens.

The adjustment is finished when the O.K! message appears on the TV screen.

Store the data to mode 099, 09A, 0AA, 0AB, 0AD, 0C9, 0CA, 0CB and 0CC.

3-2-2 Camera System Adjustment

Note : The on-screen display information.

“XX XX” means arbitrary value.

It can be different number depend on the conditions.

0DE XX XX

Fig. 3-5

(Be sure to maintain the distance.)

(3M±1cm)

LENS

CCD

Page 6

3-6

Alignment and Adjustments

Samsung Electronics

2. Zoom VR Center

1) Camera “E-E”, 3100°K gray-scale chart.

2) Video(output) jack and EVR.

3) Connect monitor TV to video(output) jack.

4) Press the “BLC (MODE UP)/FADE(MODE

DOWN)” button so that the OSD state is “OD6. XX

XX”.

5) Press “ENTER(CONFIRM)” button.

6) Then, the microprocessor will work ;

- Find the Zoom VR Center position

- Store the data to mode 0B7.

3. Auto hall

1) Camera “E-E”, 3100°K gray-scale chart.

2) Video(output) jack and EVR.

3) Connect monitor TV to video(output) jack.

4) Press the “BLC(MODE UP)/FADE(MODE

DOWN)” button so that the OSD state is “OCD. XX

XX”.

5) Press “ENTER(CONFIRM)” button.

6) Then, the microprocessor will work ;

- IRIS open, HALL maximum value found,

- IRIS closed, HALL minimum value found,

- IRIS open, HALL maximum value found,

- Store the data to mode 00A and mode 00B.

- Store the HALL min./max. data to mode 0C1 and

mode 0C2.

4. AUTO IRIS

1) Camera “E-E”, 3100°K gray-scale chart.

2) Video(output) jack and AF MICOM.

3) Connect video(output) jack to waveform monitor

input jack and monitor TV jack respectively.

4) Press the “BLC(MODE UP)/FADE(MODE

DOWN)” button so that the OSD state is “OCE. XX

XX”.

5) Press “ENTER(CONFIRM)” Button.

6) Then, the micro process will work;

- IRIS open, IRIS control minimum Value found.

- IRIS close, IRIS control minimum Value found.

- Store the data to mode 0B5, 0B6, 0C7 and 0C8.

7) The OSD shows “O.K”.

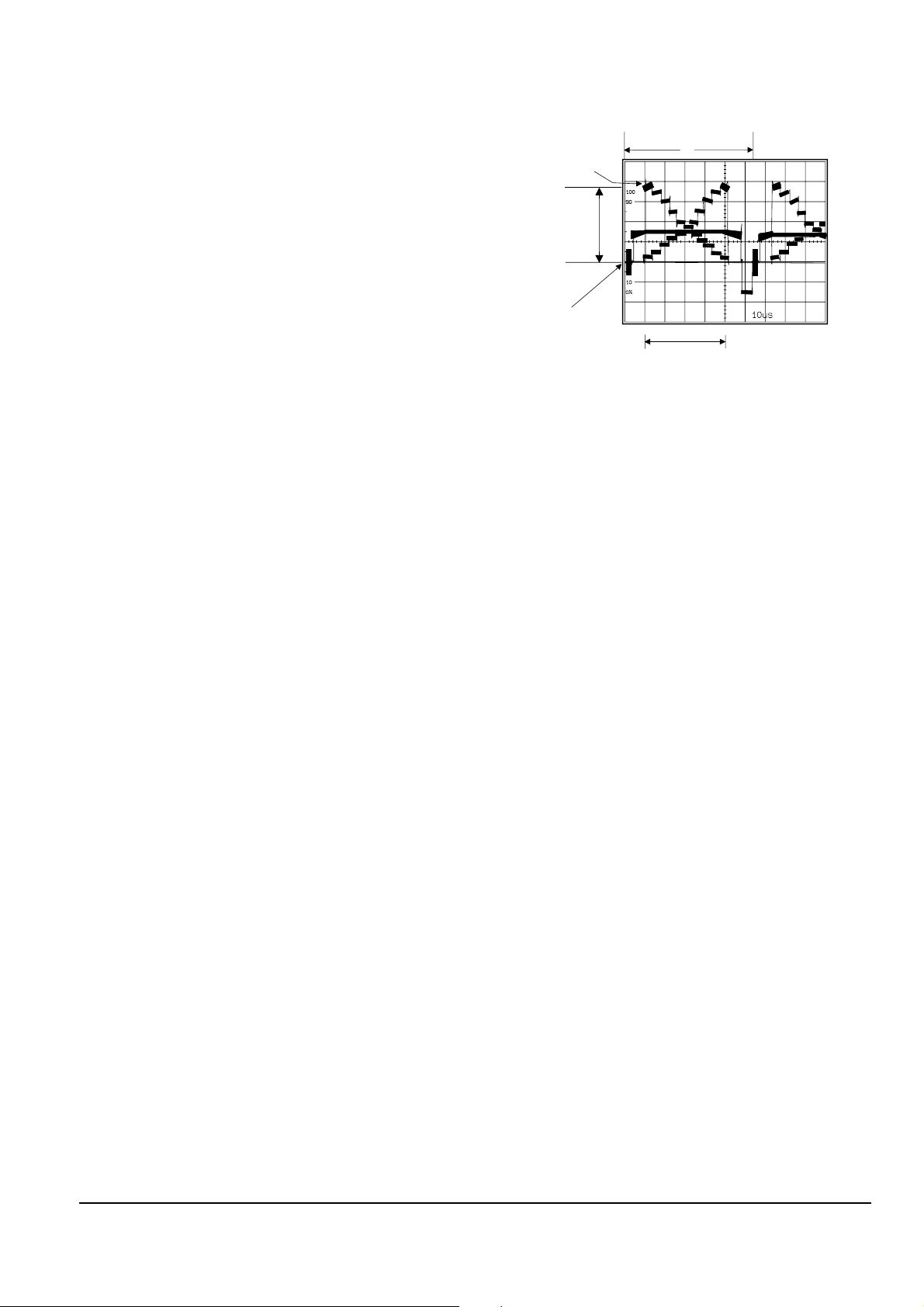

5. Auto white balance

1) Camera “E-E”, 3100°K/5100°K gray-scale chart.

2) Video(output) jack and AF MICOM.

4) Connect vectorscope input jack to video(output)

jack.

3) Press the “BLC(MODE UP)/FADE(MODE

DOWN)” button so that the OSD state is “OCF. XX

XX”.

a. W/B Indoor

a-1. Aim the camera at a 3100°K gray-scale chart

illuminated at 1500 to 2000 lx. (40us)

a-2. Press “ENTER(CONFIRM)” button so that the

white vector moves to the center on screen of the

vectorscope.

a-3. Store the data to mode 0A6, 0A7, 0A8, 0A9

a-4. The OSD shows “OK!”.

b. W/B Outdoor

b-1. Aim the camera at a 5100°K gray-scale

(3100°K+CCB12) chart illuminated at 1500 to 2000

lx. (40us)

b-2. Press “ENTER(CONFIRM)” button so

that the white vector moves to the center on

screen of the vectorscope.

b-3. Store the data to mode 0A2, 0A3, 0A4 and 0A5.

b-4. The OSD shows “OK!”.

Center of

white level

100 IRE

Optical

black level

H

40US

Fig. 3-6

Page 7

Alignment and Adjustments

3-7

Samsung Electronics

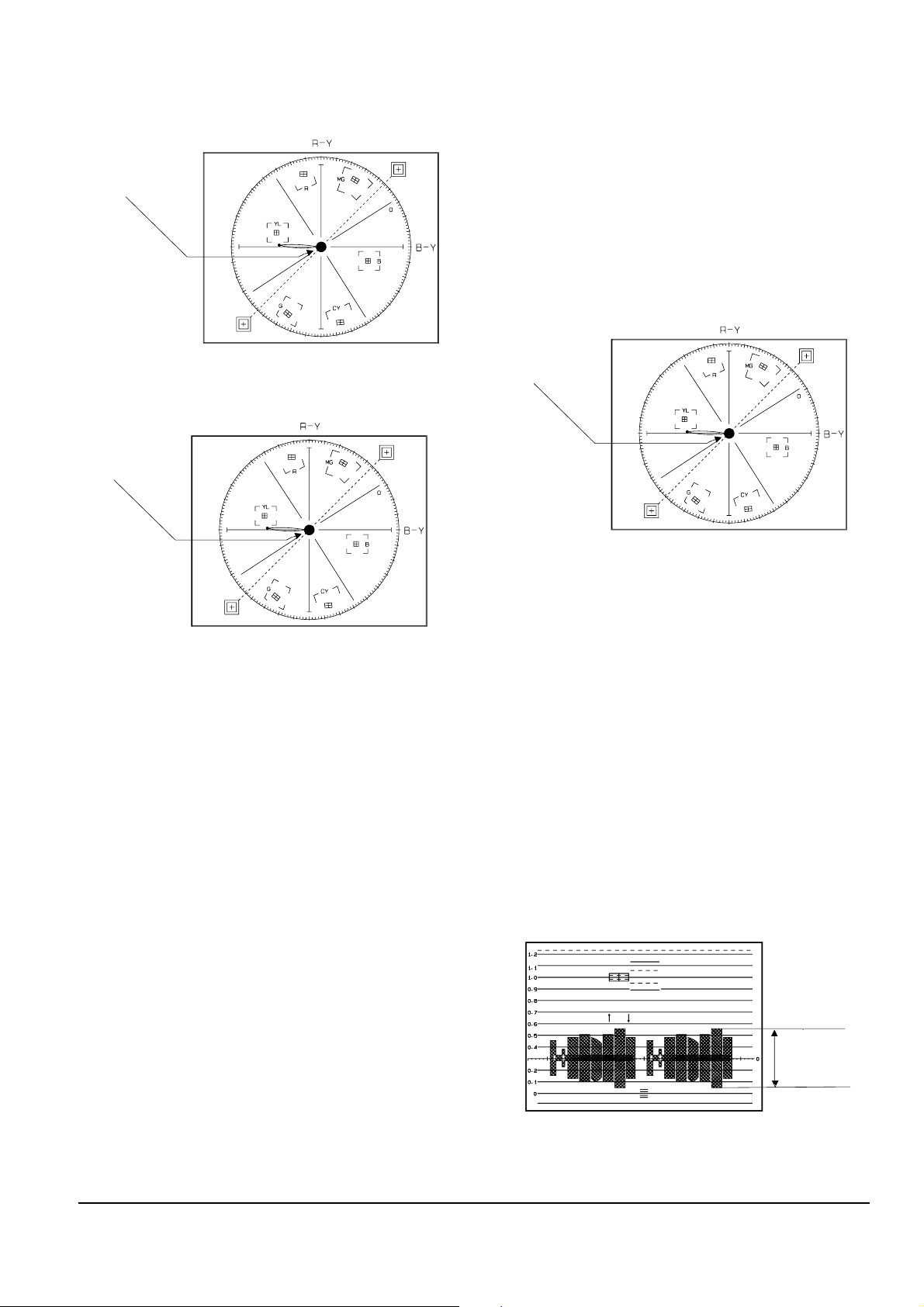

6. Pre white balance (I) ; (R-Y)

1) Camera “E-E”, 3100°K gray-scale chart.

2) Video(output) jack and AF MICOM.

3) Connect vectorscope input jack to video(output)

jack.

4) Press the “BLC(MODE UP)/FADE(MODE

DOWN)” button so that pass through 272, 273, 274,

275 and then the OSD state is “272. XX

XX(High)””273. XX XX(Low)”.

5) Aim the camera at a 3100°K gray-scale chart

illuminated at 1500 to 2000 lx.

6) Adjust the “ P.AE(DATA UP)/DSE(DATADOWN)”

button so that the white vector moves to the R-Y

axial on screen of the vectorscope.

Note : Bright dot shifts after the confirm button is

pressed.

7. Pre white balance (II) ; (B-Y)

1) Camera “E-E”, 3100°K gray-scale chart.

2) Video(output) jack and AF MICOM.

4) Connect vectorscope input jack to video(output)

jack.

3) Press the “BLC (MODE UP)/FADE(MODE

DOWN)” button so that the OSD state is “274. XX

XX(High)””275. XX XX(Low)”.

5) Aim the camera at a 3100°K gray-scale chart

illuminated at 1500 to 2000 lx.

6) Adjust the “P.AE(DATA UP) /DSE(DATADOWN)”

button so that the white vector moves to the B-Y

axial on screen of the vectorscope.

Note : Bright dot shifts after the confirm button is

pressed.

8. R-Y Gain

1) Camera “E-E”, 3100°K color bar chart.

2) Video(output) jack and register of EEPROM.

3) Connect video(output) jack to waveform monitor

input jack and monitor TV jack respectively.

4) Press the “BLC(MODE UP)/FADE(MODE

DOWN)” button so that the OSD state is “280. XX

XX(High)””281. XX XX(Low)”.

5) Aim the camera at a color bar chart illuminated at

1500 to 2000 lx.

6) Adjust the “P.AE(DATA UP)/DSE(DATA

DOWN)” button so that the red level is

NTSC : 70IRE, PAL : 500mV

7) Be sure to press the “ENTER(CONFIRM)” button to

memorize setting.

Note : Bright dot shifts after the confirm button is

pressed. (outdoor : 034, 035)

Match the white luminance

point with the

black luminance

point

Match the white luminance

point with the

black luminance

point

Fig. 3-7

Fig. 3-8

Match the white luminance

point with the

black luminance

point

Fig. 3-9

70 IRE (NTSC)

500mV (PAL)

Fig. 3-10

Page 8

3-8

Alignment and Adjustments

Samsung Electronics

9. B-Y Gain

1) Camera “E-E”, 3100°K color bar chart.

2) Video(output) jack and register of EEPROM.

3) Connect video(output) jack to waveform monitor

input jack and monitor TV jack respectively.

4) Press the “BLC(MODE UP)/FADE(MODE

DOWN)” button so that the OSD state is “283. XX

XX(High)””284. XX XX(Low)”.

5) Aim the camera at a color bar chart illuminated at

1500 to 2000 lx.

6) Adjust the “P.AE(DA TA UP)/DSE(DATA DOWN)”

button so that the blue level is NTSC :

50IRE, PAL : 350mV

7) Be sure to press the “ENTER(CONFIRM)” button to

memorize setting.

Note : Bright dot shifts after the confirm button is

pressed.

(outdoor : 036, 037)

10. R-Mg Hue

1) Camera “E-E”, 3100°K color bar chart.

2) Video(output) jack and register of EEPROM.

3) Connect video(output) jack to vectorscope input

jack and monitor TV jack respectively.

4) Press the “BLC(MODE UP)/FADE(MODE

DOWN)” button so that the OSD state is “284. XX

XX(High)””285. XX XX(Low)”.

5) Aim the camera at a color bar chart illuminated at

1500 to 2000 lx.

6) Adjust the “P.AE(DA TA UP)/ DSE(DA TA DOWN)”

button so that theRed vector is 105.

7) Be sure to press the “ENTER (CONFIRM)” button

to memorize setting.

Note : Bright dot shifts after the confirm button is

pressed.

(outdoor : 038, 039)

11. G-Cy Hue

1) Camera “E-E”, 3100°K color bar chart.

2) Video(output) jack and register of EEPROM.

3) Connect video(output) jack to vectorscope input

jack and monitor TV jack respectively.

4) Press the “BLC(MODE UP)/FADE(MODE

DOWN)” button so that the OSD state is “286. XX

XX(High)””287. XX XX(Low)”.

5) Aim the camera at a color bar chart illuminated at

1500 to 2000 lx.

6) Adjust the “P.AE(DATA UP)/ DSE(DATADOWN)”

button so that the Cyan vector is 284.

7) Be sure to press the “ENTER (CONFIRM)” button

to memorize setting.

Note : Bright dot shifts after the confirm button is

pressed.

(outdoor : 03A, 03B)

Fig. 3-12

50 IRE (NTSC)

350mV (PAL)

RED VECTOR

105 DEG.

Fig. 3-11

CYAN VECTOR

284 DEG.

Fig. 3-13

Page 9

Alignment and Adjustments

3-9

Samsung Electronics

12. B-Cy-Mg Hue

1) Camera “E-E”, 3100°K color bar chart.

2) Video(output) jack and register of EEPROM.

3) Connect video(output) jack to vectorscope input

jack and monitor TV jack respectively.

4) Press the “BLC(MODE UP)/FADE(MODE

DOWN)” button so that the OSD state is “288. XX

XX(High)””289. XX XX(Low)”.

5) Aim the camera at a color bar chart illuminated at

1500 to 2000 lx.

6) Adjust the “P.AE (DATA UP)/ DSE(DATA

DOWN)” button so that the Blue vector is 346.

7) Be sure to press the “ENTER (CONFIRM)” button

to memorize setting.

Note : Bright dot shifts after the confirm button is

pressed.

(outdoor : 03C, 03D)

13. Ye-G Hue

1) Camera “E-E”, 3100°K color bar chart.

2) Video(output) jack and register of EEPROM.

3) Connect video(output) jack to vectorscope input

jack and monitor TV jack respectively.

4) Press the “BLC(MODE UP)/FADE(MODE

DOWN)” button so that the OSD state is “28A.XX

XX(High)””28B.XX XX(Low)”.

5) Aim the camera at a color bar chart illuminated at

1500 to 2000 lx.

6) Adjust the “P.AE(DA TA UP) /DSE(DA TA DOWN)”

button so that the Yellow vector is 165.

7) Be sure to press the “ENTER(CONFIRM)” button to

memorize setting.

Note : Bright dot shifts after the confirm button is

pressed.

(outdoor : 03E, 03F)

Note : Outdoor(5100°K) color Gain & Hue adjust.

- 5100°K color bar (or 3100°K color bar with

CCB12 Filter)

- Restart step 7. prewhite balance(I) ~ step 14.

Ye-G Hue.

- The outdoor(5100°K) mode in 034~03F.

BLUE VECTOR

346 DEG.

Fig. 3-14

YELLOW VECTOR

165 DEG

Fig. 3-15

Page 10

3-10

Alignment and Adjustments

Samsung Electronics

1. Equipment :

1) Monitor TV.

2) Dual trace oscilloscope of over 20MHz band,

incorporates delay mode.

(Use 10 : 1 probe unless otherwise specified.)

3) Frequency counter

4) DC power supply.

5) Alignment tape (Colour bar : SP)

6) 8mm Video Tape for record.

2. Composition of VCR P.C.Boards

1) Main PCB (system control/servo, video, audio,

camera)

2) Rear PCB

3) Front PCB

4) Function PCB

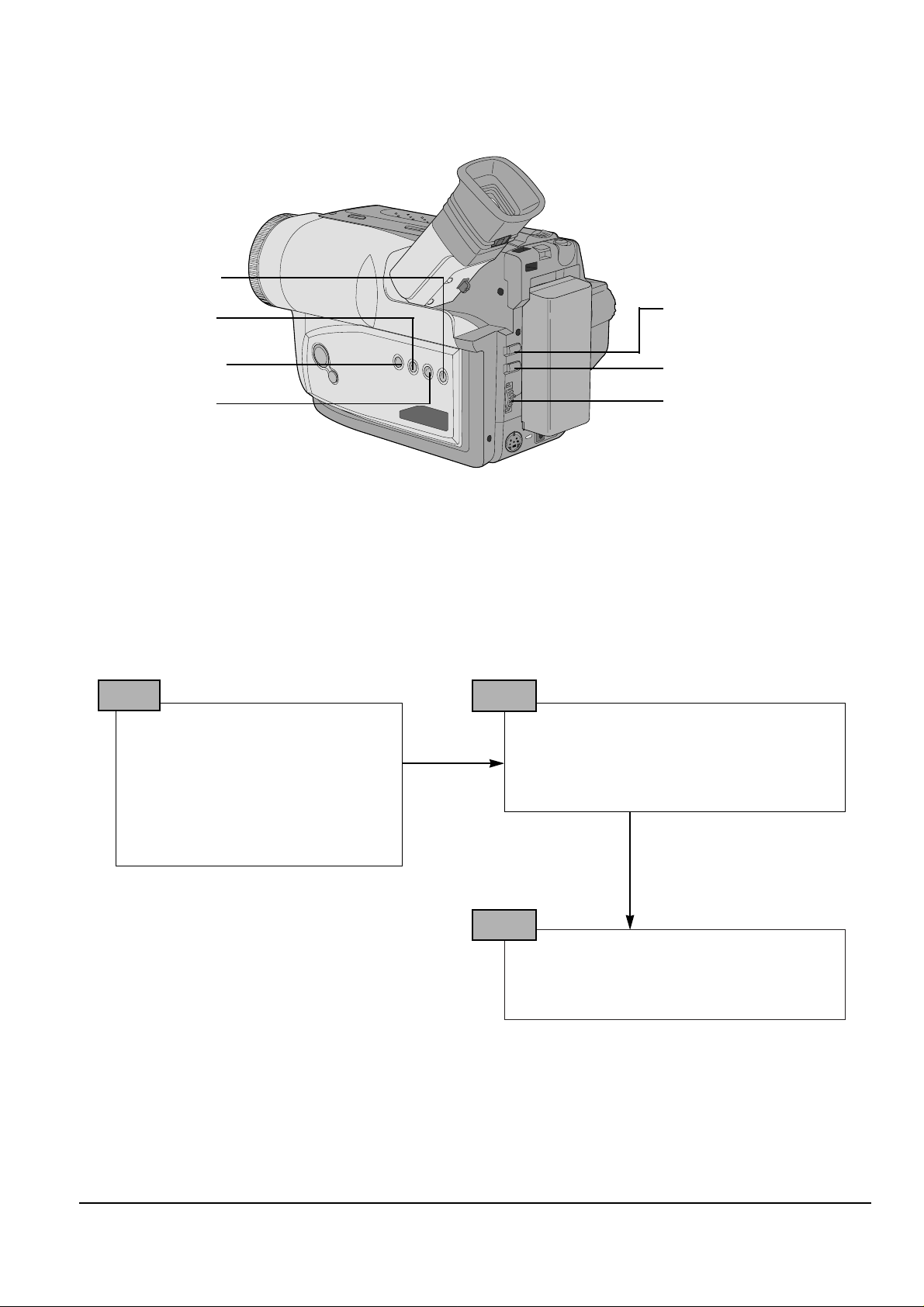

3. How to get into service “ADJUST” mode.

3-3-1 Peraration

1. Connect the power source (battery/DC cable).

2. Set the program selector of the camcorder to PLAYER

position.

3. Press the eject key to eject mode.

STEP 1

1. Press and hold “STOP” and “EJECT” button on the

Camcorder at the same time for more than 5 seconds.

2. If the adjustment mode displayed like the figure below,

VCR adjustment mode has been successfully activated.

3. Insert tape into housing ass’y and then perform the

adjustments.

STEP 2

061.

EPR:XX EVR:XX

TV or CVF monitor

Address of the adjustment mode.

: there are 061h to 1 ch.(refer xxxx)

Name of the adjustment mode.

: every address have a name like this (refer

xxx)

Present data

: be adjusted before.

New data

: be adjusted newly.

3-3 VCR Adjustment

Fig. 3-16

Page 11

4. The location of function button.

5. If you want to finish the adjustment mode, you have to do “Battery Reset”.

The “Battery Reset” means that you pull out the power source and pull in it again.

Then, the adjustment is ended and the camcorder works normally.

Alignment and Adjustments

3-11

Samsung Electronics

Note :

In service adjustment mode, button names are different from those in customer function control mode.

EX) “ENTER” button is the same as “CONFIRM”.

MENU

ON/OFF

ENTER

(MF)

UP/DOWN Dial

P

.AE

BLC

FADE

DSE

Fig. 3-17

Page 12

3-12

Alignment and Adjustments

Samsung Electronics

Note 2 : How to connect video out signal.

-Connect the video cable to ass’y A/V Jack.

3-3-2 VCR Section

Note 1 : From this point forward, the structure of every adjustment is as follows.

Test point

Step Adjustment Item

1. Mode and input signal/

alignment tape

2. Test point and ADJ. part

3. Result and Remarks

ADJ. point

Fig. 3-18 Video Signal Connection

14

13

VIDEO OUT

12

11

10

9

8

7

6

5

4

3

2

1

NC

PB RF

AUDIO OUT

HD SW

VCR UNREG

JIG CS

VCR UNREG

JIG SCK

SS GND

JIG SO

JIG DETECT

JIG SI

AUDIO GND

14

MAIN PCB

REAR PCB

FRONT PCB

CN452

13

12

11

10

9

8

7

6

5

4

3

21

Page 13

Alignment and Adjustments

3-13

Samsung Electronics

3-4 DECK Adjustment

3-4-1 Operation Without Housing Assembly

Fig. 3-20

Fig. 3-19

1. Remove the Housing Ass’y from the recorder unit.

2. Connect the mechanical chassis to the recorder circuit to supply voltage.

3. Set to Unload mode.

4. Press the S/W Push (Keep ON status) and make

loading.

5. Push the Play key.

Drum side Opposite side Movement of Chassis

+–Loading

–+Unloading

Table 3-3

3-4-2 Setting Mechanical Mode (Without Recorder Circuit)

1. Set the power-supply output to approx. 3V.

2. Choose the polarity (depending on whether loading

or unloading).

3. Supply the voltage to the Motor Loading, and set to

the desired mode.

Note : For the removals of the Housing Ass’y, refer to the

page 4-7.

S/W PUSH

CONNECTED TO THE

RECORDER CIRCUIT

Page 14

3-14

Alignment and Adjustments

Samsung Electronics

Fig. 3-21

Carry out the following periodic maintenance checks

in order not only to fully exhibit the functions and

operate the set, but also for the equipment and tape.

After repairing, service the set as follows :

1) Cleaning of Drum Assembly

1. Gently apply lens tissue soaked in ethyl alcohol to

the Drum assembly.

Clean the Upper Drum assembly while rotating it

slowly counterclockwise (by hand).

2) Cleaning of Tape Path

1. In EJECT mode, clean the tape path system (from

Pole Tension P1 through Pole Review P7, Pinch

Roller and Capstan Shaft) and the Lower Drum.

Using the lens tissue soaked in ethyl alcohol.

Note : Do not rotate the motor by power or rotate the Upper

Drum assembly clockwise. Also, the Head tip will be damaged if

the lens tissue is moved in a perpendicular direction.

Be sure to follow these instructions when cleaning the Drum

Ass’y.

Note : Make sure that no oil or grease adheres to the lens tissue.

P3

P1

P2

P6

P4

P7

PINCH

ROLLER

P5

3-4-3 Maintenance

Page 15

Alignment and Adjustments

3-15

Samsung Electronics

3) Periodic Maintenance and Check List

When overhauling, refer to the following table.

◆ When lubricating bearings, be sure to keep the oil free

of dust. (Oil contaminated with dust might cause the

bearings to wear out or seize.)

◆ A “drop” of oil is defined as the amount attached to

the tip of a ø 2mm stick as shown in Fig. 3-22.

Maintenance and check items

Hours of use (H)

Remarks

500 1000 1500 2000 2500 3000 3500 4000 4500 5000

Tape path Cleaning of tape path

OOOOOOOOOO

system

Cleaning and degaussing

OOOOOOOOOO

of drum assembly

Capstan Shaft

∆∆∆∆∆

Gear Capstan

∆∆∆∆∆

Driving system Gear Pulley Shaft

∆∆∆∆∆

Belt Timing

◆◆◆◆◆

Motor Loading

◆◆◆◆◆

Performance Abnormal noise

◆◆ ◆◆◆◆◆◆◆

Back tension measurement

◆◆◆◆◆

Confirmation Brake system

◆◆◆◆◆

PB, REV torque

◆◆◆◆◆

measurement

Table 3-4

Fig. 3-22

Be absolutely careful not to get oil on

the tape path sur-

face.

O : Cleaning ∆ : Oil ◆ : Confirmation

OIL

ø 2mm

Page 16

3-16

Alignment and Adjustments

Samsung Electronics

Fig. 3-23

1) Tension Regulator Adjustment

(A) DISASSEMBLY

1. Refer to the page 2-7 to remove the Housing Ass’y.

(B) ADJUSTMENT

1. Set to PB mode (without cassette tape).

2. Check that the overlap between external surface of

Chassis Sub and external surface of Arm Tension is

0 ~ 1mm. (Fig. 3-23)

3. If necessary, proceed to step 4.

4. If the Arm Tension 1 is located inside the position

specified, adjust the Band Adjust Tension 2 toward

arrow A.

If it is located outside, adjust toward arrow B.

(C) REASSEMBLY

1. Refer tothe page 2-7 to mount the Housing Ass’y.

Hole of Holder Loading

ARM TENSION 1

BAND ADJUST TENSION 2

C

B

A

0~1mm

Note :

Check if the arm tension can be moved toward arrow C in

PB mode. Use the tape which is fed to the end.

3-4-4 Mechanical Check and Adjustment

Page 17

Alignment and Adjustments

3-17

Samsung Electronics

Fig. 3-24

2) Back Tension Adjustment

1. Set up the cassette-torque tape.

2. Set to PB mode and check that the torque value of

Reel S is 9 ± 1.5g.cm.

(If necessary, proceed to step 3 or 4).

3. If the value is too high : While pushing the adjustment claw (rack shape) of Slider Tension toward

arrow C, shift the meshing position (with the claw

of Slider Tension toward arrow A).

See Fig. 3-24.

4. If the value is too low : While pushing the adjust

ment claw (rack shape) of Slider Tension toward

arrow C, shift the meshing position (with the claw

of Slider Tension toward arrow B).

See Fig. 3-24.

3) PB/REV Torque Check

1. Set up the cassette torque tape.

2. Set to PB mode, and check that the torque vlaue of

Reel T is 9 ± 3g.cm.

3. Set to REV mode, and check that the torque value of

Reel S is 25 ± 5g.cm.

4. If necessary, replace the defective reel assembly.

Note : When shifting the position of hooks, remove the cassette

torque tape.

* Remarks : If the cassette torque tape is recorded both in the LP/SP modes by mistake, the torque at the switching point

between SP/LP modes becomes unstable. In that case, do the torque adjustment in REC mode.

Page 18

3-18

Alignment and Adjustments

Samsung Electronics

REEL S TABLE

RESTING SURFACE

SUB CHASSIS

REEL T TABLE

RESTING SURFACE

Fig. 3-25

4) Reel Table Height Check

(A) REMOVAL

1. Refer to the page 2-7

; Remove the Housing Ass’y.

2. Refer to the page 2-9

; Remove the Idler Ass’y.

(B) CHECK

1. Using the slide calipers, check the following dis-

tances: The upper surface of the P.C.B Reel to the

Reel S table resting surface and the Reel T table resting surface should each be 5.7 ± 0.2mm.

(C) MOUNTING

1. Refer to the page 2-9

; Mount the Idler Ass’y.

2. Refer to the page 2-7

; Mount the Housing Ass’y.

Page 19

Alignment and Adjustments

3-19

Samsung Electronics

Fig. 3-27

1) Preparation for Adjustment

1. Clean the tape running surface (Poles, Drum,

Capstan Shaft, Pinch Roller).

2. Refer to the Service Manual (of camcorder).

Observe the PB RF signal and Head Switching

Pulse on an oscilloscope.

3. Play back the alignment tape.

4. Check that the waveform of the RF signal is flat

both at the inlet and outlet (Fig. 3-26 A).

If not flat (B or C in Fig. 3-26), do adjustments

2) through 5).

Fig. 3-26

REEL S

REEL T

A CORRECT

B DEFECT AT INLET

C DEFECT AT OUTLET

INLET OUTLET

3-4-5 Tape Path Adjustment

Page 20

3-20

Alignment and Adjustments

Samsung Electronics

2) Tracking Adjustment

1. Play back the alignment tape. (Tracking B or C)

2. Turn P2 to flatten the waveform at the inlet.

3. Turn P5 to flatten the waveform at the outlet.

Fig. 3-28

P2

P5

3) Not Adjustment

1. Play back the alignment tape, and confirm that the

tape is not loosened between the Capstan Motor

and Cuide Roller T.

2. Set to REV mode and observe the outlet waveform

of PB RF signal. (Fig. 3-30)

Fig. 3-29

GUIDE

ROLLER S

(P2)

TAPE SHOULD NOT BE

LOOSENED HERE

P7 CAPSTAN

GUIDE ROLLER T (P5)

Fig. 3-30

(NG) (GOOD)

Page 21

Alignment and Adjustments

3-21

Samsung Electronics

4) Check After Adjustment

(A) TRACKING CHECK

1. Play back the alignment tape.

2. Then, Confirm that the minimum amplitude value

(E min.) is 65% of the maximum value

(E max.) or larger. (Fig. 3-31)

3. Confirm that no large fluctuations occur on the

waveform. (Fig. 3-32)

Fig. 3-31

E

MIN EMAX

E

MIN

65(%)

E

MAX

(B) CUE AND REV CHECK

1. Play back the alignment tape, and set to REV mode.

Confirm that the waveform peaks have a uniform

pitch. (Fig. 3-33 )

2. Set to CUE mode.

Confirm that the waveform peaks still have a uniform pitch. (Fig. 3-33 )

Fig. 3-33

a b c

a b c

Fig. 3-32

A

C

C

C

1

A

8

a = b = c

A

>

=

B

<

=

A

Page 22

3-22

Alignment and Adjustments

Samsung Electronics

(C) RISE TIME CHECK

1. Play back the alignment tape.

2. Set to playback mode, and confirm that the waveform of PB RF signal rises flatly within 3 seconds.

Also confirm that the tape is not

loosened or curled around the Pinch Roller.

(Fig. 3-34)

3. Run the tape in CUE/REV and FF/REW modes,

then playback. Confirm the waveform of PB RF signal rises flatly within 3 seconds.

Also confirm that the tape is not loosened or curled

around the Pinch Roller.

4. Repeat steps 2. and 3.

(D) TAPE PATH CHECK

1. In CUE and REV modes, check that the tape is not

too curled around the P2 Upper Flange,

P5 Upper Flange, and P7 Upper/Lower Flanges.

(Fig. 3-35)

Fig. 3-34

Fig. 3-35

GUIDE

ROLLER T

TAPE SHOULD NOT BE

LOOSENED OR CURLED HERE

FROM THE REEL S TO THE REEL T

P7

P2

P5 P7

CAPSTAN

Loading...

Loading...