Rosemount 6888Xi Reference Manual

Rosemount™ 6888Xi

Advanced Electronics for Zirconium Oxide

Reference Manual

0809-0100-4892

0

Rev. AB

January 2019

Flue Gas O

Probes

2

B Table of Contents

Essential Instructions

Read this page before proceeding

Emerson designs, manufactures and tests its products to meet many national and international

tandards. Because these instruments are sophisticated technical products, you MUST properly

s

install, use, and maintain them to ensure they continue to operate within their normal specifications. The following instructions MUST be adhered to and integrated into your safety program

when installing, using, and maintaining Rosemount products. Failure to follow the proper instructions may cause any one of the following situations to occur: Loss of life; personal injury; property

damage; damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance of

the product.

• Install your equipment as specified in the Installation Instructions of the appropriate Reference

Manual and per applicable local and national codes. Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts specified by Emerson. Unauthorized parts and procedures can affect the product's performance,

place the safe operation of your process at risk, and VOID YOUR WARRANTY. Look-alike substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except when

maintenance is being performed by qualified persons, to prevent electrical shock and personal

injury.

The information contained in this document is subject to change without notice.

S

E

OT

N

tion

ra

for ope

se

n

e

ic Lic

ph

Gra

th

wi

.0

2

are

oftw

m S

e

t

s

y

d to S

de

upgra

t be

us

tor m

ica

n

u

omm

d C

l

Fie

5

7

3

e

Th

.

e

bov

or a

0

8.

MS

d to A

de

upgra

t be

us

m

are

softw

MS

A

e

Th

.

ics

tron

c

e

l

E

i

X

8

8

8

t 6

n

u

mo

ose

R

e

th

th

wi

tor

ica

n

u

omm

d C

l

5 Fie

7

3

e

th

r (GSC) a

e

t

n

e

C

e

ic

v

r

e

S

bal

o

’s Gl

son

r

me

t E

ac

t

on

C

software to System Software 2.0 with Graphic License.

Essential Instructions I

t 1

to upgra

4

1

3

8

-

3

3

8

-

0

0

8

-

de

II Table of Contents

Reference Manual Table of Contents

00809-0100-4892 January 2019

Contents

Essential Instructions .....................................................................................................I

Section i: Introduction

Preface .........................................................................................................................1

Definitions....................................................................................................................1

Symbols........................................................................................................................2

Overview......................................................................................................................2

Technical Support Hotline............................................................................................2

Section 1: Description and Specifications

1.1 Component Checklist...................................................................................................3

1.2 System Overview..........................................................................................................3

1.2.1 Power Supply –Current Loop Wiring ..............................................................3

1.2.2 System Configurations....................................................................................4

1.2.3 Automatic Calibration.....................................................................................5

1.2.4 Communication Options ................................................................................6

1.3 Specifications...............................................................................................................8

Section 2: Installation

2.1 System Considerations...............................................................................................12

2.2 Mechanical Installation...............................................................................................12

2.3 Electrical Installation ..................................................................................................15

Section 3: Configuration, Startup and Operation

3.1 Overview ...................................................................................................................25

3.2 Startup .......................................................................................................................25

3.2.1 Configuration................................................................................................26

3.2.2 Operation......................................................................................................26

3.2.3 Startup Display..............................................................................................26

3.2.4 Error Conditions............................................................................................27

3.2.5 Keypad..........................................................................................................27

3.2.6 Password Protection. ....................................................................................34

3.3 Optional Advanced Features......................................................................................34

3.3.1 Extended Temperature ................................................................................35

3.3.2 Stoichiometer...............................................................................................35

3.3.3 Programmable Reference.............................................................................36

3.3.4 Plugged Diffusion Element Diagnostic..........................................................36

3.4 System Parameter Descriptions ................................................................................40

3.5 Probe Parameter Descriptions. ..................................................................................40

3.6 Operation Via HART/AMS ..........................................................................................40

3.6.1 Field Communicator Signal Line Connections...............................................48

3.6.2 Field Communicator Menu Trees..................................................................48

Table of Contents III

Table of Contents Reference Manual

January 2019 00809-0100-4892

3.7 Parameter Setup ........................................................................................................48

3.7.1 Test Gas Values .............................................................................................48

.7.2Test Gas Times..............................................................................................53

3

3.7.3 Output Tracking During Calibration..............................................................54

3.7.4 Tolerance Check............................................................................................54

3.7.5 Alarm Relay Output Configuration................................................................55

3.7.6 Analog Output Configuration....................................................................... 57

3.7.7 Autocalibration ............................................................................................ 58

3.7.8 Calibration Recommended Setup................................................................ 58

3.7.9 Calibration Acknowledged Setup................................................................. 59

3.7.10 Plug Diffuser Diagnostic................................................................................59

3.7.11 Low Temperature Set Point...........................................................................61

3.8 Calibration - General ..................................................................................................62

3.8.1 General..........................................................................................................62

3.8.2 Calibration Procedure ...................................................................................62

3.8.3 Calibration Log..............................................................................................67

3.8.4 Reset Calibration...........................................................................................67

3.9 D/A Trim. ...................................................................................................................68

Section 4: Troubleshooting

4.1 Overview of Operating Principles...............................................................................71

4.2 General.......................................................................................................................72

4.2.1 Grounding.....................................................................................................72

4.2 .2 Electrical Noise..............................................................................................72

4.2.3 Electrostatic Discharge .................................................................................72

4.3 Alarm Indications .......................................................................................................72

4.4 Identifying and Correcting Fault Indications ..............................................................73

4.5 Calibration Passes, But Still Reads Incorrectly ............................................................74

4.5.1 Probe Passes Calibration, O2Still Reads High................................................75

4.5.2 Probe Passes Calibration, O2Still Reads Low.................................................76

4.5.3 How do I detect a plugged diffuser?..............................................................76

4.5.4 Can I calibrate a badly plugged diffuser?.......................................................76

Section 5: Maintenance and Service

5.1 Overview....................................................................................................................79

5.2 Maintenance Intervals................................................................................................79

5.3 Calibration..................................................................................................................80

5.3.1 Automatic Calibration...................................................................................80

5.3.2 Manual Calibration........................................................................................80

5.4 Replacement Parts.....................................................................................................81

5.5 6888Xi Components Replacement............................................................................81

5.5.1 I/O Board Replacement.................................................................................81

IV Table of Contents

Reference Manual Table of Contents

00809-0100-4892 January 2019

5.5.2 AC Relay Board Replacement........................................................................85

5.5.3 Power Supply Board Replacement................................................................87

5.5.4 Front Panel Replacement..............................................................................88

5.5.5 DR Board Replacement.................................................................................90

Section 6: Replacement Parts

6.1 6888Xi Electronics .....................................................................................................93

6.2 Calibration Components............................................................................................93

Section 7: Optional Accessories

7.1 HART Handheld 375/475 Field Communicator .........................................................95

7.2 Asset Management Solutions (AMS)..........................................................................95

7.3 By-Pass Packages........................................................................................................95

7.4 SPS 4001B Single Probe Autocalibration Sequencer..................................................96

7.5 IMPS 4000 Intelligent Multiprobe Test Gas Sequencer. .............................................97

7.6 O2Calibration Gas......................................................................................................98

7.7 OxyBalance Display and Averaging System................................................................99

Appendix A: Safety Data

A.1 Safety Instructions ...................................................................................................100

Appendix B: Return of Material

B .1 Returning Material ...................................................................................................101

Appendix C: EU Declaration of Conformity...........................................................102

Appendix D: China RoHS Table......................................................................................103

Table of Contents V

Table of Contents Reference Manual

January 2019 00809-0100-4892

VI Table of Contents

Reference Manual Section i: Introduction

00809-0100-4892 January 2019

Section i: Introduction

Preface

The purpose of this manual is to provide information concerning components, functions, installation and maintenance of the 6888Xi Electronics. Some sections may describe equipment not

used in your configuration. The user should become thoroughly familiar with the operation of

this module before operating it. Read this instruction manual completely.

Definitions

The following definitions apply to WARNINGS, CAUTIONS, and NOTES

WARNING

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not strictly

observed, could result in injury, death, or long-term health hazards of personnel.

CAUTION

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not strictly

observed, could result in damage to or destruction of equipment, or loss of effectiveness.

NOTE

Highlights an essential operating procedure, condition, or statement.

Introduction 1

Section i: Introduction Reference Manual

R

ISKOFELECTRICAL SHOCK

WARNING:REFER TOINSTRUCTIONMANUAL

PROTECTIVECONDUCT OR TERMINAL

E

ARTH(GROUND) TERMINAL

:

:

:

:

January 2019 00809-0100-4892

Symbols

Overview

The Rosemount 6888Xi is specifically designed to control a zirconium oxide probe for measuring

oxygen, usually the O2 remaining from a combustion process. Call the Rosemount Customer

Support Center (CSC) to get recommendations for other oxygen probes.

Phone : +1 855 724 2628

The 6888Xi electronics has several main functions:

1. Heater Control - The electronics receives a type K thermocouple input from an O2 probe and

switches power on and off to the probe's heater in order to maintain a temperature setpoint

of 736 °C.

2. Signal Conditioning - The electronics receives the raw millivolt signal from the O2 sensing

cell, then linearizes and amplifies the signal to provide a linear 4-20 mA output signal used

for recording or as an input into a DCS system for control purposes.

3. Calibration - A bottled calibration gas of known value is typically flowed into the probe's sensor to verify that it is reading correctly. If the signal is out of calibration, the calibration gas is

used to adjust the 4-20 mA output signal. During calibration the 6888Xi prompts the technician to flow two calibration gases into the probe and, with the calibration gases flowing,

automatically adjusts the O2 signal. With the addition of a Single Probe Sequencer (SPS), the

6888Xi Advanced Electronics can also switch the calibration gases on and off.

4. Diagnostics - Multiple alarms are available for display. The alarm displays are intended to

assist a technician in locating where an instrument problem may reside.

The Rosemount 6888Xi Advanced Electronics has been verified to operate the following probes:

• Westinghouse 218 and World Class (115 V heater only)

• Rosemount Oxymitter and 6888

• Yokogawa

The Rosemount 6888Xi Advanced Electronics will not operate the following probes:

• World Class (44 V Heater)

• XSTREAM O2 Probe (Transmitter, Integral Electronics)

Technical Support Hotline

For assistance with technical problems, please call the Customer Support Center (CSC).

Phone: +1 855 724 2638

In addition to the CSC, you may also contact Field Watch. Field Watch coordinates Emerson’s

field service throughout the U.S. and abroad.

Phone: 1-800-654-RSMT (1-800-654-7768)

2 Introduction

e-mail: gas.csc@emerson.com

Reference Manual Section 1: Description and Specifications

00809-0100-4892 January 2019

Section 1: Description and Specifications

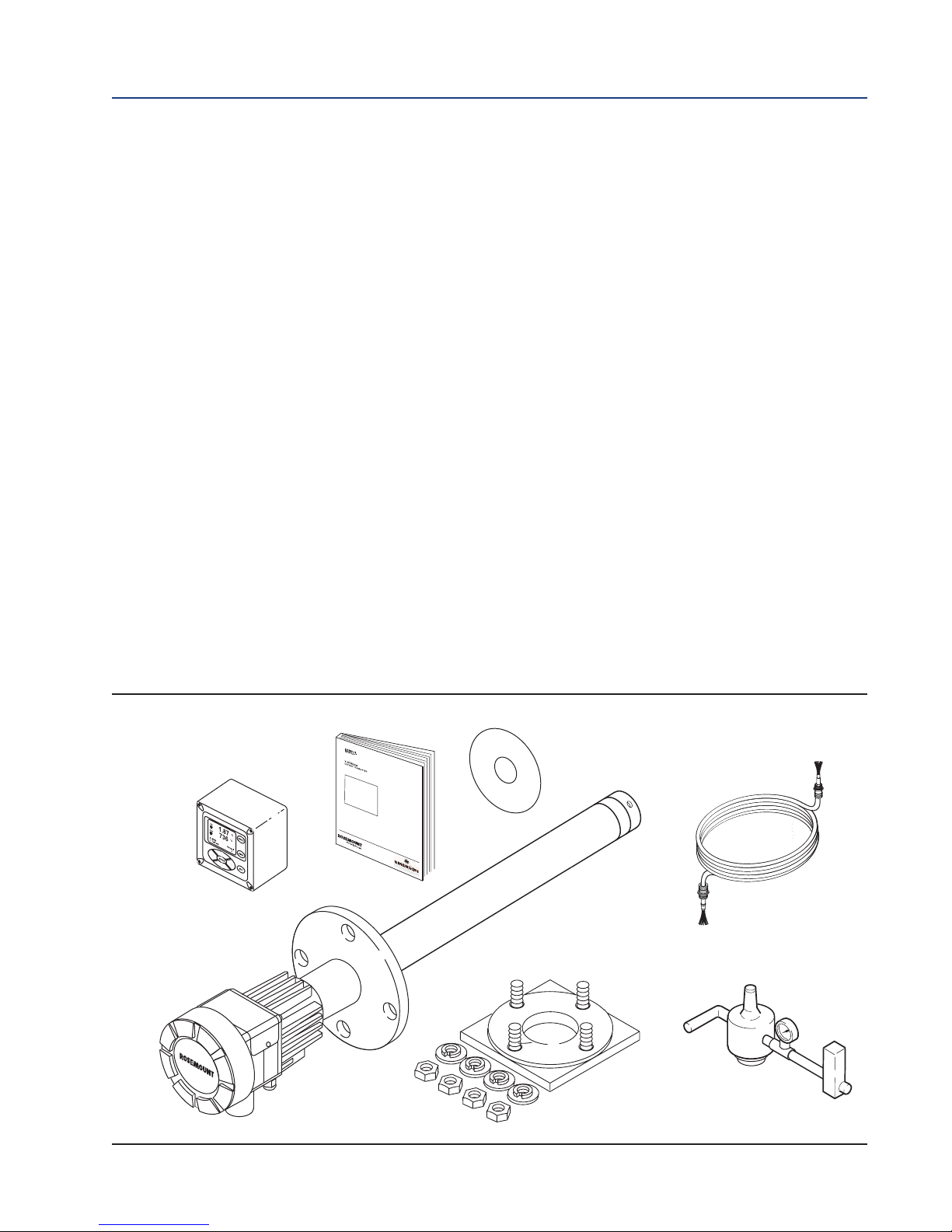

1.1 Component Checklist

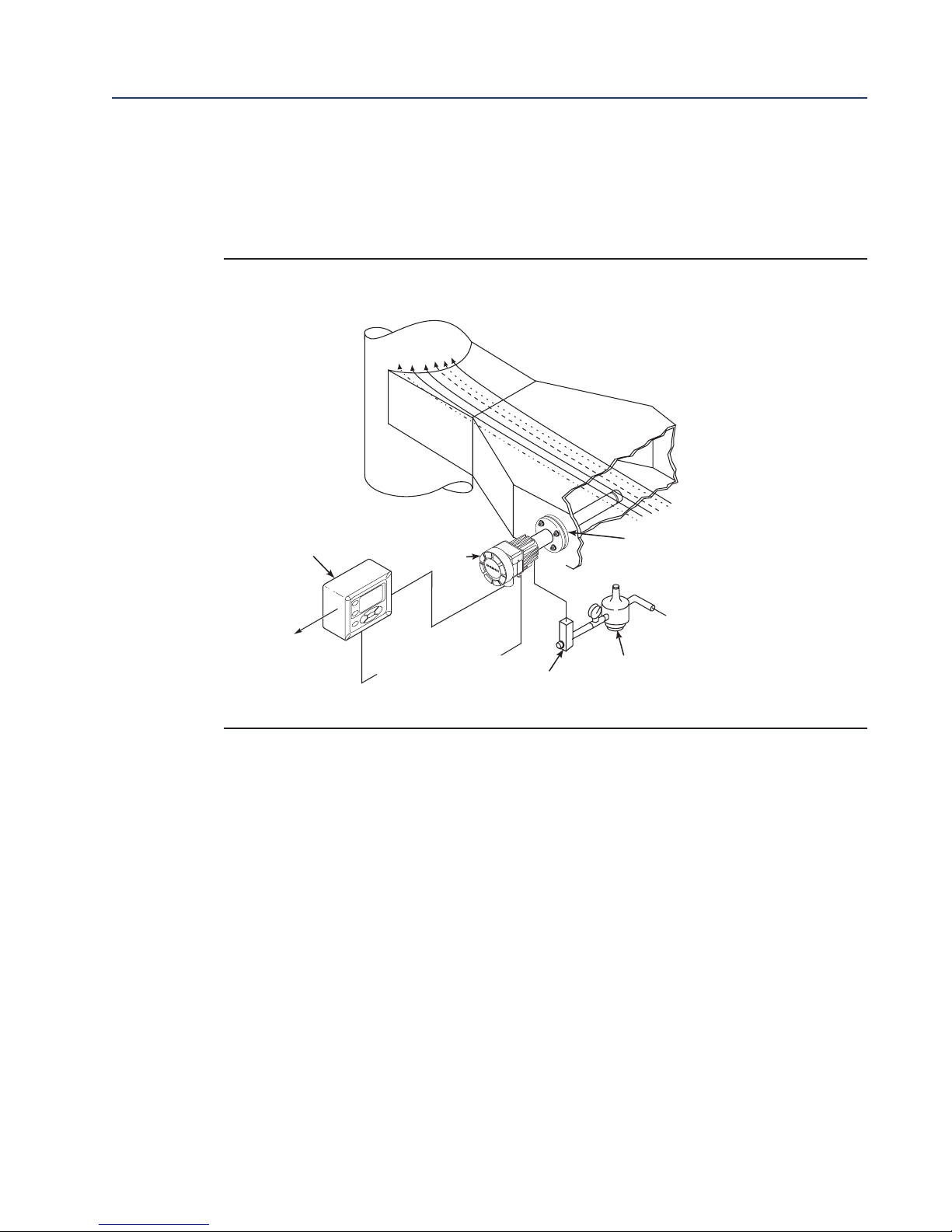

A typical Rosemount O2 Combustion Flue Gas Transmitter should contain the items shown in

Figure 1-1. A complete Oxygen Analyzer system will include some or all of the equipment

shown. However, this manual describes item 8 only. Record the part number, serial number, and

order number for the Rosemount 6888Xi Advanced Electronics in the table located on the back

cover of this manual.

Also, use the product matrix (Table 1-1) at the end of this section to compare your order number against your unit. The first part of the matrix defines the model. The last part defines the various options and features. Ensure the features and options specified by your order number are

on or included with the unit.

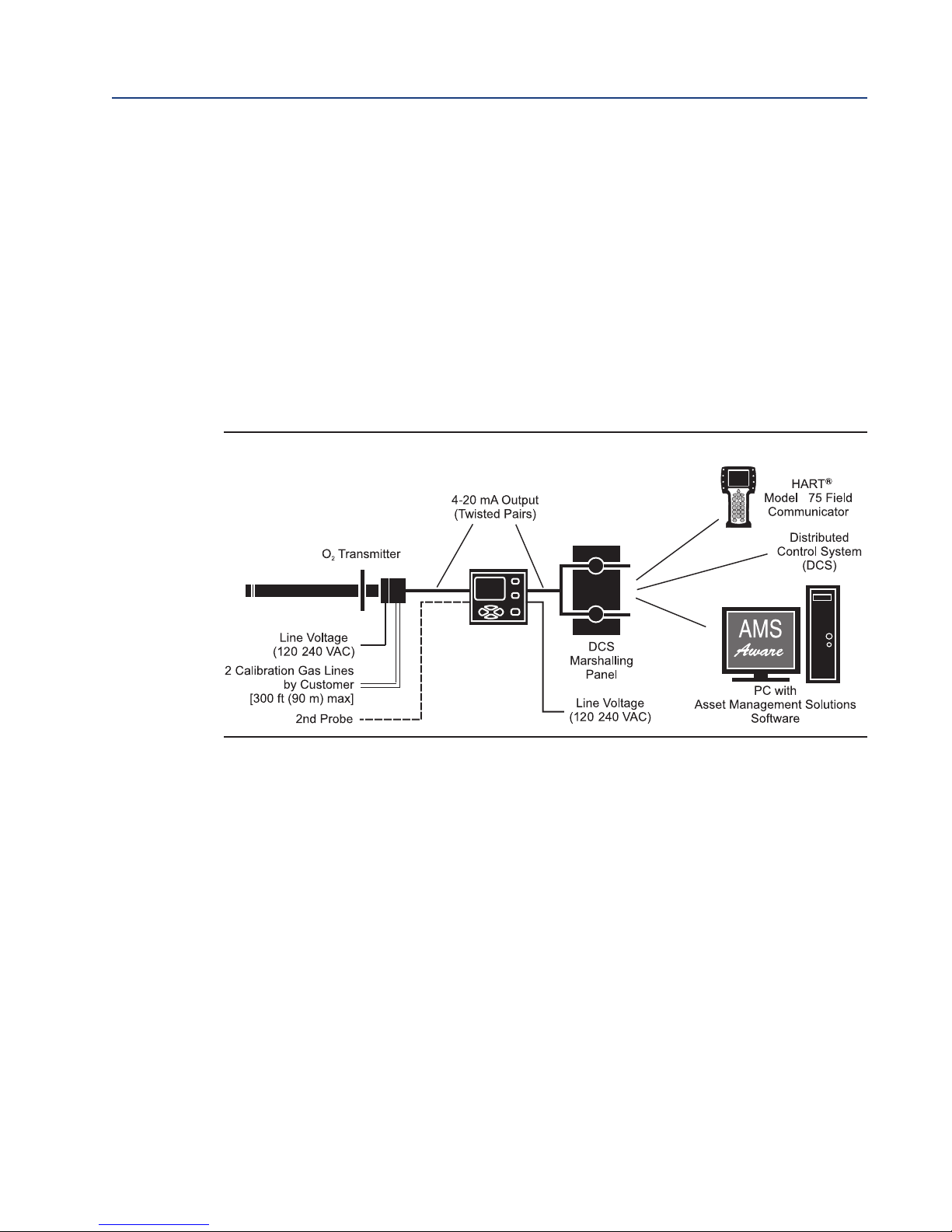

1.2 System Overview

1.2.1 Power Supply-Current Loop Wiring

This Reference Manual is designed to supply details needed to install, start up, operate, and

maintain the Rosemount 6888Xi Advanced Electronics. Signal conditioning electronics outputs a

4-20 mA signal representing an O2 value. This information, plus additional details, can be

accessed with the handheld HART Model 375/475 Field Communicator or Asset Management

Solutions (AMS) software.

Figure 1-1. Typical System Package

Quick Start

Manual

Optional 6888Xi

Advanced Electronics

Optional Mounting or

6888A Probe

Full Instruction

Manual DVD

Adapter Plate

Optional Traditional

Architecture Cable

Description and Specifications 3

Optional Reference &

Calibration Gas

Accessories

Section 1: Description and Specifications Reference Manual

6888A

6888Xi

Advanced

Electronics

4

/

/

January 2019 00809-0100-4892

1.2.2 System Configurations

Integral Transmitter Electronics,

HART and 6888Xi Communications

The Rosemount 6888Xi Advanced Electronics, Figure 1-2, provide a local display/keypad for

setting up, calibrating, and displaying O2, and for diagnosing probe problems. The 6888Xi also

offers additional features including a "Calibration Recommended" diagnostic, fully automatic

calibration, optional flame safety interface (single probe version only), extended process

temperature capability, stoichiometer, programmable reference, and plugged diffusor. These

additional features will be discussed in other sections of this manual. The 6888Xi can be

purchased to operate a single probe, or as a dual channel unit to run two probes.

Figure 1-2. 6888A with Integral Transmitter Electronics and

Optional 6888Xi Advanced Electronics

Traditional Architecture, HART and 6888Xi Communications

Some customers prefer not to mount electronics onto the probe, so a "traditional architecture"

version is offered. This probe sends raw millivolt signals via a 7-conductor cable to the 6888Xi

electronics, Figure 1-3, which does all heater control and signal conditioning in addition to its

display/keypad functions. The 6888Xi Advanced Electronics is offered to support direct replacement probes with 120 volt heaters.

4 Description and Specifications

Reference Manual Section 1: Description and Specifications

6888Xi

Advanced

Electronics

/

00809-0100-4892 January 2019

Figure 1-3. Direct Replacement Probe With Traditional Architecture Electronics

1.2.3 Automatic Calibration

Calibrations consist of introducing bottled gases of known value into the probe so the

electronics can make automatic adjustments to the O2readings to match the bottled gas value.

0.4% O2and 8% O2(balance nitrogen) gases are recommended. Never use nitrogen as a

calibration gas.

Flowmeters (for calibration gases) and regulators and flowmeters (for reference air) are available

as loose components, mounted into an optional manual calibration switching panel, or as a fully

automatic calibration system, Figure 1-4, where calibration solenoids are switched from the

6888Xi Advanced Electronics. See IM-106-340AC, SPS 4001B Single Probe Autocalibration

Sequencer or IM-106-400IMPS, IMPS 4000 Intelligent Multiprobe Test Gas Sequencer, for

additional details.

Figure 1-4. 6888A Probe with Optional 6888Xi Advanced Electronics and

Calibration Accessories

O2 Probe

6888Xi

Advanced Electronics

Description and Specifications 5

Section 1: Description and Specifications Reference Manual

January 2019 00809-0100-4892

1.2.4 Communication Options

Data Communications

An operator can configure and troubleshoot the O2 Probe system in one of two ways:

1. Using the 6888Xi Advanced Electronics keypad and display to access the following optional

advanced features:

• Probe configuration

• Fully automatic calibration

• Failure diagnostics

• Flame safety interface

• High temperature operation [above 700 °C (1292 °F) standard temperature].

• Stoichiometer feature provides the ability to indicate O2 efficiency when the combustion

process goes into reducing conditions (0% O2).

• Programmable reference provides enhanced accuracy when measuring at or near O2

level (20.95% O2).

• Plugged diffusor diagnostics

2. Using the HART Interface. The 6888Xi’s 4-20 mA output line transmits an analog signal proportional to the oxygen level. The HART output is superimposed on the 4-20 mA output

line. This information can be accessed through the following:

• Rosemount Model 375/475 Field Communicator - The handheld communicator requires

Device Description (DD) software specific to the 6888Xi. The DD software will be supplied with many Model 375/475 units but can also be programmed into existing units at

most Emerson service offices. See Section 4, Startup and Operation, for additional information.

• Personal Computer (PC) - The use of a personal computer requires AMS software available

from Emerson.

• Delta V and Ovation Distributed Control System (DCS) with AMS-inside capability.

NOTE

The 375 Field Communicator must be upgraded to System Software 2.0 with Graphic License for operation with the 6888Xi. The AMS software must be upgraded to AMS 8.0 or above.

Contact Emerson’s Global Service Center (GSC) at 1-800-833-8314 to upgrade the 375 Field

Communicator software to System Software 2.0 with Graphic License.

6 Description and Specifications

Reference Manual Section 1: Description and Specifications

A

nal

y

t

i

c

al

AAnAnaAnalAnalyAnalytAnalytiAnalyticAnalyticaAnalytical

00809-0100-4892 January 2019

3. The 6888Xi can also transmit HART information wirelessly via a wireless THUM Adapter,

Figure 1-5. The THUM Adapter threads into the

FIGURE 1-5. Wireless THUM Adapter with

6888Xi

6888Xi conduit port and converts the 4-20 mA

O2 signal to a wireless protocol. All other HART

information is also transmitted.

In addition to the wireless THUM Adapter, a

hard-wire connection of the 4-20 mA signal to

the DCS may be used at the same time. More

detailed information regarding the application

of the THUM Adapter is available in Product

Data Sheet 00813-0100-4075.

4. The 6888Xi can be configured to communicate with a 6888A FOUNDATION Fieldbus probe.

Refer to section 3.2.1 Configuration to set up for FOUNDATION Fieldbus communications.

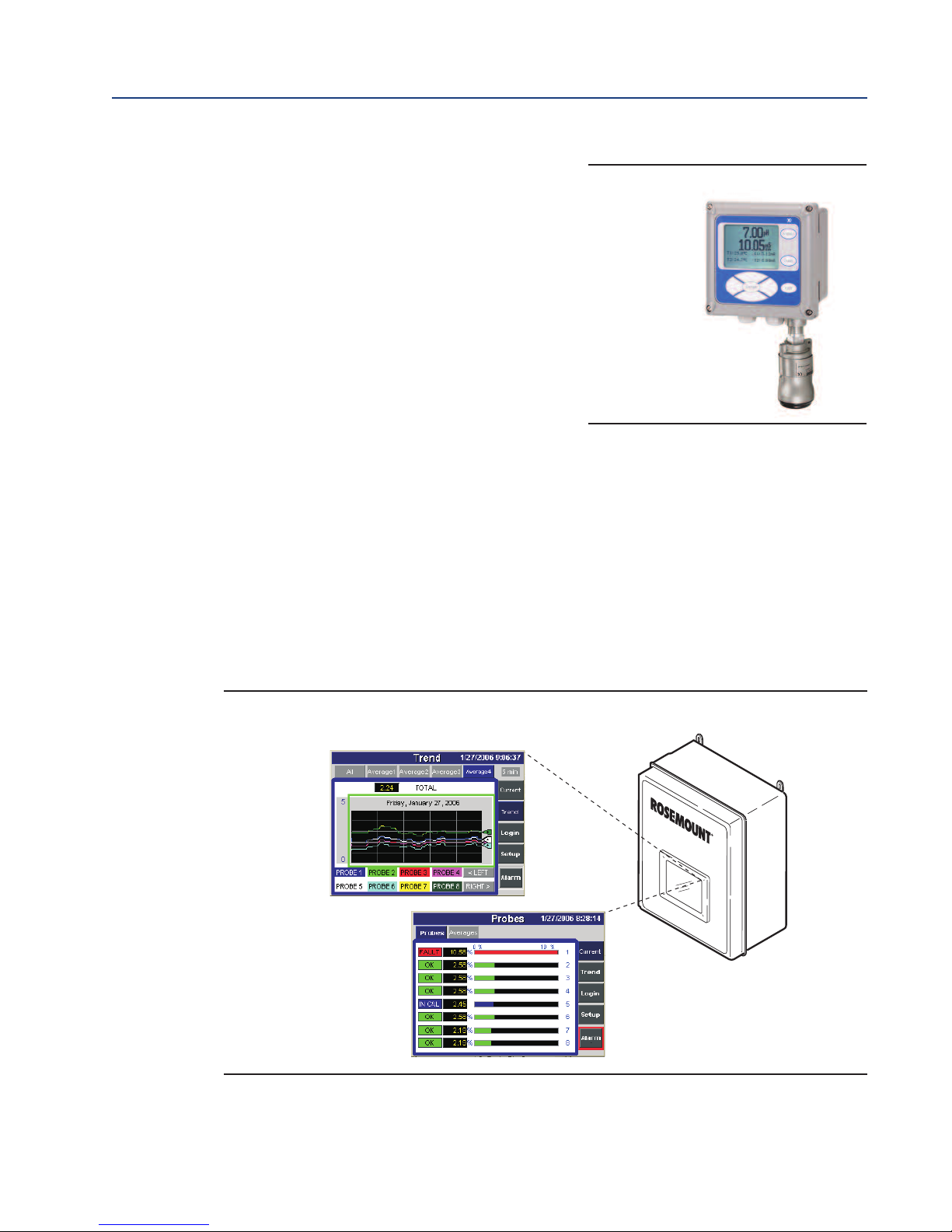

Optional OxyBalance Display and Averaging System

Receives up to eight 4-20 mA signals from individual 6888Xi units. Trends individual outputs and

calculates four programmable averages as additional 4-20 mA outputs. OxyBalance graphic displays are shown in Figure 1-5. See IM-106-4050, OxyBalance Oxygen Display and Averaging

System, for additional details.

FIGURE 1-5. OxyBalance Displays

Description and Specifications 7

Section 1: Description and Specifications Reference Manual

January 2019 00809-0100-4892

1.3 Specifications

easurement Specifications

M

Net O2 Range: 0 to 50% O2 user scalable

-2 to 50% O2 user scalable with stoichiometer

Lowest Detectable Limit: 0.01% O2

Signal Stability: ±0.03% O2

Accuracy in Reducing Conditions: ±10% of reading or 0.1% O2

System Response in Reducing Conditions: going from oxidizing to reducing -T90 in 120 seconds

going from reducing to oxidizing -T90 in 30 seconds

Ambient Temperature Effect on Xi 4-20 mA Signal: less than 0.0025% O2 per degree Celsius

Environmental Specifications

6888Xi Advanced Electronics: Type 4X, Polycarbonate Material

Ambient Temperature Limits: -20 °C to 50 °C (-4 °F to 122 °F)

-20 °C to 70 °C (-4 °F to 158 °F) as measured by electronics

6888Xi LCD display:

Ambient Temperature Limits -20 °C to 55 °C (-4 °F to 131 °F)

General Purpose Certifications:

Installation Specifications

Mounting: Panel, wall, or pipe.

Reference Air: 2 scfh (1L /min), clean, dry, instrument-quality air

(20.95% O2), regulated to 5 psi (34 kPa)

Calibration: Semi-automatic or automatic

Cal Gases: 0.4% O2 and 8% O2, balance N2 recommended

Traditional Architecture Cable 200 ft (61 m) maxmum length

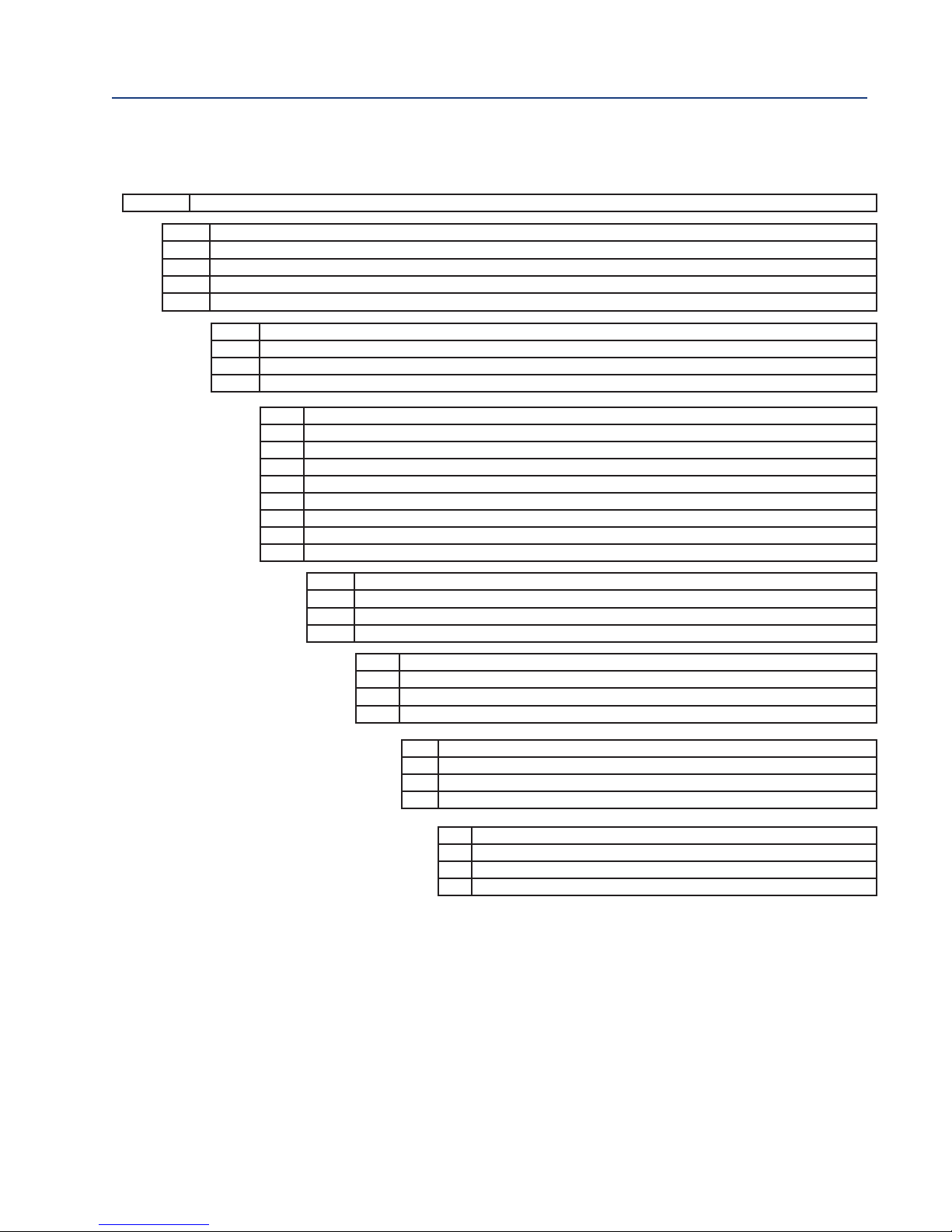

Transmitter Electrical Power: 12 - 24 VDC (loop-powered from control room or 6888Xi)

Electrical Power for 6888Xi: 120/240VAC ±10%, 50/60 Hz

Power Consumption of 6888Xi: 12 VA maximum or 1020 VA maximum with Traditional

Architecture,120V Probes

Alarm Relay Outputs: Two provided - 2 Amperes, 30 VDC, Form-C

Optional Loss of Flame Input: Internally powered input to remove heater power

actuated via dry contact output from user’s flame scanner

Emerson has satisfied all obligations from the European legislation to harmonize the

product requirements in Europe. All static performance characteristics are with operating variables constant. Specifications subject to change without notice.

8 Description and Specifications

Reference Manual Section 1: Description and Specifications

00809-0100-4892 January 2019

Table 1-1. Product Matrix, Advanced Electronics

6888Xi Advanced Electronics

Code Remote Type

1OXY Single Channel O2

2OXY Single Channel O2 with Flame Safety Interlock for Heater

3OXY Dual Channel O

4OXY Single Channel O2, Traditional Architecture for 120V Probes

Code Mounting

00 No Hardware

01 Panel Mount Kit with Gasket

02 2" Pipe / Wall Mount Kit

Code Cable

00 No Cable

10 20' (6m) Cable

11 40' (12m) Cable

12 60' (18m) Cable

13 80' (24m) Cable

14 100' (30m) Cable

15 150' (45m) Cable

16 200' (60m) Cable

Code Stoichiometer Function

00 No

01 Single Channel

02 Dual Channel

Code Programmable Reference Function

00 None

01 Single Channel

02 Dual Channel

Code Extended Temperature Function

00 None

01 Single Channel

02 Dual Channel

Code Plugged Diffuser Diagnostic Function

00 None

01 Single Channel

02 Dual Channel

Description and Specifications 9

Section 1: Description and Specifications Reference Manual

January 2019 00809-0100-4892

Table 1-2. Product Matrix, O2Autocalibration Accessories

XS O2CAL O2 Autocalibration Accessories

Code Single Probe Sequencers Autocalibration Options

00 None

01 SPS 4001B Single Probe Sequencer, general purpose NEMA 4X, includes check valve for probe

Code Intelligent Multiprobe Sequencers (IMPS)

00 None

01 IMPS single-probe, general purpose NEMA 4X, includes check valve for probe

02 IMPS two-probe, general purpose NEMA 4X, includes check valve for probe

03 IMPS three-probe, general purpose NEMA 4X, includes check valve for probe

04 IMPS four-probe, general purpose NEMA 4X, includes check valve for probe

05 IMPS single-probe, 115V heated general purpose NEMA 4X, includes check valve for probe

06 IMPS two-probe, 115V heated general purpose NEMA 4X, includes check valve for probe

07 IMPS three-probe, 115V heated general purpose NEMA 4X, includes check valve for probe

08 IMPS four-probe, 115V heated general purpose NEMA 4X, includes check valve for probe

09 IMPS single-probe, 220V heated general purpose NEMA 4X, includes check valve for probe

10 IMPS two-probe, 220V heated general purpose NEMA 4X, includes check valve for probe

11 IMPS three-probe, 220V heated general purpose NEMA 4X, includes check valve for probe

12 IMPS four-probe, 220V heated general purpose NEMA 4X, includes check valve for probe

TABLE 1-3. Calibration Glass

Part Number Description

1A99119G01 Two disposable calibration gas bottles - 0.4% and 8% O2, balance nitrogen - 550 liters each*

1A99119G02 Two flow regulators for calibration gas bottles

1A99119G03 Bottle rack

*Calibration gas bottles cannot be shipped via airfreight.

10 Description and Specifications

Reference Manual Section 2: Installation

00809-0100-4892 January 2019

Section 2: Installation

WARNING

Before installing this equipment read the "Safety instructions for the wiring and installation

ofthis apparatus" at the front of this Reference Manual. Failure to follow safety instructions

could result in serious injury or death.

WARNING

Install all protective equipment covers and safety ground leads after installation. Failure to

install covers and ground leads could result in serious injury or death.

WARNING

The 6888Xi Advanced Electronics can be installed in general purpose areas only. Do not install

the 6888Xi in hazardous areas or in the vicinity of flammable liquids.

CAUTION

If external loop power is used, the power supply must be a safety extra low voltage (SELV) type.

Installation 11

Section 2: Installation Reference Manual

6888Xi

HART/4-20 mA

Signal

Advanced

Electronics

Line

Voltage

O

2

Probe

Interconnect

Cable

Calibration

Gas

Flowmeter

Pressure

Regulator

Instrument

Air Supply

(Refernce Air)

Adapter Plate

and Flange

Stack

Gases

Duct

January 2019 00809-0100-4892

2.1 System Considerations

A typical system installation for a 6888Xi and O2Probe is shown in Figure 2-1.

FIGURE 2-1. Typical System installation

2.2 Mechanical Installation

6888Xi Advanced Electronics

12 Installation

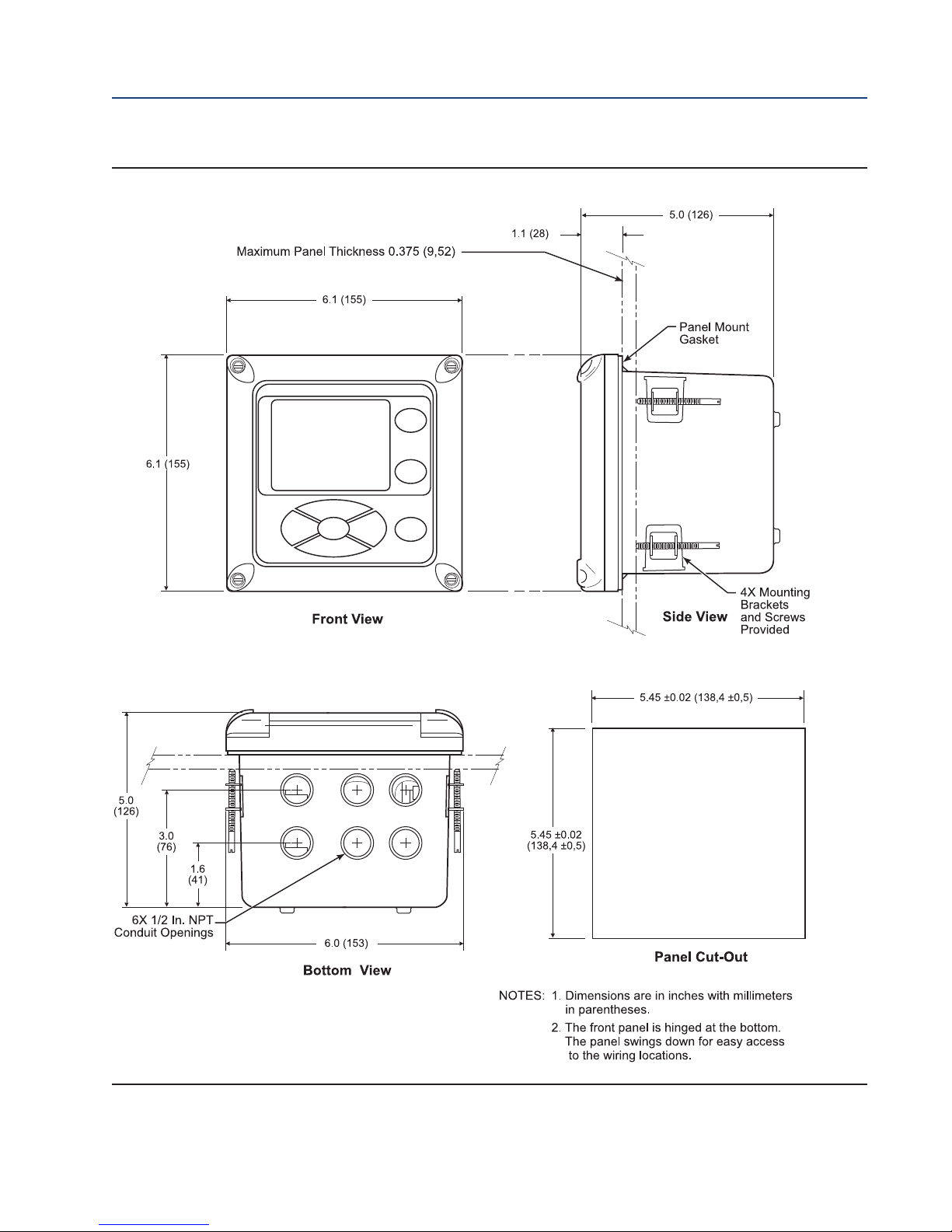

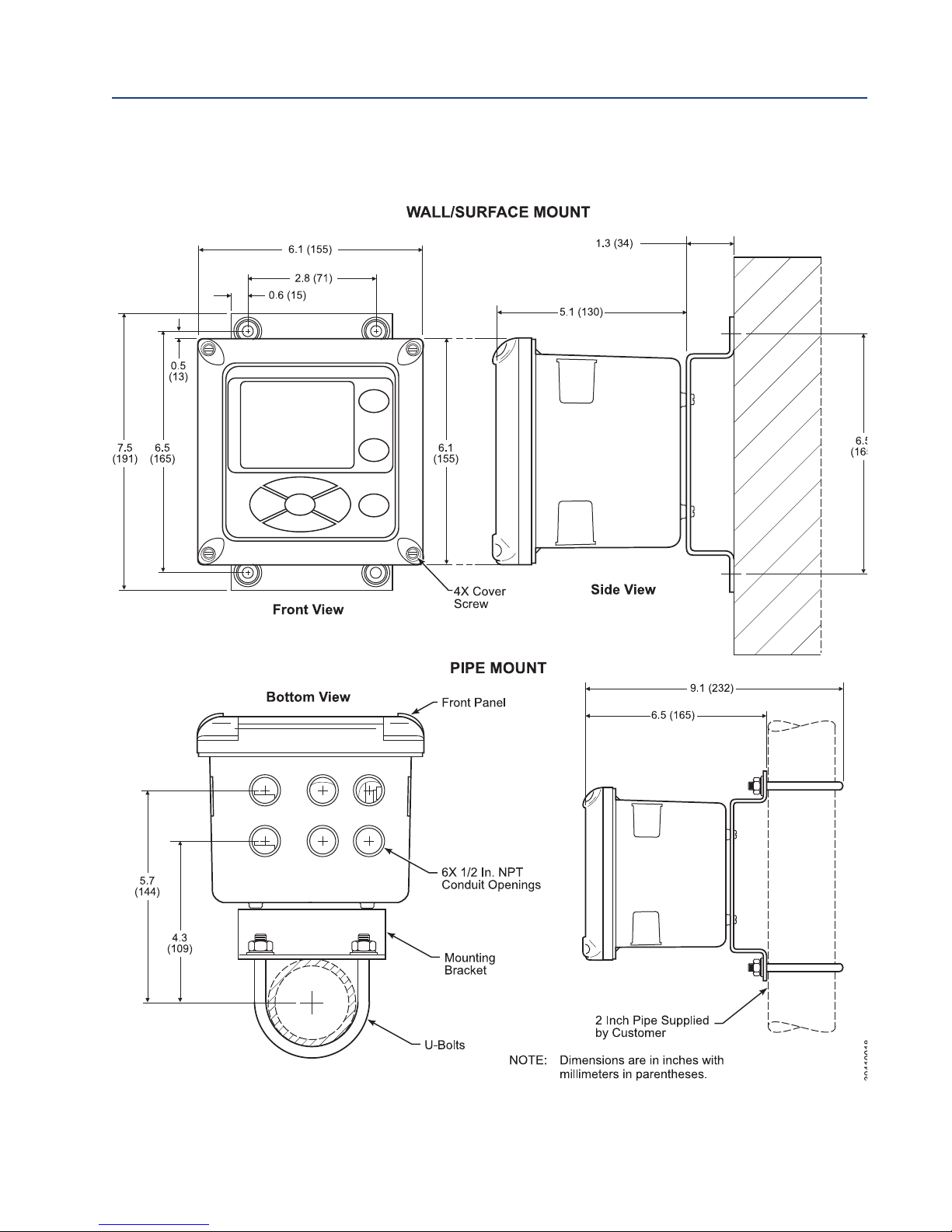

The 6888Xi Advanced Electronics is available in a panel mounting, wall mounting, or pipe

mounting configuration. Refer to Figure 2-2 or Figure 2-3 for the panel, wall, or pipe mounting

details.

1. Ensure all components are available to install the 6888Xi.

2. Select a mounting location near or removed from the O2 Probe. Consider the temperature

limitations of the 6888Xi (see "Specifications") when selecting the mounting location.

3. Mount the 6888Xi at a height convenient for viewing and operating the interface.

Approximately 5 ft (1,5 m) is recommended.

4. The keypad window on the 6888Xi may have interior and exterior protective membranes.

Remove the protective membranes prior to use of the 6888Xi enclosure. Failure to remove

the protective membranes may cause the display to appear distorted. The membrane may

be difficult or impossible to remove after extended use at elevated temperatures.

Reference Manual Section 2: Installation

00809-0100-4892 January 2019

FIGURE 2-2. 6888XI Advanced Electronics - Panel Mounting Details

Installation 13

Section 2: Installation Reference Manual

January 2019 00809-0100-4892

FIGURE 2-3. 6888XI Advanced Electronics - Wall/Surface and Pipe Mounting Details

14 Installation

Reference Manual Section 2: Installation

00809-0100-4892 January 2019

2.3 Electrical Installation

Rosemount 6888Xi Advanced Electronics

All wiring must conform to local and national codes. Multiple wiring diagrams are shown in this

section. Always refer to the diagrams that apply to your transmitter configuration and disregard

all other wiring diagrams.

WARNING

Disconnect and lock out power before connecting the power supply.

WARNING

Install all protective covers and safety ground leads after installation. Failure to install covers and ground

leads could result in serious injury or death.

WARNING

To meet the Safety Requirements of IEC 61010 (EC requirement), and ensure safe operation of this equipment, connection to the main electrical power supply must be made through a circuit breaker (min 10A)

which will disconnect all current-carrying conductors during a fault situation. This circuit breaker should

also include a mechanically operated isolating switch. If not, then another external means of disconnecting

the supply from the equipment should be located close by. Circuit breakers or switches must comply with a

recognized standard such as IEC 947.

NOTE

Line voltage, signal, and relay wiring must be rated for at least 105 °C (221 °F).

NOTE

If metal conduit is used with the 6888Xi the conduit should be reliably bonded to protective

earth. The grounding plate inside the 6888Xi is not bonded to PE and does not provide adequate

grounding.

1. Remove cover screws from the front cover of the 6888Xi. Swing down the front cover of the

interface box.

2. Pull out the I/O board on the right-hand side of the card rack inside the 6888Xi. If your sys-

tem is configured to operate two transmitter probes there are two I/O interface boards.

3. See Figures 2-5, 2-6 and 2-7. Connect the 4-20 mA signal wires at J4 of the I/O board. Attach

the supplied ferrite clamp over the 4-20 mA OUT wires that extend past the shield.

NOTE

Installation of the ferrite clamp over the 4-20 mA OUT wires is required for compliance with the

European EMC Directive.

4. Terminate the shield of the 4-20 mA signal wires at the designated ground terminal of the

6888Xi. Do not allow bare shield wires to contact the circuit boards. Insulate the shield wires

prior to termination.

5. Connect the signal wires from the SPS or IMPS (if used) to the applicable terminals of J3.

Refer to the SPS or IMPS instruction manual for wiring details.

Installation 15

Section 2: Installation Reference Manual

January 2019 00809-0100-4892

6. Connect the customer’s alarm indicator devices to the alarm indicator relay terminals.

7. Reinstall the I/O board in the card rack of the 6888Xi.

8. If your system is configured for two channel operation, repeat steps 2 through 7 to connect

the other signal wires.

9. Remove the connector from the power supply board located on the left-hand side of the

card rack inside the 6888Xi.

10. Connect the line, or L1 wire to the L1 terminal and the neutral, or L2 wire, to the N terminal.

11. Reinstall the power supply connector in the power supply board.

Flame Safety Interlock

A flame safety interlock by Emerson is available for heater power disconnect whenever there is a

loss of the process flame or a heater runaway condition (heater over-temperature) in the O

2

Probe. This input is internally powered by the 6888Xi and is actuated via a dry contact output

from the user’s flame scanner. A closed contact indicates a flame is present. An open contact

indicates a loss of flame.

1. Connect the signal wires from the burner management system flame status output to the

flame status input terminals of J2. The flame status sensing device is supplied by the customer. Refer to the applicable OEM documents for signal wiring details.

2. Remove the J1 and J2 connectors from the AC relay board.

3. Connect the AC line input to the J1 connector.

4. Connect the AC power to the 6888A probe to the J2 connector.

5. Reinstall connector J1 and J2 to the AC relay board.

Traditional Architecture Cable Connections

A traditional architecture configuration is used to provide for remote location of the transmitter

electronics. All electronics are housed inside the 6888Xi. A multi-conductor power/signal cable

connects between the probe and the 6888Xi. Use the following procedure to connect the traditional architecture probe to the 6888Xi.

NOTE

The Traditional Architecture cable is provided at the specified length and is ready for installation. The cable glands must be properly terminated to maintain EMC/EMI noise protection.

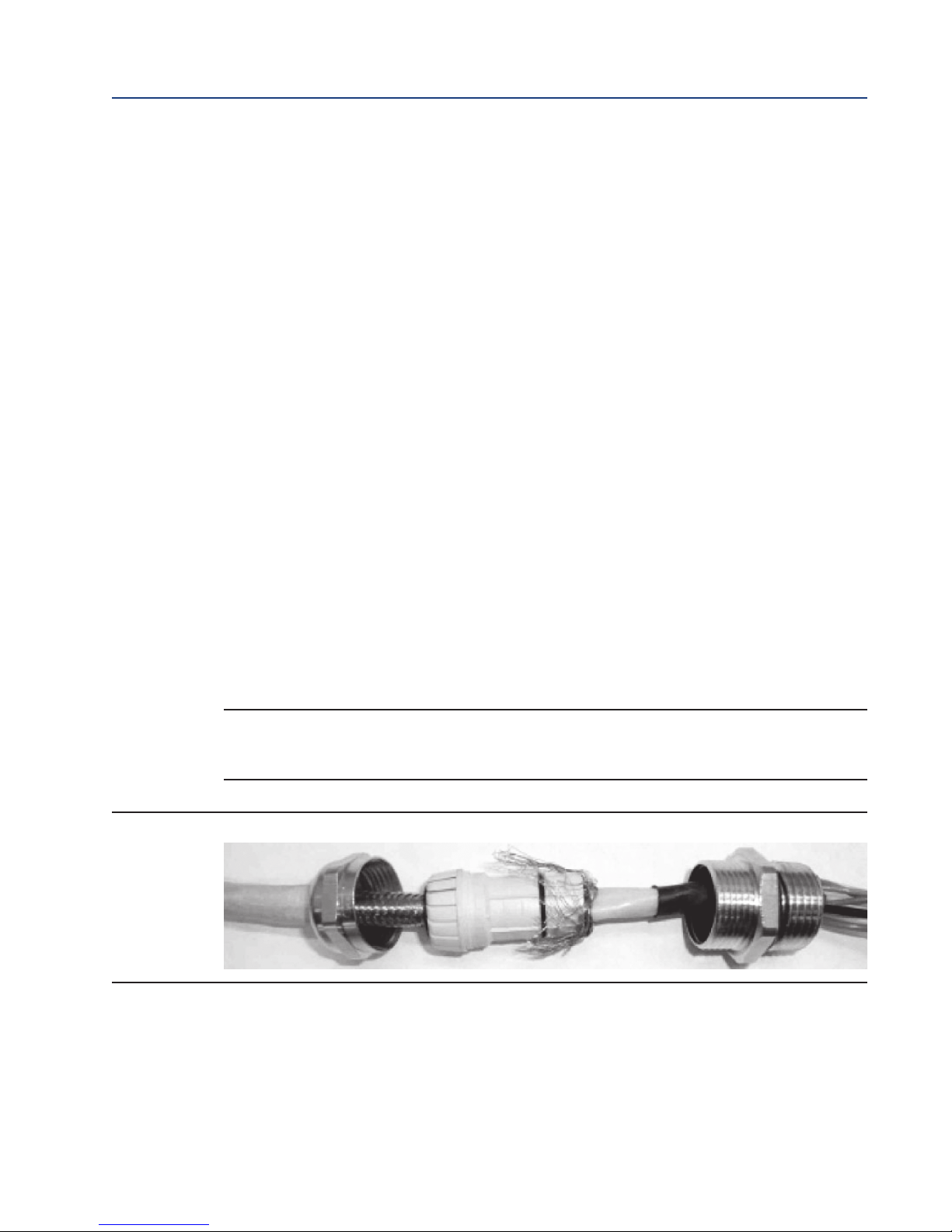

FIGURE 2-4. Traditional Architecture Cable Gland Assembly

Run the 7-conductor cable between the traditional architecture probe and the installation site for 6888Xi. Use1

new cable conduit or trough as needed.

Install the cable and lead wires to the probe per manufacturer’s instructions.2

Install the cable at the probe housing and at the 6888Xi enclosure according to the following procedure:3

a. Unscrew locking nut from gland assembly, Figure 2-4, and slide locking nut back along cable.

b. Pull the gland body away from the plastic insert. Use care not to damage the cable shield braid.

c. Insert the cable wires into the proper entry port in either the probe housing or the 6888Xi enclosure.

d. At the probe housing, apply Teflon tape or similar sealing compound to the tapered pipe threads.

Thread the gland body into the probe housing until properly seated.

16 Installation

Reference Manual Section 2: Installation

00809-0100-4892 January 2019

e. At the 6888Xi enclosure, insert the gland body into the left front cable port from the inside of the enclo-

sure. Use the rubber O-ring provided to seal the cable port.

. Ensure the cable shield braid is evenly formed over the gray insert. When properly formed, the braid

f

should be evenly spaced around the circumference of the insert and not extend beyond the narrow

diameter portion.

g. Carefully press the gray insert into the gland body. The grooves on the insert should align with similar

grooves inside the gland body. Press the insert in until it bottoms out in the gland body.

h. Slide the locking nut up and thread it onto the gland body. Tighten the locking nut so the rubber grom-

met inside the plastic insert compresses against the cable wall to provide an environmental seal.

At the 6888Xi, connect the cable leads to the connectors on the transmitter I/O board as indicated in Figure 2-7.4

Installation 17

Section 2: Installation Reference Manual

6

8

8

8

S

TA

NDA

RD P

RO

B

E

HO

US

ING

6

8

8

8

S

T

A

NDA

R

D

P

ROB

E

HOUS

IN

G

January 2019 00809-0100-4892

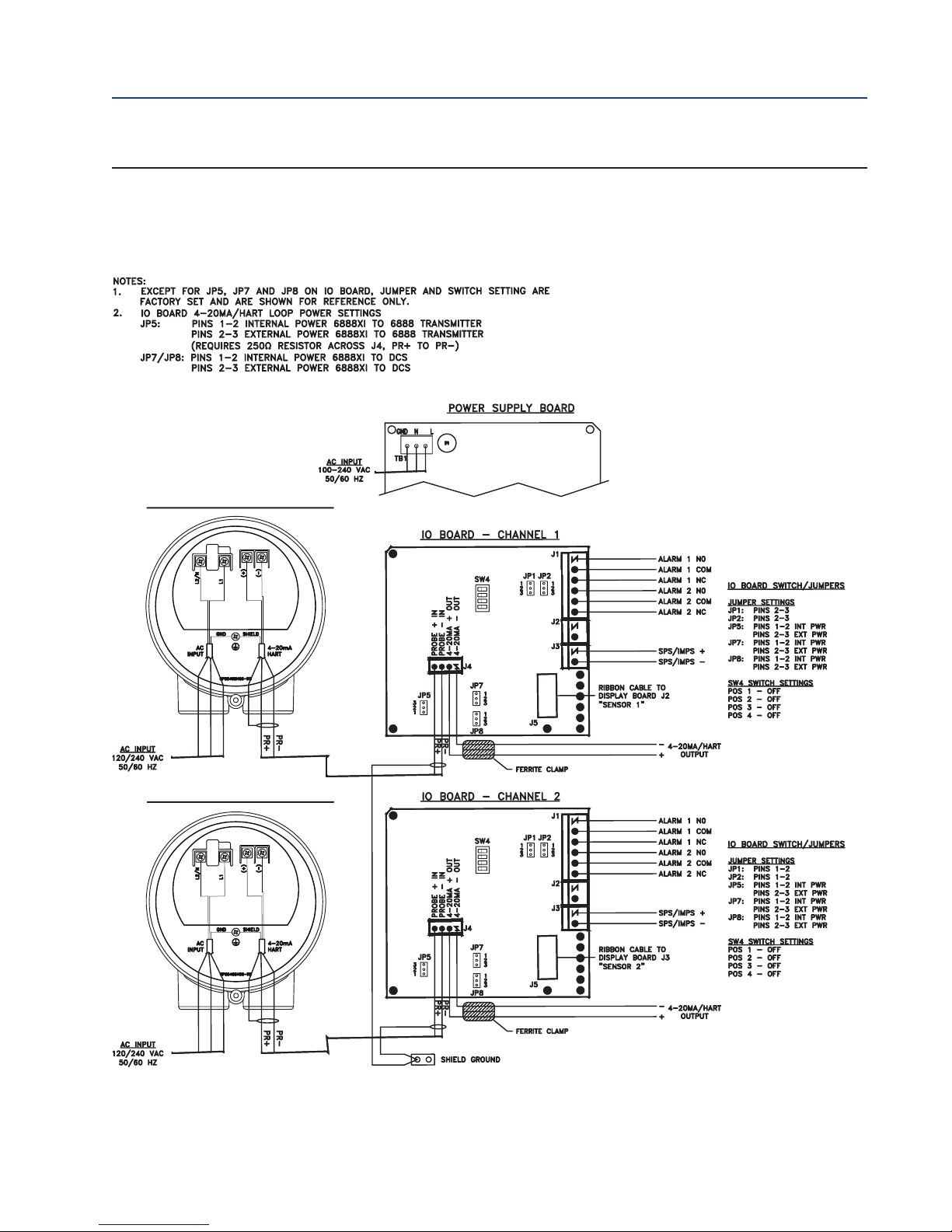

IGURE 2-5. Single/Dual Channel Wiring Diagram

F

18 Installation

Reference Manual Section 2: Installation

CHANNEL #2

CHANNEL #1

CHANNEL #2

CHANNEL #2

CHANNEL #1

CHANNEL #1

00809-0100-4892 January 2019

IGURE 2-5 cont. Single/Dual Channel Wiring Diagram

F

Installation 19

Section 2: Installation Reference Manual

5

1

-

6

8

8

8

X

i

6888 ST

AN

D

AR

D

PR

O

BE H

O

U

S

IN

G

January 2019 00809-0100-4892

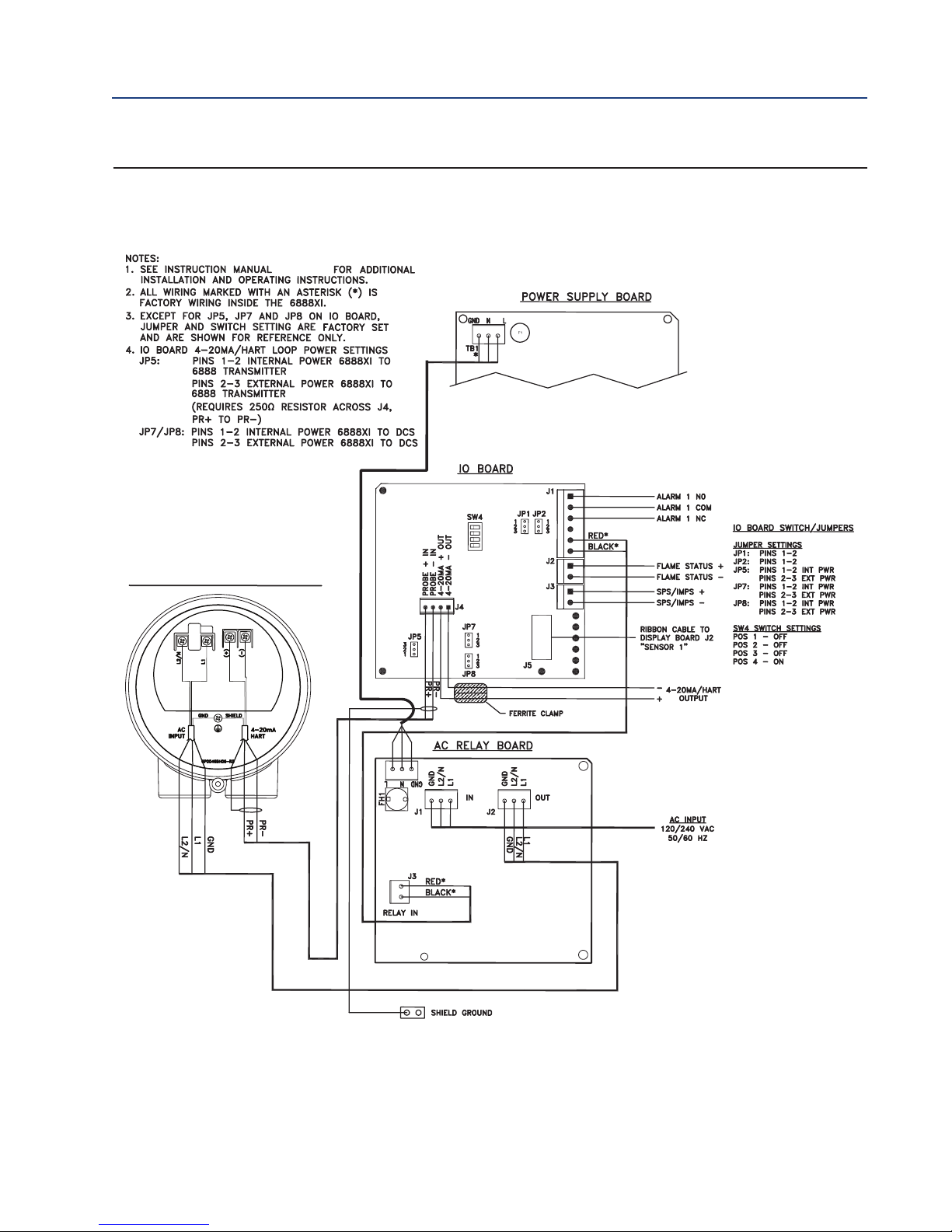

FIGURE 2-6. Single Channel with Flame Safety Wiring Diagram

20 Installation

Reference Manual Section 2: Installation

LOSS OF

FLAM

E OUTPUT TO B

URNER MANA

GEM

EN

T

SY

ST

EM

00809-0100-4892 January 2019

FIGURE 2-6 cont. Single Channel with Flame Safety Wiring Diagram

Installation 21

Section 2: Installation Reference Manual

January 2019 00809-0100-4892

FIGURE 2-7. Traditional Architecture Wiring Diagram

22 Installation

Loading...

Loading...