Page 1

Integrated Motion on the EtherNet/IP Network: Configuration and Startup

ControlLogix, CompactLogix, GuardLogix,

Compact GuardLogix, iTRAK 5730, Kinetix 350, Kinetix 5300,

Kinetix 5500, Kinetix 5700, Kinetix 6500, PowerFlex 527,

PowerFlex 755

User Manual

Original Instructions

Page 2

Integrated Motion on the EtherNet/IP Network: Configuration and Startup User Manual

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which

may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage,

or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage

may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach

dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc

Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory

requirements for safe work practices and for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020

Page 3

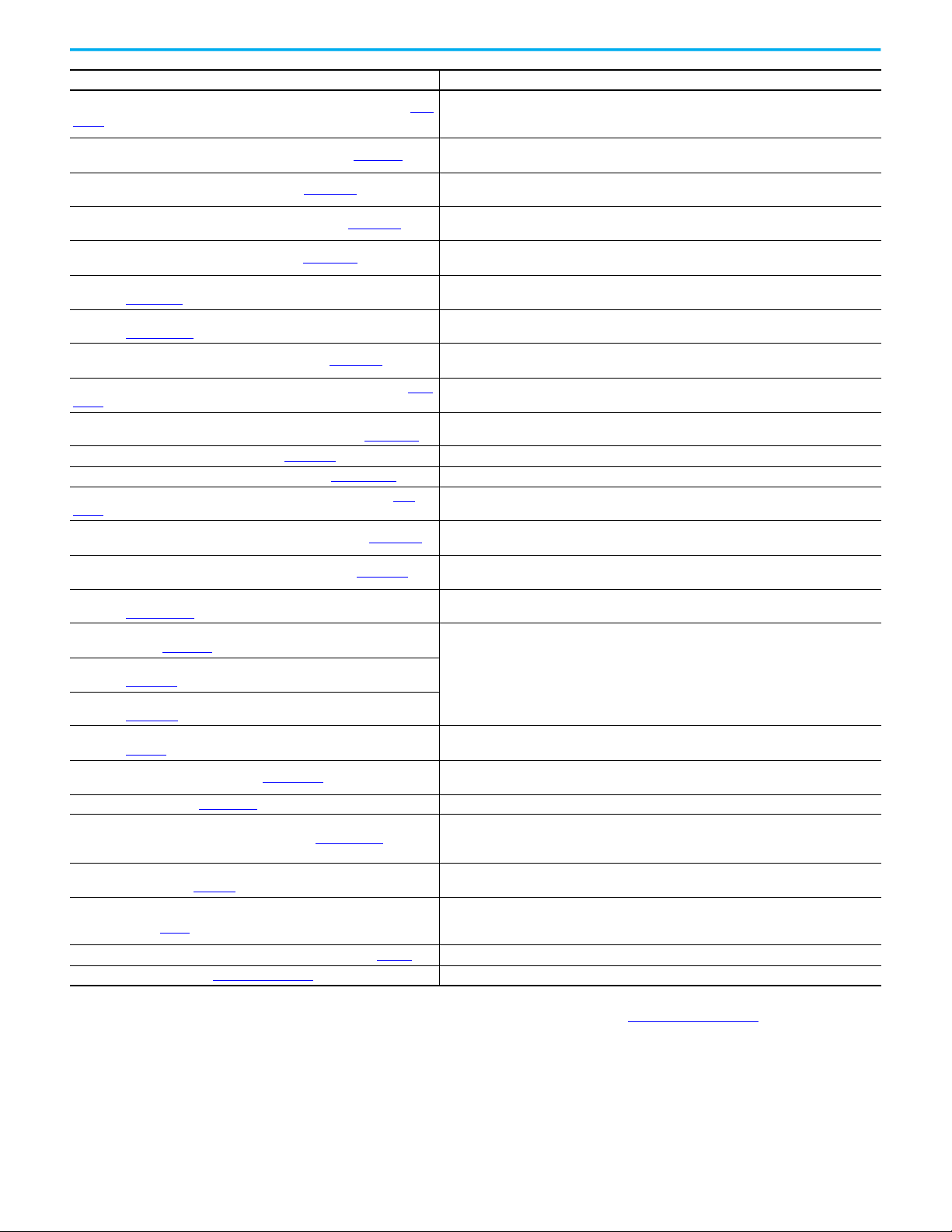

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

About This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Download Firmware, AOP, EDS, and Other Files . . . . . . . . . . . . . . . . . . . . 9

Summary of Changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1

Components of a Motion System Controller, Communication, Drive, and Software Options . . . . . . . . . . 11

Help for Selecting Drives and Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 2

Configure Drive Properties Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Add a Kinetix Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Add a PowerFlex Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Add a Peripheral Device for PowerFlex 755 Drives . . . . . . . . . . . . . . . 20

Add an iTRAK Section, Mover, or Power Supply . . . . . . . . . . . . . . . . . . . . 21

Configure Module Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Safety Application Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Connection Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Safety Instance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Motion Safety Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Configure Power Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Configure Digital Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Configure Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Configure Safety Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Configure Safety Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Generate the Safety Network Number

(Integrated safety drives only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Configure Track Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020 3

Page 4

Table of Contents

Chapter 3

Configure Axis Properties Create an Associated Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Create an Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Specify Feedback Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Create a Motion Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Set the Base Update Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Associate Axes to the Motion Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Configure an Axis and Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Specify the Motor Data Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Choose the Catalog Number as the Motor Data Source . . . . . . . . . . 50

Choose Nameplate as the Motor Data Source. . . . . . . . . . . . . . . . . . . 51

Choose Motor NV or Drive NV as the Motor Data Source . . . . . . . . 53

Display Motor Model Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Use Motor Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Assign Motor Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Configure Load Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Configure Master Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Configure Feedback Only Axis Properties . . . . . . . . . . . . . . . . . . . . . . 60

Configure Actions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Configure Exceptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Chapter 4

Axis Scheduling Timing Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

One Cycle Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Axis Scheduling Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Configure the Update Periods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Motion Utilization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Chapter 5

Configuration Examples for a

Kinetix Drive

Example 1: Position Loop with Motor Feedback Only . . . . . . . . . . . . . . . 77

Example 2: Position Loop with Dual Feedback . . . . . . . . . . . . . . . . . . . . . 80

Example 3: Feedback Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Example 4: Kinetix 5500 Drive, Velocity Loop with

Motor Feedback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Example 5: Kinetix 350 Drive, Position Loop with

Motor Feedback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Example 6: Kinetix 5700 Drive, Frequency Control with

No Feedback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Example 7: 842E-CM Integrated Motion Encoder with

Master Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

4 Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020

Page 5

Chapter 6

Tab le o f Conte nts

Axis Configuration Examples for

the PowerFlex 755 Drive

Example 1: Position Loop with Motor Feedback Via a

UFB Feedback Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Example 2: Position Loop with Dual Motor Feedback Via a

UFB Feedback Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Example 3: Velocity Loop with Motor Feedback Via a

UFB Feedback Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Example 4: Velocity Loop with No Feedback . . . . . . . . . . . . . . . . . . . . . . 114

Example 5: Frequency Control with No Feedback. . . . . . . . . . . . . . . . . . 116

Example 6: Torque Loop with Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Chapter 7

Axis Configuration Examples for

the PowerFlex 527 Drive

Example 1: Frequency Control with No Feedback. . . . . . . . . . . . . . . . . . 125

Example 2: Velocity Control with Motor Feedback. . . . . . . . . . . . . . . . . 130

Example 3: Position Control with Motor Feedback. . . . . . . . . . . . . . . . . 133

Chapter 8

Commission an Axis Scaling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Direct Coupled Rotary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Direct Coupled Linear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Rotary Transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Linear Actuator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Changing Scaling Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Hookup Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Run a Motor and Feedback Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Run a Motor Feedback Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Run a Marker Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Applying the Commutation Hookup Test. . . . . . . . . . . . . . . . . . . . . . . . . 147

Unknown Commutation Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Verification of Known Commutation Offset. . . . . . . . . . . . . . . . . . . 148

Non-standard or Incorrect Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Run a Commutation Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Autotune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Load Observer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Benefits of Load Observer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

How Load Observer Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Load Observer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Adaptive Tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Benefits of Adaptive Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

How Adaptive Tuning Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Adaptive Tuning Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Command Notch Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Load Ratio Data from Motion Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Test an Axis with Motion Direct Commands . . . . . . . . . . . . . . . . . . . . . . 166

Access Motion Direct Commands for an Axis or Group . . . . . . . . . 167

Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020 5

Page 6

Table of Contents

Understanding STO Bypass When Using

Motion Direct Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Chapter 9

Homing Guidelines for Homing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Active Homing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Passive Homing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Active Homing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Passive Homing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Absolute Position Recovery (APR). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

APR Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Position Recovery Considerations for Logix5000 Controllers . . . 180

Absolute Feedback Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

SERCOS Versus Integrated Motion on Ethernet Networks . . . . . 181

APR Scenarios. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

APR Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

APR Fault Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

APR Fault Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

APR Fault Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Resetting an APR Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Absolute Position Loss without APR Faults . . . . . . . . . . . . . . . . . . . . 190

Behavior of APR for Incremental Encoders. . . . . . . . . . . . . . . . . . . . 190

Chapter 10

Manual Tune When to Manually Tune an Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Axis Configuration Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Current Tuning Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Loop Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Tune The Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Motion Generator and Motion Direct Commands . . . . . . . . . . . . . . . . . 195

Additional Tune. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Feedforward Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Compensation Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Torque Notch Filters Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Torque Filters Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Command Notch Filters Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . 199

Adaptive Tuning Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Limits Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Planner Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Configure Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Monitor Tags with the Quick Watch Window . . . . . . . . . . . . . . . . . . . . . 203

Use Motion Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

6 Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020

Page 7

Tab le o f Conte nts

Chapter 11

Status, Faults, and Alarms Faults and Alarms Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

QuickView Pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Data Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Motion Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Drive Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Connection Faults and Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Motion Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Manage Motion Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Configure the Exception Actions for AXIS_CIP_DRIVE. . . . . . . . . . . . 213

Inhibit an Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Example: Inhibit an Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Example: Uninhibit an Axis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Appendix A

Parameter Group Dialog Boxes Parameter Group Dialog Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Appendix B

Program a Velocity Profile and

Jerk Rate

Program a Velocity Profile and Jerk Rate . . . . . . . . . . . . . . . . . . . . . . . . . 221

Definition of Jerk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Choose a Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Use % of Time for the Easiest Programming of Jerk . . . . . . . . . . . . 222

Velocity Profile Effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Jerk Rate Calculation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Profile Operand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Enter Basic Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Example Motion Control Program . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Download a Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Choose a Motion Instruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Troubleshoot Axis Motion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Why Does My Axis Accelerate When I Stop It? . . . . . . . . . . . . . . . . . 236

Why Does My Axis Overshoot Its Target Speed? . . . . . . . . . . . . . . . 237

Why Is There a Delay When I Stop and Then Restart a Jog? . . . . . 240

Why Does The Axis Reverse Direction When Stopped

and Started? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Programming with the MDSC Function . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020 7

Page 8

Table of Contents

Appendix C

PowerFlex Out-of-Box

Configuration

Recommended Out-of-Box Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Setting the ACO/AVO Attributefor PowerFlex 527 Drives Only . . . . . . 251

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

8 Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020

Page 9

Preface

About This Publication

Use this manual to configure an integrated motion on the EtherNet/IP™

network application and to start up your motion solution with a Logix

controller-based system.

This manual is designed to give you a straightforward approach to an

integrated motion control solution. If you have any comments or suggestions,

on the back cover of this manual.

Download Firmware, AOP, EDS, and Other Files

see Documentation Feedback

Download firmware, associated files (such as AOP, EDS, and DTM), and access

product release notes from the Product Compatibility and Download Center at

rok.auto/pcdc

.

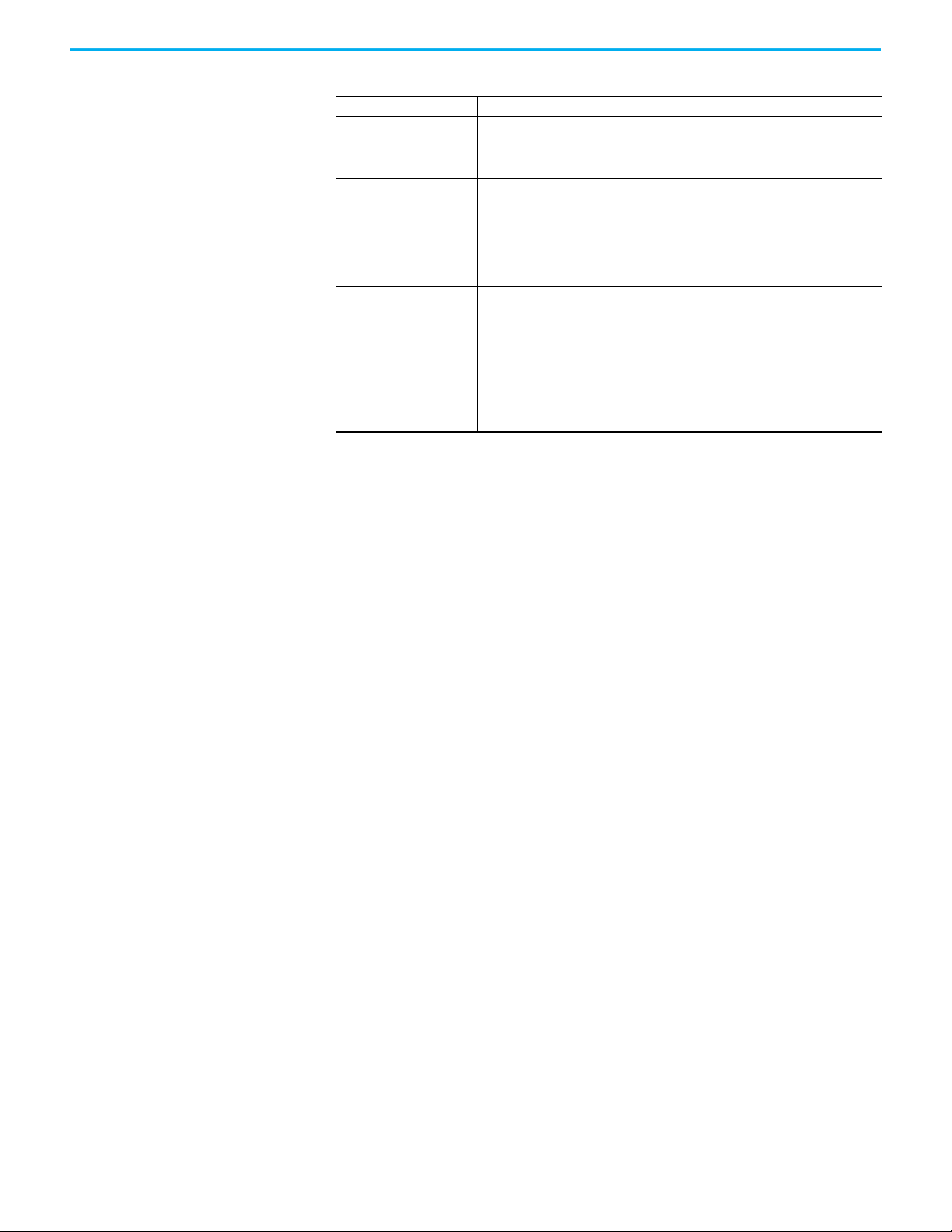

Summary of Changes This publication contains the following new or updated information. This list

includes substantive updates only and is not intended to reflect all changes.

Topic Page

Added Information on Kinetix® 5300 servo drives and the iTRAK® 5730 Intelligent Track System Throughout

Restructured Configuration Information into Chapter 1

Updated Drive Function Descriptions 29

Types of Hookup Tests 143

Adaptive Tuning Configuration 161

Revised Descriptions of Command Notch Filters 165

Revised Information on APR Recovery Scenarios 181

Updated Guidance on When to Manually Tune an Axis 191

…Chapter 3 11…37

Additional Resources These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

842E-CM Integrated Motion Encoder on EtherNet/IP User Manual,

publication 842E-UM002

ControlLogix 5580 and GuardLogix 5580 Controllers User Manual,

publication 1756-UM543

CompactLogix 5380 and Compact GuardLogix 5380 Controllers User Manual,

publication 5069-UM001

ControlLogix System User Manual, publication 1756-UM001

EtherNet/IP Network Devices User Manual, publication ENET-UM006

GuardLogix 5570 Controllers User Manual, publication 1756-UM022

GuardLogix 5570 and Compact GuardLogix 5370 Controller Systems Safety

Reference Manual, publication 1756-RM099

GuardLogix 5580 and Compact GuardLogix 5380 Controller Systems Safety

Reference Manual, publication 1756-RM012

Integrated Motion on the EtherNet/IP Network Reference Manual,

publication MOTION-RM003

Kinetix 350 Single-axis EtherNet/IP Servo Drive User Manual, publication 2097-

UM002

Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020 9

Describes the necessary tasks to install, wire, and troubleshoot your encoder.

Provides information on how to install, configure, program, and operate

ControlLogix® 5580 and GuardLogix® 5580 controllers.

Provides information on how to install, configure, program, and operate

CompactLogix™ 5380 and Compact GuardLogix 5380 controllers.

Describes the necessary tasks to install, configure, program, and operate a ControlLogix system.

Describes how to use EtherNet/IP™ communication modules in Logix 5000™ control systems.

Provides information on how to install, configure, and operate GuardLogix 5570 controllers in

Studio 5000 Logix Designer® projects, version 21 or later.

Provides information on how to meet safety application requirements for

GuardLogix 5570 controllers in Studio 5000 Logix Designer projects, version 21 or later.

Describes the necessary tasks to install, configure, program, and operate a ControlLogix system.

Provides a programmer with details about the Integrated Motion on the EtherNet/IP network

Control Modes, Control Methods, and AXIS_CIP_DRIVE Attributes.

Provides detailed information on wiring, power, troubleshooting, and integration with

ControlLogix, or CompactLogix controller platforms.

Page 10

Preface

Resource Description

Kinetix 5300 Single-axis EtherNet/IP Servo Drives User Manual, publication 2198-

UM005

Kinetix 5500 Servo Drives Installation Instructions, publication 2198-IN001

Kinetix 5500 Servo Drives User Manual, publication 2198-UM001

Kinetix 5700 Safe Monitor Functions User Manual, publication 2198-RM001

Kinetix 5700 Servo Drives User Manual, publication 2198-UM002

Kinetix 6200 and Kinetix 6500 Modular Multi-axis Servo Drives User Manual,

publication 2094-UM002

Logix 5000 Controllers Motion Instructions Reference Manual,

publication MOTION-RM002

Logix 5000 Controllers Common Procedures, publication 1756-PM001

Logix 5000 Controllers General Instructions Reference Manual, publication 1756-

RM003

LOGIX 5000 Controllers Advanced Process Control and Drives and Equipment

Phase and Sequence Instructions Reference Manual, publication 1756-RM006

Logix 5000 Controllers Quick Start, publication 1756-QS001 Describes how to get started programming and maintaining Logix5000 controllers.

Motion System Tuning Application Technique, publication MOTION-AT005

PowerFlex 527 Adjustable Frequency AC Drive User Manual, publication 520-

UM002

PowerFlex 750-Series AC Drives Programming Manual, publication 750-PM001

PowerFlex 750-Series AC Drives Reference Manual, publication 750-RM002

PowerFlex 755 Drive Embedded EtherNet/IP Adapter User Manual,

publication 750COM-UM001

PowerFlex 750-Series Safe Speed Monitor Option Module Safety Reference

Manual, publication 750-RM001

PowerFlex 750-Series Safe Torque Off Option Module User Manual,

publication 750-UM002

PowerFlex 755 Integrated Safety - Safe Torque Off Option Module User Manual,

publication 750-UM004

The Integrated Architecture and CIP Sync Configuration Application Technique,

publication IA-AT003

EtherNet/IP Network Devices User Manual, ENET-UM006

Ethernet Reference Manual, ENET-RM002

System Security Design Guidelines Reference Manual, SECURE-RM001

Industrial Components Preventive Maintenance, Enclosures, and Contact Ratings

Specifications, publication IC-TD002

Safety Guidelines for the Application, Installation, and Maintenance of Solid-state

Control, publication SGI-1.1

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1 Provides general guidelines for installing a Rockwell Automation industrial system.

Product Certifications website, rok.auto/certifications

. Provides declarations of conformity, certificates, and other certification details.

Provides detailed installation instructions to mount, wire, and troubleshoot the Kinetix® 5300

servo drives, and system integration for your drive and motor/actuator combination with a Logix

5000 controller.

Provides installation instructions for the Kinetix 5500 Integrated Axis Module and Axis Module

components.

Provides information on installation, configuration, start up, troubleshooting, and applications for

the Kinetix 5500 servo drive systems.

Explains how the Kinetix 5700 drives can be used in up to Safety Integrity Level (SIL 3),

Performance Level (PL e) applications.

Provides information on installing, configuring, start up, troubleshooting, and applications for the

Kinetix 5700 servo drive systems.

Provides information on installation, configuration, start up, troubleshooting, and applications for

the Kinetix 6200 and Kinetix 6500 servo drive systems.

Provides a programmer with details about motion instructions for a Logix-based controller.

Provides detailed and comprehensive information about how to program a Logix 5000™

controller.

Provides a programmer with details about general instructions for a Logix-based controller.

Provides a programmer with details about process and drives instructions for a Logix-based

controller.

Provides detailed information on motion system tuning.

Provides information on installation, configuration, start up, troubleshooting, and applications for

the PowerFlex® 527 drive.

Provides information that is necessary to install, start-up, and troubleshoot PowerFlex 750-

Series Adjustable Frequency AC Drives.

Provides detailed drive information including operation, parameter descriptions, and

programming of the AC drive.

Provides information on installation, configuration, start up, troubleshooting, and applications for

the PowerFlex 755 Drive Embedded EtherNet/IP Adapter.

These publications provide detailed information on installation, setup, and operation of the 750Series safety option modules.

Provides detailed configuration information on CIP™ Sync technology and time synchronization.

Describes how to configure and use EtherNet/IP devices to communicate on the EtherNet/IP

network.

Describes basic Ethernet concepts, infrastructure components, and infrastructure features.

Provides guidance on how to conduct security assessments, implement Rockwell Automation

products in a secure system, harden the control system, manage user access, and dispose of

equipment.

Provides a quick reference tool for Allen-Bradley industrial automation controls and assemblies.

Designed to harmonize with NEMA Standards Publication No. ICS 1.1-1987 and provides general

guidelines for the application, installation, and maintenance of solid-state control in the form of

individual devices or packaged assemblies incorporating solid-state components.

You can view or download publications at rok.auto/literature.

10 Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020

Page 11

Components of a Motion System

Topic Page

Controller, Communication, Drive, and Software Options 11

Help for Selecting Drives and Motors 14

Chapter 1

Controller, Communication, Drive, and Software Options

To create an Integrated Motion on EtherNet/IP™ system, you need the

following:

• A Logix 5000™ controller with a connection to the EtherNet/IP network,

either via an embedded Ethernet port or an Ethernet communication

module (See Table 1

•An Integrated Motion drive (see Table 2

•Software

- Studio 5000 Logix Designer® application

-RSLinx® Classic software, version 3.51.00 or later

- For PowerFlex® 755 drives, you need the Add-on Profile, V18 or later.

A safety controller is required for motion and safety applications.

When a PowerFlex 755 drive is used in Integrated Motion on

EtherNet/IP mode, the Logix controller and Studio 5000 Logix

Designer application are the exclusive owners of the drive. A HIM or

other drive software tools, such as DriveExplorer™ and Connected

Components Workbench software, cannot be used to control the

drive or change configuration settings. These tools can only be used

for monitoring.

See the Product Compatibility and Download Center (PCDC)

controller, Ethernet module, and drive firmware revisions, Studio 5000 Logix

Designer required revisions, and compatibility information.

)

)

for minimum

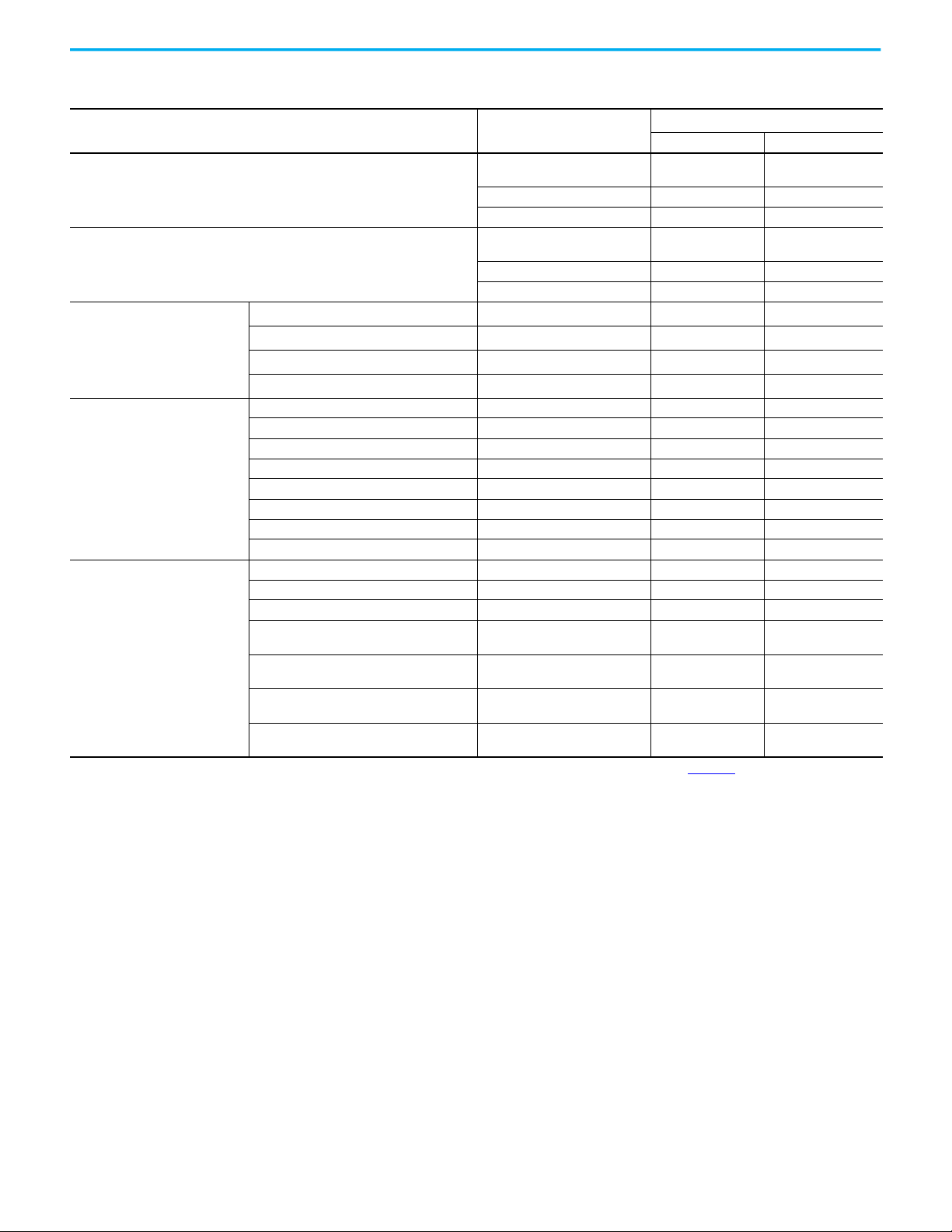

Table 1

depending on the hardware that is used in your application and the

configuration of your axes. For example, you can have eight Position Loop axes

per 1756-EN2T module. Each drive requires one TCP and one CIP™ connection.

If you have other devices that consume TCP connections on the module, it

reduces the number of drives you can support. Only the drives and axes that

are configured for Position Loop are limited. Frequency Control, Velocity

Loop, and Torque Loop configured drives and axes are not limited.

Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020 11

provides information on how many motion axes are supported

Page 12

Chapter 1 Components of a Motion System

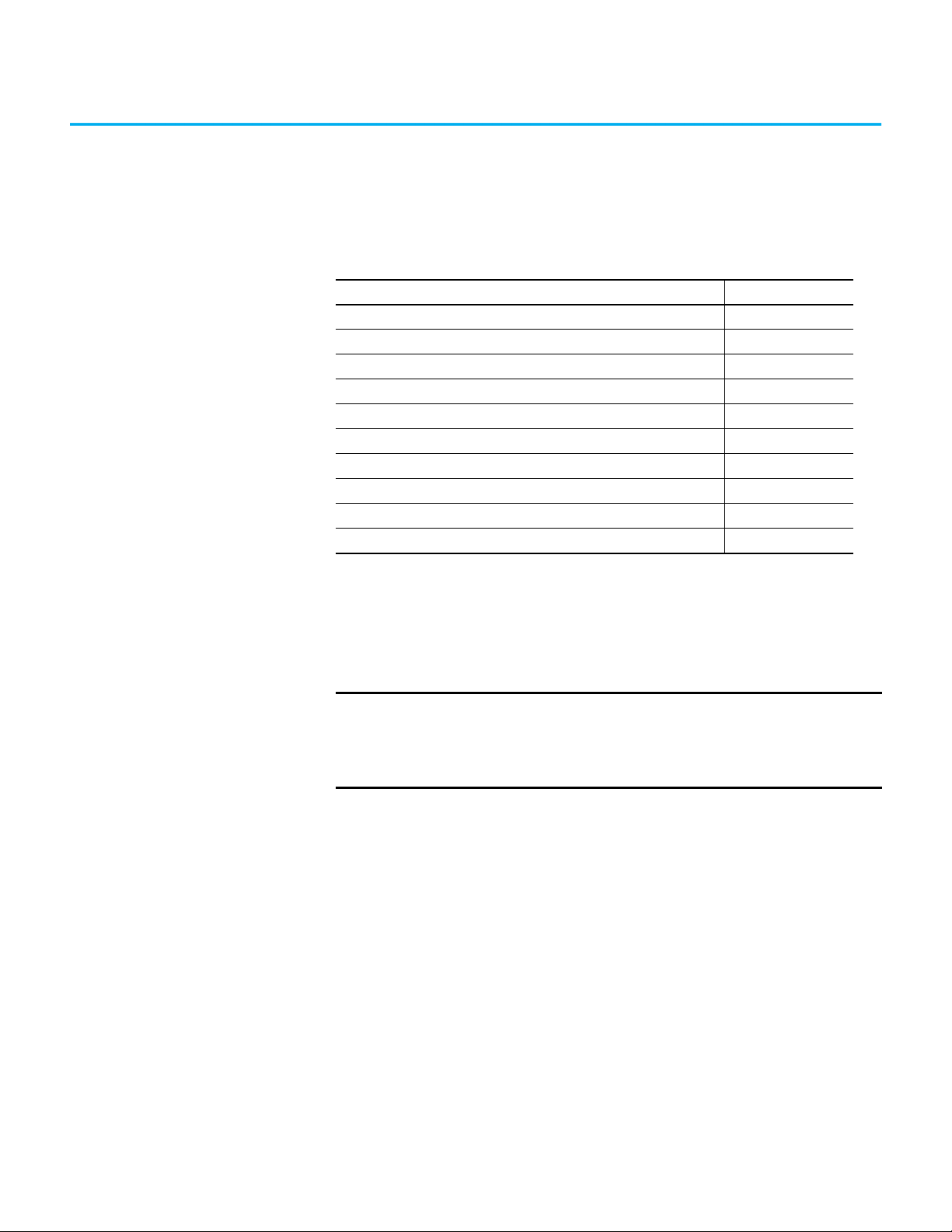

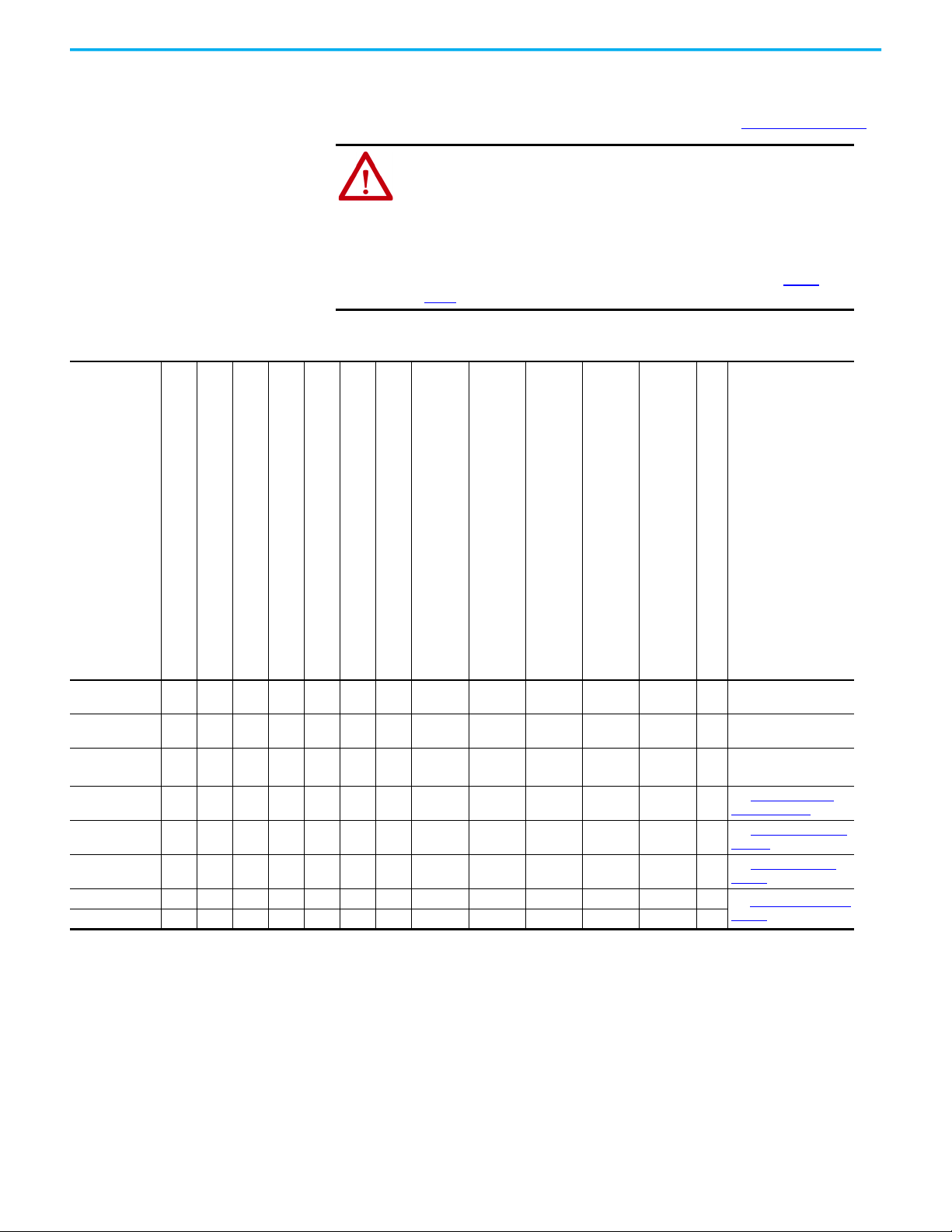

Table 1 - Supported Axes by Controller Type

Controller

ControlLogix® 5570,GuardLogix 5570

Armor™ ControlLogix 5570, Armor™ GuardLogix® 5570

Communication Modules

(1)

1756-EN2T, 1756-EN2TF,

1756-EN2TP, 1756-EN2TR

1756-EN3TR 100 Up to 100

Supported Axes

Position Loop Other Loop Types

8Up to 100

1756-EN4TR 100 Up to 100

ControlLogix 5580, GuardLogix 5580

1756-EN2T, 1756-EN2F, 1756-EN2TP,

1756-EN2TR

8Up to 256

1756-EN3TR 256 Up to 256

1756-EN4TR 256 Up to 256

ControlLogix 5580, GuardLogix 5580

1756-L81E, 1756-L81ES

1756-L82E, 1756-L82ES

1756-L83E, 1756-L83ES, 1756-L84E, 1756-L84ES

1756-L85E

Embedded Ethernet

Embedded Ethernet

Embedded Ethernet

Embedded Ethernet

(3)

(3)

(3)

(3)

256 Up to 256

256 Up to 256

256 Up to 256

256 Up to 256

5069-L306ERM, 5069-L306ERMS2 Embedded Ethernet 2 Up to 256

5069-L310ERM, 5069-L310ERMS2 Embedded Ethernet 4 Up to 256

5069-L320ERM, 5069-L320ERMS2 Embedded Ethernet 8 Up to 256

CompactLogix™ 5380, Compact

GuardLogix 5380

5069-L330ERM, 5069-L330ERMS2 Embedded Ethernet 16 Up to 256

5069-L340ERM, 5069-L340ERMS2 Embedded Ethernet 20 Up to 256

5069-L350ERM, 5069-L350ERMS2 Embedded Ethernet 24 Up to 256

5069-L380ERM, 5069-L380ERMS2 Embedded Ethernet 28 Up to 256

5069-L3100ERM, 5069-L3100ERMS2 Embedded Ethernet 32 Up to 256

1769-L18ERM Embedded Ethernet 2 Up to 100

1769-L27ERM Embedded Ethernet 4 Up to 100

1769-L30ERM, 1769-L30ERMS Embedded Ethernet 4 Up to 100

CompactLogix 5370, Compact

GuardLogix 5370, Armor

CompactLogix 5370, Armor Compact

GuardLogix 5370

(1) For more information on Ethernet communication modules, see 1756 ControlLogix Communication Modules Specifications Technical Data, publication 1756-TD003.

(2) Multiple controllers can control drives on a common 1756-ENxTx module, so based on the TCP connection limit, up to 128 can be supported.

(3) ControlLogix 5580 and GuardLogix 5580 can also use Ethernet communication modules to communicate on the EtherNet/IP network.

1769-L33ERM, 1769-L33ERMS

1769-L33ERMO, 1769-L33ERMOS

1769-L36ERM, 1769-L36ERMS

1769-L36ERMO, 1769-L36ERMOS

1769-L37ERM, 1769-L37ERMS, 1769-L37ERMO,

1769-L37ERMOS,

1769-L38ERM, 1769-L38ERMS

1769-L38ERM0, 1769-L38ERM0S

Embedded Ethernet 8 Up to 100

Embedded Ethernet 16 Up to 100

Embedded Ethernet 16 Up to 100

Embedded Ethernet 16 Up to 100

(2)

12 Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020

Page 13

Chapter 1 Components of a Motion System

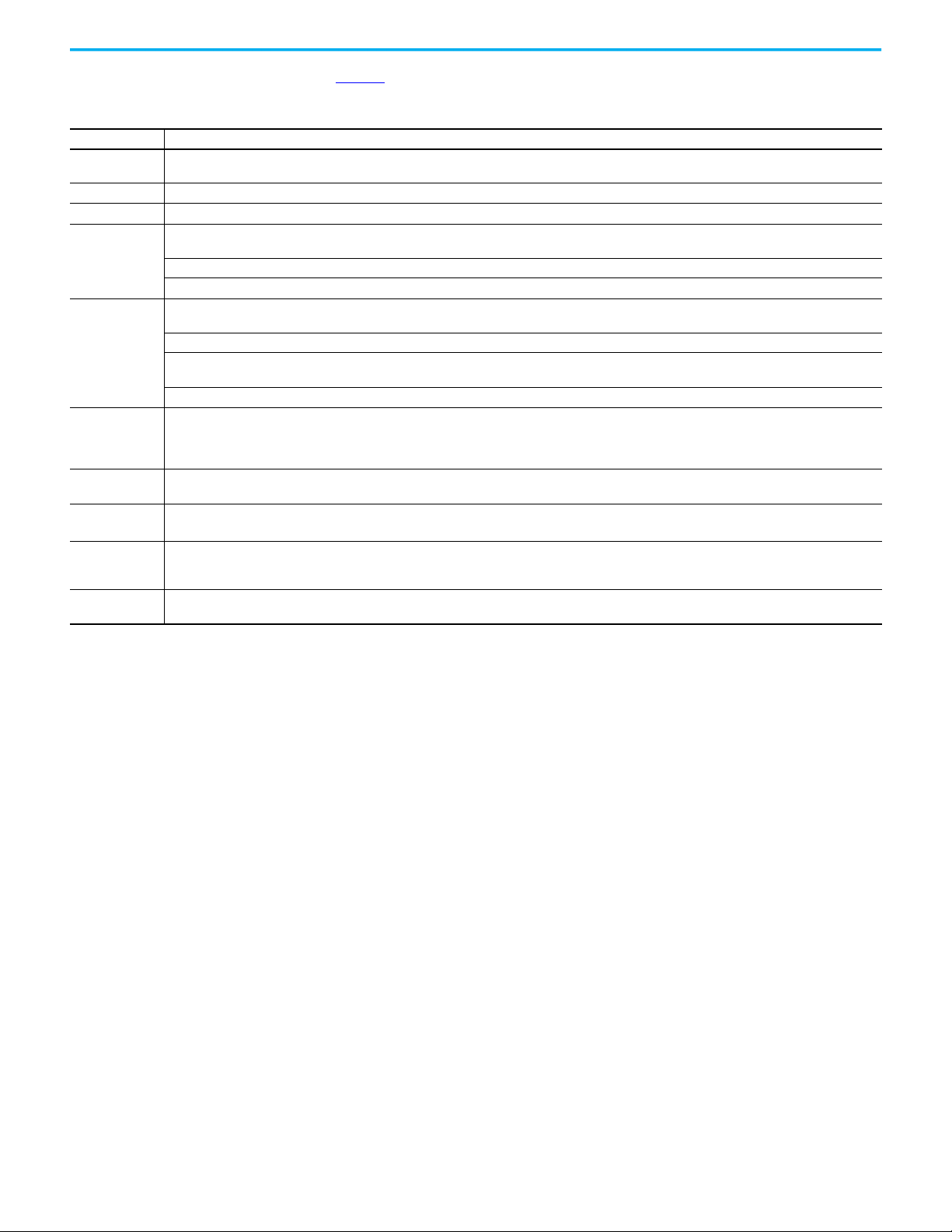

Table 2 describes the EtherNet/IP drives available for integrated motion.

Table 2 - Integrated Motion EtherNet/IP Drives

Drive Description

842E-CM Absolute

Encoders

Kinetix® 350 The Kinetix 350 drive is a single-axis EtherNet/IP servo drive with hardwired Safe Torque Off (STO) with connection to safety inputs.

Kinetix 5300 The Kinetix 5300 servo drive is an entry-level servo drive integrated on EtherNet/IP.

Kinetix 5500

Kinetix 5700

Kinetix 6500

PowerFlex 527

PowerFlex 755

iTRAK® 5730

Intelligent Track

System

iTRAK Power

Supply

(1) Integrated Motion support of the Integrated Safety Functions option module (20-750-S4) is only available when used with GuardLogix 5580 and Compact GuardLogix 5380 safety controllers.

(2) PowerFlex Drive firmware revision 14 or later required for Integrated Safe Torque Off option module (20-750-S3) Integrated Safety Functions option module (20-750-S4)

The 842E-CM is an ultra-high resolution encoder with EtherNet/IP interface with time synchronization for motion control. These encoders provide 18-bit singleturn resolution and 30-bit multi-turn resolution.

The Kinetix 5500 servo drives support the Integrated Motion on EtherNet/IP network. Single-axis and multi-axis, AC, DC, AC/DC, and AC/DC hybrid bus-sharing

configurations are possible.

2198-Hxxx-ERS servo drives support hardwired Safe Torque Off (STO) with connections to safety inputs.

2198-Hxxx-ERS2 servo drives support integrated Safe Torque Off (STO) with connections to the safety controller.

2198-Sxxx-ERS3 (single-axis) and 2198-Dxxx-ERS3 (dual-axis) series A support hardwired and integrated STO with connections to the safety controller.

Series B also support integrated Timed SS1 safety function.

2198-Sxxx-ERS4 (single-axis) and 2198-Dxxx-ERS4 (dual-axis) inverters support integrated safe monitor functions with connection to the safety controller.

2198-Pxxx DC Bus Supply provides power in a range of 7…46 kW and 10.5…69.2 A output current to Bulletin 2198 single-axis and dual-axis inverters for

applications.

2198-RPxxx Regenerative Bus Supply provides continuous output power and current to Bulletin 2198 single-axis and dual-axis inverters for applications.

The Kinetix 6500 drive is a closed-loop modular servo drive. It consists of an integrated axis (IAM) power module and up to seven axis (AM) power modules,

each coupled with a Kinetix 6500 control module.

The IAM and AM power modules provide power for up to eight axes.

The 2094-EN02D-M01-S0 control modules support Safe Torque Off (STO) and 2094-EN02D-M01-S1 control modules support safe-speed monitoring.

The PowerFlex 527 is a single-axis EtherNet/IP AC drive with hardwired and Integrated Safe Torque Off (STO).

It consists of an integrated axis power module and incremental encoder feedback (sold separately).

The PowerFlex 755 Drive EtherNet/IP AC drive can control a motor in closed loop and open loop mode. The PowerFlex 755 drive contains an EtherNet/IP

adapter that is embedded on the main control board. Drive option modules provide I/O, safety

The iTRAK 5730 system is a modular, scalable, linear motor system. This system provides independent control of multiple movers on straight or

curvilinear paths.

Catalog number 2198T-W25K-ER, DC-DC converter that generates DC-bus power for iTRAK systems.

(1) (2)

, and feedback functions to the drive.

Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020 13

Page 14

Chapter 1 Components of a Motion System

Help for Selecting Drives and Motors

Motion Analyzer helps you select the appropriate Allen-Bradley® drives and

motors that are based on your load characteristics and typical motion

application cycles. The software guides you through wizard-like screens to

collect information specific to your application.

After you enter the information for your application, such as, load inertia,

gearbox ratio, feedback device, and brake requirements, the software

generates an easy-to-read list of recommended motors, drives, and other

support equipment.

You can access Motion Analyzer at

https://motionanalyzer.rockwellautomation.com

.

14 Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020

Page 15

Configure Drive Properties

Topic Page

Before You Begin 16

Add a Kinetix Drive 18

Add a PowerFlex Drive 19

Add an iTRAK Section, Mover, or Power Supply 21

Configure Module Definition 23

Configure Power Settings 26

Configure Digital Inputs 29

Configure Digital Outputs 31

Configure Safety Settings 31

Configure Track Sections 35

Chapter 2

This chapter describes the basic steps for how to configure an integrated

motion project in the Logix Designer application. For detailed product-specific

configuration, see the user manual for your product.

IMPORTANT

When a PowerFlex® drive is used in Integrated Motion on EtherNet/IP mode,

the Logix controller and Logix Designer are the exclusive owners of the drive

(same as Kinetix® drives). A HIM or other drive software tools cannot be used

to control the drive or change configuration settings. These tools can only be

used for monitoring.

Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020 15

Page 16

Chapter 2 Configure Drive Properties

Before You Begin Before you can configure a drive in the Logix Designer application, you must

create a controller project with a connection to the EtherNet/IP™ network as

shown in Figure 1 on page 17

Keep these considerations in mind when creating your motion project.

• For a Motion and Safety application, you must add a GuardLogix®

integrated safety controller.

• For all communication modules, use the firmware revision that matches

the firmware revision of your controller. See the release notes for the

firmware version of your controller.

• The electronic keying feature automatically compares the expected

module, as shown in the configuration tree, to the physical module

before communication begins.

ATTENTION: When configuring communication modules in motion or

safety applications, set electronic keying to either Exact Match or

Compatible Keying. Never use Disable Keying with motion or safety

applications.

For more information about electronic keying, see the Electronic Keying

in Logix 5000™ Control Systems Application Technique, publication

LOGIX-AT001

• Time synchronization supports highly distributed applications that

require time stamping, sequence of events recording, distributed motion

control, and increased control coordination. All controllers and

communication modules must have time synchronization enabled for

applications that use Integrated Motion on the EtherNet/IP network.

.

.

See the Integrated Architecture® and CIP Sync Configuration

Application Technique, publication IA-AT003

on time synchronization.

For detailed information on configuring a controller or Ethernet/IP adapter,

see the publications listed in the Additional Resources

, for detailed information

on page 9.

16 Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020

Page 17

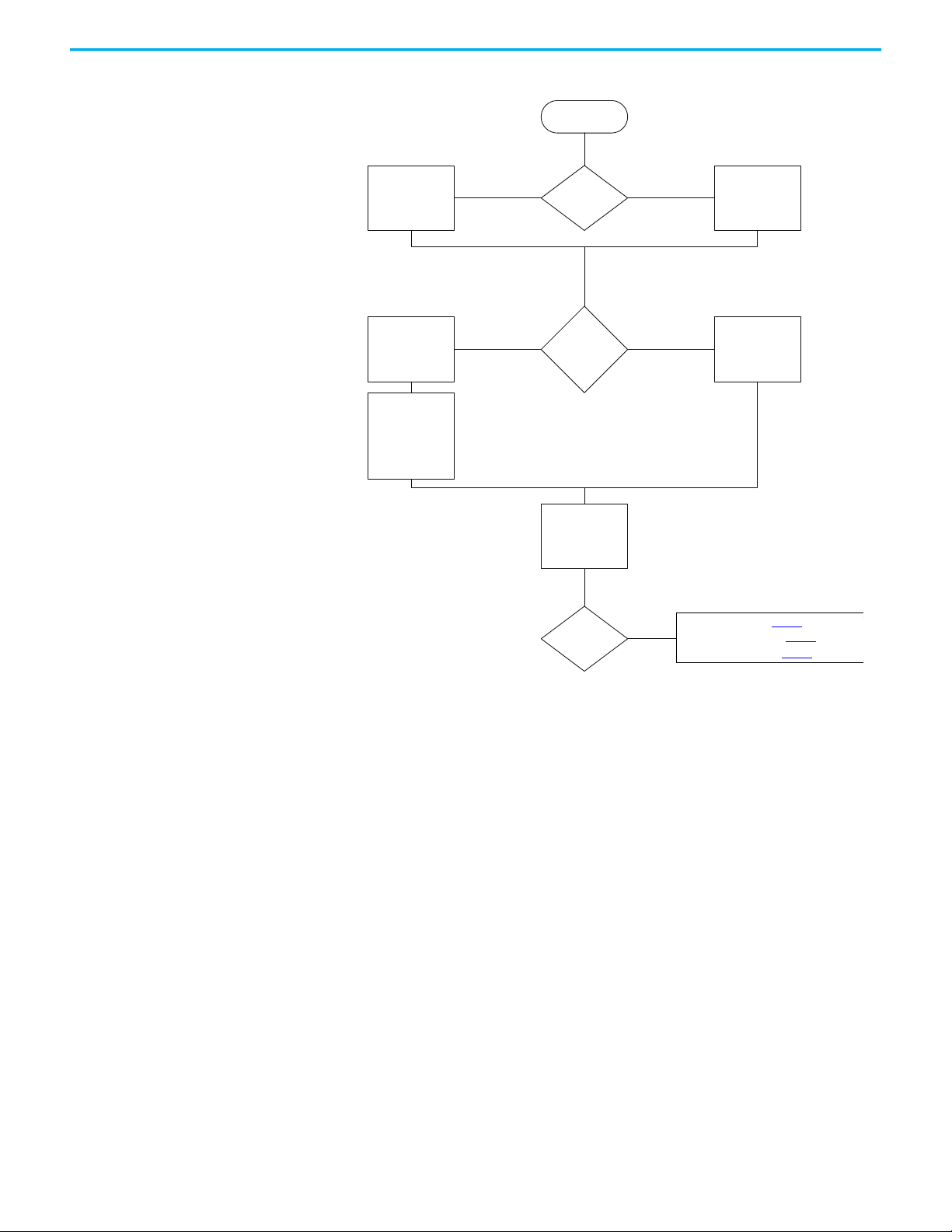

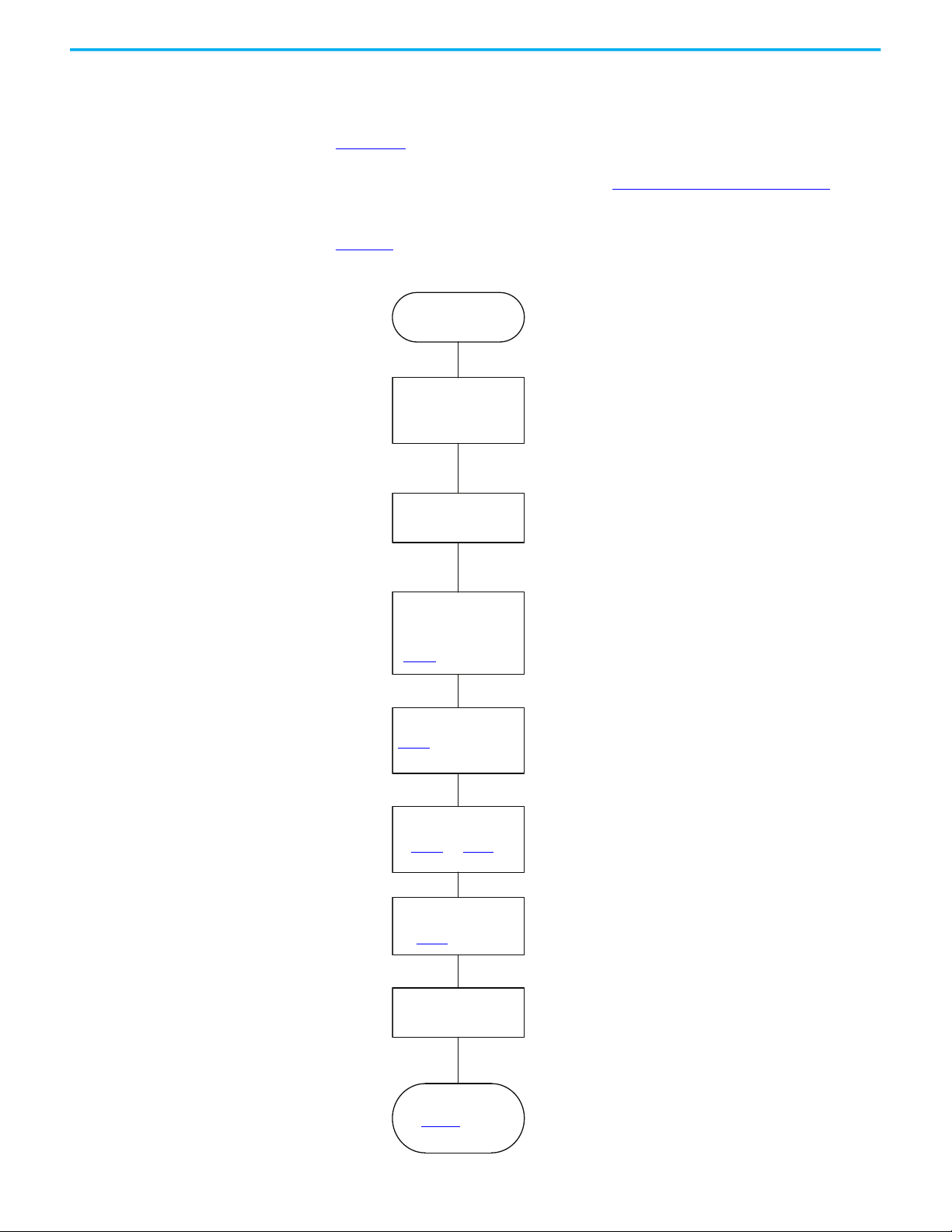

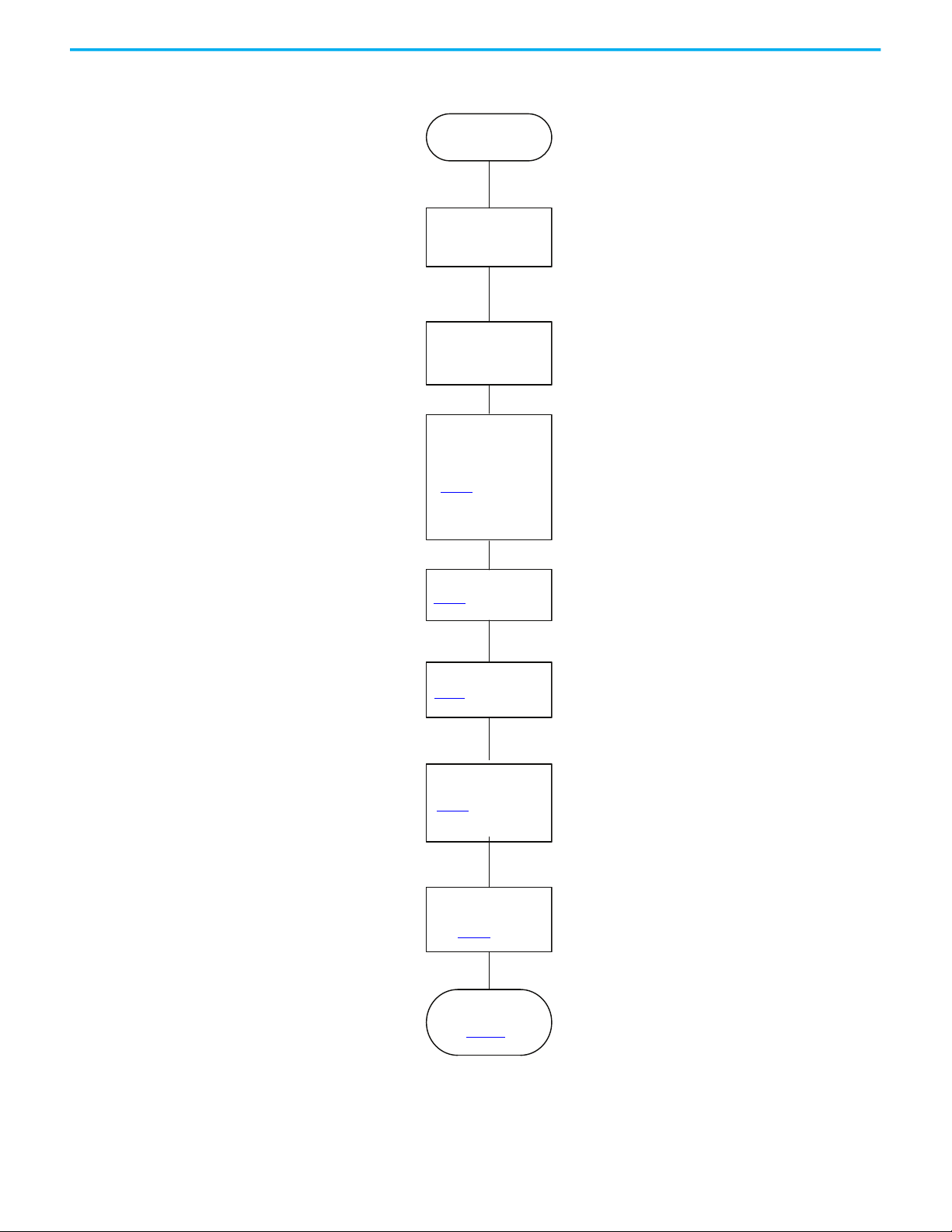

Figure 1 - Create a Motion Project

Controller Project

Enable Time

Synchronizaon

Is this a safety

applicaon?

Integrated safety

controller

Standard

controller

Does the

controller need

an EtherNet/IP

device?

Add the

EtherNet/IP

device to the

project

Use the embedded

EtherNet/IP

connecvity in the

controller

Add a Drive or

iTRAK system

For Kinex drives, see pg

For PowerFlex drives, see pg

For iTRAK systems, see pg

Set Exact Keying

to

Exact Match or

Compable Keying

on the Module

Definion dialog

box.

yes

no

yes

no

Check Enable Time Synchronizaon

on

the Date/Time tab of the Module

Properes dialog box.

Choose Time Sync and Moon as the

Time Sync Connecon type on the

Module Definion dialog box.

For Kinetix Drives, see page 18

For PowerFlex Drives, see page 19

For iTRAK® systems, see page 21

Chapter 2 Configure Drive Properties

Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020 17

Page 18

Chapter 2 Configure Drive Properties

Controller Project Ready

Controller EtherNet/IP Connectivity Time

Synchronization

Add a Kinetix Drive to

your EtherNet/IP

Network

Configure General Settings

Configure Drive Settings

in the Module Definition

Dialog Box

page 23

Type a Name and IP Address of the

drive on the General page of the

Module Properties dialog box.

Configure power settings

page 26

Configure Digital

Inputs and Outputs

page 29

and page 31

Configure Safety

Connections

page 31

Configure Motion Safety

or Drive Safety

Configure Axis Properties

See Chapter 3

See your Drive User Manual for

details on configuring your drive

safety options.

Add a Kinetix Drive The available configuration options differ depending on the controller and

drive type you chose for your project. Before you begin, verify that you have the

correct minimum software, firmware, and Add-on Profile versions. See

Chapter 1.

Refer to the drive manuals, listed in the Additional Resources on page 9, for

detailed information on drive configuration and operation.

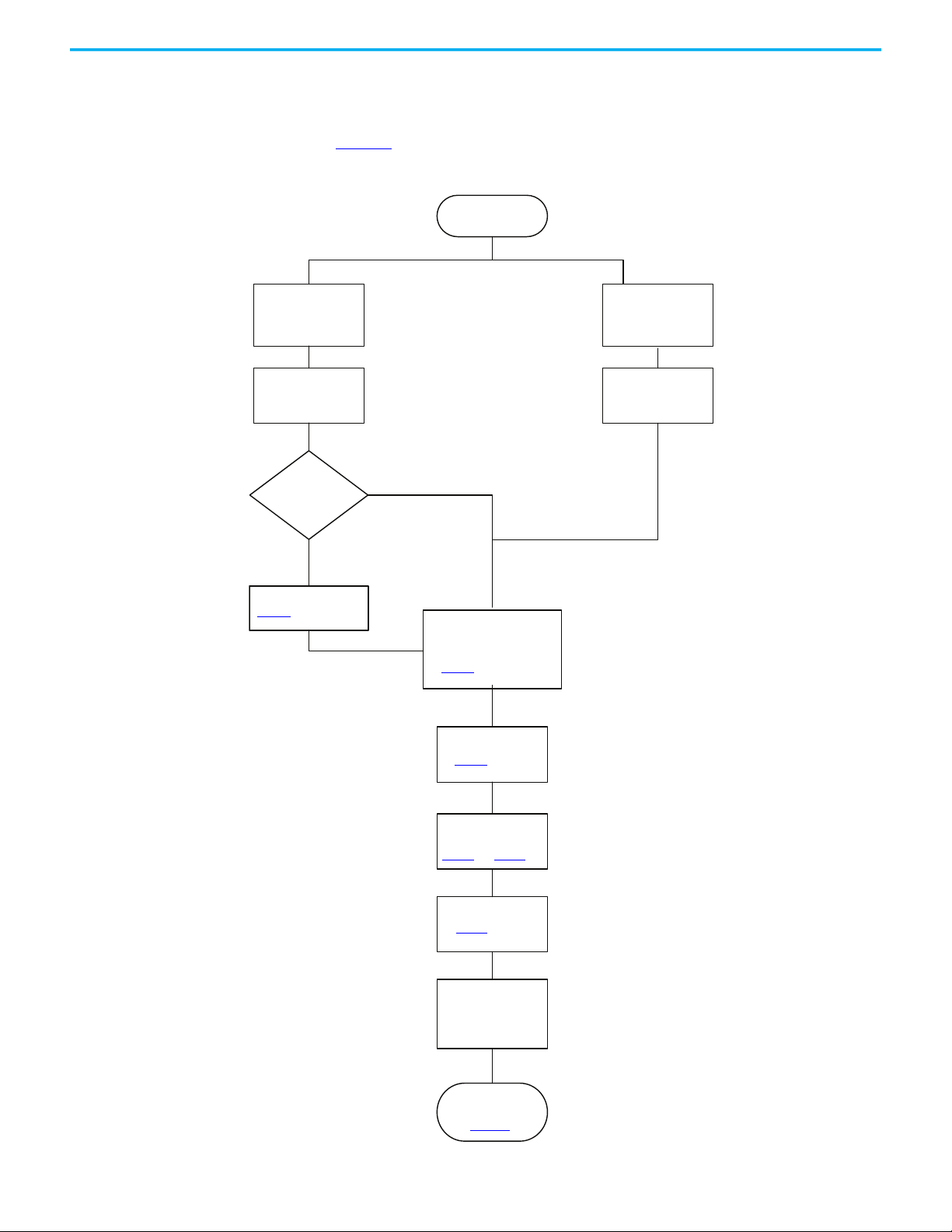

Figure 2

shows the path for configuring a Kinetix drive in a motion project.

Figure 2 - Add and Configure a Kinetix Drive

18 Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020

Page 19

Chapter 2 Configure Drive Properties

Controller Project Ready

Add PowerFlex 755 Drive

to your

EtherNet/IP Network

Add PowerFlex 527

Drive to your

EtherNet/IP Network

Configure General

Settings

Configure General

Settings

Do you need I/O

or feedback?

Type a Name and IP Address

of the drive on the General

page of the Module

Properties dialog box.

Choose a PowerFlex 755

drive catalog number that

ends in -CM or -CM-Sx for an

Integrated Motion Drive.

Add a peripheral device

page 20

Configure drive settings

in the Module Definition

dialog box

page 23

Configure power

page 26

Configure

Motion Safety

Configure Safety

page 31

Configure digital inputs

and outputs

page 29

and page 31

See your Drive User Manual for

details on configuring your drive

safety options.

Configure Axis

Properties

See Chapter 3

Add a PowerFlex Drive The available configuration options differ depending on the controller, drive

type, and PowerFlex option modules you chose for your project.

yes

Figure 3

shows the path for configuring a PowerFlex drive in a motion project.

Figure 3 - Add and Configure a PowerFlex 755 or PowerFlex 527 Drive

no

Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020 19

Page 20

Chapter 2 Configure Drive Properties

Add a Peripheral Device for PowerFlex 755 Drives

To add a peripheral device to your drive for I/O or feedback, follow these steps.

1. On the General tab of the Module Properties dialog box, click Change to

open the Module Definition dialog box.

2. Edit the Revision, if necessary.

For PowerFlex 755 drives, you must select a revision of 12 or later to add

an I/O module to port 7 as a peripheral device.

3. Right-click your drive and choose New Peripheral Device.

4. Select a port for your device.

These feedback module combinations that are supported.

Option Supported Module Catalog Number Valid Ports

Single Incremental Encoder 20-750-ENC-1 4…8

Two Feedback Options

Two Feedback Options

and One Safety Option

(1) The safe speed monitor option module must be used with the 20-750-DENC-1 Dual Incremental Encoder module

or the 20-750-UFB-1 Universal Feedback module.

Dual Incremental Encoder 20-750-DENC-1 4…8

Universal Feedback Card 20-750-UFB-1 4…6

Single Incremental Encoder 20-750-ENC-1 4 and 5

Dual Incremental Encoder 20-750-DENC-1 4 and 5

Universal Feedback 20-750-UFB-1 4 and 5

Safe Torque Off, or

Safe Speed Monitor

Integrated Safe Torque Off, or

Integrated Safety Functions

(1)

, or

20-750-S

20-750-S1

20-750-S3

20-750-S4

6

5. If you will be using a feedback option module for safe feedback with a 20750-S4 safety option, click the Safe Feedback checkbox.

20 Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020

Page 21

Chapter 2 Configure Drive Properties

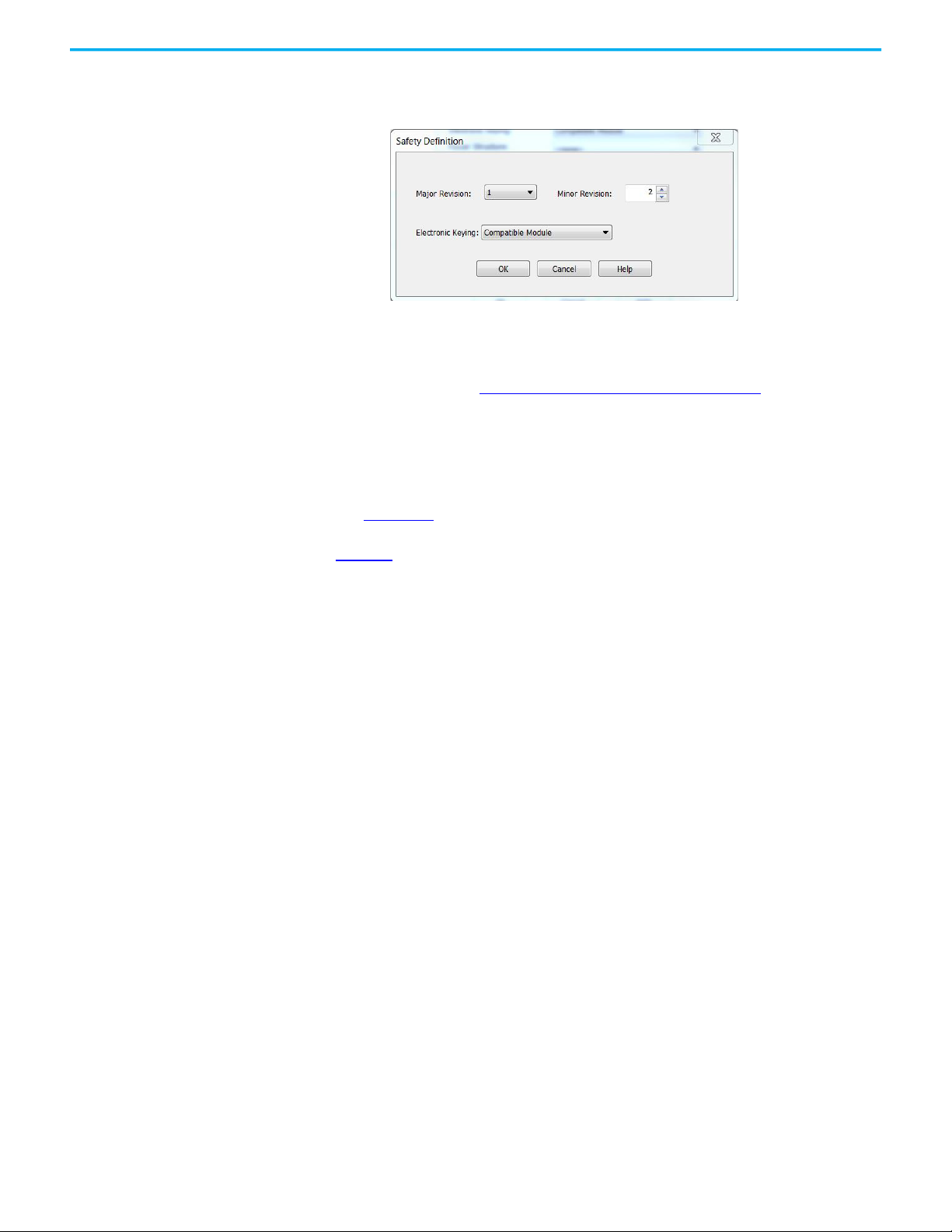

6. If your drive is equipped with an integrated safety option module (20750-S3 or 20-750-S4), click Safety Definition to define the Major and

Minor Revisions and Electronic Keying options.

When you are using integrated safety modules, you can set the electronic

keying to either Exact Match or Compatible Keying.

7. Continue with Configure Module Definition

on page 23.

Add an iTRAK Section, Mover, or Power Supply

The available configuration options differ depending on the controller, and

iTRAK device type you chose for your project. Before you begin, verify that you

have the correct minimum software, firmware, and Add-on Profile versions.

See Chapter 1.

Figure 4 shows the path for configuring an iTRAK section, mover, or power

supply in an integrated motion project.

If you are using an iTRAK power supply, add the module to the project under

the same controller as the iTRAK sections and the Kinetix 5700 power supply

(either the regenerative power supply or the DC Bus supply).

If using the iTRAK system, each section is automatically assigned an IP

address by the iTRAK backplane, in sequential order from the first iTRAK

module added to the project.

Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020 21

Page 22

Chapter 2 Configure Drive Properties

Controller Project Ready

Controller EtherNet/IP

connectivity Time

Synchronization

If you have an iTRAK power supply,

add the drive under the same

controller as the iTRAK section and

Kinetix 5700 power supply.

Type a Name and IP Address of the

drive on the General page of the

Module Properties dialog box.

Add iTRAK Drive

Configure General

Settings

Configure safety page

page 31

Configure power page

page 26

Configure drive

settings in the Module

Definition dialog box

page 23

Configure Motion Safety

page 26

See your iTRAK user manual for

details on configuring your motion

safety options.

Configure track

sections

page 35

Configure Axis

Properties

See Chapter 3

Figure 4 - Add iTRAK Drive Modules

22 Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020

Page 23

Chapter 2 Configure Drive Properties

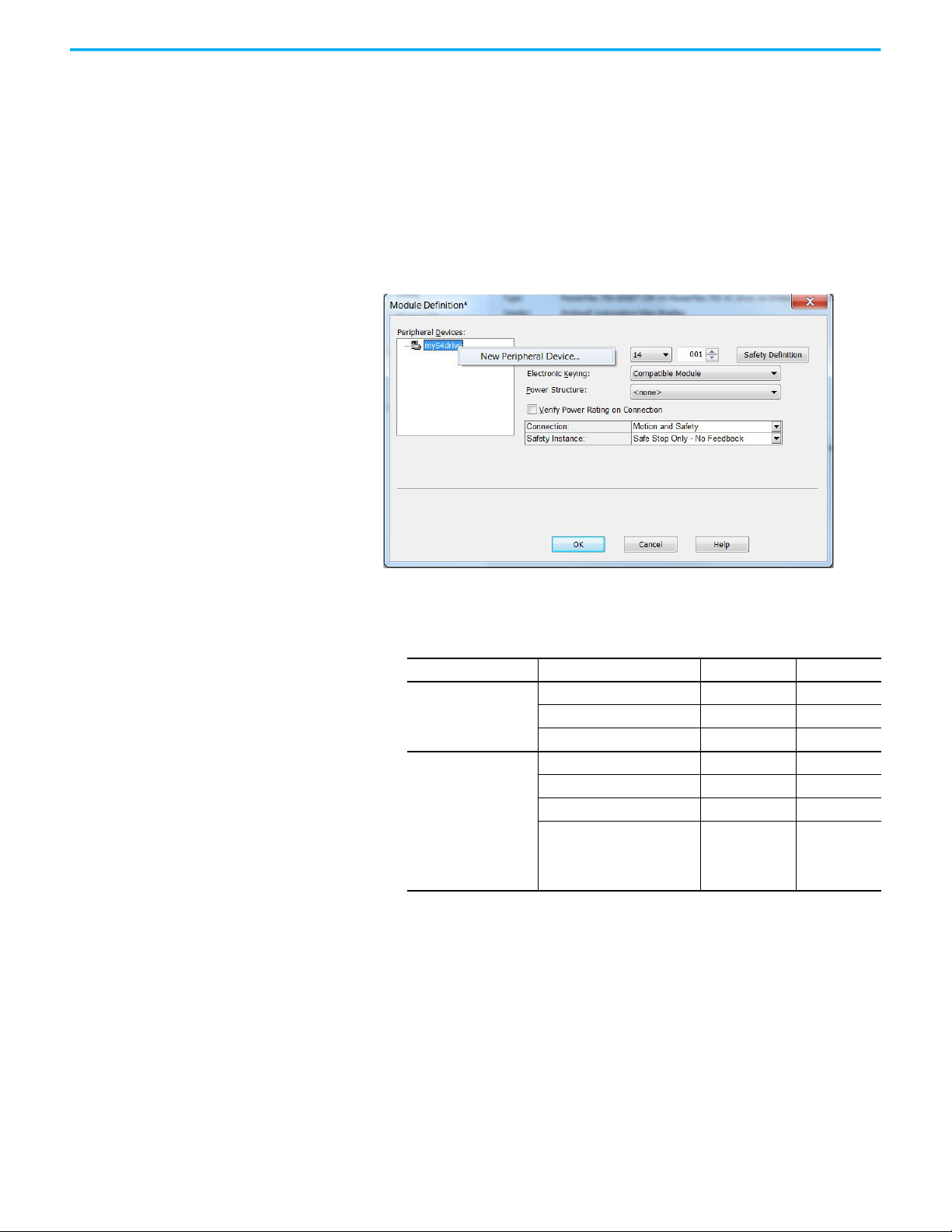

Configure Module Definition All drives let you update the drive Revision, choose an Electronic Keying type,

and choose a Power Structure. Options for Connection type and other fields

depend on the type of drive you added to your project. See Table 3 on page 23

ATTENTION: The electronic keying feature automatically compares the

expected module, as shown in the configuration tree, to the physical

module before communication begins.

When you are using devices in an integrated motion application, set the

electronic keying to either Exact Match or Compatible Keying.

Never use Disable Keying with motion or safety modules.

For more information about electronic keying, see the Electronic Keying in

Logix 5000™ Control Systems Application Technique, publication LOGIX-

AT001.

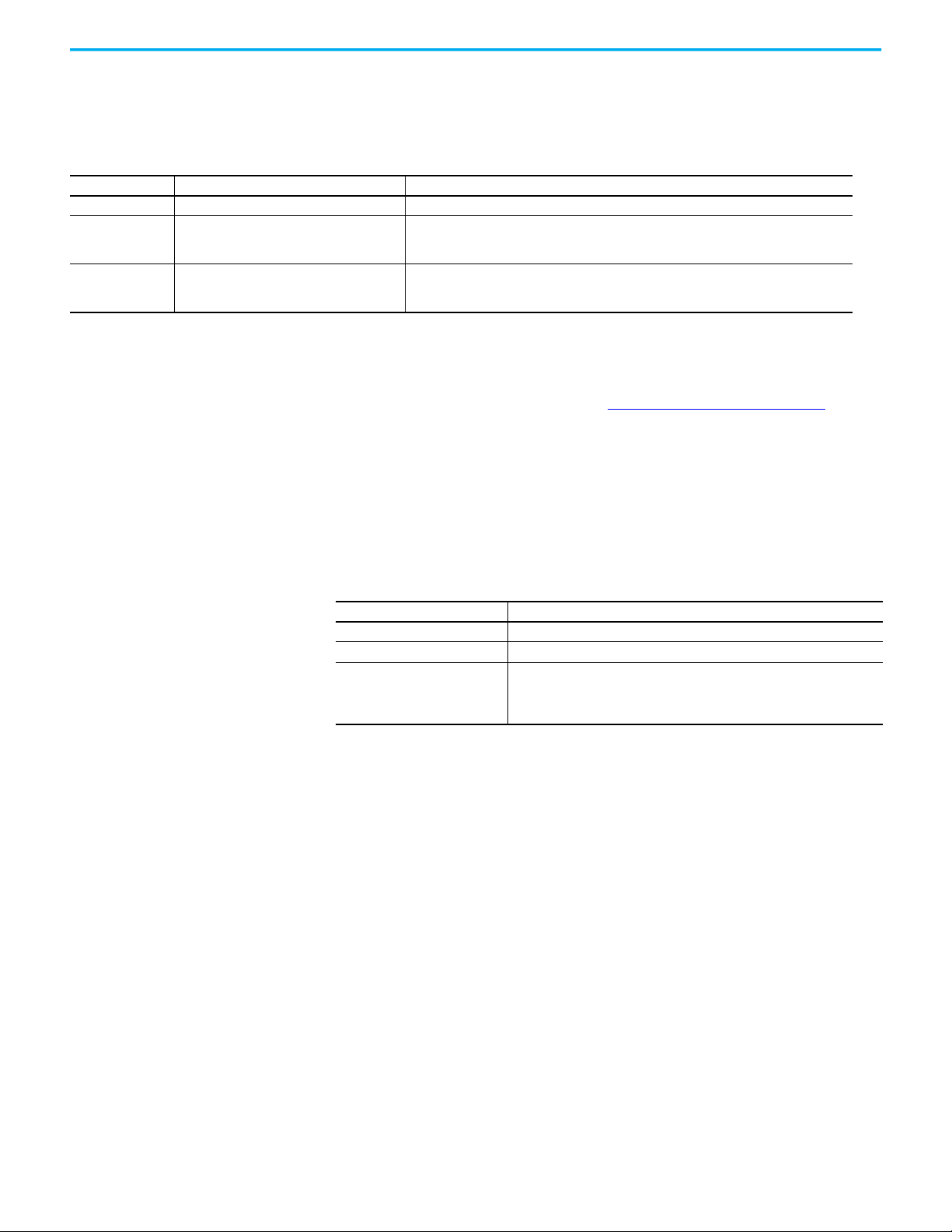

Table 3 - Module Definition Fields

.

Kinetix 350

Kinetix 5300

Kinetix 5500

Kinetix 6500

Kinetix 5700 DC - Bus Supply

Kinetix 5700 Regenerative Bus Supply

Kinetix 5700 Inverter

PowerFlex 755 Drive with Embedded Ethernet

PowerFlex 755 Hi-Power Drive with Embedded Ethernet

PowerFlex 755 Drive with Safe Torque Off

PowerFlex 755 Hi-Power Drive with Safe Torque Off

(with 20-750-S option module installed)

PowerFlex 755 Drive with Safe Speed Monitoring

PowerFlex 755 Hi-Power Drive with Safe Speed Monitoring

(with 20-750-S1 option module installed)

PowerFlex 755 Drive with Integrated Safe Torque Off

PowerFlex 755 Hi-Power Drive with Integrated Safe Torque Off

(with 20-750-S3 option module installed)

PowerFlex 755 Drive with Integrated Safety Functions

PowerFlex 755 Hi-Power Drive with Integrated Safety Functions

(with 20-750-S4 option module installed)

PowerFlex 527 Drive

Revision XXXXXX

Electronic KeyingXXXXXXXXXXXXX

Power StructureXXXXXXXXXXXXX

Safety Application X

ConnectionXXXXXXXXXXXXX

Safety Instance X X

Motion Safety 1 X

Motion Safety 2 X

(1) For 2198-xxxx-ERS3 series A drives, the firmware revision is 7 or earlier. For 2198-xxxx-ERS3 series B, drives, the firmware versions is 9 or later.

(2) For PowerFlex 755 drives, you must select a revision of 12 or later to add an I/O module to port 7 as a peripheral device.

(3) Locate the power stucture reference numbers by checking the device hardware, reviewing the product documentation, checking the purchase order, or reviewing the bill of materials.

(1)X(2)

X

(2)

X

(2)

X

(2)

X

(2)

X

Update the Revision, if

X

necessary.

Choose Exact Match or

Compatible Keying.

Assign a power structure,

if necessary.

See Safety Application

Types on page 24

See Connection Types on

page 25.

See Safety Instance on

page 25

See Motion Safety Type

page 26

(3)

on

Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020 23

Page 24

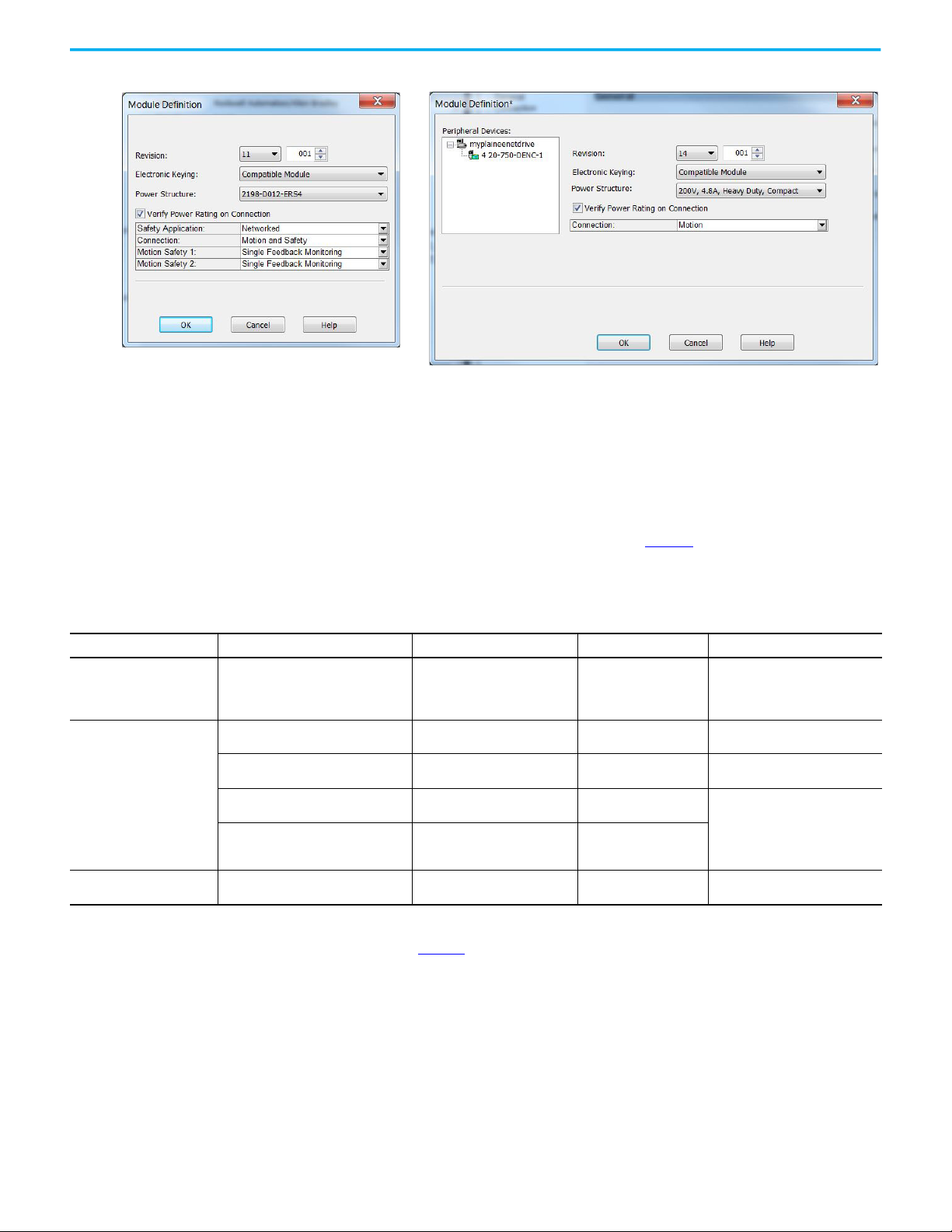

Chapter 2 Configure Drive Properties

Kinetix 5700 Drive with Integrated Safety

PowerFlex 755 Drive with Embedded Ethernet

Figure 5 - Example Module Definition Dialog Boxes

Safety Application Types

The Safety Application pull-down menu lets you choose between Hardwired

for Hardwired STO mode or Networked for a Kinetix 5700 integrated safety

application or iTRAK 5730 integrated safety. Table 4

defines the choices and

which Connection Types are available based on your choice of Safety

Application mode.

Table 4 - Safety Application Definitions

Safety Application Mode Safety Functions

Hardwired Safe Torque-off (STO)

Safe Torque-off (STO) 2198-xxxx-ERS3 (series A)

Safe Torque-off (STO) 2198T-L20-T03

Networked (integrated)

Safety Off

(1) Where a 2198-xxxx-ERS3 drive is specified, a 2198-xxxx-ERS4 drive is backwards compatible. Where a 2198-xxxx-ERS3 (series A) drive is specified, a 2198-xxxx-ERS3 (series B) drive is backwards

compatible.

(2) See the Kinetix 5700 Safe Monitor Functions Safety Reference Manual, publication 2198-RM001

Timed SS1

• Timed SS1

• Monitored SS1

• Controller-based safety functions

•none

Minimum Module

2198-xxxx-ERS3 (series A)

2198-xxxx-ERS3 (series B)

2198-xxxx-ERS3 (series B)

2198T-L20-T03

2198-xxxx-ERS4

(2)

iTRAK 5730

(1)

Required

, for more information on these Drive Safety instructions.

Connection Types Compatible Controllers

• Motion Only • ControlLogix® 5570/5580

• Motion and Safety

•Safety Only

• Motion and Safety

•Safety Only

• Motion and Safety

•Safety Only

• Motion and Safety

•Safety Only

• Motion Only • ControlLogix 5580

• CompactLogix 5370/5380

• GuardLogix 5570/5580

• Compact GuardLogix 5370/5380

• GuardLogix 5570/5580

• GuardLogix 5580

• GuardLogix 5580

• Compact GuardLogix 5380

• GuardLogix 5580

24 Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020

Page 25

Chapter 2 Configure Drive Properties

Connection Types

Choose the connection type for your drive.

Table 5 - Module Connection Definitions

Connection Type Used with the follow safety options Description

Motion and Safety • Integrated safety • Motion connections and integrated safety are managed by this controller.

Motion Only

Safety Only

• Hardwired Safe Torque Off mode

• Integrated safety, if there is a secondary safety

controller

• Integrated safety • Integrated safety is managed by this controller.

• Motion connections are managed by this controller.

• Hardwired STO is controlled by the hardwired safety inputs or integrated safety is managed by

another controller that has a Safety-only connection to the drive.

• Motion connections are managed by another controller that has a Motion only connection to the

drive.

For Motion and Safety or Safety selections, additional configuration and

considerations not covered in this manual apply. See the publications for

your drive, PowerFlex 750-series safety option module, and safety

controller, which are listed in the Additional Resources

Safety Instance

on page 9.

For PowerFlex drives with a 20-750-S4 option module installed and a

connection type of Motion and Safety or Safety only, you can choose a Safety

Instance.

Table 6 - Safety Instance Definitions

Safety Instance Mode Description

Safe Stop Only - No Feedback STO function and Timed SS1 Safe Stop functions are available.

Single Feedback Monitoring Primary feedback is used in the safety object for safe monitoring.

In addition to primary feedback, an external feedback device is used to provide

Dual Feedback Monitoring

error checking of the primary feedback device. A secondary encoder is

considered part f the encoder diagnostics and the data it produces is not rated

safety data.

Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020 25

Page 26

Chapter 2 Configure Drive Properties

Motion Safety Type

When the Connection type is Motion and Safety or Safety only and the Safety

Application mode is Networked, you can choose a Motion Safety Type.

Table 7 - Motion Safety Definitions

Motion Safety Mode Description

STO Only 2198-xxxx-ERS3 (series A and B): STO function only.

2198-xxxx-ERS4: STO function and Timed SS1 Safe Stop functions are available.

Safe Stop Only - No Feedback

Single Feedback Monitoring

Dual Feedback Monitoring

See the Kinetix 5700 Safe Monitor Functions Safety Reference Manual,

publication 2198-RM001

device or two feedback devices.

2198-xxxx-ERS3 (series B): STO function and Timed SS1 Safe Stop functions are

available.

iTRAK 5730: STO function and Timed SS1 Safe Stop functions are available.

Primary feedback is used in the safety object for safe monitoring. The feedback can be

a SIL rated Hiperface DSL encoder, for example, a VPL-B1003P-Q or W motor used in

the DSL Feedback port. This can also be a Sine/Cosine or EnDat device, for example, an

MPL-B310P-M motor used in the Universal Feedback port.

In addition to primary feedback, an external feedback device is used to improve SIL

levels. For example, the Bulletin 842HR type encoder can be used in the Universal

Feedback port as a Sine/Cosine device.

, to evaluate SIL levels possible with a single feedback

Configure Power Settings The Power page lets you configure the drive Bus Configuration, assign a Bus

Sharing Group, set Bus Regulator Action or select a Shunt Resistor Type and

configuration limits. The options for configuration differ depending on drive

type.

Consider the following when choosing the appropriate settings for your

application.

• The Logix Designer application enforces shared-bus configuration rules

for Kinetix drives, except for shared AC configurations.

ATTENTION: To avoid damage to equipment all modules that are

physically connected to the same shared-bus connection system must be

part of the same bus-sharing Group in the Studio 5000 Logix Designer

application.

• Kinetix 5500 drives with single-phase operation is limited to 2198-H003ERSx, 2198-H008-ERSx, and 2198-H015-ERSx.

• Single-phase operation is possible only when Module Properties > Power

tab > Bus Configuration is configured as Standalone and Voltage is

configured as 200…240V AC.

ATTENTION: To avoid damage to equipment, make sure the AC input

voltage that is configured in the Logix Designer application matches the

actual hardware being configured.

26 Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020

Page 27

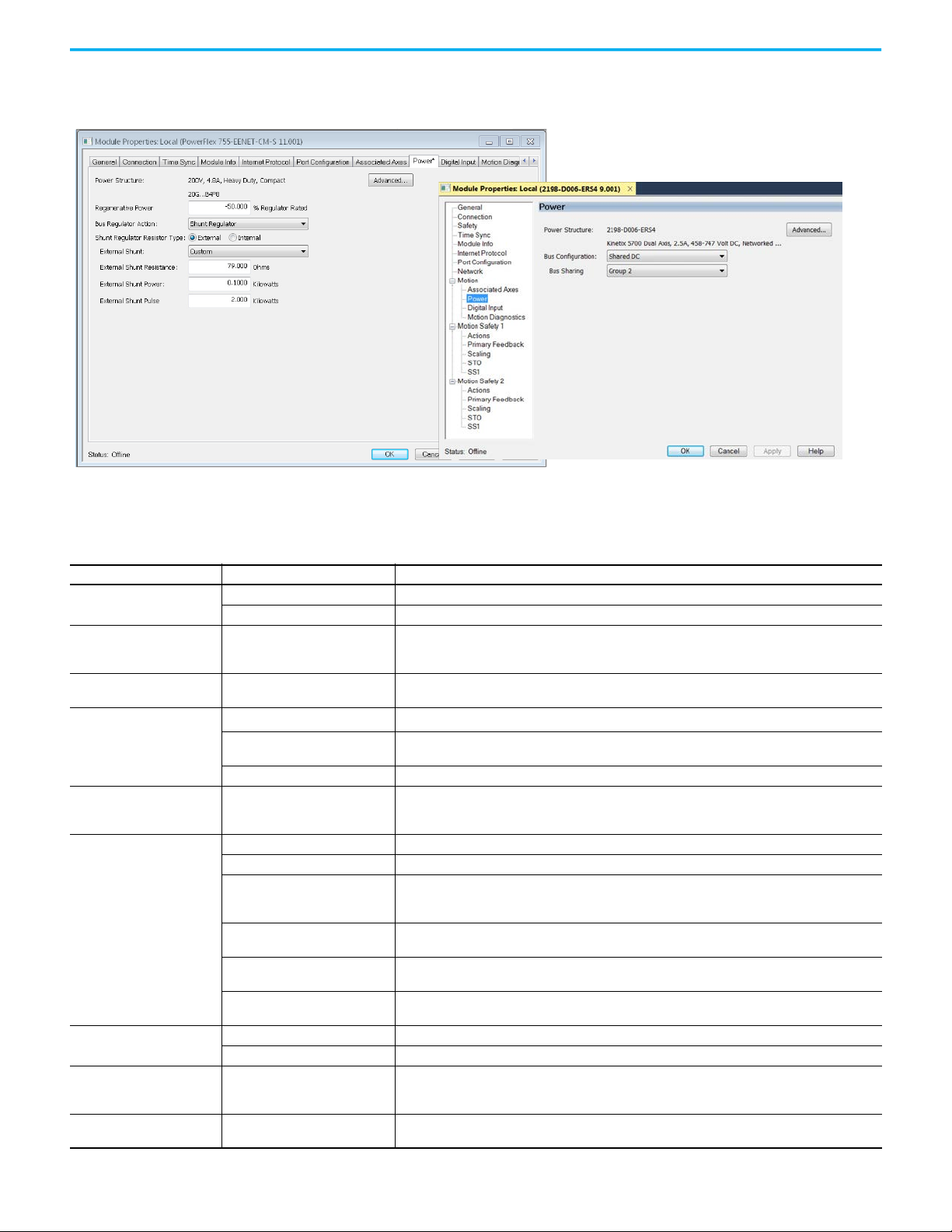

Figure 6 - Power Configuration Example Pages

PowerFlex 755 Drive

Kinetix 5700 Drive

Chapter 2 Configure Drive Properties

Table 8 - Power Settings

Attribute Settings Description

Volt age

PWM Frequency

AC Input Phasing

Bus Configuration

Bus-sharing Group

Bus Regulator Action

Shunt Regulator Resistor Type

External Shunt

External Shunt Resistance

1. Choose the appropriate power settings for your application.

400-480 VAC 324…528 AC rms input voltage

200-240 VAC 195…264 AC rms input voltage

2 kHz

4 kHz (Default)

8 kHz

• Three Phase

• Single Phase

Shared AC/DC

(1)

Standalone

Shared DC Applies to inverter drives with Shared DC input (common-bus) configurations.

(2)

•Group1

•Group2

•Group3

Disabled Disables the internal shunt resistor and external shunt option.

Shunt Regulator Enables the internal and external shunt options.

Adjustable Frequency

(3)

Shunt then Adjustable Frequency

Adjustable Frequency then Shunt

Common Bus Follower

(4)

Internal Enables the internal shunt (external shunt option is disabled).

External Enables the external shunt (internal shunt option is disabled).

•None

• Shunt catalog number

(5)

•Custom

Valid values are determined by the

type of drive.

The value sets the carrier frequency for the Pulse Width Modulation (PWM) output to the motor.

Input power phasing. Single phase operation is not available for all drives. For more information on the

power options that are available, see the user manual for your product.

Applies to 2198-Pxxx DC-bus power supply (converter) modules.

Applies to single-axis drives and drives with Shared AC input configurations.

Indicates that the converter section of the drive supplies DC Bus power only to this drive's power structure.

Applies to any bus-sharing configuration.

This selection allows the drive to either change the torque limits or ramp rate of the velocity to control the

DC bus voltage. This option is not recommended for positioning applications because it will override the

velocity and the system can overshoot or may not stop.

This selection allows the Shunt resistor to absorb as much energy as it is designed for, then transitions to

adjustable frequency control if the limit of the resistor has been reached.

This selection allows for adjustable frequency control of the DC bus. If adjustable frequency control cannot

maintain the DC bus within limits, the shunt resistor will be activated.

To configure your Kinetix 6500 IAM power module as a common-bus follower IAM

module.

Selects external shunt option.

Specifies the external shunt resistance in Ohms. Available only if External Shunt is set to Custom.

Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020 27

Page 28

Chapter 2 Configure Drive Properties

PowerFlex 755 Drive

Kinetix 5700 DC Bus Supply

Table 8 - Power Settings

Attribute Settings Description

External Shunt Power

External Shunt Pulse Power

Bus Capacitance

(1) Shared AC/DC bus configuration is the default selection for 2198-Pxxx DC-bus power supplies.

(2) For more information on bus-sharing groups, refer to Kinetix 5700 servo drives User Manual, publication 2198-UM002

(3) Default for PowerFlex 527 drives.

(4) Drive will not accept CommonBus Follower selection while three-phase power or DC bus power is applied.

(5) Only the shunt catalog number intended for the specific DC-bus power supply is shown. See the Kinetix Servo Drives Specifications Technical Data, publication KNX-TD003

shunt resistors.

Valid values are determined by the

type of drive.

Valid values are determined by the

type of drive.

Valid values are determined by the

type of drive.

Specifies the external shunt power in Kilowatts. Available only if External Shunt is set to Custom.

Specifies the external shunt power in Kilowatts. Available only if External Shunt is set to Custom.

Specifies the bus capacitance in microfarads (uF). Available only if External Shunt is set to Custom.

.

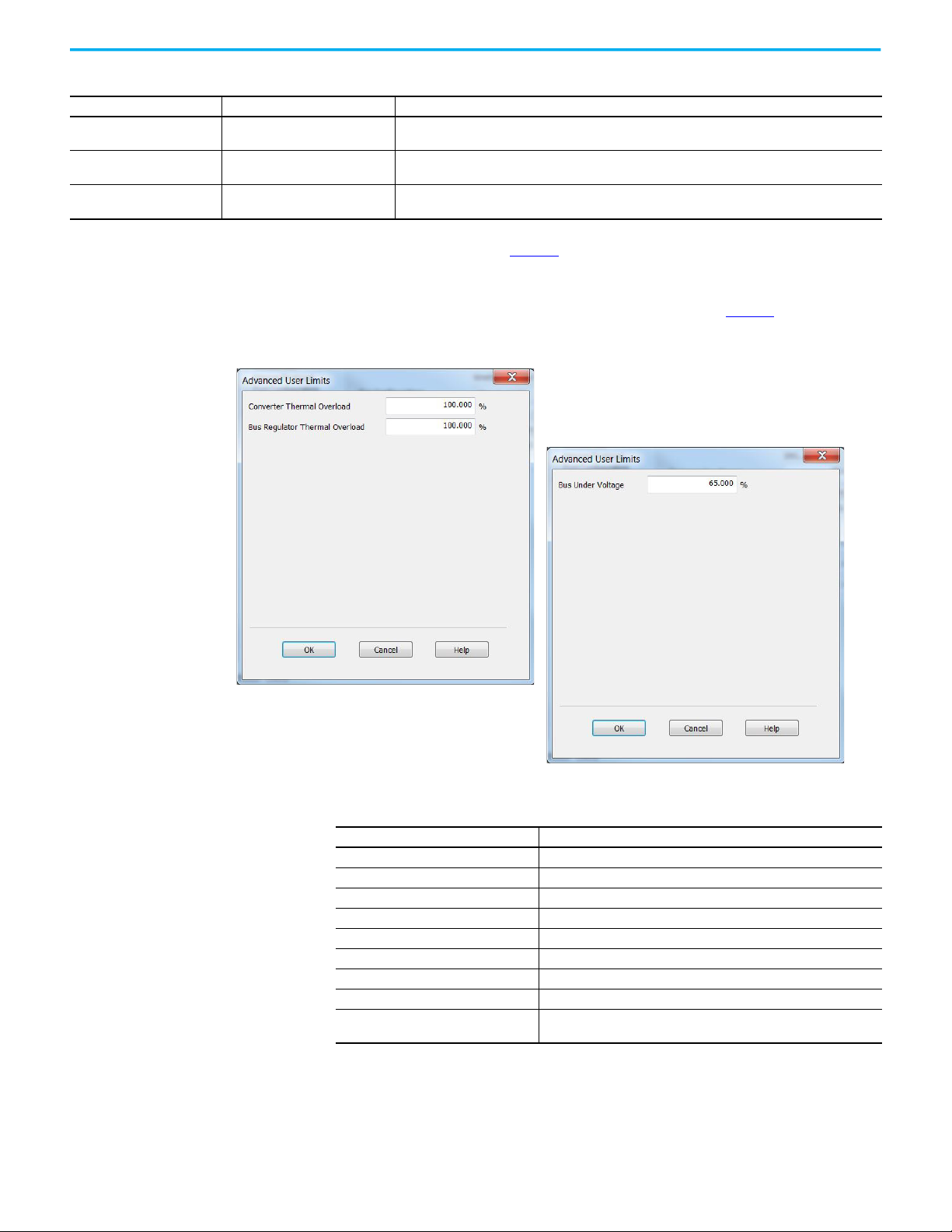

2. Click Advanced to adjust the limits for overload and voltage.

, for more information on

Table 9 - Limits for Overload and Voltage

Parameter Description

Converter Over Temperature Limit Sets the user limit for converter over temperature.

Converter Thermal Overload Limit Sets the user limit for converter thermal overload.

Converter Pre-charge Overload Limit Sets the user limit for converter pre-charge overload.

Converter Ground Current Limit Sets the user limit for the converter ground current.

Bus Regulator Over Temperature Limit Sets the user limit for bus regulator temperature.

Bus Regulator Thermal Overload Limit Sets the user limit for bus regulator overload.

Bus Over Voltage Limit Sets the user limit for bus over voltage.

Bus Under Voltage Limit Sets the user limit for bus under voltage.

Control Module Over Temperature Limit

28 Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020

Sets the user limit for the Control Module Over temperature User Limit

exception.

Page 29

Chapter 2 Configure Drive Properties

Configure Digital Inputs The following restrictions apply to settings made on this page:

• All digital input parameters, except Unassigned, must be unique.

• At least one Digital Input must be set to Regeneration OK when a module

is set to the Shared DC - Non-CIP Converter bus sharing configuration in

the Power tab.

• When you use the 2198-R014, 2198-R031, or 2198-R127 external passive

shunt resistor with a DC-bus power supply, the Shunt Thermal Switch

Digital Input must be configured.

Configure the digital inputs to monitor the status of drive functions

appropriate to your application.

Table 10 - Drive Functions

Functions Description

Enable A 24V DC input is applied to this terminal as a condition to enable each module.

Home

Registration 1

Registration 2

Home

Positive Overtravel

Negative Overtravel

Regeneration OK

AC Line Contactor OK An active indicates that the AC Line Contactor is working correctly.

Bus Capacitor OK

Shunt Thermal Switch OK

An active state indicates to a homing sequence that the referencing sensor as been

seen. Typically, a transition of this signal is used to establish a reference position for the

machine axis.

An inactive-to-active transition (also known as a positive transition) or active-to-inactive

transition (also known as a negative transition) is used to latch position values for use in

registration moves.

An active state indicates to a homing sequence that the referencing sensor has been

seen. Typically, a transition of this signal is used to

establish a reference position for the machine axis.

The positive/negative limit switch (normally closed contact) inputs for each axis require

24V DC (nominal).

In the active state the inverters can be enabled. An inactive state indicates that the bus

supply unit is not ready to supply DCbus

power. The inverters cannot be enabled.

When a Kinetix 5700 bus group is supplied by an 8720MC-RPS unit, one inverter in the

bus group must be configured in the Logix Designer application as Shared-DC Non-CIP

Motion™ Converter and assigned to Regeneration OK. This signal is wired from RDY on

the 8720MC-RPS unit and indicates to the Kinetix 5700 drive system that the 8720MC-RPS

unit is ready to supply power. Enabled inverters enumerate a Bus Power Sharing fault if

the Regeneration OK input goes inactive.

You can configure this input in the Logix Designer application and wire the module

status (MS) output from the 2198-CAPMOD-2240 capacitor module to indicate to the

inverter that a major fault is present on the capacitor module.

When the 2198-R014, 2198-R031, or 2198-R127 external shunt resistor is wired to the DCbus power supply, this input must be

configured in the Logix Designer application to monitor the status of the external shunt

module thermal switch and assigned to Shunt

thermal switch OK. This function does not apply to the 2198-R004 shunt resistor. You can

also use this input to monitor the status of an

active shunt module in the system that is connected via the capacitor module or an

extension module.

Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020 29

Page 30

Chapter 2 Configure Drive Properties

Table 10 - Drive Functions

Functions Description

u can configure this input in the Logix Designer application and wire the module

Yo

Bus Conditioner OK

Pre-charge OK

Motor Thermostat OK

status (MS) output from the 2198-DCBUSCONDRP312

conditioner module to indicate to the inverter that a major fault is present on the

conditioner module.

This feature extends the precharge input monitoring capability to the PowerFlex

755 drive in integrated motion. The event processing is as follows:

1. If the configured Pre-charge OK Input becomes inactive and the drive is in the

Stopped state, the drive enters the precharge state.

2. If the configured Pre-charge OK input becomes inactive and the drive is in the

Running state, the drive generates the Converter Pre-charge Input Deactivated

exception and performs a Fault Coast Stop.

Motor thermostat input functionality is provided through the motor thermostat

input (PTC) on the 22-Series I/O modules (installed in Port 7) when in Integrated Motion

on EtherNet/IP mode.

The functionality is the same as the motor thermostat functionality in parameter

mode. When the PTC input resistance transitions from low to high at the design

temperature, the drive issues a motor over temperature fault, 18 [Motor PTC Trip].

The functionality supports the current motor thermostat range for status trip and

reset in parameter mode. However, this functionality is not suitable for AllenBradley MPL and MPM motors due to the varying hardware capacities and thermostat

ranges of the Kinetix and 22-Series I/O modules.

30 Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020

Page 31

Chapter 2 Configure Drive Properties

Configure Digital Outputs The Digital Outputs tab is only available for PowerFlex 755 drives with a digital

I/O option card installed as a peripheral device. The appearance of the tab

varies depending on the device configuration.

Configure the digital outputs appropriately for your application.

Table 11 - Digital Output Functions

Functions Description

Unassigned The output is not assigned.

A Contactor Enable Output can be configured in the PowerFlex 755 drive in

integrated motion only. The operation of this output is tied to fault processing in

Contactor Enable

Mechanical Brake Engage Delay

the drive. The drive de-energizes the Contactor Enable Output when an

exception causes the axis to go to the ‘shut down’ state.

Note: This configuration is only valid when an auxiliary power supply is used for

control power with frames 1…7 drives or when a 24 auxiliary power supply is

used on frames 8…10 drives.

The amount of time that the power structure remains enabled after the axis has

been commanded to zero speed before disabling the power structure. The

motor decelerates to a stop, the brake output actuates, and this delay provides

time for the brake to engage.

Configure Safety Settings If your system includes a drive that supports integrated safety, note the safety

network number (SNN) on the Module Properties General page, which

populates automatically when you add a drive that supports integrated safety

to the project.

Safety network numbers for PowerFlex drives that include 20-750-S3 or 20750-S4 option modules are unique. SNNs for other drives match the SNN of

the safety controller in the project.

Often the automatically-assigned SNN is sufficient, but sometimes manual

manipulation of the SNN is required. See Generate an SNN on page xx

for

more information.

The connection between the owner controller and the drive is based on the

following:

• Servo drive safety network number

•GuardLogix slot number

• GuardLogix safety network number

• Path from the GuardLogix controller to the 2198-xxxx-ERSx drive

• Configuration signature

Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020 31

Page 32

Chapter 2 Configure Drive Properties

If any differences are detected, the connection between the GuardLogix

controller and drive is lost, and the yellow yield icon appears in the controller

project tree after you download the program.

Configure Safety Connections

1. Choose the Safety page.

2. Click Advanced to open the Advanced Connection Reaction Time Limit

Configuration dialog box.

32 Rockwell Automation Publication MOTION-UM003L-EN-P - November 2020

Page 33

Chapter 2 Configure Drive Properties

3. Analyze each safety channel to determine the appropriate settings.

The smallest Input RPI allowed is 6 ms. The selection of small RPI values

consumes network bandwidth and can cause spurious trips because

other devices cannot get access to the network.

For more information about the Advanced Connection Reaction Time

Limit Configuration, refer to the appropriate GuardLogix or Compact

GuardLogix Controllers User Manual, which is listed in Additional

Resources on page 9.

Generate the Safety Network Number (Integrated safety drives only)

The assignment of a time-based safety network number (SNN) is automatic

when you create a GuardLogix safety controller project and add new Safety

devices. This number is generally sufficient. However, manual manipulation of

an SNN is required in the following situations:

• If safety consumed tags are used

• If the project consumes safety input data from a device whose

configuration is owned by some other device

• If a safety project is copied to another hardware installation within the

same routable safety system

If an SNN is assigned manually, the SNN has to be unique.

IMPORTANT

If you assign an SNN manually, make sure that the system expansion does