Rosemount 5408 Specifications

00813-0100-4408, Rev BB

Rosemount™ 5408 and 5408:SIS Level

Transmitters

Non-Contacting Radar

Product Data Sheet

March 2018

■ Unique energy-efficient two-wire FMCW radar technology for optimal performance

■ Engineered and user tested for best in class safety, reliability, and ease-of-use

■ Built on 40 years of inventing and redefining radar level measurement

■ Intuitive commissioning experience driven by wizards and adaptive graphics

■ Rosemount 5408:SIS, optimal for safety applications and IEC 61508 certified to SIL 2

■ Safe, easy, and remote proof testing without process interruptions

G

I

LQ

I

PD[

I

PLQ

I

RXW

I

LQ

I

RXW

W

I

$

&

'

%

Rosemount 5408 Series

March 2018

Introduction

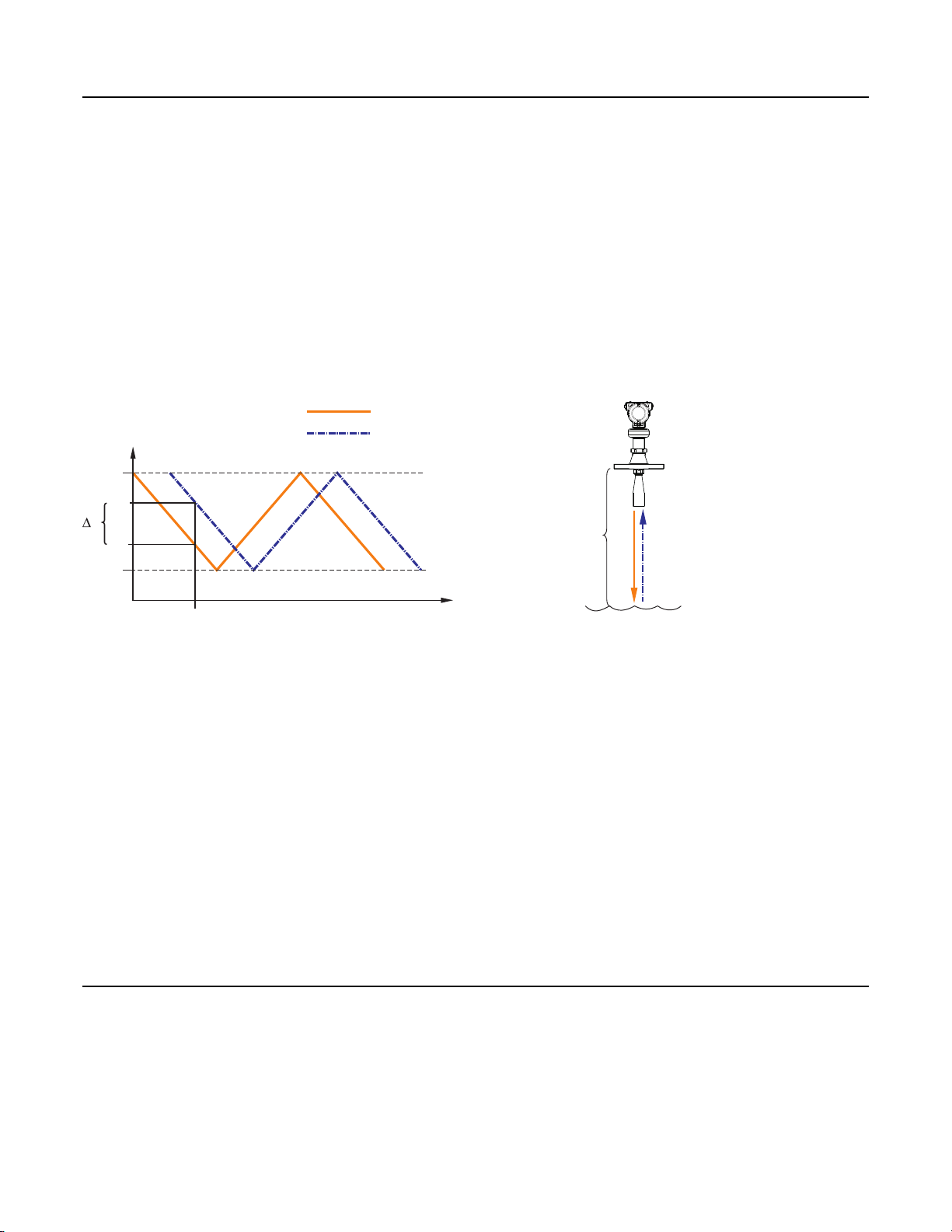

Measurement principle

The Rosemount™ 5408 and 5408:SIS are two-wire transmitters for continuous level measurements over a broad range of liquids,

slurries, and solids. The measurement principle is fast-sweep Frequency Modulated Continuous Wave (FMCW).

Radar signals are continuously transmitted towards the product surface with a microwave frequency modulated over a span. The

level is proportional to the frequency difference between currently received and transmitted signal.

FMCW-methodFigure 1:

Δ

f≈d=distance

A. Frequency (GHz)

B. Time (s)

C. Transmitted signal

D. Reflected signal

Technology to redefine reliability

The Rosemount 5408 and 5408:SIS are optimized for reliable and accurate performance even in challenging process conditions.

FMCW technology maximizes radar signal strength and produces a robust and reliable measurement (with 30 times more power on

the surface than traditional two-wire non-contacting radars).

The transmitters can operate with only 12 Vdc lift-off voltage and they are self-powered for up to 2 seconds to maintain operation

despite cable glitches or lightning.

Contents

Introduction .................................................................................................................................................................2

Ordering Information ................................................................................................................................................... 6

Specifications .............................................................................................................................................................18

Product Certifications .................................................................................................................................................41

Dimensional drawings ................................................................................................................................................59

2 Emerson.com/Rosemount

30x

March 2018

Rosemount 5408 Series

Ease-of-use at every touch point

The Rosemount 5408 and 5408:SIS are designed to simplify operator tasks. They deliver ease-of-use at every touch point, from the

pictorial user instructions and graphical, intuitive wizards to the PTFE seal that requires no O-ring material for simplifying model

selection.

Dedicated to safety

The Smart Diagnostics Suite provides operators with early alerts in case of antenna build-up, weak power supply, or abnormal

surface conditions. Also, a local memory enables full insight into the last seven days of measurements, alerts, and echo profiles.

The Rosemount 5408:SIS is the ideal choice for functional safety such as overfill prevention. It is safety certified (SIL 2/SIL 3),

supports long proof-test intervals guaranteed to suit your schedule, and can be tested remotely without any process interruption.

Emerson.com/Rosemount 3

Rosemount 5408 Series

March 2018

Application examples

The Rosemount 5408 and 5408:SIS are ideal for level measurements over a broad range of liquid and solids applications. The

transmitters are virtually unaffected by changing density, temperature, pressure, media dielectric, pH, and viscosity. Noncontacting radar level is ideal for harsh conditions such as corrosive and sticky media, or when internal tank obstructions are a

limiting factor.

Storage and buffer tanks

The Rosemount 5408 provides accurate and reliable level measurement for both metallic or non-metallic vessels containing almost

any liquid (e.g. oil, gas condensate, water, chemicals).

Reactors

The Rosemount 5408 is ideal for the most challenging applications, including reactors where there can be agitation, foaming,

condensation as well as high temperatures and pressures.

Blenders and mixers

The Rosemount 5408 can help you withstand the rigors of blenders and mixing tanks. Easy to install and commission, it is also

unaffected by virtually any fluid property change.

Open atmospheric applications

The Rosemount 5408 measures reliably in open applications, from short range sumps or ponds to long range dams.

4 Emerson.com/Rosemount

SI

L 2

March 2018

Rosemount 5408 Series

Still pipe and chamber installations

The Rosemount 5408 is an excellent choice for level measurement in tanks with still pipes. It may also be used in chambers, but

guided wave radar is generally the best fit for these applications. See Still pipe/chamber installations for installation guidelines.

Bulk solids

The Rosemount 5408 is the ideal solution for small to medium sized silos with rapid level changes. The narrow beam avoids internal

obstructions while still keeping good level measurement.

Safety applications

The Rosemount 5408:SIS is the ideal choice for safety functions such as overfill prevention, level deviation monitoring or dry-run

prevention.

Emerson.com/Rosemount 5

Rosemount 5408 Series

March 2018

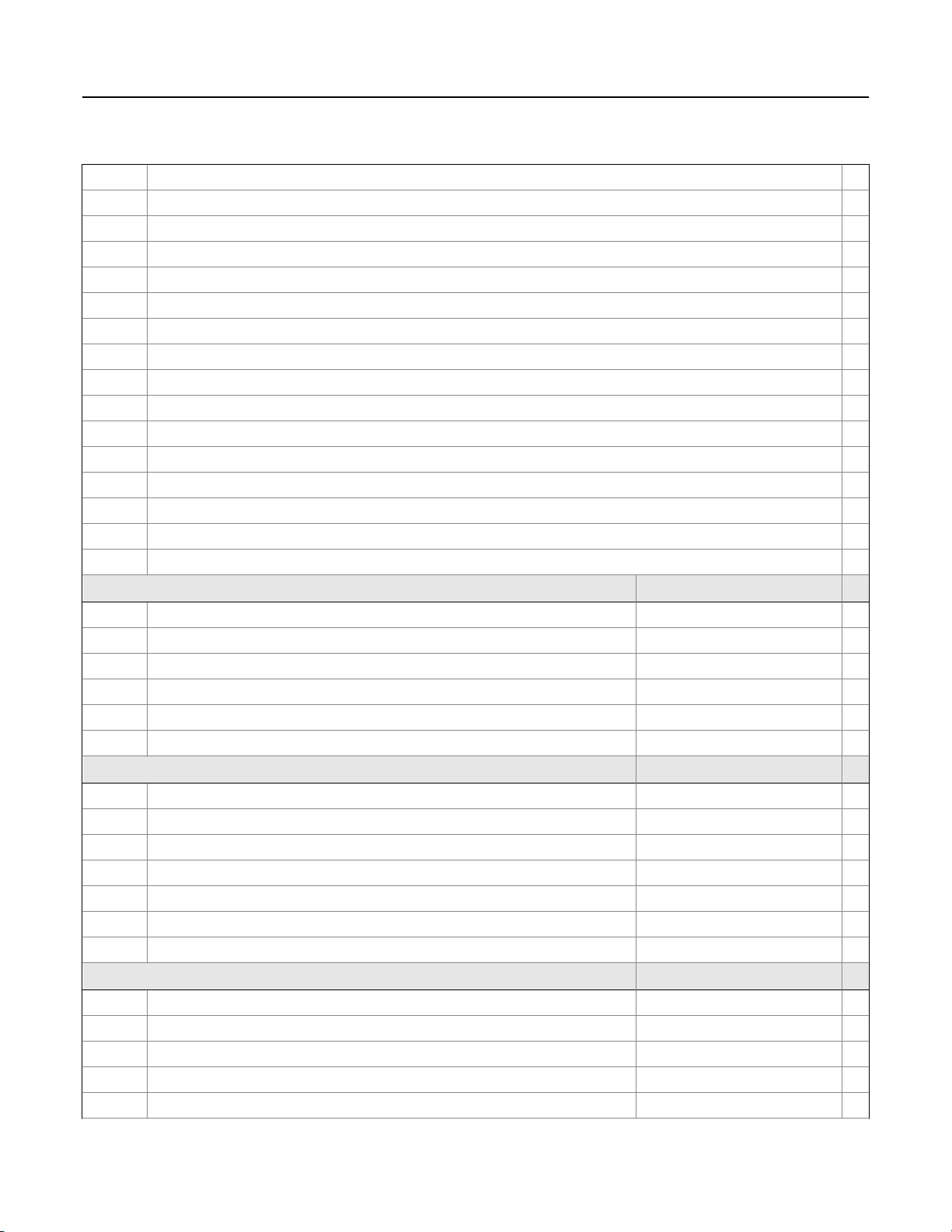

Ordering Information

Rosemount 5408 Level Transmitter

The Rosemount 5408 is a two-wire non-contacting radar transmitter for level measurements over a broad

range of liquids and slurries. It uses a unique energy efficient radar technology based on the FMCW principle

to ensure reliable performance even in challenging conditions.

Specification and selection of product materials, options, or components must be made by the purchaser of

the equipment. See Material selection for more information on material selection.

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings

are subject to additional delivery lead time.

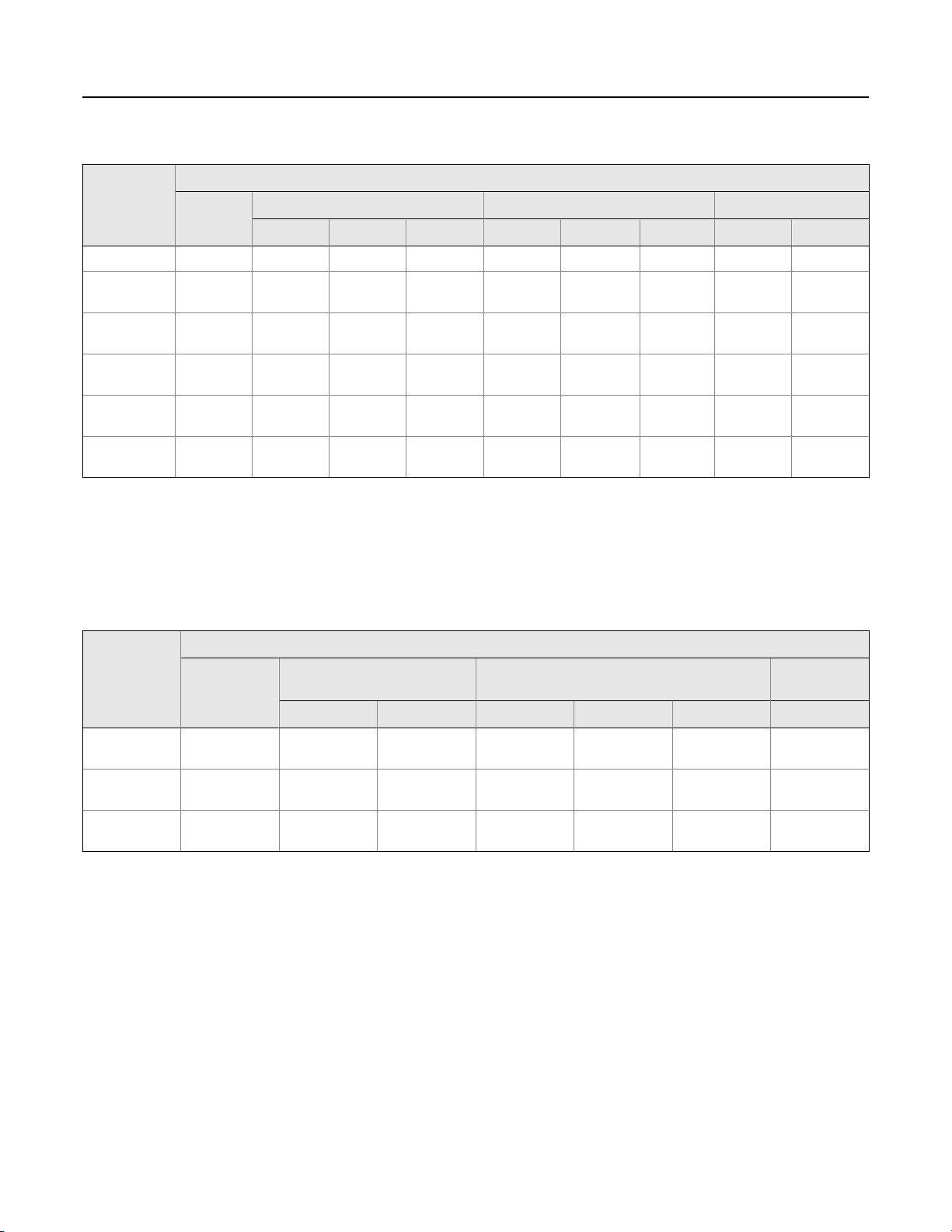

Rosemount 5408 Level Transmitter Ordering InformationTable 1:

Model Product Description

5408 Radar Level Transmitter ★

Profile

A Standard Monitoring & Control Applications ★

Measurement type

1 Liquid Level Measurement ★

3 Solids Level Measurement ★

4 Liquid & Solids Level Measurement ★

Performance class

S Standard ★

Signal output

H 4–20 mA with digital signal based on HART® Revision 6 protocol (HART Revision 7 available as option) ★

Housing material

A Aluminum ★

S Stainless Steel (SST) ★

Conduit/cable threads

1 ½-14 NPT ★

2 M20 x 1.5 ★

(1)

3

G½

Hazardous locations certifications

NA None ★

E1 ATEX Flameproof ★

6 Emerson.com/Rosemount

March 2018

Rosemount 5408 Series

Rosemount 5408 Level Transmitter Ordering Information (continued)Table 1:

I1 ATEX Intrinsic Safety ★

N1 ATEX Type n ★

E5 USA Explosion-proof, Dust Ignition-proof ★

I5 USA Intrinsically Safe; Nonincendive ★

E6 Canadian Explosion-proof, Dust Ignition-proof ★

I6 Canadian Intrinsically Safe; Nonincendive ★

E7 IECEx Flameproof, Dust Ignition-proof ★

I7 IECEx Intrinsic Safety ★

N7 IECEx Type n ★

E2 INMETRO Flameproof ★

I2 INMETRO Intrinsic Safety ★

N2 INMETRO Type n ★

E3 China Flameproof ★

I3 China Intrinsic Safety ★

N3 China Type n ★

IP Republic of Korea Intrinsic Safety ★

Materials of construction Available antenna types

1 316/316L/EN 1.4404 Cone, Parabolic ★

7 All PTFE Wetted Parts Process Seal ★

2 Alloy C-276 (UNS N10276) with Protective Plate Cone

3 Alloy 400 (UNS N04400) with Protective Plate Cone

H Alloy C-276 (UNS N10276) Process Connection, Flange, and Antenna Cone

M Alloy 400 (UNS N04400) Process Connection, Flange, and Antenna Cone

Process connection type (see Table 3, Table 4, Table 5, and Table 6) Available antenna types

(2)

F

(3)

R

Flat Face Flange Cone, Parabolic ★

Raised Face Flange All ★

N NPT Thread Cone ★

G BSPP (G) Thread Cone, Parabolic ★

B Bracket Mounting Cone ★

C Tri-Clamp

®

Process Seal ★

W Welded Connection Parabolic ★

Process connection size (see Table 3, Table 4, Table 5, and Table 6) Available antenna types

A 1½-in. Cone ★

2 2-in./DN50/50A Cone, Process Seal ★

3 3-in./DN80/80A Cone, Process Seal ★

B 3½-in. Parabolic ★

4 4-in./DN100/100A Cone, Process Seal ★

Emerson.com/Rosemount 7

Rosemount 5408 Series

March 2018

Rosemount 5408 Level Transmitter Ordering Information (continued)Table 1:

6 6-in./DN150/150A Cone ★

8 8-in./DN200/200A Cone, Parabolic ★

T 10-in./DN250/250A Parabolic ★

Z None (use when ordering bracket mounting) Cone ★

Process connection rating (see Table 3, Table 4, Table 5, and Table 6)

ZZ For use with non-flange process connection type ★

ASME flanges

AA ASME B16.5 Class 150 ★

AB ASME B16.5 Class 300 ★

AC ASME B16.5 Class 600 ★

EN flanges Note

DK EN1092-1 PN6 N/A ★

DA EN1092-1 PN16 PN10 and PN16 dimensions are identical for DN50 to DN150 ★

DB EN1092-1 PN40 PN25 and PN40 dimensions are identical for DN50 to DN150 ★

DC EN1092-1 PN63 N/A ★

DD EN1092-1 PN100 N/A ★

JIS flanges

JK JIS 5K ★

JA JIS 10K ★

JB JIS 20K ★

Antenna type Operating pressure Operating temperature

CAA Cone Antenna (PTFE seal) -15 to 363 psig (-1 to 25 bar) -76 to 392 °F (-60 to 200 °C) ★

CAB Cone Antenna (PTFE seal) -15 to 725 psig (-1 to 50 bar)

(4)

-40 to 302 °F (-40 to 150 °C) ★

CAC Cone Antenna (PTFE seal) -15 to 1450 psig (-1 to 100 bar) -40 to 212 °F (-40 to 100 °C) ★

CAD Cone Antenna (PTFE seal) -15 to 44 psig (-1 to 3 bar) -76 to 482 °F (-60 to 250 °C) ★

CBF Cone Antenna (PEEK seal, FVMQ) -15 to 754 psig (-1 to 52 bar) -76 to 338 °F (-60 to 170 °C) ★

CBK Cone Antenna (PEEK seal, Kalrez® 6375) -15 to 754 psig (-1 to 52 bar) 5 to 482 °F (-15 to 250 °C) ★

CBM Cone Antenna (PEEK seal, FKM) -15 to 754 psig (-1 to 52 bar) -13 to 428 °F (-25 to 220 °C) ★

CBV Cone Antenna (PEEK seal, Viton®) -15 to 754 psig (-1 to 52 bar) -22 to 392 °F (-30 to 200 °C) ★

SAA Process Seal Antenna -7 to 363 psig (-0.5 to 25 bar)

(5)

-76 to 392 °F (-60 to 200 °C)

(5)

PAS Parabolic Antenna, Swivel Mount -7 to 43 psig (-0.5 to 3 bar) -67 to 392 °F (-55 to 200 °C) ★

Antenna size Available antenna types

2 2-in. (DN50) Cone, Process Seal ★

3 3-in. (DN80) Cone, Process Seal ★

4 4-in. (DN100) Cone, Process Seal ★

8 8-in. (DN200) Parabolic ★

★

8 Emerson.com/Rosemount

March 2018

Rosemount 5408 Series

Rosemount 5408 Level Transmitter Ordering Information (continued)Table 1:

Options (include with selected model number)

Antenna extensions (see Figure 20) Total length

S1 Extended Cone Antenna 24-in. (600 mm) ★

S2 Extended Cone Antenna, Segmented 48-in. (1200 mm) ★

Purging connection (see Figure 12)

PC1 Purging Connector (Purge Ring) ★

Display

M5 LCD Display ★

Functional safety options

EF1 Ready for upgrade to Rosemount 5408:SIS ★

Diagnostic functionality

DA1 Smart Diagnostics Suite (see Smart Diagnostics Suite (option code DA1)) ★

HART revision configuration

HR7 4-20 mA with digital signal based on HART Revision 7 protocol ★

Open air applications configuration

OA Open Air Applications Configuration; LPR (Level Probing Radar) ★

(6)(7)

(8)

Factory configuration

C1 Factory Configuration per Configuration Data Sheet ★

Alarm limits

C4 NAMUR Alarm and Saturation Levels, High Alarm ★

C5 NAMUR Alarm and Saturation Levels, Low Alarm ★

(9)

C8

Welding standard for flanges

Standard Rosemount Alarm and Saturation Levels, Low Alarm ★

(10)

AW According to ASME IX ★

EW According to EN-ISO ★

Country certification

(11)

J1 Canadian Registration (CRN) ★

Special quality assurance

Q4 Calibration Data Certificate ★

Hydrostatic testing

(12)

Q5 Hydrostatic Testing, including certificate ★

Material traceability certification

(13)

Q8 Material Traceability Certification per EN 10204 3.1 (2.1 for non-metallic) ★

Hygienic certification

QA Certificate of compliance to 3-A

(14)

®

★

Emerson.com/Rosemount 9

Rosemount 5408 Series

March 2018

Rosemount 5408 Level Transmitter Ordering Information (continued)Table 1:

Materials certification

Q15 NACE® Material Recommendation per NACE MR0175/ISO 15156 ★

Q25 NACE Material Recommendation per ANSI/NACE MR0103/ISO 17495-1 ★

Q35 NACE Material Recommendation per NACE MR0175/ISO 15156 and ANSI/NACE MR0103/ISO 17495-1 ★

Welding procedure qualification record documentation

Q66 Welding Procedure Qualification Record (WPQR) ★

Q67 Welder Performance Qualification (WPQ) ★

Q68 Welding Procedure Specification (WPS) ★

Q79 WPQR/WPQ/WPS ★

Dye penetration test certificate

Q73 Certificate of Liquid Penetrant Inspection ★

Positive material identification certificate

Q76 Positive Material Identification Certificate of Conformance ★

Overfill prevention

U1 Overfill Prevention According to WHG/TUV ★

(15)

(10)

(10)

Extended product warranty

WR3 3-year Limited Warranty ★

WR5 5-year Limited Warranty ★

Conduit electrical connector (shipped uninstalled)

(16)

EC M 12, 4-pin, Male connector (eurofast®) ★

MC A size Mini, 4-pin, Male connector (minifast®) ★

Specials (see Engineered solutions)

PXXXX Custom Engineered Solutions beyond standard model codes. Consult factory for details.

Typical model number: 5408 A 1 S H A 1 E5 1 R 3 AB CAB 3 M5 DA1

(1) G½ thread form is not available with hazardous locations approvals.

(2) Type A flat face for EN 1092-1 flanges.

(3) Type B1 raised face for EN 1092-1 flanges.

(4) Pressure limit is derated for process temperatures above 100 °F (38 °C), see Figure 6 for details.

(5) Refer to Figure 8 for pressure/temperature ratings of Tri-Clamp connection.

(6) Option code PC1 is for cone antennas only, and requires matching flange and antenna sizes. Note that all parabolic antennas come with an

integrated air purge connection.

(7) A minimum gasket thickness of 0.125 in. (3.2 mm) is required for flanges with protective plate design.

(8) Only available with parabolic antenna and 4-in. (DN100) cone antenna.

(9) The standard alarm setting is high.

(10) Only applies to flanged process connections with welded construction or protective plate design; only applicable to cone antennas (see Table 3

and Table 4).

(11) Only available with ASME B16.5 flange connections, and materials of construction codes 1 and 7.

(12) Hydrostatic testing is only available for cone antennas and process seal antennas with flanged process connections.

(13) Certificate includes all pressure retaining and wetted parts.

(14) Only available for process seal antennas with Tri-Clamp connection.

(15) Not available with parabolic antenna.

(16) Requires ½-14 NPT conduit/cable threads (code 1). Available with Intrinsically Safe approvals only.

10 Emerson.com/Rosemount

March 2018

Rosemount 5408 Series

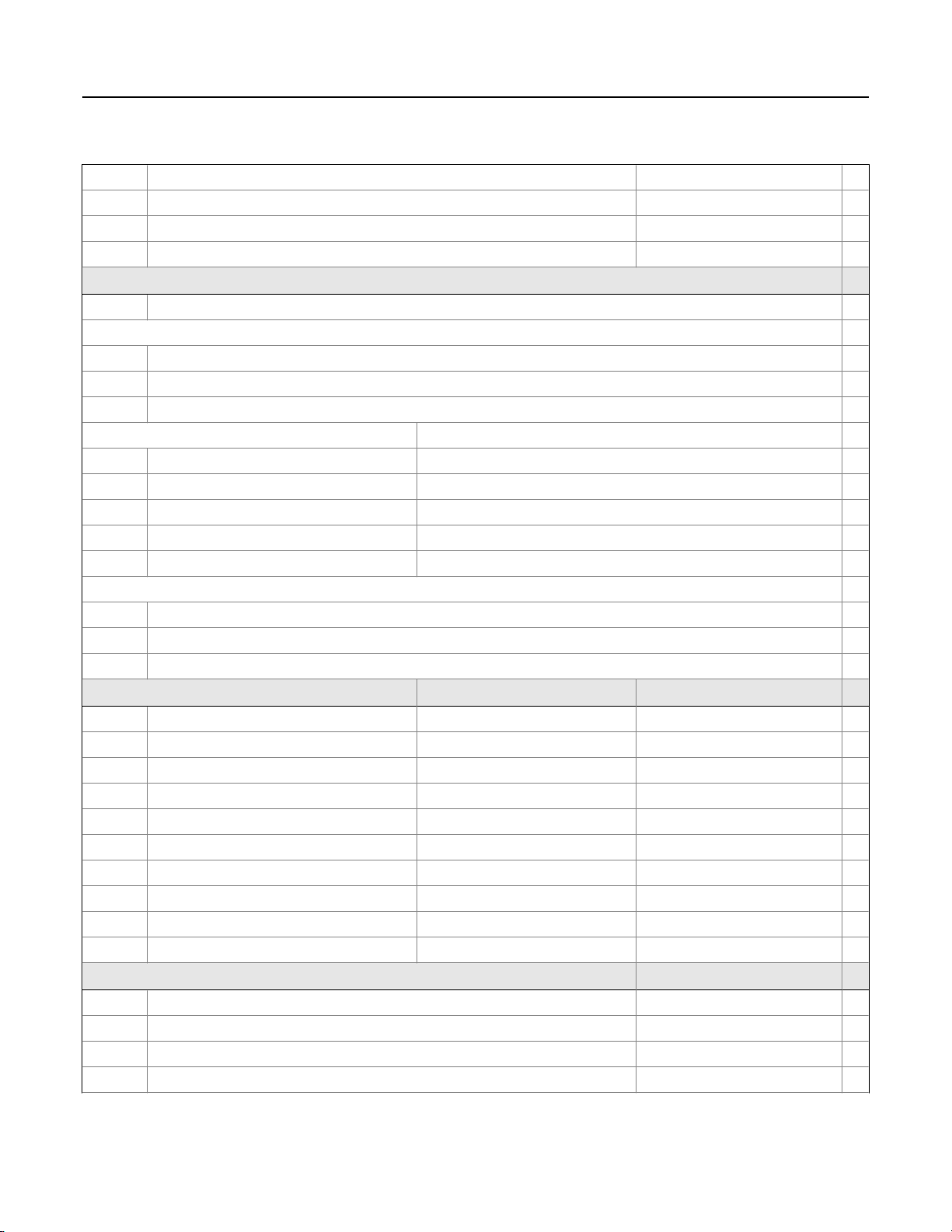

Rosemount 5408:SIS Level Transmitter

Safety certified to IEC 61508 for SIL2 applications with SIL3 capability, the Rosemount 5408:SIS reduces

cost of risk, increases efficiency and protects your staff and the environment.

Specification and selection of product materials, options, or components must be made by the purchaser of

the equipment. See Material selection for more information on material selection.

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings

are subject to additional delivery lead time.

Rosemount 5408:SIS Level Transmitter Ordering InformationTable 2:

Model Product Description

5408 Radar Level Transmitter ★

(1)

Profile

F Functional Safety / SIS Applications ★

Measurement type

1 Liquid Level Measurement ★

(2)

4

Performance class

S Standard ★

Signal output

H 4–20 mA with digital signal based on HART Revision 6 protocol (HART Revision 7 available as option) ★

Housing material

A Aluminum ★

S Stainless Steel (SST) ★

Conduit/cable threads

1 ½-14 NPT ★

2 M20 x 1.5 ★

(3)

3

Hazardous locations certifications

NA None ★

E1 ATEX Flameproof ★

I1 ATEX Intrinsic Safety ★

N1 ATEX Type n ★

E5 USA Explosion-proof, Dust Ignition-proof ★

I5 USA Intrinsically Safe; Nonincendive ★

Liquid & Solids Level Measurement ★

G½

Emerson.com/Rosemount 11

Rosemount 5408 Series

March 2018

Rosemount 5408:SIS Level Transmitter Ordering Information (continued)Table 2:

E6 Canadian Explosion-proof, Dust Ignition-proof ★

I6 Canadian Intrinsically Safe; Nonincendive ★

E7 IECEx Flameproof, Dust Ignition-proof ★

I7 IECEx Intrinsic Safety ★

N7 IECEx Type n ★

E2 INMETRO Flameproof ★

I2 INMETRO Intrinsic Safety ★

N2 INMETRO Type n ★

E3 China Flameproof ★

I3 China Intrinsic Safety ★

N3 China Type n ★

IP Republic of Korea Intrinsic Safety ★

Materials of construction Available antenna types

1 316/316L/EN 1.4404 Cone, Parabolic ★

7 All PTFE Wetted Parts Process Seal ★

2 Alloy C-276 (UNS N10276) with Protective Plate Cone

3 Alloy 400 (UNS N04400) with Protective Plate Cone

H Alloy C-276 (UNS N10276) Process Connection, Flange, and Antenna Cone

M Alloy 400 (UNS N04400) Process Connection, Flange, and Antenna Cone

Process connection type (see Table 3, Table 4, Table 5, and Table 6) Available antenna types

(4)

F

(5)

R

N NPT Thread Cone ★

G BSPP (G) Thread Cone, Parabolic ★

B Bracket Mounting Cone ★

C Tri-Clamp Process Seal ★

W Welded Connection Parabolic ★

Process connection size (see Table 3, Table 4, Table 5, and Table 6) Available antenna types

A 1½-in. Cone ★

2 2-in./DN50/50A Cone, Process Seal ★

3 3-in./DN80/80A Cone, Process Seal ★

B 3½-in. Parabolic ★

4 4-in./DN100/100A Cone, Process Seal ★

6 6-in./DN150/150A Cone ★

8 8-in./DN200/200A Cone, Parabolic ★

T 10-in./DN250/250A Parabolic ★

Z None (use when ordering bracket mounting) Cone ★

Flat Face Flange Cone, Parabolic ★

Raised Face Flange All ★

12 Emerson.com/Rosemount

March 2018

Rosemount 5408 Series

Rosemount 5408:SIS Level Transmitter Ordering Information (continued)Table 2:

Process connection rating (see Table 3, Table 4, Table 5, and Table 6)

ZZ For use with non-flange process connection type ★

ASME flanges

AA ASME B16.5 Class 150 ★

AB ASME B16.5 Class 300 ★

AC ASME B16.5 Class 600 ★

EN flanges Note

DK EN1092-1 PN6 N/A ★

DA EN1092-1 PN16 PN10 and PN16 dimensions are identical for DN50 to DN150 ★

DB EN1092-1 PN40 PN25 and PN40 dimensions are identical for DN50 to DN150 ★

DC EN1092-1 PN63 N/A ★

DD EN1092-1 PN100 N/A ★

JIS flanges

JK JIS 5K ★

JA JIS 10K ★

JB JIS 20K ★

Antenna type Operating pressure Operating temperature

CAA Cone Antenna (PTFE seal) -15 to 363 psig (-1 to 25 bar) -76 to 392 °F (-60 to 200 °C) ★

CAB Cone Antenna (PTFE seal) -15 to 725 psig (-1 to 50 bar)

(6)

-40 to 302 °F (-40 to 150 °C) ★

CAC Cone Antenna (PTFE seal) -15 to 1450 psig (-1 to 100 bar) -40 to 212 °F (-40 to 100 °C) ★

CAD Cone Antenna (PTFE seal) -15 to 44 psig (-1 to 3 bar) -76 to 482 °F (-60 to 250 °C) ★

CBF Cone Antenna (PEEK seal, FVMQ) -15 to 754 psig (-1 to 52 bar) -76 to 338 °F (-60 to 170 °C) ★

CBK Cone Antenna (PEEK seal, Kalrez 6375) -15 to 754 psig (-1 to 52 bar) 5 to 482 °F (-15 to 250 °C) ★

CBM Cone Antenna (PEEK seal, FKM) -15 to 754 psig (-1 to 52 bar) -13 to 428 °F (-25 to 220 °C) ★

CBV Cone Antenna (PEEK seal, Viton) -15 to 754 psig (-1 to 52 bar) -22 to 392 °F (-30 to 200 °C) ★

SAA Process Seal Antenna -7 to 363 psig (-0.5 to 25 bar)

(7)

-76 to 392 °F (-60 to 200 °C)

(7)

PAS Parabolic Antenna, Swivel Mount -7 to 43 psig (-0.5 to 3 bar) -67 to 392 °F (-55 to 200 °C) ★

Antenna size Available antenna types

2 2-in. (DN50) Cone, Process Seal ★

3 3-in. (DN80) Cone, Process Seal ★

4 4-in. (DN100) Cone, Process Seal ★

8 8-in. (DN200) Parabolic ★

Options (include with selected model number)

Antenna extensions (see Figure 20) Total length

S1 Extended Cone Antenna 24-in. (600 mm) ★

S2 Extended Cone Antenna, Segmented 48-in. (1200 mm) ★

★

Emerson.com/Rosemount 13

Rosemount 5408 Series

March 2018

Rosemount 5408:SIS Level Transmitter Ordering Information (continued)Table 2:

Purging connection (see Figure 12)

PC1 Purging Connector (Purge Ring) ★

Display

M5 LCD Display ★

Functional safety options

EF2 Extended SIS Package ★

Diagnostic functionality

DA1 Smart Diagnostics Suite (see Smart Diagnostics Suite (option code DA1)) ★

HART revision configuration

HR7 4-20 mA with digital signal based on HART Revision 7 protocol ★

Factory configuration

C1 Factory Configuration per Configuration Data Sheet ★

Alarm limits

C4 NAMUR Alarm and Saturation Levels, High Alarm ★

C5 NAMUR Alarm and Saturation Levels, Low Alarm ★

(10)

C8

Standard Rosemount Alarm and Saturation Levels, Low Alarm ★

Welding standard for flanges

AW According to ASME IX ★

EW According to EN-ISO ★

Country certification

(12)

J1 Canadian Registration (CRN) ★

(8)(9)

(11)

Special quality assurance

Q4 Calibration Data Certificate ★

Hydrostatic testing

(13)

Q5 Hydrostatic Testing, including certificate ★

Material traceability certification

(14)

Q8 Material Traceability Certification per EN 10204 3.1 (2.1 for non-metallic) ★

Hygienic certification

(15)

QA Certificate of compliance to 3-A ★

Quality certification for safety

QS Certificate of FMEDA Data ★

QT Safety-certified to IEC 61508 with certificate of FMEDA data ★

Materials certification

(16)

Q15 NACE Material Recommendation per NACE MR0175/ISO 15156 ★

Q25 NACE Material Recommendation per ANSI/NACE MR0103/ISO 17495-1 ★

Q35 NACE Material Recommendation per NACE MR0175/ISO 15156 and ANSI/NACE MR0103/ISO 17495-1 ★

14 Emerson.com/Rosemount

March 2018

Rosemount 5408 Series

Rosemount 5408:SIS Level Transmitter Ordering Information (continued)Table 2:

Welding procedure qualification record documentation

Q66 Welding Procedure Qualification Record (WPQR) ★

Q67 Welder Performance Qualification (WPQ) ★

Q68 Welding Procedure Specification (WPS) ★

Q79 WPQR/WPQ/WPS ★

Dye penetration test certificate

(11)

Q73 Certificate of Liquid Penetrant Inspection ★

Positive material identification certificate

Q76 Positive Material Identification Certificate of Conformance ★

Overfill prevention

U1 Overfill Prevention According to WHG/TUV ★

Extended product warranty

WR3 3-year Limited Warranty ★

WR5 5-year Limited Warranty ★

(11)

Paint option for aluminum housing

PY1 Housing and Covers in Yellow per RAL 1003 ★

PY2 Covers in Yellow per RAL 1003 ★

PR1 Housing and Covers in Red per RAL 3002 ★

PR2 Covers in Red per RAL 3002 ★

PO1 Housing and Covers in Orange per Munsell 2.5 YR 6/14 ★

PO2 Covers in Orange per Munsell 2.5 YR 6/14 ★

Conduit electrical connector (shipped uninstalled)

(17)

EC M 12, 4-pin, Male connector (eurofast) ★

MC A size Mini, 4-pin, Male connector (minifast) ★

Specials (see Engineered solutions)

PXXXX Custom Engineered Solutions beyond standard model codes. Consult factory for details.

Typical model number: 5408 F 1 S H A 1 E5 1 R 3 AB CAB 3 M5 DA1 EF2 QT

(1) The Rosemount 5408:SIS has two operational modes: Safety (SIS) and Control/Monitoring. Safety (SIS) mode must be set when used in Safety

Instrumented Systems. Control/Monitoring mode is intended for use in a Basic Process Control System (BPCS).

(2) Solids level measurement is only available when operating in Control/Monitoring mode.

(3) G½ thread form is not available with hazardous locations approvals.

(4) Type A flat face for EN 1092-1 flanges.

(5) Type B1 raised face for EN 1092-1 flanges.

(6) Pressure limit is derated for process temperatures above 100 °F (38 °C), see Figure 6 for details.

(7) Refer to Figure 8 for pressure/temperature ratings of Tri-Clamp connection.

(8) Option code PC1 is for cone antennas only, and requires matching flange and antenna sizes. Note that all parabolic antennas come with an

integrated air purge connection.

(9) A minimum gasket thickness of 0.125 in. (3.2 mm) is required for flanges with protective plate design.

(10) The standard alarm setting is high.

Emerson.com/Rosemount 15

Rosemount 5408 Series

(11) Only applies to flanged process connections with welded construction or protective plate design; only applicable to cone antennas (see Table 3

and Table 4).

(12) Only available with ASME B16.5 flange connections, and materials of construction codes 1 and 7.

(13) Hydrostatic testing is only available for cone antennas and process seal antennas with flanged process connections.

(14) Certificate includes all pressure retaining and wetted parts.

(15) Only available for process seal antennas with Tri-Clamp connection.

(16) Not available with parabolic antenna.

(17) Requires ½-14 NPT conduit/cable threads (code 1). Available with Intrinsically Safe approvals only.

March 2018

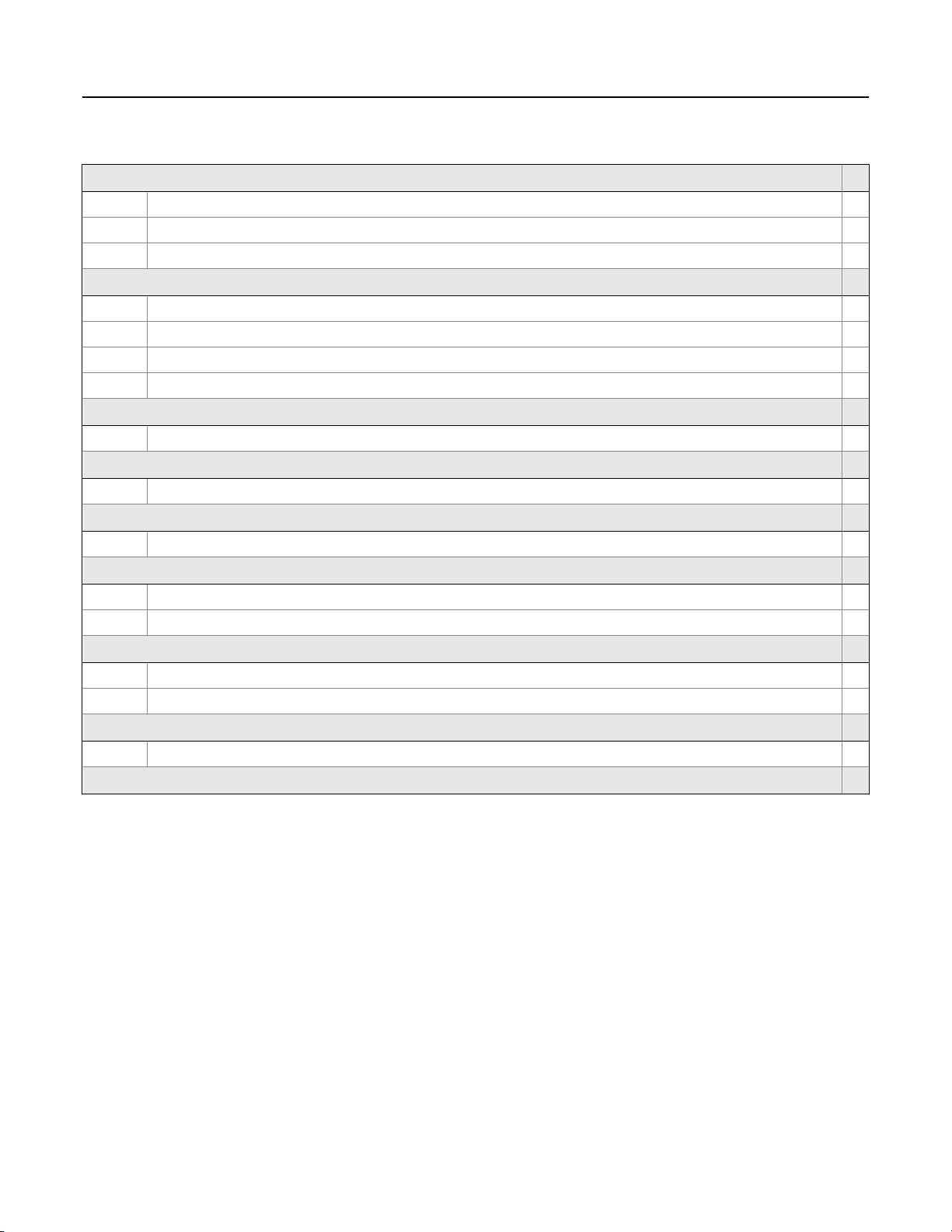

Availability of process connections

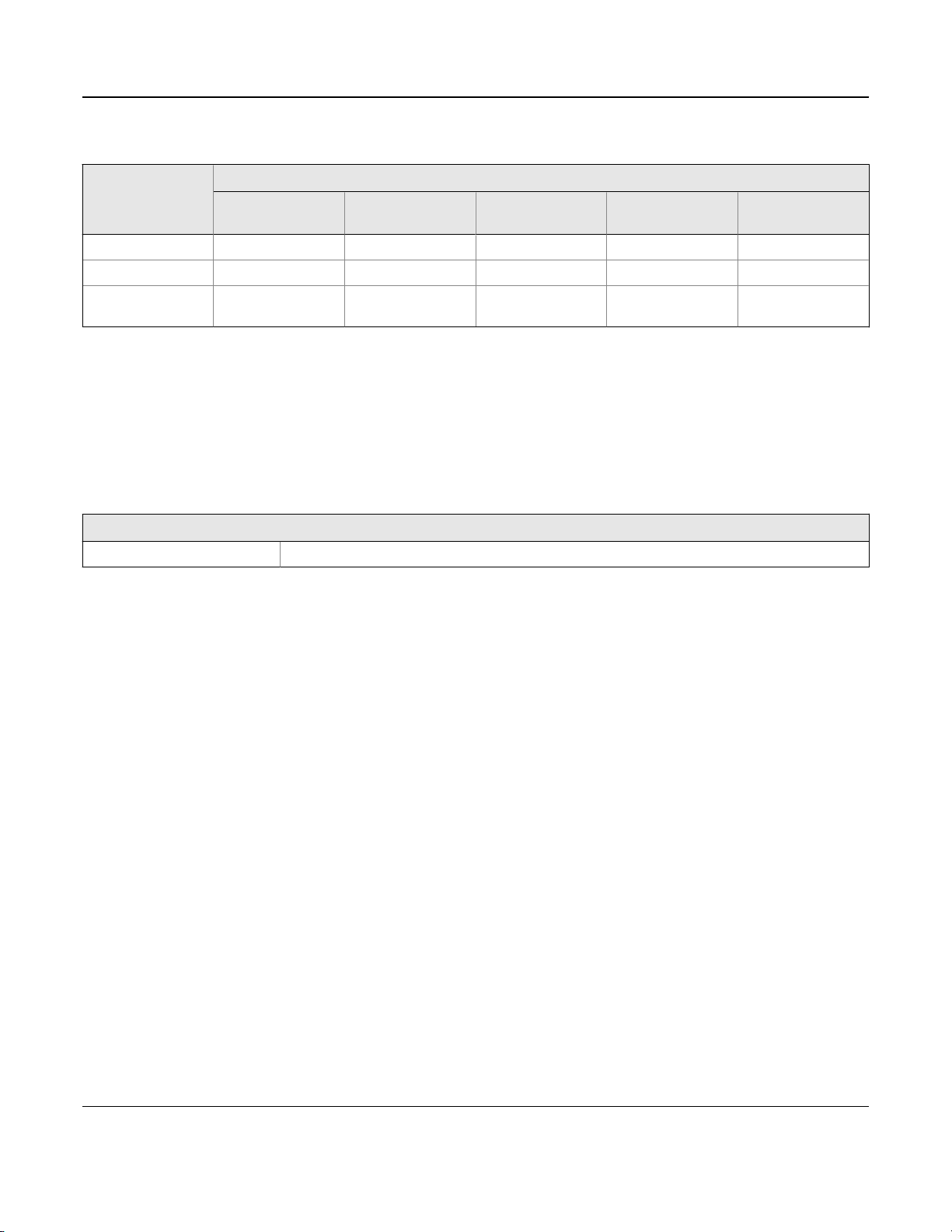

Cone Antenna - 316/316L SST/EN 1.4404 (Type vs. Size and Rating)Table 3:

Process connection rating

ASME B16.5 flanges

(2)

EN1092-1 flanges

(2)

JIS B2220 flanges

(2)

Process connection size

Thread

(1)

Class

150

(3)

Class

300

(3)

Class

600

(4)

PN16

(5)

PN40

(5)

PN63

(4)

PN100

(4)

10K

(3)

1½-in. G, N N/A N/A N/A N/A N/A N/A N/A N/A N/A

2-in./DN50/50A G, N R R R F F, R F, R F R R

3-in./DN80/80A G, N R R R F, R F, R F, R F, R R R

4-in./

G, N R R N/A F, R F, R F F R R

DN100/100A

6-in./

N/A R R N/A F, R F, R N/A N/A R R

DN150/150A

8-in./

N/A R R N/A F, R F, R N/A N/A R R

DN200/200A

(1) BSPP (G) thread (process connection type code G). N = NPT thread (process connection type code N)

(2) F = Flat Face (process connection type code F). R = Raised Face (process connection type code R)

(3) Forged one-piece flange (see Figure 24).

(4) Welded construction (see Figure 24).

(5) Welded construction for type A flat face; forged one-piece flange for type B1 raised face.

20K

(4)

16 Emerson.com/Rosemount

March 2018

Rosemount 5408 Series

Cone Antenna - Alloy C-276 and Alloy 400 (Type vs. Size and Rating)Table 4:

Process connection rating

(2)(3)

EN1092-1 flanges

Process connection size

Thread

ASME B16.5 flanges

(1)

Class 150 Class 300 Class 600 PN16 PN40 PN63 10K 20K

1½-in. N N/A N/A N/A N/A N/A N/A N/A N/A

2-in./

N R

(5)

(5)

R

(5)

R

R R R R R

DN50/50A

3-in./

N/A R

(5)

(5)

R

(5)

R

R R R R R

DN80/80A

4-in./

N/A R

(5)

(5)

R

N/A R R R R R

DN100/100A

6-in./

N/A R

(5)

(6)

R

N/A R R N/A R R

DN150/150A

8-in./

N/A R

(6)

N/A N/A R R N/A R R

DN200/200A

(1) N = NPT thread (process connection type code N)

(2) R = Raised Face (process connection type code R)

(3) Welded construction for materials of construction codes H and M (see Figure 24).

(4) Backing flange in flat face.

(5) Available with materials of construction codes 2, 3, H, and M.

(6) Only available with protective plate design (materials of construction codes 2 and 3).

(2)(4)(6)

JIS B2220 flanges

(2)(6)

Process Seal Antenna (Type vs. Size and Rating)Table 5:

Process connection rating

Process connection size

2-in./

Tri-Clamp

C R R R R R R

DN50/50A

3-in./

C R R R R R R

DN80/80A

4-in./

N/A R R R R R R

DN100/100A

(1) C = Tri-Clamp (process connection type code C)

(2) Forged one-piece flange (see Figure 24).

(3) R = Raised Face (process connection type code R)

ASME B16.5 flanges

(1)

Class 150 Class 300 PN6 PN16 PN40 10K

(2)(3)

EN1092-1 flanges

(2)(3)

JIS B2220

flanges

(2)(3)

Emerson.com/Rosemount 17

Rosemount 5408 Series

Parabolic Antenna (Type vs. Size and Rating)Table 6:

Process connection rating

March 2018

Process connection size

3½-in. G W N/A N/A N/A

8-in./DN200/200A N/A N/A R F R

10-in./

DN250/250A

(1) G = BSPP (G) thread (process connection type code G)

(2) W = Welded connection (process connection type code W)

(3) R = Raised Face face (process connection type code R)

(4) F = Flat Face face (process connection type code F)

(1)

Thread

N/A N/A R F R

Welded

(2)

ASME B16.5 Class

150 flange

(3)

EN1092-1 PN6

(4)

flange

Accessories

AccessoriesTable 7:

HART modem and cable

03300-7004-0002 MACTek® VIATOR® HART modem and cables (USB connection)

Specifications

JIS B2220 5K

(3)

flange

Performance specifications

General

Conformance to specification (±3σ [Sigma])

Technology leadership, advanced manufacturing techniques, and statistical process control ensure specification conformance to at

least ±3σ.

Reference conditions

■ Measurement target: Metal plate, no disturbing objects

■ Temperature: 68 to 86 °F (20 to 30 °C)

■ Ambient pressure: 14 to 15 psi (960 to1060 mbar)

■ Relative humidity: 25-75%

■ Damping: Default value, 2 s

Instrument accuracy (under reference conditions)

±0.08 in. (2 mm)

(1) Refers to inaccuracy according to IEC 60770-1 when excluding installation dependent offset. See the IEC 60770-1 standard for a definition of radar

specific performance parameters and if applicable corresponding test procedures.

(1)

18 Emerson.com/Rosemount

March 2018

Repeatability

±0.04 in. (±1 mm)

Ambient temperature effect

±0.04 in. (±1 mm)/10 K

(2)

Sensor update rate

Minimum 1 update per second

Maximum level rate

40 mm/s as default, adjustable up to 200 mm/s

Measuring range

Maximum measuring range

Rosemount 5408 Series

Rosemount 5408:

Rosemount 5408:SIS:

130 ft. (40 m)

130 ft. (40 m) in Control/Monitoring mode

82 ft. (25 m) in Safety (SIS) mode

(3)

(3)

Note that a combination of adverse process conditions, such as heavy turbulence, foam, and condensation, together with products

with poor reflection may affect the measuring range.

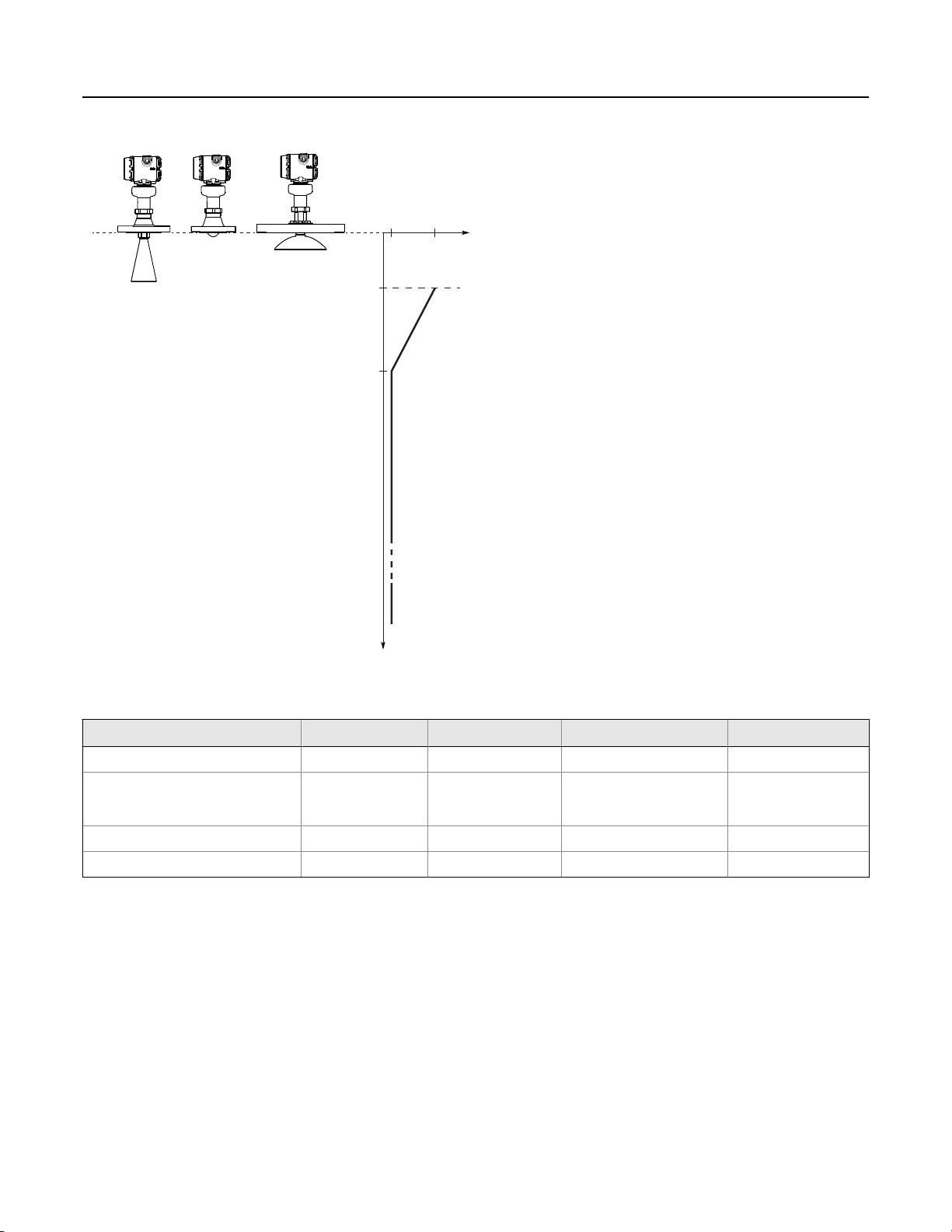

Accuracy over measuring range

The measuring range is limited by the blind zone at the very top of the tank. In the blind zone, the accuracy exceeds ±0.20 in. (±5

mm) and measurements may not be possible. Measurements close to the blind zone will have reduced accuracy (see Figure 2).

For the extended cone antennas, the reduced accuracy zone ends 11.8 in. (30 cm) below the antenna end.

(2) Ambient temperature effect specification valid over temperature range -40 °F to 176 °F (-40 °C to 80 °C).

(3) The Rosemount 5408:SIS has two operational modes: Safety (SIS) and Control/Monitoring. Safety (SIS) mode must be set when used in Safety Instru-

mented Systems. Control/Monitoring mode is intended for use in a Basic Process Control System (BPCS).

Emerson.com/Rosemount 19

±0.08 in.

(2 mm)

7.9 in.

(20 cm)

19.7 in.

(50 cm)

±0.20 in.

(5 mm)

A

Distance

Accuracy

Rosemount 5408 Series

Accuracy Over Measuring RangeFigure 2:

March 2018

A. Device Reference Point

Recommended Measuring Range for Solids, ft. (m) Table 8:

Antenna Light powder

2-in. (DN50) cone/process seal N/A

3-in. (DN80) cone/process seal

4-in. (DN100) process seal

(5)

10 (3) 49 (15) 49 (15) 59 (18)

(1)

Heavy powder

33 (10) 33 (10) 39 (12)

4-in. (DN100) cone 23 (7) 66 (20) 130 (40) 130 (40)

8-in. (DN200) parabolic 46 (14) 115 (35) 130 (40) 130 (40)

(1) Plastic powder/granules/pellets (Dielectric constant: 1.2-2.0)

(2) Lime powder, cement, sand, etc. (Dielectric constant: 1.5-2.5)

(3) Grain, kernels, brans, etc. (Dielectric constant: 1.5-4.0)

(4) Wood chips, pellets, etc. (Dielectric constant: 1.7- 4.5)

(5) Consider using the Rosemount 5303.

The figures given in Table 8 should be considered as guidelines; the total measuring range may differ depending on other

contributing application conditions such as product filling, how the product piles up, silo diameter vs. angle of repose, internal

obstacles within the silo, etc.

(2)

Grain size products

(3)

Larger particles

(4)

Beam width and beam angle

The transmitter should be mounted with as few internal structures as possible within the signal beam. Refer to Table 9 for beam

angle and Table 10 for beam width at different distances.

20 Emerson.com/Rosemount

Loading...

Loading...