Page 1

Quick Start

Computer Numerical Control (CNC) Machining

Accelerator Toolkit

For FANUC Series 30i-B, 31i-B, 32i-B, and 35i-B CNC Systems

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, CenterONE, CompactBlock, CompactLogix, ControlFLASH, ControlLogix, CrossWorks, Explorer, FactoryTalk, Guard I/O, GuardLogix, Integrated Architecture, Kinetix, MCS, PanelView, PowerFlex,

ProposalWorks, RSLogix, RSLinx, TechConnect, RailBuilder, Rockwell Automation, Rockwell Software, and Ultra are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

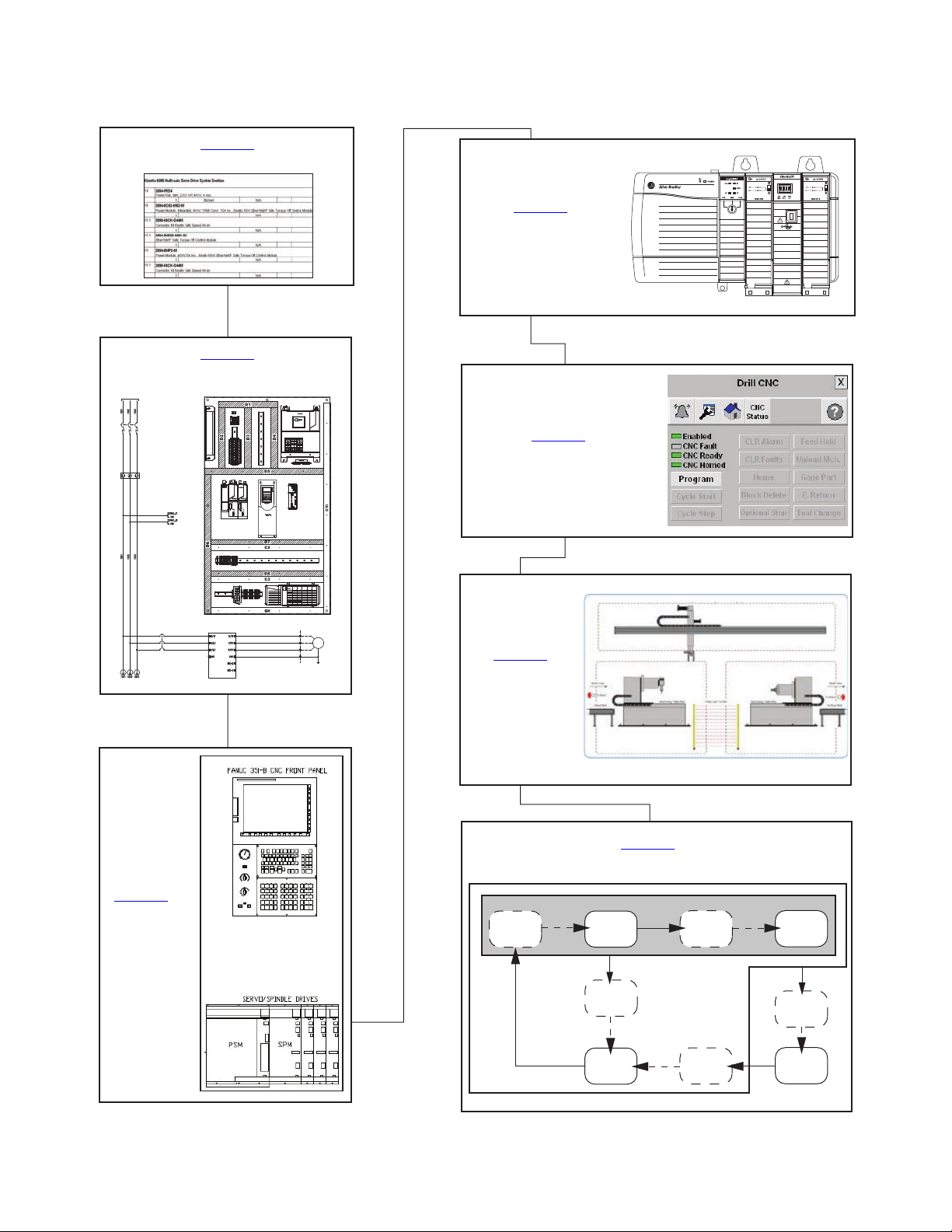

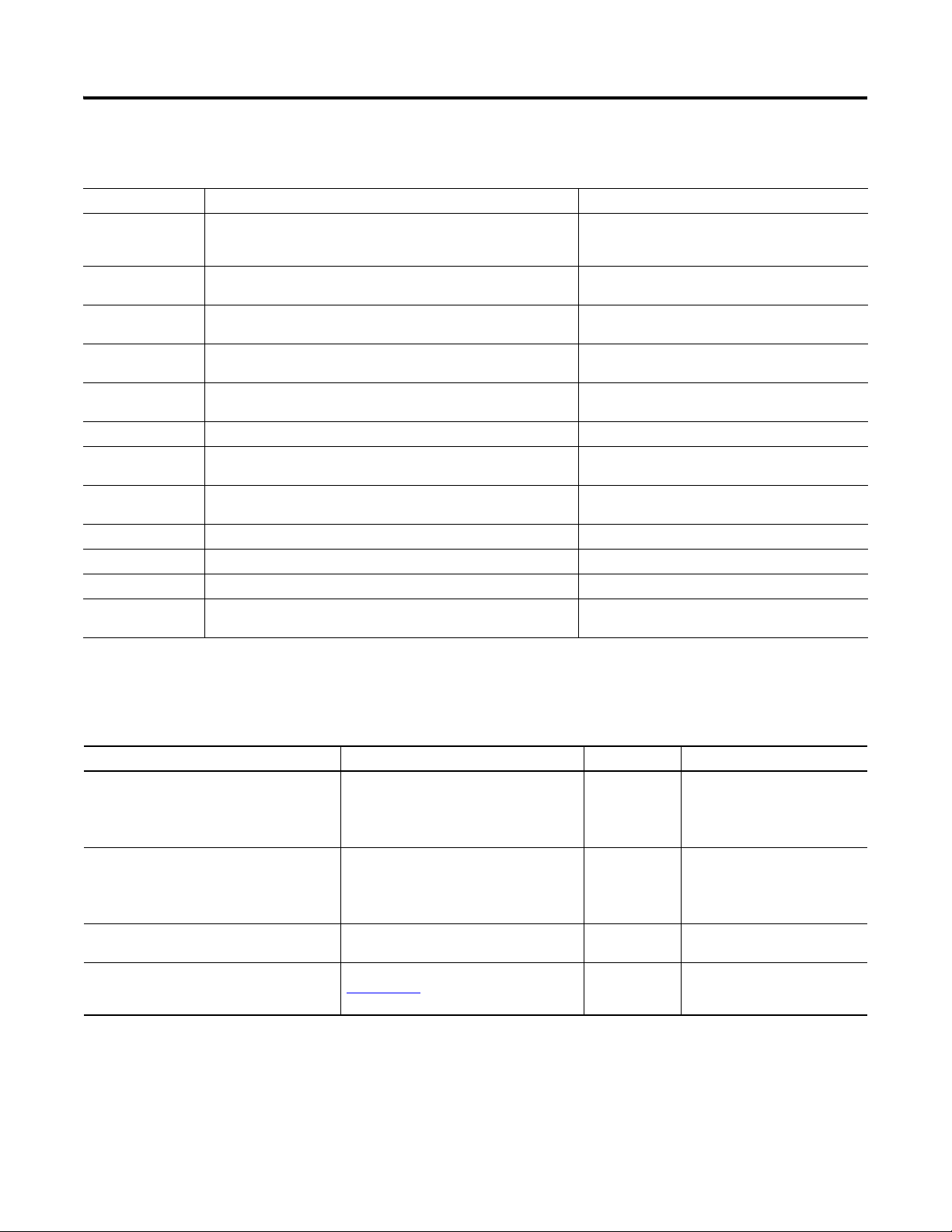

Follow this path to complete your CNC machining application.

MOTOR

FIELD SIDE

DRIVE

PROTECTION

POWERFLEX 4

AC DRIVE

MOTOR_01

USER PROTECTED

XXXVAC SUPPLY

MAINS DISCONNECT

PROTECTION

XXAMPS

FILTERED POWER

Chapter 7

Motion System Application Guide

RESETTING

IDLE

(enabled)

STARTING

START

RUNNING

STOPPING

STOP

STOPPED

(disabled)

CLEARING

ABORTED

ABORTING

RESET

ABORT

CLEAR

The machine can go from any state in the shaded box to STOPPING.

The machine can go from any state

in the solid box to ABORTING.

Chapter 2

System Layout and Wiring

Chapter 1

Architecture and Hardware Selection

Chapter 3

FANUC CNC

Configuration

Chapter 4

GuardLogix®

Configuration

Chapter 7

System Application Guide

Chapter 5

FactoryTalk® View ME

Configuration

Chapter 6

System

Commissioning

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 3

Page 4

Where to Start

Notes:

4 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 5

Table of Contents

Preface

Architecture and Hardware Selection

System Layout and Wiring

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Required Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Additional Toolkits and FANUC Publications . . . . . . . . . . . . . . . . . 14

Chapter 1

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Follow These Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Review System Selection and Configuration Tools . . . . . . . . . . . . . . . . . . 19

FANUC CNC Express Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Rockwell Automation DMAT Wizard Software . . . . . . . . . . . . . . . . 19

Rockwell Automation Safety Selection Tools . . . . . . . . . . . . . . . . . . . 20

Rockwell Automation Product Selection Toolbox. . . . . . . . . . . . . . . 21

Open FANUC CNC Express Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Create CNC System Bill of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Create Supervisory Controller and Safety System Bill of Materials. . . . 28

Chapter 2

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Follow These Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Select FANUC CNC Drawings from Drawing Library. . . . . . . . . . . . . . 31

Edit FANUC CNC Drawing Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Create a New Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Edit CNC Power Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Edit CNC Safety and Standard I/O Drawings . . . . . . . . . . . . . . . . . . 38

Edit System Communication Drawings . . . . . . . . . . . . . . . . . . . . . . . . 41

Edit CNC System Layout Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Assemble and Edit Your GuardLogix System Drawing Set . . . . . . . . . . . 44

FANUC CNC Configuration

Chapter 3

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Follow These Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Initial FANUC CNC Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

System Powerup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Parameter Write Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

High Speed Ethernet Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Configure Ethernet Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Create a New Project File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Download FANUC LADDER III Software Project

to the FANUC S35i-B CNC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 5

Page 6

Table of Contents

USB External Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

EtherNet/IP Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

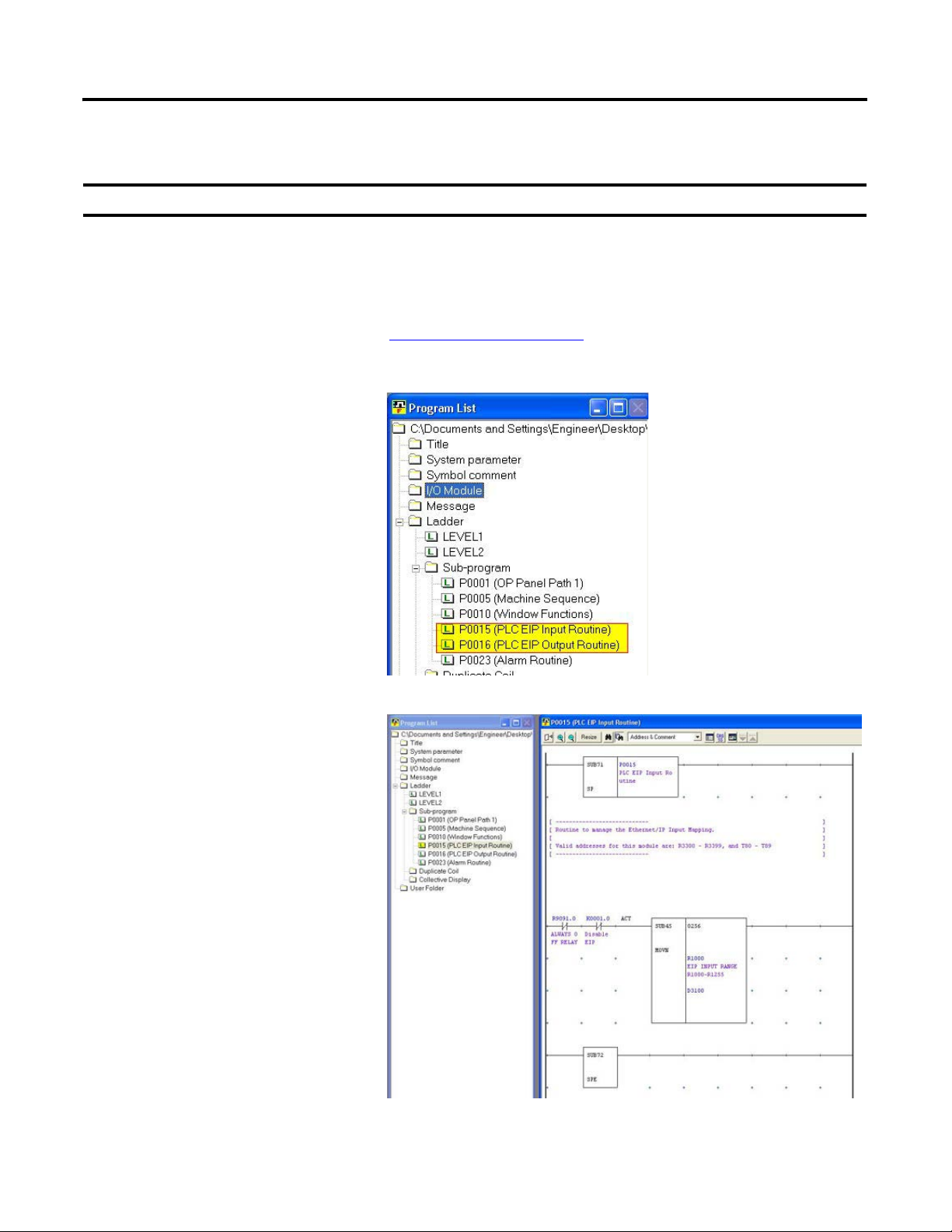

Logic Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Editing Application Logic Modules and Adding Code . . . . . . . . . . . 70

Device Logic Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Verify and Save the Project File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Download FANUC LADDER III Software Project

to the FANUC S35i-B CNC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Chapter 4

GuardLogix Configuration

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

What You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Create an Initial GuardLogix Project Using the DMAT Wizard. . . . . . 84

Order and Run the DMAT Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Import the Preconfigured RSLogix 5000 Project . . . . . . . . . . . . . . . . 84

GuardLogix Controller and Network Configuration . . . . . . . . . . . . . . . . 87

Create a New Project File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Configure Ethernet Module for your HMI Terminal

and CNC Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Save the Project File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

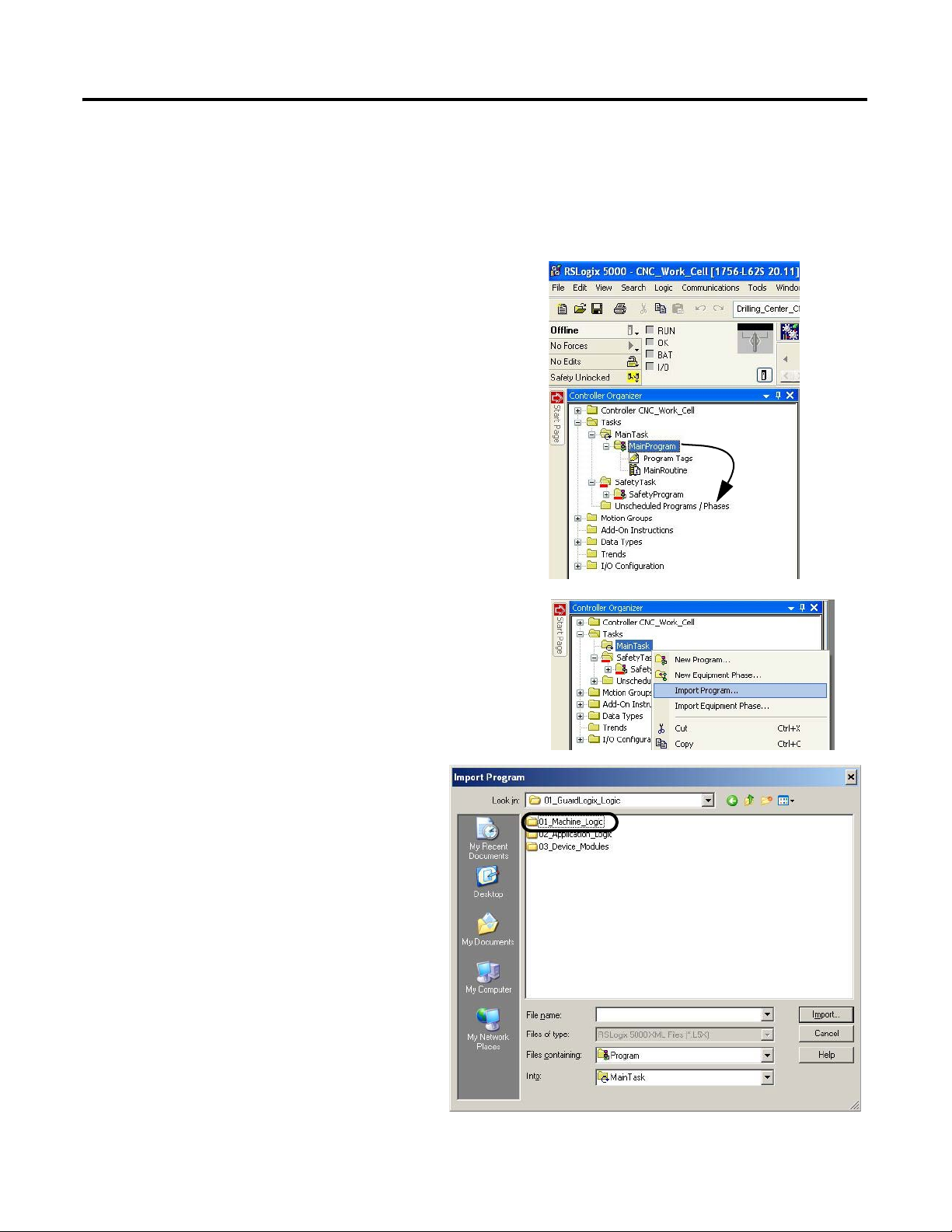

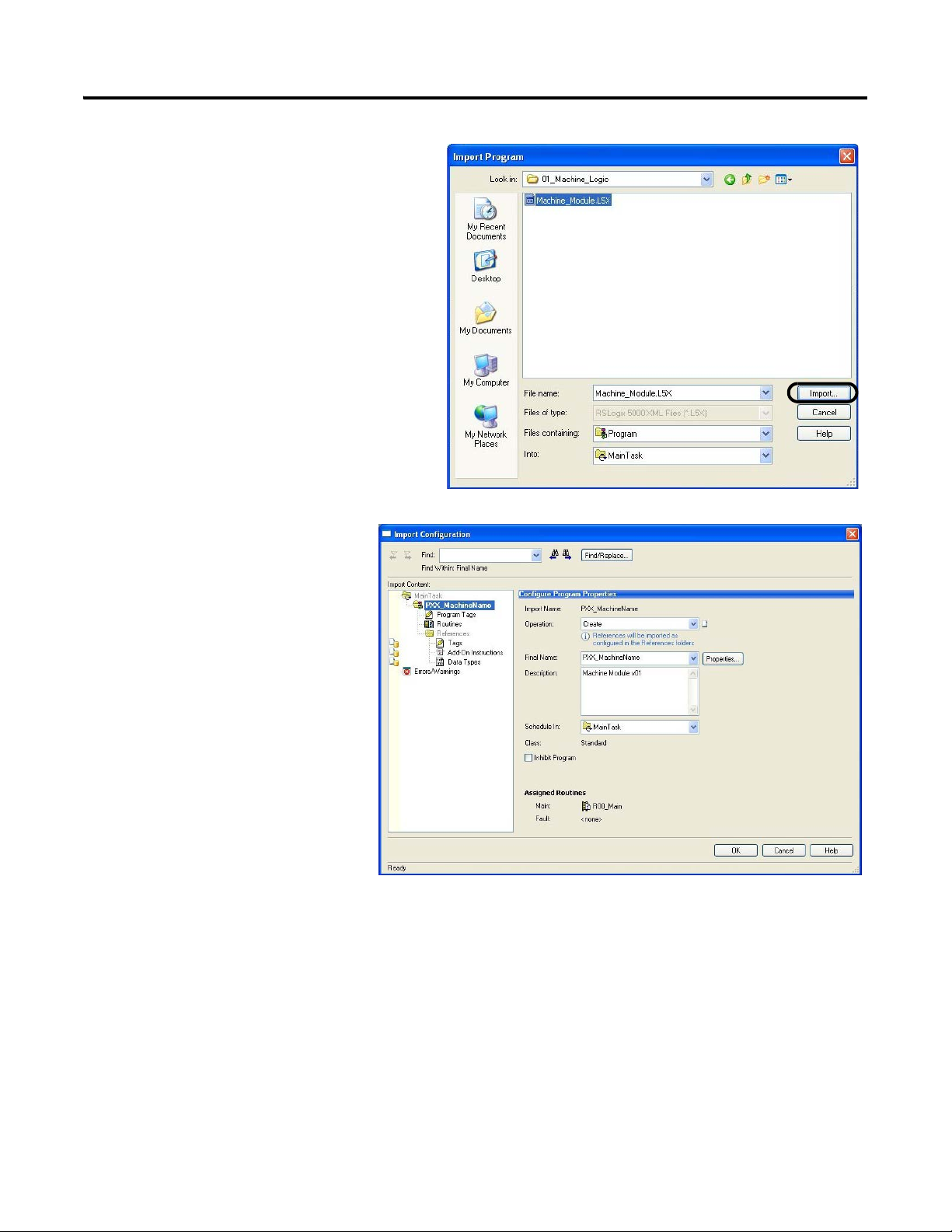

Import and Configure the Machine Logic Module . . . . . . . . . . . . . . . . . . 91

FANUC CNC AOP Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Update FANUC CNC Add-On Profile (AOP) . . . . . . . . . . . . . . . . . 95

Add and Configure FANUC CNC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Save the Project File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

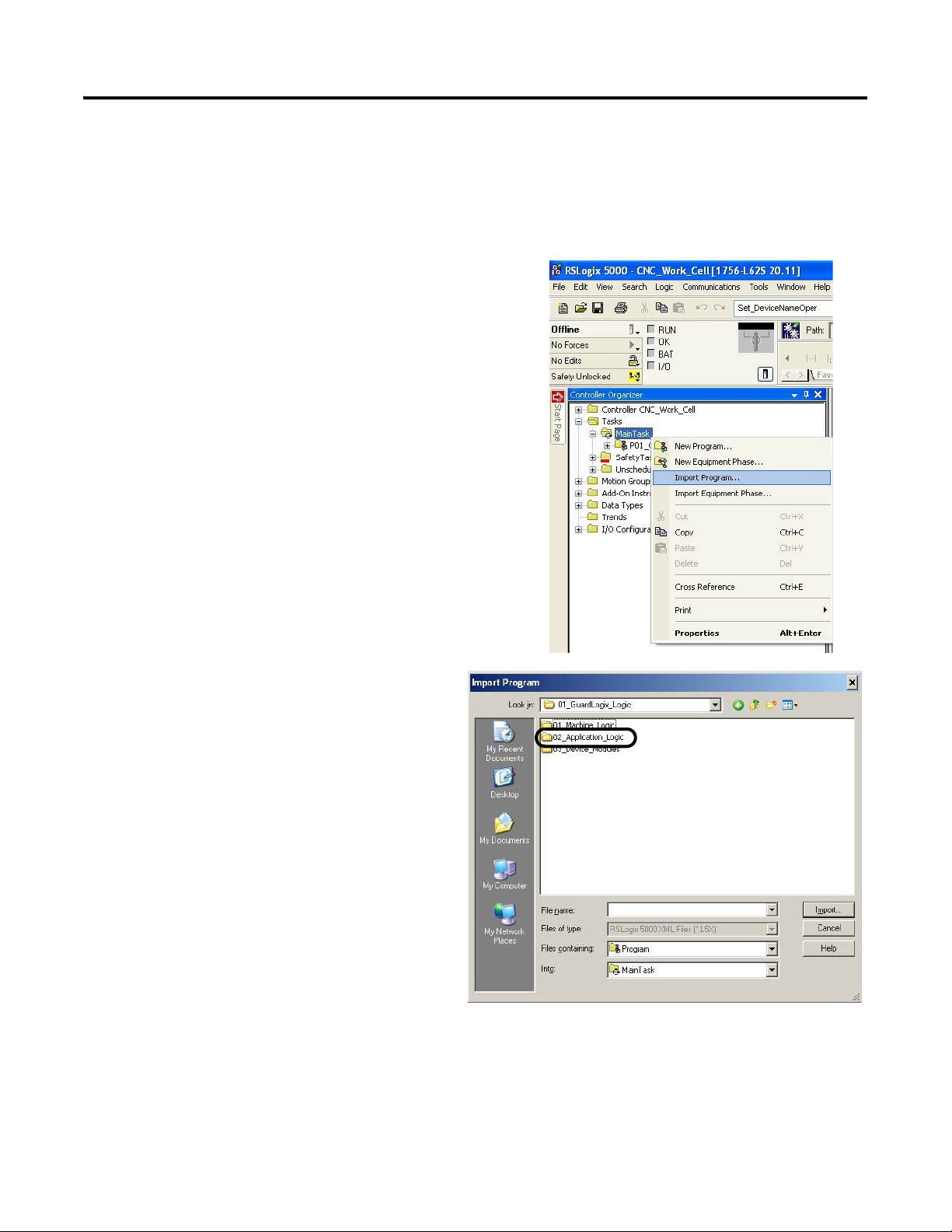

Import and Configure CNC Application Logic Module . . . . . . . . . . . . 100

Import and Configure FANUC CNC Device Logic Modules . . . . . . . 104

Set String Tag Names for Alarm History Faceplate . . . . . . . . . . . . . . . . . 108

Set Visible Rows for Equipment Status Faceplate. . . . . . . . . . . . . . . . . . . 111

Import and Configure Device and Application Status Logic. . . . . . . . . 113

Create Specific Application Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Application Code Logic Template Overview. . . . . . . . . . . . . . . . . . . 120

Application Logic Creation Steps That Use

Application Logic Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Application Logic Creation Steps That Use a Template. . . . . . . . . 136

Safety Logic Integration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Safety I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

GuardLogix Safety Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Safety Faceplate Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Verify and Save the Project File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Chapter 5

FactoryTalk View ME Configuration

6 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

What You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Page 7

Table of Contents

Design from a Preconfigured HMI Application File. . . . . . . . . . . . . . . . 151

Restore and Open a Preconfigured HMI Application. . . . . . . . . . . 151

Delete Unused Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Delete Unused Parameter Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Configure Parameter Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Delete Unused Alarm Triggers and Tags . . . . . . . . . . . . . . . . . . . . . . 160

Design from an Existing HMI Application File . . . . . . . . . . . . . . . . . . . . 162

Open Your Existing HMI Application File and Add Displays . . . 162

Add Parameter Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Configure Parameter Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Import Alarm Setup File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Delete Unused Alarm Triggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Import and Edit Alarm Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Configure Goto Display Buttons on Startup Display . . . . . . . . . . . . . . . 177

Add FANUC CNC Goto Buttons to Your Application . . . . . . . . 177

Associate Each Button to a Faceplate and Parameter File. . . . . . . . 179

Configure Equipment Status Faceplate Display . . . . . . . . . . . . . . . . . . . . 185

Add the Equipment Status Faceplate Display . . . . . . . . . . . . . . . . . . 186

Add the ME_Equipment_Parameter File. . . . . . . . . . . . . . . . . . . . . . 187

Configure Goto Buttons on the Equipment Status Faceplate . . . . 189

Configure Additional Device Value Columns. . . . . . . . . . . . . . . . . . 191

Configure Safety Faceplate Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

System Commissioning

Chapter 6

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Follow These Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Download Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Download RSLogix 5000 Software Project File

to the Logix Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Configure and Download FactoryTalk Project

to PanelView Plus Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Commissioning Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Commissioning CIP Motion Drives . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Commissioning sercos Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Commissioning PowerFlex 7-class Drives. . . . . . . . . . . . . . . . . . . . . . 205

Commissioning PowerFlex 4-class Drives. . . . . . . . . . . . . . . . . . . . . . 205

Commissioning Kinetix 300 Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Commissioning Supervisory and CNC System . . . . . . . . . . . . . . . . . . . . 206

Verify Network Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Clearing Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Operator (manual) Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Program (automatic) Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 7

Page 8

Table of Contents

Chapter 7

System Application Guide

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

What You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Machine Startup Faceplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Machine Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Machine Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Program/Operator Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

State Diagram Faceplate Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

CNC Faceplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Home View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

CNC Status Views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

CNC Control Views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Fault Indication View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Fault Diagnostic Views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Configuration View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Online Help Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Motion Drive and/or PowerFlex Drive Faceplates. . . . . . . . . . . . . . . . . . 226

Guard I/O Safety Faceplates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Equipment Status Display Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Alarm History Display Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Logic Program Overview

Logic Module Customization

Add Other Devices to the Equipment

Status Faceplate

Appendix A

Machine/Application/Device Module Relationship . . . . . . . . . . . . . . . . 230

Module Routine Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Machine Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Application Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Device Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Appendix B

Machine State Customization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Tag and Logic Modification Recommendations . . . . . . . . . . . . . . . . 246

State Display Tag Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Bypass Idle State Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Module Fault Customization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Alarm History Faceplate Logic Modification . . . . . . . . . . . . . . . . . . . . . . 252

Coordinated Reset Customization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Appendix C

Add Devices to the Equipment Status Faceplate. . . . . . . . . . . . . . . . . . . . 255

Add Optional Faceplate Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

8 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 9

Appendix D

Table of Contents

Logix Communication and Controller

Configuration

Index

Configure Personal Computer Communication Properties . . . . . . . . . 261

Configure the EtherNet/IP Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Configure the Logix Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 9

Page 10

Table of Contents

Notes:

10 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 11

Preface

IMPORTANT

Introduction

This quick start provides step by step instructions for using the CNC

Machining Accelerator Toolkit to help you design, install, operate, and

maintain a CNC work cell incorporating a GuardLogix Supervisory

Controller and FANUC Series 30i-B, 31i-B, 32i-B, or 35i-B CNC System.

Included are selection tools, layout and wiring drawings, and

pre-configured logic and HMI files to assist you in creating an Integrated

Architecture™ solution for your application requirements.

All the supporting files are included on the CNC Machining Accelerator

Toolkit DVD, publication IASIMP-SP018. The DVD provides PLC and

CNC selection tools; CAD drawings for panel layout and wiring; basic

status, control, and diagnostic logic files; FactoryTalk View ME faceplates,

and more. For a copy of the DVD, contact your local Rockwell

Automation distributor or sales representative. With these tools and the

built-in best-practices design, the system designer is free to focus on the

design of their machine control and not on design overhead tasks.

You can also download these same supporting files from the

Rockwell Automation® Integrated Architecture Tools website,

http://www.ab.com/go/iatools on the Beyond Getting Started tab.

Before using this quick start and the contents of the CNC Machining

Accelerator Toolkit DVD, read the Terms and Conditions READ ME PDF

file on the DVD.

The beginning of each chapter contains the following information. Read

these sections carefully before beginning work in each chapter:

• Before You Begin - This section lists the steps that must be

completed and decisions that must be made before starting that

chapter. The chapters in this quick start do not have to be completed

in the order in which they appear, but this section defines the

minimum amount of preparation required before completing the

current chapter.

• What You Need - This section lists the tools that are required to

complete the steps in the current chapter. This includes, but is not

limited to, hardware and software.

• Follow These Steps - This illustrates the steps in the current chapter

and identifies which steps are required to complete the examples by

using specific networks.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 11

Page 12

Preface

Conventions

Convention Meaning Example

CNC

Click

Double-click

Right-click

Drag and drop

Select Click to highlight a menu item or list choice. From the pull-down menu, choose H1-1.

Check/uncheck Click to select a checkbox option.

>

Expand Click the + to the left of a given item /folder to show its contents. In the H1-1 dialog box, expand FFLD.

Enter Used when you can type from the keyboard or choose from a list. Enter the catalog number of the product.

Type Used when the only option is to type from the keyboard. Type the catalog number of the product.

Press

Used as an abbreviation for Computer Numeric Control. In this Toolkit,

The GuardLogix PLC communicates to the FANUC CNC by using the

EtherNet/IP communication protocol.

Click the left mouse button once (assumes cursor is positioned on object

or selection). Click button to initiate action.

Click the left mouse button twice in quick succession (assumes cursor is

positioned on object or selection).

Click the right mouse button once (assumes cursor is positioned on

object or selection).

Click and hold the left mouse button on an object, move the cursor to

where you want to move the object, and release the mouse button.

Shows nested menu selections as menu name followed by menu

selection.

Press a specific button on the PanelView™ terminal or other component

with touch-screen technology.

This manual uses the following conventions.

GuardLogix PLC to FANUC CNC EtherNet/IP

configuration.

Click Browse.

Double-click the H1 icon.

Right-click the Fieldbus Networks icon.

Drag and drop the desired block into the Strategy

dialog box.

Check Consider Case if you want to conduct a

case-sensitive search.

Click File>Page Setup>Options.

Press Axis Control.

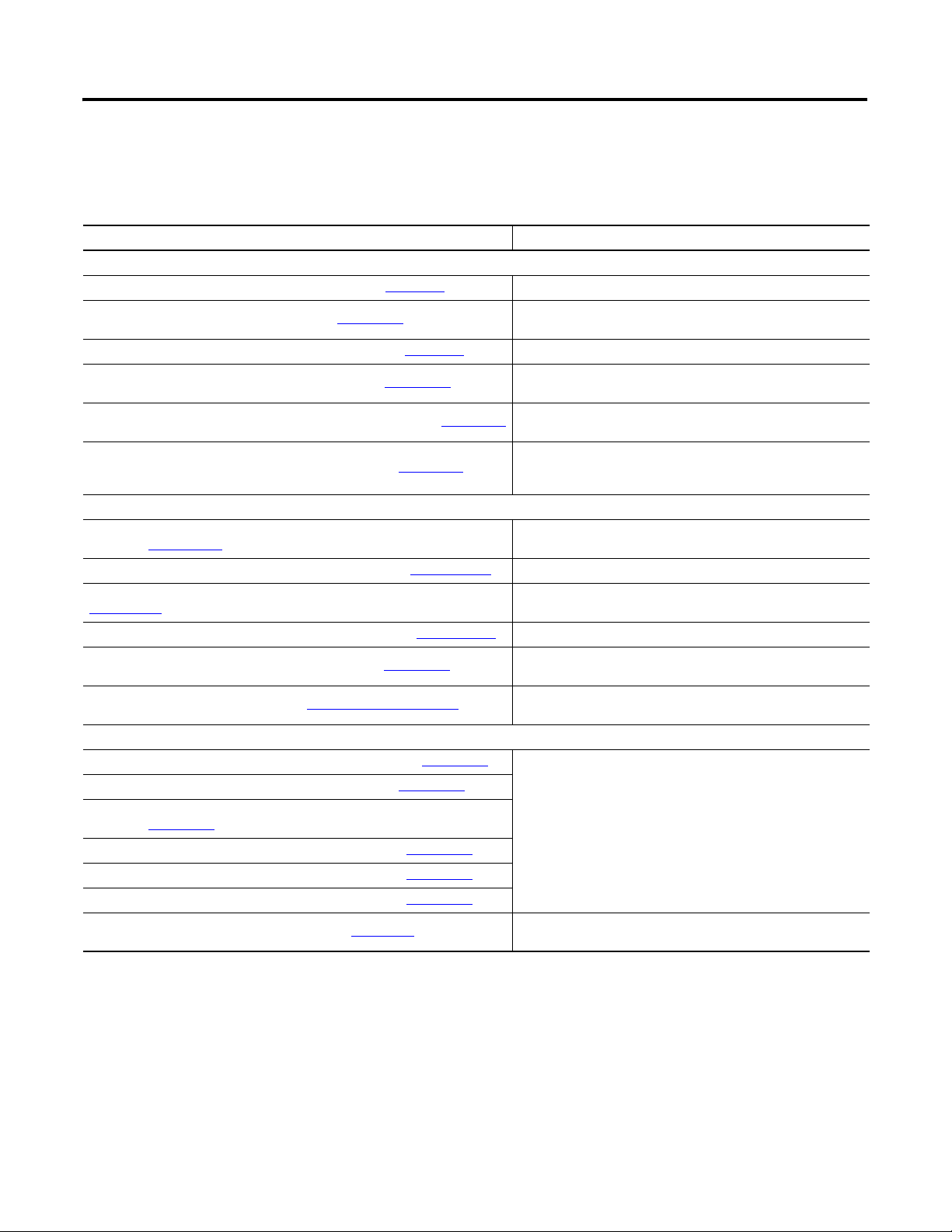

Required Software

Rockwell Automation Software Cat. No. Version Required For

RSLogix™ 5000

• ControlFLASH™

• BOOTP/DHCP utility (EtherNet/IP network)

• RSLinx® Classic

FactoryTalk View Studio for Machine Edition

• FactoryTalk Services

• RSLinx Enterprise

• RSLinx Classic

FANUC III for PMC Development

(Microsoft Windows)

CNC Machining Accelerator Toolkit DVD IASIMP-SP018

To complete this quick start, the following software is required.

9324-RLD300RNE 20.00 or later

9701-VWSTMENE 6.00 or later PanelView Plus terminals

A08B-9210-J505 6.80 or later FANUC CNC applications

N/A

All ControlLogix®/GuardLogix PLC

applications

CAD files, wiring diagrams,

application files, and other

support information

12 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 13

Preface

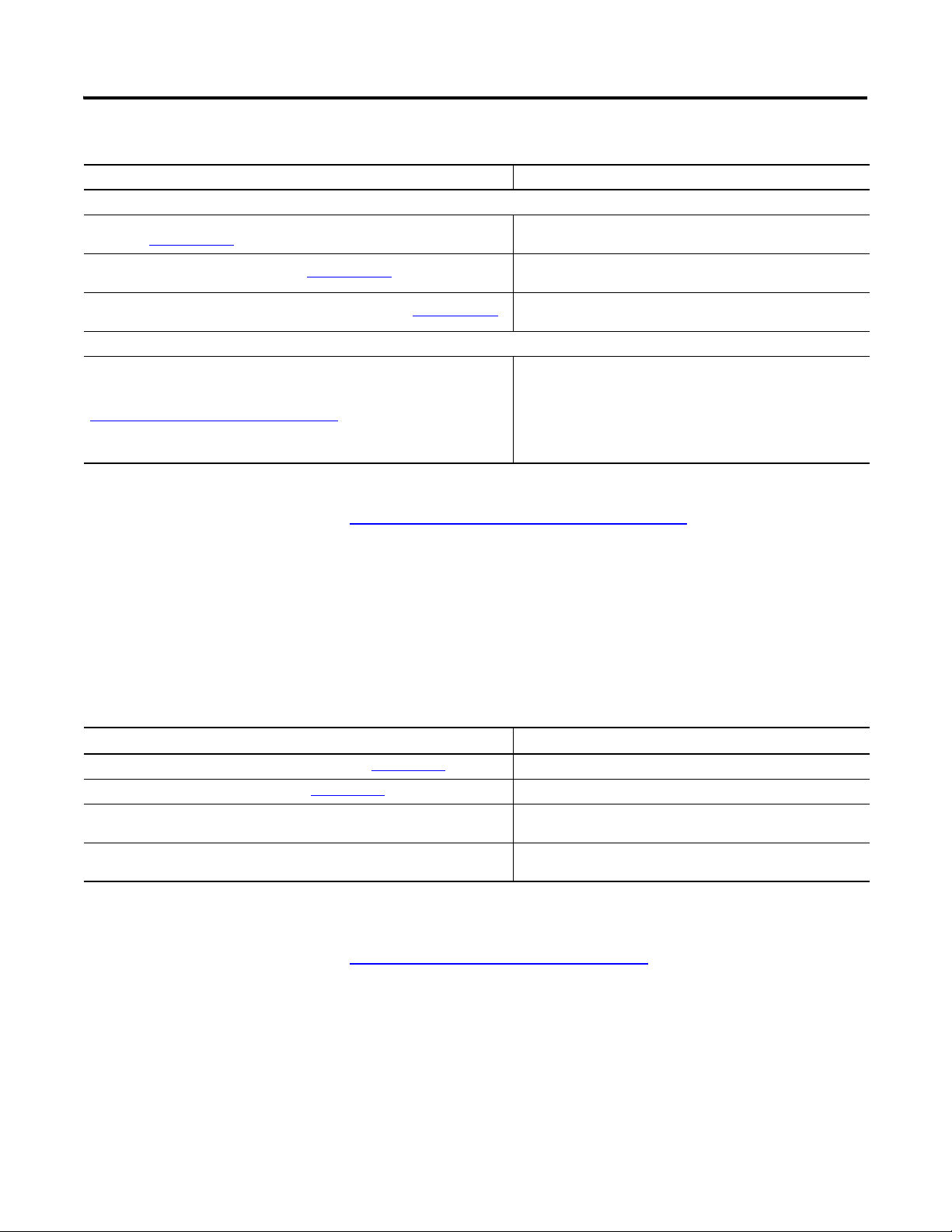

Additional Resources

These documents contain additional information concerning related

products from Rockwell Automation.

Table 1 - Additional Resources

Resource Description

Guard Logix and Compact Logix Controllers

GuardLogix Controller Installation Instructions, publication 1756-IN045 Provides information on installing the GuardLogix controller

GuardLogix Controllers User Manual, publication 1756-UM020

CompactLogix Controllers Installation Instructions, publication 1768-IN004 Provides information on installing the CompactLogix™ controller

Compact GuardLogix Controllers User Manual, publication 1768-UM002

GuardLogix Controller Systems Safety Reference Manual, publication 1756-RM093

Logix Common Procedures Programming Manual, publication 1756-PM001

Safety Modules and Products

CompactBlock Guard I/O DeviceNet Safety Module Installation Instructions,

publication 1791DS-IN002

Guard I/O DeviceNet Safety Modules User Manual, publication 1791DS-UM001 Provides information on using Guard I/O DeviceNet Safety modules

Guard I/O EtherNet/IP Safety Modules Installation Instructions, publication

1791ES-IN001

Guard I/O EtherNet/IP Safety Modules User Manual, publication 1791ES-UM001

POINT Guard I/O Safety Module User Manual, publication 1734-UM013

Safety Products Catalog S116, available at http://www.ab.com/catalogs/

Kinetix Drives

Kinetix 300 EtherNet/IP Indexing Drives User Manual, publication 2097-UM001

Kinetix 350 Single-axis EtherNet/IP Servo Drives, publication 2097-UM002

Kinetix 6200 and Kinetix 6500 Modular Multi-axis Servo Drives User Manual,

publication 2094-UM002

Kinetix 6000 Multi-axis Servo Drives User Manual, publication 2094-UM001

Kinetix 2000 Multi-axis Servo Drives User Manual, publication 2093-UM001

Kinetix 7000 Multi-axis Servo Drives User Manual, publication 2099-UM001

Kinetix Motion Control Selection Guide, publication GMC-SG001

Provides information on configuring and programming the 1756

GuardLogix system

Provides information on configuring and programming the 1768

Compact GuardLogix system

Contains detailed requirements for achieving and maintaining SIL 3

with the GuardLogix controller system

Provides information on programming Logix5000 controllers,

including managing project files, organizing tags, programming and

testing routines, and handling faults

Provides information on installing CompactBlock™ Guard I/O™

DeviceNet Safety modules

Provides information on installing CompactBlock Guard I/O

EtherNet/IP Safety modules

Provides information on using Guard I/O EtherNet/IP Safety modules

Provides information on installing, configuring and operating POINT

Guard I/O Safety Modules

Provides selection and specification information for Rockwell

Automation safety products.

Provides mounting, wiring, configuring, and troubleshooting

instructions for the Kinetix® Motion Control servo drives

Provides drive specifications, motor/servo-drive system

combinations, and accessories for Kinetix motion control products

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 13

Page 14

Preface

Table 1 - Additional Resources (Continued)

Resource Description

CIP Motion and sercos

SERCOS and Analog Motion Configuration and Startup User Manual,

publication MOTION-UM001

CIP Motion Reference Manual, publication MOTION-RM003

CIP Motion Configuration and Startup User Manual, publication MOTION-UM003

Online Configuration and Selection Tools

Rockwell Automation Configuration and Selection Tools, available at

http://www.rockwellautomation.com/en/e-tools/

Information on configuring and troubleshooting your ControlLogix

and CompactLogix sercos interface modules

Provides descriptions of the AXIS_CIP_DRIVE attributes and

RSLogix 5000 software Control Modes and Methods

Information on configuring and troubleshooting your ControlLogix

and CompactLogix EtherNet/IP network modules

These online tools install on your personal computer so that you can

quickly access information on our products:

• CrossWorks™

• Industrial Computer Selector

• Operator Interface Selection Tool

• Programmable Controller Family Selector

You can view or download publications at

http://www.rockwellautomation.com/literature. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Additional Toolkits and FANUC Publications

This table provides information for supporting toolkits and FANUC

publications.

Toolkits and FANUC Publications Description

Drives and Motion Accelerator Toolkit DVD, publication IASIMP-SP017 Toolkit for sercos interface or EtherNet/IP-based motion control

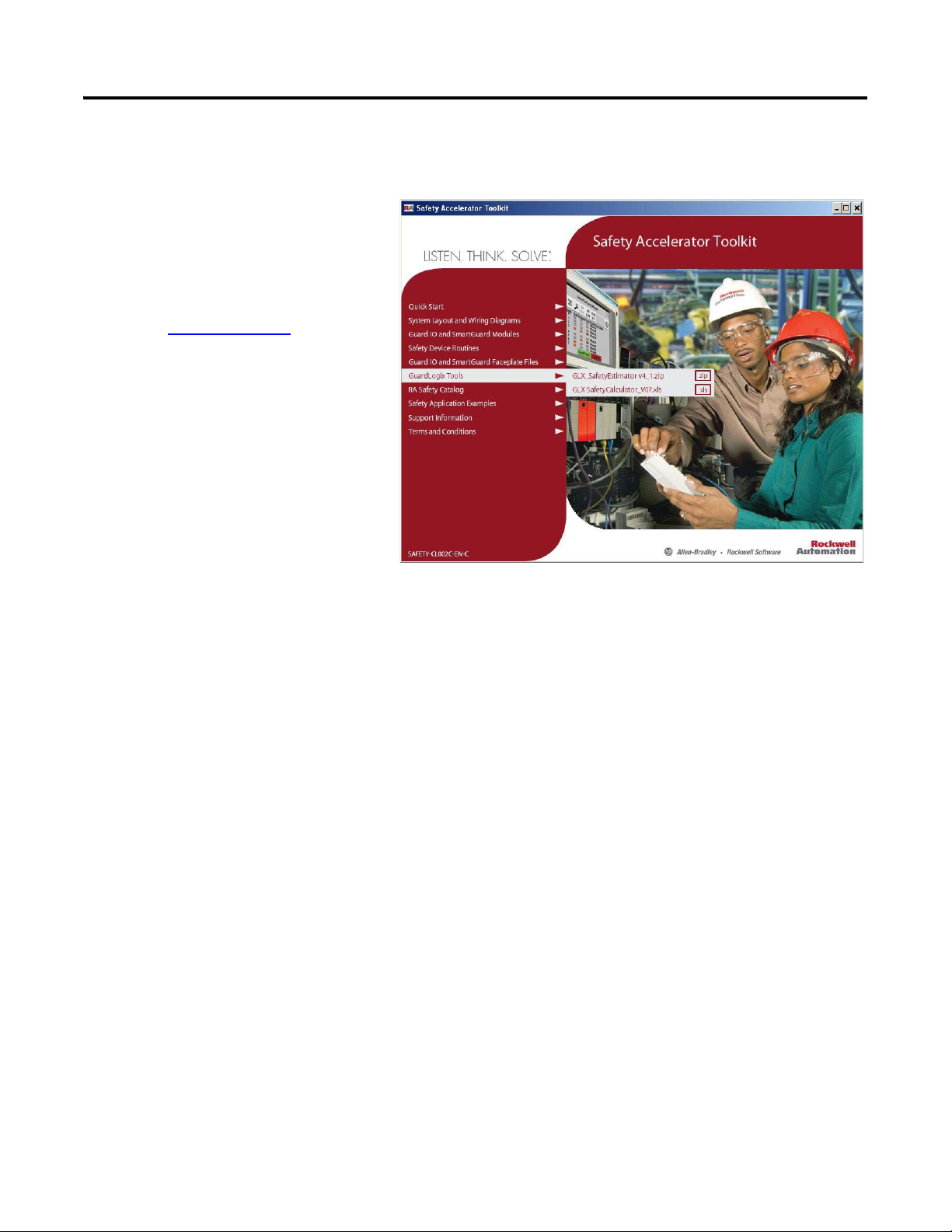

Safety Accelerator Toolkit DVD, publication SAFETY-CL002

FANUC Series 30i/31i/32i/35i -MODEL B, EtherNet/IP Adapter function,

publication B-64014EN/04-2

FANUC Series 30i/31i/32i/35i -MODEL B, FANUC Power Motion i -MODEL A,

EtherNet/IP Scanner function, publication B-64014EN/04-3

You can request the FANUC publications by contacting your local

FANUC America distributor or sales representative.

http://www.FANUCfa.com/us-en/Home

Toolkit to provide a framework for developing safety applications.

Information on configuring and troubleshooting your FANUC CNC's

EtherNet/IP network modules.

Information on configuring and troubleshooting your FANUC CNC's

EtherNet/IP network modules.

14 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 15

Chapter

1

Architecture and Hardware Selection

In this chapter you are introduced to the FANUC CNC Express software to create an EtherNet/IP bill of

materials for your CNC system. The CNC Express software provides the means to select hardware and software

from FANUC that are stocked locally in the United States. This is for reference only, and is not to be used for

final product selection. Please contact your local FANUC representative prior to purchase.

Use either the Drives and Motion Accelerator Toolkit DVD, publication IASIMP-SP017, and/or Safety

Accelerator Toolkit DVD, publication SAFETY-CL002, to configure the Rockwell Automation system, or to

select the power distribution components for the CNC control system. Be sure that an 1756-EN2TR or

1756-EN3TR Ethernet module is selected for the Rockwell Automation system.

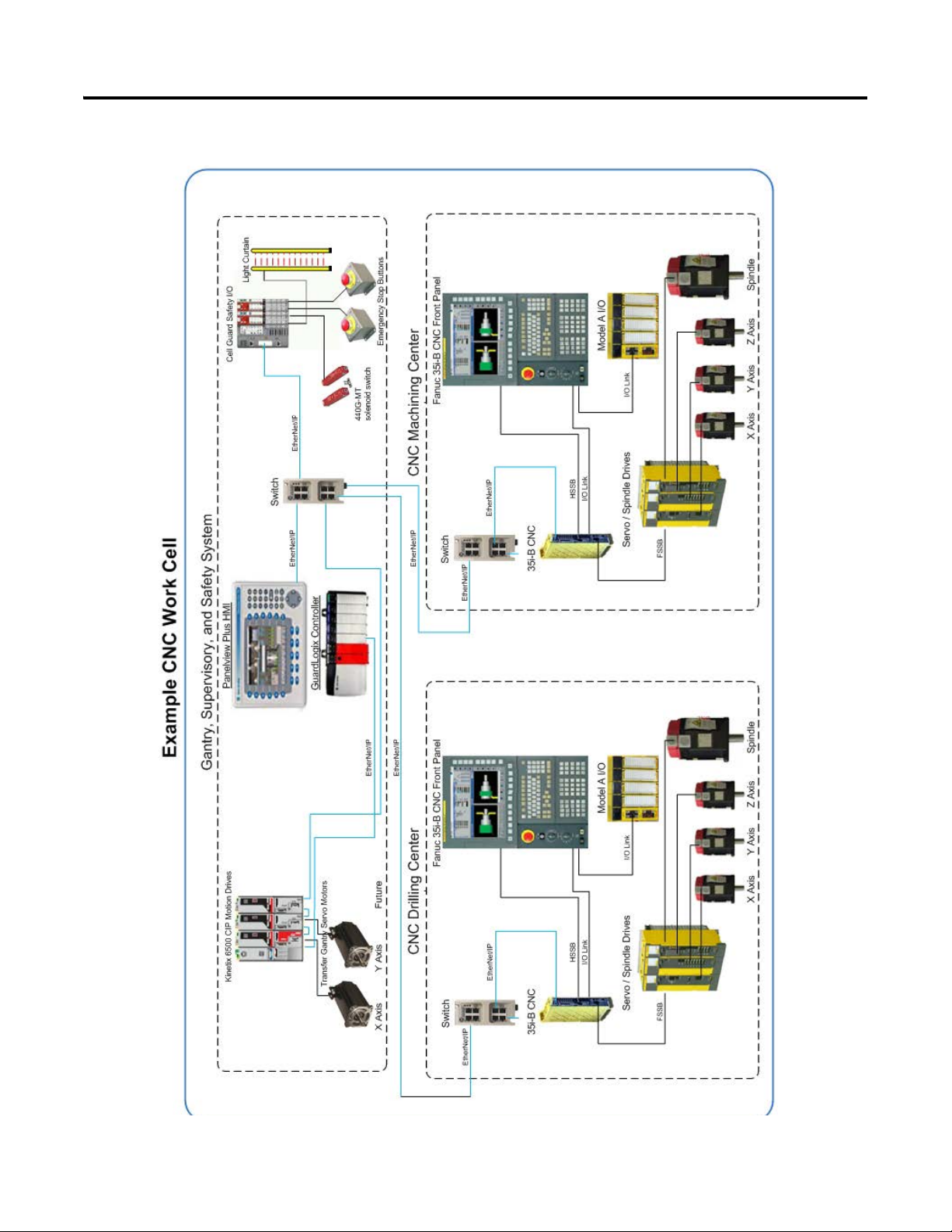

To assist you with a possible architecture and hardware selection, reference the CNC Work Cell machine

application. The CNC Work Cell machine application is an example only, with the focus of the toolkit being the

integration between the Rockwell Automation GuardLogix controller and the FANUC CNC.

See Figure 1 on page 16 for a CNC work cell application example.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 15

Page 16

Chapter 1 Architecture and Hardware Selection

Figure 1 - CNC Work Cell Application Example

16 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 17

Architecture and Hardware Selection Chapter 1

Before You Begin

Collect specific application data, for example:

• System input voltage

• System CNC model and display options

• CNC required options

• System I/O requirements

• Motor and drive sizing

• Other system sizing info

What You Need

• The CNC Machining Accelerator Toolkit DVD, publication IASIMP-SP018. For a copy of the DVD,

contact your local Rockwell Automation distributor or sales representative.

• FANUC CNC Express selection software. For a copy of the DVD, contact your local FANUC sales

representative.

• If Rockwell Automation Kinetix or PowerFlex® Drives are used in the system, the Drives and Motion

Accelerator Toolkit DVD is required, publication IASIMP-SP017. For a copy of the DVD, contact your

local Rockwell Automation distributor or sales representative.

• If Rockwell Automation GuardLogix safety controller and safety components are used in the system, the

Safety Accelerator Toolkit DVD is required, publication SAFETY-CL002. For a copy of the DVD,

contact your local Rockwell Automation distributor or sales representative.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 17

Page 18

Chapter 1 Architecture and Hardware Selection

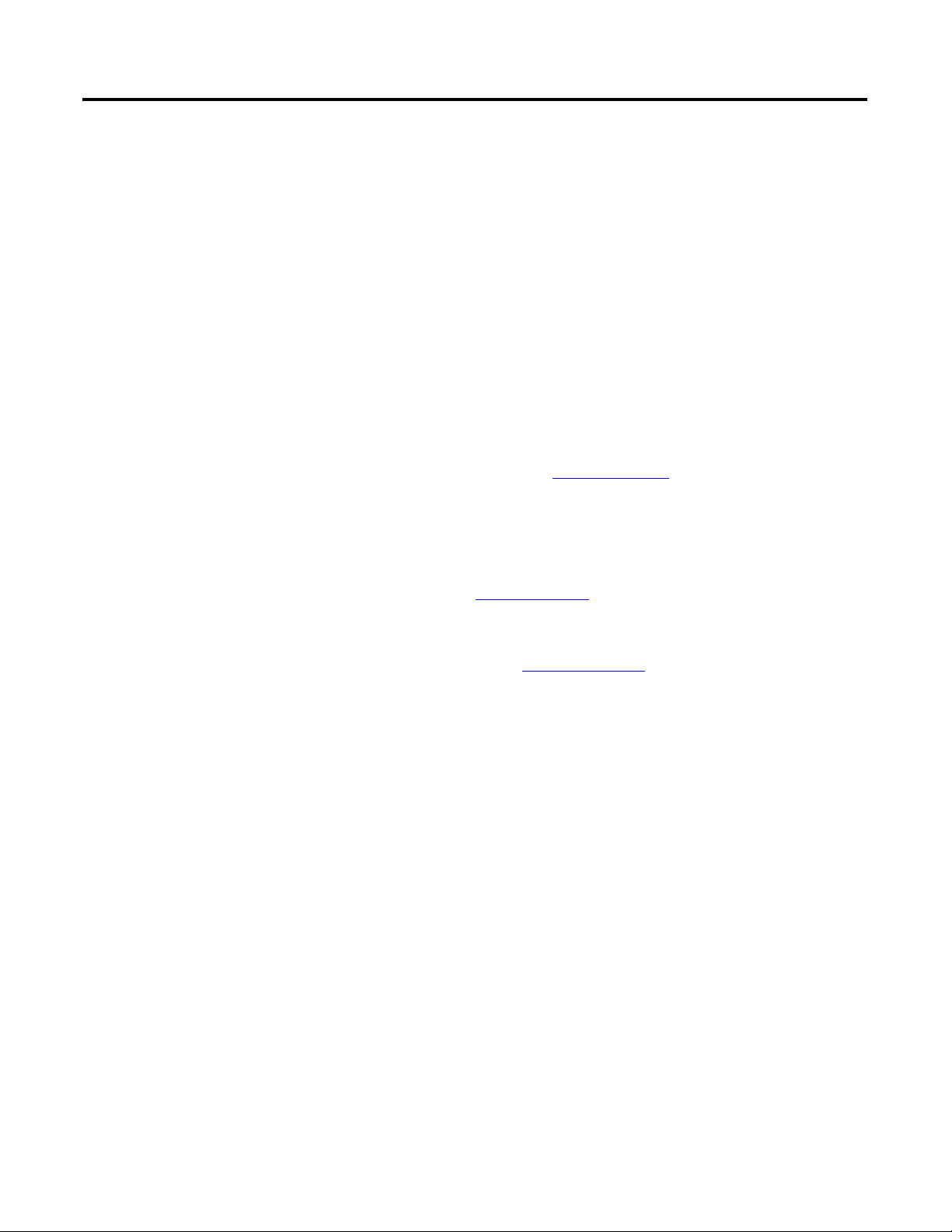

Open FANUC CNC

Express Software

page 22

Create CNC System Bill

of Materials

page 23

Review System Selection

and Configuration Tools

page 19

page 28

Create Supervisory

Controller and Safety

System Bill of Materials

Follow These Steps

Complete the following steps to create a bill of materials for your CNC system.

Start

18 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 19

Architecture and Hardware Selection Chapter 1

Review System Selection and Configuration Tools

This section provides and overview of the FANUC and Rockwell Automation system selection and

configuration tools that you may need for your FANUC configuration.

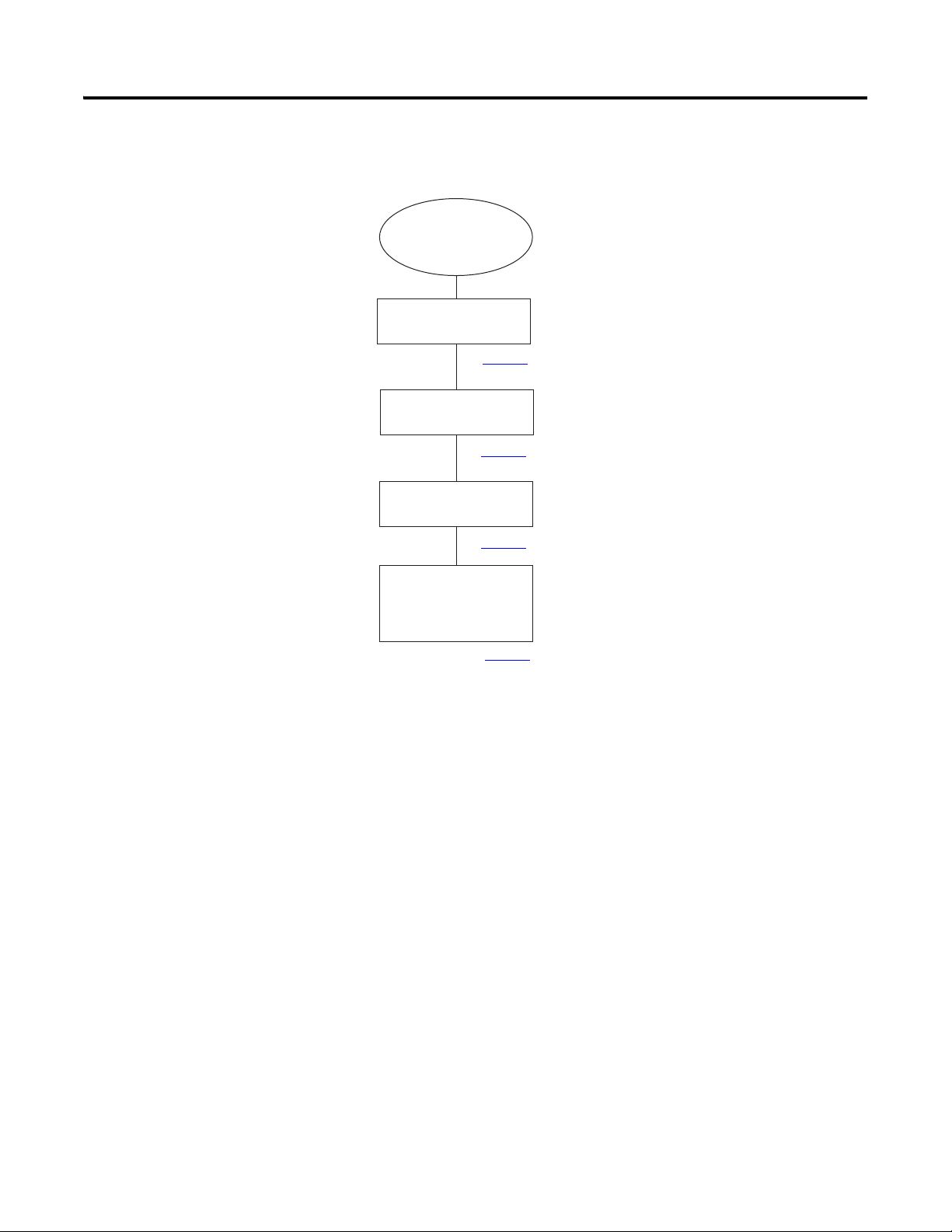

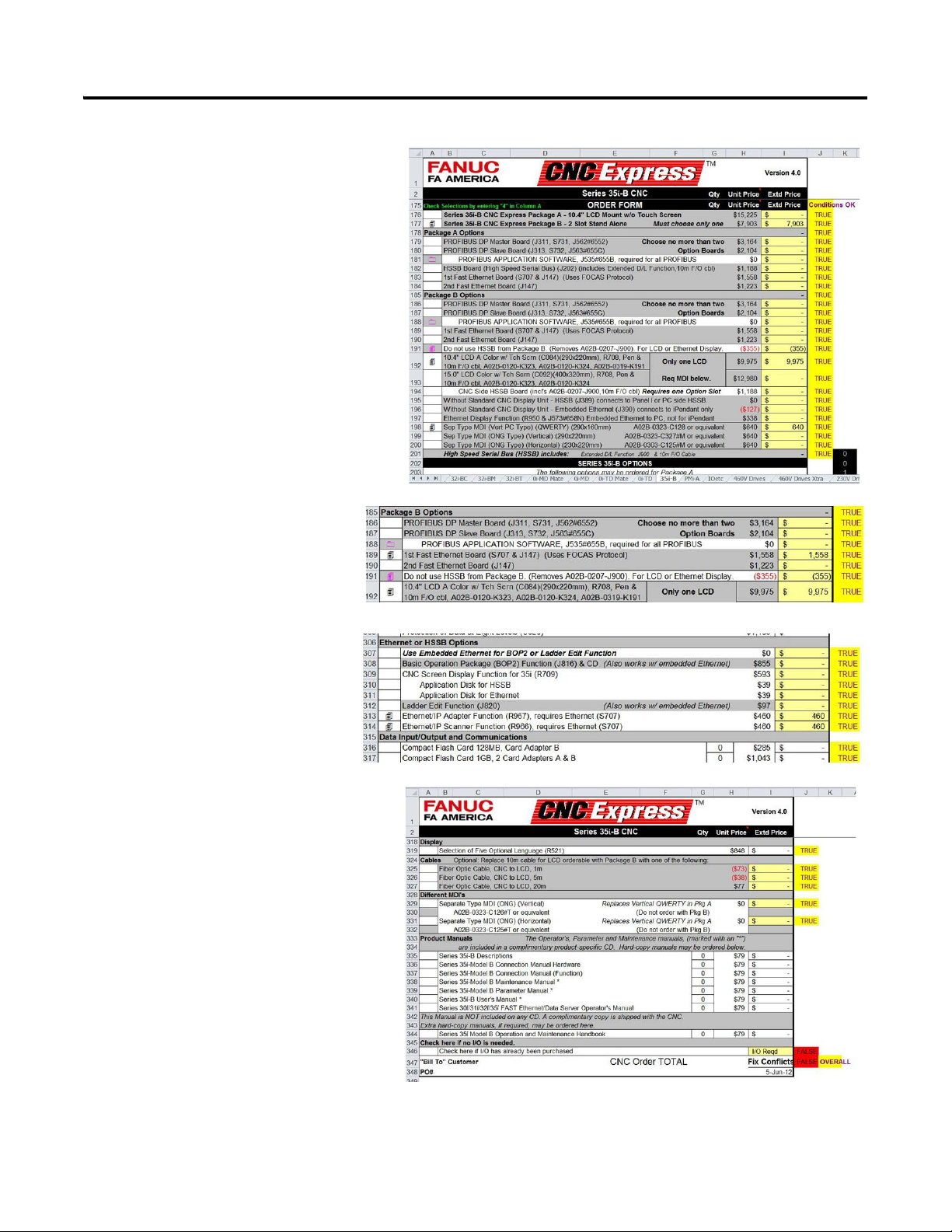

FANUC CNC Express Software

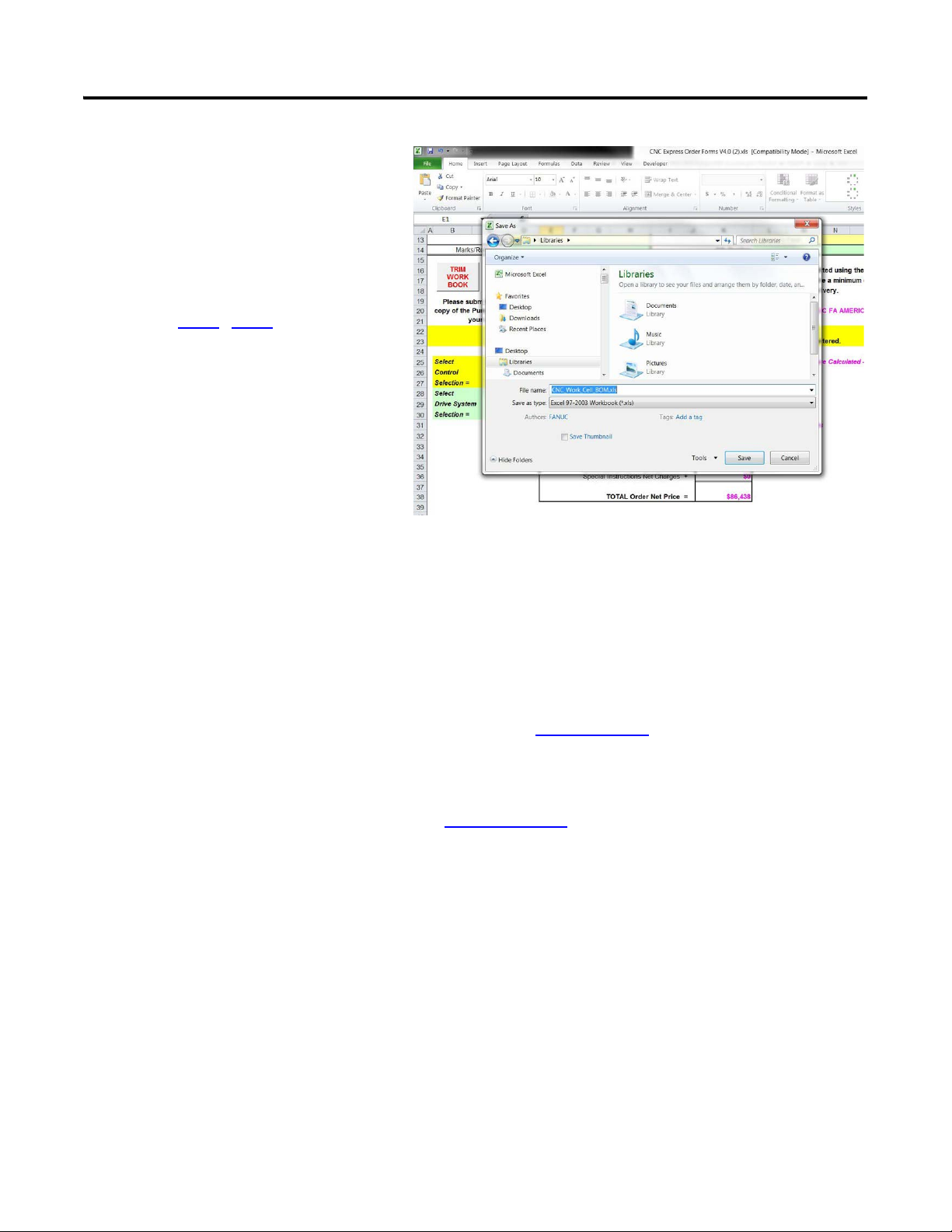

The Excel workbook CNC Express Order

Forms.xls contains the product information

and the actual order forms. Each worksheet

represents a certain product and contains the

relevant order guide information for the

product selections offered in that worksheet,

and is followed by the order form. To order

from this workbook, you make simple product

selections by using check marks, and the

workbook does the rest of the work.

Rockwell Automation DMAT Wizard Software

The Drives and Motion Accelerator Toolkit

(DMAT) Wizard software provides a

streamlined way of creating a bill of

material, assembling a system drawing set,

and creating a RSLogix 5000 project file

with a preconfigured controller, network,

drives, and initial system program logic.

This can be accomplished in minutes by

inserting simple system and drive

configuration entries, and running other

system selection tools as needed.

You can access this software tool on the

Drives and Motion Accelerator Toolkit

DVD, publication IASIMP-SP017.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 19

Page 20

Chapter 1 Architecture and Hardware Selection

Rockwell Automation Safety Selection Tools

The Safety Accelerator Toolkit provides a

number of software selection tools to assist

in hardware selection and performance

estimation for your safety systems. You may

access these software tools within the

Safety Accelerator Toolkit DVD,

publication SAFETY-CL002.

20 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 21

Rockwell Automation Product Selection Toolbox

The Rockwell Automation Product Selection Toolbox

(PST) offers a complete suite of user tools for product

selection and configuration across produc t lines from

project conception through final design. From push

buttons to drives to motor control centers and fully

networked control systems, you’ll find the product

information and configuration assistance you need to

help you and your customers succeed with Rockwell

Automation.

• Provides access to information on a broad range of

Allen-Bradley® products and services

• Easy product selection inter face to make it a snap to

determine the exact catalog numbers for the item

you need

• Access to current list pricing, and a comprehensive

supplemental product information list

• Contains features, such as product selection wizards,

agreement pricing, a spare parts generator, and the

ability to separate par t numbers to see what

Rockwell Automation components comprise them

• All of these features and more can help you select

the correct product based on your requirements and

give your customers the information they need fast

• Lets you quickly develop Logix/NetLinx control

system configurations with BOM and reports

• Integration with configurator allows configuration

of PowerFlex drives and ArmorStart motor

controllers

• Motion control drive/motor combinations and

accessories can be added through links to Motion

Analyzer software

• New Ethernet capabilities include Stratix™ switches

and physical media with enhanced graphical views

• IAB output can be easily exported to ProposalWorks

to take advantage of extended proposal generation

features, and supplementary data

Product Selection & System Design Tools

• Assists the user in selecting correct motor for application, proper drive, and gearbox

(if required)

• Effective optimization capabilities allow user to get the most out of the selected

motor and drive combination

• Allows users to have the most up-to-date applications, product, price, and

supplementary information

• All programs are scheduled for update every three weeks

• Assists in crossing competitive part numbers to Rockwell Automation equivalents

• Gives users the ability to submit crosses directly to PST and they will provide a cross or users

can go to: ab.com/e-tools

and look up existing cross references in the database

• Allows you select product 3D CAD drawings in AutoCAD software

• Provides you with access to thousands of drawings for a wide range of Allen-Bradley

products as well as assistance configuring catalog numbers

• Helps you configure Motor Control Syste m starters for rated motor voltages from 230… 690V

• Program provides the correct catalog number, wiring diagram, and layout drawing for starters

of your choice

• Provides assistance in selecting and dimensioning all of required busbar rack components

• Simplifies the design of custom terminal block rails

• Allows you to select and place terminal blocks on mounting rail along with

specifying labeling of terminal blocks, locating jumper bars between blocks,

automatically selecting end barriers, and partition plates

• Intuitive software application designed specifically for configuring Motor

Control Centers

• User friendly interface helps reduce error and enables customers to get their

MCCs quickly

Architecture and Hardware Selection Chapter 1

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 21

Page 22

Chapter 1 Architecture and Hardware Selection

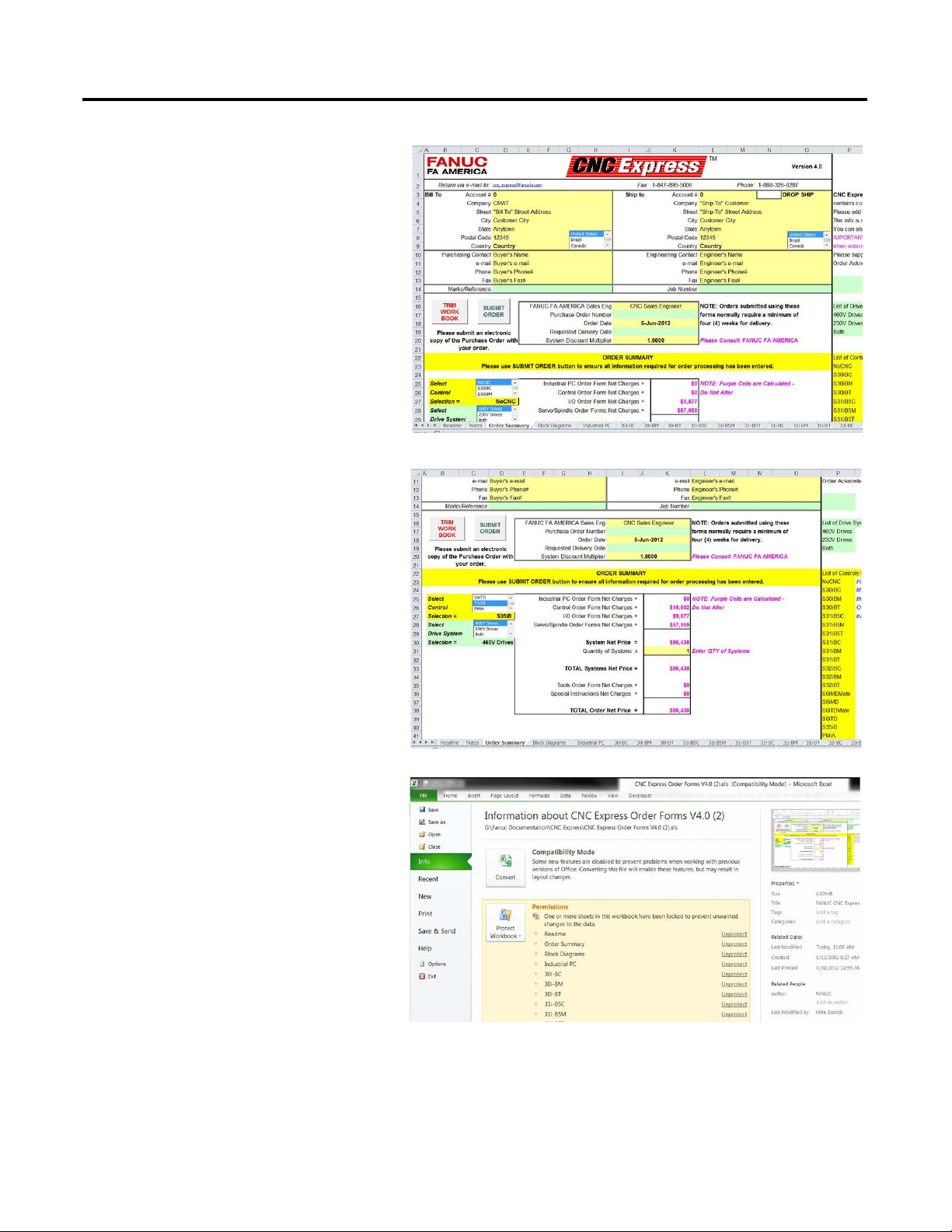

Open FANUC CNC Express Software

1. Navigate to and choose the CNC

Express application,

CNC_Work_Cell_BOM.xlsx,

on the CNC Machining Accelerator

Toolkit DVD.

The initial CNC Express dialog box

opens.

22 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 23

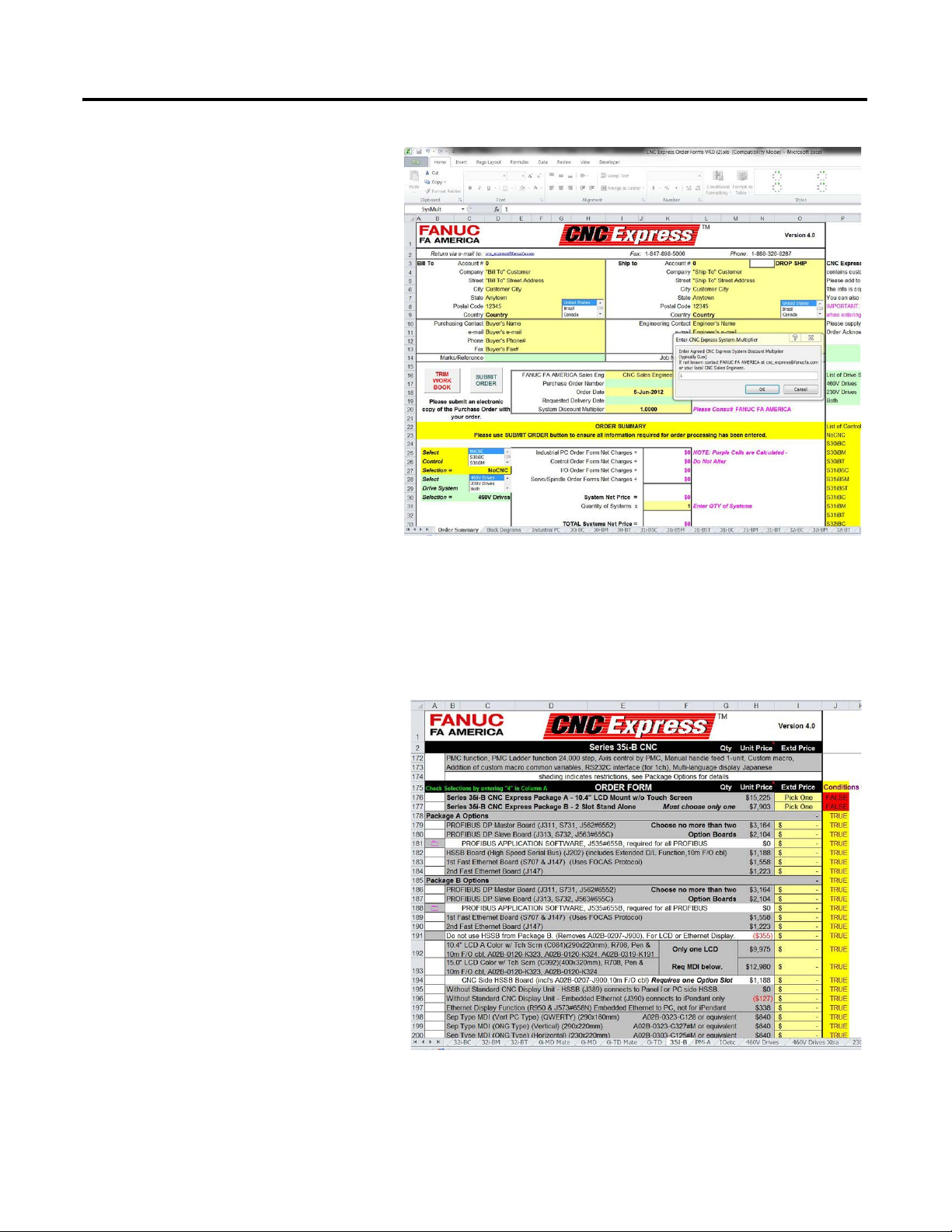

2. Click continue to leave the links as

they are. The multiplier pop up

window will then be displayed.

3. Add the multiplier that has been

approved by FANUC, and then click

OK. You are now ready to begin

creating the bill of materials (BOM).

Architecture and Hardware Selection Chapter 1

Create CNC System Bill of Materials

1. Select the CNC model, and display

options.

a. Use the tabs near the bottom of the

spreadsheet to navigate to and

select the appropriate CNC model,

based on your machining

requirements.

For the CNC Work Cell example, a

35i-B CNC is selected.

The 35i-B tab is displayed.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 23

Page 24

Chapter 1 Architecture and Hardware Selection

TIP

b. Use the cells in the spreadsheet to

navigate to and select the

appropriate CNC package, based

on your specific application

requirements.

The 35i-B selections are displayed.

c. Use the cells in the

spreadsheet to navigate to

and select the appropriate

EtherNet/IP options.

d. Use the cells in the spreadsheet to

navigate to and select the

appropriate displays and options.

When all options are selected the

cell at the bottom of the tab (J347)

will display either a TRUE

OVERALL or FALSE

OVERALL status. Make the

appropriate corrections until the

status reads TRUE OVERALL.

The Status is FALSE until the I/O

selection has been satisfied in

the next step.

The 35i-B configuration is now complete.

24 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 25

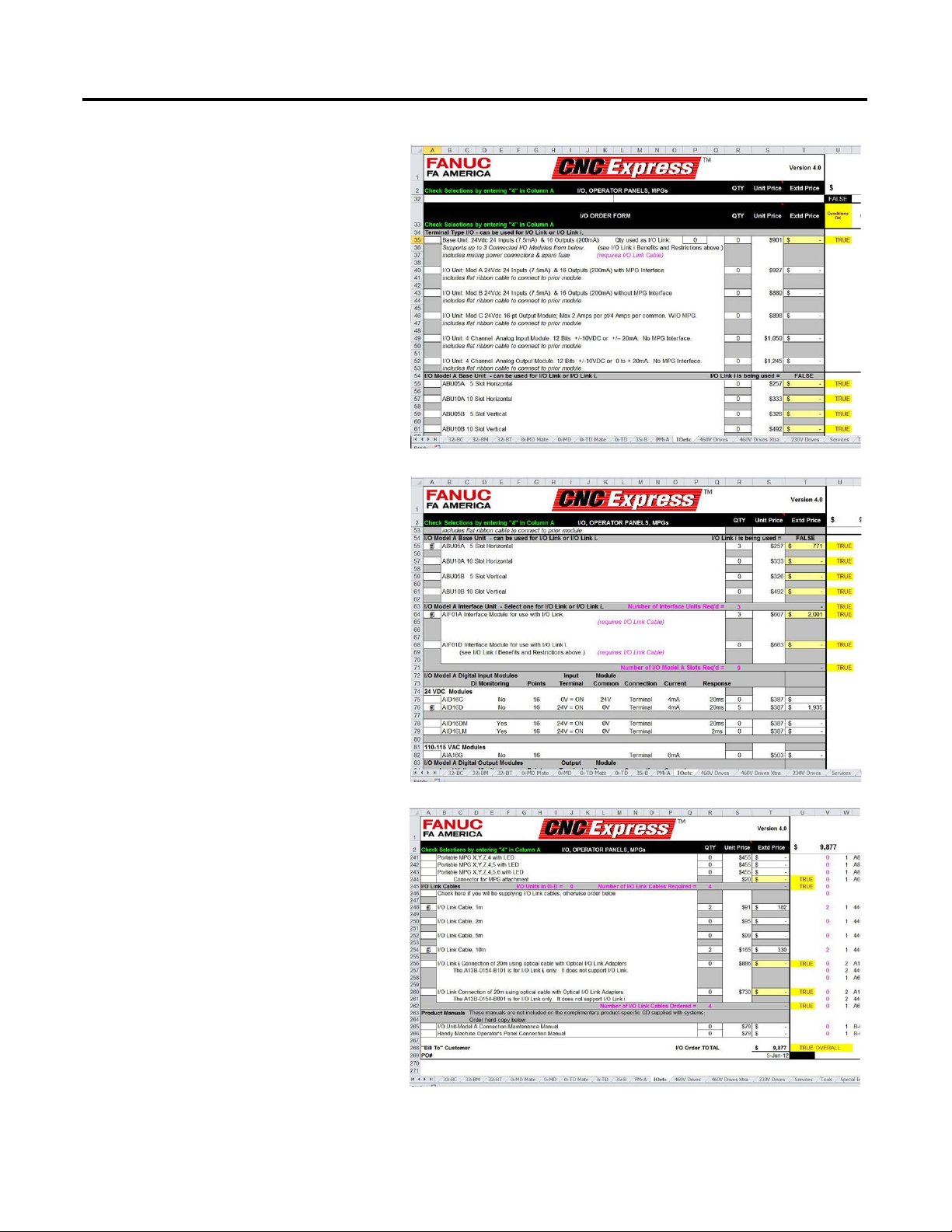

2. Select the System I/O.

TIP

a. Use the tabs near the bottom of the

spreadsheet to navigate to and select

the IOetc tab, for I/O selection.

The IOetc tab is displayed.

b. Use the cells in the spreadsheet to

navigate to and select the

appropriate I/O modules, based on

your specific application

requirements.

Architecture and Hardware Selection Chapter 1

The 35i-B selections are displayed.

c. Use the cells in the spreadsheet to

navigate to and select the

appropriate I/O and options.

When all options are selected the

cell at the bottom of the tab (U268)

will display either a TRUE

OVERALL or FALSE OVERALL

status. Make the appropriate

corrections until the status reads

TRUE OVERALL.

The Status is FALSE until the

I/O selection has been satisfied

in the next step.

The I/O configuration is now complete.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 25

Page 26

Chapter 1 Architecture and Hardware Selection

3. Select the drives and motors for the

application

a. Use the tabs near the bottom of the

spreadsheet to navigate to and

select the appropriate voltage for

the drives, based on your system

power voltage.

For the CNC Work Cell example,

460V drives is selected.

The 460V drives tab is displayed.

b. Use the cells in the spreadsheet to

navigate to and select the

appropriate motors and drives,

based on your specific application

requirements.

The 460V drives selections are

displayed.

c. Use the cells in the spreadsheet to

navigate to and select the

appropriate motor and drive

options. When all options are

selected the cell at the bottom of the

tab (U801) will display either a

TRUE OVERALL or FALSE

OVERALL status. Make the

appropriate corrections until the

status reads, TRUE OVERALL.

The 460V drives configuration is now

complete.

26 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 27

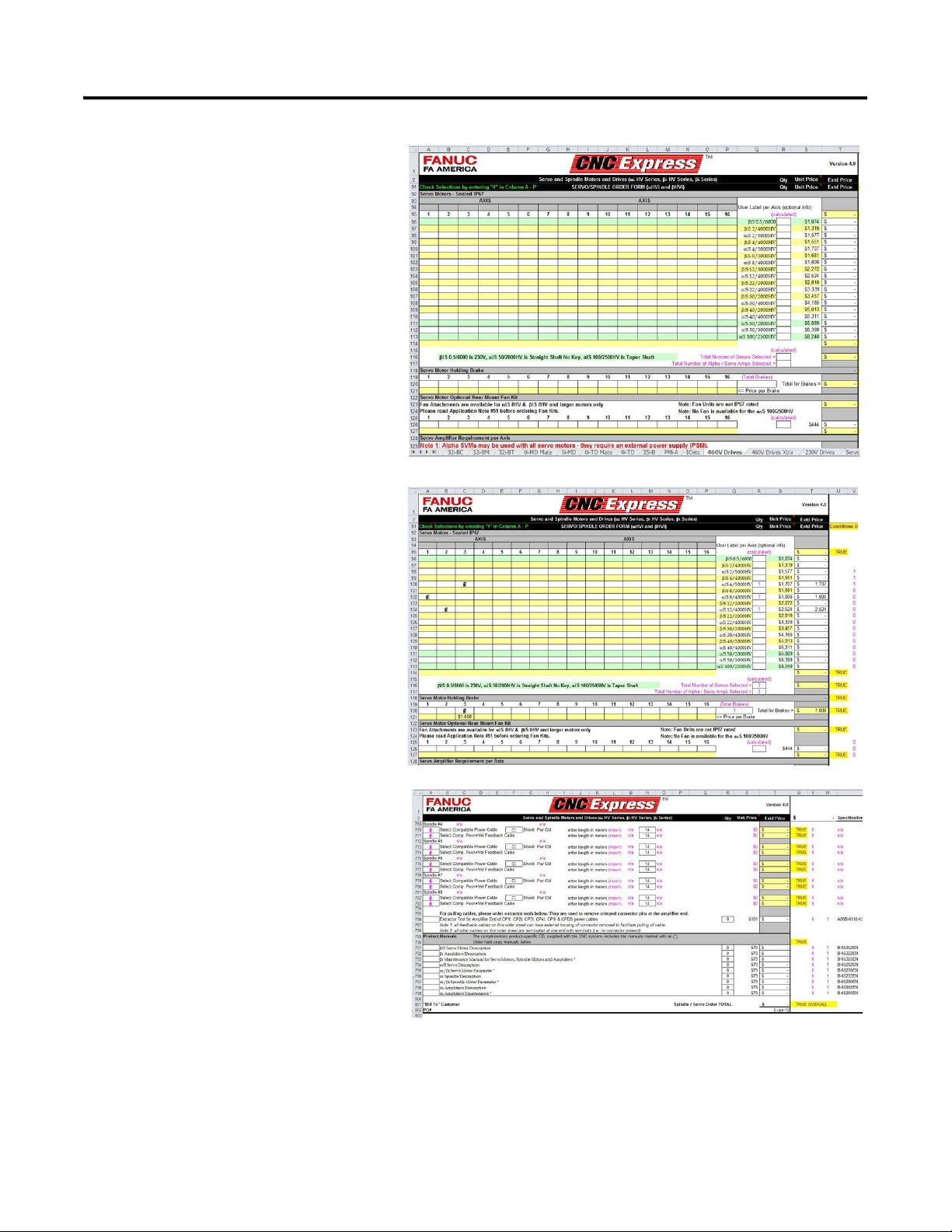

4. Review the complete CNC

configuration.

a. Use the tabs near the bottom of the

spreadsheet to navigate to and click

the Summary tab.

The Summary tab is now displayed.

b. Use the cells in the spreadsheet to

navigate to and select the

appropriate CNC control, and drive

system selection. When the system

is configured properly, the pricing is

shown. If the configured solution is

not correct, fix conflicts are

displayed in the value fields.

Architecture and Hardware Selection Chapter 1

The CNC BOM configuration is

now complete.

5. Name and save the BOM project file.

a. From the File menu, choose Save

As.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 27

Page 28

Chapter 1 Architecture and Hardware Selection

b. Type a new BOM project file name.

By creating a new BOM project file

specifically for your application, you

preserve the initial toolkit file for

future reference.

In this example, the file was named

CNC_Work_Cell_BOM.

6. Repeat step 1…step 5 for each CNC in

your system.

The BOMs can now be submitted to

FANUC for purchase. We recommend that

your local FANUC representative review

and approve the configuration prior to

purchase.

Create Supervisory Controller and Safety System Bill of Materials

Refer to the Drives and Motion Accelerator Toolkit for creating a supervisory controller bill of materials that

includes Rockwell Automation Kinetix or PowerFlex drives. For a copy of the DVD, contact your local Rockwell

Automation distributor or sales representative.

• Drives and Motion Accelerator Toolkit DVD, publication IASIMP-SP017.

Refer to the Safety Accelerator Toolkit for creating a safety system bill of materials that includes Rockwell

Automation GuardLogix controller and Guard I/O.

• Safety Accelerator Toolkit DVD, publication SAFETY-CL002.

28 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 29

Chapter

CNC Power Example

CNC I/O Example

CNC System Layout Example

2

System Layout and Wiring

In this chapter you select CNC layout and wiring drawings from a library of drawings in AutoCAD .dwg, .dxf, or

.pdf formats to start your system drawing set. If you are using AutoCAD or AutoCAD Electrical software, you

can also take advantage of the drawing editing steps included in this chapter. The library’s device wiring

references and attributes move with the devices as you edit your power drawing set.

You will use the Drives and Motion Accelerator Toolkit DVD, publication IASIMP-SP017, and/or Safety

Accelerator Toolkit DVD, publication SAFETY-CL002, to assemble your drawing set for the Rockwell

Automation components in your system.

Figure 2 - CNC Power, I/O, and Layout Drawing Examples

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 29

Page 30

Chapter 2 System Layout and Wiring

This section uses the CNC Work Cell application example to help you understand how to use the drawing

libraries. The CNC Work Cell includes the following main devices:

• Two FANUC 35i-B CNC systems

• Two Kinetix 6500 servo drives and motors

• One GuardLogix safety controller and EtherNet/IP network module

Before You Begin

Complete your system architecture and hardware selection (see Chapter 1).

What You Need

• CNC Machining Accelerator Toolkit DVD, publication IASIMP-SP018. For a copy of the DVD, contact

your local Rockwell Automation distributor or sales representative.

• AutoCAD Electrical software to open the DWG or DXF files.

• Adobe Reader software to open PDF files.

• System Design for Control of Electrical Noise Reference Manual, publication GMC-RM001.

• System Design for Control of Electrical Noise Video, publication GMC-SP004.

• If Rockwell Automation Kinetix or PowerFlex Drives are used in the system, the Drives and Motion

Accelerator Toolkit DVD is required, publication IASIMP-SP017. For a copy of the DVD, contact your

local Rockwell Automation distributor or sales representative.

• If Rockwell Automation GuardLogix safety controller and safety components are used in the system, the

Safety Accelerator Toolkit DVD is required, publication SAFETY-CL002. For a copy of the DVD,

contact your local Rockwell Automation distributor or sales representative.

30 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 31

Follow These Steps

TIP

Start

page 31

Select FANUC CNC Drawings

from Drawing Library

page 34

Edit FANUC CNC Drawing Set

Assemble and Edit Your

GuardLogix System Drawing Set

page 44

Complete the following steps to create your system layout and wiring drawings.

System Layout and Wiring Chapter 2

Select FANUC CNC Drawings from Drawing Library

The CNC drawing library is organized by these drawing file types:

• AutoCAD Electrical .dwg

• AutoCAD .dxf

• Adobe PDF

The drawings are examples only, and may not reflect your application. There are many different models of

FANUC CNCs and drive combinations available. This toolkit does not detail all possible combinations. This

toolkit uses the 35i-B CNC as an example.

If you do not have CAD software that is compatible with the .dwg/.dxf formats, the PDF files provide an excellent

reference library for wiring all your system devices.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 31

Page 32

Chapter 2 System Layout and Wiring

1. Create a project folder.

For the CNC Work Cell

example, the

CNC_Work_Cell folder was

created.

2. Browse to the CNC CAD

Drawing Library on the

CNC toolkit DVD and

select the DWG Format

Drawings, DXF Format

Drawings, or PDF Format

Drawings directory.

Each drawings directory include these files in their respective

files formats.

All drawings are associated with the FANUC CNCs, with the

exception of these three drawings:

• The 07_PLC_1791DS_IB16 and

11_PLC_1791DS_IB4XOW4 drawings are examples of

Rockwell Automation Guard I/O showing the safety I/O

interface with the FANUC Dual Check I/O.

• The 15_CNC_Ethernet_Communication drawing includes

an example of EtherNet/IP communication with the

Rockwell Automation GuardLogix controller, PanelView

Plus, and Kinetix/PowerFlex drives.

32 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 33

3. Copy the entire set of drawings in this folder.

4. Paste the drawing you copied into the

Project Drawings folder.

System Layout and Wiring Chapter 2

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 33

Page 34

Chapter 2 System Layout and Wiring

Edit FANUC CNC Drawing Set

These steps provide general instructions for how to maximize the use of the toolkit’s drawing library in creating a

complete CNC system layout and wiring drawing set. We recommend AutoCAD or AutoCAD Electrical

software to take full advantage of the drawing editing steps and the library’s device wiring references and

attributes that move with the devices as you edit your project drawing set. Some of the initial project creation

steps are illustrated by using AutoCAD Electrical software, but most are generic and can be used with a variety of

software drawing packages.

Create a New Project

1. Open your drawing software.

2. Create and name your new project.

3. Add and select the toolkit library drawings

you copied in the previous section.

34 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 35

System Layout and Wiring Chapter 2

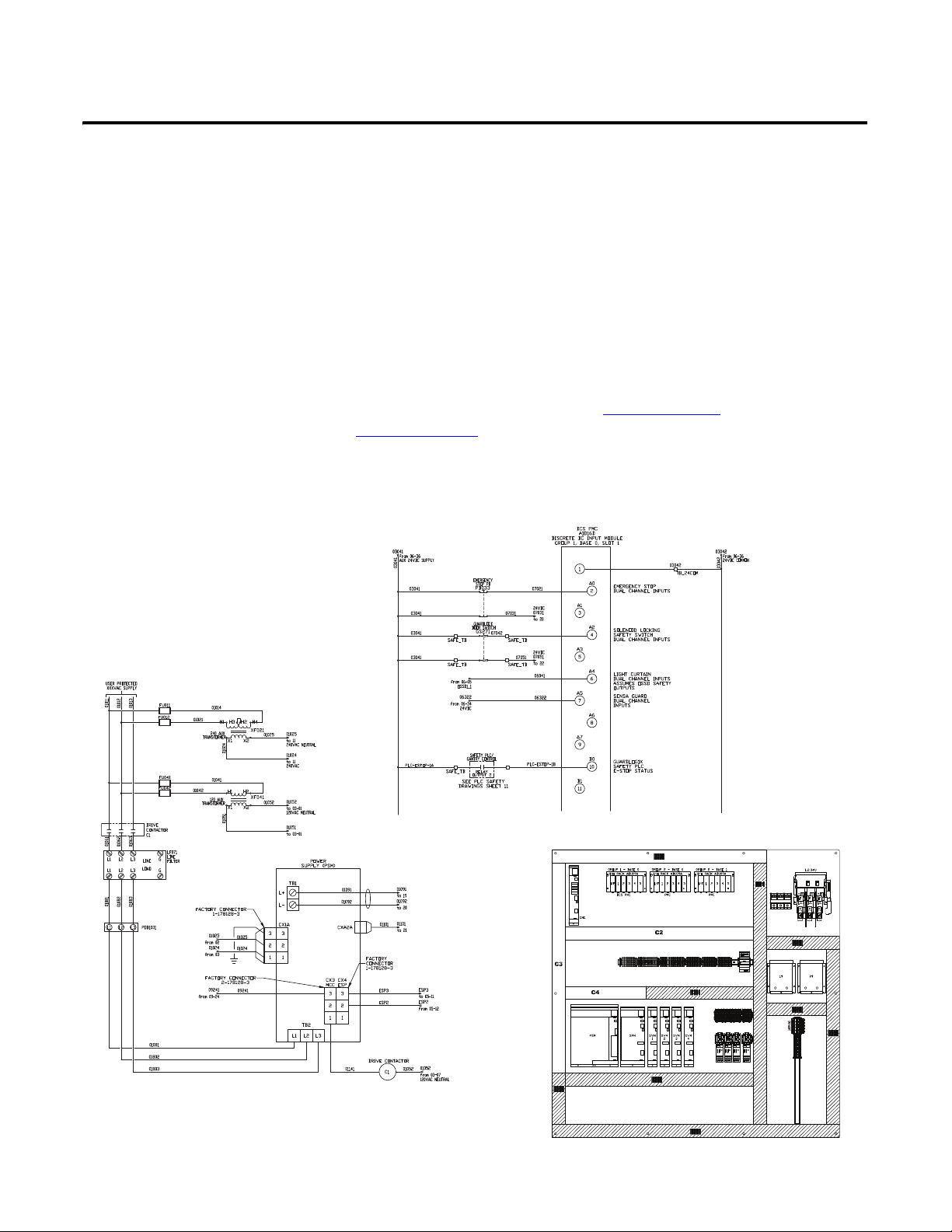

Edit CNC Power Drawings

1. Open your initial CNC power drawing that includes the main power distribution components,

01_CNC_Drives_w_Dual Check IO.dwg. See Figure 3 on page 36.

2. Modify this drawing for your project.

The 01_CNC_Drives_w_Dual Check IO includes the main power distribution components as well as the

CNC power supply, one spindle module and motor, and one servo module and motor. Typically you

would have at least these components in each of your CNC systems. Copy this drawing for every CNC you

have in your system.

For the CNC Work Cell application example, there are two FANUC CNC systems, so this drawing would

be copied for the second CNC system.

3. Open the 02_CNC_Drives_w_Dual_Check_IO drawing and modify for your project. See Figure 4 on

page 37.

The 02_CNC_Drives_w_Dual_Check_IO drawing includes three additional servo modules and motors.

You will most likely copy this drawing for every CNC you have in your system. Delete the servos and

motors not required for you system.

For the CNC Work Cell application example there are two FANUC CNC systems, so this drawing would

be copied for the second CNC system, and one spindle module and motor would be deleted from each

drawing.

4. Open the remaining CNC control power distribution drawings and edit power connections and devices as

necessary.

The drawings include:

• 03_CNC_Control_Power_Distribution

• 04_CNC_Control_Power_Distribution

• 05_CNC_Monitored_Safety_Relay

• 06_CNC_24VDC_Safety_Power

• 17_CNC_Power_Connections

• 18_CNC_Cable_Connections

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 35

Page 36

Chapter 2 System Layout and Wiring

Figure 3 - 01_CNC_Drives_w_Dual Check IO Drawing

36 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 37

Figure 4 - 02_CNC_Drives_w_Dual Check IO Drawing

System Layout and Wiring Chapter 2

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 37

Page 38

Chapter 2 System Layout and Wiring

Edit CNC Safety and Standard I/O Drawings

1. If FANUC Dual Check Safety is incorporated into your project, open the following drawings for your

project:

• 07_CNC_AID16D_Dual_Check_IO_Module

• 08_CNC_AID16D_Dual_Check_IO_Module

• 09_CNC_AOR8G_Dual_Check_IO_Module

2. Modify your Dual Check safety input module drawings.

The Dual Check safety input module drawings 07_CNC_AID16D_Dual_Check_IO_Module and

08_CNC_AID16D_Dual_Check_IO_Module include a variety of input device examples to include in

your drawing set.

a. Copy and paste input devices to match your application. See Figure 5 on page 39.

In addition to safety devices, the 07_CNC_AID16D_Dual_Check_IO_Module drawing includes

example dual channel connections from the GuardLogix Guard I/O outputs.

3. Modify your Dual Check safety output module drawing.

The Dual Check safety output module drawing, 09_CNC_AOR8G_Dual_Check_IO_Module includes

a few output device examples to include in your drawing set.

a. Copy and paste output devices to match your application. See Figure 6 on page 40

In addition to safety devices the 09_CNC_AOR8G_Dual_Check_IO_Module drawing includes example

dual channel connections to the GuardLogix Guard I/O inputs.

4. If using GuardLogix as a supervisory safety controller for your CNC cell in your project, then open and

modify the following drawings for your project:

• 07_PLC_1791DS_IB16

• 11_PLC_1791DS_IB4XOW4

These drawings show examples of the dual channel input and output connections from the FANUC Dual

Check Safety I/O.

You may copy these connections to other Guard I/O modules within the Safety Accelerator Toolkit

drawings.

5. Open and modify the following standard CNC I/O drawings for your project:

• 12_CNC_AOR16G_Output_Module

• 13_CNC_Digital_Inputs

• 14_CNC_Relay_Outputs

These drawings include a variety of input and output device examples to include in your drawing set.

38 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 39

Figure 5 - 07_CNC_AID16D_Dual_Check_IO_Module Drawing

System Layout and Wiring Chapter 2

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 39

Page 40

Chapter 2 System Layout and Wiring

Figure 6 - 09_CNC_AOR8G_Dual_Check_IO_Module Drawing

40 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 41

System Layout and Wiring Chapter 2

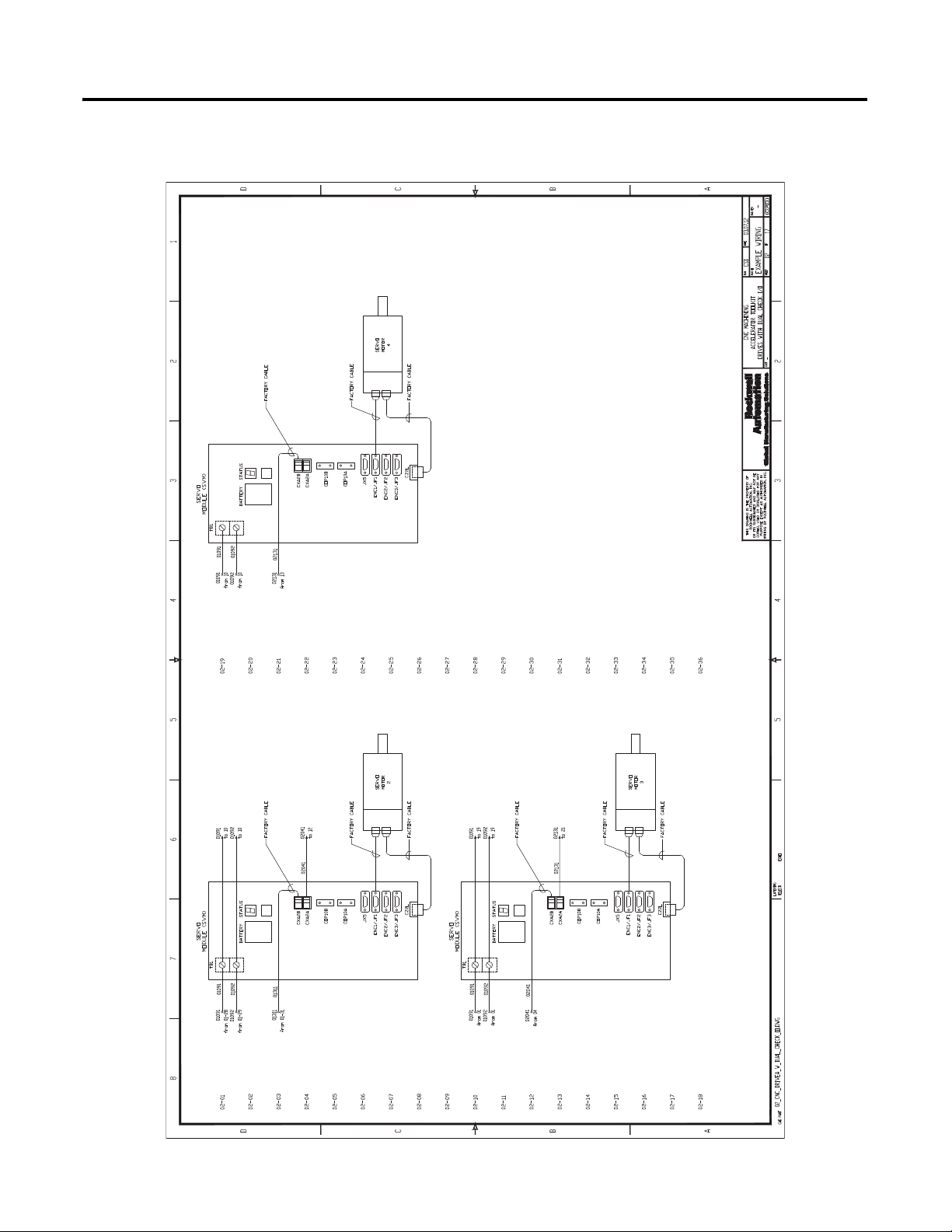

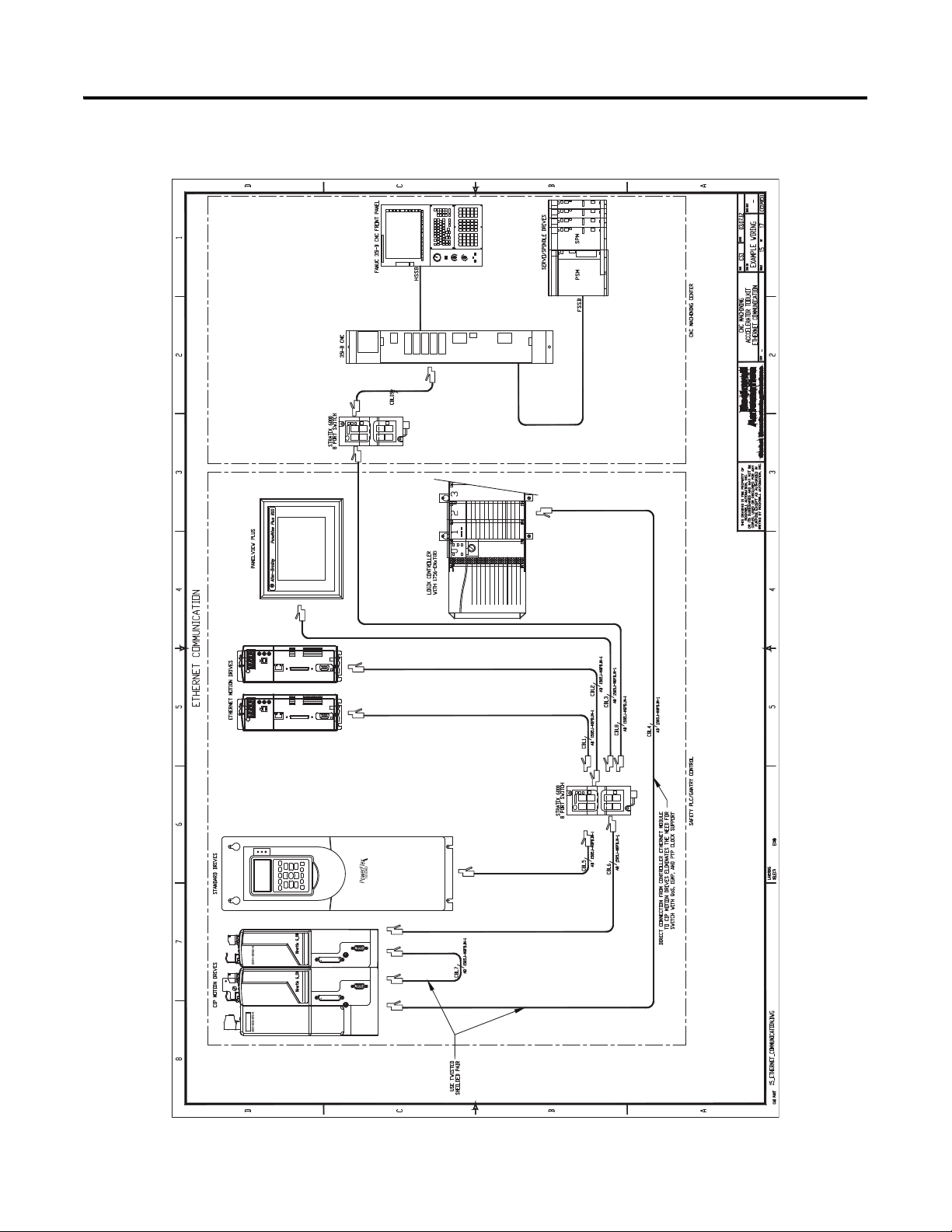

Edit System Communication Drawings

1. Open the following communication drawings to access your project's EtherNet/IP configuration drawings:

• 15_CNC_Ethernet_Communication

• 16_CNC_Ethernet_Switch

• 18_CNC_Cable_Connections

2. Delete and or copy network devices to match your system requirements.

The 15_CNC_Ethernet_Communication drawing is shown in Figure 7 on page 42. It includes both

FANUC CNC system and Rockwell Automation GuardLogix, PanelView, and Kinetix/PowerFlex Drive

EtherNet/IP connections. Simply delete and/or copy EtherNet/IP devices to match your project

requirements.

The 16_CNC_Ethernet_Switch and 18_CNC_Cable_Connections drawings include references to

FANUC CNC system and Rockwell Automation EtherNet/IP devices, cables, and connections. Delete

and or copy components to match your project requirements.

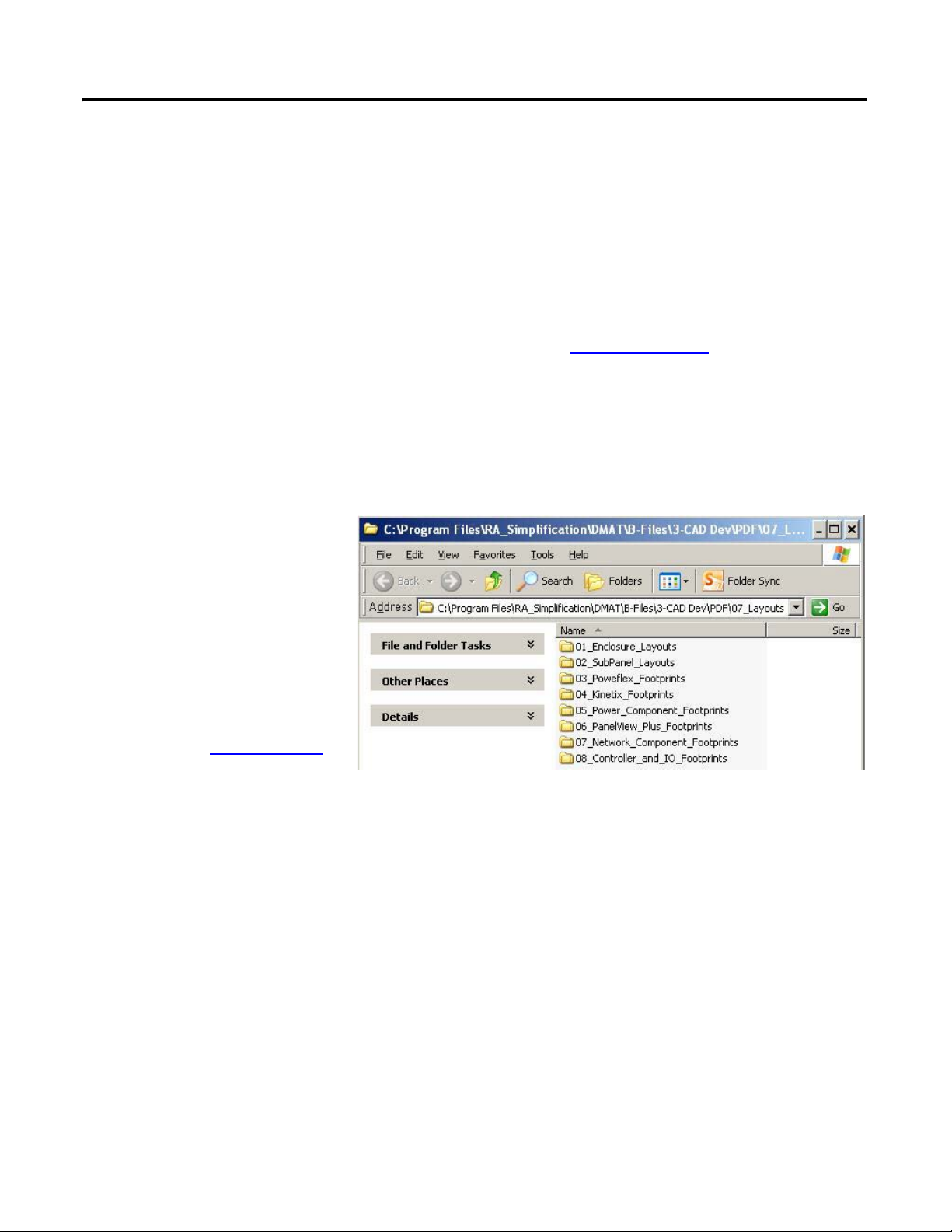

3. Access other Rockwell

Automation device footprints

required for your application.

To access Rockwell

Automation Kinetix or

PowerFlex drive system

footprints, including HMI

and other power components,

use the Drives and Motion

Accelerator Toolkit DVD,

publication IASIMP-SP017.

Navigate to the CAD drawing

libraries layout section

directories for a variety of

device footprints.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 41

Page 42

Chapter 2 System Layout and Wiring

Figure 7 - 15_CNC_Ethernet_Communication Drawing.

42 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 43

Edit CNC System Layout Drawing

CNC Subpanel Layout Drawing

CNC Enclosure Layout Drawing

1. Open the panel layout drawing for your application.

For the CNC Work Cell application example, the

19_CNC_Panel_Layout.dwg file is opened.

The panel layout drawing includes sub-panel and enclosure

drawings. The panel is designed to accommodate

best-practice techniques used to minimize electrical noise.

Refer to the System Design for Control of Electrical Noise

Reference Manual, publication GMC-RM001.

2. Delete, replace, or add

component footprints to your

panel layout drawing.

System Layout and Wiring Chapter 2

To access Rockwell

Automation power

components, use the Drives

and Motion Accelerator

Toolkit DVD, publication

IASIMP-SP017. Navigate to

the CAD drawing libraries

layout section directories for a

variety of device footprints.

3. Delete, replace, or add

components to your

enclosure drawing.

To access Rockwell

Automation HMI or power

components, use the Drives

and Motion Accelerator

Toolkit DVD, publication

IASIMP-SP017

the CAD drawing libraries

layout section directories for

a variety of device footprints.

. Navigate to

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 43

Page 44

Chapter 2 System Layout and Wiring

LIM Module

AC Line Filter

System Layout Example

Drive Power Example

Drive I/O Example

Assemble and Edit Your GuardLogix System Drawing Set

If Rockwell Automation Kinetix and PowerFlex drives are to be used in your system, use the Drives and Motion

Accelerator Toolkit DVD, publication IASIMP-SP017, to assemble and edit your GuardLogix system drawing

set. For a copy of the DVD, contact your local Rockwell Automation distributor or sales representative.

44 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 45

System Layout and Wiring Chapter 2

Drive Safety Wiring

Title

Safety Controller Power

Other Safety Devices

Guard I/O Module Wiring

Drive I/O

Safety Controller Network Drawings

Safety Controller I/O

Ethernet Switch Wiring

Panel Layout Drawings

If Rockwell Automation GuardLogix safety controller and safety components are used in the system, use the

Safety Accelerator Toolkit DVD, publication SAFETY-CL002, to assemble your safety wiring and layout

drawing set. For a copy of the DVD, contact your local Rockwell Automation distributor or sales representative.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 45

Page 46

Chapter 2 System Layout and Wiring

Notes:

46 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 47

Chapter

3

FANUC CNC Configuration

In this chapter you initially configure your FANUC 30i-B, 31i-B, 32i-B, or 35i-B CNC, set up the CNC

communication, and create a new project file for your CNC application. The intent is to provide a quick setup

for an EtherNet/IP connection between a Rockwell Automation ControlLogix/GuardLogix PLC and a

FANUC 30i-B, 31i-B, 32i-B, or 35i-B CNC.

The overall CNC configuration and parameterization is not being addressed by this quick start, and is the

responsibility of the machine tool builder.

Before You Begin

• Complete your system architecture and hardware selection (refer to Chapter 1).

• Complete your system layout and wiring (refer to Chapter 2).

What You Need

• The CNC Machining Accelerator Toolkit DVD, publication IASIMP-SP018. For a copy of the DVD,

contact your local Rockwell Automation distributor or sales representative

• FANUC LADDER III software, version 6.8 or later

• USB flash drive

• FANUC Series 30i/31i/32i/35i –MODEL B, EtherNet/IP Adapter function, publication

TMN11003E_B-64014EN@04-2.pdf

• FANUC Series 30i/31i/32i/35i -MODEL B, FANUC Power Motion i -MODEL A EtherNet/IP Scanner

function, publication TMN11095E_B-64014EN@04-3.pdf

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 47

Page 48

Chapter 3 FANUC CNC Configuration

Start

Initial FANUC CNC

Configuration

page 48

Logic Configuration

page 68

Follow These Steps

Complete these steps to configure your FANUC 30i-B, 31i-B, 32i-B, or 35i-B CNC for your application.

Initial FANUC CNC Configuration

In this example, you set up your FANUC 30i-B, 31i-B, 32i-B, or 35i-B CNC to allow configuration parameters

to be modified, to receive configuration parameters from external sources, and to select the high speed Ethernet

option.

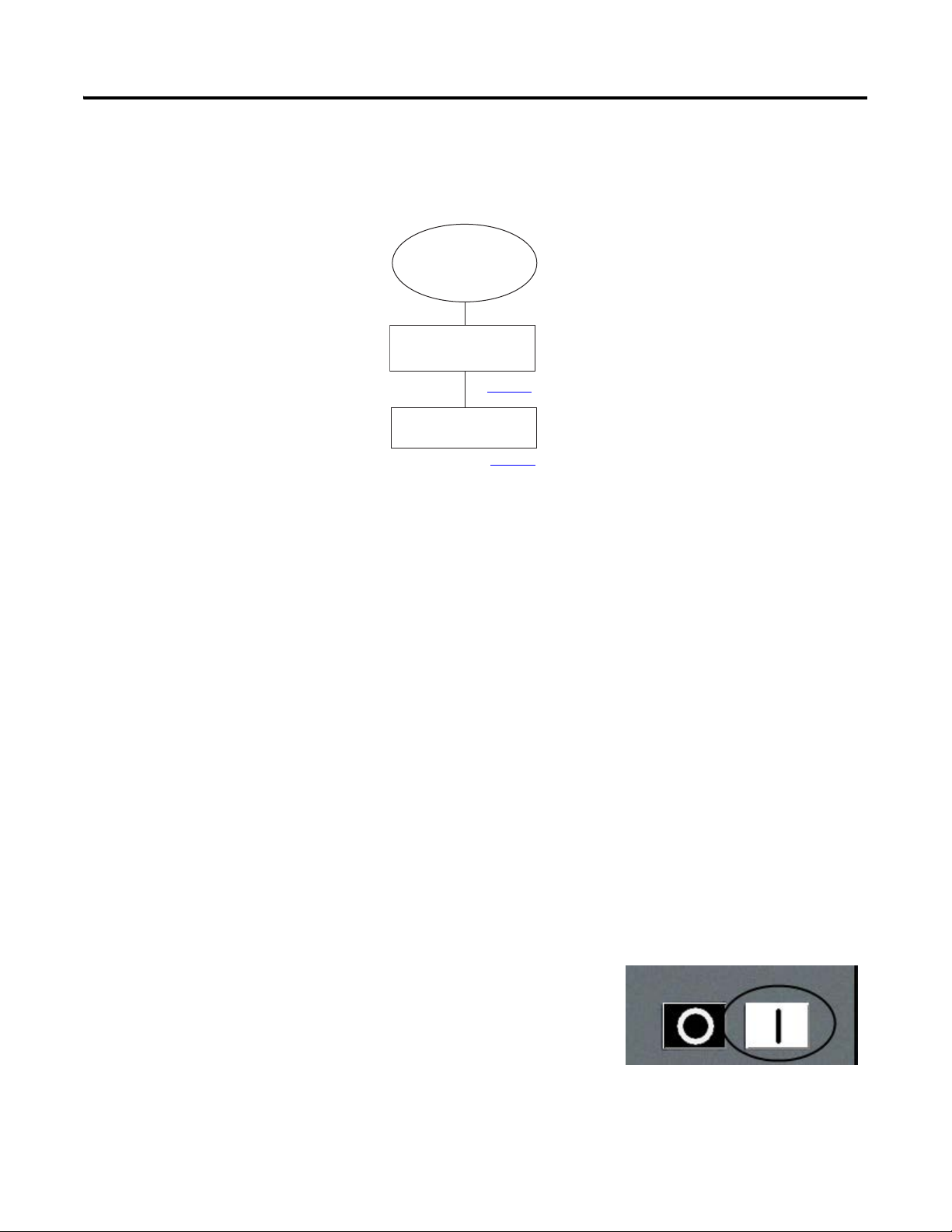

System Powerup

Locate the CNC systems power button, then press to apply power.

48 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 49

FANUC CNC Configuration Chapter 3

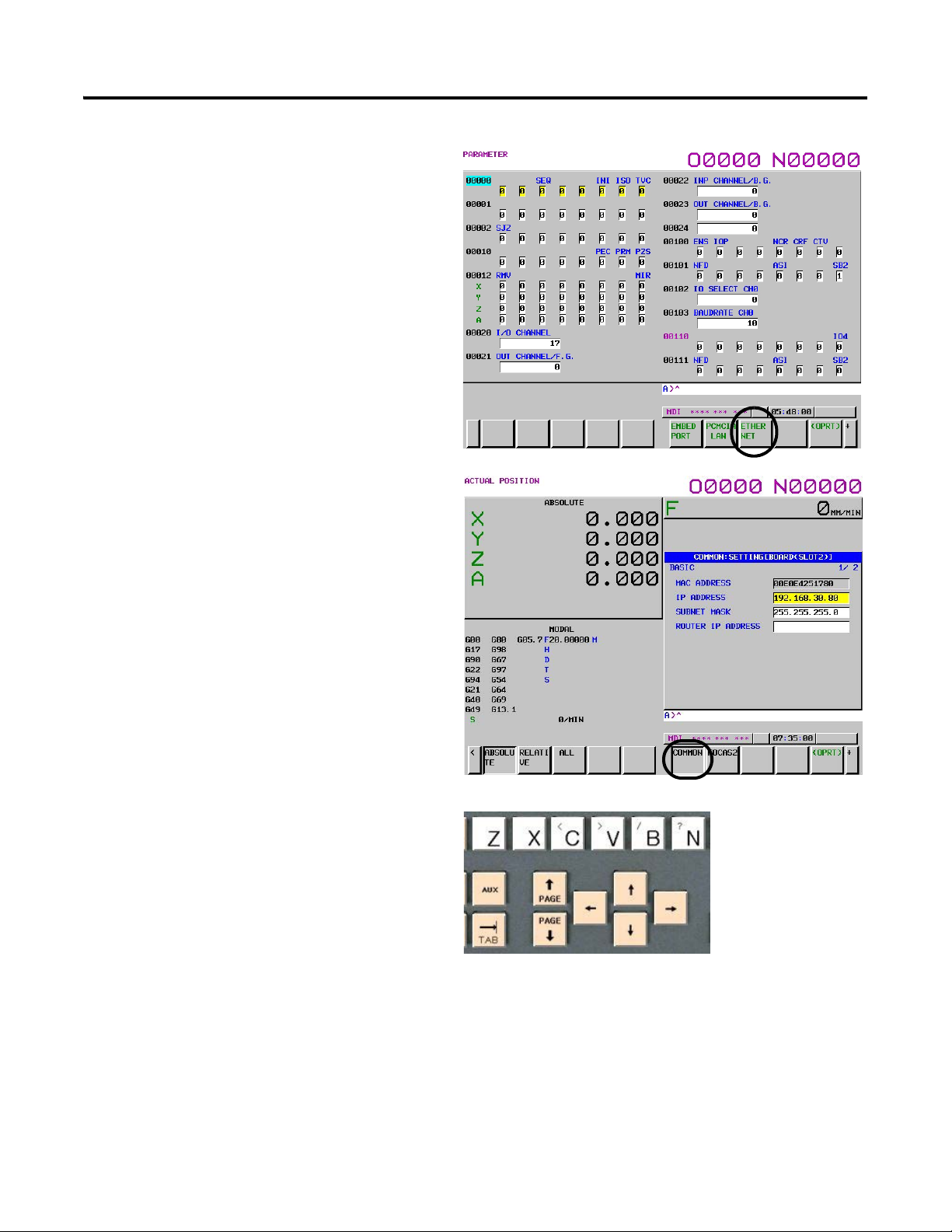

Parameter Write Enable

Set the parameter write enable (PWE, 8900#0) bit to allow the configuration parameter changes described in the

following sections.

1. Press the OFS/SET button on the

QWERTY MDI Panel to open the

SETTING (HANDY) screen.

Either the OFFSET screen or the

SETTING screen is displayed. On first

powerup, the OFFSET screen is displayed.

2. Press the SETTING button to call the

SETTING screen.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 49

Page 50

Chapter 3 FANUC CNC Configuration

IMPORTANT

3. Use the arrow keys on the MDI panel to move to the desired

selections.

4. Prior to setting the parameter, be sure that MDI modes has been

selected by pressing the button on the CNC main panel.

5. Enter 1 from the numeric entry, then press INPUT to set the

parameter write enable bit (PWE, 8900#0). This lets you set the

parameters, and configure the CNC for use.

6. Setting this may cause an alarm to be triggered and displayed.

Cancel the alarm by pressing RESET on the MDI Panel. You will

then have to open the SETTING screen again as described above.

7. Turn the parameter write enable key switch to the on position.

This will take affect after the initial program has

been downloaded later in this chapter.

50 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 51

FANUC CNC Configuration Chapter 3

High Speed Ethernet Option

Select the high speed Ethernet option to be used. This enables the fast Ethernet board to be used, and is required

for the CNC EtherNet/IP option.

1. Press the SYSTEM function key from the

MDI panel.

The system PARAMETER screen is

displayed.

2. Press either the + softkey or the right arrow

function key to advance to the chapter

selection for PMC configuration.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 51

Page 52

Chapter 3 FANUC CNC Configuration

The chapter selection screen to display the

PMC configuration options is displayed.

3. Press the PMC CONFIG softkey.

4. Press either the + softkey or the right arrow

function key to advance to the chapter

selection for PMC online configuration, then

press ONLINE.

The chapter selection screen to display the

PMC online configuration options is

displayed.

5. Use the arrow keys on the

MDI panel to move to the

HIGH SPEED field, then

select USE.

The fast ethernet board is

now available to be

configured for the

EtherNet/IP application.

52 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 53

FANUC CNC Configuration Chapter 3

Configure Ethernet Module

In this example, you configure the fast Ethernet board for communicating to the Supervisory PLC, and an offline

development personal computer. See CNC to Controller Communication on page 208 for location of the fast

Ethernet board.

IP Address, Subnet Mask, and Port Number

Configure the IP Address of the fast Ethernet board to allow

network connectivity.

1. Press the SYSTEM function key from the MDI panel.

The system PARAMETER screen is

displayed.

2. Press either the + softkey or the right arrow

function key to advance to the chapter

selection for Ethernet.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 53

Page 54

Chapter 3 FANUC CNC Configuration

The chapter selection screen to display the

fast Ethernet options is displayed.

3. Press the ETHERNET softkey to view the

settings and selections of the fast Ethernet

board.

4. Press the COMMON softkey to view the

common settings of the fast Ethernet board. It

may be necessary to press either the + softkey

or the right arrow function key to advance to

the chapter selection for Ethernet common.

5. Use the arrow keys on the MDI panel to move

to the IP ADDRESS field, then enter the IP

address for your configuration by using the

number keys on the MDI panel. The example

uses the IP address 192.168. 30.80

6. Use the arrow keys on the MDI panel to move

to the SUBNET MASK field, then enter the

mask for your configuration by using the

number keys on the MDI panel. The example

is using the mask 255.255.255.0

54 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 55

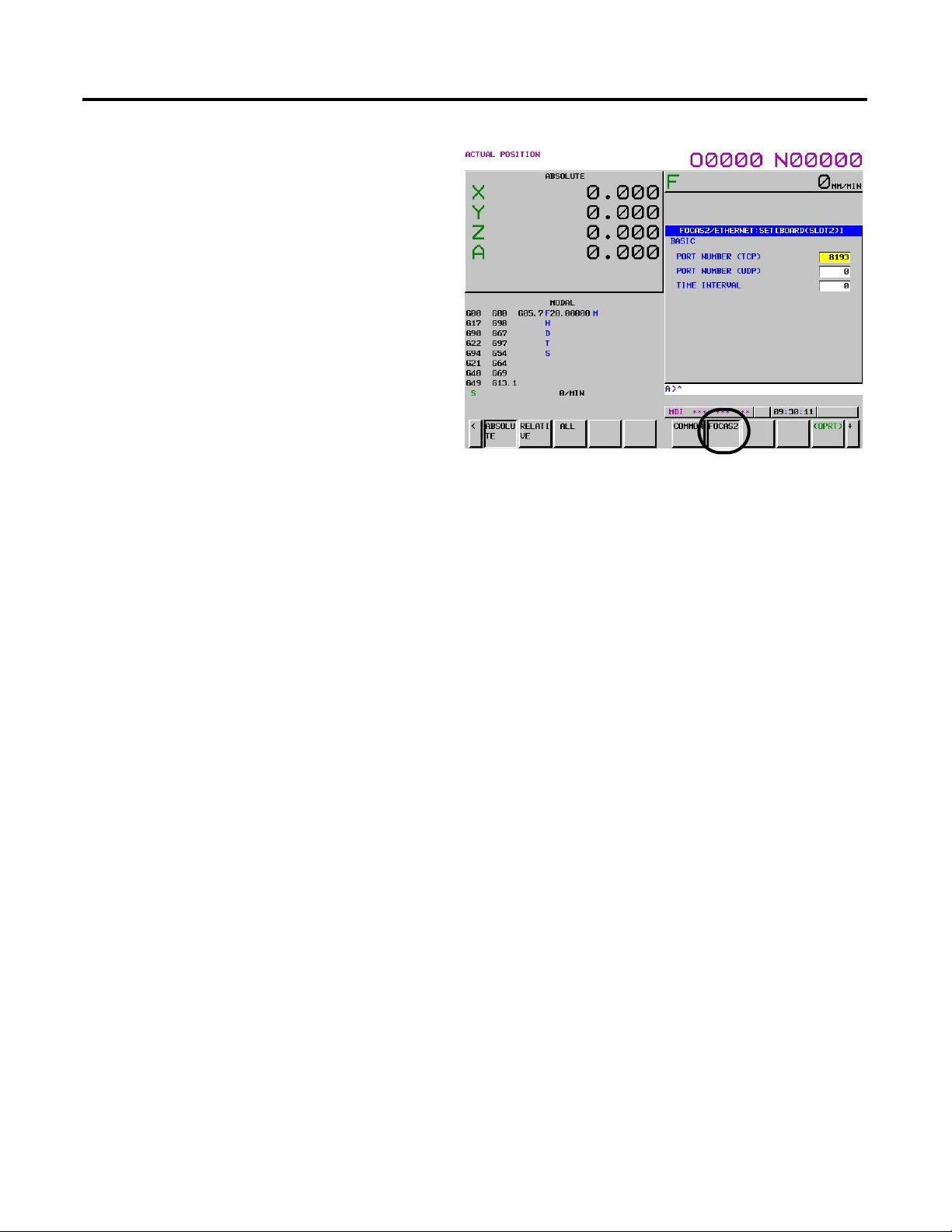

7. Press the FOCAS2 softkey to view the

FOCAS2/ETHERNET settings of the fast

Ethernet board.

8. Verify that PORT NUMBER (TCP) is 8193.

This is the default port number, and also the

default configuration for the offline

development software packages.

The Ethernet board is now configured for the

connection to the offline development

personal computer.

FANUC CNC Configuration Chapter 3

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 55

Page 56

Chapter 3 FANUC CNC Configuration

Create a New Project File

Throughout the rest of this chapter, the controller and network configuration procedures are written specifically

for an S35i-B CNC. Steps for other FANUC CNC models are similar. It is assumed that FANUC LADDER III

has been installed and is operational on the development personal computer being used for this task.

The process of creating a new project is based on using an example file that has been pre-written. You must

change the name of the file from the toolkit, to something that is relevant to the application and task being

created.

1. From the Start menu, launch the FANUC

LADDER III software.

2. From the File menu, choose Open

Program.

The Open dialog box appears.

3. Locate the CMAT 35i-B.LAD

file from the CNC Machining

Accelerator toolkit DVD, and

select OPEN.

56 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 57

The sample program opens, and is ready for

editing.

Change the CNC model for your specific

application.

FANUC CNC Configuration Chapter 3

4. From the File menu, choose PMC Type

changed and save.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 57

Page 58

Chapter 3 FANUC CNC Configuration

5. Select the model.

6. Select the control configuration for the

specific application.

58 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 59

7. From the File menu, choose Save As.

8. Save as a different file name, in a

different location.

FANUC CNC Configuration Chapter 3

9. Click OK and save with the default

options.

10. Click OK.

You are now ready to begin editing the

file for your specific application.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 59

Page 60

Chapter 3 FANUC CNC Configuration

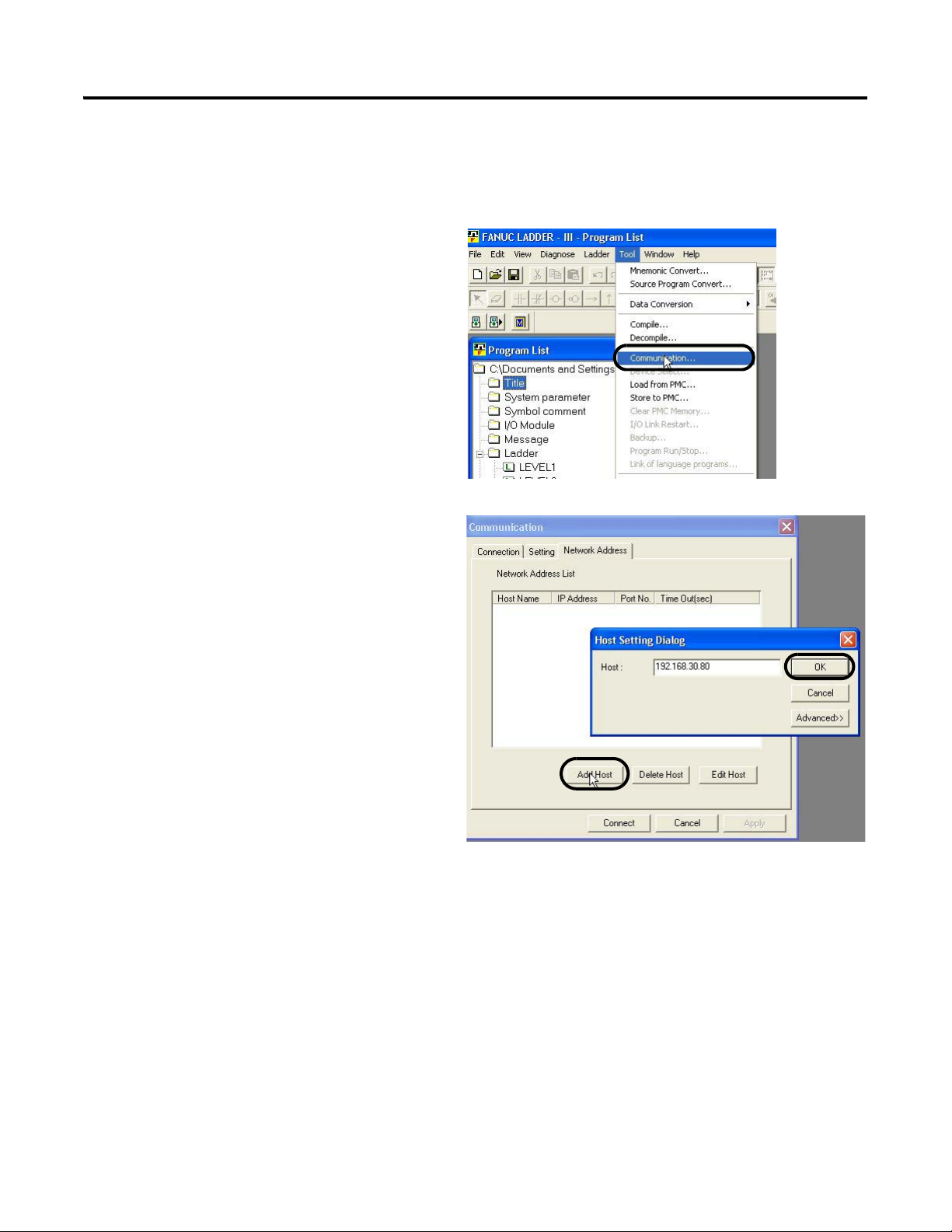

Download FANUC LADDER III Software Project to the FANUC S35i-B CNC

1. Open your FANUC LADDER III project file.

2. From the Tool menu, choose Communication.

The Communication dialog box opens.

3. Click the Network Address tab and click Add

Host.

4. Type in the IP address of the CNC that you

are working on, then click OK.

The host has now been entered into the

address list.

60 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 61

5. Click Connect to establish communication

with the CNC.

6. After the successful connection has been

established, click Close to close the

dialog box.

FANUC CNC Configuration Chapter 3

7. From the Tool menu, choose Store to

PMC.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 61

Page 62

Chapter 3 FANUC CNC Configuration

The Program transfer wizard dialog box

opens.

8. Click Next, then Finish.

9. After the download is complete, the

Program transfer wizard dialog box

closes, and the Program RUN/STOP

dialog box appears. Click Yes to run

the program.

The FANUC LADDER III PMC program

is now downloaded and running within the

s35i-B CNC.

62 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 63

FANUC CNC Configuration Chapter 3

USB External Device

Define the USB port as the punch/reader port. This lets you receive and save configuration files to an external

portable USB device.

1. Use the arrow keys as previously described to move to

the I/O CHANNEL setting and enter the value 17. You

will see the value displayed on the entry line beneath the

settings.

2. Press INPUT as previously described, to change the

parameter. You will now see the value 17 displayed in the

parameter.

The USB port has now been selected as the I/O channel

for the punch/reader function.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 63

Page 64

Chapter 3 FANUC CNC Configuration

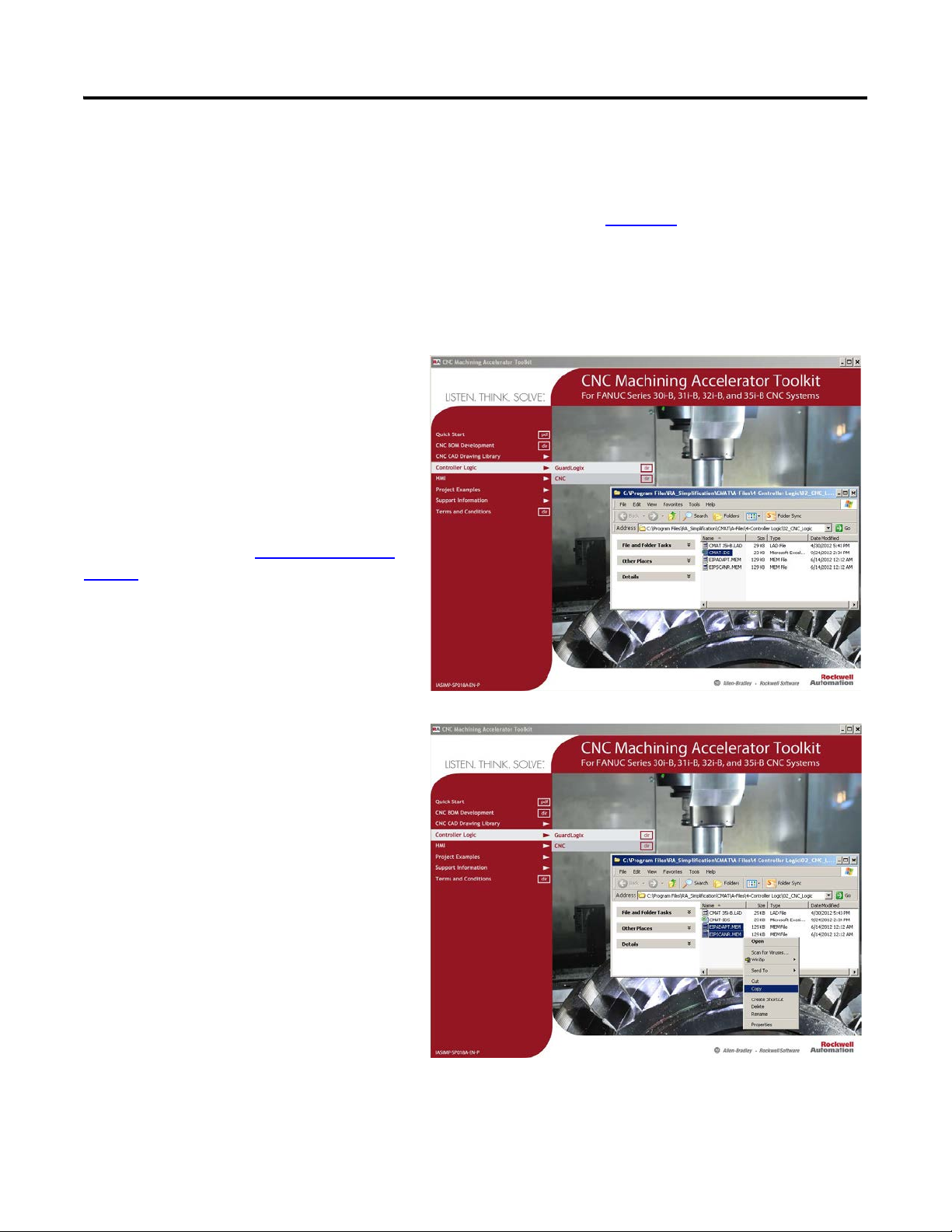

EtherNet/IP Settings

Configure the EtherNet/IP settings of the fast Ethernet board to allow the communication to the supervisory

PLC, and the connection to the Rockwell Automation AOP as detailed in Chapter 4.

The EtherNet/IP settings used throughout this quick start are the following CNC data table tags:

• PLC to FANUC tags - R1000 – R1255

• FANUC to PLC tags - R2000 – R2255

A detailed description of these addresses, and

the specific mapping between the PLC and

CNC can be found in the CMAT-IDS.xlsx file.

The path to this file is C:\Program Files\

RA_Simplification\CMAT\A-Files\

4-Controller Logic\02_CNC_Logic.

Refer to the FANUC EtherNet/IP

documentation listed in What You Need on

page 47 of this chapter, if you would like to

change these locations.

1. Use the CNC Machining Accelerator

Toolkit to navigate to the CNC Logic

folder and copy both EtherNet/IP

configuration files onto an external USB

device.

• EIPADAPT.MEM

• EIPSCANR.MEM

64 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 65

2. Take the USB device and plug it into the

CNC port next to the panel display.

FANUC CNC Configuration Chapter 3

3. Press the SYSTEM function key from the

MDI panel.

The System PARAMETER screen is

displayed.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 65

Page 66

Chapter 3 FANUC CNC Configuration

4. Press either the + softkey or the right arrow

function key to advance to the chapter

selection for Ethernet network.

The chapter selection screen to display the fast

Ethernet options is displayed.

5. Press the ETHERNET softkey to view the

settings and selections of the fast Ethernet

board.

66 Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Page 67

6. Press either the + softkey or the right arrow

function key to advance to the chapter

selection for EtherNet/IP scanner settings,

EIP S SET.

7. Press the (OPRT) softkey to display available

operations for the EtherNet/IP scanner

settings.

8. Press either the + softkey or the right arrow

function key to advance to the operation

selection for restore.

9. Press the RESTORE softkey to display

available operations for the EtherNet/IP

scanner restore operations.

FANUC CNC Configuration Chapter 3

10. Press the EXECUTE softkey to copy the

parameters from the external USB device to the

CNC parameter memory.

11. Power down the CNC to accept the changes to

the EtherNet/IP settings.

12. Power up the CNC, then repeat step 2

for the Ethernet adaptor settings (at step 6

...step 11

select EIP A SET).

The Ethernet board is now configured for the

connection to the supervisory PLC that uses

the EtherNet/IP protocol.

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012 67

Page 68

Chapter 3 FANUC CNC Configuration

IMPORTANT

IMPORTANT

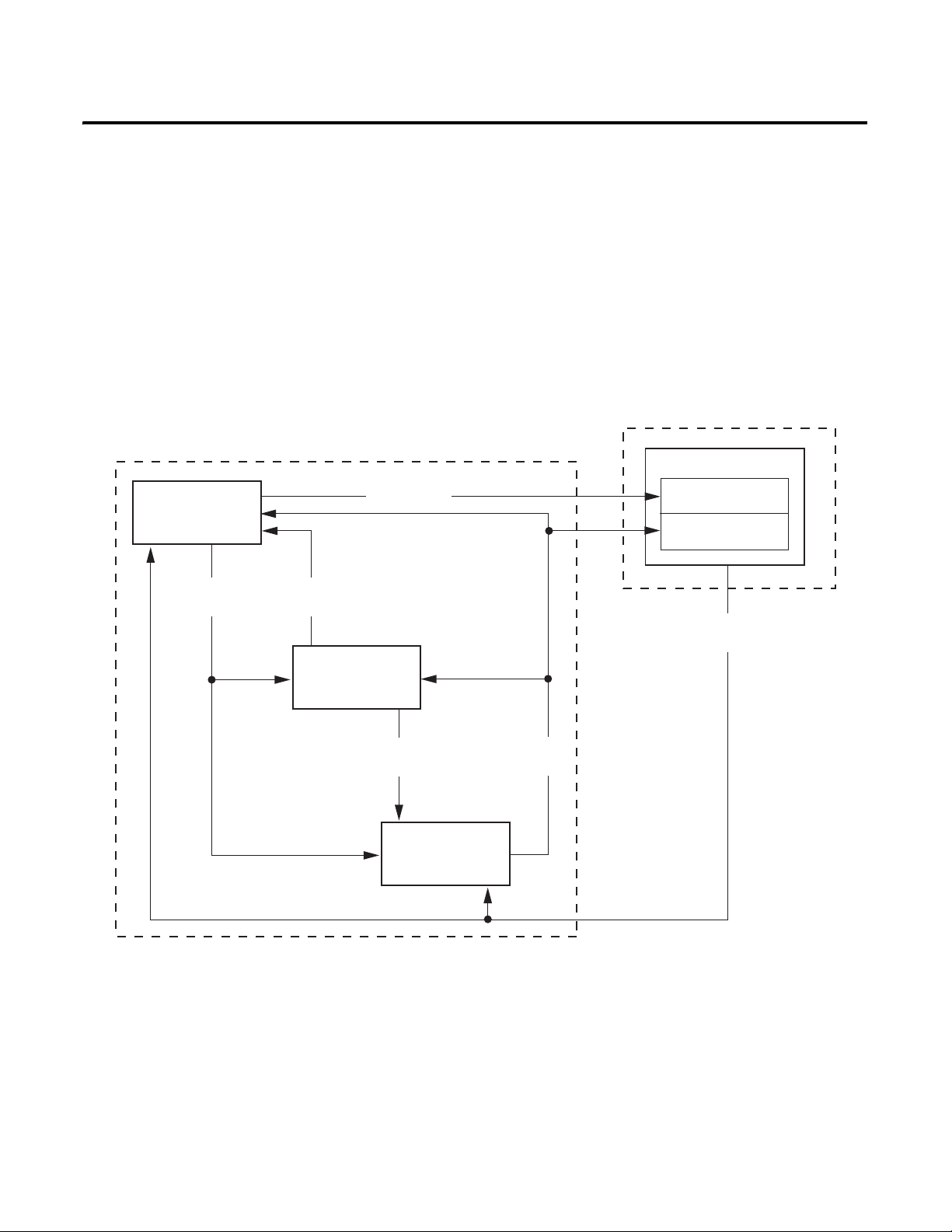

Device

Module(s)

Application

Module(s)

Machine Module

CNC

PMC

MDI Panels

Device