Page 1

Triguard SC300E

MDO16FNS

16-Channel Digital Output Module

120Vac/dc

(MDO16FNS

Issue 4

INTRODUCTION

PURPOSE

The 120Vac/dc Digital Output Module MDO16FNS provides the output control interface

between the SC300E processing environment and up to 16 high-voltage field items. All field

outputs from the module are galvanically isolated from the system.

October 2005

)

Circuit triplication and voting procedures make the module single-fault tolerant and latent

testing ensures that the failure of a normally ‘ON’ (energised) or ‘OFF’ channel will be

recognised and reported to the system. Front panel indicators show the state of all channels,

the circuit ‘on-line’ status and the health of the module.

The module, which is compatible with ‘dual slot hot repair’, can be fitted in any of the ten I

slots in the SC300E chassis. ‘wrong slotting’ is prevented by physical coding. The SC300E

MPP software software identifies the module via a built-in hardware identifier.

Channel outputs leave the module via the DIN 41612 ‘rear plug-up’ system on the ch

backplane.

The MDO16FNS has relatively high power dissipation which may place some constraints upon

its use.

This document is intended to provide a general understanding of the function of the module

sufficient to enable basic maintenance operations to be effected in the field.

ASSOCIATED DOCUMENTATION

/O

assis

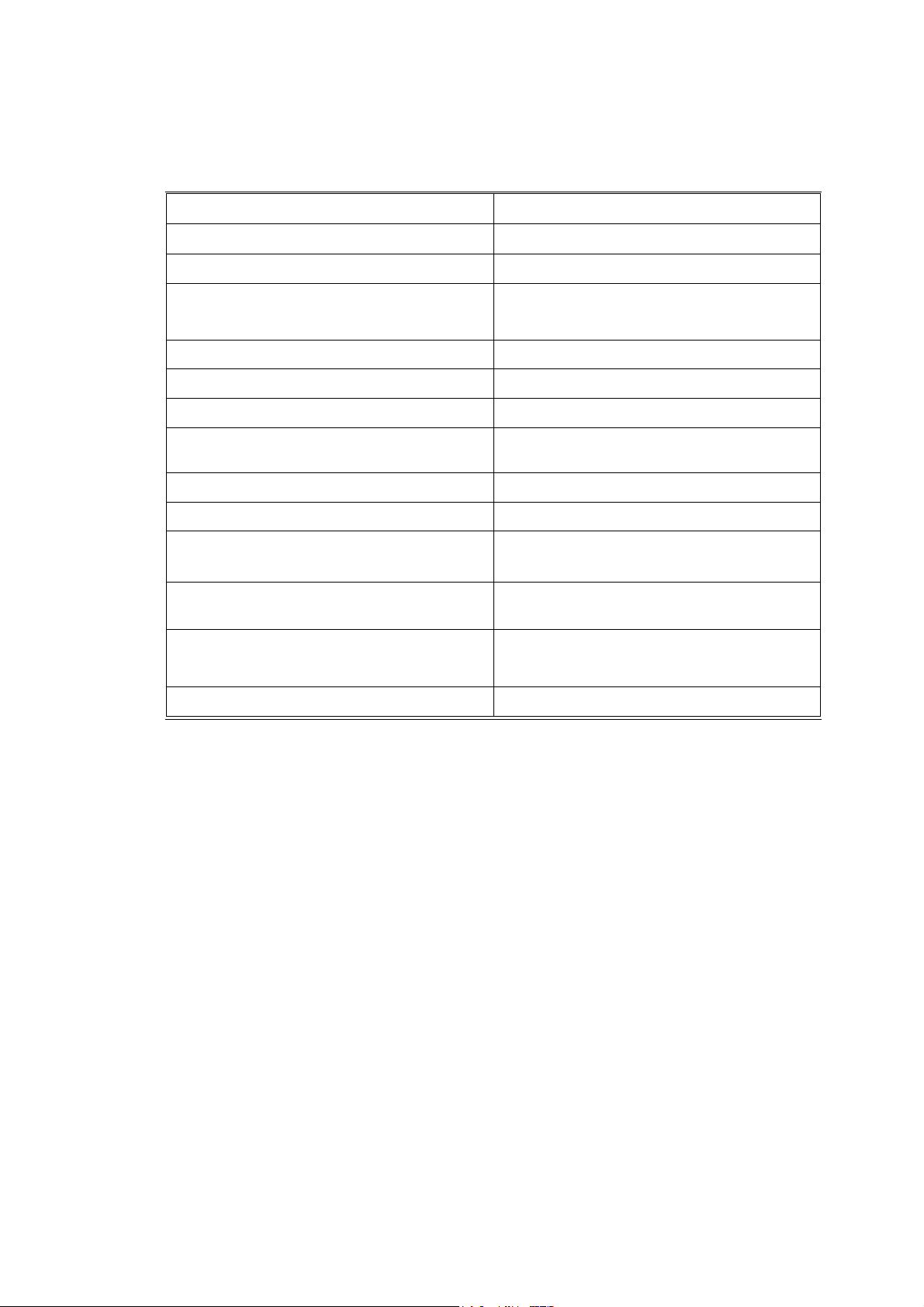

Reference No

008-5097

008-5128

Title

Chassis User Manual

TDO16AIB 16 Termination Card User Manual DIN to Screw

008-5148

Channel Digital Output

Page 2

2

MDO16FN

S

October

2005–

Issue 4

Triguard

SC300E

Terminals, Internally Powered, High Voltage

User Manual

Mechanical

block (Upper)

coding

Connector J1

Common

Module

Connector J2

Interface

(CI)

Fig

ure 1-1 General view and front panel detail

Connector J3

Protective

Mechanical

block (Lower)

Cover

coding

Page 3

MDO16FN

S

October

2005–

Issue 4

3

Triguard

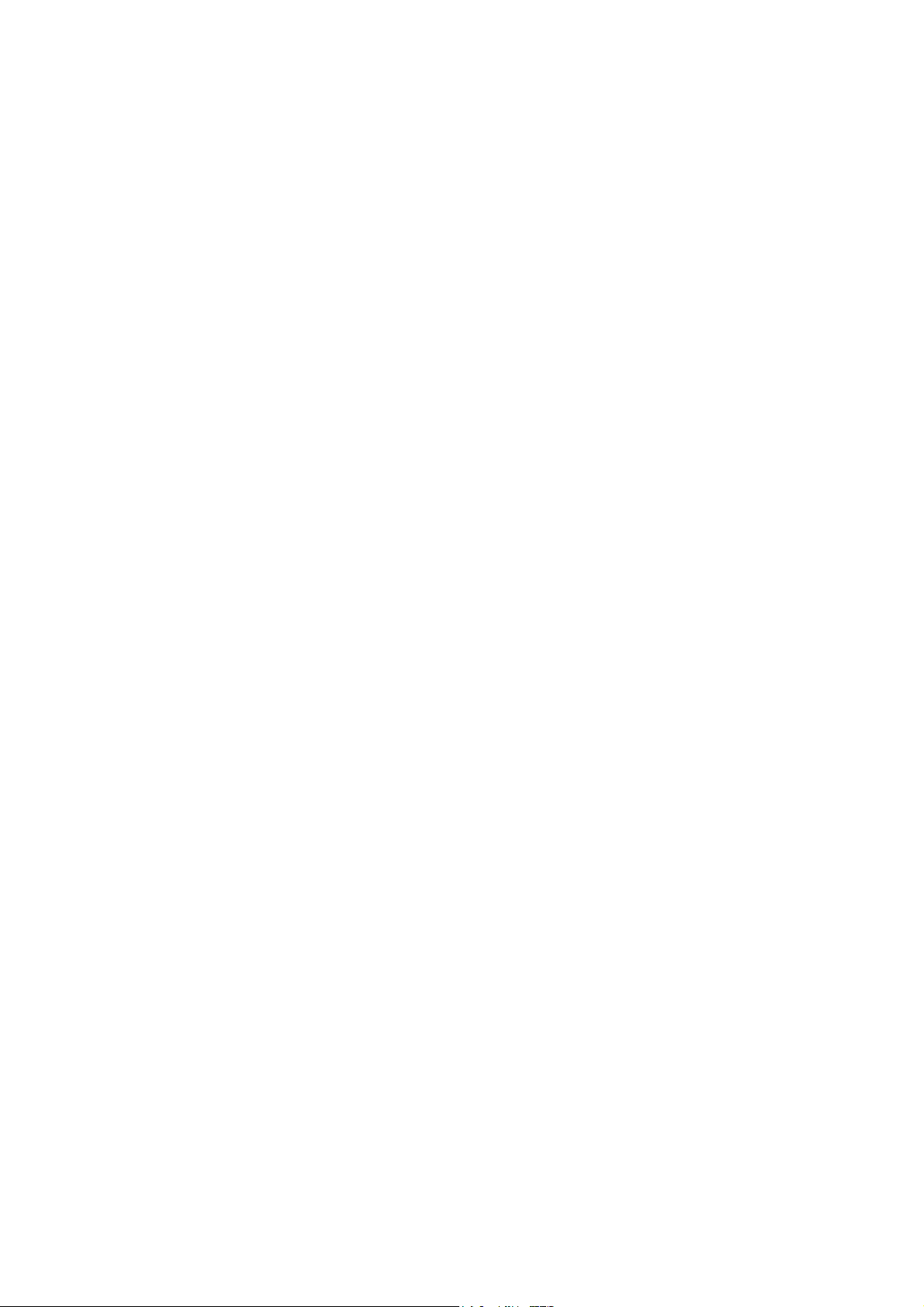

SPECIFICATION

Model

SC300E MDO16FNS 16-Channel D/O Module 120Vac/dc

MDO16FNS

Channels

Architecture

Indicators:

Outp ut d river FET

Voltage range

Voltage drop

Maximum d

Surge limiting

Isolation

Module power consumption excluding field

power dissipation in module

Module power consumption including field

power dissipation in module

Overall size (mm)

Overall size (inches)

Input

Modules

rive

16

TMR

One per point

Health, 3 x On Line

99 to 132Vac/dc

Less than 4V

Resistive load: 0.50A per channel

Tungsten load: 0.125A per channel

3A peak

1kVdc field to system, commoned supply

12mA (24mA if dual slot hot repair)

4W

2W @ minimum load

36W @ maximum load

400(9U)H x 397L x 28W

15.75H x 15.63L x 1.1W

Weight

ENVIRONMENTAL SPECIF

The maximum ambient temperature measured at the hottest point within the Triguard system

shall

Temperature operating:

Temperature

Humidity

EMC/RFI Immunity

Vibration/Shock

Certification:

General Certification: Ref. SC300E TMR Product Guide (ref 008-5209).

ICATIONS

not be greater than 60 degrees centigrade.

storage:

+5°C to +60°C

-

25°C to +70°C

5% to 95% non-condensing at ambient <40°C

Tested and certified to IEC 1131-Part 2 1994

Tested and certified to IEC 1131-Part 2 1994

2.1kg

Page 4

4

MDO16FN

S

October

2005–

Issue 4

Triguard

SC300E

TRANSPORT AND HANDLING

The MDO16FNS must be transported and stored in its original packing material which should

be retained for this purpose.

Page 5

MDO16FN

S

October

2005–

Issue 4

5

Triguard

SC300E MDO16FNS 16-Channel D/O Module 120Vac/dc

TECHNICAL DESCRIPTIO

N

PHYSICAL

The MDO16FNS is a 9U high PCB with integral front panel and rear connectors. A plug-in

daughterboard carries the common interface circuits. The board faces are protected by

detachable

the location of the connectors, covers and front panel details.

covers (see Section 3.1, Scope). Figure 1-1 shows the general layout, including

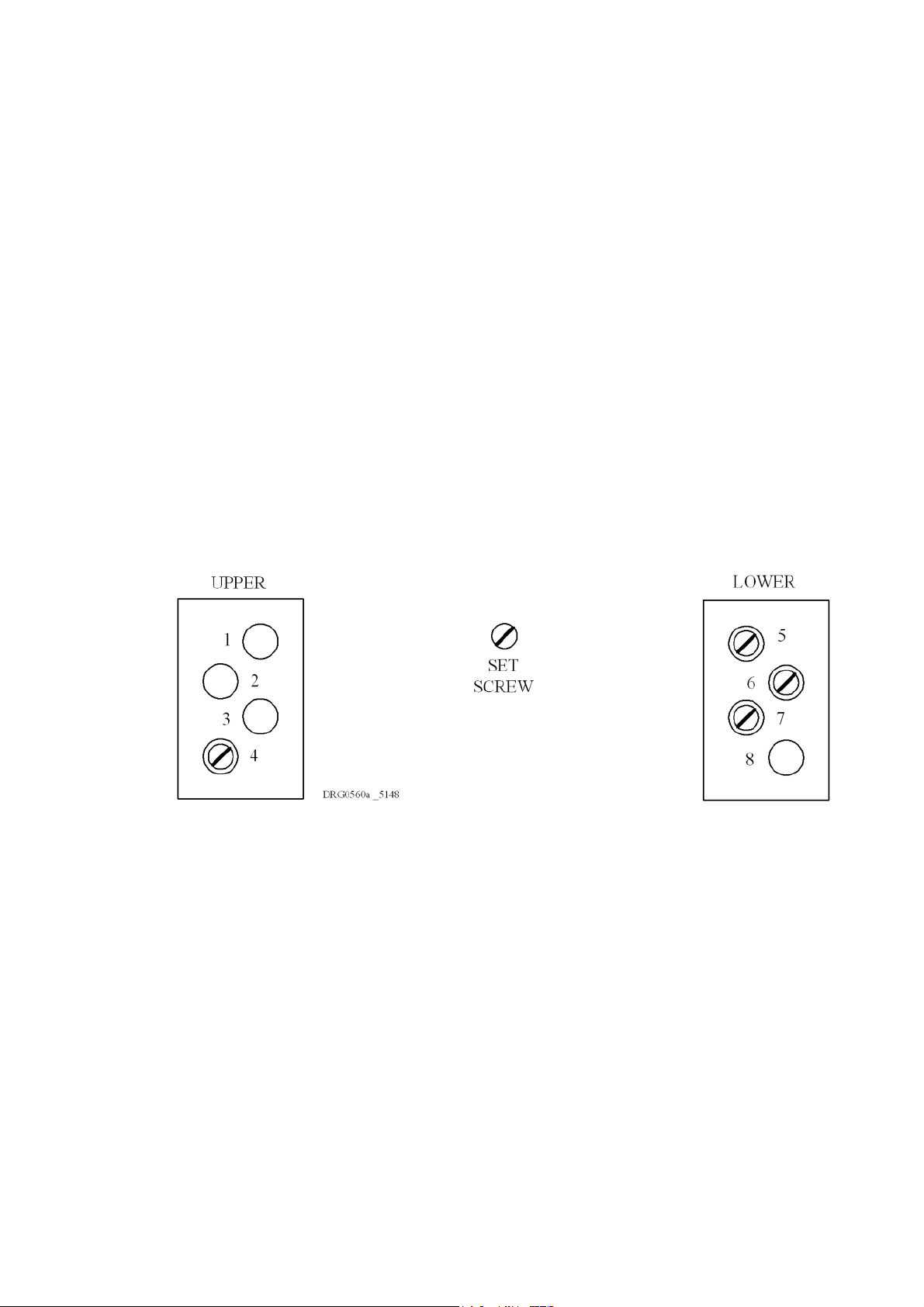

Mechanical coding blocks

All Input/Output modules carry two coder blocks equipped with pins which mate with holes in

corresponding blocks in the chassis and prevent the module being inserted into the wrong slot.

The

pins in the module blocks are factory installed in a pattern determined by the module and

corresponding

holes

are plugged with set screws. The chassis slot coder block configuration for this module

is shown in Figure 2-1.

set screws are removed from the chassis coder blocks to enable fitting. Unused

Figure 2-1 Chassis slot coder blocks configuratio

n

EXTERNAL CONNECTIONS

Field circuits

The field load circuit shown in Figure 2-2 is the typical required for the safe connection of field

loads

to

the MDO16FNS. For any unused channel a dummy field load (value 4.7k ohm) should

be used. We however, recommend the use of their 16-Channel Digital Output Termination

Cards TDO16AIB which offer full connection facilities with indicating fuses, and alarm outputs

(See

Section 1.2, Associated documentation).

Page 6

6

MDO16FN

S

October

2005–

Issue 4

Triguard

SC300E

Figure 2-2 Basic field load circuit

Module connectors

The system bus connector is J1 and the common interface is connected via J4 and J5 (not

shown).

diagram (Figure 2-3 ) the following symbols are used:

Lethal voltages earth. All other pins on J3 are connected to field supply return but this field supply

return

All the digital outputs are routed through connector J2. In the external connection

0

x = Connector pin

Earth =

+ve

-

ve

O/P = Channel output

may not be at earth potential.

=

First mate (

long pin)

Connected to chassis

=

= Field supply return

Field supply in

WARNING

Live pins on Connector J3 rear of chassis J3 pin 1c is connected to

Page 7

MDO16FN

S

October

2005–

Issue 4

7

Triguard

SC300E MDO16FNS 16-Channel D/O Module 120Vac/dc

Figure 2-3 Field output connector J2 pinouts

Connector J3 pin 1c is connected to earth.

All other pins on J3 are connected to field supply return.

THEORY OF OPERATION

In accordance with TMR practice, channel output command information from the MPP follows

three

identical paths through the MDO16FNS (see Figure 2-4 ), each path at the command of

its own microcontroller in the common interface. In order to minimise the number of data

connections

form before entering the module from the common interface. In this manner 16 output channels

can

be

The three data streams are each applied to opto-isolators which mark the interface between

the system and field sides of the circuit and provide a system-to-field channel isolation of 1kV.

across the 1kV system-to-field barrier, the channel data are converted to serial

served by just three paths instead of 48.

Page 8

8

MDO16FN

S

October

2005–

Issue 4

Triguard

SC300E

The data streams are then applied to the 16-bit output shift registers. The serial bits are

clocked successively into the shift registers until the 16th bit has been received. The registers

then latch the data and present it on the 16-bit busses (CHANA, CHANB and CHANC) to the

output switches. The data is con

of the SC300E system.

The output switch for each channel comprises six FETs connected in the series/parallel

network shown and providing 2 out of 3 majority voting between the three paths A, B and C. A

front panel LED at the switch output is lit when the switch is closed. Voltage and current

monitoring circuits are also connected to the switches to provide outputs for the Latent Fault

Detection

registers and opto-isolators. The feedback information confirms that the output has switched to

the

Testing of the output switches by the LFD circuits is co-or

the common interface. When all outputs are in the healthy condition and the microcontrollers

confirm

turn to switch its output alone to the opposite state and confirm the correct operation of its

individual output switch.

The module power requirements are served from two different sources. The power for the

output-side circuits is derived from the chassis 12V supply via dc/dc converters. All of the

supplies are monitored. Electronic fuse circuits sense the current in each output path and cut

off the upper FET if the current exceeds a predetermined limit.

(LFD) system. These outputs are fed back to the microcontrollers via dedicated shift

commanded state and that the line is not open or short circuit.

no

faults present, the SC300E processors (MPPs) will instruct each microcontroller in

tinuously refreshed in this manner and updated at each scan

dinated by the microcontrollers on

An On/Off Line Request switch on the front panel enables a request to be sent to the SC300E

system

module contains a hardware identity circuit that enables system identification of the module,

and three manual links 1, 2 and 3. Link 1 allows the module to be set up for 321 or 320 mode

operation

while still preserving overall operation. 320 mode means that the system will continue to

function with two out of three serviceable circuits. If the number falls to one out of three the last

read

serviceable

line.

Link 2 (HLV/GTZ) determines whether, in the event of a failure due to 321/320 action, the last

read values are held (HLV) or are set to zero (GTZ). Link 2 is only active however, if Link 3

(ICCB/HW)

by software.

that the module be taken off-line for maintenance purposes or returned on-line. The

which sets the threshold that determines how much of the circuit can be degraded

data is maintained. In 321 mode the system will continue to function with one out of three

circuits. If that fails the last read data is maintained and the module is taken off

is

set to HW. If Link 3 is set to ICCB Link 2 is ignored and its function determined

-

Page 9

MDO16FN

S

October

2005–

Issue 4

9

Triguard

SC300E MDO16FNS 16-Channel D/O Module 120Vac/dc

Figure 2-4 MDO16FNS -

Block diagram

Page 10

10

MDO16FN

S

October

2005–

Issue 4

Triguard

SC300E

Common Interface

The three discrete control circuits in the common interface (A, B, and C) are each responsible

for the control of the corresponding one third of the I/O module circuits. Each control circuit

comprises a microcontroller with a dedicated watchdog, data buffers and shared RAM. The

circuit is powered via the module and permits live insertion of replacement modules.

The microcontrollers co-ordinate I/O signal processing, signal path diagnostics, on-line/off-line

status and signal status read/write cycles to and from the SC300E processors via an I/O

communications bus. All I/O modules have an identification code which is read by the common

interface and passed to the MPPs for verification. The on-line/off-line status is determined by

the MPPs. If, for maintenance purposes, the On/Off Line Request switch on the front of the

module is operated, the action is read by all three microcontrollers and the request passed to

the MPPs which may then grant the request. The watchdog on each microcontroller

extinguishes

failure, LFD failure or a voting discrepancy.

the Health LED on the I/O module front panel in the event of a microcontroller

Page 11

MDO16FN

S

October

2005–

Issue 4

11

Triguard

SC300E MDO16FNS 16-Channel D/O Module 120Vac/dc

Figure 2-5 Common interface -

Block diagram

System Configuration

The Digital Output module requires adequate ventilation to operate at its full capacity. For

convection

and the hot repair partner slot should

system

adequate

cooled systems the output module should be fitted in the lowest module chassis

not be occupied. When forced air cooling is applied to a

these limitations are removed. We recommend that the module be derated by 50% if

ventilation is not provided.

Page 12

12

MDO16FN

S

October

2005–

Issue 4

Triguard

SC300E

SERVICING

SCOPE

Repair is by module replacement. Faulty modules are not repairable in the field. They should

be replaced by new modules and returned for repair.

WARNING

Lethal voltages are present in this equipment.

The protective covers are to prevent access to circuits. There are no user-serviceable

components under the covers

For your safety:

Do not remove the covers.

Do not touch any exposed circuits or insert objects such as test probes through the covers

while

the module is connected to the chassis backplane.

CAUTION 1

Before fitting a new module ensure that the setting of all three links is the same as that on the

old

module.

This module contains components that may be electrostatically sensitive. It should be

transported and stored in its original packaging material.

CAUTION 2

DIAGNOSIS

The TriBuild works

Health LED on the faulty module will be extinguished.

tation is used for fault diagnosis. In the case of an Input/Output fault the

PREPARATION

To ascertain whether the chassis I/O slot containing the faulty module has been allocated a

hot repair partner, use one of the following methods:

•

Check the system drawings

• Check the chassis wiring configuration

• Use the I/O chassis Configuration Report on the TriBuild workstation.

Page 13

MDO16FN

S

October

2005–

Issue 4

13

Triguard

Where there is a hot repair partner allocation, use the ‘Dual-slot hot repair’ procedure,

otherwise

use the ‘Single-slot hot repair’ procedure.

SC300E MDO16FNS 16-Channel D/O Module 120Vac/dc

Page 14

14

MDO16FN

S

October

2005–

Issue 4

Triguard

SC300E

CONFIGURATION

Before fitting a new module ensure that 321/320 link setting is the same as that on the old

module.

REMOVAL AND REPLACEMENT

CAUTION 3

Failure to take the faulty module off-line before removing it from the chassis could trigger a fault

alarm

or

cause plant shutdown.

When inserting a module ensure that it is aligned with the markings on the chassis rails and

that it engages with the top and bottom guides. Improper insertion may cause damage to the

module and/or chassis connectors.

CAUTION 4

SINGLE-SLOT HOT REPAIR

1.

Operate the On/Off Line Request switch on the faulty module. The three On Line LEDs

should

all extinguish to indicate that the MPPs have recognised the request and taken

the module off-line. The last read data input from the module will be maintained until

the new module is on-line.

2.

Slacken the two module securing screws and use the black ejection levers (top and

bottom) to draw the module from its slot.

3.

Insert

in the chassis. The top and bottom chassis rails carry alignment marks to assist. Pull

out the ejection levers and as the module is pushed back engage the levers on the

chassis rails. The levers should then be used to draw the module into position, some

resistance

in position with the securing screws.

4.

Operate the On/Off Line Request switch and check that the three On Line LEDs

illuminate for one second, extinguish for one second and then illuminate permanently

to indicate that the module has been put on-line. If the LEDs do not illuminate either

the

considered faulty.

the new module ensuring that it engages properly in the upper and lower guides

will be felt as the rear connector pins engage. The module should be fixed

first or second time or fail to remain illuminated, then the module must be

Page 15

MDO16FN

S

October

2005–

Issue 4

15

Triguard

SC300E MDO16FNS 16-Channel D/O Module 120Vac/dc

DUAL-SLOT HOT REPAIR

1.

Insert the new module into the vacant hot repair slot ensuring that it engages properly

in the upper and lower guides in the chassis. The top and bottom chassis rails carry

2.

3.

alignment marks to

back engage the levers on the chassis rails. The levers should then be used to draw

the module into position, some resistance will be felt as the rear connector pins

engage. The module should be fixed in position with the securing screws.

Operate the On/Off Line Request switch on the new module. Ascertain that the three

On

Line LEDs on the new module illuminate for one second, extinguish for one second

and then illuminate permanently as the LEDs on the old module extinguish. This

sequence indicates that the new module has been put on line and the old module

taken off-line. If the LEDs on the new module do not illuminate either the first or second

time or fail to remain illuminated, th

module’s

If the new module is serviceable slacken the screws on the old module and use its

ejection levers to remove it from the chassis.

LEDs should remain illuminated indicating that it is still on-line.

assist. Pull out the ejection levers and as the module is pushed

e new module must be regarded as faulty. The old

PREVENTIVE MAINTENAN

No preventive maintenance is necessary.

SERVICE SUPPORT

CE

SPARES

Spare parts and technical advice can be obtained f

rom your local area offices.

Loading...

Loading...