Page 1

Installation Instructions

HPK-Series Motor Encoder Replacement Kit

Catalog Numbers HPK-B1307C-ENC, HPK-B1307E-ENC, HPK-B1308C-ENC,

HPK-B1308E-ENC, HPK-B1310C-ENC, HPK-B1609E-ENC, HPK-B1611E-ENC,

HPK-B1613C-ENC, HPK-B1613E-ENC, HPK-B1815C-ENC, HPK-B2010C-ENC,

HPK-B2010E-ENC, HPK-B2212C-ENC, HPK-B2510C-ENC

Topic Page

About This Publication 1

Important User Information 2

Catalog Number Explanation 3

Before You Begin 4

Required Parts 5

Replacing Encoders 5

Preparing for Installation 5

Disassemble the Encoder - Original Version 6

Disassemble the Encoder - Later Version 8

Install the Replacement Encoder 10

Additional Resources 11

About This Publication

Each replacement kit is designed for the encoder type and version that is installed on a specific

model of an HPK-Series

that defines the motor and encoder combinations.

Use this document if you are responsible for replacing the encoder on an Allen-Bradley

HPK-Series motor. Read all instructions before starting the replacement procedure.

™

motor. Refer to Catalog Number Explanation on page 3 for a chart

®

Page 2

2 HPK-Series Motor Encoder Replacement Kit

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for the

Application, Installation and Maintenance of Solid State Controls (publi cation SGI-1.1

sales office or online at http://www.rockwellautomation.com/literature/

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the wide variety of uses for

solid-state equipment, all persons responsible for applying this equipment must satisfy themselves that each intended application of

this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual

use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNIN G: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from your local Rockwell Automation®

) describes some important differences between solid-state

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard and recognize the

consequences.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Rockwell Automation Publication HPK-IN002C-EN-P - May 2012

Page 3

HPK-Series Motor Encoder Replacement Kit 3

Catalog Number Explanation

HPK -B 1307 C -ENC-MA

BRAKE

A = No brake

B = Brake

FEEDBACK

M = Multi-turn high resolution encoder

S = Single-turn high resolut ion encoder

ACCESSORY TYPE

ENC = Encoder replacement kit

RATED SPEED

C = 1500 rpm

E = 3000 rpm

FRAME SIZE/STACK LENGTH

1307 = Frame size and stack length designation

1308 =

1310 =

1609 =

1611 =

1613 =

1815 =

2010 =

2212 =

2510 =

VOLTAGE RATNG

B = 460V AC

E = 400V AC

G = 750V DC

SERIES

HPK = Asynchronous servo mo tor

Rockwell Automation Publication HPK-IN002C-EN-P - May 2012

Page 4

4 HPK-Series Motor Encoder Replacement Kit

Before You Begin

Before unpacking the product, inspect the shipping carton for damage. If damage is visible,

immediately contact the shipper and request assistance.; otherwise, proceed with unpacking.

Carefully remove the encoder from its shipping container, and visually inspect it for damage. If

the encoder is undamaged, carefully examine the encoder cable and the spring mounting plate for

defects.

Keep the original packing material in case you need to return the product for repair or to

transport it to another location. Use both the inner and outer packing cartons to provide

adequate protection for a unit returned for service.

ATTENTION: Always remove power to all devices, mach ines, and systems connec ted to the motor

before connecting or disconnecting cables, or assembling or disassembling the motor and encoder.

Arcing or unexpected motion could occur if the cables are connected or disconnected while power

is applied to the motor.

Observe the professional safety regulations and accident prevention regulations applicable to your

country.

Failure to observe these safety procedures could result in personal injury or damage to the motor

and other equipment.

ATTENTION: Do not s trike t he shaf t, coup lings, o r pull eys wit h tools during instal lation or remov al.

Damage may occur to the motor bearings and the encoder if you apply a sharp impact to the shaft

during installation of couplings and pulleys, or a shaft key.

Failure to observe these safety procedures could result in damage to the motor and its

components.

ATT EN TI ON : Do not attempt to open or modify the motor. This manual describes encoder

modifications that you can perform in the field. Do not attempt other changes.

Only a qualified Allen-Bradley

Failure to observe these safety procedures could result in personal injury or damage to equipment.

ATTENTION: An unmounted motor, disconnected mechanical couplings, loose shaft keys, and

disconnected cables are dangerous, if power is applied.

Disassembled equipment should be appropriately identified (tagged-out) and access to electrical

power restricted (locked-out). Before applying power, remove the shaft key and other mechanical

couplings that could be thrown from the shaft.

Failure to observe these safety procedures could result in personal injury or damage to equipment.

ATTENTION: The National Electrical Code and local electrical codes take precedence over the

values and methods provided in this document. Implementation of these codes is the

responsibility of the machine builder and the local installer.

Rockwell Automation Publication HPK-IN002C-EN-P - May 2012

employee can service this motor.

Page 5

HPK-Series Motor Encoder Replacement Kit 5

IMPORTANT

IMPORTANT

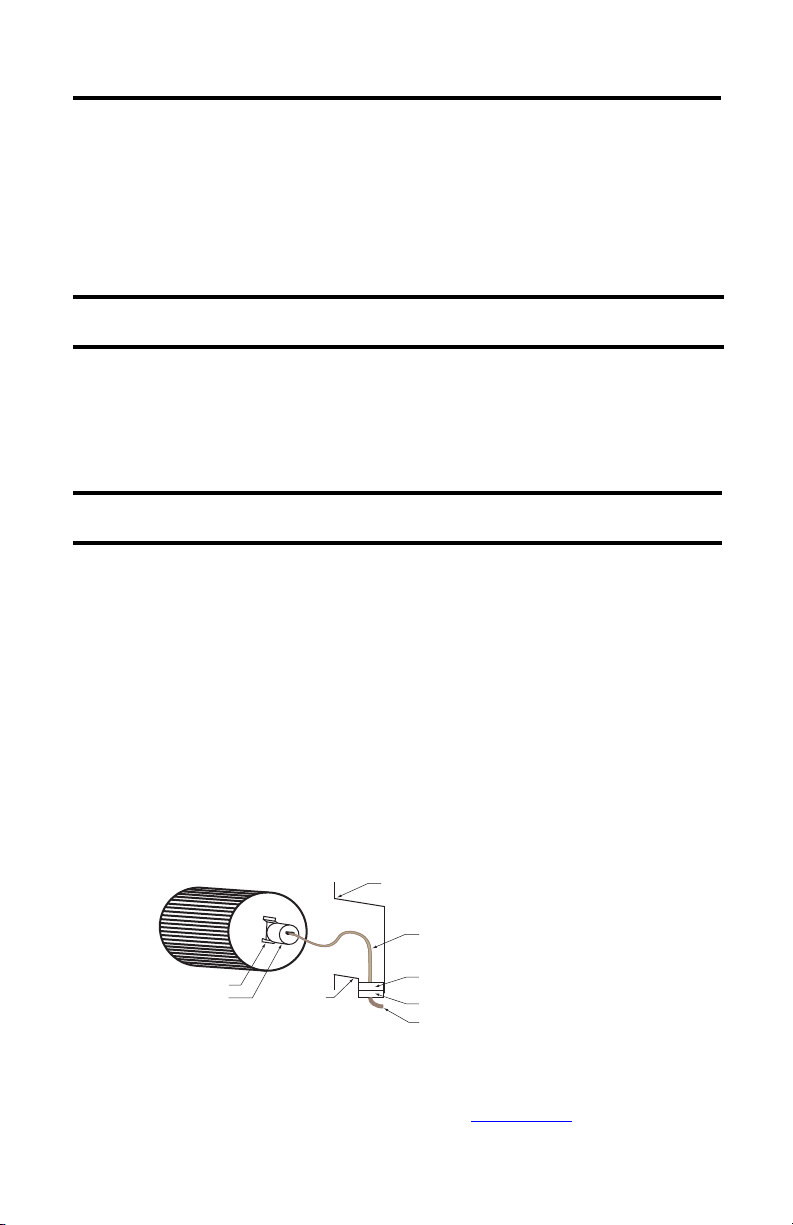

Fan Housing or Metal Shroud

Shielded Encoder Cable

Connector Housing (4 mounting screws)

Feedback Connector

Feedback Cable from Drive

Encoder Housing

Spring Mounting Plate

Fan Housing

or Metal Shroud

Required Parts

To install the HPK-Series Motor Encoder Replacement Kit, you should plan to provide the

following parts. Where possible, reuse screws and other hardware.

• Fixing screws

• Electrical tape

Reuse existing parts, such as screw s and other hardware.

Always store parts as you remove the encoder.

Replacing Encoders

Review these sections to become familiar with the steps before you begin to replace your encoder.

One of two possible versions of the encoder is installed on your HPK motor.

Use the removal instructions appropriate for the encoder installed on your HPK motor.

Preparing for Installation

Always use equipment and installation practices that promote electromagnetic compatibility

(EMC) and safety. This requires that both the encoder housing and the encoder connectors are

grounded at the motor frame. A metallic connector housing provides the encoder cable with a

physical opening and electrical shielding from the motor and the drive interface cable.

• Secure the spring mounting plate, on which the encoder is mounted, to the motor frame.

• Attach the connector housing to the fan shroud or another metal component on the

HPK motor with the four mounting screws.

These connections provide a secure mechanical mount and an electrical ground with the motor

frame.

HPK-Series Encoder Replacement Kit Overview

Use high-frequency (HF) bonding techniques to connect the encoder, feedback connector,

motor housing, and machine frame. HF bonding techniques creates a low-impedance return

path for high-frequency (HF) energy and reduce electrical noise. Refer to the System Design for

Control of Electrical Noise Reference Manual, publication GMC-RM001

the concept of electrical noise reduction.

Rockwell Automation Publication HPK-IN002C-EN-P - May 2012

, to better understand

Page 6

6 HPK-Series Motor Encoder Replacement Kit

Disassemble the Encoder - Original Version

ATTENTION: Verify that power is off or removed from all devices affected by the encoder.

Verify that all electrical connections (for example, items 9 and 10 in the HPK-Series Motor Encoder

- Original Version) are disconnected from any power source.

BURN HAZARD: Outer surfaces of the motor can reach high temperatures, 125 °C (275 °F), during

operation.

Take precautions to prevent accidental contact with hot surfaces on the motor. Consider the surface

temperature of the equipment when selecting cables and additional equipment for connection.

Failure to observe these safety procedures could result in personal injury or damage to equipment.

1. Block the motor shaft (3) to prevent rotation.

For example, use a wrench to hold the motor shaft in place.

2. Remove the mounting screws from the encoder connector (10).

3. Remove the rear cover, or fan cover if provided, from the motor.

4. Remove the wire ties that secure the encoder cable and thermostat wires to the motor

frame.

5. Remove any electrical tape covering the thermostat connectors (9).

6. Disconnect thermostat leads from the cable assembly.

7. Remove the screws (8) and washers (7) from the spring mounting plate (4).

8. Remove screw (6) and washer (5).

9. Loosen and remove the outer clamping element (2) from the motor shaft by turning the

respective slots on the clamping element.

For example, use a small flat head screwdriver to turn and loosen the clamping element.

10. Remove the motor encoder.

11. Remove the inner clamping element (1) from the motor shaft.

Rockwell Automation Publication HPK-IN002C-EN-P - May 2012

Page 7

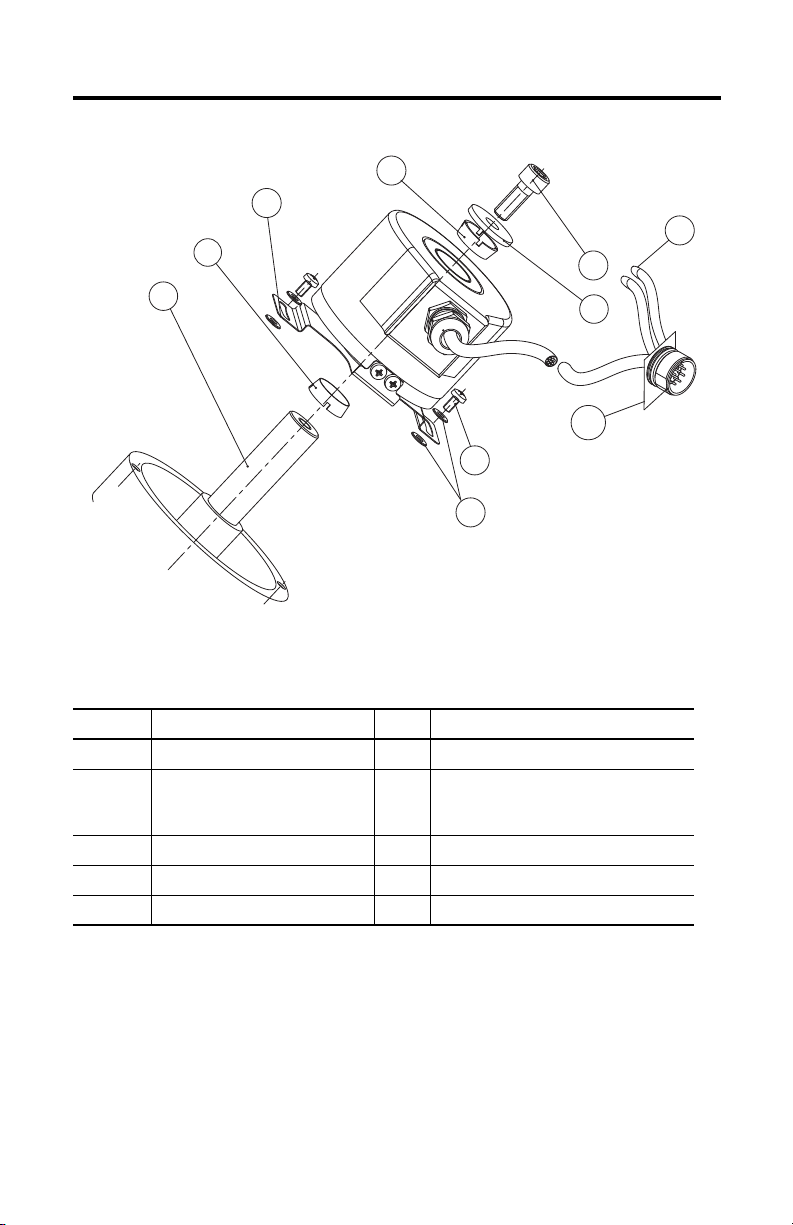

HPK-Series Motor Encoder - Original Version

1

4

2

6

5

7

9

8

10

3

This diagram shows the mechanical construction of the original version encoder.

HPK-Series Motor Encoder Replacement Kit 7

Item Description Item Description

1 Clamping element 6 Screw

2 Clamping element 7 Plastic washers (qty. 4)

3 Motor shaft 8 M2.5 fixing screw (qty. 2)

4 Spring mounting plate 9 Thermostat connectors (qty. 2)

5 Washer 10 Encoder connector (on motor)

Rockwell Automation Publication HPK-IN002C-EN-P - May 2012

The plastic washers electrically isolate the encoder

from the HPK motor.

Page 8

8 HPK-Series Motor Encoder Replacement Kit

Disassemble the Encoder - Later Version

ATTENTION: Verify that power is off or removed from all devices affected by the encoder.

Verify that all electrical connections (for example, items 9 and 10 in the HPK-Series Motor Encoder

- Later Version) are disconnected from any power source.

BURN HAZARD: Outer surfaces of the motor can reach high temperatures, 125 °C (275 °F), during

operation.

Take precautions to prevent accidental contact with hot surfaces on the motor. Consider the surface

temperature of the equipment when selecting cables and additional equipment for connection.

Failure to observe these safety procedures could result in personal injury or damage to equipment.

1. Block the motor shaft (3) to prevent rotation.

For example, use a wrench to hold the motor shaft in place.

2. Remove the mounting screws from the encoder connector (10).

3. Remove the rear cover, or fan cover if provided, from the motor.

4. Remove the wire ties that secure the encoder cable and thermostat wires to the motor

frame.

5. Remove any electrical tape covering the thermostat connectors (9), and then disconnect

the thermostat leads from the thermostat connector.

6. Remove the screws (8) and washers (7) from the spring mounting plate (4).

7. Loosen the shaft clamp screw (6).

8. Remove the motor encoder (1).

9. Remove the plastic shaft sleeve (2) from the motor shaft, if it was not removed with the

encoder.

Rockwell Automation Publication HPK-IN002C-EN-P - May 2012

Page 9

HPK-Series Motor Encoder - Later Version

This diagram shows the mechanical construction of a later version encoder.

5

1

4

6

2

HPK-Series Motor Encoder Replacement Kit 9

9

3

8

7

Item Description Item Description

1 Encoder 6 Torx clamp screw (size T10)

2 Plastic shaft sleeve 7 7 mm (0.273 in.) outside diameter washer (qty. 2)

3 Motor shaft 8 M2.5 fixing screw (qty. 2)

4 Spring mounting plate 9 Thermostat connectors (qty. 2)

(1)

5 Spacers (optional)

(1) Spacers are required only if the e ncoder has a spring mounting plate that does not fully extend to the motor frame.

10 Encoder connector (on motor)

10

Rockwell Automation Publication HPK-IN002C-EN-P - May 2012

Page 10

10 HPK-Series Motor Encoder Replacement Kit

TIP

IMPORTANT

Install the Replacement Encoder

Refer to the HPK-Series Motor Encoder - Later Version diagram on page 9 to identify specific

parts of the replacement encoder and their correct position when installed.

1. Verify the encoder replacement kit catalog number corresponds with the motor catalog

number listed on the motor nameplate.

2. Check the runout of the motor shaft, approximately 0.50 mm (0.02 in.) from the front

of the shaft.

If the runout exceeds 0.003 total indicator runout(TIR), correct it by tapping on the

motor shaft with a brass hammer.

Use a piece of soft wood or a thin rubber pad to protec t the motor shaft from physical damage.

3. Verify the plastic shaft sleeve (2) is installed in the encoder shaft (1), with the larger

diameter shoulder of the sleeve oriented at the same end of the encoder as the shaft

clamp screw (6).

4. Rotate the encoder shaft to an angular position that permits access to the shaft clamp

screw (6) when the encoder is installed.

5. Push the encoder (1) fully onto the motor shaft.

The encoder is fully seated when the plastic shaft sleeve (2) is tight against the motor

shaft shoulder, but the spring mounting plate is not bent.

6. Tighten the encoder shaft clamp screw (6) to 1.1 ± 0.1 N•m (9.7 ± 0.9 lb•in) with a

T10 Torx driver.

ATTENTION: The encoder shaft clamp can break if overtightened.

A broken shaft clamp could cause unexpected motor shaft rotation and corresponding machine

motion, due to loss of encoder feedback.

Failure to observe safety procedures could result in personal injury or damage to the motor and

other equipment.

7. If a gap exists between the spring mounting plate and the motor frame when the encoder

is fully seated on the motor shaft, fill the gap by installing spacer washers (5) or stacked

flat washers.

8. Install screws (8) and washers (7) to hold the spring mounting plate (4) on the motor.

After all screws and washers are in place, tighten the screws to 0.28 N•m (2.5 lb•in).

Original version encoders use plastic washers to electrically isolate the encoder from the motor

frame at the spring mounting plate. Later version encoders have a plastic shaft sleeve, that

electrically isolates the encoder from the motor shaft.

When replacing an original version encoder with a later version encoder, do not use the plastic

washers to secure the spring mounting plate to the motor frame. Later version encoders use

metal screws (7) and washers (8) to ground the spring mounting plate to the motor frame.

Rockwell Automation Publication HPK-IN002C-EN-P - May 2012

Page 11

HPK-Series Motor Encoder Replacement Kit 11

TIP

9. Install the white motor thermostat leads (P1 and P2) to the thermostat connectors (9).

a. Slide the plastic sleeving over the connector and fasten the sleeving with electrical

tape.

b. Tape each lead individually, and then tape the two leads together.

10. Use wire ties to secure the encoder cable and thermostat leads to the motor frame.

Restrain all cables and wires to prevent contact or entanglement with rotating fan blades,

the motor, or moving parts on machine.

11. Slide the encoder cable into the slot on the fan cover, or rear cover, and then mount the

cover on the motor bracket.

12. Mount the encoder connector (10) to the top of the fan cover with four screws.

The encoder connector typically points in the same direction as the lead outlet on the motor

conduit box.

Use the HPK-Series Motor Encoder - Later Version diagram as a visual reference during removal

and installation of the encoder.

Additional Resources

For additional information on the HPK-Series encoders, refer to HPK-Series Motor Installation

Instructions, publication HPK-IN001

You can view or download publications at http://www.rockwellautomation.com/literature/

order paper copies of technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

.

. To

Rockwell Automation Publication HPK-IN002C-EN-P - May 2012

Page 12

Rockwell Automation Support

Rockwell Automation provides tec hnical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

links to software service packs, and a MySupport feature that you can customize to make the best use of these tools. You can also visit

our Knowledgebase at http://www.rockwellautomation.com/knowledgebase

forums, software updates, and to sign up for product notification updates.

For an additional level of technical phone support for installation, configuration and troubleshooting, we offer TechConnect

programs. For more information, contact your local distributor or Rockwell Automation representative, or visit

http://www.rockwellautomation.com/support/

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review the information that's contained in this manual.

You can also contact a special Customer Support number for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Wor ldwi de Loc ator

http://www.rockwellautomation.com/support/americas/phone_en.html

Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all o f its products to ensure that they are fully operational when shipped from the manufacturing facility.

However, if your product is not functioning and needs to be returned, follow these procedures.

, you can find technical manuals, technical and application notes, sample code and

for FAQs, technical information, support chat and

sm

support

.

at

, or contact your local

United States

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Contact your distributor. You must provide a Customer Support case number (call the phone number

above to obtain one) to your distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete this form, publication RA-DU002

Allen-Bradley, HPK-Series, Rockwell Automation, Rockwell Software, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Publication HPK-IN002C-EN-P - May 2012 PN-138408

Supersedes Publication HPK-IN002B - November 2008 Copyright © 2012 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

, available at http://www.rockwellautomation.com/literature/.

Loading...

Loading...