Rosemount 5601 Specifications

Product Data Sheet

July 2014

00813-0100-4024, Rev JA

Rosemount 5600 Series

Superior Performance 4-Wire Non-Contacting Radar Level

Transmitter

Best performance and uptime provided by

market leading sensitivity

Unique signal processing allows for

challenging process conditions

Extremely reliable and accurate level

transmitter due to its high repeatability

Easy connection with adjustable power

supply, 24-240 Vac/dc, 0-60 Hz

Easy configuration and setup with intelligent

software support

High application flexibility with an extensive

selection of antennas and materials

Minimized maintenance costs with no

contact and no moving parts; no

re-calibration required

Interchangeable transmitter heads and

antennas

Rosemount 5600 Series

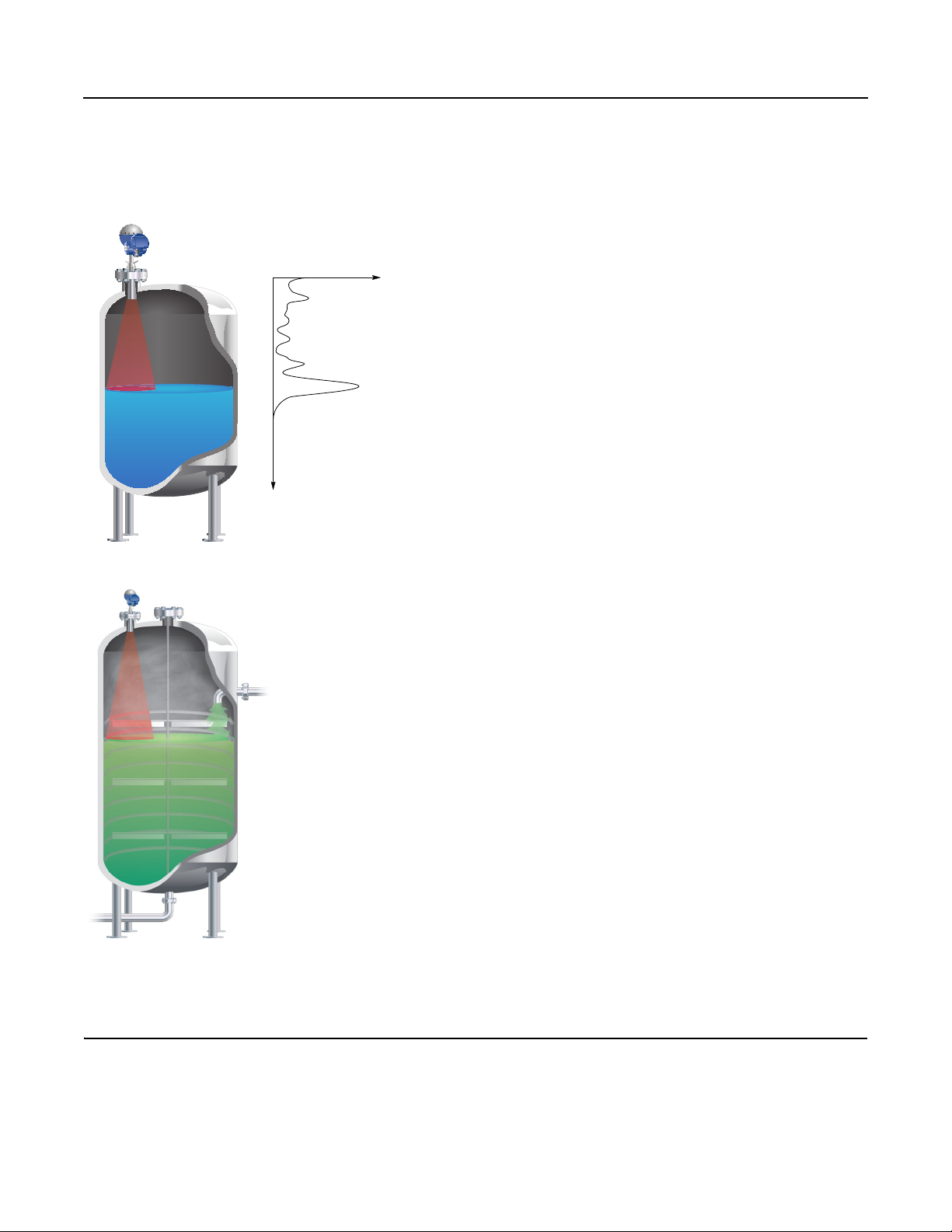

Challenging reactor and

mixing tanks, and tanks with

rapid level changes

Distance

Amplitude

Surface echo

Superior performance when applications get tough

Measurement principle

The level of the product in the tank is measured by radar signals

transmitted from the antenna at the tank top. After the radar

signal is reflected by the product surface, the echo is picked up

by the antenna. As the signal is varying in frequency, the echo

has a slightly different frequency compared to the signal

transmitted at that moment. The difference in frequency is

proportional to the distance to the product surface, and level

can be accurately calculated. This method is called Frequency

Modulated Continuous Wave (FMCW).

Applications with turbulence, foam, long measuring ranges,

disturbing objects, or low dielectric constants can reduce the

energy reflecting back and, in worst case, eliminate it

completely with the result that no surface can be detected. The

reflection intensity can however be improved by using a highly

sensitive radar, the optimal antenna type, and as large antenna

as possible.

July 2014

Radar technology benefits

Direct level measurement means virtually no compensation is

needed for changing process conditions (such as density,

conductivity, temperature, pressure, viscosity, pH, dielectric

etc.) which results in high application flexibility

Accurate, reliable measurement that requires no

re-calibration, meaning improved uptime

The non-contacting radar transmitter with no moving parts

means minimized maintenance

Good for dirty, coating, crystallizing, and corrosive

applications

Top down measurement means simple installation with no

empty tank requirements, and minimized risk for leakages

Contents

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2

Product Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

www.rosemount.com

July 2014

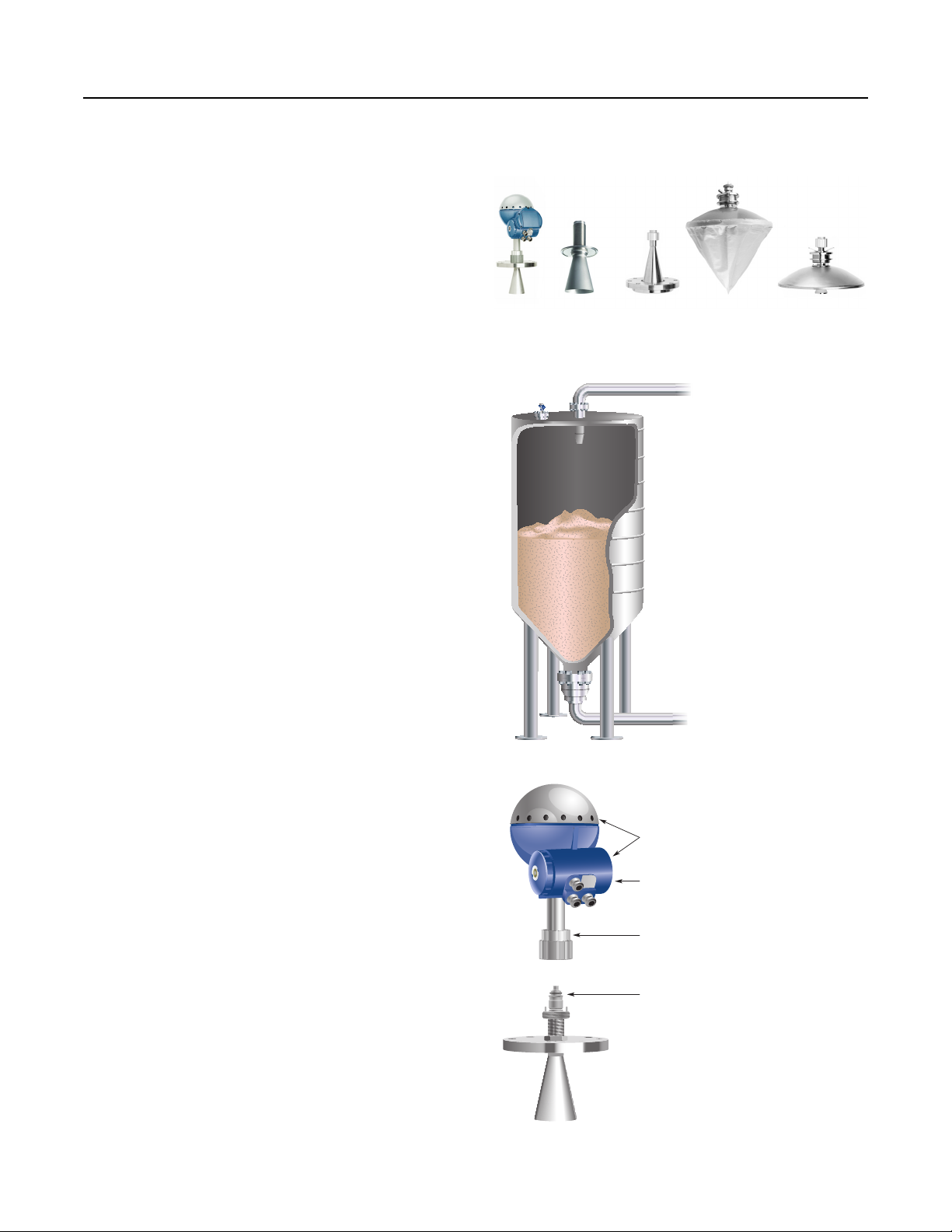

Full range of antenna styles

Detach housing without opening tank

Rotate housing in any direction

Ultra wide power supply

Dual compartment housing

Cone Tri-Clamp™ Process

Seal

Dust Cover Parabolic

Antenna

Low DK solids including lime, cement,

fly ash, corn, and many more

Special 5600 features

For the most challenging applications

4-wire transmitters with maximum sensitivity and

performance

Rosemount 5600 Series

Suitable for solids, liquids, and slurries with rapid level

changes and challenging process conditions

Manages high pressures and temperature

Handles long measuring ranges

Application flexibility with a wide selection of materials,

process connections, antenna styles, and accessories

Best performance and uptime

The power of 4 wires provides the highest sensitivity and the

ability to detect weak radar echoes in challenging process

environments

Smart EchoLogic with registration of disturbance echoes

provides the ability to handle weak echoes reliably and

identifies the true echo from the clutter

Ability to handle disturbing factors, longer measuring ranges,

and lower dielectrics

Greater measurement reliability margins result in less

downtime, higher safety, and better quality

Robust design reduces costs and increases safety

The detachable transmitter head allows the tank to remain

sealed

The dual compartment housing separates cable connections

and electronics, which provides safer handling and improved

moisture protection

Adjustable power supply, 24-240 Vac/dc, 0-60 Hz

Interchangeable transmitter heads and antennas

Allows for easy replacement by standard tank connections

www.rosemount.com

3

Rosemount 5600 Series

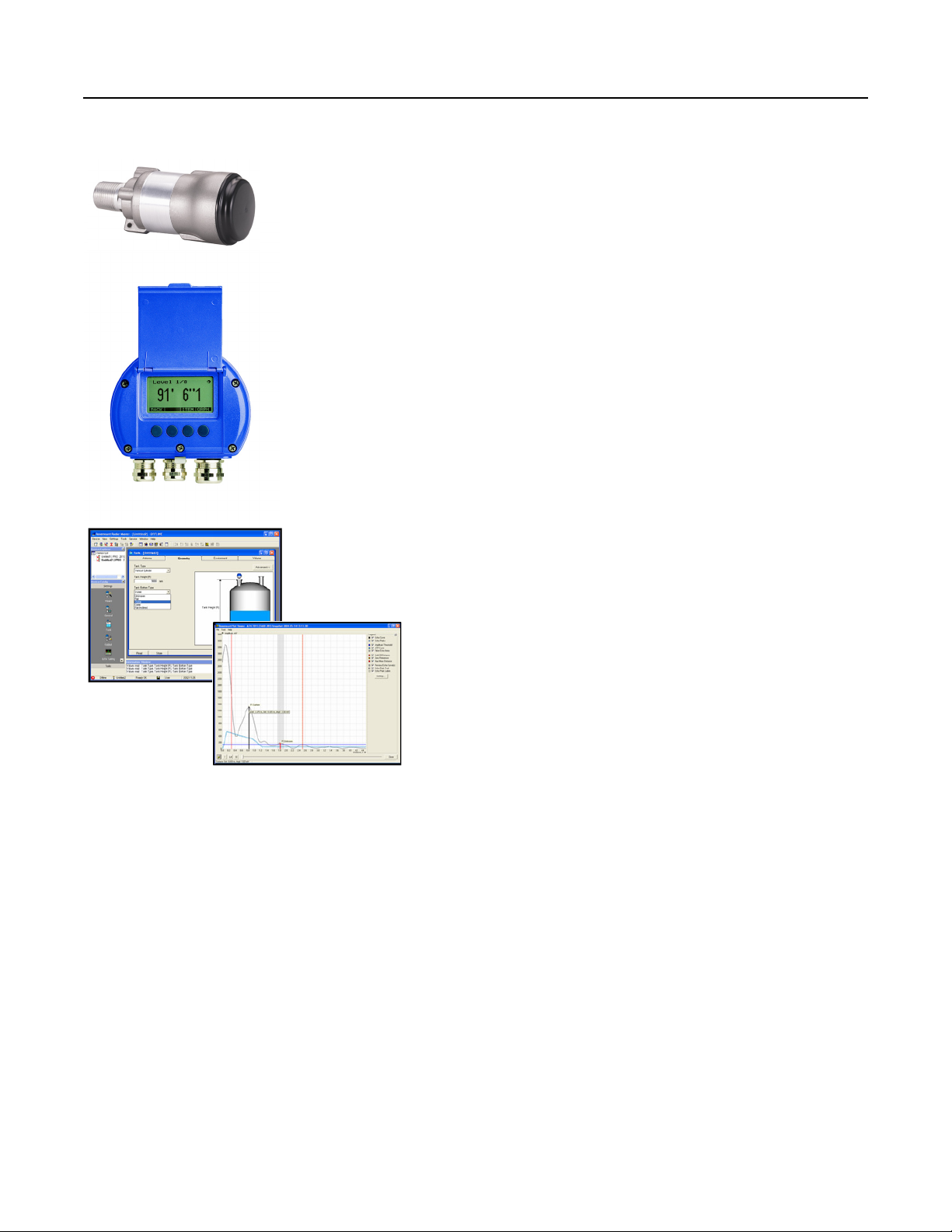

The Smart Wireless THUM

Adapter enables level

communication for additional

level information and diagnostics

Rosemount 2210

configurable display with

temperature input

The Rosemount Radar Master enables easy configuration

and service with a user-friendly interface including wizards,

echo curve with movie feature, offline/online

configuration, extensive online help, logging capabilities,

and much more.

July 2014

Easy installation and plant integration

Seamless system integration with HART

®

, Modbus®, or IEC

62591 (WirelessHART®) with the Smart Wireless THUM™

Adapter

Secondary analog 4-20 mA output

MultiVariable™ output includes the choice of level, distance,

volume, and signal strength

Pre-configured or easy, user-friendly configuration in

Rosemount Radar Master with a five-step wizard, auto

connect, and online help

Any DD-compatible configuration tool such as AMS™ Device

Manager, or Field Communicator can be used

Fully configurable with the remote- or factory-mounted LOI

Rosemount 2210 with temperature input option

Minimized maintenance reduces cost

Non-contacting, no mechanical moving parts that require

maintenance

No re-calibration or compensation needed due to changing

process conditions

The user-friendly software provides easy online

troubleshooting with the echo curve tool, registration of

disturbance echoes, and logging

Predictive maintenance with advanced diagnostics and

PlantWeb™ alerts

Adjustments without opening the tank

4

www.rosemount.com

July 2014

Rosemount 5600 Series

Ordering Information

Rosemount 5601 Radar Level Transmitter is a reliable 4-wire radar level transmitter designed for

outstanding performance in a wide range of applications and process conditions. Product features

include:

Configurable remote display or local operator interface

Extensive selection of antennas and materials

HART 4-20 mA, Modbus, or IEC 62591 (WirelessHART) with the Smart Wireless THUM Adapter

Additional information

Specifications: page 15

Product Certifications: page 28

Dimensional Drawings: page 31

Specification and selection of product materials, options, or components must be made by the purchaser of the equipment.

See page 24 for more information on Material Selections.

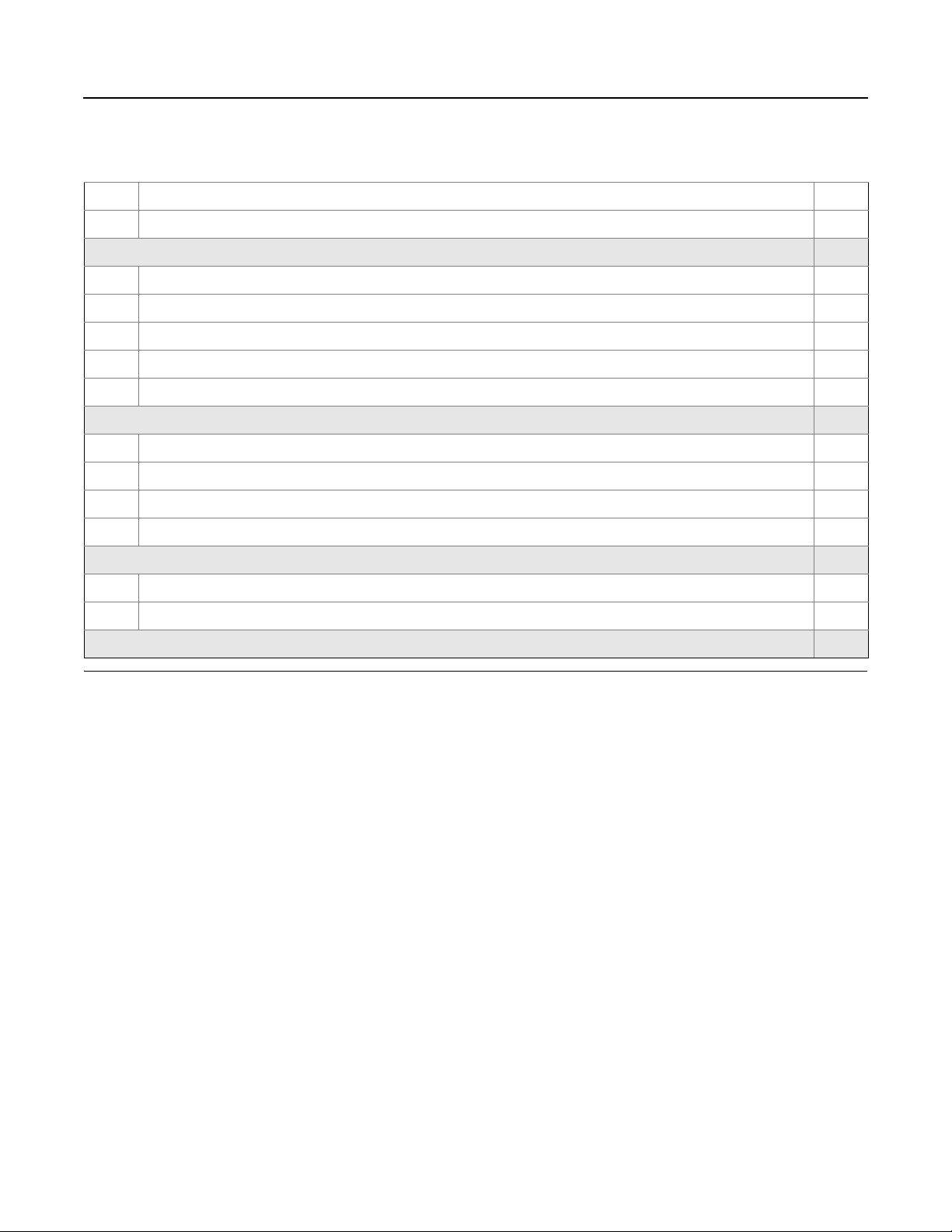

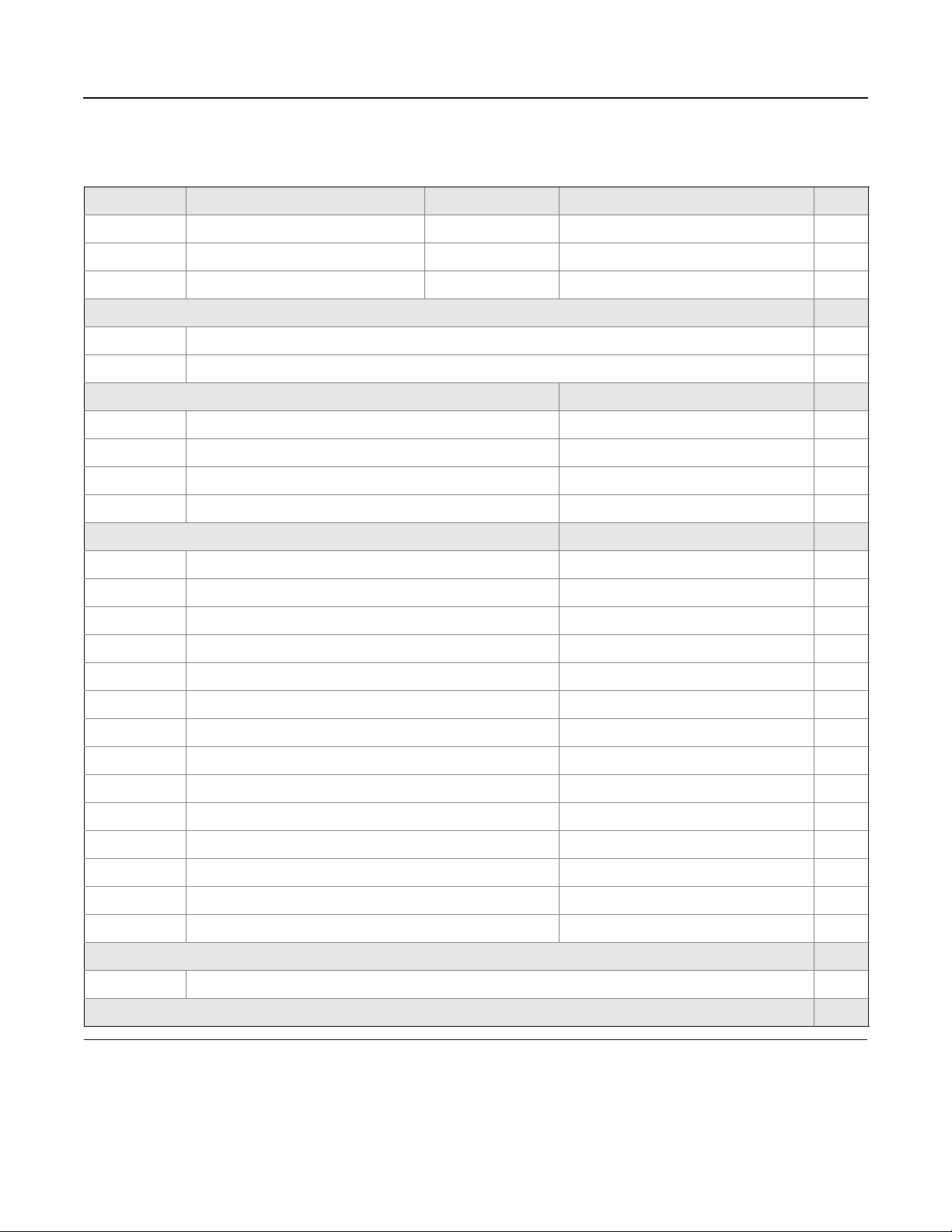

Table 1. Rosemount 5601 Radar Level Transmitter Ordering Information

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Model Product description

5601 Radar Level Transmitter for Process Applications

Frequency band

U US Market Only (10 GHz)

S Switzerland Market Only (10 GHz)

A All Other Markets (10 GHz)

Product certifications

NA None

E1 CENELEC/ATEX Flameproof

E5 FM Explosion-proof

E6 CSA Explosion-proof

E7 IECEx Flameproof

EM Technical Regulations Customs Union (EAC) Flameproof (consult factory for details)

IM Technical Regulations Customs Union (EAC) Intrinsic Safety (consult factory for details)

Power supply

P 24-240 Vdc/ac 0-60 Hz

Primary output

★

★

★

★

★

★

★

★

★

★

5A 4-20 mA with HART communication, Passive Output (HART Revision 5)

5B 4-20 mA with HART communication, Passive Output, Intrinsically Safe Circuit (HART Revision 5)

5C 4-20 mA with HART communication, Active Output (HART Revision 5)

www.rosemount.com

(1)

★

★

★

5

Rosemount 5600 Series

July 2014

Table 1. Rosemount 5601 Radar Level Transmitter Ordering Information

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

5D 4-20 mA with HART communication, Active Output, Intrinsically Safe Circuit (HART Revision 5)

(1)

★

8A RS 485 Protocol - Modbus

Secondary output

(2)(3)

0None

1 4-20 mA, Passive Output

2 4-20 mA, Passive Output, Intrinsically Safe Circuit

3 4-20 mA, Active Output

4 4-20 mA, Active Output, Intrinsically Safe Circuit

(4)(5)

(1)(4)

(5)

(1)

Display unit

NNone

P LOI, Factory mounted on transmitter

R LOI, Remote mounted

T LOI, Remote mounted with temp inputs (1-6 spot elements with common returns)

Volume calculation

E Basic Volume Equations (Standard)

V Strapping Table, up to 100 points

Typical model number: 5601 S E1 P 5A 0 P E Antenna Selection

(6)

★

★

★

★

★

★

★

★

★

★

★

★

(1) Intrinsically safe circuit only applicable if product certificate codes E1, E5, E6, or E7 is selected.

(2) Secondary output codes are not available in a combination of E6 CSA and Primary Output codes 5A, 5B, 5C, or 5D.

(3) Secondar y output codes 1, 2, 3, and 4 require an isolator when used in combination with 7A, 7B, or 8A.

(4) Not available in combination with Primary Output codes 5A, 5B, 5C, or 5D.

(5) Not allowed in combination with Display Unit codes P, R, or T.

(6) Select the antenna type and options using Tab l e 2, Ta b l e 3 , Ta b le 4, Ta b le 5, Ta b l e 6 , and Ta b le 7.

6

www.rosemount.com

July 2014

Rosemount 5600 Series

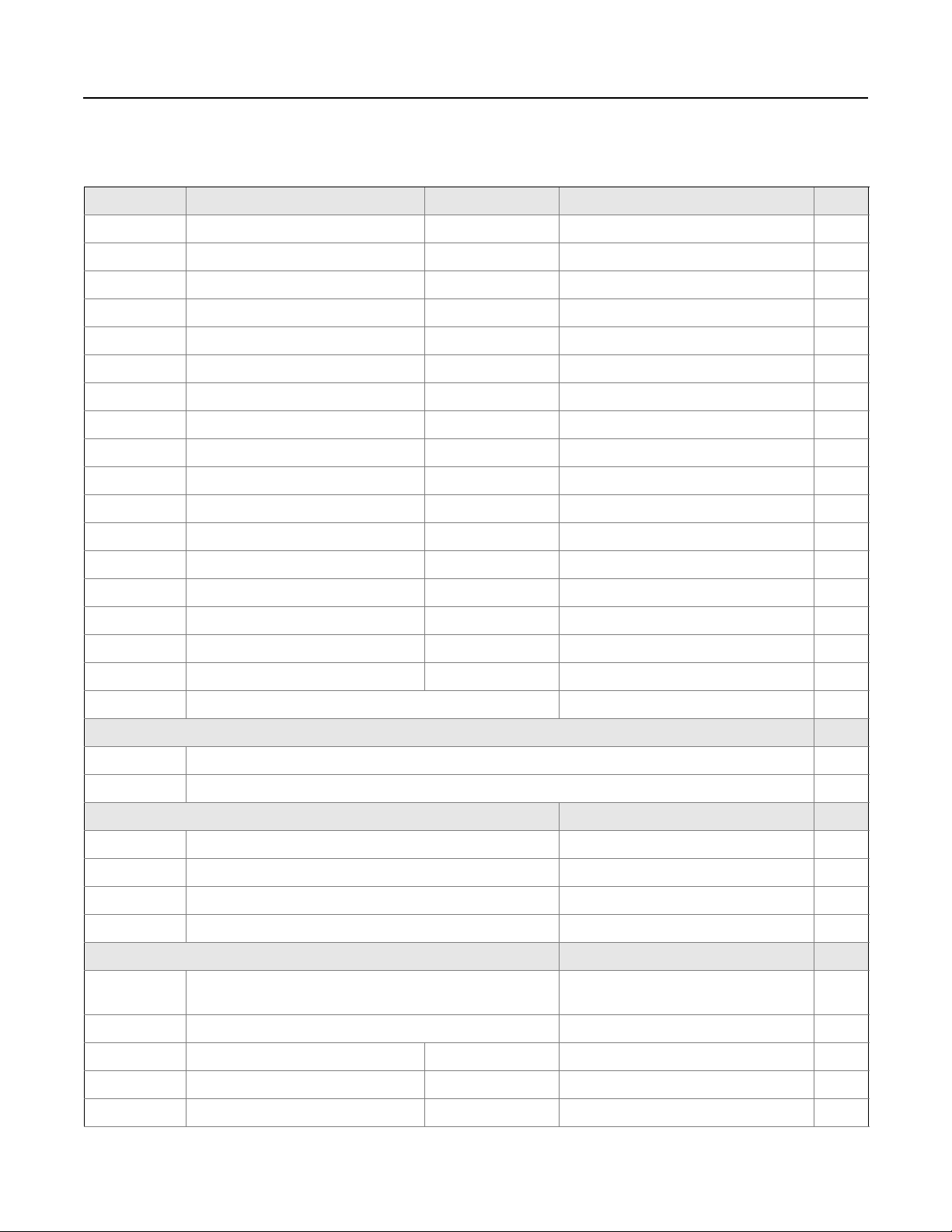

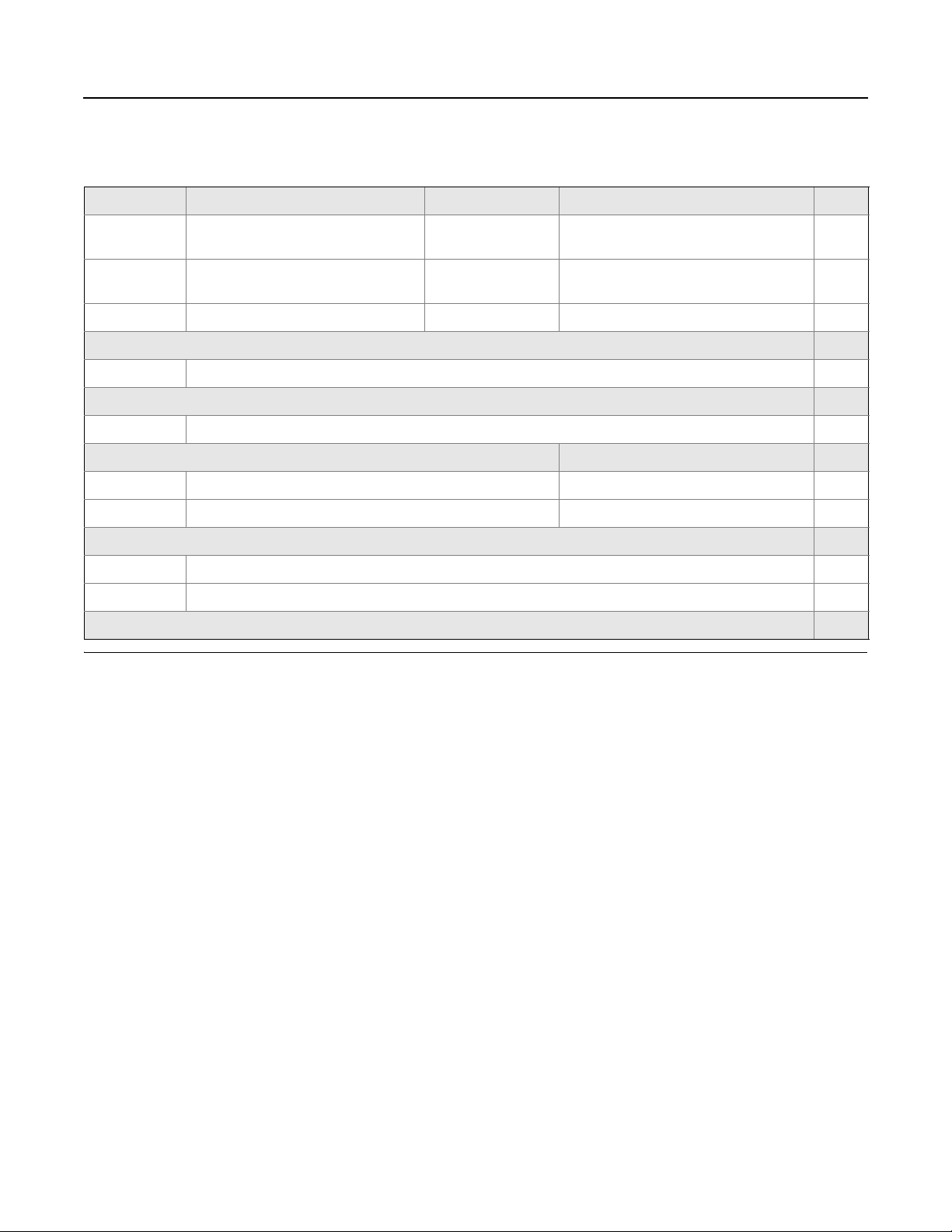

Table 2. Cone Antenna Ordering Information

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Antenna type Antenna size Antenna material Note

23S 3 in. (DN80) nozzles SST 316L Pipe Installation Only

24S 4 in. (DN100) nozzles SST 316L Free propagation or 4” pipe

26S 6 in. (DN150) nozzles SST 316L Free propagation or 6” pipe

28S 8 in. (DN200) nozzles SST 316L Free propagation only

2AS 10 in. (DN250) nozzles SST 316L Free propagation only

23H 3 in. (DN80) nozzles Alloy C22 Longer Lead-time, Consult Factory

24H 4 in. (DN100) nozzles Alloy C22 Longer Lead-time, Consult Factory

26H 6 in. (DN150) nozzles Alloy C22 Longer Lead-time, Consult Factory

28H 8 in. (DN200) nozzles Alloy C22 Longer Lead-time, Consult Factory

23T 3 in. (DN80) nozzles Titanium Gr 1/2 Longer Lead-time, Consult Factory

24T 4 in. (DN100) nozzles Titanium Gr 1/2 Longer Lead-time, Consult Factory

26T 6 in. (DN150) nozzles Titanium Gr 1/2 Longer Lead-time, Consult Factory

28T 8 in. (DN200) nozzles Titanium Gr 1/2 Longer Lead-time, Consult Factory

23M 3 in. (DN80) nozzles Alloy 400 Longer Lead-time, Consult Factory

24M 4 in. (DN100) nozzles Alloy 400 Longer Lead-time, Consult Factory

26M 6 in. (DN150) nozzles Alloy 400 Longer Lead-time, Consult Factory

28M 8 in. (DN200) nozzles Alloy 400 Longer Lead-time, Consult Factory

★

★

★

★

26Z Customer specific cone or material Consult Factory

Tank seal

PPTFE

QQuartz

O-ring material Tan k seal

VViton

KKalrez

®

Fluoroelastomer P, Q

®

6375 Perfluoroelastomer P, Q

E Ethylene Propylene (EPDM) P

B Nitrile Butadiene (NBR) P

Process connection Note

NR Antenna with Plate Design

Customer supplied flange or see Tab le 10

on page 14 for flange options

XX Special Process Connection

Tri-clamp connection Flange material Note

BT 3 in. Tri-Clamp Flange SST 316L Longer Lead-time, Consult Factory

CT 4 in. Tri-Clamp Flange SST 316L Longer Lead-time, Consult Factory

★

★

★

★

★

★

★

www.rosemount.com

7

Rosemount 5600 Series

July 2014

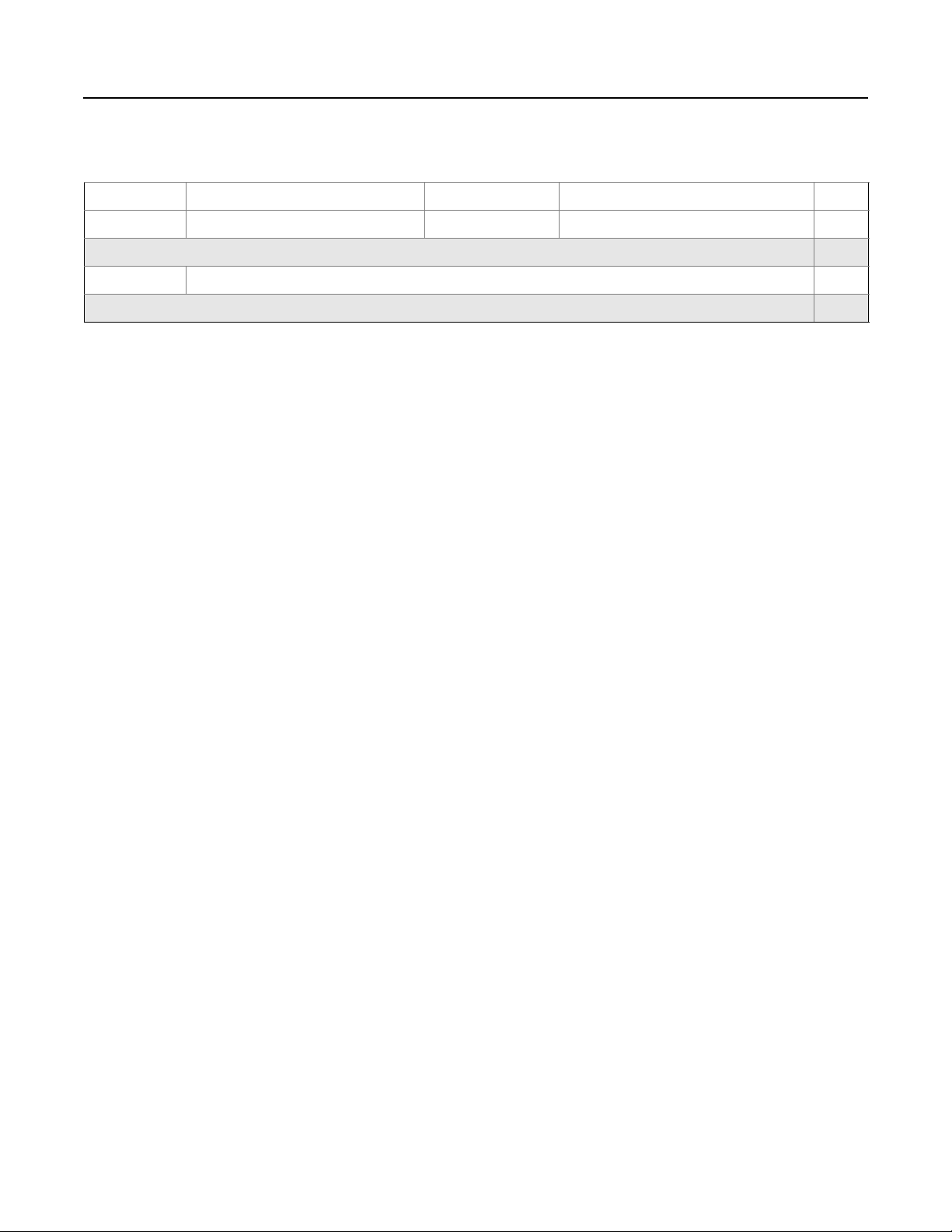

Table 2. Cone Antenna Ordering Information

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

DT 6 in. Tri-Clamp Flange SST 316L Longer Lead-time, Consult Factory

ET 8 in. Tri-Clamp Flange SST 316L Longer Lead-time, Consult Factory

Options

Q8 Material Traceability Certification per EN 10204 3.1

Typical model number: Selected code from Table 1 on page 5 24S P V NR

★

8

www.rosemount.com

July 2014

Rosemount 5600 Series

Table 3. Extended Cone Antenna Ordering Information

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Antenna type Antenna size Antenna material Note

73S 3 in. (DN80) nozzles SST 316L Standard length 20 inch (500 mm)

74S 4 in. (DN100) nozzles SST 316L Standard length 20 inch (500 mm)

76S 6 in. (DN150) nozzles SST 316L Standard length 20 inch (500 mm)

7XX Customer specific extended cone or material Consult factory

Tank seal

PPTFE

QQuartz

O-ring material Tan k seal

VViton

K Kalrez 6375 Perfluoroelastomer P, Q

E Ethylene Propylene (EPDM) P

Fluoroelastomer P, Q

B Nitrile Butadiene (NBR) P

Process connection Note

NR Antenna with Plate Design

XX Special Process Connection Consult factory

Options

Q8 Material Traceability Certification per EN 10204 3.1

Typical model number: Selected code from Table 1 on page 5 76S P V NR

Customer supplied flange or see Tab le 10

on page 14 for flange options

★

www.rosemount.com

9

Rosemount 5600 Series

July 2014

Table 4. Cone Antenna with Integrated Flushing Connection Ordering Information

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Antenna type Antenna size Antenna material Note

94S 4 in. (DN100) nozzles SST 316L Consult factory

96S 6 in. (DN150) nozzles SST 316L Consult factory

98S 8 in. (DN200) nozzles SST 316L Consult factory

Tank seal

PPTFE

QQuartz

O-ring material Tan k seal

V Viton Fluoroelastomer P, Q

K Kalrez 6375 Perfluoroelastomer P, Q

E Ethylene Propylene (EPDM) P

B Nitrile Butadiene (NBR) P

Process connection Note

XX Special Process Connection Consult factory

Stainless steel flange welded to antenna Note

(1)

CL 4 in. ASME Class 150 Max 101 psig at 392 °F (7 bar at 200 °C)

DL 6 in. ASME Class 150 Max 145 psig at 392 °F (10 bar at 200 °C)

FL 8 in. ASME Class 150 Max 145 psig at 392 °F (10 bar at 200 °C)

JL DN100 PN16 Max 72 psig at 392 °F (5 bar at 200 °C)

KL DN150 PN16 Max 87 psig at 392 °F (6 bar at 200 °C)

LL DN200 PN16 Max 87 psig at 392 °F (6 bar at 200 °C)

CH 4 in. ASME Class 150, SST, Higher Pressure Max 145 psig at 752 °F (10 bar at 400 °C)

DH 6 in. ASME Class 150, SST, Higher Pressure Max 145 psig at 752 °F (10 bar at 400 °C)

FH 8 in. ASME Class 150, SST, Higher Pressure Max 145 psig at 752 °F (10 bar at 400 °C)

JH DN100 PN 16, SST< Higher Pressure Max 145 psig at 752 °F (10 bar at 400 °C)

KH DN150 PN 16, SST< Higher Pressure Max 145 psig at 752 °F (10 bar at 400 °C)

LH DN200 PN 16, SST< Higher Pressure Max 145 psig at 752 °F (10 bar at 400 °C)

Options

Q8 Material Traceability Certification per EN 10204 3.1

★

Typical model number: Selected code from Table 1 on page 5 94S P K KL

(1) Pressure and Temperature rating may be lower depending on Tank Seal selection.

10

www.rosemount.com

July 2014

Rosemount 5600 Series

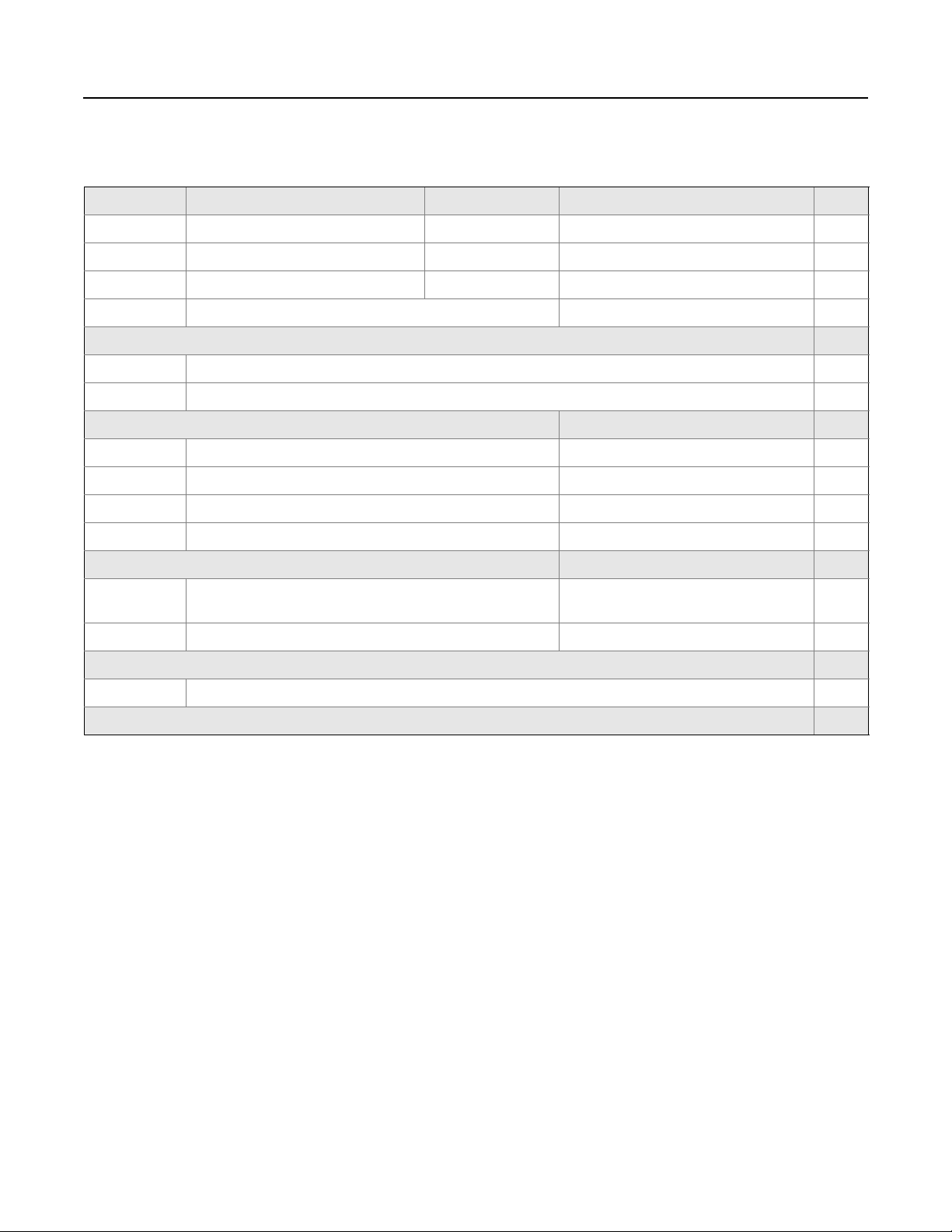

Table 5. Parabolic Antenna Ordering Information

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Antenna type Antenna size Antenna material Note

45S Ø18 in. (440mm) SST

46S Ø18 in. (440mm) SST

Clamped with Integrated Inclination,

Low pressure version

Welded with Integrated Inclination, High

pressure version

4XX Customer specific Customer specific Consult factory

Tank seal

PPTFE

O-ring material

V Viton Fluoroelastomer

Process connection Note

NF None, Flange Ready N/A

XX Special Process Connection Consult factory

Options

Q8 Material Traceability Certification per EN 10204 3.1

PB PTFE Protective Cover (PTFE Bag). Not suitable for hazardous applications.

(1)

Typical model number: Selected code from Table 1 on page 5 45S P V NR

(1) Not suitable for use in Ex environments.

★

★

★

★

★

★

www.rosemount.com

11

Loading...

Loading...