Page 1

INSTALLATION AND CON

FIGURATION GUIDE

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Supersedes Publication HSE-IN023A-EN-E–May 2012

Page 2

Contact Rockwell Automation

Customer Support Telephone — 1.440.646.3434

Online Support — http://www.rockwellautomation.com/support

Copyright Notice

Trademark Notices

Other Trademarks

© 2012 Rockwell Automation Technologies, Inc. All rights reserved. Printed in USA.

© 2010 OSIsoft, Inc. All rights reserved.

This document and any accompanying Rockwell Software products are copyrighted by Rockwell Automation

Technologies, Inc. Any reproduction and/or distribution without prior written consent from Rockwell

Automation Technologies, Inc. is strictly prohibited. Please refer to the license agreement for details.

FactoryTalk, Rockwell Automation, Rockwell Software, the Rockwell Software logo are registered trademarks

of Rockwell Automation, Inc.

The following logos and products are trademarks of Rockwell Automation, Inc.:

FactoryTalk Historian Site Edition (SE), FactoryTalk Historian Machine Edition (ME), RSView, FactoryTalk View,

RSView Studio, FactoryTalk ViewStudio, RSView Machine Edition, RSView ME Station, RSLinx Enterprise,

FactoryTalk Services Platform, FactoryTalk Live Data, and FactoryTalk VantagePoint.

The following logos and products are trademarks of OSIsoft, Inc.:

PI System, Sequencia, Sigmafine, gRecipe, sRecipe, and RLINK.

ActiveX, Microsoft, Microsoft Access, SQL Server, Visual Basic, Visual C++, Visual SourceSafe, Windows,

Windows ME, Windows NT, Windows 2000, Windows Server 2003, and Windows XP are either registered

trademarks or trademarks of Microsoft Corporation in the United States and/or other countries.

Adobe, Acrobat, and Reader are either registered trademarks or trademarks of Adobe Systems Incorporated in

the United States and/or other countries.

ControlNet is a registered trademark of ControlNet International.

DeviceNet is a trademark of the Open DeviceNet Vendor Association, Inc. (ODVA).

Ethernet is a registered trademark of Digital Equipment Corporation, Intel, and Xerox Corporation.

Restricted Rights Legend

Warranty

OLE for Process Control (OPC) is a registered trademark of the OPC Foundation.

Oracle, SQL*Net, and SQL*Plus are registered trademarks of Oracle Corporation.

All other trademarks are the property of their respective holders and are hereby acknowledged.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph

(c)(1)(ii) of the Rights in Technical Data and Computer Software clause at DFARS 252.227-7013.

This product is warranted in accordance with the product license. The product’s performance may be affected

by system configuration, the application being performed, operator control, maintenance, and other related

factors. Rockwell Automation is not responsible for these intervening factors. The instructions in this

document do not cover all the details or variations in the equipment, procedure, or process described, nor do

they provide directions for meeting every possible contingency during installation, operation, or

maintenance.

This product’s implementation may vary among users.

This document is current as of the time of release of the product; however, the accompanying software may

have changed since the release. Rockwell Automation, Inc. reserves the right to change any information

contained in this document or the software at anytime without prior notice. It is your responsibility to obtain

the most current information available from Rockwell when installing or using this product.

Page 3

Chapter 1

Table of Contents

Overview

System Requirements

Integration with Other Rockwell Automation Products .................... 8

FactoryTalk Historian Installation Package ........................................... 9

Typical Architecture ..................................................................................... 9

User Documentation .................................................................................. 10

On the Installation DVD ..................................................................... 10

On the Local Hard Drive ..................................................................... 11

In the Start Menu ................................................................................... 11

Technical Support and Resources ........................................................... 13

Technical Support ................................................................................. 13

Knowledgebase .................................................................................. 13

Worldwide Support ......................................................................... 13

Training Programs ............................................................................ 13

TechConnect Support .................................................................... 14

Find the Version and Build Numbers ............................................... 15

View Computer Platform Information ............................................ 15

Chapter 2

FactoryTalk Historian SE Server Machine ........................................... 17

FactoryTalk Historian Live Data Interface Machine ......................... 18

FactoryTalk Historian Client Machine ................................................. 18

FactoryTalk Historian Asset Framework .............................................. 19

FactoryTalk Historian DataLink ............................................................ 20

Chapter 3

Pre-Installation Tasks

Synchronize Time Settings on FactoryTalk Historian System

Computers .................................................................................................... 23

Disable the Windows Time Zone (TZ) Environment Variable ...... 24

Learn About Installation-related Recommendations ......................... 24

Chapter 4

Installing FactoryTalk Historian

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 3

Installing Core Components .................................................................... 25

Install Microsoft SQL Server .............................................................. 25

Install FactoryTalk Services Platform ............................................... 27

Specify FactoryTalk Directory Server Location ........................ 28

Install FactoryTalk Activation Manager .......................................... 30

Page 4

Table of Contents

Install RSLinx Enterprise (Data Server) ........................................... 31

Installing FactoryTalk Historian Suites ................................................. 32

Install FactoryTalk Historian Asset Framework ............................ 33

Installation Modes for FactoryTalk Historian Asset

Framework ......................................................................................... 34

Install FactoryTalk Historian Asset Framework Server .......... 36

Install FactoryTalk Historian SE Server ........................................... 39

Install FactoryTalk Historian Live Data Interface (Optional) ... 43

Install FactoryTalk Historian Management Tools (Optional) .. 47

Install Advanced Server (Optional) ................................................... 50

Install FactoryTalk VantagePoint (Optional) ................................ 52

Install Additional Historian Components ...................................... 52

Chapter 5

Post-Installation Tasks

Configuring FactoryTalk

Historian

View the Installation Log File .................................................................. 53

Verify that Historian Services are Running .......................................... 53

Verify that the Historian Server is Updating Data for Default Tags

.......................................................................................................................... 55

Add the AF Service Computer to the AFServer Group ..................... 55

Manually Create the Asset Framework Database ................................ 56

Manually Configure the Asset Framework Service ............................. 58

Perform the MDB to AF Synchronization ........................................... 59

Verify the MDB to AF Synchronization ............................................... 59

Disable Virus Scanning .............................................................................. 60

Chapter 6

Activating the Historian Server ............................................................... 61

Securing the Historian Server ................................................................... 62

Historian Security Components and Their Privileges .................. 63

Managing Historian Security Components .................................... 67

Creating Security Mappings ................................................................ 69

Managing Security of the Historian Server Database .................... 71

Configuring Firewall for FactoryTalk Historian ................................. 73

Configuring the Historian Server ............................................................ 75

Adding the Server to the FactoryTalk Directory ........................... 75

Verifying the FactoryTalk Historian Live Data Local Interface. 77

Managing Licenses ................................................................................. 77

4 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 5

Table of Contents

Types of Licenses .............................................................................. 78

How Licenses Are Distributed Between License Pools ........... 80

Assigning License Activations to the Historian Server ........... 85

Allocating Licenses to Interface Types ........................................ 86

Viewing Allocated Licenses ............................................................ 89

Configuring Points ................................................................................ 90

Adding Individual Data Points Manually................................... 90

Adding Multiple Data Points Automatically ............................. 91

Viewing Current and Archive Data................................................... 93

Viewing Current Data ..................................................................... 93

Viewing Archive Data...................................................................... 94

Archiving and Backups ......................................................................... 95

Restarting FactoryTalk Historian SE Server ................................... 96

Configuring the Data Server ..................................................................... 96

Configuring Historian Interface Connections .................................... 97

Configuring FactoryTalk Historian Live Data Interface .................. 98

Registering Live Data Interfaces ......................................................... 98

Live Data Interface Services ................................................................. 99

Enable Buffering .................................................................................. 100

Manually Enabling Excel Add-ins ........................................................ 103

Recording Messages Using FactoryTalk Diagnostics ...................... 104

Message Parameters ............................................................................ 104

Viewing Messages ................................................................................ 105

Chapter 7

Troubleshooting FactoryTalk

Historian

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 5

Using FactoryTalk Historian ME Modules with FactoryTalk

Security ....................................................................................................... 107

Verifying the Windows Administrator Privileges ............................ 108

Resolving Error and Warning Messages.............................................. 109

General .................................................................................................. 109

Error: System is a PINs Node ..................................................... 109

Error: Server Not Found .............................................................. 110

Error: Failure to Retrieve Interface Information ................... 111

No Connection to FactoryTalk Directory ................................... 111

Schema Creation ............................................................................ 112

Folders Creation ............................................................................ 113

Page 6

Table of Contents

Firewall-related Errors ....................................................................... 114

Configuring Windows Firewall with WFCU ........................ 115

Appendix A

Configuring Historian Servers in

High Availability Mode

Configuring Live Data Interface

Redundancy

FactoryTalk View SE TrendX

High Availability (HA) Architecture .................................................. 117

Working with Server Collectives .......................................................... 119

Creating Server Collectives .................................................................... 120

Verifying Communication Between Server Collective Members . 122

Verifying Replication of Configuration Changes in the Primary

Server ........................................................................................................... 124

Assigning License Activations to Server Collectives ........................ 125

Configuring Interfaces and Buffering Services for Historian Server

Collectives .................................................................................................. 128

Appendix B

Overview ..................................................................................................... 129

Appendix C

Creating Security Trusts for the FactoryTalk View TrendX Display

Object .......................................................................................................... 131

Configuring Trend Properties .............................................................. 134

Appendix D

Upgrading FactoryTalk

Historian

Upgrading FactoryTalk Historian to the Current Version ........... 137

Appendix E

Removing FactoryTalk Historian

6 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Removing the Suite Using the Start Menu ........................................ 140

Removing the Suite Using Control Panel .......................................... 140

Removing the Suite Using the Installation DVD ............................. 141

Page 7

Chapter 1

Overview

FactoryTalk Historian Site Edition (SE) provides the capability to

collect, store, analyze, and visualize data using a powerful engine and

a set of reporting tools such as time-series trends, bar charts, pie

charts, pareto and tabular trends, and a method of generating reports

using Microsoft Excel. It also uses compressed-storage data

algorithms to contain a vast amount of data in a small format.

In the following chapters, you will find information on how to

install, secure, configure, use, and troubleshoot FactoryTalk

Historian SE:

• System Requirements (page 17)

• Pre-Installation Tasks (page 23)

• Installing FactoryTalk Historian (page 25)

• Post-Installation Tasks (page 53)

• Configuring FactoryTalk Historian (page 61)

• Troubleshooting FactoryTalk Historian (page 107)

• Appendix A: Configuring Historian Servers in High

Availability Mode (page 117)

• Appendix B: Configuring Live Data Interface Redundancy

(page 129)

• Appendix C: FactoryTalk View SE TrendX (page 131)

• Appendix D: Upgrading FactoryTalk Historian (page 137)

• Appendix E: Removing FactoryTalk Historian (page 139)

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 7

Page 8

Chapter 1 Overview

Integration with Other Rockwell Automation Products

FactoryTalk Historian SE is closely integrated with FactoryTalk

Services Platform and the following Rockwell Automation

applications:

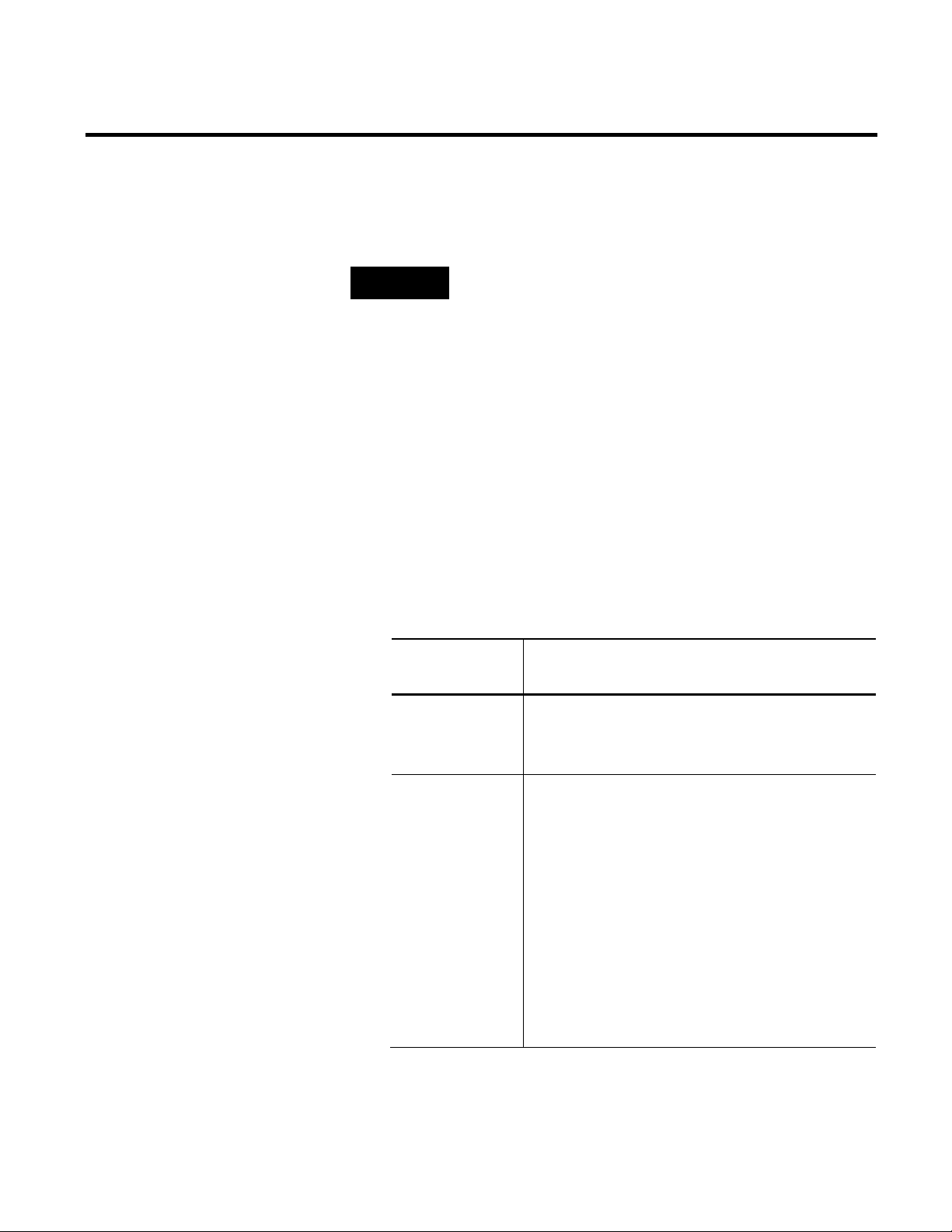

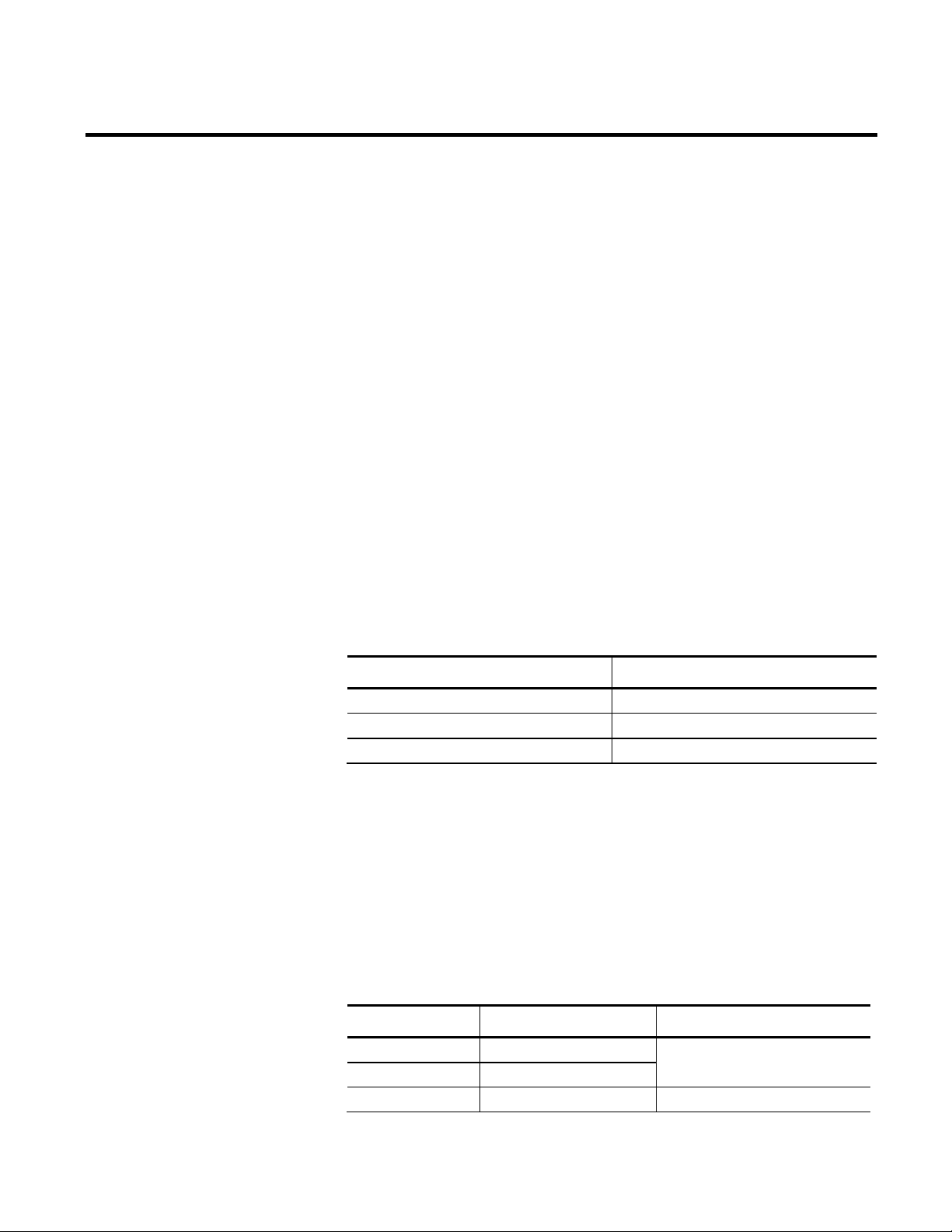

Application Description

FactoryTalk Live Data

(FTLD)

A direct data interface to FTLD delivers native FTLD data directly to

FactoryTalk Historian SE without requiring intermediate interfaces

and standards such as OPC.

FactoryTalk Directory FactoryTalk Historian SE uses FactoryTalk Directory to look up data

points for configuring points to historize. The FactoryTalk Directory

is also used for auto-discovering controller data sources and tags in

the initial configuration process.

FactoryTalk

Activation

FactoryTalk Historian SE is activated by Rockwell Automation's

central licensing system based on the FactoryTalk Activation

Server.

FactoryTalk

Diagnostics

Because of a close integration of FactoryTalk Historian SE with

FactoryTalk Diagnostics, all system and diagnostics messages from

FactoryTalk Historian SE are centrally stored and maintained in the

FactoryTalk Diagnostics database.

FactoryTalk Audit All FactoryTalk Historian SE Server auditing messages are stored

and available in the FactoryTalk Audit database.

FactoryTalk View SE

Trending

FactoryTalk Historian

Machine Edition (ME)

FactoryTalk View Site Edition natively trends data from FactoryTalk

Historian SE.

FactoryTalk Historian ME provides a Data Transfer service to allow

its logged data to be transferred to the FactoryTalk Historian SE for

long-term storage and analysis.

FactoryTalk

VantagePoint

The data from multiple FactoryTalk Historian SE Servers and

FactoryTalk Historian ME Servers can be brought together into a

single information management and decision support system

using FactoryTalk VantagePoint.

FactoryTalk Batch The event journal data from your FactoryTalk Batch system can be

collected through the FactoryTalk Batch Interface and stored

within FactoryTalk Historian SE.

8 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 9

Overview Chapter 1

FactoryTalk Historian Installation Package

Typical Architecture

The FactoryTalk Historian SE installation DVD contains the

following software products:

• FactoryTalk Services Platform (with FactoryTalk Directory)

• FactoryTalk Historian Asset Framework

• FactoryTalk Historian SE (includes FactoryTalk Historian SE

Server, FactoryTalk Historian Live Data Interface, and

FactoryTalk Activation Manager)

• FactoryTalk Historian Management Tools

• RSLinx Enterprise

• FactoryTalk Historian DataLink

The following diagram shows a typical architecture of the

FactoryTalk Historian SE environment.

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 9

Page 10

Chapter 1 Overview

User Documentation

On the Installation DVD

The user documentation on FactoryTalk Historian SE is available in

the following locations:

• The FactoryTalk Historian SE installation DVD (page 10).

• The computer on which you have installed FactoryTalk

Historian SE (page 11).

• The Help folder in the Start menu (page 11).

There are the following locations on the FactoryTalk Historian SE

installation DVD with the user documentation and

documentation-related resources:

• The Open Installation Instructions > Installation

Instructions page

On this page you will find the following resources:

• FactoryTalk Historian SE Installation Assistant

• FactoryTalk Historian SE Installation and Configuration

Guide

• Adobe Reader required to open PDF files.

• The Read Documentation > Documentation page

On this page you will find the following resources:

• FactoryTalk Historian SE Upgrade and Migration Guide

• FactoryTalk Historian SE Installation and Configuration

Guide

• FactoryTalk Historian SE Reference Guide

• FactoryTalk Historian Live Data Interface User Guide

• Introduction to Historian SE Server System Management

Guide

• FactoryTalk Historian SE Release Notes

10 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 11

Overview Chapter 1

• Adobe Reader required to open the PDF files.

• A link to the Redist\Docs folder on the installation DVD

that stores all the user documentation.

• A link to the Rockwell Automation Literature Library

(http://literature.rockwellautomation.com/idc/groups/pu

blic/documents/webassets/browse_category.hcst).

• The Watch Historian How-to Videos on YouTube link on

the main page of the installation wizard.

A link to a Rockwell Automation channel at YouTube

devoted to FactoryTalk Historian

(http://www.youtube.com/playlist?list=PLB6E76CAA1F7F

F7B5&feature=plcp).

On the Local Hard Drive

In the Start Menu

To access the user documentation available on your computer, go to

the following locations:

• On a 32-bit operating system:

C:\Program Files\Common Files\Rockwell\Help.

• On a 64-bit operating system:

C:\Program Files (x86)\Common Files\Rockwell\Help.

Go to Start > All Programs > Rockwell Software > FactoryTalk

Historian SE > Help to access the following documents:

• Auditing the FactoryTalk Historian SE Server User Guide

(.pdf)

• Configuring FactoryTalk Historian SE Security User Guide

(.pdf)

• FactoryTalk Historian DataLink Online Help (.chm)

• FactoryTalk Historian SE Live Data Interface User Guide

(.pdf)

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 11

Page 12

Chapter 1 Overview

• FactoryTalk Historian SE AF 2010 R2 Installation and

Maintenance Guide (.pdf)

• FactoryTalk Historian SE Applications User Guide (.pdf)

• FactoryTalk Historian SE Buffering User Guide (.pdf)

• FactoryTalk Historian SE High Availability Administrator

Guide (.pdf)

• FactoryTalk Historian SE Interface Configuration Utility User

Guide (.pdf)

• Introduction to Historian SE Server System Management (.pdf)

• FactoryTalk Historian SE MDB to AF Transition Guide (.pdf)

• FactoryTalk Historian SE OPC DA Interface Failover Manual

(.pdf)

• FactoryTalk Historian SE OPC Interface Manual (.pdf)

• FactoryTalk Historian SE Server Reference Guide (.pdf)

• FactoryTalk Historian SE System Explorer User Guide (.pdf)

• FactoryTalk Historian SE System Management Guide (.pdf)

• FactoryTalk Historian DataLink User Guide (.pdf)

• FactoryTalk Historian SE Installation and Configuration

Guide (.pdf)

• FactoryTalk Historian SE Upgrade and Migration Guide (.pdf)

• FactoryTalk Historian SE Online Help (.chm)

• FactoryTalk Historian DataLink Release Notes (.htm)

• FactoryTalk Historian SE Release Notes (.chm)

12 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 13

Overview Chapter 1

Technical Support and Resources

Technical Support

Knowledgebase

Rockwell provides dedicated technical support internationally, 24

hours a day, 7 days a week.

You can read complete information about technical support

options, and access all of the following resources at the Rockwell

Automation Support Web site

(http://www.rockwellautomation.com/support/).

Please visit Rockwell Automation Customer Support Center

(http://www.rockwellautomation.com/support/) for access to user

forums, sample code, software and firmware updates, product

manuals, and other downloads.

The Customer Support Center offers an extensive online

knowledgebase that includes frequently asked questions (FAQs) and

the latest patches. Please visit the support site

(http://www.rockwellautomation.com/resources/support.html)

and select the Knowledgebase link located under Tools &

Resources to:

• View technical and application notes.

• Obtain software patches and firmware updates.

• Subscribe to product and service e-mail notifications.

• Ask questions.

Worldwide Support

If you are not located in North America and want to contact

Rockwell Automation Support, use the Worldwide Locator

(http://www.rockwellautomation.com/locations/) for worldwide

contact information.

Training Programs

Rockwell Automation offers a wide range of training programs that

include e-learning, regularly scheduled and custom-tailored classes,

self-paced training, and certificate programs. For more information

on the trainings, visit the Rockwell Automation Training site

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 13

Page 14

Chapter 1 Overview

(http://www.rockwellautomation.com/services/training/) or call

1.440.646.3434.

If you are not located in North America and want to contact

Rockwell Automation Support, use the Worldwide Locator

(http://www.rockwellautomation.com/locations/) for worldwide

contact information.

TechConnect Support

With TechConnect Support, your site has unlimited, real-time

access to Rockwell Automation's global network of Customer

Support Centers and technical resources. TechConnect service

levels are provided at the TechConnect site

(http://www.rockwellautomation.com/services/onlinephone/techc

onnect/).

When you contact Rockwell Technical Support, please provide:

• Product name, version, and/or build numbers.

• Computer platform (CPU type, operating system, and version

number).

• Exact wording of any messages that appeared on your screen.

• The message log(s) at that time.

• Descriptions of:

• What happened and what you were doing when the

problem occurred.

• How you tried to solve the problem.

14 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 15

Overview Chapter 1

Find the Version and Build Numbers

To find version and build numbers for each Historian Server

subsystem (which vary depending on installed upgrades, updates, or

patches), use either of the following methods:

To check the numbers with System Management Tools (SMT):

1. Go to Start > All Programs > Rockwell Software > FactoryTalk

Historian SE > System Management Tools. The System

Management Tools dialog box appears.

2. Under Collectives and Servers, select the name of the server

you want to check.

3. Under System Management Tools, select Operation > PI

Version.

The Version in Memory and Version on Disk columns

display information on versions of all the server subsystems.

If you do not have System Management Tools installed, open a

command prompt, change to the pi\adm directory, and type

piversion -v. To see individual version numbers for each subsystem,

change to the pi\bin directory and type the subsystem name

followed by the option -v (for example, piarchss.exe -v).

View Computer Platform Information

To view platform specifications, right-click My Computer and

select Properties. For more detailed information, choose Start >

Run, and type msinfo32.exe.

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 15

Page 16

Chapter 1 Overview

16 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 17

Chapter 2

System Requirements

The hardware required with FactoryTalk Historian Site Edition

depends on the demands an application places on the system. The

greater the demand, the more powerful a system is required. In any

application, faster processors and more memory will result in better

performance. In addition, there should always be sufficient disk

space to provide virtual memory that is at least twice the size of the

physical memory.

FactoryTalk Historian SE Server Machine

Learn about the system requirements for the following components

of FactoryTalk Historian SE:

• FactoryTalk Historian SE Server Machine (page 17)

• FactoryTalk Historian Live Data Interface Machine (page 18)

• FactoryTalk Historian Client Machine (page 18)

• FactoryTalk Historian Asset Framework (page 19)

• FactoryTalk Historian DataLink (page 20)

Item Description

System requirements

• FactoryTalk Historian SE 25,000 points and below

Minimum: Intel Pentium Xeon, 3.2 GHz, 4GB RAM

• FactoryTalk Historian SE 50,000 points and below

Minimum: Intel Pentium Xeon, 3.2 GHz, 4GB RAM

• FactoryTalk Historian SE 100,000 points and below

Minimum: Intel Pentium Xeon dual processor, 3.4 GHz, 4GB

RAM

Hardware

• 100 Megabit or faster Ethernet card, network cable,

concentrator if using twisted pair wiring; TCP/IP protocol.

• SVGA TrueColor monitor with 1 MB of video RAM and

1024x768 resolution.

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 17

Page 18

Chapter 2 System Requirements

•

Item Description

Operating systems Microsoft Windows Server 2008 R2 with Service Pack 1 64-bit

FactoryTalk Historian Live Data Interface Machine

FactoryTalk Historian Client Machine

Item Description

Hardware Minimum: Intel Celeron D, 3.0Ghz, 512MB RAM

Operating systems

Microsoft Windows 7 with Service Pack 1 32-bit and 64-bit

• Microsoft Windows XP with Service Pack 3 32-bit

• Microsoft Windows Server 2003 R2 with Service Pack 2 32-bit

and 64-bit

• Microsoft Windows Server 2008 R2 with Service Pack 1 64-bit

• Microsoft Windows Server 2008 with Service Pack 2 32-bit and

64-bit

Item Description

Hardware

• 100 Megabit or faster Ethernet card, network cable;

concentrator if using twisted pair wiring; TCP/IP protocol

• SVGA TrueColor monitor with 1 MB of video RAM and

1024x768 resolution

• Minimum: Intel Pentium III, 600Mhz, 512MB RAM

• Recommended: Intel Celeron, 3GHz or higher, 1GB RAM or

more

Operating systems

• Microsoft Windows 7 with Service Pack 1 32-bit and 64-bit

• Microsoft Windows XP with Service Pack 3 32-bit

• Microsoft Windows Server 2008 R2 with Service Pack 1 64-bit

• Microsoft Windows Server 2008 with Service Pack 2 32-bit and

64-bit

Other software

• Microsoft Internet Explorer 6SP1, IE7, IE8

• Microsoft Excel 2003 or newer for FactoryTalk Historian

DataLink or FactoryTalk Historian System Management Tools

(SMT)

18 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 19

System Requirements Chapter 2

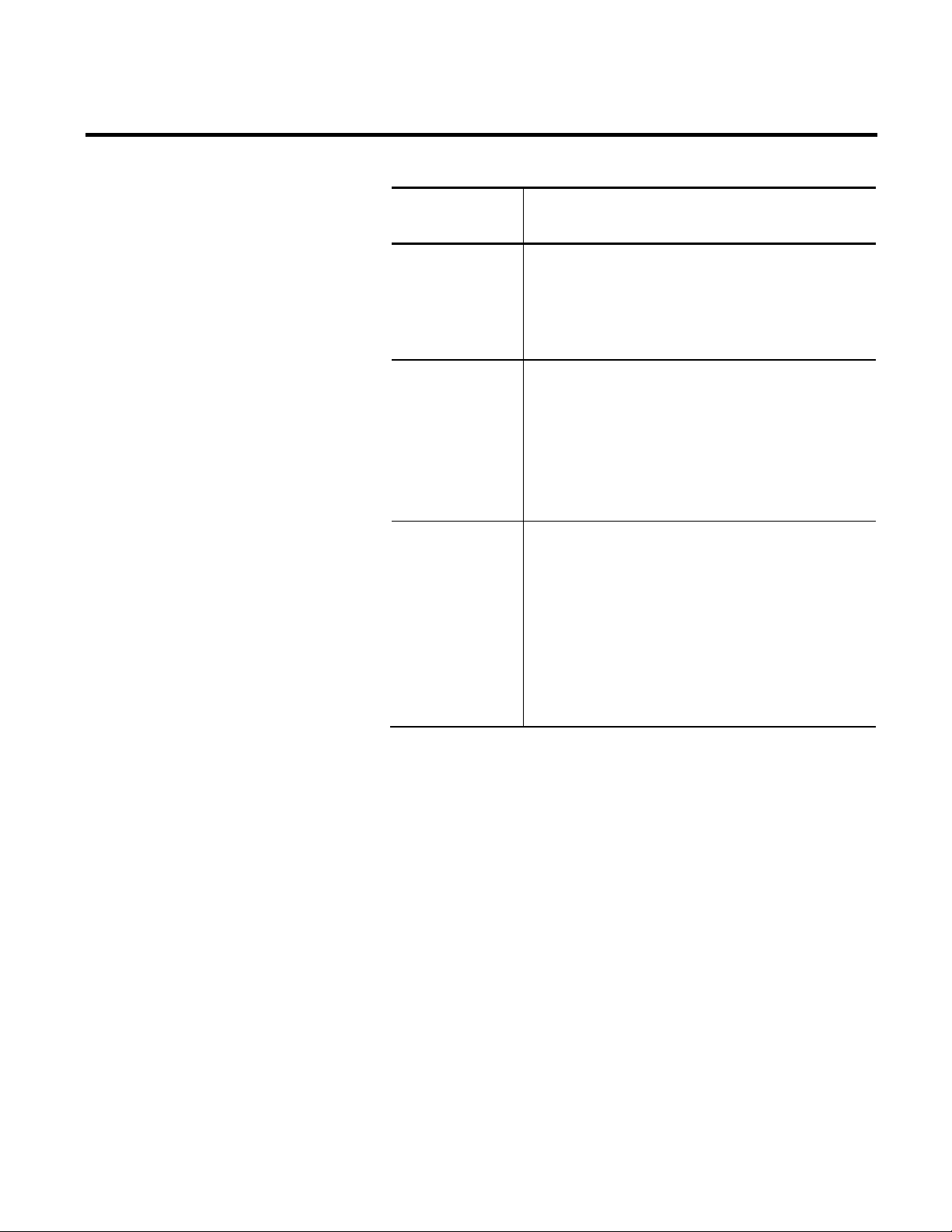

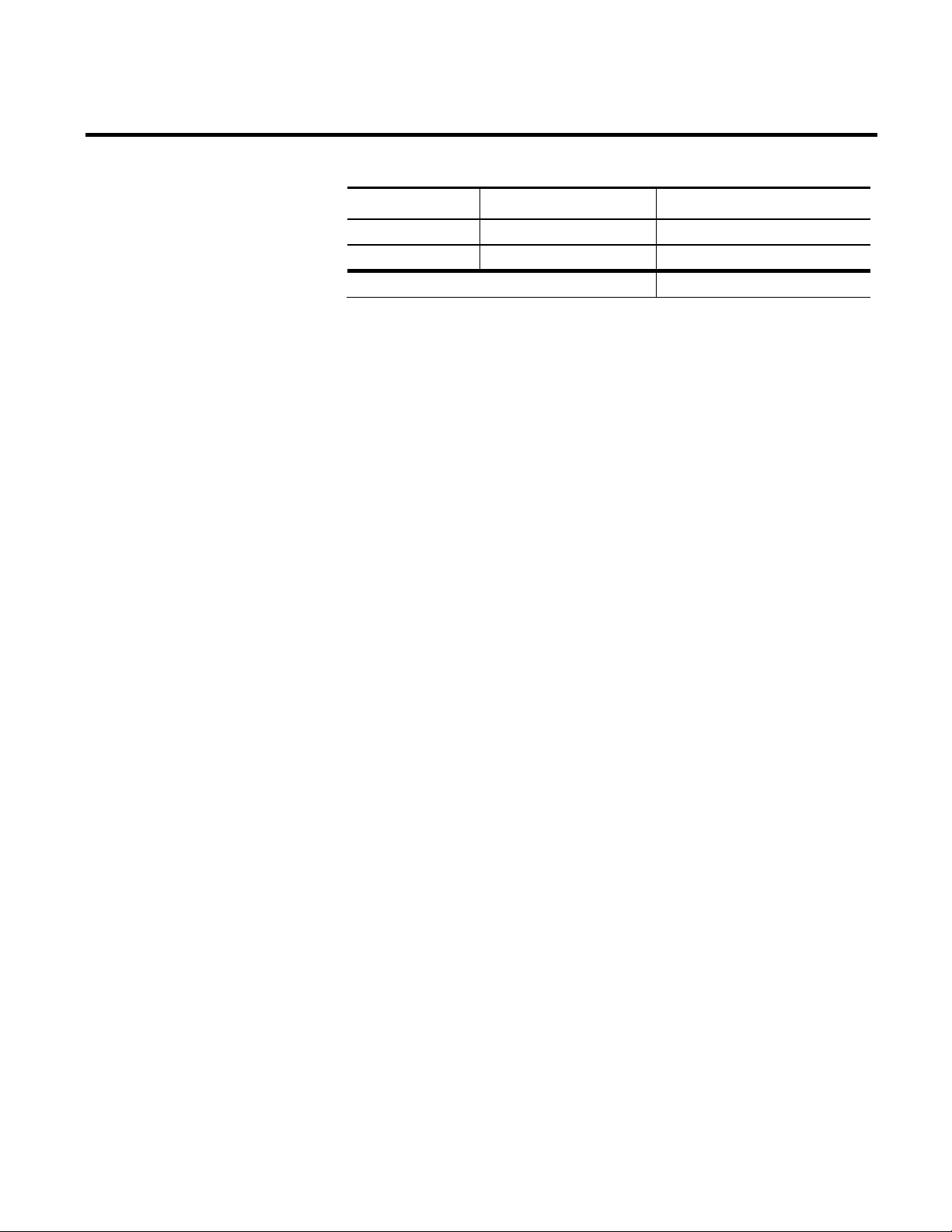

FactoryTalk Historian Asset Framework

FactoryTalk Historian Asset Framework requirements

Item Description

Hardware Processor: a single quad-core processor, minimum 2.2 GHz

Operating systems

(both 32-bit and

64-bit versions, if

available)

• Microsoft Windows Server 2008 R2

• Microsoft Windows Server 2008

• Microsoft Windows Server 2003 (with Service Pack 1 or later)

• Microsoft Windows 7

• Microsoft Windows Vista

• Microsoft Windows XP with Service Pack 2 or later

Database size

Database storage is consumed depending on the type and quantity of

FactoryTalk Historian Asset Framework objects. The table below

shows approximate database sizes of some representative Asset

Framework systems.

AF Element

Count

(in MB)

Event Frames

Count

(in MB)

SQL DB

Size

(in MB)

Recommended

Memory

(in MB)

0 0 40 24

1,000 10,000 165 99

2,000 20,000 285 171

3,000 30,000 400 240

4,000 40,000 520 312

5,000 50,000 640 384

6,000 60,000 755 453

10,000 100,000 1,100 660

20,000 200,000 2,230 1,338

30,000 300,000 3,300 1,980

40,000 400,000 4,320 2,592

50,000 500,000 5,380 3,228

100,000 1,000,000 10,640 6,384

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 19

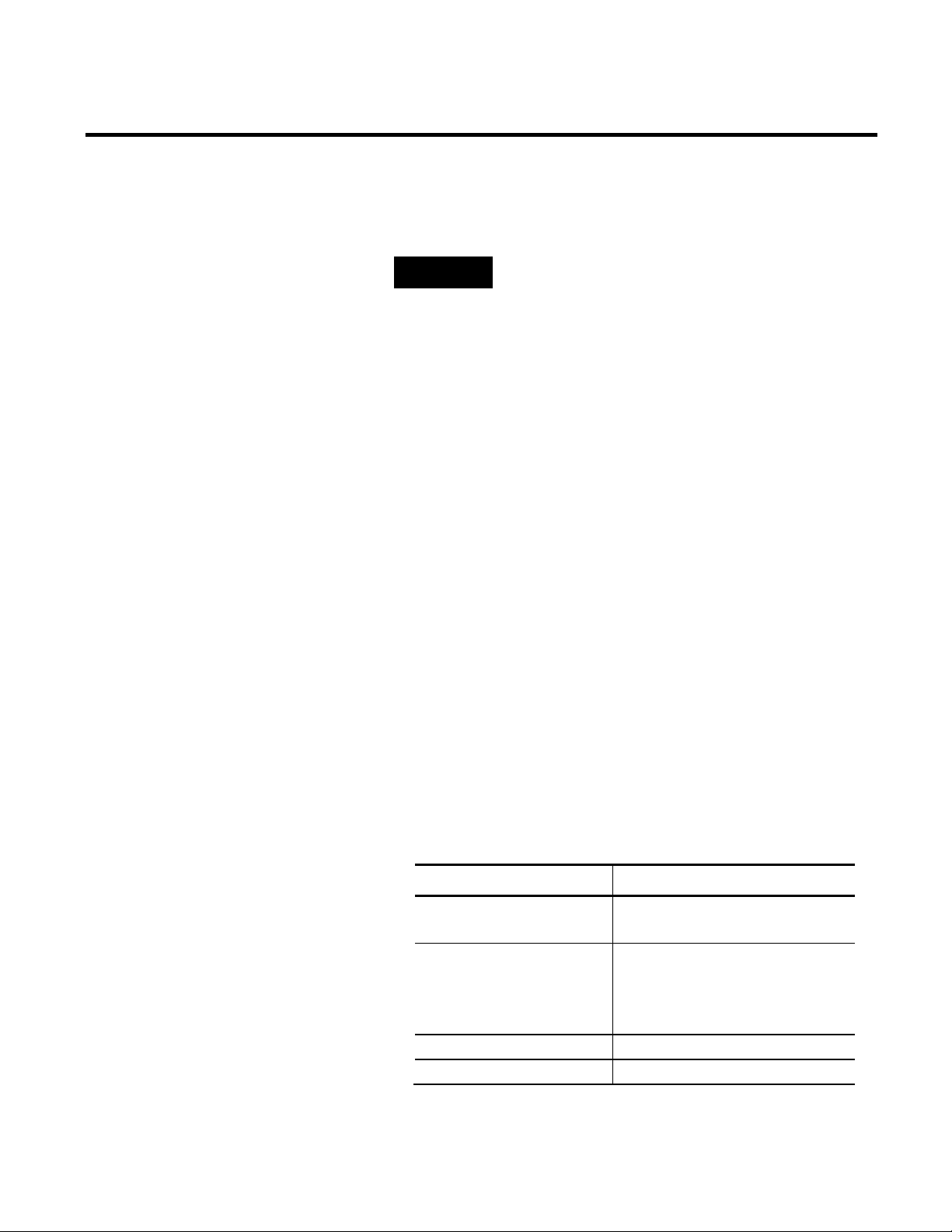

Page 20

Chapter 2 System Requirements

SQL Server requirements

Item Description

Supported SQL Server editions

Supported SQL Server versions (both

32-bit and 64-bit versions, if

available)

Required SQL Server components

Required memory

NOTE

For databases with up to 1000 elements, Asset Framework may be

installed on the FactoryTalk Historian server.

For more information on the Microsoft SQL Server system requirements,

refer to the Microsoft Development Network

(http://msdn.microsoft.com/en-us/library/ms143506(SQL.90).aspx).

• Express

• Standard

SQL Server 2008

• Database Engine

• Agent (backup and replication)

• 1GB for databases with up to 50000 elements

• 4 GB for databases with up to 200000 elements

FactoryTalk Historian DataLink

Item Description

Hardware

• Physical memory:

Min. 32 MB, recommended 128 MB

• Processor: Pentium or higher

• Disk space requirements:

Min. 120 MB for application files and registry entries as well as

space for keeping a backup copy of the pisdk.msi and

ProcessBook.msi files.

Operating systems

• Microsoft Windows Server 2008 R2

• Microsoft Windows 7

• Microsoft Windows XP with Service Pack 2 or higher

20 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 21

•

•

Item Description

System Requirements Chapter 2

Other software

NOTES

• Microsoft Excel Versions:

Microsoft Excel 2010 (32-bit) *, **

Microsoft Excel 2007 *

• FactoryTalk Services Platform 2.50 (CPR 9 SR 5)

* If this is a Microsoft Office upgrade and there is a pre-existing

installation of DataLink 4.x on that machine, a removal and

reinstallation of DataLink may be necessary. Refer to the KB article

254380

(http://rockwellautomation.custhelp.com/app/answers/detail/a_id/25

4380/kw/254380) to eliminate VBA related errors that might occur

after an Excel upgrade.

** In rare instances, the PI tab does not appear on the ribbon

immediately following the installation of the Microsoft Excel add-in.

Refer to the KB article 254379

(http://rockwellautomation.custhelp.com/app/answers/detail/a_id/25

4379/kw/254379) to resolve the situation.

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 21

Page 22

Chapter 2 System Requirements

22 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 23

Chapter 3

Pre-Installation Tasks

Before you install FactoryTalk Historian SE, do the following:

• Synchronize time settings on Historian system computers

(page 23).

Synchronize Time Settings on FactoryTalk Historian System Computers

• Disable the Windows time zone (page 23).

• Learn about installation-related recommendations (page 24).

For all machines that are part of the FactoryTalk Historian system,

you must ensure that the time is set correctly and synchronized with

the FactoryTalk Historian server. In addition, make sure that all

Windows machines have the proper time-zone settings and that they

are set to automatically adjust for daylight-saving changes.

The clocks of the FactoryTalk Historian server computer and client

computers should all be synchronized. This is typically done through

the domain controller. The domain controller's time is synchronized

first by an NTP source. Then, the domain controller synchronizes

all the other computers that are a part of the FactoryTalk Historian

system.

For details, search the Rockwell Automation Technical Support

(http://rockwellautomation.custhelp.com/) web site for daylight

saving time.

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 23

Page 24

Chapter 3 Pre-Installation Tasks

Disable the Windows Time Zone (TZ) Environment Variable

The Windows time zone (TZ) environment variable adversely

affects the Historian server. You must ensure that TZ is not set on

the Historian server computer.

To confirm that the TZ variable is not set on computers prior to

Windows 2008:

1. Go to Start > My Computer.

2. Right-click and select Properties.

3. In the System Properties dialog box, click the Advanced tab.

4. Click Environment Variables.

5. If the TZ variable is present, delete it.

6. If prompted, restart the computer.

To confirm that the TZ variable is not set on Windows Server

2008 and 2008 R2:

1. Go to Start > My Computer.

2. Right-click and select Properties.

3. Click Advanced system settings.

4. Click Environment Variables.

5. If the TZ variable is present, delete it.

6. If prompted, restart the computer.

Learn About

We recommend that you use the default installation options.

Installation-related

Recommendations

24 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

If you want to use the SMT software installed on a FactoryTalk

Historian SE server computer to manage a FactoryTalk Historian

Live Data Interface installed on another computer, you must log on

to both computers with the same user name. (The user must have

administrator privileges on both computers.)

Page 25

Chapter 4

Installing FactoryTalk Historian

In this chapter you will find instructions on how to install the

following:

• Core components of the product (page 25).

Installing Core Components

Install Microsoft SQL Server

• FactoryTalk Historian suites (page 32).

In this section you will find instructions on how to install the

following core components of FactoryTalk Historian SE:

• Microsoft SQL Server (page 25)

• FactoryTalk Services Platform (page 27)

• FactoryTalk Activation Manager (page 30)

• RSLinx Enterprise (Data Server) (page 31)

Microsoft SQL Server 2008 is a requirement for running

FactoryTalk Historian Asset Framework.

FactoryTalk Historian SE 3.01 supports SQL Server Express and

Standard Editions. Rockwell Automation recommends using the

SQL Server Express Edition, which is available on the FactoryTalk

Historian SE installation DVD. If you choose to use the SQL

Standard Edition (for example, from the FactoryTalk VantagePoint

installation DVD), please acquire appropriate Client Access

Licenses (CAL) and/or processor licenses from Microsoft. For more

information, refer to the Microsoft site

(http://www.microsoft.com/sqlserver/en/us/get-sql-server/how-tobuy.aspx).

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 25

Page 26

Chapter 4 Installing FactoryTalk Historian

If you already have an SQL Server, you will be able to point to it

during the installation of FactoryTalk Historian Asset Framework.

If you are going to use FactoryTalk VantagePoint as your Historian

client, you can use Microsoft SQL Server 2008 R2 that is provided

on the FactoryTalk VantagePoint installation DVD. Refer to the

following documentation before the installation of the SQL Server:

• FactoryTalk VantagePoint Getting Results Guide, section

"Installing and Configuring IIS". The guide is available on

the FactoryTalk VantagePoint installation DVD.

• Article 279061 - How to install Microsoft SQL Server 2008

R2 for use with FactoryTalk VantagePoint v3.1.5 and higher.

The article is available on the Rockwell Automation

Knowledgebase

(http://rockwellautomation.custhelp.com/).

NOTE

If you want to install the Asset Framework SQL database

only, you need to run the installation on the machine with

the Microsoft SQL Server installed.

To install Microsoft SQL Server 2008 Express:

1. Run the FactoryTalk Historian SE installation DVD.

2. On the welcome page of the installation wizard, click Install

FactoryTalk Historian SE > Install FactoryTalk Historian Asset

Framework > Install Microsoft SQL Server 2008 Express.

The installation wizard appears.

3. Follow the on-screen instructions to complete the process.

NOTE

For more information on installing Microsoft SQL Server 2008

Express, refer to the product documentation.

4. If instructed, restart the computer.

26 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 27

Installing FactoryTalk Historian Chapter 4

Install FactoryTalk Services Platform

When you select this option, the following components will be

installed:

• FactoryTalk Diagnostics

• Windows Firewall Configuration Utility (WFCU)

• FactoryTalk Services Platform

FactoryTalk Services Platform is an underlying architecture and a set

of common services (such as diagnostic messages, health monitoring

services, access to real-time data, and shared plant resources such as

tags and graphic displays) that Rockwell Automation products build

upon. It is a prerequisite for all FactoryTalk-enabled software

products, such as FactoryTalk Historian SE, FactoryTalk View, and

RSLinx Enterprise.

FactoryTalk Diagnostics collects and provides access to activity,

status warnings, and error messages generated throughout a

FactoryTalk system.

For more information on FactoryTalk, refer to FactoryTalk Help.

You can access it from Start > All Programs > Rockwell Software >

FactoryTalk Tools > FactoryTalk Help after you have installed

FactoryTalk Services Platform on your machine.

NOTE

Make sure to install FactoryTalk Services Platform on all the computers,

including the computer that will serve as the FactoryTalk Directory.

To install FactoryTalk Services Platform:

1. Run the FactoryTalk Historian SE installation DVD.

2. On the welcome page of the installation wizard, click Install

FactoryTalk Historian SE > Install FactoryTalk Services

Platform > Install FactoryTalk Services Platform.

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 27

Page 28

Chapter 4 Installing FactoryTalk Historian

The system checks if you have all the required components

installed. If any components are missing, a dialog box appears

prompting you to install the missing components. Click

Install to install the components.

The installation wizard appears.

3. On the Welcome... page, click Next.

4. On the License Agreement page, read and accept the terms of

the license agreement, selecting the I accept... option.

Click Next.

5. On the Setup Type page, select Standard and click Next.

6. On the Ready to Install the Program page, click Install to

start the installation.

Specify FactoryTalk Directory Server Location

The Installing page appears with the status of the installation.

7. On the InstallShield Wizard Completed page, click Finish

to exit the wizard.

You may be prompted to restart your computer to complete

the installation. If you do not choose to restart your computer

at this time, be sure to restart it at the completion of the

required installation steps for FactoryTalk Historian SE.

This configuration points your client computer to the FactoryTalk

Directory server computer. Once your computer is connected to the

FactoryTalk Directory server, you can use the client computer to

administer the Network directory on the FactoryTalk Directory

server computer. Also, the FactoryTalk Administration Console

window on your client computer reflects the content of the

Network Directory server computer.

28 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 29

Installing FactoryTalk Historian Chapter 4

To specify the FactoryTalk Directory server location:

1. Run the FactoryTalk Historian SE installation DVD.

2. On the welcome page of the installation wizard, click Install

FactoryTalk Historian SE > Install FactoryTalk Services

Platform > Specify FactoryTalk Directory Server Location.

The FactoryTalk Directory Server Location Utility dialog

box appears.

3. In the FactoryTalk Directory Server Location Utility dialog

box, identify the computer that hosts the FactoryTalk

Directory server. If it is the current computer, leave localhost in

the text box. Otherwise, do the following to point to the

proper FactoryTalk Directory computer:

1. Click the ellipsis button (

). The Login User dialog box

appears.

2. In the User name and Password text boxes, type the

credentials to the current FactoryTalk Directory machine.

The FactoryTalk Directory Server Configuration dialog

box appears.

3. Select the Remote computer option and click the ellipsis

button (

) to open the Browse for Computer dialog box.

4. Select the machine that hosts the FactoryTalk Directory

and click OK.

The name of the machine appears in the FactoryTalk

Directory Server Location Utility dialog box.

5. Click OK.

6. In the message box informing you that you will need to

restart the computer, click OK.

7. In the Log On to FactoryTalk (New Server) dialog box,

type the user name and password to the newly selected

FactoryTalk Directory machine.

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 29

Page 30

Chapter 4 Installing FactoryTalk Historian

8. Click OK. The system connects to the FactoryTalk

Directory server.

Install FactoryTalk Activation Manager

NOTE

On the computers that have FactoryTalk Services Platform

installed, you can open the Specify FactoryTalk

Directory Server Location Utility dialog box also from

Start > All Programs > Rockwell Software > FactoryTalk

Tools > Specify FactoryTalk Directory Location.

FactoryTalk Activation Manager allows you to download activation

files using an Internet connection, and transfer activation files to a

computer that does not have an Internet connection. Install this

software on the same computer as the FactoryTalk Directory server.

To install the FactoryTalk Activation Manager:

1. Run the FactoryTalk Historian SE installation DVD.

2. On the welcome page of the installation wizard, click Install

FactoryTalk Historian Site Edition > Install FactoryTalk

Services Platform > Install FactoryTalk Activation.

The FactoryTalk Activation Manager installation wizard

appears with a list of prerequisite packages.

Click Continue.

3. In the message box that appears:

• Click Yes, if you want to install the software for Rockwell

Automation USB dongles.

The drivers are used to support mobile activations which

are locked in a hardware dongle.

Follow the on-screen instruction to install the software.

• Click No, if you want to skip this step.

4. On the Welcome... page, click Next.

30 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 31

Installing FactoryTalk Historian Chapter 4

5. On the License Agreement page, read and accept the terms of

the license agreement, selecting the I accept... option.

Click Next.

6. On the Ready to Install the Program page, click Install to

start the installation.

The Installing page appears with the status of the installation.

7. On the InstallShield Wizard Completed page, click Finish

to exit the wizard.

You may be prompted to restart your computer to complete

the installation. If you do not choose to restart your computer

at this time, be sure to restart it before running FactoryTalk

Activation.

Install RSLinx Enterprise (Data Server)

NOTE

For more information on FactoryTalk Activation, see "Activating

FactoryTalk Historian SE Server 61".

RSLinx Enterprise is a FactoryTalk Live Data server and a

device-based alarm and event server. RSLinx Enterprise links

Allen-Bradley networks and devices to Microsoft Windows

products such as the FactoryTalk View SE (HMI software) and the

RSLogix family of device programming software. RSLinx Enterprise

provides FactoryTalk Historian SE with the data points (tags) it

collects from Rockwell Automation controllers.

NOTE

It is recommended to install RSLinx Enterprise (Data Server) on the

same machine as FactoryTalk Historian Live Data Interface, remote

from the FactoryTalk Historian SE server.

To install RSLinx Enterprise:

1. Run the FactoryTalk Historian SE installation DVD.

2. On the welcome page of the installation wizard, click Install

FactoryTalk Historian Site Edition > Install RSLinx Enterprise.

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 31

Page 32

Chapter 4 Installing FactoryTalk Historian

The system checks if you have all the required components

installed. If any components are missing, a dialog box appears

prompting you to install the missing components. Click OK.

The installation wizard appears.

3. On the Welcome page, click Next.

4. On the License Agreement page, read and accept the terms of

the license agreement, selecting the I accept... option.

Click Next.

5. On the Setup Type page, select Standard Feature Set

Installation, and click Next.

6. On the Ready to Install the Program page, click Install to

start the installation.

Installing FactoryTalk Historian Suites

The Installing... page appears with the status of the

installation.

7. In the Windows Security dialog box, select Always trust

software from "Rockwell Automation", and click Install to

proceed with the installation of the software.

8. On the InstallShield Wizard Completed page:

• Clear the check box next to Review Release Notes, if you

do not want to have them displayed.

• Click Finish to exit the wizard.

In this section you will find instructions on how to install the

following suites of FactoryTalk Historian SE:

• FactoryTalk Historian Asset Framework (page 33)

• FactoryTalk Historian SE Server (page 39)

• (Optional) FactoryTalk Historian Live Data Interface (page

43)

Applicable only to the customers who want to install the

interface on a remote computer.

32 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 33

Installing FactoryTalk Historian Chapter 4

• (Optional) FactoryTalk Historian Management Tools (page

47)

Applicable only to the customers who want to administer the

FactoryTalk Historian SE server from a remote computer.

• (Optional) Install Advanced Server (page 50)

• (Optional) Install FactoryTalk VantagePoint (page 52)

• Install Additional Historian Components (page 52)

Install FactoryTalk Historian Asset Framework

NOTE

To install FactoryTalk Historian SE, use a local Administrator

account or any other account that is a member of the Domain

Admins group. Do not use the built-in Domain Administrator

account of the domain created on Microsoft Windows Server

2008 R2.

When you select this option, the following components will be

installed:

• (Optional) Microsoft SQL Server 2008 Express

• FactoryTalk Historian Asset Framework Server

FactoryTalk Historian Asset Framework is a prerequisite for

installing FactoryTalk Historian SE. AF replaces the Historian

Module Database (MDB). Over time, Rockwell Automation will

transform MDB applications into AF applications. To provide

backward compatibility, FactoryTalk Historian SE 3.01 copies the

contents of Historian MDB over to AF, in a process called

transition. After the migration, the Historian server constantly

synchronizes the MDB content with AF, allowing you to access

MDB content from AF clients as well as MDB clients. Similarly, you

can access AF content from MDB clients, as well as AF clients. This

allows you to access your AF content with MDB-based tools, such as

ACE, or with an AF client such as FactoryTalk Historian System

Explorer.

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 33

Page 34

Chapter 4 Installing FactoryTalk Historian

AF itself requires Microsoft SQL Server. See "Install Microsoft SQL

Server (page 25)" for more information.

Installation Modes for FactoryTalk Historian Asset Framework

NOTE

Before installing FactoryTalk Historian Asset Framework, learn about

the installation options it offers. See "Installation Modes for FactoryTalk

Historian Asset Framework (page 34)" for more information.

For the best performance and improved security, Rockwell

Automation recommends that you install the SQL Server and the

Asset Framework service on different computers.

During the installation process, you can decide how the AF service

and the AF SQL database will be installed on your computer, by

choosing one of five installation modes representing the following

scenarios:

• Both the service and the database are located on the same

machine:

Installation

Description

mode

AF Application

Service and AF

The service and the database are installed on the same

machine.

SQL Database

AF Application

Service and AF

SQL Database

with

unprocessed

database scripts

The service is installed on the machine, the system is

prepared for the database installation, and the database

scripts are copied to the following location in the Program

Files directory: Rockwell Software\FactoryTalk

Historian\PIPC\AF\SQL.

You can create the database manually, using the provided

scripts. See "Manually Create the Asset Framework

Database (page 56)" for more information.

If you select this option, you need to provide in the DB

Server Name text box the name of the SQL Server machine

and (optionally) the name of the instance of the SQL Server

with which the AF service will communicate.

• The service and the database are located on different

machines:

34 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 35

Installation

mode

Installing FactoryTalk Historian Chapter 4

Description

AF Application

Service

AF SQL Database

AF SQL Database

with

unprocessed

database scripts

Only the service is installed on the machine.

If you select this option, you need to provide in the DB

Server Name text box the name of the SQL Server machine

and (optionally) the name of the instance of the SQL Server

with which the AF service will communicate.

Note: This option must be executed on the machine with

the Microsoft SQL Server installed.

Only the database is installed on the machine.

If you select this option, the database scripts will be copied

to the machine and executed during the installation. This

will result in creating the PIFD Asset Framework SQL

database.

Note: This option must be executed on the machine with

the Microsoft SQL Server installed.

The system is prepared for the database installation, and

the database scripts are copied to the following location in

the Program Files directory: Rockwell

Software\FactoryTalk Historian\PIPC\AF\SQL.

You can create the database manually, using the provided

scripts. See "Manually Create the Asset Framework

Database (page 56)" for more information.

You may choose to create the AF SQL database manually using the

provided scripts, for example when the configuration of your SQL

server does not allow for the integrated Windows authentication.

During the execution of the database scripts you can provide the

user name and the password to the SQL Server.

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 35

Page 36

Chapter 4 Installing FactoryTalk Historian

If you want to install the Asset Framework SQL database only, you need

Install FactoryTalk Historian Asset Framework Server

NOTE

to run the installation on the machine with the Microsoft SQL Server

installed.

To install FactoryTalk Historian Asset Framework Server:

1. Run the FactoryTalk Historian SE installation DVD.

2. On the welcome page of the installation wizard, click Install

FactoryTalk Historian SE > Install FactoryTalk Historian Asset

Framework > Install FactoryTalk Historian AF Server.

The installation wizard appears.

If there are any software prerequisites missing from the

computer, they are listed in red at the bottom of the

installation wizard Welcome page. Click Cancel and Finish

to exit the wizard, install the prerequisites, and start the

installation wizard again.

3. On the Welcome... page, click Next.

4. On the License Agreement page, read and accept the terms of

the license agreement, selecting the I accept... option.

5. Click Next.

6. On the Review Component Installation page, review the list

of the components that are already installed and those that will

be installed during the installation process.

Click Next.

7. On the Destination Drive page, select the drive on which you

want to install the product.

If the space available on the drive is not sufficient for the

installation, a warning message will appear below the

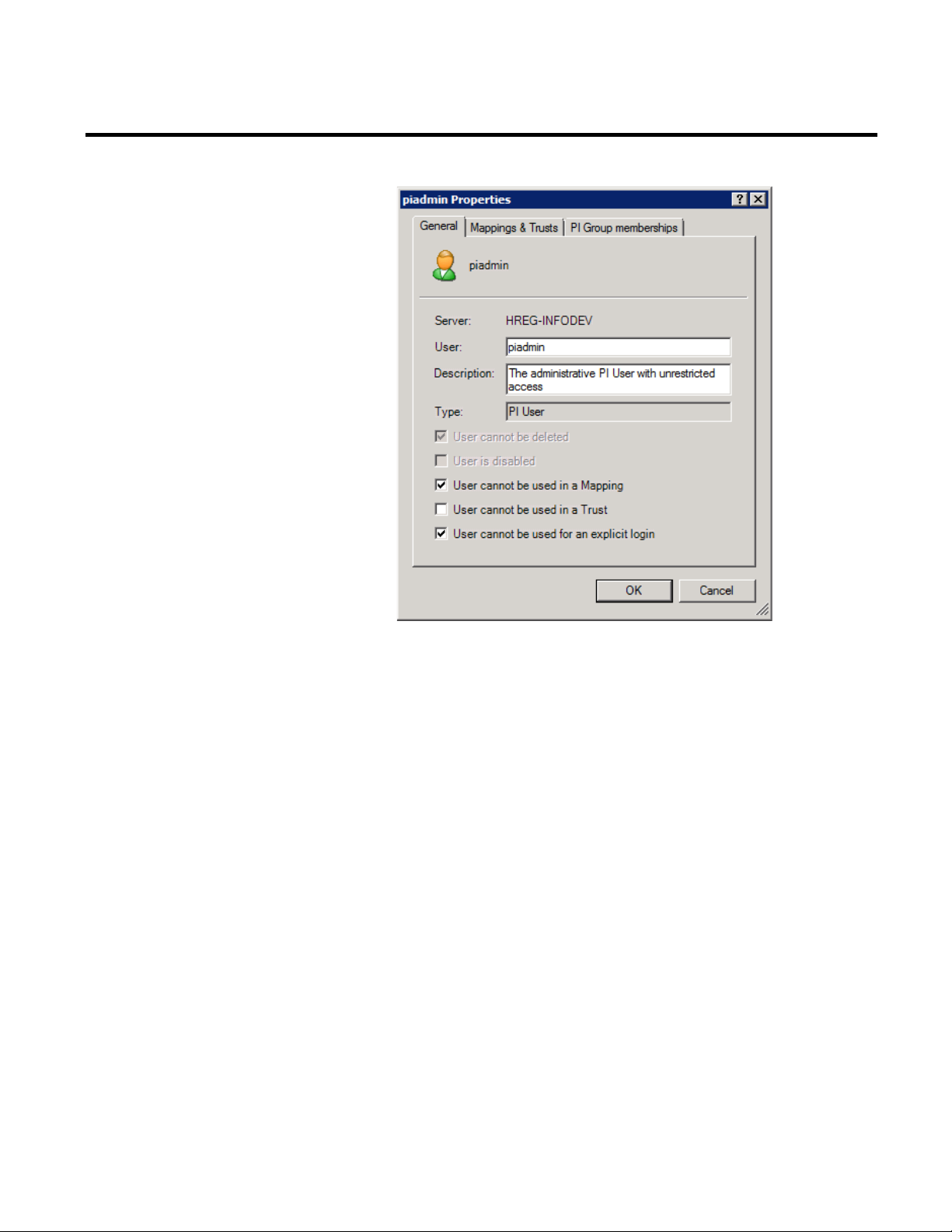

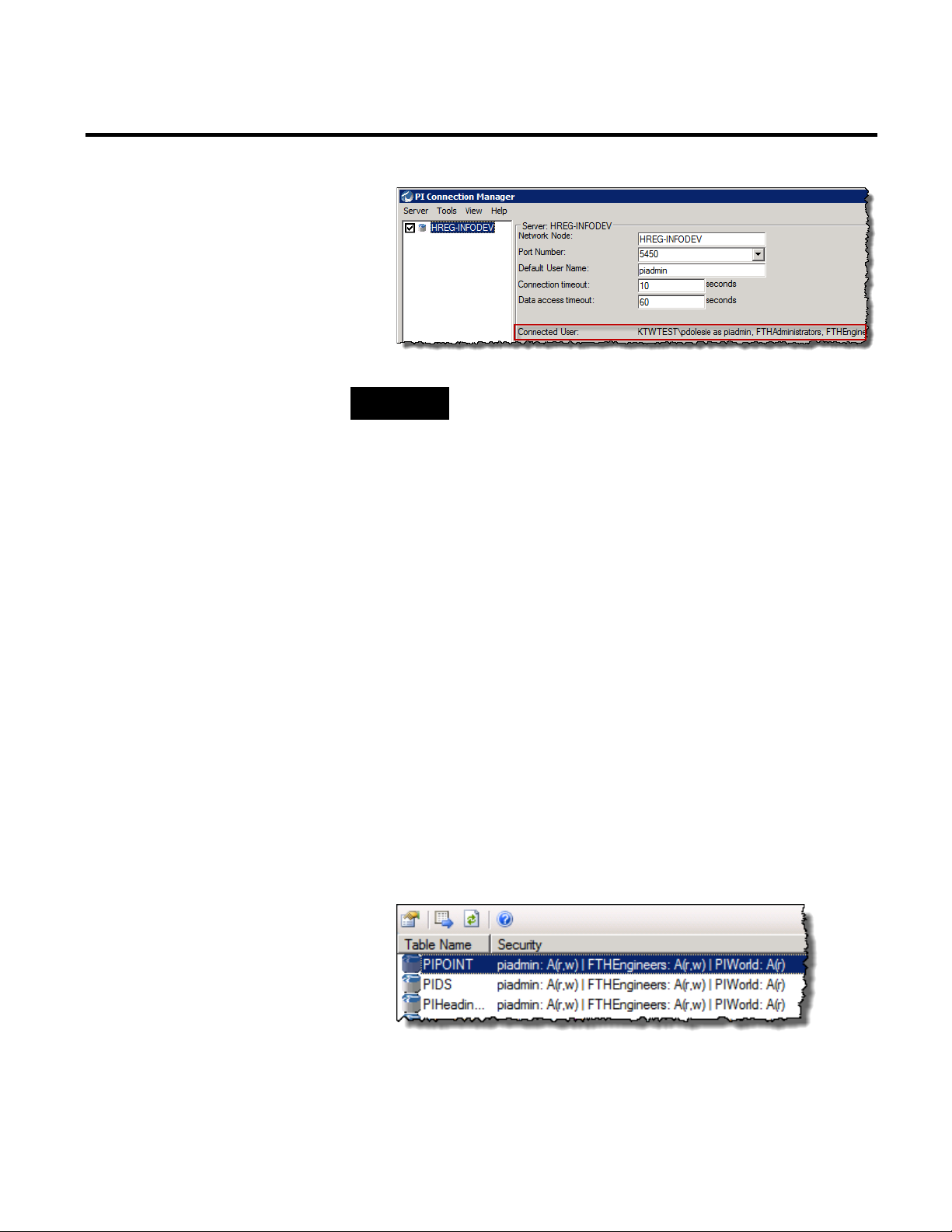

Installation drive list. In such a case, select another drive or

increase the available space on the drive you have originally

selected. For more information on the disk space

36 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

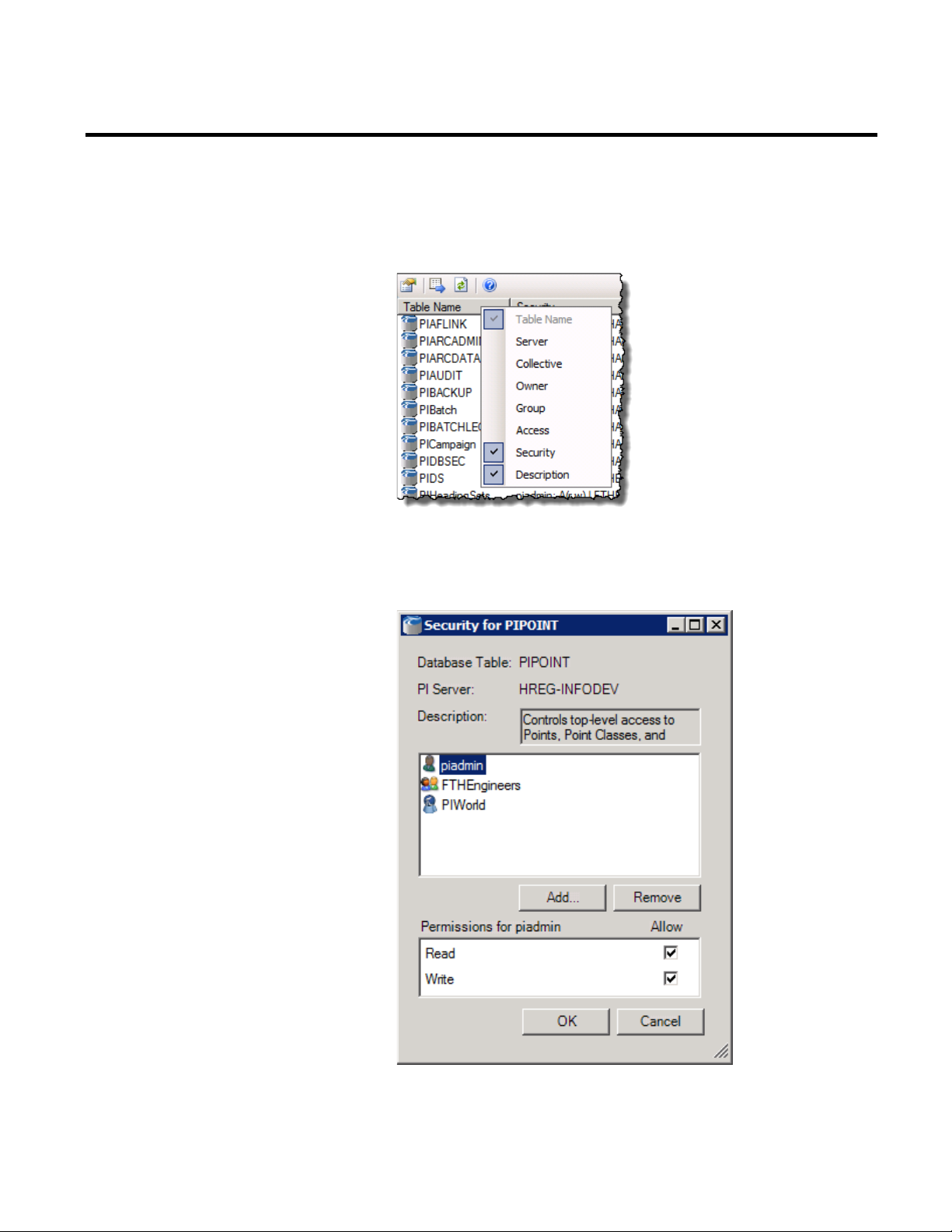

Page 37

Installing FactoryTalk Historian Chapter 4

(1) AF Application Service and AF

(2) AF Application Service and AF

requirements, refer to the FactoryTalk Historian SE Release

Notes.

NOTE

You can choose the destination drive only if you install the

component on the selected machine for the first time. If there have

been any FactoryTalk Historian components installed on the

machine before, the Installation drive list will not be enabled.

Click Next.

8. On the AF Server Components Configuration page, choose

the Microsoft SQL Server name and the installation mode.

1. In the DB Server Name text box, type the name of a

Microsoft SQL Server or an SQL Server named instance

that will host the AF SQL database.

• To use the local default instance created by Microsoft

SQL Server Express, leave the default database name

displayed in the text box.

• To use another SQL Server database instance, type the

name of the computer on which the database is located,

followed by the name of the instance that hosts the AF

SQL database, if the instance name is different than the

default one. For example:

SQLDBSERVER\SQLDBINSTANCE.

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 37

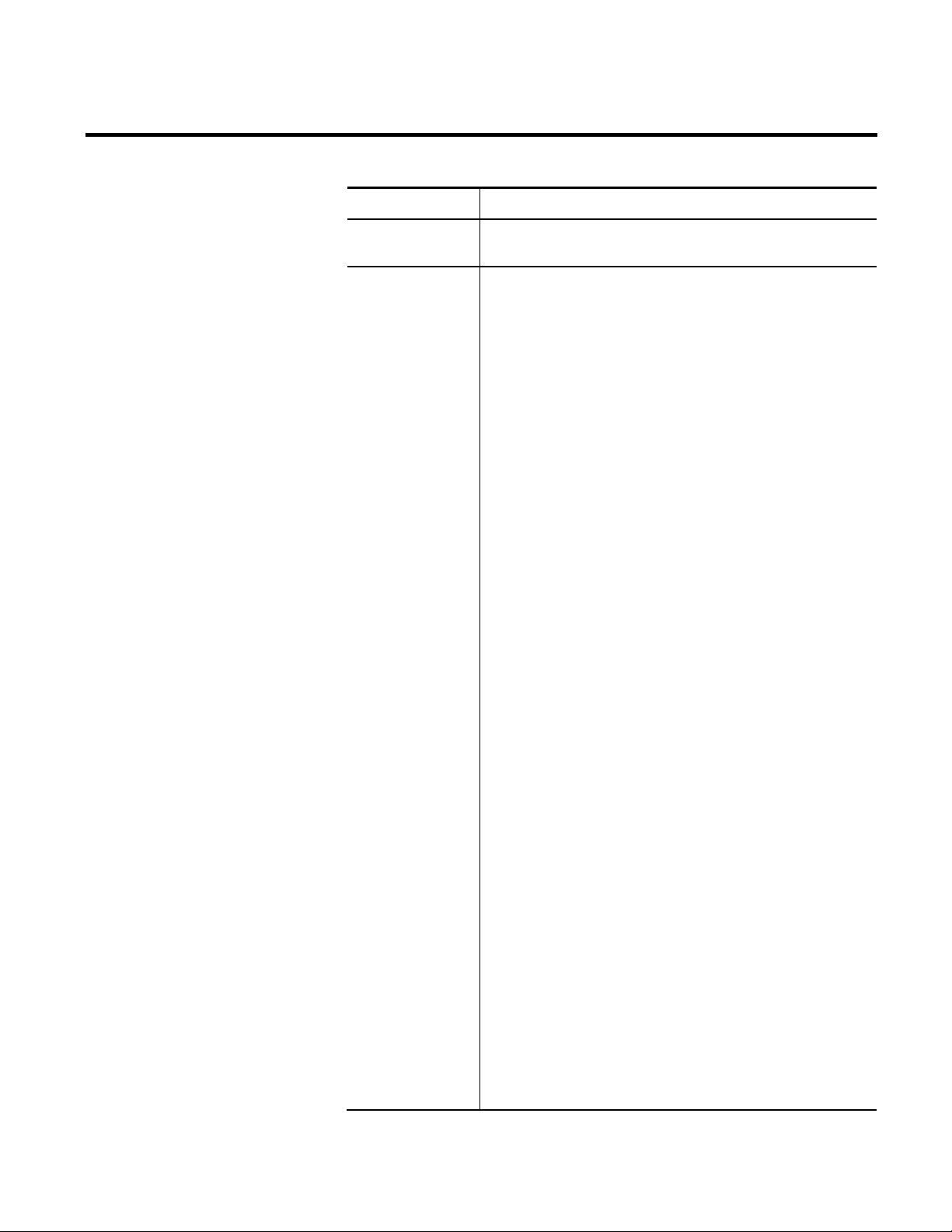

2. From the list, select the installation mode. See "Installation

Modes for FactoryTalk Historian Asset Framework (page

34)" for more information.

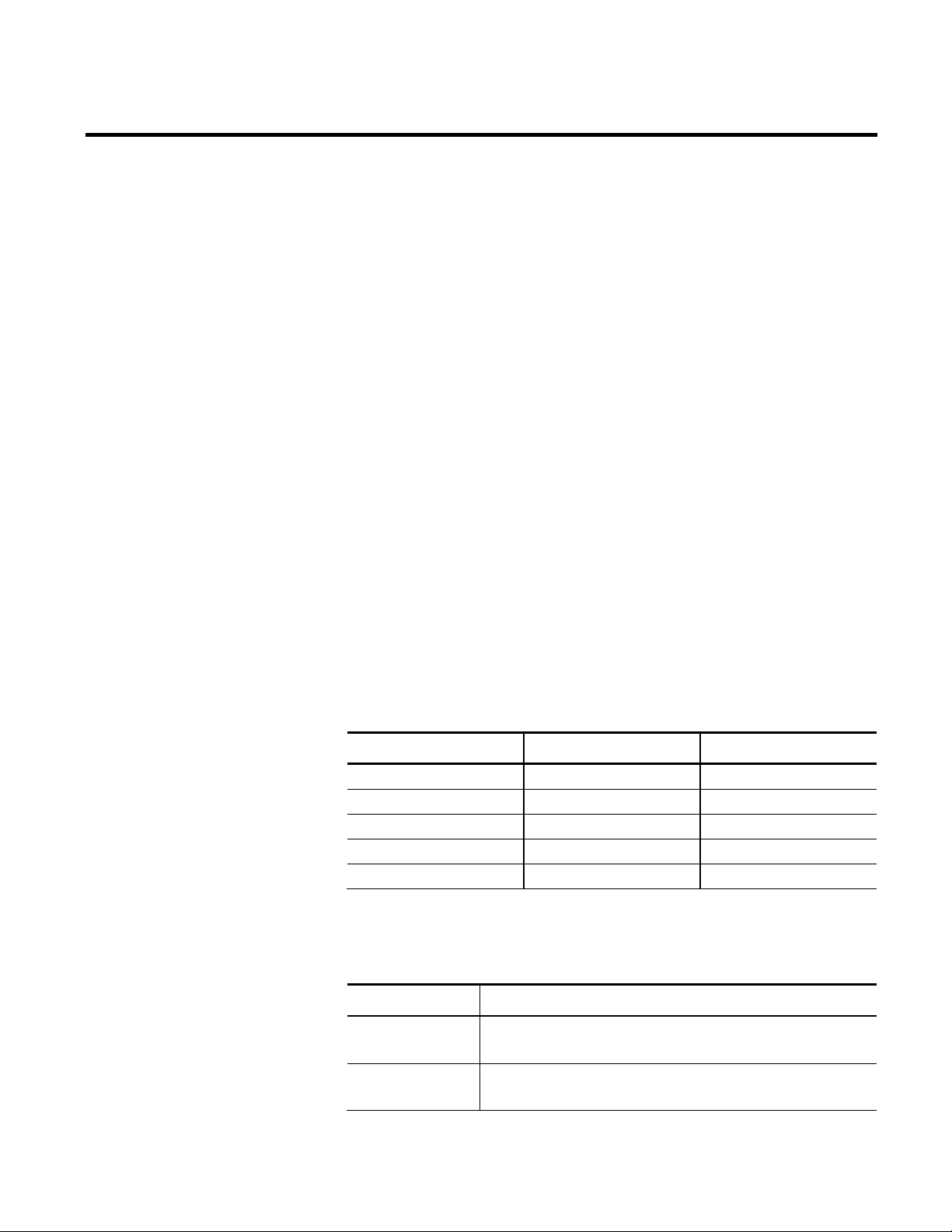

Choose this mode: To:

Install both the service and the database

SQL Database

SQL Database with unprocessed

database scripts

(3) AF Application Service Install the service only.

(4) AF SQL Database Install the database only.

on the same machine.

Install the service, prepare the system

for the database installation, and copy

the database executable scripts to the

machine.

Page 38

Chapter 4 Installing FactoryTalk Historian

Choose this mode: To:

(5) AF SQL Database with

unprocessed database scripts

Prepare the system for the database

installation, and copy the database

executable scripts to the machine.

NOTE

For more information on using the database scripts to manually

create the database, see "Manually Create the Asset Framework

Database (page 56)".

9. Click Next.

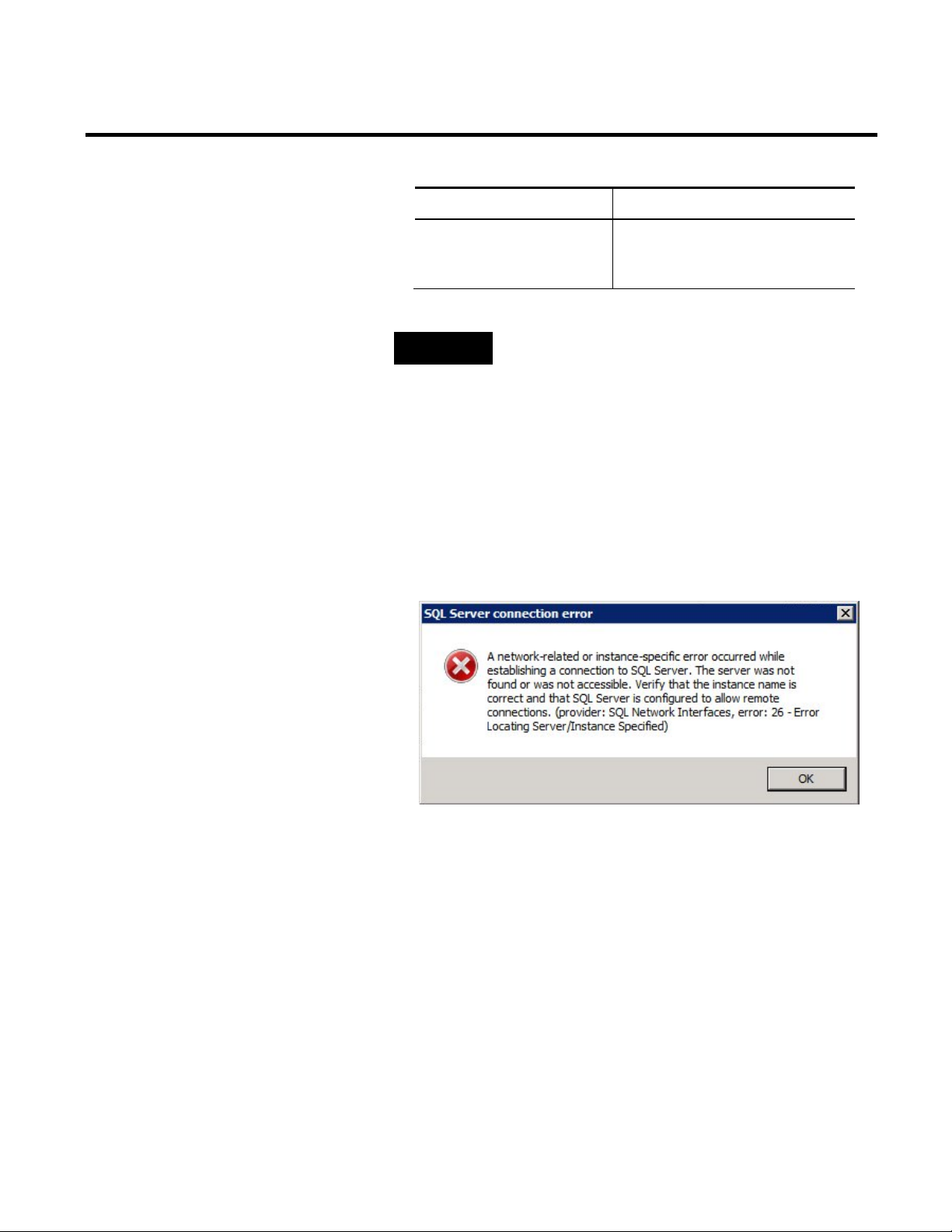

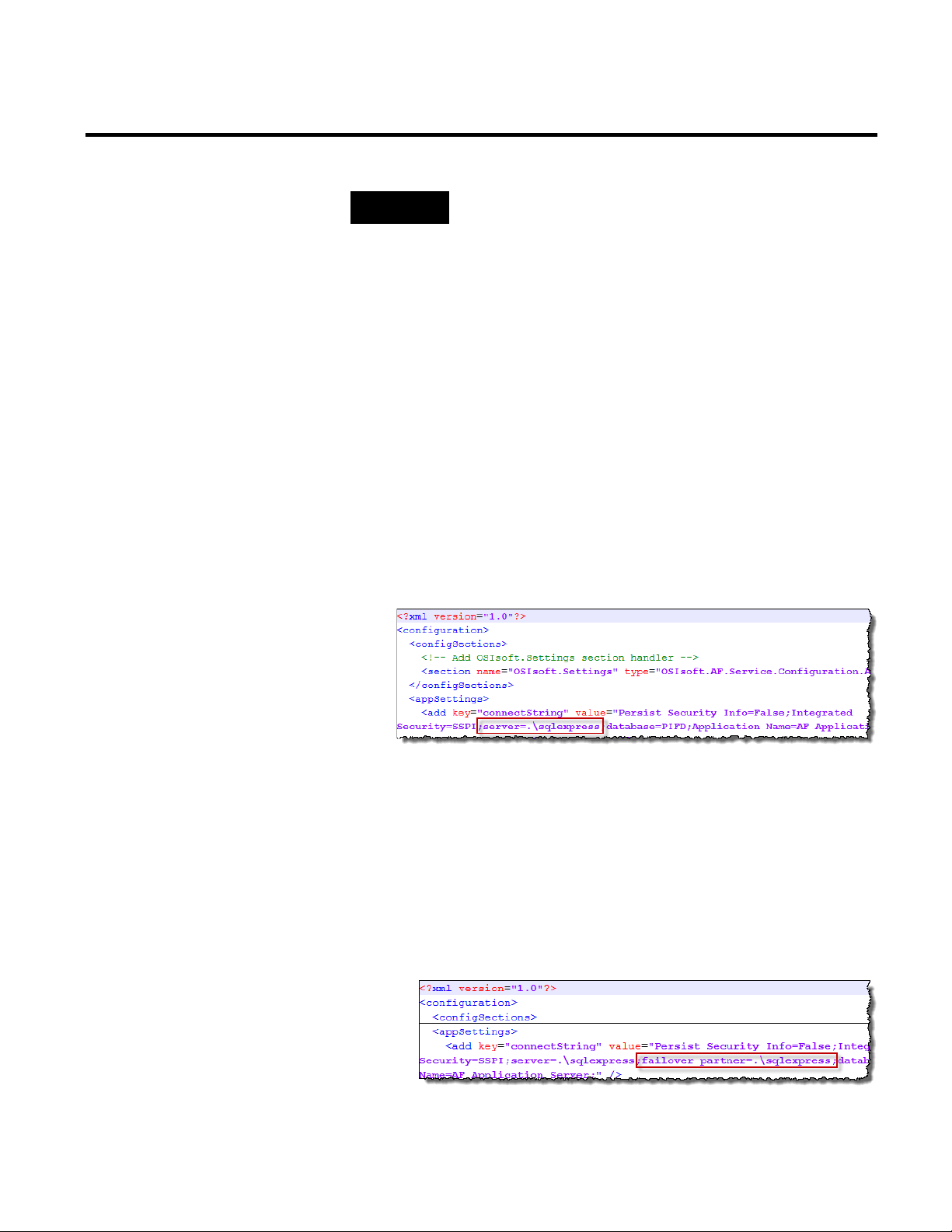

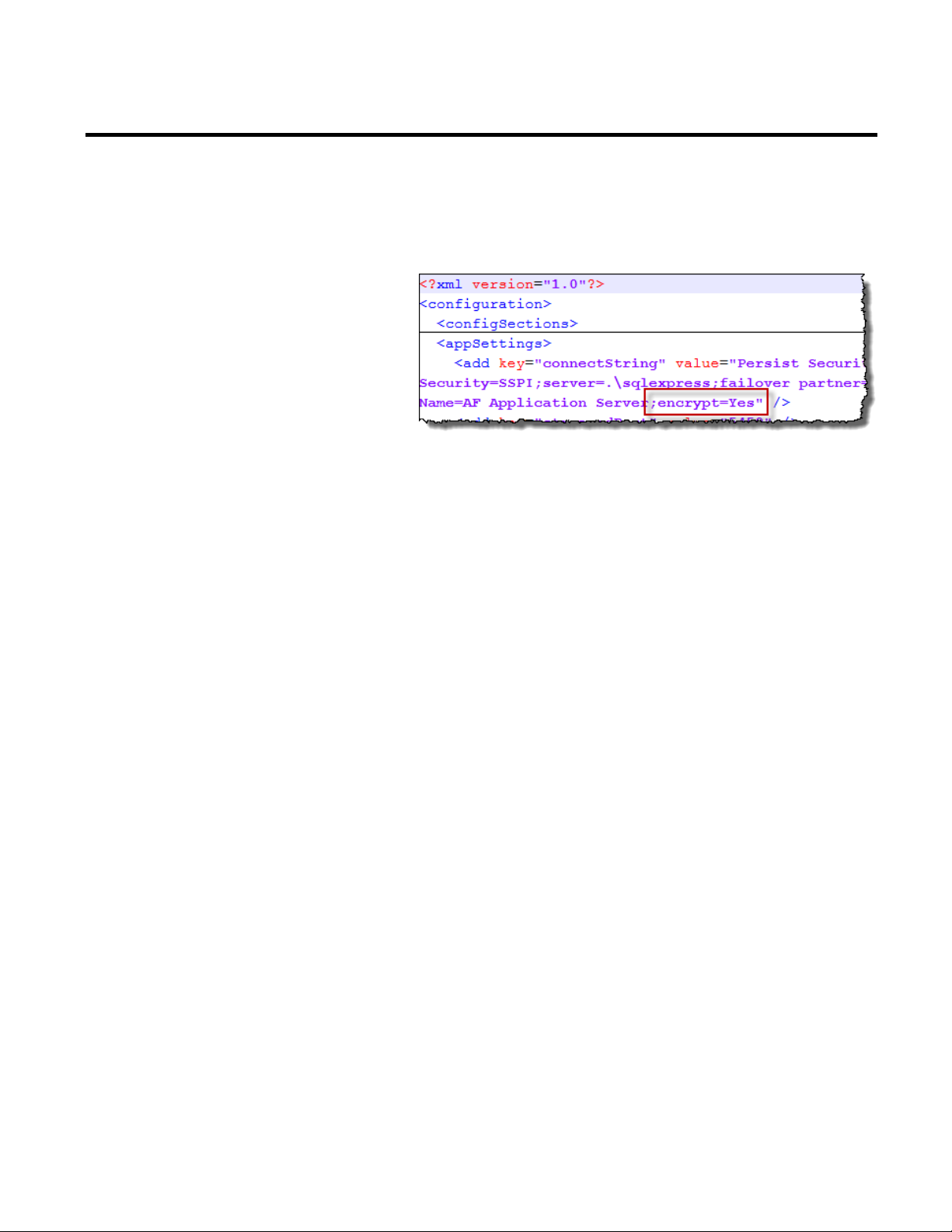

• If you have selected to install both the AF service and the

AF SQL database (installation mode 1) or the database only

(installation mode 4), the installation wizard will test the

connection with the database instance. If the connection

test fails, an error message generated by the database server

appears, for example:

Click OK to close the message. Follow the instructions

provided in the message to verify the connection and then

click Next on the wizard page to resume the installation.

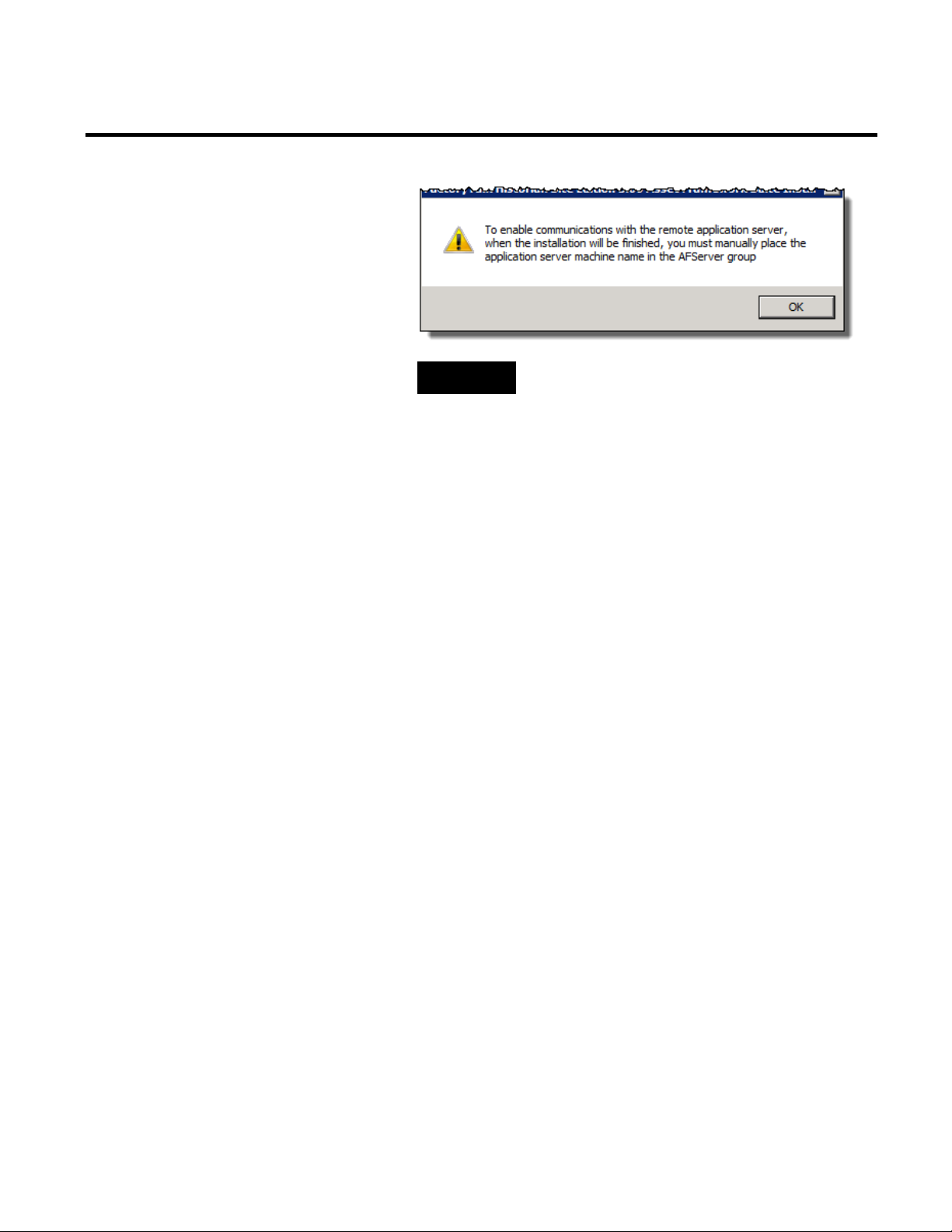

• If you have selected either to install the AF SQL database

only (installation mode 4) or the AF SQL database with the

unprocessed database scripts (installation mode 5), a

message will appear prompting you to manually add the

machine with the AF service installed to the Windows

AFServer user group, which is created during the

installation of the Asset Framework.

38 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 39

Installing FactoryTalk Historian Chapter 4

Install FactoryTalk Historian SE Server

NOTE

See "Add the AF Service Computer to the AFServer Group

55" for more information.

The Installation Progress page appears. It lists the

components that are going to be installed. The status of the

installation is displayed in the Status column of the

component table.

10. Click Install to start the installation.

11. Wait until the components are installed. The installation time

will vary depending on the selected installation mode and the

computer performance. The installation status is displayed on

the progress bar below the component table.

12. On the Installation Wizard Completed page, click Show the

installation log, if you want to view the installation log after

the installation wizard closes.

13. Click Finish to exit the installation wizard.

The FactoryTalk Historian SE server is installed with the following

FactoryTalk Historian components:

• FactoryTalk Historian server

• FactoryTalk Historian Live Data Interface

• Historian Interface Configuration Utility (ICU)

• RA Components

• FactoryTalk Activation Manager

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 39

Page 40

Chapter 4 Installing FactoryTalk Historian

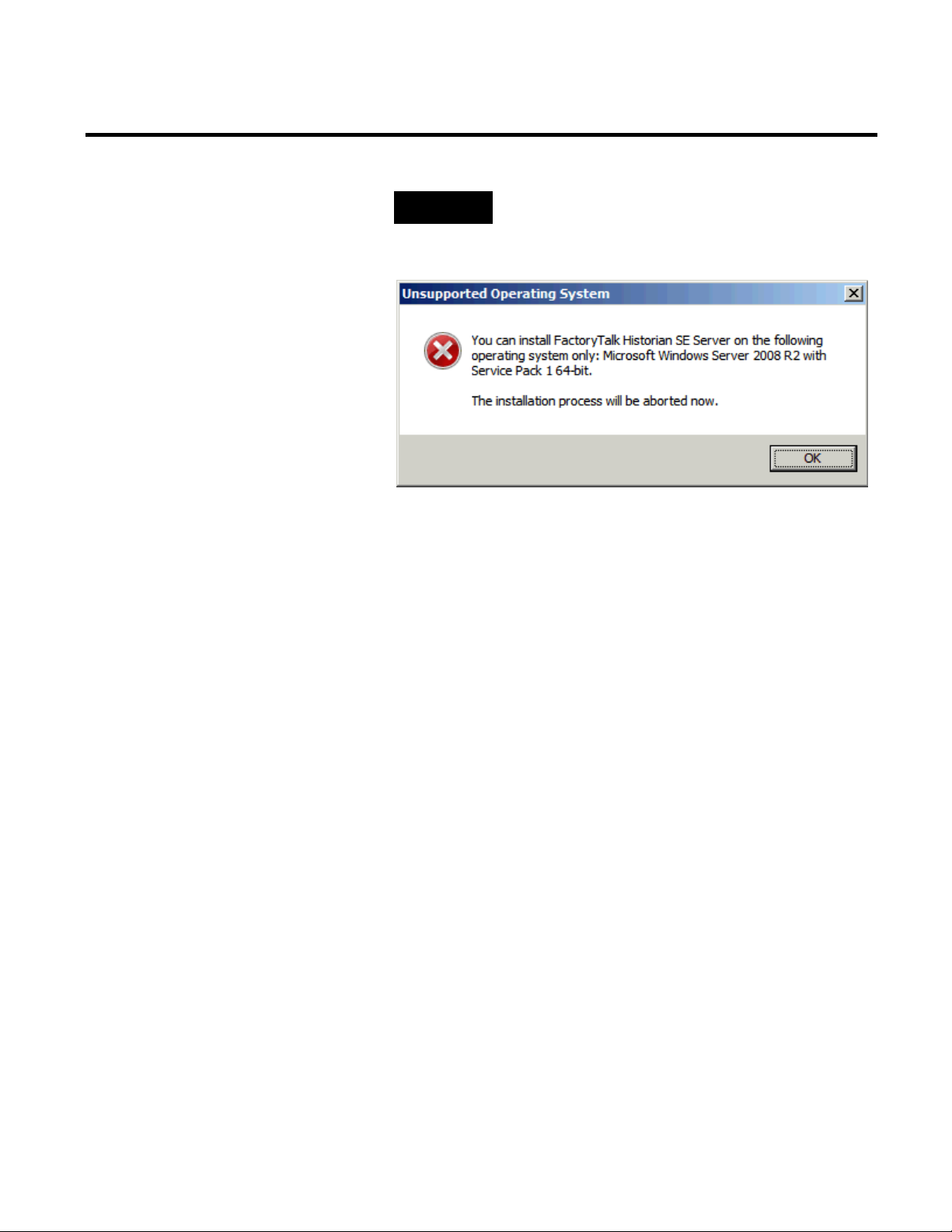

NOTE

The FactoryTalk Historian SE Server must be installed on Microsoft

Windows Server 2008 R2 with Service Pack 1 64-bit. If you try to

install it on any other operating system, the message presented

below will appear and the installation will be aborted.

To install the FactoryTalk Historian SE server:

1. Run the FactoryTalk Historian SE installation DVD.

2. On the welcome page of the installation wizard, click Install

FactoryTalk Historian SE > Install FactoryTalk Historian

Server.

The installation wizard appears.

If there are any software prerequisites missing from the

computer, they are listed in red at the bottom of the

installation wizard Welcome page. Click Cancel and Finish

to exit the wizard, install the prerequisites, and start the

installation wizard again.

3. On the Welcome... page, click Next.

4. On the License Agreement page, read and accept the terms of

the license agreement, selecting the I accept... option.

5. Click Next.

6. On the Customer Information page, type your user name,

organization, and the 10-digit product serial number, e.g.

0123456789.

40 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 41

Installing FactoryTalk Historian Chapter 4

7. On the Review Component Installation page, review the list

of the components that are already installed and those that will

be installed during the installation process.

Click Next.

8. On the Destination Drive page, select the drive on which you

want to install the product.

If the space available on the drive is not sufficient for the

installation, a warning message will appear below the

Installation drive list. In such a case, select another drive or

increase the available space on the drive you have originally

selected.

NOTE

You can choose the destination drive only if you install the

component on the selected machine for the first time. If there have

been any FactoryTalk Historian components installed on the

machine before, the Installation drive list will not be enabled.

Click Next.

The Installation Progress page appears. It lists the

components that are going to be installed. The status of the

installation is displayed in the Status column of the

component table.

9. Click Install to start the installation.

10. Wait until the components are installed. The installation time

will vary depending on the number of components being

installed and the computer performance. The installation

status is displayed below the component table.

During the installation process, the Release Notes appear. Close

the dialog box to proceed with the installation.

If the FactoryTalk Activation Manager has not been installed

yet, the wizard for installing USB dongles software appears.

The FactoryTalk Activation Manager installation wizard

appears with a list of prerequisite packages.

Click Continue.

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 41

Page 42

Chapter 4 Installing FactoryTalk Historian

11. In the message box that appears:

• Click Yes, if you want to install the software for Rockwell

Automation USB dongles.

The drivers are used to support mobile activations which

are locked in a hardware dongle.

Follow the on-screen instruction to install the software.

• Click No, if you want to skip this step.

The installation wizard appears.

12. Follow the instructions displayed on the screen to complete

the installation.

13. In the FactoryTalk Directory Server Location Utility dialog

box, identify the computer that hosts the FactoryTalk

Directory server. If it is the current computer, leave localhost in

the text box. Otherwise, do the following to point to the

proper FactoryTalk Directory computer:

1. Click the ellipsis button (

). The Login User dialog box

appears.

2. In the User name and Password text boxes, type the

credentials to the current FactoryTalk Directory machine.

The FactoryTalk Directory Server Configuration dialog

box appears.

3. Select the Remote computer option and click the ellipsis

button (

) to open the Browse for Computer dialog box.

4. Select the machine that hosts the FactoryTalk Directory

and click OK.

The name of the machine appears in the FactoryTalk

Directory Server Location Utility dialog box.

5. Click OK.

6. In the message box informing you that you will need to

restart the computer, click OK.

42 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 43

Installing FactoryTalk Historian Chapter 4

7. In the Log On to FactoryTalk (New Server) dialog box,

type the user name and password to the newly selected

FactoryTalk Directory machine.

8. Click OK. The system connects to the FactoryTalk

Directory server.

14. On the Installation Wizard Completed page, click Show the

installation log, if you want to view the installation log after

the installation wizard closes.

Install FactoryTalk Historian Live Data Interface (Optional)

NOTE

See "View the Installation Log File (page 53)" for more

information.

If any of the installed components requires rebooting the

computer, a relevant message will appear on the installation

wizard page, and you will be prompted to restart the machine

after the installation wizard closes.

15. Click Finish to exit the installation wizard.

16. In the message box prompting you to restart the computer,

click Yes.

The FactoryTalk Historian Live Data Interface collects data points

(tags) from the data server and passes them to the FactoryTalk

Historian SE server. Install the FactoryTalk Historian Live Data

Interface component on the same computer as the data server and

separate from the computer that has the FactoryTalk Historian SE

server installed.

After installing the interface, configure the buffering service on the

data server computer. The buffering service stores data in its

memory so that in the event the interface is not able to

communicate with the FactoryTalk Historian SE server, the data

will not be lost.

By default, the FactoryTalk Historian Live Data Interface is

installed during the installation of the FactoryTalk Historian SE

Server. Such a configuration is typically used for demonstration

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 43

Page 44

Chapter 4 Installing FactoryTalk Historian

purposes rather than real-life production environments. It is

recommended to install the FactoryTalk Historian Live Data

Interface on a different computer than the FactoryTalk Historian

server, typically on a data server computer.

NOTE

For more information on buffering, see "Enable Buffering (page 100)".

To install the FactoryTalk Historian Live Data Interface on the

data server computer:

1. Run the FactoryTalk Historian SE installation DVD.

2. On the welcome page of the installation wizard, click Install

FactoryTalk Historian SE > Install FactoryTalk Historian Live

Data Interface.

The installation wizard appears.

If there are any software prerequisites missing from the

computer, they are listed in red at the bottom of the

installation wizard Welcome page. Click Cancel and Finish

to exit the wizard, install the prerequisites, and start the

installation wizard again.

3. On the Welcome... page, click Next.

4. On the License Agreement page, read and accept the terms of

the license agreement, selecting the I accept... option.

5. Click Next.

6. On the Review Component Installation page, review the list

of the components that are already installed and those that will

be installed during the installation process.

Click Next.

7. On the Destination Drive page, select the drive on which you

want to install the product.

If the space available on the drive is not sufficient for the

installation, a warning message will appear below the

44 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 45

Installing FactoryTalk Historian Chapter 4

Installation drive list. In such a case, select another drive or

increase the available space on the drive you have originally

selected.

NOTE

You can choose the destination drive only if you install the

component on the selected machine for the first time. If there have

been any FactoryTalk Historian components installed on the

machine before, the Installation drive list will not be enabled.

Click Next.

The Installation Progress page appears. It lists the

components that are going to be installed. The status of the

installation is displayed in the Status column of the

component table.

8. Click Install to start the installation.

9. Wait until the components are installed. The installation time

will vary depending on the number of components being

installed and the computer performance. The installation

status is displayed below the component table.

During the installation process, the Release Notes appear. Close

the dialog box to proceed with the installation.

If the FactoryTalk Activation Manager has not been installed

yet, the wizard for installing USB dongles software appears.

The FactoryTalk Activation Manager installation wizard

appears with a list of prerequisite packages.

Click Continue.

10. In the message box that appears:

• Click Yes, if you want to install the software for Rockwell

Automation USB dongles.

The drivers are used to support mobile activations which

are locked in a hardware dongle.

Follow the on-screen instruction to install the software.

• Click No, if you want to skip this step.

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 45

Page 46

Chapter 4 Installing FactoryTalk Historian

The installation wizard appears.

11. Follow the instructions displayed on the screen to complete

the installation.

12. In the FactoryTalk Directory Server Location Utility dialog

box, identify the computer that hosts the FactoryTalk

Directory server. If it is the current computer, leave localhost in

the text box. Otherwise, do the following to point to the

proper FactoryTalk Directory computer:

1. Click the ellipsis button (

). The Login User dialog box

appears.

2. In the User name and Password text boxes, type the

credentials to the current FactoryTalk Directory machine.

The FactoryTalk Directory Server Configuration dialog

box appears.

3. Select the Remote computer option and click the ellipsis

button (

) to open the Browse for Computer dialog box.

4. Select the machine that hosts the FactoryTalk Directory

and click OK.

The name of the machine appears in the FactoryTalk

Directory Server Location Utility dialog box.

5. Click OK.

6. In the message box informing you that you will need to

restart the computer, click OK.

7. In the Log On to FactoryTalk (New Server) dialog box,

type the user name and password to the newly selected

FactoryTalk Directory machine.

13. Click OK. The system connects to the FactoryTalk Directory

server.

14. On the Installation Wizard Completed page, click Show the

installation log (page 53), if you want to view the installation

log after the installation wizard closes.

46 Rockwell Automation Publication HSE-IN024A-EN-E–December 2012

Page 47

Installing FactoryTalk Historian Chapter 4

If any of the installed components requires rebooting the

computer, a relevant message will appear on the installation

wizard page, and you will be prompted to restart the machine

after the installation wizard closes.

15. Click Finish to exit the installation wizard.

16. If prompted, restart the computer.

Install FactoryTalk Historian Management Tools (Optional)

The FactoryTalk Historian Management Tools are installed

automatically as a part of the FactoryTalk Historian SE installation.

This option allows you to install just the Management Tools on a

non-FactoryTalk Historian Server computer, typically a FactoryTalk

View SE client computer or a remote computer, from which you can

perform administrative tasks.

The FactoryTalk Historian Management Tools are installed with

the following FactoryTalk Historian components:

• Historian Software Development Kit (PI SDK)

• Historian Interface Configuration Utility (ICU)

• FactoryTalk Historian SE RA Components

• FactoryTalk Activation Manager

• Rockwell MS Runtime Redistributables

To install the FactoryTalk Historian Management Tools:

1. Run the FactoryTalk Historian SE installation DVD.

2. On the welcome page of the installation wizard, click Install

FactoryTalk Historian SE > Install FactoryTalk Historian

Management Tools.

The installation wizard appears.

If there are any software prerequisites missing from the

computer, they are listed in red at the bottom of the

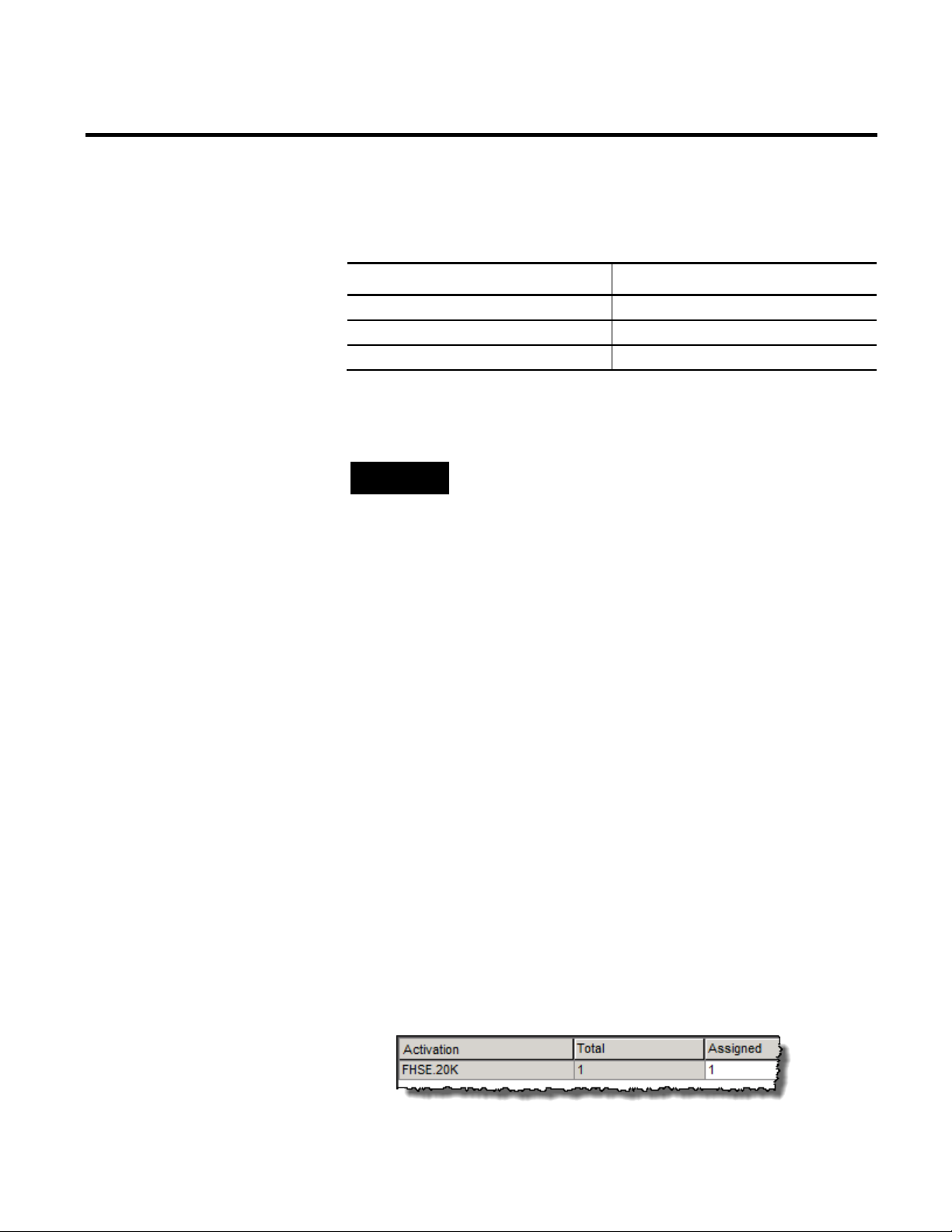

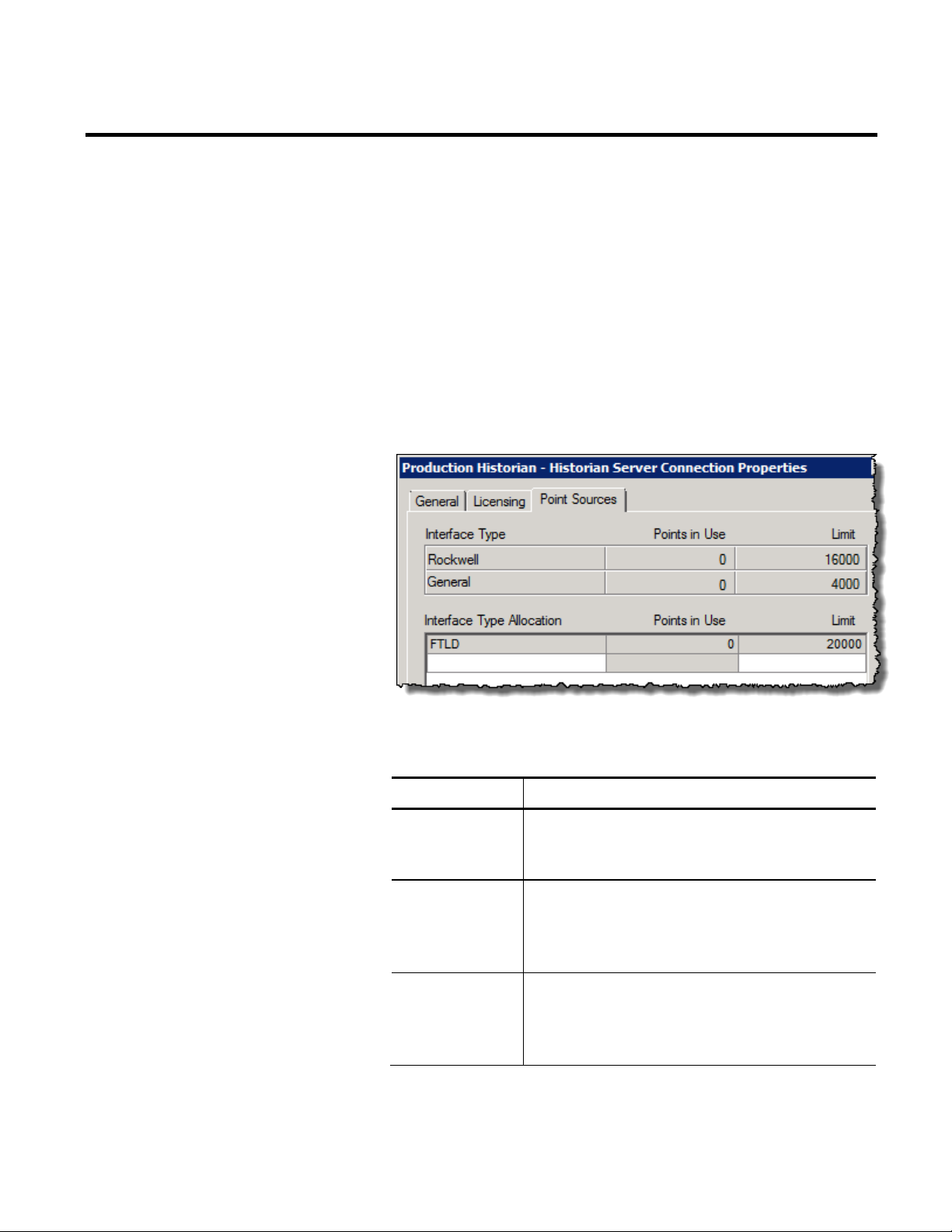

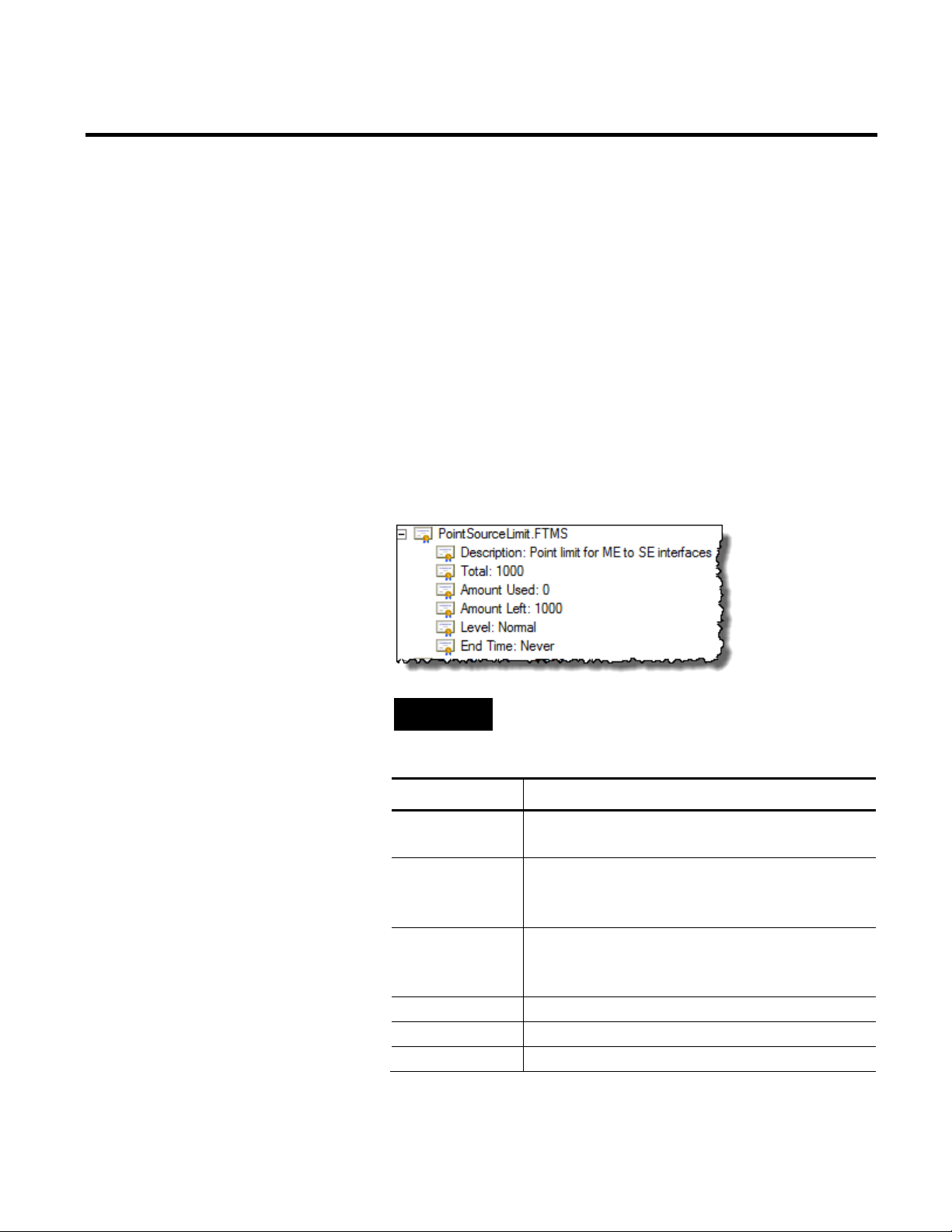

Rockwell Automation Publication HSE-IN024A-EN-E–December 2012 47