Page 1

Integrate Endress+Hauser Instruments

in a PlantPAx Distributed Control System

System Release 5.0

Selection Guide

Original Instructions

Page 2

Integrate Endress+Hauser Instruments in a PlantPAx Distributed Control System Selection Guide

What’s Inside

Top ic Co nt en ts Page

Summary of the steps to integrate Endress+Hauser instruments in a PlantPAx® process system, including:

Application Overview

Process Device Configuration How to configure process devices by using FDT/DTM technology 5

Process Device Integration Allen-Bradley® and Endress+Hauser device integration options 5

HART System Requirements Required Allen-Bradley® control hardware for HART connectivity 10

Integrated HART Devices Endress+Hauser HART devices 11

EtherNet/IP System

Requirements

Integrated EtherNet/IP Devices Endress+Hauser EtherNet/IP devices 27

• hardware options

• software options

• integration components

Required Allen-Bradley control hardware for EtherNet/IP™ connectivity 26

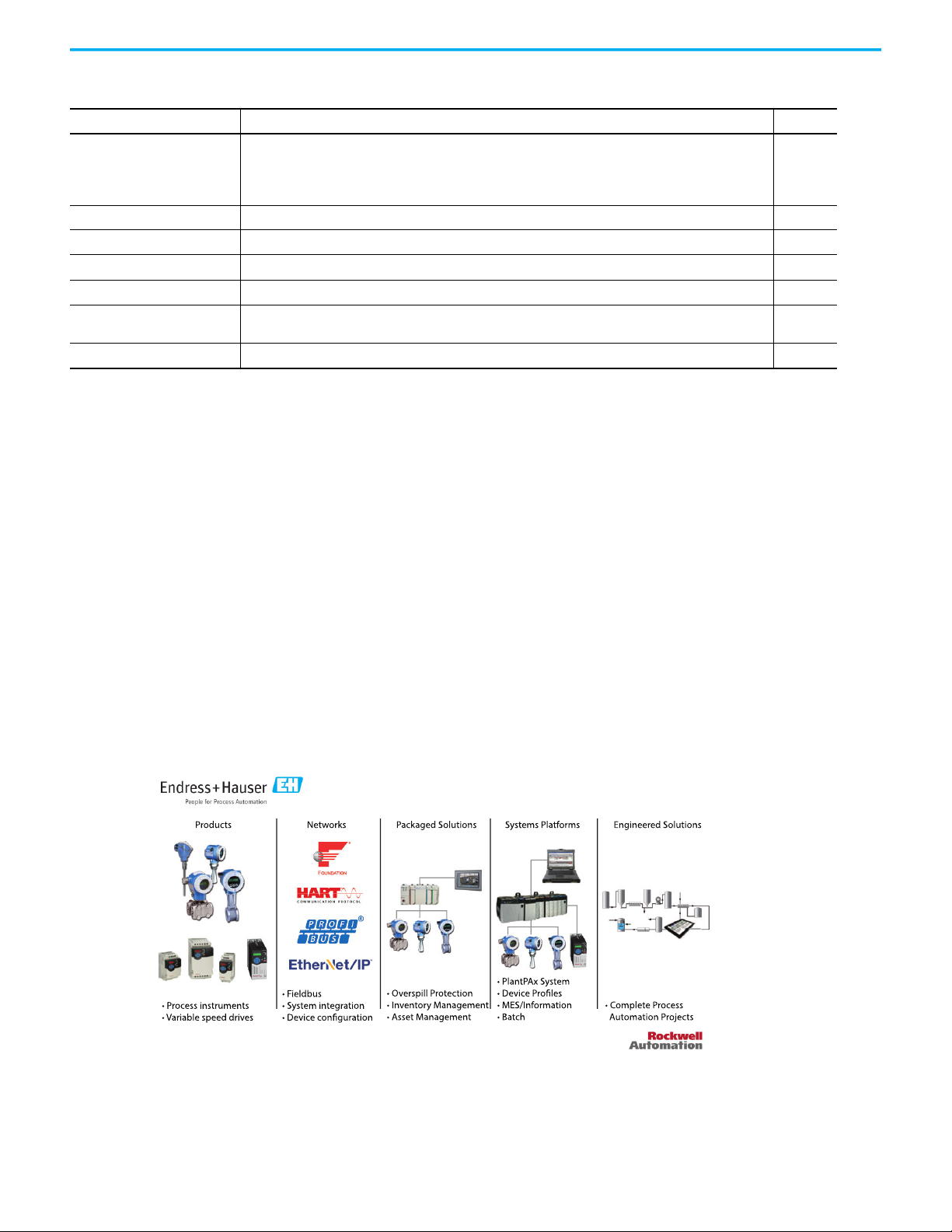

Preferred Integration

Manufacturers often prefer to select components from different suppliers so they can achieve the best control system with the best

measurement components. This approach can pose risks because integration of components from different sources is often problematic.

There are hundreds of different components in a typical plant: controllers, remote I/O, electrical drives, safety equipment, and sensors. Each

component must be integrated, configured, and optimized during startup and operation.

3

Rockwell Automation and Endress+Hauser have strengthened their strategic alliance to provide complete process automation solutions that

include instrumentation, software, and control systems. Rockwell Automation and Endress+Hauser continuously develop pre-engineered,

pre-tested, supported, and maintained integrated solutions for plant-wide diagnostics and lifecycle management for seamless operation

between products from both companies. This preferred integration provides you with the following:

• Reduced integration costs throughout engineering, commissioning, and start-up

• Optimized plant availability and output

• Increased product quality and consistency

• Optimized traceability to meet regulatory demands

• Predictive maintenance through intelligent instruments

Integration tools from both companies include Add-on Profiles (AOPs) and process objects, that include Add-On Instructions and faceplates.

This document helps you select the Endress+Hauser instruments to integrate with a Rockwell Automation control system.

2 Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 3

Integrate Endress+Hauser Instruments in a PlantPAx Distributed Control System Selection Guide

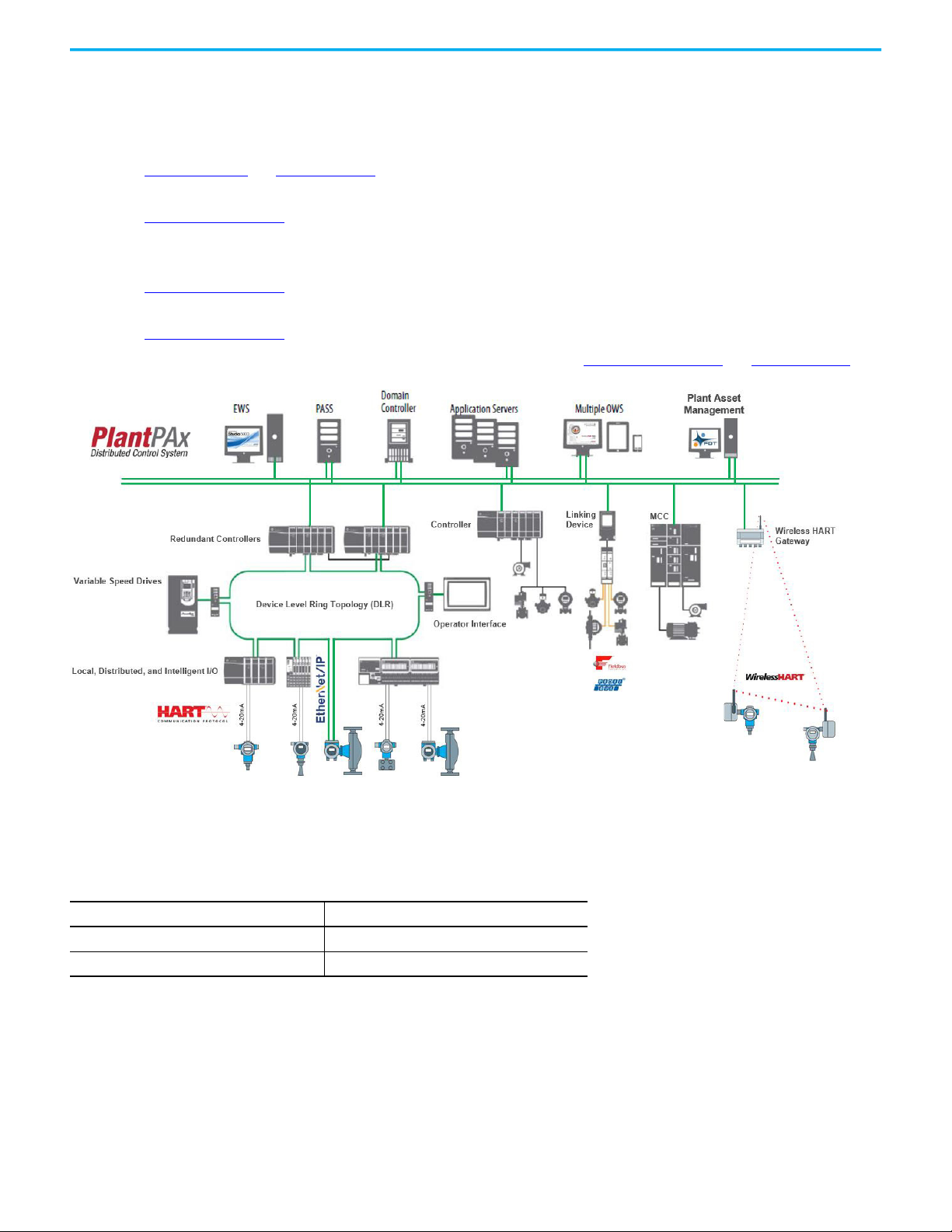

Application Overview

The standard integration process involves the following steps:

1. Install the control system hardware and instrumentation.

See Hardware Options

2. Install Add-on Profiles and any other accessory files (such as EDS files).

See Integration Components

These files are necessary to configure the control hardware and instrumentation in the controller program.

3. Use the Add-On Instructions in the Process Object Library to develop the application.

See Integration Components

4. Use the faceplates and graphical files to create an operator interface to monitor the application.

See Integration Components

5. Use FDT/DTM technology to get access to the process device configuration. See Integration Components and Software Options

and Software Options

Hardware Options

Select communication modules that support the protocol that connects the Endress+Hauser instruments.

Protocol See Page

HART 9

EtherNet/IP 25

Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020 3

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 4

Integrate Endress+Hauser Instruments in a PlantPAx Distributed Control System Selection Guide

Software Options

Software Description

The PlantPAx system is a distributed control system (DCS) that meets scalability and availability requirements for process

control systems. The system shares common technology (the Integrated Architecture® system) with all other automation

PlantPAx® Distributed Control System

Studio 5000® Integrated Design

Environment

Endress+Hauser Device Configuration

Management

Endress+Hauser Netilion Industrial Internet

of Things (IIoT) Services

disciplines in the plant. This approach creates a seamless information flow across the plant for optimization opportunities

and enables a connected enterprise.

For more information, see the PlantPAx Distributed Control System Selection Guide, publication PROCES-SG001

The design environment for the configuration of an Integrated Architecture system, including the PlantPAx system.

For more information, see: Automation System Design Software

FieldCare is the Endress+Hauser configuration tool for field devices. The software provides a range of functionality that

includes device parameterization, replacement, and condition monitoring. The software uses DTM or EDD files to integrate

devices.

For more information see: Endress + Hauser Device Configuration Managerment

Endress+Hauser solution for the Industrial Internet of Things. Improve and optimize plant productivity.

For more information see: Endress+Hauser Netilion Services

Integration Components

Component Description Download

Rockwell Automation I/O modules: Find downloads

Add-on Profile (AOP)

Add-On Instruction

(AOI)

Faceplate

An AOP file is the device description that integrates modules and

devices into the Rockwell Automation Studio 5000 environment. An AOP

file integrates configuration parameters and tag data into the controller

program. This premier integration eliminates the need for you to map

data or create tag aliases.

Add-On Instructions are reusable code objects that contain

encapsulated logic. The objects let you create your own instruction set

for programming logic to supplement the instruction set that is native

to the controller. An Add-On Instruction is defined once in each

controller project, and can be instantiated multiple times in your

application code.

A faceplate is a graphical representation on an operator workstation of

a specific function. Plant operators and engineers use the faceplates to

monitor device performance, identify faults, and take corrective action.

The faceplates create a flow of information between key components of

the manufacturing process — from the Endress+Hauser

instrumentation to an enterprise business system.

In the search field, type AOP and select Add-on Profiles.

Endress+Hauser Ethernet instruments: Downloads

Select Media Type = Software and Software Type = Device Driver.

In the search field, type AOP

The Rockwell Automation Library of Process Objects is a predefined

library of controller code (Add-On Instructions), display elements

(global objects), and faceplates.

Find downloads

In the search field, type process library and select the version.

For more information, see:

• Rockwell Automation Library of Process Objects,

publication PROCES-RM200

• Rockwell Automation Library of Process Objects: HART Modules for

PlantPAx DCS Reference Manual, publication PROCES-RM010

Rockwell Automation devices: Find downloads

Electronic data

sheet (EDS)

Communication DTM

(FactoryTalk® Linx

CommDTM)

Gateway DTMs

Device DTMs

4 Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020

An EDS file is the device description that integrates EtherNet/IP

modules and instrumentation into the Rockwell Automation Studio 5000

environment.

A Communication DTM is the first DTM to be activation upon

communication setup in an FDT/FRAME system. This DTM standardizes

the communication channel to the corresponding communication

operations of the mapped network protocol. This DTM acts as the

standardized device driver for one or multiple protocols.

Gateway DTMs let communication transition between the

communications paths of different protocols in the FDT architecture.

Gateway DTMs act as a link between the CommDTM and the device.

A Device Type Manager™ (FDT/DTM™) is a software component for an

intelligent device or communication component within a digital

network. It contains all of the parameters, functions, user interfaces,

and other items that represent the devices features. The user interface

to the DTM is supplied by the manufacturer.

In the search field, type EDS file.

Endress+Hauser instruments: Downloads

Select Media Type = Software and Software Type = Device Driver.

In the search field, type EDS

Rockwell Automation devices: Find downloads

In the search field, type FactoryTalk Linx CommDTM and select the

version.

Rockwell Automation devices: Find downloads

In the search field, type DTM and select the version

Endress+Hauser Device DTMs: Downloads

Select Media = Device Driver

Type = Device Type Manager (DTM)

Type in the name for the desired device

Download any other 3rd party Device DTMs direct on the FDT Group

website (https://www.fdtgroup.org) or from the appropriate device

vendor homepage

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 5

Integrate Endress+Hauser Instruments in a PlantPAx Distributed Control System Selection Guide

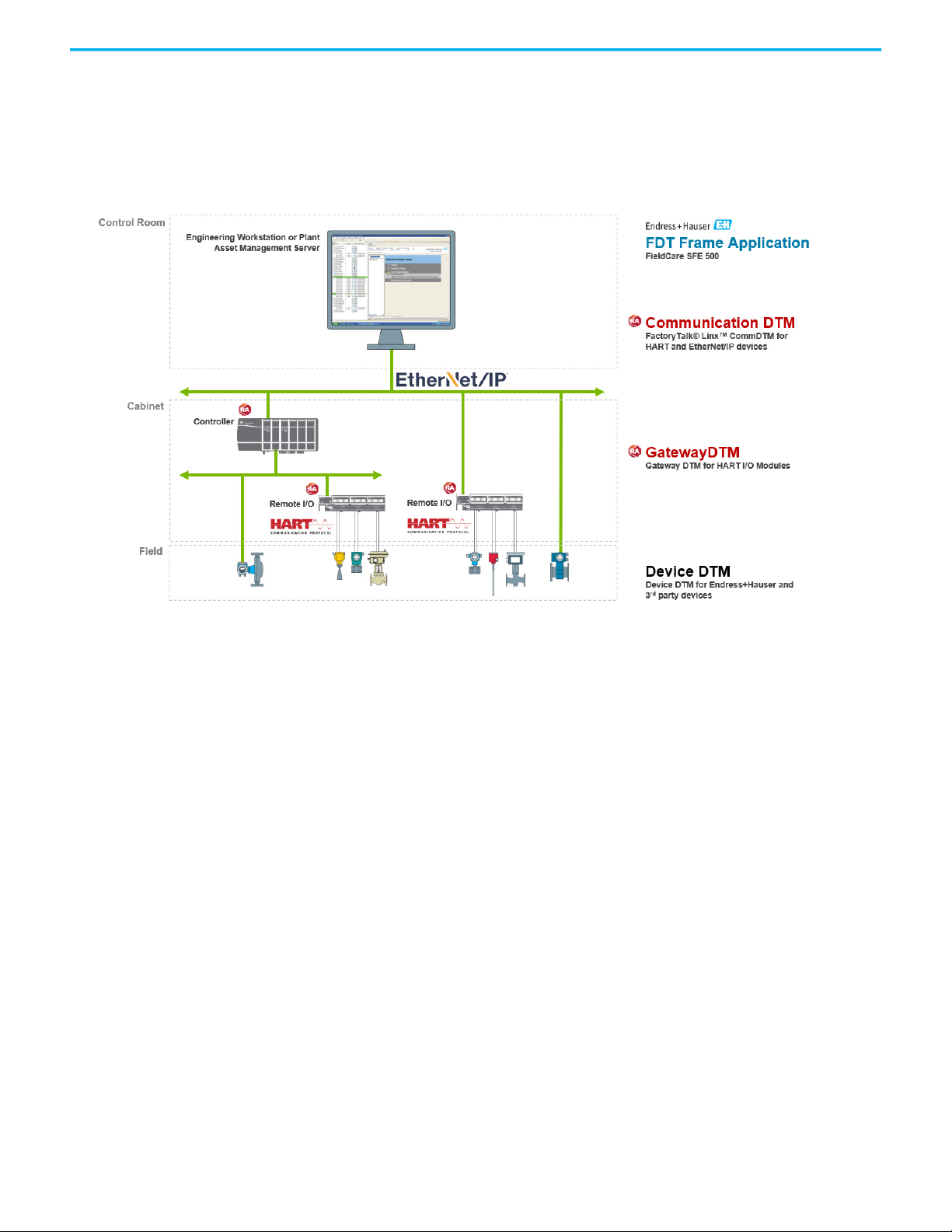

Process Device Configuration

Use FDT® Technology to configure, maintain, and monitor your smart field devices. Everything you need is in an FDT/DTM compatible frame

application with the appropriate Communication, Gateway and device DTMs. Together an FDT Frame and a DTM, or a collection of DTMs,

create an FDT-enabled application, which can be scaled from a single device to tens of thousands of devices controlled by a single FRAME

throughout the automation system.

Process Device Integration

Most PlantPAx device integrations require that you instantiate one Add-On module Profile (AOP) and two Add-On Instructions (AOI)

per field device:

• Module or Device-specific Add-On module Profile for Studio 5000 software to create the item in the I/O Configuration list, required

for device tags

• Device-specific Add-On Instruction that gathers the required device tags and prepares the data for use

• Generic object that uses the device data, along with custom-made device diagnostic and unit tables, to enable visibility with the

PlantPAx Distributed Control System

Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020 5

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 6

Integrate Endress+Hauser Instruments in a PlantPAx Distributed Control System Selection Guide

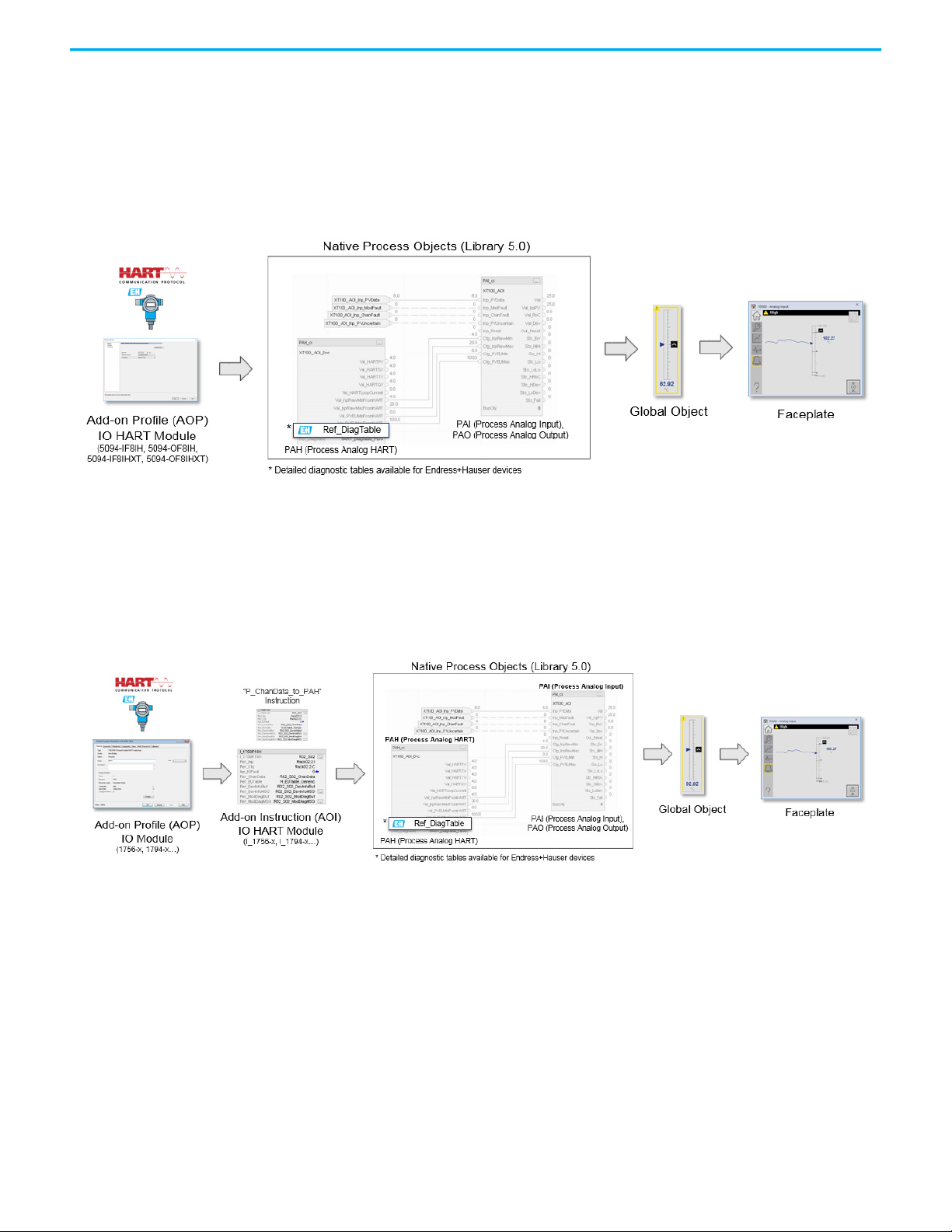

Devices on Rockwell Automation HART I/O Modules

Highly-integrated HART provides a PlantPAx data type in the process controller for use with FLEX 5000 modules:

• Configuration of devices within the I/O Configuration tree (no Add-On Instruction needed)

• Device diagnostics automatically propagate to the controller project

Figure 1 - PlantPAx System Release 5.0 and FLEX 5000™ Highly Integrated HART I/O Modules

1. HART device in Studio 5000 I/O Configuration for device connection.

2. Add-on Profile for Module creation in (IOC) list, provides connection and device tags.

3. Process Controller PlantPAx Instructions for application logic/process strategies/alarms.

4. PlantPAx HMI Global Object to support Faceplates.

5. PlantPAx Faceplates.

Figure 2 - PlantPAx System Release 5.0 and 1756, 1794, 1718, 1719, 1734, 1769 or 1715 HART I/O Modules

1. HART device is not entered in Controllers I/O Configuration list.

2. Add-on Profile for Modules creation in (IOC) list, provides connection and device tags.

3. AOI to access device tags.

4. Add-on Instruction to interface device with PlantPAx Instructions.

5. Process Controller PlantPAx Instructions for application logic/process strategies/alarms.

6. PlantPAx HMI Global Object to support Faceplates.

7. PlantPAx Faceplates.

6 Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 7

Integrate Endress+Hauser Instruments in a PlantPAx Distributed Control System Selection Guide

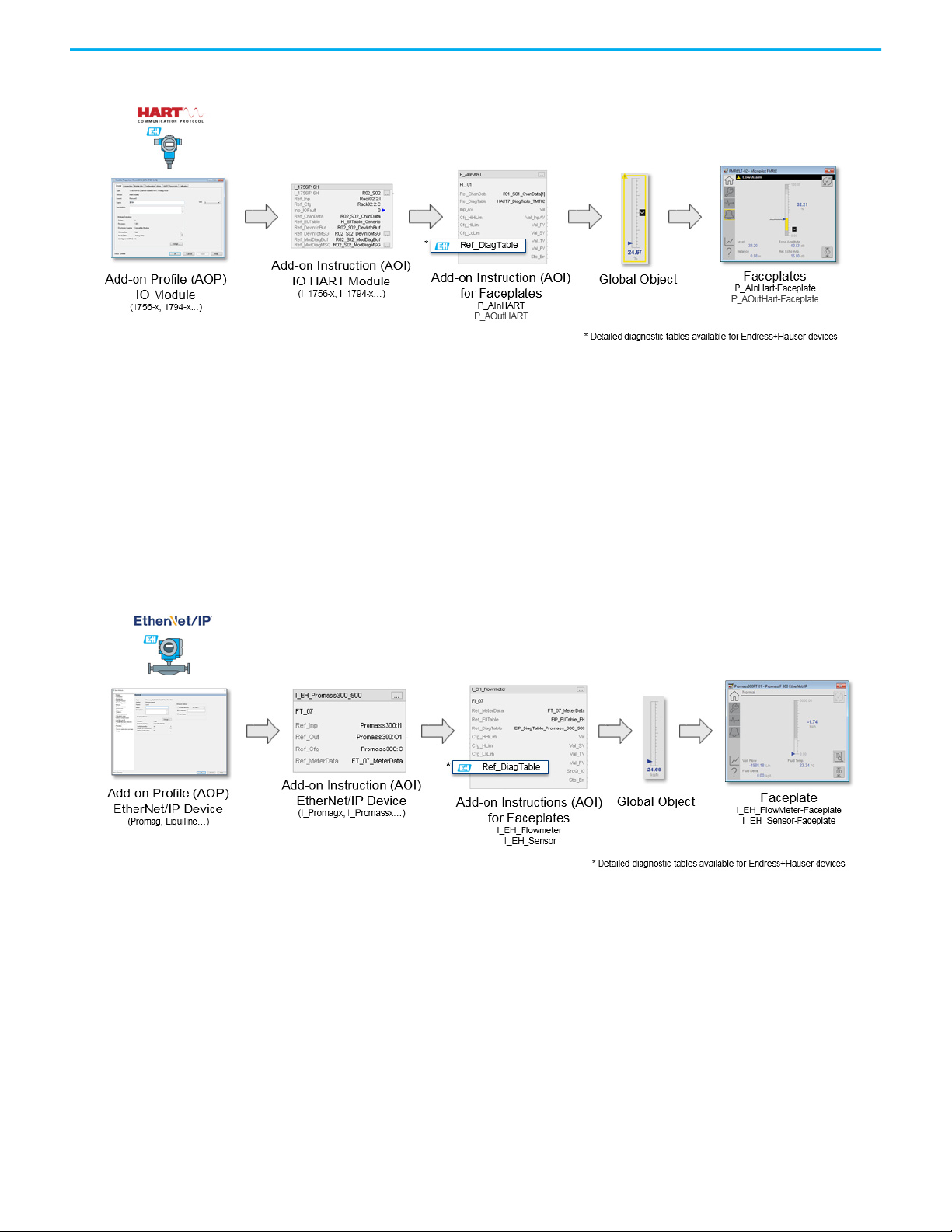

Figure 3 - PlantPAx System Release 4.6 and 1756, 1794, 1718, 1719, 1734, 1769 or 1715 HART I/O Modules

1. HART device is not entered in Controllers I/O Configuration list.

2. Add-on Profile for Modules creation in (IOC) list, provides connection and device tags.

3. Add-on Instruction to access device tags for use with application logic / process strategies.

4. Add-on Instruction for diagnostics and control to the HMI Global Object.

5. PlantPAx HMI Global Object to support Faceplates.

6. PlantPAx Faceplates, such as P_AInHART-Faceplate and P_AOutHART-Faceplate.

Devices on EtherNet/IP (Custom Add-On Profile)

Figure 4 - PlantPAx System Release 4.6 and 5.0 and EtherNet/IP device with Custom AOP (for example, Endress+Hauser)

1. Endress+Hauser device in Studio 5000 I/O Configuration for device connection.

2. Add-on Profile for device creation and configuration, such as Promag, Liquiline.

3. Add-on Instruction to device tags, such as I_Promagx, I_Promassx… for use with application logic / process strategies.

4. Add-on Instruction for diagnostics and control to the HMI Global Object.

5. PlantPAx HMI Global Object to support Faceplates.

6. PlantPAx Faceplates, such as I_EH_FlowMeter-Faceplate and I_EH_Sensor-Faceplate.

Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020 7

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 8

Integrate Endress+Hauser Instruments in a PlantPAx Distributed Control System Selection Guide

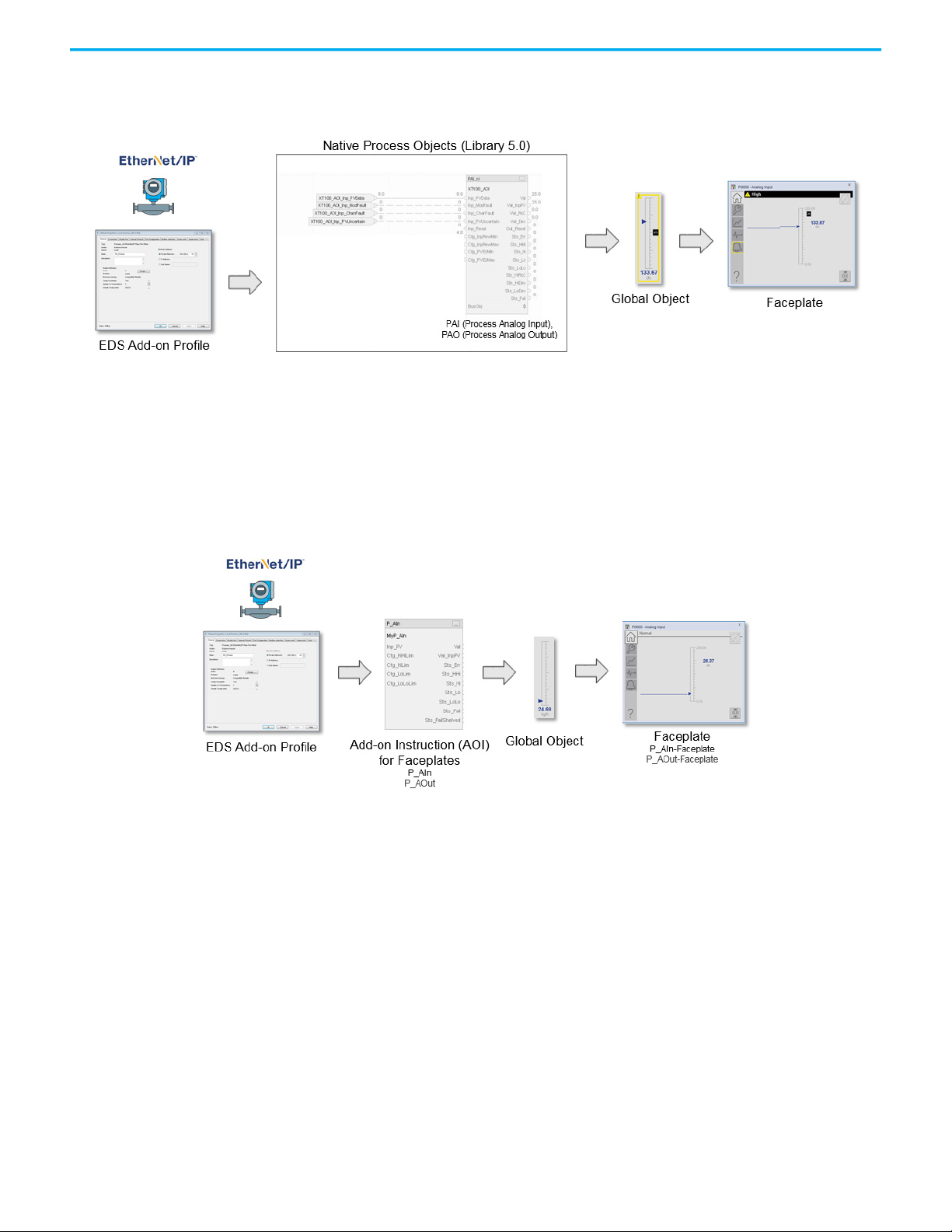

Devices on EtherNet/IP (Electronic Data Sheet Add-On Profile)

Figure 5 - PlantPAx System Release 5.0 and EtherNet/IP device with EDS AOP

1. Device in Studio 5000 I/O Configuration for device connection.

2. Add-on Profile created via Electronic Data Sheet (EDS) file, is used for device creation and configuration.

3. EDS files are text files that contain details about the readable and configurable parameters of the device.

4. Process Controller PlantPAx Instructions for application logic / process strategies /alarms.

5. PlantPAx HMI Global Object to support Faceplates.

6. PlantPAx Faceplates.

Figure 6 - PlantPAx System Release 4.6 and EtherNet/IP device with EDS AOP

1. Device in Studio 5000 I/O Configuration for device connection.

2. Add-on Profile created via EDS file, is used for device creation and configuration.

3. Add-on Profile for HMI Faceplates, such as P_AIn and P_AOut.

4. PlantPAx HMI Global Object to support Faceplates.

5. PlantPAx Faceplates, such as P_AIn and P_AOut.

8 Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 9

Integrate HART Devices

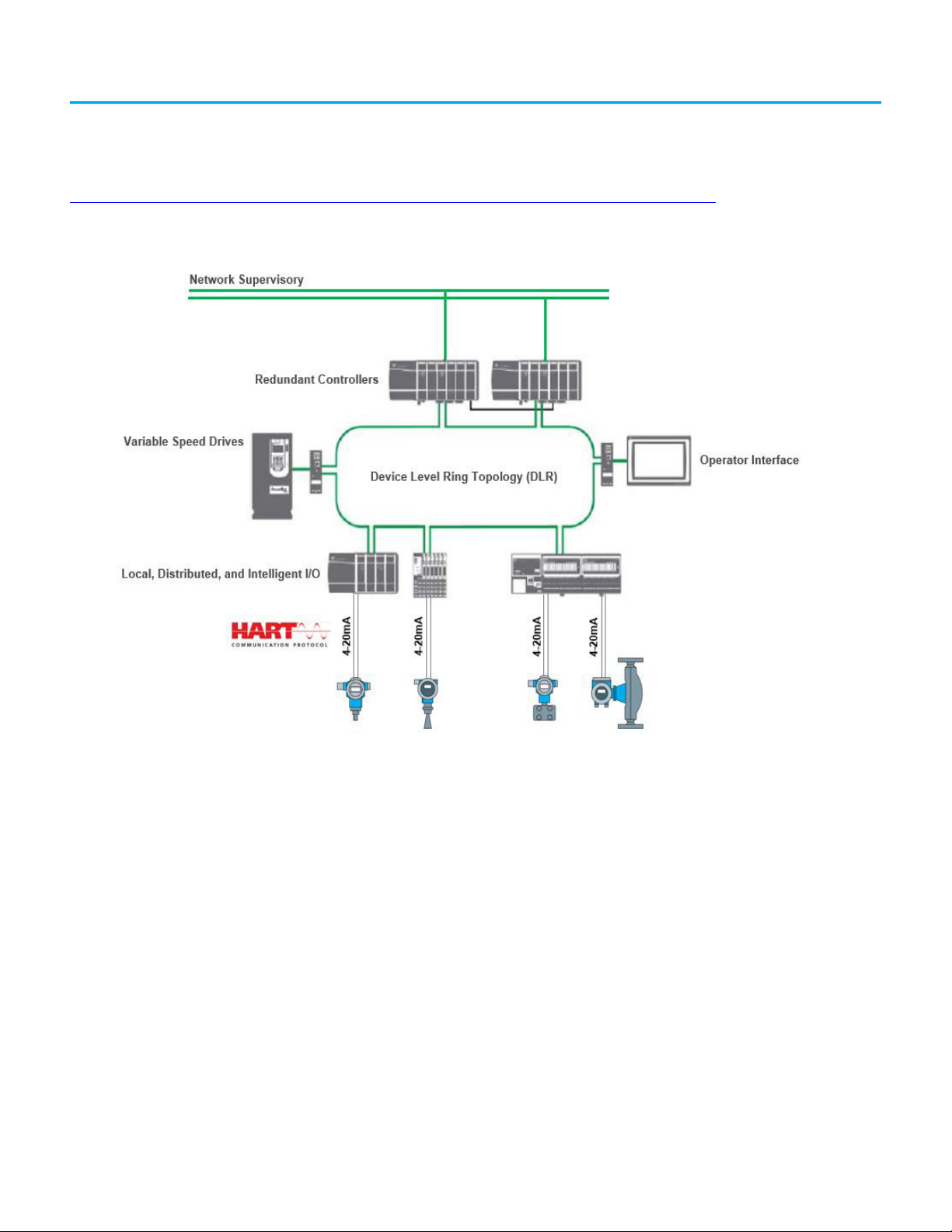

The Highway Addressable Remote Transducer (HART) protocol supports industrial process measurement and control applications. The HART

protocol combines analog and digital communication in both wired and wireless architectures. The analog signal uses a range of

4.0…20.0 mA DC, and the digital communication signal is superimposed on the analog signal. Additional information can be found in

Publication PROCES-RM010, Rockwell Automation® Library of Process Objects: HART Modules for PlantPAx® DCS,

Example Topology

Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020 9

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 10

Integrate HART Devices

HART System Requirements

Supported I/O Modules

Family Module Description

1715 Redundant I/O Modules

Redundant I/O System User Manual, publication 1715-

UM001

1719 EX I/O Modules

1715-IF16 Allen-Bradley® redundant I/O 16-channel analog input module with HART

1715-OF8I Allen-Bradley redundant I/O 8-channel isolated analog input module with HART

1719-CF4H Allen-Bradley 4-channel configurable HART analog I/O module

1719 EX I/O Modules User Manual, publication 1719-

UM001

1756 ControlLogix I/O Modules

ControlLogix HART Analog I/O Modules User Manual,

publication 1756-UM533

1794 FLEX I/O Modules

FLEX I/O Isolated Input/Output HART Analog Modules

User Manual, publication 1794-UM065

1734 POINT I/O Modules

http://www.spectrumcontrols.com

1769 Compact I/O Modules

http://www.spectrumcontrols.com

FLEX 5000 I/O Modules

publication 5094-UM007

WirelessHART Fieldgate Gateway

WirelessHART Fieldgate Technical Information

WirelessHART Adapter

WirelessHART Adapter Technical Information

Memograph

Memograph Technical Information

1719-IF4HB Allen-Bradley 4-channel HART analog input module

1756-IF8H Allen-Bradley ControlLogix® 8-channel HART analog input module

1756-IF8IH Allen-Bradley ControlLogix 8-channel isolated HART analog input module

1756-IF16H Allen-Bradley ControlLogix 16-channel HART analog input module

1756-IF16IH Allen-Bradley ControlLogix 16-channel isolated HART analog input module

1756-OF8H Allen-Bradley ControlLogix 8-channel HART analog output module

1756-OF8IH Allen-Bradley ControlLogix 8-channel isolated HART analog output module

1794-IF8IH Allen-Bradley FLEX™ I/O 8-channel isolated HART analog input module

1794-IF8IHNFXT

1794-OF8IH Allen-Bradley FLEX I/O 8-channel isolated HART analog output module

1734sc-IE2CH Spectrum Controls POINT I/O™ 2-channel HART analog input module

1734sc-IE4CH Spectrum Controls POINT I/O 4-channel HART analog input module

1734sc-OE2CIH Spectrum Controls POINT I/O 2-channel isolated HART analog output module

1769sc-IF4IH Spectrum Controls Compact I/O™ 4-channel isolated HART analog input module

1769sc-OF4IH Spectrum Controls Compact I/O 4-channel isolated HART analog output module

5094-IF8IH

5094-OF8IH

5094-IF8IHXT

5094-OF8IHXT

SWG70 Endress+ Hauser WirelessHART gateway with Ethernet interface

SWA70 Endress+ Hauser WirelessHART interface with power supply for field devices

RSG45 Endress+ Hauser data manager

Allen-Bradley FLEX I/O-XT™ extended temperature 8-channel isolated HART

analog input module

Allen-Bradley Flex 5000™ Analog 8-channel analog isolated HART

Allen-Bradley Flex 5000 Analog 8-channel output isolated HART

Allen-Bradley Flex 5000 Analog 8-channel input isolated HART (Extreme

environment)

Allen-Bradley Flex 5000 Analog 8-channel output isolated HART (Extreme

environment)

Download add-on profile and accessory files from the Product and Compatibility Download Center at:

https://compatibility.rockwellautomation.com/Pages/home.aspx

10 Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 11

Integrated HART Devices

HART Analytical Devices

Family Device Documentation

Liquiline

Multichannel transmitter for monitoring processes

CM44P: multichannel;

combines process

photometers and

Memosens sensors

CM442: 1 or 2 channel

Liquiline CM44P Operating Instructions

Integrate HART Devices

Liquiline M

Transmitter for pH/ORP, conductivity, or oxygen

measurement

Liquistation

Stationary sampler for water and wastewater

treatment

CM444: 4 channel

CM448: 8 channel

CM442R: DIN rail or

cabinet; 1 or 2 channel

CM444R: DIN rail or

cabinet; 4 channel

CM448R: DIN rail or

cabinet; 8 channel

CM42:

Two-wire transmitter

for Ex and non-Ex

areas

CSF34: North America

version

CSF48: integrated

controller

Liquiline CM442/CM444/CM448 Operating Instructions

Liquiline CM442R/CM444R/CM448R Operating Instructions

Technical Information Liquiline M CM42

Liquistation CSF34 Operating Instructions

Liquistation CSF48 Operating Instructions

Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020 11

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 12

Integrate HART Devices

HART Analytical Devices

Family Device Documentation

CLM223: panel device;

conductivity

Liquisys M

Continuous plausibility, process, and sensor checks

for liquid analysis

Smartec S

Toroidal conductivity measurement system

transmitter

CLM253: field device;

conductivity

transmitter

COM223: panel device;

dissolved oxygen

transmitter

COM253: field device;

dissolved oxygen

transmitter

CPM223: panel device;

pH/ORP transmitter

CPM253: field device;

pH/ORP transmitter

CLD132: hygienic

applications

Liquisys M CLM223/253 Operating Instructions

Liquisys M COM223/253 Operating Instructions

Liquisys M CPM223/253 Operating Instructions

Field Communication with SmarTec S CLD 132 Operating Instructions

CLD134: hygienic and

sterile applications

Smartec CLD134 Operating Instructions

HART Flow Devices

Family Devices Documentation

CNGmass DCI

Coriolis flowmeter for refueling applications

8DF CNGmass DCI HART Operating Instructions

Cubemass DCI

Ultra-compact Coriolos flowmeter for small

quantities

8CN Cubemass DCI HART Operating Instructions

Proline t-mass

Thermal mass flowmeter that is designed for the

direct mass flow measurement of industrial gases,

and compressed air

65F: inline

65I: integrated gas

engine

Proline t-mass 65 Operating Instruction

12 Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 13

HART Flow Devices

Family Devices Documentation

Proline t-mass 150

Thermal mass flowmeter that is designed for the

direct mass flow measurement of industrial gases,

and compressed air

A 150 utility gases;

inline

B 150: utility gases;

insertion Proline t-mass B 150 HART Operating Instructions

T 150: water; insertion Proline t-mass T 150 HART Operating Instructions

Proline t-mass A 150 HART Operating Instructions

Integrate HART Devices

Proline t-mass 300

Flowmeter with long-term stability and a sense for

utility gases

Proline t-mass 500

Versatile instrument for pure gases and

gas mixtures

Promag 10

Electromagnetic flowmeter

F 300: utility and

process gases, inline,

easy cleaning

I 300: utility and

process gases,

insertion, flexible

mounting location

F 500: utility and

process gases, inline,

remote, easy cleaning

I 500: utility and

process gases,

insertion, remote,

flexible mounting

10D: wafer version

10E: basic chemical

applications

10H: food and

beverage and life

science industries

10L: water and

wastewater industries

with a lap-joint flange

Proline t-mass F/I 300/500 Operating Instructions

Proline t-mass F/I 300/500 Operating Instructions

Proline t-mass F/I 300/500 Operating Instructions

Proline t-mass F/I 300/500 Operating Instructions

Proline Promag 10 HART Operating Instructions

10P: chemical and

process applications

with corrosive liquids

and high medium

temperatures

10W: IP68 protection

(Type 6P enclosure)

Proline Promag 100

Electromagnetic flowmeter

Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020 13

Endress+Hauser Publication SP01010A/04/EN/01.19

E 100: chemical

applications Proline Promag E 100 HART Operating Instructions

H 100: hygienic

applications Proline Promag H 100 HART Operating Instructions

P 100: chemical and

process applications

with corrosive liquids

and high medium

temperatures

Proline Promag P 100 HART Operating Instructions

Page 14

Integrate HART Devices

HART Flow Devices

Family Devices Documentation

Proline Promag 200

Electromagnetic flowmeter

Proline Promag 300

Electromagnetic flowmeter

Proline Promag 400

Electromagnetic flowmeter

H 200: hygienic

applications Proline Promag H 200 HART Operating Instructions

P 200: chemical and

process applications

with corrosive liquids

and high medium

temperatures

H 300: hygienic

applications Proline Promag H 300 HART Operating Instructions

P 300: chemical and

process applications

with corrosive liquids

and high medium

temperatures

W 300: corrosive

protection for water

and wastewater

applications

D 400: wafer

flowmeter for water

applications

Proline Promag P 200 HART Operating Instructions

Proline Promag P 300 HART Operating Instructions

Proline Promag W 300 HART Operating Instructions

Proline Promag D 400 HART Operating Instructions

Proline Promag 500

Electromagnetic flowmeter

W 400: corrosive

protection for water

and wastewater

applications

H 500: hygienic

applications

P 500:chemical and

process applications

with corrosive liquids

and high medium

temperatures

W 500: corrosive

protection for water

and wastewater

applications

Proline Promag W 400 HART Operating Instructions

Proline Promag H 500 HART Operating Instructions

Proline Promag P 500 HART Operating Instructions

Proline Promag W 500 HART Operating Instructions

14 Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 15

HART Flow Devices

Family Devices Documentation

A 100: small quantities

Proline Promass 100

Coriolis flowmeter

of liquids and gases

for high pressure and

low pressure

E 100: smallest

footprint

Proline Promass A 100 HART Operating Instructions

Proline Promass E 100 HART Operating Instructions

Integrate HART Devices

Proline Promass 200

Coriolis flowmeter

F 100: multiple

process applications

G 100: liquids and

gases in high

pressure applications

up to 350 bar (5080

psi)

H 100: corrosion

resistant

I 100: in-line viscosity

and flow

measurement

O 100: liquids and

gases at the highest

process pressures in

the oil and gas

industry

P 100: life science

applications

E 200: loop power;

hazardous area

F 200: loop power Proline Promass F 200 HART Operating Instructions

Proline Promass F 100 HART Operating Instructions

Proline Promass G 100 HART Operating Instructions

Proline Promass H 100 HART Operating Instructions

Proline Promass I 100 HART Operating Instructions

Proline Promass O 100 HART Operating Instructions

Proline Promass P 100 HART Operating Instructions

Proline Promass E 200 HART Operating Instructions

Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020 15

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 16

Integrate HART Devices

HART Flow Devices

Family Devices Documentation

Proline Promass 300

Coriolis flowmeter

A 300: small

quantities of liquids

and gases for high

pressure and low

pressure

E 300: smallest

footprint

Proline Promass A 300 HART Operating Instructions

Proline Promass E 300 HART Operating Instructions

F 300: multiple

process applications

H 300: corrosion

resistant

I 300: in-line viscosity

and flow

measurement

O 300: liquids and

gases at the highest

process pressures in

the oil and gas

industry

P 300: life science

applications

Q 300: liquids and

gases at the highest

process pressures in

the oil and gas

industry

S 300: self-drainable

single-tube system

for food and beverage

applications

X 300: on- and

offshore applications

in the oil and gas

industry

Proline Promass F 300 HART Operating Instructions

Proline Promass H 300 HART Operating Instructions

Proline Promass I 300 HART Operating Instructions

Proline Promass O 300 HART Operating Instructions

Proline Promass P 300 HART Operating Instructions

Proline Promass Q 300 HART Operating Instructions

Proline Promass S 300 HART Operating Instructions

Proline Promass X 300 HART Operating Instructions

16 Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 17

HART Flow Devices

Family Devices Documentation

Proline Promass 500

Coriolis flowmeter

A 500: small

quantities of liquids

and gases for high

pressure and low

pressure

E 500: smallest

footprint

Proline Promass A 500 HART Operating Instructions

Proline Promass E 500 HART Operating Instructions

Integrate HART Devices

F 500: multiple

process applications

H 500: corrosion

resistant

I 500: in-line viscosity

and flow

measurement

O 500: liquids and

gases at the highest

process pressures in

the oil and gas

industry

P 500: life science

applications

Q 500: liquids and

gases at the highest

process pressures in

the oil and gas

industry

S 500: self-drainable

single-tube system

for food and beverage

applications

X 500: onshore and

offshore applications

in the oil and gas

industry

Proline Promass F 500 HART Operating Instructions

Proline Promass H 500 HART Operating Instructions

Proline Promass I 500 HART Operating Instructions

Proline Promass O 500 HART Operating Instructions

Proline Promass P 500 HART Operating Instructions

Proline Promass Q 500 HART Operating Instructions

Proline Promass S 500 HART Operating Instructions

Proline Promass X 500 HART Operating Instructions

Proline Prosonic Flow

Ultrasonic flowmeter

91W: clamp-on sensor

92F: loop powered

93C: inline for large

pipes up to DN 2000 Prosonic Flow 93 HART Operating Instructions

93P: clamp-on sensor

for hazardous

locations

B 200: biogas

G 300: inline

measurement of

natural and process

gas in chemical, oil,

and gas industries

G 500: inline

measurement of

natural and process

gas in chemical, oil,

and gas industries

Prosonic Flow 91 Operating Instructions

Prosonic Flow 92F PROFIBUS PA Operating Instructions

Prosonic Flow 93 HART Operating Instructions

Proline Prosonic Flow B 200 HART Operating Instructions

Proline Prosonic Flow G 300 HART Operating Instructions

Proline Prosonic Flow G 500 HART Operating Instructions

Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020 17

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 18

Integrate HART Devices

HART Flow Devices

Family Devices Documentation

Prowirl

Vortex flowmeter for steam quality measurement

C 200: carbon-steel

sensor

D 200: disc/wafer

model

Proline Prowirl C 200 HART Operating Instructions

Proline Prowirl D 200 HART Operating Instructions

F 200: heavy duty

applications

O 200: high-pressure

applications

R 200: integrated

reduction of the line

size by 1 or 2

diameters

Proline Prowirl F 200 HART Operating Instructions

Proline Prowirl O 200 HART Operating Instructions

Proline Prowirl R 200 HART Operating Instructions

HART Level Devices

Family Device Documentation

Gammapilot M

Compact transmitter for point level detection,

continuous level, interface, and density

measurement

FMG60 Gammapilot M FMG60 HART Operating Instructions

18 Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 19

HART Level Devices

Family Device Documentation

Levelflex

Guided-radar, continuous-level, and interface

measurement

Liquicap M

Continuous level and interface measurement in

liquids

FMP50: basic level

applications in liquids

FMP51: standard

sensor for liquids

(level and interface

measurement)

FMP52: coated probe

for use in aggressive

liquids (level and

interface

measurement)

FMP54: high-

temperature and

high-pressure

applications in the oil

and gas, chemical,

and power industries

(level and interface

measurement)

FMP53: hygiene

requirements in the

food and life sciences

industries

FMP55:

multiparameter

device (level and

interface

measurement)

FMP56: basic model

for all level

applications in bulk

solids

FMP57: standard

sensor for level

measurement in bulk

solids

FMI51: fully insulated

rod probe

FMI52: fully insulated

rope probe

Levelflex FMP50 HART Operating Instructions

Levelflex FMP51, FMP52, FMP54 HART Operating Instructions

Levelflex FMP53 HART Operating Instructions

Levelflex FMP55 HART Operating Instructions

Levelflex FMP56, FMP57 HART Operating Instructions

Operating Instructions Liquicap M FMI51, FMI52 FEI50H HART

Integrate HART Devices

Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020 19

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 20

Integrate HART Devices

HART Level Devices

Family Device Documentation

Micropilot

Level measurement in liquids or solids

Prosonic M

Non-contact level measurement in fluids, pastes,

and coarse bulk materials; flow measurement in

open channels or at weirs

FMR20: water and

wastewater and

utilities

FMR50: basic model

for level liquid

applications

FMR51: standard

sensor for level liquid

applications

FMR52: aggressive

liquids or applications

with hygiene

requirements

FMR53: simple liquid

measurement

FMR54: strong steam

or ammonia

applications

FMR56: basic model

for level

measurement in

solids

FMR57: standard

sensor for bulk solids

level measurement

FMR60: standard

sensor for liquid level

measurement with

80 GHz technology

FMR62: 80 GHz level

measurement in

aggressive liquids or

applications with

hygiene requirements

FMR67: standard

sensor for bulk solids

level measurement

with 80 GHz

technology

FMU40: level

measurement in

liquids and bulk solids

for up to 5 m (16.04 ft)

FMU41: measurement

in liquids and bulk

solids for up to 8 m

(26.25 ft)

Micropilot FMR20 HART Operating Instructions

Micropilot FMR50 HART Operating Instructions

Micropilot FMR51, FMR52 HART Operating Instructions

Micropilot FMR53, FMR54 HART Operating Instructions

Micropilot FMR56, FMR57 HART Operating Instructions

Micropilot FMR60 HART Operating Instructions

Micropilot FMR62 HART Operating Instructions

Micropilot FMR67 HART Operating Instructions

FMU42: measurement

in liquids and bulk

solids for up to 10 m

(32.81 ft)

FMU43: measurement

in liquids and bulk

solids for up to 15 m

(49.21 ft)

FMU44: measurement

in liquids and bulk

solids for up to 20 m

(65.62 ft)

20 Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020

Prosonic M FMU40/41/42/43/44 Operating Instructions

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 21

HART Level Devices

Family Device Documentation

Prosonic S

Continuous, non-contact level measurement of

fluids, pastes, sludge, and powdery to coarse bulk

solids

FMU90: level/flow

measurement and

pump control

Integrate HART Devices

FDU90, FDU91, FDU91F,

FDU92, FDU93. FDU95:

transmitter in housing

for field or top hat rail

mounting for up to 2

sensors

Waterpilot

Hydrostatic level measurement

FMX21: level probe

with ceramic cell

Prosonic S FMU90

Waterpilot FMX21 Operating Instructions

HART Pressure Devices

Family Device Documentation

Cerabar M

Digital pressure transmitter with sensor for

measurement in gases or liquids

PMC51: oil-free

ceramic sensor

PMP51: fully-welded

metal sensor

Cerabar M, Deltabar M, Deltapilot M HART (V 01.00.zz)

Cerabar S

Digital pressure transmitter with sensor for

measurement in gases or liquids

Deltabar

Differential pressure system that is used to measure

the pressure or level, volume, or mass of liquids in

pressurized tanks or distillation columns/

evaporators

PMP55: fully-welded

metal diaphragm seal

PMC71: oil-free

ceramic sensor

PMP71: fully-welded

metal sensor

PMP75: fully-welded,

metal diaphragm seal

FMD71: oil-free

ceramic sensors

FMD72: fully-welded

sensors

Cerabar S PMC71, PMP71, PMP75 HART V02.30.zz Operating Instructions

Deltabar FMD71, FMD72 Operating Instructions

Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020 21

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 22

Integrate HART Devices

HART Pressure Devices

Family Device Documentation

Deltabar M

Differential pressure transmitter for measurement

of pressure differences

PMD55: metal sensor Cerabar M, Deltabar M, Deltapilot M HART (V 01.00.zz)

Deltabar S

Differential pressure transmitter for level

measurement

FMD77: one

diaphragm seal (fixed)

Deltapilot M

Pressure sensor with the condensation-tight,

Contite cell for hydrostatic level measurement

Deltapilot S

High-performance pressure sensor with the

condensation-tight, Contite cell for hydrostatic level

measurement

FMD78: one

diaphragm seal

(capillary)

PMD75: metal sensor

FMB50: fully

condensate-resistant

metal pressure

(CONTITEM) sensor

FMB51: rod version in

fixed process

connection

FMB52: cable version

in fixed process

connection

FMB53: cable version

with mounting clamp

FMB70: fully

condensate-resistant

metal pressure

(CONTITEM) sensor

Deltabar S FMD77, FMD78, PMD75 HART V02.30.zz Operating Instructions

Cerabar M, Deltabar M, Deltapilot M HART (V 01.00.zz)

Deltapilot S FMB70 HART V02.30.zz Operating Instructions

22 Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 23

HART Tank Gauge Devices

Family Device Documentation

Micropilot S

Custody transfer and inventory control applications

Proservo

Servo measurement for liquid level, interface, and

density

FMR530: custody

transfer and inventory

control applications

with NMi- and PTB-

approvals

FMR532: non-contact

level measurement in

stilling well

applications in

custody transfer

FMR540: horn antenna

and parabolic

antenna for custody

transfer

NMS80: rude oil,

gasoline, diesel,

petrochemical, and

chemical applications

NMS81: crude oil,

gasoline, diesel,

petrochemical, and

chemical applications

Micropilot S FMR530 HART Operating Instructions

Micropilot S FMR532 HART Operating Instructions

Micropilot S FMR540 HART Operating Instructions

Proservo NMS80 Operating Instructions

Proservo NMS81 Operating Instructions

Integrate HART Devices

Prothermo

Average temperature measurement

Tank Side Monitor

Field gateway for tank sensor operation and

monitoring, and for integration into inventory

control system

NMS83: hygienic

applications

NMT532: intrinsically

safe multi-signal

converter with

precision average

temperature sensor

for inventory control

NMT539: intrinsically

safe multi-signal

converter with

precision average

temperature and

water bottom sensor

for inventory control

and custody transfer

NRF81: standalone

NRF590: integrates

with Micropilot radar

or Proservo level

gauges

Proservo NMS83 Operating Instructions

Prothermo NMT532 - Operating Instructions

Prothermo NMT539 - Operating Instructions and Description of Device Function

Tankside Monitor NRF81 Operating Instructions

Tankside Monitor NRF590 Operating Instructions

Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020 23

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 24

Integrate HART Devices

HART Temperature Devices

Family Device Documentation

iTEMP TMT142

iTEMP HART TMT142 Temperature Field Transmitter

TMT162

TMT82 iTEMP TMT82 Operating Instructions

TMT72 iTEMP TMT72 Operating Instructions

iTERM TrustSens

TM371/372 iTHERM TrustSens TM371, TM372 Operating Instructions

Temperature field transmitter iTEMP TMT162, HART 7 specification

HART Display Devices

Family Device Documentation

Process Indicator

RIA15 RIA15 Operating Instructions

24 Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 25

Integrate EtherNet/IP Devices

The PlantPAx system is built on open industry standards, leveraging the EtherNet/IP™ network as its backbone. The EtherNet/IP network

helps support seamless integration of the system components, as well as to provide connectivity to higher-level business systems. In a

PlantPAx system, the EtherNet/IP network provides the communication backbone for the supervisory network for the workstations, servers,

and the controllers. The EtherNet/IP network also supports connections to remote I/O and field device interfaces. Additional information can

be found in Publication PROCES-RM012, Rockwell Automation® Library of Process Objects: EtherNet/IP Instrumentation for PlantPAx DCS.

Example Topology

Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020 25

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 26

Integrate EtherNet/IP Devices

EtherNet/IP System Requirements

Supported EtherNet/IP Communication Modules

Family Module Description

1756-EN2T

1756 ControlLogix EtherNet/IP Communication Modules

EtherNet/IP Modules Installation Instructions,

publication ENET-IN002

1756-EN2TP

1756-EN2TR

1756-EN3TR

1756-EN2F

EtherNet/IP bridge

1769 CompactLogix™ Controllers with embedded

EtherNet/IP interface

CompactLogix 5370 Controllers User Manual,

publication 1769-UM021

1769 Compact I/O™ EtherNet/IP interface

EtherNet/IP Modules Installation Instructions,

publication ENET-IN002

1734 POINT EtherNet/IP interface

POINT I/O EtherNet/IP Adapter Module User Manual,

publication 1734-UM011

POINT I/O and ArmorPOINT® I/O 2 Port EtherNet/IP

Adapters User Manual, publication 1734-UM014

Compact 5000 EtherNet/IP Adapters,

publication 5069-UM007

FLEX 5000 EtherNet/IP Adapter,

publication 5094-UM005

1738 ArmorPoint EtherNet/IP interface

1738 ArmorPOINT I/O EtherNet/IP Adapters User Manual,

publication 1738-UM005

POINT I/O and ArmorPOINT I/O 2 Port EtherNet/IP

Adapters User Manual, publication 1734-UM014

1794 FLEX EtherNet/IP interface

FLEX™ I/O EtherNet/IP Adapters Installation

Instructions, publication 1794-IN082

FLEX I/O Dual Port EtherNet/IP Adapter Modules

Installation Instructions, publication 1794-IN131

1769-L33ER

1769-L36ERM

1769-L19ER-BB1

1769-L24ER-QBFC1B

1769-AENTR Compact I/O EtherNet/IP communication adapter

1734-AENT

1734-AENTR

5069-AENTR

5069-AEN2TR 5069 EtherNet/IP Adapters

5094-AENTR

5094-AENTRXT

5094-AEN2TR

5094-AEN2TRXT

5094-AENSFPR

5094-AENSFPRXT

5094-AEN2SFPR

5094-AEN2SFPRXT

1738-AENT

1738-AENTR

1794-AENT

1794-AENTR

1794-AENTRXT

CompactLogix 5370 controllers with embedded EtherNet/IP interface

POINT I/O EtherNet/IP communication adapter

5094 EtherNet/IP Adapters

ArmorPOINT I/O EtherNet/IP communication adapter

FLEX I/O EtherNet/IP communication adapter

Download add-on profile files from the Product and Compatibility Download Center at:

https://compatibility.rockwellautomation.com/Pages/home.aspx

26 Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 27

Integrated EtherNet/IP Devices

EtherNet/IP Analytical Devices

Family Device Documentation

CA80AL: Aluminum

Liquiline System CA80AL Operating Instructions

Integrate EtherNet/IP Devices

Liquiline System

Liquiline

Multichannel transmitter for monitoring processes

CA80HA: water

hardness

CA80SI: Silica

CA80AM: ammonium

CA80COD: chemical

oxygen demand

CA80CR: chromate

CA80FE: iron

CA80NO: nitrite

CA80PH:

orthophosphate Liquiline System CA80PH Operating Instructions

CA80TP: total

phosphorous

CM44P: multichannel;

combines process

photometers and

Memosens sensors

CM442: 1 or 2 channel

CM444: 4 channel

CM448: 8 channel

CM442R: DIN rail or

cabinet; 1 or 2 channel

Liquiline System CA80HA Operating Instructions

Liquiline System CA80SI Operating Instructions

Liquiline System CA80AM Operating Instructions

Liquiline System CA80COD Operating Instructions

Liquiline System CA80CR Operating Instructions

Liquiline System CA80FE Operating Instructions

Liquiline System CA80NO Operating Instructions

Liquiline System CA80TP Operating Instructions

Liquiline CM44P Operating Instructions

Liquiline CM442/CM444/CM448 Operating Instructions

Liquistation

Stationary sampler for water and wastewater

treatment

CM444R: DIN rail or

cabinet; 4 channel

CM448R: DIN rail or

cabinet; 8 channel

CSF34: North America

version Liquistation CSF34 Operating Instructions

CSF48: integrated

controller

Liquiline CM442R/CM444R/CM448R Operating Instructions

Liquistation CSF48 Operating Instructions

Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020 27

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 28

Integrate EtherNet/IP Devices

EtherNet/IP Flow Devices - Promag

Family Devices Documentation

Proline Promag 100

Electromagnetic flowmeter

E 100: basic chemical applications Proline Promag E 100 EtherNet/IP Operating Instructions

H 100: hygienic applications Proline Promag H 100 EtherNet/IP Operating Instructions

Proline Promag 300

Electromagnetic flowmeter

Proline Promag 400

Electromagnetic flowmeter

Proline Promag 500

Electromagnetic flowmeter

P 100: chemical and process applications with

corrosive liquids and high medium temperatures

H 300: hygienic applications Proline Promag H 300 EtherNet/IP Operating Instructions

P 300: chemical and process applications with

corrosive liquids and high medium temperatures

W 300: corrosive protection for water and wastewater

applications

D 400: basic water applications Proline Promag D 400 EtherNet/IP Operating Instructions

W 400: corrosion protection

H 500: hygienic applications Proline Promag H 500 EtherNet/IP Operating Instructions

P 500:chemical and process applications with

corrosive liquids and high medium temperatures

W 500: corrosive protection for water and wastewater

applications

Proline Promag P 100 EtherNet/IP Operating Instructions

Proline Promag P 300 EtherNet/IP Operating Instructions

Proline Promag W 300 EtherNet/IP Operating Instructions

Proline Promag W 400 EtherNet/IP Operating Instructions

Proline Promag P 500 EtherNet/IP Operating Instructions

Proline Promag W 500 EtherNet/IP Operating Instructions

28 Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 29

EtherNet/IP Flow Devices - Promass

Integrate EtherNet/IP Devices

Proline Promass 100

Coriolis flowmeter

Proline Promass 300

Coriolis flowmeter

A 100: measures small quantities of liquids and gases Proline Promass A 100 EtherNet/IP Operating Instructions

Cubemass C 100: direct mass and density

measurement

E 100: basic applications; smallest footprint Proline Promass E 100 EtherNet/IP Operating Instructions

F 100: basic process applications Proline Promass F 100 EtherNet/IP Operating Instructions

G 100: high pressure applications Proline Promass G 100 EtherNet/IP Operating Instructions

H 100: corrosion resistant Proline Promass H 100 EtherNet/IP Operating Instructions

I 100: combines flow measurement with in-line

viscosity

O 100: resistant to stress corrosion cracking Proline Promass O 100 EtherNet/IP Operating Instructions

P 100: life science applications Proline Promass P 100 EtherNet/IP Operating Instructions

A 300: small quantities of liquids and gases for high

pressure and low pressure

E 300: smallest footprint Proline Promass E 300 EtherNet/IP Operating Instructions

F 300: multiple process applications Proline Promass F 300 EtherNet/IP Operating Instructions

H 300: corrosion resistant Proline Promass H 300 EtherNet/IP Operating Instructions

I 300: in-line viscosity and flow measurement Proline Promass I 300 EtherNet/IP Operating Instructions

S 300: self-drainable single-tube system for food and

beverage applications

X 300: on- and offshore applications in the oil and gas

industry

O 300: on- and offshore applications in the oil and gas

industry at the highest pressures

P 300: specialist for sterile processes dedicated to

biotech applications

Proline Promass C 100 EtherNet/IP Operating Instructions

Proline Promass I 100 EtherNet/IP Operating Instructions

Proline Promass A 300 EtherNet/IP Operating Instructions

Proline Promass S 300 EtherNet/IP Operating Instructions

Proline Promass X 300 EtherNet/IP Operating Instructions

Proline Promass O 300 EtherNet/IP Operating Instructions

Proline Promass P 300 EtherNet/IP Operating Instructions

Q 300: custody transfer applications Proline Promass Q 300 EtherNet/IP Operating Instructions

Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020 29

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 30

Integrate EtherNet/IP Devices

Proline Promass 500

Coriolis flowmeter

A 500: small quantities of liquids and gases for high

pressure and low pressure

E 500: smallest footprint Proline Promass E 500 EtherNet/IP Operating Instructions

F 500: multiple process applications Proline Promass F 500 EtherNet/IP Operating Instructions

H 500: corrosion resistant Proline Promass H 500 EtherNet/IP Operating Instructions

I 500: in-line viscosity and flow measurement Proline Promass I 500 EtherNet/IP Operating Instructions

O 500: liquids and gases at the highest process

pressures in the oil and gas industry

P 500: life science applications Proline Promass P 500 EtherNet/IP Operating Instructions

Q 500: liquids and gases at the highest process

pressures in the oil and gas industry

S 500: self-drainable single-tube system for food and

beverage applications

X 500: onshore and offshore applications in the oil and

gas industry

Proline Promass A 500 EtherNet/IP Operating Instructions

Proline Promass O 500 EtherNet/IP Operating Instructions

Proline Promass Q 500 EtherNet/IP Operating Instructions

Proline Promass S 500 EtherNet/IP Operating Instructions

Proline Promass X 500 EtherNet/IP Operating Instructions

EtherNet/IP Interface Devices

Family Device Documentation

WirelessHART gateway with Ethernet interface

SWG70 WirelessHART Fieldgate SWG70 Operating Instructions

WirelessHART adapter

For use with then WirelessHART gateway

SWA70 WirelessHART Adapter SWA70 Operating Instructions

EtherNet/IP Recorder Devices

Family Devices Documentation

Memograph M

Store, visualize, and analyze process values

RSG45

Memograph M, RSG45 Operating Instructions

Additional instructions Memograph M, RSG45 EtherNet/IP communication

30 Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 31

Integrate Endress+Hauser Instruments in a PlantPAx Distributed Control System Selection Guide

Additional Resources

These websites provide additional information.

Resource Description

https://www.rockwellautomation.com/global/capabilities/process-solutions Information about Rockwell Automation process control.

http://literature.rockwellautomation.com Available Rockwell Automation documentation.

https://rockwellautomation.custhelp.com Rockwell Automation customer support center.

http://www.endress.com

https://www.endress.com/en/downloads Available Endress+Hauser documentation.

https://www.endress.com/en/solutions-lowering-costs/field-networkengineering

https://www.endress.com/en/Endress-Hauser-group/life-cyclemanagement/Optimized-operations/access-device-information/deviceviewer

Information about Endress+Hauser products, solutions, and services.

Information about assistance with the:

• selection of technology, components, and devices

• design of the network according to your requirements

• integration of devices into a PlantPAx distributed control system

• operation and maintenance of the network

The device viewer requires the serial number of the device.

Or download the Operations App (available via App Store and Google Play) for upto date device details by serial number, or scan the data matrix code on the

device.

Rockwell Automation Publication PROCES-SG003C-EN-P - October 2020 31

Endress+Hauser Publication SP01010A/04/EN/01.19

Page 32

Rockwell Automation Support

Use these resources to access support information.

Technical Support Center Find help with how-to videos, FAQs, chat, user forums, and product notification updates. rok.auto/support

Knowledgebase Access Knowledgebase articles. rok.auto/knowledgebase

Local Technical Support Phone Numbers Locate the telephone number for your country. rok.auto/phonesupport

Literature Library Find installation instructions, manuals, brochures, and technical data publications. rok.auto/literature

Product Compatibility and Download Center

(PCDC)

Get help determining how products interact, check features and capabilities, and find

associated firmware.

rok.auto/pcdc

Documentation Feedback

Your comments help us serve your documentation needs better. If you have any suggestions on how to improve our content, complete the

form at rok.auto/docfeedback

Endress+Hauser Support

For technical support, see https://www.endress.com/support

For technical documentation and downloads, see https://www.endress.com/downloads

To find local contacts for your country, see https://www.endress.com/contact

Endress+Hauser is trusted by more than 100,000 customers to make their processes safe, efficient and environmentally friendly. We offer a range of measurement products, including level,

flow, pressure, temperature, analytical, and complete engineered solutions designed to help customers acquire, transmit, control, and record process information needed to manage operations

in a safe, reliable, and profitable manner.

www.endress.com

International:

Endress+Hauser

Instruments International

Kaegenstr. 2, CH-4153 Reinach/BL.

Switzerland

Tel: +41 61 715 81 00, Fax: +41 61 715 25

.

Canada:

Endress+Hauser, Canada

Instruments International

1075 Sutton Drive

Burlington, ON L7L 5Z8

Tel: (1) 905 681 9292, Fax: (1) 905 681 9444

USA:

Endress+Hauser, Inc.

2350 Endress Place

Greenwood, IN 46143

Tel: (1) 317 535 7138, Fax: (1) 317535 8498

Mexico:

Endress+Hauser Mexico, S.A. de C.V.

Fernando Montes de Oca 21 Edif A Piso 3

San Nicolas, 54030 Tlalnepantla,

Edo de Mexico

Tel: +52 55 5321 2080, Fax: +52 55 5321 2099

Rockwell Automation, Inc. (NYSE-ROK), the worlds largest company dedicated to industrial automation, makes it’s customers more productive and the world more sustainable. Throughout the

world, our flagship Allen-Bradley and Rockwell Software product brands are recognized for innovation and excellence.

www.rockwellautomation.com/solutions/process

Americas:

Rockwell Automation

I1201 South Second Street

Milwaukee, WI 53204-2496 USA

Tel: (1) 414 382 2000, Fax: (1) 414 382 4444

Allen-Bradley, ArmorPOINT, CompactLogix, Compact I/O, ControlLogix, FactoryTalk, FLEX, FLEX I/O-XT, PlantPAx, POINT, POINT I/O, Rockwell Automation, Rockwell Software, and Studio 5000 are

trademarks of Rockwell Automation, Inc.

EtherNet/IP is a trademark of ODVA, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Rockwell Automation maintains current product environmental information on its website at rok.auto/pec.

Rockwell Otomasyon Ticaret A.Ş. Kar Plaza İş Merkezi E Blok Kat:6 34752, İçerenkÖy, İstanbul, Tel: +90 (216) 5698400 EEE YÖnetmeliğine Uygundur

Asia Pacific:

Rockwell Automation

Level 14, Core F, Cyberport 3

100 Cyberport Road, Hong Kong

Tel: (852) 2887 4788, Fax: (852) 2508 1846

Europe/Middle East/Africa:

Rockwell Automation

NV, Pegasus Park, De Kleetlaan 12a

1831 Diegem, Belgium

Tel: (32) 2 663 6000, Fax: (32) 2 663 0640

Publication PROCES-SG003C-EN-P - October 2020 Endress+Hauser Publication SP01010A/04/EN/01.19

Supersedes Publication PROCES-SG003B-EN-P - Janua ry 2019 Copyright © 2020 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...