Samsung ML 1660, ML 1665 Service Manual

Service Manual

1. Speed

• Up to 16 ppm in A4 (17 ppm in Letter)

2. Processor

• Jupiter4e 150 MHz

3. Printer Language

• GDI

The keynote of Product

Laser Printer

ML-1660/1665

4. Memory

• 8 MB

5. Interfaces

• Compatible with USB 2.0

6. Toner cartridge

• Initial : 0.7K

• Sales : 1.5K

ⓒ

Samsung Electronics Co.,Ltd. December. 2009

Printed in Korea.

VERSION NO. : 1.00 CODE : 1660-00000E

chapter 1 Precautions

1.1 Safety Warning …………………………………………………… 1-1

1.2 Caution for safety ………………………………………………… 1-2

1.2.1 Toxic material ………………………………………………… 1-2

1.2.2 Electric Shock and Fire Safety Precautions ……………… 1-2

1.2.3 Handling Precautions ……………………………………… 1-3

1.2.4 Assembly / Disassembly Precautions ……………………… 1-3

1.2.5 Disregarding this warning may cause bodily injury ……… 1-4

1.3 ESD Precautions ………………………………………………… 1-5

Contents

chapter 2 Product Overview

2.1 Product Specications …………………………………………… 2-1

2.1.1 Product Overview …………………………………………… 2-1

2.1.2 Specications ………………………………………………… 2-2

2.1.3 Model Comparison Table …………………………………… 2-7

2.2 System Overview ………………………………………………… 2-8

2.2.1 Front View …………………………………………………… 2-8

2.2.2 Rear View …………………………………………………… 2-9

2.2.3 System Layout ……………………………………………… 2-10

2.2.4 Engine H/W Specications ………………………………… 2-17

2.2.5 Engine F/W Contol Algorithm ……………………………… 2-23

2.2.6 S/W Descriptions …………………………………………… 2-25

chapter 3 Maintenance and Disassembly

3.1 Precautions when replacing parts ……………………………… 3-1

3.1.1 Precautions when assembling and disassembling ……… 3-1

3.1.2 Preautions when handling PBA …………………………… 3-1

3.1.3 Releasing Plastic Latches ………………………………… 3-1

Contents

3.2 Screws used in the printer ……………………………………… 3-2

3.3 Cover ……………………………………………………………… 3-3

3.3.1 Left/Right cover ……………………………………………… 3-3

3.3.2 Rear bracket ………………………………………………… 3-3

3.3.3 Cover-open ………………………………………………… 3-4

3.3.4 Top/Front cover ……………………………………………… 3-4

3.4 Main PBA ………………………………………………………… 3-5

3.5 SMPS/HVPS board ……………………………………………… 3-6

3.6 Fuser unit ………………………………………………………… 3-7

3.7 LSU ………………………………………………………………… 3-8

3.8 Drive unit ………………………………………………………… 3-9

3.9 Step motor ………………………………………………………… 3-10

3.10 Pick up roller …………………………………………………… 3-11

chapter 4 Alignment and Troubleshooting

4.1 Alignment and Adjustments ……………………………………… 4-1

4.1.1 Control Panel ………………………………………………… 4-1

4.1.2 Understanding the LEDs …………………………………… 4-2

4.1.3 JAM Removal ……………………………………………… 4-3

4.1.4 Printing a report ……………………………………………… 4-5

4.1.5 Periodic Defective Image …………………………………… 4-8

4.1.6 Firmware upgrade …………………………………………… 4-9

4.1.7 Using the smart panel program …………………………… 4-10

4.2 Troubleshooting…………………………………………………… 4-12

4.2.1 Procedure of Checking the Symptoms …………………… 4-12

4.2.2 Bad discharge ……………………………………………… 4-15

4.2.3 Malfunction …………………………………………………… 4-19

4.2.4 Bad image …………………………………………………… 4-24

chapter 5 System Diagram

5.1 Block Diagram …………………………………………………… 5-1

5.2 Connection Diagram……………………………………………… 5-2

chapter 6 Reference Information

6.1 Tool for Troubleshooting ………………………………………… 6-1

6.2 Acronyms and Abbreviations …………………………………… 6-2

6.2.1 Acronyms …………………………………………………… 6-2

6.2.2 Service Parts ………………………………………………… 6-4

Contents

6.3 A4 ISO 19798 Standard Pattern ………………………………… 6-8

6.3.1 A4 ISO 19752 Standard Pattern …………………………… 6-8

6.4 Selecting a location ……………………………………………… 6-9

attached Exploded Views & Parts List

Precautions

1. Precautions

In order to prevent accidents and damages to the equipment please read the precautions listed below

carefully before servicing the product and follow them closely.

1.1 Safety warning

(1) Only to be serviced by a factory trained service technician.

High voltages and lasers inside this product are dangerous. This product should only be serviced by a

factory trained service technician.

(2) Use only Samsung replacement parts.

There are no user serviceable parts inside the product. Do not make any unauthorized changes or

additions to the product as these could cause the product to malfunctions and create an electric shocks

or re hazards.

(3) Laser Safety Statement

The product is certied in the U.S. to conform to the requirements of DHHS 21 CFR, chapter 1

Subchapter J for Class 1(1) laser products, and elsewhere, it is certied as a Class I laser product conforming to the requirements of IEC 825. Class I laser products are not considered to be hazardous. The

laser system and product are designed so there is never any human access to laser radiation above a

Class I level during normal operation, user maintenance, or prescribed service condition.

Warning >> Never operate or service the product with the protective cover removed from Laser/Scanner

assembly. The reected beam, although invisible, can damage your eyes.

When using this product, these basic safety pre-cautions should always be followed to reduce

risk of re, electric shock, and personal injury.

Service Manual

1-1

Samsung Electronics

Precautions

Service Manual

1-2

Samsung Electronics

1.2 Caution for safety

1.2.1 Toxic material

This product contains toxic materials that could cause illness if ingested.

(1) If the LCD control panel is damaged, it is possible for the liquid inside to leak. This liquid is toxic.

Contact with the skin should be avoided. Wash any splashes from eyes or skin immediately and contact

your doctor. If the liquid gets into the mouth or is swallowed, see a doctor immediately.

(2) Please keep imaging unit and toner cartridge away from children. The toner powder contained in the

imaging unit and toner cartridge may be harmful, and if swallowed, you should contact a doctor.

1.2.2 Electric shock and re safety precautions

Failure to follow the following instructions could cause electric shock or potentially cause a re.

(1) Use only the correct voltage, failure to do so could damage the product and potentially cause a re or

electric shock.

(2) Use only the power cable supplied with the product. Use of an incorrectly specied cable could cause the

cable to overheat and potentially cause a re.

(3) Do not overload the power socket, this could lead to overheating of the cables inside the wall and could

lead to a re.

(4) Do not allow water or other liquids to spill into the product, this can cause electric shock. Do not allow

paper clips, pins or other foreign objects to fall into the product, these could cause a short circuit leading

to an electric shock or re hazard.

(5) Never touch the plugs on either end of the power cable with wet hands, this can cause electric shock.

When servicing the product, remove the power plug from the wall socket.

(6) Use caution when inserting or removing the power connector. When removing the power connector, grip it

rmly and pull. The power connector must be inserted completely, otherwise a poor contact could cause

overheating possibly leading to a re.

(7) Take care of the power cable. Do not allow it to become twisted, bent sharply around corners or wise

damaged. Do not place objects on top of the power cable. If the power cable is damaged it could overheat

and cause a re. Exposed cables could cause an electric shock. Replace the damaged power cable

immediately, do not reuse or repair the damaged cable. Some chemicals can attack the coating on the

power cable, weakening the cover or exposing cables causing re and shock risks.

(8) Ensure that the power sockets and plugs are not cracked or broken in any way. Any such defects should

be repaired immediately. Take care not to cut or damage the power cable or plugs when moving the

machine.

(9) Use caution during thunder or lightning storms. Samsung recommends that this machine be disconnected

from the power source when such weather conditions are expected. Do not touch the machine or the

power cord if it is still connected to the wall socket in these weather conditions.

(10) Avoid damp or dusty areas, install the product in a clean well ventilated location. Do not position the

machine near a humidier or in front of an air conditioner. Moisture and dust built up inside the machine

can lead to overheating and cause a re or cause parts to rust.

(11) Do not position the product in direct sunlight. This will cause the temperature inside the product to rise

possibly leading to the product failing to work properly and in extreme conditions could lead to a re.

(12) Do not insert any metal objects into the machine through the ventilator fan or other part of the casing, it

could make contact with a high voltage conductor inside the machine and cause an electric shock.

Precautions

Service Manual

1-3

Samsung Electronics

1.2.3 Handling precautions

The following instructions are for your own personal safety to avoid injury and so as not to damage the

product.

(1) Ensure the product is installed on a level surface, capable of supporting its weight. Failure to do so could

cause the product to tip or fall.

(2) The product contains many rollers, gears and fans. Take great care to ensure that you do not catch your

ngers, hair or clothing in any of these rotating devices.

(3) Do not place any small metal objects, containers of water, chemicals or other liquids close to the product

which if spilled could get into the machine and cause damage or a shock or re hazard.

(4) Do not install the machine in areas with high dust or moisture levels, beside on open window or close to a

humidier or heater. Damage could be caused to the product in such areas.

(5) Do not place candles, burning cigarettes, etc on the product, These could cause a re.

1.2.4 Assembly / Disassembly precautions

Replace parts carefully and always use Samsung parts. Take care to note the exact location of parts and also

cable routing before dismantling any part of the machine. Ensure all parts and cables are replaced correctly.

Please carry out the following procedures before dismantling the product or replacing any parts.

(1) Check the contents of the machine memory and make a note of any user settings. These will be erased if

the main board or network card is replaced.

(2) Ensure that power is disconnected before servicing or replacing any electrical parts.

(3) Disconnect interface cables and power cables.

(4) Only use approved spare parts. Ensure that part number, product name, any voltage, current or

temperature rating are correct.

(5) When removing or re-tting any parts do not use excessive force, especially when tting screws into

plastic.

(6) Take care not to drop any small parts into the machine.

(7) Handling of the OPC Drum

- The OPC Drum can be irreparably damaged if it exposed to light.

Take care not to expose the OPC Drum either to direct sunlight or to uorescent or incandescent room

lighting. Exposure for as little as 5 minutes can damage the surface of the photoconductive properties

and will result in print quality degradation. Take extra care when servicing the product. Remove the OPC

Drum and store it in a black bag or other lightproof container. Take care when working with the Covers

(especially the top cover) open as light is admitted to the OPC area and can damage the OPC Drum.

- Take care not to scratch the green surface of OPC Drum Unit.

If the green surface of the Drum Cartridge is scratched or touched the print quality will be compromised.

Precautions

Service Manual

1-4

Samsung Electronics

1.2.5 Disregarding this warning may cause bodily injury

(1) Be careful with the high temperature part.

The fuser unit works at a high temperature. Use caution when working on the printer. Wait for the fuser to

cool down before disassembly.

(2) Do not put nger or hair into the rotating parts.

When operating a printer, do not put hand or hair into the rotating parts (Paper feeding entrance, motor,

fan, etc.). If do, you can get harm.

(3) When you move the printer.

This printer weighs 6kg including toner cartridge and cassette. Use safe lifting and handling techniques.

Use the lifting handles located on each side of the machine. Back injury could be caused if you do not lift

carefully.

(4) Ensure the printer is installed safely.

The printer weighs 6kg, ensure the printer is installed on a level surface, capable of supporting its weight.

Failure to do so could cause the printer to tip or fall possibly causing personal injury or damaging the

printer.

(5) Do not install the printer on a sloping or unstable surface. After installation, double check that the printer

is stable.

Precautions

Service Manual

1-5

Samsung Electronics

1.3 ESD precautions

Certain semiconductor devices can be easily damaged by static electricity. Such components are commonly

called “Electrostatically Sensitive (ES) Devices” or ESDs. Examples of typical ESDs are: integrated

circuits,some eld effect transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help reduce the incidence of component damage

caused by static electricity.

Caution >>Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

1. Immediately before handling a semiconductor component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a known earth ground. Alternatively, employ a

commercially available wrist strap device, which should be removed for your personal safety reasons prior

to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESDs, place the assembly on a conductive surface,

such as aluminum or copper foil, or conductive foam, to prevent electrostatic charge buildup in the vicinity

of the assembly.

3. Use only a grounded tip soldering iron to solder or desolder ESDs.

4. Use only an “anti-static” solder removal device. Some solder removal devices not classied as “anti-static”

can generate electrical charges sufcient to damage ESDs.

5. Do not use Freon-propelled chemicals. When sprayed, these can generate electrical charges sufcient to

damage ESDs.

6. Do not remove a replacement ESD from its protective packaging until immediately before installing it.

Most replacement ESDs are packaged with all leads shorted together by conductive foam, aluminum foil,

or a comparable conductive material.

7. Immediately before removing the protective shorting material from the leads of a replacement ESD, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

8. Maintain continuous electrical contact between the ESD and the assembly into which it will be installed,

until completely plugged or soldered into the circuit.

9. Minimize bodily motions when handling unpackaged replacement ESDs. Normal motions, such as

the brushing together of clothing fabric and lifting one’s foot from a carpeted oor, can generate static

electricity sufcient to damage an ESD.

Product spec and feature

2. Product spec and feature

2.1 Product Specications

2.1.1 Product Overview

1. Speed

• Up to 16 ppm in A4 (17 ppm in Letter)

2. Processor

• Jupiter4e 150 MHz

3. Printer Language

• GDI

ML- 1660

4. Memory

• 8 MB

5. Interfaces

• Compatible with USB 2.0

6. Toner cartridge

• Initial : 0.7K

• Sales : 1.5K

Service Manual

2-1

Samsung Electronics

Product spec and feature

Service Manual

2-2

Samsung Electronics

2.1.2 Specications

• Product Specications are subject to change without notice. See below for product specications.

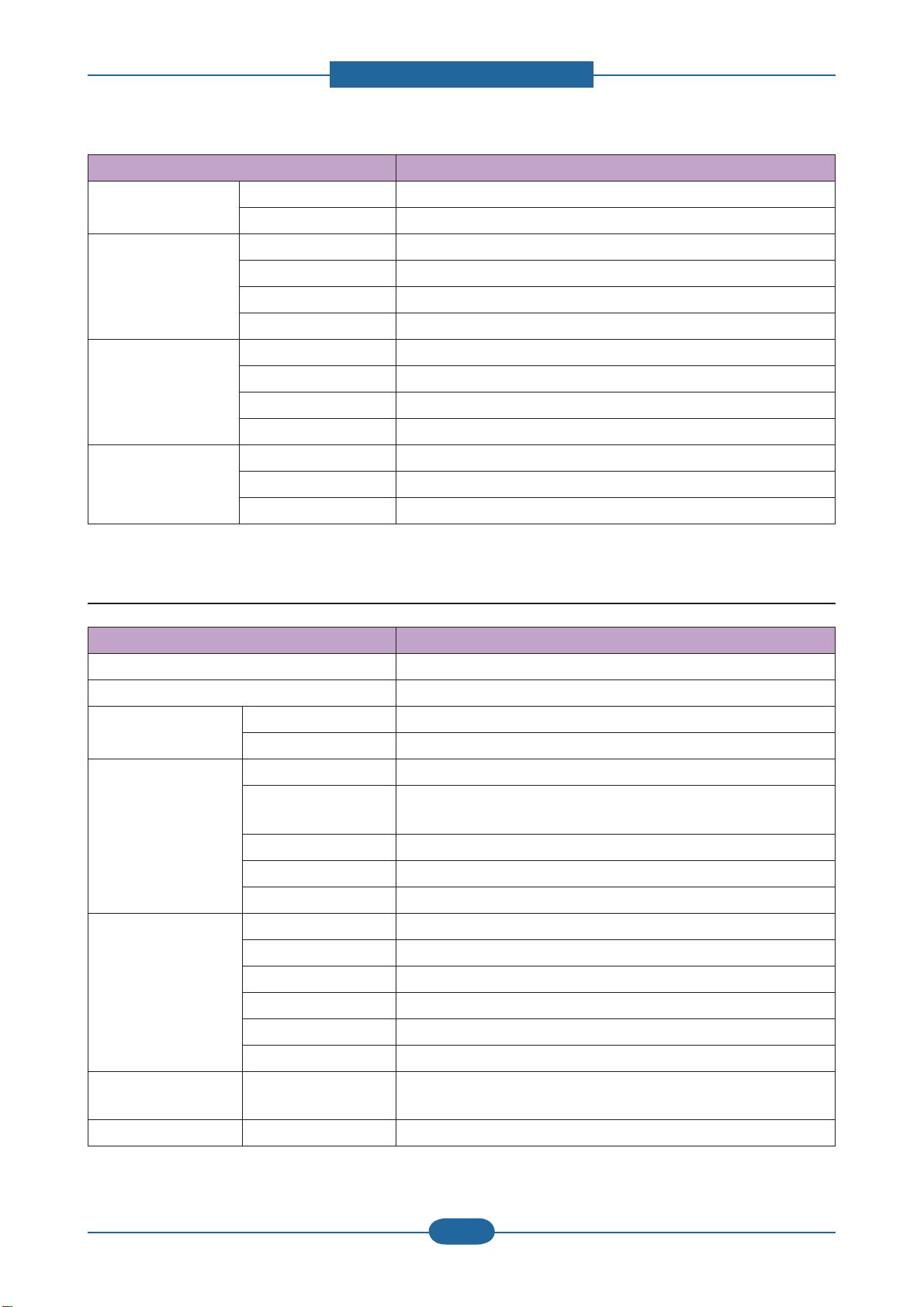

2.1.2.1 General Print Engine

Items Specication

Engine Speed Simplex Up to 16 ppm in A4 (17 ppm in Letter)

Duplex Manual

Warmup time From Sleep ≤ 30 sec

FPOT From Ready ≤ 10 sec

From Sleep ≤ 30 sec

Resolution Up to 1200 x 600 dpi effective output

2.1.2.2 Controller & S/W

Items Specication

Processor Jupiter4e 150 MHz

Memory Std. 8 MB

Option N/A

Printer Languages GDI GDI

Fonts - Windows Fonts

Driver Default Driver SPL

Install SPL

Supporting OS Windows 2000/XP(32/64bits)/Vista(32/64bits)/2003

Server(32/64bits)/2008 Server(32/64bits) / Win7 /2008 R2

Various Linux OS:

- Red Hat 8~9,

- Fedora Core 1~4

- Mandrake 9.2~10.1

- SuSE 8.2~9.2

Mac OS 10.3~10.6

WHQL Windows 2000/XP(32/64bits)/Vista(32/64bits)/2003

Server(32/64bits)/2008 Server(32/64bits) / Win7 /2008 R2

Compatibility Win 2000/XP(32/64bits)/2003 Server/Vista(32/64bits),2008

Wired Network Protocol N/A

Supporting OS N/A

Server(32/64bits)/ WIn7 /2008 R2

Product spec and feature

Items Specifi cation

Wireless Network Protocol N/A

Supporting OS N/A

Application Smart Panel SmartPanel for Windows/ Macintosh/LINUX

Printer Setting N/A

Network Management N/A

IP Setting N/A

Interface Parallel N/A

USB Compatible with USB 2.0

Wired Network N/A

Wireless Network N/A

User Interface LCD N/A

LED 2 LED

Key 2 key

2.1.2.3 Paper Handling

Items Specifi cation

Standard Capacity 150-sheet Tray@80g/㎡

Max. Capacity 150 sheets @ 80g/㎡

Printing Max. Size 216 x 356 mm (8.5" x 14")

Min. Size 76 x 183 mm (3.0" x 7.2")

Standard

Cassette Tray

Optional

Cassette Tray

Capacity 150 sheets @ 80g/㎡

Media sizes A4, A5, A6, ISO B5, JIS B5, Executive, Letter, O cio, Folio,

Legal,Custom

Media types Plain, Thin, Recycled, Thick, Archive

Media weight 16~32lb (60 to 120g/㎡)

Sensing Paper Empty

Capacity N/A

Media sizes N/A

Media types N/A

Media weight N/A

Sensing N/A

Output Stacking

Output Stacking Face-Down 100 sheets @ 75g/㎡(Base Line Paper : Samsung Premium/

Xerox4200) NN Condition

Duplex Supporting N/A

Service Manual

2-3

Samsung Electronics

Product spec and feature

Service Manual

2-4

Samsung Electronics

2.1.2.4 Consumables

Items Specication

Toner Cartridge Black Initial : Average Cartridge Yield 0.7K standard pages.

Sales : Average cartridge Yield 1.5K standard pages.

Declared cartridge yield in accordance with ISO/IEC 19752.

Key Electronic key(CRUM) Only

Life detect Toner gauge sensor by dot count

2.1.2.5 Maintenanace part

Items Life

Transfer roller 30K pages

Fuser unit 30K pages

Pick up roller 30K pages

2.1.2.6 Reliability & Service

Items Specication

Printing Volume (SET AMPV) 75 sheets/month

MPBF 10,000 sheets

MTTR 30 min.

SET Life Cycle 30,000 sheets or 5 years (whichever comes rst)

2.1.2.7 Environment

Items Specifi cation

Product spec and feature

Operating

Environment

Acoustic Noise

Level(Sound Power/

Pressure)

Power Consumption Ready Less than 40W

Dimension

(W x D x H)

Weight SET 4.12kg

Temperature 10C to 32C

Humidity 20% to 80%

Printing 49 dBA

Standby Back Ground Level

Sleep Back Ground Level

AVG. Less than 270W

Max/Peak Less than 300W

Sleep / Power Off Less than 2.8W / Less than 0.45W (Conformity to EPA)

SET 341 x 224 x 184 mm (13.42” x 8.81” x 7.24”)

SET Packing 394 x 278 x 241 mm (15.5” x 10.0” x 9.5”)

Toner 284 x 231.5 x 47.8mm

Toner Packing 361 x 270 x 113 mm

Toner 0.68kg

Gross 5.6kg

2.1.2.8 Packing & Accessory

Items Life

Driver & Network Install CD-ROM

Power Cable

In-Box

USB Cable (CIS/China/Korea/India)

Quick Install Guide

Warranty Registration Card

User’s Manual (PDF File)

Service Manual

2-5

Samsung Electronics

Product spec and feature

Service Manual

2-6

Samsung Electronics

2.1.2.9 Options

Items Specication

Memory N/A

Second Cassette N/A

Wired Network N/A

Wireless Network N/A

Hard Disk N/A

Duplex Unit N/A

Product spec and feature

Service Manual

2-7

Samsung Electronics

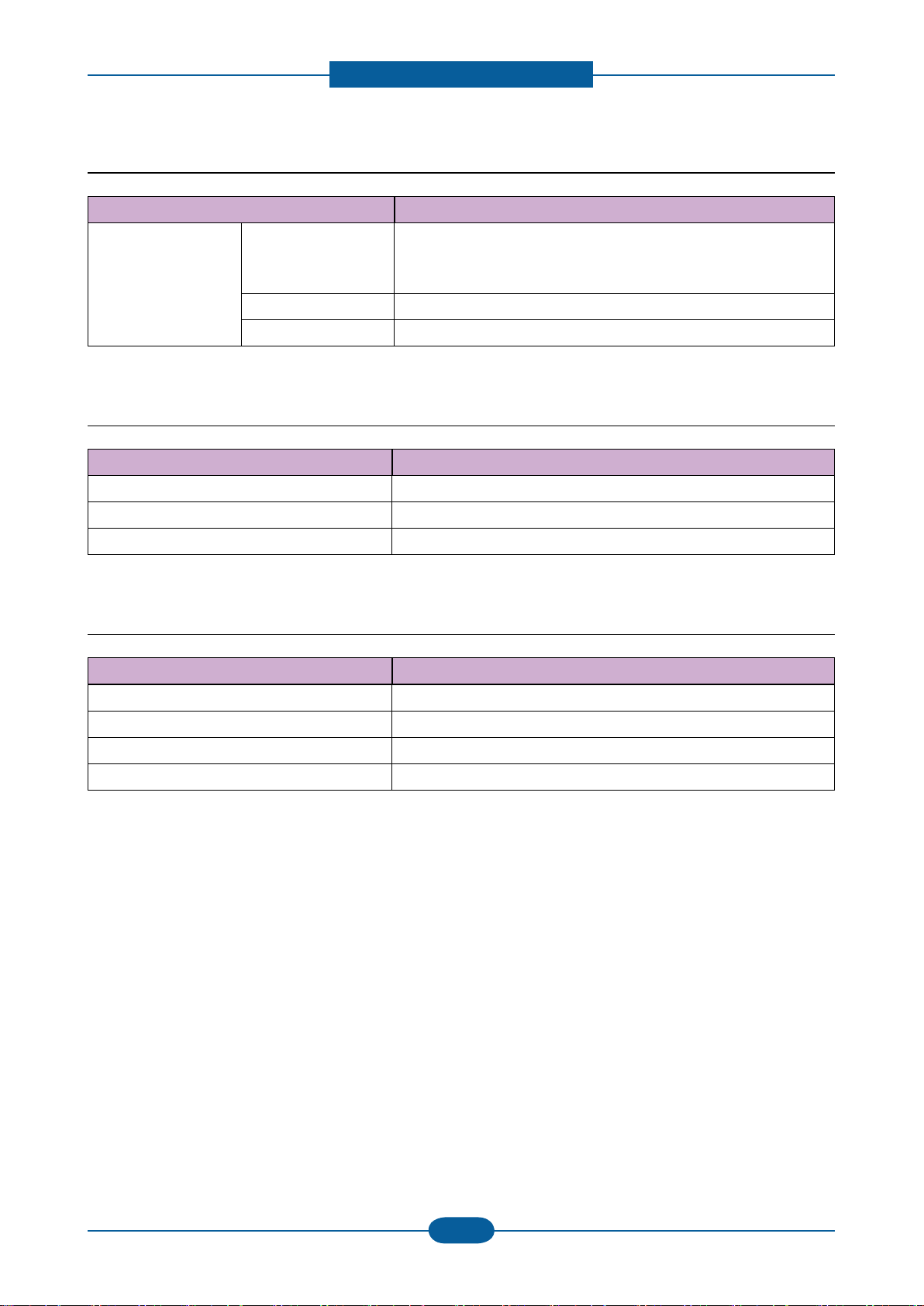

2.1.3 Model Comparison Table

Samsung

ML- 1660

Image

Speed 16 ppm (A4) 22 ppm (A4) 23 ppm (A4)

processor 150 MHz 150 MHz 266 MHz

Memory 8 MB 8 MB 32 MB

Print Language GDI GDI PCL5e

Input 150 sheets Bin 150 sheets Bin

Duplex Manual Manual Manual

Interface USB 2.0 USB 2.0 USB 2.0

Size (mm) 341 x 224 x 184 mm 353 x 298 x 213 mm 379 x 243 x 225 mm

Samsung

ML- 2240

HP

P1505n

250 sheets Bin,

10 Manual

Toner Standard 0.7K / 1K Standard 1.5K Standard 2K

Product spec and feature

Service Manual

2-8

Samsung Electronics

2.2 System Overview

This chapter describes the functions and operating principal of the main component.

2.2.1 Front View

This illustration may differ from your machine depending on its model.

1 Control panel 5 Paper length guide

2 Top cover 6 Paper width guides

3 Toner cartridge 7 Output support

4 Tray 8 Output tray (face down)

Product spec and feature

Service Manual

2-9

Samsung Electronics

2.2.2 Rear View

This illustration may differ from your machine depending on its model.

1 USB port 2 Power receptacle

Product spec and feature

Service Manual

2-10

Samsung Electronics

13

5

12

11

7

1

2

9

14

10

3

6

4

8

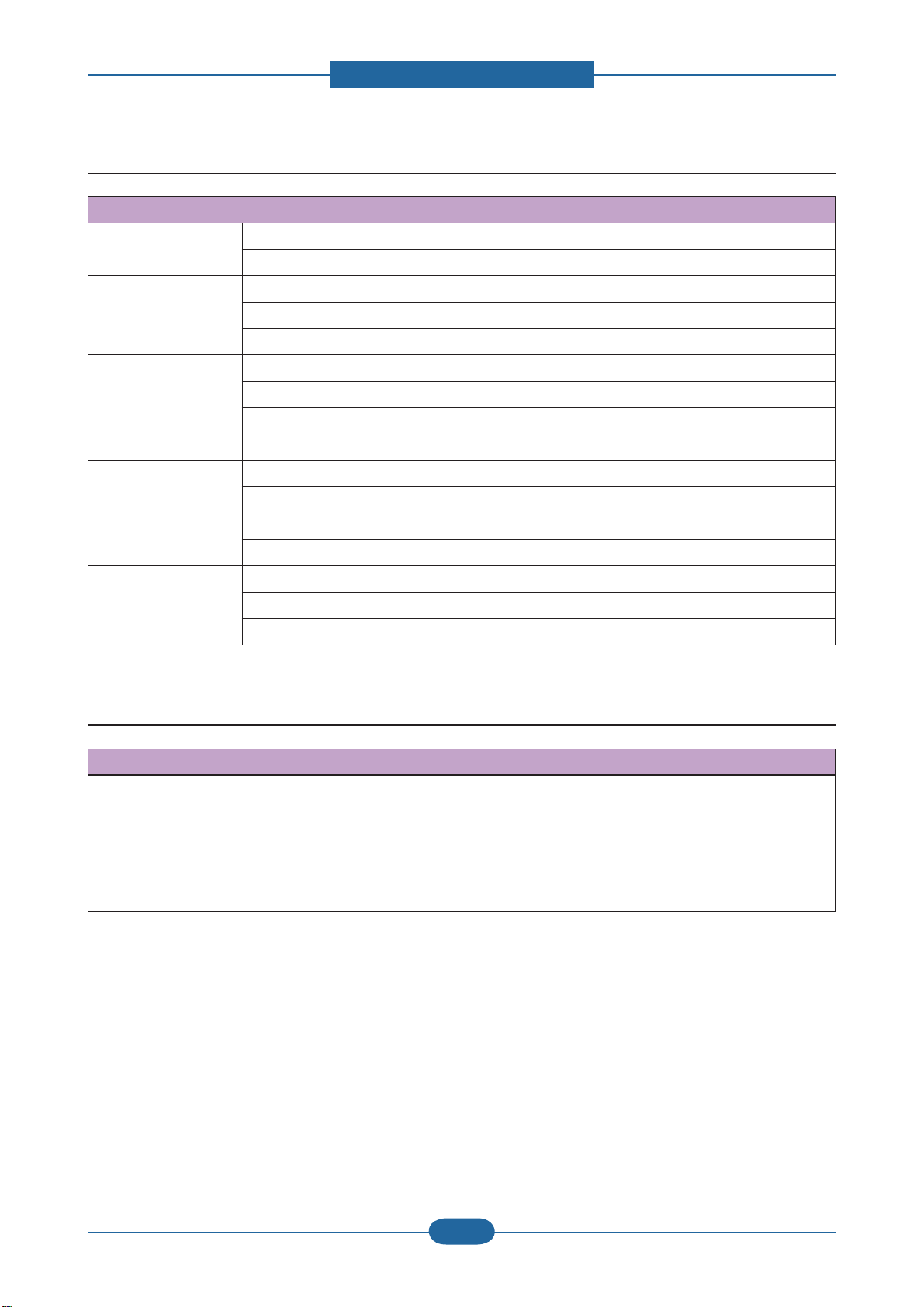

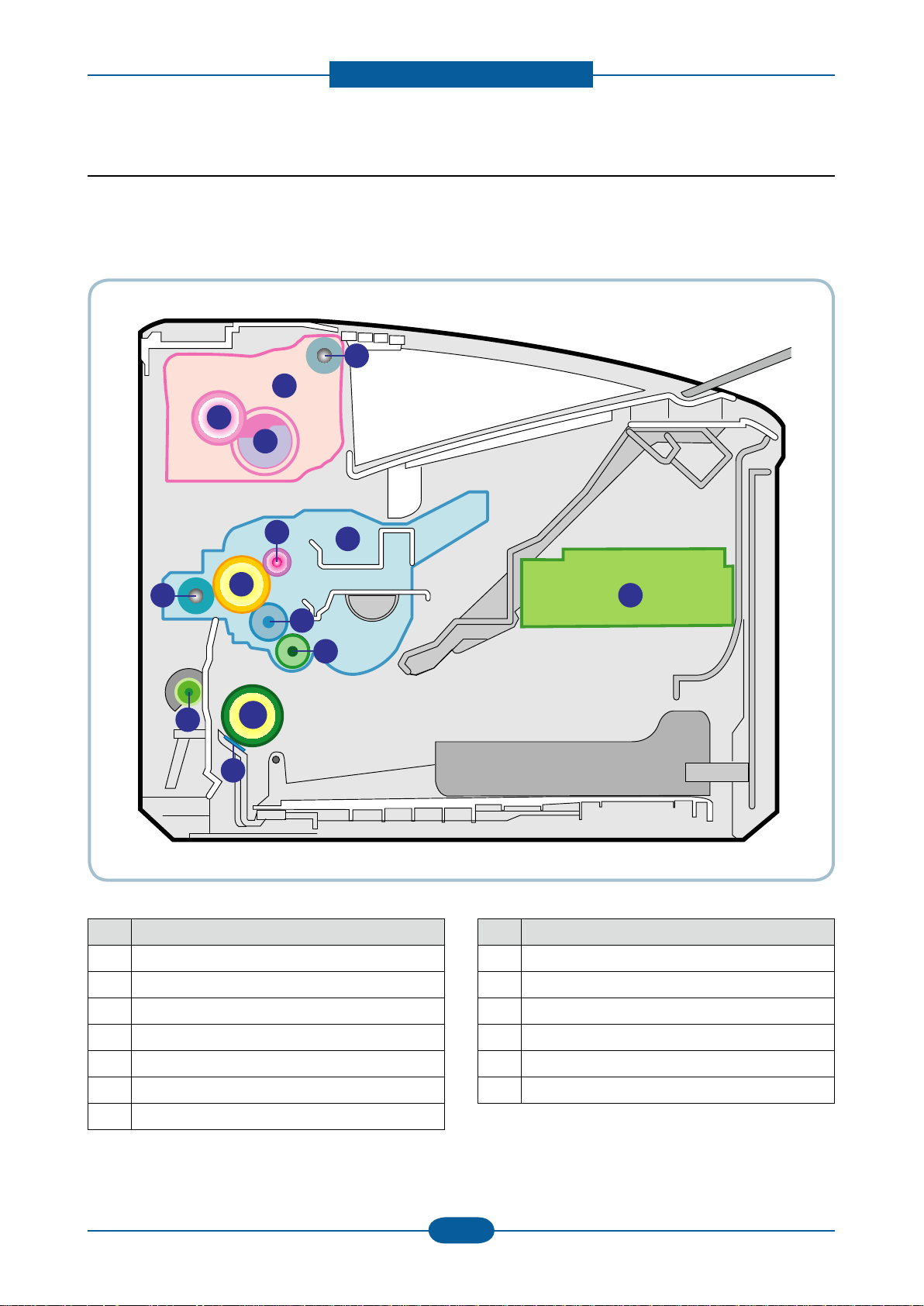

2.2.3 System Layout

This model is consisted of the Engine parts and F/W, and said engine parts is consisted of the mechanical

parts comprising Frame, Feeding, Developing, Driving, Transferring, Fusing, Cabinet and H/W comprising

the main control board, power board, operation panel, PC Interface.

NO. NAME

1 Pressure roller

2 Heat roller

3 Exit roller

4 Toner Cartridge

5 LSU

6 Charge roller

7 OPC

NO. NAME

8 Transfer roller

9 Deve roller

10 Supply roller

11 Feed roller

12 Friction pad

13 Pickup roller

Product spec and feature

Service Manual

2-11

Samsung Electronics

2.2.3.1 Feeding Part

It is consists of a basic cassette, an MP tray for supplying different types of media (envelope, label, special

paper) and parts related to paper transferring.

1) Separation method

Paper is separated by the friction pad mounted to the center of the cassette.

2) Input tray

This model has a bin-type tray.

It takes a center loading method and applies ‘friction pad

separating method.’

Both the side guide and the rear guide can be adjusted for for

various types of papers from A6 to legal size paper.

It has a paper existence sensing function

(Capacity: 150 sheets (80g/㎡ paper standard), paper

arranging function, various size papers accepting function.

In the front side, there is a paper level indicator.

3) Pick- up roller

It has functions such as a paper pickup function, driving

control function, paper feeding function, and removing

electronic static function. Pick up roller is drive by solenoid.

Product spec and feature

Service Manual

2-12

Samsung Electronics

2.2.3.2 Transfer Roller

- The transfer roller delivers the toner of the OPC drum to the paper.

- There is no PTL Ass’y.

- Life Span : Print over 30,000 sheets (in15~30℃)

2.2.3.3 Driver Assy

- In ML-1660, the driving device is consisted of OPC, Pick- up, Feed, Fuser, Gear- Train connected with

Mounting member. A step motor for driving is assembled to the left frame.

• Driving Frequency: Step Motor 840 PPS (1050rpm)

• It is a power delivery unit by gearing: Step Motor → Pick-up/Feeder/Transfer/Fuser/Exit

Product spec and feature

Service Manual

2-13

Samsung Electronics

2.2.3.4 Fuser

It is consisted of a halogen lamp, heat roller, pressure roller, thermistor and thermostat. It sticks the toner on

a paper by heat and pressure to complete the printing job.

1) Thermostat

When a heat lamp is overheated, a Thermostat cuts off the main power to prevent over- heating.

- Thermostat Type : Non- Contact type dual THERMOSTAT

- Control Temperature : 170℃ ± 5 ℃

2) Thermistor

It is a temperatrue detecting sensor.

- Temperature Resistance : 7 ㏀ (180 ℃ )

3) Heat roller

The heat roller transfers the heat from the lamp to apply a heat on the paper.

The surface of a heat roller is coated with Teon, so toner does not stick to the surface.

4) Pressure roller

A pressure roller mounted under a heat roller is made of a silicon resin, and the surface also is coated with

Teon. When a paper passes between a heat roller and a pressure roller, toner adheres to the surface of a

paper permanently.

5) Halogen Lamp

- Voltage 120 V : 115 ± 5 %

220 V : 230 ± 5 %

- Capacity : 600 Watt ± 25 W

Product spec and feature

Service Manual

2-14

Samsung Electronics

6) Items for safety

Protecting device for overheating

- 1st protection device: Hardware cuts off when overheated

- 2nd protection device: Software cuts off when overheated

- 3rd protection device: Thermostat cuts off main power.

Safety device

- A fuser power is cut off when a front cover is opened

- Maintain a temperature of fuser cover’s surface under 80(C for user, and attach a caution label at

where customer can see easily when customer open a rear cover.

Product spec and feature

Service Manual

2-15

Samsung Electronics

OPC Drum

Photo Diode

LD Driver circit

Protector panel

LD(Laser Diode)

Polygon Mirror

Polygon Motor

Motor Driver

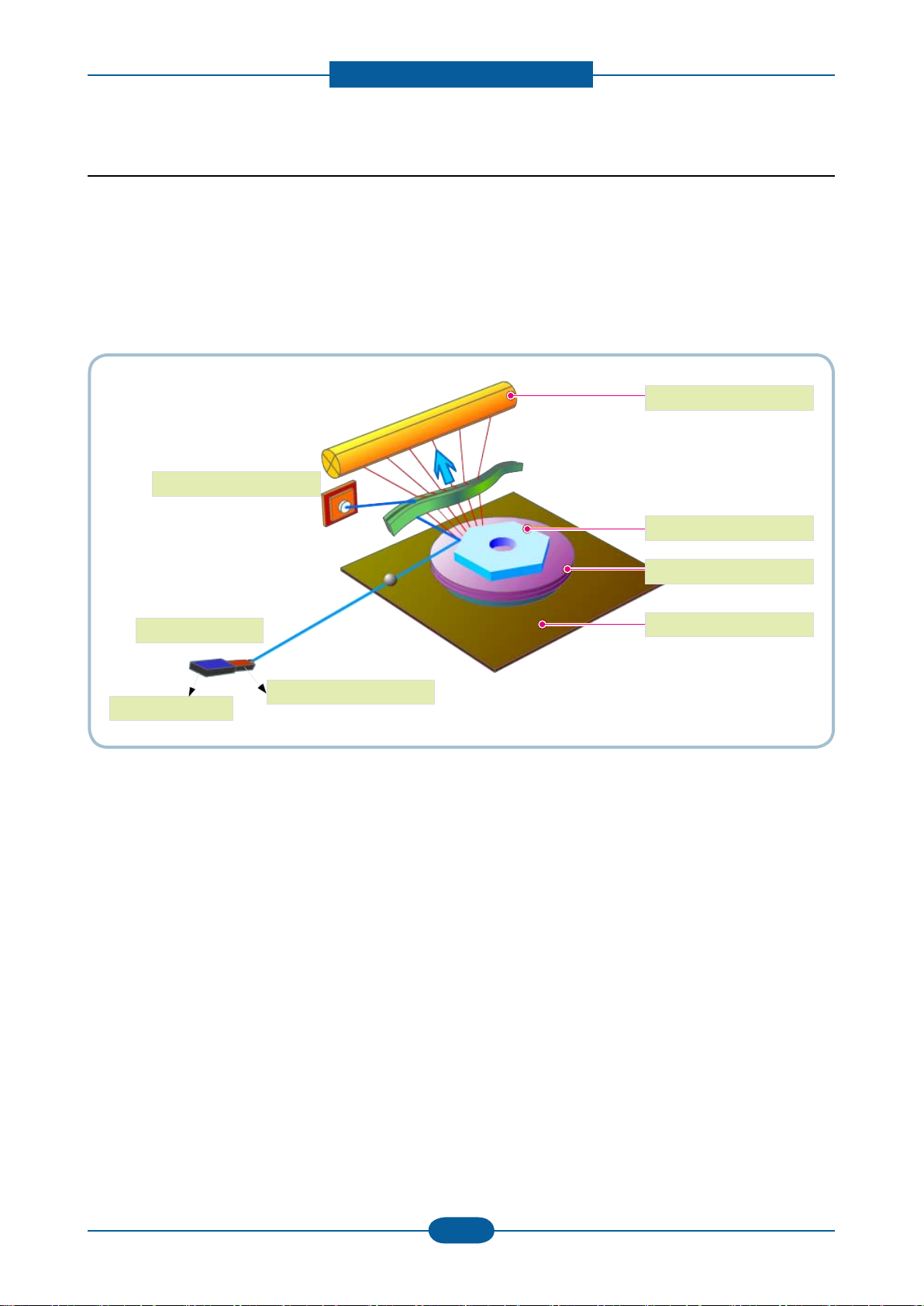

2.2.3.5 LSU (Laser Scanner Unit)

It is the core part of the LBP which switches from the video data received to the controller to the electrostatic

latent image on the OPC drum by controlling laser beam, exposing OPC drum, and turning principle of

polygon mirror. The OPC drum is turned with the paper feeding speed. The /HSYNC signal is created when

the laser beam from LSU reaches the end of the polygon mirror, and the signal is sent to the controller.

The controller detects the /HSYNC signal to adjust the vertical line of the image on paper. In other words,

after the /HSYNC signal is detected, the image data is sent to the LSU to adjust the left margin on paper.

The one side of the polygon mirror is one line for scanning.

Product spec and feature

Service Manual

2-16

Samsung Electronics

Cleaning Roller

Cleaning Blade

-720V

-350V

-550V

0.20mW

Max -1.4KV

-100V

1

2

3

4

5

6

7

8

+3.5kV

-150V↓

2.2.3.6 Toner Cartridge

By using the electronic photo process, it creates a visual image. In the toner cartridge, the OPC unit and the

developing unit are in a body. The OPC unit has OPC drum and charging roller, and the toner cartridge unit

has toner, supply roller, developing roller, and blade (Doctor blade)

• Developing Method : Non magnetic 1 element contacting method

• Toner : Non magnetic 1 element shatter type toner

• Charging capacity : - 39.1 ± 3 μC/g

• Average OD : 8.0 ± 0.5㎛ (Toner)

• The life span of toner (ISO 19752 pattern / A4 standard)

→ Initial toner : 0.7K

→ Sales toner : 1.5K

• Toner Residual Sensor : Dot count with CRUM(CRU Monitor)

• OPC Cleaning : Collect the toner by using cleaning blade

• Handling of wasted toner : Collect the wasted toner in the cleaning frame by using cleaning blade

• OPC Drum Protecting Shutter : None

• Classifying device for toner cartridge: ID is classied by CRUM.

Product spec and feature

Service Manual

2-17

Samsung Electronics

CN4, LSU I/F CN8, Pick

up_clutch

CN2, Fuser

CN1, Hyper

CN5, Sensor

CN7, Main

motor drive

CN6, Power I/F

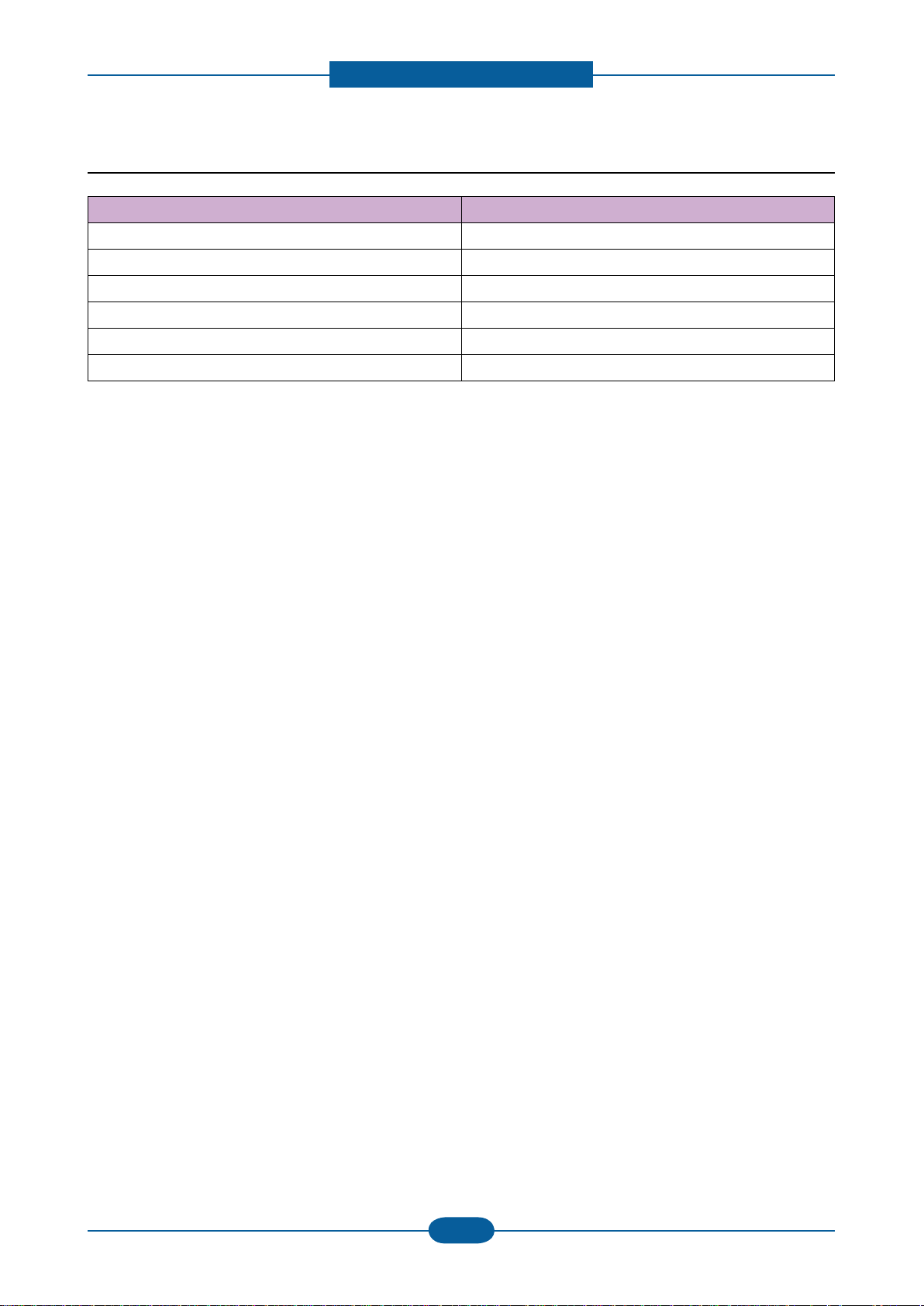

2.2.4 Engine H/W Specications

2.2.4.1 Main PBA

The Engine Board and the Controller Board are in one united board, and it is consisted of CPU part and

print part in functional aspect. The CPU is functioned as the bus control, I/O handling, drivers, and PC

interface. The main board sends the Current Image of Video data to the LSU and manages the conduct of

Electrophotography for printing. It is consisted of the circuits of the motor (paper feed, pass) driving, clutch

driving, pre- transfer lamp driving, current driving.

The signals from the paper feed jam sensor and paper empty sensor are directly inputted to the main board.

Product spec and feature

Service Manual

2-18

Samsung Electronics

(a) Asic(Jupiter4e)

• CPU Core : Use 32Bit RISC Processor of Jupiter4e, and control system by operating Operation Block of

the System Program inside Flash Memory.

- Main Function Block:

▶ Completely Integrated System for Embedded Applications,

▶ 32 Bit Risc Architecture, Efcient and Powerful ARM9 CPU

▶ LSU Interface Module for Interfacing PVC with LSU

▶ 2 Channel General Purpose DMA Controller for High Speed I/O

▶ Dual Memory Bus Architecture

- Operation Frequency : 150MHz

- Operation Voltage : 3.3V

- POWER ON RESET TIME : 6.6ms below

(b) Memory

1) Flash Memory

Store System Program and can be download System Program through PC Interface

- Capacity : 0.5M Byte

- Access Time : 70 nsec

2) SDRAM

When Printing, use Band Buffer, System Working Memory Area .

- 8M capa : 8M Byte basic.

8M :Printing System Working Memory Area

- Access Time : 60 nsec

Product spec and feature

Service Manual

2-19

Samsung Electronics

(c) Sensor Input Circuit

■ Paper Empty Sensing

The Paper empty sensor on the tray detects the state of paper empty and the state of paper width i.e. narrow

paper width or not.

■ Regi Sensing

N/A

■ Paper Feeding

When paper passes the actuator (feed sensor part), it detects the signal of Photo interrupter, informs the

paper feeding state to CPU, and then sprays the image data after certain time.

If it doesn’t detect the feed sensor within 1sec. after paper is fed, paper Jam0 is occurred (LED will be display

Orange color).

■ Paper Exit Sensing

N/A

■ Cover Open Sensing

The Cover open sensor is located on the HVPS. After the top cover is opened, +24VS (Solenoid, Main Motor,

Polygon motor part of LSU and HVPS), which is supplied to the each unit, is cut off.

In case, the red will be ON for informing the facts to user.

■ SOLENOID Driving

Clutches are driven by turning on TRs, which is controlled by CPU. The diode in the Clutch driving circuits

protects TR driven from the noise pulse, which is occurred when the solenoid is de-energized.

■ Motor Driving

The main motor driving circuits is on the main board

There is motor driver IC on the main board control the step motor.

Product spec and feature

Service Manual

2-20

Samsung Electronics

Main board

Fuser

2.2.4.2 HVPS and SMPS Board

The HVPS Board and SMPS Board are in one united board.

The HVPS board creates the high voltage of THV/MHV/Supply/Dev and supplies it to the developer part for

making best condition to display the image. The HVPS part takes the 24V and outputs the high voltage for

THV/MHV/BIAS, and the outputted high voltage is supplied to the toner, OPC cartridge, and transfer roller

It is the power source of entire system. It is assembled by an independent module, so it is possible to use for

common use. It is mounted at the side of the set.

It is consisted of the SMPS part, which supplies the DC power for driving the system, and the AC heater

control part, which supplies the power to fuser. SMPS has two output channels. Which are +3.3V and +24V.

Loading...

Loading...