Rockwell Automation Kinetix 5300 Installation Manual

Installation Instructions

Original Instructions

Kinetix 5300 Single-axis EtherNet/IP Servo Drives

Catalog Numbers 2198-C1004-ERS, 2198-C1007-ERS, 2198-C1015-ERS, 2198-C1020-ERS, 2198-C2030-ERS, 2198-C2055-ERS,

2198-C2075-ERS, 2198-C4004-ERS, 2198-C4007-ERS, 2198-C4015-ERS, 2198-C4020-ERS, 2198-C4030-ERS, 2198-C4055-ERS,

2198-C4075-ERS

Top ic Pa ge

About the Kinetix 5300 Drives 1

Before You Begin 2

Mount the Kinetix 5300 Drive 2

Connector Data 4

Wiring Requirements 6

Attach the Motor Cable Shield Clamp 8

Circuit Breaker/Fuse Selection 9

Motor Overload Protection 11

Additional Resources 11

About the Kinetix 5300 Drives

Kinetix 5300 servo drives provide an Integrated Motion over the EtherNet/IP network solution for applications with continuous 3-phase output power and current

requirements in the range of 0.72…14.7 kW and 2.3…67.5 A 0-pk, respectively.

See the Kinetix 5300 Servo Drives User Manual, publication 2198 -UM005

ControlLogix® 5570, ControlLogix 5580, CompactLogix™ 5370, or CompactLogix 5380 controllers, and Studio 5000 Logix Designer® application.

, for detailed information on wiring, applying power, troubleshooting, and integration with

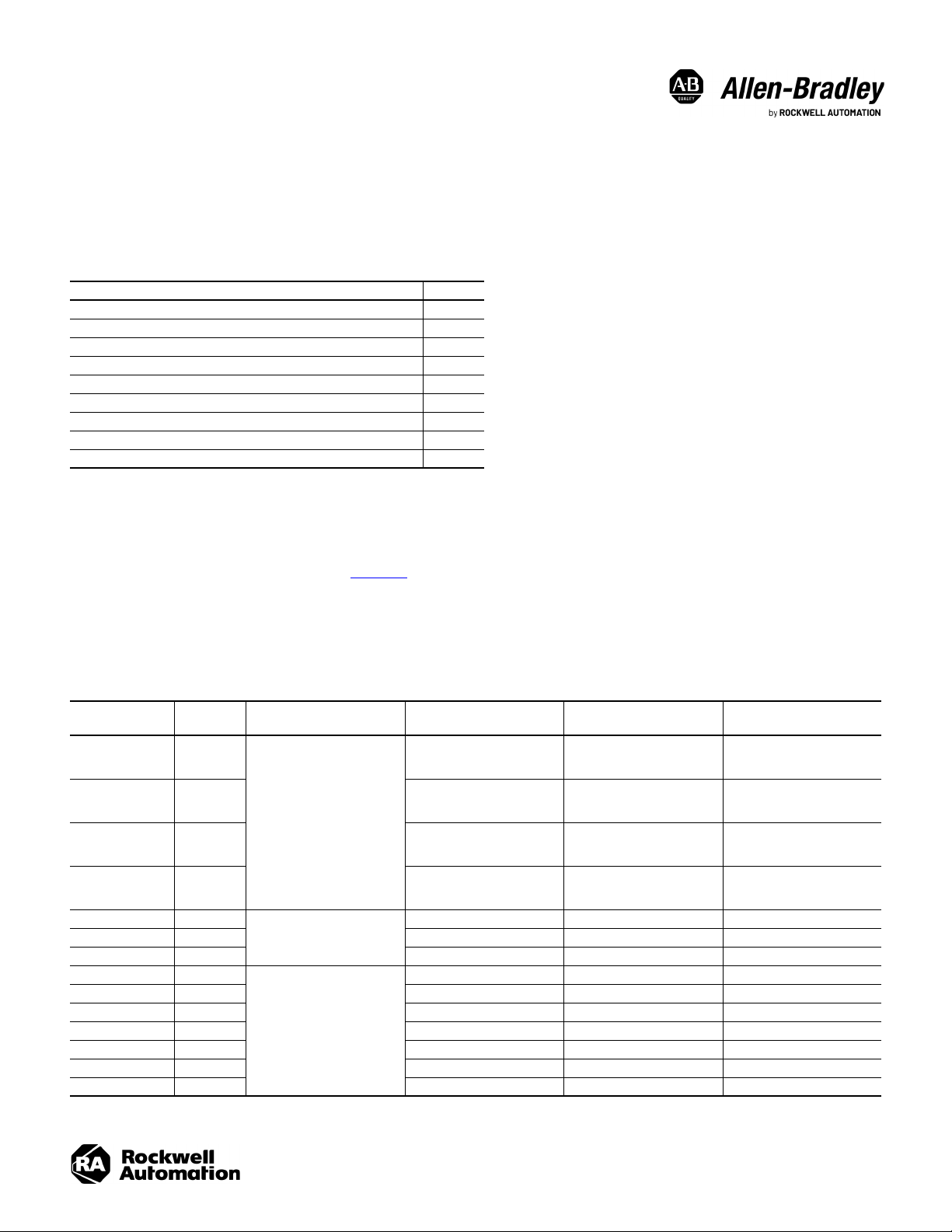

Catalog Number Explanation

This publication applies to the following Kinetix 5300 servo drives.

Kinetix 5300 Drive Catalog Numbers

Cat. No. Frame Size

2198-C1004-ERS 1

2198-C1007-ERS 1

2198-C1015-ERS 2

2198-C1020-ERS 2

2198 -C203 0-ER S 2

2198-C2055-ERS 3 10.30 40.2 56.9

2198-C2075-ERS 3 12.22 47.7 67.5

2198-C4004-ERS 1

2198-C4007-ERS 1 1.55 2.9 4.1

2198-C4015-ERS 2 2.78 5.2 7.4

2198-C4020-ERS 2 3.90 7.3 10.3

2198-C4030-ERS 2 6.25 11.7 16.5

2198-C4055-ERS 3 12.08 22.6 32.0

2198-C4075-ERS 3 14.70 27.5 38.9

(1) Nominal input voltage rating (110, 230, or 480V rms) is required to achieve full power.

Input Voltage

85…132V rms single-phase

170…253V rms single-phase

170…253V rms three-phase

170…253V rms three-phase

342…528V rms three-phase

(1)

Continuous Output Power

kW

0.22

0.46

0.72

0.36

0.76

1.18

0.67

1.41

2.18

0.97

2.02

3.13

5.02 19.6 27.7

0.86 1.6 2.3

Continuous Output Current

A (rms)

2.8 4.0

4.6 6.5

8.5 12.0

12.2 17.3

Continuous Output Current

A (0-pk)

Kinetix 5300 Single-axis EtherNet/IP Servo Drives Installation Instructions

MBRK

W

V

U

1

10

1

2

Clearance right of the

drive is not required.

Clearance left of the

drive is not required.

Kinetix 5300

Servo Drive

40 mm (1.57 in.) clearance below

drive for airflow

40 mm (1.57 in.) clearance above

drive for airflow

Refer to the Kinetix Servo Drives

Technical Data, publication KNX-TD003

,

for Kinetix 5300 drive dimensions.

MBRK

W

V

U

1

10

1

2

MFB

MBRK

W

V

U

1

10

1

2

MFB

MBRK

W

V

U

1

10

1

2

MFB

Zero-st ack Tab and

Cutout Aligned

Mount drives in descending order, left to

right, according to frame size.

The optional 24V shared-bus connection

system is not shown for clarity.

Before You Begin

Remove all packing material, wedges, and braces from within and around the components. After unpacking, check the item nameplate catalog number against the purchase

order.

The Kinetix 5300 servo drives include the following:

• Wiring-plug connector set for AC input power, 24V control input power, digital inputs/auxiliary feedback, motor power, motor brake, shunt (installed and wired to

the internal shunt), and safe torque-off (STO) connector. Spare shunt wiring plug for optional external shunt.

• Clamp spacer for motor shield clamp

• The frame 3 clamping plate, for cables too large to fit within the standard shield clamp

• These installation instructions, publication 2198-IN021

Replacement connector sets are also available. See the Kinetix Servo Drives Specifications Technical Data, publication KNX-TD003, for more

information.

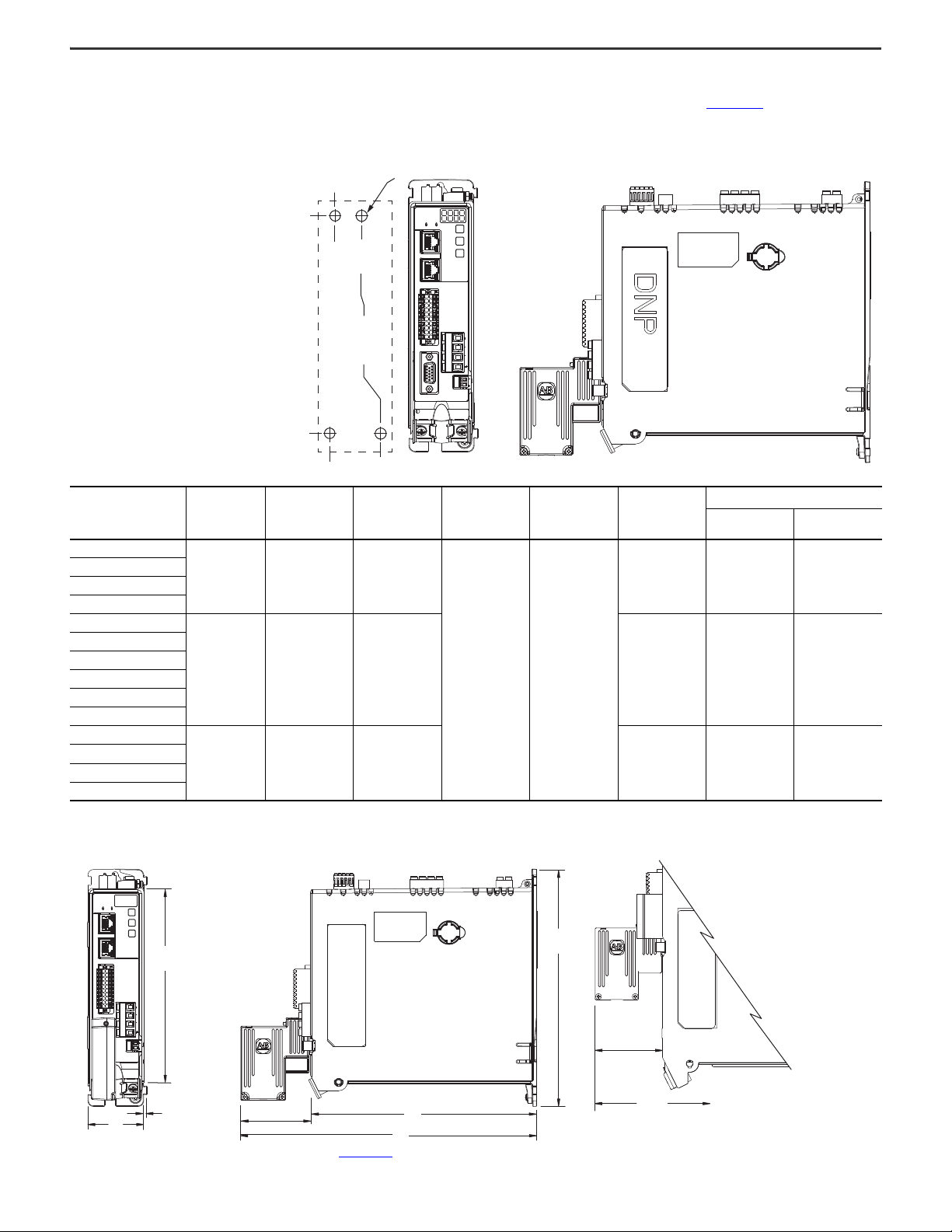

Mount the Kinetix 5300 Drive

Follow these steps to mount the drive in single-axis configurations.

1. Observe these clearance requirements when mounting a single drive to the panel:

• Additional clearance is required for cables and wires connected to the top of the drive.

• Additional clearance is required if other devices are installed above and/or below the drive and have clearance requirements of their own.

• Additional clearance left and right of the drive is required when mounted adjacent to noise sensitive equipment or clean wire ways.

• The recommended minimum cabinet depth is 300 mm (11.81 in.).

IMPORTANT

Mount the drive in an upright position as shown to provide proper air flow. Do not mount the drive on its side. Mount drives in descending

order, left to right, according to frame size.

Drives can be spaced by aligning the zero-stack tab and cutout. For the zero-stack feature to engage properly (when more than one frame size exists in the drive

system) frame 3 drives must mount left of frame 1 or 2 drives, and frame 2 drives must mount left of frame 1 drives. For additional mounting and 24V shared-bus

information, refer to the Kinetix 5300 Servo Drives User Manual, publication 2198-UM00 5

Rockwell Automation Publication 2198-IN021A-EN-P - June 2020 2

2. Mount the Kinetix 5300 drive to the cabinet subpanel with M4 (#8-32) steel machine screws torqued to 2.0 N•m (17.7 lb•in) max.

2

1

10

U

1

V

W

MBRK

MFB

.

2

2

1

1

10

MBRK

MFB

2

2

1

1

10

U

V

W

MBRK

MFB

1

1

1

1

10

10

U

V

W

MFB

U

U

V

V

W

W

MBRK

MBRK

Kinetix 5300 Single-axis EtherNet/IP Servo Drives Installation Instructions

MBRK

W

V

U

1

10

1

2

MFB

F

0.0

0.0

G

52.50

34.00

Ø M4 (#8-32)

Dimensions are in mm

2198-C1004-ERS

Drive is Shown

Applies to

Only

Frame 3

Hole spacing is measured in millimeters

and not converted to inches to avoid

errors due to rounding.

65.0

(2.56)

E

A

3.0

(0.12)

B

D

265

(10.43)

65.0

(2.56)

MBRK

W

V

U

1

10

1

2

C

Dimensions are in mm (in.)

Frame 1 Servo Drive

2198-K53CK-D15M

Feedback Connector Kit

Mounted on Frame 1 Drive

2198 -K53C K-D15 M

Feedback Connector Kit

Mounted on a Frame 2 or 3 Drive

Product Dimensions

Included in this figure are the drill hole patterns for standalone drives. Refer to the Kinetix 5300 Servo Drives User Manual, publication 2198 -UM00 5, for multi-axis drill-hole

patterns.

Kinetix 5300 Drives with 2198-K53CK-D15M Connector Kit

Kinetix 5300 Drive

Cat. No.

Frame

A

mm (in.)

B

mm (in.)

2198-C1004-ERS

2198-C1007-ERS

2198-C4004-ERS

1 50 (1.97) 175 (6.89)

2198-C4007-ERS

2198-C1015-ERS

2198-C1020-ERS

2198 -C203 0-ER S

2198-C4015-ERS

2 55 (2.16) 225 (8.86) 265 (10.43) 243.84 5.00

2198-C4020-ERS

2198-C4030-ERS

2198-C2055-ERS

2198-C2075-ERS

2198 -C405 5-ER S

3 85.2 (3.35) 250 (9.84) 294 (11.57) 273.70 0.0

2198-C4075-ERS

(1) Hole spacing is measured in millimeters and not converted to inches to avoid errors due to rounding.

Kinetix 5300 Drives with 2198-K53CK-D15M Connector Kit

C

mm (in.)

D

mm (in.)

204 (8.03) 265 (10.43)

E

mm (in.)

215 (8.46) 193.68 4.51

Drill Hole Patterns

F

mm

(1)

mm

G

Refer to Kinetix Servo Drives Technical Data, publication KNX-TD003, for motor/actuator compatibility with the 2198-K53CK-D15M connector kit and product dimensions.

Rockwell Automation Publication 2198-IN021A-EN-P - June 2020 3

Kinetix 5300 Single-axis EtherNet/IP Servo Drives Installation Instructions

18

17

16

15

L3

L2

L1

1

8

2

3

11

4

5

9

10

14

6

7

13

12

L3L2

L1

24+

DC+ SH

24-

SB+

SB-

S1

SC

S2

7

2

1

2

1

MOD NET

MBRK

W

V

U

1

10

1

2

MFB

SELECT

BACK

NEXT

KINETIX

5300

DANGER

Electric shock

risk. Power

off and wait

5 minutes.

U

V

W

SB+

SB-

S1

SC

S2

Kinetix 5300 Drive, Front View

(2198-C1004-ERS drive is shown)

Kinetix 5300, Top View

(2198-C1004-ERS drive is shown)

Shared-bus 24V Input

Wiring Connector

Kinetix 5300, Bottom View

(frame 2 and 3 drives only)

Cooling Fan

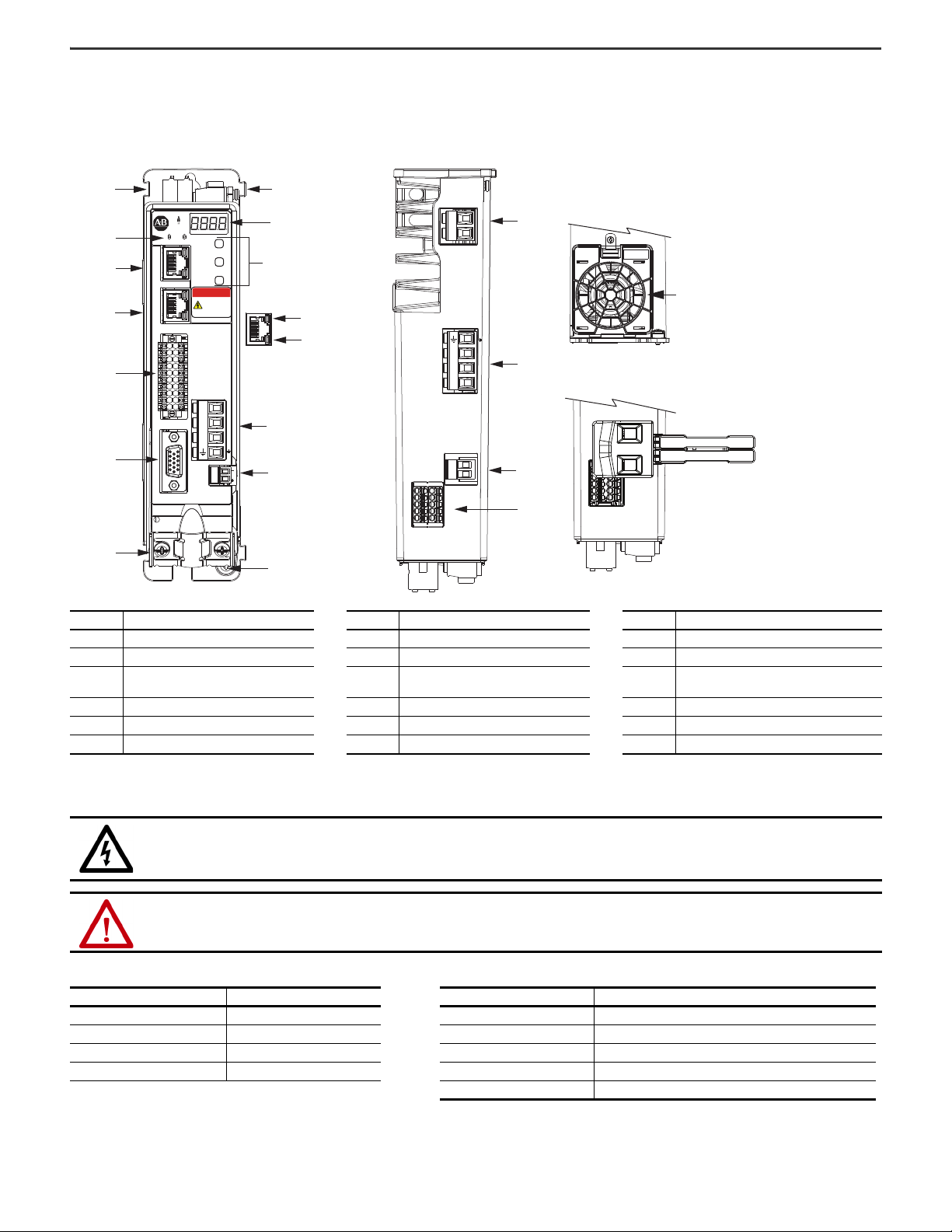

Connector Data

Use these illustrations to identify the Kinetix 5300 drive features and indicators.

Kinetix 5300 Drive Features and Indicators

Item Description Item Description Item Description

1 Motor cable shield clamp 7 Zero-stack mounting tab/cutout 13 Motor brake connector

2 Motor feedback (MFB) connector 8 Four-character status display 14 Ground terminal

Digital inputs and auxiliary feedback

3

connector

9 Navigation pushbuttons 15 Shunt resistor connector

4 Ethernet (PORT1) RJ45 connector 10 Link speed status indicators 16 AC input power connector

5 Ethernet (PORT2) RJ45 connector 11 Link/Activity status indicators 17 24V control input power connector

6 Module and Network status indicators 12 Motor power connector 18 Safe torque-off (STO) connector

These procedures assume that you have prepared your panel and understand how to bond your system. For installation instructions regarding equipment and accessories

not included here, refer to the instructions that came with those products.

Kinetix 5300 Drive Connectors

Description Connector Description Connector

AC input power 4-position plug, terminal screws Motor feedback (MFB) 15-position plug

24V control input power 2-position plug, terminal screws Brake power (MBRK) 2-position plug, terminal screws

Shunt power 2-position plug, terminal screws Digital inputs / Auxiliary feedback 20-position plug, spring terminals

Motor power 4-position plug, terminal screws Safe torque-off (STO) 10-position plugs, spring terminals, 2x (2 rows of 5 pins)

SHOCK HAZARD: To avoid hazard of electrical shock, perform all mounting and wiring of the Kinetix 5300 drive prior to applying power. Once power is

applied, connector terminals can have voltage present even when not in use.

ATTENTION: Plan the installation of your system so that you can perform all cutting, drilling, tapping, and welding with the system removed from the

enclosure. Because the system is of the open type construction, be careful to keep any metal debris from falling into it. Metal debris or other foreign

matter can become lodged in the circuitry and result in damage to components.

Ethernet communication ports RJ45 Ethernet

4 Rockwell Automation Publication 2198-IN021A-EN-P - June 2020

Loading...

Loading...