Page 1

Low-Voltage Switchgear and Controlgear

Technical Document

Page 2

LVSAM-WP001A-EN-P - April 2009

0-2

Page 3

Disclaimer

The present document is designed to provide general technical information about the selection

and application of low-voltage switching and control devices and does not claim to provide a

comprehensive or conclusive presentation of the considered material. Errors or changes – for

example as a consequence of changed standards or technical progress – cannot be excluded.

This documentation has been worked out with utmost diligence. Nevertheless the authors and

Rockwell Automation do not warrant the correctne

cannot exclude typing errors. Claims on the authors or Rockwell Automation based on this

documentation cannot be accepted. Rockwell Automation reserves the right to make changes at

any time and at its own discretion. Correspondingly, qualified professional advice should be

obtained before making decisions and initiating activities that could have an effect on technical

equipment.

The authors thank the International Electrotechnical Commission (IEC) for permission to

reproduce information from its International Stan

IEC 60947-1 ed.5.0 (2007) / IEC 60947-4-1 Am2 (2005) / IEC 60947-2 ed.4.0 (2006) / IEC

60269-1 ed.4.0 (2006) / IEC 60947-8 ed.1.1 (2006) / IEC 60947-5-1 ed.3.0 (2003 ) / IEC 60038

ed.6.2 (2002) / IEC 60079-14 ed.4.0 (2007).

All such extr

acts are copyright of IEC, Geneva, Switzerland. All rights reserved. Further

information on the IEC is available from www.iec.ch. IEC has no respon

and context in which the

extracts and contents are reproduced by the authors, nor is IEC in any

way responsible for the other content or accuracy therein.

Rockwell Automation would like to thank the authors of the present document and their assistants for their valuable contributions.

Authors:

Dr. Werner Breer, Paul Hug, Urs Hunziker, Rey Kaltenrieder, Heinz Unterweger,

Dr. Hans Weichert

With the inclusion of oth

er specialists

Copyright © 2009 by Rockwell Automation, Milwaukee, USA

ss of the contents and recommendations and

dard:

sibility for the placement

LVSAM-WP001A-EN-P - April 2009

0-3

Page 4

General preliminary comments

The present technical manual is intended as an aid in project design and the application of lowvoltage switchgear and controlgear in switchgear assemblies and machine control. The focus of

the document is on electromechanical switchgear, however electronic devices used in lowvoltage engineering have also been included. They are in many cases an effective alternative to

mechanical devices.

The discussions relate – insofar relevant – to the IEC standards, which correspond to the

European CENELEC standards. W

are listed. The numbering of the CENELEC standards (EN) largely corresponds to that of the

IEC standards. National standards (e.g. DIN/VDE or BS) in some cases have differing numbering for historical reasons, but in terms of content are largely identical to the IEC and EN

standards, apart from rare national deviations. In relation to the requirements of other standard

zones, especially in North America, reference is made to specific publications. The physical

characteristics are generally applicable.

For switchgear combinations the standard IEC 60439-1 is referred to that is in effect at issuance

of this docum

ent. It is expected that IEC 61439-1 will shortly replace IEC 60439-1. The state-

ments in the present documentation for switchgear assemblies also apply for IEC 61439-1.

Statements made in this document concentrate on the underlying principles and fact

– insofar as this is possible – stating technical data relating to specific products in order to avoid

premature obsolescence of the information contained. The applicable technical data about the

products should be obtained from the latest valid product documentation as published in printed

and “electronic” catalogs and electronic documentation like RALVET.

here standards are quoted, the respective IEC designations

s and avoid

LVSAM-WP001A-EN-P - April 2009

0-4

Page 5

0 Table of contents

0 Table of contents.................................................................................................. 0-5

1 Load characteristics and utilization categories................................................. 1-1

1.1 Utilization categories simplify the selection of devices ................................... 1-1

1.2 Electrical heating devices....................................................................................1-4

1.3 Lamps and illumination equipment .................................................................... 1-4

1.3.1 Incandescent lamps................................................................................................ 1-4

1.3.1.1 Halogen lamps........................................................................................................ 1-4

1.3.2 Discharge lamps..................................................................................................... 1-4

1.4 Transformers......................................................................................................... 1-5

1.5 Reactive power compensation and switching of capacitors............................ 1-6

1.5.1 Reactive power compensation................................................................................ 1-6

1.5.1.1 Individual compensation......................................................................................... 1-6

1.5.1.2 Group compensation .............................................................................................. 1-7

1.5.1.3 Central compensation............................................................................................. 1-7

1.5.2 Switching of capacitors........................................................................................... 1-7

1.5.2.1 Switching-on single capacitors ............................................................................... 1-8

1.5.2.2 Switching of long, screened lines ........................................................................... 1-8

1.5.2.3 Switching capacitors of central compensation units............................................... 1-8

1.6 Control circuits, semiconductor load and electromagnetic load..................... 1-9

1.7 Three-phase asynchronous motors.................................................................... 1-9

1.7.1 Principle of operation.............................................................................................. 1-9

1.7.1.1 Slip-ring motors..................................................................................................... 1-11

1.7.1.2 Squirrel-cage induction motors............................................................................. 1-12

1.7.1.2.1 High efficiency motors .......................................................................................... 1-14

1.7.1.3 Influence of the voltage across the windings........................................................ 1-15

1.7.1.4 Performance of squirrel-cage induction motors with changing frequency............1-16

2 Switching tasks and selecting the appropriate switchgear.............................. 2-1

2.1 Electrical equipment complying with standards and matching

the application requirements............................................................................... 2-1

2.2 Basic switching tasks and criteria for device selection ................................... 2-1

2.2.1 Device types........................................................................................................... 2-2

2.2.1.1 Disconnectors (isolating switches).......................................................................... 2-2

2.2.1.2 Load switches......................................................................................................... 2-3

2.2.1.3 Switch disconnectors.............................................................................................. 2-3

2.2.1.4 Circuit breakers....................................................................................................... 2-3

2.2.1.5 Supply disconnecting devices................................................................................. 2-3

2.2.1.6 Supply disconnecting EMERGENCY STOP devices.............................................. 2-4

2.2.1.7 Summary supply disconnect and EMERGENCY STOP devices............................ 2-5

2.2.1.8 Fuses...................................................................................................................... 2-5

2.2.1.9 Devices for thermal protection................................................................................ 2-5

2.2.1.10 Contactors .............................................................................................................. 2-5

2.3 Parameters for the correct selection and sizing................................................ 2-5

2.3.1 Rated isolation voltage Ui....................................................................................... 2-7 U

2.3.2 Rated operational voltage Ue, rated operational current Ie and utilization category 2-7 U

2.3.3 Rated impulse withstand voltage U

imp

..................................................................... 2-7 U

2.3.4 Short-circuit withstand capacity and short-circuit protection................................... 2-9

2.3.4.1 Joule integral I2t.................................................................................................... 2-10

2.3.4.2 Cut-off current ID................................................................................................... 2-10

2.3.4.3 Rated short-time withstand current lCW................................................................. 2-10

LVSAM-WP001A-EN-P - April 2009

0-5

Page 6

2.3.4.4 Current limiting protective equipment................................................................... 2-11

2.3.4.5 Coordination of electrical equipment .................................................................... 2-12

2.3.4.5.1 Coordination in respect of the switching capacity of the contactor

(overcurrent selectivity)......................................................................................... 2-12

2.3.4.5.2 Coordination with respect to the operability after a short-circuit........................... 2-13

2.3.4.6 Short-circuit switching capacity............................................................................. 2-14

2.3.4.6.1 Rated short-circuit making capacity Icm................................................................. 2-14

2.3.4.6.2 Rated short-circuit breaking capacity Icu and Ics.................................................... 2-14

2.3.5 Thermal protection................................................................................................ 2-15

2.3.5.1 Ambient temperature............................................................................................2-15

2.3.5.2 Operational overcurrents, heavy-duty starting...................................................... 2-15

2.3.6 Life span............................................................................................................... 2-16

2.3.6.1 Prospective service life......................................................................................... 2-17

2.3.6.2 Mechanical life span............................................................................................. 2-17

2.3.6.3 Electrical life span................................................................................................. 2-17

2.3.7 Intermittent and short-time duty, permissible frequency of operation................... 2-20

2.3.7.1 Intermittent duty and relative ON-time.................................................................. 2-22

2.3.8 Rated frequency and harmonics........................................................................... 2-24

2.3.9 Safety clearances................................................................................................. 2-24

2.3.10 Mounting position.................................................................................................. 2-25

2.3.11 Protective separation............................................................................................ 2-25

2.3.12 Site altitude........................................................................................................... 2-26

2.3.13 Shock and vibration.............................................................................................. 2-26

2.4 Specific application conditions and switching tasks...................................... 2-27

2.4.1 Parallel and series connection of poles................................................................ 2-27

2.4.1.1 Parallelling............................................................................................................ 2-27

2.4.1.2 Series connection................................................................................................. 2-27

2.4.2 AC switchgear in DC applications......................................................................... 2-28

2.4.3 Applications at supply frequencies < 50 Hz and > 60 Hz. Effect of harmonics.... 2-29

2.4.3.1 Effect of the supply frequency on the thermal load............................................... 2-29

2.4.3.2 Effect of the supply frequency on the switching capacity ..................................... 2-31

2.4.3.3 Performance of release units at supply frequencies < 50 Hz and > 60 Hz........... 2-32

2.4.3.4 Switchgear used with soft starters........................................................................ 2-32

2.4.3.5 Switchgear for use with frequency converters (inverters)..................................... 2-33

2.4.4 Application of four-pole switchgear devices.......................................................... 2-35

2.4.4.1 Applications of switchgear with 4 NO contacts..................................................... 2-35

2.4.4.2 Applications of switchgear with 2 NO and 2 NC contacts..................................... 2-36

2.4.4.3 Applications of switchgear with 3 NO and 1 NC contact....................................... 2-37

2.4.5 Application of circuit breakers in IT networks ....................................................... 2-37

2.4.6 Switchgear for safety applications........................................................................ 2-38

2.4.6.1 Mechanically linked contacts................................................................................ 2-38

2.4.6.2 Mirror Contacts..................................................................................................... 2-39

2.4.7 Installations in hazardous atmospheres ............................................................... 2-40

2.4.7.1 History, guidelines and regulations....................................................................... 2-40

2.4.7.2 Classification of hazardous areas......................................................................... 2-41

2.4.7.3 Motors for hazardous areas.................................................................................. 2-43

2.4.7.4 Protection of motors of ignition protection type Increased Safety “e”...................2-45

2.4.7.5 ATEX 100a (Directive 94/9/EC)............................................................................ 2-46

2.4.7.6 IECEx and other approval schemes for hazardous areas .................................... 2-47

LVSAM-WP001A-EN-P - April 2009

0-6

Page 7

3 Starting and switching motors............................................................................ 3-1

3.1

Selection criteria................................................................................................... 3-1

3.2 Direct starting of squirrel-cage induction motors............................................. 3-3

3.2.1 Starting time............................................................................................................ 3-3

3.2.2 Reversing starters................................................................................................... 3-4

3.3 Star-delta (Y-Δ, wye-delta) starting ..................................................................... 3-4

3.3.1 Normal star-delta starting ....................................................................................... 3-5

3.3.2 Motor connection for clockwise and counterclockwise direction of rotation............ 3-8

3.3.3 Influence of the third harmonic on motor protection relays................................... 3-10

3.3.4 Uninterrupted star-delta starting (closed transition).............................................. 3-11

3.3.5 Amplified star-delta starting.................................................................................. 3-12

3.3.6 Part-winding star-delta starting............................................................................. 3-13

3.4 Auto-transformer starting.................................................................................. 3-14

3.4.1 Circuit and function............................................................................................... 3-14

3.4.2 Rating of the starter.............................................................................................. 3-15

3.5 Starting via chokes or resistors........................................................................ 3-15

3.5.1 Starting via chokes ............................................................................................... 3-15

3.5.2 Starting via resistors............................................................................................. 3-16

3.6 Stator resistance soft starting........................................................................... 3-16

3.6.1 Circuit and function............................................................................................... 3-16

3.7 Pole-changing motors........................................................................................ 3-17

3.7.1 Speed change by pole changing .......................................................................... 3-17

3.7.2 Ratings of starters for pole changing.................................................................... 3-18

3.7.3 Rating of the starter for steps with star-delta starting........................................... 3-19

3.8 Starting wound-rotor motors............................................................................. 3-20

3.9 Electronic soft starters....................................................................................... 3-22

3.9.1 Voltage ramp versus current limitation ................................................................. 3-23

3.9.2 Voltage ramp ........................................................................................................ 3-24

3.9.3 Kickstart................................................................................................................ 3-24

3.9.4 Current limitation................................................................................................... 3-25

3.9.5 Soft stop................................................................................................................ 3-25

3.9.6 Soft starters for pump controls.............................................................................. 3-26

3.9.7 Motor braking........................................................................................................ 3-27

3.9.8 Positioning speed and controlled braking............................................................. 3-27

3.9.9 Linear acceleration and deceleration by speed feedback..................................... 3-28

3.9.10 Direct start with full voltage................................................................................... 3-28

3.10 Frequency converters ........................................................................................ 3-29

3.10.1 Principle of operation............................................................................................ 3-29

3.10.1.1 Rectifier................................................................................................................. 3-29

3.10.1.2 Intermediate circuit ............................................................................................... 3-30

3.10.1.3 Inverter.................................................................................................................. 3-30

3.10.2 Operational performance...................................................................................... 3-30

3.10.3 Change of sense of rotation and braking.............................................................. 3-31

3.10.4 Motor protection.................................................................................................... 3-31

4 Protection.............................................................................................................. 4-1

4.1 Protection requirements ...................................................................................... 4-1

4.1.1 Protection against electric shock............................................................................ 4-1

4.1.1.1 Protection against direct contact............................................................................. 4-1

4.1.1.2 Protection against indirect contact.......................................................................... 4-2

4.1.1.3 Complementary protection...................................................................................... 4-3

4.1.2 Protection against overload and excess temperature............................................. 4-3

4.1.2.1 Different loading curves of various kinds of electrical equipment........................... 4-3

LVSAM-WP001A-EN-P - April 2009

0-7

Page 8

4.1.2.2 Protection in continuous duty and at transient loads.............................................. 4-4

4.1.2.3 Overload and overtemperature protection by measurement of current and

measurement of temperature ................................................................................. 4-7

4.1.2.4 Protective functions ................................................................................................ 4-8

4.1.2.4.1 Protection during starting, monitoring of starting time, start interlocking.............. 4-10

4.1.2.4.2 Asymmetry protection........................................................................................... 4-10

4.1.2.4.3 Phase failure protection........................................................................................ 4-11

4.1.2.4.4 Stalling protection................................................................................................. 4-13

4.1.2.4.5 Underload protection ............................................................................................ 4-14

4.1.2.4.6 Automatic switching-over during start-up.............................................................. 4-14

4.1.2.4.7 Ground fault protection......................................................................................... 4-14

4.1.2.5 Display, warning and control functions................................................................. 4-15

4.1.3 Protection against high overcurrents, short-circuit protection............................... 4-16

4.1.3.1 Definition and characteristic of a short-circuit....................................................... 4-16

4.1.3.2 Effects of and dangers in case of short-circuits.................................................... 4-17

4.1.3.3 Protection requirements........................................................................................ 4-18

4.1.3.3.1 Switching capacity................................................................................................ 4-18

4.1.3.3.2 Current limitation................................................................................................... 4-18

4.1.3.3.3 Selectivity.............................................................................................................. 4-19

4.1.3.3.4 Short-circuit coordination...................................................................................... 4-22

4.2 Protective devices .............................................................................................. 4-22

4.2.1 Fuses.................................................................................................................... 4-22

4.2.1.1 Principle of operation............................................................................................ 4-22

4.2.1.1.1 Current limitation................................................................................................... 4-23

4.2.1.1.2 Breaking capacity ................................................................................................. 4-23

4.2.1.2 Standards and utilization categories..................................................................... 4-23

4.2.1.2.1 Classification and time/current zones................................................................... 4-24

4.2.1.3 Designs................................................................................................................. 4-25

4.2.2 Circuit breakers..................................................................................................... 4-26

4.2.2.1 Principle of operation and design ......................................................................... 4-26

4.2.2.2 Standards, functions and utilization categories .................................................... 4-26

4.2.2.2.1 Standards ............................................................................................................. 4-26

4.2.2.2.2 Functions and utilization categories...................................................................... 4-26

4.2.2.3 Design of a circuit breaker.................................................................................... 4-28

4.2.2.3.1 Thermal overcurrent releases............................................................................... 4-28

4.2.2.3.2 Electromagnetic overcurrent releases..................................................................4-29

4.2.2.3.3 Main contact system and switching capacity........................................................ 4-29

4.2.2.4 Application of circuit breakers............................................................................... 4-32

4.2.2.4.1 Application as circuit breaker................................................................................ 4-32

4.2.2.5 Installation of circuit breakers, safety clearances................................................. 4-34

4.2.3 Miniature Circuit Breakers MCB ........................................................................... 4-35

4.2.3.1 Principle of operation and design ......................................................................... 4-35

4.2.3.2 Standards, tripping characteristics and rated switching capacity.......................... 4-35

4.2.3.3 Installation of Miniature Circuit Breakers, safety clearances................................ 4-36

4.2.4 Motor protection relays (overload relays) ............................................................. 4-36

4.2.4.1 Thermal motor protection relays........................................................................... 4-36

4.2.4.2 Electronic motor protection relays ........................................................................ 4-40

4.2.4.2.1 Principle of operation............................................................................................ 4-41

4.2.4.3 Thermistor protection relays.................................................................................4-42

4.2.4.3.1 Relays for PTC sensors........................................................................................ 4-42

4.2.4.3.2 Relays for NTC sensors........................................................................................ 4-43

4.2.4.3.3 Metal resistance sensors...................................................................................... 4-43

LVSAM-WP001A-EN-P - April 2009

0-8

Page 9

5 Control circuits ..................................................................................................... 5-1

5.1

Utilization categories............................................................................................ 5-1

5.2 Control voltages ................................................................................................... 5-1

5.2.1 Alternating voltage.................................................................................................. 5-1

5.2.1.1 Control transformers for contactor controls ............................................................ 5-2

5.2.1.2 Frequencies < 50 Hz and > 60 Hz.......................................................................... 5-2

5.2.2 Direct voltage.......................................................................................................... 5-2

5.3 Switching contactors ........................................................................................... 5-3

5.3.1 Alternating current magnets.................................................................................... 5-3

5.3.1.1 Conventional alternating current magnets.............................................................. 5-3

5.3.1.2 Electronic coil control.............................................................................................. 5-3

5.3.2 Direct current drives................................................................................................ 5-4

5.3.2.1 “Conventional” ........................................................................................................ 5-4

5.3.2.2 Double winding coils............................................................................................... 5-5

5.3.2.3 Electronic coil control.............................................................................................. 5-5

5.3.3 Electromagnetic compatibility and protective circuits.............................................. 5-5

5.3.3.1 Protective circuits in coil circuits............................................................................. 5-5

5.3.4 Effect of long control lines....................................................................................... 5-7

5.3.4.1 Voltage drop ........................................................................................................... 5-7

5.3.4.2 Effect of the cable capacitance............................................................................... 5-8

5.3.5 Contact reliability .................................................................................................... 5-9

6 Considerations when building control systems and switchgear assemblies6-1

6.1 Temperature rise................................................................................................... 6-1

6.1.1 Temperature rise limit values.................................................................................. 6-1

6.1.2 Laboratory test conditions and real practical environment...................................... 6-2

6.1.3 Verification of temperature-rise............................................................................... 6-3

6.1.4 Important aspects regarding device temperature rise; Recommendations............ 6-3

6.1.4.1 Rated current.......................................................................................................... 6-3

6.1.4.2 Thermal protective devices..................................................................................... 6-4

6.1.4.3 Conductor cross sections ....................................................................................... 6-4

6.1.4.4 Conductor length .................................................................................................... 6-5

6.1.4.5 Tightening torques.................................................................................................. 6-5

6.1.4.6 Line ducting ............................................................................................................ 6-5

6.1.4.7 Operating frequency and harmonics....................................................................... 6-6

6.1.4.8 Mounting devices side-by-side ............................................................................... 6-6

6.1.4.9 Mounting position.................................................................................................... 6-6

6.1.5 Thermal imaging cameras......................................................................................6-6

6.2 Short-circuit withstand capacity ......................................................................... 6-7

LVSAM-WP001A-EN-P - April 2009

0-9

Page 10

LVSAM-WP001A-EN-P - April 2009

0-10

Page 11

1 Load characteristics and utilization categories

The characteristics of the load to be switched or controlled determine the loading of the

switchgear and correct selection of the latter for the respective application. In particular the

loading of contacts by current and voltage when circuits are made and broken is of high

significance. Thus the making and breaking current under resistance load corresponds to the

continuous operational current while for example squirrel-cage induction motors draw a multiple

of the rated operational current when they are switched on and accelerate.

1.1 Utilization categories simplify the selection of devices

In order to make the choice of devices easier, utilization categories are defined in the standards

for low-voltage switchgear (IEC 60947-1, -2, -3, -4, -5, -6) that take into account the intended

application and hence the associated loading of the various low-voltage switchgear types, such

as contactors, disconnectors, circuit breakers and load switches (Tab. 1.1-1). The rated

operational currents or r

usually for various rated operational voltages. For the sake of universal applicability the data is

usually stated for several utilization categories for one and the same piece of switchgear. For

project engineers, the selection of devices is basically reduced to the comparison of performance data of the switchgear for the respective utilization category with the ratings of the load

and the choice of a device which meets or exceeds the ratings of the load.

When the rated operational voltage U

certain utilization category, the required making and breaking capacity for the item of switchgear

is defined. Thus in general no further agreements between users and manufacturers are

required. The selection of a suitable device and comparison of products is thus facilitated.

The test regulations in the IEC standards define the test parameters for the individual utilization

categories. Manufacturers are oblige

ensures the suitability of the tested devices for the respective application and frees the user

from getting “bogged down” in technical details.

The conditions for application in practice may differ considerably – in a favorable as well as

adverse sense – from these standardized cond

frequency of operation, especially long equipment life span. In such cases, the users and

manufacturers must agree the permitted loads. In the catalogs as well as in the RALVET

electronic documentation, the corresponding performance data are stated for the most common

special applications.

Because of the very high and cost-intensive expenditures for testing, data for the most important

and common utilization

consultation is required.

ated operational powers are listed in the technical data for the devices –

and the rated operational current Ie are stated for a

e

d to carry out tests according to these standards. This

itions. Examples are heavy-duty starting, high

categories are usually provided. In cases going over and beyond this

LVSAM-WP001A-EN-P - April 2009

1-1

Page 12

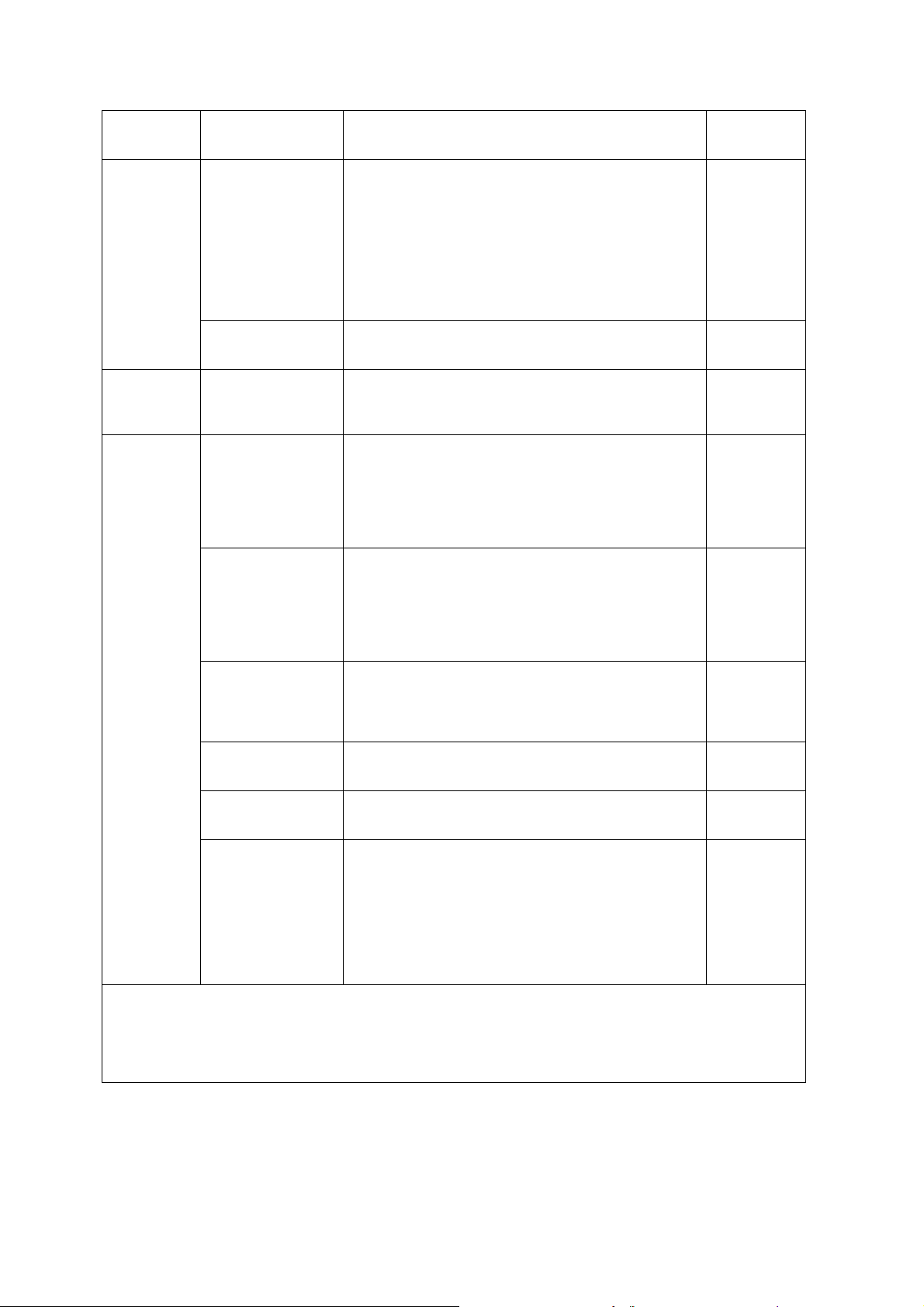

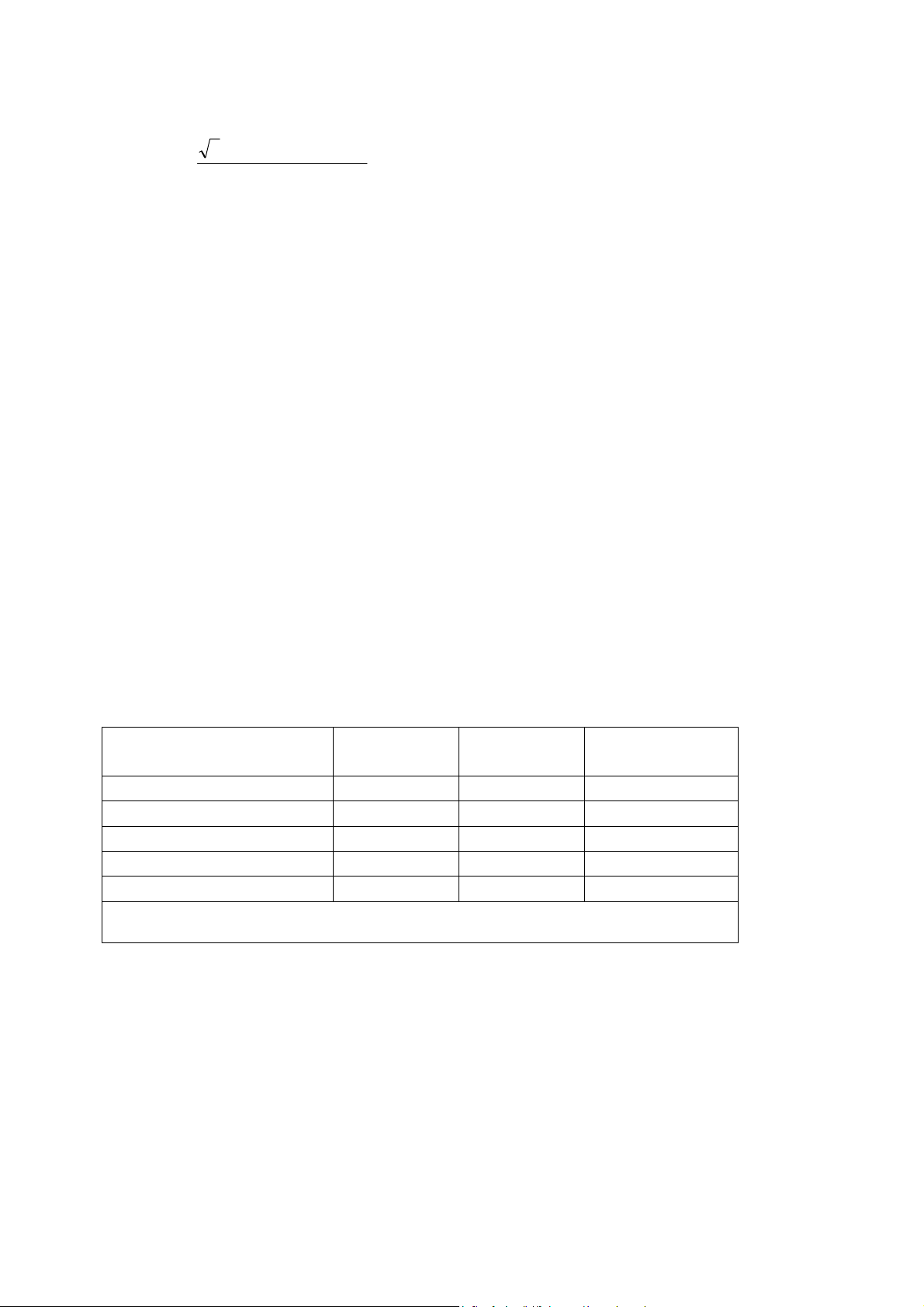

Nature of

current

AC-20A, AC-20B

a.c. AC-1

AC-52a

AC-51

AC-12

AC-12

AC-31A, AC-31B

Category Typical applications

Connecting and disconnecting under no-load conditions

AC-21A, AC-21-B

AC-22A, AC-22B

AC-23A, AC-23B

3)

AC-2

AC-3

AC-4

AC-5a

AC-5b

AC-6a

AC-6b

AC-7a

AC-7b

AC-8a

AC-8b

AC-52b

AC-53a

AC-53b

AC-58a

AC-58b

AC-55a

AC-55b

AC-56a

AC-56b

AC-13

AC-14

AC-15

AC-140

AC-33A, AC-33B

AC-35A, AC-35B

AC-36A, AC-36B

3)

Switching of resistive loads, including moderate

overloads

S

witching of mixed resistive and inductive loads,

including moderate overloads

Switching of motor loads or other highly inductive loads

Non-inductive or slightly inductive loads, resistance

furnaces

Slip-ring motors: starting, switching off

Squirrel-cage motors: starting, switching off motors

during run

Squirrel-cage motors: starting, plugging1), inching2)

Switching of electric discharge lamp controls

Switching of incandescent lamps

Switching of transformers

Switching of capacitor banks

Slightly inductive loads in household appliances and

similar ap

Motor-loads for household applications

Hermetic refrigerant compressor motor control with

manual resetti

Hermetic refrigerant compressor motor control with

automatic resetting of overload releases

Control of slip ring motor stators: 8 h duty with on-load

currents for start, acceleration, run

Control of slip ring motor stato

Control of squirrel-cage motors: 8 h duty with on-load

currents for start, acceleration, run

Control of squirrel-cage motors: intermittent duty

Control of hermetic refrigerant

automatic resetting of overload releases: 8 h duty with

on-load currents for start, acceleration, run

Control of hermetic refrigerant compressor motors w

automatic resetting of overload releases: intermittent

duty

Non-inductive or slightly inductive loads, resistance

furnaces

Switching of electric discharge lamp controls

Switching of incandescent lamps

Switching of transformers

Switching of capacitor banks

Control of resistive loads and solid-state loads with

isolation by optocouplers

Control of solid-state loads with transformer isolation

Control of small electromagnetic loads

Control of a.c. electromagnetic loads

Control of resistive loads and solid state loads with

optical isolation

Control of small electromagnetic loads with holding

(closed) current ≤ 0,2 A, e.g. contactor relays

Non inductive or slightly inductive loads

Motor loads or mixed loads including motors, resistive

load

s and up to 30 % incandescent lamp loads

Electric discharge lamp loads

Incandescent lamp loads

ning

plications

ng of overload releases

r

s: intermittent duty

compressor motors w

Relevant

IEC product

standard

60947-3

60947-4-1

60947-4-2

ith

ith

60947-4-3

60947-5-1

60947-5-2

60947-6-1

LVSAM-WP001A-EN-P - April 2009

1-2

Page 13

Nature of

current

a.c. AC-40

AC-7a

a.c. and d.c. A

DC-20A, DC-20B

d.c. DC-1

DC-12

DC-31

DC-40

1) By plugging is understood stopping or reversing the motor rapidly by reversing motor primary connections

while the motor is running.

2) By inching (jogging) is understood energizing a motor once or repeatedly for short periods to obtain small

movements of the driven mechanism.

3) The utilization categories with annex A apply for frequent operations, those with annex B for infrequent/occasional operations

Category Typical applications

Distribution circuits comprising mixed resistive and

AC-41

AC-42

AC-43

AC-44

AC-45a

AC-45b

AC-7b

B

DC-21A, DC21B

DC-22A, DC22B

DC-23A, DC23B

3)

DC-3

DC-5

DC-6

DC-12

DC-13

DC-14

DC-13

DC-33

DC-36

DC-41

DC43

DC-45

DC-46

reactive loads having a resultant inductive reactance

Non-inductive or slightly inductive loads, resistance

furnaces

Slip-ring motors; starting, switching off

Squirrel-cage motors: starting, switching off motors

during run

Squirrel-cage motors: starting, plugging1), inching2)

Switching of electric discharge lamp controls

Switching of incandescent lamps

Slightly inductive loads for household appliances and

similar applications

Motor-loads for household applications

Protection of circuits, with no rated short-time withstand

current

Protection of circuits, with a rated short-time withstand

current

Connecting and disconnecting under no-load conditions

Switching of resistive loads, including moderate

overloads

witching of mixed resistive and inductive loads,

S

including moderate overloads (e.g. shunt motors)

Switching of highly inductive loads (e.g. series motors)

Non-inductive or slightly inductive loads, resistance

furnaces

Shunt-motors, starting, plugging1), inching2). Dynamic

breaking of motors

Series-motors, starting, plugging1), inching2). Dynamic

breaking of motors

Switching of incandescent lamps

Control of resistive loads and solid-state loads with

isolati

Control of electromagnets

Control of electromagnetic loads having economy

resistors in circuit

Control of resistive loads and solid state loads with

optical isolation

Control of electromagnets

Resistive loads

Motor loads or mixed loads including motors

Incandescent lamp loads

Distribution circuits comprising mixed resistive and

reactive l

Non-inductive or slightly inductive loads, resistance

furnaces

Shunt-motors: starting, plugging1), inching2). Dynamic

breaking of d.c

Series-motors: starting, plugging1), inching2). Dynamic

breaking of d.c. motors

Switching of incandescent lamps

ning

y optocouplers

on b

oads

having a resultant inductive reactance

. motors

Relevant

IEC product

standard

60947-6-2

61095

60947-2

60947-3

60947-4-1

60947-5-1

60947-5-2

60947-6-1

60947-6-2

Tab. 1.1-1

Examples of utilization categories for low-voltage switchgear as pe r IEC 60947-1 ed. 5.0 Appendix A.

Copyright © 2007 IEC, Geneva, Switzerland. www.iec.ch

LVSAM-WP001A-EN-P - April 2009

1-3

Page 14

1.2 Electrical heating devices

Electrical heating devices are for example used for heating rooms, industrial resistance furnaces

and air-conditioning plants.

In the case of wound resistance elements, the making current can be 1.4 times the rated

current. In the select

ion of switchgear devices it should be noted with respect to the rated

operational current that (in contrast to the motor) the current consumption increases when the

mains voltage increases. When contactors are used, utilization category AC-1 should be used

as a basis for alternating current and DC-1 for direct current. For manual switching, a loadswitch with corresponding load-switching capacity (AC-21) is sufficient.

Furthermore, if the ambient temperature is very high this must be taken into account.

Heating circuits are often single pole circuits. Usually multi-pole switchgear devices with poles

connected in parallel are used, which enables to

load-carrying capacity of switchgear units with poles connected in parallel, see section

increase the permissible load current. For the

2.4.1.1.

1.3 Lamps and illumination equipment

The illumination devices are subject to constant change due to developments in energy

efficiency and electronics. For the choice of associated switching (e.g. contactors) and protective equipment (e.g. miniature circuit breakers and circuit breakers) not only the type of lighting

equipment itself should be taken into account but also the kind of control circuit. Particular

attention should be paid to inrush currents caused by compensation capacitors and charging of

electronic control devices. This loading may be reduced by the attenuating effect of long lines.

The startup and operational current loads should be obtained from the respective manufacturers. The below descriptions relate to the basic

In general it is recommended to utilize a max. of 90 % of the current capacity of the switchgear

as the current consumption of light

ing equipment typically increases when the voltage in-

creases.

characteristics. Also see Tab. 1.3-1.

1.3.1 Incandescent lamps

The filaments of incandescent lamps have a very low ohmic resistance when cold. This creates

a high current peak when they are switched on (up to 15 · l

). The making capacity of the

e

switchgear must thus at least correspond to this value (utilization category AC-5b). Upon

switching off, only the rated current has to be disconnected due to the high resistance of the hot

filaments.

1.3.1.1 Halogen lamps

Halogen lamps are actually a version of incandescent lamps and their behavior is basically the

same as the latter. The lamps are often designed for low voltages and powered via a transformer or electronic mains adapter. Their inrush currents should be taken into account for

switching on.

1.3.2 Discharge lamps

Discharge lamps such as fluorescent tubes, energy saving lamps, mercury vapor lamps,

halogen metal vapor lamps or sodium vapor lamps require both a starting circuit and a current

limitation device. These devices may be conventional or electronic. Discharge lamps with

electromagnetic series chokes have a low power factor and are therefore usually compensated.

The compensation capacitance leads to high inrush currents that must be taken into account

when the switchgear is selected.

Most electronic series devices have a high power factor (e.g. cosφ ≈ 0.95), nevertheless during

switching on

When selecting the switchgear for high in-rush currents, the permitted rated power for the

switching of capacitor

to prevent undesired release of miniature circuit breakers with the simultaneous activation of a

number of fluorescent tubes, information is provided by the tube manufacturers on the maxi-

there occurs a charging current surge that loads the switchgear accordingly.

s should be taken into account as per utilization category AC-6b. In order

LVSAM-WP001A-EN-P - April 2009

1-4

Page 15

mum number of luminescent tubes (including series devices) that can be operated via a single

protective switch.

Lamp type,

(switch)

Incandescent lamps 15 · I

Halogen lamps

- Transformer operation

1

- ECG

operation

Luminescent lamps

(choke operation)

- uncompensated

- parallel compensated

- DUO circuit

Luminescent lamps

1

- ECG

) operation, AC

Mercury vapor high

pressure lamps

- uncompensated

- parallel-compensated

Halogen metal vapor

lamps

- uncompensated

- parallel-compensated

Sodium vapor high

pressure lamps

- uncompensated

- parallel-compensated

Dual-source lamps ≈ 1.3 · I

Making

current

peaks

e

10 · I

e

≈ 2 · I

e

≈ 20 · I

≈ 2 · I

e

10 · I

e

≈ 2 · I

e

≈ 20 · I

≈ 2 · I

e

≈ 20 · I

≈ 2 · I

e

≈ 20 · I

e

e

e

e

e

Startup

time

[min]

Starting

current

cos φ Calculation

- - 1 ≤ I

-

-

-

-

-

3 – 5

3 – 5

5 – 10

5 – 10

5 – 10

5 – 10

≈ 3 ≈ 1.3 · I

-

-

-

-

-

≈ 2 · I

≈ 2 · I

≈ 2 · I

≈ 2 · I

≈ 2 · I

≈ 2 · I

e

e

e

e

e

e

e

0.95

0.5

0.9

0.9

0.9 ≤ 0.7 · I

0.4 – 0.6

0.9

0.4 – 0.5

0.9

0.4 – 0.5

0.9

1 ≤ 0.9 · I

basis for I

see Section1.4

≤ 0.7 · I

≤ I

≤ I

≤ I

≤ 0.5 · I

≤ 0.5 · I

≤ 0.5 · I

≤ 0.5 · I

≤ 0.5 · I

≤ 0.5 · I

eAC-5b

eAC-5a

eAC-1

eAC-1

eAC-3

, ≤ I

eAC-3

eAC-1

eAC-1

eAC-1

eAC-1

eAC-1

eAC-1

eAC-1

e

eAC-6b

, ≤ I

, ≤ I

, ≤ I

eAC-6b

eAC-6b

eAC-6b

Tab. 1.3-1

Making currents for lamps and notes on selecting switchgear

1

) ECG … Electronic control gear

1.4 Transformers

If a low-voltage transformer is switched on, there is a short-term current surge (rush). The peak

surge currents evoked by field set-up can be up to 30 times greater than the transformer rated

current. The inrush currents vary according to the transformer type. They depend on the

position of the coil, the characteristics of the magnetic circuit and especially on the phase angle

of the voltage during switching on. The switchgear must have a correspondingly high making

capacity in order to avoid contact welding.

IEC 60947-4-1 provides the utilization category AC-6a for switching transformers. The permitted

I

rated operational current

can be determined as per IEC 60947-4-1 (Tab.7b) from the data of the AC-3 switching capacity:

= 0.45 · I

I

eT30

eAC-3

for n ≤ 30

n = peak value of the making current/peak value of the rated operational current

In the case of larger rush factors the following applies:

I

eTn

= I

eT30

· 30/n

The factor «n» should be specified by the transformer supplier. If no specifications are available,

the following guideline v

(AC-6a) for switching transformers with a making rush factor of ≤ 30

eT

alues apply for «n»:

LVSAM-WP001A-EN-P - April 2009

1-5

Page 16

Transformers up to approx. 1 kVA at 230 V n ≈ 20

at 400 V n ≈ 15

larger transf

ormers at 400 V n ≈ 15 ... 30

Note

The thermal continuous current

I

may not be exceeded.

th(e)

Transformers in welding machines are usually designed so

that inrush current peaks and the

short-circuit current with electrodes short-circuited are limited (n ≈ 10). The contactor is selected

for switching these currents operationally.

If the individual welding current surges are not switched by power semiconductors but by the

primary contactor, this means that th

e latter has a high switching frequency and a very high

number of operations. It is essential that the contactor selected is checked with respect to the

permitted frequency of operation and the electrical life span. For the electrical endurance the

selection can be based on approx. 70 % of the AC-1-ratings as long as the inrush currents are

limited.

1.5 Reactive power compensation and switching of capacitors

1.5.1 Reactive power compensation

In electrical networks in which inductive consumers (e.g. motors) are switched on and off, the

power factor cos φ often changes with each switching operation. The Power Utilities demand

from their consumers that the ratio of the consumed effective power P to the drawn apparent

power S does not fall below a certain value, as the transmission of apparent power is uneconomic.

The reactive power of motors, luminescent lamps with series chokes and other inductive loads

is therefore fr

load of transformers and lines by the reactive current.

In deciding whether it is more advantageous to compensate individual consumers with fixed

capacitor

definitive. Control units for central compensation have a higher price per power unit (kVA). If

allowance is made however for the fact that in most operations not all consumers are switched

on at the same time, a lower installed capacitor power is often sufficient for central compensation.

equently compensated by connecting capacitors, in order to reduce the additional

s or to provide central compensation units, economic and technical considerations are

1.5.1.1 Individual compensation

For individual compensation (Fig. 1.5-1 a) the capacitors are directly connected to the terminals

of the individual consumer (e.g. motor, transformer, induction heater, luminescent lamp) and

switched together with these via a common switchgear unit. Single compensation is recommended with large consumers with constant power consumption and long ON-times. They offer

the advantage that the lines to the consumers are also relieved of load. The capacitors can

frequently be connected directly to the terminals of the individual consumer and be switched on

and off with a common switchgear device.

~

Ne

Xe

Na

a) Individual compensation b) Group compensation c) Central compensation

Fig. 1.5-1

Compensation types

LVSAM-WP001A-EN-P - April 2009

1-6

~~

~~

~

~

~

Page 17

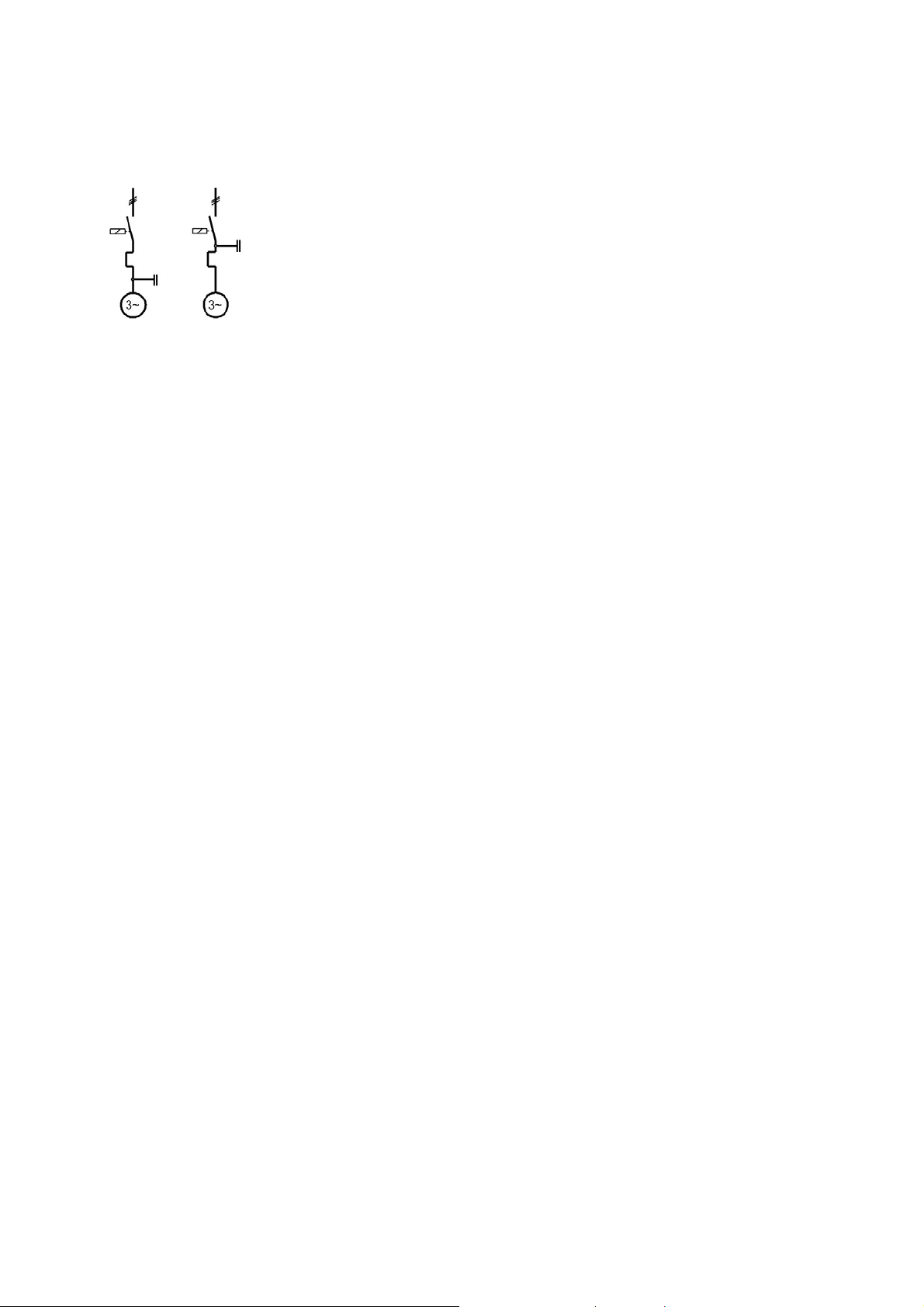

In the case of motors, the capacitors can be connected up- or downstream the motor protection

unit (Fig. 1.5-2). In most cases the capacitor will be connected parallel to the motor (case 1). In

this case th

rated current I

e motor protection unit should be set to a smaller setting current I

as the magnitude of the line current falls due to the compensation:

N

than the motor

e

Case 1 Case 2

Fig. 1.5-2

Individual compensation of motors

I

= (cos φ1/cos φ2) · IN

e

cos φ

cos φ

= power factor of the uncompensated motor

1

= power factor of the compensated motor

2

1.5.1.2 Group compensation

For group compensation each compensation device is assigned to one consumer group. This

may consist of motors or also for example of luminescent lamps that are connected to the mains

via a contactor or a circuit breaker (Fig. 1.5-1 b).

1.5.1.3 Central compensation

Mostly reactive power control units are used for central compensation which are directly

assigned to a main- or sub-distribution station (

many consumers with differing power requirements and variable on-times are instal

Fig. 1.5-1 c). This is especially advantageous if

led in the

network.

Central compensation also offers the advantage that

the compensation device is easy to monitor due its central location,

any retrospective installation or extension is relatively simple,

the capacitive power is continuously adapted to the reactive power requirement of the

consumers and

making allowance for a simultaneity factor a lower capacitance is often required than for

individual co

mpensation.

See IEC 61921; Power capacitors – Capacitor batteries for correcting the low-voltage power

factor

1.5.2 Switching of capacitors

Capacitors form oscillator circuits together with the inductances of the lines and the transformers. During closing, very high transient currents with higher frequencies may flow. Typical

values are 10 ... 30 times the capacitor rated current at frequencies of 2 ... 6 kHz. For this

reason, the switching of capacitors represents a very heavy load on switchgear and can result in

increased contact burn-off or under adverse conditions even welding of the contacts. Especially

when capacitors are switched by contactors, it should be ensured that they are discharged

before switching-on to avoid even higher transient currents and welding of the contacts in case

of adverse phase angles.

A harmonic component in the supply voltage leads to increased current consumption by the

capacitors a

undesired temperature rise, the rated operational current of the contactors, load switches and

circuit breakers shall be higher than the capacitor rated current. Generally this should only be 70

… 75 % of the rated current of the circuit breaker.

LVSAM-WP001A-EN-P - April 2009

nd results in additional heating of the current carrying circuits. To prevent any

1-7

Page 18

Taking into account the aforementioned facts, the switchgear should be dimensioned so that

it does not weld at the high making currents and

that no unacceptable temperature rise occurs during continuous duty.

1.5.2.1 Switching-on single capacitors

If a capacitor with a specific capacity is connected to the power supply, then the making current

is largely determined by the transformer size and by the network impedance to the capacitors,

i.e. from the prospective short-circuit current at the installation site of the capacitor.

The loading of the switchgear increases as

the capacitance of the capacitors increases,

as the rated power of the supplying transformer increases and hence its short-circuit

impedance decreases,

decreasing impedance of the connecting lines.

Table 7 in I

the rated operational current I

−

at

x

valid for

EC 60947-4-1 states the below derivation of capacitor switching capacity I

in relation to the prospective short-circuit current ik:

eAC-3

2

x

⋅=

iI

)6(

kbACe

x

I

ACe

3.13−⋅=

i

k

2

)1( −

)3(

eAC-6b

from

205−⋅>

Ii

)3(

ACek

1.5.2.2 Switching of long, screened lines

Long screened lines have comparatively large capacitances and therefore create high transient

current loads during switching. Typical applications are variable frequency drives. The peak

currents to be expected should be taken into account when selecting switchgear to the same

extent as for the switching of single capacitors.

1.5.2.3 Switching capacitors of central compensation units

If individual capacitors of capacitor banks are switched – for example in reactive power control

units - especially adverse conditions occur at closing of the switchgear contacts as the capacitors already connected to the power supply represent an additional source of energy.

The inrush current is limited by the impedance of the circuit (conductors, capacitor inductance,

inductances

The loading of the switchgear is therefore determined by

the power ratio of the switched capacitors to those already connected to the power supply

and

the impedance of the individual circuit branches

For avoiding welding of t

e.g. be increased, by additional

of the connecting wires).

With special capacitor-contactors or capacitor-c

ces to the power supply via pre-charging resistances, a very high switchable capacitance at a

minimum of interference with the supplying network can be achieved, as the making currents

are specifically limited by the resistances and strongly reduced.

AC-6b is defined in IEC 60947-4-1 as the utilization category for the switching of capacitor

banks.

between the individual capacitor branches).

he switching contacts of the contactors the switchable capacitance can

inductances in the capacitor branches (e.g. a few winding turns

ontactor-combinations that connect capacitan-

LVSAM-WP001A-EN-P - April 2009

1-8

Page 19

1.6 Control circuits, semiconductor load and electromagnetic load

Regarding the specific aspects of the switching of control circuits, also refer to Section 5.

The utilization categories AC-12 to AC-15 for alternating current and DC-12 to DC-14 for direct

current (see

control circui

Tab. 1.1-1) make allowance for the specific loading of switchgear for switching of

ts with semi-conductors or electromagnetic loads. When electromagnets are

switched, for example contactor coils, particular attention is paid to the increased making load

because of the pull-in current of the magnets and the increased breaking load due to the high

inductance of the closed magnets.

In addition to the switching capacity of the contact in the sense of a maximum permitted load,

very often the key criterion in the switching of co

ntrol circuits is contact reliability, i.e. the

capability of a contact or a chain of contacts to reliably switch small signals. This is especially

the case for contacts in circuits of electronic controllers and in the signal range of ≤ 24 V / ≤ 20

mA (also see section

5.3.5).

1.7 Three-phase asynchronous motors

The three-phase asynchronous motor – also known as the induction motor – is the most

frequently used motor type for industrial drives. Especially in the form of a squirrel-cage

induction motor, it dominates the field of industrial electrical drive technology.

1.7.1 Principle of operation

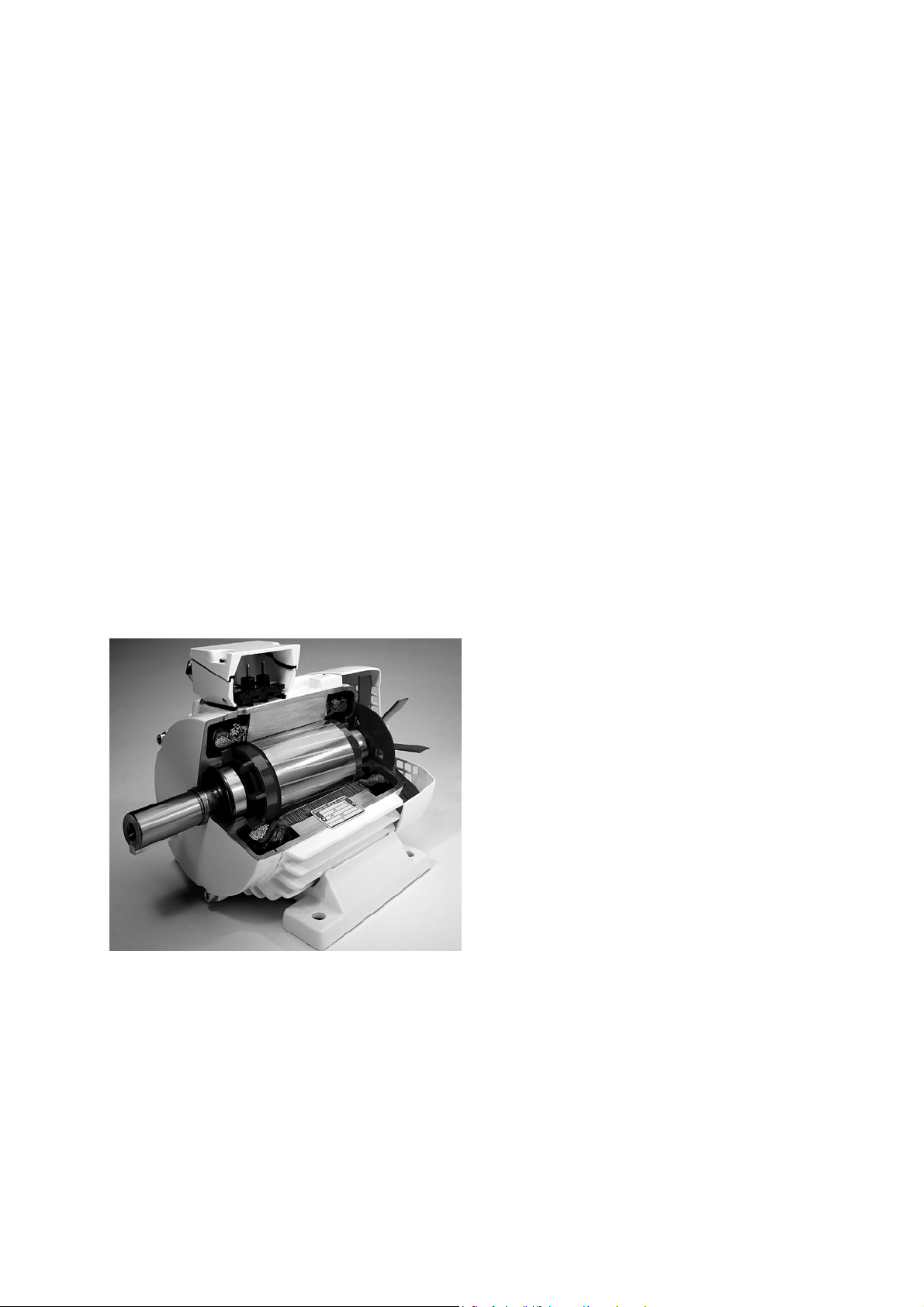

The key functional elements of the three-phase asynchronous motor (see Fig. 1.7-1) are the

fixed stator with a three-phase coil supplied by the three-phase supply network and the revolving rotor. There is no electrical connection between the stator and rotor. The currents in the

rotor are induced by the stator across the air-gap. The stator and rotor are composed of highly

magnetizable dynamo plates with low eddy current and hysteresis losses.

Fig. 1.7-1

Sectional view of a squirrel-cage three-phase motor with enclosed design

When the stator coil is connected to the power supply, the current initially magnetizes the

laminated metal body. This magnetizing current generates a field that rotates with the synchronous speed n

n

n

f = frequency in s

.

s

= 60 · f/p

s

= synchronous speed in min-1

s

-1

p = pole pair number (pole number/2)

For the smallest pole number of 2p = 2, with a 50 Hz power supply, the synchronous speed is

n

= 3000 min-1. For synchronous speeds with other pole numbers and for 50 and 60-Hz power

s

LVSAM-WP001A-EN-P - April 2009

1-9

Page 20

supplies, see Tab. 1.7-1.

Pole

2 4 6 8 10 12 16 24 32 48

number

n

s 50 Hz

n

s 60 Hz

3000 1500 1000 750 600 500 375 250 188 125

3600 1800 1200 900 720 600 450 300 225 150

Tab. 1.7-1

Synchronous speeds for 50 and 60 Hz power supplies

The rotating field of the stator induces a voltage in the coil of the rotor, which in turn creates a

current flow therein. With the interaction of the rotating field of the stator with the conductors in

the rotor through which a current flows, a torque is created in the direction of the rotating field.

The speed of the rotor is always smaller than the synchronous speed by the so-called slip s.

s = (n

-n)/n

s

s

s slip

n

synchronous speed

s

n operational speed

It is only because of this speed differential that a voltage can be induced in the rotor and hence

the rotor curr

ent that is the prerequisite for the generation of the motor-torque. The slip increases with the load torque. Its rated value at the rated load of the motor depends on the rotor

resistance and hence on the energy efficiency of the motor.

The torque curve of the induction motor is characterized by the breakdown-torque. This means

that the torque of the motor increase

s with increasing speed to a maximum value and then

rapidly falls back to zero at the synchronous speed. If the mechanical load of a motor running at

normal service is increased beyond the value of the breakdown torque, it will stall, i.e. it comes

to a halt. The magnitude of the breakdown torque is determined by the electrical reactance of

the motor and hence by the motor’s design. The slip that occurs at breakdown torque can be

influenced by the rotor resistance. This effect is exploited in slip-ring motors by switching on

external resistors (

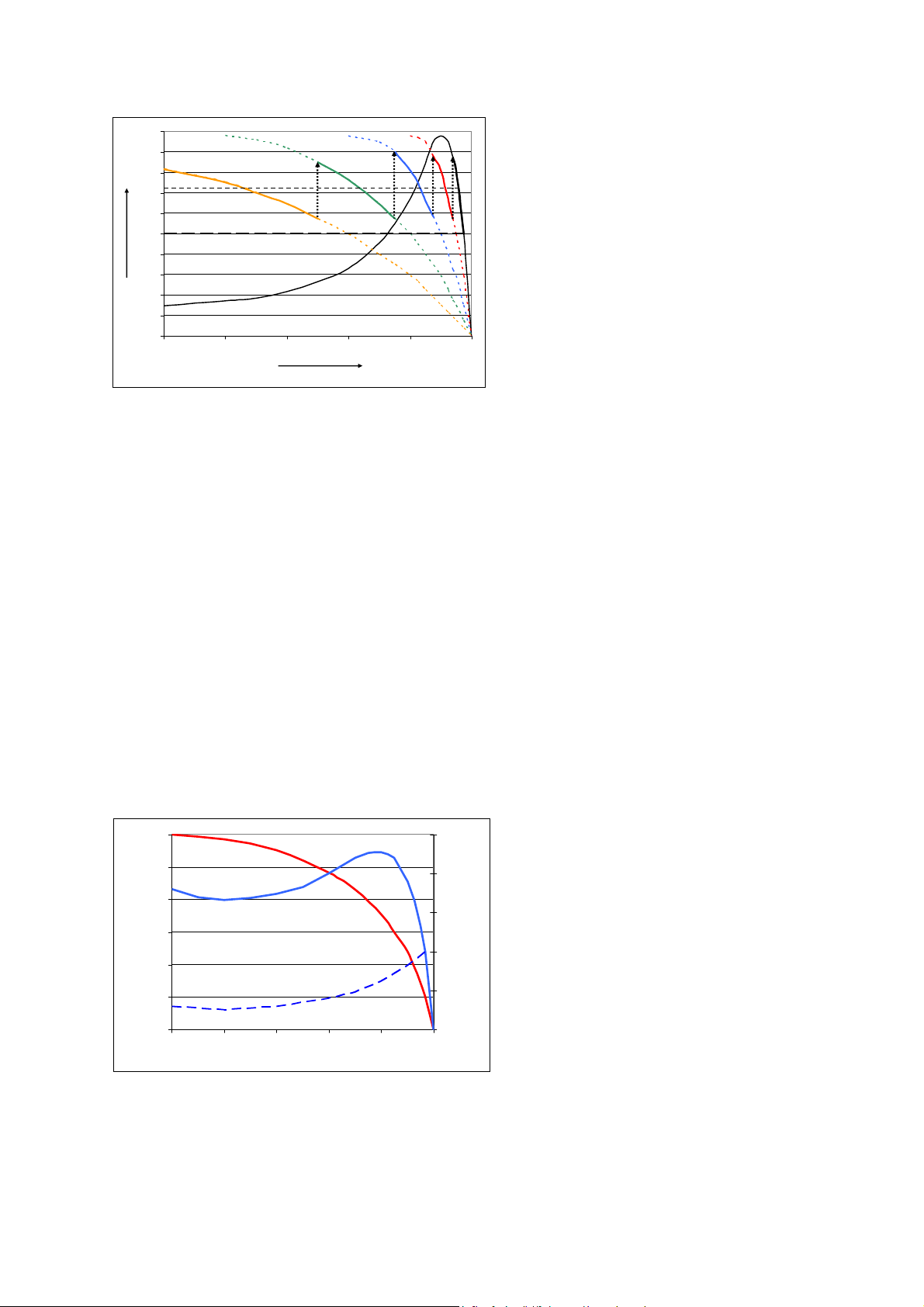

Fig. 1.7-2 and Fig. 1.7-3).

T

b

T

3*R

2

2*R

2

R

2

s

s

10

b

s

3

s

b

b

2

1

Fig. 1.7-2

The torque characteristic of asynchronous motors can quasi be extended by connecting resistors in the

rotor circuit.

breakdown torque

T

b

s slip

breakdown slip

s

b

R

1-10

rotor resistance

2

LVSAM-WP001A-EN-P - April 2009

Page 21

Asynchronous motors behave electrically like transformers. The secondary winding is the rotor

and the mechanical power output of the motor acts on the primary side like a – variable – load

resistance. If no mechanical power output is produced at rest (on initiation of start-up), this load

resistance is zero, i.e. the transformer is in effect secondarily shorted. This leads – depending

on the rotor-internal resistance – to a high or very high current consumption of the motor during

starting. In the case of slip-ring motors, the current consumption is reduced by connecting

external resistors and hence the torque characteristic is adapted to the driven machine. With

squirrel-cage induction motors (see section

torque characteristic ar

e influenced by the design of the rotor cage.

1.7.1.2) the current consumption and hence the

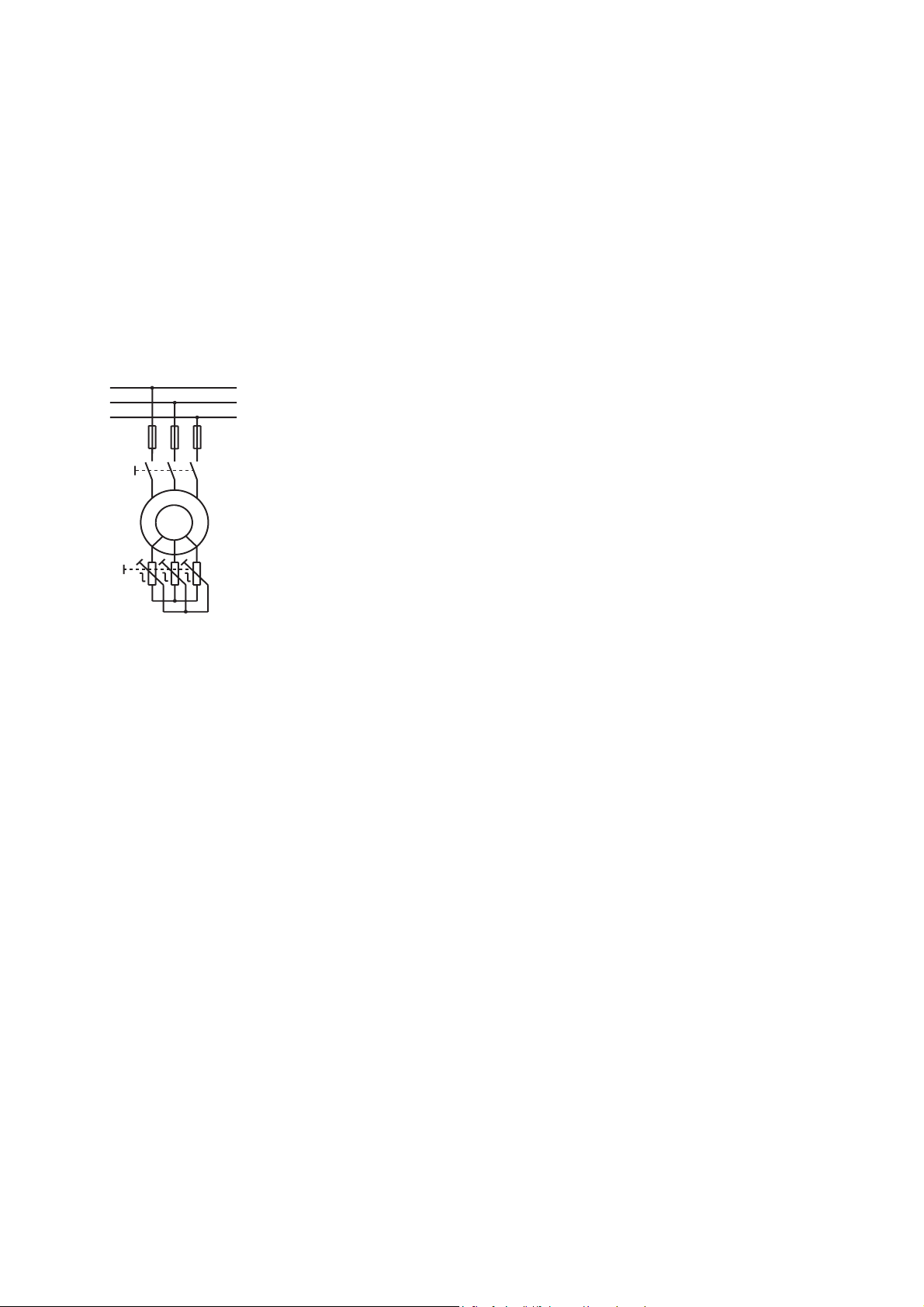

1.7.1.1 Slip-ring motors

With slip-ring motors, the rotor winding is connected to slip rings and terminated with external

resistances. The resistance of the external resistors influences the current flowing through the

rotor and the speed-torque characteristic.

M

3~

Fig. 1.7-3

Principal diagram of a slip-ring motor with external rotor resistances

Slip-ring motors represent the conventional method of controlling starting torque (and the

current consumption) by selection of the rotor resistances. The highest attainable starting torque

corresponds to the breakdown torque of the motor. This is independent of the magnitude of the

rotor resistance. The primary current consumption of slip-ring motors is proportional to the rotor

current. Thanks to these characteristics, slip-ring motors can achieve a high starting torque with

relatively low current consumption.

The external resistors are usually changed in steps during motor startup. The rotor windings are

shorted in normal contin

uous duty. By designing the rotor resistances for continuous duty, it is

even possible to continuously influence the speed, albeit at the cost of high heat dissipation.

LVSAM-WP001A-EN-P - April 2009

1-11

Page 22

2.0

1.8

e

1.6

T/T

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0.0 0.2 0.4 0.6 0.8 1.0

T

T

av-acc

T

e

≈

4

T

L

T

3

T

0

n/n

T

1

T

2

s

Fig. 1.7-4

Torque characteristic of a slip-ring motor with full-load start-up and stepped change of the rotor resistance

during start-up

T4 … T1 motor torque with series-connected resistance stages (R4>R3>R2>R1)

T

motor torque with shorted rotor windings

0

T

average starting torque

av-acc

T

≈ TL rated torque corresponds to load torque

e

1.7.1.2 Squirrel-cage induction motors

In the case of asynchronous machines with squirrel-cage induction rotors, the rotor consists of a

grooved cylindrical laminated rotor package with rods of highly conductive metal (preferably

aluminum), that is joined on the face side by rings to form a closed cage. The cage – at least in

the case of small motors – is usually cast into the rotor.

To reduce the starting current and influence the starting torque characteristic, the coil rods are

specially designed so th

current displacement. They are usually placed crosswise at an angle to the axis of rotation to

avoid variations in torque and to ensure smooth running characteristics.

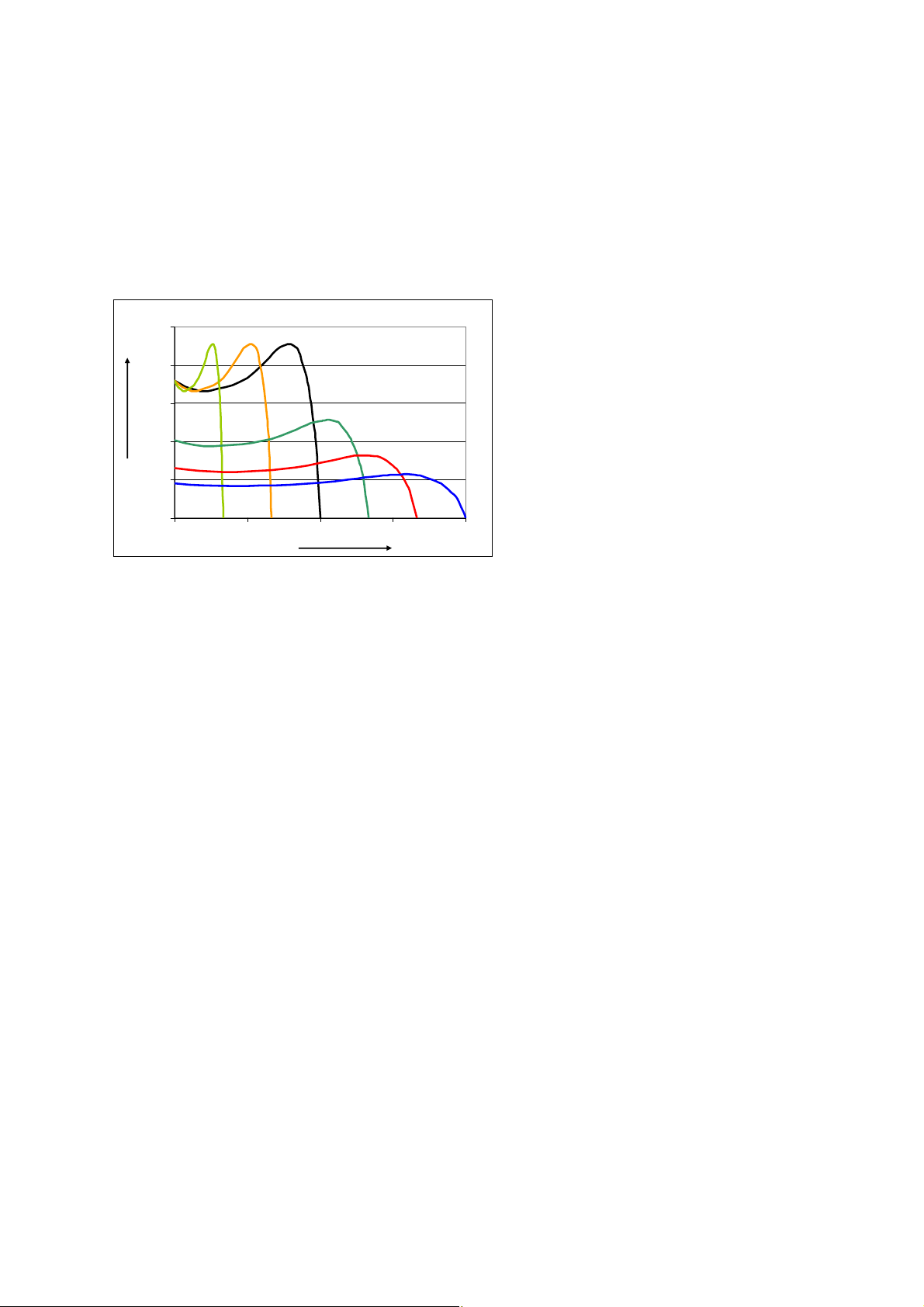

Fig. 1.7-5 shows the typical characteristic of the torque and of the current in a cage induction

motor in the speed range from rest to synchronous speed. Material and de

influence the shape of the characteristic curves.

at they create a high rotor resistance at rest and at low speeds by

sign form of the cage

6.00

I

5.00

4.00

e

3.00

I/I

2.00

1.00

0.00

0 20406080100

Δ

T

Δ

T

L

n/ns [%]

2.50

2.00

1.50

1.00

0.50

0.00

e

T/T

Fig. 1.7-5

Typical current and torque characteristic of a squirrel-cage induction m otor bet ween rest and synchronous speed.

current characteristic with delta-connected windings

I

Δ

torque characteristic with delta-connected windings

T

Δ

load torque (example)

T

L

LVSAM-WP001A-EN-P - April 2009

1-12

Page 23

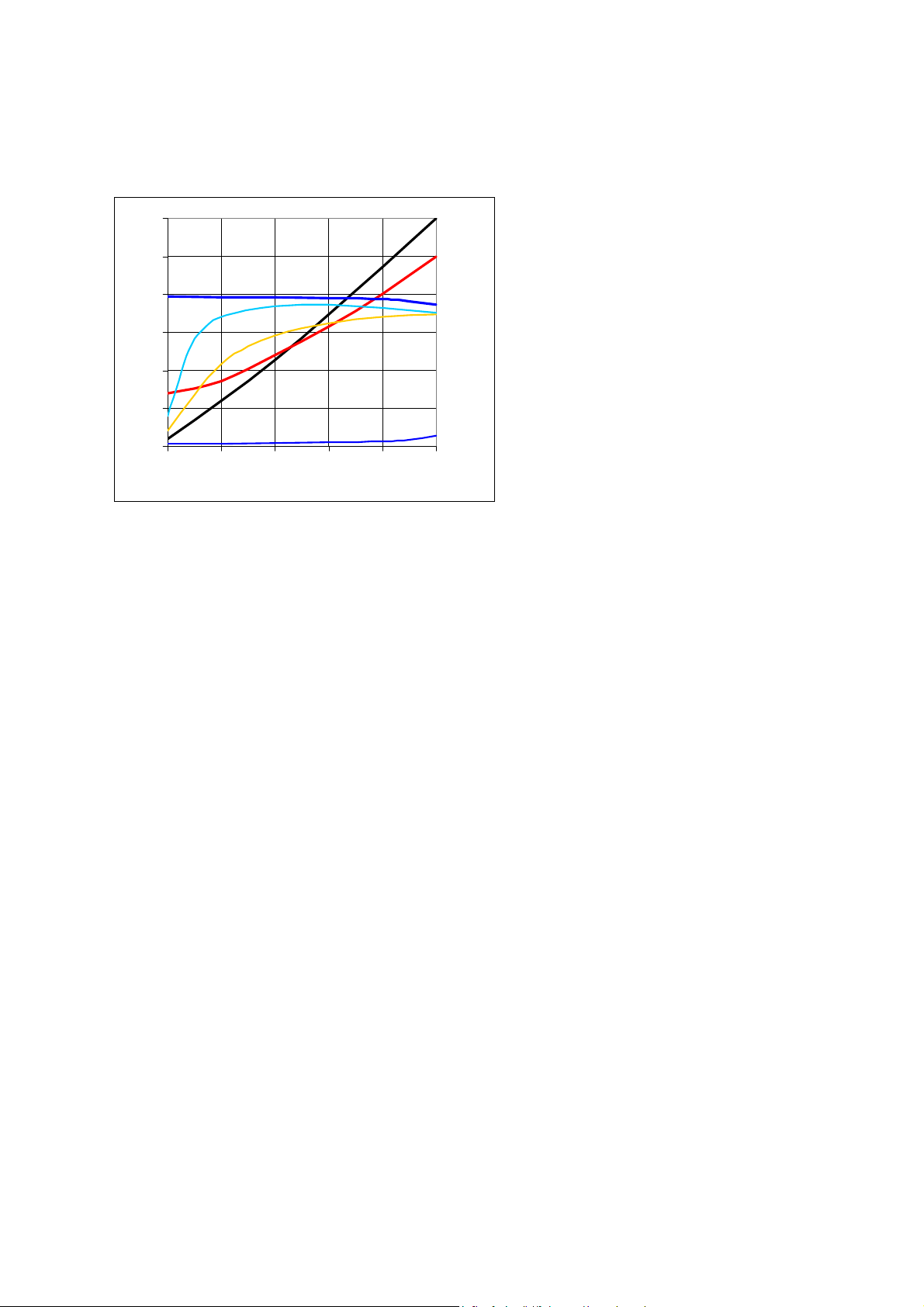

The operating characteristics (Fig. 1.7-6) show that the asynchronous motor has a so-called

I

φ

“hard” speed characteristic, i.

e. the speed changes only slightly with a change in loading. At low

loading, the current consumption approaches the value of the idle running current, which is

basically the same as the magnetization current of the motor.

P

P

1.50

/

1

e

1.25

/

I

e

1.00

n/n

s

0.75

η

cos

0.50

0.25

s

0.00

0.00 0.25 0.50 0.75 1.00 1.25

P

P

/

2

e

Fig. 1.7-6

Operating characteristics of an asynchronous motor as a function of load

n = speed

= synchronous speed

n

s

s = slip

= power intake

P

1

= power output

P

2

P

= rated operational power

e

η = efficiency

s φ = power factor

co

I = current consumption

= rated operational current

I

e

n The speed n only decreases slightly with increasing load. Normal squirrel-cage induction

motors thus have “hard” speed characteristics.

s The slip s in

cos φ The power factor cos φ is strongly d

creases roughly proportionally with increasing load.

ependent on the load and only reaches its highest

value in a state of overload. The power factor is relatively adverse in the part-load range,

as the magnetization is practically constant.

η The efficien

cy η remains relatively constant and in the upper half-load range remains

practically unchanged. It generally reaches its highest value below the rated operational

power P

I The current I increase

falls less strongly and then goes over to the idle running current I

.

e

s proportionally from around the half-load mark. Below this point it

(constant magnetiza-

0

tion)

Starting from the idle running consumption, the power intake P1 increases roughly

P

1

proportionately to the load. In the overload range, its rate of increase is somewhat higher

as losses increase more strongly.

LVSAM-WP001A-EN-P - April 2009

1-13

Page 24

T The torque in the operating range is calculated as follows:

T

=

IU

55.9cos3 ⋅⋅⋅⋅⋅

ηϕ

[]

Nm

n

U voltage across the motor [V]

I current [A]

cosφ power factor

η efficiency of the motor

n speed [min

-1

]

The rated operational currents, starting currents and the torque characteristic of cage induction

motors depend, among other things, on their design, especia

lly the material and form of the

cage, as well as on the number of poles. The specifications provided by the motor manufacturer

apply in each individual case. Typical values for motors can be obtained from the RALVET

electronic documentation.

For switching asynchronous motors, under IEC 60947 the utilization categories AC-2 to AC-4

among others are defined to facilitat

(Tab. 1.1-1). These utilization categories make allowance for the loading

e the user in the selection of suitable contactors

of the switchgear by

the increased making currents when stationary motors are switched on and for the fact that the

effective switching voltage of a running motor is only around 17 % of the rated operational

voltage because the running motor develops a back-e.m.f. (counter voltage to supply voltage).

1.7.1.2.1 High efficiency motors

In the context of the efforts of saving energy and pollution control, the efficiency of electric

motors and drives has become an issue. This on the background of appr. 40% of the global

electricity being used for operating electric motors. The IEC standard 60034-30 (2008) defines

efficiency classes for general purpose induction motors of the power range of 0.75 …375 kW

and with 2, 4 or 6 poles (Tab. 1.7-2). The term MEPS (Minimum Energy Performance Standard)

is being us

minimum level for new motors in the area of the European Union, IE3 may be required in a

further step (minimum requirements, if any, are subject of national legislation).

IEC Class IEC Code EFF Code

Super Premium Efficiency IE4

Premium Efficiency IE3 NEMA Premium

High Efficiency IE2 EFF1 EPAct

Standard Efficiency IE1 EFF2

Below stand Efficiency ‘--- EFF3

1) CEMEP classification (CEMEP = European sector committee of Manufacturers of

Electrical Machines)

ed in this context [25]. It is expected that efficiency class IE2 shall become the

NEMA

1)

Tab. 1.7-2

Efficiency classes for general purpose induction motors according to

IEC 60034-30 (2008) in comparison to the EFF-codes of CEMEP and the codes used by NEMA. IE4 is

not yet defined and reserved for the future.

High efficiency motors that comply with the MEPS standard may have higher starting currents

and cause hi

gher transient current peaks upon switching. The starting torque may be compara-

tively lower for the same starting current, while the breakdown torque may be higher.

When selecting switchgear for starting high efficiency motors, attention should be paid to the

selection of

the proper release class of overload relays (start-up time could become longer at

higher starting current levels). In case of using (current-limiting) circuit breakers the choice of

LVSAM-WP001A-EN-P - April 2009

1-14

Page 25

breakers with high magnetic trip (c.b.’s for transformer protection) may be required for avoiding

nuisance tripping due to high switching transients.

Above factors should particularly be considered in retrofit applications when replacing old

standard motors with new high efficiency motors.

Also, if soft

should be made to ensure the equip

starters are used, the start current may be higher for a given start torque, so a check

ment is rated accordingly. The available start torque may

also need to be evaluated to ensure matching to the load characteristics.

1.7.1.3 Influence of the voltage across the windings

In order to reduce the high current consumption of squirrel-cage induction motors on starting

and the associated, often disruptive, power supply loading and to reduce the high starting

torque when driving sensitive machines, a wide variety of methods is available that is based on

the reduction of the voltage applied across the motor windings. A reduced voltage across a