Page 1

5

5

5-1

Samsung Electronics

System Outline

Service Manual

5 System Outline

This chapter describes the functions and operating principals of the main components.

5.1 CLP (Color Laser Printing) Process

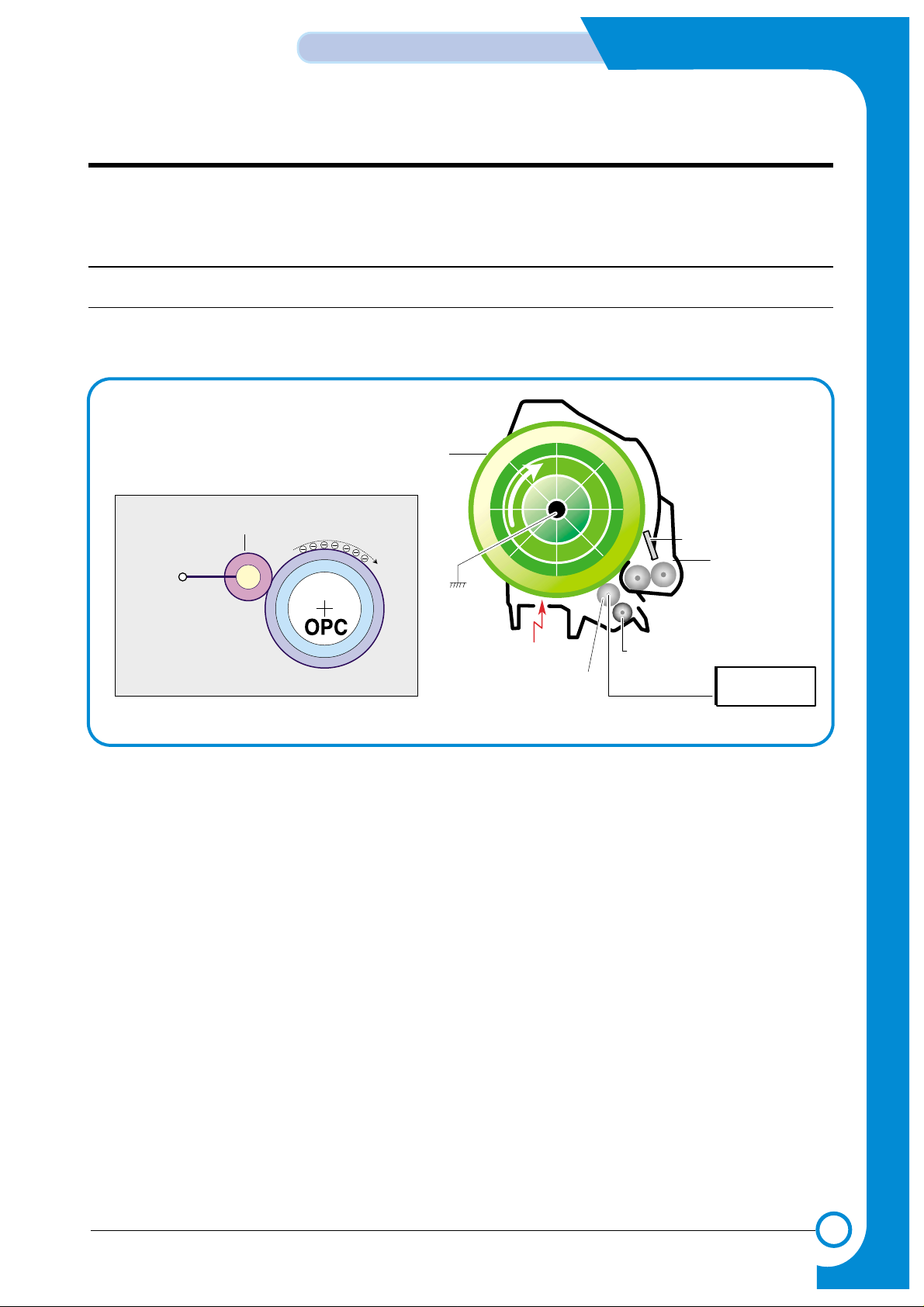

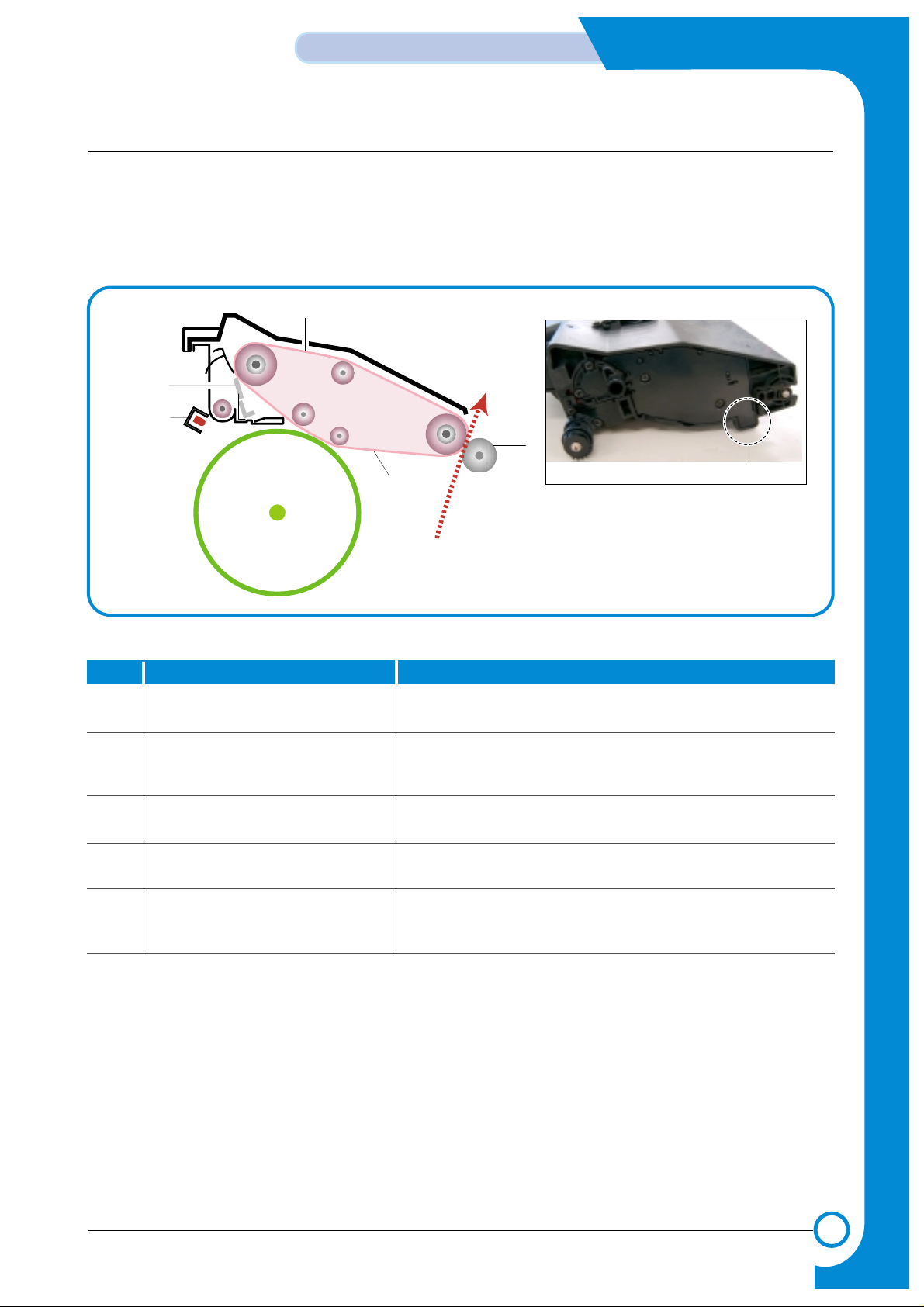

5.1.1 OPC Drum Unit (Charge Section)

The OPC Unit is the image formation unit and it consists of the OPC drum, waster toner assembly, charge

roller assembly, etc. (see diagram below).

LSU

Charge Bias

Waste Toner Tank

Cleaning Roller

Cleaning Blade

Charge Roller

OPC Drum

-1000V ~ -1500V

Charge Roller

HVPS

1) Structure

* OPC drum: The laser light coming from the LSU forms an latent electric image on the surface of

the OPC drum.

* Cleaning Blade: Removes remaining unwanted toner from the OPC drum.

* Waste toner tank: Collects and stores the waste toner.

* Charge roller: The charge roller is charged to a negative high voltage (-1KV~1.5KV) It is in con-

tact with the OPC drum and produces a uniform (-) voltage on its surface of approximately -500~-

800V.

2) Type

* Life span: 50K Images (Color 12.5K)

* Waste toner removal: Transferred to a user replaceable tank

* Waste tank sensors: LED type, detects tank present and tank full

* OPC drum diameter: 120mm

* Power: Main motor (BLDC)

* Charging method: Charge roller

* Eraser method: LED lamp (+5V/2Pin)

* PTL: LED lamp (+5V/2Pin)

Page 2

5-2

System Outline

Samsung Electronics

Service Manual

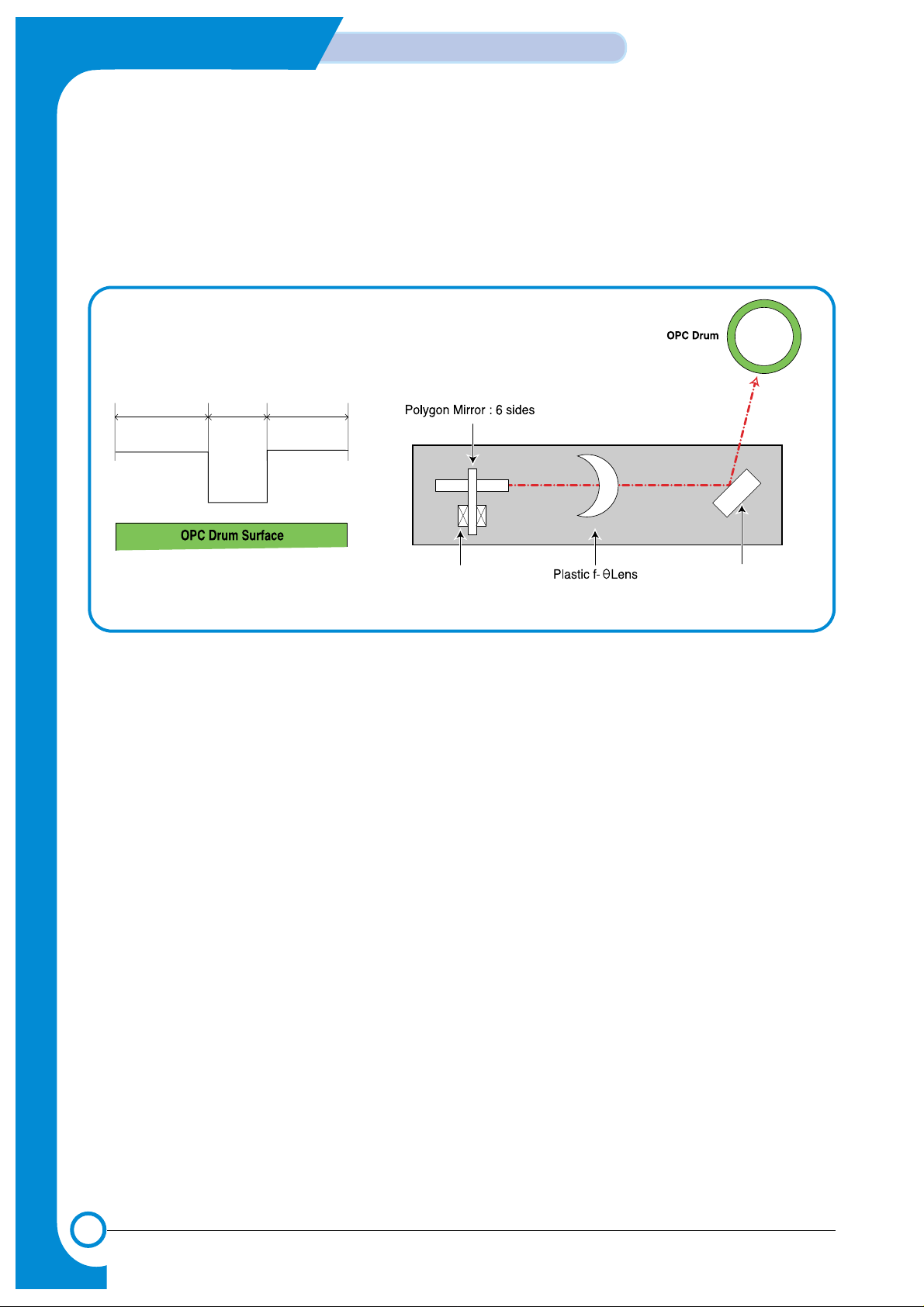

5.1.2 LSU (Exposure)

The bitmap image data stream is used to switch the LSU data beam. Where white paper is

required the beam is off, where ink is required the beam is turned on. When the laser is on

and the beam strikes the OPC drum surface the charge is reduced to -50V, where the beam is

switched off the charge on the OPC surface remains at -600V. In consequence a latent image is

formed on the drum surface.

-600V -600V

-50V

Reflecting MirrorPolygon Motor

(30,000rpm)

Unexposed Expesed Unexposed

Page 3

5-3

Samsung Electronics

System Outline

Service Manual

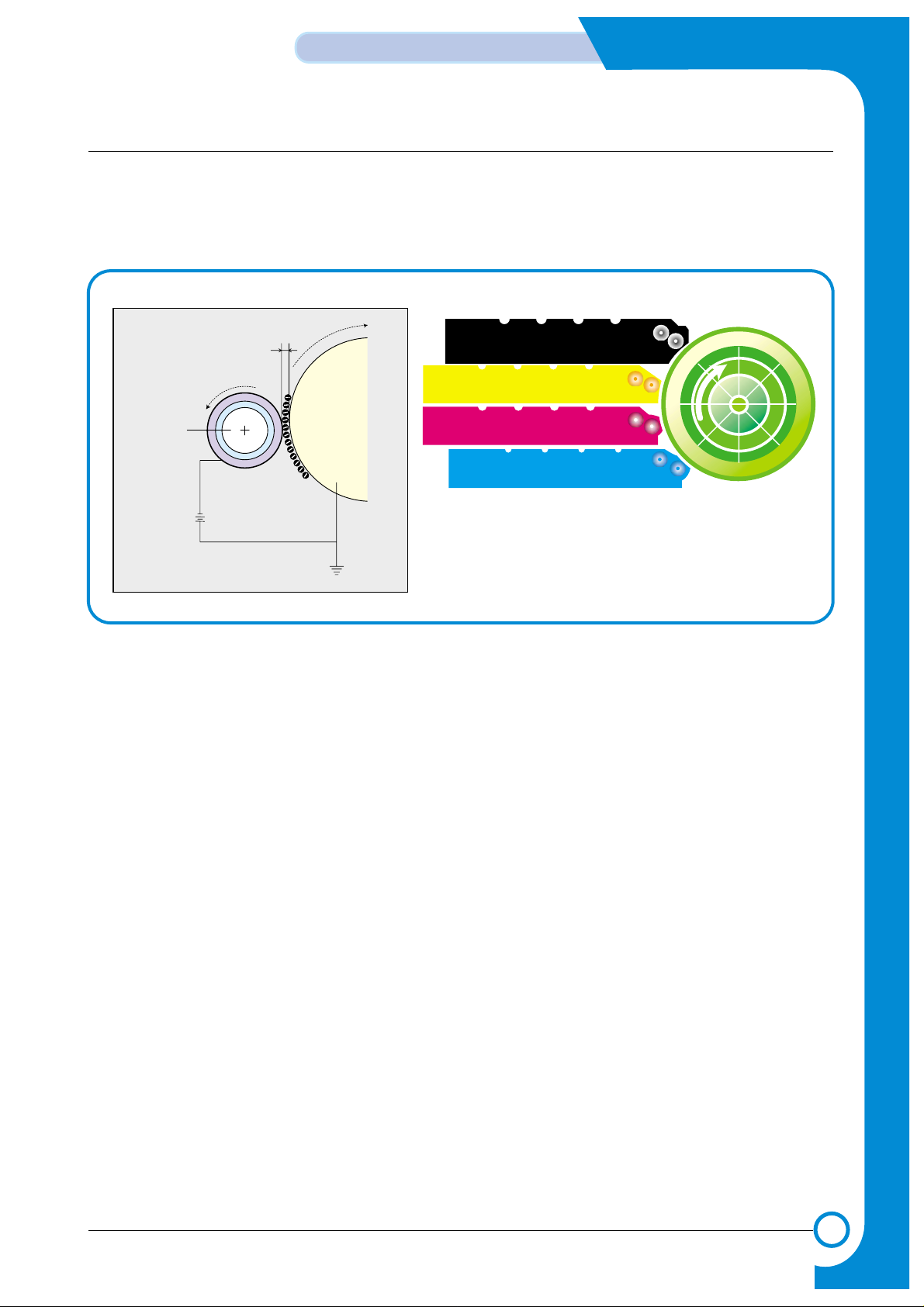

5.1.3 Toner Cartridge (Development Section)

In the development stage toner particles are transferred from the toner cartridge onto the surface

of the OPC drum. The OPC drum and the developer roller rotate in opposite directions. Toner on

the developer roller is charged to the developing voltage (-370V ± 3%). Toner is attracted to the

OPC drum in those areas where the OPC drum surface charge is -50V. Toner is not attracted to

those areas of the surface carrying a -600V charge.

1) Type

* Developing method: Non-magnetic, Mono-component developing system.

* Toner cartridge order: K, Y, M, C from top.

* Developing sequence: Y, M, C, K

* Life span: 7K(K) / 5K(C, M, Y)

* Power: DEVE motor (BLDC)

* Power transmission: Electric clutch

* Dot counting method

DEV . - Black

DEV . - Yellow

DEV . - Magenta

DEV . - Cyan

DEV . - Black

DEV . - Yellow

OPC

DEV . - Magenta

DEV . - Cyan

OPC

Drum

OPC

Dev Roller

Developing

Voltage

Dev Gap

Page 4

5-4

System Outline

Samsung Electronics

Service Manual

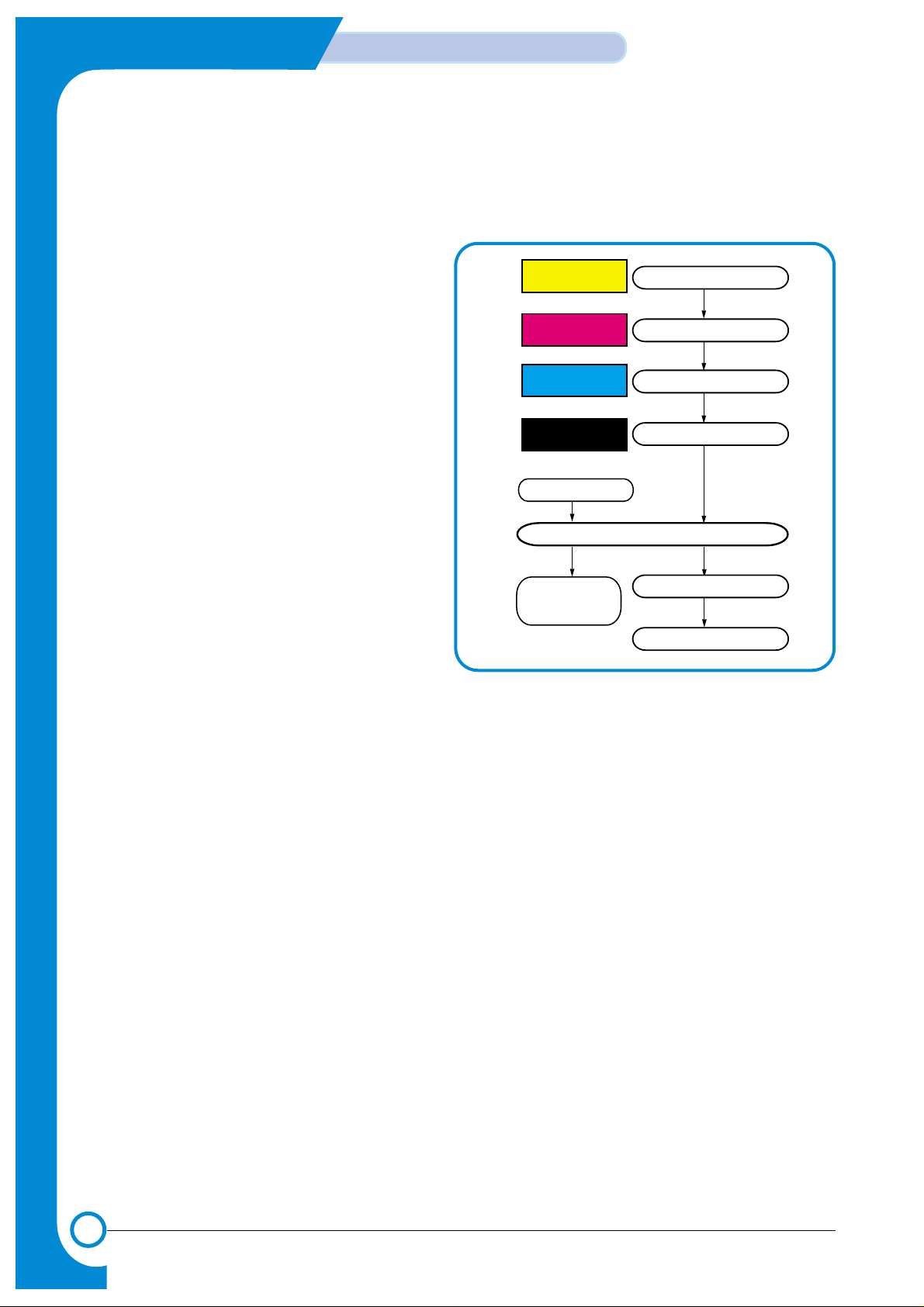

2) Developing state of color

The page image is built up from each of the 4 colors and transferred to the paper as described below.

> Developing sequence: Y, M, C, and K

1) A latent image containing only yellow toner is

created on the OPC drum and then transferred

onto the ITB.

2) A latent image containing only magenta toner

is created on the OPC drum and then transferred onto the ITB to add to the yellow image

already in the ITB.

3) A latent image containing only cyan toner is

created on the OPC drum and then transferred

onto the ITB, adding to the 2 colors already

present on the ITB

4) A latent image containing only black toner is

created on the OPC drum and then transferred

onto the ITB, creating an image on the ITB

consisting of the 4 colors.

5) The Image on the ITB is secondly transferred

onto paper using the T2 transfer roller.

6) The image on the page is then fused and the

paper is ejected into the output tray.

3) Toner cartridge empty detection

Software Dot count.

Developing and Image Transfer

Developing and Image Transfer

Developing and Image Transfer

Paper Take-up

Fusing

Cleaning of

Image Transfer Belt

Paper Exit

Image Transfer to page

Developing and Image Transfer

Yellow ColorYellow Color

Magenta ColorMagenta Color

Cyan ColorCyan Color

Blacl BolorBlack Color

Page 5

5-5

Samsung Electronics

System Outline

Service Manual

5.1.4 Image Transfer Section

The toner image formed on the OPC drum is transferred to the ITB (Image Transfer Belt), this is called the

primary image transfer. When the final image has been built on the ITB it is transferred onto paper, this is

called the secondary image transfer.

1) Structure

DUPLEX

OPC DRUM

1

2

3

5

4

Paper Path

NO. Name Description

1. Image Transfer Belt Used to build up the 4 color image from the OPC drum.

Colors are transferred in the order Y, M, C, K

2. Image Transfer Belt cleaner After the final image is transferred onto paper any waste

toner is removed from the transfer belt using this cleaning

blade

3. PTL (Pre-Transfer Lamp) Reduce the electric potential of OPC Drum surface before

primary image transfer the image on the OPC Drum.

4. Image Transfer Roller (T2 Roller) This transfers the final toner image on the image transfer belt

to paper.

5. ITB Home Sensor This sensor is used to ensure that each of the 4 color

images starts at exactly the same point on the ITB. It works

by detecting a fixed point on the belt.

ITB Home Sensor

Page 6

5-6

System Outline

Samsung Electronics

Service Manual

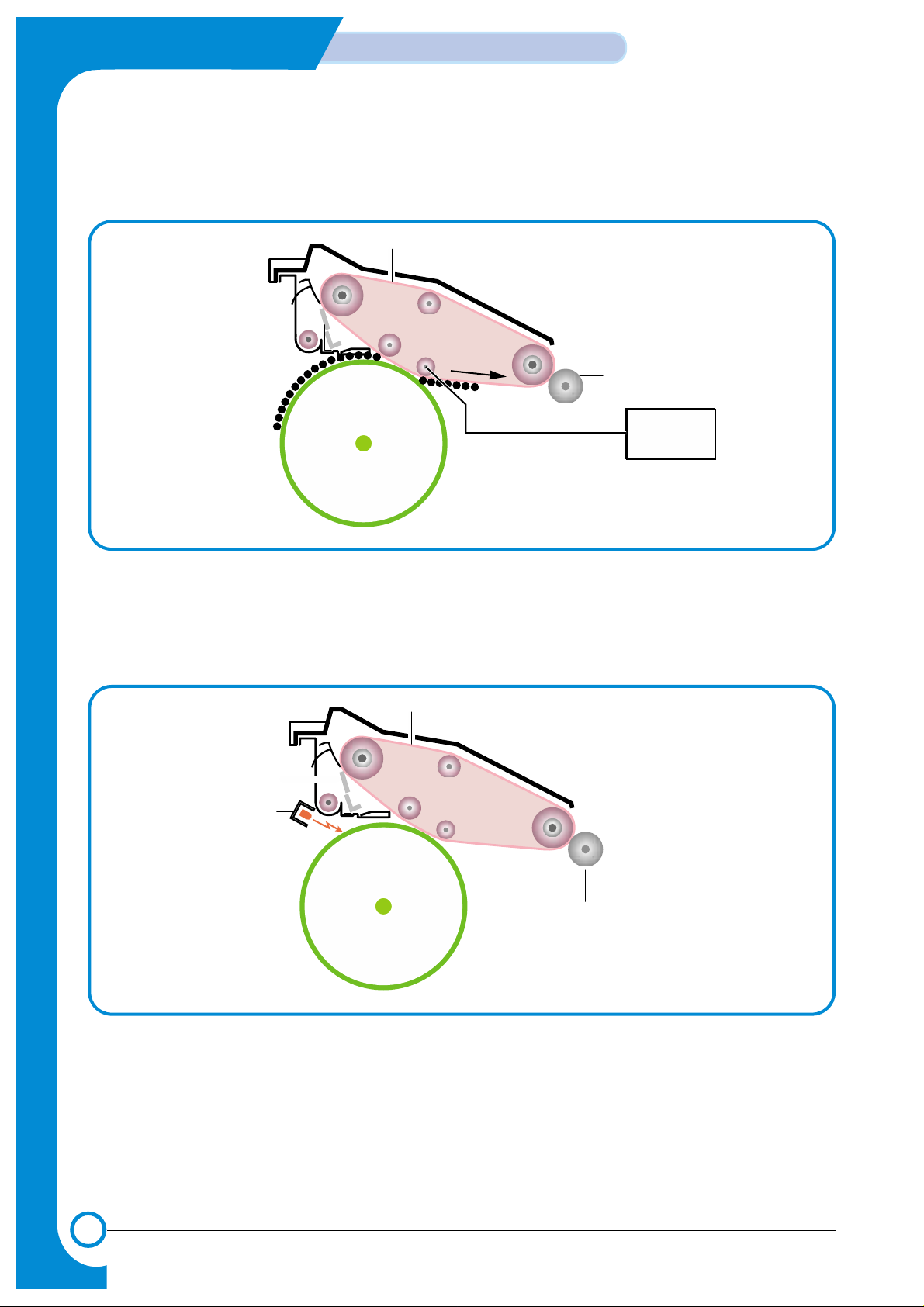

2) Primary Image Transfer

A colored page is split into 4 component color parts and developed one color at a time in turn on

the OPC (in the order Y, M, C, K). The final image is built up on the ITB by transferring these separate color images from the OPC drum.

DUPLEX

OPC DRUM

Primary Image Transfer Bias

Image Transfer Belt

Image Transfer Roller

HVPS

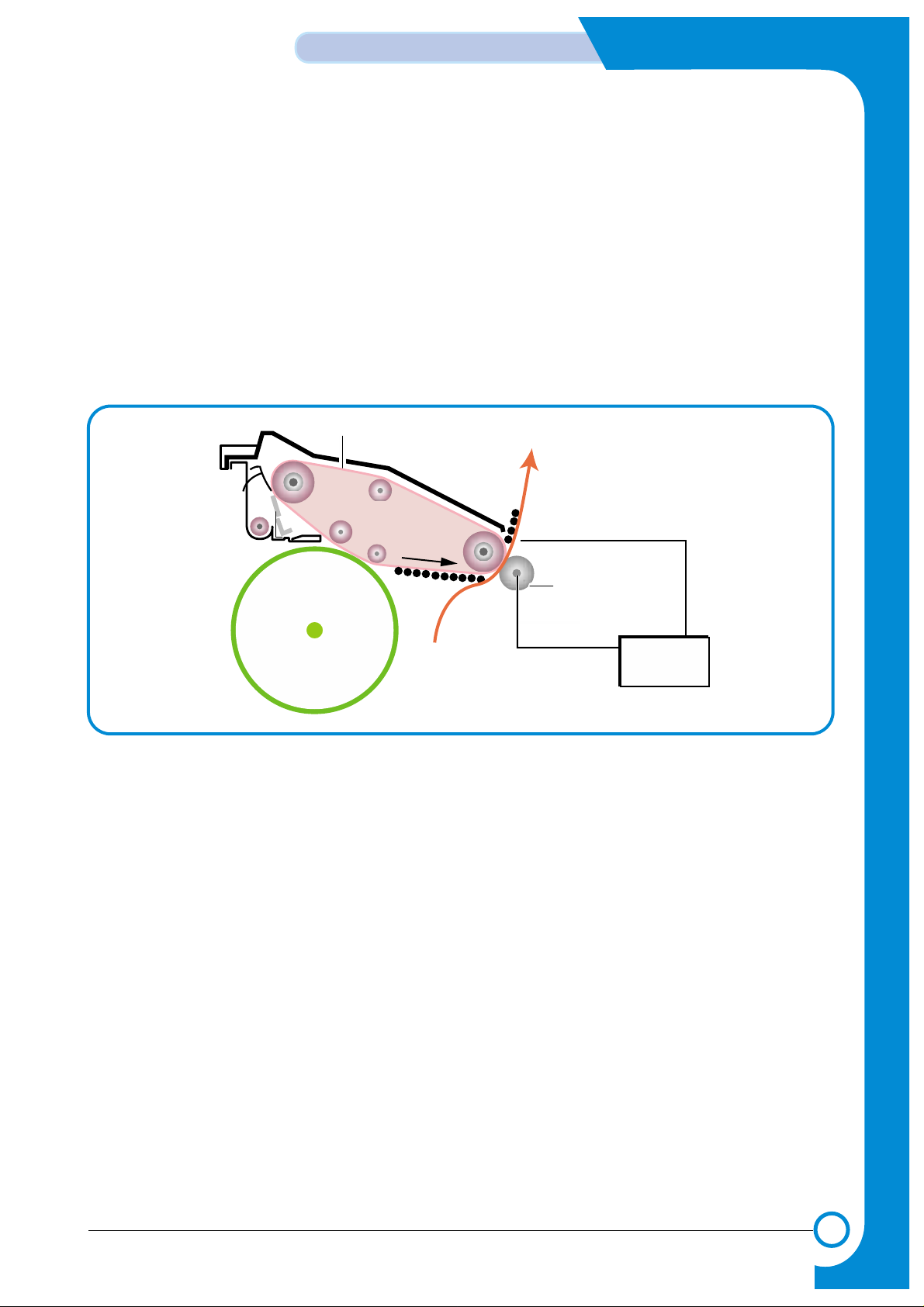

3) PTL (Pre-Transfer Lamp)

It is arrayed LED on PCB Board. Main function is improving the T1 utility factor by reducing the

adhesive strength of OPC and Toner by irradiation on the OPC Drum formatted the image.

DUPLEX

OPC DRUM

(LED)

PTL

Image Transfer Belt

Image Transfer Roller

Page 7

5-7

Samsung Electronics

System Outline

Service Manual

4) Secondary Image Transfer

The image is built up on the ITB (primary image transfer). This image is then transferred onto paper

using the T2 transfer roller (roller transfer system) this process is known as the secondary image

transfer.

* The HVPS applies the Image Transfer Bias voltage to the Image Transfer Roller (T2), this

transfers the image from the belt onto the paper.

* When the image is to be transferred from the ITB to the paper the image transfer roller

pressure contact solenoid is activated and this activates a cam which moves the T2 roller

into contact with the belt.

*After the transfer has taken place any remaining charge on the paper is removed by

applying a charge removal bias (generated in the HVPS) to a charge removal plate

>T ype

* Transfer method: Semi-conductive roller contact method

* Effective transferring range: 218mm (i.e. maximum image length)

OPC DRUM

Paper

Image Transfer Bias

Charge Removal Bias

Image Transfer Belt

Image Transfer Roller

HVPS

Page 8

5-8

System Outline

Samsung Electronics

Service Manual

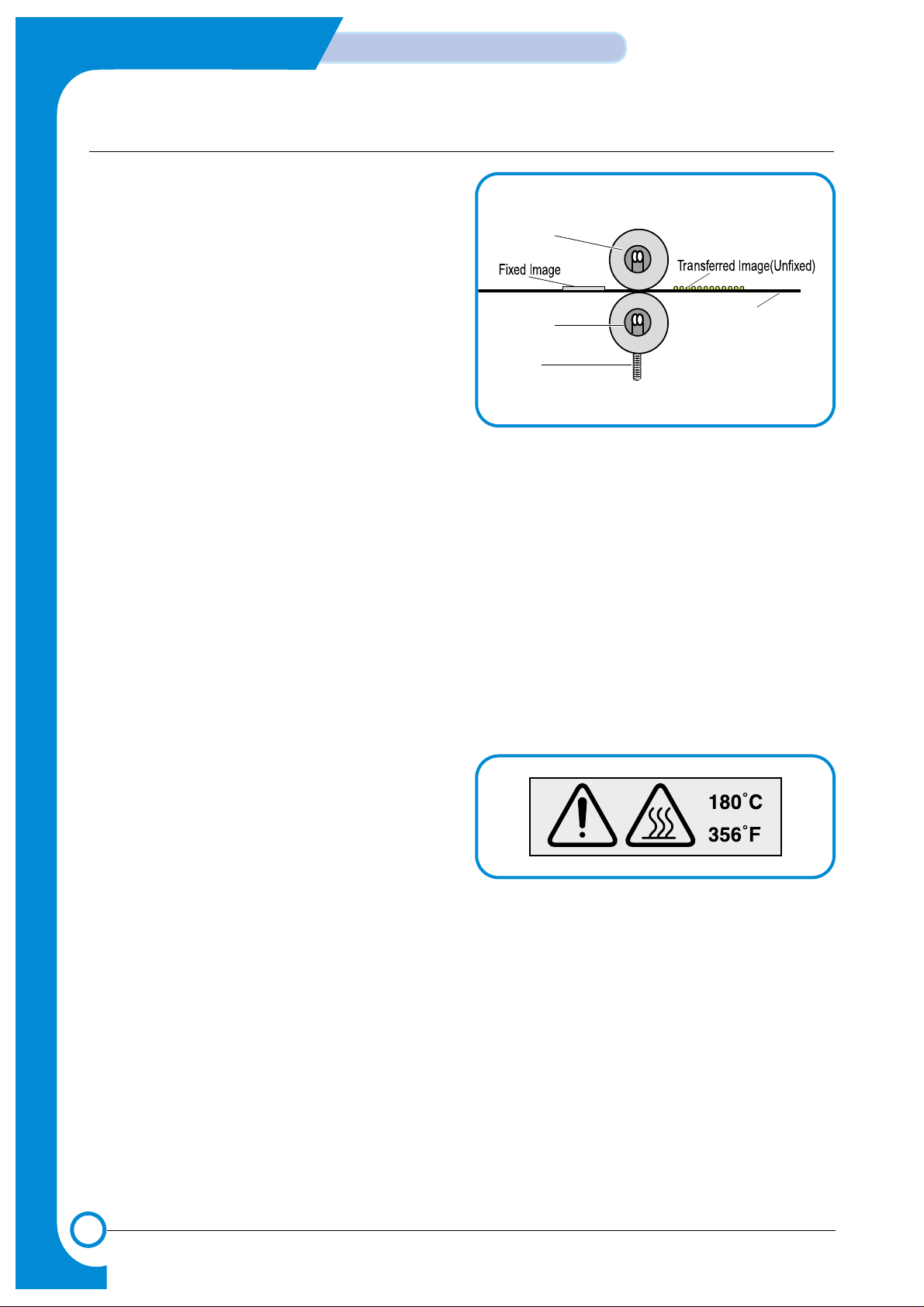

5.1.5 Fuser (Fusing Section)

Toner that has been through the primary and

secondary image transfer processes is fixed,

semi-permanently, to the paper.

The fuser unit consists of heat lamps (2 ea), heat

rollers (2 ea), thermistor, and thermostats (2 ea). It

melts the toner onto the paper using pressure and

high temperature to complete the printing process.

1) Thermostat (2pieces)

If the heat lamps or heat rollers overheat the

thermostat turns off power to the lamps in the

fuser unit to prevent fire. It is a temperature

cut-off device.

2) Thermistor

The thermistor detects the temperature of the heat roller's surface, and feedbacks the information

to the main processor which uses this information to control power to the fuser lamps in order to

maintain the heat roller at a steady temperature.

3) Heat Roller (2pieces)

Halogen lamps are used to heat the heat rollers. The heat rollers have a special Teflon surface

which ensures that any melted toner which comes into contact with the heat roller surface does not

stick. Paper passes between the two rollers which evenly heat the paper from both sides to melt

the toner and semi-permanently fix it to the paper.

4) Safety Information

> Overheat protection

* 1st level protection: Print engine is stopped if overheat is detected

* 2nd level protection: Software turns off lamp power if overheat is detected.

* 3rd level protection: Thermostat turns off lamp power if overheat is detected.

> Protecting device

* Fuser unit power is turned off when

the duplex cover or the toner

cartridge door is open.

* This machine keeps the surface

temperature of the fuser unit cover

under 80°C, and it has a caution

label attached inside the exit cover

where it can be easily seen by the user.

Heat Roller

Heat Roller

Heat Lamp

(500W)

Heat Lamp

(300W)

Paper

Spring

Page 9

5-9

Samsung Electronics

System Outline

Service Manual

5.1.6 Exit

After passing through the fuser paper is ejected into the paper exit tray. Any static electrical charge

is removed by static discharge brushes.

When operating in duplex print mode, after printing the front side of the page, the paper exit roller

reverses to feed the paper back into the machine in order to print the second side of the page.

5.1.7 Waste Toner Collection Process

Waste toner on the OPC drum and on the image transfer belt is collected into the waste toner tank.

* After transferring the toner image on the OPC drum to the ITB, a cleaning blade scrapes waste

toner from the OPC drum, and the waste toner is collected into a waste toner tank.

* An Image Transfer Belt cleaner scrapes waste toner from the image transfer belt, and the waste

toner is collected into a waste toner tank.

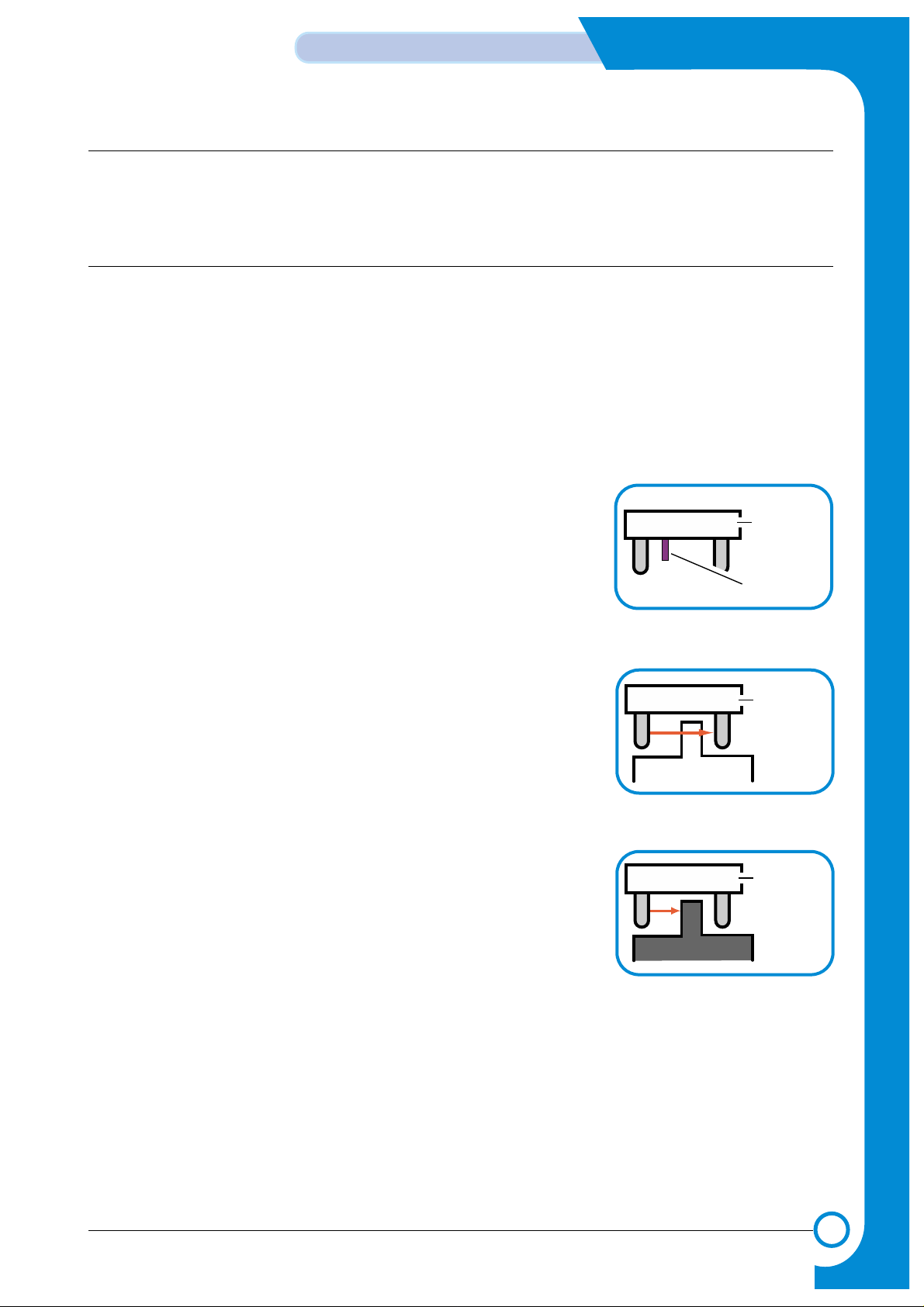

1) Waste toner tank sensor

A waste toner sensor detects the presence of the waste toner tank and also detects if the tank is full.

This is an On / Off detection. Do not operate the printer without a waste toner tank.

> No waste toner tank

When the waste toner tank is not installed the waste toner senor

actuator blocks light from the senor LED.

> A little waste toner

When the sensor LED light reaches the photo sensor passing

through the waste toner tank this indicates that the tank is not full.

> Waste toner tank full

When the waste toner tank is full to the level of the waste toner

sensor, the senor LED light is blocked by waste toner indicating

that the tank is full.

Waste Toner Sensor Actuator

Waste Toner Sensor

Waste Toner T ank

Waste Toner Sensor

Waste Toner TankWaste Toner T ank

Waste Toner Sensor

Page 10

5-10

System Outline

Samsung Electronics

Service Manual

5.2 Outline of Engine Firmware

The CLP 510/510N use 4 different colored toners (Yellow, Magenta, Cyan, Black) and it is a laser color

printer. Engine firmware controls the print processes, driving the print engine, paper feed, developer, fuser,

and paper discharge systems. It has both color and mono printing modes. The printer process sequence is

as follows:

System Initialization

When power to the system is turned on all system values are

initialized

Print Printer performs the actual printing job.

Post-Print

The finishing state of printing job. The printer puts all systems back

into a state ready to start the next job and then enters the Ready state.

Warm-Up Each part of system is activated and the system automatically

checks its status and all systems are prepared to accept a job for printing.

Pre-Print As soon as a printing order is inputted from host, the printer checks

the status of each part before performing the printing job.

Ready The normal state of the printer, waiting to receive a command from

a host to start a job. After a predefined length of time in the Ready

state if no print jobs are received the Power Save mode is entered.

Page 11

5-11

Samsung Electronics

System Outline

Service Manual

5.2.1 System Initialization

The system initialization process is carried out immediately after power on. The following tasks are performed.

1) Initialize ASIC

2) Initialize system variables

3) Initialize a virtual timer

4) Initialize fuser control

5) Initialize ADC

6) Set-up ITB HOME interrupt

5.2.2 Warm-Up

In the warm-up stage, the following tasks are performed.

1) Self Test

* System error check

* Cover open check

* Device (ITB, OPC, DEVE cartridge) check

* Heating error check

* Motion of motor and jam & paper empty check

* Check Feed and exit sensors. If paper is detected it is ejected. If the paper detection does not

clear a jam recovery is carried out and the paper drive unit is instructed to drive for the maximum

permitted paper length.

2) Heat Control

The heater control unit separately manages the temperature of the heat lamps.

* Target temperature (165°C)

* Temperature below 130°C - heat unit fully on,

* Temperature above 135°C temperature is controlled by reading the temperature value

every 10msec.

3) Cleaning

Transfer rollers, OPC and ITB are electrically and mechanically cleaned.

Page 12

5-12

System Outline

Samsung Electronics

Service Manual

5.2.3 Ready

1) Host interface is monitored for print commands

2) Heat control

* Target temperature (165°C)

* Every 40 seconds, temperature value for the previous 250ms is read and a proportional control

process is carried out

3) This is the standby mode entered after warm-up or after completing a print job.

4) System Error check

5) Power save state is entered after timeout

> Wakeup condition

* When a "wakeup" order is received

* When a cover is opened and then closed

* When the level of the paper empty sensor changes.

> Heat lamp is off

5.2.4 Pre-Print

This is the preparation stage before processing a printing job and after receiving a print command from a host.

1) Start LSU

* Run Scanning motor

* Check motor ready

* Turn LD on

2) Start BLDC motor, Eraser/PTL on

* Run main motor

* Check lock signal

* Run developer roll motor

* Check lock signal

3)Turn High Voltage On

* Charger on

* Developer high voltage off

4) Cleaning

* OPC cleaning (Mechanical motion)

* ITB cleaning

5) Jam check

6) Motor Unlock Check

7) Check and Set a High Voltage Condition (T1, T2, Charger)

8) Initialize Printing Parameters

* Paper size, copies, cassette ...

* Image pixels, image times, y-offset, x-offset

* Flags

9) Check Print mode

* Color print mode:

- Except legal & OHP/Legal/OHP

- Simplex/Duplex

* Mono pint mode: Simplex/Duplex/OHP

Page 13

5-13

Samsung Electronics

System Outline

Service Manual

5.2.5 Print

After sensing the ITB home position the following tasks are performed,

Send Psync signal to controller -> Operates virtual timer for each color(Vdata) -> Forms latent

image on OPC drum -> Supplies toner on OPC drum -> Transfers image to ITB (T1 ) -> Pickups a

paper -> Transfers image to a paper (T2)

1)Check ITB Home (Treated by Home interrupt): It is designed to detect ITB HOME every 3 seconds.

a) ITB Home sensing

b) If a test mode is set up, a test pattern is printed.

c) Acounter value is set up that addresses the timing to turn on page sync.

d) The virtual timer for each color (Y, M, C, and K) is set up

e) If Home is not detected every 3 seconds, an error is reported.

2)Paper path and print

a) Printing paper from cassette, MPT and SCT is picked up

b) Control paper path

* Stop when the leading edge of a piece of paper reaches the feed sensor.

* If the leading edge doesn't reach the feed sensor, it is an error.

* While transferring the last color to the ITB, re-feed the paper.

* Checks if the paper reaches the exit sensor in certain time. If it reaches too soon, or it doesn't

reach, it is an error.

* Checks that the paper passes the exit sensor or not.

c) Jam check

* Check reaching time and passing time for the paper reaching and passing the feed and exit

sensors. If time exceeds a certain time, it is an error.

d) Duplex control

* After passing the exit sensor, the duplex clutch is operated to mechanically change the direction

of the paper flow in order to print the other side.

e) Printing sequence and motion for each color

* Use a virtual timer for printing the colors in sequence. (Yellow, Magenta, Cyan, Black)

> What is a Virtual Timer?

A virtual timer is a mathematical function for creating regular action at fixed time intervals. The standard setting is for a 5msc timer interrupt.

5.2.6 Post-Print

This is the last stage of the printing process. Its functions are described below.

a) Clean transfer rollers

b) Stop all virtual timers

c) Initialize parameters used in the printing process.

d) Stop motors

Page 14

5-14

System Outline

Samsung Electronics

Service Manual

MEMO

Loading...

Loading...