Page 1

7

7

7-1

Samsung Electronics

Alignment & Adjustments

Service Manual

7. Alignment and Adjustments

This chapter describes some of the main service procedures including:

Using the EDC mode; Clearing paper jam and test patterns.

Much of this chapter is also included in the user's guide.

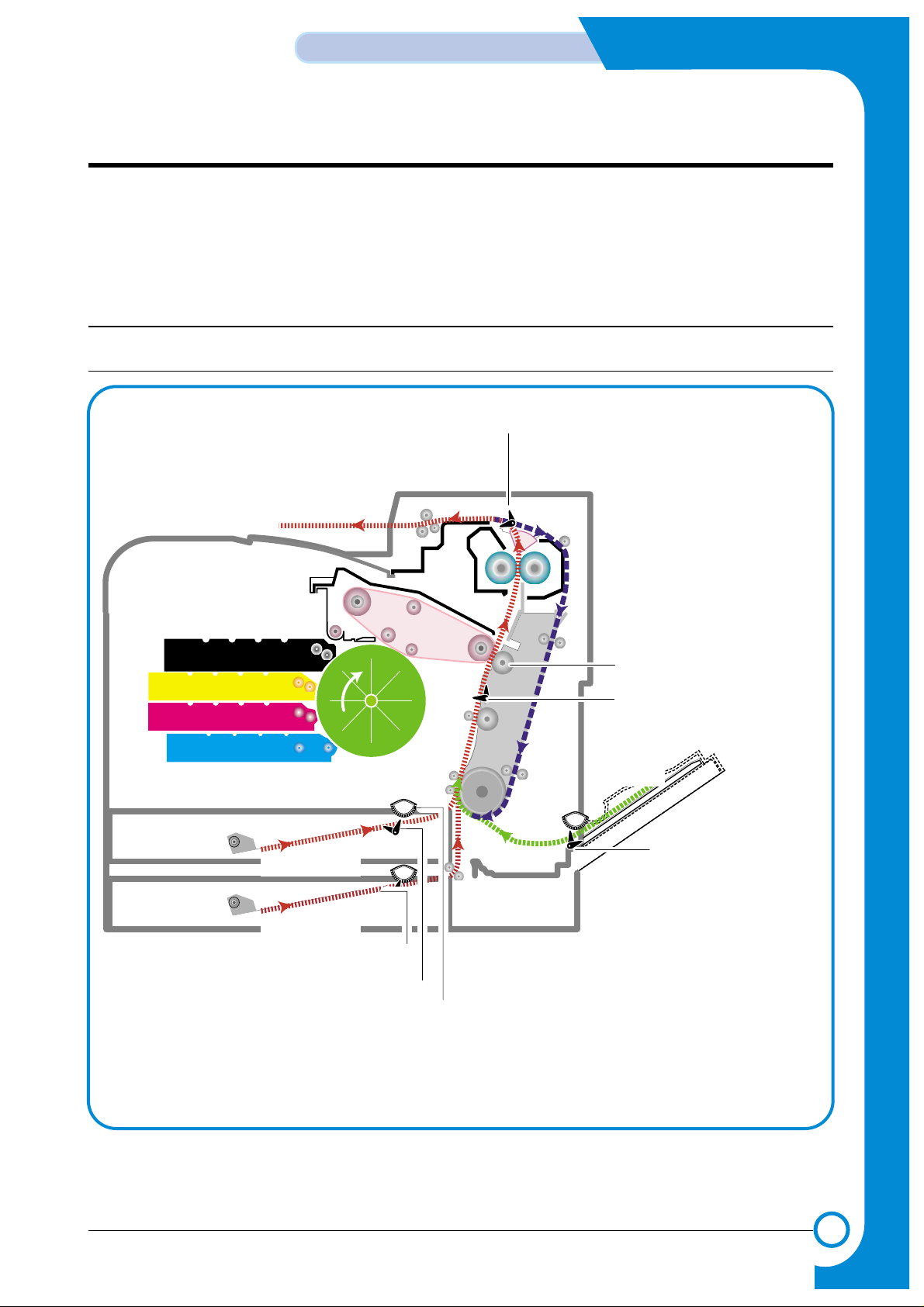

7.1. Paper path and Paper jam

7.1.1 Paper path

DEV. - Black

DEV. - Yellow

Pick-up

Roller

DEV. - Magenta

DEV. - Cyan

CASSETTE

Feeder

DUPLEX

Fuser Unit

EXIT Ass’y

MPF Path

Duplex PathDuplex Path

MPFMPT

DEV. - Black

DEV. - Yellow

OPCOPC

DEV. - Magenta

DEV. - Cyan

SCF

SCF

FCF

ITBITB

Feeder

DUPLEX

Fuser Unit

EXIT Unit

SCF Path

Transfer Roller

Exit Sensor

Paper Pick-Up Roller

Paper Empty Sensor(FCT)

Paper Empty Sensor(SCT)

Paper Empty Sensor(MPT)

Feed Sensor

SCT Path

FCT Path

MPT Path

Page 2

7-2

Alignment & Adjustments

Samsung Electronics

Service Manual

7.1.2 Jams

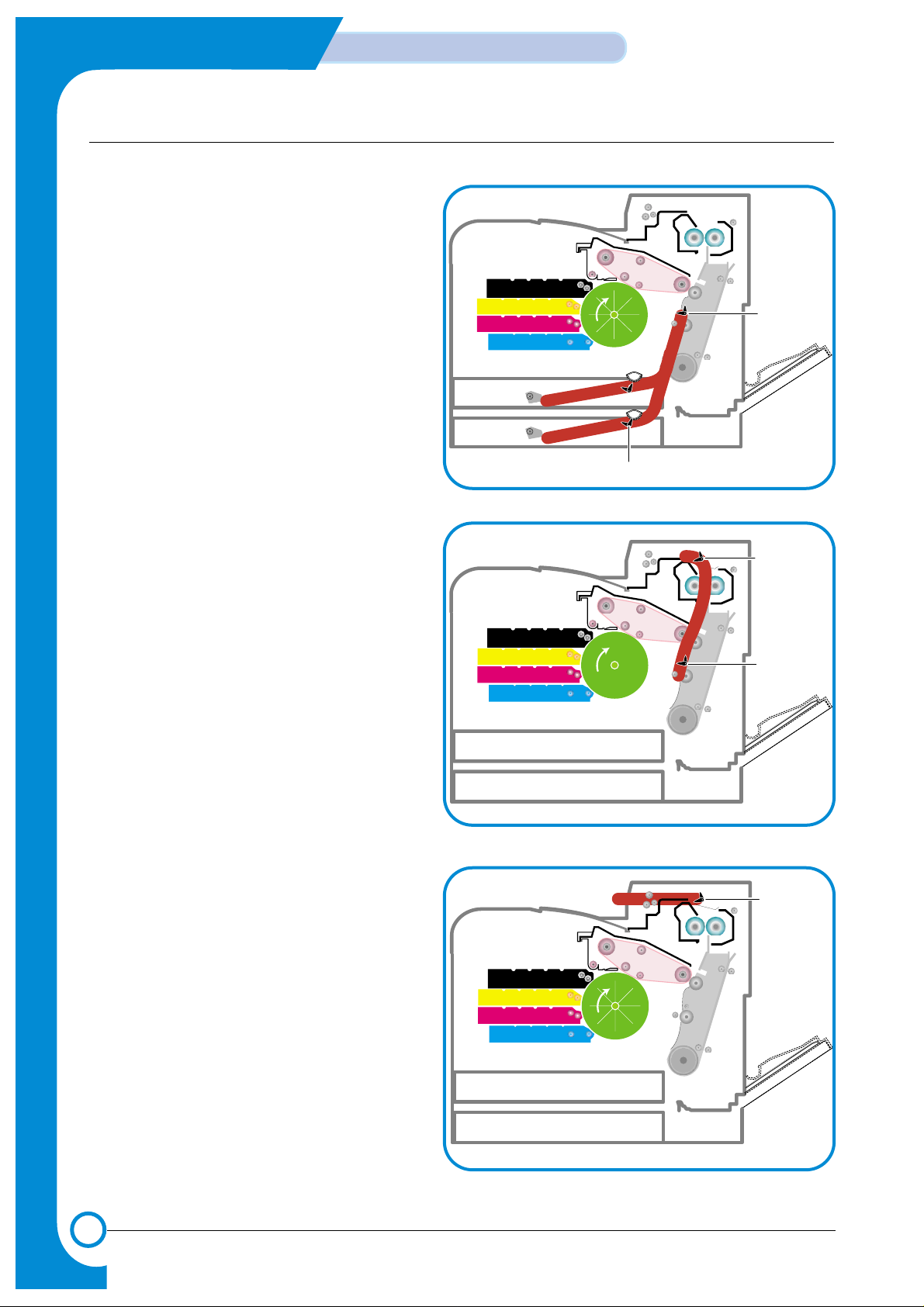

1) Jam0 (Jam in feed area)

* After a page was picked up, it was not fed.

* Paper does not reach the feed sensor in a

certain time.

* Feed sensor is faulty and does not detect

paper.

- FCF pickup error: When a paper is not

picked up in the 1st cassette.

- SCF pickup error: When a paper is not

picked up in the 2nd cassette.

2) Jam1 (Jam inside printer)

* After the leading edge of the paper has

reached the feed sensor, the feed sensor

doesn't turn off (fails to detect the trailing edge

of the paper) in a certain time

* After the leading edge of the paper has

passed the feed sensor, it doesn't reach the

exit sensor in a certain time.

* Exit senor is faulty and does not detect paper.

3) Jam2 (Jam in exit area)

* After the leading edge of the paper has

passed, the trailing edge of the paper has not

passed the exit sensor within a certain time

* The paper drive motor has been driving for

longer than the time needed for the longest

paper size and the exit sensor is not off.

Pick-up

Roller

Feed Sensor

Paper Empty Sensor

Exit Sensor

Feed Sensor

Exit Sensor

Page 3

7-3

Samsung Electronics

Alignment & Adjustments

Service Manual

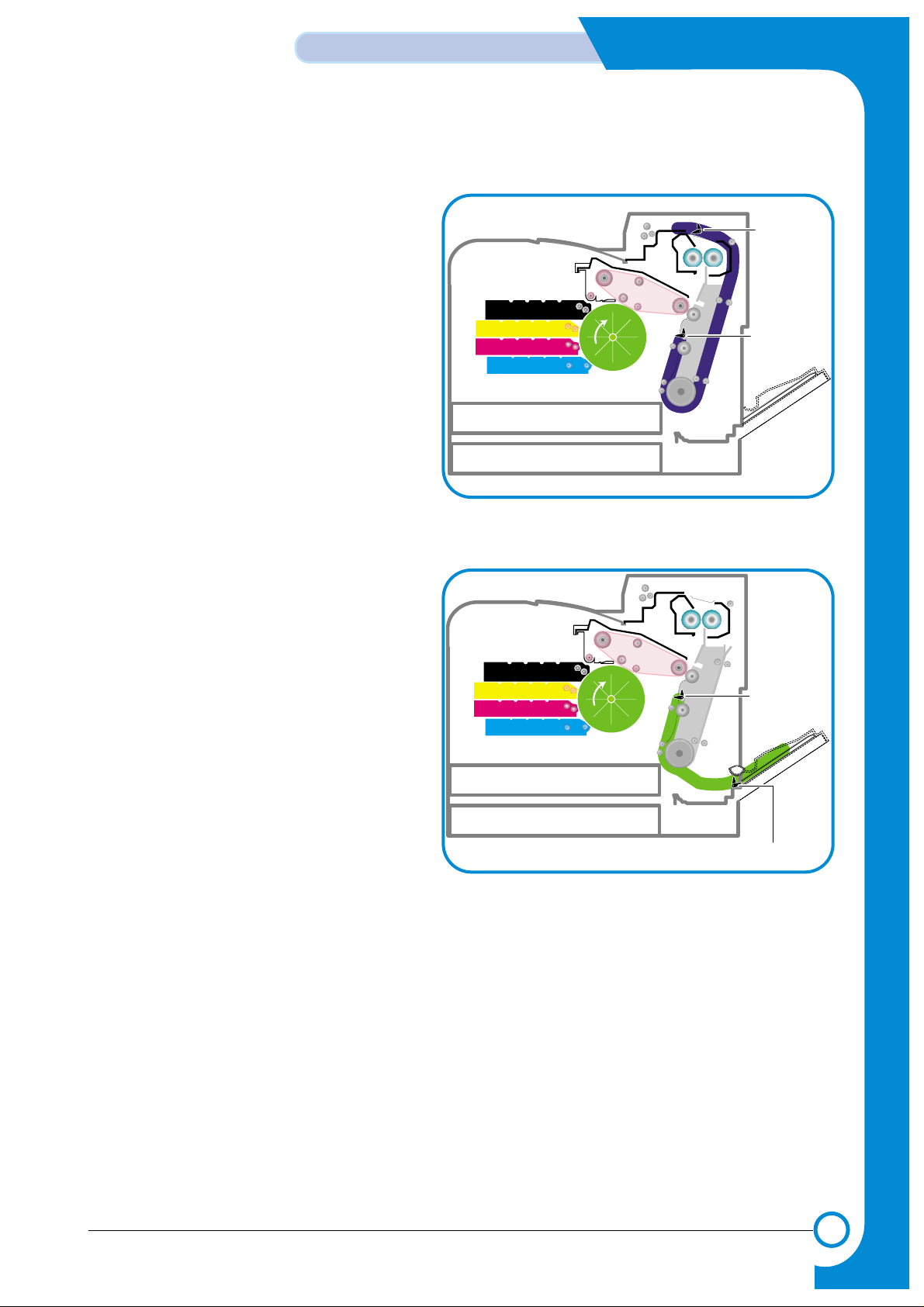

4) Jam duplex (Jam in duplex area)

* Jam duplex occurs when printing the reverse

side of the paper during duplex printing. After

printing the front side the duplex solenoid must

operate in order to feed the paper back into the

duplex path. If the solenoid fails paper may be

stuck in the exit roller and is not fully elected

into the exit tray

* If the duplex solenoid operates paper is fed

back into the machine. If the leading edge of

the paper does not reach the feed sensor in a

certain time then Jam Duplex occurs.

- This can be cause by paper being jammed

in the duplex path area.

5) Jam MPF

* Paper could not be picked up from the MPF tray.

* After pickup, a paper has been fed, but it

doesn't reach the feed sensor in a certain time.

* Feed sensor is faulty and does not detect paper.

Exit Sensor

Feed Sensor

CASSETTE

SCF

SCF Path

MP Empty Sensor

Feed Sensor

Page 4

7-4

Alignment & Adjustments

Samsung Electronics

Service Manual

7.2 Jam Removal

When a jam occurs while printing a jam message is displayed on the control panel.

* Jam0 In Tray 1:

Paper jam in the main cassette.

* Jam0 In MP Tray:

Paper jam in the MP tray

* Jam0 Tray2:

Paper jam in the SCT (Second cassette tray)

* Jam Inside Printer:

Jam 1, Paper is jammed inside the printer.

* Jam In Exit Area:

Jam2, Paper is jammed in the exit area when ejecting paper.

* Jam In Duplex Path:

While duplex printing, paper is jammed in the duplex unit.

CAUTION: When removing jammed paper, always pull it firmly and evenly without any sudden jerks. If

at all possible, remove the paper as a single sheet. If the paper tears ensures ALLpaper

fragments are removed. Any fragments left inside the machine will cause it to jam again.

7.2.1 Factors that cause paper to jam

- Too much paper is loaded in the cassette.

- Paper in not loaded correctly in the cassette.

- Duplex cover opened while printing.

- Cassette removed while printing.

- Incorrect thickness of paper used.

- Incorrect size of paper used.

- Cassette paper guides not correctly set (loose or too tight).

- Foreign object or other contamination of internal paper path and paper guide ribs.

- Badly damaged or folded leading or trailing edges of the paper.

Page 5

7-5

Samsung Electronics

Alignment & Adjustments

Service Manual

7.2.2 Tips for Avoiding Paper Jams

By selecting the correct paper types, most paper jams can be avoided. If a paper jam occurs, follow the

steps outlined below:

• Ensure that the adjustable guides are positioned correctly.

• Do not overload the tray. Ensure that the paper is below the paper capacity mark on the right

inside the tray.

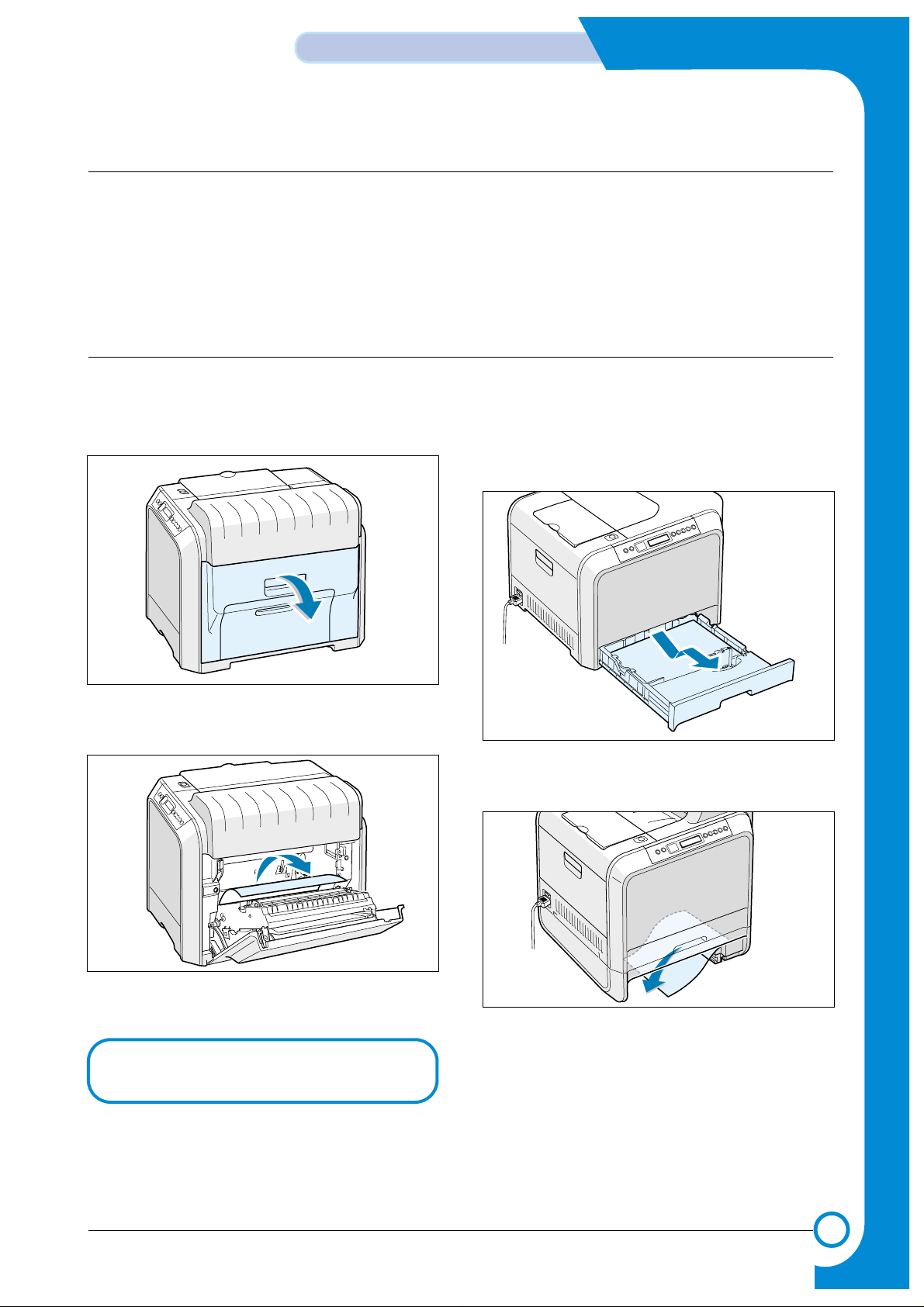

7.2.3 Jam 0 In Tray 1

If paper is jammed in the paper feed area,'Jam0 In Tray1 ' appears on the display.

1. Using the handle open the right cover.

2. Carefully remove the misfed paper in the

direction as shown.

3. Close the right cover .The printer resumes printing.

4. Pull the tray open. After you pull it all the way

out lift up the front part of the tray slightly to

release the tray from the machine.

5. Remove the jammed paper by gently pulling it

straight out.

6. To replace the tray lower the rear edge, align it

to the slot and slide it into the printer.

7. Close the right cover .The printer resumes printing.

If there is any resistance, and the paper

does not move immediately when you pull,

stop pulling and go to step 4.

Page 6

7-6

Alignment & Adjustments

Samsung Electronics

Service Manual

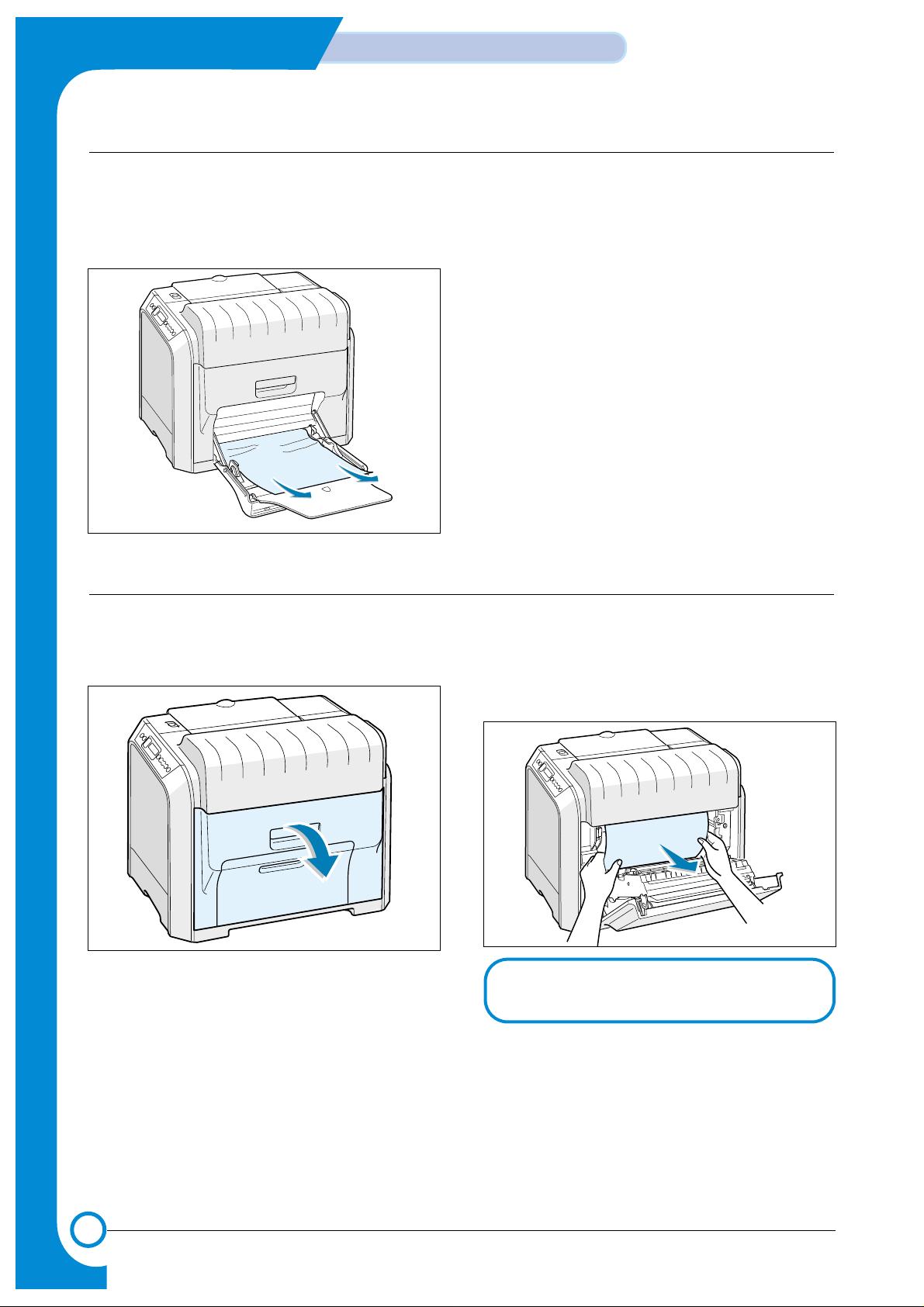

1. If the paper is not feeding properly pull the

paper out of the machine..

2. To resume printing, open and close the right

cover.

7.2.4 Jam 0 in MP Tray 1

'Jam0 In MP Tray' appears on the display when you are printing using the Multi-purpose Tray and the printer detects either there is no paper or the paper is improperly loaded.

1. Using the handle open the right cover. 2. Remove the jammed paper in the direction

shown. To avoid the paper tearing pull it out

gently and slowly.

3.Close the right cover. The printer resumes

printing.

7.2.5 Jam Inside Printer : Jam1

‘If paper is jammed inside the printer 'Jam Inside Printer' appears on the display.

NOTE : If the paper tears make sure that

all of the paper fragments are

removed from the printer.

Page 7

7-7

Samsung Electronics

Alignment & Adjustments

Service Manual

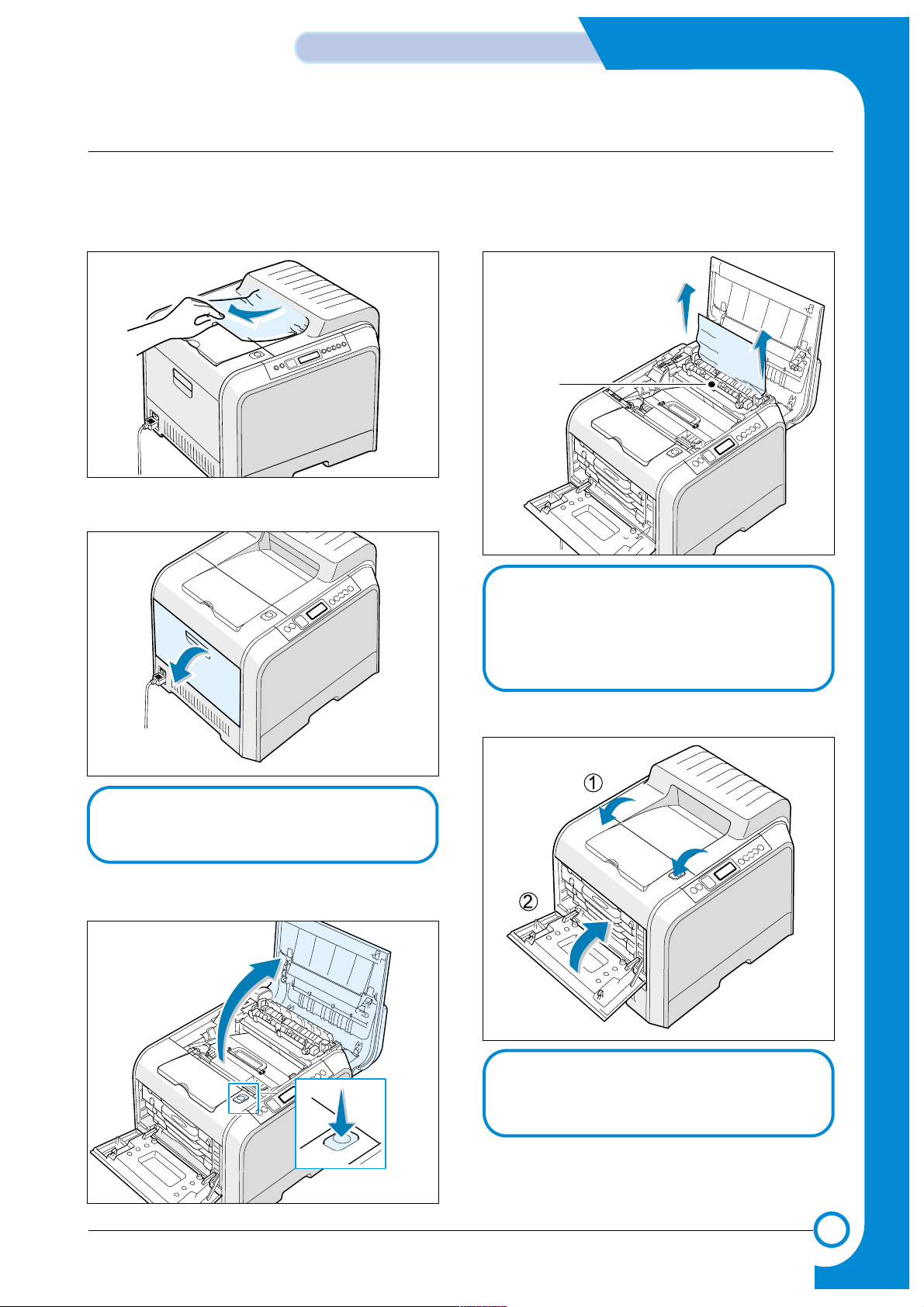

7.2.6 Jam In Exit Area : Jam2

If paper is jammed in the paper exit area 'Jam In Exit Area ' appears on the display.

1. If a long portion of the paper is visible pull it

straight out. If not continue to step 2.

2. Using the handle open the left cover completely.

3. Press the top cover release button to unlatch

the top cover and open it all the way.

4. Carefully take the jammed paper out of the

printer.

5. Close the top cover and the left cover firmly

6. Open and close the right cover to resume printing.

CAUTION : If the left cover is not completely

open the top cover release button

will not press.

Fuser

CAUTION : Do not touch the fuser it is hot and

could cause burns! The fuser's

operating temperature is 180 °C

(356 °F). Take care when removing

paper from the machine.

CAUTION : Do not try to close the top cover with

the left cover closed. This may cause

damage to the machine.

Page 8

7-8

Alignment & Adjustments

Samsung Electronics

Service Manual

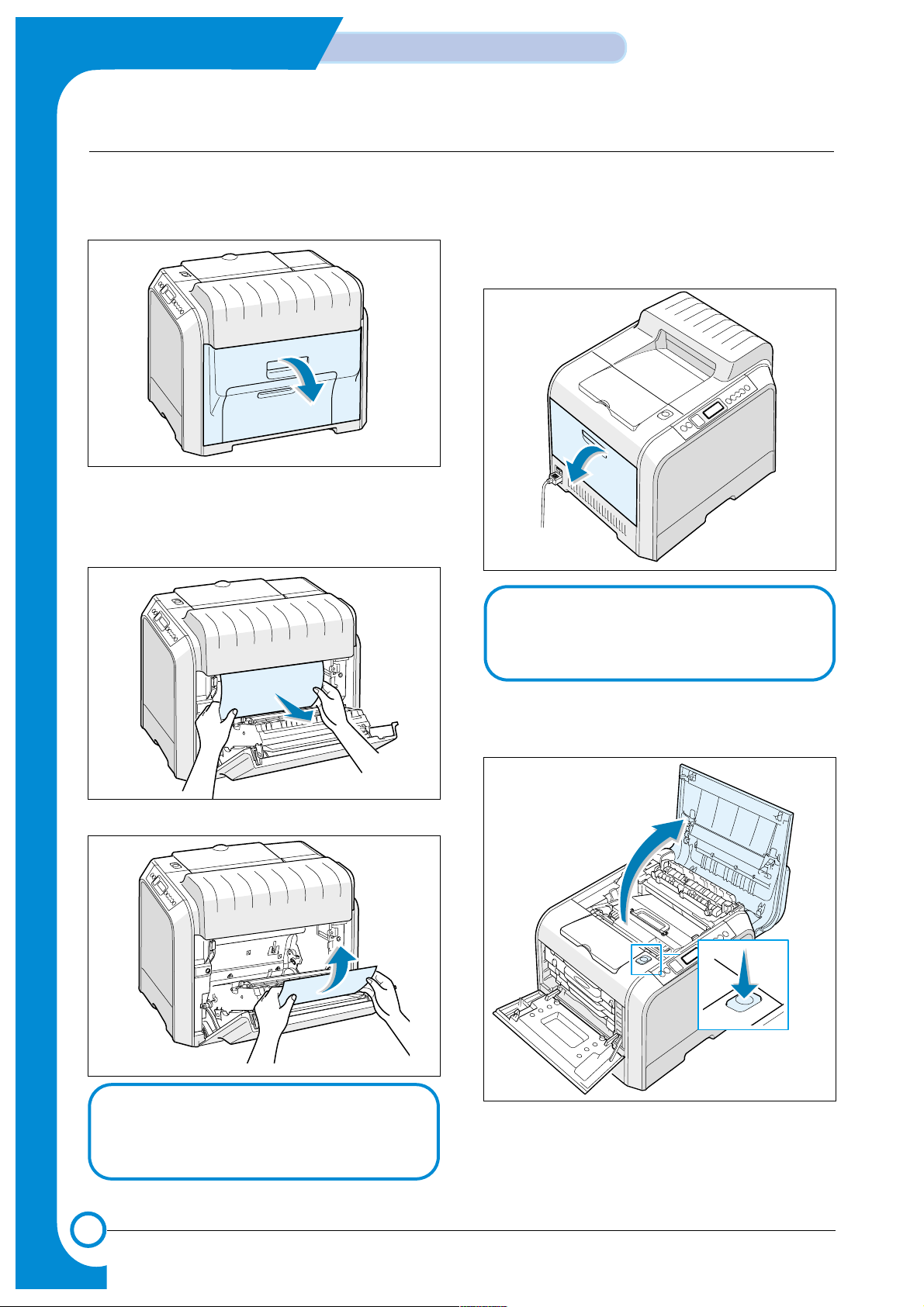

7.2.7 Jam In Duplex Path : Jam Duplex

If paper is jammed in the duplex area 'Jam In Duplex Path' appears on the display.

1. Using the handle open the right cover.

2. Locate the jammed paper and then pull it out

gently and slowly to avoid the paper tearing.

Close the right cover. The printer resumes printing.

or

3. If you cannot find the jammed paper or there is

any resistance removing the paper go to step 4.

4. Using the handle open the left cover completely.

5. Press the top cover release button to unlatch

the top cover and open it all the way.

CAUTION : If the left cover is not completely

open the top cover release button

will not press.

Note : If the paper tears make sure that all of the

paper fragments are removed from the

printer.

Page 9

7-9

Samsung Electronics

Alignment & Adjustments

Service Manual

6. Locate the jammed paper and then carefully

take it out of the printer.

7. Close the top cover and the left cover firmly

Fuser

CAUTION : Do not touch the fuser it is hot and

could cause burns! The fuser's

operating temperature is 180 °C

(356 °F). Take care when removing

paper from the machine.

CAUTION : Do not try to close the top cover

with the left cover closed. This may

cause damage to the machine.

Page 10

7-10

Alignment & Adjustments

Samsung Electronics

Service Manual

7.2.8 Jam In the Optional Second Tray

1. Using the handle open the right cover.

2. Remove the jammed paper in the direction

shown. To avoid the paper tearing pull it out

gently and slowly.

3. Close the right cover. The printer resumes

printing.

4. If you cannot find the jammed paper in the

machine open the Tray2 outer jam cover.

5. Open the inner cover of Tray 2.

6. Pull the jammed paper out in the direction

shown. To avoid the paper tearing pull it out

gently and slowly. If there is any resistance, and

paper does not move immediately when you

pull, stop pulling and continue to step 8.

Page 11

7-11

Samsung Electronics

Alignment & Adjustments

Service Manual

7. Close the two jam covers. Go to step 11.

8.Pull the optional tray, Tray 2, out of the printer.

9. If you see the jammed paper remove the paper

from the machine by gently pulling it straight out.

10. Slide the tray back into the printer and close

the two jam covers.

11. Open and close the right cover. The printer

resumes printing.

Page 12

7-12

Alignment & Adjustments

Samsung Electronics

Service Manual

7.3 Sample Pattern

This product provides several printable test patterns for maintenance purposes. These patterns can be used to aid the

diagnosis of print quality problems.

7.3.1 Printing a Demo Page

Print a demo page to make sure that the printer is operating correctly.

1. Press the Menu button on the control panel until you see “Information ” on the bottom line of the display..

2. Press the Enter button to access the Menu.

3. Press the scroll button until you see “Demo Page ” on the bottom line.

4. Press the Enter button .

A demo page showing the printer ’s features and capabilities prints out.

7.3.2 Printing a Configuration Page

Print a demo page to make sure that the printer is operating correctly.

1. Press the Menu button on the control panel until you see “Information ” on the bottom line of the display..

2. Press the Enter button to access the Menu.

3. Press the scroll button until you see “Configuration ” on the bottom line.

4. Press the Enter button .

A demo page showing the printer ’s features and capabilities prints out.

Page 13

7.4 Checking the Remaining Toner and Others

7.4.1 Checking the Remaining Toner

You can check the level of toner left in each cartridge.

1. In ready mode press the Menu button on the control panel several times until you see ‘Setup ’on the bottom line

of the display.

2 Press the Enter button to access the menu.

3 Press the scroll button until ‘Maintenance ’ displays on the bottom line.

4 Press the Enter button

5 When ‘Check Toner ’displays on the bottom line,,press the Enter button .

6 Press the scroll button until the color of the toner cartridge you want to check displays on the bottom line.

7 Press the Enter button The display shows the percentage of the remaining toner.

8. Press the Upper Level button to return to step 6 and select a different cartridge.

9. To return to the Ready condition press the Upper Level button several times until 'Ready' appears in the display

7.4.2 Checking the Remaining Others

You can check the level of each item.

1. In ready mode press the Menu button on the control panel everal times until you see ‘Setup ’on the bottom line

of the display.

2 Press the Enter button to access the menu.

3 Press the scroll button until ‘Maintenance ’ displays on the bottom line.

4 Press the Enter button

5 When ‘Check Others ’ displays on the bottom line,,press the Enter button .

6 Press the scroll button until the item you want to check displays on the bottom line.

7 Press the Enter button The display shows the percentage of item.

8. Press the scroll button display either 'Image Count' or 'Reset'

9a. Choose 'Reset' and press enter to reset the counter after replacing a consumable item

or

9b Choose Image count to display the counter.

10. Press the Upper Level button to return to step 7 and select a different choice or press it a second time to return to step

6 and choose a different item.

11. To return to the Ready condition press the Upper Level button several times until 'Ready' appears in the display.

7-13

Samsung Electronics

Alignment & Adjustments

Service Manual

Page 14

7-14

Alignment & Adjustments

Samsung Electronics

Traninung Manual

7.5 Understanding the Control Panel

The control panel on the top right side of your printer has a display and seven buttons.

7.5.1 Display

Buttorns

Status Map Display : dispaly the printer

status and job in progress.

Message Description

Ready •The printer is on-line and ready to print.

•If you press On Line/Continue ,the printer switches to off-line.

Offline •The printer is off-line and cannot print.

•If you press On Line/Continue ,the printer switches to on-line.

Processing... •The printer is printing.

•If you want to cancel printing,press Cancel .

Sleeping... •The printer is in Power Save mode, using less power.When a print job is

received from the computer or if any button is pressed,the printer switches to

on-line.

•To deactivate the Power Save mode or change the power-saving time.

Page 15

7-15

Samsung Electronics

Alignment & Adjustments

Service Manual

Message Description

When an error occurs,a lamp turns on at the corresponding location on the Status map.An error

message appears on the display so that you can locate the error.

•Press to switch between on-line and off-line.

•In menu mode,press to return to ready mode.

The color of the On Line/Continue button indicates the status of the printer.

• Press to enter menu mode.

• In menu mode,press to scroll through the menus.

In menu mode,press to select the displayed submenu item or confirm the changed setting.The

selected item is marked with an *.

In menu mode,press to scroll through submenu items or setting options.Pressing • moves you to

the next option and pressing • sends you back to the previous option.

• Press to cancel the current print job.

• In menu mode,press to return to ready mode.

In menu mode,press to go back to the upper menu level.

•The printer is off-line and cannot print.

•The printer is in Power Save mode. When data is received,it switches to on-line.

Green

Orange

Off

On

Blanking

On

Blanking

Status map

The printer is on-line and can receive data from the computer.

• When the backlight blinks slowly,the printer is receiving data from

the computer.

• When the backlight blinks quickly,the printer is receiving and printing data.

The printer stops printing due to a major error.Check the display

message.

A minor error has occured and the printer is waiting for the error to

be cleared.Check the display message.When the problem is

cleared,the printer resumes printing.If you want to ignore this warning,press this button.

7.5.2 Buttons

Page 16

7-16

Alignment & Adjustments

Samsung Electronics

Service Manual

7.5.3 Using Control Panel Menus

A number of menus are available to make it easy for you to change the printer settings.

You can configure your printer from the printer’s control panel.You can also use the control panel menus while the printer

is in use.

1. In ready mode press the Menu button until you see the menu you want on the bottom line of the display.

2. Press the Enter button to access the menu.

3. Press the scroll button until the menu item you want displays on the bottom line.

4. Press the Enter button to confirm the selected item.

5. If the menu item has submenus, repeat steps 3 and 4.

6. Press the scroll button until the setting option you want displays on the bottom line or enter the required value.

7. Press the Enter button to save your input or selection.

- An asterisk (*) appears next to the selection on the display, indicating that it is now the default.

8. To exit the menu, press the Upper Level button repeatedly, or the Cancel button .

- After 60 seconds of inactivity (no key has been pressed), the printer automatically returns to ready mode.

NOTE: Print settings made from the printer driver override the settings on the control panel.

Informa tion Paper Layout Graphics Printer

Configuration Tray Source Orientation

Resolution Default Set

Menu Map Media Size Duplex Current Job

Demo Page Width Duplex Margin

PS3 Font List Custom

Custom

Height Simplex Margin

PCL Font List Media Type Copies

Network PostScript PCL Setup Color

Config. Network Print PS Error Typeface LCD Language Calibration

Reset Network

Symbol

Emulation

Custom Color

Default Set Lines Power Save

Print Net CFG Pitch Auto Continue

Jam Recovery

Altitude Adj.

Auto CR

Job Time Out

Maintenance

Page 17

7-17

Samsung Electronics

Alignment & Adjustments

Service Manual

7.6 Periodic Defective Image

If an image defects appears at regular intervals on the printed-paper, it is due to a faulty or damaged roller.

Refer to the table below and check the condition of the appropriate roller.

No Roller Defective image Typical defect

1 OPC Drum same position in each page white spot on black image or black spot

2 Charge Roller 43.96 mm black spot

3 Supply Roller 31.41 mm light or dark horizontal image band

4 Developing Roller 35.34 mm horizontal image band

5 ITB(T1) same position in each page black spot

6 Transfer Roller(T2) 75.36 mm ghost

7 Heat Roller 109.9 mm Black spot and ghost, printing backside pollution

Page 18

7-18

Alignment & Adjustments

Samsung Electronics

Service Manual

7.7 How to use EDC (Engine Diagnostic Control) Mode

7.7.1 EDC Establishment

EDC Mode is feature that allows the engineer to check the condition of the print engine. It can check the operating condition of the motors, sensors, solenoids and clutches, measure the High Voltage from the HVPS and check the operation of

the fuser and LSU.

7.7.1.1 How to enter the EDC Mode

a) Turn on the printer while pressing the "Enter" key. Hold the key until 'Select Test mode' appears in the display.

b) Press the direction key until "<EDC Test>" is displayed.

c) Press the "Enter" key.

d) <Enter Access Key> appears in the display. Press the cancel key twice.

Note. There are a number of other test modes. Only EDC Test and Panel Tests should be used by service engineers, all

other functions are for factory use only.

7.7.1.1 Functions of the keys on the Panel and how to use them.

Key Function Description

On Line Not used

Cancel Not used

Menu Menu Display Top Menu of EDC Mode

Left/Right Arrow Find Menu Move Menu

Confirm Run/Select Run run the Function / Select Menu

Upper Menu Stop/Move Stop Stop the selected Function or go to Upper Menu.

7.7.1.2 LCD Function and Directions

Upper Line : Upper Line messages mainly show the current test menu or sub-menu.

[Main Menu] or [Function] is displayed.

Lower Line : Lower Line messages mainly the current test and status.

Buttorns

Status Map Display : dispaly the printer

status and job in progress.

Page 19

7-19

Samsung Electronics

Alignment & Adjustments

Service Manual

7.7.2 EDC Whole Menu

Motor Test

Main Motor

Dev Motor

Waste Motor

SCF Motor

Fan Motor

HVPS Test

Solenoid Test

Y Clutch

M Clutch

C Clutch

K Clutch

Y Solenoid

M Solenoid

C Solenoid

K Solenoid

Feed Clutch

T2 Solenoid

FCF Solenoid

MPF Solenoid

SCF Solenoid

ITB Solenoid

Duplex Solenoid

Feed Sensor

Exit Sensor

FCF Empty Sensor

MPF Empty Sensor

SCF Empty Sensor

SCF Cover Sensor

Waste Box Sensor

Cover Check

Sensor Test

LSU Motor

Laser Diode

Fuser

LSU & Fuser Test

Charger

T1

T2

Dev DC

Dev AC

Test Print

Select Tray

Select Pattern

Print Pattern

Print Menu Map

Interface Test

SCF Interface

Page 20

7-20

Alignment & Adjustments

Samsung Electronics

Service Manual

7.7.2.1 Motor Test

This function allows the operation of the various motors to be checked.

<How to operate>

a) Press the "<" or ">" key until "Motor Test" is displayed.

b) Press the "Enter" key to select this function.

c) Press the "<" or ">" key until you see the name of the motor you wish to test.

d) Press the "Enter" key to run the test. The test is stopped by pressing the "Upper Level" key.

e) Pressing the "Upper Level" key when the test is already stopped will return to step 'c' above.

f) Pressing the "Upper Level" key again will return to the EDC main menu.

Item Description Remarks

Main Motor Operates Main Motor Displays "Succeed" if Motor Lock Signal is Normal, "Failed" otherwise.

Dev Motor Operates Dev Motor Displays "Succeed" if Motor Lock Signal is Normal, "Failed" otherwise.

Waste Motor Operates Waste Motor Display motor status - "On" or "Off".

SCF Motor Operates SCF Motor Display motor status - "On" or "Off".

Fan Motor Operates Fan Motor Display motor status - "On" or "Off".

Page 21

7-21

Samsung Electronics

Alignment & Adjustments

Service Manual

7.7.2.2 Solenoid Test

This function allows the operation of various solenoids and clutches to be checked.

<How to operate>

a) Press the "<" or ">" key until "Solenoid Test" is displayed.

b) Press the "Enter" key to select this function.

c) Press the "<" or ">" key until you see the name of the clutch or solenoid you wish to test.

d) Press the "Enter" key to run the test. The test is stopped by pressing the "Upper Level" key.

e) Pressing the "Upper Level" key when the test is already stopped will return to step 'c' above.

f) Pressing the "Upper Level" key again will return to the EDC main menu.

Item Description Remarks

Y Clutch Operates Yellow Developer Clutch Displays clutch status - "On" or "Off".

M Clutch Operates Magenta Developer Clutch Displays clutch status - "On" or "Off".

C Clutch Operates Developer Clutch Displays clutch status - "On" or "Off".

K Clutch Operates Black Developer Clutch Displays clutch status - "On" or "Off".

Y Solenoid Operates Yellow Developer Solenoid Displays solenoid status - "On" or "Off".

M Solenoid Operates Magenta Developer Solenoid Displays solenoid status - "On" or "Off".

C Solenoid Operates Cyan Developer Solenoid Displays solenoid status - "On" or "Off".

K Solenoid Operates Black Developer Solenoid Displays solenoid status - "On" or "Off".

Feed Clutch Operates Feed Clutch Displays clutch status - "On" or "Off".

T2 Solenoid Operates T2 Clutch Solenoid Displays solenoid status - "On" or "Off".

FCF Solenoid Operates FCF pick-up Displays solenoid status - "On" or "Off".

MPF Solenoid Operates MPF pick-up Displays solenoid status - "On" or "Off".

SCF Solenoid Operates SCF pick-up (Only if SCF is fitted) Displays solenoid status - "On" or "Off".

ITB Solenoid Operates ITB cleaning Solenoid Displays solenoid status - "On" or "Off".

Duplex Solenoid OperateS Duplex Solenoid Displays solenoid status - "On" or "Off".

Page 22

7-22

Alignment & Adjustments

Samsung Electronics

Service Manual

7.7.2.3 Sensor Test

This function allows the operation of various sensors to be checked

<How to operate>

a) Press the "<" or ">" key until "Sensor Test" is displayed.

b) Press the "Enter" key to select this function.

c) Press the "<" or ">" key until you see the name of the sensor you wish to test.

d) Press the "Enter" key to display the sensor status. If the sensor actuator is moved the displayed status will change to

reflect the new sensor position..

e) Pressing the "Upper Level" key will return to step 'c' above.

f) Pressing the "Upper Level" key again will return to the EDC main menu.

Item Description LCD indication

Feed Feed Sensor Status "With Paper" is displayed when Paper is detected,

"Without paper" is displayed when paper is not detected.

Exit Exit Sensor Status "With Paper" is displayed when Paper is detected,

"Without paper" is displayed when paper is not detected.

FCF Empty FCF Empty Sensor status "With Paper" is displayed when Paper is detected,

"Without paper" is displayed when paper is not detected.

MPF Empty MPF Empty Sensor Status "With Paper" is displayed when Paper is detected,

"Without paper" is displayed when paper is not detected.

SCF Empty SCF Empty Sensor Status "With Paper" is displayed when Paper is detected,

"Without paper" is displayed when paper is not detected.

SCF Cover SCF Cover Sensor Status "Cover Opened" or "Cover Closed" is displayed.

Waste Box Waste Toner Sensor Status "Not Installed" is displayed when either the Waste toner tank is not installed or

it is full.

"Installed" is displayed when the Waste Toner tank is installed and is not full.

Cover Left or Right Cover Sensor Status "Cover Opened" or "Cover Closed" is displayed.

Page 23

7-23

Samsung Electronics

Alignment & Adjustments

Service Manual

7.7.2.4 LSU & Fuser Test

This function allows the Fuser, LSU Motor and Laser Diode to be tested.

<How to operate>

a) Press the "<" or ">" key until "LSU & Fuser Test" is displayed.

b) Press the "Enter" key to select this function.

c) Press the "<" or ">" key until you see the name of part you wish to test.

d) Press the "Enter" key to run the test. The test is stopped by pressing the "Upper Level" key.

e) Pressing the "Upper Level" key when the test is already stopped will return to step 'c' above.

f) Pressing the "Upper Level" key again will return to the EDC main menu.

• The LSU Motor Lock Time is a maximum 15 seconds depending on the environment. It may take over 15 seconds until

the <Succeed> or <Failed> message is displayed.

• For safety - after printing a test pattern if you need to return to EDC mode turn the printer off and then re-enter EDC.

Item Description Remarks

LSU Motor Operates LSU Motor The LSU motor must come into lock within 6 seconds. After 7 secs the

status is displayed either:

"Succeed" if lock is successful within the time limit

"Failed" if lock is not achieved

LD Operates Laser Diode

Fuser Heats the Fuser Repetitive cycle (10secs) - Lamp on for 500msec then off again.

7.7.2.5 Interface Test

This function tests communications between the Main PBAcontroller and the SCF controller.

<How to operate>

a) Press the "<" or ">" key until "Interface Test" is displayed.

b) Press the "Enter" key to select and run this function.

c) "Succeed" or "Failed" is displayed..

d) Pressing the "Upper Level" key again will return to the EDC main menu.

Page 24

7-24

Alignment & Adjustments

Samsung Electronics

Service Manual

7.7.2.6 Test Print

This function allows you to test the overall function of the print engine. You can select either a 4 * 4 color bar pattern or a

solid color pattern. If the solid pattern is selected 4 pages are printed - one for each color. You can also print the EDC

Mode Menu Map.

<How to operate>

a) Press the "<" or ">" key until "Test Print" is displayed.

b) Press the "Enter" key to select this function.

c) Press the "<" or ">" key until "Select Tray" is displayed.

d) Press the "Enter" key to select this function.

e) Press the "<" or ">" key until required tray is displayed and then press the "Enter Key"

f) Press the "Upper Level" key.

g) Press the "<" or ">" key until "Select Pattern" is displayed.

h Press the "Enter" key to select this function.

i) Press the "<" or ">" key until required pattern is displayed and then press the "Enter Key"

j) Press the "Upper Level" key.

k) Press the "<" or ">" key until "Print Pattern" is displayed.

l) Press the "Enter" key to print the pattern.

For safety - after printing a test pattern if you need to return to EDC mode turn the printer off and then re-enter EDC

Mode by turning power on whilst holding in the "Enter" key.

Page 25

7-25

Samsung Electronics

Alignment & Adjustments

Service Manual

7.7.2.7 HVPS Test

This function allows the HVPS to be tested

<How to operate>

a) Press the "<" or ">" key until "HVPS Test" is displayed.

b) Press the "Enter" key to select this function.

c) Press the "<" or ">" key until you see the name of the voltage you wish to test.

d) Press the "Enter" key to select the test.

e) Press the "<" or ">" key to select the appropriate Duty Cycle and press "Enter" to start the test

The test is stopped by pressing the "Upper Level" key.

The display shows the acceptable range for this setting (column 4 in the table below)

The mid range (nominal) voltage is shown in column 3 in the table below.

e) Pressing the "Upper Level" key when the test is already stopped will return to step 'c' above.

f) Pressing the "Upper Level" key again will return to the EDC main menu.

Item Description

Lower Menu & Input

LCD Indication

V oltage

Charger Supply Voltage to the Charger Duty 50% : -1262V Duty 50% : -1224V ~ -1300V

Duty 80% : -2037V Duty 80% : -1976V ~ -2098V

T1 Supply Voltage to T1 Duty 50% : 1174V Duty 50% : 1139V ~ 1209V

Duty 90% : 2080V Duty 90% : 2018V ~ 2142V

T2 Supply Voltage to T2 Duty 30% : 1800V Duty 30% : 1746V ~ 1854V

Duty 80% : 4540V Duty 80% : 4404V ~ 4676

Reverse Bias : -900V Reverse Bias : -800V ~1200V

Dev DC Supply DC Voltage to Dev Duty 45% : -370V Duty 45% : -359V ~ -381V

Dev AC Supply AC Voltage to Dev Duty 35% : -2200V Duty 35% : -2134V ~ -2266V

* The allowed tolerance is commonly +/- 3%, this is the value Displayed, in case of "Dev AC", it is the value of Vpp.

* T2 Reverse Bias.(Tolerance : +/-20%)

Page 26

7-26

Alignment & Adjustments

Samsung Electronics

Service Manual

MEMO

Loading...

Loading...