Rosemount MS Specifications

Product Data Sheet

00813-0100-8780, Rev AB

December 2019

Rosemount™ Slurry Magnetic Flow Meter

Featuring the Rosemount 8782 transmitter and Rosemount

MS Sensor

■

Industry leading performance:

— Standard reference accuracy of 0.25% of rate

— High reference accuracy of 0.15% of rate (optional)

— For complete specifications, see Product Specifications.

■

Rosemount 8782 Transmitter: Wall mount design, backlit display (optional), 15-Button tactile key pad (optional)

■

Available in 4-20mA with HART®, Intrinsically Safe (I.S.) outputs, Process Diagnostics, and Smart™ Meter Verification to improve

reliability and performance

■

Rosemount Magflow Slurry (MS) sensor: Fully welded sensor available for maximum protection

■

Rosemount 8785 Calibration Standard for on-site calibration capabilities, and independent verification of meter calibration

December 2019

Product Overview

The Rosemount Slurry Magnetic Flow Meter is available in a variety of sizes and configurations to ensure compatibility with many

applications and installations.

Appearance Characteristics

8782 Transmitter

MS Sensor

8785 Calibration

Standard

■

Wall mount configuration for wall or pipe mounting

■

HART/Analog and pulse outputs available

■

Process diagnostics and Smart Meter Verification available

■

Local Operator Interface with Display (shown, optional) or LCD Display only (optional)

■

Two discrete channels (optional)

■

Designed for use with the MS sensor, compatible with the 8707 high signal sensor.

■

Magnetic flow meter sensor designed for high solids content, high pulp stock, or slurry flows

■

Flanged process connections

■

Fully welded, sealed coil housing (optional)

■

3 inch (80 mm) to 36 inch (900 mm)

■

Standard, reference, bullet-nose, and flat electrodes available

■

For independent verification of transmitter calibration

■

Suitable for on-site calibration of transmitter

■

Compatible with the 8782 transmitter

Contents

Product Overview.............................................................................................................................................................................. 2

Magnetic Flow Meter Diagnostics...................................................................................................................................................... 3

Magnetic flow meter sizing................................................................................................................................................................4

Ordering Information........................................................................................................................................................................ 7

Product Specifications..................................................................................................................................................................... 22

Product Certifications......................................................................................................................................................................39

Dimensional drawings..................................................................................................................................................................... 40

2 Rosemount™ Slurry Magnetic Flow Meter

December 2019

Magnetic Flow Meter Diagnostics

Rosemount diagnostics reduce cost & improve output by enabling new practices

Rosemount Magnetic Flow Meters provide device diagnostics that detect and warn of abnormal situations throughout the life of

the meter - from installation to maintenance and meter verification. With Rosemount Magnetic Flow Meter diagnostics enabled,

plant availability and throughput can be improved, and costs through simplified installation, maintenance and troubleshooting can

be reduced.

Table 1: Magnetic flow meter diagnostics

Diagnostic name Diagnostic category Product capability

Basic diagnostics

Grounding and Wiring Fault Installation Standard

Empty Pipe Process Standard

Reverse Flow Process Standard

Electrode saturation Installation/process Standard

Transmitter Fault Meter Health Standard

Electronics Temperature Meter Health Standard

Coil Circuit Fault Meter Health Standard

Advanced diagnostics

High Process Noise Process Suite 1 (DS1)

Coated Electrode Detection Process Suite 1 (DS1)

Commanded Smart Meter Verification Meter Health Suite 2 (MV)

Continuous Smart Meter Verification Meter Health Suite 2 (MV)

4-20 mA Loop Verification Installation Suite 2 (MV)

Options for accessing diagnostics

Rosemount magnetic flow meter diagnostics can be accessed through the Local Operator Interface (LOI), ProLink® III Software, a

HART Communicator (including AMS Trex Device Communicator), and AMS Device Manager. Contact an Emerson Flow

representative (see back page) to activate diagnostics or for diagnostic availability on existing transmitters.

Access diagnostics through the LOI for quick installation, maintenance, and meter verification

Rosemount magnetic flow meter diagnostics are available through the LOI to simplify maintenance.

Access diagnostics through ProLink III Software

Simplify maintenance and troubleshooting practices by utilizing ProLink III Software to access diagnostics and troubleshooting

information, log variable data, run Smart Meter Verification, and print verification reports.

www.emerson.com/Rosemount 3

Velocity =

Flow Rate

Factor

Velocity =

300 (gpm)

39.679

Velocity = 7.56 ft/s

Velocity =

800 (L/min)

492.78

Velocity = 1.62 m/s

December 2019

Magnetic flow meter sizing

Selecting the appropriate sensor size is an important step when considering a magnetic flow meter. The physical properties of the

process fluid, as well as the fluid velocity should be considered. It may be necessary to select a flow sensor that is larger or smaller

than the adjacent piping to ensure the fluid velocity is in the recommended flow range for the application.

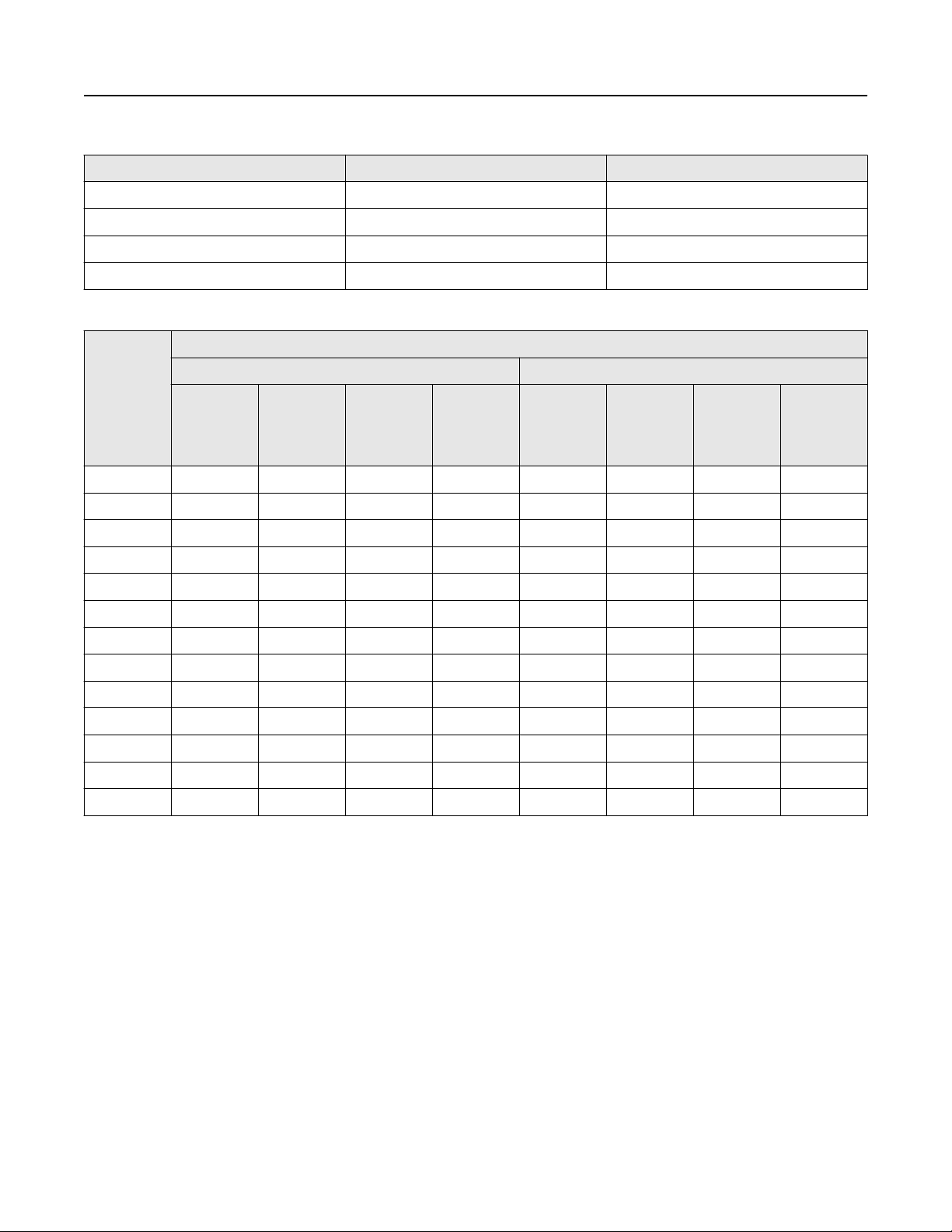

Table 2: Sizing guidelines

Application Velocity range (ft/s) Velocity range (m/s)

Full Range –39 to +39 –12 to +12

Preferred Service 2 to 20 0.6 to 6.1

Abrasive Slurries 3 to 10 0.9 to 3.1

Non-Abrasive Slurries 5 to 15 1.5 to 4.6

Note

Operation outside these guidelines may also give acceptable performance.

To convert flow rate to velocity, use the appropriate factor listed in Table 3 and the following equation:

Example: English units Example: SI units

Magmeter Size: 4 in. (factor from Table 3 = 39.679) Normal

Flow Rate: 300 GPM

Magmeter Size: 100 mm (factor from Table 3 = 492.78)Normal

Flow Rate: 800 L/min

Table 3: Line size vs. conversion factor

Nominal line size—Inches (mm) Gallons per minute factor Liters per minute factor

3 (80) 23.042 286.17

4 (100) 39.679 492.78

6 (150) 90.048 1,118.3

8 (200) 155.93 1,936.5

10 (250) 245.78 3,052.4

12 (300) 352.51 4,378.0

14 (350) 421.70 5,237.3

16 (400) 550.80 6,840.6

18 (450) 697.19 8,658.6

4 Rosemount™ Slurry Magnetic Flow Meter

December 2019

Table 3: Line size vs. conversion factor (continued)

Nominal line size—Inches (mm) Gallons per minute factor Liters per minute factor

20 (500) 866.51 10,761

24 (600) 1,253.2 15,564

30 (750) 2006.0 24,913

36 (900) 2,935.0 36,451

Table 4: Line size vs. velocity/rate

Nominal

line size in

inches

(mm)

3 (80) 0.922 23.042 69.13 907.17 3.434 85.85 286.17 3,434.0

4 (100) 1.587 39.679 119.04 1,562.2 5.913 147.84 492.78 5,913.4

6 (150) 3.602 90.048 270.14 3,545.2 13.42 335.50 1,118.3 13,420

8 (200) 6.237 155.93 467.79 6,138.9 23.24 580.96 1,936.5 23,238

10 (250) 9.831 245.78 737.34 9,676.3 36.63 915.73 3,052.4 36,629

12 (300) 14.10 352.51 1,057.5 13,878 52.54 1,313.4 4,378.0 52,535

14 (350) 16.87 421.71 1,265.1 16,603 62.85 1,571.2 5,237.3 62,848

16 (400) 22.03 550.80 1,652.4 21,685 82.09 2,052.2 6,840.6 82,087

18 (450) 27.89 697.19 2,091.6 27,448 103.90 2,597.6 8,658.6 103,903

20 (500) 34.66 866.51 2,599.5 34,114 129.14 3,228.4 10,761 129,137

24 (600) 50.13 1,253.2 3,759.6 49,339 186.77 4,669.2 15,564 186,769

30 (750) 80.24 2,006.0 6,018.0 78,976 298.96 7,474.0 24,913 298,959

Minimum/maximum flow rate

Gallons per minute Liters per minute

at 0.04 ft/s

(low-flow

cutoff)

at 1 ft/s

(min range

setting)

at 3 ft/s at 39.37 ft/s

(max range

setting)

at 0.012

m/s

(low-flow

cutoff)

at 0.3 m/s

(min range

setting)

at 1 m/s at 12 m/s

(max range

setting)

36 (900) 117.40 2,935.0 8,805.1 115,553 437.42 10,935 36,451 437,416

www.emerson.com/Rosemount 5

December 2019

Upstream and downstream piping

To ensure specified accuracy over widely varying process conditions, it is recommended to install the sensor with a minimum of five

straight pipe diameters upstream and two pipe diameters downstream from the electrode plane.

Figure 1: Upstream and downstream straight pipe diameters

A

C

A. Five pipe diameters (upstream)

B. Two pipe diameters (downstream)

C. Flow direction

Installations with reduced upstream and downstream straight runs are possible. In reduced straight run installations, the meter

may not meet accuracy specifications. Reported flow rates will still be highly repeatable.

B

Sensor process reference grounding

In addition to grounding required by applicable safety/electrical standards or codes, a reliable process reference ground path is

required between the sensor and the process fluid. Optional grounding rings, process reference electrode, and lining protectors are

available with the sensor to ensure proper process reference grounding. See Table 5 and Table 6.

6 Rosemount™ Slurry Magnetic Flow Meter

December 2019

Ordering Information

Rosemount 8782 transmitter

The Rosemount 8782 Transmitter with “Best in Class” performance, coupled with advanced diagnostics, provides unparalleled

process management capabilities. An optional backlit 2-line by 16-character display/local operator interface is available. The

transmitter can be configured using the 15 button tactile keypad.

Note

The starred (★) offerings represent standard options, and should be selected for best delivery.

Ordering information

Example model code with one selection out of each category: 8782AW 1 A 1 N5 DS2 AX M4 B6 C1 D1 Q4 RT05

Table 5: Requirements - select one from each available choice

Code Description

8782 Magnetic Flow Meter Slurry Transmitter

Transmitter revision level

A Revision Level A ★

Transmitter mount

W Remote wall mount ★

Power supply

1 AC power supply (90–250VAC, 50/60Hz) ★

2 DC power supply (12–42VDC) ★

Outputs

A 4–20mA output with Digital HART Protocol and scalable pulse output ★

(1)

B

Conduit entry

1 ½–14 NPT ★

(2)

2

4–20mA intrinsically safe output with Digital HART Protocol and scalable intrinsically safe pulse

output

M20–1.5 ★

★

www.emerson.com/Rosemount 7

December 2019

Table 5: Requirements - select one from each available choice (continued)

Code Description

Safety approvals

NH Ordinary locations (non-hazardous) ★

ND ATEX dust ★

NF IECEx dust ★

(3)

N1

N5 North America approvals, Class I Div 2, non-incendive and dust ★

(3)

N7

(1)

Intrinsically safe outputs must be externally powered.

(2)

M20–1.5 connections provided with an adapter.

(3)

DC power only.

Table 6: Options – Not required, but must be included in the model number if desired

Code Description

Meter verification

MV Smart Meter Verification Professional ★

ATEX non-sparking and dust ★

IECEx non-sparking and dust ★

Advanced diagnostics

DS1 Process diagnostics; high process noise; electrode coating ★

Discrete input/discrete output

AX Two discrete channels (DI/DO 1, DO 2) ★

Display

M4 Local operator interface with display ★

M5 Local display only ★

Mounting bracket

B6 316 stainless steel 4-bolt kit and for 2 inch pipe mount ★

Software configuration

C1 Custom configuration (completed CDS form required with order) ★

Calibration accuracy

(1)

D1

High accuracy calibration

Quality certificate

Q4 Calibration data, per ISO 10474 3.1B / EN 10204 3.1 ★

Remote cable kit

RTxx Standard temperature component cables (-20°C to 75°C)

For xx: 01 = 10 ft, 02 = 20 ft, 03 = 30 ft, 04 = 40 ft, 05 = 50 ft, 10 = 100 ft, 15 = 150 ft, 20 = 200 ft, 25

= 250 ft, 50 = 500 ft

★

RHxx Extended temperature component cables (-50°C to 125°C)

★

For xx: 01 = 10 ft, 02 = 20 ft, 03 = 30 ft, 04 = 40 ft, 05 = 50 ft, 10 = 100 ft, 15 = 150 ft, 25 = 250 ft, 50

= 500 ft

8 Rosemount™ Slurry Magnetic Flow Meter

December 2019

Table 6: Options – Not required, but must be included in the model number if desired (continued)

Code Description

Quick Start Guide language

YF French

YG German

YI Italian

YM Chinese–Mandarin

YP Portuguese–Brazil

YR Russian

YS Spanish

(1)

The high accuracy calibration requires the transmitter and sensor to be ordered together and paired during calibration. Spare or replacement

transmitters ordered with the D1 option will receive standard calibration.

www.emerson.com/Rosemount 9

December 2019

Rosemount MS sensor

All sensors are fabricated from stainless and carbon steel and welded and sealed to protect against moisture and other

contaminants. Sizes range from 3 inch (80 mm) to 36 inch (900 mm). The sealed housing ensures maximum sensor reliability by

protecting all internal components and wiring from the most hostile environments.

Note

The starred (★) offerings represent standard options, and should be selected for best delivery.

Model code structure

Example model code with one selection out of each category: MS 060 A R 1 T S A C A 1 M0 NH D2

After selecting the requirements in Table 7, options can be selected as needed from Table 8.

Ordering requirements and options

Table 7: Requirements

Code Description

Base model

MS Base model

Line size/Liner availability ("✔" = available)

Code Line size ★ PTFE

code T

030 3 inch (80 mm) ★ ✔ ✔ ✔ ✔ ✔ ✔

040 4 inch (100 mm) ★ ✔ ✔ ✔ ✔ ✔ ✔

060 6 inch (150 mm) ★ ✔ ✔ ✔ ✔ ✔ ✔

080 8 inch (200 mm) ★ ✔ ✔ ✔ ✔ ✔ ✔

100 10 inch (250 mm) ★ ✔ ✔ ✔ ✔ ✔ ✔

120 12 inch (300 mm) ★ ✔ ✔ ✔ ✔ ✔ ✔

140 14 inch (350 mm) ✔ ✔ ✔ ✔ ✔

160 16 inch (400 mm) ✔ ✔ ✔ ✔

Poly

code P

Neoprene

code N

Linatex

code L

Adiprine

code D

PFA+

code K

180 18 inch (450 mm) ✔ ✔ ✔ ✔

200 20 inch (500 mm) ✔ ✔ ✔ ✔

240 24 inch (600 mm) ✔ ✔ ✔ ✔

300 30 inch (750 mm) ✔ ✔ ✔ ✔

360 36 inch (900 mm) ✔ ✔ ✔ ✔

10 Rosemount™ Slurry Magnetic Flow Meter

December 2019

Table 7: Requirements (continued)

Code Description

Revision level

A Revision level A ★

Mounting configuration

R Remote mount ★

Conduit entries

1 ½ –14 NPT ★

2 M20 – 1.5 ★

Lining material

(1)

T PTFE. Available in the following line sizes:

3 inch to 24 inch (80 mm to 600 mm) ASME Class 150, Class 300, Class 600 (derated), and EN

1092-1

30 inch and 36 inch (750 mm and 900 mm) Class 150 and Class 300

P Polyurethane. Available in the following line sizes:

3 inch to 24 inch (80 mm to 600 mm) ASME Class 150, Class 300, and EN 1092-1, PN16 and PN25

30 inch and 36 inch (750 mm and 900 mm) Class 150

3 inch to 18 inch (80 mm to 450 mm) ASME Class 600, EN1092-1 PN40

3 inch to 12 inch (80 mm to 300 mm) ASME Class 900

3 inch to 10 inch (80 mm to 250 mm) ASME Class 1500, Class 2500

N Neoprene. Available in the following line sizes:

3 inch to 24 inch (80 mm to 600 mm) ASME Class 150, Class 300, Class 600 (fully rated) and EN

1092-1

30 inch and 36 inch (750 mm and 900 mm), Class 150, Class 300

3 inch to 20 inch (80 mm to 500 mm) ASME Class 900

3 inch to 12 inch (80 mm to 300 mm) ASME Class 1500

3 inch to 8 inch (80 mm to 200 mm) ASME Class 2500

36 inch (900 mm) EN 1092-1 PN10 and PN16

L Linatex - natural rubber. Available in the following line sizes:

3 inch to 24 inch (80 mm to 600 mm) ASME Class 150, Class 300, Class 600 (fully rated) and EN

1092-1

30 inch and 36 inch (750 mm and 900 mm), Class 150, Class 300

3 inch to 20 inch (80 mm to 500 mm) ASME Class 900

3 inch to 12 inch (80 mm to 300 mm) ASME Class 1500

3 inch to 8 inch (80 mm to 200 mm) ASME Class 2500

36 inch (900 mm) EN 1092-1 PN10 and PN16

★

★

★

D Adiprene. Available in the following line sizes:

3 inch to 12 inch (80 mm to 300 mm) ASME Class 150, Class 300, Class 600, and Class 900

3 inch to 10 inch (80 mm to 250 mm) EN1092-1

3 inch to 8 inch (80 mm to 200 mm) ASME Class 1500, Class 2500

K PFA+. Available in line sizes 3 inch to 14 inch (80 mm to 350 mm) ASME Class 150, Class 300, and

EN 1092-1 Flanges.

www.emerson.com/Rosemount 11

December 2019

Table 7: Requirements (continued)

Code Description

Electrode material

S 316L stainless steel ★

H Nickel alloy 276 (UNS N10276) ★

P 80% platinum - 20% iridium ★

N Titanium ★

W Tungsten-carbide coated 316L ★

Y Tungsten-carbide coated nickel alloy 276

Electrode type

A 2 Measurement electrodes - standard ★

(2)

B

T 2 Measurement electrodes - flat head

E 2 Measurement electrodes plus 1 reference electrode - standard ★

(2)

F

2 Measurement electrodes - bulletnose ★

2 Measurement electrodes plus 1 reference electrode - bulletnose ★

U 2 Measurement electrodes plus 1 reference electrode - flat head

Flange material

C Carbon steel ★

S 304/304L stainless steel ★

P 316/316L stainless steel

Flange type

A Slip-on raised face ★

B Slip-on flat face

C Weld-neck raised face

D Weld-neck flat face

E Weld-neck RTJ groove

(3)

G

Grooved coupling ★

12 Rosemount™ Slurry Magnetic Flow Meter

December 2019

Table 7: Requirements (continued)

Code Description

Flange rating

1 Class 150:

ASME B16.5, 3 to 24 inch

Mod MSS-SP44, 30 and 36 inch with Slip-on flange

ASME B16.47 Series A, 30 and 36 inch with Weld-neck flange

3 Class 300:

ASME B16.5, 3 to 24 inch

Mod MSS-SP44, 30 and 36 inch with Slip-on flange

ASME B16.47 Series A, 30 and 36 inch with Weld-neck flange

6 ASME B16.5, Class 600 (maximum working pressure: derated 1000 psig)

7 ASME B16.5, Class 600

(4)

9

(4)

M

(4)

N

ASME B16.5, Class 900

ASME B16.5, Class 1500

ASME B16.5, Class 2500

D EN 1092-1, PN10

E EN 1092-1, PN16 ★

F EN 1092-1, PN25

H EN 1092-1, PN40 ★

K AS2129, Table D

L AS2129, Table E

(5)

P

(5)

R

(6)

T

JIS B 2220, 10K

JIS B 2220, 20K

JIS B 2220, 40K

★

★

U AS4087, PN16

W AS4087, PN21

Y AS4087, PN35

Coil housing configuration

M0 Sealed, welded housing:

★

Potted terminal block with NH approval

Field replaceable terminal block with Nx Approval

Field replaceable socket module with Kx Approval

(7)

M1

Sealed, welded housing with pressure relief port and field replaceable socket module

M2 Sealed, welded housing with sealed electrode compartments and field replaceable socket module

M4 Sealed, welded housing with sealed electrode compartments with port and field replaceable socket

module

www.emerson.com/Rosemount 13

December 2019

Table 7: Requirements (continued)

Code Description

Safety approval

NH Ordinary locations - (non-hazardous) ★

ND ATEX dust ★

NF IECEx dust ★

N1 ATEX Non-Sparking, Increased Safety (Ex ec) with Intrinsically Safe Electrodes; ATEX dust ★

N5 North America approvals, Class I Div 2, non-incendive with Intrinsically Safe electrodes and dust ★

N7 IECEx Non-Sparking, Increased Safety (Ex ec) with Intrinsically Safe Electrodes; IECEx dust ★

K1 ATEX increased safety (Ex eb) with intrinsically safe electrodes; ATEX dust

K6 North America Class I Zone 1 with Intrinsically Safe Electrodes; dust

K7 IECEx increased safety (Ex eb) with intrinsically safe electrodes; IECEx dust

(1)

Availability based on line size and flange type/rating. See Table 9 (slip on flanges) and Table 10 (weld neck). Consult an Emerson Flow

representative (see back page) for availability with AS or JIS flanges.

(2)

Not available in Tantalum.

(3)

Grooved Coupling is only available with flange codes SG1 or PG1 in line sizes 3 inch to 10 inch (80mm to 250mm); not available with grounding

rings or lining protectors. See Table 22 for Maximum Working Pressure.

(4)

Not available with lining protectors.

(5)

Available line sizes 3 inch to 24 inch (80 mm to 600 mm); not available with lining protectors.

(6)

Available line sizes 3 inch to 16 inch (80 mm to 400 mm); not available with lining protectors.

(7)

Pressure relief valve must be installed appropriately to maintain the approvals on the meter. Recovery piping diameter must not be smaller than

M6 to avoid building pressure after the valve.

Options

Note

These are not required, but they must be included in the model number if desired.

14 Rosemount™ Slurry Magnetic Flow Meter

December 2019

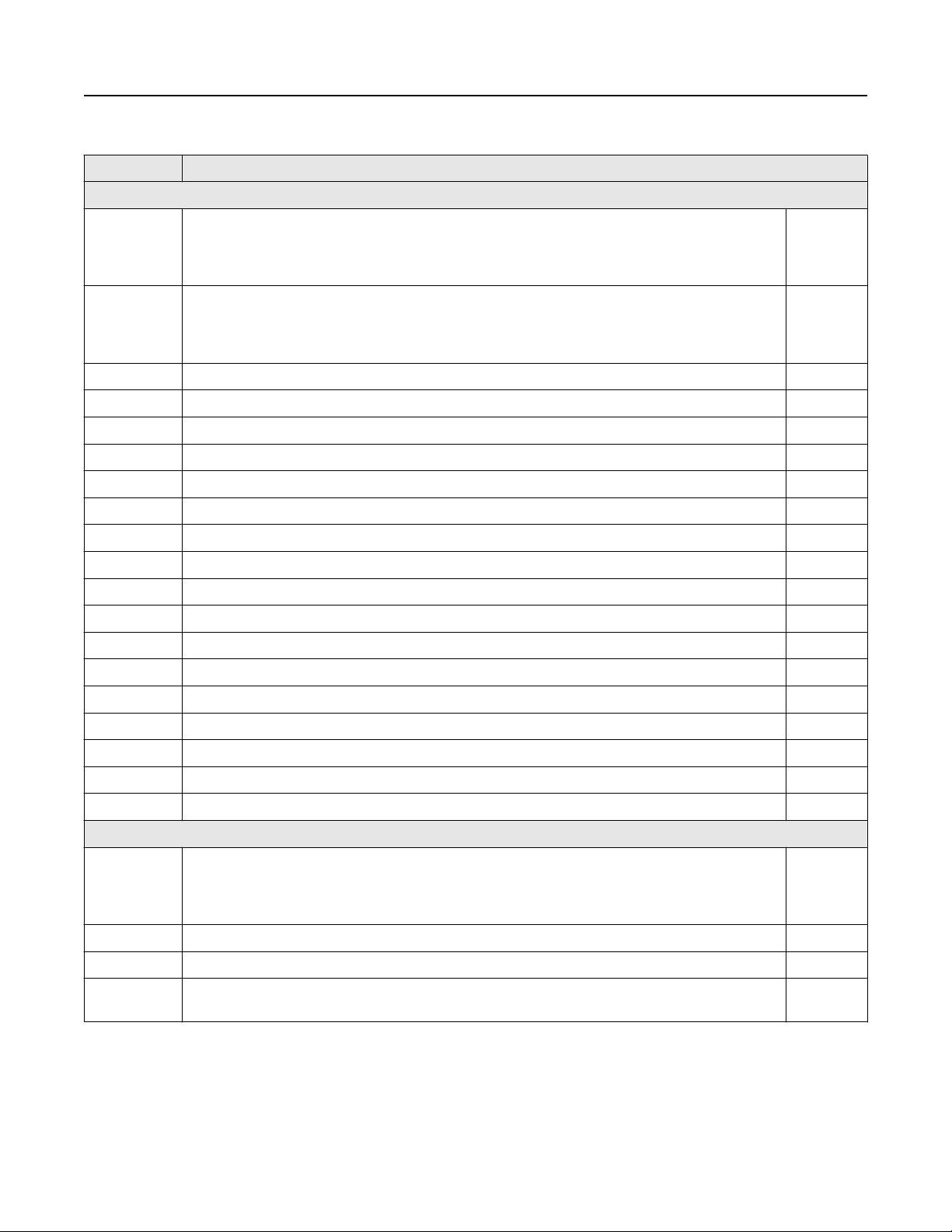

Table 8: Options

Code Description

Grounding rings or lining protectors

G1 (2) 316L SST ground rings ★

G2 (2) Nickel alloy 276 (UNS N10276) ground rings ★

G3 (2) Titanium ground rings

G4 (2) Tantalum ground rings

G5 (1) 316L SST ground ring ★

G6 (1) Nickel alloy 276 (UNS N10276) ground ring ★

G7 (1) Titanium ground ring

G8 (1) Tantalum ground ring

L1 (2) 316L SST lining protectors ★

L2 (2) Nickel alloy 276 (UNS N10276) lining protectors

L3 (2) Titanium lining protectors

L5 (1) 316L SST lining protector ★

(1)

L6 (1) Nickel alloy 276 (UNS N10276) lining protector

L7 (1) Titanium lining protector

Special lay length

(2)

H2 8701 lay length

H4 ISO lay length

Calibration option

(3)

D1

High accuracy calibration (0.15% of rate for matched sensor and transmitter).

Dual calibration option

D2 Dual calibration at 500 mA and 2A

Quality certificate

Q4 Calibration certificate per ISO 10474 3.1B/EN 10204 3.1 ★

Q5 Hydrostatic test certificate ★

Q8 Material traceability per ISO 10474 3.1B/EN 10204 3.1 ★

Q25 Certificate of compliance to NACE MR0175 and MR0103 ★

Q66 Weld procedure package (weld map, weld procedure specification, weld procedure

qualification record, welder performance qualification)

Q70 NDE weld examination inspection certificate, ISO 10474 3.1B

(4)

Q71

NDE weld examination inspection certificate, ISO 10474 3.1B with images

★

Q76 Positive material identification (PMI) on flanges and pipe, per ASTM E1476-97

Q77 Positive Material Identification (PMI) with Carbon Content on Flange and Pipe per ASTM

E1476-97

www.emerson.com/Rosemount 15

December 2019

Table 8: Options (continued)

Code Description

Enhanced corrosion resistance options

(5)

SJ

(5)

SH

European Pressure Equipment Directive

PD European Pressure Equipment Directive (PED) certification ★

Special paint

V1 Coal tar paint

V2 Offshore/near shore marine paint (3 layer epoxy)

Canadian registration number

CR Canadian Registration Number (CRN) certification ★

Non-standard calibration verification

(6)

P05

(7)

P10

316 SST remote junction box

316 SST coil housing and remote junction box

5 Point calibration verification

10 Point calibration verification

Dual seal

DS Dual seal per ISA/ANSI 12.27.01

Witness

WG Witness inspection

Quick Install Guide language

YF French ★

YG German ★

YI Italian ★

YM Chinese–Mandarin ★

YP Portuguese–Brazil ★

YR Russian ★

YS Spanish ★

(1)

Grounding Rings and Lining Protectors provide the same process reference function.

(2)

Consult Technical Support for Special Lay Length availability; Lining material and flage type/rating dependent.

(3)

The high accuracy calibration requires the transmitter and sensor to be ordered together and paired during calibration. Spare or replacement

sensors ordered with the D1 option will receive standard calibration.

(4)

Weld-Neck only.

(5)

Not available with US/Canadian Approval N5.

(6)

Available for: 3 inch to 24 inch (80 mm to 600 mm) Velocities 1, 3, 5, 7, 10 ft/s; 30 inch (700 mm) Velocities 1, 3, 5, 7, 8 ft/s; 36 inch (900 mm)

Velocities 1, 2, 3, 5, 6 ft/s.

(7)

Available for: 3 inch to 24 inch (80 mm to 600 mm) Velocities 1, 2, 3, 4, 5, 6, 7, 8, 9, 10 ft/s; 30 inch to 36 inch (700 mm to 900 mm) not

available.

16 Rosemount™ Slurry Magnetic Flow Meter

ASME Class 150

ASME Class 300

ASME Class 600 Derated

ASME Class 600 Full Rated

ASME Class 900

AS2129 Table D

AS2129 Table E

AS4087 PN16

AS4087 PN21

AS4087 PN35

ASME Class 150

ASME Class 300

ASME Class 600 Derated

ASME Class 600 Full Rated

ASME Class 900

ASME Class 1500

ASME Class 2500

December 2019

Slip on flanges

Table 9: Slip on flange options by line size

Flange code and rating

1 3 6 7 9 D E F H K L P R T U W Y

Size

code

030 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

040 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

060 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

080 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

100 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

120 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

140 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

160 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

180 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

200 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

240 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

300 ✔

360 ✔

(1)

Modified MSS-SP44.

(1)✔(1)

(1)✔(1)

✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔

Weld neck flanges

Table 10: Weld neck flange options by line size

Flange code and rating

1 3 6 7 9 D E F H M N

Size code

030 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

040 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

060 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

www.emerson.com/Rosemount 17

ASME Class 150

ASME Class 300

ASME Class 600 Derated

ASME Class 600 Full Rated

ASME Class 900

ASME Class 1500

ASME Class 2500

December 2019

Table 10: Weld neck flange options by line size (continued)

Flange code and rating

1 3 6 7 9 D E F H M N

Size code

080 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

100 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

120 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

140 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

160 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

180 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

200 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

240 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

300 ✔

360 ✔

(1)

ASME B16.47 Series A.

(1)

(1)

(1)

✔

(1)

✔

✔ ✔

18 Rosemount™ Slurry Magnetic Flow Meter

December 2019

Rosemount 8785 Slurry Calibration Standard

Table 11: Rosemount 8785 Slurry Calibration Standard ordering information

Model Product

8785 Slurry Magnetic Flow Meter Calibration Standard

Transmitter revision level

A Revision level A

Calibrator version

1 Standard version for use with the 8782 Slurry Transmitter

Quality certificate

Q4 Calibration data per ISO 10474 3.1B/EN 10204 3.1

www.emerson.com/Rosemount 19

Ordering flowmeter equipment

Ordering procedure

To order, select the desired sensor and/or transmitter by specifying model codes from the ordering table.

Note the cable specification requirements.

Standard configuration

Unless the Configuration Data Sheet is completed, the transmitter will be shipped as follows:

Engineering units: ft/sec

4mA: 0

20mA: 30

Sensor size: 3-in.

Empty pipe: On

Sensor calibration number: 1000085010000000

Custom configuration (option code C1)

If Option Code C1 is ordered, the Configuration Data Sheet (CDS) must be submitted at the time of order.

December 2019

Standard tagging

Instrument tags for the transmitter and sensors are as follows:

■

316SST laser etched label, permanently attached

■

Main label - Tag name: 1 line 21characters

■

Additional 316SST 'wire-on' tag available: 5 lines, 17 characters per line (6mm height)

Interconnecting cable

Interconnecting cables are required to connect a remote mount transmitter to the sensor. When ordering cable, review the

hazardous area approval requirements and the installation location requirements for proper cable selection.

■

Cables can be ordered as part of the transmitter model number or as a spare parts kit.

■

Individual component cables require equal lengths of coil drive cable and electrode cable and should be limited to less than 330

feet (100 m). Consult an Emerson Flow representative (see back page) for lengths between 330-1000 feet (100-300 m).

20 Rosemount™ Slurry Magnetic Flow Meter

December 2019

Component cable kits

Standard temp (-20 °C to 75 °C)

Cable kit # Description Component Rosemount p/n Alpha p/n

08732-0065-0001

(feet)

08732-0065-0002

(meters)

08732-0065-0003

(feet)

08732-0065-0004

(meters)

Extended temp (-50 °C to 125 °C)

Cable kit # Description Component Rosemount p/n Alpha p/n

08732-0065-1001

(feet)

08732-0065-1002

(meters)

08732-0065-1003

(feet)

Kit, Component Cables,

Std Temp, (includes Coil

and Electrode)

Kit, Component Cables,

Std Temp (includes Coil

and Electrode)

Kit, Component Cables,

Std Temp (includes Coil

and I. S. Electrode)

Kit, Component Cables,

Std Temp (includes Coil

and I. S. Electrode)

Kit, Component Cables,

Ext Temp (includes Coil

and Electrode)

Kit, Component Cables,

Ext Temp (includes Coil

and Electrode)

Kit, Component Cables,

Ext Temp (includes Coil

and I. S. Electrode)

Coil 08732-0060-0001 2442C

Electrode 08732-0061-0001 2413C

Coil 08732-0060-0002 2442C

Electrode 08732-0061-0002 2413C

Coil 08732-0060-0001 2442C

I. S. Electrode 08732-0061-0003 Not available

Coil 08732-0060-0002 2442C

I.S. Electrode 08732-0061-0004 Not available

Coil 08732-0060-1001 Not available

Electrode 08732-0061-1001 Not available

Coil 08732-0060-1002 Not available

Electrode 08732-0061-1002 Not available

Coil 08732-0060-1001 Not available

I. S. Electrode 08732-0061-1003 Not available

08732-0065-1004

(meters)

Kit, Component Cables,

Ext Temp (includes Coil

and I. S. Electrode)

Coil 08732-0060-1002 Not available

I.S. Electrode 08732-0061-1004 Not available

www.emerson.com/Rosemount 21

December 2019

Product Specifications

Rosemount 8782 Slurry Magnetic Flow Meter Platform Specifications

The tables below outline some of the basic performance, physical, and functional specifications of the Rosemount 8782 Slurry

Magnetic Flow Meter platform.

■

Table 12 provides an overview of the Rosemount 8782 Transmitter.

■

Table 13 provides an overview of the Rosemount MS Sensor.

Table 12: Rosemount 8782 Slurry transmitter specifications

Model 8782

Base accuracy

Mounting Remote

Power supply Global AC or DC

User interface LCD display with 15 button tactile keypad

(1)

0.25% Standard 0.15% High Accuracy Option

LCD display only

No display

Communication protocol HART 7

Diagnostics Basic, MV, DS1

Sensor compatibility Rosemount MS and 8707 sensors only

Detailed specifications Transmitter specifications

Ordering information Rosemount 8782 transmitter

(1)

For complete accuracy specifications, please refer to Transmitter functional specifications.

Table 13: Rosemount MS Sensor Specifications

Model MS

Style Flanged

Base accuracy

Line sizes 3 inch to 36 inch (80 mm to 900 mm)

Design features Standard process design

Transmitter compatibility Rosemount 8782, 8732EM, and 8712EM

Detailed specifications MS Sensor Specifications

Ordering information Rosemount MS sensor

(1)

For complete accuracy specifications, refer to the sensor detailed specifications.

(1)

0.25% Standard 0.15% High Accuracy Option

22 Rosemount™ Slurry Magnetic Flow Meter

December 2019

Table 14: Lining Material Selection

Liner material General characteristics

PFA+ Best permeation resistance

Best chemical resistance

Better abrasion resistance than PTFE

Best high temperature capabilities

Excellent for pulp and paper, or liquor applications

Process temperature: -58 to 350 °F (-50 to 177 °C)

PTFE Highly chemical resistant

Excellent high temperature capabilities

Process temperature: -58 to 350 °F (-50 to 177 °C)

Polyurethane Limited chemical resistance

Excellent abrasion resistance for slurries with small and medium particles

Process temperature: 0 to 140 °F (-18 to 60 °C)

Typically applied in clean water

Neoprene Very good abrasion resistance for small and medium particles

Better chemical resistance than polyurethane

Typically applied in water with chemicals, and sea water

Preferred liner for high pressure > ASME B16.5 Class 900

Process temperature: 0 to 176 °F (-18 to 80 °C)

Linatex rubber Limited chemical resistance especially in acids

Very good abrasion resistance for large particles

Softer material than polyurethane and neoprene

Typically applied in mining slurries

Process temperature: 0 to 158 °F (-18 to 70 °C)

Adiprene Ideal for applications with high salinity and/or hydrocarbon carryover

Excellent abrasion resistance

Typically used for Water Injection, Recovered Water, and Coal Gasification Slurries

Preferred liner for high pressure > ASME B16.5 Class 900

Process temperature: 0 to 200 °F (-18 to 93 °C)

www.emerson.com/Rosemount 23

Loading...

Loading...