Page 1

LOGIX HOT BACKUP

BEGIN

SOLUTIONS

Reduce unplanned downtime with Logix

redundant control solutions

Page 2

Downtime is

a certainty.

What’s the plan?

Lost production is inevitable, so planning for outages is critical.

Part of that planning process should include an understanding of control system

reliability. This has a different meaning in every industry, so going back to the

basics is necessary. Identifying the type of disruption and severity of the outcome

can help you evaluate risk mitigation options should a downtime incident occur.

A good place to start is with a risk assessment. Depending on your specific

manufacturing environment and application, the results of the assessment

can help determine suggested techniques to help keep your people and your

equipment safe.

One of those suggestions may be to build controller redundancy into your

operations. Before diving into the details, what are some of the considerations

in your specic industry and application?

What ’s the plan?

PG 2

The cost of doing nothing

PG 4

Redundant capability

PG 5

Controller redundancy options

PG 6

2

Page 3

WITH SOME PROCESSES,

REDUNDANT CONTROLLERS

ARE TWICE AS NICE!

Some production environments are continuous

or irreversible and require high availability at

all costs. Disruption of the process could be

catastrophic from both a safety and profitability

perspective. If any failure or stoppage occurs

after production starts, the product is often

scrapped, and the process reinitiated to realize

a quality output. Think life sciences, food and

beverage, pulp and paper, oil and gas, mining,

cement, etc.

Other industries or applications simply can’t

afford to restart their production because it

can take days, weeks, even up to a month to get

back to full operation. A perfect example is the

metals industry. What if a large furnace in a steel

mill experiences a failure? It could take days to

reach a stable operating temperature again so

production can resume.

Although these examples are more aligned with

critical industries where reliability at the highest

levels is required, some applications need high

availability for other reasons, including customer

service. Think baggage handling.

In ALL these cases, what might be the cost of

not implementing redundant control?

What ’s the plan?

PG 2

The cost of doing nothing

PG 4

Redundant capability

PG 5

Controller redundancy options

PG 6

3

Page 4

WHAT’S THE COST OF DOING NOTHING?

Wouldn’t it be great if you could predict anomalies in your operations so

you could identify and potentially eliminate downtime before it occurs?

Technology advancements in artificial intelligence and machine learning

might be a good strategy, but often require a data scientist to mine

and make sense of the data. In the end, there are several alternatives

to consider to help prevent stoppages, including system redundancy.

Weighing the costs and the risks of those options is part of the critical

decision-making process. One of those alternatives is the “do nothing”

scenario, but that can come at a high price:

Loss of product

As mentioned previously, any interruption of continuous processes can

result in loss of profit, uptime, and product. Machines sit idle, materials are

scrapped, and processes and people must recalibrate and start over.

Increased downtime

When your capital assets are out of commission, there’s more at stake

than lost production. Downtime leads to the non-utilization of resources,

not only for the equipment that’s experiencing the breakdown, but also for

the upstream and downstream equipment in your process workflow. This

translates to non-utilization of your human resources as well.

Increased TCO/decreased ROI

When human and capital resources are not in use due to a downtime incident,

tangible and intangible company resources continue to be consumed which

affects the bottom line. Total cost of ownership increases while your return

on investment decreases, and that’s not a good combination.

Avoid these scenarios by choosing an alternative that’s somewhere in

between the “do nothing” and the data scientist — controller redundancy

with Logix. With an investment in extra hardware and the accompanying

software, you can help reduce unplanned downtime caused by failures,

faults or system maintenance requirements.

What’s the plan?

PG 2

The cost of doing nothing

PG 4

Redundant capability

PG 5

Controller redundancy options

PG 6

4

Page 5

Logix controllers

with redundant capability

Reliable control systems deliver consistent

operation of yourproduction oor. To increase

reliability, consider implementing redundant

control into your system.

Redundant capability isn’t new to the Logix family of

controllers. In fact, it’s been available in different form factors

for quite some time. Continued investment now makes this

functionality available in the latest additions to the Logix

product portfolios.

Whether you have a need for large or small control, you have

options with ControlLogix® and CompactLogix™ controllers.

And whether you need one-click activation or would

rather program the data sync yourself, Studio 5000 Logix

Designer® software provides the design environment for

configuring your redundant control.

What’s the plan?

PG 2

The cost of doing nothing

PG 4

Redundant capability

PG 5

Controller redundancy options

PG 6

5

5

Page 6

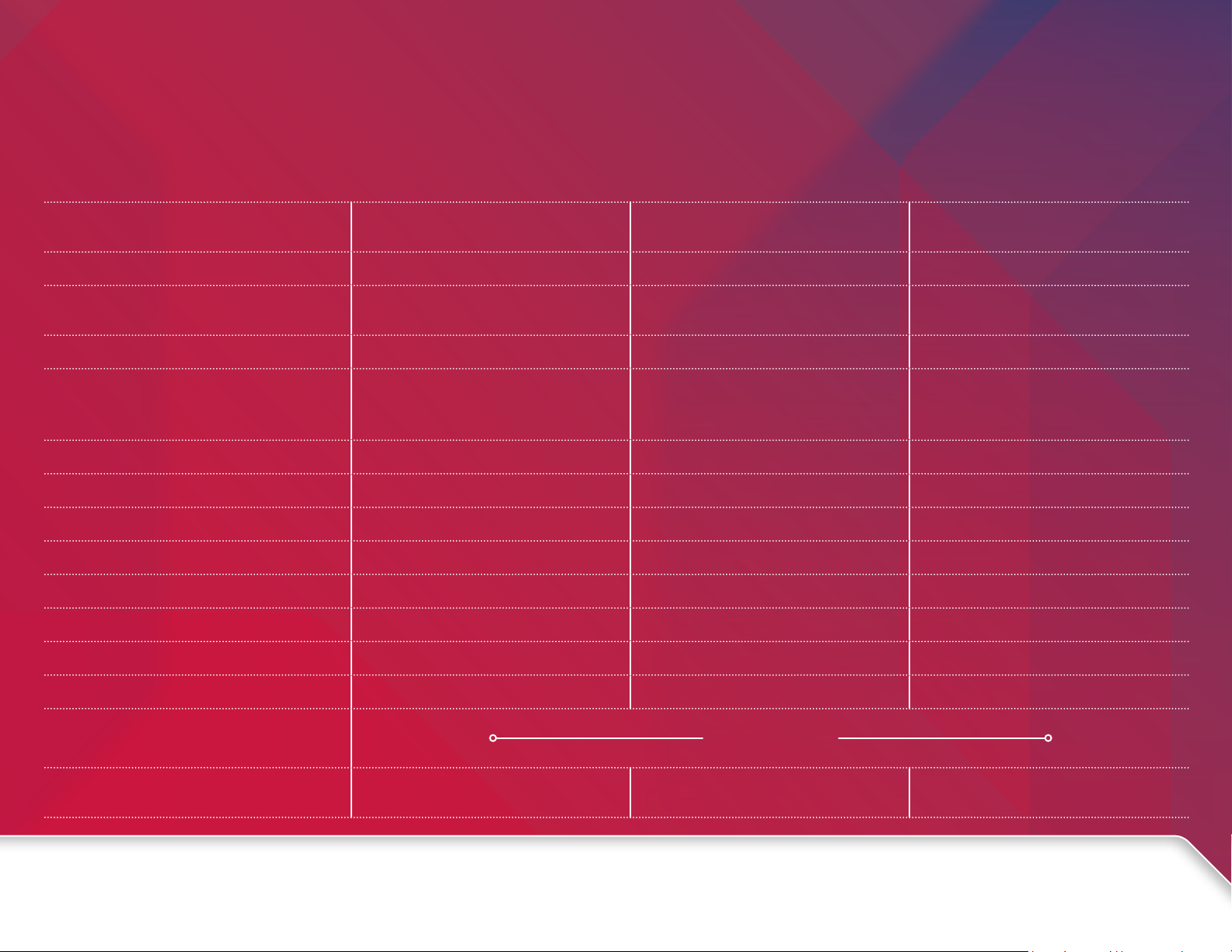

Logix control redundancy details

DOWNLOADDOWNLOAD

DOWNLOADDOWNLOAD

DOWNLOADDOWNLOAD

CONTROLLOGIX REDUNDANCY HOT BACKUP

Controller support ControlLogix 5580 ControlLogix 5570

Required module 1756-RM2 1756-RM2 n/a

Network support EtherNet/IP

I/O support 1756, 5094, 1794, 1734, 1738, 1715 1756, 1794, 1734, 1738, 1715 1756, 1794, 5069

Software Studio 5000 Logix Designer v33

Data synchronization Automatic Automatic User congured

Switchover time >= 20ms >= 20ms >= 250ms

Program duplication for secondary controller Automatic Automatic User initiated

Online edits Automatically sent to both controllers Automatically sent to both controllers User initiated in both controllers

Network address swap for HMI Yes Yes, onEtherNet/IP No

Forced status equalization Yes Yes No

Output status during switchover Maintained Maintained Maintained

TM

EtherNet/IP and ControlNet

Studio 5000 Logix Designer

RSNetWorx

TM

(if using ControlNet)

TM

ControlLogix 5570/5580

CompactLogix 5370/5380

EtherNet/IP

ControlNet (ControlLogix only)

Studio 5000 Logix Designer

LogixHot BackupCodeGenerator

RSNetworx (if using ControNet)

High availability systems reference manual

What’s the plan?

PG 2

Firmware update in run mode Yes Yes Yes

User manual

The cost of doing nothing

PG 4

Redundant capability

PG 5

Controller redundancy options

PG 6

Contact local sales oce

(Reference Technical Note 68593)

6

Page 7

ControlLogix 5580 controller quick look

Controller

catalog

1756-L8xE

1756-L8xE-NSE

1756-L8xEK

1756-L8xEXT

1756-L8xEP

1756-L8xES

Description Ethernet

Standard

controller

No stored

energy

Conformally

coated

Extreme

temperature

Process

controller

Safety

controller

■

■

■

■

■

■ ■ ■ ■ ■ ■

Network Support I/O Support Security Process

Use of

embedded

Ethernet port

▲ ▲

▲ ▲

▲ ▲

▲ ▲

▲ ▲

ControlNet /

DeviceNet /

DHRIO

Existing

I/O*

■

■

■

■

■

5069

I/O

▲

▲

▲

▲

▲

5094

I/O

■

■

■

■

■

CIP

security

62443-4-2

compliant

▲ ▲

▲ ▲

▲ ▲

▲ ▲

▲ ▲

● ● ●

Embedded

process

objects

●

●

●

●

■ ■

Phase

Manager™

software

■

■

■

■

■

Sequence Manager™

software

High

Availability

Default

Process Tasking

model

● ●

● ●

● ●

● ●

●

● ● ●

■ ■

Supports a

redundancy

conguration**

■

■

■

■

■ Supported in all congurations

▲ Supported in standard (but not redundant) conguration

● Not Supported

* ControlLogix® 5580 controllers congured for redundancy will support the same I/O as a ControlLogix® 5570 redundant controller; for example, 1769 I/O isn’t supported in a ControlLogix® 5570 redundant controller,

so it’s also not supported with ControlLogix® 5580 redundancy

** New functionality delivered through the Studio 5000 Logix Designer® application version 33 rmware and software; no new controller catalog number required to enable this feature

What’s the plan?

PG 2

The cost of doing nothing

PG 4

Redundant capability

PG 5

Controller redundancy options

PG 6

7

7

Page 8

Whether you are in an industry where near 100% uptime with

BACK

full backup capabilities is required, or work in a different

industry where high availability is needed for other reasons, you

have options.

With scalable alternatives for I/O, memory, and cost, Logix

redundant controllers deliver high performance and high

availability for all industries and application needs.

LEARN MORE

rockwellautomation.com

ControlLogix

CompactLogix

Contact your local RA sales/distributor

Connect with us.

Allen-Bradley, ControlLogix, CompactLogix, expanding human possibility, FactoryTalk, Rockwell Automation, RSNetWorx, Studio 5000 Logix Designer are trademarks of Rockwell Automation, Inc.

ControlNet and EtherNet/IP are trademarks of ODVA, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 1756-PP014C-EN-P - November 2020 | Supersedes Publication 1756-PP014B-EN-P - December 2012

Copyright © 2020 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Loading...

Loading...