Page 1

Installation Instructions

LDAT-Series Integrated Linear Thrusters

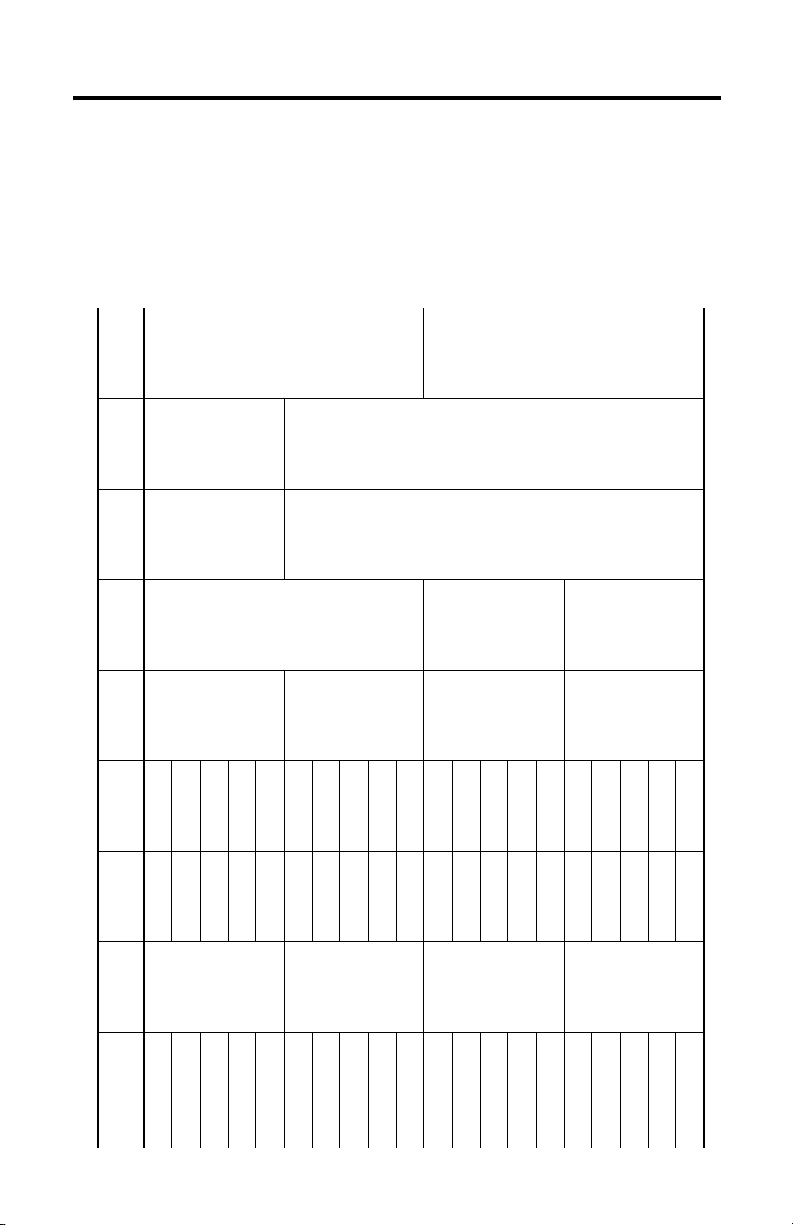

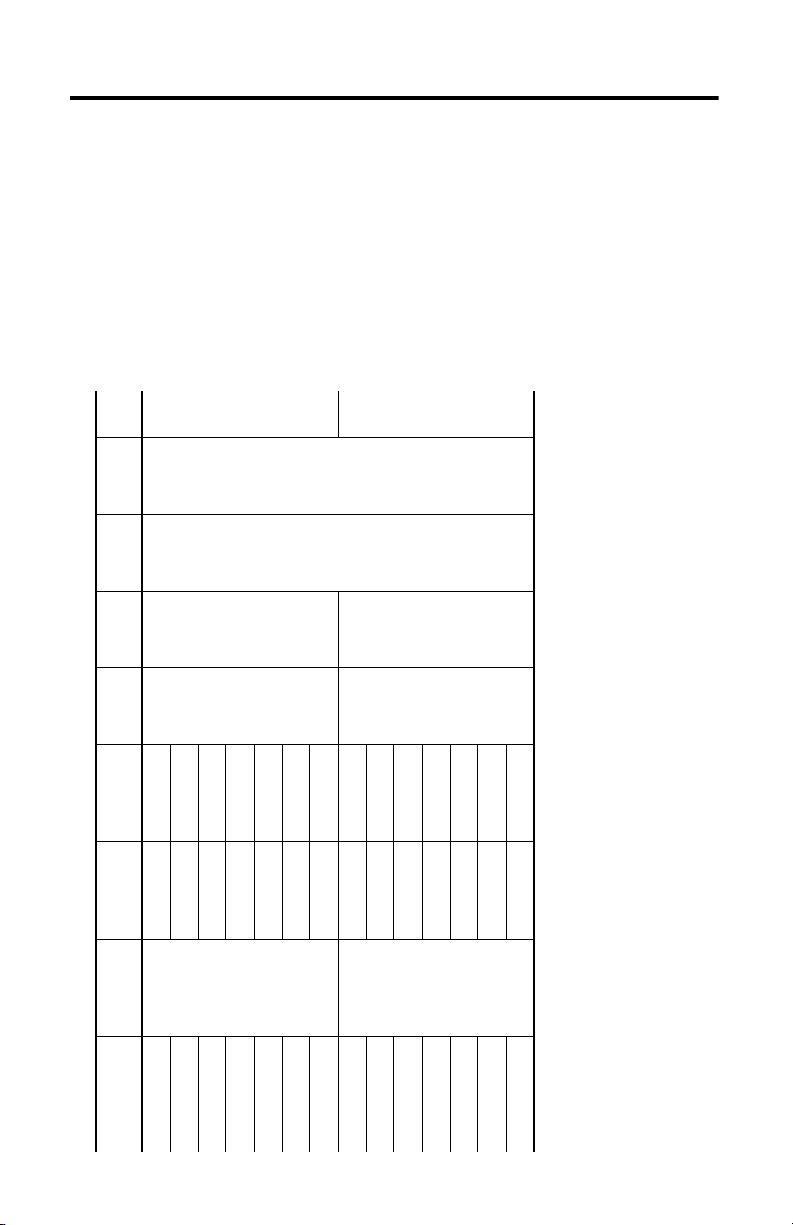

Catalog Numbers

LDAT Frame 30 LDAT Frame 50 LDAT Frame 75 LDAT Frame 100 LDAT Frame 150

LDAT-S03xxxx-DB LDAT-S05xxxx-DB LDAT-S07xxxx-DB LDAT-S10xxxx-DB LDAT-S15xxxx-DB

LDAT-S03xxxx-DBS LDAT-S05xxxx-DBS LDAT-S07xxxx-DBS LDAT-S10xxxx-DBS LDAT-S15xxxx-DBS

LDAT-S03xxxx-EB LDAT-S05xxxx-EB LDAT-S07xxxx-EB LDAT-S10xxxx-EB LDAT-S15xxxx-EB

LDAT-S03xxxx-EBS LDAT-S05xxxx-EBS LDAT-S07xxxx-EBS LDAT-S10xxxx-EBS LDAT-S15xxxx-EBS

LDAT-S03xxxx-DD LDAT-S05xxxx-DD LDAT-S07xxxx-DD LDAT-S10xxxx-DD LDAT-S15xxxx-DD

LDAT-S03xxxx-DDS LDAT-S05xxxx-DDS LDAT-S07xxxx-DDS LDAT-S10xxxx-DDS LDAT-S15xxxx-DDS

LDAT-S03xxxx-ED LDAT-S05xxxx-ED LDAT-S07xxxx-ED LDAT-S10xxxx-ED LDAT-S15xxxx-ED

LDAT-S03xxxx-EDS LDAT-S05xxxx-EDS LDAT-S07xxxx-EDS LDAT-S10xxxx-EDS LDAT-S15xxxx-EDS

Topi c Page

Important User Information 2

Safety Considerations 3

Catalog Number Explanation 7

About the LDAT-Series Integrated Linear Thruster 8

Before You Begin 9

Install the Linear Thruster 12

Dimensions 20

Connector Data 32

Commissioning 33

Maintenance 52

Troubleshooting 55

Accessories 57

Replacement Parts 59

Install Replacement Parts 60

Interconnect D iagrams 71

Specifications 75

Additional Resources 78

Page 2

2 LDAT-Series Integrated Linear Thrusters

IMPORTANT

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for

the Application, Installation and Maintenance of Solid State Controls, publication SGI-1.1

Automation® sales office or online at http://www.rockwellautomation.com/literature

between solid state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves that

each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or li able for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibilit y or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNIN G: Identifies information about practices or circumstances that can cause an explosion in a

hazardous environment, which may lead to personal injury or death, property damage, or economic loss.

, available from your local Rockwell

describes some important differences

ATT EN TI ON : Identifies information about practices or circumstances that can lead to personal injury or

death, property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard and

recognize the consequences.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people

that dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people

that surfaces may reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 3

LDAT-Series Integrated Linear Thrusters 3

Product Nameplate

D

E

C

B

A

B

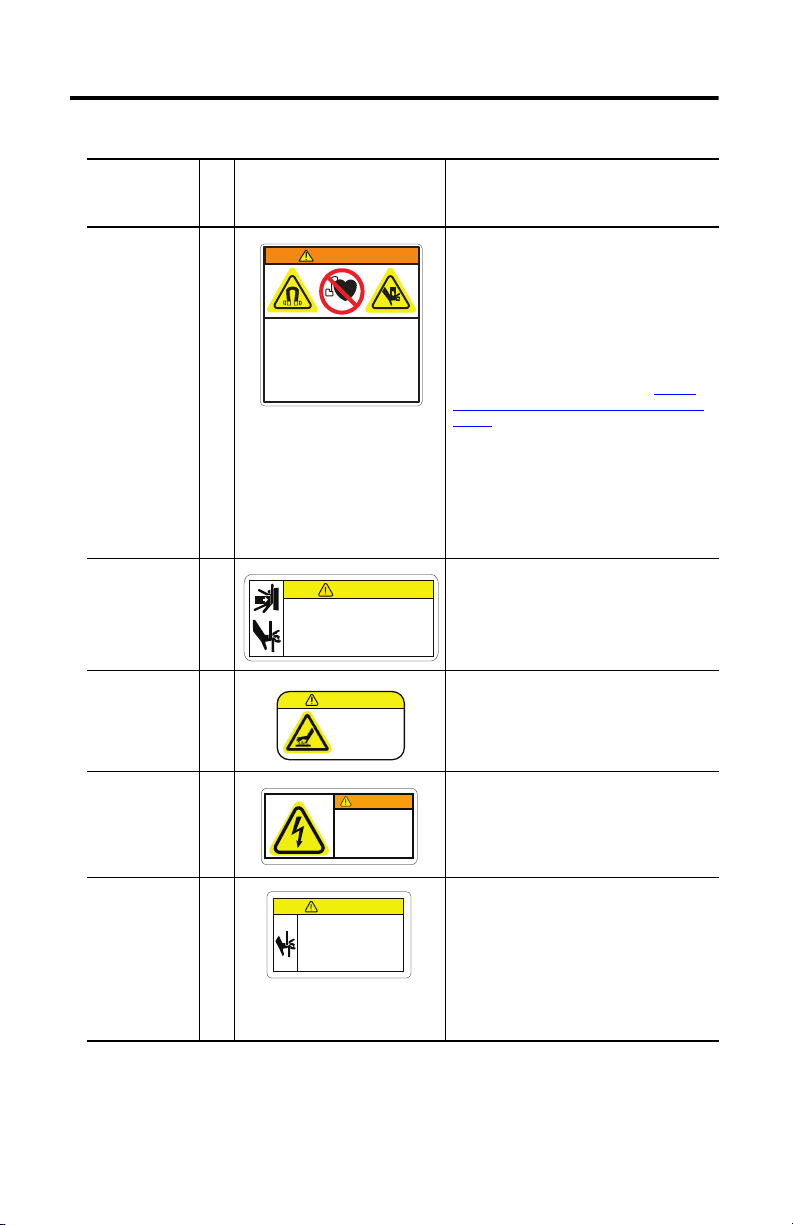

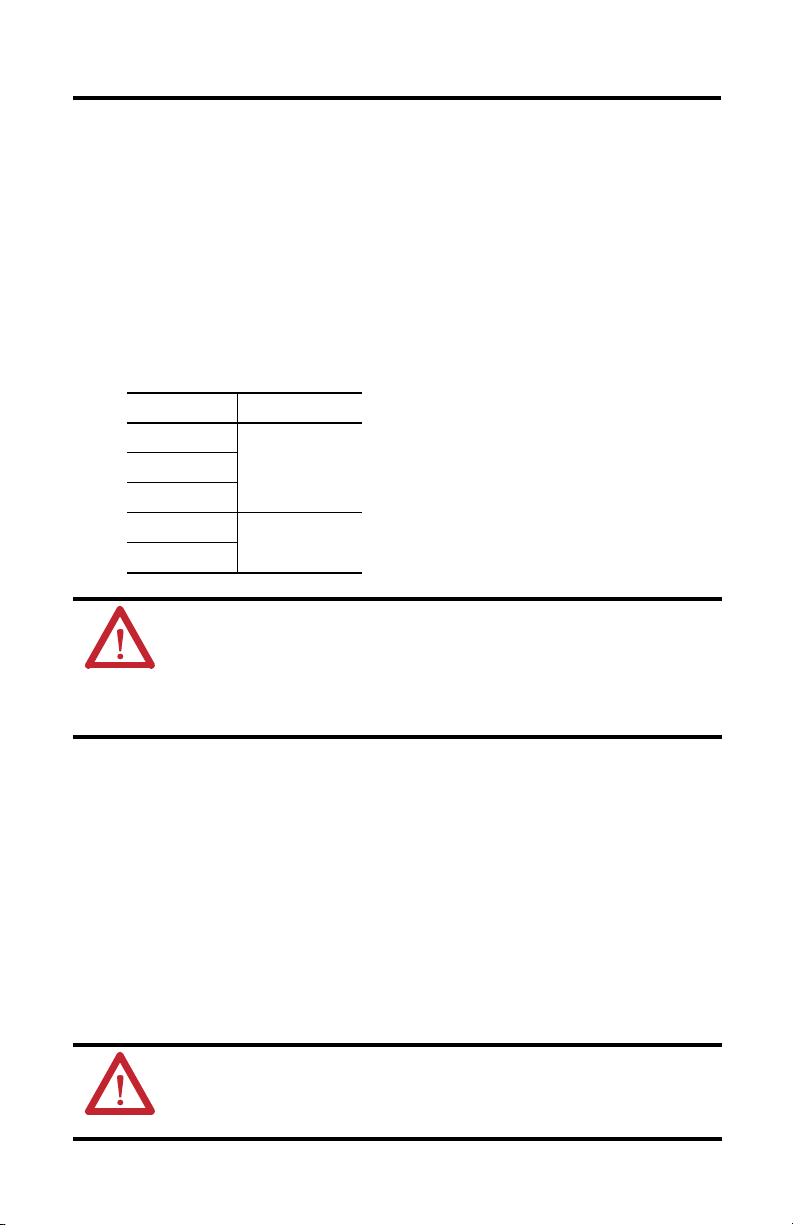

Safety Considerations

This section describes the safety issues encountered while using a linear thruster and the

precautions you can take to minimize risk. Potential hazards discussed here are identified by

labels affixed to the device.

Labels

Here you will find the safety and identification labels affixed to your linear thruster. To prevent

injury and damage to the linear thruster, review the safety label and its details and location before

using the actuator.

Labels on the Linear Thruster

before opening.

Disconnect power

inside.

Hazardous voltage

WARNING

CAUTION

Loosen set screw to just below flush

to free slider motion prior to operation.

When slider is free, unexpected

motion and weight shift may occur

during handling.

Tighten set screw to 2.3 N·m (20 lb·in)

to prevent movement during

installation and maintenance.

Stand clear when machine is in motion.

Pitch point.

Keep clear during operation.

Sudden machine motion can cause

injury.

CAUTION

Keep clear during operation.

Pitch point.

Stand clear when machine is in motion.

injury.

WARNING

High magnetic field exerts strong

forces.

Pacemaker and ICD wearers maintain

minimum of 300 mm distance.

Tools, metal objects and surfaces can be

attracted and cut, pinch or entrap hands

CAUTION

and fingers.

Sudden machine motion can cause

WARNING

Hazardous voltage

inside.

Disconnect power

before opening.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 4

4 LDAT-Series Integrated Linear Thrusters

CAUTION

Hot surface.

Do not touch.

Safety Labels

Title

Label Details

Location

Strong Magnets A The linear thruster slide uses strong magnets over its

WARNING

High magnetic field exerts strong

forces.

Pacemaker and ICD wearers maintain

minimum of 300 mm distance.

Tools, metal objects and surfaces can be

attracted and cut, pinch or entrap hands

and fingers.

entire length. The magnetic field generated can

disrupt the functionality of automatic implantable

cardioverter defibrillators (AICD). Peop le with cardia c

pacemakers should not work near the linear thruster.

The strong magnets of the linear thruster slider will

attract metal objects that up are in its proximity.

During handling and installation maintain distance

between the linear thruster slider and metal

mounting surfaces or structures. Refer to Remove

the Linear Thruster from the Shipping Container on

page 11

Maintenance personnel should avoid the use of

metallic tools and secure items such as badge cli ps

other personnel effect that could be attracted to the

strong magnetic field.

Strong magnets can erase magnetic media. Never let

credit cards or electronic media contact or come near

the linear thruster.

Pitch Point/ Motion

Hazard

Hot Surface C Indicates that the surface can be hot enough to burn

B The linear thruster is capable of sudden and fast

CAUTION

Sudden machine motion can cause

injury.

Stand clear when machine is in motion.

Pitch point.

Keep clear during operation.

motion. Never stand in the axis of motion when

under power. Do not put fingers inside the slider.

Lock out - tag out if access to the linear thruster is

required during maintenance while the connectors

are installed.

if touched.

High Voltage D Do not open linear thruster covers or right angle

Shipping/handling

Set Screw

E When handling the linear thruster during

WARNING

Hazardous voltage

inside.

Disconnect power

before opening.

CAUTION

Loosen set screw to just below flush

to free slider motion prior to operation.

When slider is free, unexpected

motion and weight shift may occur

during handling.

Tighten set screw to 2.3 N·m (20 lb·in)

to prevent movement during

installation and maintenance.

connectors while the cables are connected. Lock

out-tag out if access to the linear thruster is required

during maintenance while the connectors are

installed.

maintenance or installation the set screw must be

tightened to 2.3 N•m (20 lb•in) to prevent

unexpected movement of the slide and weight shift

of the linear thruster.

After installation, loosen the set screw ed so that the

slider is free to move for normal operation. The set

screw is loose when the head of the screw is flush

with the surface of the stator housing.

High Energy Magnets

Linear thruster magnet tracks contain high energ y magnets that attract ferrous metals from a

considerable distance. Precautions must be taken while unpacking, handling, and shipping by air.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 5

LDAT-Series Integrated Linear Thrusters 5

Unpacking and Handling

Leave protective wrapping, cardboard and flux containment plates in place until linear thruster is

installed. Clear the inspection and repacking area of any ferrous metals that will be attracted to or

attract the linear thruster. If you are working multiple linear thrusters, maintain a distance of

1.5 m (5 ft) between each linear thruster.

Air Freight Restrictions

When air freighting linear thruster special preparations and precautions must be taken. The

following information outlines the basic requirements at the publication date of this document.

However, regulations are subject to change and additional area or carrier restrictions may be

imposed. Always check with your carrier or logistics specialist regarding current local, regional,

and national transportation requirements when shipping this product.

Linear thruster magnet track contain magnetized material, as classified by International Air

Transport Association (IATA) Dangerous Goods Regulations. An IATA trained individual must

be involved when shipping this product via domestic or international air freight. Packing

Instruction 902 provides information regarding the preparation of this product for air

transportation. Follow these regulations for general marking and labeling requirements, the

application of specific Magnetized Material Handling Labels, and instructions for preparing the

Shipper's Declaration for Dangerous Goods.

As a minimum, refer to the following IATA Dangerous Goods Regulations:

• Subsection 1.5: Training

• Subsection 3.9.2.2: Classification as Magnetized Material

• Subsection 4.2: Identification as UN 2807, Magnetized Material, Class 9, Packing

Instruction 902

• Subsection 7.1.5: Marking

• Subsection 7.2: Labeling

• Subsection 7.4.1: Magnetized Material Label

• Section 8: Shipper's Declaration for Dangerous Goods

When shipped via ground in the United States, these products are not considered a U.S. D.O.T.

Hazardous Material and standard shipping procedures apply.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 6

6 LDAT-Series Integrated Linear Thrusters

IMPORTANT

Vertical or Incline Installation

A linear thruster driven system mounted vertically or on an incline will not maintain position

when the power is removed. Under the influence of gravity the motion platform and its payload

will fall to the low end of travel. Design engineers should allow for this by designing in controlled

power down circuits or mechanical controls to prevent the linear thruster driven system and its

payload from being damaged when the power fails.

Any person that teaches, operates, maintains, or repairs these linear thruster must be

trained and demonstrate the competence to safely perform the assigned task.

ATTENTION: Linear thrusters are capable of high accelerations, sudden and fast motion. Rockwell

Automation is not responsible for misuse, or improper implementation of this equipment.

ATTENTION: Linear thrusters driven systems must have the payload must be secured to the

system such that it will not sheer off in the event of an impact in excess of the bumper ratings.

ATTENTION: The Hall effect module and motor feedback encoder contain an electrostatic

discharge (ESD) sensitive devises. Follow static-control precautions when you install, test, service,

or repair this assembly. If you do not follow ESD control precautions, components can be damaged.

If you are not familiar with static control precautions, refer to Guarding Against Electrostatic

Damage, publication 8000-4.5.2,

or any other applicable ESD awareness handbook.

BURN HAZARD: When the linear thruster are running at their maximum rating the temperature

of attached heat sink can reach 100 ºC (212 ºF).

SHOCK HAZARD: An assembled linear thruster will generate power if the coil or magnet track is

moved. Un-terminated power cables present an electrical shock hazard. Never handle flying leads

or touch power pins while moving the motor.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 7

LDAT-Series Integrated Linear Thrusters 7

Lubrication

Blank = Standard

Bearing Seal

Blank = Standard

Bearing Protection

Blank = No Cover

S = Strip Cover

Encoder Type

B = Incremental, magnetic scale, 5 μm resolution

D = Absolute, magnetic scale, hiper face

(1)

Winding

D = High Speed

E = Low Speed

Trave l

010 = 100 mm (3.94 in.) 060 = 600 mm (23.62 in.)

020 = 200 mm (7.87 in.) 070 = 700 mm (27.56 in.)

030 = 300 mm (11.81 in.) 080 = 800 mm (31.50 in.)

040 = 400 mm (15.75 in.) 090 = 900 mm (35.43 in.)

050 = 500 mm (19.68 in.)

Motor Coil Length

1 = 100 mm (3.94 in.) 4 = 400 mm (15.75 in.)

2 = 200 mm (7.87 in.) 6 = 600 mm (23.62 in.)

3 = 300 mm (11.81 in.)

Frame Size

03 = 030 10 = 100

05 = 050 15 = 150

07 = 075

Versio n

S = Base Version

Bulletin Number

LDAT = LDAT-Series Integrated Linear Thruster

(1) Magnetic strip has 1 mm pole pitch. Final resolution when used with a Kinetix® 300 servo drive is 0.488 μm. Absolute encoder is only compatible

with Kinetix 300 single-axis drives.

LDAT - x xx x xxx -xx x x x

Catalog Number Explanation

This is the catalog explanation for the LDAT-Series integrated linear thruster.

See Accessories

on page 57 for accessory catalog numbers.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 8

8 LDAT-Series Integrated Linear Thrusters

9

15 (X6)

2

1

Top Vie w o f

LDAT-Series Integrated Linear Thruster

(LDAT-S73010xx is shown)

5

7 (X2)

10 (X4)

13 (X4 sets)

6

Bottom View of

LDAT-Series Integrated Linear Thruster

(LDAT-S73010xx is shown)

4

12

11

6

14 (x4 sets)

8

3

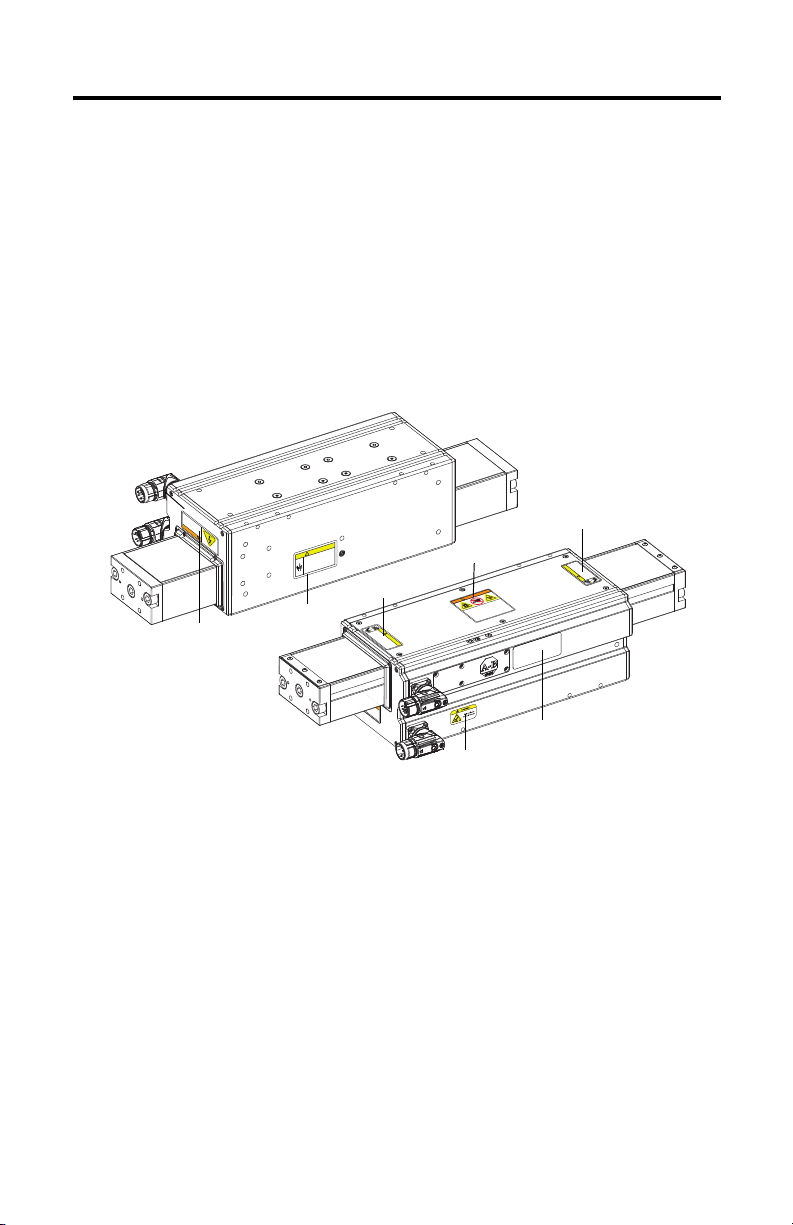

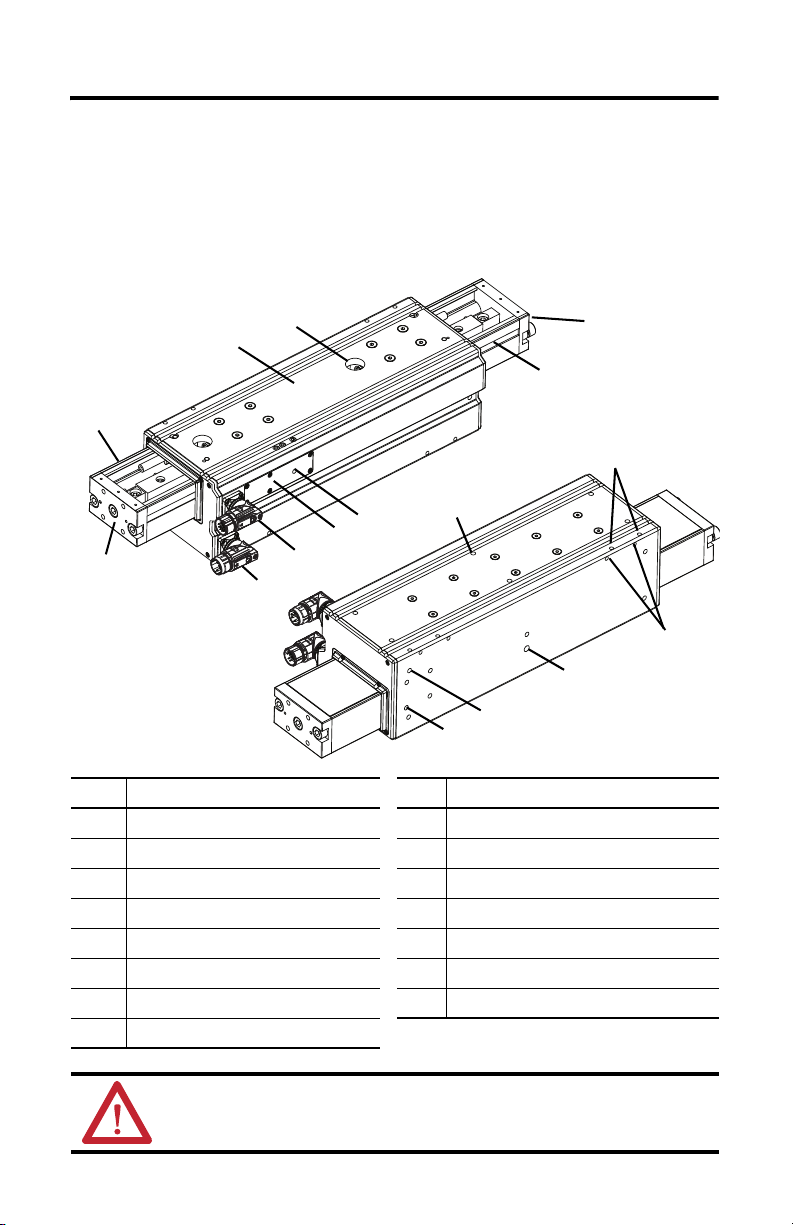

About the LDAT-Series Integrated Linear Thruster

LDAT-Series integrated linear thrusters feature high resolution encoders. The linear motor

extends or retracts the slider within the linear thruster housing. The linear thrusters have been

designed for exact positioning at high speeds.

Item Description Item Description

1 Power connector 9 Slider

2 Feedback connec tor 10 Clevis accessory threaded mounting holes

3 Encoder access panel 11 Side sur face threaded direct-mount holes

4 Encoder alignment access 12 Shipping and handling set screw

5 M agnetic Encoder scal e 13 Acces sory feet bottom-mount threaded holes

6 Payload mounting surface 14 Accessory feet side -mount threaded holes

7 Grease access (not a pplicable on frame 30) 15 Bottom sur face threaded direct-mount holes

8Stator body

ATTENTION: Magnetized tools can cause damage if they come too close to surface magnetic

encoder scale tape.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 9

LDAT-Series Integrated Linear Thrusters 9

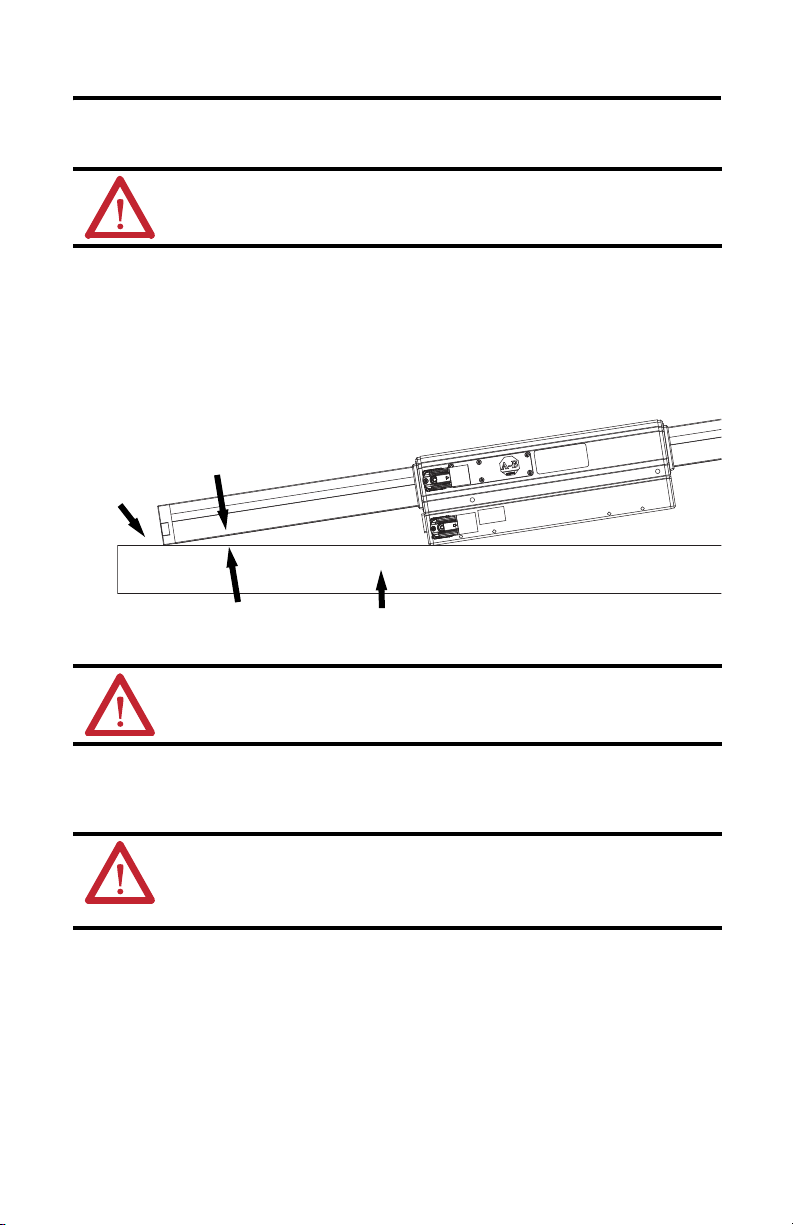

Ferrous Surface

Slider has Strong

Magnetic Forces

Sliders shown without cardboard

sleeve for demonstration purposes.

Pinch Point

Hazard

Before You Begin

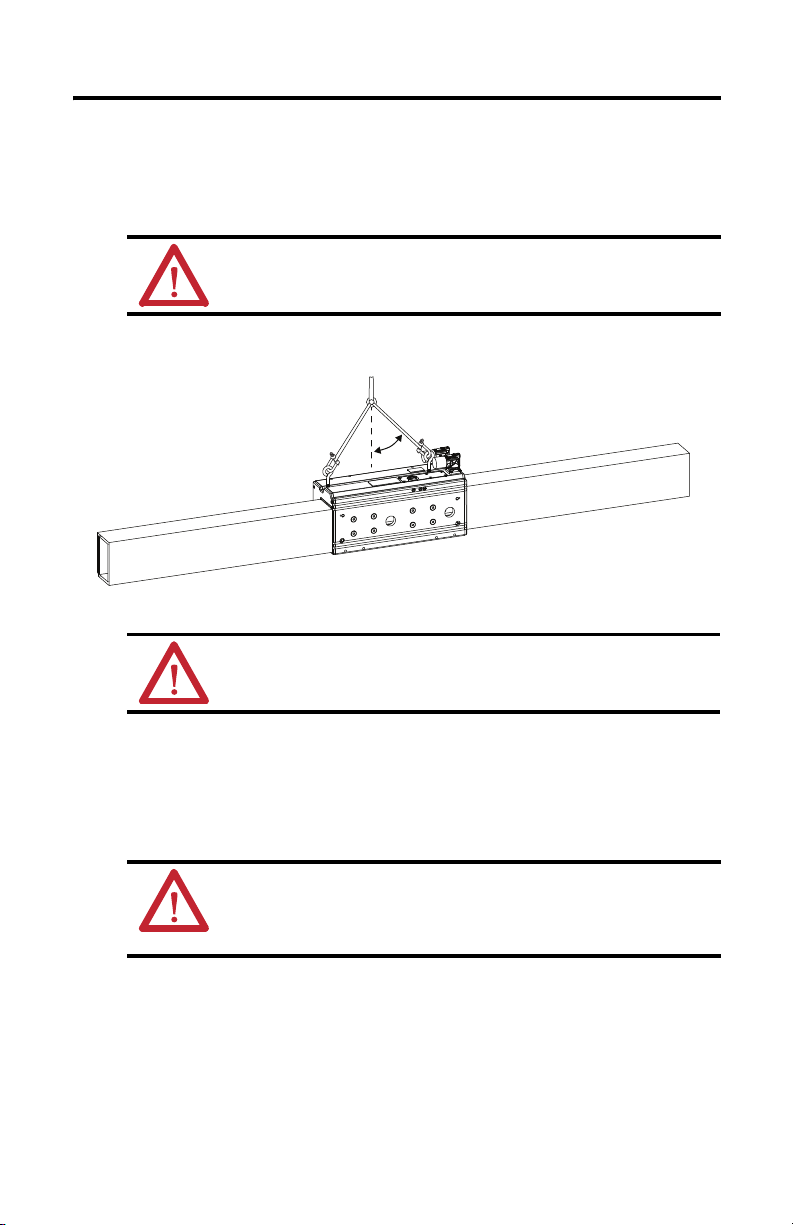

ATTENTION: To avoid personal injury and structural damage to the linear thruster, never attempt

lift or move the linear thruster by any means other than those listed in this publication.

Keep the packaging material on the linear thruster to minimize the possibility of it tipping. Do

not remove any of the corrugated or foam inserts until the linear thruster is at the installation

area. Leave corrugated cardboard tube on slider until the linear thruster has been installed in its

final location. If necessary for accessory installation cut the cardboard sleeve to gain access to the

slider ends.

ATTENTION: High force magnets are located inside the corrugated cardboard tubes that cover the

sliders. The corrugated tubes reduce, but does not eliminate magnetic attraction forces.

Overhead lifting is the recommended method for removing the linear thruster from its

container. Eye bolts are supplied with linear thrusters of frame 50 and larger and are taped to one

of the slider protective tubes.

ATTENTION: Be sure that the load ratings of the lifting device, slings, hooks and shackles have a

lifting capacity rated equal to or greater than the load. Failure to do so may result in personal injury

and/or equipment damage. For your system’s specific weight, refer to the system nameplate label

or shipping weights on the packing slip.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 10

10 LDAT-Series Integrated Linear Thrusters

Planning Your Installation

Refer to the Kinetix Linear Motion Specifications GMC-TD002, for the specifications and

additional products referenced in this section:

• Include unobstructed access to the linear thrusters shipping and handling setscrew in

your application design.

• This product can be operated in compliance with the relevant safety regulations, only if

the maximum loading limits are observed.

• If you are mounting your linear thruster in a vertical or sloping position, include safety

measures that will control the work load, should the power fail.

ATTENTION: Uncontrolled moving masses can cause injury or damage to propert y.

If there is a power failure, the working mass will drop down.

Check whether additional external safety measures are required to prevent damage in

the event of a power failure.

• Corrosive environments reduce the service life of linear thrusters.

• Factory-manufactured feedback and power cables are available in standard cable lengths.

They provide environmental sealing and shield termination. Contact your

Allen-Bradley® sales office or refer to the Kinetix Motion Accessories Specifications,

publication GMC-TD004, for additional information.

General safety standards and requirements include, but are not limited to, the following:

• UL 1740 Safety of Robots and Robotic Equipment

• ANSI/RIA R15.06, Industrial Robots and Robot Systems Safety Requirements -

Teaching Multiple Robots

• ANSI/NFPA 79, Electrical Standard for Industrial Machinery

• CSA/CAN Z434, Industrial Robots and Robot Systems- General Safety Requirements

• EN60204-1, Safety of Machinery. Electrical Equipment of Machines

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 11

LDAT-Series Integrated Linear Thrusters 11

Remove the Linear Thruster from the Shipping Container

1. Consider the weight of the linear thruster.

Depending on the design, the linear thruster can weigh up to 106.7 kg (235.2 lb).

ATTENTION: Linear thrusters that exceed 22.7 kg (50.0 lb) require a two man lift.

Do not lift the linear thruster by the slider. Use supplied eye bolts when ever possible.

2. Attach two eye bolts to connector side of the linear thruster.

3. Select or adjust the rigging lengths to compensate for the weight distribution.

ATTENTION: Do not pass ropes or cables through the eye bolts. Use hooks or shackles

with load-rated slings.

The angle between the lifting cables must not exceed 45° angle from vertical as shown.

Maintain the linear thruster in a balanced position.

4. Test lift the linear thruster a minimal amount.

Verify that it is properly secured and balanced before moving it further. The lift points

may not be equidistant from the center of gravity.

ATTENTION: Do not loosen the shipping and handling set screw until the linear thruster

is installed in your application. The slider is free to move once the shipping set screw is

loosened. Use additional care when working with the linear thruster after the set screw

is loosened. Unexpected slider movement can cause personal injury.

5. Lift the linear thruster.

6. Visually inspect the linear thruster for damage.

Closely examine the mounting surface, frame, and slider for defects.

7. Notify the carrier of shipping damage immediately.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 12

12 LDAT-Series Integrated Linear Thrusters

Prolonging Linear Thruster Life

Thoughtful design and proper maintenance can increase the life of a linear thruster. Follow these

guidelines to maximize the life of a linear thruster especially within a food processing

environment:

• Always provide a drip loop in each cable to carry liquids away from the connection to the

motor.

• If design requirements permit, provide shields that protect the motor housing, slider,

and their junctions from contamination by foreign matter or fluids.

• Inspect the bearings and strip cover, if equipped, for damage or wear on a regular basis. If

damage or excessive wear is observed, replace the item.

Preventing Electrical Noise

Electromagnetic interference (EMI), commonly called electrical noise, can reduce linear thruster

performance. Effective techniques to counter EMI include filtering the AC power by using

shielded cables, separating signal cables from power wiring, and practicing good grounding

techniques.

Follow these guidelines to avoid the effects of EMI:

• Isolate the power transformers or install line filters on all AC input power lines.

• Separate signal cables from motor cabling and power wiring. Do not route signal cables

with motor and power wires, or over the vent openings of servo drives.

• Ground all equipment by using a single-point parallel ground system that employs

ground bus bars or large straps. If necessary, use additional electrical noise reduction

techniques to reduce EMI in noisy environments.

Refer to System Design for Control of Electrical Noise Reference Manual, publication

GMC-RM001

, for additional information on reducing the effects of EMI.

Install the Linear Thruster

The installation must comply with all local and national safety and electrical codes and use of

equipment and installation practices that promote electromagnetic compatibility and safety.

Only qualified service personnel may install or service a linear thruster.

ATTENTION: Do not loosen the shipping and handling set screw until the linear thruster is

installed in its application.

ATTENTION: Install linear thruster to avoid interference with buildings, structures, utilities other

machines and equipment may create a trapping hazard or pinch points.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 13

LDAT-Series Integrated Linear Thrusters 13

ATTENTION: Unmounted linear thrusters, disconnected mechanical couplings, and disconnected

cables are dangerous if power is applied.

Appropriately identify (tag-out) disassembled equipment, and restrict (lock-out) access to

electrical power.

Failure to observe these safety precautions could result in personal injury.

Follow these steps to prepare the linear thruster for installation on the machine.

1. Provide sufficient clearances in the area of the linear thruster for it to stay within its

specified operating temperature range.

Refer to Specifications

on page 75 for the operating temperature range. Do not enclose

the linear thruster unless forced air is blown across the linear thruster for cooling. Keep

other heat producing devices away from the linear thruster.

2. Make sure the mounting surface supports the linear thruster evenly so that it is free of

mechanical stress and distortion. Evenness of the mounting surface must be within

0.127 mm (0.005 in.).

3. Attach mounting accessories, shown on page

If you are installing with this accessory Refer to this table or procedure

Clevis mount Install with Clevis Mount Accessory on page 16

Foot mount Install with Foot Mount Accessory on page 16

None Direct Mount the Linear Thruster on page 17

57, to the linear thruster.

4. Attach slider-end accessories, see on page 58, to the work load as outlined below.

Be sure the work load center of gravity is centric to the slider.

ATT EN TI ON : Damage may occur to the linear thruster bearings and the feedback device

if sharp impact to the slider is applied during installation. Do not strike the slider with

tools during installation or removal.

Failure to observe these safety precautions could result in damage to the linear thruster

and its components.

Use these torque values to attach a rod eye, rod clevis or payload bracket to the slider.

Cat. No. Torque, max

LDAT-S03

6.8 N•m (5 lb•ft)LDAT-S05

LDAT-S07

LDAT-S10

LDAT-S15

(1) Unless otherwise noted, torque specifications have a ±20% tolerance.

14.7 N•m (10.83 lb•ft)

(1)

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 14

14 LDAT-Series Integrated Linear Thrusters

If installing a counterbalance kit, install counter balance end bracket between slider end

cap and slider-end accessory. Complete counter balance kit installation by following

steps in Install Counterbalance Kit

on page 14.

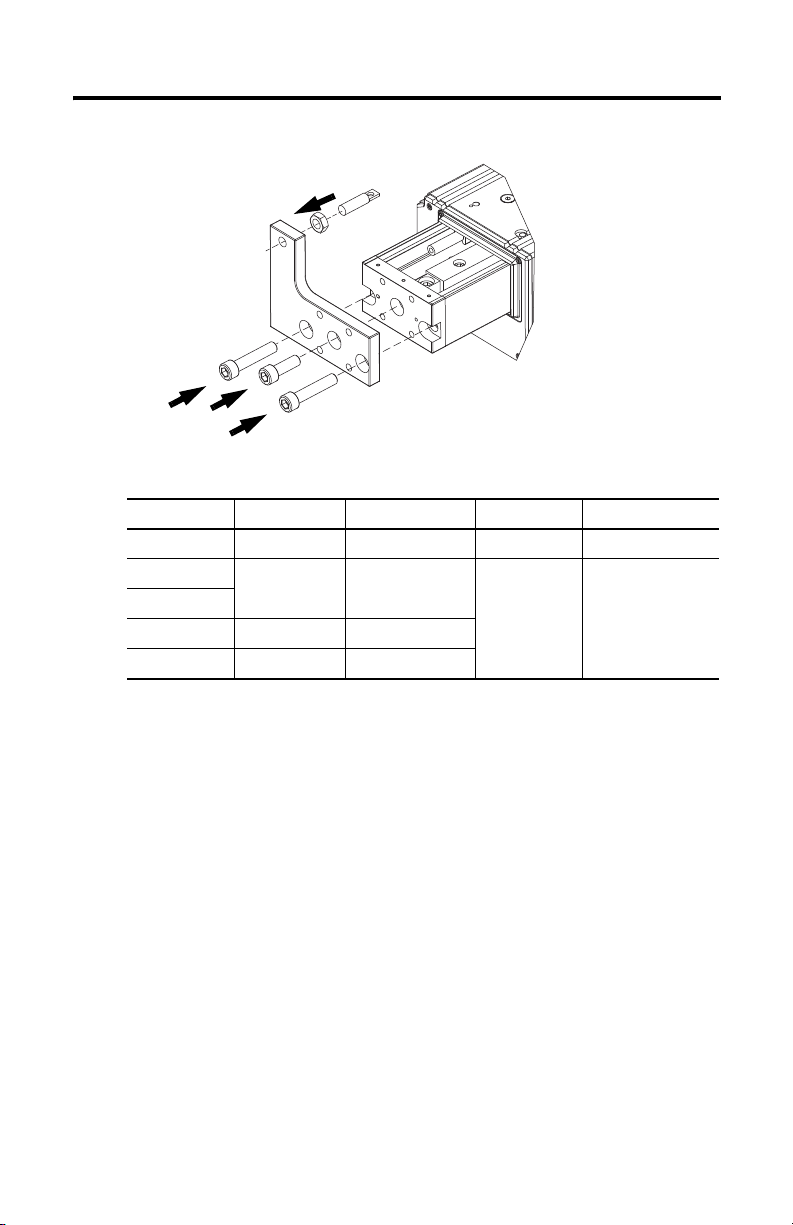

Install Counterbalance Kit

Follow these steps to install the counter balance kit.

Unless otherwise noted, torque specifications have a ±20% tolerance.

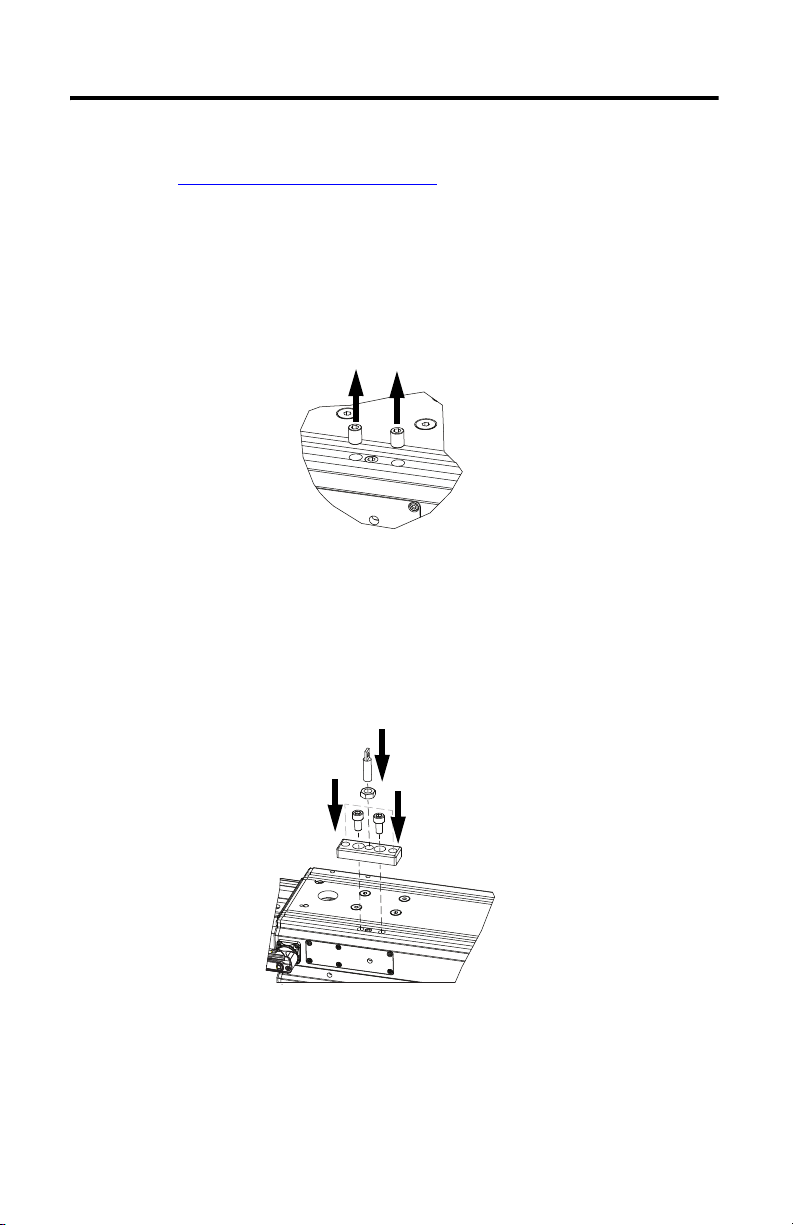

1. Remove M8 set screws from stator body.

2. Install stator bracket with two M8 x 1.25 x 16 socket head cap screws (SHCS).

Torque screw to 19.2 N•m (14.2 lb•ft).

3. Screw one 3/8 in. hex nut onto a spring anchor.

4. Install hex nut and spring anchor assemble in one of the three threaded mount locations.

Torque nut to 33.9 N•m (25.0 lb•ft).

5. Remove three screws that secure the slider-end cap and discard.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 15

LDAT-Series Integrated Linear Thrusters 15

6. Install the counter balance and slider-end cap the screws that came with the kit.

7. Torque to values shown in table.

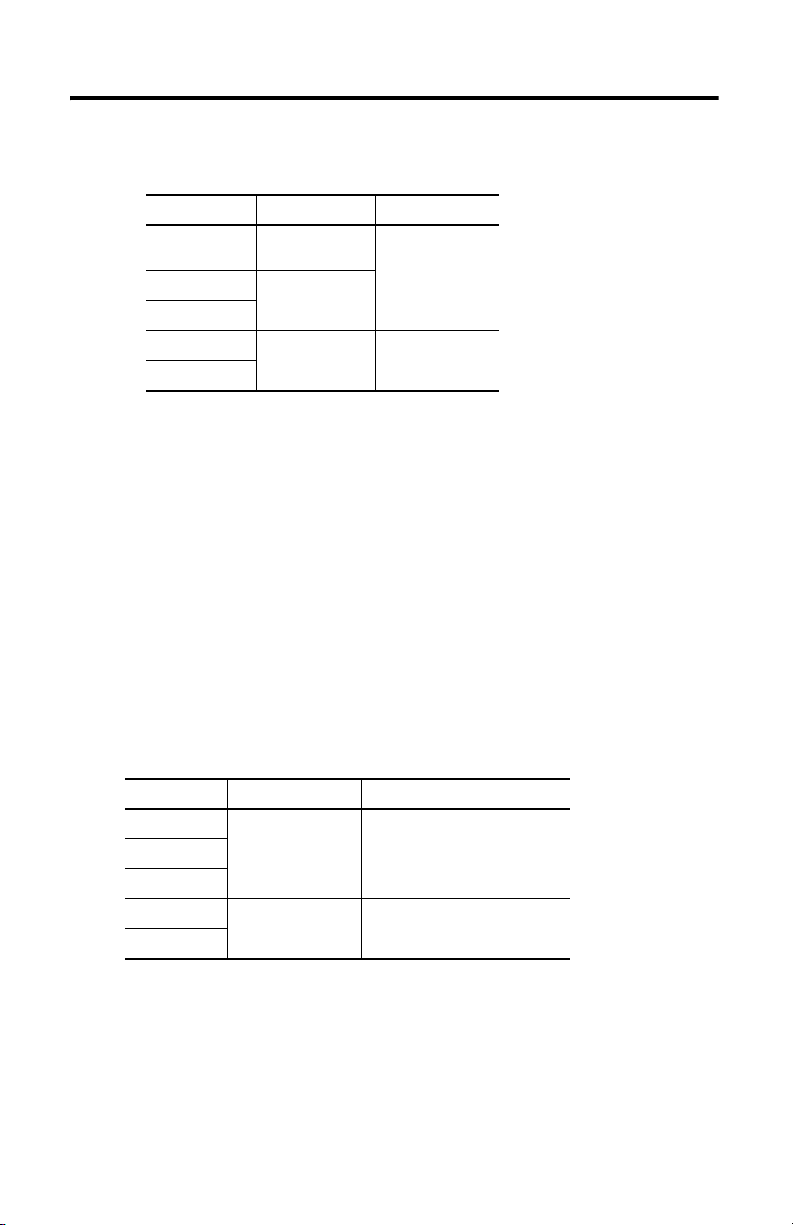

LDAT Frame Size S1 S1 Torque N•m (lb•in) S2 S2 Torque N•m (lb•in)

30 M8 x1.25 x 40 13.5 (10.0) M6 x1.0 x 30 9.0 (6.6)

50

75

100 M12 x1.75 x 60 54.8 (40.4)

150 M14 x2.05 x 60 84.7 (62.5)

M10 x1.5 x 50 33.9 (25.0)

M10 x1.5 x 30 33.9 (25.0)

8. Screw one 3/8 in. hex nut onto a spring anchor.

9. Install hex nut and spring anchor assemble in the counter balance bracket.

Torque nut to 33.9 N•m (25.0 lb•ft).

Attach your counter balance spring between the two spring anchor pins.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 16

16 LDAT-Series Integrated Linear Thrusters

Install with Clevis Mount Accessory

Install the clevis mount accessory with screws included in the kit and torque to the values shown.

Cat. No. Clevis Kit

LD AT-S 03 LD AT-03 -C LVSM or

LDAT-S05

LDAT-S07

LDAT-S10

LDAT-S15

LDAT-03-CLVSF

LDAT-0507-CLVSM or

LDAT-0507-CLVSF

LDAT-1015-CLVSM or

LDAT-1015-CLVSF

Torq ue, m ax

6.8N•m (5.00lb•ft)

14.7 N•m (10.83 lb•ft)

Install with Foot Mount Accessory

Follow these steps to mount the linear thruster on your application with the foot mount

accessory.

1. Verify the mounting surface flatness.

The mounting surface must be flat or shimmed flat to the mounting surface of the linear

thruster within 0.127 mm (0.005in.) to avoid distortion and damage to the actuator

housing.

2. Loosely install the all of the foot mounts on to your application with your fasteners.

3. Loosely install linear thruster to foot mounts by using two of the supplied screws per

foot mount.

4. Tighten mounting fasteners to your application.

5. Torque the foot mount screw to linear thruster to the following values.

Cat. No. Foot Mount Torque, max

LDAT-S03

LDAT-MID-FTMOUNT 4.5 N•m (3.33 lb•in)LDAT-S05

LDAT-S07

LDAT-S10

LDAT-S15

(1) Unless otherwise noted, torque specifications have a ±20% tolerance.

LDAT-LARGE-FTMOUNT 6.8 N•m (5.00 lb•in)

(1)

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 17

LDAT-Series Integrated Linear Thrusters 17

Direct Mount the Linear Thruster

Follow these steps to mount the linear thruster on directly on your machine.

1. Verify the mounting surface flatness.

The mounting surface must be flat or shimmed flat to the mounting surface of the linear

thruster within 0.127 mm (0.005 in.) to avoid distortion and damage to the actuator

housing.

2. Install and evenly tighten the steel fasteners so the linear thruster.

Torque the steel fasteners evenly to following values.

Cat. No. Torque, max

LDAT-S03

4.5N•m (3.33lb•in)LDAT-S05

LDAT-S07

LDAT-S10

LDAT-S15

ATTENTION: When installed, pinch points with high forces are created that have the potential for

causing physical damage. The risk area surrounding the linear thruster must be enclosed or clearly

marked, including signage in accordance with national and international requirements.

The risk area must be protected by a safety system that stops the equipment if anyone enters the

risk area. Personnel who enter the risk area must be authorized, trained, and qualified for any task

performed inside t he risk area.

6.8N•m (5.00lb•in)

Build and Route Cables

Knowledgeable cable routing and careful cable construction improves system electromagnetic

compatibility (EMC).

To build and install cables, perform these steps.

1. Keep wire lengths as short as possible.

2. Route signal cables (encoder or serial) away from motor and power wiring.

3. Separate cables by 0.3 m (1 ft) minimum for every 9 m (30 ft) of parallel run.

4. Ground both ends of the encoder cable shield and twist the signal wire pairs to prevent

electromagnetic interference (EMI) from other equipment.

ATTENTION: High voltage can be present on the shield of a power cable, if the shield is not

grounded.

Make sure there is a connection to ground for any power cable shield.

Failure to observe these safety precautions could result in personal injury or damage to equipment.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 18

18 LDAT-Series Integrated Linear Thrusters

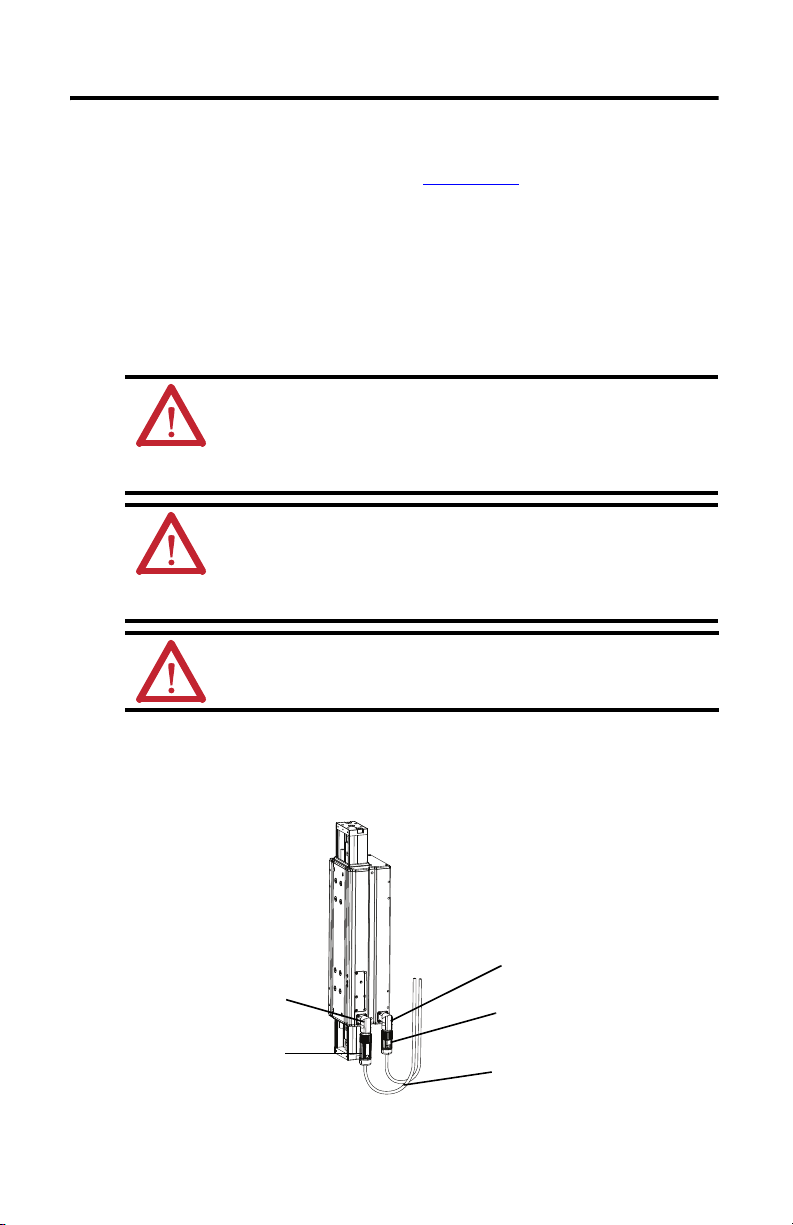

Flat Surface

with Logo on Top

Feedback Connector

Drip Loop

Power Connector

Flat Surface

with Logo on Top

The cable length from the linear thruster to the drive should be limited to 10 m (32.8 ft). If

longer cables are necessary, a 1321-3Rx-x series line reactor is required. Refer to the 1321 Power

Conditioning Products Technical Data, publication 1321- TD001

, to choose a line reactor for

applications requiring cable longer than 10 m (32.8 ft).

Attach Motor Cables

Use this procedure to attach the power and feedback cables after the linear thruster is mounted.

1. Carefully align each cable connector with the respective linear thruster connector as

shown in the diagram.

ATT EN TI ON : Keyed connectors must be properly aligned and hand-tightened the

recommended number of turns.

Improper connector alignment is indicated by the need for excessive force to seat

connectors. For example, the need to use tools to fully seat connectors.

Failure to observe these safety precautions could result in damage to equipment.

ATT EN TI ON : When installing a threaded DIN cable with a M4 designation, an O-ring

must be installed in the groove immediately adjacent to the body of the linear thruster

connector. This O-ring dampens the effects of vibration at the cable-to-linear thruster

connection.

Cables requiring O-rings includ e 2090-XXNFMF-Sxx (standard, non-flex) feedback cables.

ATT EN TI ON : When installing cables with a SpeedTec DIN connector with M7

designation, remove the O-ring.

2. Fully seat the feedback connector and the power/brake connector.

• Hand tighten the collar of a threaded DIN (M4) connector six turns.

• Hand tighten the collar of a SpeedTec (M7) connector one-quarter turn.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 19

LDAT-Series Integrated Linear Thrusters 19

As Manufactured

ATTENTION: Make sure cables are installed and restrained to prevent uneven tension or

flexing at the cable connectors. Excessive and uneven lateral force at the cable

connectors may result in the connector’s environmental seal opening and closing as the

cable flexes.

Failure to observe these safety precautions could result in damage to the linear thruster

motor and its components.

3. Form a drip loop in the cable to keep liquids away from the connectors.

4. Verify the continuity and functionality of the thermal switch signals, TS+ and TS-.

These signals are transmitted through the feedback cable that connects the motor to its

controlling drive.

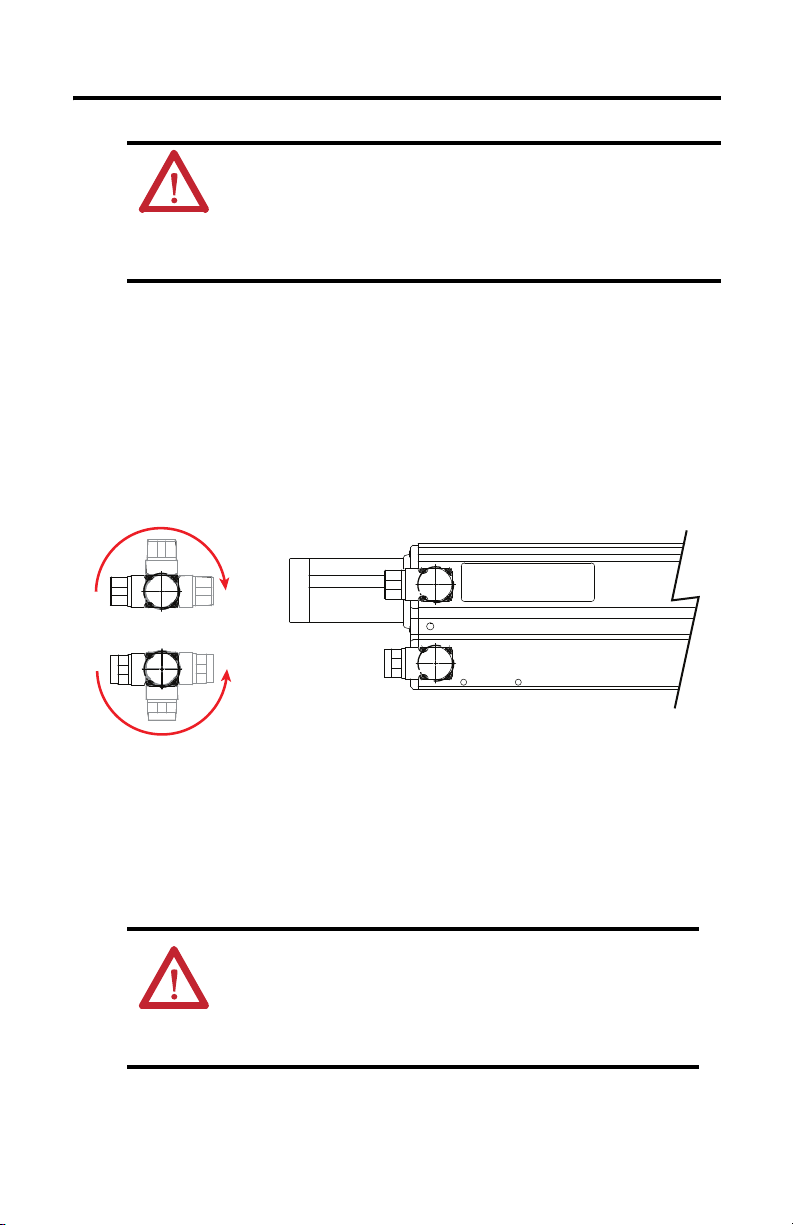

Change Connector Orientation

You can rotate the circular DIN connector housings up to 180°.

Follow these steps to rotate the DIN connectors.

1. Mount and fully seat a mating cable on the connector.

2. Grasp the connector and the cable plug by their housings and slowly rotate them to the

outside of the motor.

If necessary, repeat these steps for the other connector (feedback or power/brake).

ATT EN TI ON : Only apply force to the connectors; do not apply force to the cable. Do

not use tools (for example, pliers and vise-grips) to assist with the rotation of the

connector.

Failure to observe these safety precautions could result in personal injury or damage

to equipment.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 20

20 LDAT-Series Integrated Linear Thrusters

52.50

(2.07)

60.48

(2.38)

To Stop

1/2 stroke

Typical both ends

(1)

Typical both ends

(1)

46.35

(1.82)

60.00

(2.36)

Typical

M

14.56

(0.57)

Typical

A

26.35

(1.04)

Typical

90.00

(3.54)

174.03

(6.85)

55.00

(2.17)

165.00

(6.50)

125.00

(4.92)

125.00

(4.92)

Reference

35.00

(1.38)

L

147.00

(5.79)

B

66.35

(2.612)

81.00

(3.19)

35.00

(1.38)

22.00

(0.87)

Square

50.00

(1.97)

Dowel Pin Clearance

(2X) M3 x 6.0 (0.24)

1.00

(0.04)

Detail A

Slider end mounting

typical both ends

Accessory Mounting Holes

(4X) M6 x 1.0-6H x 9.0 (0.35)

A

26.35

(1.04)

Typical

55.00

(2.17)

C

112.00

(4.41)

130.00

(5.12)

32.50

(1.28)

Square

25.10

(0.99)

M

53.85

(2.120)

90.00

(3.54)

M6 x 1.0-6h x 7.0

Mounting Holes in N places.

LDAT-MID-FTMOUNT optional foot

mounting uses (4X) M8 x1.25 x 20 min

socket head cap screw.

Optional Clevis Mounting Holes

(4X) M6 x 1.0-6h x 7.0

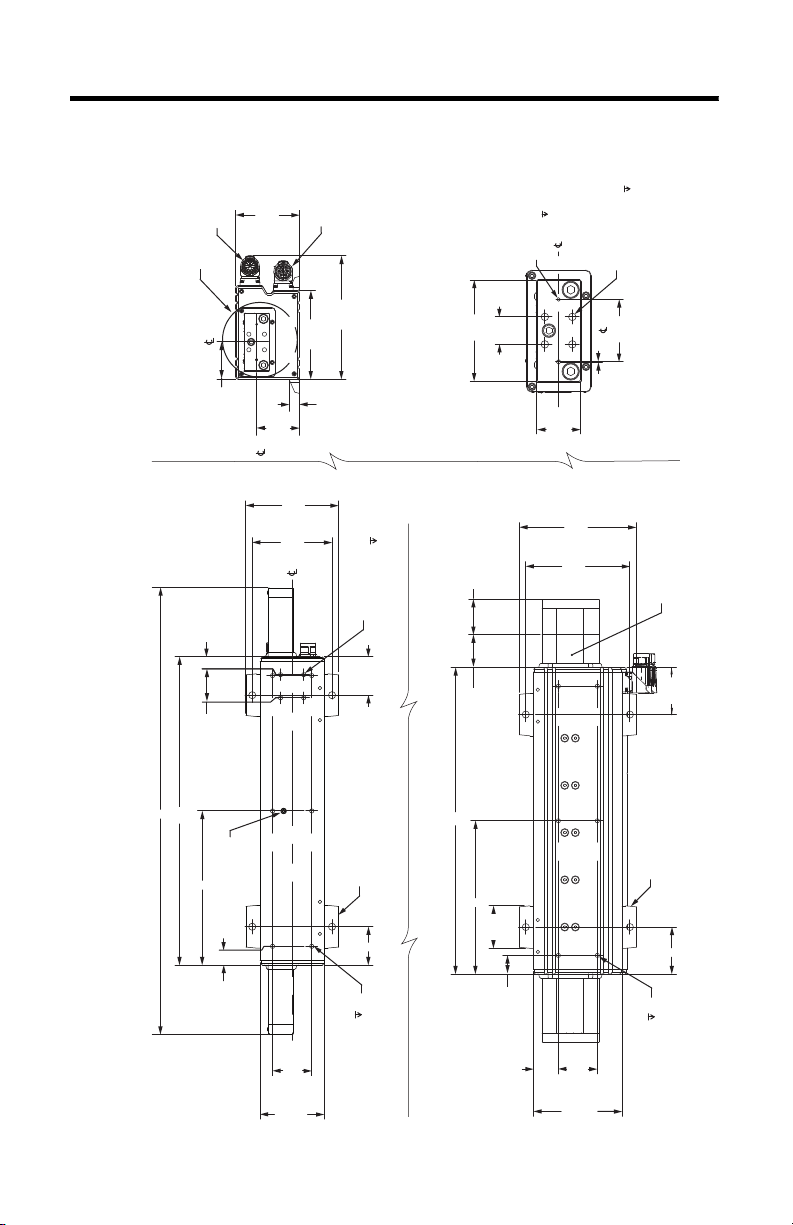

Feedback Connector

Power Connector

(1) Up to approximately 5 mm (0.2 in.) overtravel at each end. An additional 12.7 mm (0.5 in.) overtravel each end when stop is fully compressed in a crash condition.

Bottom View of Side Mounting

Bottom View of Bottom Mounting

End View of Bottom Mounting

Shipping/

Handling Lockscrew

ATTENTION: High magnetic eld.

Use caution with tools and loose hardware.

Pacemaker wearers maintain

300 mm (12 in.) distance.

LDAT-MID-FTMOUNT optional foot

mounting uses (4X) M8 x 1.25 x 20, min

socket head cap screws.

Power and feedback

connectors can rotate 180°

See Detail A

M6 x 1.0-6h x 7.0

Mounting Holesin N places

Dimensions are in mm (in.)

Linear Thruster Dimensions (frame 30)

Dimensions

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 21

LDAT-Series Integrated Linear Thrusters 21

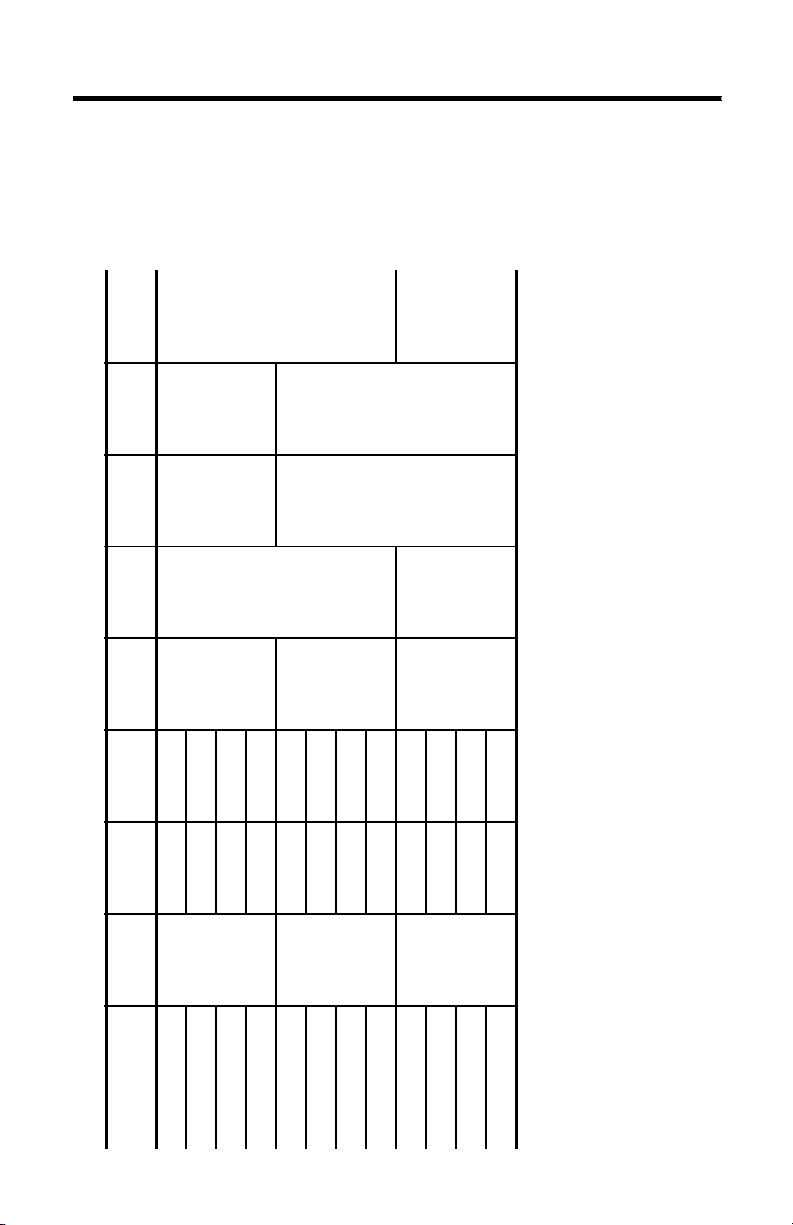

N

C

mm (in.)

B

mm (in.)

A

mm (in.)

M

mm (in.)

L

mm (in.)

Stroke

mm (in.)

100 (3.9) 425.4 (16.75)

51.35 (2.022) 38.85 (1.5 30)

232.70 (9.161)

4

66.35 (2.612) 53.85 (2.1 20)

—

332.70

(13.098)

100 (3.9) 525.4 (20.69)

216.35 (8.518) 6

432.70

(17.035)

100 (3.9) 625.4 (24.62)

Motor size

(reference)

)

Linear Thruster

(frame 30) Cat. No.

Dimensions (frame 30

100

LDAT-S031010-xxx

LDAT-S031020-xxx 200 (7.9) 525.4 (20.69)

LDAT-S031030-xxx 300 (11.8) 625.4 (24.62)

LDAT-S031040-xxx 400 (15.7) 725.4 (28.56)

200

LDAT-S032010-xxx

LDAT-S032020-xxx 200 (7.9) 625.4 (24.62)

LDAT-S032030-xxx 300 (11.8) 725.4 (28.56)

LDAT-S032040-xxx 400 (15.7) 825.4 (32.50)

300

LDAT-S033010-xxx

LDAT-S033020-xxx 200 (7.9) 725.4 (28.56)

LDAT-S033030-xxx 300 (11.8) 825.4 (32.50)

LDAT-S033040-xxx 400 (15.7) 925.4 (36.43)

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 22

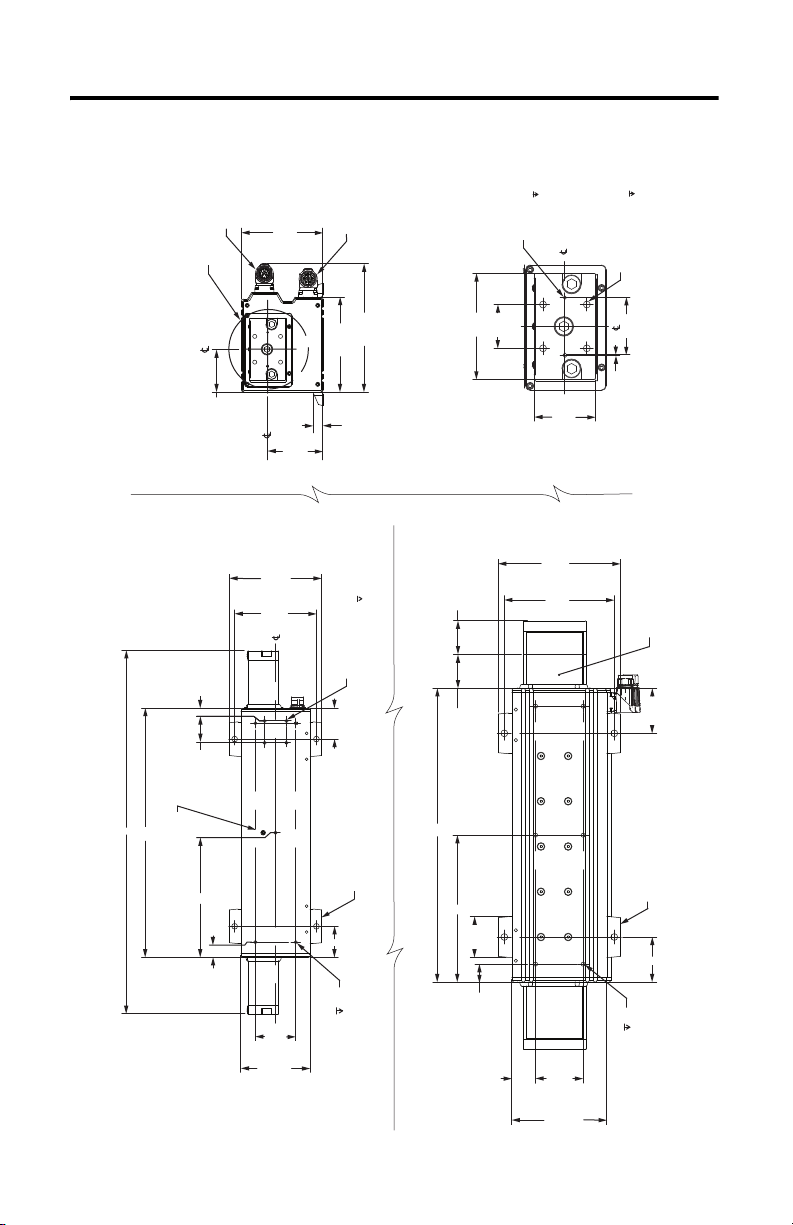

22 LDAT-Series Integrated Linear Thrusters

1/2 stroke

Typical both ends

(1)

B

26.35

(1.04)

Typical

A

140.00

(5.51)

120.00

(4.72)

60.00

(2.36)

Typical

Typical

14.56

(0.57)

70.00

(2.76)

35.00

(1.38)

M

162.00

(6.38)

180.00

(7.09)

189.03

(7.44)

Shipping/

Handling Lockscrew

L

63.00

(2.48)

81.49

(3.21)

66.35

(2.612)

140.00

(5.51)

To Stop

Typical both ends

(1)

49.53

(1.95)

Detail A

Slider end mounting

typical both ends

ATTENTION: High magnetic eld.

Use caution with tools and loose hardware.

Pacemaker wearers: maintain

300 mm (12 in.) distance.

38.00

(1.50)

Square

53.00

(2.09)

50.00

(1.97)

1.00

(0.04)

92.00

(3.62)

Mounting Holes

(4X) M6 x 1.0-6H x 9.0

Dowel Pin Clearance

(2X) M3 x 6.0 [.24]

A

70.00

(2.76)

160.00

(6.30)

142.00

(5.59)

C

38.00

(1.50)

Square

26.35

(1.04)

Typical

22.35

(0.88)

M

53.85

(2.120)

120.00

(4.72)

Reference

Optional Clevis Mounting Holes

(4X) M6 x 1.0-6H x 7.0 (.35)

(1) Up to approximately5 mm (0.2 in.) overtravel at each end. An additional 12.7 mm (0.5 in.) overtravel each end when stop is fully compressed in a crash condition.

LDAT-MID-FTMOUNT optional foot

mounting uses (4X) M8 x 1.25 x 20, min

socket head cap screws.

LDAT-MID-FTMOUNT optional foot

mounting uses (4X) M8 x 1.25 x 20, min

socket head cap screws.

Power and feedback

connectors can rotate 180°.

Feedback Connector

Power Connector

See Detail A

M6 x 1.0-6h x 7.0

Mounting Holes in N places.

M6 x 1.0-6h x 7.0

Mounting Holes in N places.

Bottom View of Side Mounting

Bottom View of Bottom Mounting

End View of Bottom Mounting

Linear Thruster Dimensions (frame 50 and 75)

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 23

LDAT-Series Integrated Linear Thrusters 23

N

C

mm (in.)

B

mm (in.)

A

mm (in.)

M

mm (in.)

L

mm (in.)

Stroke

mm (in.)

51.35 (2.022) 38.85 (1.530)

232.70 (9.161)

100 (3.9) 431 .8 (16.998)

4

66.35 (2.612) 53.85 (2.120)

—

332.70 (13.098)

100 (3.9) 531 .8 (20.935)

432.70 (17.035) 216.35 (8.518)

100 (3.9) 631 .8 (24.872)

5

532.70 (20.972) 266.35 (10.486)

100 (3.9) 731 .8 (28.809)

Motor size

(reference)

Linear Thruster

(frame 50) Cat. No.

Dimensions (frame 50)

100

LDAT-S051010-xxx

LDAT-S051020-xxx 200 (7.9) 531 .8 (20.935)

LDAT-S051030-xxx 300 (11.8) 631.8 (24.872)

LDAT-S051040-xxx 400 (15.7) 731.8 (28.809)

LDAT-S051050-xxx 500 (19.7) 831.8 (32.746)

200

LDAT-S052010-xxx

LDAT-S052020-xxx 200 (7.9) 631 .8 (24.872)

LDAT-S052030-xxx 300 (11.8) 731.8 (28.809)

LDAT-S052040-xxx 400 (15.7) 831.8 (32.746)

LDAT-S052050-xxx 500 (19.7) 931.8 (36.683)

300

LDAT-S053010-xxx

LDAT-S053020-xxx 200 (7.9) 731 .8 (28.809)

LDAT-S053030-xxx 300 (11.8) 831.8 (32.746)

LDAT-S053040-xxx 400 (15.7) 931.8 (36.683)

LDAT-S053050-xxx 500 (19.7) 1031.8 (40.620)

400

LDAT-S054010-xxx

LDAT-S054020-xxx 200 (7.9) 831 .8 (32.746)

LDAT-S054030-xxx 300 (11.8) 931.8 (36.683)

LDAT-S054040-xxx 400 (15.7) 1031.8 (40.620)

LDAT-S054050-xxx 500 (19.7) 1131.8 (44.557)

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 24

24 LDAT-Series Integrated Linear Thrusters

N

C

B

A

M

L

Stroke

mm (in.)

mm (in.)

mm (in.)

mm (in.)

mm (in.)

mm (in.)

100 (3.9) 531.8 (20.94)

4

53.850

(2.120)

66.35

(2.612)

—

332.70

(13.098)

100 (3.9) 631.8 (24.87)

216.35

432.70

5

(8.52)

(17.035)

Motor size

(reference)

Linear Thruster

(frame 75) Cat. No.

Dimensions (frame 75)

LDAT-S072010-xxx

LDAT-S072020-xxx 200 (7.9) 631.8 (24.87)

LDAT-S072030-xxx 300 (11.8) 731.8 (28.81)

200

LDAT-S072040-xxx 400 (15.7) 831.8 (32.75)

LDAT-S072050-xxx 500 (19.7) 931.8 (36.68)

LDAT-S072060-xxx 600 (23.6) 1031.8 (40.62)

LDAT-S072070-xxx 700 (27.6) 1131.8 (44.56)

LDAT-S073010-xxx

LDAT-S073020-xxx 200 (7.9) 731.8 (28.81)

LDAT-S073030-xxx 300 (11.8) 831.8 (32.75)

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

300

LDAT-S073040-xxx 400 (15.7) 931.8 (36.68)

LDAT-S073050-xxx 500 (19.7) 1031.8 (40.62)

LDAT-S073060-xxx 600 (23.6) 1131.8 (44.56)

LDAT-S073070-xxx 700 (27.6) 1231.8 (48.49)

Page 25

LDAT-Series Integrated Linear Thrusters 25

53.850

66.35

5

(2.120)

(2.612)

100 (3.9) 931.8 (36.68)

366.350

732.70

(14.42)

(28.85)

N

C

mm (in.)

B

mm (in.)

266.350

532.70

(10.49)

(20.97)

A

mm (in.)

M

mm (in.)

L

mm (in.)

Stroke

mm (in.)

100 (3.9) 731.8 (28.81)

(continued)

Motor size

(reference)

400

600

LDAT-S074010-xxx

Linear Thruster

(frame 75) Cat. No.

LDAT-S074020-xxx 200 (7.9) 831.8 (32.75)

LDAT-S074030-xxx 300 (11.8) 931.8 (36.68)

LDAT-S074040-xxx 400 (15.7) 1031.8 (40.62)

LDAT-S074050-xxx 500 (19.7) 1131.8 (44.56)

LDAT-S074060-xxx 600 (23.6) 1231.8 (48.49)

LDAT-S074070-xxx 700 (27.6) 1331.8 (52.43)

LDAT-S076010-xxx

LDAT-S076020-xxx 200 (7.9) 1031.8 (40.62)

LDAT-S076030-xxx 300 (11.8) 1131.8 (44.56)

LDAT-S076040-xxx 400 (15.7) 1231.8 (48.49)

LDAT-S076050-xxx 500 (19.7) 1331.8 (52.43)

LDAT-S076060-xxx 600 (23.6) 1431.8 (56.37)

Dimensions (frame 75)

LDAT-S076070-xxx 700 (27.6) 1531.8 (60.31)

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 26

26 LDAT-Series Integrated Linear Thrusters

52.70

(2.075)

18.00

(0.709)

Typical

140.00

(5.512)

190.00

(7.480)

239.12

(9.414)

92.49

(3.641)

84.00

(3.307)

L

212.00

(8.346)

230.00

(9.055)

66.35

(2.612)

Typical

85.00

(3.346)

26.35

(1.037)

Typical

A

M

62.00

(2.441)

Typical

52.50

(2.067)

190.00

(7.480)

Reference

To Stop

1/2 stroke

Typical both ends

(1)

Typical both ends

(1)

ATTENTION: High magnetic eld.

Use caution with tools and loose hardware.

Pacemaker wearers: maintain

300 mm (12 in.) distance.

135.00

(5.315)

63.00

(2.480)

50.00

(1.969)

45.00

(1.772)

Square

1.00

(0.039)

Mounting Holes

(4x) M8 x 1.25-6h x 12.0

Dowel Pin Clearance

(2x) M3 x 6.0 (0.24)

M

A

26.35

(1.037)

Typical

162.00

(6.378)

180.00

(7.087)

53.85

(2.120)

85.00

(3.346)

56.50

(2.224)

Square

23.10

(0.909)

140.00

(5.512)

Reference

M8 x 1.25-6H x 12.0

Mounting Holes in N places.

M8 x 1.25-6H x 12.0

LDAT-LARGE-FTMOUNT optional foot

mounting uses quanitity S M10 x 1.5 x 20 min

socket head cap screw.

LDAT-LARGE-FTMOUNT optional foot

mounting uses quanitity S M10 x 1.5 x 20 min

socket head cap screw.

Optional Clevis Mounting Holes

(4X) M8 x 1.25-6H x 12.0

(1) Up to approximately 5 mm (0.2 in.) overtravel at each end. An additional 12.7 mm (0.5 in.) overtravel each end when stop is fully compressed in a crash condition.

Bottom View of Side Mounting

Bottom View of Bottom Mounting

End View of Bottom Mounting

Shipping/

Handling Lockscrew

Power and feedback

connectors can rotate 180°.

See Detail A

Detail A

Slider end mounting

typical both ends

Feedback Connector

Power Connector

Linear Thruster Dimensions (frame 100)

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 27

NS

A

mm (in.)

LDAT-Series Integrated Linear Thrusters 27

4

M

mm (in.)

L

mm (in.)

Stroke

mm (in.)

100 (3.9) 538.1 (21.18)

Motor size

(reference)

Linear Thruster

(frame 100) Cat. No.

LDAT-S102010-xx

Dimensions (frame 100)

LDAT-S102020-xx 200 (7.9) 638.1 (25.12)

332.70 (13.098) — 4

432.70 (17.035) 216 .35 (8.518) 6

100 (3.9) 638.1 (25.12)

200

LDAT-S102030-xx 300 (11.8) 738.1 (29.06)

LDAT-S102040-xx 400 (15.7) 838.1 (33.00)

LDAT-S102050-xx 500 (19.7) 938.1 (36.93)

LDAT-S102060-xx 600 (23.6) 1038.1 (40.87)

LDAT-S102070-xx 700 (27.6) 1138.1 (44.81)

LDAT-S102080-xx 800 (31.5) 1238.1 (48.74)

LDAT-S102090-xx 900 (35.4) 1338.1 (52.68)

LDAT-S103010-xx

LDAT-S103020-xx 200 (7.9) 738.1 (29.06)

300

LDAT-S103030-xx 300 (11.8) 838.1 (33.00)

LDAT-S103040-xx 400 (15.7) 938.1 (36.93)

LDAT-S103050-xx 500 (19.7) 1038.1 (40.87)

LDAT-S103060-xx 600 (23.6) 1138.1 (44.81)

LDAT-S103070-xx 700 (27.6) 1238.1 (48.74)

LDAT-S102080-xx 800 (31.5) 1338.1 (52.68)

LDAT-S102090-xx 900 (35.4) 1438.1 (56.62)

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 28

LDAT-Series Integrated Linear Thrusters 28

NS

A

mm (in.)

M

mm (in.)

L

mm (in.)

100 (3.9) 738.1 (29.06)

Stroke

mm (in.)

Motor size

(reference)

532.70 (20.972) 266 .35 (10.486)

400

66

732.70 (28.846) 366 .35 (14.423)

100 (3.9) 938.1 (36.93)

600

LDAT-S104010-xx

LDAT-S104020-xx 200 (7.9) 838.1 (33.00)

LDAT-S104030-xx 300 (11.8) 938.1 (36.93)

LDAT-S104040-xx 400 (15.7) 1038.1 (40.87)

LDAT-S104050-xx 500 (19.7) 1138.1 (44.81)

LDAT-S104060-xx 600 (23.6) 1238.1 (48.74)

LDAT-S104070-xx 700 (27.6) 1338.1 (52.68)

LDAT-S104080-xx 800 (31.5) 1438.1 (56.62)

LDAT-S104090-xx 900 (35.4) 1538.1 (60.55)

Linear Thruster

(frame 100) Cat. No.

Dimensions (frame 100) (continued)

LDAT-S106010-xx

LDAT-S106020-xx 200 (7.9) 1038.1 (40.87)

LDAT-S106030-xx 300 (11.8) 1138.1 (44.81)

LDAT-S106040-xx 400 (15.7) 1238.1 (48.74)

LDAT-S106050-xx 500 (19.7) 1338.1 (52.68)

LDAT-S106060-xx 600 (23.6) 1438.1 (56.62)

LDAT-S106070-xx 700 (27.6) 1538.1 (60.55)

LDAT-S106080-xx 800 (31.5) 1638.1 (64.49)

LDAT-S106090-xx 900 (35.4) 1738.1 (68.43)

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 29

52.70

(2.075)

M

26.35

(1.037)

Typical

262.00

(10.315)

280.00

(11.024)

150.00

(5.906)

240.00

(9.449)

289.02

(11.379)

130.00

(5.118)

55.00

(2.165)

109.50

(4.311)

96.49

(3.799)

A

18.00

(0.709)

Typical

L

62.00

(2.441)

Typical

66.35

(2.612)

Typical

240.00

(9.449)

To Stop

1/2 stroke

Typical both ends

(1)

Typical both ends

(1

)

Optional Clevis Mounting Holes

(4X) M8 x 1.25-6H x 12.0

Shipping/

Handling Lockscrew

Detail A

Slider end mounting

typical for both ends.

179.00

(7.047)

45.00

(1.772)

Square

73.00

(2.874)

50.00

(1.969)

1.00

(0.039)

Dowel Pin Clearance

(2X) M3 x 6.0 [.24]

Mounting Holes

(4X) M8 x 1.25-6H x 12.0

Feedback Connector

Power Connector

26.35

(1.037)

Typical

172.00

(6.772)

190.00

(7.480)

A

53.85

(2.120)

Typical

M

56.50

(2.224)

Square

23.10

(0.909)

100.00

(3.937)

150.00

(5.906)

Reference

Power and feedback

connectors can rotate 270°

See Detail A

Bottom View of Side Mounting

Bottom View of Bottom Mounting

End View of Bottom Mounting

ATTENTION: High magnetic eld.

Use caution with tools and loose hardware.

Pacemaker wearers: maintain

300 mm (12 in.) distance.

M8 x 1.25-6H x 12.0

Mounting Holes in N places.

M8 x 1.25-6H x 12.0

Mounting Holes in N places.

LDAT-LARGE-FTMOUNT optional foot

mounting uses quanitity S M10 x 1.5 x 20 min

socket head cap screw.

LDAT-LARGE-FTMOUNT optional foot

mounting uses quanitity S M10 x 1.5 x 20 min

socket head cap screw.

Linear Thruster Dimensions (frame 150)

LDAT-Series Integrated Linear Thrusters 29

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 30

30 LDAT-Series Integrated Linear Thrusters

NS

A

mm (in.)

M

mm (in.)

L

mm (in.)

100 (3.9) 538.1 (21.18)

mm (in.)

(reference)

200 (7.9) 638.1 (25.12)

Stroke

Motor size

300 (11.8) 738.1 (29.06)

400 (15.7) 838.1 (33.00)

44

332.70 (13.098) —

500 (19.7) 938.1 (36.93)

600 (23.6) 1038.1 (40.87)

700 (27.6) 1138.1 (44.81)

800 (31.5) 1238.1 (48.74)

200

900 (35.4) 1338.1 (52.68)

64

432.70 (17.035) 216.35 (8.518)

100 (3.9) 638.1 (25.12)

200 (7.9) 738.1 (29.06)

300 (11.8) 838.1 (33.00)

400 (15.7) 938.1 (36.93)

500 (19.7) 1038.1 (40.87)

600 (23.6) 1138.1 (44.81)

700 (27.6) 1238.1 (48.74)

800 (31.5) 1338.1 (52.68)

900 (35.4) 1438.1 (56.62)

300

Linear Thruster

Dimensions (frame 150)

(frame 150) Cat. No.

LDAT-S152030-xxx

LDAT-S152040-xxx

LDAT-S152050-xxx

LDAT-S152060-xxx

LDAT-S152070-xxx

LDAT-S152080-xxx

LDAT-S152020-xxx

LDAT-S152010-xxx

LDAT-S152090-xxx

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

LDAT-S153010-xxx

LDAT-S153030-xxx

LDAT-S153040-xxx

LDAT-S153050-xxx

LDAT-S153060-xxx

LDAT-S153070-xxx

LDAT-S153080-xxx

LDAT-S153020-xxx

LDAT-S153090-xxx

Page 31

LDAT-Series Integrated Linear Thrusters 31

NS

A

mm (in.)

M

mm (in.)

L

mm (in.)

100 (3.9) 738.1 (29.06)

mm (in.)

(reference)

200 (7.9) 838.1 (33.00)

Stroke

Motor size

66

532.70 (20.972) 266.35 (10.486)

300 (11.8) 938.1 (36.93)

400 (15.7) 1038.1 (40.87)

500 (19.7) 1138.1 (44.81)

600 (23.6) 1238.1 (48.74)

700 (27.6) 1338.1 (52.68)

800 (31.5) 1438.1 (56.62)

900 (35.4) 1538.1 (60.55)

100 (3.9) 938.1 (36.93)

200 (7.9) 1038.1 (40.87)

400

732.7 (28.846) 366.35 (14.423)

300 (11.8) 1138.1 (44.81)

400 (15.7) 1238.1 (48.74)

500 (19.7) 1338.1 (52.68)

600 (23.6) 1438.1 (56.62)

700 (27.6) 1538.1 (60.55)

800 (31.5) 1638.1 (64.49)

900 (35.4) 1738.1 (68.43)

600

LDAT-S154010-xxx

Linear Thruster

(frame 150) Cat. No.

Dimensions (frame 150) (continued)

LDAT-S154030-xxx

LDAT-S154040-xxx

LDAT-S154050-xxx

LDAT-S154060-xxx

LDAT-S154070-xxx

LDAT-S154080-xxx

LDAT-S154090-xxx

LDAT-S156010-xxx

LDAT-S156020-xxx

LDAT-S156030-xxx

LDAT-S156040-xxx

LDAT-S156050-xxx

LDAT-S156060-xxx

LDAT-S156070-xxx

LDAT-S156080-xxx

LDAT-S154020-xxx

LDAT-S156090-xxx

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 32

32 LDAT-Series Integrated Linear Thrusters

Intercontec P/N

BEDC091NN00000202000

Intercontec P/N

AEDC113NN00000202000

Connector Data

This table lists the signal descriptions for connector pins on the linear thruster.

Feedback Power and Brake

Pin Signal Name

LDAT-xxxxxxx-xBx

(incremental encoder)

Signal Name

LDAT-xxxxxxx-xDx

(absolute encoder)

(2)

1A+ Sin+ A Phase U

2A- Sin- B Phase V

3B+ Cos+ C Phase W

4 B- Cos- D Ground

5 Index+ Data+ E Reserved

6 Index- Data- F

7 Reser ved Reser ved G

8H

9+5VDC L

10 Common Common Case Cable Shield and GND

11 Reserved +9V DC

12 Reserved

13 TS+

14 TS-

(1)

(1)

TS+

TS-

(1)

(1)

15 S1 Reserved

16 S2

17 S3

Case Shield Shield

(1) The normally closed thermal switch opens at 100 °C (212 °F).

(2) Absolute encoder is only compatible with Kinetix 300 single-axis drives.

(3) Power pins A, B, C, and D may be labeled as U, V, W, and GND respectively.

Reserved pins E and H may be numbered 1 or 2.

Pin

(3)

Signal Name

1

11

12

13

16

10

2

3

9

17

1415

4

8

6

7

5

ACBD

G

F

L

H

E

ATTENTION: Be sure that cables are installed and restrained to prevent uneven tension or

flexing at the cable connectors. Excessive and uneven lateral force at the cable connector may

result in damage to the housing and contacts as the cable flexes.

Failure to observe these safety precautions could result in damage to the motor and its

components.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 33

LDAT-Series Integrated Linear Thrusters 33

Commissioning

This section provides guidelines for using RSLogix™ 5000 and MotionView software to

configure your linear thruster servo drive system.

Required Files

Firmware revisions and software versions required to support the linear thrusters include the

following.

Drive Firmware

Versi on min

Kinetix 2000 with SERCOS 1.199 RSLogix 16.xx LDAT_7_6_12.cmf

Kinetix 6000 with SERCOS 1.120

Ultra™ 3000 with SERCOS 1.52

Kinetix 6200 1.040 18.xx

Kinetix 6500 2.006 19.xx

Kinetix 300 1.067 MotionView n/a RSLogix software, version 17.xx with

Ultra3000 1.52 Ultraware 1.84 Motion Database (.mdb) June 2012

Kinetix 3 2.10

(1) See Kinetix 300 EtherNet/IP Indexing Servo Drives User Manual, publication 2097-UM001.

Software Software

Version min

Supplemental File

min

Add-on profiles

(1)

You can use Motion Analyzer software, version 6.0 or later as required.

Download these files from http://www.rockwellautomation.com/support

. Contact Rockwell

Automation Technical Support at (440) 646-5800 for assistance.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 34

34 LDAT-Series Integrated Linear Thrusters

IMPORTANT

Configure Your Linear Thruster

Configure the linear thruster by using the basic parameter settings described in this section. Use

the procedure appropriate for your motion axis.

LDAT-Sxxxxxx-xB linear thrusters with incremental encoders, are compatible with all Kinetix

drives and have a default resolution of 5 μm. LDAT-Sxxxxxx-xD linear thrusters with absolute

encoders are only compatible with Kinetix 300 drives.

The type of Allen-Bradley drive connected to the linear thruster determines the configuration

procedure. The following table to shows you the configuration procedures to follow.

Drive Refer to:

Kinetix 2000

Kinetix 6000

Kinetix 6200

Ultra3000 with SERCOS

Kinetix 6500 Configure Your Kinetix 6500 EtherNet/IP Ser vo Drive with RSLogix 5000 Software on page 40.

Kinetix 300 Configure Your Kinetix 300 EtherNet/IP Servo Drive with MotionView Software on page 42

Ultra3000 and Kinetix 3 Configure Your Servo Drive with Ultraware Software on page 45.

Configure and Commission Your SERCOS Servo Drive with RSLogix 5000 Software on page 35

ATTENTION: Moving parts can cause injuries. Before running the linear thruster, make sure all

components are secure and safe guards are in place to prevent access to the path of moving

machinery.

Safeguards should prevent access to the linear thruster until all motion has stopped.

Check that the linear thruster is clear of foreign matter and tools. Objects hit by the moving thrust

rod can become projectiles that can cause personal injury or damage to the equipment.

You must verify that the servo control system safely controls the linear thruster with regard to

maximum force, acceleration, and speed.

Positive Motion Direction

Positive motion is defined as the slider extending from the stator body opposite the power and

feedback connectors.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 35

LDAT-Series Integrated Linear Thrusters 35

EXAMPLE

Configure and Commission Your SERCOS Servo Drive with RSLogix 5000 Software

For each linear thruster that is powered by a Kinetix 2000, Kinetix 6000, Kinetix 6200, or an

Ultra3000 servo drive, use the next four sections to configure, hookup test, tune, fine tune and

set up homing for the linear thruster.

These procedure assumes the linear thruster and a Kinetix2000, Kinetix 6000, Kinetix 6200, or

an Ultra3000 servo drive has been installed and wired as one axis of the motion system.

For help using RSLogix 5000 software as it applies to setting up your linear thruster, refer to

Additional Resources

software.

Conf igure

Follow these steps to configure your drive for the linear thruster.

1. Loosen shipping and handling set screw till it is just flush with the stator body surface.

2. Run the RSLogix 5000 software.

3. Complete the basic system configuration to create an axis.

4. Right-click on your axis and select Properties.

5. Set these values in the appropriate Axis Properties tab of RSLogix 5000 software.

on page 78. This procedure assumes you are familiar with RSLogix 5000

ATTENTION: Incorrect parameter settings may result in uncontrolled motion, with the

potential for damage to the linear thruster. Setting the Positioning Mode to Rotary can

cause damage to the linear thruster or the machine due to incorrect positioning.

Axis Properties Tab Parameter Entry/Selection

Drive/Motor Motor Catalog Number Select your linear thruster catalog number

Drive Resolution 200,000 drive counts /motor millimeter

Attribute 1 Position Error (recommended)

Attribute 2 TorqueFeedback (recommended)

Units Position Units mm

Conversion Positioning Mode Linear

Conversion Constant 200,000.0 drive counts /1.0 mm

The LDAT linear thrusters display a different suffix depending on the servo drive you are

using. Systems using a 230V drive show linear thruster with a _A suffix and those using a

460V drive will show _B suffix.

LDAT -S031020-Bx_A catalog numbers are shown when 230V drive is selected.

LDAT -S031020-Bx_B catalog numbers are shown when 460V drive is selected.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 36

36 LDAT-Series Integrated Linear Thrusters

Hookup Test

Run the hookup test before the linear thruster loads or fixtures are installed. Vertical loads or

external forces of more than 10% of the rated load may prevent the hookup test from passing,

even though the unit is wired correctly.

Follow these steps to do the hookup test for the linear thruster.

1. From the Hookup Axis Properties tab enter the following

Param eter Entr y/Sel ectio n

Test Increment 60 mm

Driv e Polarit y Posit ive

2. Click Test Command & Feedback.

Tun e

The linear thruster is a direct drive actuator. Tuning the linear thruster establishes a stable axis.

ATTENTION: Before you tune your li near th ruster read and under stand Preventing Undetected and

Repetitive High Energy Impacts and Preventing Reduced Dynamic Control Performance on page 39

Follow these steps to tune the linear thruster.

1. Attach your application load to the linear thruster.

2. From the Tune tab enter the following recommended tuning parameters.

Param eter Entr y/Sel ectio n

Travel Limit 100 m m

Speed 500 mm/s

Torque/Force 100%

Direct ion Forward /Bi-direc tional

Damping Factor 0.8 (default)

For preliminary Autotune do not check tune parameter boxes.

3. Click Start Tuning.

You can fine tune the linear thruster for your specific application requirements by using

the suggestions made in the next section.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 37

LDAT-Series Integrated Linear Thrusters 37

Fine Tune

Use the Gains tab to fine tune your linear thruster. The following bullets show you how to get

the best results.

• For precise positioning applications, add position integral gain and increase the position

proportional gain as necessary.

• For stiffer and more precise tracking of motion profiles, increase the velocity gain.

• For stable operation increase the velocity gain until you hear the axis oscillate, and then

reduce the velocity gain by one half.

• For applications with very high acceleration, > 30 m/s/s (1.2 in/s/s), add acceleration

feed forward.

• For linear thrusters with long travel, > 500 mm (20 in.) or with large mass attached to

the slider, you may notice the axis is vibrating or resonating after AutoTune. If it does, use

the Output screen to add a low pass filter or a notch filter to remove the resonance.

Set up Homing

Enter these parameters to set up homing for the linear thruster.

Parameter Entry/Selection

Mode Active

Posit ion 0, typica l

Offset 10 mm

Sequence Torque Level-Marker

Direction Reverse Bi-directional

Torque Level 20%, min

Speed 5 mm/s

Return Speed 10 mm/s

(1) The 10mm offset sets the home position to an axis location clear of the spring stops.

(1)

Greater if the system friction, force, or weight exceeds 30% of the

Continuous Force Rating at any point in the range of motion

ATTENTION: Avoid excessive force while homing the linear thruster. Do not exceed

100 mm/s (4.0 in/s) during a home routine. Speeds greater than 100 mm/s (4.0 in/s)

may damage the linear thruster when the slider reaches the end of travel.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 38

38 LDAT-Series Integrated Linear Thrusters

Preventing Undetected and Repetitive High Energy Impacts

To prevent high energy impacts, take normal motion system precautions and make sure the

Position Error Tolerance is suitable for your application.

Normal motion system precautions include the following:

• Interlocks for access

• Range of motion hardware and software limits

In addition you should complete these tasks:

• Determine limit positions based on maximum speed and load, and stopping distance at

peak capability of motor or drive. You can use Motion Analyzer to determine these

positions

• Program the position error fault action to Disable Drive (default) or Stop.

• Program the Limits tab in Axis Properties to reduce the Position Error Tolerance.

Typically, a value less than 10 mm (0.39 in.) is achievable without causing nuisance

Position Error (E19) faults.

• In higher speed applications, implement 100% Velocity Feed-forward on the Axis

Properties Gains tab. This value reduces the Position Error during normal axis motion.

• After performing an Auto-Tune, always set the Position Error Tolerance back to the

established reduced values.

ATTENTION: Motor capacity may be exceeded by load changes, obstructions or equipment

dynamic responses.

When a closed-loop servo system is operating, changes in loads, obstructions, or equipment

dynamic response can cause motor capacity to be exceeded. Under these conditions, the Kinetix

6000 and Kinetix 2000 drives fold back the current to the motor to prevent thermal damage.

Typically, the fold back causes a closed-loop servo system to operate with reduced dynamic

control performance, particularly when accelerating and decelerating. If the reduced dynamic

control results in undesirable Position Error and the Position Error Tolerance is set to a relatively

large value, such as, the default value, the increase in Position Error may go undetected. If proper

precautions are not in place, this could lead to equipment damage and/or serious injury.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 39

LDAT-Series Integrated Linear Thrusters 39

Preventing Reduced Dynamic Control Performance

To prevent reduced dynamic control, you should take normal motion system precautions and

monitor the drive's motor capacity.

Normal motion system precautions include:

• Interlocks for access.

• Range of motion hardware and software limits.

• Use Motion Analyzer to size your Motor/Drive combination with sufficient margin. We

recommend that you monitor motor capacity when commissioning the axis.

Additionally, you should monitor the drive's motor capacity in case of unexpected obstruction or

axis mechanical failures. Take the following steps to monitor the motor capacity:

• Make sure the Position Error Tolerance is set appropriately for your axis.

• Turn on Motor Capacity Real Time Attribute on the Axis Properties Drive/Motor tab.

• Determine your worst case expected axis.MotorCapacity during normal axis operation.

• In your application run-time code, monitor the axis.MotorCapacity real time attribute.

Drive Foldback occurs when axis.MotorCapacity reaches 108% of rated continuous

torque.

• Implement a program that brings your axis to a controlled stop before

axis.MotorCapacity reaches 100%.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 40

40 LDAT-Series Integrated Linear Thrusters

Configure Your Kinetix 6500 EtherNet/IP Servo Drive with RSLogix 5000 Software

For each linear thruster that is powered by a Kinetix 6500 servo drive use the next four sections

to configure, hookup test, tune, fine tune and set up homing for the linear thruster.

These procedure assumes the linear thruster and a Kinetix 6500 servo drive has been installed

and wired as one axis of the motion system.

For help using RSLogix 5000 software as it applies to setting up your linear thruster, refer to

Additional Resources

software.

Conf igure

Follow these steps to configure your drive for the linear thruster.

1. Loosen the shipping and handling set screw till it is just flush with the stator body

surface.

2. Run the RSLogix 5000 software.

3. Complete the basic system configuration to create an axis.

4. From the Motor category click Change Catalog.

5. Select your linear thruster from the Change Catalog Number dialog box.

6. From the Scaling category set the Units to mm.

on page 78. This procedure assumes you are familiar with RSLogix 5000

Hookup Test

If possible, run hookup test before the linear thruster loads or fixtures are installed. Vertical loads

or external forces of more than 10% of the rated load may prevent hookup test from passing,

even though the unit is wired correctly.

Follow steps to do a hookup test for the linear thruster.

1. Set the Test Distance to 60 mm.

2. Click Start.

3. Verify that the Motor Polarity, Feedback Polarity and Motion Polarity are normal.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 41

LDAT-Series Integrated Linear Thrusters 41

Tu ne

The linear thruster is a direct drive actuator. Tuning the linear thruster establishes a stable axis.

ATTENTION: Before you tune your linear thruster read and understand Preventing Undetected and

Repetitive High Energy Impacts and Preventing Reduced Dynamic Control Performance on page 39

Follow these steps to tune the linear thruster.

1. Attach your application load to the linear thruster.

2. From the Autotune category enter the following recommended tuning parameters.

Parameter Entry/Selection

Application Type Basic

Loop Response Medium

Load Coupling Compliant

3. Click Start.

Fine Tune

Use the facilities in the Tune, Velocity, Position and Accelerations Loop categories to meet your

specific application requirements.

Home

The Kinetix 6500 drive does not support Home-to-Torque homing. Use this link to the Sample

Code Library to download the AOI file called CIP Home to Torque.

http://samplecode.rockwellautomation.com/idc/groups/public/documents/webassets/sc_legal

_info.hcst?dID=75636

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 42

42 LDAT-Series Integrated Linear Thrusters

Configure Your Kinetix 300 EtherNet/IP Servo Drive with MotionView Software

For each linear thruster that is powered by a Kinetix 300 servo drive use the next four sections to

configure, hookup test, tune, fine tune and set up homing for the linear thruster.

These procedure assumes the linear thruster and a Kinetix 300 servo drive has been installed and

wired as one axis of the motion system. Linear thrusters with the absolute encoder option require

the use of the supplied feedback connector LDAT-CONKIT-ABS.

For help using MotionView software as it applies to setting up your linear thruster, refer to

Additional Resources

software.

Conf igure

Follow these steps to configure your drive for linear thrusters.

1. Loosen the shipping and handling set screw till it is just flush with the stator body

surface.

2. Run the MotionView software.

3. From the Motor category, click Change Motor.

For linear thruster with absolute encoders skip to step 6.

4. From the Vendor pull-down menu, select Allen-Bradley Linear.

5. From the Motor Model pull-down menu, select your linear thruster catalog number.

6. Click Update Drive.

7. Click Yes.

on page 78. This procedure assumes you are familiar with MotionView

Hook up Test

Follow these steps to do a hookup test for the linear thruster with an incremental encoder.

ATTENTION: This procedure causes the linear thruster to move in the negative direction.

1. Position the slider in the center of travel.

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 43

LDAT-Series Integrated Linear Thrusters 43

2. From the Motor category, set the Feedback>Encoder parameters to the following.

Paramete r Value

Resolution (x1) 20 μm

Resolution (x4) 5 μm

Halls order 3

Inverted Checked

B lead A for forward Unchecked

3. From the Motor category, click Check Phasing.

Tune with Absolute Encoder

The linear thruster is a direct drive actuator. Tuning the linear thruster establishes a stable axis.

ATTENTION: Before you tune your linear thruster read and understand Preventing Undetected and

Repetitive High Energy Impacts and Preventing Reduced Dynamic Control Performance on page 39

Follow these steps to tune the linear thruster with an absolute encoder.

1. Attach your application load to the linear thruster.

2. From the General category, set the Drive Mode to Auto Tune.

3. From the Dynamics category, set the Feedback Filter to On.

4. Enable drive.

5. Click Autotuning.

6. We recommend you check Position Tuning and Velocity Tuning.

7. Set the Travel Limit to 50.0 User Units.

8. Click Start.

The linear thruster will oscillate.

9. To accept the autotune parameters, click Yes.

10. Adjust the Gain Scaling by adding -1.

11. Set the Feed back Filter to Off

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Page 44

44 LDAT-Series Integrated Linear Thrusters

Tune with Incremental Encoder

The linear thruster is a direct drive actuator. Tuning the linear thruster establishes a stable axis.

ATTENTION: Before you tune your li near th ruster read and under stand Preventing Undetected and

Repetitive High Energy Impacts and Preventing Reduced Dynamic Control Performance on page 39

Follow these steps to tune the linear thruster with an incremental encoder.

1. Attach your application load to the linear thruster.

2. From the General category, set the Drive Mode to Auto Tune.

3. From the Dynamics category, set the Feedback Filter to On.

4. Set the Feedback Filter Time Constant to 1 ms.

5. Enable the drive.

6. Click Autotuning.

7. We recommend you check Position Tuning and Velocity Tuning.

8. Set the Travel Limit to 50.0 User Units.

9. Click Start.

The linear thruster will oscillate.

10. To accept the autotune parameters, click Yes

Fine Tune

To increase the precision of the positioning of your linear thruster use the Position I-Gain and

increase the Position I-Limit to a value > 1.

Home

To home your linear thruster with an incremental encoder you must have a home switch