Page 1

External Bus Resistor Kit

for LiquiFlo AC Drives

Drive M/N’s 41L4060, 41LR4060, LF150414W4

Instruction Manual D2-3535

ATTENTION: Only qualified electrical personnel familiar with the construction and operation of this

equipment and the hazards involved should install, adjust, operate, or service this equipment. Read and

!

understand this manual and other applicable manuals in their entirety before proceeding. Failure to

observe this precaution could result in severe bodily injury or loss of life.

ATTENTION: Do not install or remove modification kits with power applied to the drive. Disconnect

and lock out incoming power before attempting such installation or removal. Failure to observe this

!

precaution could result in severe bodily injury or loss of life.

ATTENTION: DC Bus capacitors retain hazardous voltages after input power has been disconnected.

After disconnecting input power, wait five (5) minutes for the DC bus capacitors to discharge and then

!

check the voltage with a voltmeter to ensure that the DC bus capacitors are discharged before touching

any internal components. Failure to observe this precaution could result in severe bodily injury or loss of

life.

ATTENTION: The user is responsible for conforming with all applicable local, national, and

international codes. Failure to observe this precaution could result in damage to, or destruction of, the

!

equipment.

ATTENTION: The drive contains ESD- (Electrostatic Discharge) sensitive parts and assemblies. Static

control precautions are required when installing, testing, servicing or repairing the drive. Erratic machine

!

operation and damage to, or destruction of, equipment can result if this procedure is not followed.

Failure to observe this precaution could result in severe bodily injury or loss of life.

What the Kit

Contains

External Resistor Kit M/N 180788-A02 can be used only with B-frame (414A)

LiquiFlo AC drives, model numbers: 41L4060, 41LR4060 and LF150414W4. Verify

that you have the correct resistor assembly by verifying that the harness is labeled,

“414AMP EXT BUS RESIS KIT.”

Quantity: Description

1 Resistor Assembly

6 M4 x 16 Mounting Screws with captive locking hardware

1Protective Cover

1 Drilling Template / Cabinet Guard

This kit is for field upgrade only. You should not use it if you are replacing the drive. If

you replace the drive in the future, you should remove the resistor kit from the drive

system.

©2004 Rockwell Automation. All rights reserved.

Page 2

2 Instruction Manual D2-3535

What You Need to Do

Step 1: Verifying the DC Bus

Capacitors are Discharged

To install the external bus resistor kit you need to:

❐ Step 1: Verify that the DC Bus Capacitors are discharged

❐ Step 2: Identify a mounting location for the resistor assembly

❐ Step 3: Drill mounting holes for the resistor assembly, using the

template

❐ Step 4: Mount the resistor assembly

❐ Step 5: Unplug connectors P1 and P2, and route harness

❐ Step 6: Connect the ground wire

❐ Step 7: Connect the harness

❐ Step 8: Verify installation

❐ Step 9: Register installation

ATTENTION: DC Bus capacitors retain hazardous voltages

after input power has been disconnected. After disconnecting

!

input power, wait five (5) minutes for the DC bus capacitors to

discharge and then check the voltage with a voltmeter to ensure

that the DC bus capacitors are discharged before touching any

internal components. Failure to observe this precaution could

result in severe bodily injury or loss of life.

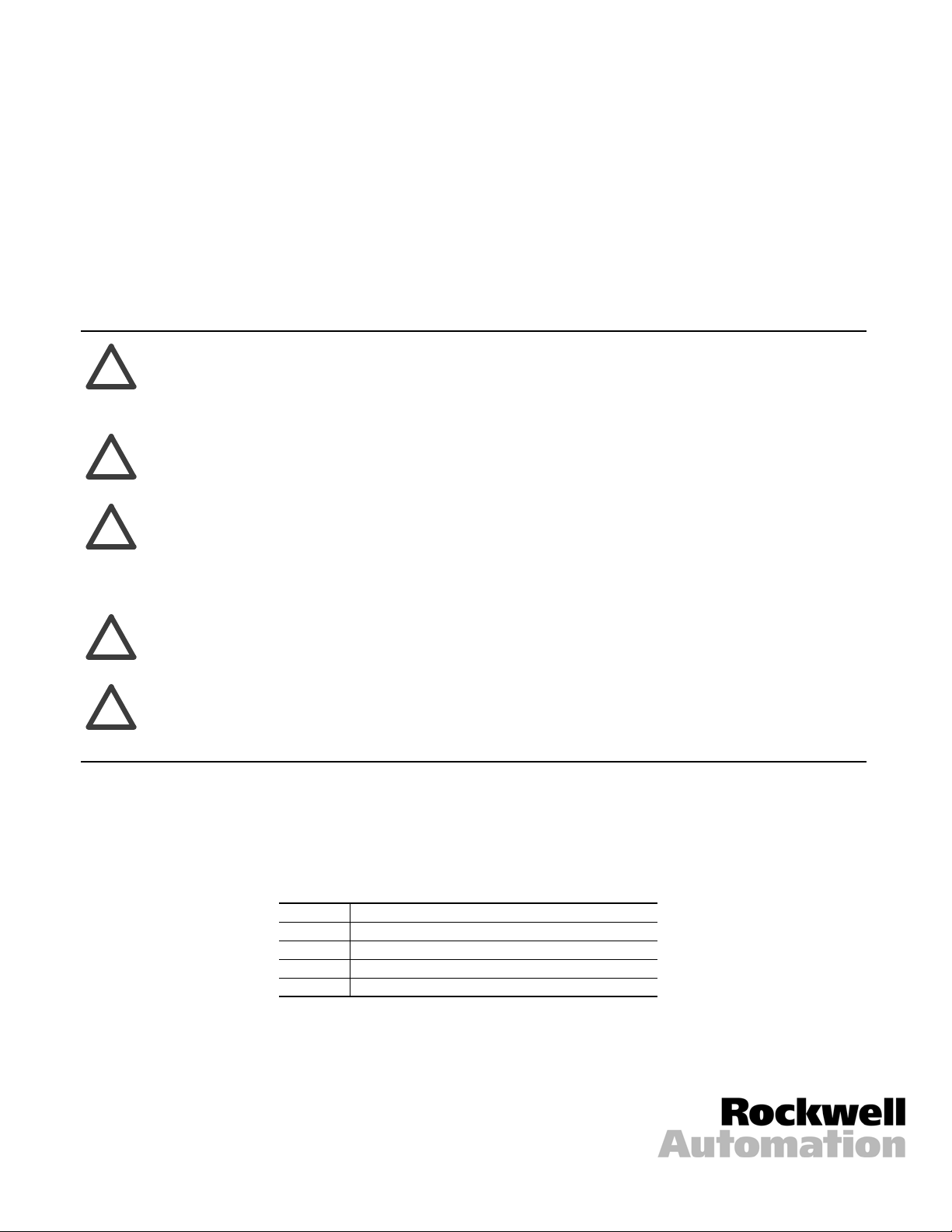

Task Description

Turn off and lock out input power. Wait five minutes

A

Verify that there is no voltage at the drive’s input power terminals

B

Remove front cover

C

Measure the DC bus potential with a voltmeter while standing on a non-conductive surface

D

and wearing insulated gloves (1000V)

Test Points for initial

DC Bus Voltage

Measurement

Pos

(+)

D

J3

J4

TP1 TP2

D13

D34

U16

U22

R8 R9 R10

U32

U3

D31U8D30

D35

D61

U37

R11 R12 R13 R6

C6

D14

D15

U4

D25

U7

D32

U9

U17

U23

U24

D58

DS2

D62

U33

D63

J8

J5

R5

R7

RV2

RV6

RV7

RV8

J7

C12

C10

C11

D21

R25C17

D23

D22

C18 R26

C19

R27

U5

C21

T6

T7 T8

R34

R32

R33

C26

U11

U12

U10

D37

C28

D41

D42

D39

D40

C30

U18

U19

U20

D46

D45

D48

D47

U25

U26

D53

D54

D55

U27

U28

DS3

DS4

D59

C48

U34

J1

J6

RV1

R1

C1

C4

C2 C3

C5

Neg

(-)

TP2TP1

Q2Q1

D10

T1

D11

U1 C13

R19

D12

Q4

D16

T2

D24

L1

C20

U6

D26

C22

R36

R35

T10

Q5

D52

D49

D50

D51

U21

R37

Q6

T11

1

D56

D60

C39

C41

U36

C49

D65

D64

D66

C50

FUSE1

R14

R15

R16 R17

R2

R3J2R4

RV4

RV3

C8

C7

D18

R23

D17 R22

C15

C14

T3

T4 T5

C23

R29 R30

D27

T9

D29

DS1

U14

U15

D44

D43

C33

C32

C31

C38

C37

C36

C35

L2

FUSE2

C40

U29

U30

U35

C42

C44

C43

C45

R18

D3

D4

D2

D5

D1

D7

D8 D9

D6

RV5

Q3

C9

R20

C16 R24

D19

U2

R21

D20

R28

R31

D28

C24

C25

D33

C27

U13

D36

C29

D38

C34

Made in USA

BARCODE

ASSY

R38

R39 D57

R41

R40

R43

R42

U31

C47

C46

TP4TP5TP6 TP3

Page 3

Instruction Manual D2-3535 3

Step 2: Identifying the

Mounting Location

Consider the following factors when choosing the location for the resistor

assembly:

• the resistor assembly must be mounted inside the drive cabinet

• the resistor assembly must be mounted vertically, with the closed part of

the protective cover pointing towards the front of the enclosure

• the wiring harness must be able to reach connectors P1 and P2 inside the

drive

• the wiring harness must not pass over unprotected sharp edges or hot

surfaces

• the resistor assembly must not be mounted on the enclosure door

Resistor assembly shown without

harness for clarity

Towards

Enclosure

Door

Protective

Cover

Page 4

4 Instruction Manual D2-3535

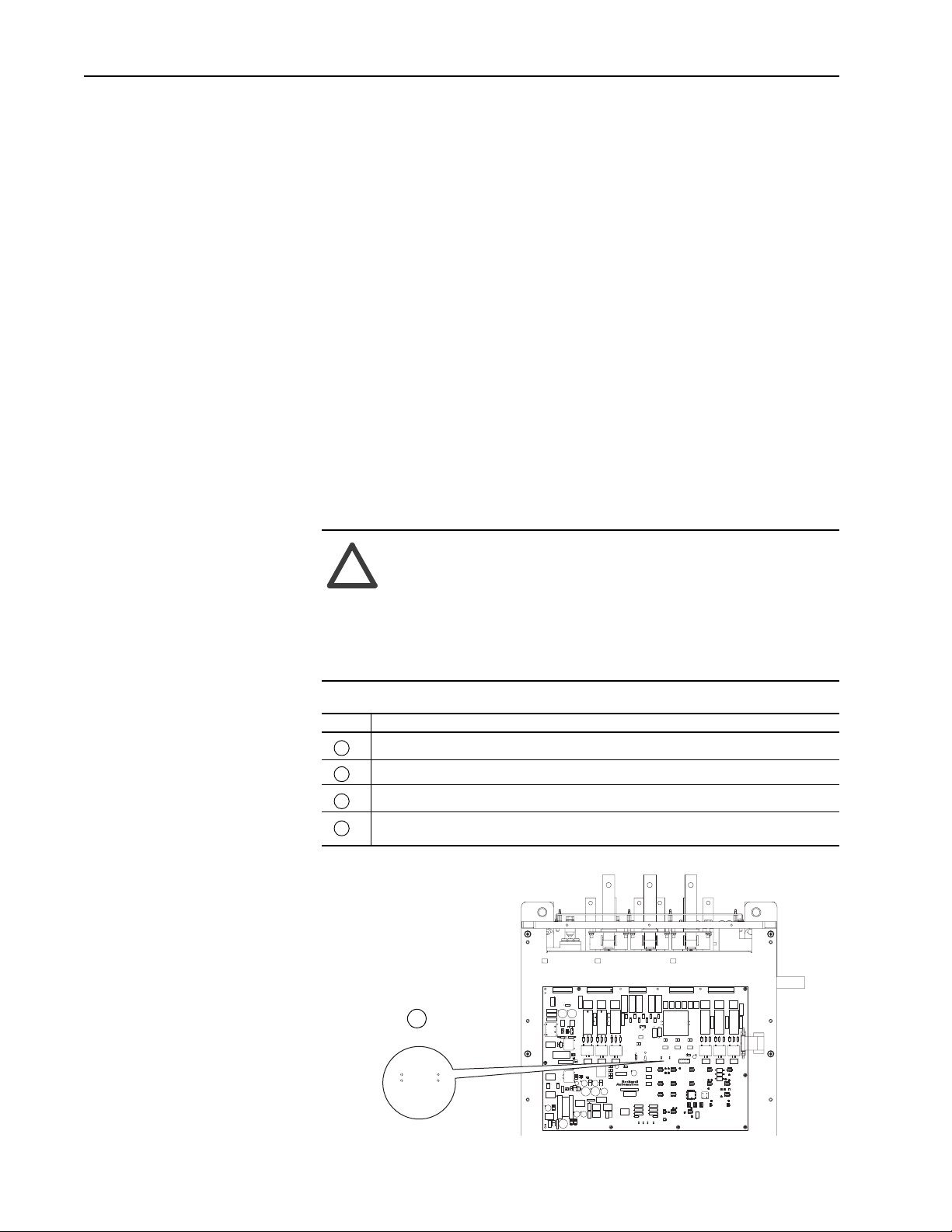

Step 3: Drilling the Mounting

Holes

ATTENTION: Metal debris or other foreign matter must be

kept from falling into the drive. Metal debris or other foreign

!

matter may become lodged in the drive circuitry resulting in

component damage. Failure to observe this precaution could

result in severe bodily injury or loss of life and/or damage to, or

destruction of, equipment.

Task Description

Protect internal components from drilling debris

A

Using the template, mark locations for six mounting holes

B

Drill six 5mm (3/16 inch) mounting holes

C

B

B

Drilling Template /

A

Cabinet Guard

TIP: The template is symmetrical, so you have the options of drilling from

the outside or inside of the enclosure. Drilling outside reduces the risk of

debris falling into the drive.

B

B

B

B

Page 5

Instruction Manual D2-3535 5

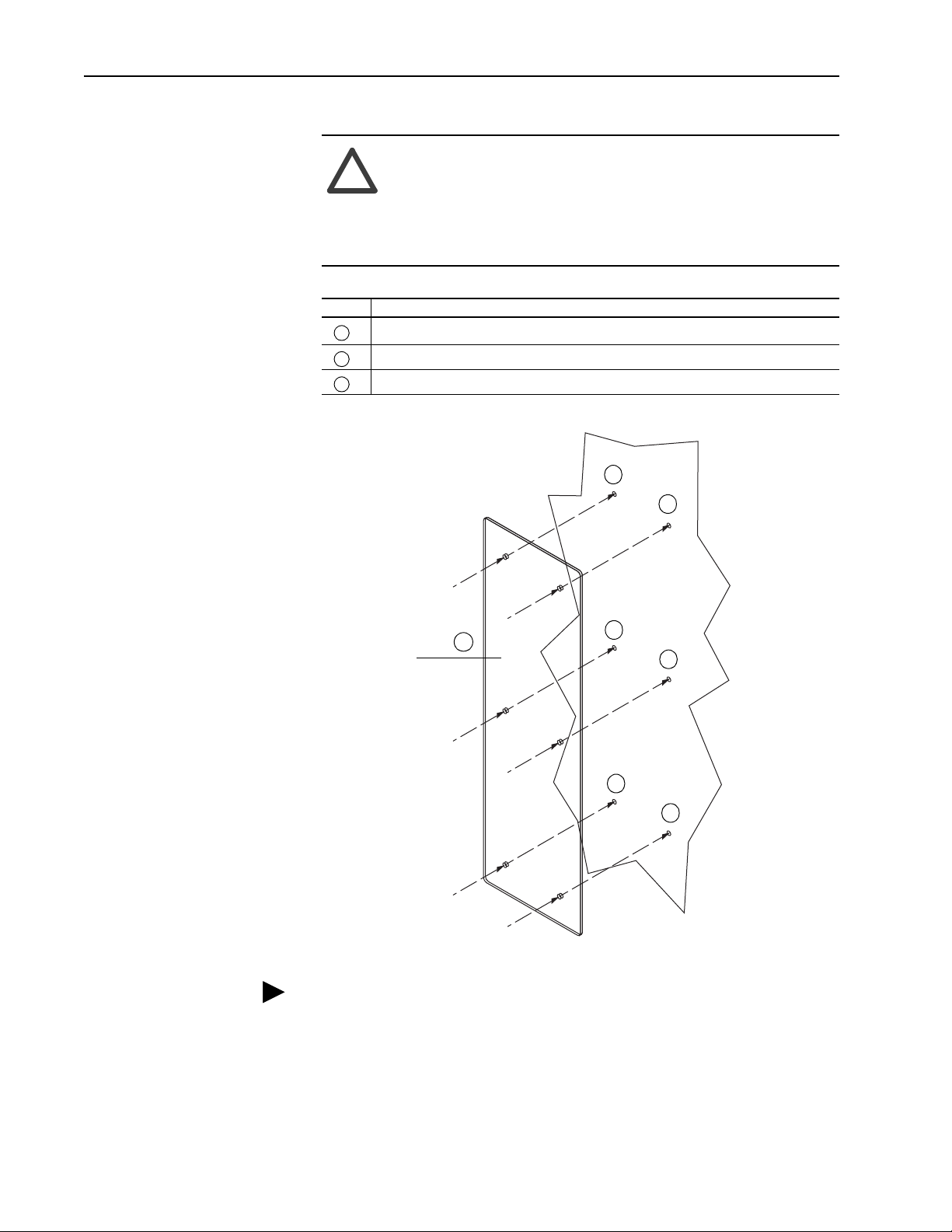

Step 4: Mounting the

Resistor Assembly

A

A

Task Description

Using a Phillips screw driver, install and tighten the six M4 x 16 mounting screws (torque 12

A

in-lb)

!

A

A

ATTENTION: The cabinet can be very hot where the resistor

assembly is mounted. HOT surfaces can cause severe burns. You

must install the cabinet guard to protect personnel from

accidental contact with the hot cabinet surface.

Cabinet Guard

Enclosure Wall

Resistor assembly

mounted on inside of

enclosure

A

Mounting Screws

inserted from outside

of enclosure

A

Resistor assembly shown

without harness for clarity

Page 6

6 Instruction Manual D2-3535

Step 5: Unplugging

Connectors P1 and P2 and

Routing the Wiring Harness

P1 and P2

Push Here

to Release

Connector

Locate the P1 and P2 Connectors near the upper-left part of the power

structure and unplug them.

To Resistor Assembly

Important: The harness connections are considered power level wiring.

Run them separately from I/O and signal wiring.

Page 7

Step 6: Connecting the

Ground Wire

Typical installations can use the existing ground stud originally intended for

grounding the enclosure door.

This figure illustrates recommended practices for connecting grounds to an

enclosure.

Ground Lug

Star Washer

Instruction Manual D2-3535 7

Welded Stud

BoltPaint Free

Area

Nut

Star Washer

Component

Ground Conductor

Ground Lug

Nut Component

Star Washer

Ground Conductor

Star Washer

Page 8

8 Instruction Manual D2-3535

Step 7: Connecting the

Harness

Task Description

Plug P1A into P1

A

Plug P2A into P2

B

Harness to Resistor Assembly

P1

A

P1A

P2A

P2

B

Wires

to

Drive

Wires

from

Drive

Page 9

Instruction Manual D2-3535 9

Step 8: Verifying the

Installation

J1

J6

RV1

R1

C1

C4

C2 C3

C5

Q2Q1

D10

T1

D11

U1 C13

R19

D12

Q4

D16

T2

D24

L1

C20

U6

D26

C22

R36

R35

T10

Q5

D52

D49

D50

D51

U21

R37

Q6

T11

1

D56

D60

C39

C41

U36

C49

D65

D64

D66

C50

FUSE1

Task Description

A

B

C

J3

R14

R15

R2

R3J2R4

RV4

RV3

D2

D1

D6

RV5

C8

C9

C7

D18

C16 R24

R23

D17 R22

C15

C14

D19

T3

T4 T5

R29 R30

U15

D43

FUSE2

C40

C43

R28

R31

D28

D27

C24

T9

D33

C27

U13

D36

D38

D44

C33

Made in USA

C38

C37

BARCODE

ASSY

L2

U29

U30

R38

R40

R42

U31

U35

C44

C45

C23

D29

DS1

U14

C32

C31

C36

C35

C42

Disconnect J4 from PMC Board

Confirm continuity between the points specified in Ta bl e A

Reconnect J4 to PMC Board

J4

Pin 1

R16 R17

Q3

A

B

J4

R9 R10

J5

R5

R11 R12 R13 R6

C6

C10

D21

D15

U5

D25

C21

T6

U7

R32

U10

D39

U18

U24

DS2

DS3

DS4

D59

C48

D62

U34

D63

J8

R11 R12

R7

RV2

RV6

RV7

RV8

J7

C12

C11

R25C17

D22

C18 R26

D23

C19

R27

T7 T8

R34

R33

C26

U11

U12

D37

C28

D41

D42

D40

C30

U19

U20

D46

D45

D47

D48

U25

U26

D53

D54

D55

U27

U28

C

J4

R18

R8 R9 R10

D3

D4

D5

D7

D8 D9

R20

U2

D14

D13

R21

D20

U3

U4

TP1 TP2

D32

D31U8D30

C25

U9

C29

D34

D35

C34

U16

U17

U23

U22

D58

R39 D57

U32

R41

D61

U33

R43

C47

C46

U37

TP4TP5TP6 TP3

Table A J4 Continuity Tests

J4:Pin 1 BUS (+) Continuity or

J4:Pin 3 BUS MID

J4:Pin 5 BUS (-)

(1)

If you are unfamiliar with continuity tests, refer to Performing Continuity

Te st s on page 9.

(2)

See Wiring Diagram for Reference on page 11.

Test Points

Resistor Assembly

End of Cable

(1)

(2)

Meter ReadingJ4 End of Cable

approximately zero ohms

Follow the normal steps for verifying drive installation and operation. Refer to the

drive Hardware Reference and Software Start-up manuals.

If you have a... ... refer to these publications:

LiquiFlo 1.0 drive

•

D2-3410,

LiquiFlo AC General Purpose (Volts/Hertz) and Vector Duty Drive

Software Start-up

•

D2-3411,

LiquiFlo AC Power Modules Hardware Reference, Installation and

Troubleshooting

LiquiFlo 1.5 drive

•

D2-3494,

LiquiFlo 1.5 AC Power Modules Hardware Reference, Installation,

and Troubleshooting

•

D2-3495,

LiquiFlo 1.5 AC General Purpose (Volts/Hertz) and Vector Duty

Drive Software Start-Up and Reference Manual

Performing Continuity Tests

In these tests you are verifying continuity, a short circuit, between the two test

points. The continuity mode on a digital multi-meter provides the easiest method

for performing this test. Place one meter lead on the first test point and the meter

should beep when you place the other lead on the second test point.

If your meter does not have a continuity mode, you can use a resistance mode.

Place one meter lead on the first test point and the meter should indicate a short

circuit (read approximately zero ohms) when you place the other lead on the

second test point.

Page 10

10 Instruction Manual D2-3535

Step 9: Registering

the Installation

C

Register the installation of the External Bus Resistor kit on the Rockwell

Automation Warranty And Returns Processing (WARP) website

http://www.automation.rockwell.com/warp/

(

Click on “Continue”

Click on “Field Retrofits”

A

).

B

Select “External Bus

Resistor Upgrade” from

the drop-down

D

Click on “Register Retrofit”

Enter all the required and

E

pertinent information.

Click on “Create Registration”

F

Page 11

Wiring Diagram for

Reference

Instruction Manual D2-3535 11

BUS (+)

BUS (-)

2600 Ohm

2600 Ohm

BUS MID

EXTERNAL BUS RESISTOR ASSEMBLY

RESISTOR 24708-501-12

1

P2

1

2

3

DISCHARGE RESISTOR

10K Ohms

Note:

The old resistors and their

connecting wires remain

in the drive.

1

2

3

R1 R2

DISCHARGE RESISTOR

10K Ohms

24708-501-13 24708-501-13

63481-105SFY OR 63481-105SFY OR

TEMP

SWITCH

CHILLPLATE

TEMP

SWITCH

REACTOR

FAN

9 8 7 6 5

4 2 3

DC+ BUS

DC MIDPT

DC- BUS

P2A

P1A

P1

1

1

2

BLEEDER (+)

4

4 2 3

4 5 6

3

BLEEDER (-)

6

5

TEMPSW1

7 8 9

FANPWR (+)

TEMPSW2

9 8 7

9 8 7 6 5

FANPWR (-)

Page 12

U.S. Drives Technical Support

Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, Email: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication D2-3535-July 2004 Copyright © 2004Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Loading...

Loading...