Page 1

Release Notes

iTRAK System, Firmware Revision 3.003

Bulletin 2198T

This publication contains release notes for the iTRAK® system, firmware revision 3.003, when used with the Studio

5000 Logix Designer® application.

Topic Page

Considerations 1

Restrictions 2

Enhancements 3

Corrected Anomalies 14

Known Anomalies 14

Additional Resources 15

Considerations

When using this firmware, consider the following.

• The example Logix program file is being deprecated and may be eliminated in a future release of the firmware.

You are encouraged to use the ICT Libraries to write your Logix programs for your iTRAK systems.

• When upgrading from a previous revision of firmware, and your Logix program is based on the example Logix

program, the following items must be imported or copy/pasted:

- P01_iTRAK_Communications

-P01_Main_Program

- P00_Faults_Version_and_CIP_Messaging

-UDT_iT_Faults

- UDT_iT_Fault_Array

- UDT_iT_Fault_Strings

- Controller Tag iTRAK_Faults (Copy/Paste)

- Controller Tag iTRAK_Fault_Strings (Copy/Paste)

• To make the EtherNet/IP™ connection and complete initialization, the following conditions are required:

- The controller must be on.

- The Logix program must be running.

- If iTRAK Power Supplies (iPS) are being used, the associated Diode Front End (DFE) must be ready and

communicating.

• Headway checking is done only in the gateway. The Logix program no longer performs this task.

• Changes to the track configuration that are made while the track is enabled do not take effect until the track is

disabled and reenabled. If configuration changes do not match the actual track configuration, faults are

generated when the track is reenabled.

• The default timing model is for the ControlLogix® 5580 controller.

Page 2

iTRAK System, Firmware Revision 3.003 Release Notes

• The 400-byte configuration packet is required for both ControlLogix 5570 and 5580 controllers. The first byte

represents the timing model of the controller. The default is 2, to represent 2-cycle timing in the program.

- For the ControlLogix 5570 controller, which is not supported, the controller tag

Gateway_Movers0to15:C.Data [0] must be changed to 1, to represent 1-cycle timing.

- For the ControlLogix 5580 controller, the controller tag

Gateway_Movers0to15:C.Data [0] is set to 2

(default), to represent 2-cycle timing.

• Unicast Ethernet Communication is the only communications method that works with networks other than

192.168.x.y.

• Multicast Ethernet Communication is required for the second and succeeding I/O modules (more than 16

movers).

• The only support for more than 16 movers is a 192.168.x.y network.

• The mover torque percentage range is 0…125%.

Restrictions

Unless updated in a section for a later revision, these restrictions apply from their revision of introduction.

• In order for the iTRAK system to function properly, a USB-IIRO-4 device from Access IO Products, Inc, must be

connected to the gateway via a USB connection, regardless of the Power Supply Mode (PCM or iPS) that is

specified. This hardware does not have to be used in any other way. However, failure to connect this hardware

to the gateway prevents the gateway from fully initializing and running.

• This firmware release supports the third-generation gateway hardware. Only V3.xxx versions of firmware will

run on the third-generation gateway.

• The Position Loop and Velocity Loops are synchronized and run in the same period.

• When more than five movers are present on or seen by a single motor module, the minimum time that the

motor module requires to process the movers is 1000 microseconds. This forces the minimum Position Loop

Period to be 2 milliseconds. If your application can guarantee that no more than five movers can be seen at any

one time on any given motor module, the iT_MPM AOI can be used to set the maximum number of movers-permotor module that is used by the motion profile, and ease the 2 millisecond restriction.

• When a program is downloaded, the time or master time is changed, or the EtherNet/IP™ connection is broken

and restored, the following can occur:

-The

iTRAK_Control.StatusGatewayRunning tag is set to 0 for several seconds. If there are more than 16

movers on the system, the time that

The system auto-restarts the gateway to make sure that there is communication between the controller and

gateway.

- If the iTRAK system was enabled, a FaultCode 9 is generated and displayed when the

iTRAK_Control.Status.GatewayRunning tag returns to a value of 1.

- If motion was being performed, the motion stops, and faults are generated depending on the stopped

position of the movers.

- If there was a program download and an iTRAK power supply was in use, the power supply must be reset and

the FaultCode 30 cleared.

iTRAK_Control.StatusGatewayRunning tag dwells at 0 can be longer.

2 Rockwell Automation Publication 2198-RN001P-EN-P - February 2021

Page 3

iTRAK System, Firmware Revision 3.003 Release Notes

Enhancements

These enhancements correspond to the iTRAK system firmware revision when used with the Logix Designer

application.

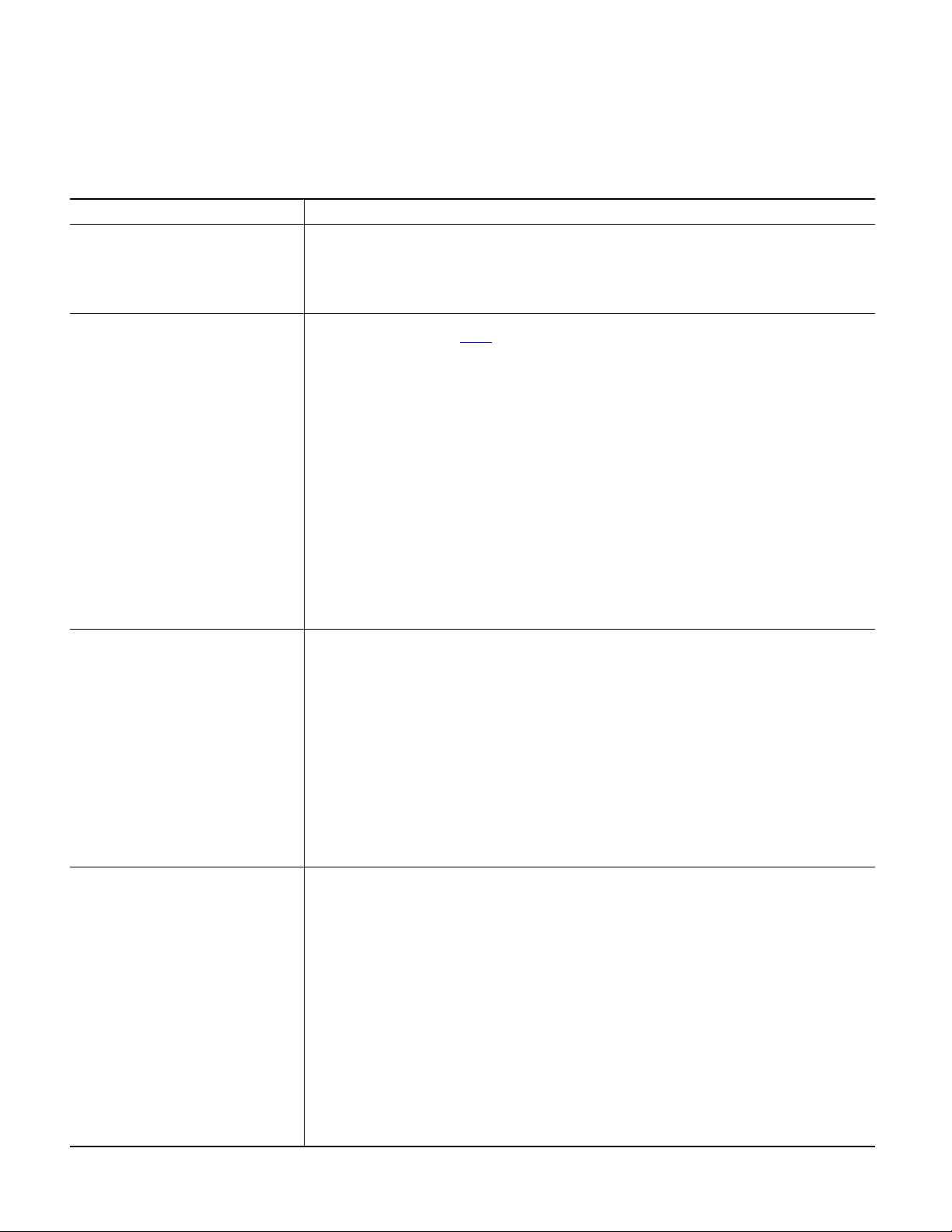

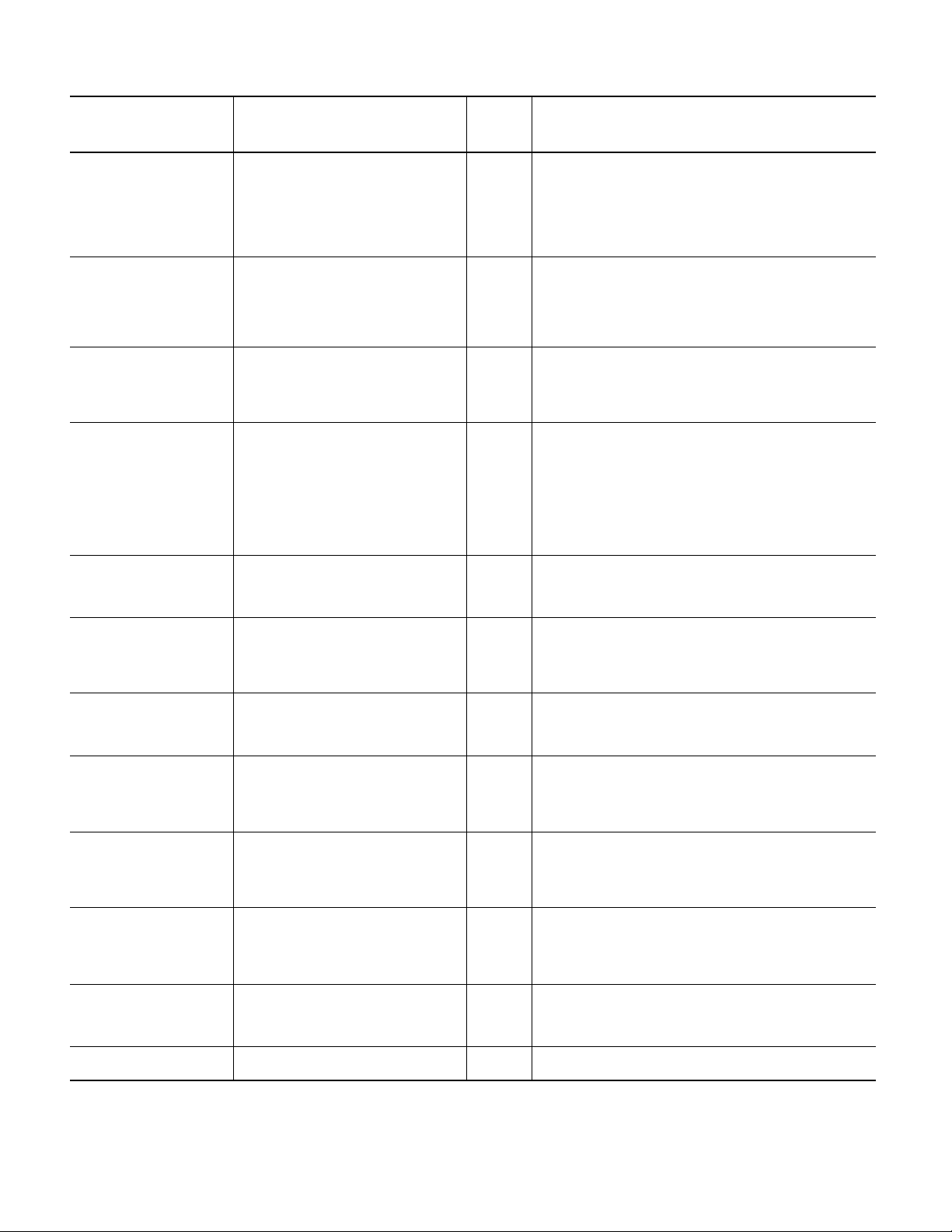

Table 1 - Enhancements with Revision 3.003

Enhancement Description

Support for Additional Movers The iTRAK firmware and associated example Logix file have been modified and tested to allow up to 104 movers on a track,

with a potential of up to 250 movers in the future.

New Fault Codes and New Fault Code Structure The complicated set of gateway fault codes and section fault codes has been replaced with a simplified single fault code and

Ability to View Multiple Generated Faults Frequently on the iTRAK system, several faults are generated when fault conditions occur. However, only information about

extended information. Please see Tab le 2

To accommodate the new set of faults, members of UDT_iTRAK_Status have been changed.

The following members have been removed:

• GatewayFaultCode

• SectionFaultCode

• SectionNumberFaulted

• SectionDeviceFaulted

• SectionFaultData

• FaultMessageLine1

• FaultMessageLine2

The following new members have been added:

•ERR DINT New fault code

• EXERR DINT New extended numeric fault information

• FaultDescription STRING New fault description

As before, the new fault-related fields in the controller tag iTRAK_Control.Status will contain information on

the first fault that is generated when fault conditions occur.

The fault information is not persistent. When the controller tag iTRAK_Control.Cmd.FaultReset is

latched, all fault information is cleared.

the first generated fault would be sent to the Logix controller. Often this meant that the most relevant fault would not be

displayed.

To address this issue, the User-defined type UDT_iT_Faults and the associated controller tag iTRAK_Faults have

been added. This array of 64 elements of type UDT_iT_Faults supplies information about the first 64 faults that occur on the

iTRAK system whenever fault conditions happen. The following members belong to UDT_iT_Faults:

• TimeStamp DINT Relative timestamp in nanoseconds from the first reported fault

• ERR DINT New fault code

• EXERR DINT New extended numeric fault information

• FaultName STRING New fault name

• FaultDescription STRING New fault description

for details about the new set of fault information.

This array of faults is neither cumulative nor persistent. When the controller tag

iTRAK_Control.Cmd.FaultReset is latched, all fault information is cleared, and the information is stored in

the persistent, cumulative fault log file that is maintained internally on the gateway.

Persistent Fault Log The iTRAK system now maintains a persistent, cumulative fault log file that is stored internally on the gateway. This comma-

separated value (.csv) file contains the following information about each of the faults:

• Timestamp Absolute Eastern Daylight system date and time (in year, month, day, hour, minute, second, and

nanosecond) when the fault was generated.

•ERR New fault code

• FaultName New fault name

• FaultDescription New fault description

• EXERR New extended numeric fault information

Whenever the controller tag iTRAK_Control.Cmd.FaultReset is latched or the gateway is reset, any

faults that currently exist are added to the fault log file.

The fault log file is limited to a maximum size of 100 megabytes. If an attempt to save additional faults would exceed this limit,

the faults are temporarily saved and a fault 249 (‘Fault Log File too Large to Add Faults’) is generated. This gives the user one

last opportunity to retrieve the fault log from the iTRAK system before resetting the faults once again. On the fault reset

immediately following the fault 249, the fault log file is removed, and the faults generated prior to and including the fault 249

are stored in the newly emptied fault log file.

The fault log file can be retrieved using the V3.003 version of the iTRAK Log Retrieval Tool.

Rockwell Automation Publication 2198-RN001P-EN-P - February 2021 3

Page 4

iTRAK System, Firmware Revision 3.003 Release Notes

Table 1 - Enhancements with Revision 3.003 (Continued)

Customer Log File Simplification As fault reporting on the iTRAK system has been significantly improved, the amount and kind of data that is supplied in the

Addition of Developer Log Files The iTRAK system now generates very detailed log files for use by Customer Support Engineers, Motion Solution Consultants,

Improved Initial Connectivity between the Logix

Controller and the iTRAK System

Addition of Clean Startup Capability to Simplify

Commissioning, Static Addition and Removal of

Movers, and Motor Module Replacement

standard iTRAK log files has been greatly reduced and simplified. The resulting log files are much easier to read and

understand.

These log files can be retrieved using the iTRAK Log Retrieval Tool.

GOTCs, Firmware Developers, and other Rockwell Automation employees. These encoded log files can be retrieved using the

V3.003 version of the iTRAK Log Retrieval Tool and sent to the appropriate Rockwell Automation employees whenever

additional assistance is required.

With the introduction of the third-generation gateway hardware, the gateway often had to be restarted automatically to

establish solid and robust Ethernet/IP communications between the Logix Controller and the iTRAK system. Firmware

modifications and improvements have been made such that the automatic restart is no longer required.

The iTRAK system maintains information about the last position and status of all movers when the system was shut down. In

certain instances (for example, when initially commissioning a track, when replacing motor modules, and when adding or

removing movers), this mover position and status information may be invalid, and must be regenerated from information

obtained from the track.

To assist in this “scratch build” of mover position and status information, a Clean Startup capability has been created, and the

member “CleanAndResetGateway” has been added to the user-defined type UDT_iTRAK_Cmd.

When the controller tag iTRAK_Control.Cmd.CleanAndResetGateway is latched, the stored mover

position and status information are removed, and the gateway is reset. This causes the gateway to rebuild the stored mover

position and status information from new information obtained from the track.

To ensure that the stored mover information gets reconstructed cleanly and accurately, it is best to adhere to the following

rules regarding mover positioning during a Clean Startup:

1. No Movers on Curves

2. For tracks with more than 8 motor modules, no movers next to curves.

3. No more than five 50 mm movers, three 100 mm movers, and two 150 mm movers on a single motor module.

4. No movers on or within +/- 3 mm of motor module transitions.

To assist in following these rules, faults are generated for any violations. However, the new stored mover information is

still generated, and may be valid, despite any faults.

The usual procedure for a Clean Startup is as follows:

1. Shut down the track.

2. Make all the mover adjustments, additions, removals, and motor module replacement.

3. Restart the track.

4. When the track comes up, if the correct number and position of all movers is displayed in the controller tag

iTRAK_Control.Status.ActualPosition, the process is complete, and any faults that may have

occurred can be ignored and reset.

5. Otherwise, issue the iTRAK_Control.Cmd.CleanAndResetGateway command.

6. After the system comes up completely, if the correct number and position of all movers is displayed in the controller tag

iTRAK_Control.Status.ActualPosition, the process is complete and any faults that may have

occurred can be ignored and reset.

7. Otherwise, make appropriate mover position adjustments as any faults may recommend, and repeat steps 5 and 6 until

iTRAK_Control.Status.ActualPosition accurately reflects the state of the track.

4 Rockwell Automation Publication 2198-RN001P-EN-P - February 2021

Page 5

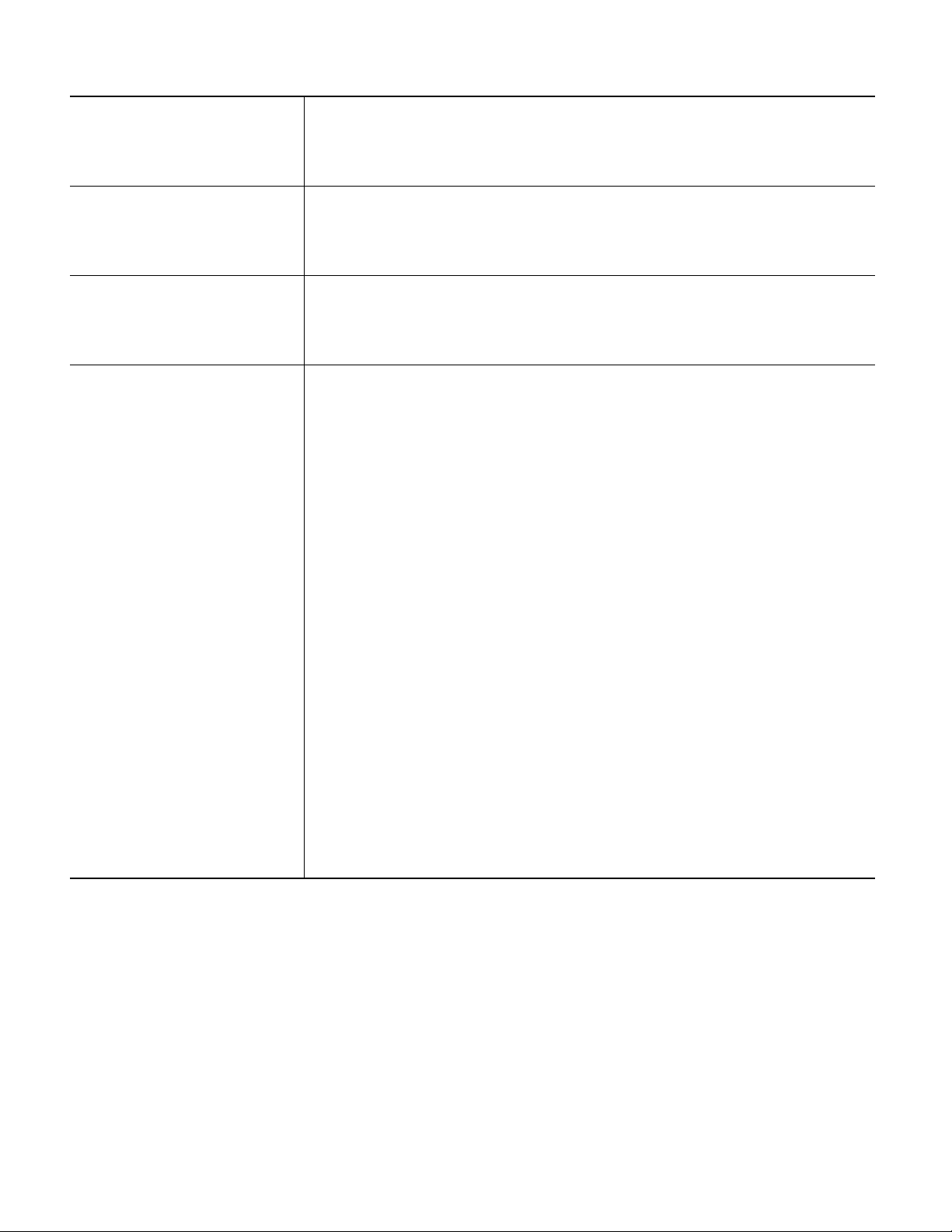

Table 1 - Enhancements with Revision 3.003 (Continued)

iTRAK System, Firmware Revision 3.003 Release Notes

Relaxed Restrictions on Motion Polarity and

Numbering Order Tags

Power on self-test (POST) on Demand The power on self-test (POST) no longer runs as part of the initialization sequence at power-up or gateway reset. Instead, the

ECO Current Mode Eco Current Mode decreases the amount of current used by the iTRAK system as the movers cross transition between motor

The controller tags iTRAK_Control.Data.MotionPolarity,

iTRAK_Control.Data.ReverseMoverNumbering, and

iTRAK_Control.Data.MoverNumberingOffset no longer require a First Scan condition to take

effect. However, the track must be de-energized for these tags and the

iTRAK_Control.Data.PositionOffset tag to take effect.

Controller tag iTRAK_Control.Cmd.RunPOST has been added to allow you to choose when the POST is to be run.

The POST can only be run when the track is not energized. When the POST completes, the Controller Tag

iTRAK_IPSSupport.POSTDone is set to ‘1’. This tag is used for both PCM and iPS power supply modes. If the

POST fails while it is running, the appropriate faults indicating the problem are generated.

It is recommended that the POST be run during the application's power-up sequence, as soon as high-voltage power is

available. Otherwise, motor module problems that could cause damage to the track and/or tooling, such as a bad motor coil

or driver chip, go undetected until the damage occurs.

modules. However, Eco Current Mode also has the side effect of significantly decreasing performance across the track.

Eco Current mode is OFF by default. It can be turned off or on using the Controller Tag

iTrak_Control.Cmd.ToggleEcoCurrentMode.

Toggling this tag causes the Gateway to reset.

Table 2 - Fault Code and Fault Code Structure

ERR – Fault Name Fault Description EXERR Details

1 – Internal Error Internal gateway error during initialization. The gateway failed during initialization due to an internal error. Check all

2 – iMF Initialization Failure Track initialization failure. Initialization of the gateway failed. Check all power and communications

power and communications cables and connections. Then, power-cycle

the system. If the problem persists, contact ICTSupport@ra.rockwell.com

for assistance.

cables and connections. Then, power-cycle the system. If the problem

persists, contact ICTSupport@ra.rockwell.com for assistance.

3 – Internal Motor Module Failure Internal error in motor module EXERR. Motor

4 – Power-on Self-test Internal

Error

5 – Bad Motor Module Coils Bad coils on motor module EXERR during POST. Motor

6 – Motor Module Coil Overheat Coils overheated in motor module EXERR. Motor

7 – IRAM Error Threshold Exceeded Recoverable IRAM errors on motor module EXERR

iPS fault-clearing failure caused POST failure. The Power-On Self-Test failed due to the inability to clear an iPS fault. Make

exceeded threshold.

Module

Number

Module

Number

Module

Number

Motor

Module

Number

The motor module specified in EXERR had an internal error. Check all

power and communications cables and connections. Then, power-cycle

the system. If the problem persists, contact ICTSupport@ra.rockwell.com

for assistance.

sure that all the DFE and iPS modules are functioning correctly. Then,

power-cycle the system. If the problem persists, contact

ICTSupport@ra.rockwell.com for assistance.

One or more bad coils on the motor module specified in EXERR were found

during the Power-On Self-Test. If power-cycling and a subsequent rerun of

the POST does not eliminate the problem, the motor module should be

replaced.

One or more coils has overheated in the motor module specified in EXERR.

Shut down the system, allow it to cool down for 10…15 minutes, and then

restart it. If the problem persists, contact ICTSupport@ra.rockwell.com for

assistance.

Recoverable errors on the IRAM board of the motor module specified in

EXERR have exceeded the allowable threshold. If power-cycling and a

subsequent rerun of the POST does not eliminate the problem, the motor

module should be replaced.

Rockwell Automation Publication 2198-RN001P-EN-P - February 2021 5

Page 6

iTRAK System, Firmware Revision 3.003 Release Notes

Table 2 - Fault Code and Fault Code Structure (Continued)

ERR – Fault Name Fault Description EXERR Details

8 – High IRAM Voltage Motor module EXERR IRAM avg or peak high or

common rail voltage too high.

Motor

Module

Number

Either the IRAM average high rail voltage, or the IRAM average common rail

voltage, or the peak high rail voltage is too high in the motor module

specified in EXERR. Check bus voltages, the DFE, and iPS modules for

problems.

9 – EIP Communications Failure Time Sync information changed or gateway timed

out waiting for PLC EIP packet

10 – Headway Tolerance Failure Position of mover EXERR is too close to another

mover.

11 – I2T Error Current in motor module EXERR exceeded

threshold for too long.

13 – Coil Current out-of-range Current value for a coil in motor module EXERR is

out of range.

14 – IRAM Over Temperature IRAM temperature for motor module EXERR is too

high.

Mover

Number

Motor

Module

Number

Motor

Module

Number

Motor

Module

Number

Time Sync information has suddenly changed, or the gateway has timed

out while waiting for the next packet from the controller. This is usually due

to Grandmaster Time Clock changes (time change, source change), or

program downloads. Reset the fault, and reset the gateway if necessary.

The positions of the mover specified in EXERR is closer to another mover

than the distance specified for Headway Tolerance. Adjust the Motion

Profile to correct this situation.

The continuous current required by the motor module specified by EXERR

has exceeded the threshold limit for too long. This is referred to as an ‘I2T

error’, which is often caused by jammed movers, or a very demanding

Motion Profile. Perform a clean startup, shut down the system if needed,

check the Motion Profile, clear any jams, allow the system to cool down for

10…15 minutes, and restart the system. If the problem persists and there is

no jam, the motor module may need to be replaced. Running the POST may

help assess the situation. If necessary, contact

ICTSupport@ra.rockwell.com for assistance.

The current value for a coil in the motor module specified in EXERR is out of

range. If power-cycling and a subsequent rerun of the POST does not

eliminate the problem, the motor module should be replaced.

The IRAM temperature for the motor module number specified in EXERR is

too high. This can be caused by an ambient temperature greater than

55 °C, inactive water cooling, or lack of water cooling. Shut down the

system, allow it to cool down for 10…15 minutes, and restart it. If the

problem persists, the motor module may need to be replaced. Contact

ICTSupport@ra.rockwell.com for assistance.

15 – Out-of-range ADC Position

Sensor Value

16 – ADC Timeout Motor module EXERR position ADC timed out. Motor

17 – Position Error Tolerance

Fai lu re

18 – External Current Limit Map

Fai lu re

19 – External Force Compensation

Map Failure

6 Rockwell Automation Publication 2198-RN001P-EN-P - February 2021

Value of a position sensor on motor module EXERR

is out of range.

Position error of mover EXERR is too large. Mover

Incorrect External Current Limit table information

specified in Logix.

Incorrect External Force Compensation table

information specified in Logix.

Motor

Module

Number

Module

Number

Number

The Analog to Digital Converter value for a position sensor in the motor

module specified in EXERR is out of range of its internal limits. If powercycling and a subsequent running of the POST does not eliminate the

problem, the motor module should be replaced.

A response from the position sensing Analog to Digital Converters for the

motor module specified by EXERR was not received in a timely manner. The

motor module must be replaced.

The position error of the mover specified in EXERR has exceeded the

Position Error Tolerance value. Determine the cause of the lack of motion

on the specified mover. Possible causes include a jam, or insufficient

motor module high power. Clear the fault, correct the problem, and, if

necessary, power-cycle the system.

Incorrect information was specified in the External Current Limit table in

the Logix program. Fix the program and reload the information.

Incorrect information was specified in the External Force Compensation

table in the Logix program. Fix the program and reload the information.

Page 7

Table 2 - Fault Code and Fault Code Structure (Continued)

ERR – Fault Name Fault Description EXERR Details

20 – Common Rail Voltage High Motor module EXERR common rail voltage greater

than 250 volts.

Motor

Module

Number

The common rail voltage for the motor module specified in EXERR is

greater than 250 volts. Check bus voltages, the DFE, and iPS modules for

problems.

iTRAK System, Firmware Revision 3.003 Release Notes

21 – Common Rail Voltage Low Motor module EXERR common rail voltage less

22 – High Rail Voltage High Motor module EXERR high rail voltage greater than

23 – High Rail Voltage Low Motor module EXERR high rail voltage less than 35

24 – Common and High Rails

Miswired High

25 – Common and High Rails

Miswired Low

26 – Mover Size Mismatch Motor module EXERR mover size does not match

than 17 volts.

500 volts.

volts.

Motor module EXERR common rail voltage greater

than 90% of high rail voltage.

Motor module EXERR common rail voltage less

than 50% of high rail voltage.

that of motor module 0.

Motor

Module

Number

Motor

Module

Number

Motor

Module

Number

Motor

Module

Number

Motor

Module

Number

Motor

Module

Number

The common rail voltage for the motor module specified in EXERR is less

than 17 volts. Check bus voltages, the DFE, and iPS modules for problems.

The high rail voltage for the motor module specified in EXERR is greater

than 500 volts. Check bus voltages, the DFE, and iPS modules for problems.

The high rail voltage for the motor module specified in EXERR is less than

35 volts. Check bus voltages, the DFE, and iPS modules for problems.

The common rail voltage for the motor module specified in EXERR is

greater than 90% of the high rail voltage. Check bus voltages, the DFE, and

iPS modules for problems.

The common rail voltage for the motor module specified in EXERR is less

than 50% of the high rail voltage. Check bus voltages, the DFE, and iPS

modules for problems.

The mover size reported by the motor module specified in EXERR does not

match that of the mover size reported by motor module 0. Reflash the

motor module firmware from Logix with the correct mover size.

28 – Power Supply type

Unspecified

30 – iPS Not Ready iPS not in READY state after being enabled. The iPS did not indicate that it was in the READY state after being enabled.

31 – iPS Faults Not Cleared Gateway timed out while clearing iPS faults. The gateway timed out while attempting to clear iPS faults. Check the

32 – iPS Enable Timeout Gateway timed out while enabling iPS. The gateway timed out while attempting to enable the iPS. Check the wiring

33 – DFE Bus Unload DFE in Bus Unload state. The DFE is in a Bus Unload state. Check the DFE module for problems.

34 – USB/IO Module

Communication Fault

Logix Controller tag

iTRAK_Control.Data.PwrSupplyType

set to 0.

Communication problem between USB/IO Module

and iPS. Check wiring.

The Logix Power Supply type is set to 0. For an iPS, this value must be 1.

For a PCM, this value must be 2. Set the value appropriately, clear the fault,

and reset the gateway.

Check the DFE and iPS modules for problems.

wiring of the USB/IO Module to the iPS. Also check the DFE and iPS modules

for problems.

of the USB/IO Module to the iPS. Also check the DFE and iPS modules for

problems.

The gateway is not able to communicate with the iPS via the USB/IO

module. This is usually a mis-wiring problem at the USB/IO module. Check

and confirm that the wiring is correct, and fix if not.

Rockwell Automation Publication 2198-RN001P-EN-P - February 2021 7

Page 8

iTRAK System, Firmware Revision 3.003 Release Notes

Table 2 - Fault Code and Fault Code Structure (Continued)

ERR – Fault Name Fault Description EXERR Details

41 – USB/IO Module Configuration

Fai lu re

Configuration failure on one or more connected

USB/IO modules.

The configuration of one or more associated USB/IO modules failed. Check

and confirm the USB connection between the USB/IO modules and the

gateway. Then, power-cycle the system. If the problem persists, the USB/IO

module may need to be replaced. If needed, contact

ICTSupport@ra.rockwell.com for assistance.

42 – No USB/IO Modules Present No USB/IO modules connected to gateway. No USB/IO modules were connected to the gateway. Check and confirm the

43 – USB/IO Module Write Failure Output port write failure on one or more

47 – Motor Module Velocity Loop

Timeout

50 – Corrupt Tuning File Corrupt gateway tuning information file. Download

51 – Invalid Velocity Gains Read Could not read velocity loop tuning information

52 – No Tuning File Non-existent gateway tuning information file.

connected USB/IO modules.

Motor module EXERR timeout while waiting for

gateway communications packet.

gains again.

from motor modules.

Download gains again.

Motor

Module

Number

USB connection between the USB/IO modules and the gateway. Then,

power-cycle the system. If the problem persists, contact

ICTSupport@ra.rockwell.com for assistance.

Writing to the output ports of one or more of the connected USB/IO

modules failed. Check and confirm the USB connection between the USB/IO

modules and the gateway.

The motor module specified in EXERR did not receive a communications

packet from the gateway in more than three position loop periods of time.

This can be caused either by a position Loop period that is too short or by

electrical noise. Check for proper grounding, the presence of ferrite cores

in the motor module, and a loose communications cable between the

motor module and the gateway. Then contact

ICTSupport@ra.rockwell.com for assistance.

The file on the gateway that contains the stored tuning information for the

track has become corrupted. Reset the gateway.

An error occurred when attempting to read the velocity loop tuning

information from the motor modules. Reset the gateway. If the problem

persists, contact ICTSupport@ra.rockwell.com for assistance.

The file on the gateway that contains the stored tuning information for the

track does not exist. Reset the gateway.

53 – Track Energized before

Reading Gains

54 – Invalid Motor Module Number

for Gains

55 – Invalid Mover Number for

Gains

56 – Invalid Velocity Ki Value Invalid Velocity Ki value in SetGains user request. The value specified for the Velocity Ki in a SetGains… command is invalid.

57 – Invalid Velocity Kp Value Invalid Velocity Kp value in SetGains user request. The value specified for the Velocity Kp in a SetGains… command is invalid.

8 Rockwell Automation Publication 2198-RN001P-EN-P - February 2021

Track energized before reading velocity loop gains

from motor modules.

Invalid motor module number EXERR specified in

SetGains user request.

Invalid mover number EXERR specified in SetGains

user request.

Bad Motor

Module

Number

Bad Mover

Number

The track was energized during an attempt to read the velocity loop tuning

information from the motor modules. Clear the fault, make sure the track is

not energized, and try again.

The motor module number specified in a SetGains… request is invalid. The

invalid motor module number is specified in EXERR. Correct the value in the

Logix program, clear the fault, and try again.

The mover number specified in a SetGains… request is invalid. The invalid

mover number is specified in EXERR. Correct the value in the Logix

program, clear the fault, and try again.

Correct the value in the Logix program, clear the fault, and try again.

Correct the value in the Logix program, clear the fault, and try again.

Page 9

Table 2 - Fault Code and Fault Code Structure (Continued)

ERR – Fault Name Fault Description EXERR Details

61 – Invalid ADC Calibration Data Invalid calibration data for position sensor ACDs in

motor module FaultData.

Motor

Module

Number

The calibration data for position sensor Analog-to-Digital Converters in the

motor module specified in EXERR is invalid. The motor module must be

replaced.

iTRAK System, Firmware Revision 3.003 Release Notes

63 – Invalid Current Calibration

Data

65 – Invalid User Request Data Invalid user request information sent to gateway

71 – Invalid Current Gains Data Invalid current gains data for a coil on motor

72 – Invalid Position Loop

Calculation File

73 – Invalid Motor Module

Configuration

74 – Motor Module

Communications Failure

Invalid current calibration data for motor module

EXERR.

from PLC.

module EXERR.

Corrupt position loop calculations file ignored. The position loop calculations file that is stored on the gateway is

Invalid configuration data read from motor

module EXERR.

EXERR contains the count of Improperlycommunicating motor modules.

Motor

Module

Number

Motor

Module

Number

Motor

Module

Number

Number of

Bad Motor

Modules

Fou nd

The current calibration data for the motor module specified in EXERR is

invalid. The motor module must be replaced.

Invalid or out-of-range information was sent to the gateway in a user

request from the Controller. Correct the value in the Logix program, clear

the fault, and try again.

The current gains data for a coil on the motor module specified in EXERR is

invalid. The motor module must be replaced.

corrupted, and has been invalidated. After resetting the gateway, the

default position loop calculations are used. If a position loop period value

other than the default is desired, the ‘P’ console command must be used. If

needed, contact ICTSupport@ra.rockwell.com for assistance with this

console command.

The configuration that was read from the motor module specified in EXERR

is invalid. This usually indicates a transmission problem from the motor

module to the gateway, which is most frequently caused by electrical

noise. Check for grounding, the presence of ferrite cores in the motor

module, and a loose communication cable.

Either no properly communicating motor modules were found, or one or

more improperly functioning motor modules were found. The number of

‘bad’ motor modules is specified in EXERR. Check all power cables,

communication cables, and connections. Then, power-cycle the system. If

the problem persists, contact ICTSupport@ra.rockwell.com for assistance.

75 – No Movers found on Track Gateway unable to find movers on track during

76 – Overtemp Error Temperature inside motor module EXERR too high. Motor

77 – Motor Module Config

Communications Error

initialization.

Module

Number

Communication failure while reading track

configuration from motor modules.

Rockwell Automation Publication 2198-RN001P-EN-P - February 2021 9

The gateway was unable to find any movers present on the track at

initialization time. Check all power cables, communication cables, and

connections. Check mover position magnets. Then, power-cycle the

system. If the problem persists, contact ICTSupport@ra.rockwell.com for

assistance.

The temperature inside the motor module specified in EXERR is too high.

This can be caused by an ambient temperature greater than 55 °C, inactive

water cooling, or lack of water cooling. Shut down the system, allow it to

cool down for 10…15 minutes, and restart it. If the problem persists,

contact ICTSupport@ra.rockwell.com for assistance.

A communication failure occurred while the gateway was attempting to

read the track configuration from the motor modules. Check all power

cables, communication cables, and connections. Then, power-cycle the

system. If the problem persists, contact ICTSupport@ra.rockwell.com for

assistance.

Page 10

iTRAK System, Firmware Revision 3.003 Release Notes

Table 2 - Fault Code and Fault Code Structure (Continued)

ERR – Fault Name Fault Description EXERR Details

78 – Trace Data Range Error Motor Module EXERR Internal Trace Array Out-of-

range Reference.

Motor

Module

Number

The internal array for trace data experienced an out-of-range reference.

Power-cycle the system. If the problem persists, contact

ICTSupport@ra.rockwell.com for assistance.

110 – Track Length Mismatch Track length in Logix program does not match

actual length.

111 – Mover Count Mismatch EXERR actual mover count does not match the

mover count in the Logix program.

112 – Mover Limit Exceeded Number of movers specified in Logix program

greater than 250.

113 – Unmatched Mover Fault Position of mover EXERR not reported by motor

modules.

114 – No Movers to Renumber Gateway renumbering failed due to no movers

found.

Actual Mover

Count

Mover

Number

Upon energizing the track, the track length specified in the Logix program

did not match the actual track length. Either the Logix program is incorrect,

or the number of motor modules seen on the track is incorrect. Fix the

problem, clear the fault, and reenergize the track.

The number of movers found on the track did not match the value found in

the Logix Program. If this fault occurred when the track was being

energized, either the Logix program is incorrect, or the number of movers

seen on the track is incorrect. Fix the problem, clear the fault, and

reenergize the track. If this fault occurred after the track had been

previously energized, check mover position magnets.

Upon energizing the track, the number of movers specified in the Logix

program exceeded the maximum number of 250 allowed movers. Change

the Logix program to specify the correct number of movers, clear the fault,

and reenergize the track.

The mover specified in EXERR has not been reported by a motor module for

too many position loops in a row. Check mover position magnets. Increase

the threshold value via the ‘L’ console command. If needed, contact

ICTSupport@ra.rockwell.com for assistance with this console command.

The gateway renumbering operation failed because no movers could be

found. Check mover position magnets. Check all power, communication

cables, and connections. Then, power-cycle the system. If the problem

persists, contact ICTSupport@ra.rockwell.com for assistance.

115 – Automatic Renumbering

Performed

116 – Movers on or Next to Curve on

Clean Startup

117 – Too Many Movers on Module

for Clean Startup

118 – Mover on Transition for Clean

Startup

Gateway was unable to find all movers in

previously reported positions.

Motor module EXERR that is or next to a curve

contains movers during a clean startup

Motor Module EXERR contains too many currentsize movers during a clean startup

Motor Module EXERR contains movers found on a

transition during a clean startup

Motor

Module

Number

Motor

Module

Number

Motor

Module

Number

The gateway was unable to find all of the movers in their previously

reported positions. Check mover position magnets. Renumber the track

and clear the fault.

During a Clean Startup, motor modules that are curves or next to curves

cannot have any movers on them. The motor module specified in EXERR is

a curve, or is next to a curve. Note: This fault may be reset and disregarded

if, upon startup, the correct number of movers are all found in the correct

positions as shown in the Actual Positions.

During a Clean Startup, motor modules may have no more than 2 movers

on them. The motor module specified in EXERR has more than two movers.

Note: This fault may be reset and disregarded if, upon startup, the correct

number of movers are all found in the correct positions as shown in the

Actual Positions.

During a Clean Startup, motor modules may have no movers on transition.

The motor module specified in EXERR has one or more movers on

transitions. Note: This fault may be reset and disregarded if, upon startup,

the correct number of movers are all found in the correct positions as

shown in the Actual Positions.

10 Rockwell Automation Publication 2198-RN001P-EN-P - February 2021

Page 11

Table 2 - Fault Code and Fault Code Structure (Continued)

ERR – Fault Name Fault Description EXERR Details

120 – Internal Comm Gateway comms error with one or more motor

modules.

Motor

Module

Number

If motor module information is specified in EXERR, then a communication

problem between the motor module and the gateway has occurred.

Otherwise, a general communication problem between the gateway and

one or more unspecified motor modules has occurred. If no other morespecific faults are present, check all power cables, communications

cables, and connections. Then, power-cycle the system. If the problem

persists, contact ICTSupport@ra.rockwell.com for assistance.

iTRAK System, Firmware Revision 3.003 Release Notes

121 – Communications Error

Threshold Exceeded

122 – Invalid Motor Module

Communications Packet

123 – Invalid Gateway

Communications Packet

124 – Communications Failure: No

Motor Modules

125 – Communications Rate

Change Failure

Motor module EXERR had too many minor

communications errors in a row.

Invalid communications packet received by

gateway from motor module EXERR.

Invalid communications packet received by motor

module EXERR from the gateway.

Gateway unable to establish communications with

any motor modules.

Gateway cannot change motor module

communications rate for firmware download.

Motor

Module

Number

Motor

Module

Number

Motor

Module

Number

The motor module specified in EXERR has experienced too many minor

communications problems in a row, making the built-in recovery algorithm

too inaccurate. This error is often caused by electrical noise. Check for

grounding, the presence of ferrite cores in the motor module, and a loose

communication cable.

The gateway received an invalid communications packet from the motor

module specified in EXERR. This error is often caused by electrical noise.

Check for grounding, the presence of ferrite cores in the motor module,

and a loose communication cable.

An invalid communications packet was received from the gateway by the

motor module specified in EXERR. This error is often caused by electrical

noise. Check for grounding, the presence of ferrite cores in the motor

module, and a loose communications cable.

The gateway was unable to establish communications with any of the

motor modules on the track. Check all power cables, communication

cables, and connections. Then, power-cycle the system. If the problem

persists, contact ICTSupport@ra.rockwell.com for assistance.

The gateway was unable to change the communication rate between itself

and the motor modules. This rate change occurs both preceding and

following a download of firmware to the motor modules. Check all power

cables, communication cables, and connections. Then, power-cycle the

system. If the problem persists, contact ICTSupport@ra.rockwell.com for

assistance.

126 – Motor Module Packet

Checksum Error

127 – Gateway Packet Checksum

Error

128 – Motor Module Response

Communications Timeout

Gateway-calculated checksum different from that

in motor module EXERR packet.

Motor module EXERR-calculated checksum

different from that in gateway packet.

Motor modules did not respond to gateway. Motor

Rockwell Automation Publication 2198-RN001P-EN-P - February 2021 11

Motor

Module

Number

Motor

Module

Number

Module

Number

The gateway calculated a different checksum value than what was

supplied in a communications packet from the motor module specified in

EXERR. This error is often caused by electrical noise. Check for grounding,

the presence of ferrite cores in the motor module, and a loose

communication cable.

The motor module specified in EXERR calculated a different checksum

value than what was supplied in a communications packet from the

gateway. This error is often caused by electrical noise. Check for

grounding, the presence of ferrite cores in the motor module, and a loose

communication cable.

One or more motor modules did not respond to the gateway in a timely

manner with a communications packet. If information is contained in

EXERR, it is the failing motor module number. Check communication cables

and power-cycle the system. If the problem persists, contact

ICTsupport@ra.rockwell.com for assistance.

Page 12

iTRAK System, Firmware Revision 3.003 Release Notes

Table 2 - Fault Code and Fault Code Structure (Continued)

ERR – Fault Name Fault Description EXERR Details

129 – Gateway Response

Communications Timeout

Motor module EXERR timed out while processing

gateway communications packet.

Motor

Module

Number

The motor module specified in EXERR timed out during the processing of a

communications packet from the gateway. Check communication cables

and power-cycle the system. If the problem persists, contact

ICTsupport@ra.rockwell.com for assistance.

130 – Motor Module Packet Read

Fai lu re

131 – Unsolicited Packet from Motor

Module

132 – Motor Module

Communications Device Failure

140 – Firmware Download Failure Gateway unable to download firmware to motor

141 – Firmware Block Download

Fai lu re

Motor modules packet read failures in gateway. Motor

Motor module EXERR sent unrequested

communications packet to gateway.

Motor module EXERR communications hardware

has failed.

modules.

Firmware block download fail to motor modules. A failure to download a block of firmware to one or more of the motor

Module

Number

Motor

Module

Number

Motor

Module

Number

The gateway was unable to read a communications packet from one or

more of the motor modules on the track. If information is contained in

EXERR, it is the failing motor module number. Check communication cables

and power-cycle the system. If the problem persists, contact

ICTsupport@ra.rockwell.com for assistance.

The motor module specified in EXERR sent a communications packet that

was not requested by the gateway. Check communication cables and

power-cycle the system. If the problem persists, contact

ICTsupport@ra.rockwell.com for assistance.

The communication device on the motor module specified in EXERR failed.

The motor module must be replaced. Contact ICTSupport@ra.rockwell.com

for assistance.

The gateway was unable to download firmware to the motor modules.

Check all communication cable connections, power-cycle the system, and

attempt the firmware download again. If the problem persists, contact

ICTSupport@ra.rockwell.com for assistance.

modules on the track has occurred. If information is contained in EXERR, it

is the failing motor module number. Check all communications cable

connections, power-cycle the system, and attempt the firmware download

again. If the problem persists, contact ICTSupport@ra.rockwell.com for

assistance.

142 – Track Energized before

Downloading Firmware

143 – Firmware Position Board

Download Failure

144 – Firmware PWM Board

Download Failure

Track energized when downloading firmware to

motor modules.

Download of Position board firmware to motor

modules failed.

Download of PWM board firmware to motor

modules failed.

The track was energized during an attempt to download firmware to the

motor modules. Make sure the track is not energized, clear the fault, and

attempt the firmware download again.

The download of Position board firmware to the motor modules failed.

Check all communication cable connections, power-cycle the system, and

attempt the firmware download again. If the problem persists, contact

ICTSupport@ra.rockwell.com for assistance.

The download of PWM board firmware to the motor modules failed. Check

all communications cable connections, power-cycle the system, and

attempt the firmware download again. If the problem persists, contact

ICTSupport@ra.rockwell.com for assistance.

12 Rockwell Automation Publication 2198-RN001P-EN-P - February 2021

Page 13

Table 2 - Fault Code and Fault Code Structure (Continued)

ERR – Fault Name Fault Description EXERR Details

145 – Firmware Download Invalid

Motor Module Type

An invalid firmware type was specified for motor

module EXERR.

Motor

Module

Number

This fault only occurs with the ‘U’ console command. The motor module

firmware type number specified for the motor module specified in EXERR is

not a valid firmware type number. Clear the fault, confirm the motor

module number and motor module firmware type number, and reissue the

‘U’ console command with the correct values. If needed, contact

ICTSupport@ra.rockwell.com for assistance with this console command.

iTRAK System, Firmware Revision 3.003 Release Notes

249 – Fault Log File too Large to

Add Faults

No more new fault information can be stored.

Please retrieve the file.

The fault Log file has grown to a size of 100 MB. No more new fault

information can be stored. If previous information in the fault log file is

needed, retrieve the file using the iMF Log Retrieval Tool. If the file is not

retrieved, it is automatically reset the next time that faults are cleared from

Logix.

Rockwell Automation Publication 2198-RN001P-EN-P - February 2021 13

Page 14

iTRAK System, Firmware Revision 3.003 Release Notes

Corrected Anomalies

These corrections apply either generally, or to the firmware versions as indicated. Unless updated in a section for a

later revision, these corrections apply from their revisions of introduction.

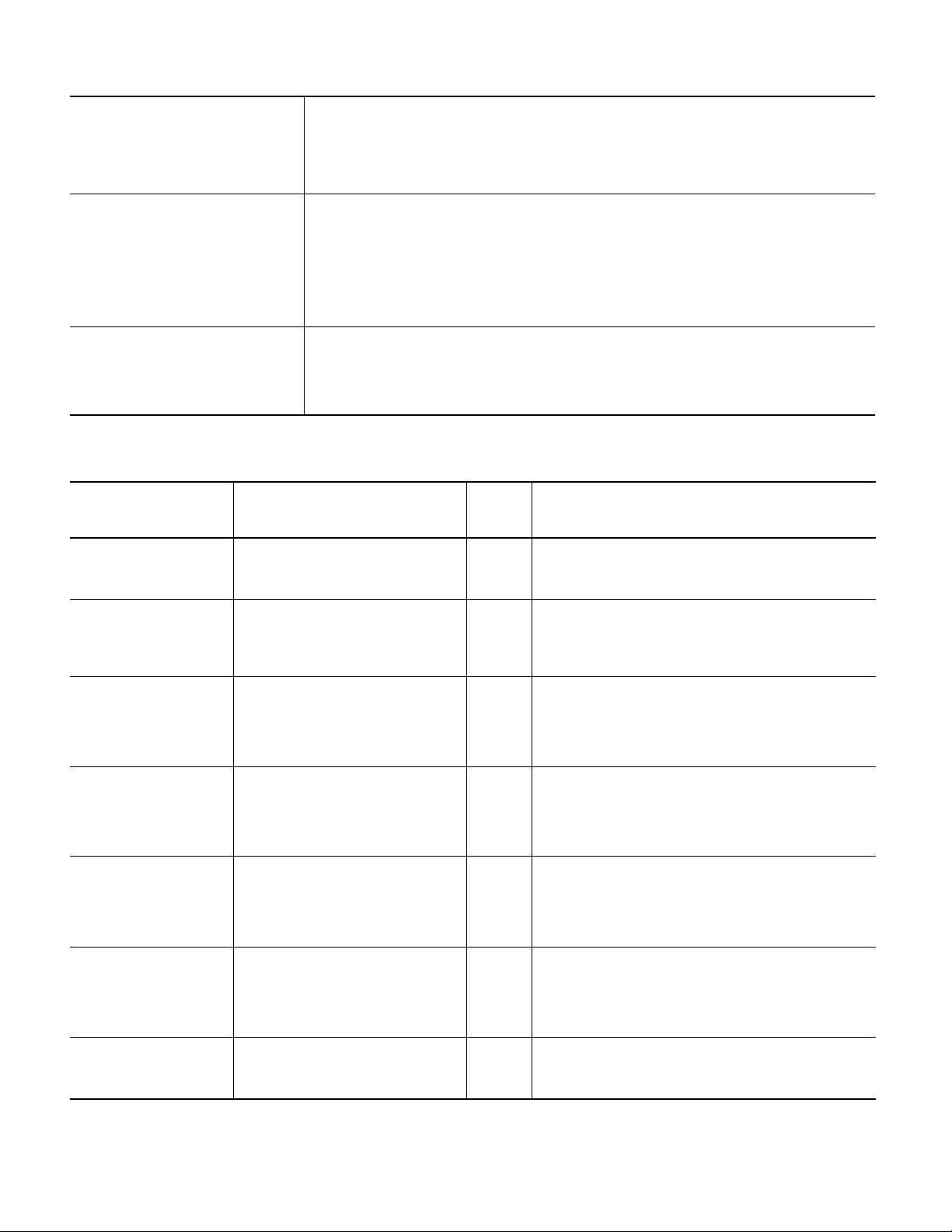

Table 3 - Corrected Anomalies with Revision 3.003

Correction Description

Erroneous Fault Code 28 at Startup CORRECTED: Changes have been made, including the addition of POST on demand, to eliminate the generation of Fault Code 28

DC Bus Contactor Status may not return

after E-Stop.

unless there is an unspecified power supply type in the Logix file.

CORRECTED: Changes have been made in the sample Logix ACD file and the associated firmware to provide the appropriate DFE Bus

Status to the firmware and allow the firmware to return the correct DC bus contactor status.

Known Anomalies

These known anomalies apply either generally, or to the firmware versions as indicated. Unless updated in a section

for a later revision, these known anomalies apply from their revisions of introduction.

Table 4 - Known Anomalies with Revision 3.003

Anomaly Description

Incorrect Relative TimeStamp in iTRAK_Faults

Controller Tag

If the time difference between two successive faults is significantly long enough, the information sent to the TimeStamp field of the

associated elements in the Fault Array field of the iTRAK_Faults Controller tag may overflow and display an erroneous

value. This most commonly happens at track initialization and startup.

Resetting Gateway Required before Program

Download, or Changing to Program Mode

Disconnected Motor Module Causes System to

Hang

Occasional Fault Code 47 Faults Generated While the track is running, occasionally a Fault Code 47 may be generated. Usually, this indicates that an electrical noise-related

Retrieving Tuning Parameter Information Does

Not Work Properly

Gravity Compensation Does Not Work The Gravity compensation feature does not work properly and should not be used. There is no workaround.

Per-mover Tuning Limited to First 16 Movers;

More than 16 use 16th Mover Information

Immediately before downloading a program, or switching to Program Mode in Logix, the gateway must be reset. In the example

code, this is accomplished by latching the iTRAK_Control.Cmd.ResetGateway tag. Otherwise, communications

between the PLC and gateway may not be restored upon returning to Run Mode.

WORKAROUND: If communications are not restored, either power-cycle the gateway, or power-cycle the whole track.

If one or more motor modules, other than those at the very end of the track are disconnected either externally or internally, the

iTRAK system hangs, and fault information is not displayed in Logix. The issue can be seen in the log file.

WORKAROUND: Find any motor modules that are either externally disconnected (bad/cut cables, loose connectors) or internally

disconnected (loose or bad cables inside the motor module or gateway), correct the situation, and restart.

communication issue has prevented a motor module from receiving information from the gateway in a timely manner. This fault

occurs more frequently on larger tracks, as the potential for noise issues is greater. This fault can also occur if the Position Loop

Update Period is shorter than required by the motion profile.

WORKAROUND: Keep the Gateway and communications cables isolated from sources of electrical noise. Apply standard Rockwell

Automation grounding procedures. If everything appears to be okay, and changes do not resolve the problem, contact

ICTSupport@ra.rockwell.com for assistance with adjusting the Position Loop Update Period.

Retrieving tuning parameters using the

expected parameters are set, reapply them using the

iTRAK_Control.Cmd.SetGainsCurves controller tags.

Currently, tuning on a per-mover basis has been, and is still limited to, the first 16 movers on the iTRAK System. There is no

workaround.

iTRAK_Control.Cmd.GetGainsAll tag does not work. To make sure that the

iTRAK_Control.Cmd.SetGainsAll followed by the

Trends Reverse-ordered with Reverse Motion

Polarity

14 Rockwell Automation Publication 2198-RN001P-EN-P - February 2021

When reverse polarity motion is used, the iTRAK_Control_status_tracedata tag reports the last 16 movers

instead of the first 16 movers.

Page 15

iTRAK System, Firmware Revision 3.003 Release Notes

Additional Resources

These documents contain additional information concerning related products from Rockwell Automation.

Resource Description

iTRAK System with TriMax Bearings User Manual, publication 2198T-UM002

iTRAK System User Manual, publication 2198T-UM001 Provides specifications and information on how to install, configure, and troubleshoot your

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

Product Certifications website: rok.auto/certifications

Independent Cart Technology Libraries Application Code Manager:

rok.auto/pcdc

From the Product Compatibility and Download Center (PCDC) main page, search

for ‘Independent Cart Technology Libraries Application Code Manager ‘.

Provides specifications and information on how to install, configure, and troubleshoot your

iTRAK system with TriMax Bearings.

iTRAK system.

Provides general guidelines for installing a Rockwell Automation industrial system.

Provides declarations of conformity, certificates, and other certification details.

Independent Cart Technology Libraries for iTRAK and MagneMotion® product lines are ready-to-

use verified, tested, and documented object-oriented libraries.

You can view or download publications at rok.auto/literature

.

Rockwell Automation Publication 2198-RN001P-EN-P - February 2021 15

Page 16

Rockwell Automation Support

Use these resources to access support information.

Technical Support Center Find help with how-to videos, FAQs, chat, user forums, and product notification updates. rok.auto/support

Knowledgebase Access Knowledgebase articles. rok.auto/knowledgebase

Local Technical Support Phone Numbers Locate the telephone number for your country. rok.auto/phonesupport

Literature Library Find installation instructions, manuals, brochures, and technical data publications. rok.auto/literature

Product Compatibility and Download Center

(PCDC)

Download firmware, associated files (such as AOP, EDS, and DTM), and access product release

notes.

rok.auto/pcdc

Documentation Feedback

Your comments help us serve your documentation needs better. If you have any suggestions on how to improve our

content, complete the form at rok.auto/docfeedback

.

Waste Electrical and Electronic Equipment (WEEE)

At the end of life, this equipment should be collected separately from any unsorted municipal waste.

Rockwell Automation maintains current product environmental compliance information on its website at rok.auto/pec.

Your comments help us serve your documentation needs better. If you have any suggestions on how to improve our content, complete the form at rok.auto/docfeedback.

For technical support, visit

Rockwell Otomasyon Ticaret A.Ş. Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400 EEE Yönetmeliğine Uygundur

Allen-Bradley, ControlLogix, expanding human possibility, FactoryTalk, iTRAK, MagneMotion, Rockwell Automation, and Studio 5000 Logix Designer are trademarks of Rockwell Automation, Inc.

EtherNet/IP is a trademark of ODVA, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 2198-RN001P-EN-P - February 2021 | Supersedes Publication 2198-RN001O-EN-P - April 2020

Copyright © 2021 Rock well Automation, Inc. All rights reserved. Printed in the U.S.A.

rok.auto/support.

Loading...

Loading...