Page 1

4

4

4-1

Samsung Electronics

Summary of product

Service Manual

4. Summary of Product

This chapter describes the functions and operating principles of the main components.

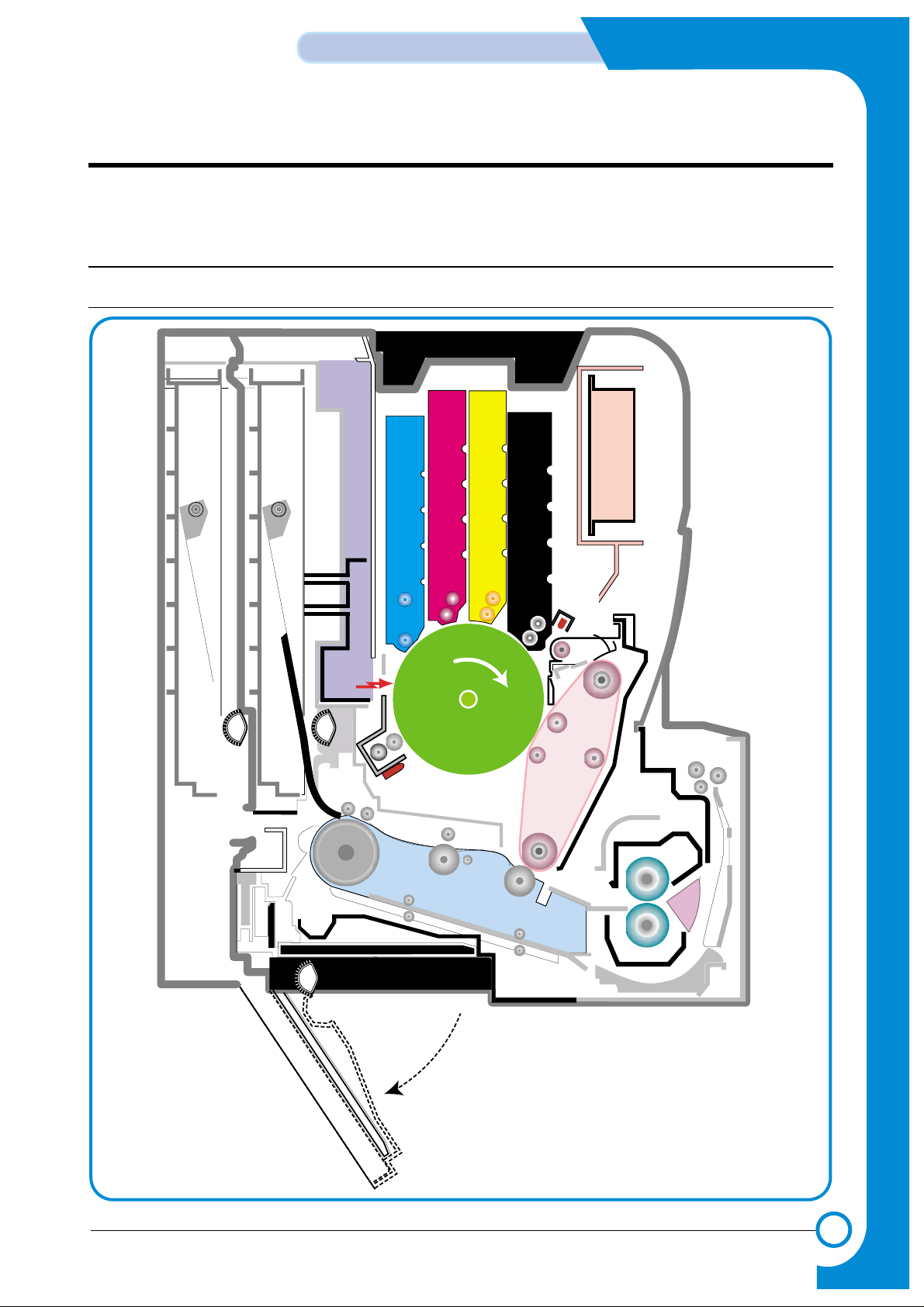

4.1 System Structure

4.1.1 Main Parts of System

HVPS

Eraser LampEraser Lamp

HVPS

DEV. - Black

DEV. - Yellow

OPC

Pick-up

Roller

DEV. - Magenta

DEV. - Cyan

CASSETTE

LSU

ITB Unit

Feeder

DUPLEX

T2 Roller

Fuser Unit

EXIT Unit

MPF Path

MPFMPT

DEV. - Black

DEV. - Yellow

OPC

Pick-up

Roller

DEV. - Magenta

DEV. - Cyan

SCF

SCT

FCT

LSU

Deve CoverDeve Cover

ITB Unit

Feeder

DUPLEX

T2 Roller

Fuser Unit

EXIT Unit

PTL

PTL

SCF Path

Pick-up

Roller

Pick-up

Roller

Pick-up

Roller

Pick-up

Roller

Page 2

4-2

Summary of Product

Samsung Electronics

Service Manual

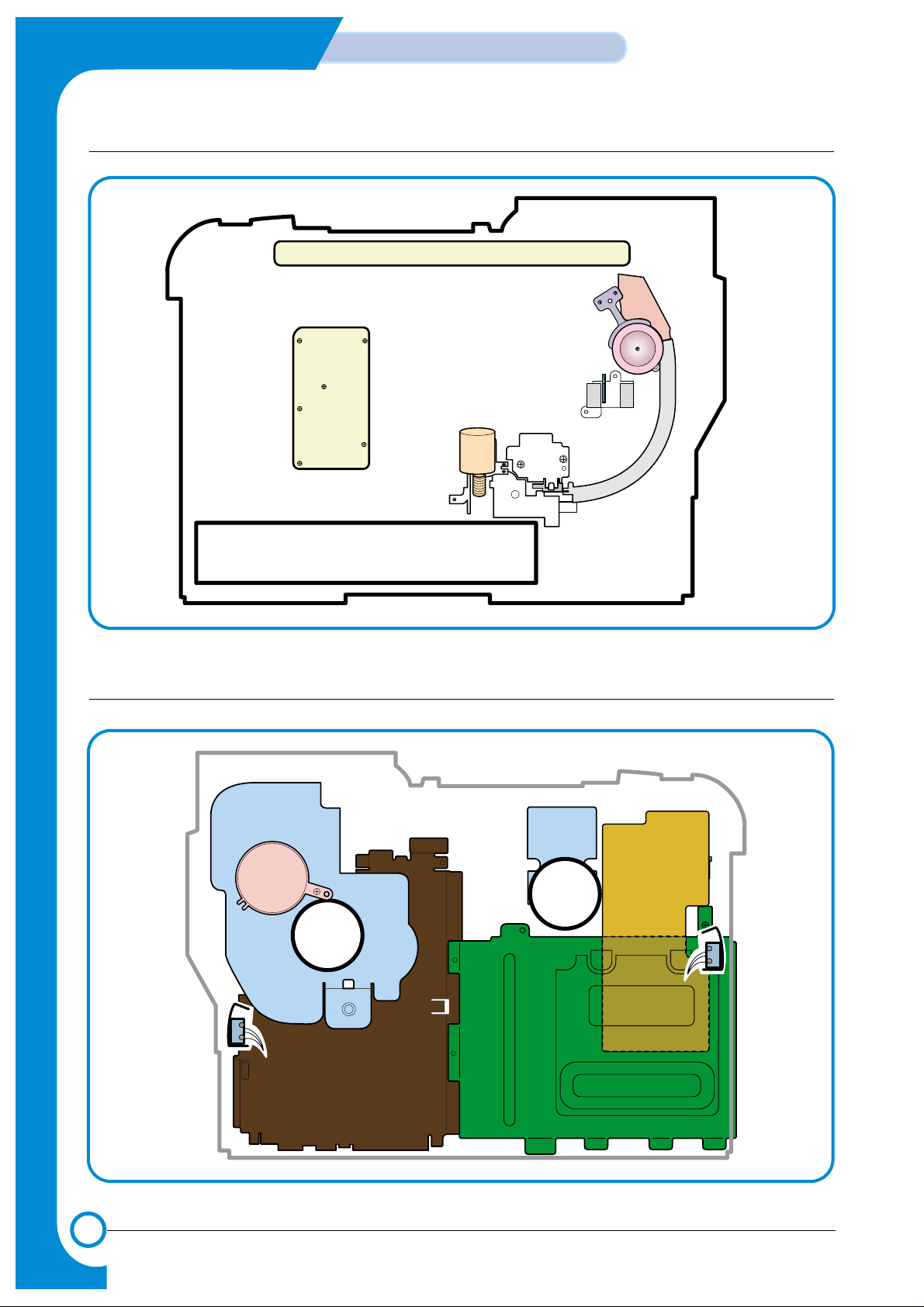

>> Front View

Deve OEM

PBA

Panel PBA

Waster Toner Sensor

Waster Toner Motor

SMPSSMPS

Main DriveMain Drive

Fan Fan

Deve DriveDeve Drive

Deve Drive PBADeve Drive PBA

Duplex Cover

Open S/W

Duplex Cover

Open S/W

Deve Cover

Open S/W

Deve Cover

Open S/W

Main Conrtoller PBAMain Conrtoller PBA

>> Rear View

Page 3

4-3

Samsung Electronics

Summary of product

Service Manual

1) OPC Unit

Images are created on the OPC unit using an electro-photographic process. The unit consists of:* OPC Drum

* Waste Toner Ass'y used to collect waste toner remaining on the OPC drum,

* Charge Roller Assy

2) ITB Unit

ITB stands for Image Transfer Belt. An image developed on the OPC Drum is transferred first to the

ITB. This is called the T1 Transfer (Primary Image Transfer).

Images are built up in layers on the ITB.

First the Yellow (Y) colour image is created on the OPC and transferred to the ITB

Next the Magenta (M) colour image is created on the OPC and transferred to the ITB

Followed by the Cyan (C) and Black (K) images.

3) Transfer Roller

Once the complete, full colour, image, has been built up on the ITB the Transfer Roller is used to

transfer the image onto paper. This is called the T2 Transfer (Secondary Image Transfer)

4) FCT (First Cassette Tray)

It stores and automatically feeds print paper.

Pick-up Roller picks up paper, controls drive, feeds paper, removes static electricity, and so on.

> Spec.

* Paper arrange way : Side Registration

* Paper Direction : FISO (Front-in, Side-Out)

* Cassette Type : A4, Ltr

* Paper Discharge : Separation Claw

* Capacity : 250 Sheets (Standard paper 75mg/m? 20lb)

* Paper Size : A4, Letter

* Paper Weight (average) : 60~90g/m2(16~24lbs)

* Paper Type : General Printing Paper

* Additional Function : Paper Empty Sensor

5) SCT (Second Cassette Tray)

This additionally stores and automatically feeds printing paper. Its function is the same as the FCT

(First Cassette Tray)

> Spec.

* Paper arrangement : Side Registration

* Paper Direction : FISO (Front-in, Side-Out)

* Cassette Type : A4, Ltr

* Paper Discharge : Separation Claw

* Capacity : 500 Sheets (Standard paper 75mg/m220lb)

* Paper Size : A4, Letter

* Paper Weight (average) : 60~90g/m2(16~24lbs)

* Paper Type : General Printing Paper

* Additional Function : Paper Empty Sensor

Page 4

4-4

Summary of Product

Samsung Electronics

Service Manual

6) MPT (Multi Purpose Tray)

The Multi-Purpose Tray not only feeds general printing paper but is also used for many other kinds

of paper such as those paper sizes not supported by the cassette, envelopes, OHP, etc.

> Spec.

* Capacity : Cut Sheet : 100 Sheets (Standard paper 75mg/m220lb)

* OHP : 300 Sheets

* Envelope & Label & Card Stock : 10 Sheets

* Paper Arrangement : Side Registration

* Power : Main Motor (BLDC)

* Driving Management : Solenoid

* Paper Discharge : Friction Pad Method

* Paper Size : Legal, Folio, A4, Letter, Executive, JIS B5, A5, A6

* Paper Weight (Average) : 60~163g/m

2

* Paper Type : General, Label, Post Card, Transparency, Envelope, Card Stock (Tracing

Paper is not served)

* Additional Function : Paper Empty Sensor

7) Feeder

* Paper Arrangement : Side Registration.

* Power : Main Motor (BLDC)

* Paper Management : Solenoid

8) Duplex Unit

The Duplex Unit is used to reverse feed paper when printing on the second side (known as Double

sided or Duplex printing). The Duplex Unit is not an optional extra, it is built-in at manufacturing

time and is integral with the Transfer Roller.

> Spec.

* Power : Main Motor (BLDC)

* Paper Reverse Function: After the front side of the original document is printed, it is transferred

to the duplex unit in order to print the reverse side of original document. The motor drives

the exit roller in the reverse direction to feed the paper back into the machine.

9) Exit Unit

The Exit Unit guides paper that is just about to leave the print engine. Printed-paper is discharged

by the Exit Roller and Kicker into the Output Tray.

> Spec.

* Capacity : 250 sheets (Standard A4, 75g/m2)

* Paper Direction : Face Down

* Exit Drive Roller : It is driven by Main Motor (BLDC), and it rotates clockwise for normal

feed and antic-clockwise when reverse feeding for duplex printing.

* Bin Full Sensor : There is no Bin Full sensor fitted on this model.

10) Toner Cartridge

There are four toner cartridges, each containing a different colour ink : C (Cyan), M (Magenta), Y

(Yellow) , and K (Black).

Each one of these toner cartridge is independent and can be changed independently.

11) Fuser Unit

This unit consists of 2 Heat Lamps, 2 Heat Rollers, 2 Thermostats and a Thermister. It melts and

fuses the toner, transferred by the transfer roller onto the paper, by applying pressure and high

temperature to complete printing job.

12) LSU

This is a core part of LBP. It forms a latent image on the surface of OPC drum using a static

charge.

* Resolution: Real 600 dpi

Page 5

4-5

Samsung Electronics

Summary of product

Service Manual

13) Main Drive Unit

This motor drives, by way of a gearbox, the OPC unit, ITB unit, feeder unit, fuser unit, exit unit and

duplex unit.

> Spec.

* Power : 20W Max (24V)

* Drives : OPC unit, ITB unit, Fuser, Feeder, Duplex unit, Exit unit

14) DEVE Drive Unit

This motor drives, by way of a gearbox, the toner cartridges and ITB cleaning cam.

> Spec.

* Power : 20W Max (24V)

* Drives : DEV (4 Color)/ITB Cleaning)

15) SMPS (Switching Mode Power Supply)

This power supply uses the AC supply voltage to generate the DC voltages used by the system.

The SMPS has 4 output channels (+3.3V, +5V, +24V, +24VF).

The AC Heater Control Unit that supplies power to the fuser is also located on the SMPS.

16) HVPS (High Voltage Power Supply)

The HVPS creates the high voltages (Charger, Supply, T1, T2, Developer) used for the electro

photographic process. The high voltage is created from the 24V line from the SMPS. High Voltage

output is supplied to the toner cartridge, OPC drum unit, ITB unit, and Transfer roller.

17) Main Controller PBA

The Main controller PBA is very important as it is the heart of printer. It has several major function

blocks.

* CPU and SPGPm Block: This manages the printing order from the host, creates bitmap data for

the engine to print and controls various devices that are needed to operate the printer.

*Engine Control Block: This manages images and controls various kinds of I/O

* Memory Block : The operating system uses this to store video data and printing orders given by host.

* ROM Block : The printer OS and PDL Interpreter are stored here.

* In addition there are USB 2.0 Block, IEEE 1284 Block, Option Block, OPE Panel, etc.

18) DEVE Drive PBA

Each toner cartridge requires the HV Supply only when that colour image is being processed. This

unit takes its HV source from the HVPS and using 4 solenoids selects which cartridge is to receive

the Supply voltage. This section also contains the DEVE motor, DEVE clutch, and DEVE solenoid

drives. These are activated in sequence as required by the printing process.

19) DEVE OEM PBA

This detects new or used toner cartridges and also checks that cartridges are approved parts. If a

toner cartridge is not suitable for the machine an error message is displayed.

20) Waste Toner Ass’y

A cleaner blade on the OPC unit cleans waste toner from the OPC drum after every image is

transferred to the ITB. Once the complete image is transferred from the ITB onto paper the ITB

Cleaning Solenoid activates and a cleaning blade removes waste toner from the ITB. Waste toner

is transferred to the waste toner tank.

The error message "Waste Toner Tank Full/ Not Install" is indicated on the LCD Panel. Replace the

Waste Toner Tank immediately or the printer may be damaged

Page 6

4-6

Summary of Product

Samsung Electronics

Service Manual

4.1.2 Motor & Fan Layout

Fan

1. Main Motor

2. DEVE Motor

4. Waste Toner Motor

Fan

1. Main Motor

2. DEVE Motor

4. Waste Toner Motor

NO. Name Description

1 Main Motor Drives the OPC unit, ITB unit, feeder unit, fuser unit, exit unit and

duplex unit.

2. DEVE Motor Drives C, M, Y and K toner cartridges and ITB cleaning cam.

3. Fan Forces cold air into the printer and takes out heat from the fuser.

4. Waste Toner Motor Transfers collected waste toner from the OPC drum and ITB to the

waste toner tank. (Refer to front view picture on 4-2 page)

Page 7

4-7

Samsung Electronics

Summary of product

Service Manual

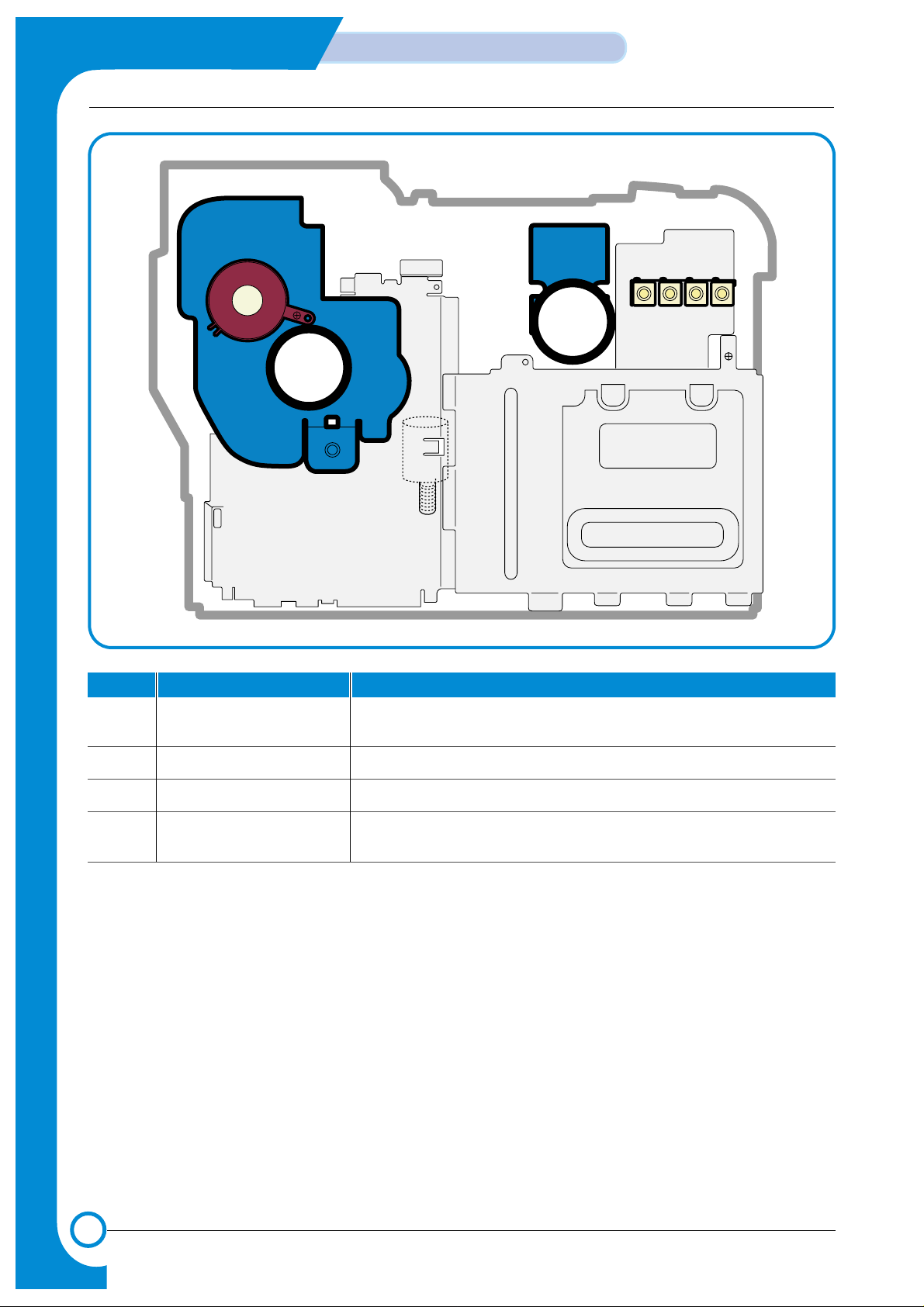

14.1.3 Clutch & Solenoid Layout

>>Solenoid

Cartridge Solenoid(C, M, Y, K)

Duplex Solenoid

ITB Cleaning

Solenoid

Black Deve

Clutch

Black Deve

Clutch

Yellow Deve Clutch

Magenta Deve Clutch

Cyan Deve Clutch

Cartridge Solenoid(C, K, Y, M)

Yellow Deve Clutch

Magenta Deve Clutch

Cyan Deve Clutch

T2 Home SolenoidT2 Home Solenoid

MP Pick_up

Solenoid

MP Pick_up

Solenoid

Feed Regi

Clutch

Pick_up Solenoid

NO. Name Description

1. C DEVE solenoid Controls the High Voltage supply to the cyan cartridge.

2. K DEVE solenoid Controls the High Voltage supply to the black cartridge.

3. Y DEVE solenoid Controls the High Voltage supply to the yellow cartridge..

4. M DEVE solenoid Controls the High Voltage supply to the magenta cartridge.

5. Pick-up solenoid Controls the pick-up roller drive.

6. MP Pick-up solenoid Controls the MP pick-up roller drive.

7. Duplex solenoid When operating in duplex print mode, this reverses the direction

of paper feeding to feed paper into the duplex unit.

8. T2 Home solenoid This forces the transfer roller into contact with the ITB unit.

9. ITB cleaning solenoid This brings the cleaning blade into contact with the ITB unit

Page 8

4-8

Summary of Product

Samsung Electronics

Service Manual

>>Clutch

NO. Name Description

1. Yellow DEVE clutch Controls Yellow color toner cartridge drive

2. Magenta DEVE clutch Controls Magenta color toner cartridge drive

3. Cyan DEVE clutch Controls Cyan color toner cartridge drive

4. Black DEVE clutch Controls Black color toner cartridge drive

5. Feed Regi. Clutch Controls the location of picked-up paper

4.1.4 Sensor & Micro S/W Layout

NO. Name Description

1. Paper Empty Sensor(FCT) This sensor detects paper in the first (main) cassette.

2. Paper Empty Sensor(SCT) This sensor detects paper in the second (optional) cassette.

3. Paper Empty Sensor(MPT) This sensor detects paper in the multi-purpose tray.

4. Feed Sensor This sensor must operate within a certain time after paper pick-

up otherwise a JAM is detected

5. ITB Home Sensor This detects the position of the image transfer belt, and in

dicates the start location for image writing. It is used to ensure

that all 4 colour images are correctly registered.

6. Waste Toner Sensor This detects whether the waste toner tank is mounted or not and

the amount of waste toner in the tank.

7. Exit Sensor This detects whether printing paper is discharged or not.

8. DEVE Cover Open S/W This detects the open/closed status of the DEVE Cover.

9. Duplex Cover Open S/W This detects the open/closed status of the Duplex Cover.

Note: * ITB Home Sensor is located in the ITB unit. If it develops a fault replace the ITB unit.

* Please, refer to the Chap. 7 Arrangement and Adjustment, "Paper Path diagram", for the location

of the paper empty sensor, feed sensor, and exit sensor.

* Please, refer to page 4-2 for the location of the waste toner sensor, DEVE cover open S/W, and

duplex cover open S/W.

Page 9

4-9

Samsung Electronics

Summary of product

Service Manual

4.1.5 Main Controller PBA

USB

CN24

CN27

CN28

CN29

CN30

CN31

CN32

CN33

DUPLEX

CN26

T2 HOME

BLDC1

TH1

FUSER_FAN

SMPS

MP_EMPT

MP SOL

FEED

CN25

PICK_UP

CN23

CLT_FEED

CN21

EMPT

CN1

CN16

SCF

CN12

LSU

CN6

OPC KEY

CN5

DEVE_DRIVERDEVE_DRIVER

CN14

LSU SW

CN17

WASTE TONER & EXIT

CN15

TH3

CN4

PANEL

LAN

CN7

HVPS

CN11

PTL & TH4

CN35

SOL_ITB_CLN

CN38

BLDC2

CN37

OEM_CONN

For Test

CN10

ITB

CN9

NIC

Option : NIC

Page 10

4-10

Summary of Product

Samsung Electronics

Service Manual

RAM

DIMM

SPGPm

Main Control

FLASH MEMORY

OSC2 12MHz

(Reserved)

OSC1

12MHz

LPEC1

(ENGINE CONTROL)

OSC3

23.8807368MHz

U36

(Counter Memory)

Page 11

4-11

Samsung Electronics

Summary of product

Service Manual

USB 2.0

SDRAM

64MB

EEPROM

4k bit

Flash Memory

2MB

NPC / (W-LAN)

Opti onal

Full Function

Engine

Control

Block

LPEC1

SDRAM DIMM

34MB~128MB

SPGPm

Panel

16x2 LCD

5pinUART

1) CPU BLOCK

This is the heart of the machine. A120MHz - 32bit RISC processor is used to manage commands

and data supplied by the host. This is converted into a bitmap image which is passed to the engine

block for printing. The CPU is also used to control various other devices e.g. the USB 2.0 Interface

chip.

2) SPGPm overview

* Package

- 272 pins PBGA

* Power

- 1.8V(Core), 3.3V(IO) power operation

- P1284 inputs : 5V tolerant

* Speed

- 120MHz core(ARM946ES) operation, 60MHz bus operation

- Supportable Engine Speed : under 30ppm

* Dual bus architecture for bus traffic distribution

- AMBAHigh performance Bus (AHB)

- System Bus with SDRAM

* Integrated ARM946ES

- 32-bit RISC embedded processor core

- 16KB instruction cache and 16KB data cache

- No Tightly Coupled Memory

- Memory Protection Unit & CP15 control program

Page 12

4-12

Summary of Product

Samsung Electronics

Service Manual

* Direct connection up to 4 Flash ROM banks

- Burst capability

- Programmable timing per bank

- Up to 16MB address per bank (Limited to 8MB per bank when nDREQ0 is enabled)

* Direct connection up to 6 I/O banks & 4 DMA I/O banks

- Programmable timing per bank

- Programmable recovery timing per bank for slow devices

- Up to 16MB address per bank (Limited to 8MB per bank when nDREQ0 is enabled)

* Direct connection up to 5 SDRAM arrays

- SDRAM controller supports PC-66, PC-100 and PC-133 SDRAMs running at 60MHz

- Up to 128MB per array, up to 512MB totally

- Wide support of various SDRAM configurations, including programmable band and column

address

- Programmable SDRAM refresh time interval

* 4 General Purpose DMA controllers

- Extensible architecture allows peripheral devices such as scan devices to have access to SDRAM

arrays through DMA channels

- 8bits, 16bits and 32bits Data Transfer Modes are supported

- IO to Memory, Memory to IO, Memory to Memory transfer support

* IEEE1284 compliant parallel port interface

- Compatible ECP communications are supported

- Direct support for IEEE1284 compliant data transceivers

* RSH

- Fully Hardware Rotator, Scaler and Halftoner support

- Variable Image Scaler and Image Halftoning Unit for PCL6

- Pattern & Gamma Table Memory : 1024 x 8, 256 x 8 x 4

* Graphic Execution Unit for Banding support of Printer Languages

- Support up to 256 Bit Block Transfer

- Scan Line Transfer

- Polygon Filling

- Enhanced Graphic Order

* Compression / Decompression

- CODEC : Simplified JBIG algorithm for band compression / decompression

- HCT : Halftone Compression Technology (Byte Run-Length Type)

- Independent use of both Codec, but enabling only one Codec is desirable for bus traffic

* UART

- 3 Independent Full Duplex UART channels

- Max 16 bytes FIFO to handle SIR Bit Rate Speed

- DMA support for RX and TX of Channel0

* Printer Video Controller for LBP engines

- 20MHz video rate are targeted

- Two different kinds of Printer Video Controller (Selected by Software)

- PVC : Printer Video Controller without RET Algorithm

- HPVC : Printer Video Controller with RET algorithm

(Line Memory & Lookup Table Memory : 512 x 8 , 4096 x 16)

- High performance DMA based Interface to Printer Engine

- Engine Controller

- Motor Control Unit

- Motor Speed Lookup Table Memory (128 x 16 x 2)

- Pulse Width Modulation Unit

- 4 Channels are supported

- ADC Interface Unit

- 3 ADC Channels are available

- ADC Core (ADC8MUX8) maximum clock frequency : 3 MHz

- Coversion time : 4.3us (@3MHz)

- LSU Interface Unit

Page 13

4-13

Samsung Electronics

Summary of product

Service Manual

* Timer

- 3 Independent Programmable Timers

- Watch Dog Timer for S/W Trap and Tone Generator for MFP Application

* Up to 5 External Interrupts support

- High active interrupt signals

- FIQ/IRQ Interrupt mode selectable

* Ethernet Controller (MAC)

- Full compliance with IEEE standard 802.3, 802.3u specification

- Support 10/100 Mbps data transfer rates

- DMA engine with burst modes (4 words burst and 8 words burst are supported)

* USB 2.0 interface

- USB 1.1 backward compatible

- UDC(USB Device Controller) block and USB Physical block are integrated

- Both of High Speed(480Mbps) and Full Speed(12Mbps) are supported

- 2 DMA channels support : one RX Channel and one TX Channel

- Interrupt transfer support up to 6 Endpoints

- EP0 In/Out (Control transfer), EP1 In/Out (Bulk transfer), EP2 In/Out (Bulk transfer)

* Debug support

- Only MultiICE logic support from ARM9 series

- 5 JTAG connections : TCK, TnRST, TMS, TDI, TDO

- Internal logic for synchronizing TCK and high speed CLK

- Maximum TCK frequency : 20MHz (CLK x 1/6)

Page 14

4-14

Summary of Product

Samsung Electronics

Service Manual

3) Memory Block

The operating program runs from memory (see below). It is used to store video data and printing

jobs from the host. Standard factory fitted memory is 64MB, and can be expanded using a DIMM

module mounted in the SODIMM connector. This is a user fit option, DIMMs from 64Mb - 256MB

can be used giving a total of up to 320MB of memory. DIMM modules are non standard - only

Samsung product should be used.

The memory controller is located in the SPGPm controls the SDRAM memory connected using a

32 bit 60 MHz bus.

4) ROM Block

An 8MB flash ROM is used to store the OS. The ROM controller is contained in the SPGPm

processor. When initializing after power on the contents of ROM are downloaded into memory and

the OS is run from within memory.

5) USB 2.0 Block

A Netchip Co. NET2270 is used to provide support for USB2.0 and is capable of interface speeds

up to 480Mbps. Under control of the SPGPm chip DMA is used to transfer incoming data directly

into memory.

6) IEEE 1284 Block - Korea, Russia and Asia Only

An IEEE 1284 controller is controlled directly by the SPGPm processor. ECP mode is supported.

7) Option Block

An Ethernet card can be attached using the 100 pin connector. It is connected directly to the

SPGPm processor and communicates using a 16bit bus.

8) OPE Panel

The OPE panel is controlled by a UART Block located in the SPGPm and it displays printer status

and helps the user to setup the printer. Various data is transferred using a serial interface between

a Mycom located in the OPE panel and the UART in the SPGPm.

9) Memory

There are two types of memory, program memory that uses flash and a working memory that uses

SDRAM. When printing working memory is used as band memory.

10) Sensor

Various sensors are used to detect various conditions during the printing process. These include

paper empty sensor, feed sensor, exit sensor, ITB sensor, etc.

11) Actuator Control

This section drives the various motors and clutches that are required for the paper feed and printing process. These include DEVE cartridge clutches (4 off), Feed Regi clutch, DEVE solenoids (4

off), Pick solenoids (2 off), Duplex solenoid, ITB and T2 solenoids.

12) ADC

Recognize the current of T1/T2 roll, Recognize the fixing temperature, Recognize the Waste Toner

tank, Recognize the current of Waste agitator DC Motor,Recognize the OPC/ITM key, Recognize

the Developer(Y.M.C.K) key, Recognize the set temperature.

Page 15

4-15

Samsung Electronics

Summary of product

Service Manual

4.1.6 SMPS (Switching Mode Power Supply) PBA

The SMPS unit supplies DC power for driving the whole system, it also contains an AC heater control unit

that supplies power to the fuser.

1) DC output

- Main controller PBA, OP panel, SCF, Developer driver PBA

2) AC output

-Fuser unit (Heat lamp, Thermostat)

3) Output voltage

NO Item CH1 CH2 CH3 CH4

1 Channel name +3.3V +5V +24.0V +24.0VF

2 Rated outputting voltage 3.3V ± 4% +5V ± 4% +24V + 15%/-10% +24V + 15%/-10%

3 Rated outputting crrunt 2.5A 0.5A 1A 2A

4 Uses MICOM,CMOS MICOM,CMOS MOTOR,F AN MOTOR,F AN

LOGIC LOGIC

CON4

CON3

CON1 CON2

CON4

CON3

CON4

CON3

CON1

Fuse

CON2

Page 16

4-16

Summary of Product

Samsung Electronics

Service Manual

4.1.7 HVPS (High Voltage Power Supply) PBA

The HVPS PBA uses the 24V created by the SMPS to generate the high voltages used by the charger,

supply, T1,T2 and DEVE processes. For bests quality images these high voltages must be ,

controlled accurately to maintain the print quality. The high voltages produced are supplied to toner,

OPC cartridge, ITB unit, and transfer roller.

CHARGER (RED)

T1

(BLACK)T2(RED)

SUPPLY (BLACK)

CN1

CN2

T1

T2

SUPPLYSUPPLY

T1

T2

CHARGERCHARGER

CN1CN1

CN2CN2

Page 17

4-17

Samsung Electronics

Summary of product

Service Manual

1) Charging Voltage: Charger

* Function : This high voltage is used to charge the surface of the OPC to about -500volt~800volt.

* Output voltage : -200V~-2.0KV DC +/- 3% (Duty is changeable, no loading)

* Error type :If MHV was not present, the surface of the OPC is not charged. As a result, toner on

the developer roller is transferred over to the OPC drum: therefore, black paper could

be printed out.

2) Transfer high voltage: T1(+)

* Function : This high voltage is used to transfer toner from the OPC drum to the ITB unit.

* Output voltage : +400V~ +3.5KV DC +/- 3% (Duty is changeable, no loading)

* Error type : If T1 was not present, it is not possible to transfer toner from the OPC drum to the

ITB. As a result, printer output could be faint.

3) Transfer High Voltage: T2 (+)

* Function : this high voltage is use to transfer toner from the ITB to the paper.

* Output voltage : +400V~ +5KV DC +/- 3% (Duty is changeable, no loading)

* Error type : If T2 was not present, it is not possible to transfer toner from the ITB to the paper. As

a result, printing output could be faint

4) Cleaning voltage: T2 (-)

* This high voltage is used to transfer (-)toner, remains on transfer roller, from the Transfer Roller

to the ITB unit.

* Output voltage : There is no feedback control, and it outputs a fixed voltage (-900V).

* Error type : Toner contamination occurs on the reverse side of the printed-paper.

5) Supplying voltage: Supply

* Function : Supply the duplicated (AC+DC) voltage from the HVPS to the Deve Drive Board.

* Output voltage

AC Voltage f : 1 KHz ~ 3KHz (Duty is changeable)

AC Voltage V

p-p

: 1KV ~ 3KV

DC : -100V ~ -1000V

* Error type: 1. If this voltage is GND, print density is extremely low.

2. If this voltage is floating due to unstable contact point at the HV terminal, density

becomes so low as that printing results are not visible to the naked eye.

Page 18

4-18

Summary of Product

Samsung Electronics

Service Manual

MEMO

Loading...

Loading...