Page 1

LPM20

Liquid-Cooled

Adjustable Frequency

AC Drive

With High Performance Drive Control

Installation Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at http://

www.rockwellautomation.com/literature) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for solid

state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect

or consequential damages resulting from the use or application of this

equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with any

particular installation, Rockwell Automation, Inc. cannot assume responsibility

or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of

safety considerations.

WARNING: Identifies information about practices or

circumstances that can cause an explosion in a hazardous

!

environment, which may lead to personal injury or death, property

damage, or economic loss.

Important: Identifies information that is critical for successful application and

understanding of the product.

ATT E NT I ON : Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss. Attentions help you identify a hazard,

avoid the hazard, and recognize the consequences.

Shock Hazard labels may be located on or inside the equipment

(e.g., drive or motor) to alert people that dangerous voltage may be

present.

Burn Hazard labels may be located on or inside the equipment

(e.g., drive or motor) to alert people that surfaces may be at

dangerous temperatures.

Allen-Bradley, PLC, DriveExplorer, DriveExecutive, DriveLogix, SCANport, and SynchLink are either registered

trademarks or trademarks of Rockwell Automation, Inc.

Page 3

Summary of Changes

The information below summarizes the changes to this manual since the last

release (July 2005):

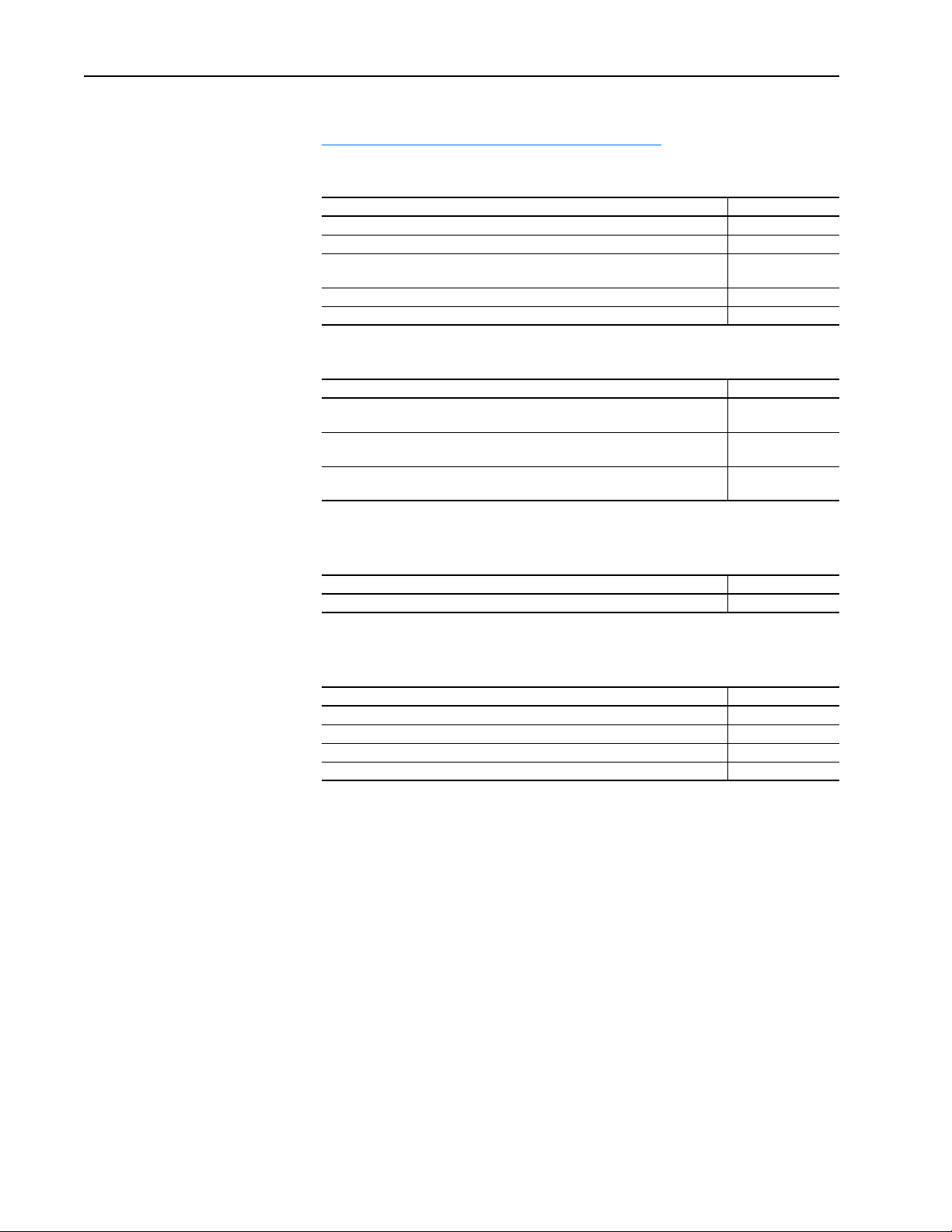

Description of Changes Page

In Table 1.A, changed column heading from “Output Current at 2 kHz (Amps)” to “Output

Current at 4 kHz (Amps).” Changed the last sentence in footnote 2 from “…also capable of

running at 3 kHz or 4 kHz…” to “…also capable of running at 2 kHz or 3 kHz.”

Changed Table 3.A columns and information. 3-7

Deleted Table 3.B, and added replacement fuses subheading and reference to the drive

wiring diagram.

In the“Control” category specifications section for the “Carrier Frequency,” changed the

statement “Drive rating based on 2 kHz” to “Drive rating based on 4 kHz.”

The information below summarizes the changes to this manual since the last

release (January 2005):

Description of Changes Page

Deleted Chapter 3 - Programming and Parameters. The active converter information

formerly contained in Chapter 3 is now contained in the PowerFlex 700 Active Converter

Power Module User Manual (Publication No. PFLEX-UM002…), which is referenced in the

Preface.

Changed the following catalog string information:

• In Digits 4 through 7 (Input Voltage & Output Current Rating), deleted Cat. Code D405.

Also removed all “405A” drive information from Table 1.A, Table 1.B, Table 1.C, Table

3A, Table 3B, and the VFD Power Module Table on page C-11.

• In Digit 12 (Input Filter Items), deleted Cat. Code C.

Added a reference to the PowerFlex 700 Active Converter Power Module User Manual

(Publication No. PFLEX-UM002…) for more information about active converter

communication.

Added a reference to the PowerFlex 700 Active Converter Power Module User Manual

(Publication No. PFLEX-UM002…) for more information about wiring the active converter

control board I/O terminals.

Re-numbered Chapter 4 - Troubleshooting to be Chapter 3. Chapter 3

Added a reference to the PowerFlex 700 Active Converter Power Module User Manual

(Publication No. PFLEX-UM002…) for active converter fault descriptions and related

troubleshooting information.

In Table 3.B, changed replacement Voltage Feedback Resistor Assembly, 460 V kit

number from “180924-A03” to “180923-A03.”

1-1

3-7

A-2

P-1

P-5

1-33

1-34

3-3

—

Page 4

soc-ii Summary of Changes

Page 5

Preface Overview

Who Should Use this Manual? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

What Is Not in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Reference Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-4

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-5

Chapter 1 Installation/Wiring

Power Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Enclosure Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Drive Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

AC Supply Source Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Mounting the Drive, Determining Wire Routing, and Grounding . . . . . . . . . . . . . . . . . 1-12

Coolant Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Installing Input Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Installing Output Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Power Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Using Input/Output Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

I/O Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Main Control Board I/O and Encoder Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

Connecting SynchLink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

Active Converter Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Auto Tune Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Pre-charge Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

Wiring the Active Converter Control Board I/O Terminals . . . . . . . . . . . . . . . . . . . . . . 1-34

CE Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

C-Tick Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

Table of Contents

Chapter 2 Start Up

Prepare For Drive Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Assisted Start Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Chapter 3 Troubleshooting

Faults and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Drive Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Manually Clearing Drive Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Drive Fault Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Active Converter Fault Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Clearing Drive Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Common Symptoms and Corrective Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Test Equipment Needed To Troubleshoot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Verifying That DC Bus Capacitors Are Discharged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Appendix A Supplemental Drive Information

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Communication Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Page 6

ii Table of Contents

Appendix B HIM Overview

Remote HIM Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

LCD Display Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

ALT Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Viewing and Editing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Removing/Installing the HIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Appendix C Wiring Diagrams

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Power Module – Overall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Power Module – Active Converter Control and Rectifier Power Interface . . . . . . . . . . . C-6

Power Module – High Voltage Interconnect and Inverter Power Interface . . . . . . . . . . . C-8

Power Module – Rectifier IGBT and Inverter IGBT . . . . . . . . . . . . . . . . . . . . . . . . . . . C-10

Index

Page 7

Preface

Overview

The purpose of this manual is to provide you with the basic information

needed to install and troubleshoot the LPM20 Liquid-Cooled AC Drive with

High Performance Drive Control.

For information on ... See page ...

Who Should Use this Manual?

What Is Not in this Manual P-1

Reference Materials P-2

Manual Conventions P-3

General Precautions P-4

Catalog Number Explanation P-5

P-1

Who Should Use this

Manual?

What Is Not in this Manual

This manual is intended for qualified personnel. You must be able to mount

and wire Adjustable Frequency AC Drive devices.

This manual is designed to provide only installation, wiring, and

troubleshooting information.

PowerFlex 700 Active Converter Power Module Information

LPM20 Liquid-Cooled Adjustable Frequency AC Drives are equipped with

a PowerFlex 700 Active Converter Power Module. For details on active

converter I/O wiring, start-up, programming, and other related information,

please refer to the PowerFlex 700 Active Converter Power Module User

Manual (Publication No. PFLEX-UM002…).

PowerFlex 700S Phase II Control Information

LPM20 Liquid-Cooled Adjustable Frequency AC Drives are equipped with

a PowerFlex 700S Phase II control cassette. Please refer to the Power Fl ex

700S High Performance AC Drive — Phase II Control User Manual

(Publication No. 20D-UM006…) in the locations shown in parenthesis

below for information on:

• Start-up (Chapter 2).

• Drive programming and parameters (Chapter 3).

• Application notes (Appendix C).

Page 8

P-2 Overview

Reference Materials

Publications can be obtained online at

http://www.rockwellautomation.com/literature

The following manuals are recommended for general drive information :

Title Publication

Wiring and Grounding Guidelines for Pulse Width Modulated (PWM) AC Drives DRIVES-IN001…

Preventive Maintenance of Industrial Control and Drive System Equipment DRIVES-TD001…

Safety Guidelines for the Application, Installation and Maintenance of Solid

State Control

A Global Reference Guide for Reading Schematic Diagrams 0100-2.10

Guarding Against Electrostatic Damage 8000-4.5.2

The following publications provide specific feedback card information:

Title Publication

Hi-Resolution (Stegmann) Feedback Option Card Installation Instructions for

PowerFlex 700S Drives (also LPM20 with High Performance Drive Control)

Resolver Feedback Option Card Installation Instructions for

PowerFlex 700S Drives (also LPM20 with High Performance Drive Control)

Multi-Device Interface Option Card Installation Instructions for

PowerFlex 700S Drives (also LPM20 with High Performance Drive Control)

The following publication provides information that is necessary when

applying the 700S Phase II Control DriveLogix5730 Controller:

.

SGI-1.1

20D-IN001 …

20D-IN002 …

20D-IN004 …

Title Publication

DriveLogix5730 Controller User Manual 20D-UM003 …

The following publications provide information that is useful when

planning and installing communication networks:

Title Publication

ControlNet Coax Tap Installation Instructions 1786-5.7

ControlNet Cable System Planning and Installation Manual 1786-6.2.1

ControlNet Fiber Media Planning and Installation Guide CNET-IN001 …

SynchLink Design Guide 1756-TD008 …

For Allen-Bradley Drives Technical Support:

E-mail: support@drives.ra.rockwell.com

Tel: (1) 262.512.8176

Fax (1) 262.512.2222

Online: www.ab.com/support/abdrives

Page 9

Overview P-3

Manual Conventions

• In this manual we refer to the LPM20 Liquid-Cooled AC Drive as; drive,

LPM20 or LPM20 Drive.

• To help differentiate parameter names and LCD display text from other

text, the following conventions will be used:

– Parameter Names will appear in [brackets].

For example: [DC Bus Voltage].

– Display Text will appear in “quotes.” For example: “Enabled.”

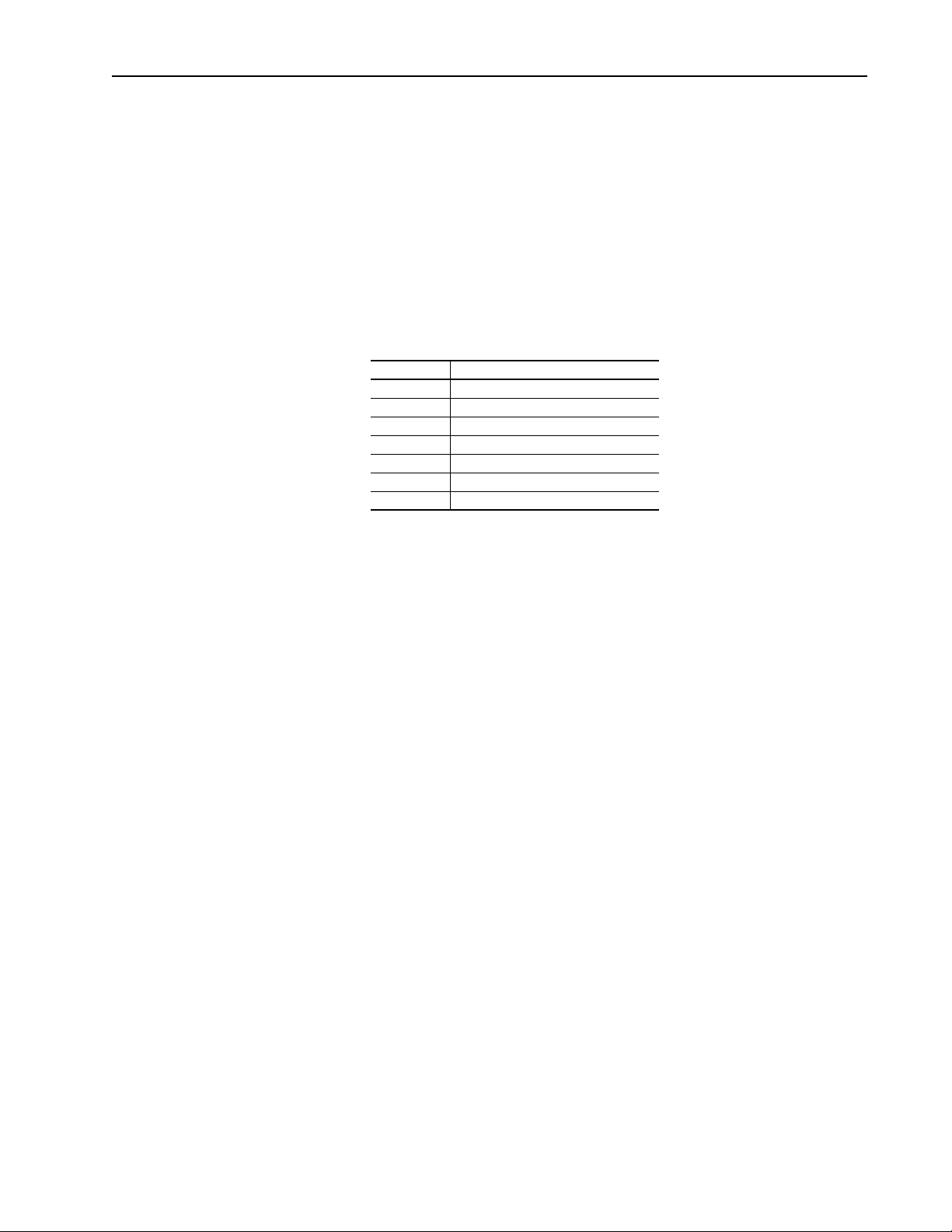

• The following words are used throughout the manual to describe an

action:

Word Me aning

Can Possible, able to do something

Cannot Not possible, not able to do something

May Permitted, allowed

Must Unavoidable, you must do this

Shall Required and necessary

Should Recommended

Should Not Not recommended

Page 10

P-4 Overview

General Precautions

Class 1 LED Product

ATTENTION: Risk of permanent eye damage exists when using

optical transmission equipment. This product emits intense light

!

and invisible radiation. Do not look into module ports or fiber

optic cable connectors.

ATTENTION: This drive contains ESD (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are

!

required when installing, testing, servicing or repairing this

assembly. Component damage may result if ESD control

procedures are not followed. If you are not familiar with static

control procedures, refer to Allen-Bradley publication 8000-4.5.2,

“Guarding Against Electrostatic Damage” or any other applicable

ESD protection handbook.

ATTENTION: An incorrectly applied or installed drive can

result in component damage or a reduction in product life. Wiring

!

or application errors, such as, undersizing the motor, incorrect or

inadequate AC supply, or excessive ambient temperatures may

result in malfunction of the system.

ATTENTION: Only qualified personnel familiar with adjustable

frequency AC drives and associated machinery should plan or

!

implement the installation, start-up, and subsequent maintenance

of the system. Failure to comply may result in personal injury and/

or equipment damage.

ATTENTION: To avoid an electric shock hazard, verify that the

voltage on the bus capacitors has discharged before performing

!

any work on the drive. After removing power to the drive, wait 5

minutes for the bus capacitors to discharge. Measure the DC bus

voltage at the locations shown in Figure 3.2

zero.

ATTENTION: Risk of injury or equipment damage exists. DPI

or SCANport host products must not be directly connected

!

together via 1202 cables. Unpredictable behavior can result if two

or more devices are connected in this manner.

ATTENTION: Risk of injury or equipment damage exists.

Parameters 365 [Fdbk LsCnfg Pri] - 394 [VoltFdbkLossCnfg] let

!

you determine the action of the drive in response to operating

anomalies. Precautions should be taken to ensure that the settings

of these parameters do not create hazards of injury or equipment

damage.

ATTENTION: Risk of injury or equipment damage exists.

Parameters 383 [SL CommLoss Data] - 392 [NetLoss DPI Cnfg]

!

let you determine the action of the drive if communications are

disrupted. You can set these parameters so that the drive continues

to run. Precautions should be taken to ensure that the settings of

these parameters do not create hazards of injury or equipment

damage.

. The voltage must be

Page 11

Overview P-5

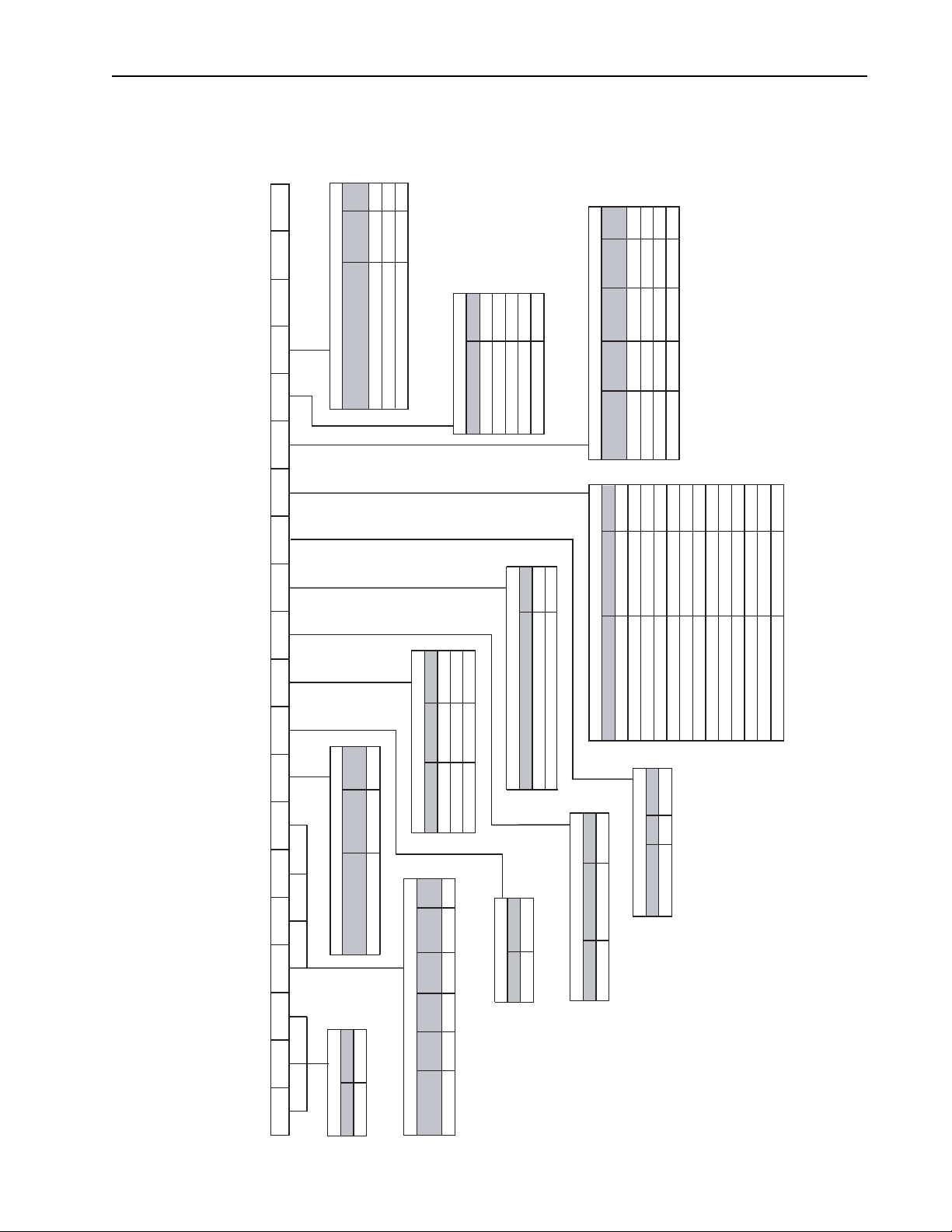

Catalog Number Explanation

1817 19 20

The LPM20 with High Performance Drive Control catalog numbering

scheme is shown below.

L

ENo

K

Cat.

Code

Comm.

No

Embedded

Options

CONTROL CONFIGURATIONS

Ethernet/IP

700S Phase II Control

700S Phase II Control w/DriveLogix™

700S Phase II Control w/DriveLogix™

1B 1

C 1E

A

Cat. CodeType

FEEDBACK OPTIONS

None N

Resolver

Stegmann Encoder

Multi-Device Interface

Cat.

1

2nd Encoder

Requires Expanded Cassette.

1

Logix

CONTROL OPTIONS

Control

Code

No A

SyncLink

No

Expansion

Cassette

Expanded

Option

700S Phase II

D

2D 2

B

C

YesNoYes

No

Yes

Yes

Expanded

Expanded

Expanded

700S Phase II

700S Phase II

700S Phase II

2

C

Q

Requires DriveLogix™5730 Controller.

42 43 44 45 46 4

1

E

E

N

Q

No

Yes

Yes

Ship CartonDocument(s) Cat. Code

Cat.

Code

DOCUMENTS & SHIPPING CARTON

English Doc Set

No Doc Set

HP

(Ref.)

Cat.

Code

Output

Current

Type

Source

No Doc Set

HIM

Coat

None

LPM20 with High Performance Drive Control

PRODUCT CATALOG NUMBER EXPLANATION

068

Conformal

Rating

Enclosure

Open Chassis / IP00 N

ENCLOSURE TYPE AND CONFORMAL COATING

A

N

Options Cat. Code

INPUT FILTER ITEMS

Replacement Power Module Only

Assembled Input Filter with Power Module

None N

Version Cat. Code

Note: HIM is ordered separately.

DPI Cat. Code

3

None N

DeviceNet

RIO R

ControlNet (Coax)

COMM SLOTS

DriveLogix (NetLinx)

None

N/A

N/A

N/A

NoNo N

EMC Cat. Code

INTERNAL EMC FILTERING

NoneNone N

Brake ResistorBrake IGBT Cat. Code

DYNAMIC BRAKE IGBT & BRAKE RESISTOR

Common Mode

N/A

ControlNet (Fiber)

N/A

N/A

RS485 DF-1 S

Ethernet

N/A

N/A

ControlNet (Coax)

ControlNet Redundant (Coax)

N/A

ControlNet (Fiber)

N/A

N/A

N/A

DeviceNet

ControlNet Redundant (Fiber)

EtherNet/IP (Twisted Pair)

Note that selections are mutually exclusive. For two Comm devices

Requires 700S Phase II Control with Logix Expansion.

(DPI and NetLinx), select the NetLinx Comm option and order the

DPI Comm kit separately.

3

4

12345678910111213141516

20ND NNE NNNNANE

PRODUCT

LPM20 20N

Product Cat. Code

Input

608 A 3 PH. 608 A D608 500

Current

INPUT VOLTAGE & OUTPUT CURRENT RATING

Input

380 - 480 VAC

Voltage Range

Page 12

P-6 Overview

Notes:

Page 13

Chapter 1

Installation/Wiring

This chapter provides information on mounting and wiring the LPM20 Drive.

For information on ... See page ...

Powe r R at in gs

Enclosure Ratings 1-2

Drive Component Locations 1-2

AC Supply Source Considerations 1-11

Mounting the Drive, Determining Wire Routing, and Grounding 1-12

Coolant Considerations 1-14

Installing Input Power Wiring 1-17

Installing Output Power Wiring 1-19

Powe r W ir ing 1-20

Using Input/Output Contactors 1-22

I/O Wiring 1-23

Main Control Board I/O and Encoder Settings 1-31

Connecting SynchLink 1-32

Active Converter Communication 1-33

Auto Tune Operation 1-33

Pre-charge Operation 1-34

Wiring the Active Converter Control Board I/O Terminals 1-34

CE Conformity 1-36

C-Tick Conformity 1-37

1-1

Power Ratings

Catalog Number

(positions 1-7 only)

20ND608 505 380 to 480 608 608 500 9000/3000

(1)

110% output current capability for one minute, 150% output current capability for 5 seconds.

(2)

Note that LPM20 drives are rated for use with water at specified temperatures and pressures as the coolant. Some coolant fluids may allow an increased

output rating while others may require the output to be derated. LPM20 drives are also capable of running at 2 kHz or 3 kHz.

Input

Power (KVA)

Most start-up difficulties are the result of incorrect wiring. Every precaution

must be taken to assure that the wiring is done as instructed. All items must

be read and understood before the actual installation begins.

ATTENTION: The following information is merely a guide for

proper installation. The Allen-Bradley Company cannot assume

!

responsibility for the compliance or the noncompliance to any

code, national, local or otherwise for the proper installation of this

drive or associated equipment. A hazard of personal injury and/or

equipment damage exists if codes are ignored during installation.

LPM20 Drives with High Performance Drive Control have power ratings as

described in Tabl e 1.A

Table 1.A Power Ratings

Input

Vol t a g e ( V )

Input

Current (Amps)

below:

(1)

Output Current

(2)

at 4 kHz

(Amps)

HP Ratings

Full Load Power Loss

Watts Fluid/Air

Page 14

1-2 Installation/Wiring

Enclosure Ratings

Drive Component Locations

LPM20 drives have the following enclosure rating:

• Open-Chassis Style: Intended to be installed in an enclosure.

LPM20 drives must be placed in an enclosure.

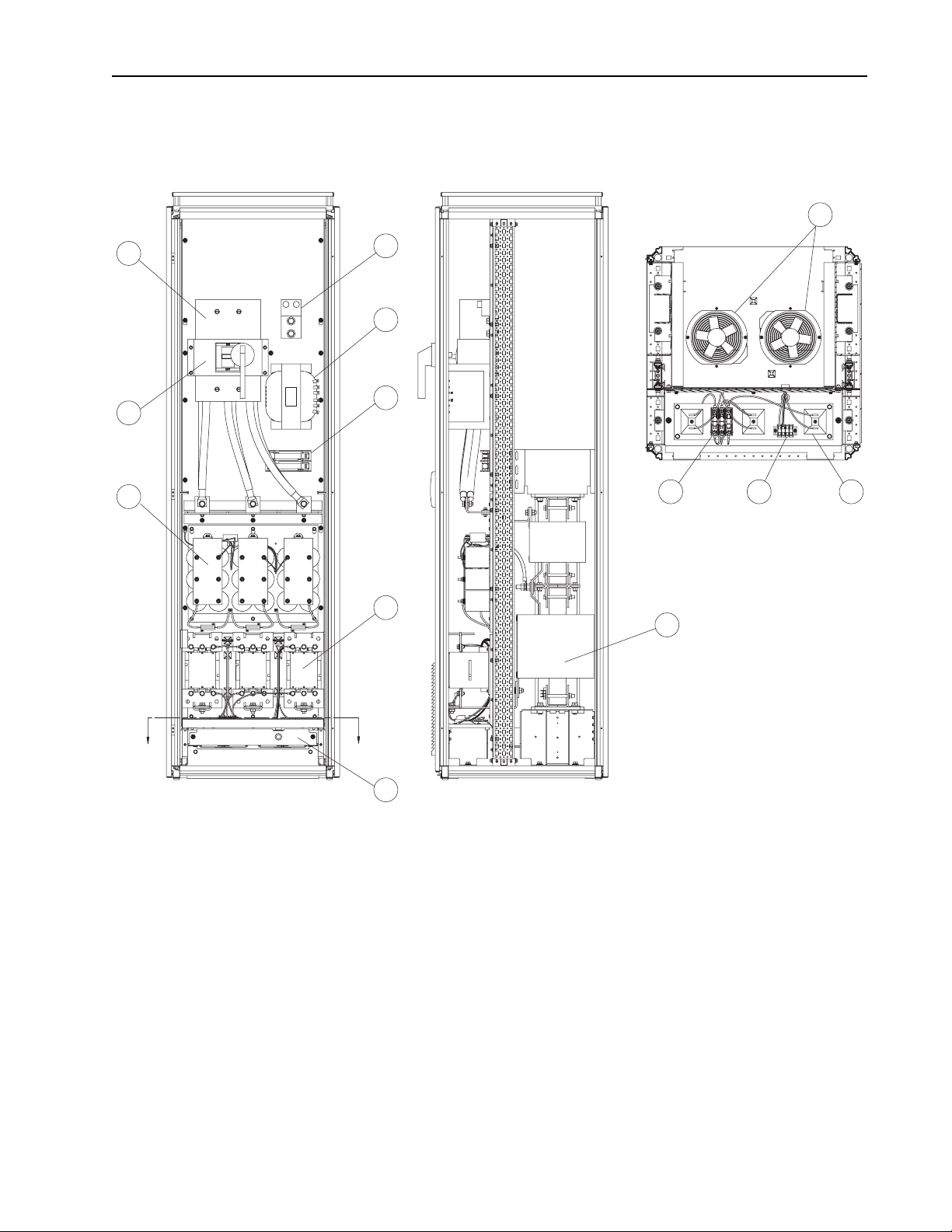

LPM20 Liquid-Cooled AC drives with High Performance Drive Control are

comprised of an input components section and a power module section.

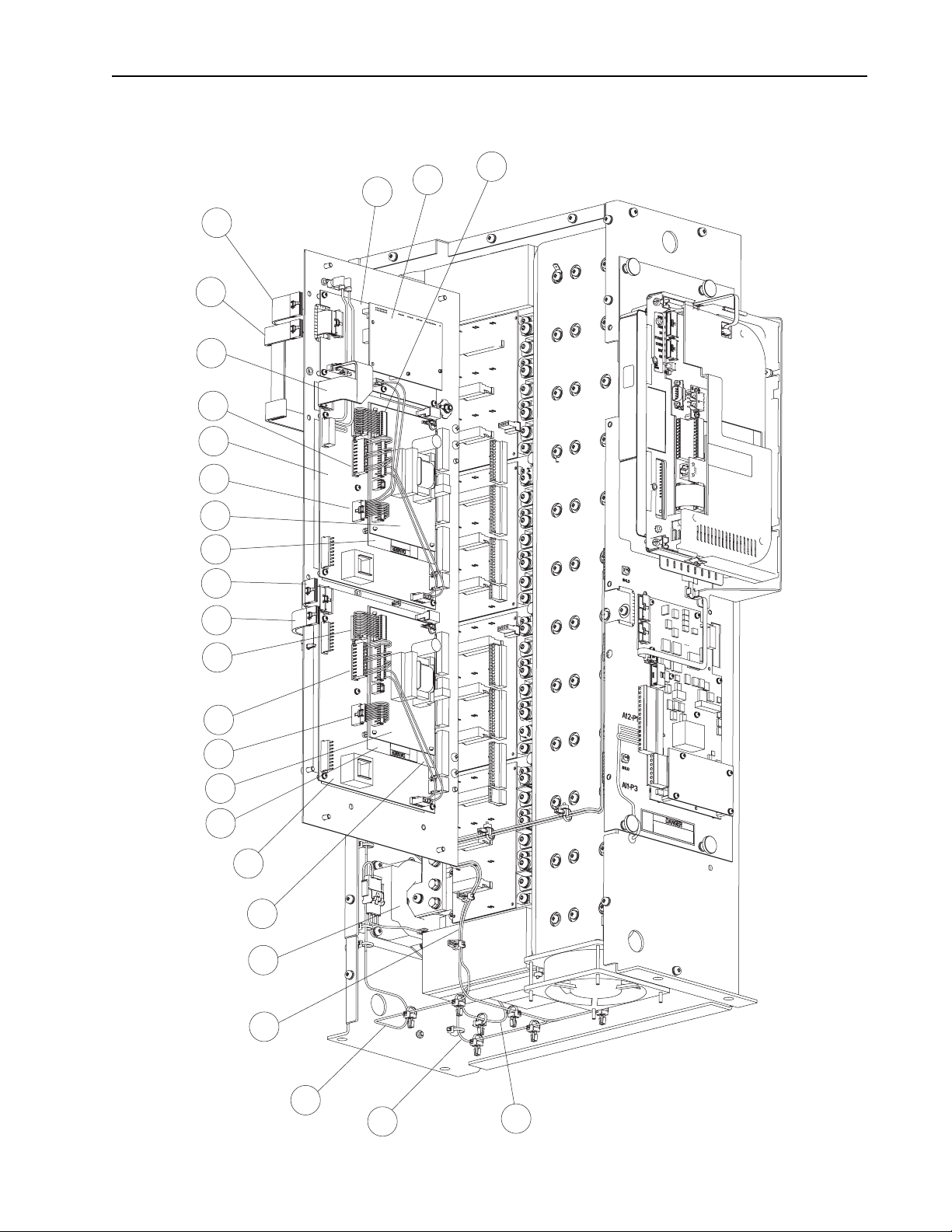

Drive Input Component Locations

The input components section contains the following main components.

The numbered items listed below correspond to the numbers used in

Figure 1.1

1. Main Circuit Breaker

2. Circuit Breaker Operating Mechanism

3. Capacitor Bank Filter

4. Fan Tray

5. Precharge AC Contactors (3)

6. Fuses, 15A, Primary Control Transformer (2)

7. Control Transformer, 120 VAC, 1 Phase, 3 KVA

8. Ground Lug, 2-600 MCM

9. Inductor

10. Fuses, Precharge Resistors, 20A, 600V (3)

11. Terminal Block, 4-Position

12. Precharge Resistors (3)

13. 115V Fans (2)

. Replacement parts are listed in Chapter 3.

Page 15

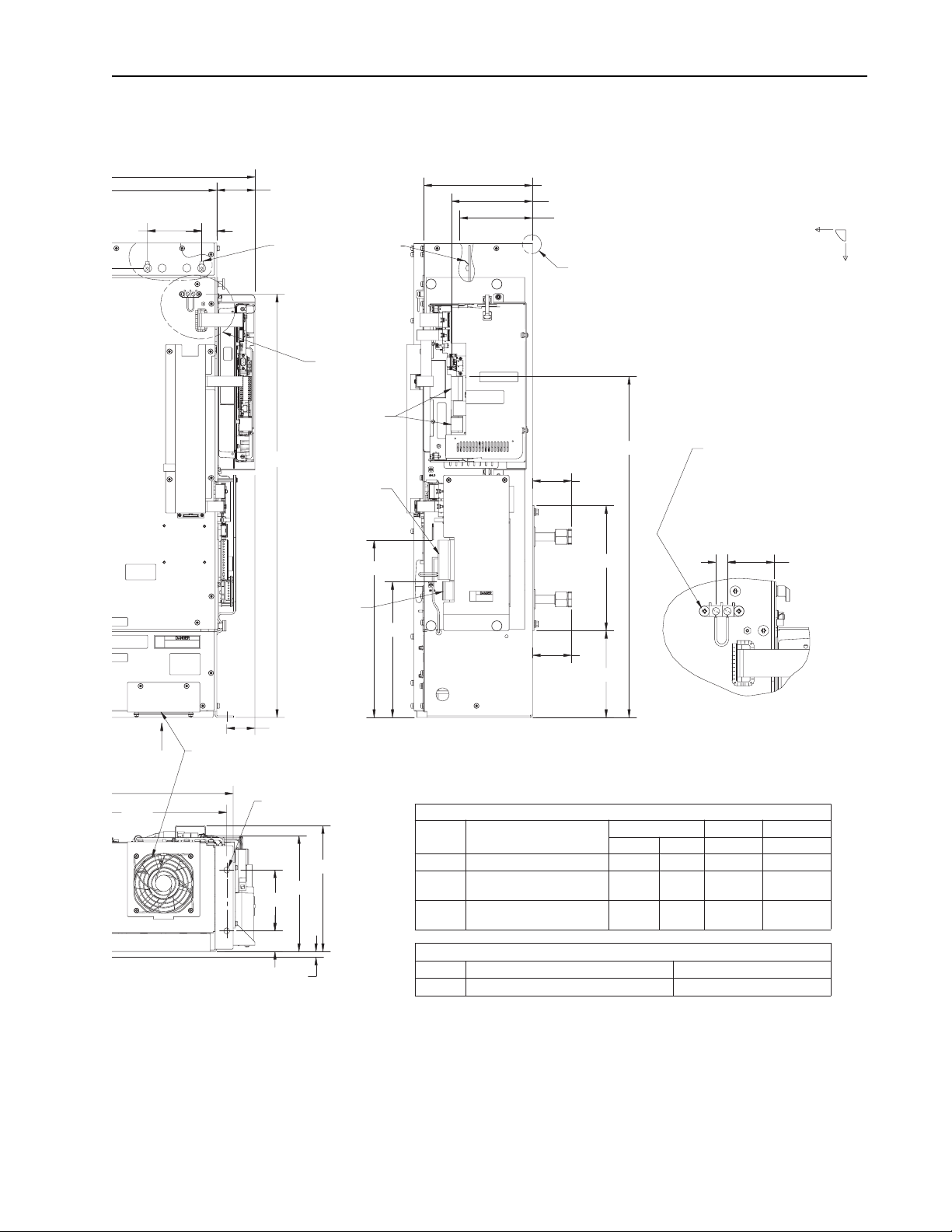

Figure 1.1 Drive Input Components

Installation/Wiring 1-3

13

1

2

3

8

7

6

10 11 12

SECTION A-A

5

9

A

A

4

See SECTION A-A

Page 16

1-4 Installation/Wiring

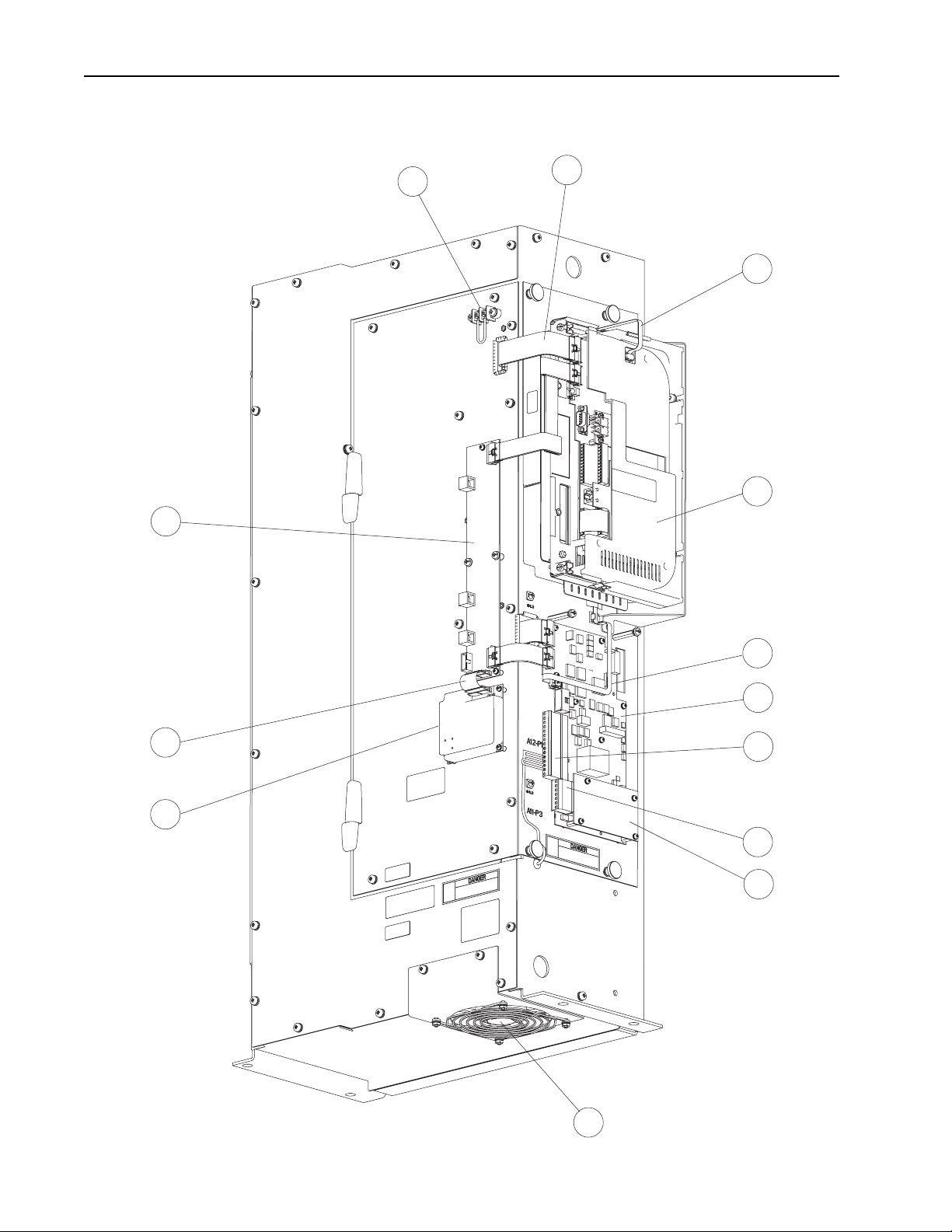

Power Module Component Locations

The power module section contains the following main components. The

numbered items listed below correspond to the numbers used in Figure 1.2

and Figure 1.3

1. Cable Assembly, 40-pin, 0.050 in. Pitch, Flex Film (1)

2. Cable Assembly, 30-pin, 0.050 in. Pitch, Flex Film (1)

3. Cable Assembly, 40-pin, 0.050 in. Pitch, Flex Film (1)

4. Wire Harness Assembly, Power Supply, Upper Gate (2)

5. Inverter Power Interface Assembly

6. Wire Harness Assembly, Power Supply, Lower Gate, PF700S (1)

7. 80 W Power Supply Assembly (2)

8. Insulation Sheet (2)

9. Cable Assembly, 40-pin, 0.050 in. Pitch, Flex Film (1)

10. Cable Assembly, 30-pin, 0.050 in. Pitch, Flex Film (1)

11. Wire Harness Assembly, Power Supply, Logic (2)

12. Wire Harness Assembly, Power Supply, Lower Gate (1)

13. Rectifier Power Interface Assembly

14. Current Feedback Device, 1000A (6)

15. Wire Harness Assembly, Gate Driver

16. Wire Harness Assembly, Current Feedback Device

17. Wire Harness Assembly, Input Filter (1)

18. Wire Harness Assembly, DC Bus Bleeder Resistors (1)

19. High Voltage Interconnect Assembly (1)

20. PF700S Voltage Feedback, 400V Class, Assembly (1)

21. Terminal Block, 2-Position (1)

22. Cable Assembly, 10-Position, Ribbon (1)

23. PF700S Control Cassette

24. Active Converter Assembly

25. Connector, Terminal Block, 15-pin

26. Connector, Terminal Block, 7-pin

27. Voltage Feedback Resistor, 460V, Assembly

28. Internal Fan

29. Communications Interface Assembly

30. Cable Assembly, 20-pin, 0.050 in. Pitch, Flex Film (optional)

31. Communications Module (optional)

. Replacement parts are listed in Chapter 3.

Page 17

Figure 1.2 Power Module Component Locations – Door Open

Installation/Wiring 1-5

19

1

2

3

4

5

6

7

8

9

20

11

10

11

4

12

7

8

13

4

14

15

16

17

18

Page 18

1-6 Installation/Wiring

Figure 1.3 Power Module Component Locations – Door Closed

29

21

1

22

23

30

31

22

24

25

26

27

28

Page 19

Installation/Wiring 1-7

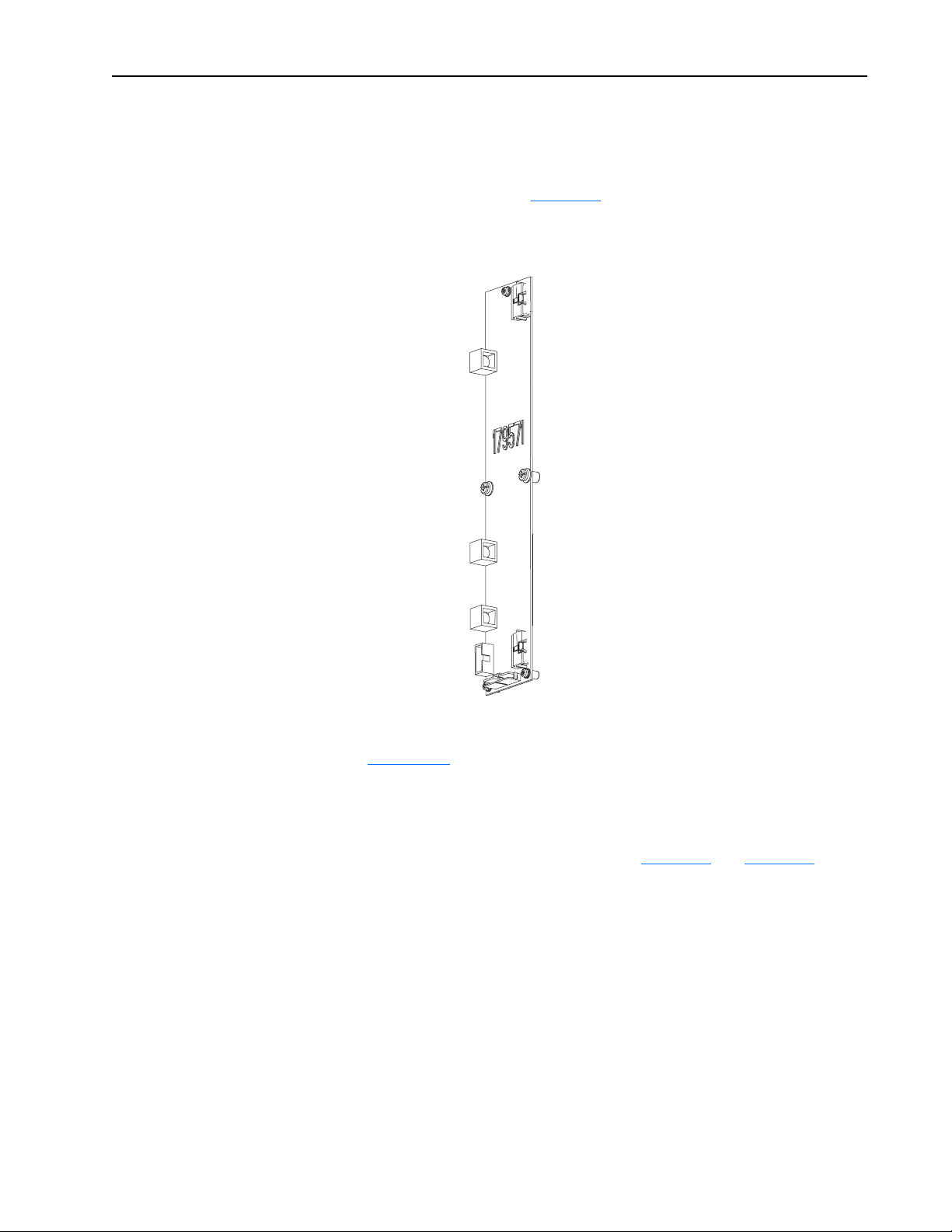

DPI Communication Port

The Communication Interface PCB contains an eight-position, female,

locking mini-DIN connector that is used as a DPI communication port. This

port (DPI Port 4 shown in Figure 1.4

between the LPM20 drive and another DPI device (for example, a HIM).

Figure 1.4 DPI Communication Interface Board

DPI

Port 3

below) provides communication

DPI

Port 4

DPI

Port 5

For more information regarding operating LPM20 drives with a HIM, refer

to Appendix

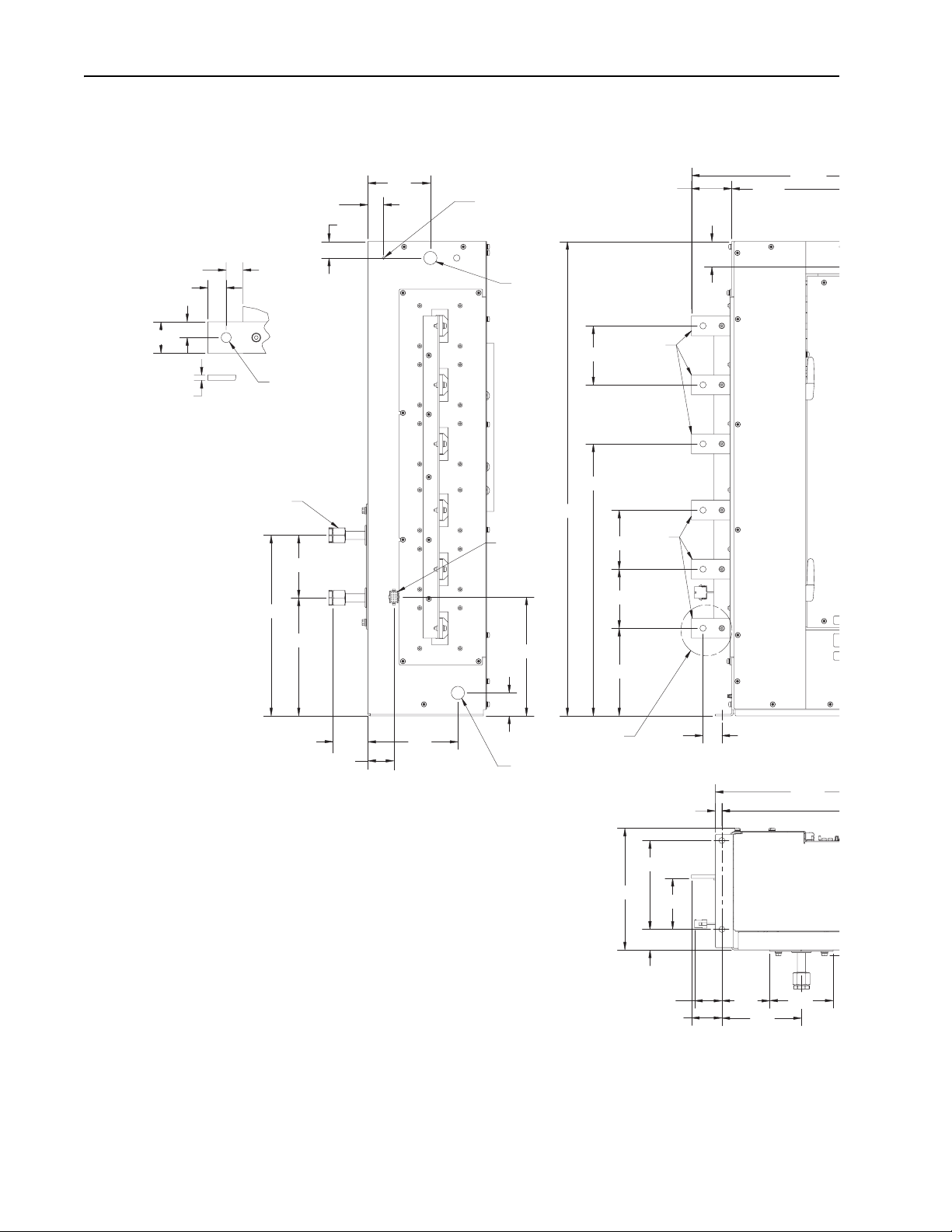

Determining Total Area Required Based on Drive Dimensions

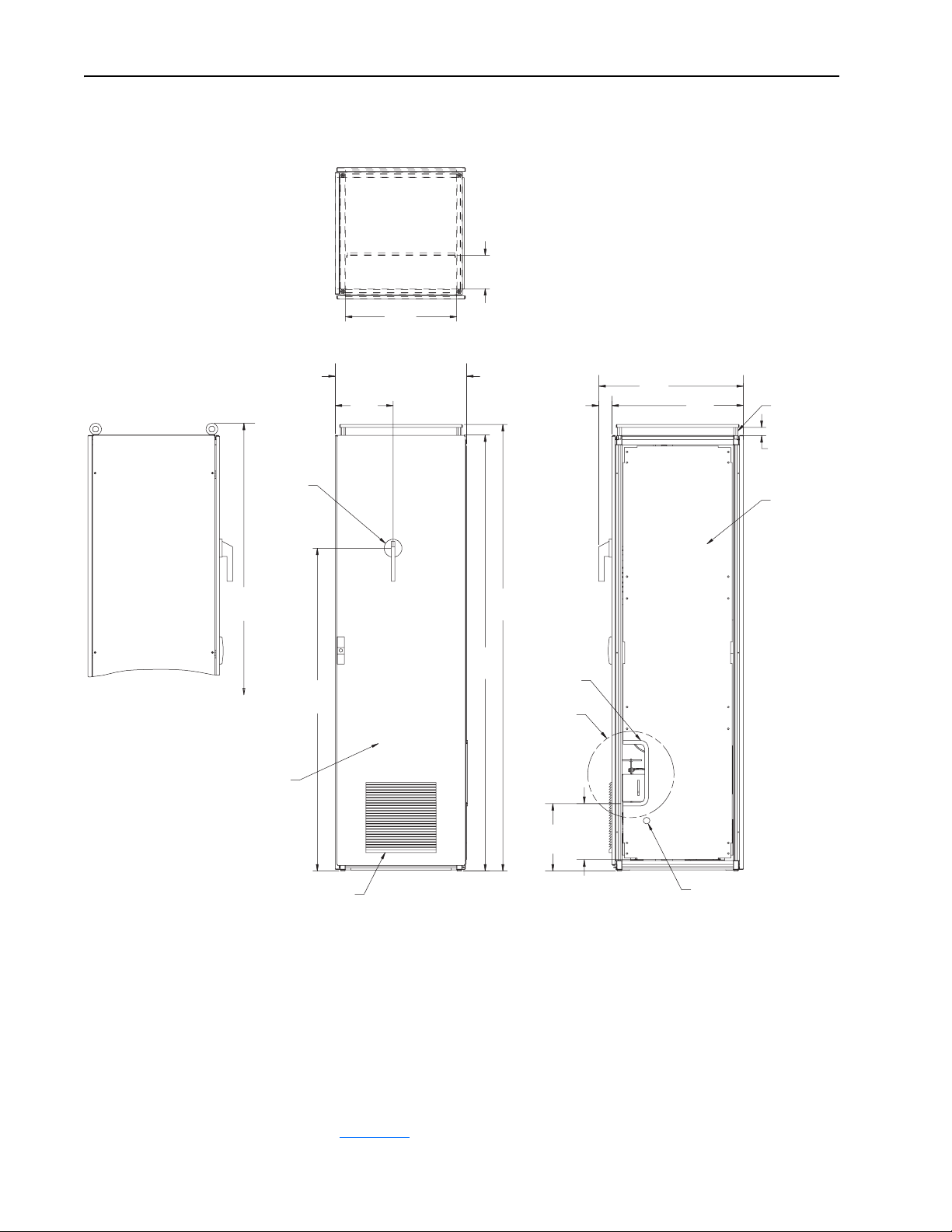

Overall drive dimensions are illustrated in Figure 1.5 and Figure 1.6 as an

aid in calculating the total area required by the LPM20 drives.

B.

Page 20

1-8 Installation/Wiring

Figure 1.5 Power Module Dimensions and Mounting

1.19

0.80

0.88

0.75

1.50

0.25

Ø.472

DETAIL A

Input and Output Wiring Connection

SCALE 1:2

Coolant Connections

See Notes 2 and 3

OUT

4.76

13.72

IN

8.96

1.25

4.75

Ø.213 Thru

For M6 TAPTITE

Screw with Enclosure

Mounting Bracket

Lifting

Ø1.00

Both Sides

W

V

U

L3

A1-P1

L2

Input Filter

Harness

Connector

L1

9.03

36.04

4.48

20.66

Output

Wiring

to Motor

4.48

4.48

6.66

3.05

Drive

Drive

Input

Wiring

21.97

16.00

1.92

1.75

2.65 From Back of

Chassis to ORFS of

Sealing Surfaces

6.84

1.98

SEE DETAIL A

Lifting Ø1.00 Both Sides

LEFT SIDE VIEW

NOTES:

1. Floor Mounting Flange Holes:

A. Accept M8 Thread-Rolling Screws per SAE J1237.

B. Tightening Torque: 20-24 [N-M], 15-17 [FT-LBF].

2. Inlet and Outlet Coolant Connection Hardware Provided With Unit:

A. ORFS Braze Sleeve:

a. Material: Brass; for 5/8" O.D. Copper Tube.

b. Reference: Parker Hannifin P/N 10 TL-B, or equivalent.

B. ORFS Nut:

a. Material: Brass; for 5/8" O.D. Copper Tube, 1-14 UN/UNF-2B Thread.

b. Tightening Torque: 37-45 [N-M], 27.1-33.3 [FT-LBF].

c. Reference: Parker Hannifin P/N 10 BL-B, or equivalent.

3. Coolant Connection Hardware Provided by User:

A. ORFS Braze Adapter:

a. Material: Brass; for 5/8" O.D. Copper Tube, 1-14 UN/UNF-2A Thread.

b. Reference: Parker Hannifin P/N 10 LHB3-B, or equivalent.

B. ORFS O-Ring:

a. Material: Neoprene Rubber.

b. Size: 0.614 I.D., 0.070 Width.

c. Reference: Parker Hannifin P/N 2-016-C0873-70, or equivalent.

C. O-Ring Lubricant: Parker Hannifin Super-O-Lube, or equivalent.

9.25

6.75

1.56

2.08

1.43

0.50

3.88

2.31

FRONT

VIEW

3.64

6.05

18.49

4.81

Page 21

Installation/Wiring 1-9

Neg (-)

4.12

DC

A31

A32

A33

DC

Pos (+)

2.92

DC Bus Measurement

1.15

Points on Laminated

Bus Ass'y 0.25" x 0.032"

Male Faston. Accessible

by Removal of Top Cover.

SEE DETAIL

GATE KILL

A22-TB1 & TB2

Main Control Ass'y

Terminal Blocks

32.16

A12-P1 Active

Converter Control

Ass'y Terminal

Block 15-Pos.

A11-P2 Voltage

Feedback

Resistor Ass'y

Terminal

Block 7-Pos.

13.47

10.32

8.27 (A33)

6.17 (A22-TB1 & TB2)

5.54 (DC Bus Measurement Points)

SEE DETAIL COG

25.90

2.96

OUT

9.50

0.44

DETAIL COG

SCALE 5:16

CENTER OF GRAVITY:

X = 17.5"

Y = 3.1"

Z = 7.4" (into Plane

of Drawing)

WEIGHT:

162 LBS.

A33 Gate Kill

2-Pos. Terminal Block

With #6-32 Phillips/Slotted

Screws. Accepts #6 Stud Size

Spade Tongue Terminal.

Max. Width is 0.37".

IN

2 1

A33

2.96

6.60

Y

X

1.78

AIRFLOW

17.50

BOTTOM VIEW

2.15

Cooling Fan Requires 1.13" Minimum

Unobstructed Space Below Fan

Ø.453 (4)-PL. See Note 1

4.63

1.56

9.56

8.80

0.44

DETAIL GATE KILL

RIGHT SIDE VIEW

FIELD CONTROL WIRING

Name Reference

A33 #6-32 Screw 0.90 8 24 to 10

A12-P1

A11-P2

A22-TB1

A22-TB2

A1-P1

MATE

Screwdriver Blade:

0.032" Thk. x 0.125" Wide

Screwdriver Blade:

0.017" Thk. x 0.094" Wide

A1-P1 LINE SYNC. ASS'Y HARNESS CONNECTOR

Socket Housing, AMP P/N 172163-1 Socket, AMP P/N 770903-3

Pin Housing, AMP P/N 172171-1

Torque

[N-M] [IN-LBF] [AWG] [Inch]

0.79 7 26 to 12 0.31

0.22 1.9 28 to 16 0.25

SCALE 5:8

Wire Size Strip Length

Pin, AMP P/N 770904-3

−

Page 22

1-10 Installation/Wiring

C/B

Disconnect

Handle

Figure 1.6 Drive Input Dimensions

6.076

Area for Input Power Wiring

[154,3]

20.157

[512]

Area for Input Power Wiring

23.80

Left Panel/Divider Panel

[605]

10.49

[266]

2.38

[60]

26.20

[665]

23.82

[605]

Field Install

Roof Spacers

Rittal p/n

DK7967.000

Exhaust Air

Space Required

Divider Panel

Rittal p/n

TS8609.060

Left View Shown

with Lifting Eye-Bolts

as Shipped

Rittal TS8 Enclosure

600mm x 600mm x 2000mm

81.11

[2060]

80.89

[2055]

78.99

[2006]

58.48

[1485]

Intake Louver

323mm x 323mm

Edge Guard

Power Cable

Opening Input

to Power Module

10.13

[257]

12.24

Ref

[311]

Control Cable

Opening Input

to Power Module

Verifying that Site Provides for Recommended Air Flow Clearances

Be sure there is adequate clearance for air circulation around the

user-supplied enclosure. A 6-inch minimum clearance is required wherever

vents are located in the cabinet.

For proper cabinet ventilation, roof spacers must be field installed as shown

in Figure 1.6

.

Page 23

Installation/Wiring 1-11

Verifying Power Module Input Ratings Match Supplied Power

It is important to verify that plant power will meet the input power

requirements of the LPM20 drive’s Power Module circuitry. See Ta ble 1 . A

for input power rating specifications. Be sure input power to the drive

corresponds to the drive nameplate voltage and frequency.

AC Supply Source Considerations

LPM20 drives are suitable for use on a circuit capable of delivering up to a

maximum of 100,000 rms symmetrical amperes, and a maximum of 480 volts.

A circuit breaker with shunt trip as supplied with input drive components with

the appropriate kAIC rating must always be used upstream of the power module.

ATTENTION: To guard against personal injury and/or equipment

damage caused by improper circuit breaker selection, use only the

!

recommended circuit breakers specified in Tab le 1 . B

Unbalanced or Ungrounded Distribution Systems

LPM20 drives should not be used with a supply system that is ungrounded and

when the phase-to-phase voltage exceeds 125% of normal line-to-line voltage.

ATTENTION: LPM20 drives contain protective MOVs on the

drive’s printed circuit boards. The MOVs are referenced to ground.

!

The MOVs should not be disconnected.

Input Power Conditioning

Certain events on the power system supplying a drive can cause component

damage or shortened product life. They are:

.

• The power system has power factor correction capacitors switched in and

out of the system, either by the user or by the power company.

• The power source has intermittent voltage spikes in excess of 6000 volts.

These spikes could be caused by other equipment on the line or by events

such as lightning strikes.

• The power source has frequent interruptions.

Wiring Requirements for the Drive

Certain drive requirements should be checked before continuing with the

drive installation. Wire sizes, branch circuit protection, encoder feedback (for

FVC regulation), and wiring to disable the drive are all areas that need to be

evaluated.

Operation of the drive can be disabled in two locations. Gate Kill terminal

block (A33) on the front of the power structure can be used to disable the

firing of inverter IGBTs. When the connection between terminals 1 and 2 is

opened, inverter IGBTs are disabled independent of any software control.

This action also generates fault 207 in the inverter to enunciate this

Page 24

1-12 Installation/Wiring

condition. As a result of this fault, the active converter is also turned off, but

this is done via software operation. The firing of IGBTs in the active

converter can be disabled independently of any software control by opening

the connection between terminals 13 and 14 on the active converter control

assembly terminal block A12-P1. This action also genrates a fault in the

inverter to enunciate this condition. Wiring diagrams are shown in

Figure 1.5

Input Line Branch Circuit Protection

!

Table 1.B AC Input Circuit Breaker Values

and on page C-3.

ATTENTION: Most codes require that upstream branch

circuit protection be provided to protect input power wiring.

The circuit breaker values provided in the Drive Input

Components are listed in Tabl e 1.B

.

Mounting the Drive, Determining Wire Routing, and Grounding

LPM20 Drive Catalog Number

(positions 1-7 only)

20ND608 380-480 VAC 800 A

Note: One 120 VAC shunt trip to be installed as shown in the drive wiring

diagram on page C-2

This section shows how to mount the drive and properly ground it. Also

described is the wiring to be routed in and out of the drive.

Lifting and Mounting the Power Module

Use the following procedure to lift the LPM20 power module and mount it

in the required enclosure:

1. Install two s-hooks into the power module to serve as lifting points. Two

1-inch through holes are provided in the sheet metal chassis.

2. Connect 18 inches (nominal) of chain between the s-hooks and secure

them with a clevis clamp.

3. Using an overhead or portable hoist (minimum 1/2-ton rated capacity),

attach a free-fall chain to the chain secured to the drive. Take up any

vertical slack in the chain.

Input Voltage

.

Circuit Breaker

Provided

4. Using the hoist, lift the power module from the horizontal shipping pallet.

5. Position the power module in the enclosure.

6. In order to maintain a flat mounting surface and to ensure that bolt tightness

is maintained, use flat washers and split-ring lock washers under the bolt

heads. Refer to Figure 1.5

7. Remove the s-hooks and chain.

for power module mounting dimensions.

Page 25

Installation/Wiring 1-13

Verifying the Drive’s Watts Loss Rating

When mounting the drive inside of an enclosure, you should determine the

watts loss rating of the drive from Tabl e 1.A

load power loss watts value at 2 kHz (rated carrier frequency). Ensure that

the enclosure is adequately ventilated with 0

the drive’s watts loss rating.

Determining Input, Motor Output, Ground, and Control Wire Routing for the Drive

All wiring should be installed in conformance with the applicable local,

national, and international codes (e.g., NEC/CEC). Signal wiring, control

wiring, and power wiring must be routed in separate conduits to prevent

interference with drive operation. Use grommets, when hubs are not

provided, to guard against wire chafing. Figure 1.5

wire routing, grounding terminal, and power terminal strips of LPM20

drives with High Performance Drive Control.

. This table lists the typical full

° to 40° C ambient air based on

and Figure 1.6 show the

ATTENTION: Do not route signal and control wiring with

!

Do not route more than three sets of motor leads through a single conduit.

This will minimize cross-talk that could reduce the effectiveness of noise

reduction methods. If more than three drive/motor connections per conduit

are required, shielded cable must be used. If possible, each conduit should

contain only one set of motor leads.

!

Grounding the Drive

power wiring in the same conduit. This can cause interference

with drive operation. Failure to observe this precaution could

result in damage to, or destruction of, the equipment.

ATTENTION: Unused wires in conduit must be grounded at

both ends to avoid a possible shock hazard caused by induced

voltages. Also, if a drive sharing a conduit is being serviced or

installed, all drives using this conduit should be disabled to

eliminate the possible shock hazard from cross-coupled motor

leads. Failure to observe these precautions could result in bodily

injury.

ATTENTION: The user is responsible for conforming with

!

Use the following steps to ground the drive:

1. Open the door of the enclosure.

all applicable local, national, and international codes. Failure to

observe this precaution could result in damage to, or

destruction of, the equipment.

Page 26

1-14 Installation/Wiring

2. Run a suitable equipment grounding conductor unbroken from the drive

to the motor’s ground terminal and then to earth ground. Use one of the

bolts that pass through the drive baseplate and are used to fasten the drive

to the wall or cabinet. See Figure 1.6

connections to the proper torque as shown in Table 1 . D

3. Connect a suitable grounding conductor to the motor frame and the

remote control station (if used). Run each conductor unbroken to earth

ground. When adding more than one grounding conductor wire to a

single chassis ground, twist the conductors together. Tighten these

grounding connections to the proper torque as shown in Table 1.D

4. Close the door of the enclosure.

. Tighten these grounding

.

.

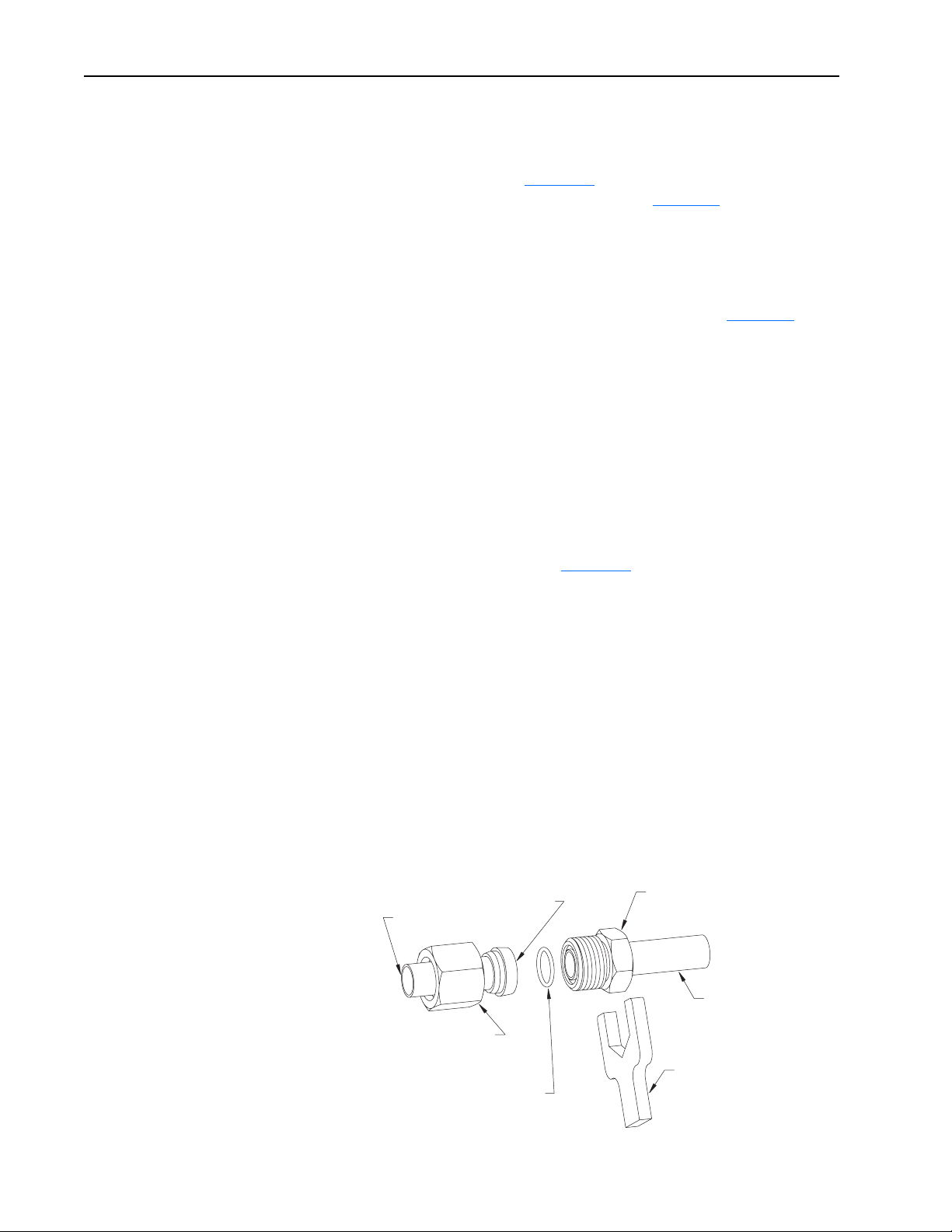

Coolant Considerations

LPM20 drives use o-ring face seal fittings for connection to the coolant

supply. The coolant is typically clean water with a corrosion inhibitor as

described in this section.

LPM20 drive coolant connections are made with o-ring face seal fittings.

The copper tube running from the heatsink to the o-ring fittings is covered

with closed cell foam insulation.

The mating connection is shown in Figure 1.7

the following steps:

1. Coat the o-ring with the o-ring lubricant. The goal is a thin film covering

the entire o-ring surface. Avoid excess globs of lubricant.

2. Insert the o-ring into the o-ring groove in the external thread-side fitting

on the user side. Avoid any twisting of the o-ring.

3. Assemble the fittings and tighten to a torque of 37 to 45 N-m (or 27 to 33

lb.-ft.). Use a backup wrench on the user side fitting to avoid twisting the

drive side tubing.

Figure 1.7 Mating Connection

DRIVE SIDE CONNECTION

ORFS Braze Sleeve

5/8-inch O.D.

Copper Tube

(Parker p/n 10-TL-B)

. The mating process includes

USER SIDE CONNECTION

ORFS Braze Adapter

(Parker p/n 10-LOHB3-B)

ORFS Nut

(Parker p/n 10-BL-B)

O-Ring, Neoprene

(Parker p/n 2-016-CO873-70)

(Parker p/n 884-2GRAMS-LUBE)

O-Ring Lubricant

5/8-inch O.D.

Copper Tube

Backup Wrench

(Use to prevent twisting

during nut tightening.)

Page 27

Installation/Wiring 1-15

Other recommendations include:

1. The allowable coolant temperature range is 0°C to 40°C (32°F to 105°F).

When using coolant at a temperature below the dew point of the

surrounding air, condensation could accumulate on the drive heatsink

and/or circuit boards and damage the drive. In this situation, install a

coolant flow regulating device and tube/hose insulation. A flow

regulating device modulates the coolant flow rate to a level that permits

the drive heatsink temperature to rise above the dew point. Insulation for

customer side tube or hose may be closed-cell foam insulation with

minimum 1/2-inch wall thickness.

2. Install a flow switch after the coolant outlet connection to shutoff the

drive if coolant flow drops below 4 gpm.

3. Circulate water through the drive only when the drive is also powered.

Failure to do this may result in condensation accumulating on the drive

heatsink and/or circuit boards, which could damage the drive.

4. For applications requiring a closed loop coolant system, ensure the

system is vented to remove air that would otherwise degrade the

performance of the drive heatsink.

Coolant Connections

LPM20 drives with High Performance Drive Control have inlet and outlet

connections as shown in Figure 1.5

are bolted to the heatsink.

The rated working pressure of the drive is 185 psig. Coolant supply and

return lines should be sized for 10 gpm/185 psig service with a maximum

operating temperature of 40°C (105°F). The required operating flow rate

and pressure drop is specified in Tabl e 1.C

Coolant Requirements

LPM20 drives are rated for use with coolant consisting of clean water with a

corrosion inhibitor. Deionized water is prohibited. Use distilled water or

water with the following concentrations:

• Less than 50 ppm of sulfate and chloride.

• Less than 50 ppm of hard water ions such as Mg++ and Ca++.

Coolant must be properly strained and/or filtered to ensure it is free of

contamination.

. Tube assemblies with O-ring fittings

.

The coolant must be compatible with the following materials: Copper,

brass, aluminum, and neoprene.

Page 28

1-16 Installation/Wiring

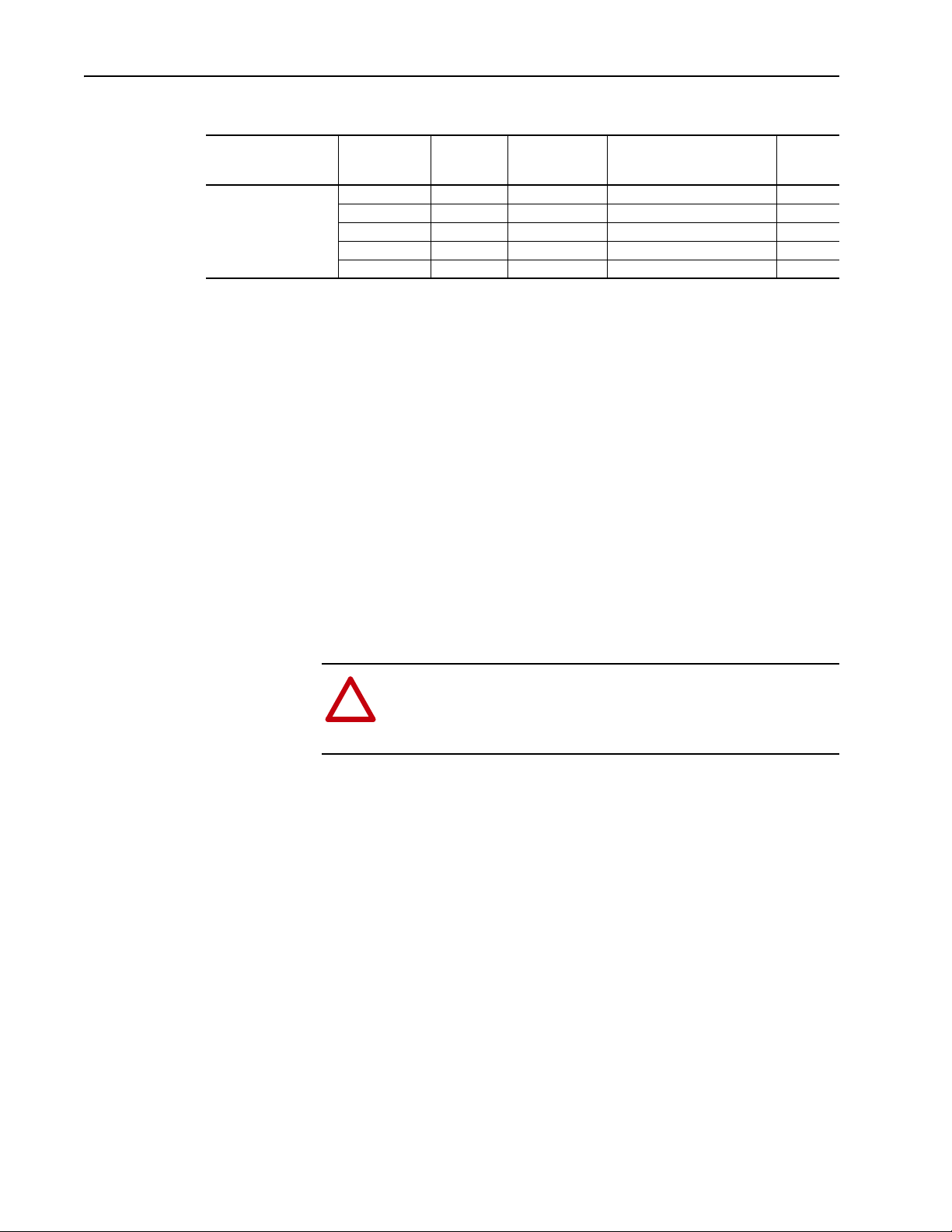

Table 1.C Coolant Requirements for LPM20 Drives

LPM20 Drive

Catalog Number

(positions 1-7 only)

20ND608

(1)

Water equals good quality or distilled water with Chemtool, Inc. corrosion inhibitor, 2% inhibitor by volume.

(2)

WEG25 equals good quality or distilled water with approved ethylene glycol, 25% glycol by volume.

(3)

WEG50 equals good quality or distilled water with approved ethylene glycol, 50% glycol by volume.

Max. Output

Current (Amps)

608 5 to 40 7 10 Water

608 0 to 40 7 10 WEG25

550 0 to 40 7 10 WEG50

608 0 to 40 10 22 WEG50

608 0 to 30 7 10 WEG50

Corrosion Inhibitor

A corrosion inhibitor is required. The following two options are approved

sources:

1. Chemtool, Inc. (www.chemtool.com) part number Watertool 4435-C.

The recommended concentration of the inhibitor is 8 to 10% by volume.

2. Dow Chemical (www.dow.com) Dowtherm

glycol. The recommended concentration of the inhibitor is 25% by

volume.

Coolant

Temperature

Range (°C)

Minimum

Coolant Flowrate

(GPM)

Pressure Drop From Drive

Inlet to Drive Outlet (PSIG) at

Minimum Coolant Flow Rate

®

SR-1 inhibited ethylene

Coolant

Typ e

(1)

(2)

(3)

(3)

(3)

Dowtherm is a registered trademark of the Dow Chemical Company.

ATTENTION: Ethylene glycol must be inhibited and silicate

!

Biocide

A biocide may be needed to control biological growth. Use of a biocide is

permitted. For specific recommendations, consult a reputable water

treatment company.

free. Use of common silicate-containing, automotive-type

ethylene glycol solutions is prohibited as they may damage the

drive and cooling module equipment.

Page 29

Installation/Wiring 1-17

Installing Input Power Wiring

Circuit Breaker

Line Side Lugs

This section describes incoming line components and how to install them.

Installing Transformers and Reactors (Not Recommended)

The LPM20 AC drive may be used on distribution systems with 100,000

amps or less symmetrical fault current capacity. The Drive Input

components consists of a 3% line reactor and a harmonic line filter.

Additional input inductance is not recommended.

Figure 1.8 Drive Input Wiring

Ground Lug

2-600 MCM

Torque Label for

Line Side Lugs

L1 L2 L3

NOTE: Proper torque for Line Side Lugs is labeled on the circuit breaker.

Page 30

1-18 Installation/Wiring

Installing a Required External/Separate Input Disconnect

An input disconnect must be installed in the line before the drive input

terminals in accordance with local, national, and international codes (e.g.,

NEC/CEC). The disconnect should be sized according to the in-rush current

as well as any additional loads the disconnect might supply. The trip rating

for the inrush current (10-12 times full load current) should be coordinated

with that of the input isolation transformer, if used. Refer to Installing

Transformers and Reactors (Not Recommended) on page 1-17 for

additional information.

Installing Power Wiring from the Input Filter Section to the Power Module

Use the following steps to connect AC input power to the drive:

ATTENTION: Do not route signal and control wiring with

!

power wiring in the same conduit. This can cause interference

with drive operation. Failure to observe this precaution could

result in damage to, or destruction of, the equipment.

1. Connect the three-phase AC input power leads (three-wire 380-480

VAC) to the appropriate terminals.

2. Tighten the AC input power terminals to the proper torque as shown in

Table 1.D

Table 1.D Terminal Tightening Torques

Terminals Hardware Type

L1 to L6 M10, CI. 9.8 43 N-m (31 lb.-ft.)

U, V, W M10, CI. 9.8 43 N-m (31 lb.-ft.)

GND, PE M8, CI. 9.8 22 N-m (16 lb.-ft.)

.

Maximum Tightening Torque

(+

10%)

Page 31

Installation/Wiring 1-19

Installing Output Power Wiring

This section provides instructions on wiring output contactors, motor

overload protection, and output wiring to the motor.

Installing Mechanical Motor Overload Protection (Optional)

To provide the motor with overload protection, local, national, and

international codes (e.g., NEC/CEC) may require one of the following:

• a motor thermostat be installed internal to the motor.

• a mechanical thermal motor overload relay, sized to protect the motor, be

installed between the motor and the drive’s output terminals.

In multiple motor applications (V/Hz regulation only), each motor must

have its own user-supplied overload and branch circuit protection.

Installing Output Wiring from the Drive Output Terminals to the Motor

Important: The total motor lead length must not exceed 76 meters (250 feet).

Use the following steps to connect the AC output power wiring from the

drive to the motor:

1. Wire the three-phase AC output power motor leads by routing them as

shown in Figure 1.5

.

Do not route more than three sets of motor leads through a single

conduit. This will minimize cross-talk that could reduce the effectiveness

of noise reduction methods. If more than three drive/motor connections

per conduit are required, shielded cable must be used. If possible, each

conduit should contain only one set of motor leads.

ATTENTION: Do not route signal and control wiring with

!

!

2. Connect the three-phase AC power motor leads to the appropriate output

terminals. Figure 1.5

3. Tighten the three-phase AC output power terminals to the proper torque

as shown in Tab le 1. D

power wiring in the same conduit. This can cause interference

with drive operation. Failure to observe these precautions could

result in damage to, or destruction of, the equipment

ATTENTION: Unused wires in conduit must be grounded at

both ends to avoid a possible shock hazard caused by induced

voltages. Also, if a drive sharing a conduit is being serviced or

installed, all drives using this conduit should be disabled to

eliminate the possible shock hazard from cross-coupled motor

leads. Failure to observe these precautions could result in

bodily injury.

shows the locations of the output power terminals.

.

Page 32

1-20 Installation/Wiring

Power Wiring

ATTENTION: National Codes and standards (NEC, VDE, BSI

etc.) and local codes outline provisions for safely installing

!

electrical equipment. Installation must comply with specifications

regarding wire types, conductor sizes, branch circuit protection,

and disconnect devices. Failure to do so may result in personal

injury and/or equipment damage.

Cable Types Acceptable for 200-600 Volt Installations

A variety of cable types are acceptable for drive installations. For many

installations, unshielded cable is adequate, provided it can be separated

from sensitive circuits. As an approximate guide, allow a spacing of 0.3

meters (1 foot) for every 10 meters (32.8 feet) of length. In all cases, long

parallel runs must be avoided. Do not use cable with an insulation thickness

less than or equal to 15 mils (0.4mm/0.015 in.). Use Copper wire only. Wire

gauge requirements and recommendations are based on 75°C. Do not

reduce wire gauge when using higher temperature wire.

Unshielded

THHN, THWN or similar wire is acceptable for drive installation in dry

environments provided adequate free air space and/or conduit fill rates

limits are provided. Do not use THHN or similarly coated wire in wet

areas. Any wire chosen must have a minimum insulation thickness of 15

mils and should not have large variations in insulation concentricity.

ATTENTION: To avoid a possible shock hazard caused by

induced voltages, unused wires in the conduit must be grounded at

!

both ends. For the same reason, if a drive sharing a conduit is being

serviced or installed, all drives using this conduit should be

disabled. This will help minimize the possible shock hazard from

“cross coupled” motor leads.

Shielded/Armored Cable

Shielded cable contains all of the general benefits of multi-conductor cable

with the added benefit of a copper braided shield that can contain much of

the noise generated by a typical AC Drive. Strong consideration for shielded

cable should be given in installations with sensitive equipment such as

weigh scales, capacitive proximity switches and other devices that may be

affected by electrical noise in the distribution system. Applications with

large numbers of drives in a similar location, imposed EMC regulations or a

high degree of communications/networking are also good candidates for

shielded cable.

Shielded cable may also help reduce shaft voltage and induced bearing

currents for some applications. In addition, the increased impedance of

shielded cable may help extend the distance the motor can be located from

the drive without the addition of motor protective devices such as terminator

Page 33

Installation/Wiring 1-21

networks. Refer to Reflected Wave in Wiring and Grounding Guidelines for

PWM AC Drives, publication DRIVES-IN001.

Consideration should be given to all of the general specifications dictated by

the environment of the installation, including temperature, flexibility,

moisture characteristics and chemical resistance. In addition, a braided

shield should be included and specified by the cable manufacturer as having

coverage of at least 75%. An additional foil shield can be greatly improve

noise containment.

A good example of recommended cable is Belden® 295xx (xx determines

gauge). This cable has 4 XLPE insulated conductors with a 100% coverage

foil and an 85% coverage copper braided shield (with drain wire)

surrounded by a PVC jacket.

Table 1.E Recommended Shielded Wire

Location Rating/Type Description

Standard

(Option 1)

Standard

(Option 2)

Class I & II;

Division I & II

600V, 90°C (194°F)

XHHW2/RHW-2 Anixter

B209500-B209507,

Belden 29501-29507, or

equivalent

Tray rated 600V, 90°C

(194°F) RHH/RHW-2

Anixter OLF-7xxxxx or

equivalent

Tray rated 600V, 90°C

(194°F) RHH/RHW-2

Anixter 7V-7xxxx-3G or

equivalent

• Four tinned copper conductors with XLPE insulation.

• Copper braid/aluminum foil combination shield and

tinned copper drain wire.

• PVC jacket.

• Three tinned copper conductors with XLPE insulation.

• 5 mil single helical copper tape (25% overlap min.) with

three bare copper grounds in contact with shield.

• PVC jacket.

• Three bare copper conductors with XLPE insulation

and impervious corrugated continuously welded

aluminum armor.

• Black sunlight resistant PVC jacket overall.

• Three copper grounds on #10 AWG and smaller.

Other types of shielded cable are available, but the selection of these types

may limit the allowable cable length. Particularly, some of the newer cables

twist 4 conductors of THHN wire and wrap them tightly with a foil shield.

This construction can greatly increase the cable charging current required

and reduce the overall drive performance. These cables are not

recommended.

Page 34

1-22 Installation/Wiring

Using Input/Output Contactors

Input Contactor Precautions

ATTENTION: A contactor or other device that routinely

disconnects and reapplies the AC line to the drive to start and stop

!

the motor can cause drive hardware damage. The drive is designed

to use control input signals that will start and stop the motor. If an

input device is used, operation must not exceed one cycle per

minute or drive damage will occur.

ATTENTION: The drive start/stop/enable control circuitry

includes solid state components. If hazards due to accidental

!

contact with moving machinery or unintentional flow of liquid, gas

or solids exist, an additional hardwired stop circuit may be required

to remove the AC line to the drive. An auxiliary braking method

may be required.

Output Contactor Precaution

ATTENTION: To guard against drive damage when using output

contactors, the following information must be read and understood.

!

One or more output contactors may be installed between the drive

and motor(s) for the purpose of disconnecting or isolating certain

motors/loads. If a contactor is opened while the drive is operating,

power will be removed from the respective motor, but the drive will

continue to produce voltage at the output terminals. In addition,

reconnecting a motor to an active drive (by closing the contactor)

could produce excessive current that may cause the drive to fault. If

any of these conditions are determined to be undesirable or unsafe,

an auxiliary contact on the output contactor should be wired to a

drive digital input that is programmed as “Enable.” This will cause

the drive to execute a coast-to-stop (cease output) whenever an

output contactor is opened.

Page 35

Installation/Wiring 1-23

I/O Wiring

Important points to remember about I/O wiring:

• Use Copper wire only. Wire gauge requirements and recommendations

are based on 75°C. Do not reduce wire gauge when using higher

temperature wire.

• Wire with an insulation rating of 600V or greater is recommended.

• Control and signal wires should be separated from power wires by at

least 0.3 meters (1 foot).

• 4100CCF3 Flex I/O cable for use with DriveLogix is 0.9 meters (3 ft.)

maximum length.

Important: I/O terminals labeled “(–)” or “Common” are

earth ground and are designed to greatly reduce common mode

interference. Grounding these terminals can cause signal noise.

ATTENTION: Configuring an analog input for 0-20mA

operation and driving it from a voltage source could cause

!

component damage. Verify proper configuration prior to applying

input signals.

ATTENTION: Hazard of personal injury or equipment damage

exists when using bipolar input sources. Noise and drift in

!

sensitive input circuits can cause unpredictable changes in motor

speed and direction. Use speed command parameters to help

reduce input source sensitivity.

not referenced to

Signal and Control Wire Types

Table 1.F Recommended Signal Wire

Signal Type/

Where Used Wire Type(s) Description

Standard Analog I/O Belden 8760/9460 (or equiv.) 0.750 mm

pair, 100% shield with drain

Remote Pot Belden 8770 (or equivalent) 0.750 mm

Encoder/Pulse I/O

Less 30.5 m (100 ft.)

Encoder/Pulse I/O

30.5 m to 152.4 m

(100 ft. - 500 ft.)

Encoder/Pulse I/O

152.4 m to 259.1 m

(500 ft. - 850 ft.)

(1)

Belden 9730 is 3 individually shielded pairs (2 channel plus power). If 3 channel is required, use Belden 9728 (or equivalent).

(2)

Belden 8790 is 1 shielded pair.

(3)

Belden 9892 is 3 individually shielded pairs (3 channel), 0.33 mm2 (22 AWG) plus 1 shielded pair 0.5 mm2 (20 AWG) for power.

(4)

Belden 9773 is 3 individually shielded pairs (2 channel plus power). If 3 channel is required, use Belden 9774 (or equivalent).

(5)

If the wires are short and contained within a cabinet which has no sensitive circuits, the use of shielded wire may not be

necessary, but is always recommended.

Combined: Belden 9730 (or

equivalent)

Signal: Belden 9730/9728

(or equivalent)

Power: Belden 8790

Combined: Belden 9892

Signal: Belden 9730/9728

(or equivalent)

Power: Belden 8790

Combined: Belden 9773/9774

(or equivalent)

(1)

shielded

0.196 mm2(24AWG),

individually shielded

0.196 mm2(24AWG),

(1)

individually shielded

(2)

0.750 mm2(18AWG)

(3)

0.330 mm2 or 0.500 mm2

0.196 mm2(24AWG),

(1)

individually shielded

(2)

0.750 mm2(18AWG)

0.750 mm2(18AWG),

(4)

individually shielded pair

2

(18AWG), twisted

2

(18AWG), 3 cond.,

Minimum

Insulation Rating

(5)

300V,

75-90°C

(167-194°F)

(3)

Page 36

1-24 Installation/Wiring

Table 1.G Recommended Control Wire for Digital I/O

Typ e Wire Type (s ) Desc rip ti on

Unshielded Per US NEC or applicable national

or local code

Shielded Multi-conductor shielded cable

such as Belden 8770 (or equivalent)

Wiring the Main Control Board I/O Terminals

Terminal blocks TB1 and TB2 contain connection points for all inputs,

outputs, and standard encoder connections. Both terminal blocks reside on

the Main Control Board of the PF700S Control Cassette.

Remove the terminal block plug from the socket, and make connections.

Important: For NEMA 1 applications, all wiring must be routed through

the conduit plate on the drive. Route any wires from the

expanded cassette to the base cassette and out of the drive.

Reinstall the plug when wiring is complete. The terminal blocks have keys,

which make it difficult to insert a terminal plug into the wrong socket.

Figure 1.9 Main Control Board I/O Terminal Locations

— 300V,

0.750 mm

3 conductor, shielded.

2

(18AWG),

Insulation

Rating

60°C

(140°F)

minimum

TB1 Terminals

TB2 Terminals

Page 37

Installation/Wiring 1-25

I/O Terminal Blocks

Table 1.H Main Control Board I/O Terminal Block Specifications

Name Description

I/O Blocks Signal and encoder

power connections

(1)

Maximum/minimum that the terminal block will accept - these are not recommendations.

Table 1.I TB1 Terminals

Wire Size Range

Maximum Minimum Maximum Recommended

2

1.5 mm

(16 AWG)

(1)

0.14 mm

(28 AWG)

2

0.25 N-m

(2.2 lb.-in.)

Torque

0.22 N-m

(1.9 lb.-in.)

Terminal Signal Description

1 Analog Input 1 Common Bipolar, differential input, +/-10V, 0-20 mA, 13 bit + sign

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

2 Analog Input 1 (+/-) 800

3 Shield Analog Input Shield

4 Analog Input 2 Common Bipolar, differential input, +/-10V, 0-20 mA, 13 bit + sign

5 Analog Input 2 (+/-) 806

6 Analog Input 3 [NTC-] Common Differential input, 0-10V, 10 bit (for motor control mode FVC2,

7 Analog Input 3 [NTC+] 812

8 Shield Analog Output Shield

9 Analog Output 1 (-) Bipolar, differential input, +/-10V, 0-20 mA, 11 bit + sign

10 Analog Output 1 (+)

11 Analog Output 2 (-) 839, 840

12 Analog Output 2 (+)

13 +10V Reference Rating: 20 mA maximum load (recommend 5K ohm

14 Reference Common

15 -10V Reference

16 Encoder A Normal current draw per channel: 20 mA 230-233

17 Encoder A (Not)

18 Encoder B

19 Encoder B (Not)

20 Encoder Z

21 Encoder Z (Not)

22 Encoder Reference (+) 12 or 5 V dc power supply for primary encoder interface

23 Encoder Reference (-)

24 Encoder Shield Connection point for encoder shield

20K ohm impedance at Volt; 500 ohm impedance at mA

20K ohm impedance at Volt; 500 ohm impedance at mA

this is the temperature adaptation input).

2K ohm minimum load

potentiometer)

Rating: 300 mA maximum

Related

Parameter

832, 833

Page 38

1-26 Installation/Wiring

Figure 1.10 TB1 Terminals — Analog Wiring Examples

Input/Output Connection Example

0-10V Analog Input 0-10V Analog Input - Internal Source Required Parameter Changes

1

2

3

4

5

6

7

8

9

10

11

12

0-10V Analog Input - Bipolar

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

13

14

15

16

17

18

19

20

21

22

23

24

0-10V Analog Input - External Source

1

2

3

4

5

6

7

8

9

10

11

12

-Signal or Source Common

+Signal

Shield / Common

-Signal or Source Common

+Signal

Shield / Common

-Signal or Source Common

+Signal

Shield / Common

Page 39

Figure 1.10 TB1 Terminals — Analog Wiring Examples (Continued)

-

+

-

+

Input/Output Connection Example

Installation/Wiring 1-27

Analog Output

+/- 10V dc

Used to drive analog meters

displaying speed and current.

Primary Encoder Interface -

Supports 5V dc/12 V dc

differential encoders with

internal power supply.

0-10V Analog Output Required Parameter Changes

1

2

3

4

5

6

7

8

9

10

11

12

Using Analog Output 1 (-10V to +10V) to meter

Motor RPM and direction:

• Send the data to the Analog Output Parameter

833 [Anlg Out1 Real], the destination, linked to

Parameter 71 [Filtered SpdFdbk], the source.

• Scale the Output to the source parameter.

Example: Parameter 835 [Anlg Out1 Scale] =

175 (where Parameter 4 [Motor NP RPM] 1750

is divided by 10V output).

Using Analog Output 2 (-10V to +10V) to meter

Motor current:

• Send the data to the Analog Output Parameter

840 [Anlg Out2 Real], the destination, linked to

Parameter 308 [Output Current], the source.

• Scale the Output to the source parameter.

Example: Parameter 822 [Anlg Out2 Scale] = xx

(where Parameter 2 [Motor NP FLA] is divided

by 10V output).

Primary Encoder - Internal Supply Using Encoder 0 as speed feedback:

13

14

15

16

17

18

19

20

21

22

23

24

Encoder

A

A-

B

B-

The Z channel is not

Z

required in typical

Z-

applications

+

-

• Set Parameter 222 [Motor Fdbk Sel Pri] to a

value of 0 (Encoder 0 = default), so the drive will

use this encoder as the primary motor speed

feedback device.

• Set the value of Parameter 232 [Encoder 0

PPR] to match the installed encoder’s resolution

(Pulses per Revolution).

Primary Encoder - External Supply

13

14

15

16

17

18

19

20

21

22

23

24

Power +V

Common -V

Shield

Encoder

A

A-

B

B-

The Z channel is not

Z

required in typical

Z-

applications

+

-

Page 40

1-28 Installation/Wiring

Table 1.J TB2 Terminals

Terminal Signal Description

1 24V dc Common (-) Drive supplied 24V dc logic input power

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

2 24V dc Source (+)

3 Digital Output 1 24V dc Open Collector (sinking logic)

4 Digital Output 1/2 Common Common for Digital Outputs 1 and 2

5 Digital Output 2 24V dc Open Collector (sinking logic)

6 Relay Output 3 (NC) Relay contact output

7 Relay Output 3 Common

8 Relay Output 3 (NO)

9 Digital Input 1-3 Common Common for Digital Inputs 1, 2, and 3

10 Digital Input 1 High speed 12-24V dc sourcing Digital Input

11 Digital Input 2 826

12 Digital Input 3 Load: 15 mA at 24V dc sourcing 827

13 Digital Input 4-6 Common Common for Digital Inputs 4, 5, and 6

14 Digital Input 4 Load: 10 mA at 24V dc sinking/sourcing

15 Digital Input 5 829

16 Digital Input 6 (HW Enable) 830

Rating: 300 mA maximum load

Rating: Internal Source = 150 mA maximum

External Source = 750 mA

Rating: Internal Source = 150 mA maximum

External Source = 750 mA

Rating: 115V ac or 24V dc = 2 A maximum Inductive/Resistive

Load: 15 mA at 24V dc

Load: 7.5 mA at 115V ac

Related

Parameter

816, 847

851, 852

856, 857

825

828

Page 41

Figure 1.11 TB2 Terminals — Digital Wiring Examples

Input/Output Connection Example

Installation/Wiring 1-29

Digital Inputs used for enable

and precharge control.

Note:

24V dc Supply - supports

only on-board digital inputs.

Do not use for circuits outside

the drive.

Note:

The factory default for all

Digital Inputs is 24V. This must

be switched in order to use

115V.

Note:

Digital Inputs 1, 2, and 3 are

always 24V dc.

Sourcing Digital Inputs - using internal power supply Sourcing and Sinking Definitions

Com

1

24V DC

2

3

4

5

6

7

8

Sourcing Digital Outputs - using internal power supply

Com

1

24V dc

2

3

4

5

6

7

8

Sinking Digital Inputs - using internal power supply

Com

1

24V dc

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

9

10

11

12

13

14

15

16

The digital inputs and digital outputs of the LPM20

with High Performance Drive Control support

Sourcing or Sinking configuration. Typically, digital

inputs are sourcing devices and digital outputs are

sinking devices. The following definitions apply

throughout this section:

Sourcing a Digital Input

A. Connect the digital input common (return) directly

to the power supply common.

B. Applying positive voltage to the digital input will

cause it to activate (pull up).

Sourcing a Digital Output

A. Connect the digital output common (return)

directly to the power supply common.

B. Connect the device to be controlled by the digital

output to the positive voltage, and the device

common to the digital output.

Sinking a Digital Input

A. Connect the digital input common to the power

supply positive voltage.

B. Applying 0V or common to the digital input will

cause it to activate (pull down).

Sinking a Digital Output

A. Connect the digital output common (return) to the

power supply positive voltage.

B. Connect the digital output to the device to be

controlled, and the device common to the power

supply common.

Note:

Digital Inputs 1, 2, and 3 can only be configured as

sourcing inputs. Digital Inputs 4, 5, and 6 can be

configured as sourcing or sinking inputs.

Sinking Digital Outputs - using internal power supply

Com

1

24V dc

2

3

4

5

6

7

8

Page 42

1-30 Installation/Wiring

Figure 1.11 TB2 Terminals — Digital Wiring Examples (Continued)

Input/Output Connection Example

Digital Inputs - 24V dc Sourcing Digital Inputs - using internal power supply, 2-Wire

Control

Com

1

24V DC

2

3

4

5

6

7

8

Sourcing Digital Inputs - using internal power supply, 3-Wire

Control

Com

1

24V DC

2

3

4

5

6

7

8

10

11

12

13

14

15

16

10

11

12

13

14

15

16

9

RUN

Enable

9

START

STOP

Enable

Required Parameter Changes

• Set Parameter 829 [DigIn 5 Sel] to a value of 7

(Run).

• Parameter 153 [Control Options] bit 8

(3WireControl) will automatically be OFF for 2-wire

control.

• Set Parameter 168 [Normal Stop Mode] for the

desired stopping mode:

0 = Ramp Stop

1 = CurLim Stop

2 = Coast Stop

• Set Parameter 829 [DigIn 5 Sel] to a value of 14

(Normal Stop).

• Set Parameter 828 [DigIn 4 Sel] to a value of 5

(Start).

• Parameter 153 [Control Options] bit 8

(3WireControl) will automatically be ON for 3-wire

control.

• Set Parameter 168 [Normal Stop Mode] for the

desired stopping mode:

0 = Ramp Stop

1 = CurLim Stop

2 = Coast Stop

Hard Enable Circuitry

A dedicated hardware enable input is provided on TB2 - Terminal 16

(Digital Input 6) for applications that require the drive to be disabled

without software interpretation.

Page 43

Main Control Board I/O and Encoder Settings

SWITCH S5

SIDE VIEW

Up = Open = Off

FRONT

TOP VIEW

S1

Installation/Wiring 1-31

JUMPER P22

34

= HW Enable

12

34

= No HW Enable

12

Down = Closed = On

SWITCH S2

Up = Open = Off

Down = Closed = On

SIDE VIEW

SWITCH S3

Up = Open = Off

Down = Closed = On

Table 1.K Switch Settings

12