Page 1

Snubber Braking Kits for A C Drives

Enclosed Resistor Modules, Enclosed Transistor Modules

Model Numbers

M3575RH__, M3575RL__, M3575TH__, M3575TL__

Instruction Manual D2-3439-1

ATTENTION:Only qualified electrical personnel familiar with the construction and operation of

this equipment and the hazards involved should install, adjust, operate, and/or service this

!

Product Description

Snubber Braking kits connect to 230 VAC and 460 VAC GV3000/SE, SP120, SP500, and VSM500 drives.

These kits dissipate the power regenerated by the motor during rapid deceleration or during overhauling load

conditions.

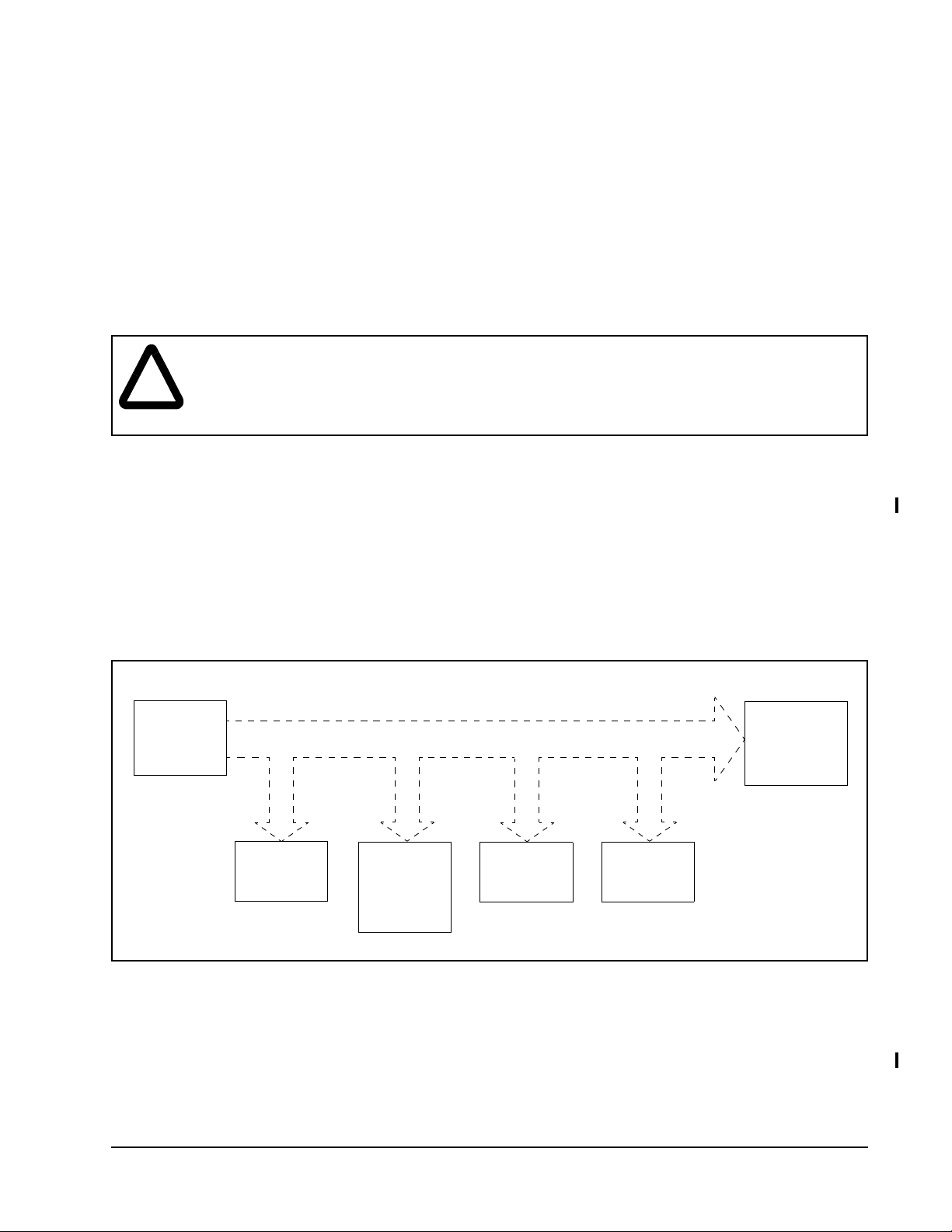

The regenerated energy is normally consumed, as shown in figure 1, by mechanical loss, by the motor, and by

the drive. The remaining energy is stored in the drive’s DC bus capacitor. If the remaining energy causes the

capacitor voltage to rise above the normal operating range, the Braking Unit will discharge the regenerated

energy before the drive voltage becomes excessive.

equipment. Read and understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in severe bodily injury or loss

of life.

Energy

Regenerated

by t h e Moto r

Consumption

by Mechanical

Loss

Consumption

in th e Mo to r

Itself (approx.

10 to 20% of

Output

Figure 1 – Dissipation of Energy Regenerated by the Motor

Consumption

by the Drive

Itself

Storage in

Capacitor of

the Drive

Discharge of

Regenerated

Energy at

Braking Unit

Power resistors are used to dissipate the energy. When the DC bus voltage rises above normal level, either a

built-in transistor (in GV3000/SE bookshelf drives) or an external transistor (used with NEMA-type GV3000/SE,

SP500, and VSM500 drives) automatically switches the dynamic braking resistors on in

pulse-width-modulation (PWM) mode to absorb the excess energy. The transistor is turned fully on at 375 VDC

for 230 VAC input drives and at 750 VDC for 460 VAC input drives. The snubber resistors are sized to provide

the power dissipating capability required for the duty cycle of the application.

Snubber Braking Kits for AC Drives

1

Page 2

Snubber Braking kits are available:

• as an Enclosed Resistor module for use with an AC drive containing a built-in transistor switching circuit

(such as the GV3000/SE Bookshelf AC drive) or for use in conjuction with an enclosed transistor module

(M/N M3575T__)

• as an Enclosed Tr ansistor module (M/N M3575T__) for use with AC drives that do not contain a built-in

transistor switching circuit and for use with the enclosed resistor modules (M/N M3575R__)

Note that all of the Enclosed Resistor modules and Enclosed Transistor modules are rated for a maximum

on-time of 60 seconds at a specified duty cycle (see tables 1, 2, 5 and 6).

For GV3000/SE Bookshelf drives: Refer to tables 1, 2, and 3 to ensure that the Enclosed Resistor kit

matches your drive.

For AC Drives requiring both an Enclosed Resistor kit and an Enclosed Transistor kit: Refer to tables 4,

5, and 6 to ensure that the braking kits match your drive and your braking horsepower requirements.

Snubber Resistor Kits (M3575RH__, M3575RL__)

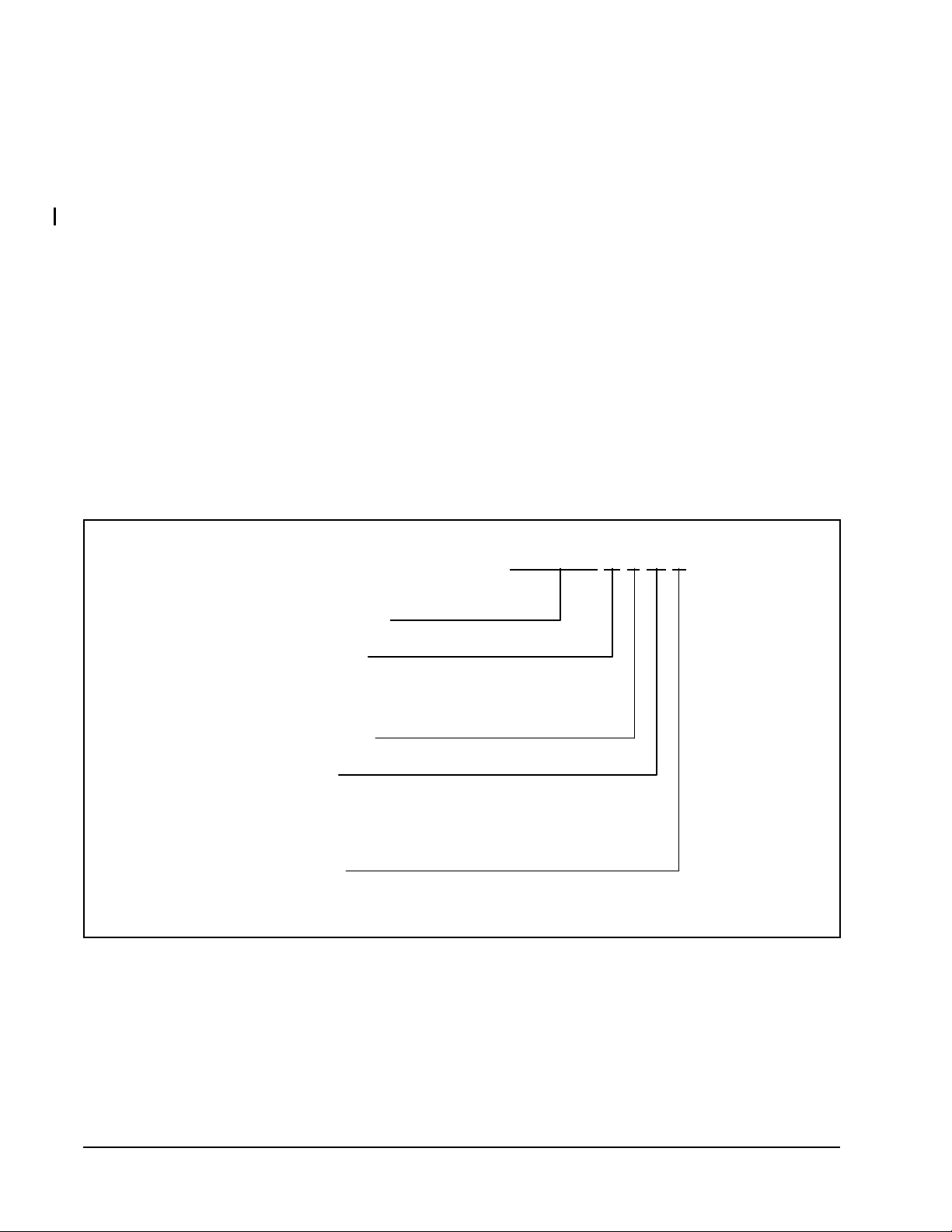

The figure below depicts the breakdown of the Snubber Resistor kit part number.

M3575R H 2 M F

Base Model Number

AC Voltage Rating

L = 230 VAC

H = 460 VAC

Horsepower Rating

Chassis Style

B = Bookshelf Style

M = Mini (Standard Enclosed S t y le)

G = Grid Resistors (G1, G2, G3)

Cooling Option

F = Internal Fan

Enclosed Resistor Braking Unit Fault Outpu t

Enclosed Resistor Braking units have one normally-closed contact (NC) rated at 1 amp @ 24 VDC or

0.5 amp @ 115 VAC that opens on an overtemperature fault condition ( 85 C or higher).

2

Enclosed Resistor Modules, Enclosed Transistor Modules

Page 3

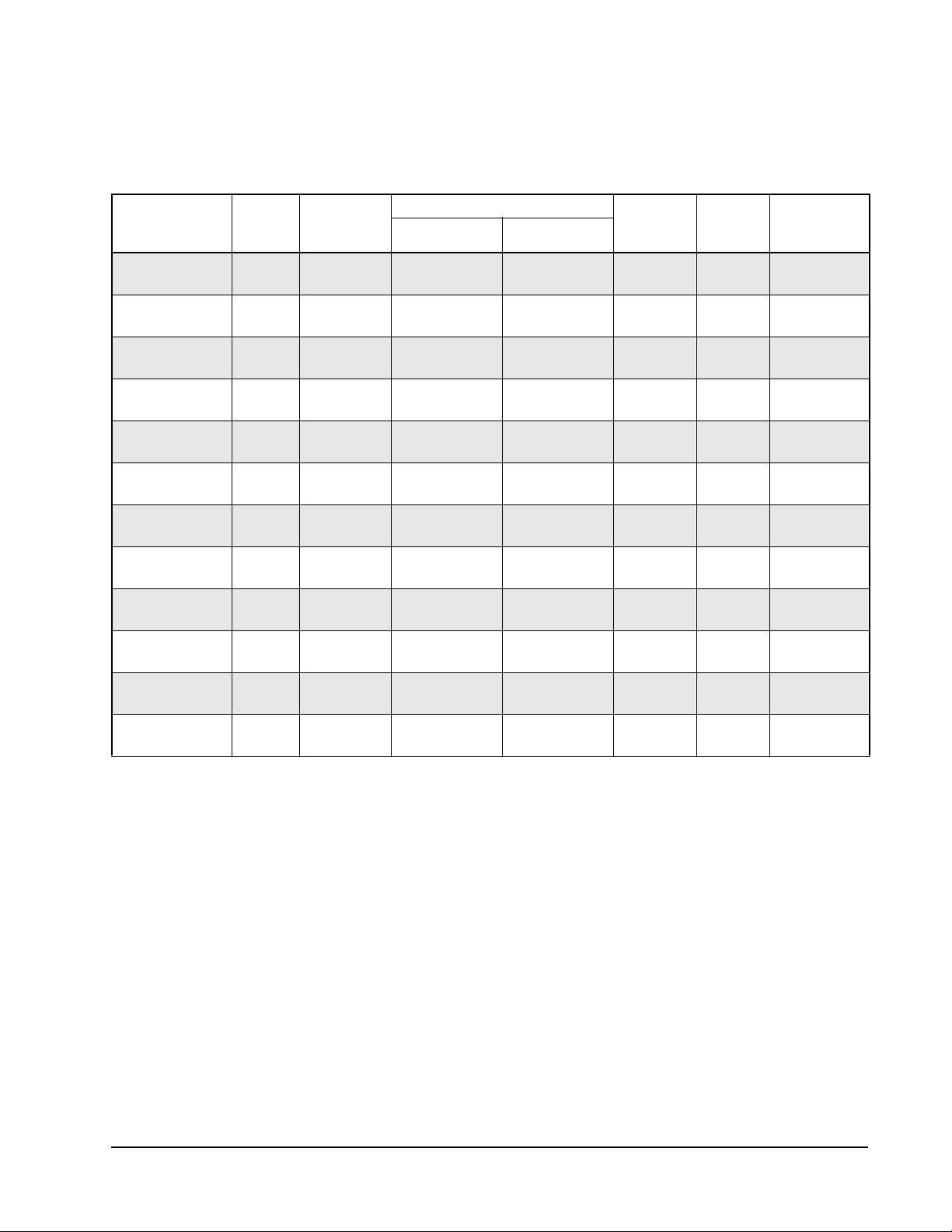

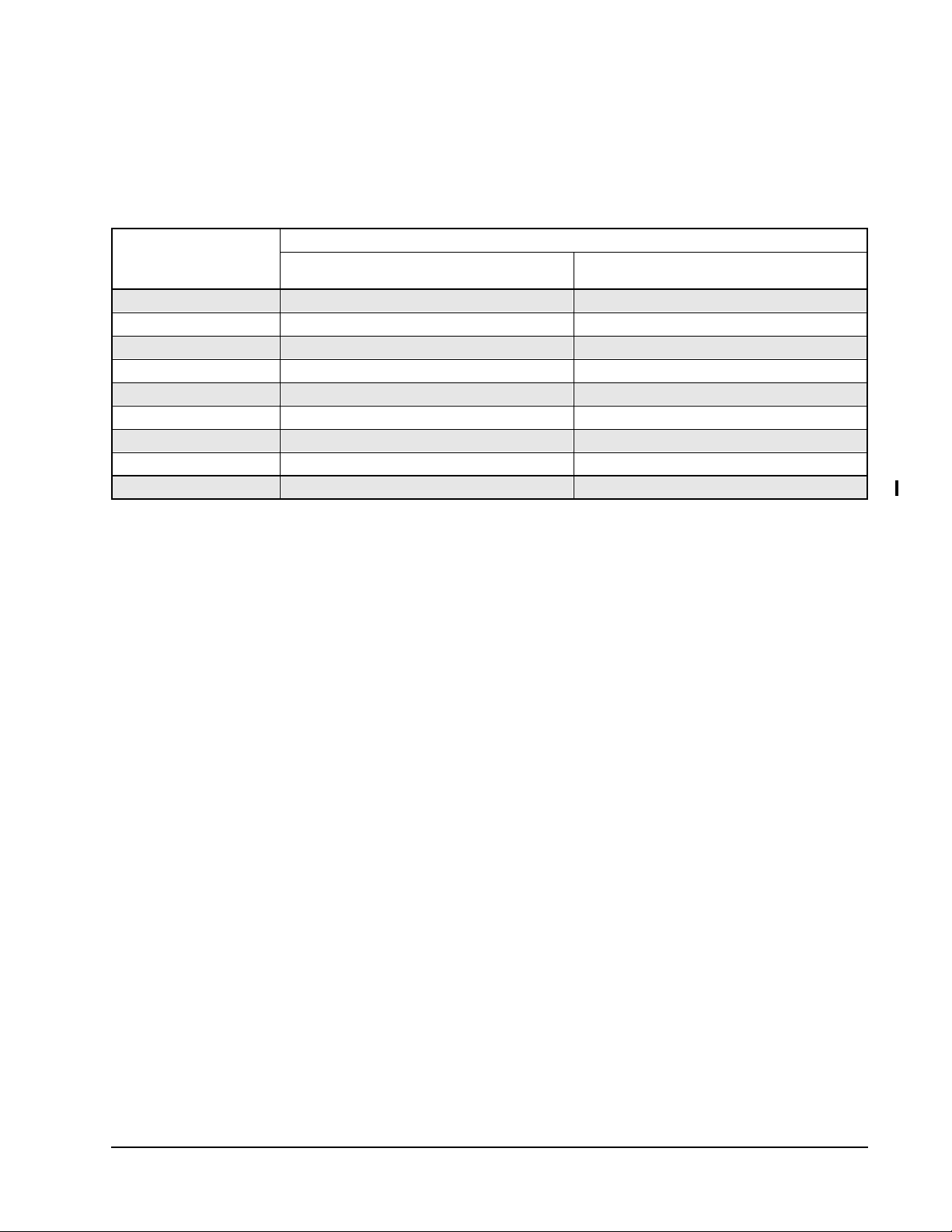

Tables 1 and 2 show the rating data for the Enclosed Resistor Braking kits.

Table 1 – Enclosed Resistor Braking Kit Ratings (230 VAC)

Braking Kit

Model Number

M3575RL1M

Braking

HP

1 6%

M3575RL1MF

M3575RL2M

2 6%

M3575RL2MF

M3575RL3B

3 6%

M3575RL3BF

M3575RL3M

36%

M3575RL3MF

M3575RL4M

4 6%

M3575RL4MF

M3575RL5B

56%

M3575RL5BF

M3575RL6M

6 6%

M3575RL6MF

M3575RL8B

86%

M3575RL8BF

M3575RL9M

9 6%

M3575RL9MF

M3575RL11B

11 6%

M3575RL11BF

M3575RL16B

16 6%

M3575RL16BF

M3575RL24B

24 6%

M3575RL24BF

1.

Maximum on-time is 60 seconds.

Braking

Duty

Cycle

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

20%

Braking Watts

1

746 50

Max.

Amp

Rating

2 190 M4

Load

Ohms

±10%)

(

Enclosure

TypePeak Continuous

150

1492 100

4 95 M4

300

1989 100

5 75 B4

400

2238

150

6 63 M4

450

2984 200

8 48 M7

600

3979 200

10 38 B4

800

4476 300

12 32 M7

900

5968 300

15 25 B4

1200

6714 450

18 21 M10

1350

7967 400

20 19 B7

1600

11936 600

31 13 B7

2400

17904 900

47 8 B10

3600

Enclosed Resistor Modules, Enclosed Transistor Modules

3

Page 4

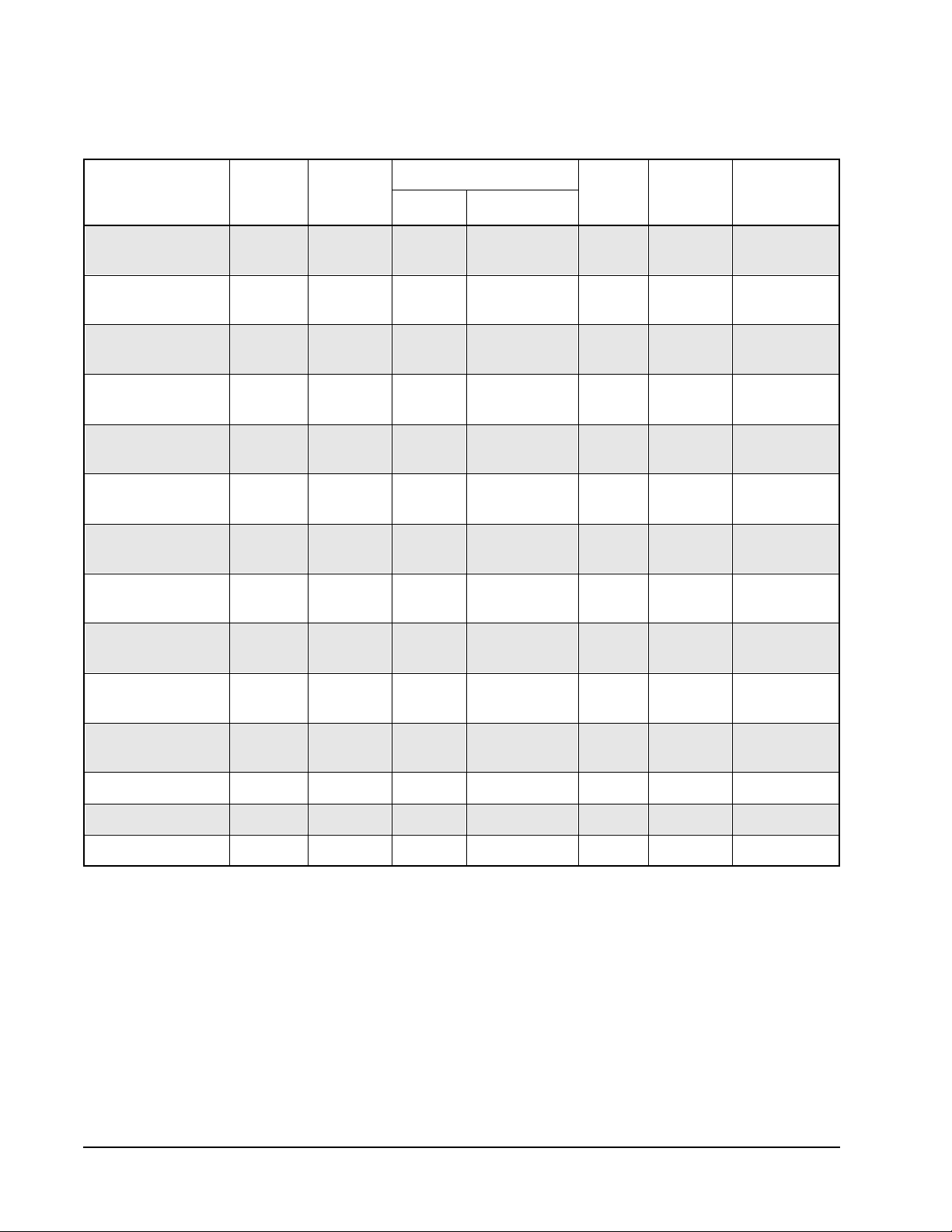

Table 2 – Enclosed Resistor Braking Kit Ratings (460 VAC)

Braking Kit

Model Number

M3575RH1M

M3575RH1MF

M3575RH2M

M3575RH2MF

M3575RH3M

M3575RH3MF

M3575RH4M

M3575RH4MF

M3575RH5B

M3575RH5BF

M3575RH6M

M3575RH6MF

M3575RH8B

M3575RH8BF

M3575RH9M

M3575RH9MF

Braking

HP

1 6%

2 6%

3 6%

4 6%

5 6%

6 6%

8 6%

9 6%

Braking

Duty

Cycle

20%

20%

20%

20%

20%

20%

20%

20%

Braking Watts

1

746 50

1492 100

2238 150

2984 200

4000 250

4476 300

6000 350

6714 400

150

300

450

600

800

900

1200

1350

Max.

Amp

Rating

Load

Ohms

±10%)

(

Enclosure

1 780 M4

2 390 M4

3 260 M4

4 195 M7

5 150 B4

6 130 M7

8 90 B4

9 87 M10

TypePeak Continuous

M3575RH11B

M3575RH11BF

M3575RH16B

M3575RH16BF

M3575RH24B

M3575RH24BF

11 6%

20%

16 6%

20%

24 6%

20%

8000 450

1600

12000 700

2400

18000 1000

3600

11 60 B7

16 45 B7

24 30 B10

M3575RH50G1F 50 20% 40000 8000 53 14 G1

M3575RH100G2F 100 20% 80000 16000 106 7 G2

M3575RH150G3F 150 20% 120000 24000 159 5 G3

1.

Maximum on-time is 60 seconds.

4

Enclosed Resistor Modules, Enclosed Transistor Modules

Page 5

Table 3 shows the acceptable matches, by braking horsepower, between GV3000/SE Bookshelf drives and

Enclosed Resistor Braking kits. For actual sizing information, refer to “Selecting and Sizing Snubber Braing

Resistors” on page 18 of this manual.

Table 3 – Matching Enclosed Resistor Braking Kits with GV3000/SE Bookshelf Drives

GV3000/SE

Can use snubber resistor kits rated at the following braking HP

Bookshelf Drive

Model Number

Volts/Hertz Vector

31ER/31ET4060 1 HP to 3 HP 1 HP to 2 HP

38ER/38ET4060 1 HP to 4 HP 1 HP to 3 HP

55ER/55ET4060 1 HP to 4 HP 1 HP to 4 HP

85ER/85ET4060 1 HP to 6 HP 1 HP to 6 HP

126ER/126ET4060 1 HP to 9 HP 1 HP to 6 HP

150ER/150ET4060 1 HP to 9 HP 1 HP to 8 HP

240ER/240ET4060 1 HP to 11 HP 1 HP to 11 HP

300ER/300ET4060 1 HP to 16 HP 1 HP to 16 HP

430ER/430ET4060 1 HP to 24 HP 1 HP to 24 HP

Enclosed Resistor Modules, Enclosed Transistor Modules

5

Page 6

Sized for 1/4” Bolts or Studs

Enclosure

Type

M3 323,8

M4 323,8

M7 323,8

M10 323,8

B4 450,8

B7 450,8

B10 450,8

.75

A

E

G

F

Terminal Strip

.28 .28

1.00

A BCDEFGH

(12.75)

(12.75)

(12.75)

(12.75)

(17.75)

(17.75)

(17.75)

D

76,2

(3.0)

101,6

(4.0)

177,8

(7.0)

254

(10.0)

101,6

(4.0)

177,8

(7.0)

254

(10.0)

B

Dimension in mm (in)

95,6

(7.70)

95,6

(7.70)

95,6

(7.70)

95,6

(7.70)

95,6

(7.70)

95,6

(7.70)

95,6

(7.7)

n/a 304,8

44,5

(1.75)

127

(5.0)

203,2

(8.0)

44,5

(1.75)

127

(5.0)

203,2

(8.0)

C

H

(12.0)

304,8

(12.0)

304,8

(12.0)

304,8

(12.0)

425,5

(16.75)

425,5

(16.75)

425,5

(16.75)

266,7

(10.5)

266,7

(10.5)

266,7

(10.5)

266,7

(10.5)

381

(15.0)

381

(15.0)

381

(15.0)

28,7

(1.13)

28,7

(1.13)

28,7

(1.13)

28,7

(1.13)

35,1

(1.38)

35,1

(1.38)

35,1

(1.38)

221

(8.7)

221

(8.7)

221

(8.7)

221

(8.7)

221

(8.7)

233,7

(9.2)

246,4

(9.7)

Figure 2 – Resistor Braking Kit Enclosure Dimensions

6

Enclosed Resistor Modules, Enclosed Transistor Modules

Page 7

Front View Side View

29"

Field Connection

Terminals Are

Located Behind

Filte r S c re en

0.56"

25"

2.0"

2.0"

22"

18"

3.5"

A

4.25"

2.5"

B

Foot Print

Dimensions

Chassis Dim.A Dim.B

21.88"

1.0"

0.56"

Figure 3 – Resistor Braking Kit Enclosure Dimensions (Floor-Mount Models)

14.75"

1.63"

.56" X 1.0"

(4 Places)

G1

G2

G3

31"

40"

49"

38.75"

47.75"

47.75"

56.75"

Enclosed Resistor Modules, Enclosed Transistor Modules

7

Page 8

Installing the Enclosed Resistor Braking Kit

ATTENTION:Equipment is at line voltage when AC power is connected to the drive. The drive’s

DC bus capacitors retain hazardous voltages after input power has been disconnected. After

!

Choose the installation site for the Enclosed Resistor Braking Unit with the following considerations in mind:

• The unit must be mounted in a clean, dry environment. The maximum ambient air temperature should not

exceed 40° C (104° F).

• The mounting surface must be non-flammable, as the unit may generate high temperatures during operation.

• The unit requires a minimum clearance of (2 inches) in all directions.

Use the following procedure to install Braking Units housed in NEMA 1 enclosures.

Step 1. Disconnect, lock out, and tag input power to the drive. Wait five minutes for the DC bus capacitors to

disconnecting input power, w ait five (5) minutes for the DC bus capacitors to discharge and then

check the DC bus voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this precaution could result in severe

bodily injury or loss of life.

ATTENTION:The user is responsible for conforming with all applicable local, national, and

international codes. Failure to observe this precaution could result in damage to, or destruction

of, the equipment.

discharge.

Step 2. Verify that there is no voltage at the drive’s input power terminals.

Step 3. Measure the drive’s DC bus potential with a voltmeter to ensure that the DC bus capacitors have fully

discharged as described in the drive’s instruction manual.

Step 4. Select a location for the Braking Unit within 8 feet of the drive where the heat generated by the

snubber resistors will not affect surrounding components. Do not mount the Braking Unit under the

drive or where convective air flow is restricted.

Step 5. Mount the Braking Unit vertically with the fan at the bottom. Mounting hardware is not provided. See

figure 2 or 3 for mounting dimensions.

Step 6. Install the wiring between the drive and the Braking Unit. See figures 4, 5, and 8. Use wire that is

rated at a minimum of 300 volts for 230 VAC Braking Units and 600 volts for 460 VAC Braking Units.

ATTENTION:It is important to use wire rated at 300 volts for 230 VAC Braking Units (600 volts

for 460 V AC Braking Units) or greater because this wiring may come into contact with uninsulated

!

Step 7. Reapply input power to the drive. Refer to the drive’s instruction manual for complete start-up

230 VAC (or 460 VAC) components. Failure to observe this precaution could result in damage

to, or destruction of, the equipment.

information.

8

Enclosed Resistor Modules, Enclosed Transistor Modules

Page 9

Braking Resistor Unit Field Connection Notes

C

ATTENTION: Only qualified personnel familiar with the construction and operation of this

equipment and the hazards involved should install or service this equipment. The user is

!

Observe the following precautions when making field connections:

• Do not connect the Braking Resistor Unit directly across the DC bus. This would exceed the maximum

duty cyle rating of the load. The extreme overheating generated by the load resistors under this condition

could present a fire hazard in and around the resistive load module.

• Be sure the Braking Resistor Unit being connected meets the minimum load resistance requirements listed

in table 1 or table 2.

• Field connection terminals used on the bookshelf style and standard enclosed style Braking Resistor units

will accept a 10 AWG maximum wire size. Wires should be stripped 0.25”. Crimp-style terminations are not

recommended.

• Wire types and sizes should be chosen in accordance with local, national, and/or international electrical

codes as well as module termination limitations to meet the voltage and current levels present for the

application.

responsible for conforming with all applicable local, national, and international codes. Failure to

observe these precautions could result in personal injury and/or damage to, or destruction of,

the equipment.

M3575R Braking Resistor Unit Field Connections

For Drives With Internal Braking Transistor (such as GV3000/SE Bookshelf drives)

RES RES

12345

NOTES

1.

Temp alarm opens up on a faul t and is rated at 0. 5 amps (115 VAC ).

Refer to drive ins truction manual for d rive con necti ons.

2.

TEMP

ALARM

Se e No te 1

FAN

(

OPTIONAL

115VAC 115VAC

)

6

Ground

Figure 4 – Wall-Mounted Braking Resistor Unit Field Connections

M3575R

To Braking

Module

Ground

+ Brake Out

- Brake Out

(+) 47

(-)

L1

L2

L3

45

48

U

V

W

18 AW G

Motor and Drive

Se e No te 2

115 VA

3 Line

Enclosed Resistor Modules, Enclosed Transistor Modules

9

Page 10

Typical Resistive Load

S ee T e rmin a l S trip D e ta il

12

Resistive Load Connections

1/2" Coarse Threaded Studs

r

e

w

FAN

o

P

n

a

F

.

h

c

t

i

w

S

p

m

e

T

h

p

c

t

m

i

e

w

T

S

r

t

l

e

u

v

a

O

F

#8 Screw Terminals

123 546

JUMPER

(DO NOT REMOVE)

HOT

115 VAC

NEUT

OVERTEMP115 VAC

ALARM OUTPUT

10

Fan Power / Alarm Connections

Figure 5 – Floor-Standing Grid Resistor Unit Field Connections

Enclosed Resistor Modules, Enclosed Transistor Modules

Page 11

Snubber Transistor Kits (M3575TH__, M3575TL__)

The figure below depicts the breakdown of the Enclosed Transistor kit part number.

M3575T L 30

Base Model Number

AC Voltage Rating

L = 230 VAC

H = 460 VAC

DC Current Rating

Enclosed Transistor Braking Unit Status Indicators

Braking units have the following status indicators:

• DC BUS: A green LED that turns on when the DC bus voltage is equal to or greater than 90 VDC.

• ACTIVE BRAKING: A red LED that turns on when the dynamic braking transistor turns on. Note that if this

indicator is on continuously, the AC line voltage may be high. Use an input transformer to reduce the

incoming AC line voltage to the AC drive or consult your local Rockwell Automation - Reliance Electric sales

office for assistance.

Enclosed Transistor Braking Unit Fa ult Outputs

Enclosed Transistor Braking units have one normally-closed contact (NC) rated at 2 amps, 125 VDC or

125 VAC that opens on the following fault conditions:

• loss of DC bus voltage

• open load

AC Line

Voltage

230 M3575TL15 15 25 M3

M3575TL30 30 12.5

M3575TL60 60 6.25 M4

460 M3575TH15 15 50 M3

M3575TH30 30 25

M3575TH75 75 10 M4

M3575TH125 125 6 B4

M3575TH150 150 5

M3575TH200 200 3.75 B7

M3575TH300 300 2.5

Braking Kit

Model Number Amps DC RMS

• Overtemperature

• transistor failure

Table 4 – Enclosed Transistor Kit Ratings

Minimum Load

Resistance (

Ω)

Enclosure

Type

Enclosed Resistor Modules, Enclosed Transistor Modules

11

Page 12

12

Table 5 – Matching Enclosed Transistor Kits and Enclosed Resistor Kits (230 VAC)

Enclosed Resistor Modules, Enclosed Transistor Modules

Transistor

Braking Kit

Model Number

Braking

HP

DC

Amps

RMS

6% Duty Cycle

Resistor

Braking Kit

Model Numb er

Peak

Braking

Watts

1

Continuous

Braking

Watts

20% Duty Cycle

Resistor

Braking Kit

Model Number

Peak

Braking

Watts

1

Continuous

Braking

Watts

Enclosure

Type

M3575TL15 1 2 M3575RL1M 746 50 M3575RL1MF 746 150 M4

2 4 M3575RL2M 1492 100 M3575RL2MF 1492 300 M4

3 6 M3575RL3M 2238 150 M3575RL3MF 2238 450 M4

3 5 M3575RL3B 1989 100 M3575RL3BF 1989 400 B4

4 8 M3575RL4M 2984 200 M3575RL4MF 2984 600 M7

5 10 M3575RL5B 3979 200 M3575RL5BF 3979 800 B4

6 12 M3575RL6M 4476 300 M3575RL6MF 4476 900 M7

8 15 M3575RL8B 5968 300 M3575RL8BF 5968 1200 B4

M3575TL30 9 18 M3575RL9M 6714 450 M3575RL9MF 6714 1350 M10

11 20 M3575RL11B 7967 400 M3575RL11BF 7967 1600 B7

M3575TL60 16 31 M3575RL16B 11936 600 M3575RL16BF 11936 2400 B7

1.

Maximum on-time is 60 seconds

24 47 M3575RL24B 17904 900 M3575RL24BF 17904 3600 B10

Page 13

Enclosed Resistor Modules, Enclosed Transistor Modules

Table 6 – Matching Enclosed Transistor Kits and Enclosed Resistor Kits (460 VAC)

6% Duty Cycle

1

20% Duty Cycle

1

Transistor

Braking Kit

Model

Number

Braking

HP

DC

Amps

RMS

Resistor

Braking Kit

Model Number

Peak

Braking

Watts

Continuous

Braking

Watts

Resistor Braking

Kit Model

Number

Peak

Braking

Watts

Continuous

Braking

Watts

Enclosure

Type

M3575TH15 1 1 M3575RH1M 746 50 M3575RH1MF 746 150 M4

2 2 M3575RH2M 1492 100 M3575RH2MF 1492 300 M4

3 3 M3575RH3M 2238 150 M3575RH3MF 2238 450 M4

4 4 M3575RH4M 2984 200 M3575RH4MF 2984 600 M7

5 5 M3575RH5B 4000 250 M3575RH5BF 4000 800 B4

6 6 M3575RH6M 4476 300 M3575RH6MF 4476 900 M7

8 8 M3575RH8B 6000 350 M3575RH8BF 6000 1200 B4

9 9 M3575RH9M 6714 400 M3575RH9MF 6714 1350 M10

11 11 M3575RH11B 8000 450 M3575RH11BF 8000 1600 B7

M3575TH30 16 16 M3575RH16B 12000 700 M3575RH16BF 12000 2400 B7

24 24 M3575RH24B 18000 1000 M3575RH24BF 18000 3600 B10

13

M3575TH75 50 53 — — — M3575RH50G1F 40000 8000 G1

M3575TH125 100 106 — — — M3575RH100G2F 80000 16000 G2

M3575TH200 150 159 — — — M3575RH150G3F 120000 24000 G3

1.

Maximum on-time is 60 seconds

Page 14

Sized for 1/4” Bolts or Studs

Enclosure

Type

M3 323,8

M4 323,8

M7 323,8

M10 323,8

B4 450,8

B7 450,8

B10 450,8

.75

A

E

G

F

Terminal Strip

.28 .28

1.00

A BC D E F G H

(12.75)

(12.75)

(12.75)

(12.75)

(17.75)

(17.75)

(17.75)

D

B

Dimension in mm (in)

76,2

(3.0)

101,6

(4.0)

177,8

(7.0)

254

(10.0)

101,6

(4.0)

177,8

(7.0)

254

(10.0)

Figure 6 – Enclosed Transistor Braking Kit Enclosure Dimensions

95,6

(7.70)

95,6

(7.70)

95,6

(7.70)

95,6

(7.70)

95,6

(7.70)

95,6

(7.70)

95,6

(7.7)

n/a 304,8

44,5

(1.75)

127

(5.0)

203,2

(8.0)

44,5

(1.75)

127

(5.0)

203,2

(8.0)

C

(12.0)

304,8

(12.0)

304,8

(12.0)

304,8

(12.0)

425,5

(16.75)

425,5

(16.75)

425,5

(16.75)

H

266,7

(10.5)

266,7

(10.5)

266,7

(10.5)

266,7

(10.5)

381

(15.0)

381

(15.0)

381

(15.0)

28,7

(1.13)

28,7

(1.13)

28,7

(1.13)

28,7

(1.13)

35,1

(1.38)

35,1

(1.38)

35,1

(1.38)

221

(8.7)

221

(8.7)

221

(8.7)

221

(8.7)

221

(8.7)

233,7

(9.2)

246,4

(9.7)

14

Enclosed Resistor Modules, Enclosed Transistor Modules

Page 15

Installing the Enclosed Transistor Braking Kit

ATTENTION:Equipment is at line voltage when AC power is connected to the drive. The drive’s

DC bus capacitors retain hazardous voltages after input power has been disconnected. After

!

Choose the installation site for the Enclosed Transistor Braking Unit with the following considerations in mind:

• The unit must be mounted in a clean, dry environment. The maximum ambient air temperature should not

exceed 40° C (104° F).

• The unit requires a minimum clearance of (2 inches) in all directions.

Use the following procedure to install Braking Units housed in NEMA 1 enclosures.

Step 1. Disconnect, lock out, and tag input power to the drive. Wait fiv e minutes for the DC bus capacitors to

Step 2. Verify that there is no voltage at the drive’s input power terminals.

disconnecting input power, wait five (5) minutes for the DC bus capacitors to discharge and then

check the DC bus voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this precaution could result in severe

bodily injury or loss of life.

ATTENTION:The user is responsible for conforming with all applicable local, national, and

international codes. Failure to observe this precaution could result in damage to, or destruction

of, the equipment.

discharge.

Step 3. Measure the drive’s DC bus potential with a voltmeter to ensure that the DC bus capacitors have fully

discharged as described in the drive’s instruction manual.

Step 4. Select a location for the Braking Unit within 8 feet of the drive where the heat generated by the

snubber resistors will not affect surrounding components. Do not mount the Braking Unit under the

drive or where convective air flow is restricted.

Step 5. Mount the Braking Unit vertically with the fan at the bottom. Mounting hardware is not provided. See

figure 6 for mounting dimensions.

Step 6. Install the wiring between the drive and the Braking Unit. See figures 7 and 8. Use wire that is rated at

a minimum of 300 volts for 230 VAC Braking Units and 600 volts for 460 VAC Braking Units.

ATTENTION:It is important to use wire rated at 300 volts for 230 VA C Braking Units (600 volts

for 460 V AC Braking Units) or greater because this wiring may come into contact with uninsulated

!

Step 7. Reapply input power to the drive. Refer to the drive’s instruction manual for complete start-up

230 VAC (or 460 V AC) components. Failure to observe this precaution could result in damage

to, or destruction of, the equipment.

information.

Enclosed Resistor Modules, Enclosed Transistor Modules

15

Page 16

Field Connections

24VDC FAN

(Not used on

15A to 30A units)

DC BUS (+)

DC BUS (--)

123456

TB3

RED 12AWG

BLACK 12AWG

RED 12AWG

RES

ACTIVE

BRAKING

22 AWG

TWISTED

BRAKING

RED

LED

WHITE

RED

BLACK

DC - RES -

ACTIVE

BRAKING

3575C1

CONTROL

BOARD

WHITE

RES

ALARM

ALARM

See Note 1

BLUE 18AWG

WHITE 12AWG

BLUE TRACK 18AWG

22 AW G RE D

22 AW G BLU E

TB2

TB1

1

2

1 (C)

2 (NC)

3 (NO)

HEAT SINK

GREEN

LED

22 AWG

TWISTED

RED

RED

RES +

DC BUS

WHITE

RED

+--+

CONTROL

POWER

DC+

Indicators

NOTES

1.

TB3 alarm contact opens upon a fault.

Figure 7 – Transistor Braking Unit Wiring Diagram

16

Enclosed Resistor Modules, Enclosed Transistor Modules

Page 17

Braking Transistor Unit Field Connection Notes

ATTENTION: Only qualified personnel familiar with the construction and operation of this

equipment and the hazards involved should install or service this equipment. The user is

!

Observe the following precautions when making field connections:

• The maximum wire sizes accepted by the Braking Transistor Unit field connection terminals are as follows:

responsible for conforming with all applicable local, national, and international codes. Failure to

observe these precautions could result in personal injury and/or damage to, or destruction of,

the equipment.

Model Number Max Wire

Size

M3575TL15

M3575TL30

M3575TH15

M3575TH30

10 AWG

M3575TL60 M3575TH75 6 AWG

M3575TH125

M3575TH150

M3575TH200

M3575TH300

3/8” ring lug

• Minimum load resistance requirements listed in tables 1 and 2 must be followed when selecting a resistive

load for use with the Braking Transistor Unit.

M3575T with M3575R Braking Module Field Connections

Motor And Drive

AC

DRIVE

Se e N o te 3

Ground

115 VAC

3 Line

DC BUS

RES RES

+1

23456

RES RES

23456

1

FAULT

ALARM

See

Note 2

TEMP

ALARM

See

Note 4

(

OPTIONAL

115VAC

FAN

115VAC

Ground

)

DC+

RES

DC-

To Braking

Module

M3575T

-DC Bus

+DC Bus

M3575R

Notes

The minimum load requirement must be followed.

1.

Alarm contacts open upon a fault and are rated at 0.5 amps (115 VAC).

2.

3.

Refer to drive instruction manual for drive connections.

Alarm contacts open upon a fault and are rated at 2.0 amps (125 VDC o r 125 VAC ).4.

Figure 8 – Braking Transistor and Braking Resistor Unit Field Connections

Enclosed Resistor Modules, Enclosed Transistor Modules

Ground

17

Page 18

Selecting and Sizing Snubber Braking Resistors

Continuous duty snubber braking resistors must be selected for the transistor switching circuit versions of the

Braking unit.

Use the following procedure to select the snubber resistors:

Step 1. Calculate the regenerated power (P

= 0.5 x Pp x t/T

P

ave

Where: P

= Peak Power

p

t = Rise/Fall Time

T = Period

Duty Cycle =

v

Braking

Power

t

brake

) from the load and the pattern of operation. See figure 9.

ave

t

brake

t

cycle

time

t

cycle

t

= on-time

brake

M3575T

Transistor Only

Max On-Time = 60 seconds

Duty Cycle

≤ 0.20 or 20%

Figure 9 – Braking Unit Duty Cycles

Step 2. Calculate the power dissipation of the resistor (P

(energy dissipation by the machine and the motor) from the regenerated power (P

Maximum On-Time = 60 Seconds

Duty Cycle ≤ 20% with fans

Duty Cycle

) by deducting 15% of the motor’s rated output

d

M3575R

Resistors

≤ 6% without fans

ave

Step 3. Use the following formula to determine the required resistor power rating (Pr) in watts:

= (3 to 4) x Pd watts

P

r

).

18

Enclosed Resistor Modules, Enclosed Transistor Modules

Page 19

Troub leshooting

If a problem occurs on start-up or during normal operation, refer to the table below.

Problem Corrective Action

Resistor Braking Unit

Drive trips on overvoltage or

self-limits its decel rate

The cooling fan doesn’t turn on

Temp alarm contact is open

indicating an overtemp fault is

present

Temp alarm contact does not open

on overtemp condition

Green DC Bus P o wer LED does n ot

come on

Red Active Bra king LED sta ys on or

flashes during motoring operation

Fault output on unit is open

indicating a fault is present

– Ensure that the resistive load module is properly connected to the drive’s

braking control c irc uitry. T his c an b e a c ho ppe r module internal to the driv e o r

an external braking kit.

– Verify the ohmic value of the resistive load (see table 1).

– Ensure that the resistive load is adequately sized for the application.

– Verify that temperature of load module exceeds 45

– Verify that 115 VAC is present for fan voltage.

– If the fault output is open and the chassis is hot, allow the unit to cool and

recheck the fault output; it should return to its normally closed state.

– If the fault output is open and the chassis is cool, replace the unit.

– If the fault output remains cl os ed and the chassis tem perature ex ce ed s 85

disconnect the load module and allow the unit to cool. Once the chassis has

cooled, replace the unit.

Transistor Braking Unit

– Ensure proper DC bus voltage at the unit’s input terminals. If the proper bus

voltage is not present, en sure that the voltage rating of the unit matches the

drive.

– Ensure that the voltage rating of the unit matches the drive.

– If line vol tage i s abno rmally hig h or low , t he uni t ma y require spec ial c alibr ation

adjustments. Contact Reliance for assistance.

– If the fault output is open and the chassis is hot, allow the unit to cool and

recheck the fault output; it should return to its normally closed state.

– If the fault output is open and the chassis is cool, check the resistor path to

make sure it is not open.

– Remove DC bus pow er from the un it and then restor e pow er. If the f ault outp ut

remains open, replace the unit.

° C.

° C,

Drive trips on overvoltage or

self-limits its decel rate

Enclosed Resistor Modules, Enclosed Transistor Modules

– Ensure that the green DC Bus Power LED is on.

– Ensure that the proper resisti ve lo ad v alue is connec ted to the unit an d that the

maximum current rating is not exceeded.

– Ensure the unit is not exceeding the current rating. The braking IGBT will shut

down on overcurrent conditions. Check for a fault output.

19

Page 20

U.S. Drives Technical Support

Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, Email: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication D2-3439-1 - March 2000 Copyright © 2000 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Loading...

Loading...