Page 1

Reach Drive User Manual

Manufactured for DBT

Instruction Manual

D2-3561

Page 2

The information in this manual is subject to change without notice.

Throughout this manual, the following notes are used to alert you to safety considerations:

ATTENTION:Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss.

!

Important: Identifies information that is critical for successful application and understanding of the product.

ATTENTION:Only qualified electrical personnel familiar with the construction and operation of

this equipment and the hazards involved should install, adjust, operate, or service this equipment.

!

Read and understand this manual and other applicable manuals in their entirety before

proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input power has been

disconnected. After disconnecting input power, wait five (5) minutes for the DC bus capacitors to

discharge and then check the voltage with a voltmeter to ensure the DC bus capacitors are

discharged before touching any internal components. Failure to observe this precaution could

result in severe bodily injury or loss of life.

ATTENTION:The drive can operate at and maintain zero speed. The user is responsible for

assuring safe conditions for operating personnel by providing suitable guards, audible or visual

alarms, or other devices to indicate that the drive is operating or may operate at or near zero

speed. Failure to observe this precaution could result in severe bodily injury or loss of life.

ATTENTION:Do not install modification kits with power applied to the drive. Disconnect and lock

out incoming power before attempting such installation or removal. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:The drive start/stop/enable control circuitry includes solid state components. If

hazards due to accidental contact with moving machinery or unintentional flow of liquid, gas or

solids exist, an additional hardwired stop circuit may be required to remove the AC line to the

drive. An auxiliary braking method may be required.

ATTENTION:The drive contains ESD- (Electrostatic Discharge) sensitive parts and assemblies.

Static control precautions are required when installing, testing, servicing, or repairing the drive.

Erratic machine operation and damage to, or destruction of, equipment can result if this procedure

is not followed. Failure to observe this precaution can result in bodily injury.

ATTENTION:The user is responsible for conforming with all applicable local, national, and

international codes. Failure to observe this precaution could result in damage to, or destruction

of, the equipment.

Copyright © 2006 Rockwell Automation. All rights reserved.

Page 3

Chapter 1

Chapter 2

CONTENTS

Introduction

1.1 Who Should Use this Manual? ........................................................................ 1-1

1.2 Manual Conventions ........................................................................................ 1-1

1.3 Identifying the Drive by Nameplate.................................................................. 1-1

1.4 Identifying the Drive by Model Number ........................................................... 1-2

Installation/Wiring

2.1 AC Supply Source Considerations .................................................................. 2-1

2.1.1 Unbalanced or Ungrounded Distribution Systems ................................ 2-2

2.1.2 Input Power Conditioning ...................................................................... 2-2

2.2 General Grounding Requirements................................................................... 2-3

2.2.1 Safety Ground - PE ............................................................................... 2-4

2.2.2 Shield Termination - SHLD.................................................................... 2-4

2.2.3 RFI Filter Grounding.............................................................................. 2-5

2.3 Fuses and Circuit Breakers ............................................................................. 2-5

2.4 Power Wiring ................................................................................................... 2-5

2.4.1 Cable Types Acceptable for 200-600 Volt Installations......................... 2-5

2.4.2 Motor Cable Lengths ............................................................................. 2-5

2.4.3 Power Termination Location Notes ....................................................... 2-6

2.5 I/O Wiring......................................................................................................... 2-7

2.5.1 I/O Terminal Designations..................................................................... 2-8

2.5.2 Encoder Terminal Block ...................................................................... 2-11

2.5.3 Signal and Control Wire Types............................................................ 2-12

2.5.4 The I/O Control Board ......................................................................... 2-14

2.5.5 I/O Terminal Blocks ............................................................................. 2-14

2.5.6 Hardware Enable Circuitry .................................................................. 2-15

2.5.7 Resistance Temperature Detector (RTD) Board ................................. 2-15

2.5.7.1 Connections .......................................................................... 2-17

2.5.7.2 Hardware .............................................................................. 2-17

2.5.7.3 Microcontroller Software ....................................................... 2-19

Contents

Chapter 3

Parameter Descriptions

3.1 Parameters ...................................................................................................... 3-2

3.2 Advanced Tuning Parameters (Vector Control Only) .................................. 3-141

Chapter 4

Troubleshooting

4.1 About Alarms ................................................................................................... 4-2

4.1.1 Alarm Descriptions ................................................................................ 4-3

4.2 About Faults .................................................................................................... 4-7

4.2.1 About the Fault Queue .......................................................................... 4-7

4.2.2 Clearing Faults ...................................................................................... 4-8

4.2.3 Fault Descriptions and Corrective Actions ............................................ 4-9

4.3 Testpoint Parameter ...................................................................................... 4-15

4.4 Troubleshooting the Drive Using the LCD HIM ............................................. 4-16

4.4.1 Accessing the Fault Queue ................................................................. 4-16

1

Page 4

Appendix A

Appendix B

Appendix C

Appendix D

Technical Specifications........................................................................................... A-1

Logic Command/Status Words ................................................................................ B-1

HIM Overview........................................................................................................... C-1

Application Notes ..................................................................................................... D-1

2

DBT Reach Drive User Manual

Page 5

CHAPTER 1

198

270

432-528

Nom. Coolant Pressure: 25psig

Input: 3 Phase, 47-63 Hz

MFD. in 2006 on AUG 15

3 Sec. Overload Amps

1 Min. Overload Amps

Continuous Amps

Base Hz (default)

AC Voltage Range

Output: 3 Phase, 0-400Hz

AC Voltage Range

Normal Duty Power

Amps

60 Hz

180

0-460

169

480V

150 HP

Serial Number: MEAZ0NNO

Original Firmware V. 1.001

Series: A

Cat No.

Madein the U.S.A. by Rockwell Automation Co. (FAC1C)

I/O:

Frame: 1

DBT

CNMD180W0ENNNC1

CNMD180W0ENNNC1

The purpose of this manual is to provide you with the basic information needed to

install, start-up, and troubleshoot the Reach Drive.

1.1 Who Should Use this Manual?

This manual is intended for qualified personnel. You must be able to program and

operate adjustable frequency AC drives devices. In addition, you must have an

understanding of the parameter settings and functions.

1.2 Manual Conventions

Parameter names: In most instances, parameter names are shown as the parameter

name followed by the parameter number.

For example: Ramped Speed (22).

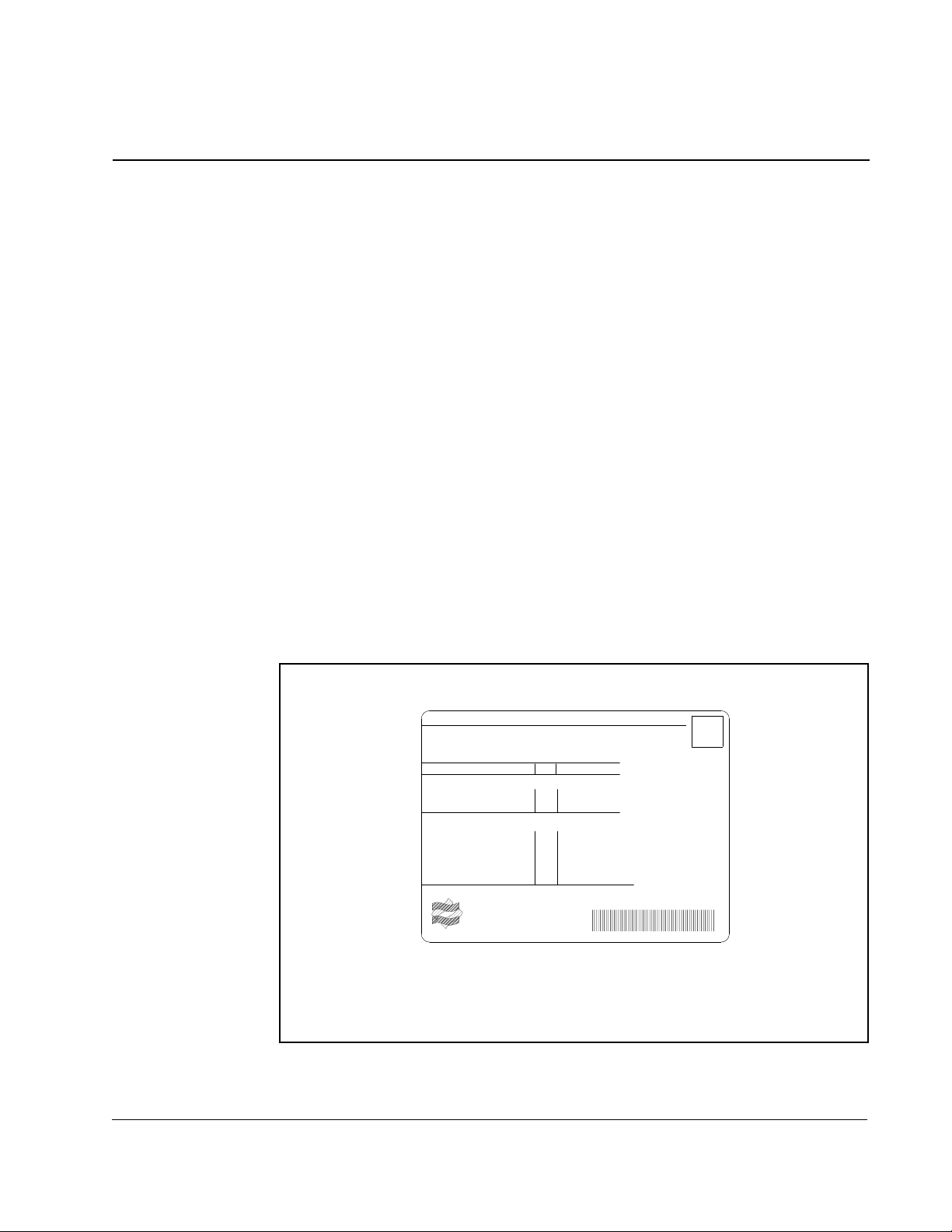

1.3 Identifying the Drive by Nameplate

Introduction

Introduction

Each Reach Drive can be identified by its nameplate.

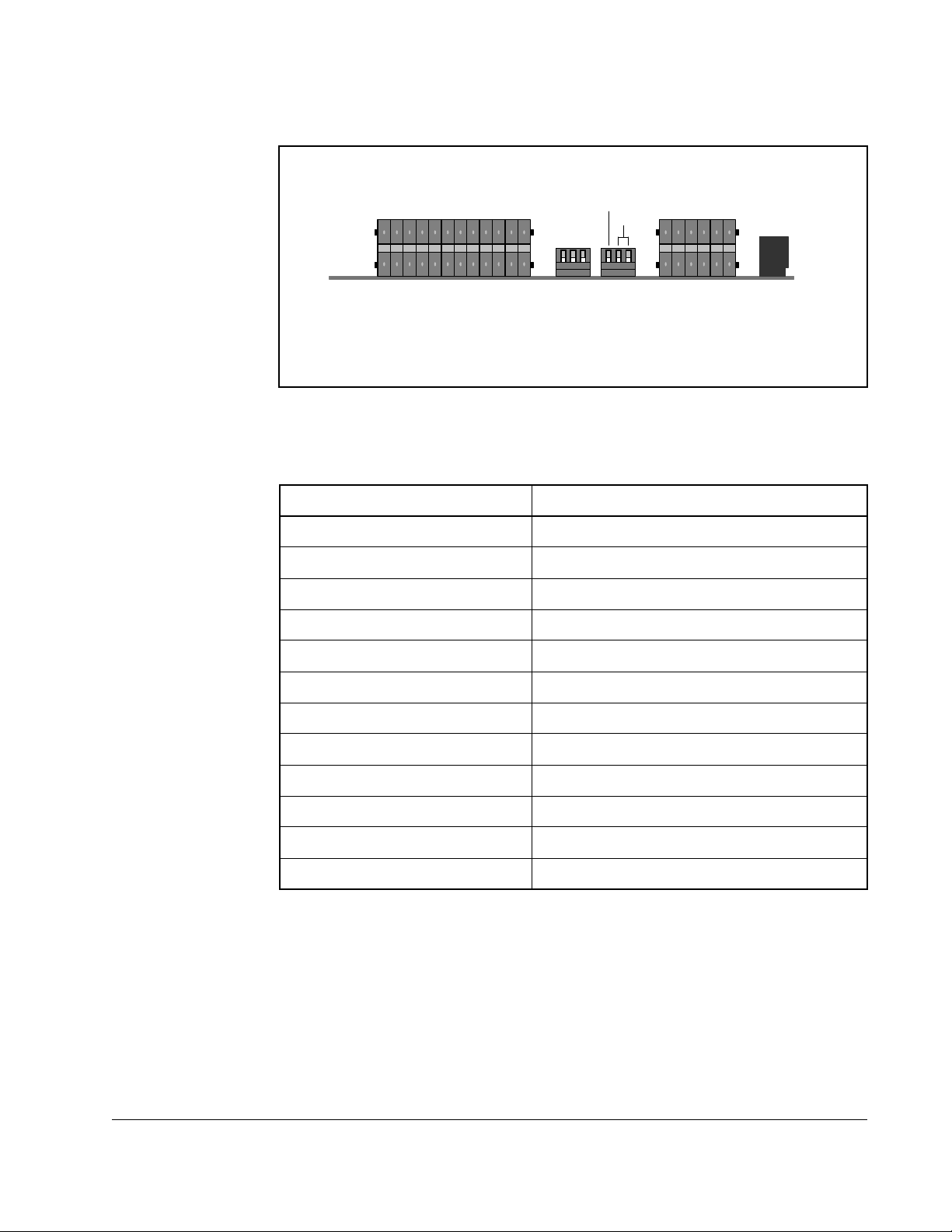

Figure 1.1 – Identifying the Drive by Nameplate

1-1

Page 6

1.4 Identifying the Drive by Model Number

Each Reach Drive and Reach Drive Kit can be identified by its model number. The

model number is on the shipping label and drive nameplate. The model number

includes the drive and any factory-installed options.

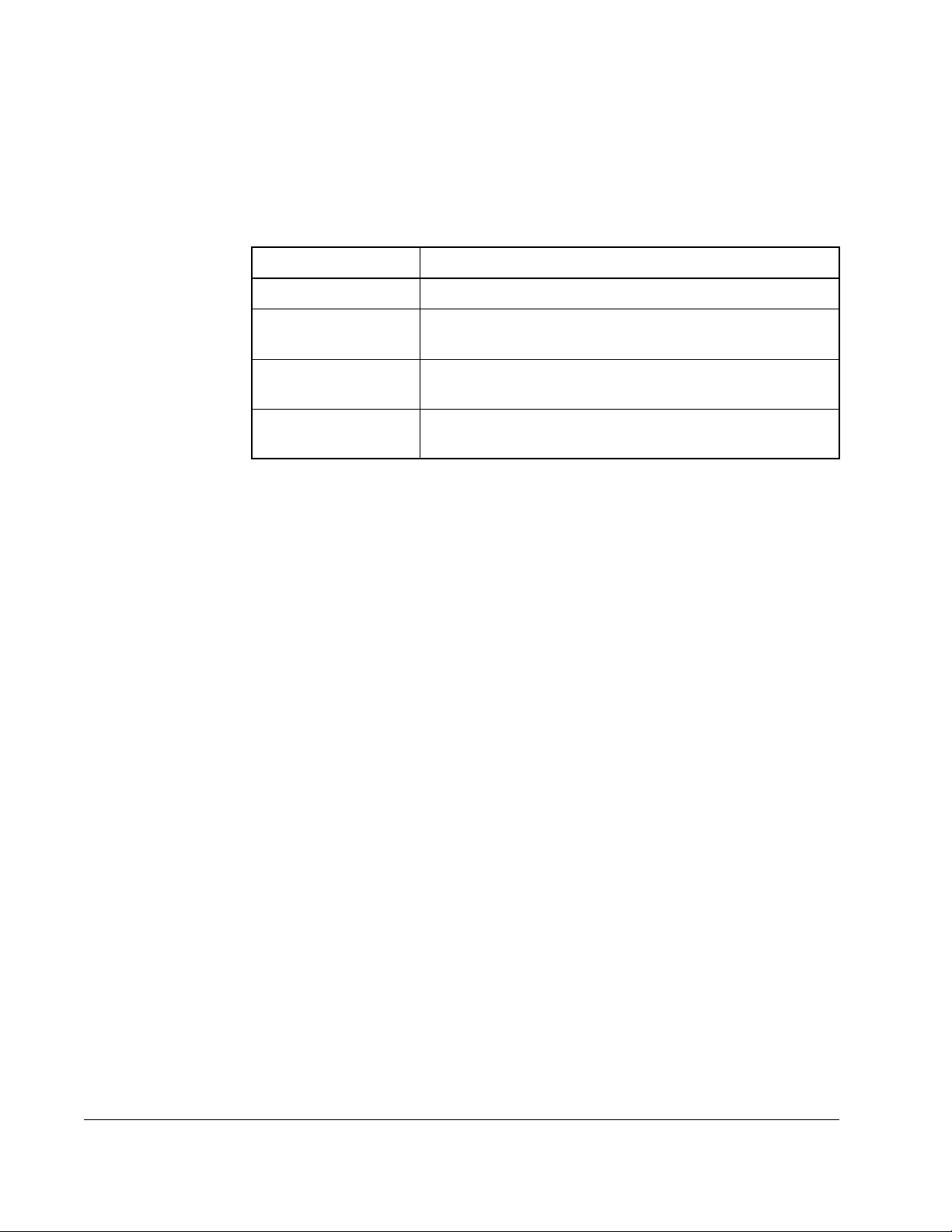

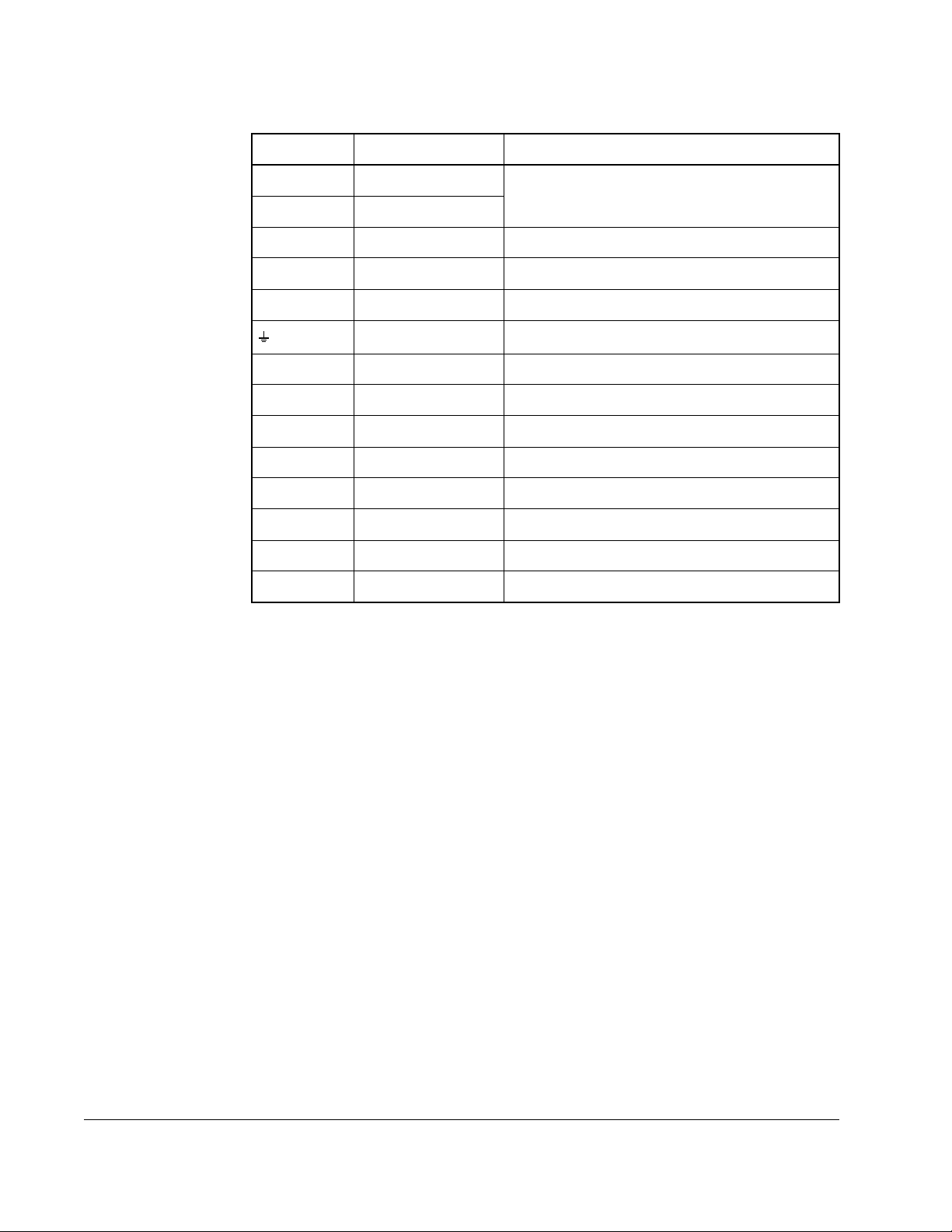

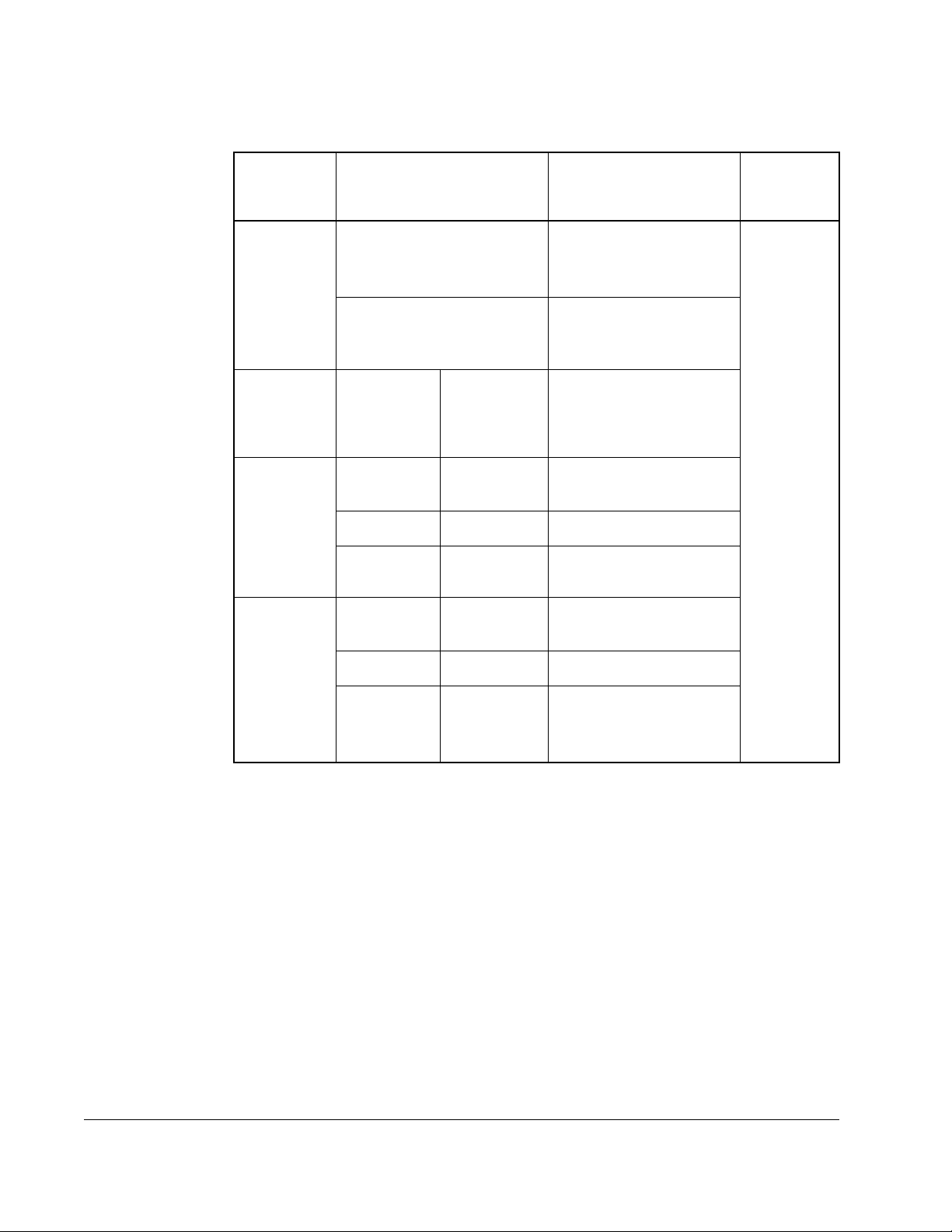

Table 1.1 – Reach Drive Model Numbers

Part Model Number

Reach Drive CNMD180W0ENNNC1

ControNet Comm

Adapter Fiber Kit

Pump Control

Adapter Kit

Dynamic Brake

Resistor Kit

CNM-CNETGF-11

CNM-PCTRL-11

CNM-R2-019P600

1-2

DBT Reach Drive User Manual

Page 7

Installation/Wiring

This chapter provides information on mounting and wiring the Reach Drive.

Most start-up difficulties are the result of incorrect wiring. Every precaution must be

taken to assure that the wiring is done as instructed. All items must be read and

understood before the actual installation begins

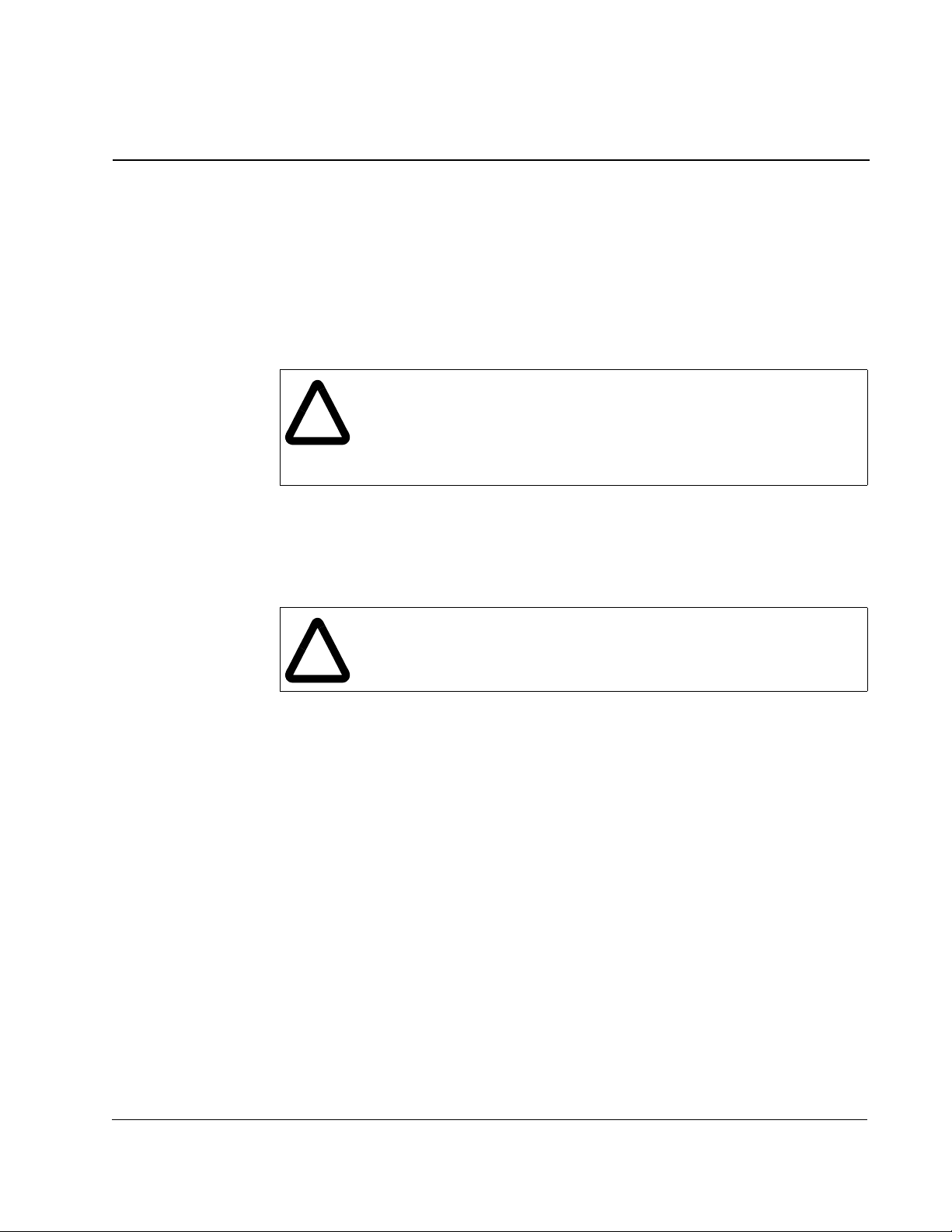

ATTENTION:The following information is merely a guide for proper

installation. Rockwell Automation cannot assume responsibility for the

!

2.1 AC Supply Source Considerations

Reach Drives are suitable for use on a circuit capable of delivering up to a maximum

of 200,000 rms symmetrical amperes and a maximum of 600 volts.

compliance or the noncompliance to any code, national, local or

otherwise for the proper installation of this drive or associated equipment.

A hazard of personal injury and/or equipment damage exists if codes are

ignored during installation.

CHAPTER 2

ATTENTION:To guard against personal injury and/or equipment

damage caused by improper fusing or circuit breaker selection, use only

!

If a system ground fault monitor (RCD) is to be used, only Type B (adjustable) devices

should be used to avoid nuisance tripping.

the recommended line fuses/circuit breakers specified in Appendix A.

Installation/Wiring

2-1

Page 8

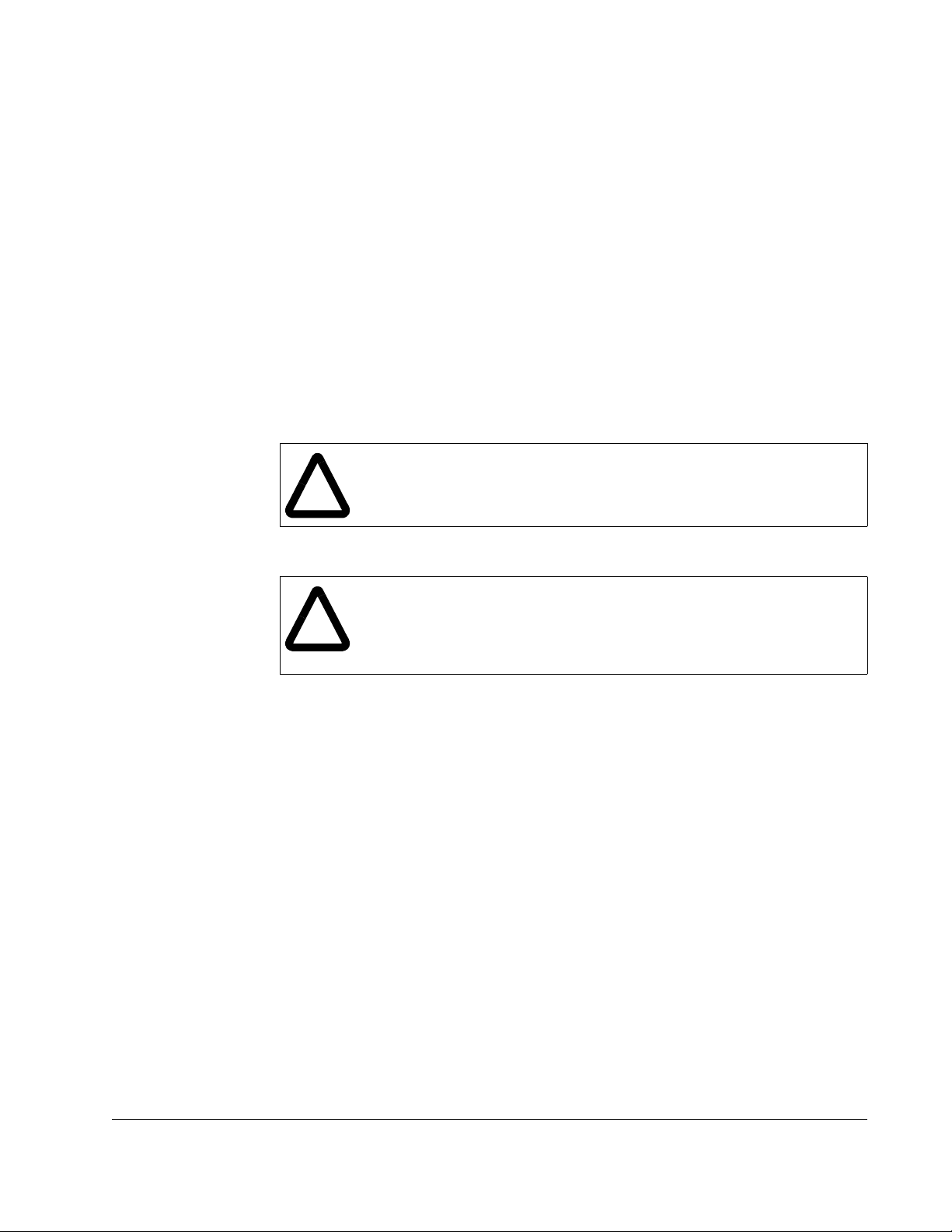

2.1.1 Unbalanced or Ungrounded Distribution Systems

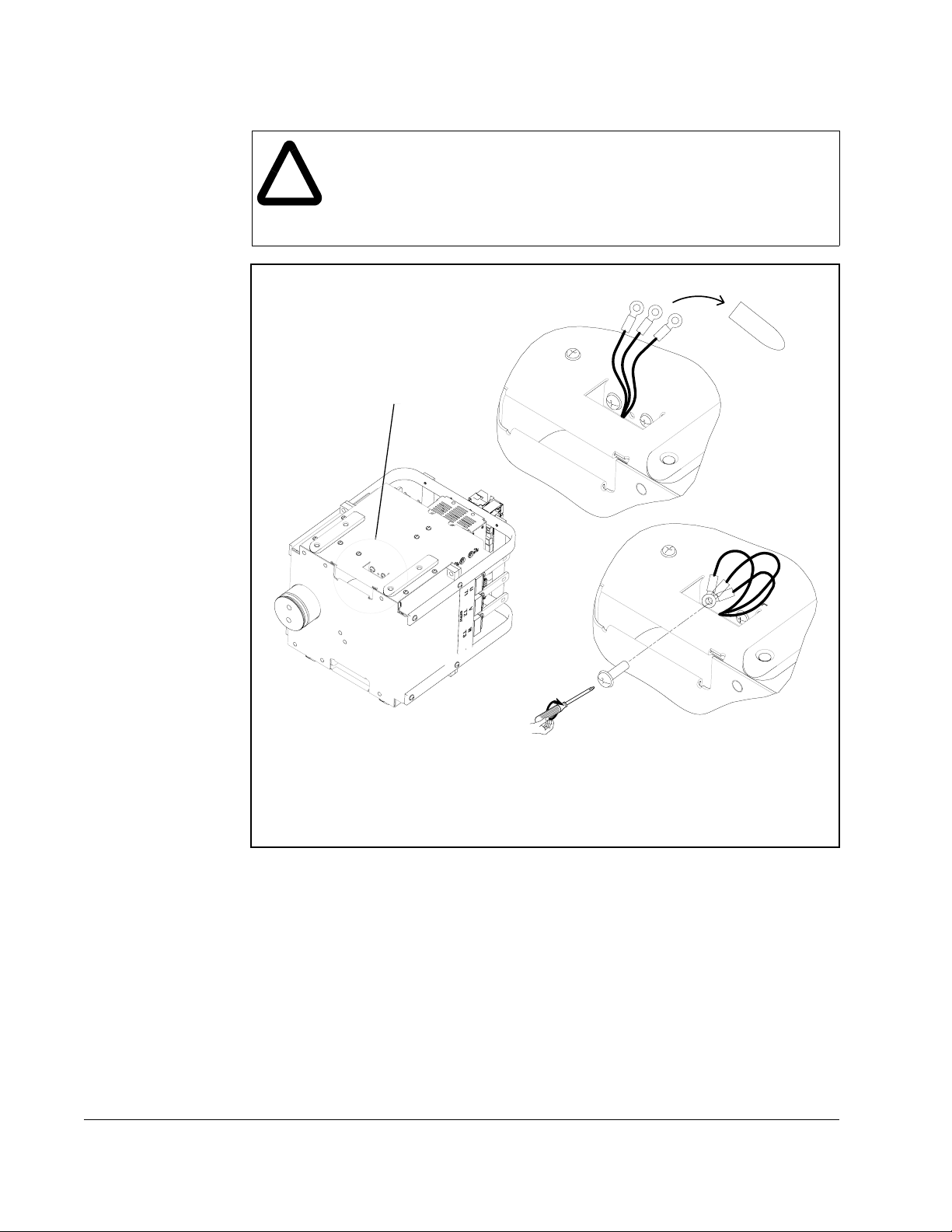

ATTENTION:Power distribution to Reach Drives is intended to be from

the ungrounded secondary of the system’s step down transformer.

!

Protective MOVs, the EMI Snubber Board, and common mode capacitors

(3 places) in the drive have been disconnected. They should typically be

reconnected in any application where the power distribution at the drive

is grounded. Refer to Figure 2.1

STEP 1

SEE CONNECTION

DETAILS

STEP 2

CUT TY-WRAP

PULL INSULATED LEADS FREE

REMOVE INSULATED COVER

SEPARATE LEADS

2-2

REMOVE SCREW

FASTEN LUGS WITH SCREW TO FLANGE

TIGHTEN SCREW TO 28 in-lbs

TUCK LEADS BACK INTO UNIT

Figure 2.1 – Protective Circuit Connections for Grounded Drive Systems

2.1.2 Input Power Conditioning

Certain events on the power system supplying a drive can cause component damage

or shortened product life. The following events can cause such damage.

• The power system has power factor correction capacitors switched in and out of

the system, either by the user or by the power company.

• The power source has intermittent voltage spikes in excess of 6000 volts. These

spikes could be caused by other equipment on the line or by events such as

lightning strikes.

DBT Reach Drive User Manual

Page 9

• The power source has frequent interruptions.

GROUNDPOINT

GROUNDPOINT

GROUNDPOINT

If these conditions exist, it is recommended that the user install a minimum amount of

impedance between the drive and the source. This impedance could come from the

supply transformer itself, the cable between the transformer and drive or an additional

transformer or reactor.

2.2 General Grounding Requirements

The drive Safety Ground - PE must be connected to system ground. Ground

impedance must conform to the requirements of national and local industrial safety

regulations and/or electrical codes. The integrity of all ground connections should be

periodically checked.

For installations within a cabinet, a single safety ground point or ground bus bar

connected directly to building steel should be used. All circuits including the AC input

ground conductor should be grounded independently and directly to this point/bar.

Refer to Figure 2.2 and Table 2.1.

Installation/Wiring

Figure 2.2 – Recommended Ground Locations

2-3

Page 10

Table 2.1 – Power Termination Locations Notes

Terminal Description Notes

BR1 DC Brake (+) DB Resistor Connection

BR2 DC Brake (-)

DC+ DC Bus (+)

DC- DC Bus (-)

PE PE Ground

Motor Ground

U U (T1) To motor

V V (T2) To motor

W W (T3) To motor

R R (L1) AC Line Input Power

S S (L2) AC Line Input Power

T T (L3) AC Line Input Power

PS+ AUX (+) Auxiliary Control Voltage

PS- AUX (-) Auxiliary Control Voltage

2.2.1 Safety Ground - PE

This is the safety ground for the drive that is required by code. This point must be

connected to adjacent building steel (girder, joist), a floor ground rod or bus bar (see

above). Grounding points must comply with national and local industrial safety

regulations and/or electrical codes.

2.2.2 Shield Termination - SHLD

The Shield terminal provides a grounding point for the motor cable shield. The motor

cable shield should be connected to this terminal on the drive (drive end) and the

motor frame (motor end). A shield terminating cable gland may also be used.

When shielded cable is used for control and signal wiring, the shield should be

grounded at the source end only, not at the drive end.

2-4

DBT Reach Drive User Manual

Page 11

2.2.3 RFI Filter Grounding

Using an optional RFI filter may result in relatively high ground leakage currents.

Therefore, the filter must only be used in installations with grounded AC supply

systems and be permanently installed and solidly grounded (bonded) to the

building power distribution ground. Ensure that the incoming supply neutral is solidly

connected (bonded) to the same building power distribution ground. Grounding must

not rely on flexible cables and should not include any form of plug or socket that would

permit inadvertent disconnection. Some local codes may require redundant ground

connections. The integrity of all connections should be periodically checked. Refer to

the instructions supplied with the filter.

2.3 Fuses and Circuit Breakers

The Reach Drive includes input fuses. National and local industrial safety regulations

and/or electrical codes may determine additional requirements for these installations.

Refer to Appendix A for recommended fuses/circuit breakers.

ATTENTION:The Reach Drive does not provide branch short circuit

protection. Specifications for the recommended fuse or circuit breaker to

!

provide protection against short circuits are provided in Appendix A.

2.4 Power Wiring

ATTENTION:National Codes and standards (NEC, VDE, BSI etc.) and

local codes outline provisions for safely installing electrical equipment.

!

Installation must comply with specifications regarding wire types,

conductor sizes, branch circuit protection and disconnect devices. Failure

to do so may result in personal injury and/or equipment damage.

2.4.1 Cable Types Acceptable for 200-600 Volt Installations

A variety of cable types are acceptable for drive installations. For many installations,

unshielded cable is adequate, provided it can be separated from sensitive circuits. As

an approximate guide, allow a spacing of 0.3 meters (1 foot) for every 10 meters (32.8

feet) of length. In all cases, long parallel runs must be avoided. Do not use cable with

an insulation thickness less than or equal to 15 mils (0.4mm/0.015 in.). Use Copper

wire only. Wire gauge requirements and recommendations are based on 75 degrees

C. Do not reduce wire gauge when using higher temperature wire.

Unshielded

THHN, THWN or similar wire is acceptable for drive installation in dry environments

provided adequate free air space and/or conduit fill rates limits are provided. Do not

use THHN or similarly coated wire in wet areas. Any wire chosen must have a

minimum insulation thickness of 15 Mils and should not have large variations in

insulation concentricity.

2.4.2 Motor Cable Lengths

Typically, motor lead lengths less than 91 meters (300 feet) are acceptable.

Installation/Wiring

2-5

Page 12

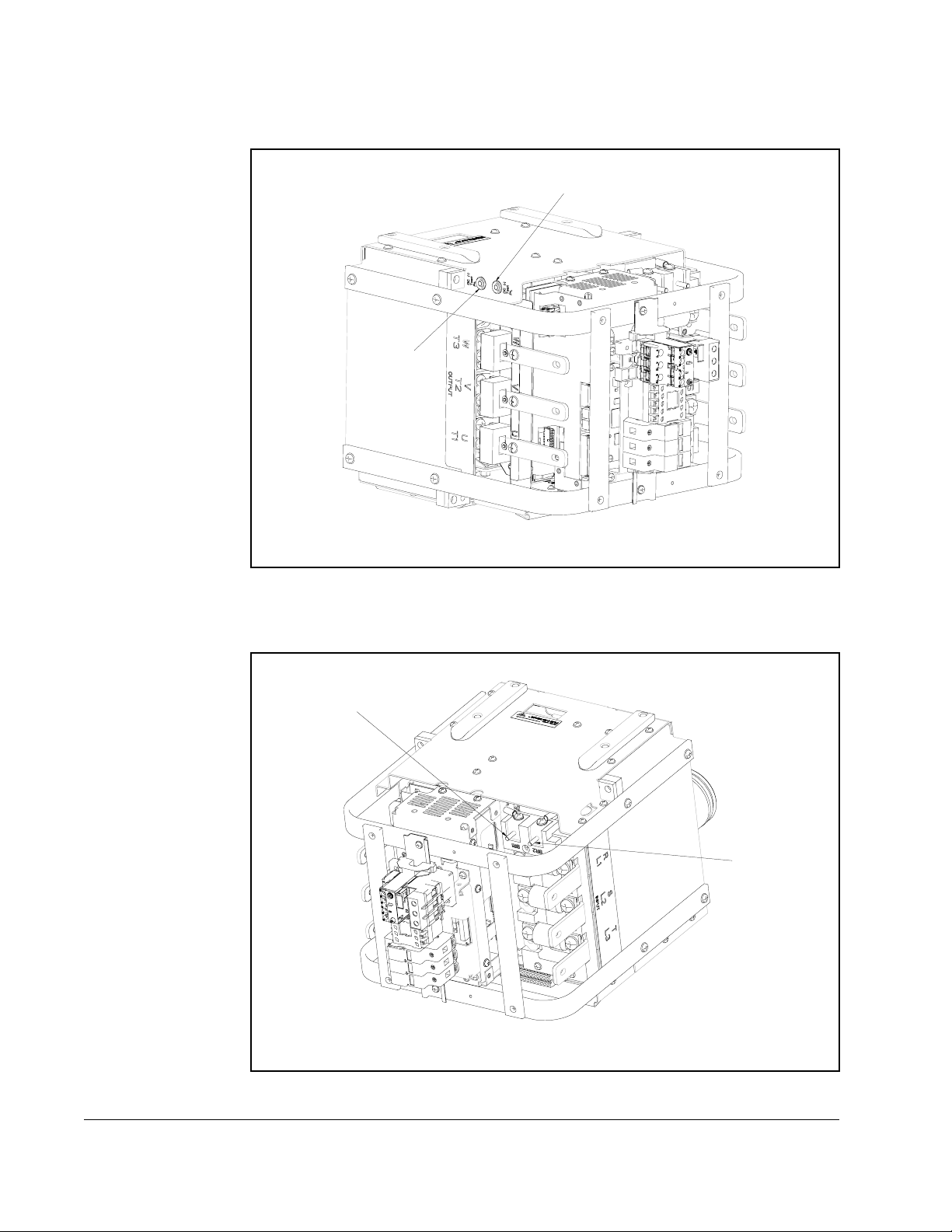

2.4.3 Power Termination Location Notes

BR1

BR2

(+) DC BUS

TEST POINT

(-) DC BUS

TEST POINT

Figure 2.3 – Power Termination Locations (DC+ and DC-)

2-6

Figure 2.4 – Power Termination Locations (BR1 and BR2)

DBT Reach Drive User Manual

Page 13

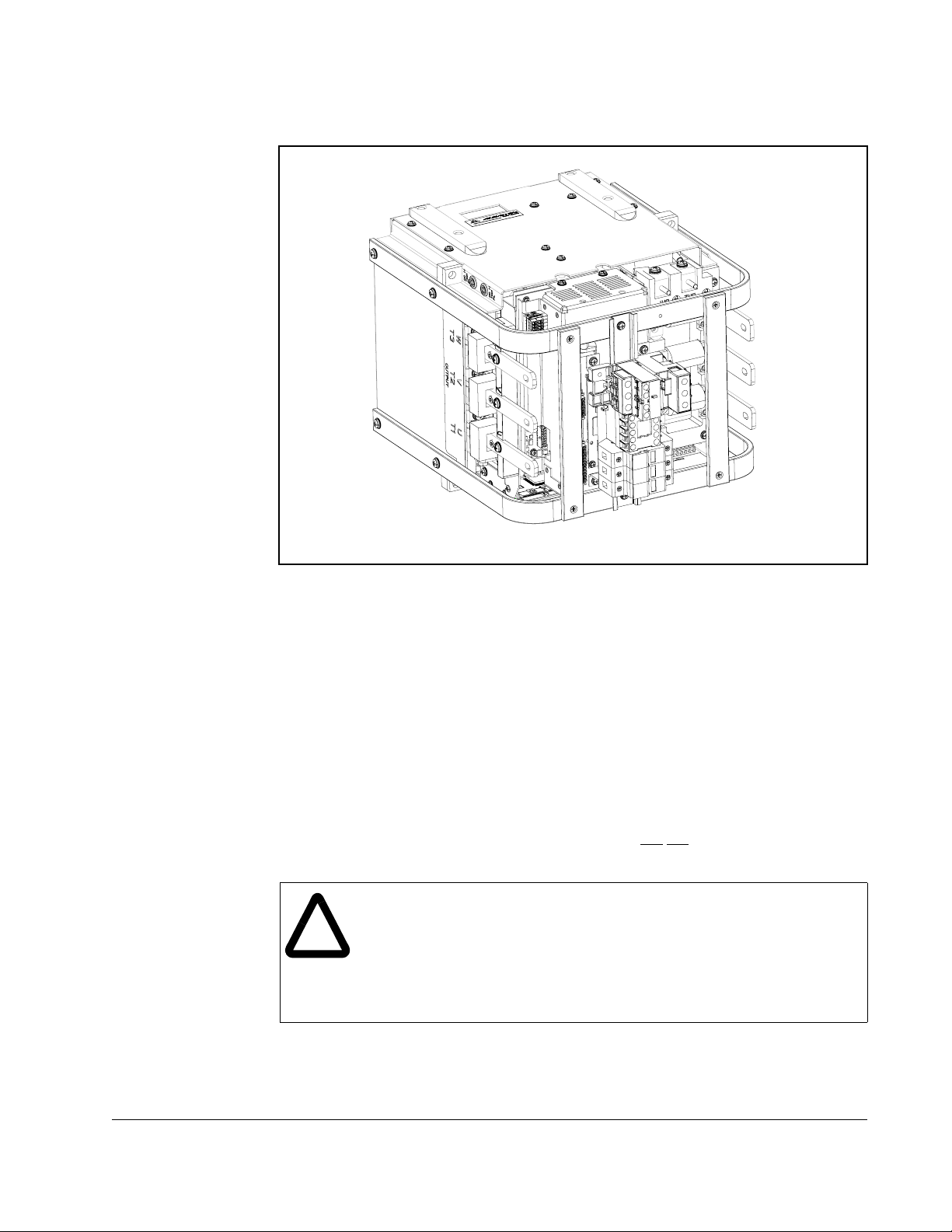

2.5 I/O Wiring

T

S

R

Important points to remember about I/O wiring:

• Use Copper wire only. Wire gauge requirements and recommendations are based

on 75 degrees C. Do not reduce wire gauge when using higher temperature wire.

• Wire with an insulation rating of 600V or greater is recommended.

• Control and signal wires should be separated from power wires by at least 0.3

meters (1 foot).

Figure 2.5 – Power Termination Locations (U, V, W, R, S, T)

Installation/Wiring

Important: I/O terminals labeled “(–)” or “Common” are

ground and are designed to greatly reduce common mode interference.

Grounding these terminals can cause signal noise.

ATTENTION:Configuring an analog input for 0-20mA operation and

driving it from a voltage source could cause component damage. Verify

!

proper configuration prior to applying input signals.

ATTENTION:Hazard of personal injury or equipment damage exists

when using bipolar input sources. Noise and drift in sensitive input circuits

can cause unpredictable changes in motor speed and direction. Use

speed command parameters to help reduce input source sensitivity.

not referenced to earth

2-7

Page 14

2.5.1 I/O Terminal Designations

Table 2.2 – I/O Terminal Designations

No. Signal

1

Analog In 1 (-)

2

Analog In 1 (+)

3

Analog In 2 (-)

4

Analog In 2 (+)

12

1

1

1

Factory

Default Description

1

16

32

Isolated3, bipolar, differential

+/- 10V/4-20mA, 11 bit and

sign, 88k ohm input

impedance. For 4-20mA, a

jumper must be installed at

terminals 17 and 18 (or 19

and 20).

Rel.

Param.

320327

5 Port Common - For (+) and (-) 10V port

references.

6 Analog Out 1 (-)

2

Bipolar (current output is not

bipolar), +/- 10V/4-20mA, 11

7 Analog Out 1 (+)

8 Analog Out 2 (-)

bit and sign, voltage mode limit current to 5 mA. Current

mode - maxz load resistance

9 Analog Out 2 (+)

is 400 ohms.

10 HW PTC Input 1 - 1.8k ohm PTC, Internal 3.32k

ohm pull-up resistor

11

Digital Out 1 - N.C.

4

Fault Max. Resistive Load:

240V AC/30V DC -- 1200VA,

12 Digital Out 1 Common

13

Digital Out 1 - N.O.

14

Digital Out 2 - N.C.

4

4

NOT

Fault

NOT

Run

150W

Max. Current: 5A, Min. Load

10mA

Max. Inductive Load:

240V AC/30V DC - 840VA,

105W

15 Digital Out 2/3 Com

16

Digital Out 3 - N.O.

4

Run

Max. Current: 3.5A, Min.

Load: 10mA

340347

238

259

380391

2-8

DBT Reach Drive User Manual

Page 15

Table 2.2 – I/O Terminal Designations

Factory

No. Signal

17

Current In Jumper

In 1

18

19

Current In Jumper

Analog In 2

20

1

- Analog

1

–

Default Description

Placing a jumper across

terminals 17 and 18 (or 19

and 20) will configure that

analog input for current.

(Parameter 320 must be set

ON.)

21 –10V Pot Reference – 2k ohm minimum load.

22 +10V Pot Reference –

23 HW PTC Input 1 – See above

24

+24VDC

5

– Drive supplied logic input

power.

5

25 Digital In Common –

26

24V Common

(5)

– Common for internal power

supply.

27 Digital In 1 Stop - CF115V AC, 50/60 Hz

- Opto

isolated

Low State: less than 30V AC

28 Digital In 2 Start

29 Digital In 3 Auto/M

an.

30 Digital In 4 Speed

Sel 1

High State: greater than 100V

AC

24V DC

- Opto isolated

Low State: less than 5V DC

High State: greater than 20V

DC

11.2 mA DC

31 Digital In 5 Speed

Sel 2

Rel.

Param.

361366

Installation/Wiring

32 Digital In 6/Hardware Enable Speed

Sel 3

1.

Important: 4-20mA operation requires a jumper at terminals 17 and 18 (or 19 and 20). Drive damage may

occur if jumper is not installed.

2.

These inputs/outputs are dependant on a number of parameters (see “Rel. Param.).

3.

Differential Isolation - External source must be maintained at less than 160V with respect to PE. Input

provides high common mode immunity.

4.

Contacts in unpowered state. Any relay programmed as Fault or Alarm will energize (pick up) when power

is applied to drive and deengergize (drop out) when a fault or alarm exists. Relays selected for other

functions will energize only when that condition exists and will deenergize when condition is removed.

5.

150mA maximum load. Not present on 115V versions.

2-9

Page 16

32 POSITION I/O PLUG

REMOVE FROM CONTROL PCB

TERMINATE WIRE HARNESS TO PLUG

THEN MATE PLUG TO HEADER AND

FASTEN SCREWS TO 7 in-lbs

SCREW ON PLUG

NUT ON PCB HEADER

Figure 2.6 – I/O Plug

2-10

DBT Reach Drive User Manual

Page 17

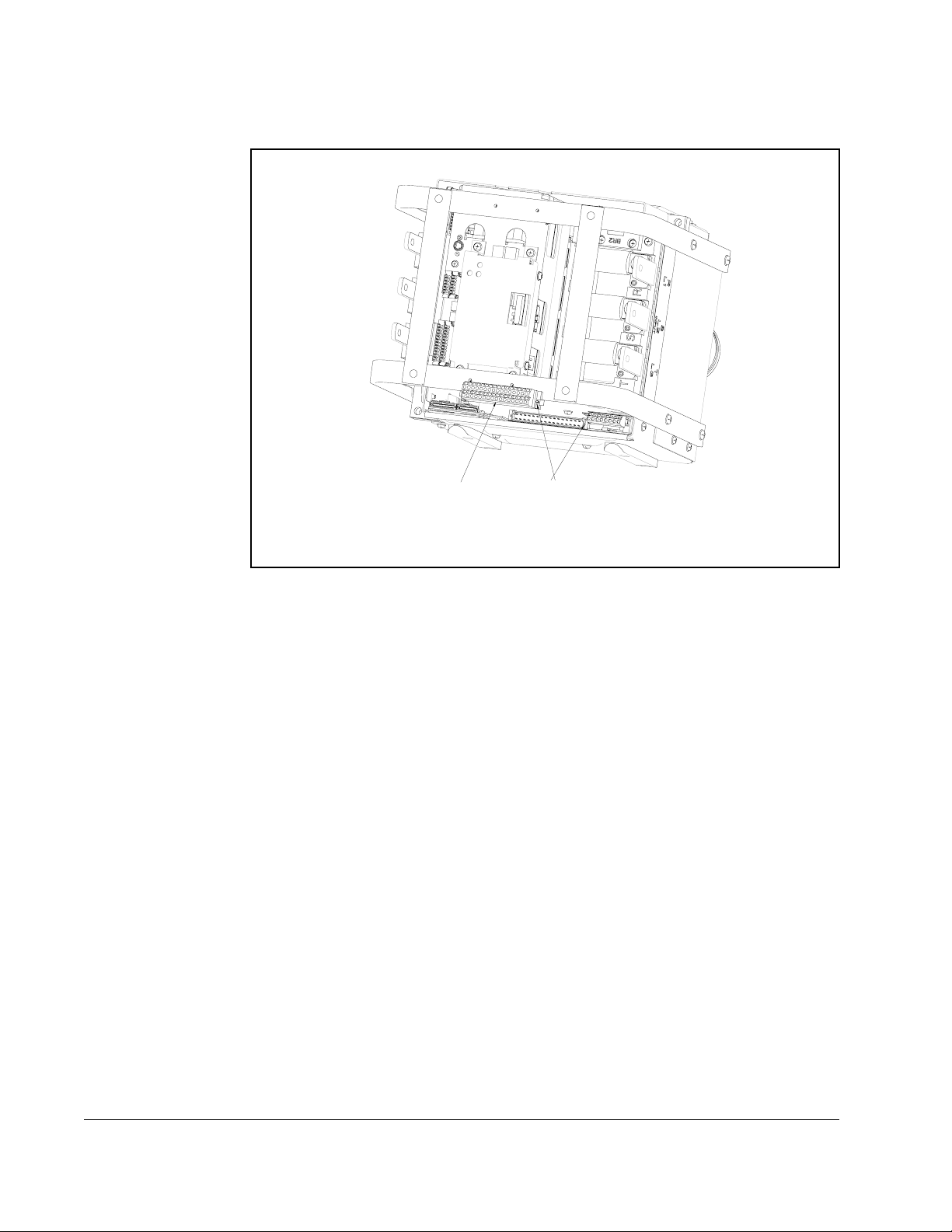

2.5.2 Encoder Terminal Block

Table 2.3 – Encoder Terminal Designations

No. Description

8

+12V

1

DC Power

7 +12V <Footnote>(1) DC

Return (Common)

8

6 Encoder Z (NOT) Pulse, marker or

5 Encoder Z

4 Encoder B (NOT) Quadrature B

3 Encoder B

1

2 Encoder A (NOT) Single channel

1 Encoder A

1.

Jumper selectable +5/12V is available on 20B-ENC-2 Encoder Boards only.

2.

Z channel can be used as a pulse input while A & B are used for encoder.

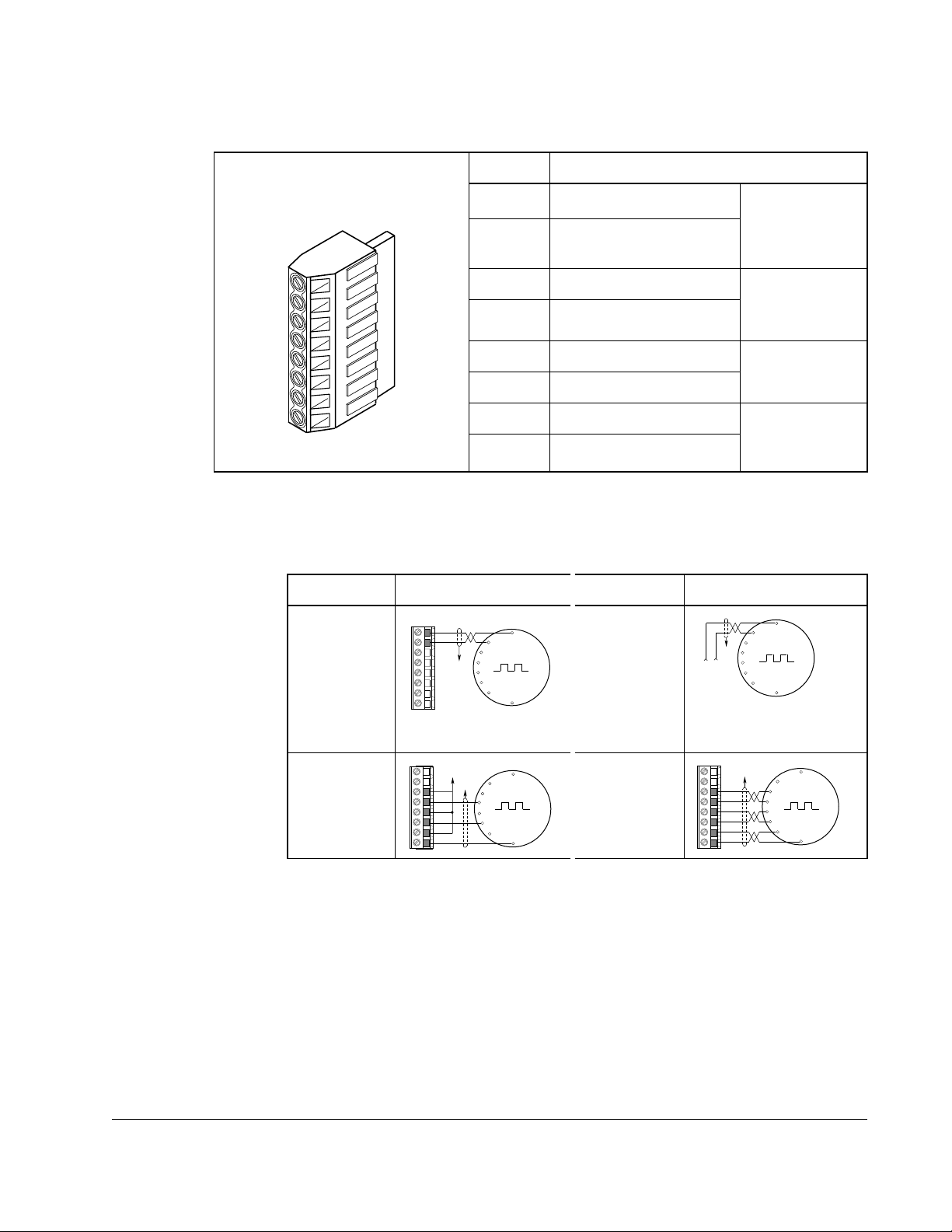

Table 2.4 – Sample Encoder Wiring

I/O Connection Example I/O Connection Example

Encoder

Power

1

–

Internal

Drive Power

Internal

+12V DC

(250 mA)

8

7

Common

6

5

to SHLD

4

3

2

1

Encoder

Power

–External

Power

Source

(drive) 12V

DC, 250mA

Internal power

source

250 mA.

registration

input.

input.

or quadrature A

input.

to

+

Common

SHLD

External

Power

Supply

2

Installation/Wiring

Encoder

Signal

–SingleEnded, Dual

Channel

1.

SHLD connection is on drive chassis.

to Power Supply

8

Common

7

6

5

4

3

2

1

Z NOT

Z

B NOT

B

A NOT

A

to SHLD

Encoder

Signal

–Differential,

Dual Channel

to SHLD

8

7

Z NOT

6

Z

5

B NOT

4

B

3

A NOT

2

A

1

2-11

Page 18

2.5.3 Signal and Control Wire Types

Table 2.5 – Recommended Signal Wire

Signal Type/

Where Used

B e l d e n W i r e T y p e ( s )

(or equivalent)

Description

Minimum

Insulation

Rating

Analog I/O

and PTC

Encoder/

Pulse I/O

<30 m (100

ft.)

Encoder/

Pulse I/O

30 to 152 m

(100 to 500

ft.)

Encoder/

Pulse I/O

152 to 259 m

(500 to 850

ft.)

8760/9460

8770

Combined:

Signal:

Power:

Combined:

Signal:

Power:

Combined:

2

9730

9730/9728

3

8790

4

9892

9730/9728

3

8790

9773/9774

2

0.750 mm

(18AWG),

twisted pair, 100% shield

with drain

0.750 mm

1

.

2

(18AWG), 3

cond., shielded for remote

pot only.

0.196 mm2(24AWG),

individually shielded.

2

0.196 mm2(24AWG),

individually shielded.

0.750 mm2(18 AWG)

0.330 mm2 or 0.500 mm2

4

2

0.196 mm2(24AWG),

individually shielded.

0.750 mm2(18 AWG)

5

0.750 mm2 (18 AWG) or

2

0.500 mm

, individually

shielded pair

300V,

75-90

degrees C

(167-194

degrees F)

2-12

1.

If the wires are short and contained within a cabinet which has no sensitive circuits, the use of shielded

wire may not be necessary, but is always recommended.

2.

9730 is 3 individually shielded pairs (2 channel + power). If 3 channel is required, use 9728.

3.

8790 is 1 shielded pair.

4.

9892 is 3 individually shielded pairs (3 channel), 0.332 (22 AWG) + 1 shielded pair 0.5 mm2 (20 AWG)

for power.

5.

9773 is 3 individually shielded pairs (2 channel + power). If channel 3 is required, use 9774.

DBT Reach Drive User Manual

Page 19

Table 2.6 – Recommended Control Wire for Digital I/O

Type Wire Type(s) Description

Minimum Insulation

Rating

Unshielded Per US NEC or applicable

national or local code

Shielded Multi-conductor shielded

cable such as Belden

8770(or equiv.)

– 300V,

60 degrees C

(140 degrees F)

0.750

2

(18AWG), 3

mm

conductor,

shielded.

Installation/Wiring

2-13

Page 20

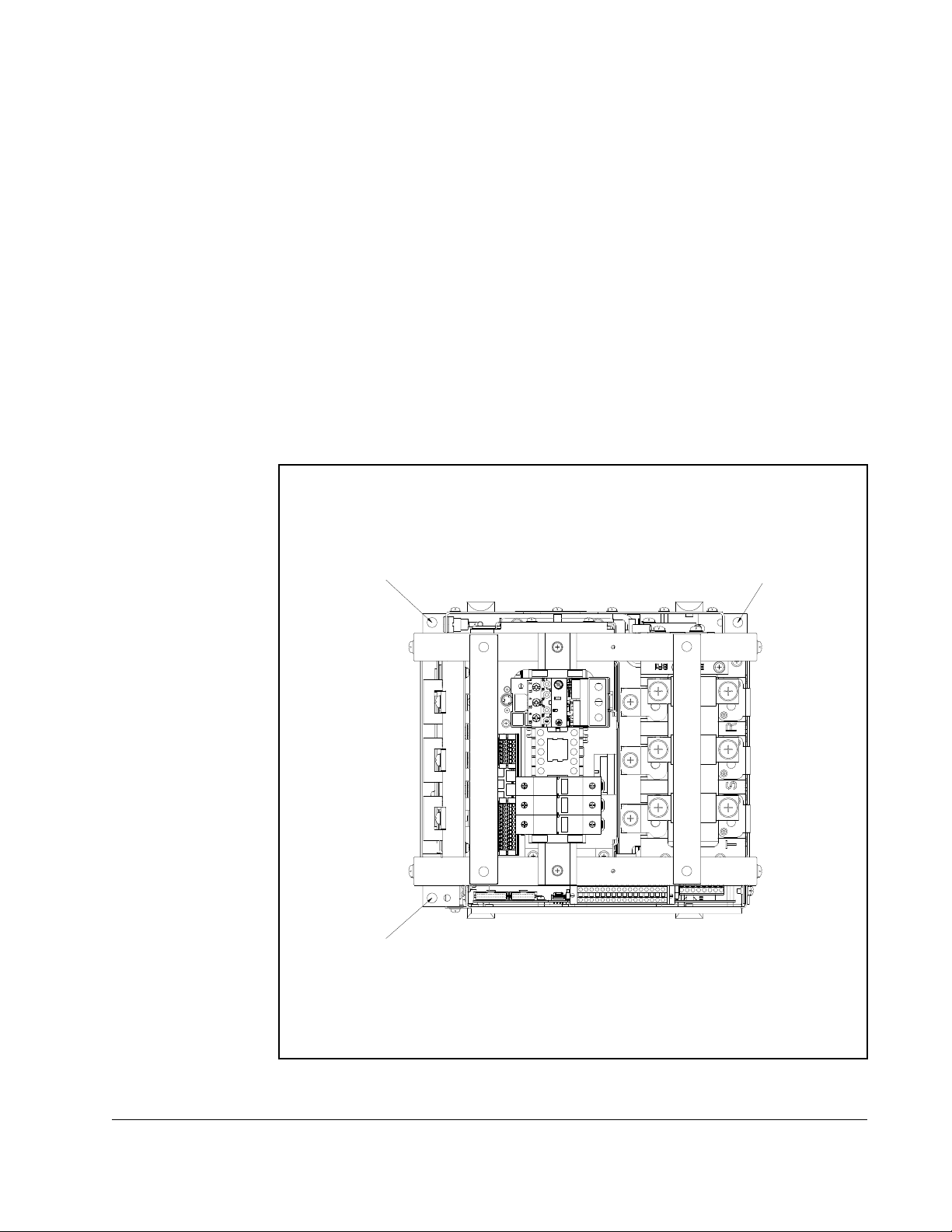

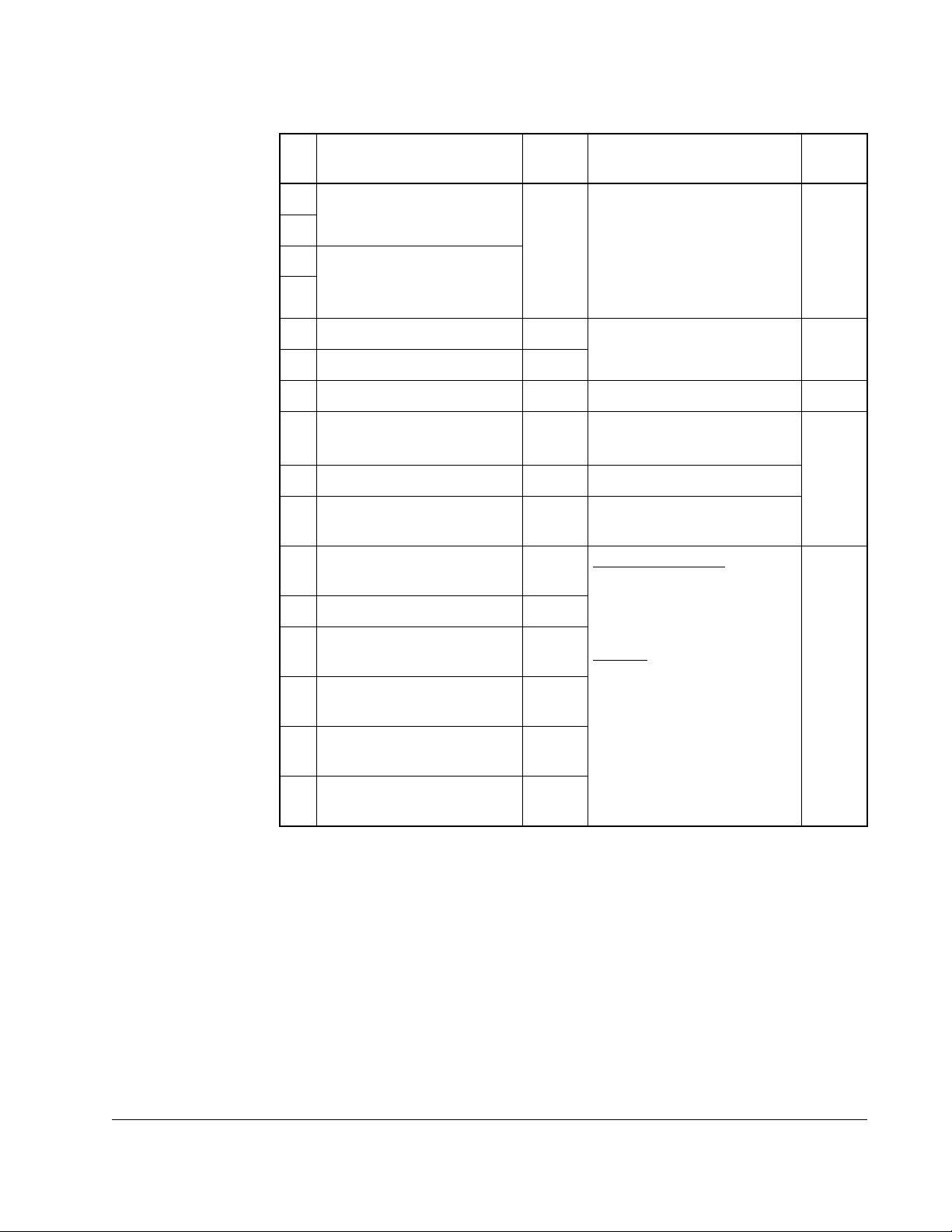

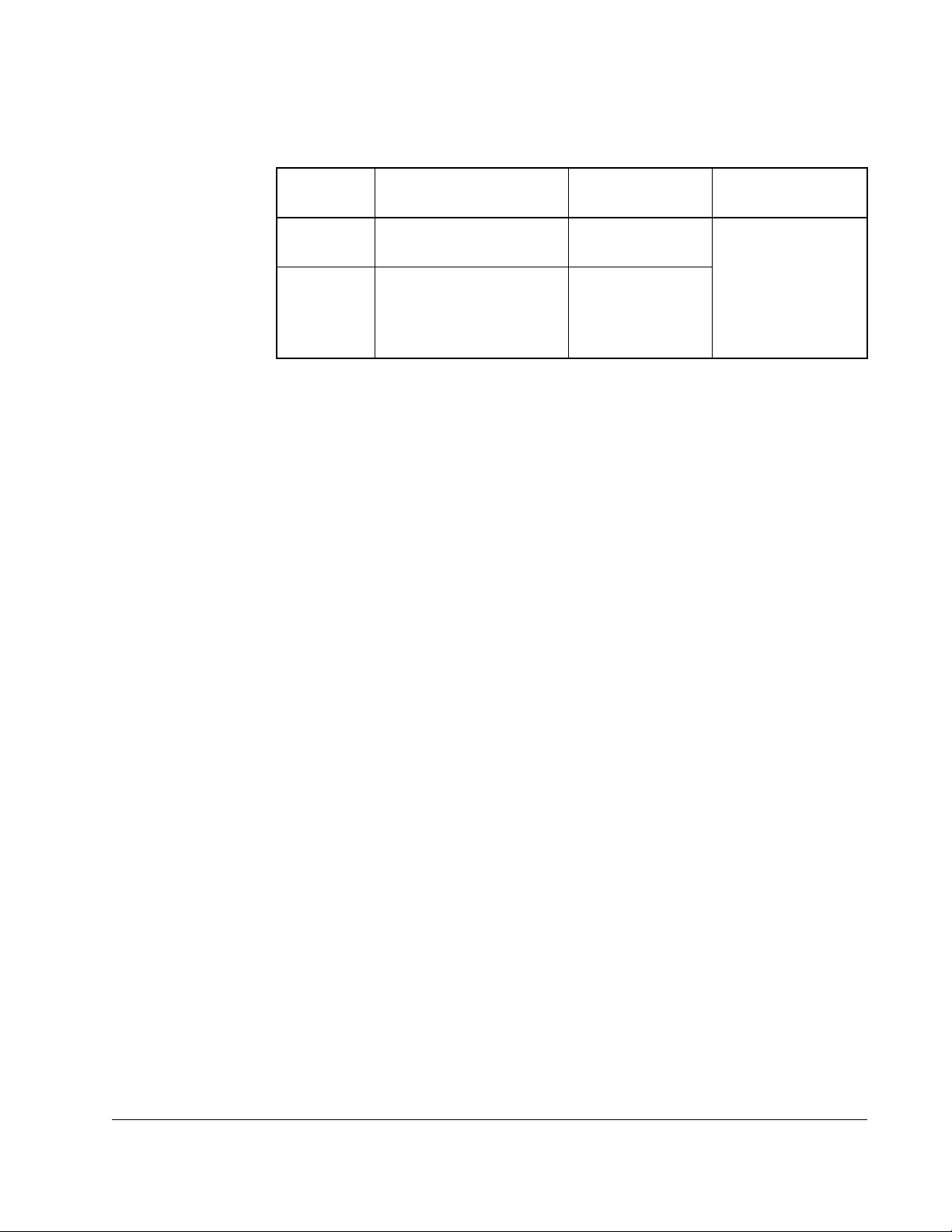

2.5.4 The I/O Control Board

4. Maximum/minimum sizes that the terminal block will accept - these are not recommendations.

4

Figure 2.2 shows the I/O control board and terminal block locations. The control board

provides a mounting point for the various Reach Drive I/O options. To remove the

cassette, loosen the two screw latches as shown in Figure 2.7. (A).

ATTENTION: You must stay within the minimum and maximum wire size

range. Failure to observe this precaution can result in severe equipment

!

damage, bodily injury, or loss of life.

2.5.5 I/O Terminal Blocks

No. Name Description Wire Size Range4 Torque

1

2

I/O

Terminal

Block

Encoder

Terminal

Block

Signal &

control

connections

Encoder

power &

signal

connections

Table 2.7 – I/O Terminal Block Specifications

Maximum Minimum Maximum Recommended

2.1 mm

2

(14 AWG)

0.30

mm

2

0.6 N-m

(5.2 lb.-in.)

(22

AWG)

0.75 mm

(18 AWG)

2

0.196

2

mm

0.6 N-m

(5.2 lb.-in.)

(24

AWG)

JUMPER

0.6 N-m

(5.2 lb.-in.)

0.6 N-m

(5.2 lb.-in.)

PIN 1

1

2

Figure 2.7 – Reach Drive Typical Control Board and I/O Terminal Blocks

2-14

A

PIN 1

DBT Reach Drive User Manual

Page 21

2.5.6 Hardware Enable Circuitry

By default, the user can program a digital input as an Enable input. The status of this

input is

disabled

can be utilized. This is done by removing a jumper and wiring the enable input to

“Digital In 6.” (See tables 2.5 and 2.6 for more information).

1. Remove the I/O Control board.

2. Locate and remove Jumper 10 on the Main Control Board (see Figure 2.7).

3. Re-assemble the I/O Control board.

4. Wire enable to Digital In 6.

5. Verify that Digital In6 Sel (366) is set to “1, Enable.”

interpreted by drive software

without

software interpretation, a “dedicated” hardware enable configuration

. If the application requires the drive to be

2.5.7 Resistance Temperature Detector (RTD) Board

Up to eight RTD or NTC (negative temperature coefficient) temperature sensors are

supported by the Reach Drive RTD board. The number of I/O required from an upper

level controller to utilize the RTD Board can be managed by selecting one of several

configuration options.

Installation/Wiring

2-15

Page 22

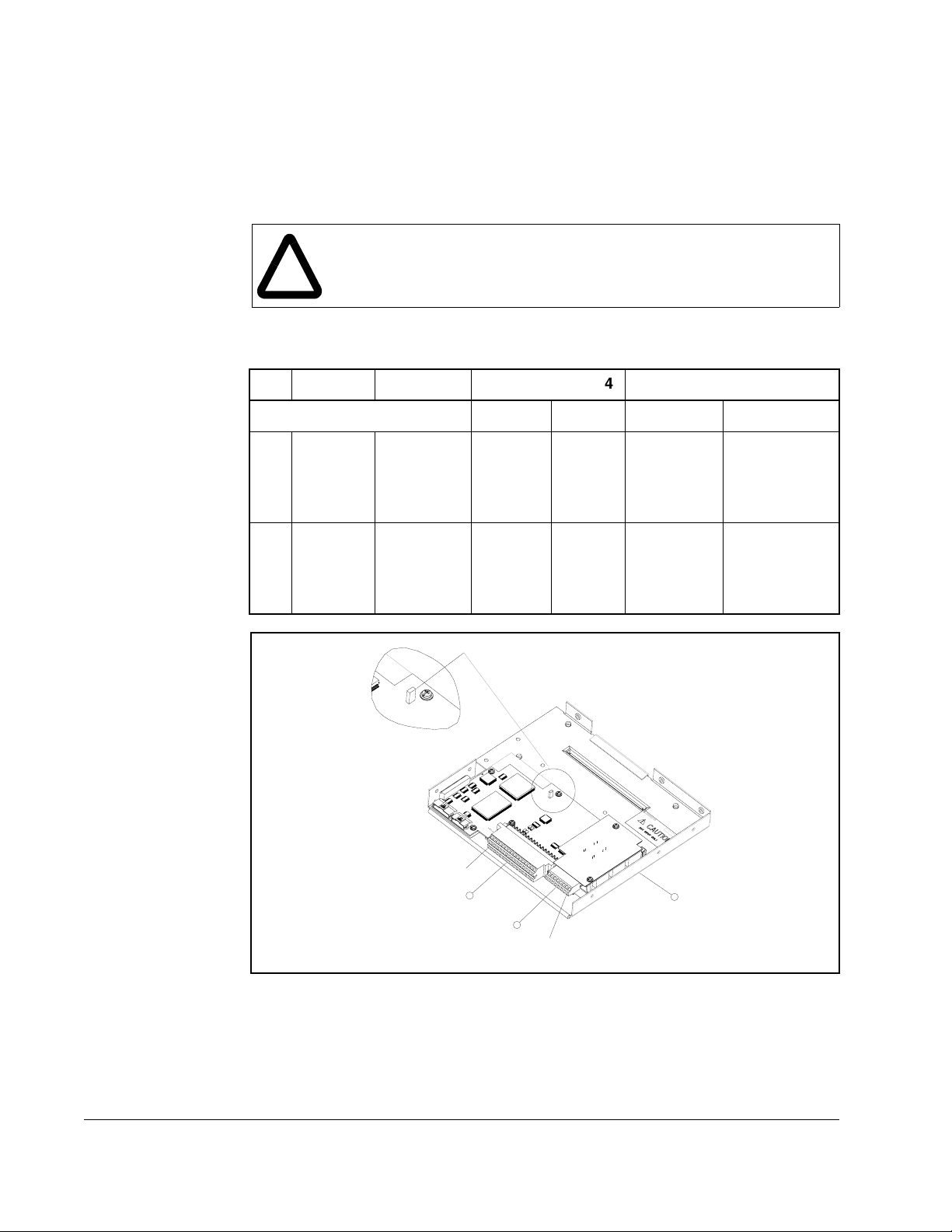

PIN 1

PIN 6

RTD PC BOARD

PIN 1

PIN 12

2-16

RTD PC BOARD ASSEMBLED IN ENCLOSURE

Figure 2.8 – RTD Board

DBT Reach Drive User Manual

Page 23

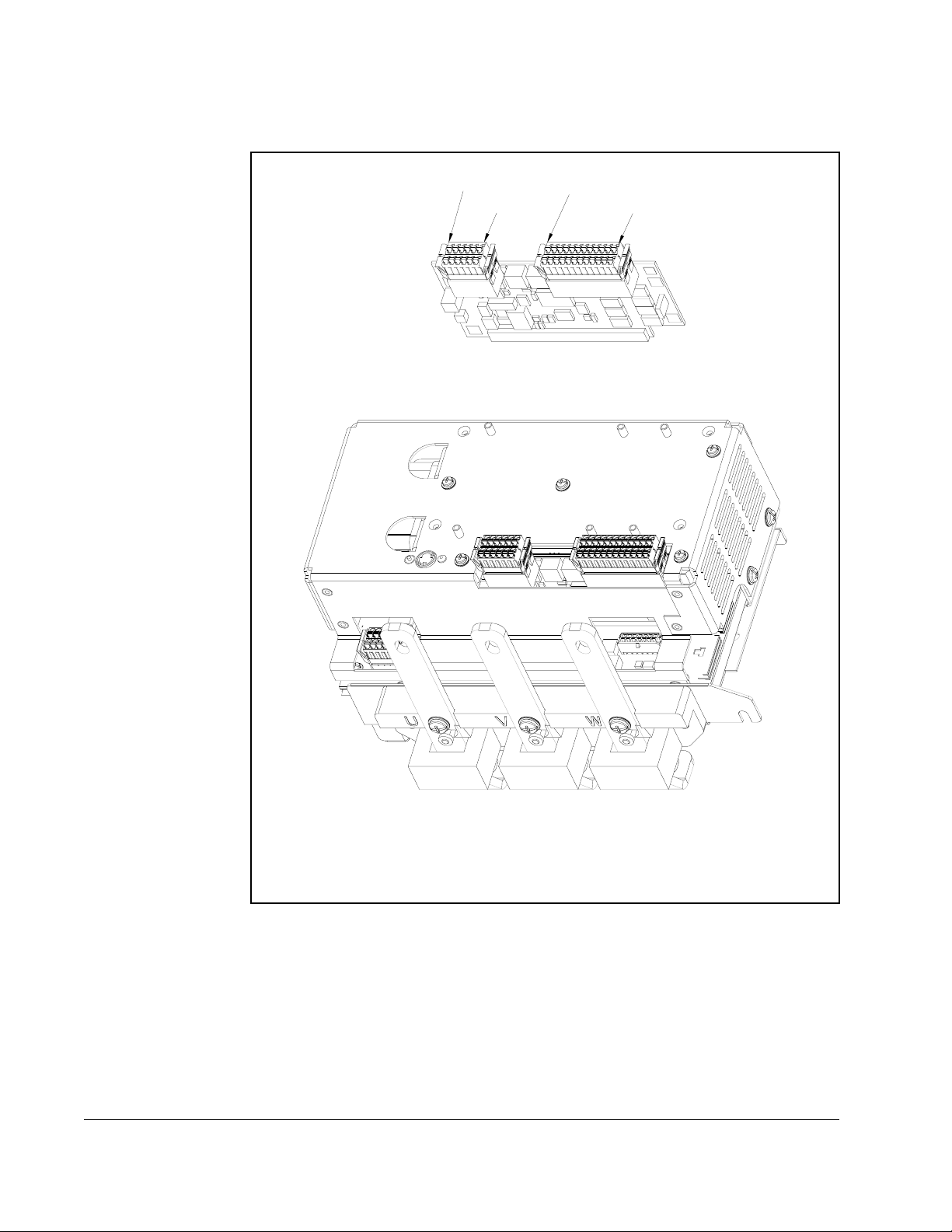

2.5.7.1 Connections

Gain

123

Mode

Time

123

24

13

112

712

16

S1 S2 J3 - I/OJ2 - RTD Inputs J2

Figure 2.9 – RTD Board Connections

Table 2.8 – J2 RTD Board I/O Function

Position I/O Function

1 +24V COM

2LOUT1 COM

3LOUT2 COM

4LOUT3 COM

5LIN COM

6AOUT COM

7 +24VDC

8LOUT1 NO

9LOUT2 NO

10 LOUT3 NO

11 LIN

12 AOUT

Important: A motor temperature sensor (RTD, NTC, or thermocouple) should be

2.5.7.2 Hardware

The hardware consists of a single PC board with two wired connectors, one for

temperature sensors and the second for power and I/O signals.

considered equivalent to a motor thermostat and wired with the same

considerations. Motor thermostat contacts are generally not isolated from

the drive/controller digital inputs. Therefore, the sensor inputs will not be

isolated on the RTD board.

Installation/Wiring

2-17

Page 24

RTD/NTC Sourcing

A 2-wire RTD or NTC temperature sensor may be used. A chassis connection is

available for each sensor for use with shielded cable. Each channel requires up to

three connections.

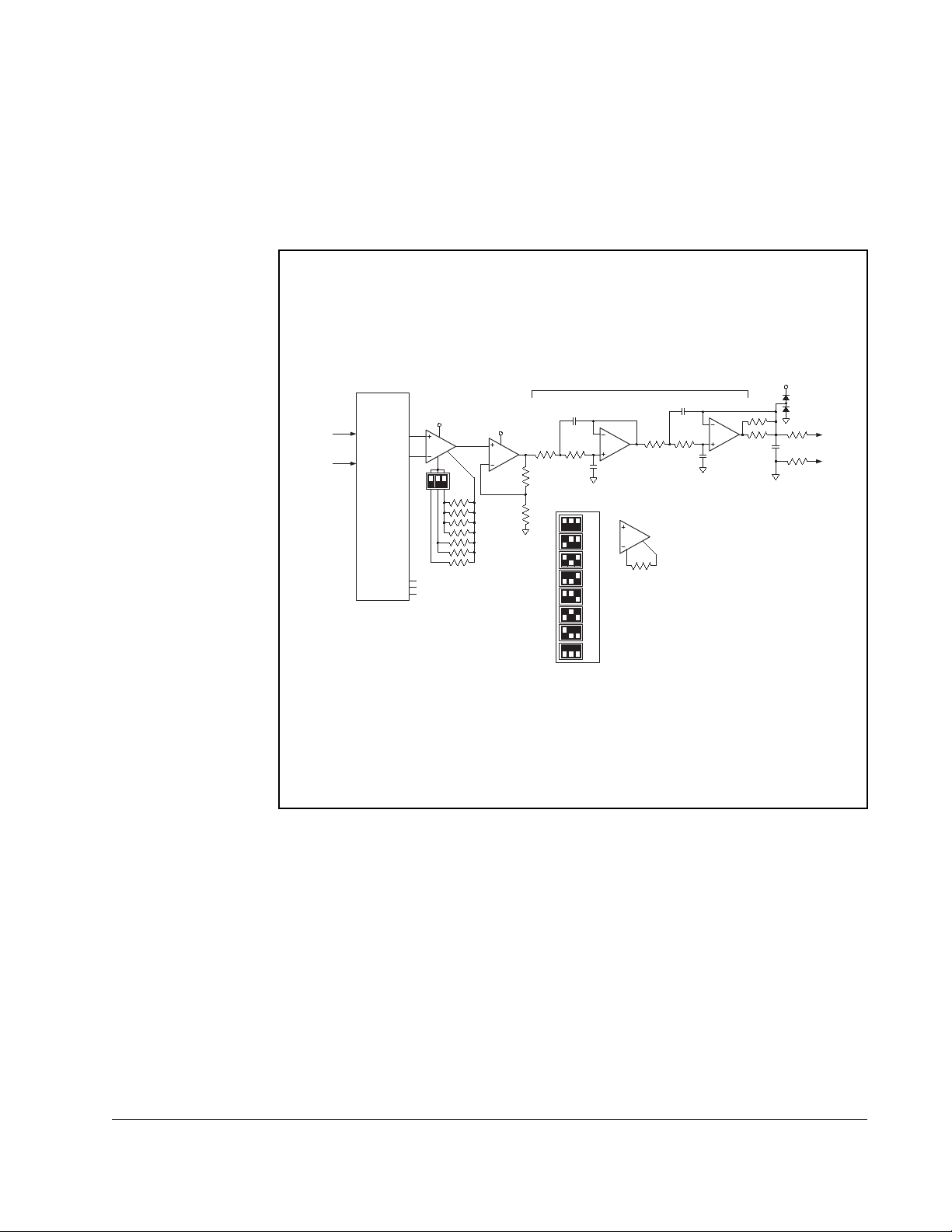

Multiplexer and Amplifier

An analog multiplexer sequentially connects the temperature sensors one at a time to

the analog output. The active sensor channel is indicated by a 3-bit output (A0-A2).

When using an RTD or NTC, a simple voltage divider is formed and the device is

probed differentially.

The sensor voltages are amplified using a high-quality, rail-to-rail instrumentation

amplifier with gain adjustment. To accomodate a variety of sensors and temperature

ranges, an amplifier boosts the analog sensor voltage in order to increase the

temperature resolution. Discrete gains of x10 through x80 are selectable through DIP

switch settings. A 4th order low pass filter rejects normal-mode noise at the analog

input with a cutoff frequency of approximately 16 Hz.

To determine the proper gain setting:

1. Determine R

, the maximum resistance of the sensor over the temperature

MAX

range to be measured.

2. Determine the maximum voltage across R

V

= 1.00V X

MAX

3. Select the largest gain that results in V

R

MAX

MAX

than 10 volts.

using the following equation:

MAX

/ (

R

+ 998)

MAX

* Gain (x10, x20, or x40), being less

2-18

DBT Reach Drive User Manual

Page 25

Example:

Using a 100 Ohm Pt RTD (a=0.00385) to measure temperatures from 0 degrees

Celsius to 200 degrees Celsius, the maximum resistance occurs at 200 degrees

Celsius and is approximately 177 Ohm. The maximum voltage across the sensor is

151 mV. If the x40 gain is used, the output voltage at 200 degrees Celsius is 6.04

Volts.

NTC/RTD

Sourcing

SA (1 of 8)

SB (1 of 8)

Analog Multiplexer

F

x10

x20

x30

x40

x50

x60

x70

x80

4th Order Low Pass Filter

MAX4194

Gain = 1 + 50K/Rg

Instrumentation Amp

Gain Adjustable

DA

DB

A0

Channel

A1

Address

A2

MAX4194

Rail-to-Rail

5V

S1

50K

12V

x10

100K

11.1K

F

100K 100K

Gain Adjust

DIP Switch Settings, S1

(overall gain)

up

down

Figure 2.10 – Scaled Analog Output for RTD Board

F

= 16Hz

C

100K 100K

LMC6484

Quad Op Amp

Rail-to-Rail

Rg

F

F

0.01 F

12V

10

Analog

Out

0-10V

10

Installation/Wiring

Digital I/O

The digital outputs are isolated with solid state relays. The outputs are internally short

circuit protected. The digital input is optically isolated.

2.5.7.3 Microcontroller Software

A microcontroller monitors three DIP switches to determine the operational mode of

the RTD board. A single “Mode” switch determines whether the board uses an internal

timebase or the digital input as a clock to step through the eight analog input

channels. When using the internal timebase, the other two DIP switches select one of

four clock periods.

2-19

Page 26

When the “Mode” switch is up (open) the board uses the digital input as an

enable/reset. When the board’s digital input is inactive (open or ground), the analog

output is held at the first channel. When the digital input is active (24V), the

microcontroller sequentially cycles through the eight temperature sensor channels.

Each channel is available at the analog output for the selected period of time. After the

eighth channel is completed, the cycle begins again with the first channel.

Deactivating the digital input will asynchronously reset the sequence back to the first

channel. The “Period” jumpers/dip switches select one of four time periods between

temperature sensor channels.

Table 2.9 – Microcontroller Settings

Period S2-2 S2-3

1 second Down Down

10 seconds Up Down

30 seconds Down Up

60 seconds Up Up

When the “Mode” switch (S2-1) is down (closed) the board uses the digital input as an

external clock to sequentially cycle through the eight temperature sensor channels.

The analog output channel advances with both the rising and falling edges of the

digital input. In both modes the active channel is output as a 3-bit binary address on

the RTD board’s digital outputs. An inactive output (open) indicates a “0.” When using

the digital input as an external clock, it may be necessary to monitor the address lines

in order to maintain synchronization with the controller. When using the internal clock

mode, the digital outputs may be ignored to reduce the required number of I/O. In

either mode, the board’s digital input is debounced with a period of 50mS.

2-20

DBT Reach Drive User Manual

Page 27

CHAPTER 3

Parameter Descriptions

The following information is provided for each parameter along with its description:

Parameter Number: Unique number assigned to each parameter.

Parameter Name: Unique name assigned to each parameter.

Range: Predefined parameter limits or selections. Note that a

negative Hz value indicates reverse rotation.

Default: Factory default setting.

Access: Parameter access level.

0 = Basic (reduced parameter set)

1 = Standard

2 = Advanced (full parameter set)

Path: Menu selections to reach specified parameter. The path is

indicated in this manner: File>Group

See also: Associated parameters that may provide additional or

related information.

What the Symbols Mean

Symbol Meaning

Drive must be stopped before changing parameter value.

Parameter is only displayed when Motor Cntl Sel (53) is set to

FV

The parameters are presented in numerical order.

“4.” (FVC Vector)

Parameter Descriptions

3-1

Page 28

3.1 Parameters

1 Output Freq

Range: +/-400.0 Hz [0.1 Hz]

Default: Read Only

Access: 0 Path: Monitor>Metering

See also:

The output frequency present at T1, T2, and T3 (U, V, and W).

2 Commanded Speed

Range: +/- [P.082 Maximum Speed] [0.1 Hz or 0.1 RPM]

Default: Read Only

Access: 0 Path: Monitor>Metering

See also: 79

The value of the active Speed/Frequency Reference. Displayed in Hz or RPM,

depending on value of Speed Units (79).

3 Output Current

Range: 0.0 to Drive Rated Amps x 2 [0.1 A]

Default: Read Only

Access: 0 Path: Monitor>Metering

See also:

The total output current present at T1, T2, and T3 (U, V, and W).

4 Torque Current

Range: Drive Rating x -2/+2 [0.1 A]

Default: Read Only

Access: 1 Path: Monitor>Metering

See also:

The amount of current that is in phase with the fundamental voltage component.

5 Flux Current

Range: Drive Rating x -2/+2 [0.1 A]

Default: Read Only

Access: 1 Path: Monitor>Metering

See also:

3-2

The amount of current that is out of phase with the fundamental voltage component.

DBT Reach Drive User Manual

Page 29

6 Output Voltage

Range: 0.0 to Drive Rated Volts [0.1 VAC]

Default: Read Only

Access: 0 Path: Monitor>Metering

See also:

The output voltage present at terminals T1, T2, and T3 (U, V, and W).

7 Output Power

Range: 0 to Drive Rated kW x 2 [0.1 kW]

Default: Read Only

Access: 0 Path: Monitor>Metering

See also:

The output power present at T1, T2, and T3 (U, V, and W).

8 Output Powr Fctr

Range: 0.00 to 1.00 [0.01]

Default: Read Only

Access: 2 Path: Monitor>Metering

See also:

The output power factor.

9Elapsed MWh

Range: 0.0 to 214,748,352.0 MWh [0.1 MWh]

Default: Read Only

Access: 2 Path: Monitor>Metering

See also:

The accumulated output energy of the drive.

10 Elapsed Run Time

Range: 0.0 to 214,748,352.0 Hr [0.1 Hr]

Default: Read Only

Access: 1 Path: Monitor>Metering

See also:

The accumulated time the drive has been outputting power.

Parameter Descriptions

3-3

Page 30

11 MOP Reference

Range: +/- [Maximum Speed] [0.1 Hz or 0.1 RPM]

Default: Read Only

Access: 1 Path: Monitor>Metering

See also: 79

The value of the signal at the MOP (Motor-Operated Potentiometer).

12 DC Bus Voltage

Range: 0 to Based on Drive Rating [0.1 VDC]

Default: Read Only

Access: 1 Path: Monitor>Metering

See also:

The present DC bus voltage level.

13 DC Bus Memory

Range: 0 to Based on Drive Rating [0.1 VDC]

Default: Read Only

Access: 2 Path: Monitor>Metering

See also:

A six-minute average of the DC bus voltage level.

14 Elapsed kWh

Range: 0 to 429,496,729.5 kWh [0.1 kWh]

Default: Read Only

Access: 1 Path: Monitor>Metering

See also:

The accumulated output energy of the drive.

1617Analog In1 Value

Analog In2 Value

Range: 0.000 to 20.000 mA [0.001 mA]

-/+10.000 V [0.001 V]

Default: Read Only

Access: 1 Path: Monitor>Metering

See also:

The value of the signal of the analog input.

3-4

DBT Reach Drive User Manual

Page 31

18 PTC HW Value

Range: 0.00 to 5.00 Volts [0.01 Volts]

Default: Read Only

Access: 2 Path: Monitor>Metering

See also:

This parameter displays the value present at the drive’s PTC input terminals. When a

motor is provided with a PTC (positive temperature coefficient) thermal sensor, it can

be connected to terminals 10 and 23.

21 Spd Fdbk No Filt

Range:

Default: Read Only

Access: 2 Path: Monitor>Metering

See also:

Displays the unfiltered value of the actual motor speed based on either the measured

encoder feedback or on an estimation when an encoder is not present.

22 Ramped Speed

Range: +/- 400.0 Hz or +/- 24,000.0 RPM [0.1 Hz or 0.1 RPM]

Default: Read Only

Access: 1 Path: Monitor>Metering

See also: 79

The value of commanded speed after Accel/Decel and S-Curve are applied.

23 Speed Reference

Range: +/- 400.0 Hz or +/- 24,000.0 RPM [0.1 Hz or 0.1 RPM]

Default: Read Only

Access: 0 Path: Monitor>Metering

See also: 79

The summed value of ramped speed, process PI and droop. When FVC Vector mode

is selected, droop will not be added

Parameter Descriptions

3-5

Page 32

24 Commanded Torque

FV

Range: +/- 800.0% [0.1%]

Default: Read Only

Access: 0 Path: Monitor>Metering

See also: 53

The final torque reference value after limits and filtering are applied. Percent of motor

rated torque.

25 Speed Feedback

Range: +/- 400.0 Hz or +/- 24,000.0 RPM [0.1 Hz or 0.1 RPM]

Default: Read Only

Access: 1 Path: Monitor>Metering

See also:

Displays the lightly filtered value of the actual motor speed based on measured

encoder feedback or an estimation.

26 Rated kW

Range: 0.00 to 3000.00 kW [0.01 kW]

Default: Read Only

Access: 0 Path: Monitor>Drive Data

See also:

3-6

The drive power rating.

27 Rated Volts

Range: 0.0 to 65535.0 VAC [0.1 VAC]

Default: Read Only

Access: 0 Path: Monitor>Drive Data

See also:

The drive input voltage class (208, 240, 400, etc.).

28 Rated Amps

Range: 0.0 to 6553.5 Amps [0.1 Amps]

Default: Read Only

Access: 0 Path: Monitor>Drive Data

See also:

DBT Reach Drive User Manual

Page 33

The drive rated output current.

29 Control SW Ver

Range: 0.000 to 65535.000 [0.001]

Default: Read Only

Access: 0 Path: Monitor>Drive Data

See also: 196

The Main Control board software version.

40 Motor Type

Range: 0 = Induction

Default: 0 = Induction

Access: 2 Path: Motor Control>Motor Data

See also: 53, 157, 158, 159

Set to match the type of motor connected: Induction, Synchronous Reluctance, or

Synchronous Permanent Magnet.

Important: Selecting option 1 or 2 also requires selection of “Custom V/Hz,” option 2

1 = Synchr Reluc

2 = Synchr PM

in Motor Cntl Sel (53).

41 Motor NP Volts

Range: 0.0 to Drive Rated Volts [0.1 VAC]

Default: Based on Drive Rating

Access: 1 Path: Motor Control>Motor Data

See also:

Set to the motor nameplate rated volts. The motor nameplate base voltage defines the

output voltage when operating at rated current, rated speed, and rated temperature.

42 Motor NP FLA

Range: 0.0 to Rated Amps x 2 [0.1 Amps]

Default: Based on Drive Rating

Access: 1 Path: Motor Control>Motor Data

See also: 47, 48

Set to the motor nameplate rated full load amps. The motor nameplate FLA defines

the output amps when operating at rated voltage, rated speed, and rated temperature.

It is used in the motor thermal overload and in the calculation of slip.

Parameter Descriptions

3-7

Page 34

43 Motor NP Hertz

Range: 5.0 to 400.0 Hz [0.1 Hz]

Default: Based on Drive Type

Access: 1 Path: Motor Control>Motor Data

See also:

Set to the motor nameplate rated frequency. The motor nameplate base frequency

defines the output frequency when operating at rated voltage, rated current, rated

speed, and rated temperature.

44 Motor NP RPM

Range: 60.0 to 25200.0 RPM [0.1 RPM]

Default: 1780 RPM

Access: 1 Path: Motor Control>Motor Data

See also:

Set to the motor nameplate rated RPM. The motor nameplate RPM defines the rated

speed when operating at motor nameplate base frequency, rated current, base

voltage, and rated temperature. This is used to calculate slip.

45 Motor NP Power

Range: 0.00 to 1000.00 [0.01 kW or 0.01 HP]

Default: Based on Drive Type

Access: 1 Path: Motor Control>Motor Data

See also: 46

3-8

Set to the motor nameplate rated power. The motor nameplate power is used with the

other nameplate values to calculate default values for motor parameters to assist the

commissioning process. This may be entered in horsepower or in kilowatts as

selected in Mtr NP Pwr Units (46).

46 Mtr NP Pwr Units

Range: 0 = Horsepower (changes power units to HP without rescaling values)

1 = kilowatts (changes power units to kW without rescaling values)

2 = Convert HP (Converts all power units to HP and rescales values)

3 = Convert kW (changes power units to kW and rescales values)

Default: Based on Drive Rating

Access: 2 Path: Motor Control>Motor Data

See also:

Selects the motor power units to be used. This parameter determines the units for

Motor NP Power (45).

Convert HP = Converts all power units to Horsepower.

Convert kW = Converts all power units to kilowatts.

DBT Reach Drive User Manual

Page 35

47 Motor OL Hertz

Range: 0.0 to Motor NP Hz [0.1 Hz]

Default: Motor NP Hz/3

Access: 2 Path: Motor Control>Motor Data

See also: 42, 220

Selects the output frequency below which the motor operating current is derated. The

motor thermal overload will then generate a fault at lower levels of current.

48 Motor OL Factor

Range: 0.20 to 2.00 [0.1]

Default: 1.00

Access: 2 Path: Motor Control>Motor Data

See also: 42, 220

Sets the amps threshold for motor overload fault.

Motor FLA x OL Factor = Operating Level

49 Motor Poles

Range: 2 to 40 [1 Pole]

Default: 4

Access: 0 Path: Motor Control>Motor Data

See also:

Defines the number of poles in the motor.

53 Motor Cntl Sel

Range: 0 = Sensrls Vect

Default: 0 = Sensrls Vect

Access: 2 Path: Motor Control>Torq Attributes

See also: 80

Sets the method of motor control used in the drive.

Important: “FVC Vector” mode with encoder feedback requires autotuning of the

Sensrls Vect = Maintains consistent magnetizing current up to base speed. Voltage

increases as a function of load.

1 = SV Economize

2 = Custom V/Hz

3 = Fan/Pmp-V/Hz

4 = FVC Vector

motor, both coupled and uncoupled to the load. Being coupled to the load

will determine inertia (preferably lightly loaded). Total Inertia (450) will

have to be estimated if uncoupled for tuning of the speed loop or

separately adjust Ki (445) and Kp (446).

Parameter Descriptions

3-9

Page 36

SV Economize = Allows the drive to automatically adjust output voltage as the load

changes to minimize current supplied to the motor. The voltage is adjusted by means

of flux current adaptation.

Custom V/Hz = Allows the user to tailor the volts/hertz curve by adjusting parameters

Maximum Voltage (54), Maximum Frequency (55), Run Boost (70), Break Voltage (71)

and Break Frequency (72).

Fan/Pmp V/Hz = This mode sets a fan load volts/hertz curve profile exponential to

base frequency (and linear from base to maximum frequency). Run Boost (70) can

offset the low speed curve point.

FVC Vector = This mode requires autotuning of the motor, both coupled and

uncoupled to the load.

54 Maximum Voltage

Range: (Rated Volts x 0.25) to Rated Volts [0.1 VAC]

Default: Drive Rated Volts

Access: 2 Path: Motor Control>Torq Attributes

See also:

Sets the highest voltage the drive will output.

55 Maximum Freq

Range: 5.0 to 420.0 Hz [0.1 Hz]

Default: 110.0 or 130.0 Hz

Access: 2 Path: Motor Control>Torq Attributes

See also: 83

Sets the maximum allowable frequency the drive will output. Note that this is not

maximum speed, which is set in parameter 82. Refer to figure 3.1.

ATTENTION: The user is responsible for ensuring that the driven

machinery, all drive-train mechanisms, and application material are

!

capable of safe operation at the maximum operating speed of the drive.

Overspeed detection in the drive determines when the drive shuts down.

The factory default for overspeed detection is set to 10.0 Hz (or 300.0

RPM) greater than the Maximum Speed (82). Failure to observe this

precaution could result in equipment damage, sever injury or loss of life.

3-10

DBT Reach Drive User Manual

Page 37

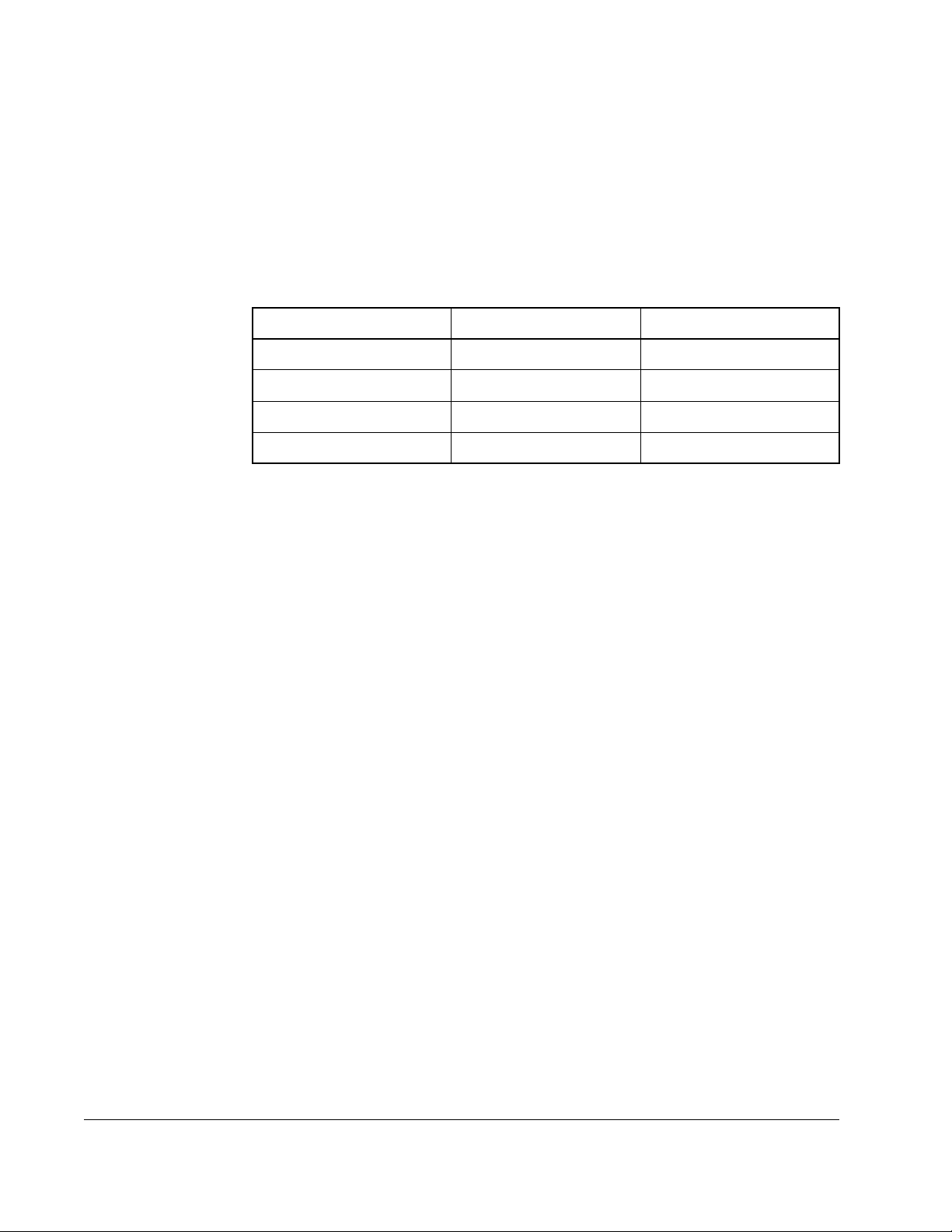

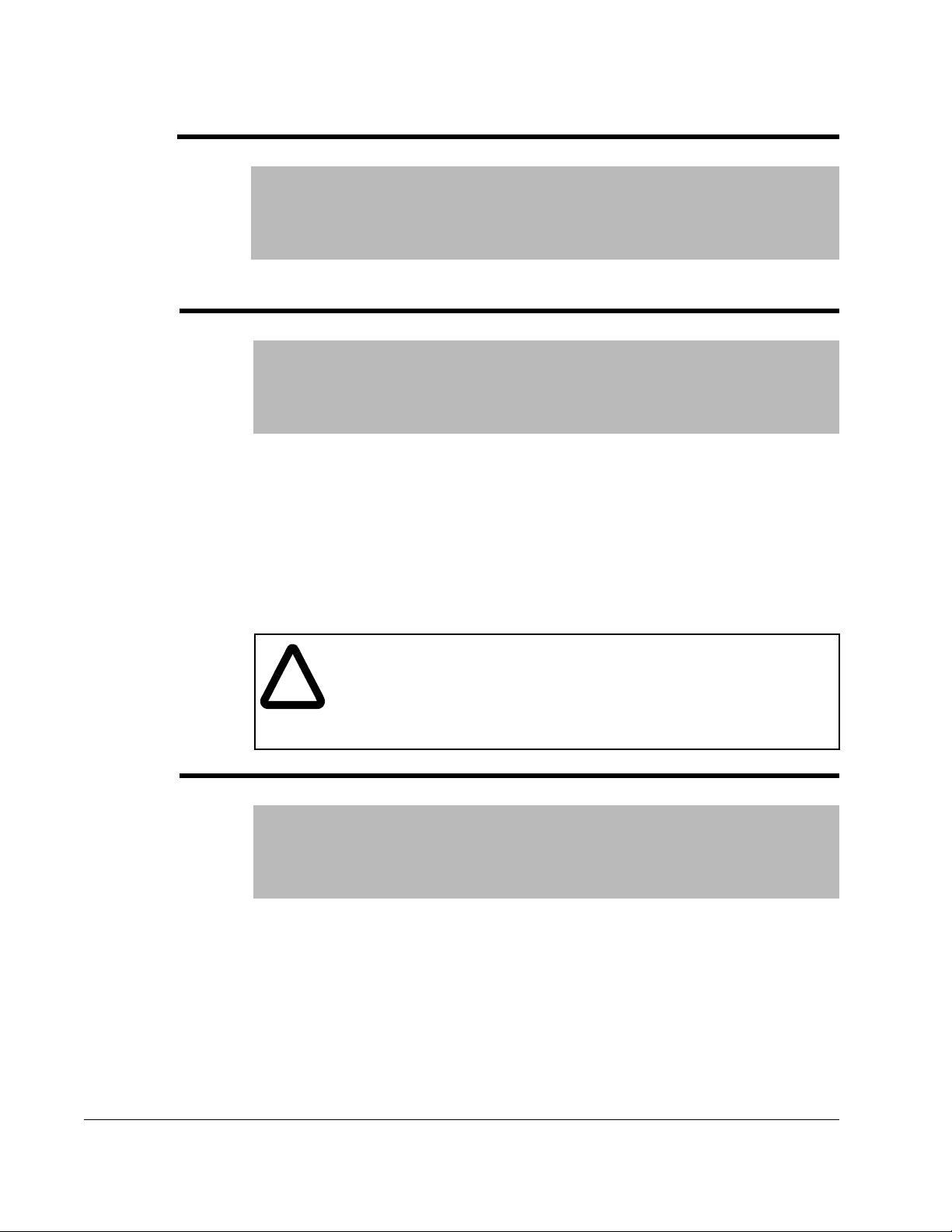

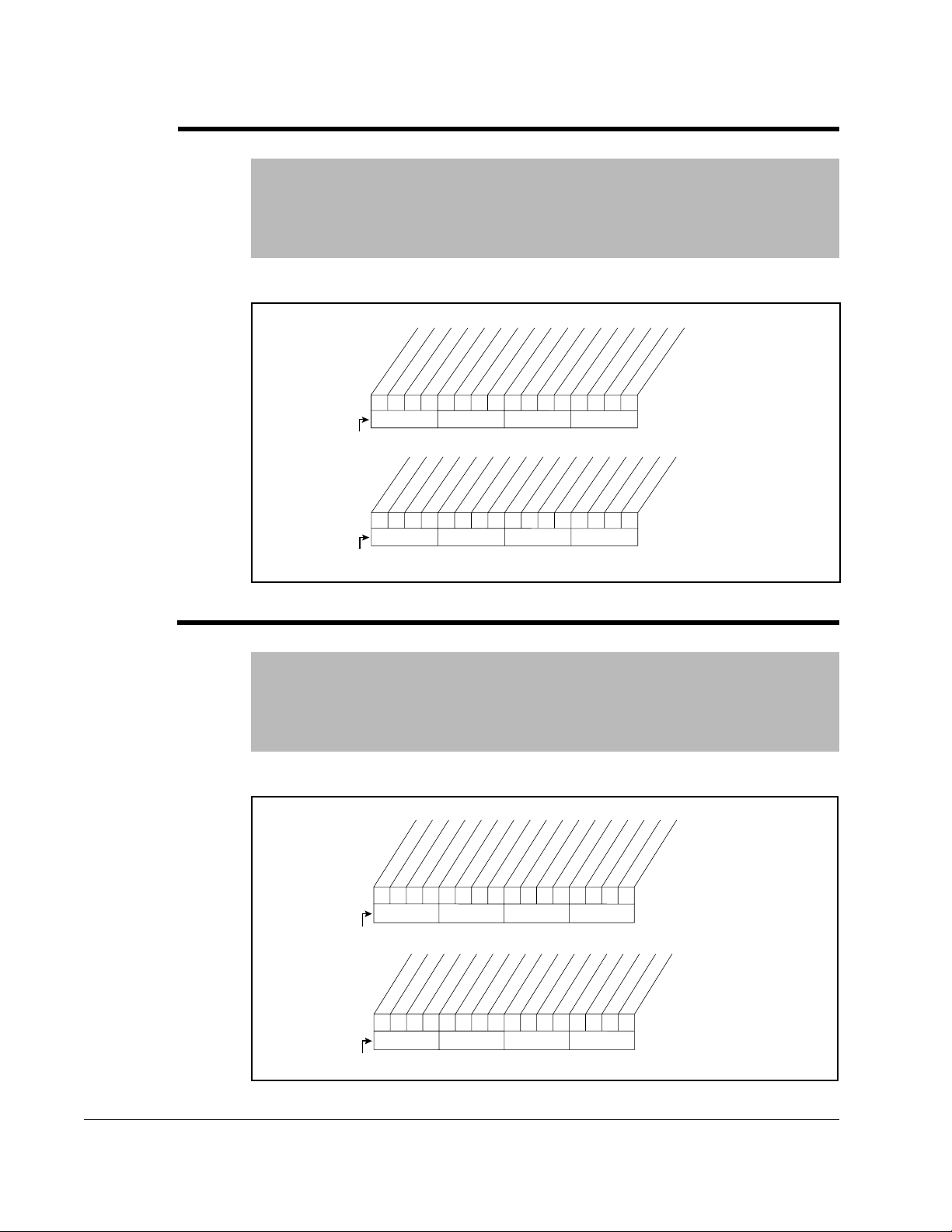

Allowable Output Frequency Range -

Bus Regulation or Current Limit

V

Max Volts

o

(54)

l

t

Motor Volts

a

(41)

g

e

Break Volts

(71)

Start Boost

(69)

Run

Boost

(70)

0 Break

56 Compensation

Range: See figure 3.2

Default: See figure 3.2

Access: 2 Path: Motor Control>Torq Attributes

See also:

Allowable Output Frequency Range - Normal Operation

Allowable Speed Reference Range

Frequency Trim

due to Speed

Control Mode

Min

Speed

(81)

Frequency

(72)

Motor NP Hz

(43)

Frequency

Figure 3.1 – Speed Limits

Overspeed

Max

Speed

(82)

Limit

(83)

Output

Freq Limit

Maximum

Freq

(55)

Parameter Descriptions

Enables/disables the compensation correction options.

(1)

ave

x

Rs Adapt

Mtr Lead Rev

Xsistor Diag

Ixo AutoCalc

101110

Enable Jerk

Reflect W

1

0

x =Reserved

=Enabled

=Disabled

10 01234567891112131415

Bit #

Factory Default Bit Values

PWM FreqLock

TPEncdless

0

0

xxxxxxx

(1)

For current limit (except FVC Vector mode).

Figure 3.2 – Compensation (56)

Reflect Wave = Enables/disables reflected wave correction software, which reduces

overvoltage transients from the drive to the motor. For lead lengths beyond 300 feet,

enable this feature.

3-11

Page 38

Enable Jerk = Enables/disables the jerk limit in the current limiter that helps to

eliminate overcurrent trips on fast accelerations. Disable this feature if your application

requires the actual acceleration of the motor to be faster than .25 sec. In non-FVC

Vector modes, disabling jerk removes a short S-curve at the start of the accel/decel

ramp.

Ixo AutoCalc = Reserved

Xsistor Diag = Enables/disables power transistor power diagnostic tests that execute

at each Start command.

Rs Adapt = (FVC w/Encoder only) Disabling may improve torque regulation at lower

speeds (although this is typically not needed).

Mtr Lead Rev = Reverses the phase rotation of the applied voltage, effectively

reversing the motor leads.

PWM Freq Lock = Keeps the PWM frequency from decreasing to 2 kHz at low

operating frequencies in FVC Vector mode without encoder.

57 Flux Up Mode

Range: 0 = Manual

1 = Automatic

Default: 0 = Manual

Access: 2 Path: Motor Control>Torq Attributes

See also: 53, 58

Manual (0): Flux is established for Flux Up Time (58) before acceleration

Auto (1): Flux is established for a calculated time period based on motor nameplate

data. Flux Up Time (58) is not used.

58 Flux Up Time

Range: 0.000 to 5.000 sec [0.001 sec]

Default: 0.000 sec

Access: 2 Path: Motor Control>Torq Attributes

See also: 53, 58

Sets the amount of time the drive will use to try to achieve full motor stator flux. When

a start command is issued, DC current at current limit level is used to build stator flux

before accelerating.

59 SV Boost Filter

Range: 0 to 32767 [1]

Default: 500

Access: 0 Path: Motor Control>Torq Attributes

See also:

Sets the amount of filtering used to boost voltage during Sensorless Vector and FVC

Vector (encoderless) operation.

3-12

DBT Reach Drive User Manual

Page 39

61 Autotune

Range: 0 = Ready

Default: 3 = Calculate

Access: 1 Path: Motor Control>Torq Attributes

See also: 53, 62

Provides a manual or automatic method for setting IR Voltage Drop (62), Flux Current

Ref (63) and Ixo Voltage Drop (64). Valid only when Motor Cntl Sel (53) is set to

Sensrls Vect, SV Economize or FVC Vector.

Ready (0) = Parameter returns to this setting following a Static Tune or Rotate Tune. It

also permits manually setting IR Voltage Drop (62), Ixo Voltage Drop (64) and Flux

Current Ref (63).

Static Tune (1) = A temporary command that initiates a non-rotational motor stator

resistance test for the best possible automatic setting of IR Voltage Drop (62) in all

valid modes and a non-rotational motor leakage inductance test for the best possible

automatic setting of Ixo Voltage Drop (64) in FVC Vector Mode. A start command is

required following the initiation of this setting. The parameter returns to Ready (0)

following the test, at which time another start transition is required to operate the drive

in normal mode. Used when the motor cannot be rotated.

1 = Static Tune

2 = Rotate Tune

3 = Calculate

Rotate Tune (2) = A temporary command that initiates a Static Tune followed by a

rotational test for the best possible automatic setting of Flux Current Ref (63). In FVC

Vector mode, with encoder feedback, a test for the best possible automatic setting of

Slip RPM @ FLA is also run. A start command is required following initiation of this

setting. The parameter returns to Ready (0) following the test, at which time another

start transition is required to operate the drive in normal mode.

Important: Rotate Tune (2) is used when the motor is uncoupled from the load.

Results may not be valid if a load is coupled to the motor during this

!

Calculate (3) = This setting uses motor nameplate data to automatically set IR

Voltage Drop (62), Ixo Voltage (64) and Flux Current Ref (63).

procedure.

ATTENTION:Rotation of the motor in an undesired direction can occur

during this procedure (Autotune (61) = Rotate Tune (2)). To guard against

possible injury and/or equipment damage, it is recommended that the

motor be disconnected from the load before proceeding.

Parameter Descriptions

3-13

Page 40

62 IR Voltage Drop

Range: 0.0 to Motor NP Volts x 0.25 [0.1 VAC]

Default: Based on Drive Rating

Access: 1 Path: Motor Control>Torq Attributes

See also: 53, 61

Value of volts dropped across the resistance of the motor stator. Used only when

Motor Cntl Sel (53) is set to Sensrls Vect, SV Economize or FVC Vector.

63 Flux Current Ref

Range: 0.00 to Motor NP FLA [0.01 Amps]

Default: Based on Drive Rating

Access: 1 Path: Motor Control>Torq Attributes

See also: 53, 61

Value of amps for full motor flux. Used only when Motor Cntl Sel (53) is set to Sensrls

Vect, SV Economize or FVC Vector.

64 Ixo Voltage Drop

Range: 0.00 to 230.0, 460.0 or 575.0 VAC [0.1 VAC]

Default: Based on Drive Rating

Access: 1 Path: Motor Control>Torq Attributes

See also:

Sets the value of the voltage drop across the leakage inductance of the motor at rated

motor current. Used only when Motor Cntl Sel (53) is set to Sensrls Vect, SV

Economize or FVC Vector.

66 Autotune Torque

Range: 0.0 to 150% [0.1%]

FV

Default: 50%

Access: 1 Path: Motor Control>Torq Attributes

See also: 53

Specifies motor torque applied to the motor during the flux current and inertia tests

performed during an autotune.

3-14

DBT Reach Drive User Manual

Page 41

67 Inertia Autotune

FV

Range: 0 = Ready

Default: 0 = Ready

Access: 1 Path: Motor Control>Torq Attributes

See also: 53, 450

Provides an automatic method of setting Total Inertia. This test is automatically run

during Start-Up motor tests.

Important: Use when motor is coupled to the load. Results may not be valid if the

Ready = Parameter returns to this setting following a completed inertia tune.

Inertia Tune = A temporary command that initiates an inertia test of the motor/load

combination. The motor will ramp up and down, while the drive measures the amount

of inertia.

1 = Inertia Tune

load is not coupled to the motor during this procedure.

69 Start/Acc Boost

Range: 0.0 to Motor NP Volts x 0.25 [0.1 VAC]

Default: Based on drive rating

Access: 2 Path: Motor Control>Volts per Hertz

See also: 53, 70

Sets the voltage boost level for starting and acceleration when Custom V/Hz mode is

selected.

70 Run Boost

Range: 0.0 to Motor NP Volts x 0.25 [0.1 VAC]

Default: Based on drive rating

Access: 2 Path: Motor Control>Volts per Hertz

See also: 53, 69,

Sets the boost level for steady state or deceleration when Fan/Pmp V/Hz or Custom

V/Hz modes are selected.

71 Break Voltage

Range: 0.0 to Motor NP Volts [0.1 VAC]

Default: Motor NP Volts x 0.25

Access: 2 Path: Motor Control>Volts per Hertz

See also: 53, 72

Sets the voltage the drive will output at Break Frequency (72).

Parameter Descriptions

3-15

Page 42

72 Break Frequency

Range: 0.0 to Maximum Freq [0.1 Hz]

Default: Motor NP Freq x 0.25

Access: 2 Path: Motor Control>Volts per Hertz

See also: 53, 71

Sets the frequency the drive will output at Break Voltage (71).

79 Speed Units

Range: 0 = Hz

1 = RPM

2 = Convert Hz

3 = Convert RPM

Default: 0 = Hz

Access: 0 Path: Speed Command>Spd Mode & Limits

See also:

Selects the units to be used for all speed related parameters. Options 0 and 1 indicate

status only. Options 2 and 3 will convert and/or configure the drive for that selection.

Convert Hz (2) = Converts all speed based parameters to Hz and changes the value

proportionately (i.e. 1800 RPM = 60 Hz).

Convert RPM (3) = Converts all speed based parameters to RPM and changes the

value proportionately.

80 Feedback Select

Range: 0 = Open Loop

Default: 0 = Open Loop

Access: 2 Path: Speed Command>Spd Mode & Limits

See also: 53, 152, 412

Selects the source for motor speed feedback. Note that all selections are available

when using Process PI.

1 = Slip Comp

2 = Reserved

3 = Encoder

4 = Reserved

5 = Simulator

3-16

DBT Reach Drive User Manual

Page 43

ATTENTION: When operating the drive with encoder feedback selected

(Feedback Select (80) = 3 (Encoder)), a loss of encoder signal may

!

Open Loop (0) = Provides no speed compensation due to load variations. This is

strict volts per hertz output as a function of the speed reference. Slip compensation is

not needed and encoder is not present.

Slip Comp (1) = Provides for frequency output adjustment as a function of load. The

amount of compensation is defined by the value of Slip RPM @ FLA (121). It is used

when tight speed control is needed and an encoder is not present.

Encoder (3) = An encoder is present and connected to the drive.

Simulator (5) = Simulates a motor for testing drive operation and interface check.

produce an overspeed condition. For differential encoders, Motor Fdbk

Type (412) should be selected as option 1 or 3 to detect the loss of an

encoder signal. The user is responsible for ensuring that the driven

machinery, all drive-train mechanisms, and application material are

capable of safe operation at the maximum operating speed of the drive.

Overspeed detection in the drive determines when the drive shuts down.

The factory default for overspeed detection is set to 10.0 Hz (or 300.0

RPM) greater than the Maximum Speed (82). Failure to observe this

precaution could result in equipment damage, sever injury or loss of life.

81 Minimum Speed

Range: 0.0 to Maximum Speed [0.1 Hz or 0.1 RPM]

Default: 0.0

Access: 0 Path: Speed Command>Spd Mode & Limits

See also: 79, 83, 92, 95

Sets the low limit for the speed reference after scaling is applied.

ATTENTION:The drive can operate at and maintain zero speed. The

user is responsible for assuring safe conditions for operating personnel

!

by providing suitable guards, audible or visual alarms, or other devices

to indicate that the drive is operating or may operate at or near zero

speed. Failure to observe this precaution could result in severe bodily

injury or loss of life.

82 Maximum Speed

Range: 5.0 to 400.0 [0.1 Hz] or 75.0 to 24000.0 RPM [0.1 RPM]

Default: 50.0 or 60.0 Hz (Volt Class) [Motor NP RPM]

Access: 0 Path: Speed Command>Spd Mode & Limits

See also: 55, 79, 83, 91, 94, 202

Sets the high limit for the speed reference after scaling is applied.

Parameter Descriptions

3-17

Page 44

ATTENTION: The user is responsible for ensuring that the driven

machinery, all drive-train mechanisms, and application material are

!

capable of safe operation at the maximum operating speed of the drive.

Overspeed detection in the drive determines when the drive shuts down.

The factory default for overspeed detection is set to 10.0 Hz (or 300.0

RPM) greater than the Maximum Speed (82). Failure to observe this

precaution could result in equipment damage, sever injury or loss of life.

83 Overspeed Limit

Range: 0.0 to 20.0 Hz [0.1 Hz] or 0.0 to 600.0 RPM [0.1 RPM]

Default: 10.0 Hz or 300.0 RPM

Access: 2 Path: Speed Command>Spd Mode & Limits

See also: 55, 79, 82

Sets the incremental amount of the output frequency (above Maximum Speed)

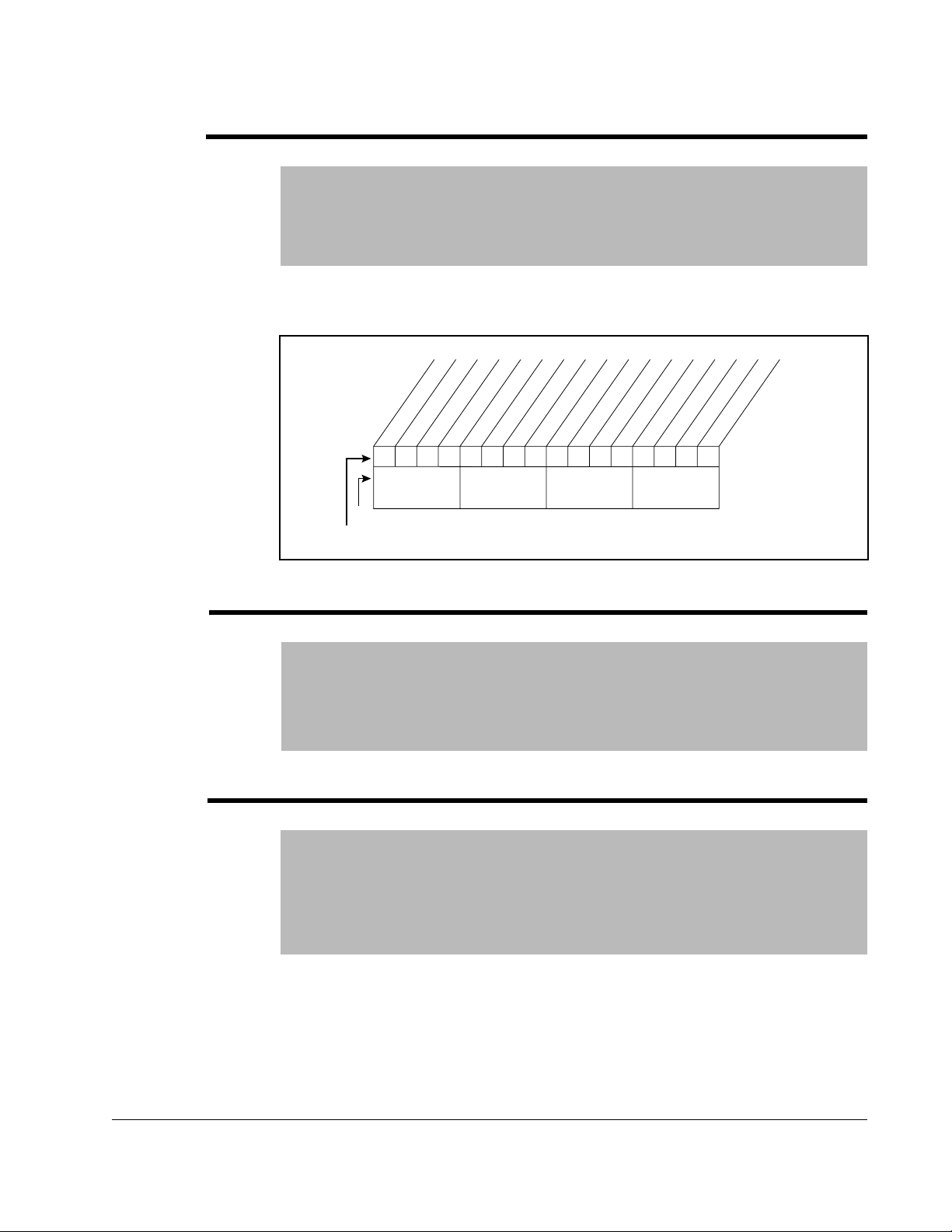

allowable for functions such as slip compensation. See figure 3.3.

Maximum Speed + Overspeed Limit must be ≤ to Maximum Frequency

ATTENTION: The user is responsible for ensuring that the driven

machinery, all drive-train mechanisms, and application material are

!

capable of safe operation at the maximum operating speed of the drive.

Overspeed detection in the drive determines when the drive shuts down.

The factory default for overspeed detection is set to 10.0 Hz (or 300.0

RPM) greater than the Maximum Speed (82). Failure to observe this

precaution could result in equipment damage, sever injury or loss of life.

3-18

V

Max Volts

o

l

t

Motor Volts

a

g

e

Break Volts

Start Boost

(54)

(41)

(71)

(69)

Run

Boost

(70)

0 Break

Speed

Allowable Output Frequency Range -

Bus Regulation or Current Limit

Allowable Output Frequency Range - Normal Operation

Allowable Speed Reference Range

Frequency Trim

due to Speed

Control Mode

Min

(81)

Frequency

(72)

Figure 3.3 – Speed Limits

Motor NP Hz

(43)

Frequency

Overspeed

Limit

(83)

Max

Speed

(82)

Output

Freq Limit

DBT Reach Drive User Manual

Maximum

Freq

(55)

Page 45

84

85

86

Skip Frequency 1

Skip Frequency 2

Skip Frequency 3

Range: -/+ Maximum Speed [0.1 Hz]

Default: 0.0 Hz

Access: 2 Path: Speed Command>Spd Mode & Limits

See also: 87

Sets a frequency at which the drive will not operate (also called an avoidance

frequency). Requires that both Skip Frequency 1-3 and Skip Frequency Band (87) be

set to a value other than 0.

87 Skip Freq Band

Range: 0.0 to 30.0 Hz [0.1 Hz]

Default: 0.0 Hz

Access: 2 Path: Speed Command>Spd Mode & Limits

See also: 84, 85, 86

Determines the bandwidth around a skip frequency (half the band above and half the

band below the skip frequency). The same bandwidth applies to all skip frequencies.

88 Speed/Torque Mod

Range: 0 = Zero Torque

1 = Speed Reg

FV

Default: 1 = Speed Reg

Access: 1 Path: Speed Command>Spd Mode & Limits

See also: 53

!

Selects the torque reference source.

2 = Torque Reg

3 = Min Torq/Spd

4 = Max Torq/Spd

5 = Sum Torq/Spd

6 = Absolute Min

7 = Pos/Spd Prof

ATTENTION: When selecting operation in a torque mode configuration,

the user is responsible for ensuring that the driven machinery, all

drive-train mechanisms, and application material are capable of safe

operation at the maximum operating speed of the drive. Overspeed

detection in the drive determines when the drive shuts down. The factory

default for overspeed detection is set to 10.0 Hz (or 300.0 RPM) greater

than the Maximum Speed (82). Failure to observe this precaution could

result in equipment damage, sever injury or loss of life.

Parameter Descriptions

Zero Torque (0) = Torque Command = 0.

3-19

Page 46

Speed Reg (1) = Drive operates as a speed regulator.

Torque Reg (2) = An external torque reference is used for the torque command.

Min Torq/Spd (3) = Selects the smallest algebraic value to regulate to when the

torque reference and torque generated from the speed regulator are compared.

Max Torq/Spd (4) = Selects the largest algebraic value to regulate to when the torque

reference and torque generated from the speed regulator are compared.

Sum Torq /Spd (5) = Selects the sum of the torque reference and the torque

generated from the speed regulator.

Absolute Min (6) = Selects the smallest absolute algebraic value to regulate to when

the torque reference and torque generated from the speed regulator are compared.

Pos/Spd Prof (7) = Drive operates as a speed or position regulator as determined by

the steps configured by the Profile Step parameters (720-877) and Setup parameters

(705-719).

89 Logic Source Sel

Range: 0 = Terminal Blk

Default: 1 = Local HIM

Access: 0 Path: Speed Command>Control Src Sel

See also:

1 = Local HIM

2 = DPI Port 2

3 = DPI Port 3

4 = Reserved

5 = Network

6 = Reserved

7 = All Ports

3-20

Selects the only control source for these logic commands:

• Start (Run)

• Jog

• Direction

• Clear Faults

• Stop (Any attached HIM Stop Key is always functional. A Network stop command is

effective only for Network or All Ports. A Terminal Block Stop command is effective

only for Terminal Blk or All Ports.

Selecting All Ports (7) enables control from any control source (or port).

DBT Reach Drive User Manual

Page 47

ATTENTION: Changing parameter 89 to Terminal Blk or Network

while Start At PowerUp is enabled may start the drive if a start

!

Important: Asserting an HIM Control digital input or acquiring Manual with Save HIM

command is on from the newly selected logic source.

When Start At PowerUp is enabled, the user must ensure that

automatic start up of the driven equipment will not cause injury to

operating personnel or damage to the driven equipment. In addition,

the user is responsible for providing suitable audible or visual alarms or

other devices to indicate that this function is enabled and the drive may

start at any moment. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION: Removing and replacing the LCD HIM while the drive is

running may cause an abrupt speed change if the LCD HIM is the

selected reference source, but is not the selected control source. The

drive will ramp to the reference level provided by the HIM at the rate

specified in Accel Time 1 (140), Accel Time 2 (141), Decel Time 1

(142) and Decel Time 2 (143). Be aware that an abrupt speed change

may occur depending upon the new reference level and the rate

specified in these parameters. Failure to observe this precaution could

result in bodily injury.

Ref (192) bit 1 (Manual Mode) True (1) will override this parameter’s

selection.

90 Speed Ref A Sel

Range: 1 = Analog In 1

Default: 18 = Local HIM

Access: 0 Path: Speed Command>Speed References

See also: 2, 91-93, 101-107, 117-120, 192-194, 213, 272, 273, 320, 361-366

2 = Analog In 2

3-6 = Reserved

7 = Pulse In

8 = Encoder

9 = MOP Level

10 = Reserved

11 = Preset Spd 1

12 = Preset Spd 2

13 = Preset Spd 3

14 = Preset Spd 4

15 = Preset Spd 5

16 = Preset Spd 6

17 = Preset Spd 7

18 = Local HIM

19 = DPI Port 2

20 = DPI Port 3

21 = DPI Port 4

22 = Network

23-24 = Reserved

25 = Scale Block 1

26 = Scale Block 2

27 = Scale Block 3

28 = Scale Block 4

Speed Command>Control Src Select

Parameter Descriptions

3-21

Page 48

Selects the source of the speed reference to the drive unless Preset Speed 1-7

(101-107)

Note that the manual reference command and input HIM Control can override the

reference control source.

or Speed Ref B (93) is selected.

ATTENTION:Removing and replacing the LCD HIM while the drive is

running may cause an abrupt speed change if the LCD HIM is the

!

selected reference source. The drive will ramp to the reference level

provided by the HIM at the rate specified in Accel Time 1 (140), Accel

Time 2 (141), Decel Time 1 (142) and Decel Time 2 (143). Be aware that

an abrupt speed change may occur depending upon the new reference

level and the rate specified in these parameters. Failure to observe this

precaution could result in bodily injury.

91 Speed Ref A Hi

Range: -/+Maximum Speed [0.1 Hz or 0.1 RPM]

Default: Maximum Speed

Access: 1 Path: Speed Command>Speed References

See also: 79, 82, 190

Scales the upper value of the Speed Ref A Sel (90) selection when the source is an

analog input.

92 Speed Ref A Lo

Range: -/+Maximum Speed [0.1 Hz or 0.01 RPM]

Default: 0.0

Access: 1 Path: Speed Command>Speed References

See also: 79, 81, 190

Scales the lower value of the Speed Ref A Sel (90) selection when the source is an

analog input.

3-22

DBT Reach Drive User Manual

Page 49

93 Speed Ref B Sel

Range: 1 = Analog In 1

2 = Analog In 2

3-6 = Reserved

7 = Pulse In

8 = Encoder

9 = MOP Level

10 = Reserved

11 = Preset Spd 1

12 = Preset Spd 2

13 = Preset Spd 3

14 = Preset Spd 4

15 = Preset Spd 5

16 = Preset Spd 6

17 = Preset Spd 7

18 = Local HIM

19 = DPI Port 2

20 = DPI Port 3

21 = DPI Port 4

22 = Network

23-24 = Reserved

25 = Scale Block 1

26 = Scale Block 2

27 = Scale Block 3

28 = Scale Block 4

Default: 11 = Preset Spd 1

Access: 0 Path: Speed Command>Speed References

Speed Command> Control Src Select

See also: 2, 91-93, 101-107, 117-120, 192-194, 213, 272, 273, 361-366

Selects the source of the speed reference to the drive unless Preset Speed 1-7

(101-107)

Note that the manual reference command and input HIM Control can override the

reference control source.

!

is selected.

ATTENTION:Removing and replacing the LCD HIM while the drive is

running may cause an abrupt speed change if the LCD HIM is the

selected reference source. The drive will ramp to the reference level

provided by the HIM at the rate specified in Accel Time 1 (140), Accel

Time 2 (141), Decel Time 1 (142) and Decel Time 2 (143). Be aware that

an abrupt speed change may occur depending upon the new reference

level and the rate specified in these parameters. Failure to observe this

precaution could result in bodily injury.

Parameter Descriptions

3-23

Page 50

94 Speed Ref B Hi

Range: -/+Maximum Speed [0.1 Hz or 0.01 RPM]

Default: Maximum Speed

Access: 1 Path: Speed Command>Speed References

See also: 79, 93, 190

Scales the upper value of the Speed Ref B Sel (93) selection when the source is an

analog input.

95 Speed Ref B Lo

Range: -/+Maximum Speed [0.1 Hz or 0.01 RPM]

Default: 0.0

Access: 1 Path: Speed Command>Speed References

See also: 79, 90, 93, 190

Scales the lower value of the Speed Ref B Sel (93) selection when the source is an

analog input.

96 TB Man Ref Sel

Range: 1 = Analog In 1

2 = Analog In 2

3-8 = Reserved

9 = MOP Level

3-24

Default: 2 = Analog In 2

Access: 1 Path: Speed Command>Speed References

See also: 97, 98

Specifies the manual speed reference source when a digital input is configured for

auto/manual.

Important: Analog ln 2 is not a valid selection if it was selected for Trim ln Select

(117), PI Feedback Sel (128), PI Reference Sel (126), Current Lmt Sel

(147) or Sleep Wake Ref (179).

97 TB Man Ref Hi

Range: -/+Maximum Speed [0.1 Hz or 0.01 RPM]

Default: Maximum Speed

Access: 1 Path: Speed Command>Speed References

See also: 79, 96

Scales the upper value of the TB Man Ref Sel selection when the source is an analog

input.

DBT Reach Drive User Manual

Page 51

98 TB Man Ref Lo

Range: -/+Maximum Speed [0.1 Hz or 0.01 RPM]

Default: 0.0

Access: 1 Path: Speed Command>Speed References

See also: 79, 96

Scales the lower value of the TB Man Ref Sel selection when the source is an analog

input.

99 Pulse Input Ref

Range: -/+ 400.0 Hz or -/+ 24000.0RPM [0.1 Hz or 0.1 RPM]

Default: Read Only

Access: 0 Path: Speed Command>Speed References

See also:

Displays the pulse input value as seen at terminals 5 and 6 of the Encoder Terminal

Block if Encoder Z Chan (423) is set to “Pulse Input.”

100 Jog Speed 1

Range: +/- Maximum Speed [0.1 Hz or 0.1 RPM]

101

102

103

104

105

106

107

Default: 10.0 Hz or 300.0 RPM

Access: 0 Path: Speed Command>Discrete Speeds

See also: 79

Sets the output frequency/speed when a jog command is issued. Units are selected

by Speed Units (79).

Preset Speed 1

Preset Speed 2

Preset Speed 3

Preset Speed 4

Preset Speed 5

Preset Speed 6

Preset Speed 7

Range: -/+Maximum Speed [0.1 Hz or 1 RPM]

Default: See table 3.1

Access: See table 3.1 Path: Speed Command>Discrete Speeds

See also: 79, 90, 93

Provides an internal fixed speed command value. In bipolar mode, direction is

commanded by the sign of the reference.

Parameter Descriptions

3-25

Page 52

Parameter No. Parameter Name Default Access

101 Preset Speed 1 5.0 Hz or 150 RPM 0