Page 1

USER GUIDE

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Supersedes Publication HIST-UM001J-EN-P-December 2011

Page 2

Contacting Rockwell

Copyright Notice

Trademark Notices

Other Trademarks

Warranty

Customer Support Telephone — 1.440.646.3434

Online Support — http://www.rockwellautomation.com/support/overview.page

© 2014 Rockwell Automation Technologies, Inc. All Rights Reserved.

This document and any accompanying Rockwell Software products are copyrighted by Rockwell Automation,

Inc. Any reproduction and/or distribution without prior written consent from Rockwell Automation, Inc. is

strictly prohibited. Please refer to the license agreement for details.

FactoryTalk, FactoryTalk Activation, FactoryTalk Diagnostics, FactoryTalk Directory, FactoryTalk Live Data,

FactoryTalk Metrics, FactoryTalk Services Platform, FactoryTalk Transaction Manager, FactoryTalk

VantagePoint, FactoryTalk ProductionCentre, Report Expert, Rockwell, Rockwell Automation, Rockwell

Software, and RSBizWare are trademarks of Rockwell Automation, Inc.

Any Rockwell Automation logo, software or hardware not mentioned herein is also a trademark, registered or

otherwise, of Rockwell Automation, Inc.

For a complete list of products and their respective trademarks, go to

http://www.rockwellautomation.com/rockwellautomation/legal-notices/overview.page?%23tab4#/tab4

.

ActiveX, Microsoft, Microsoft Access, SQL Server, Visual Basic, Visual C++, Visual SourceSafe, Windows,

Windows ME, Windows NT, Windows 2000, Windows Server, Windows XP, Windows 7, Windows Vista, and

Windows 8 are either registered trademarks or trademarks of Microsoft Corporation in the United States

and/or other countries.

Adobe, Acrobat, and Reader are either registered trademarks or trademarks of Adobe Systems Incorporated in

the United States and/or other countries.

ControlNet is a registered trademark of ControlNet International.

DeviceNet is a trademark of the Open DeviceNet Vendor Association, Inc. (ODVA)

OLE for Process Control (OPC) is a registered trademark of the OPC Foundation.

Oracle, SQL*Net, and SQL*Plus are registered trademarks of Oracle Corporation.

All other trademarks are the property of their respective holders and are hereby acknowledged.

This product is warranted in accordance with the product license. The product’s performance may be affected

by system configuration, the application being performed, operator control, maintenance, and other related

factors. Rockwell Automation is not responsible for these intervening factors. The instructions in this

document do not cover all the details or variations in the equipment, procedure, or process described, nor do

they provide directions for meeting every possible contingency during installation, operation, or

maintenance. This product’s implementation may vary among users.

This document is current as of the time of release of the product; however, the accompanying software may

have changed since the release. Rockwell Automation, Inc. reserves the right to change any information

contained in this document or the software at any time without prior notice. It is your responsibility to obtain

the most current information available from Rockwell when installing or using this product.

Page 3

Welcome to FactoryTalk

Historian Classic

Getting Started

Collecting FactoryTalk Historian

Classic Data

Analyzing FactoryTalk Historian

Classic Data

Table of Contents

Chapter 1

What is FactoryTalk Historian Classic? .................................................. 9

Features and Benefits .............................................................................. 9

Intended Audience ........................................................................................ 9

Where Can I Go for Help? ....................................................................... 11

Chapter 2

The RSBizWare Architecture .................................................................. 13

Connecting to the Information Services Manager .............................. 14

Using the Information Services Manager in Internet Explorer .. 14

Using the Configuration Console ..................................................... 15

Exploring the User Interface ..................................................................... 16

The Report Explorer ............................................................................. 16

The Report Design and Display Work Area ................................... 16

Shortcut Menus ...................................................................................... 17

Chapter 3

The Plant Model .......................................................................................... 19

Configuring the Plant Model .............................................................. 20

Configure Time-Series Data Collection ................................................ 22

Types of control connectors for the data collection ...................... 23

Enterprise Connectors .......................................................................... 24

Tutorial .................................................................................................... 25

Step 1: Start the Time-Series Data Collection Wizard ........... 25

Step 2: Select the Source and Destination of the Time-Series

Data 25

Step 3: Create or Select Data Points ............................................ 27

Step 4: Configure Collection Parameters ................................... 31

Step 5: Configure Transaction Settings ...................................... 34

Step 6: Create Transactions ........................................................... 36

Organize FactoryTalk Historian Classic Reporting Tags ................. 36

Start Data Collection ................................................................................. 39

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 3

Chapter 4

Create a New RSBizWare Report ........................................................... 41

Insert Text, Pictures, and Hyperlinks ..................................................... 42

Page 4

Table of Contents

Save the Report ............................................................................................ 44

Add a Saved Report Object to Your Report ......................................... 45

Configure the Report Object To Use Global Credentials ................ 48

Create a New Chart .................................................................................... 51

Step 1: Plan the Chart ........................................................................... 52

Step 2: Select the Data On Which To Report ................................ 53

Step 3: Choose a Chart Type .............................................................. 53

Step 4: Describe the Data ..................................................................... 53

Step 5: Select Summary or Detail ....................................................... 54

Step 6: Select the Fields To Be Charted ........................................... 55

Step 7: Enter the Chart Title .............................................................. 56

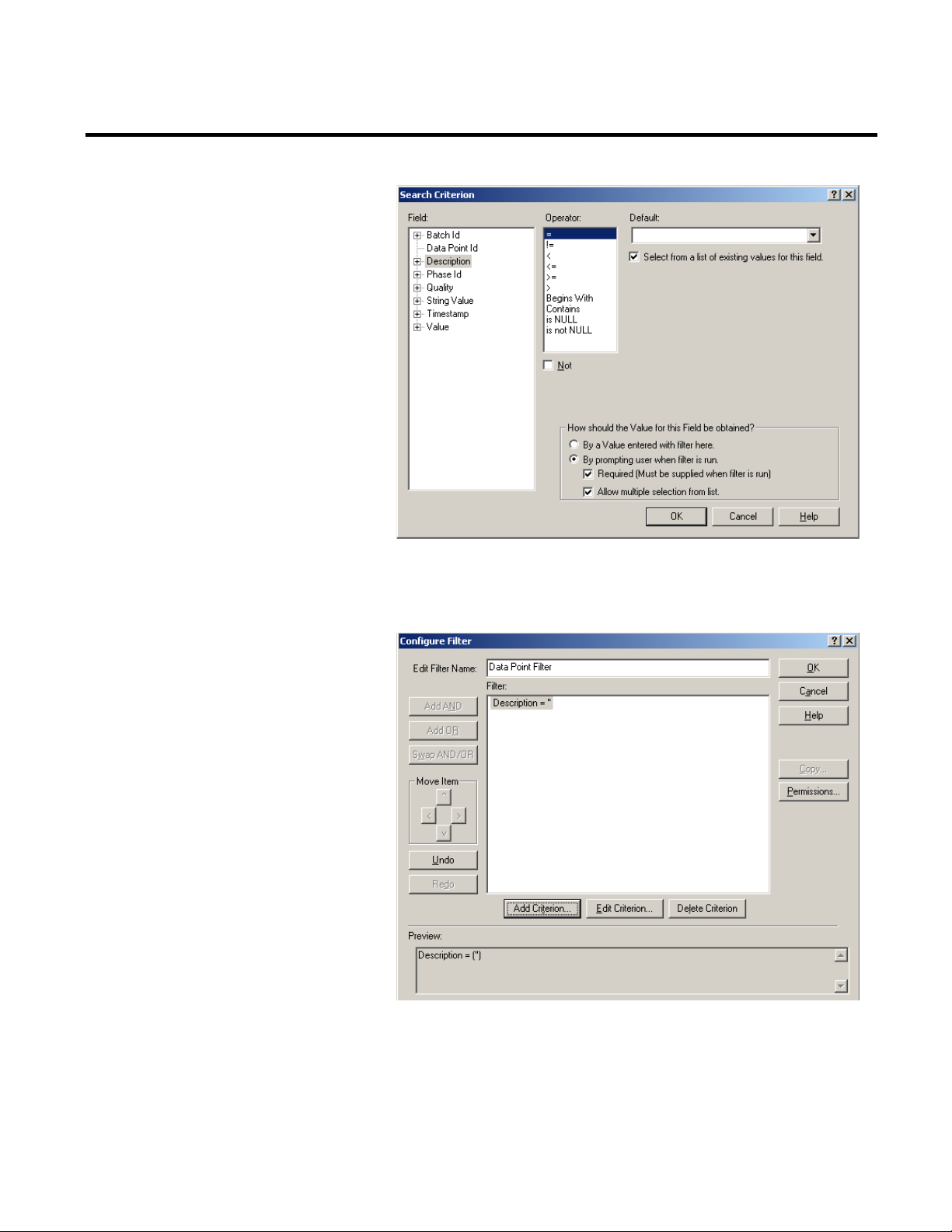

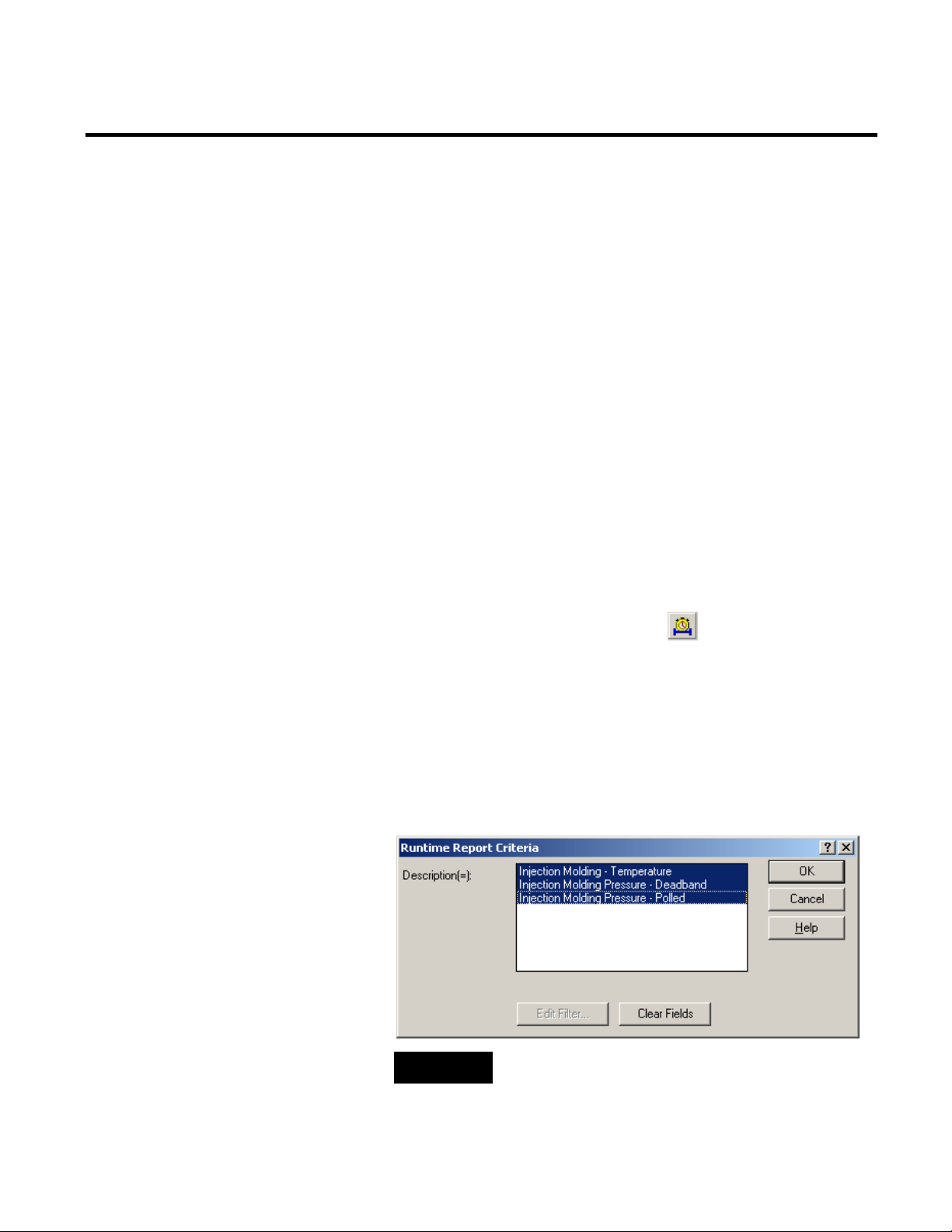

Step 8: Filter the Data ........................................................................... 56

Step 9: Insert Your New Chart Into the Report ............................ 59

Create a New Text Report Object .......................................................... 60

Step 1: Start the Text Report Object Wizard ................................. 61

Step 2: Select the Data On Which To Report ................................ 61

Step 3: Group the Records ................................................................... 62

Step 4: Sort the Records ....................................................................... 63

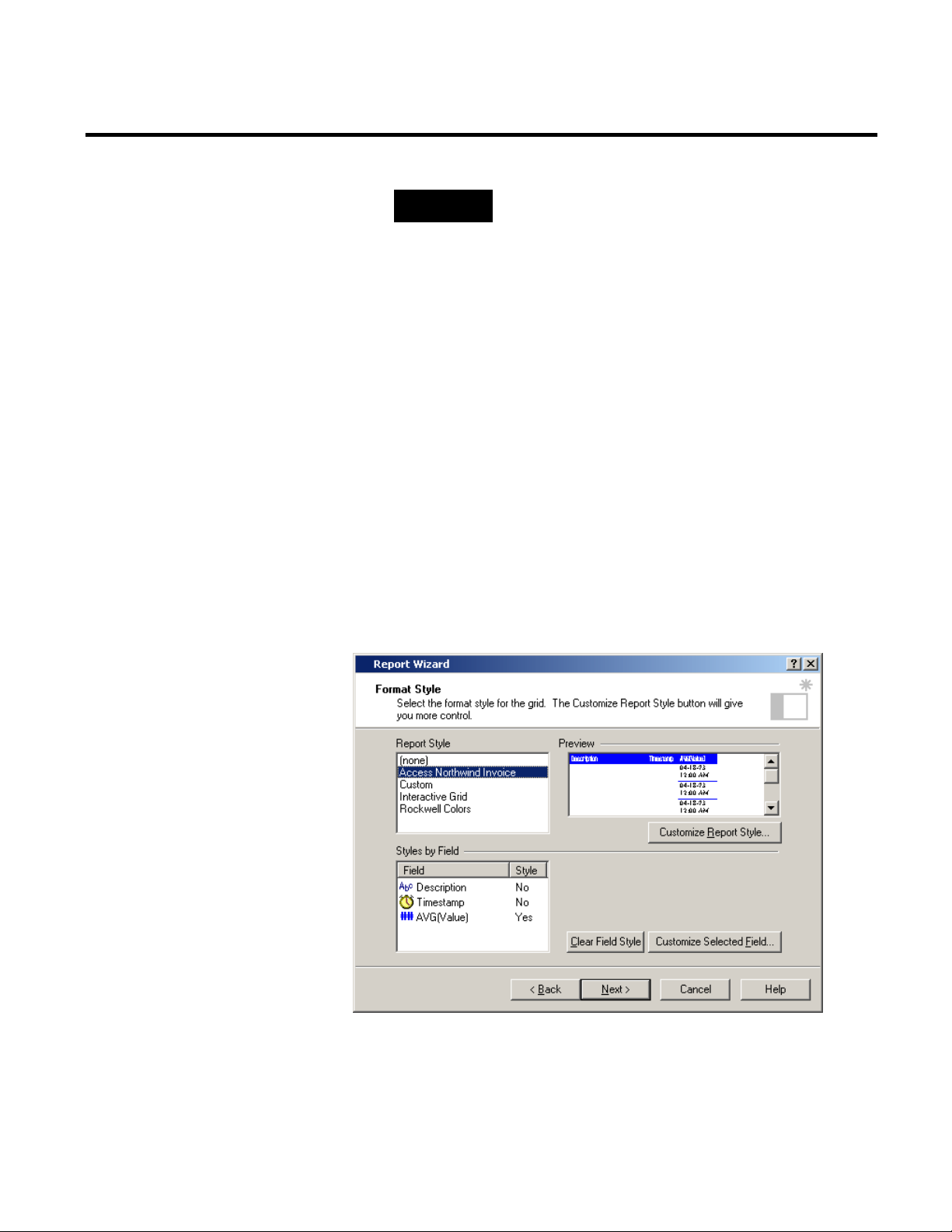

Step 5: Format the Table ...................................................................... 64

Step 6: Name the Report Object ........................................................ 66

Step 7: Filter the Data ........................................................................... 66

Step 8: Insert Your New Table Into the Report ............................. 66

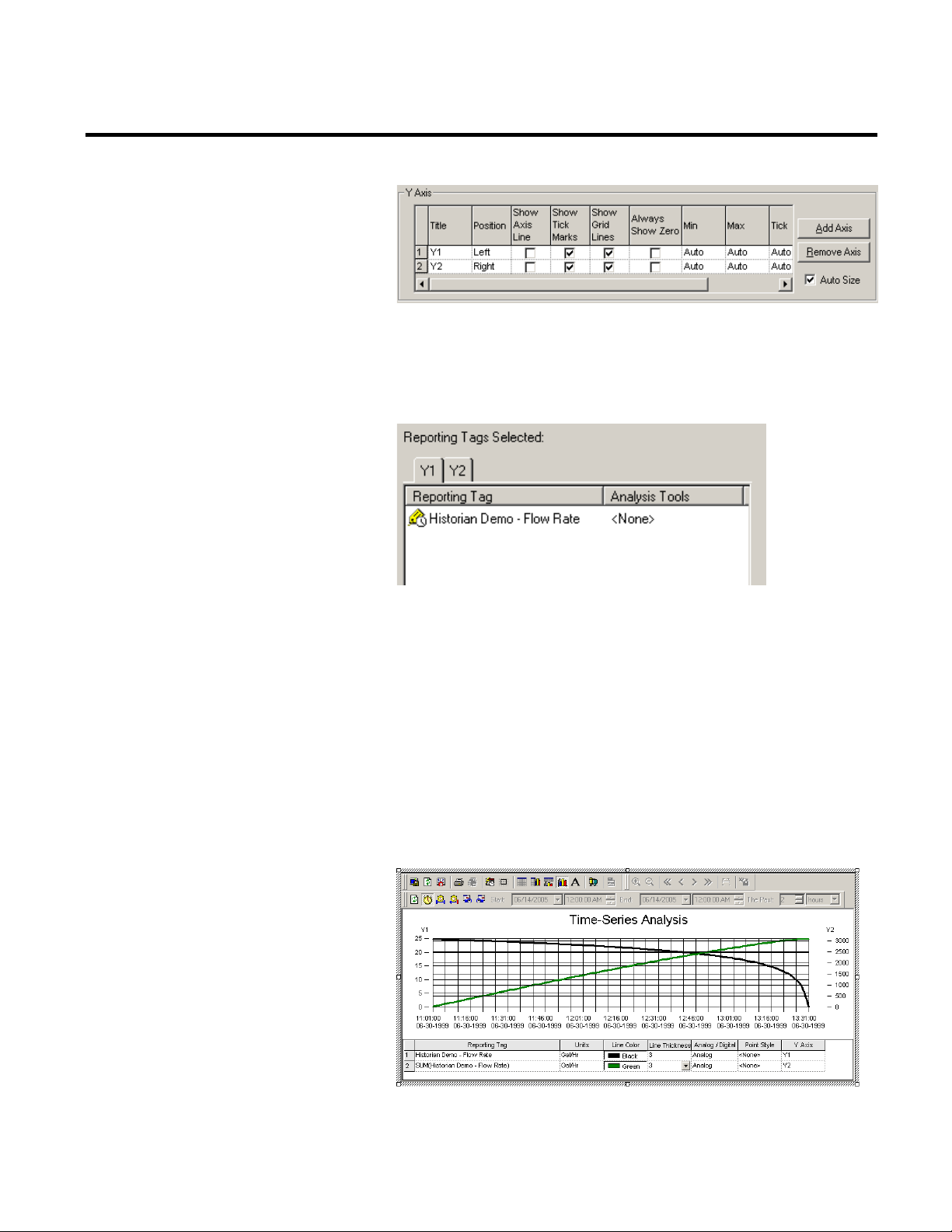

Create a Time-series Chart ....................................................................... 67

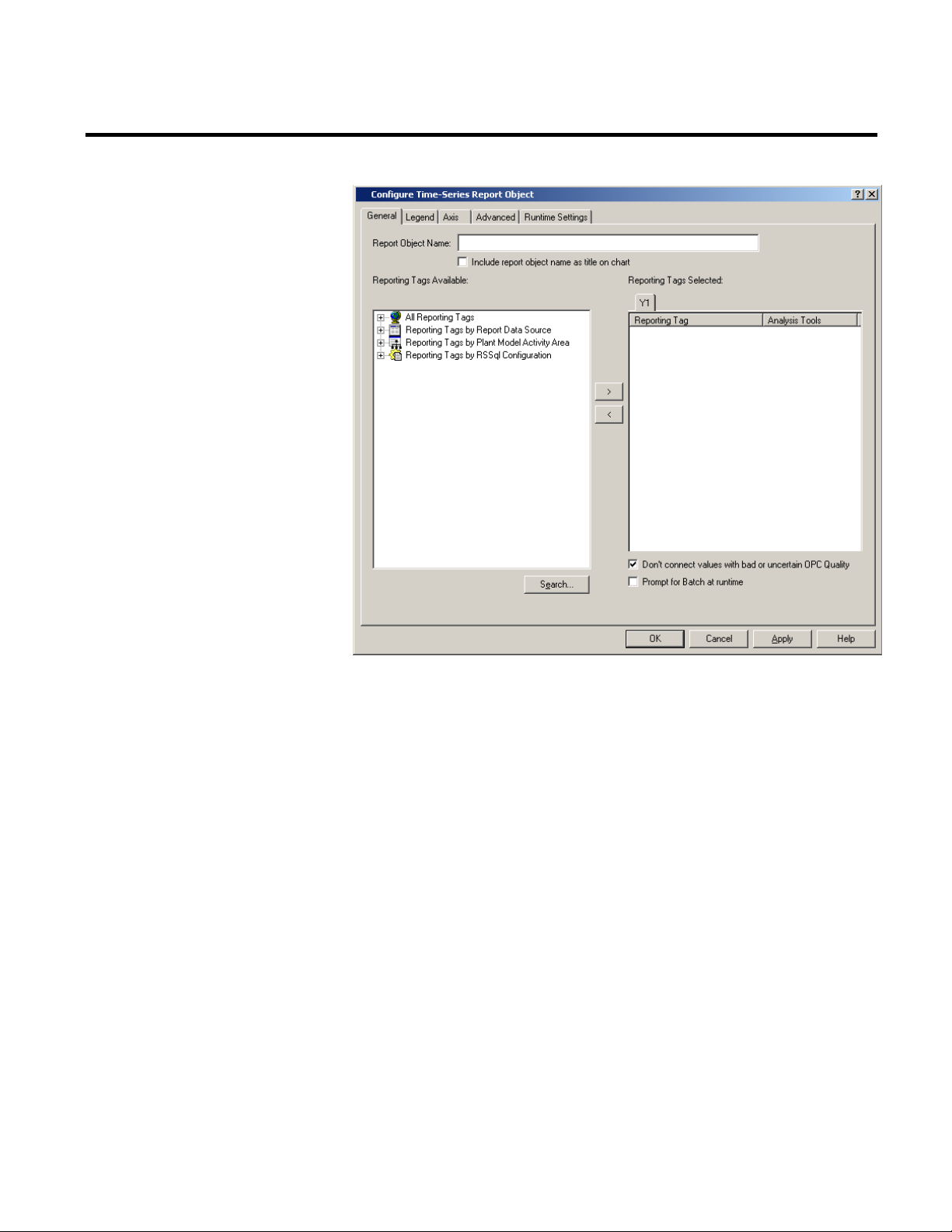

Step 1: Create the Report Object ....................................................... 67

Step 2: Name the Report Object ........................................................ 68

Step 3: Add Reporting Tags ................................................................ 68

Step 4: Apply an Analysis Tool ........................................................... 69

Step 5: Customize the Chart Legend ................................................ 70

Step 6: Insert Your New Chart Into the Report ............................ 71

Step 7: Adjust the Time Range ........................................................... 71

Step 3: Add Reporting Tags ................................................................ 73

Step 9: Remove a Reporting Tag or an Analysis Tool ................... 76

Create a Simple Batch/Event Chart ....................................................... 76

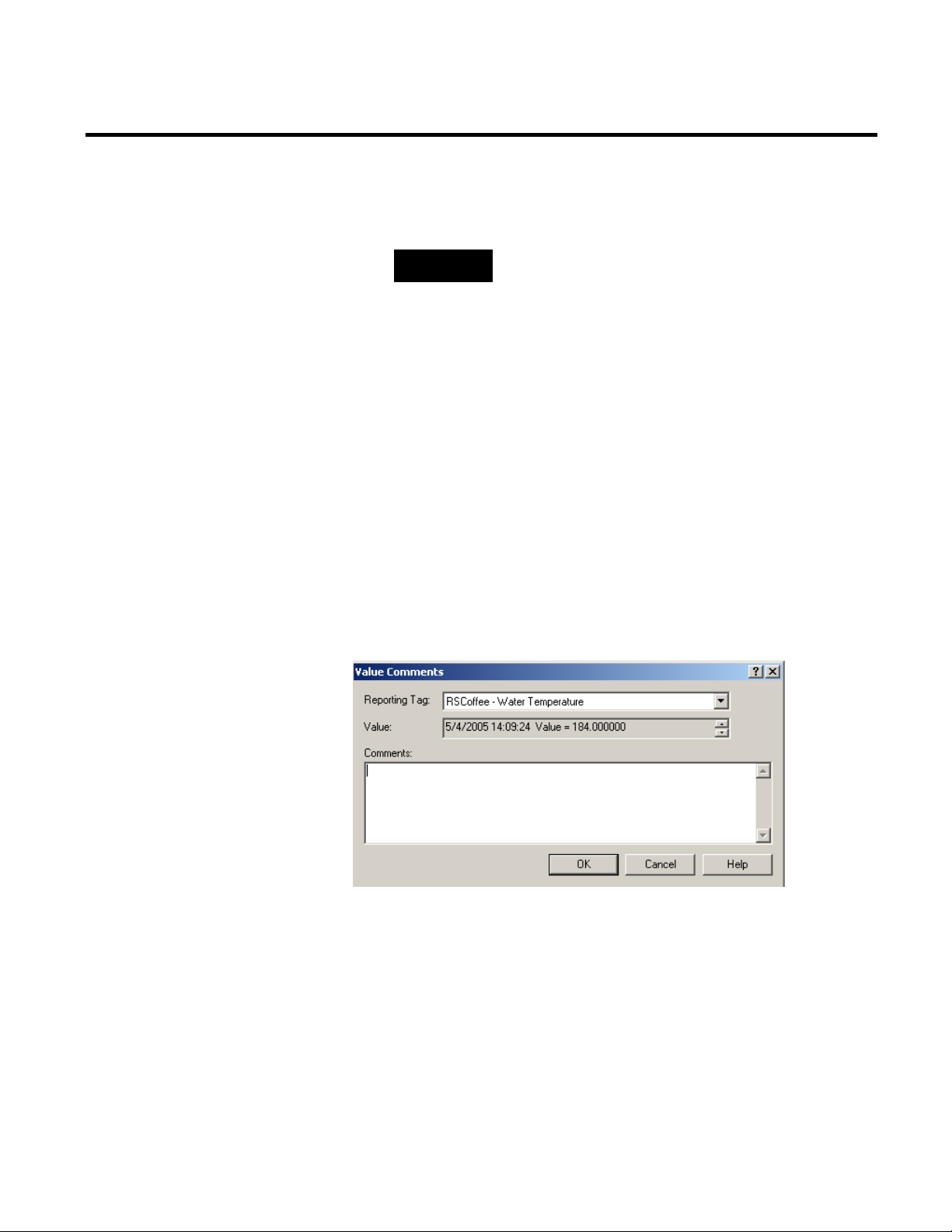

Add a Comment to a Value, X-axis, or Y-axis on a Time-series Chart

79

Value Comments ................................................................................... 80

4 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Page 5

Table of Contents

Customizing RSBizWare Charts

and Tables

Advanced Reporting Topics

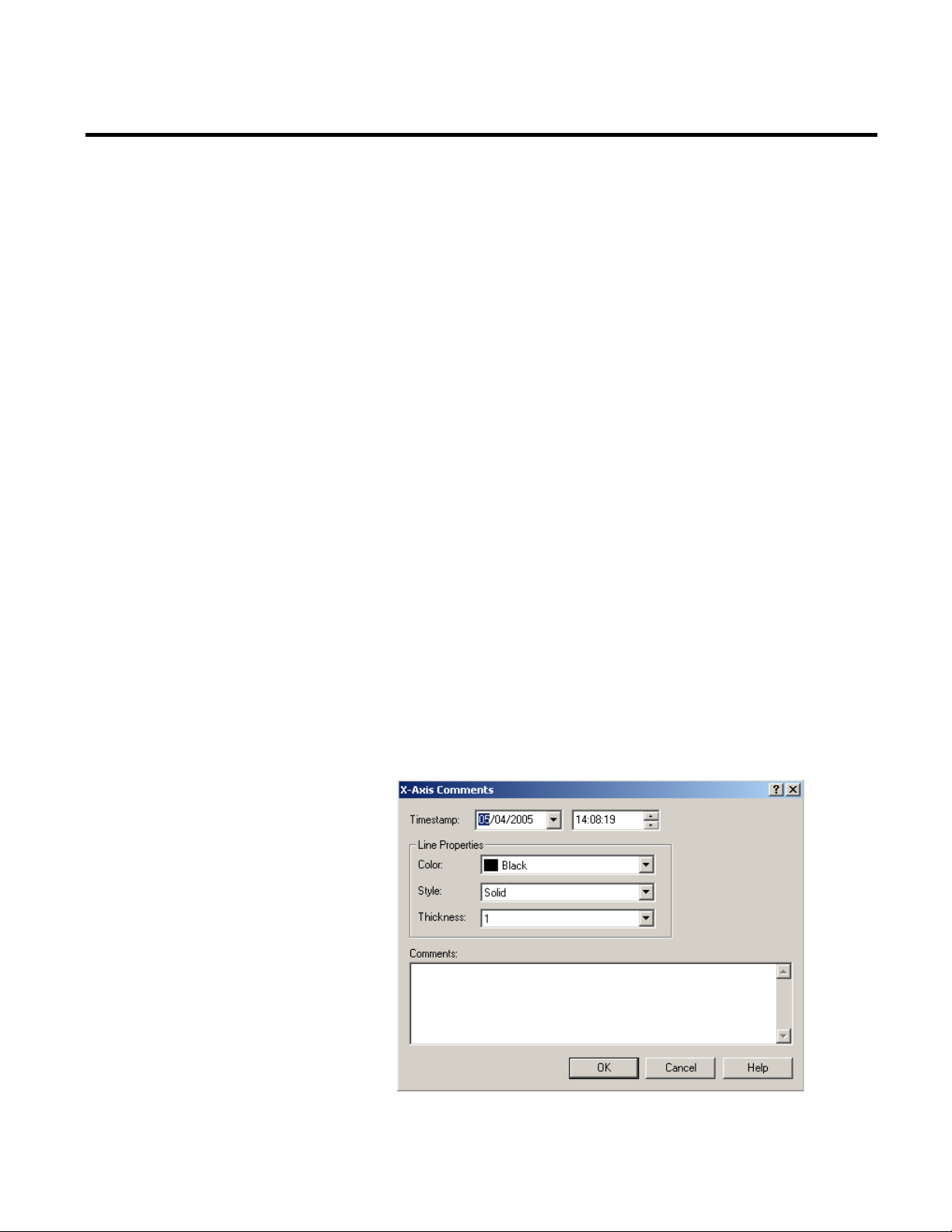

X-axis Comments .................................................................................. 81

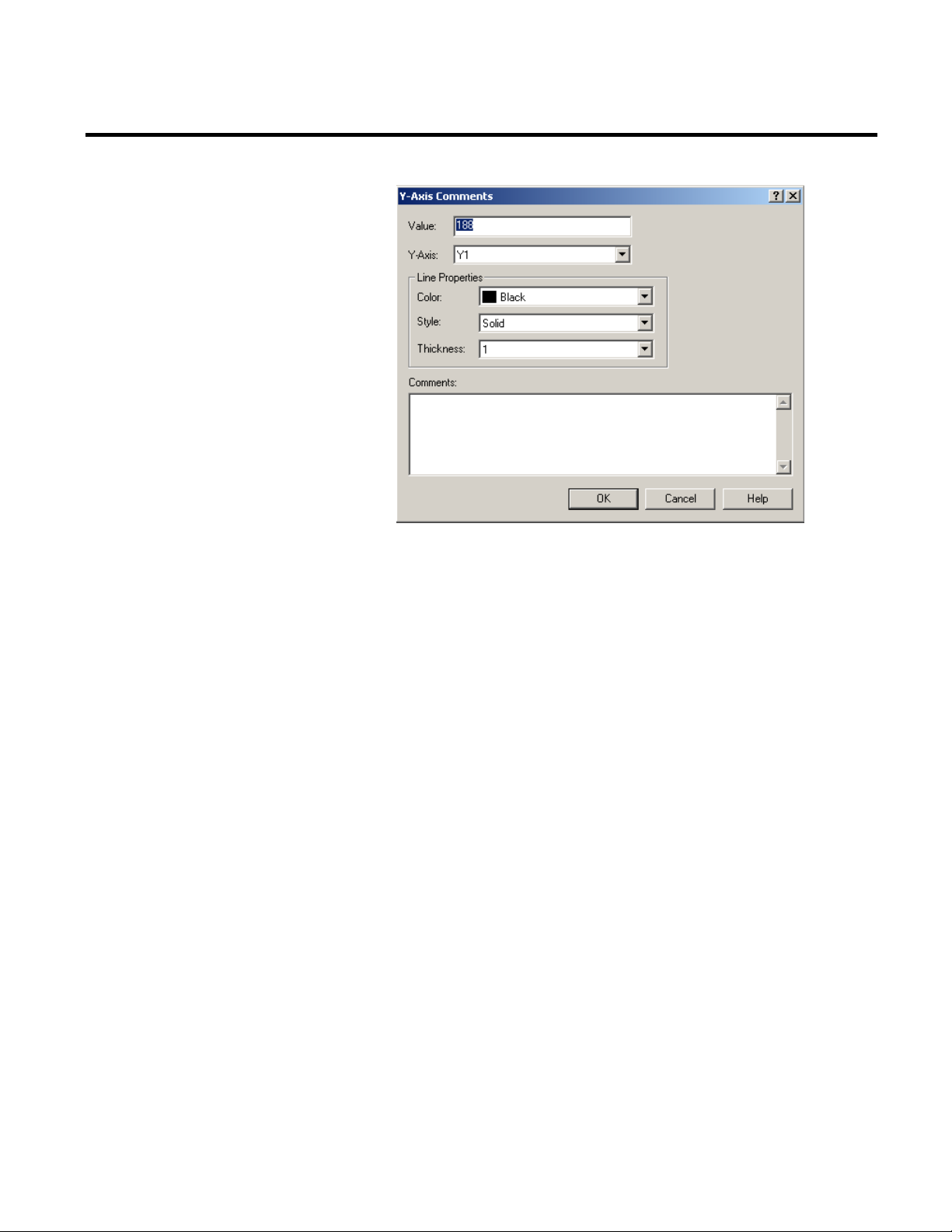

Y-axis Comments ................................................................................... 82

Ad Comment As .................................................................................... 84

Export the Report to HTML ................................................................... 84

Load the Report From File ........................................................................ 85

Chapter 5

Customizing Charts ................................................................................... 87

Working With the Component Parts of a Chart .......................... 88

Resizing a Component .................................................................... 89

Moving a Component ..................................................................... 89

Deleting a Component .................................................................... 89

Editing the Chart Title or Text Field .......................................... 89

Changing Chart Component Properties .................................... 90

Working With Chart “Pens” .................................................................... 90

Customizing Text Report Objects .......................................................... 90

Show and Hide Columns ..................................................................... 91

Resize Table Columns .......................................................................... 92

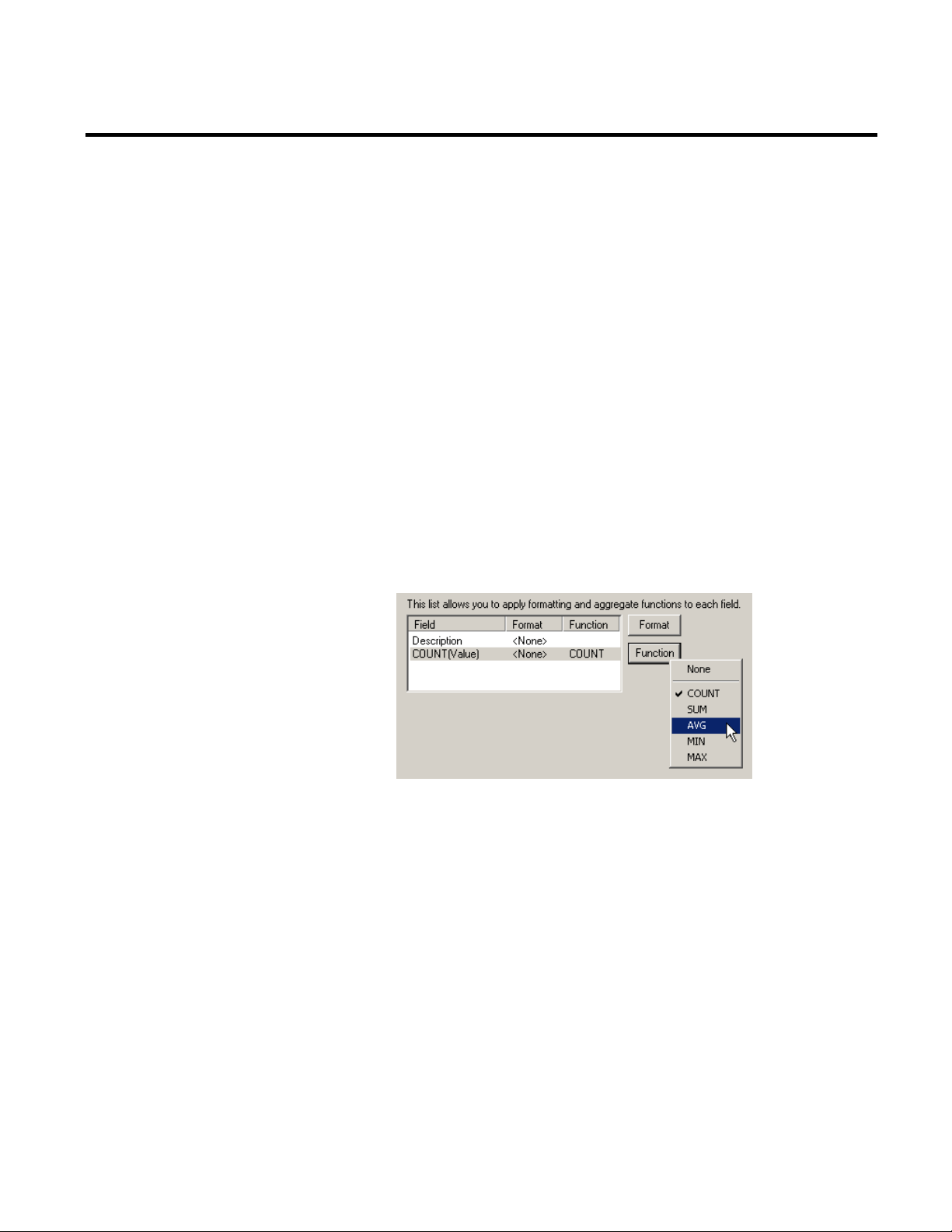

Aggregate, Group, Format, Sort, Chart, and Rename Columns 92

Aggregate ............................................................................................ 93

Group 94

Format 94

Sort 94

Chart 95

Rename 95

Quick Filter ................................................................................................... 95

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 5

Chapter 6

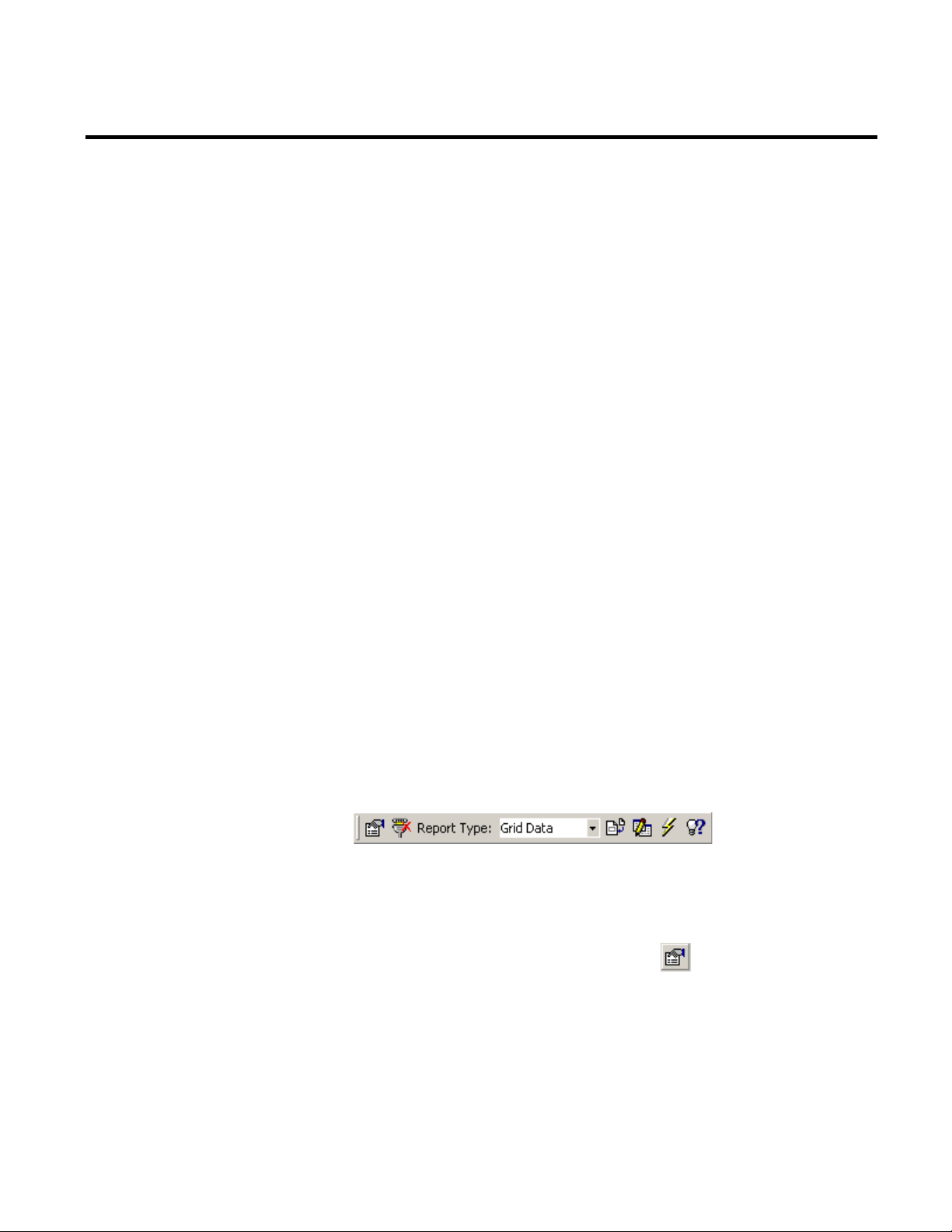

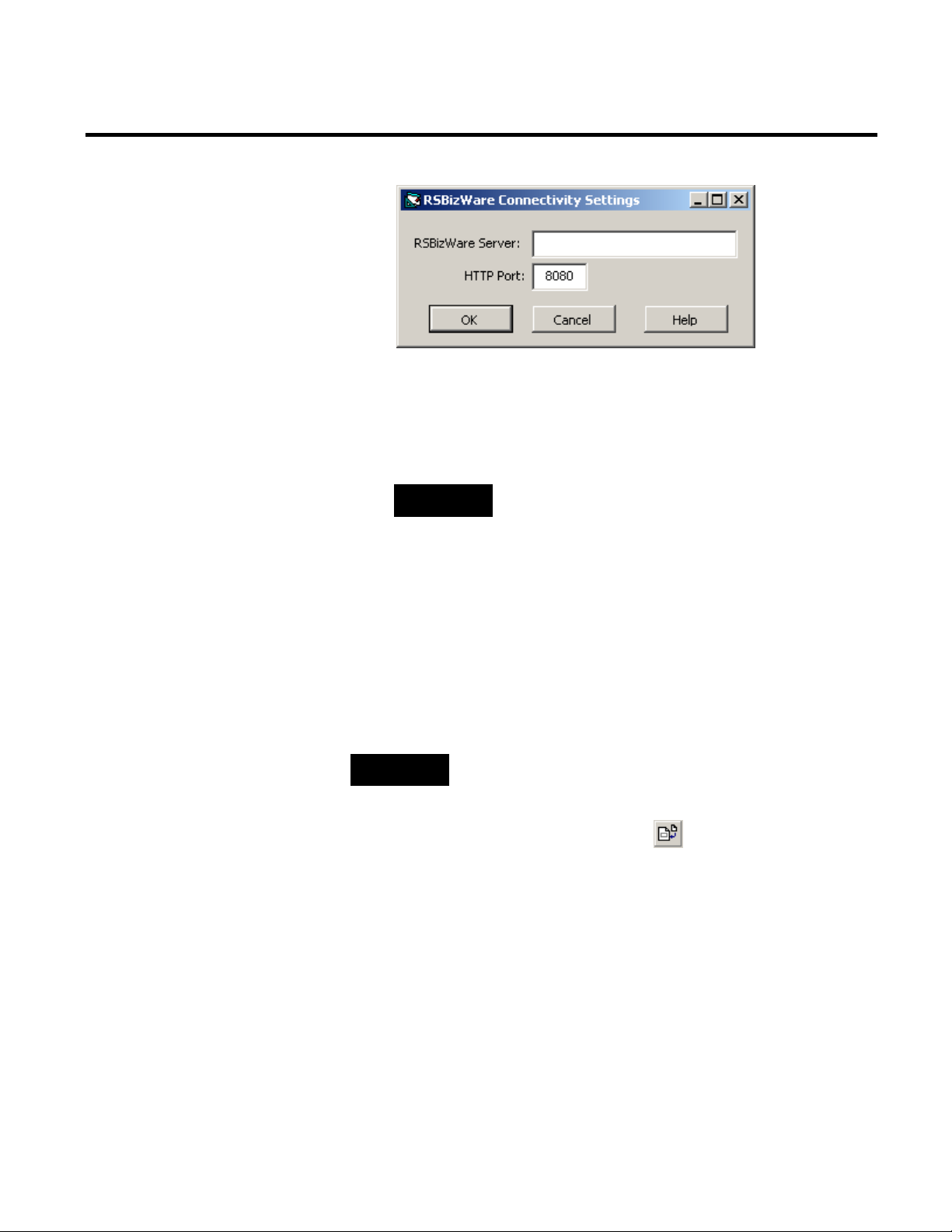

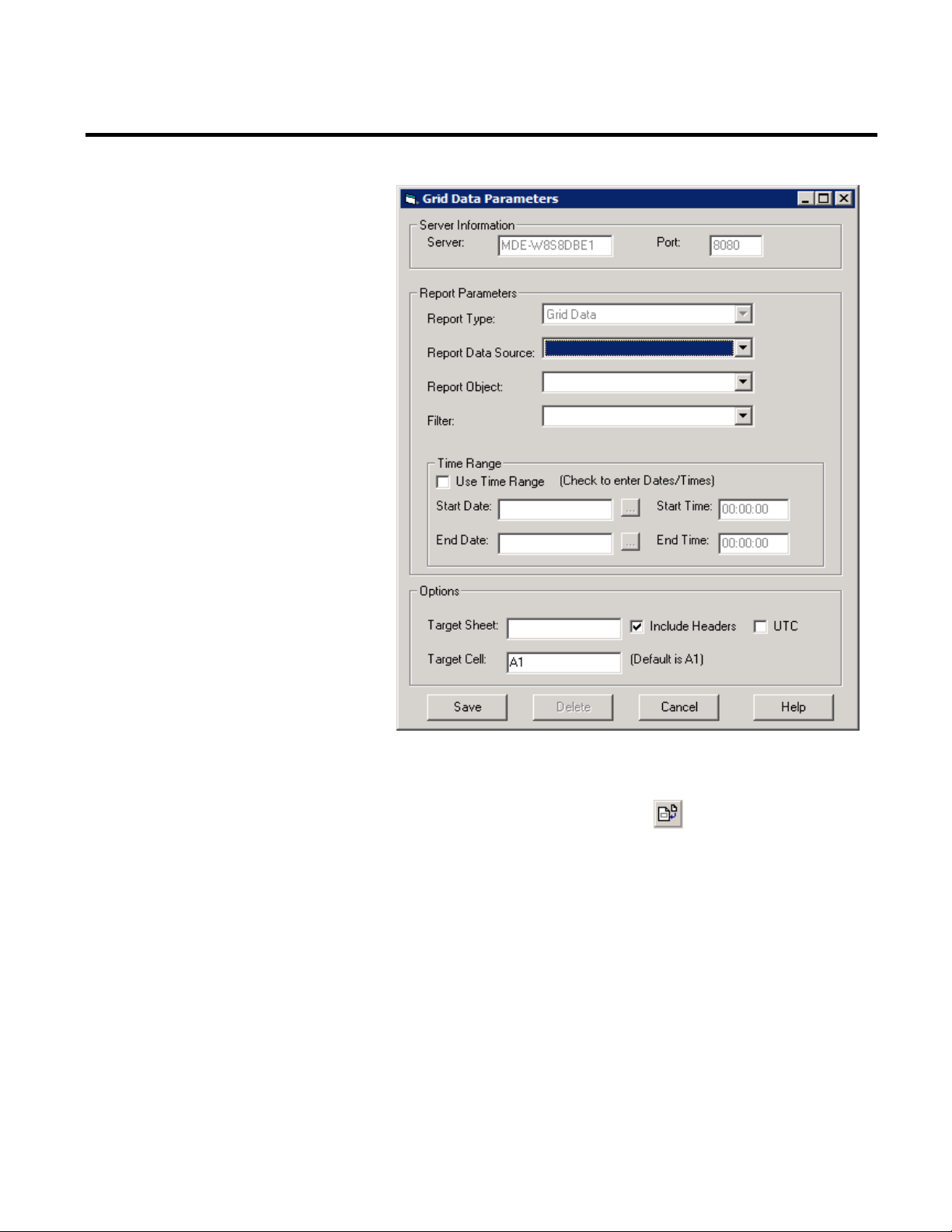

The Excel Add-in ........................................................................................ 97

Scheduling Report Objects and Reports ............................................. 101

Schedule a Report Object .................................................................. 102

Schedule a Report ............................................................................... 105

View the History of the Scheduled Task ....................................... 109

Analyzing Non-RSBizWare Data ........................................................ 110

Create an External Data Source....................................................... 110

Create a Report Data Source ............................................................ 111

Step 1: Start the Report Data Source Wizard ......................... 111

Page 6

Table of Contents

Creating RSBizWare Custom

Analysis Tools

Step 2: Give the Report Data Source a Name ......................... 116

Step 3: Select a Database Table or View ................................... 117

Step 4: Choose the Columns That Will Be Included ........... 117

Step 5: Enable the Time Selection Toolbar ............................. 119

Step 6: Specify the Format of the Table or View.................... 120

Step 7: Specify the Role That Each Field Plays In Time-Series

Analysis 122

Step 8: Create a Data Point Configuration Table ................. 123

Chapter 7

Why Use Custom Analysis Tools? ....................................................... 125

Intended Audience ................................................................................... 125

A Quick Tour of a Sample Custom Analysis Tool .......................... 126

Registering a Sample Analysis Tool ................................................ 127

Using the Sample Analysis Tool for Time-series Analysis ........ 129

What You Need to Know Before You Start ...................................... 129

Analysis Tool Architecture ............................................................... 130

What a Time-series Data Set Looks Like ...................................... 132

Interpreting the Parameters Passed into the Calculate() Function

133

Limitations ........................................................................................... 134

The RSBizWare Calculator COM Interface ..................................... 134

Looking at the Type Library ............................................................. 135

Developing Analysis Tools with Visual Basic .................................... 136

Creating a New Project...................................................................... 137

Configuring Important Project Settings ....................................... 137

Referencing the RSBizWare Calculator Component ................ 138

Writing the Calculate() Function ................................................... 138

Saving and Compiling the Project .................................................. 140

Trying Out the New Custom Analysis Tool ................................ 141

Debugging Custom Analysis Tools in Visual Basic .................... 142

Developing Analysis Tools with Visual C++ .................................... 143

Creating a New Project...................................................................... 144

Referencing the RSBizWare Calculator Component ................ 145

Working with VARIANTs in Visual C++ .................................. 147

Writing the Calculate() Function ................................................... 148

6 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Page 7

Table of Contents

Object Permissions

Saving and Compiling the Project .................................................. 151

Trying Out the Custom Analysis Tool.......................................... 153

Debugging Custom Analysis Tools in Visual C++ .................... 154

Why Use Custom Analysis Tools? ....................................................... 155

Chapter 8

Filter permissions ..................................................................................... 158

Report permissions ................................................................................... 158

Report data source permissions ............................................................. 159

Report object permissions ...................................................................... 159

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 7

Page 8

Table of Contents

8 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Page 9

What is FactoryTalk Historian Classic?

Features and Benefits

Intended Audience

Chapter 1

Welcome to FactoryTalk Historian Classic

The RSBizWare software is a suite of tools and services aimed at

increasing your manufacturing floor effectiveness and profitability

with solutions that target performance analysis and improvement

and with data acquisition and integration. FactoryTalk Historian

Classic is just one of the applications that is available within the

RSBizWare software. FactoryTalk Historian Classic is a repository

for historical data, built for today’s networked and distributed

enterprise. Tightly coupled to FactoryTalk Transaction Manager for

data collection, FactoryTalk Historian Classic ships with a

complete, predesigned data model for time-series data logging, and

offers the ability to analyze data from external database tables.

FactoryTalk Historian Classic offers the following features and

benefits:

• Rich reporting, graphing, time-series analysis, and querying

functionality provide a complete and easy-to-use solution for

performance analysis.

• A direct link between the shop floor, where data is collected,

and the enterprise, where data can be analyzed and reported

on.

• The ability to embed a report object in any Microsoft ActiveX

container, such as Visual Basic or Internet Explorer.

• The ability to analyze data contained in non-RSBizWare

databases.

The FactoryTalk Historian Classic User Guide is designed to help

you understand how to access and use the FactoryTalk Historian

Classic product. This document focuses on the end-user functions of

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 9

Page 10

Chapter 1 Welcome to FactoryTalk Historian Classic

FactoryTalk Historian Classic and does not cover installation and

operation of underlying system services.

This document is intended for the following types of users of the

RSBizWare software:

• RSBizWare administrators

RSBizWare administrators configure the RSBizWare system

so that it can capture performance data for use by report

designers and report users.

They should be familiar with:

• Control systems, process information (line and plant), and

databases.

• Microsoft Windows operating system.

• The location and structure of databases.

• Report designers

Report designers create the reports that will be used by report

users.

They should be familiar with:

• Process information (the physical representation of the

production line and plant).

• Microsoft Windows operating systems.

• Query logic (how to write a database query).

• Web publishing tools.

• The location and structure of databases.

• Report users

Report users make use of the reports created by the report

designer to perform their jobs.

They should be familiar with:

10 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Page 11

Welcome to FactoryTalk Historian Classic Chapter 1

Where Can I Go for Help?

• Microsoft Windows operating systems.

Consult the following resources for additional information about

the product:

• Release Notes

The release notes contain current information about the

product, including hardware and software requirements, new

features, known and fixed anomalies.

• RSBizWare Administration Guide

The administration guide helps the RSBizWare administrator

install and configure the software as well as understand the

architecture of the RSBizWare suite and its components.

• Online help

The online help provides general information and step-by-step

procedures for working with the product.

• Rockwell Automation Support Center

The support center provides a variety of services, such as

trainings, webinars, and online support that will improve your

experience using the RSBizWare suite.

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 11

Page 12

Chapter 1 Welcome to FactoryTalk Historian Classic

12 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Page 13

The RSBizWare Architecture

Chapter 2

Getting Started

Before you walk through the examples and tutorials that are

discussed in this book, it is assumed that the RSBizWare

administrator has installed, configured, and started the Information

Services Manager on the server computer.

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 13

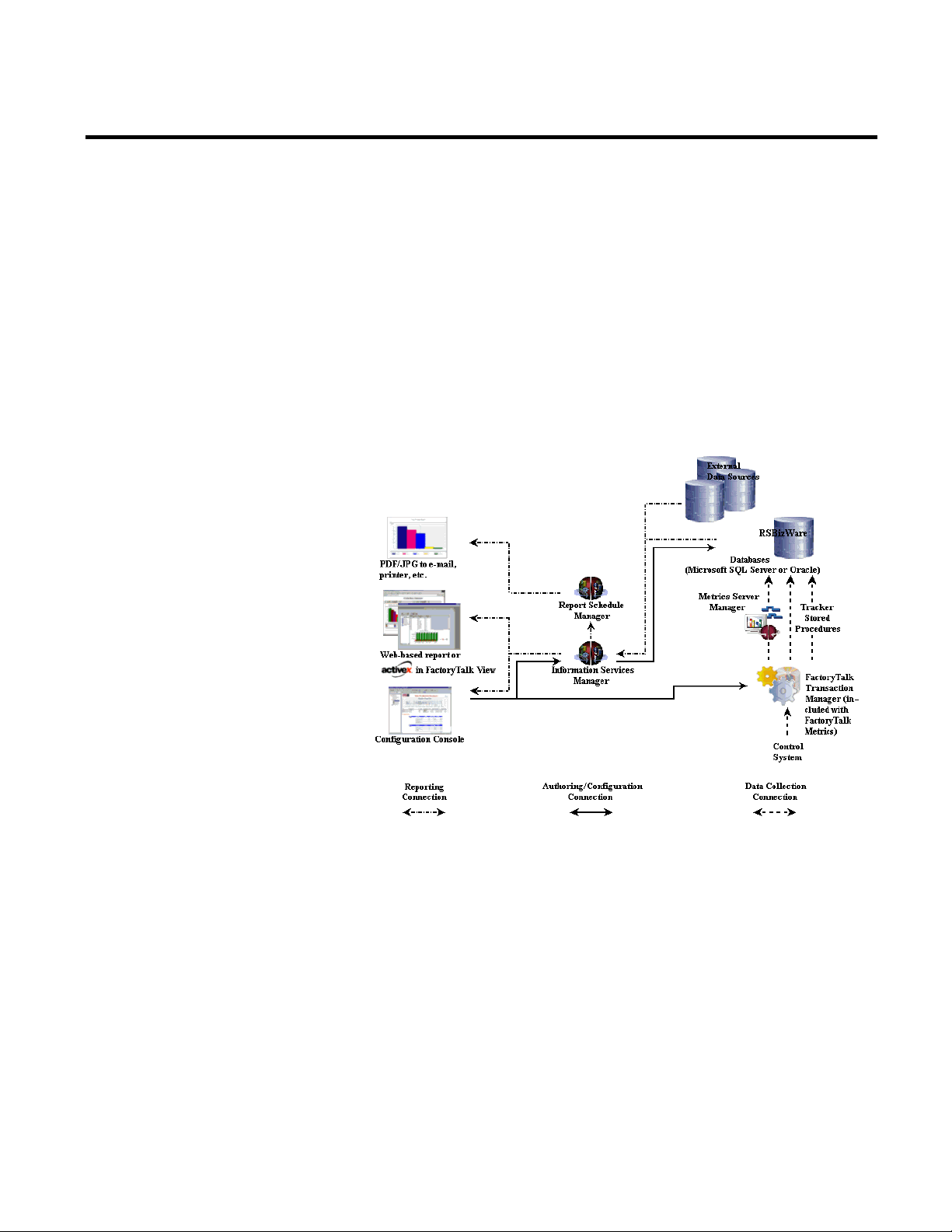

The RSBizWare architecture is a scalable, multi-tiered, distributed

architecture consisting of a data collection subsystem, an Oracle or

SQL Server database repository, the Information Services Manager,

and clients. Rockwell Automation’s FactoryTalk Transaction

Manager is the embedded engine that collects data from the control

system(s), and the Metrics Server Manager logs it to the predefined

RSBizWare database repository. There are several types of clients,

including the Configuration Console and the Internet Explorer

Web client.

Page 14

Chapter 2 Getting Started

Connecting to the Information Services Manager

Using the Information Services Manager in Internet Explorer

The RSBizWare architecture can be configured to run on a single

computer, or it can be distributed across multiple computers. In the

simplest case, the Configuration Console, the Information Services

Manager, the RSBizWare administrative tools used by the

RSBizWare administrator, the database, the Metrics Server

Manager, and the FactoryTalk Transaction Manager data collection

engine run on a single computer. In a distributed setting, these

components may reside on separate computers. Clients connect to

the Information Services Manager using TCP/IP, so they can be

deployed over a LAN, WAN, intranet, or the Internet. The

scalability of the RSBizWare architecture allows many clients to

connect to a single server.

RSBizWare reports created by the report designer are saved to the

Information Services Manager, and are available online over a

TCP/IP network. If you wish to create and edit RSBizWare reports

using Microsoft Internet Explorer, you need to run the

Configuration Console.

Using Microsoft Internet Explorer to view RSBizWare reports, you

can connect to the Information Services Manager without having

the RSBizWare software installed on your computer. Instead, the

server hosts a special Web page, the Quick Web, to give you access to

the RSBizWare reports stored on the server. This option only allows

you to view RSBizWare reports.

To access the Quick Web, open Internet Explorer, type the Web

address for the Information Services Manager computer, and press

Enter on your keyboard.

The Web address is made up of the name of the server computer and

the HTTP port number used by the server computer, separated by a

colon.

For example, if you were attempting to connect to a server computer

named

rsi-rockwell that uses the default HTTP port 8080, you

14 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Page 15

Getting Started Chapter 2

Using the Configuration Console

would use the following address: http://rsi-rockwell:8080.

Please contact your RSBizWare administrator for the specific

Information Services Manager Web address to which you should

connect.

The first time you try to use the Quick Web, you need to download

several ActiveX controls from the server computer. The download

will begin automatically.

After you have downloaded the ActiveX controls from the

Information Services Manager, you may be prompted to log on. If

prompted, type the user name and password for the account that

your RSBizWare administrator has authorized for you, and then

click OK. A connection to the RSBizWare server is established.

If you wish to configure your plant model, manage the collection of

control system data, and/or edit RSBizWare reports, you should

connect to the Information Services Manager via the Configuration

Console. Your RSBizWare administrator must assign a FactoryTalk

Metrics Author license and the appropriate privileges to you before

you will be able to perform these functions.

You must have the Client software installed on your computer

before you can run the Configuration Console. To install the

Configuration Console from the RSBizWare CD, select the

“Minimal” install option.

1. To start the Configuration Console, select Programs >

Rockwell Software > RSBizWare > Configuration Console.

2. If you have not already logged into RSBizWare, the Login

dialog will display. Enter the user name and password for the

account your RSBizWare administrator has authorized for

you. Enter the name of the server computer where the

Information Services Manager is running in the Server box.

Click Login.

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 15

Page 16

Chapter 2 Getting Started

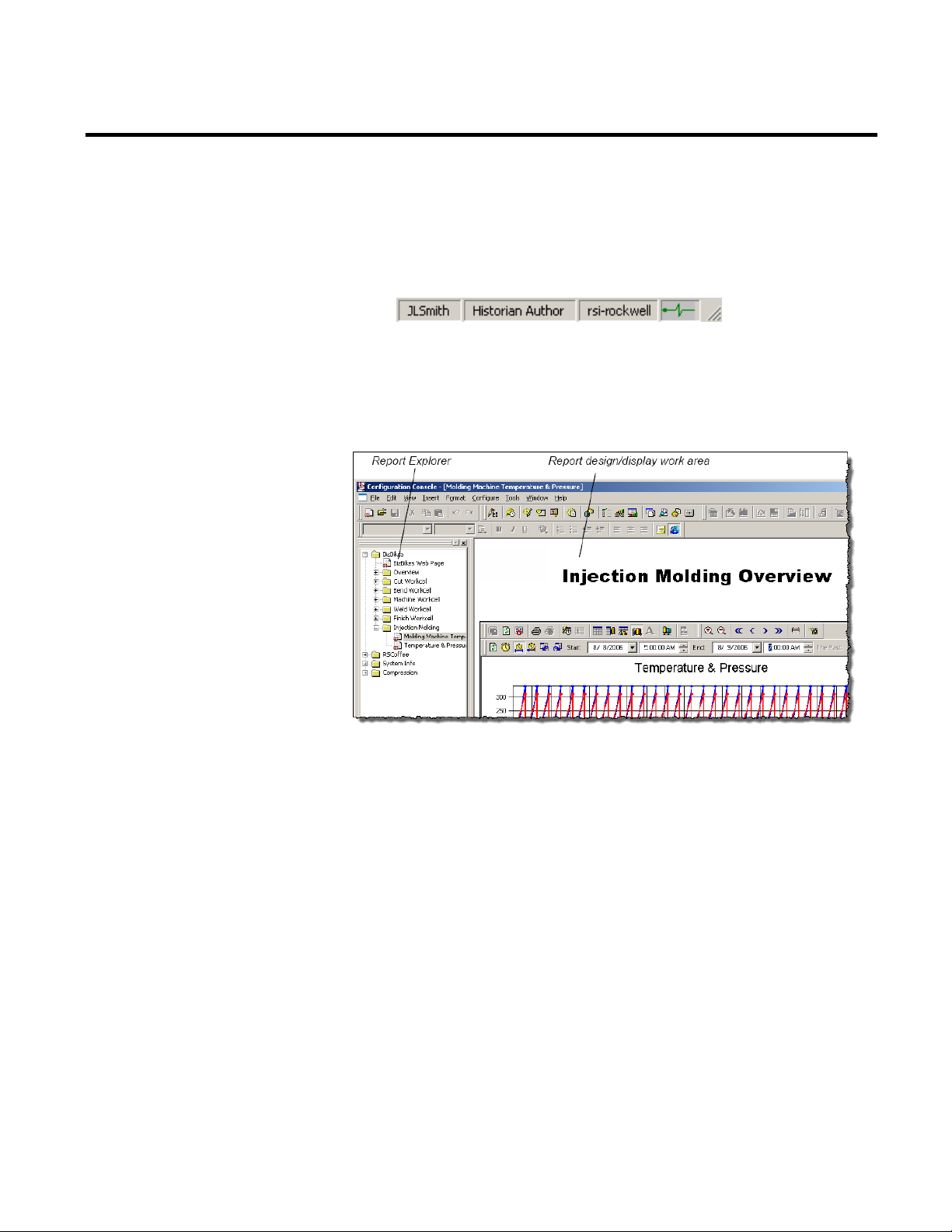

Exploring the User Interface

The Report Explorer

The Report Design and Display Work Area

The status bar at the bottom of the client application shows

your user name, the activations that have been assigned to you,

and the Information Services Manager to which you are

connected.

When you start the Configuration Console, you will notice that the

user interface is made up of two main components: the Report

Explorer and the report design and display work area.

16 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

The Report Explorer is a hierarchical navigation tool used for

organizing RSBizWare reports that have been saved for future use.

The Report Explorer contains the reports that have been saved on

the Information Services Manager to which you are connected and

for which you have been granted view permissions. Your ability to

modify and delete the reports listed on the Report Explorer is

dependent on the licenses and features that have been assigned to

you by your RSBizWare administrator and the permissions that

have been granted to you by the creator of each individual report.

When you click an item in the Report Explorer, the specified

RSBizWare report will display in the work area to the right of the

Page 17

Getting Started Chapter 2

Shortcut Menus

Report Explorer. The work area is the region where report designers

can create and modify reports.

Many areas of the application give you access to shortcut menus.

The shortcut menu allows you to perform frequently used

commands without using the main application menu or toolbar

buttons. To view the shortcut menu, you need to right-click in the

area of the desired application. The shortcut menu contains

commands that are appropriate for the selected area. For example, if

you right-click the Report Explorer, the shortcut menu will contain

commands that apply to the Report Explorer.

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 17

Page 18

Chapter 2 Getting Started

18 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Page 19

The Plant Model

Chapter 3

Collecting FactoryTalk Historian Classic Data

The primary functions of FactoryTalk Historian Classic are to

collect and analyze time-series data. Before the report designer can

create time-series analysis reports for the report user, the RSBizWare

administrator must set up the application to collect data from the

control system. The tutorials in this chapter will help you

understand how to use FactoryTalk Historian Classic to collect

time-series data. We will:

• Configure the plant model for your FactoryTalk Historian

Classic installation

• Configure time-series data collection

• Organize FactoryTalk Historian Classic reporting tags

• Start and stop data collection

The tutorial in "Analyzing FactoryTalk Historian Classic Data (page

41)" will help you understand how to analyze the data that is

collected in FactoryTalk Historian Classic.

The plant model is made up of activity areas - enterprises, sites, areas,

lines, and workcells - as well as of equipment and labor resources.

The activity areas are based on the terms defined by the Instrument

Society of America (ISA) S95 standard in order to provide common

terminology for improved communication and integration between

control systems and enterprise systems.

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 19

Page 20

Chapter 3 Collecting FactoryTalk Historian Classic Data

workcell in the line).

location.

location at which products are manufactured.

Enterprise

The highest-level activity area, typically representing the business.

To create and edit the plant model, you must be granted the

Activity Areas".

Configuring the Plant Model

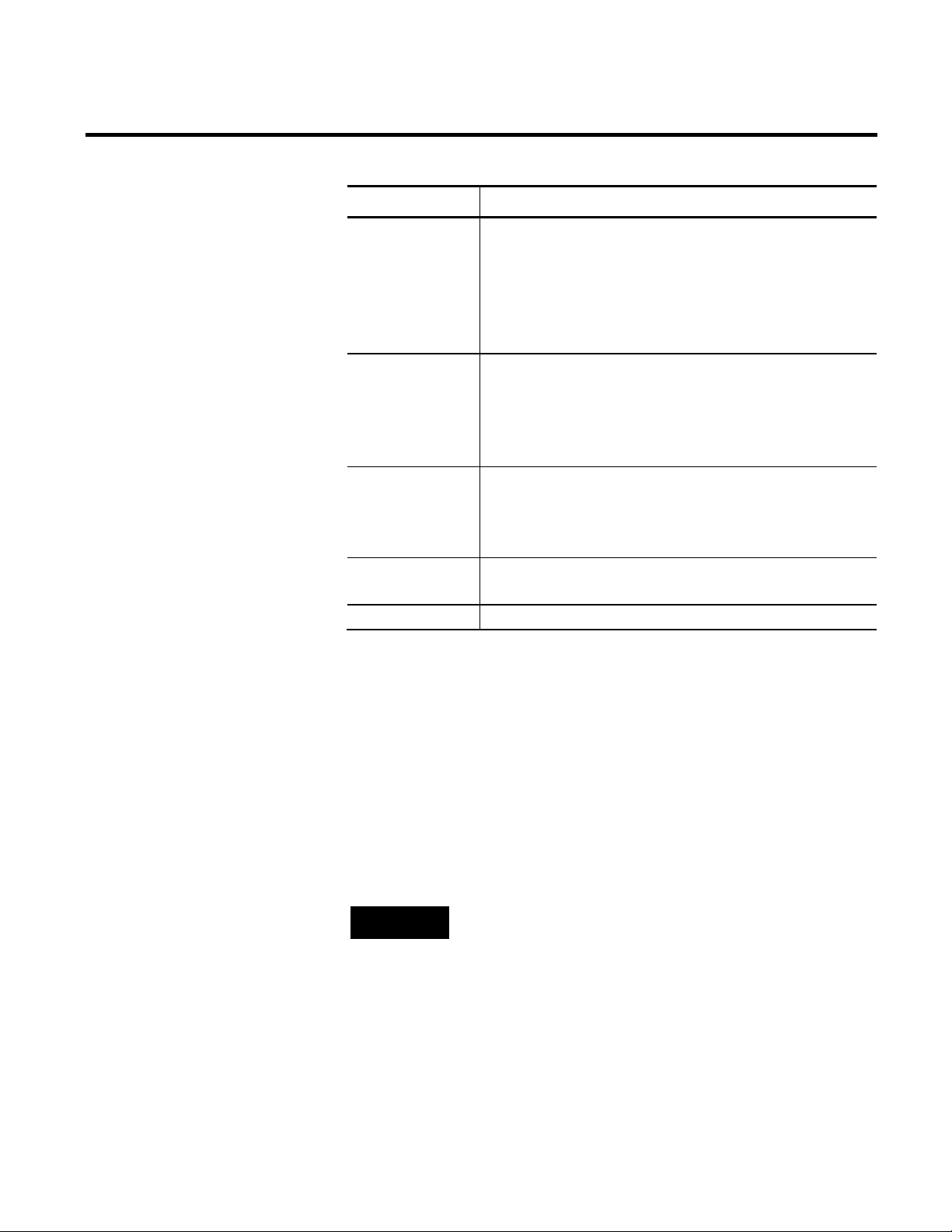

Item Description

Workcell A location and/or group of equipment used to perform work in a

Line A collection of one or more workcells that are combined to perform

Area A physical, geographical, or logical grouping of lines and/or

manufacturing process. The operations in a manufacturing process

are performed at workcells. A workcell is typically a physical

location and a primary resource (e.g., a machine); however, it may

also represent a logical grouping of primary resources from which a

selection is made.

work. The workcells in a line are either physically located close to

one another, or are related to one another in the production process

(the production result of the first workcell in a line feeds the second

workcells within a site, typically representing a main production

capability (e.g., electronic assembly) within a manufacturing

Site A group of areas, lines, and workcells representing a geographical

The plant model may be used by all RSBizWare applications in your

organization (FactoryTalk Metrics, FactoryTalk Historian Classic,

and FactoryTalk Scheduler). The enterprises, sites, areas, lines, and

workcells in your plant model are the subjects of your performance

parameter evaluation. For implementations of RSBizWare that

incorporate the FactoryTalk Scheduler application, the plant model

also includes capacity, which is the property of an activity area

describing its availability over time. The performance parameters

can also be configured for resources.

NOTE:

Organize Plant Model privilege by your RSBizWare administrator.

If you want to have access to sample data, see "Loading Sample

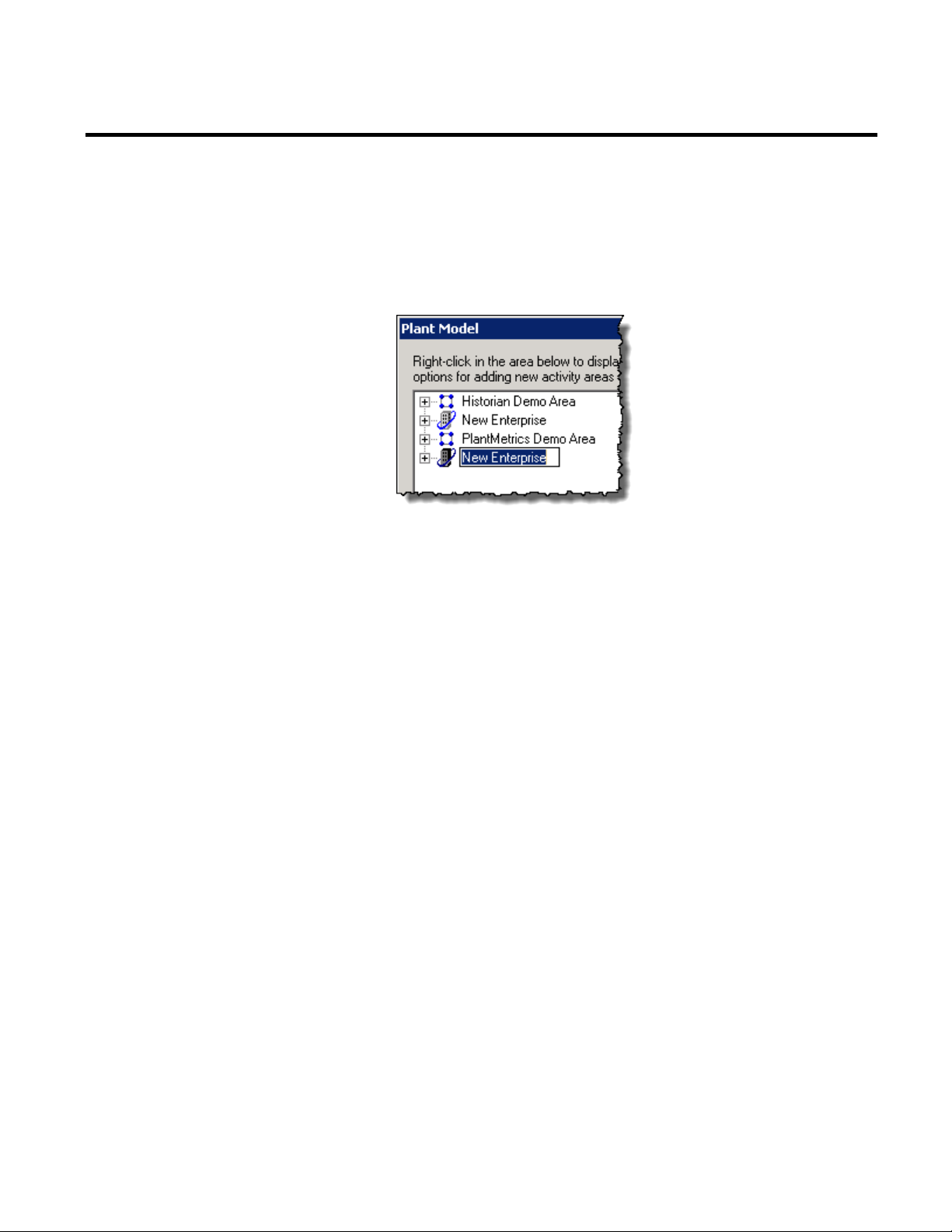

To configure the plant model in the Configuration Console:

20 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

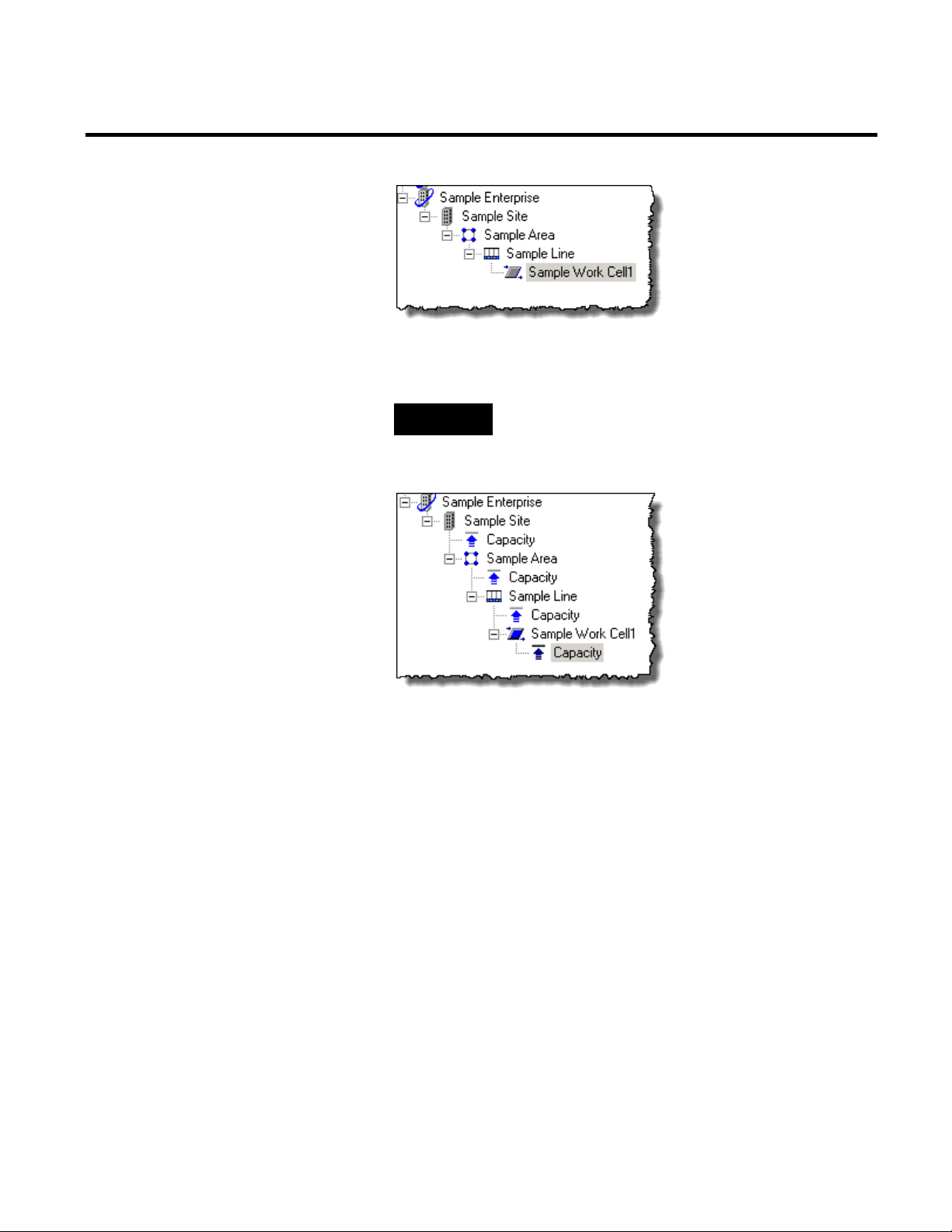

1. On the Configure menu, click Plant Model.

Page 21

Collecting FactoryTalk Historian Classic Data Chapter 3

The Plant Model dialog box appears.

2. Right-click in the area under the plant model tree, and then

click New Root Enterprise.

A new enterprise is added to the tree.

3. Change the default name to

Sample Enterprise, and then press

Enter.

4. Right-click Sample Enterprise, and then click New Activity

Area > Site.

A new site is added to the tree.

5. Change the default name to

Sample Site.

6. Right-click Sample Site, and then click New Activity Area >

Area.

A new area is added to the tree.

7. Change the default name to

Sample Area.

8. Right-click Sample Area, and then click New Activity Area >

Line.

A new line is added to the tree.

9. Change the default name to

Sample Line.

10. Right-click Sample Line, and then click New Activity Area >

Work Cell.

A new workcell is added to the tree.

11. Change the default name to

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 21

Sample Work Cell 1.

Page 22

Chapter 3 Collecting FactoryTalk Historian Classic Data

them with time patterns.

Configure Time-Series Data Collection

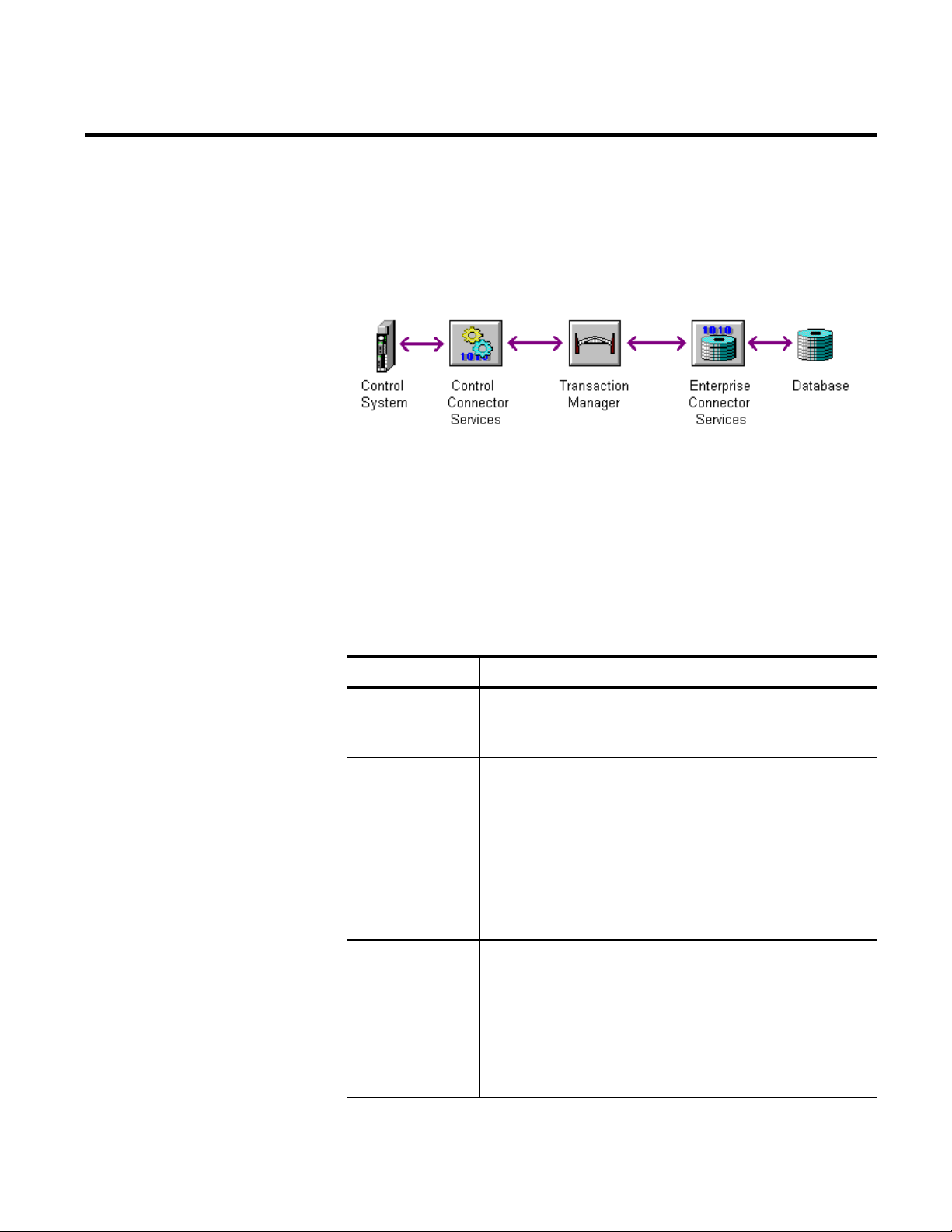

12. Right-click each activity area that you have created, and then

click Add Capacity.

TIP

The capacity of an activity area describes its availability over

time.

Add capacity for your activity areas so that you can associate

13. Click OK.

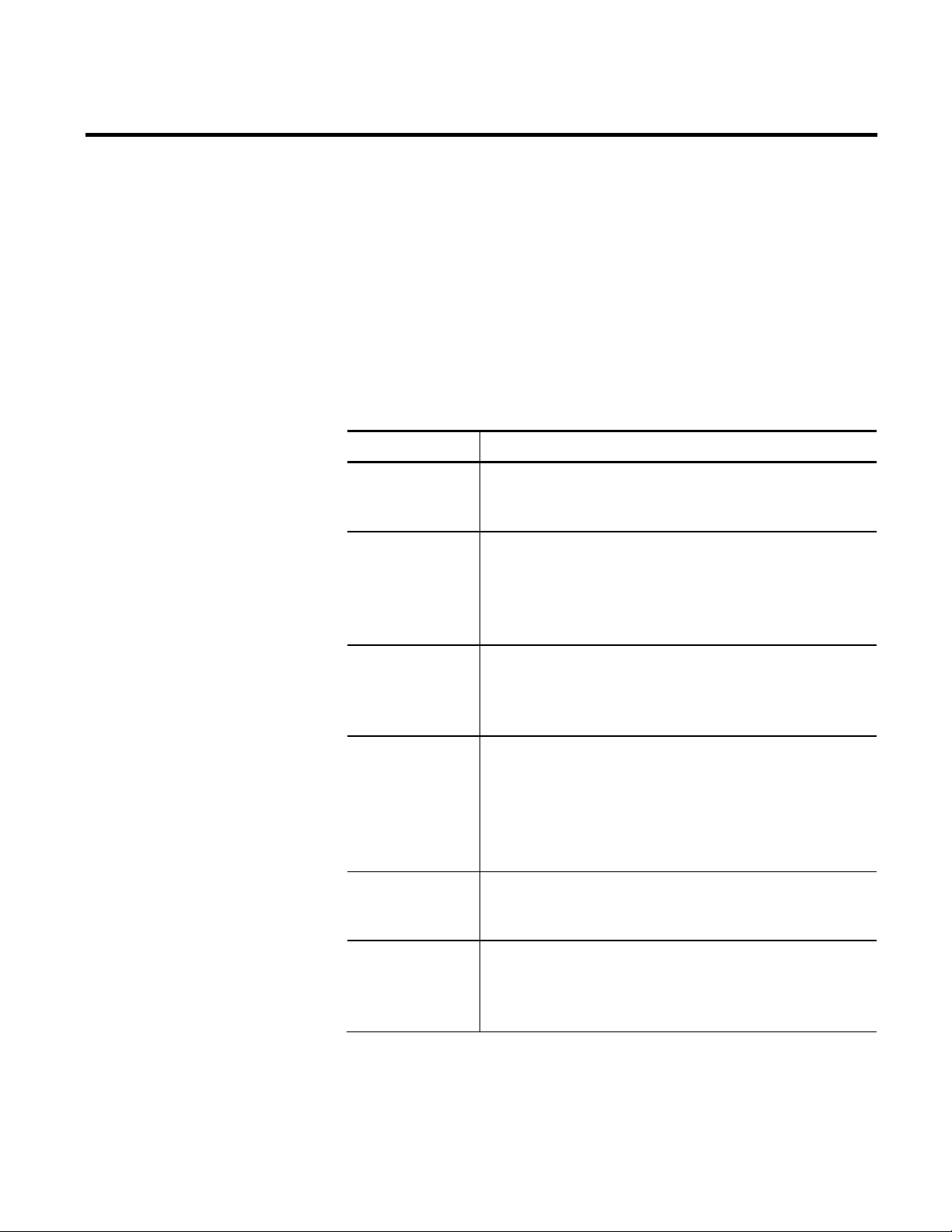

FactoryTalk Historian Classic uses FactoryTalk Transaction

Manager to collect data from the control system and log it into the

RSBizWare database. A FactoryTalk Transaction Manager

configuration connects any control system from which data will be

collected to the predefined data model used by the RSBizWare

database to store time-series data. The configuration consists of

transactions and the connectors, data points, and data objects

required to implement the transactions.

22 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

A transaction is a single exchange of data between the industrial

control system - typically a network of programmable logic

controllers (PLCs) - and a database. An example of a transaction is a

temperature value that is collected from a data point on a

programmable logic controller and logged to a database table.

Page 23

Collecting FactoryTalk Historian Classic Data Chapter 3

supported by the OPC specification.

with ControlLogix 555x processors.

specifications.

online edits with your configuration.

Types of control connectors for the data collection

A data point is a specific data location or register in the control

system that is made available to FactoryTalk Transaction Manager

transactions. After it is defined, a data point can be used by any

FactoryTalk Transaction Manager transaction.

The FactoryTalk Transaction Manager interfaces with the industrial

control system device via a control connector. A control connector is

a Windows service that collects data from a data server, such as a

PLC and sends it to the FactoryTalk Transaction Manager.

You can use the following types of control connectors:

Item Description

Dynamic Data

Exchange (DDE)

RSLinx Classic OPC The RSLinx Classic control connector service is the preferred method

Generic OPC The Generic OPC control connector service is used to interface with

FactoryTalk LiveData

Connector

The DDE control connector service is provided for legacy

connections to DDE servers or to provide functionality that is not

to use when browsing for data tags that reside in Allen-Bradley

Programmable Logic Controllers, except for ControlLogix 555x

processor items. You should use Generic OPC control connectors

items provided by any OPC server that conforms to OPC interface

FactoryTalk Transaction Manager uses FactoryTalk Live Data to

communicate with FactoryTalk Live Data servers, such as RSLinx

Classic and RSView Supervisory Edition. FactoryTalk Transaction

Manager connects to the FactoryTalk Directory, which allows

FactoryTalk Transaction Manager to browse the available data

items. This control connector is required if you plan to perform

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 23

Page 24

Chapter 3 Collecting FactoryTalk Historian Classic Data

The ODBC enterprise database connector allows you to interface

Access, Microsoft SQL Server 6.5 or later, IBM DB2 or Sybase.

to an Oracle database versions 9i through 11g.

name (DSN) and is the preferred method of connection.

Professional installations.

RSBizWare database.

Transaction Manager Professional installations.

Enterprise Connectors

The FactoryTalk Transaction Manager interfaces with the database

via an enterprise connector. An enterprise connector is a Windows

service that receives data from the FactoryTalk Transaction

Manager and logs it to a database.

The following are the types of enterprise connectors that you can

use:

Item Description

ODBC

with virtually any ODBC-compliant database including Microsoft

Oracle OCI

Microsoft OLE DB

Microsoft COM+

FactoryTalk

Metrics

SAP

The Oracle Call Interface (OCI) enterprise database connector allows

you to connect to database objects from an Oracle server. If you are

using Oracle OCI, you need to install locally SQL*NET 2.3x or later,

Net8, or Oracle Net services (all from Oracle). You can then connect

The Microsoft OLE DB enterprise database connector should only be

used for interfacing with Microsoft SQL Server. Microsoft OLE DB

allows you to browse an SQL Server database without a data source

The Microsoft COM+ enterprise application connector allows you to

interface with Microsoft COM+ application components. These

components must be integrated into a Windows 2000 COM+

environment. RSBizWare-only applications do not support this

connector. It is for use only with FactoryTalk Transaction Manager

The FactoryTalk Metrics enterprise application connector is used

only with FactoryTalk Metrics. The connector stores data in the

The SAP enterprise application connector allows you to interface

with SAP R/3 systems modules. RSBizWare-only applications do not

support this connector. It is for use only with FactoryTalk

24 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Page 25

Compression".

administrator.

Tutorial

Step 1: Start the Time-Series Data Collection Wizard

Step 2: Select the Source and Destination of the Time-Series Data

Item Description

Collecting FactoryTalk Historian Classic Data Chapter 3

Time-series Data

Compression

This connector stores time-series data in a pre-defined compressed

format in either an Oracle database or a Microsoft SQL Server

database. The compressed data point records contain binary data

that can only be viewed through FactoryTalk Historian Classic. For a

detailed description of data compression and the Compression

connector, see the Administration Guide, section "Data

This tutorial will help you understand how to use the Time-Series

Data Collection Wizard to collect reporting tag data. A reporting

tag is a particular item of collected time-series data—independent of

the method or source of collection—that can be charted in

RSBizWare reports.

For this tutorial, we will be using the Time-Series Data Collection

Wizard to configure FactoryTalk Transaction Manager transactions

that will collect values from the control system and log the values to

a reporting tag in the RSBizWare database.

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 25

NOTE

To configure time-series data collection, you must be granted a

FactoryTalk Historian Classic Author license by your RSBizWare

From the Configuration Console menu, select Configure >

FactoryTalk Historian Classic >Time-Series Data Collection to

display the Time-Series Data Collection Wizard welcome screen.

Click Next on the Welcome dialog box.

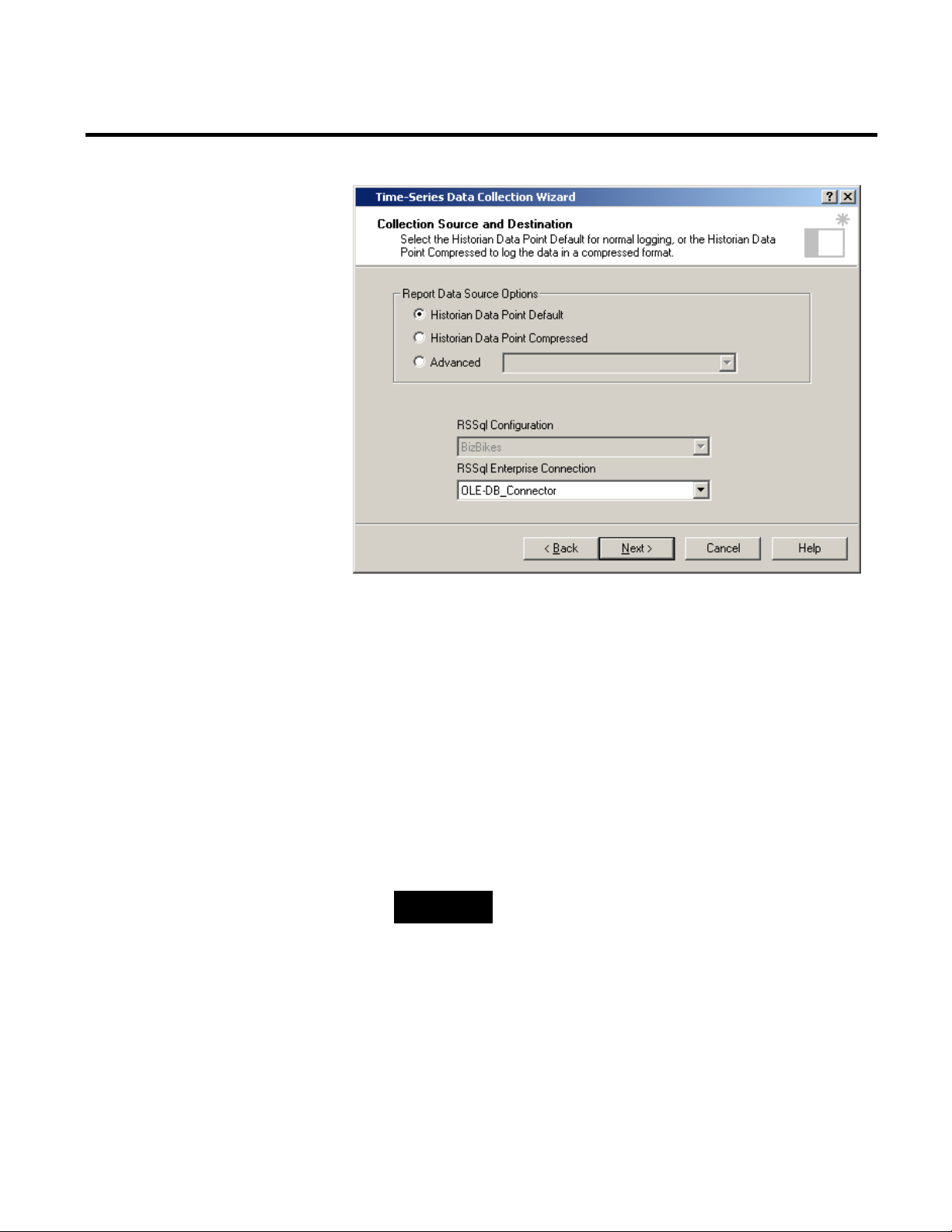

The Collection Source and Destination dialog box, which allows

you to specify where the time-series data will be collected from and

where it will be stored in the RSBizWare database, will display.

Page 26

Chapter 3 Collecting FactoryTalk Historian Classic Data

sources, refer to "Analyzing Non-RSBizWare Data (page 110)".

1. The report data source is the database table or view where the

data will be stored. FactoryTalk Historian Classic is capable of

logging data to the FactoryTalk Historian Classic Data Point

Default report data source (the RSDataPointSample table in

the RSBizWare database), the FactoryTalk Historian Classic

Data Point Compressed report data source (the

RSSQL_CMPCOMPRESS table in the RSBizWare

database), or to any other database table or view that your

organization identifies as supporting the required time-series

data model (Advanced option). For this tutorial, accept the

default Historian Data Point Default option.

TIP

For more information about creating additional report data

2. Now you must specify the FactoryTalk Transaction Manager

configuration that will be used to support data collection. The

FactoryTalk Transaction Manager Configuration list contains

the configurations that have been associated with FactoryTalk

Historian Classic for the server to which you are connected. If

we had selected a compression report data source in the

previous step, only FactoryTalk Transaction Manager

26 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Page 27

Collecting FactoryTalk Historian Classic Data Chapter 3

Edits” topic in the online help.

Step 3: Create or Select Data Points

configurations that had Compression Enterprise Connections

would be available here. Since we selected a non-compression

report data source, any FactoryTalk Transaction Manager

configurations that have non-compression (OLE DB, OCI, or

ODBC) enterprise connectors will be available.

3. The Enterprise Connector is the service that will manage the

connection between the FactoryTalk Transaction Manager

configuration and the database. The FactoryTalk Transaction

Manager Enterprise Connection list contains the enterprise

connectors that are available from the configuration that you

selected. From the Enterprise Connection list, select the

OLE-DB_Connector.

4. Click Next to continue.

If the FactoryTalk Transaction Manager configuration is

already running and is enabled for online edits, you can edit

the configuration without stopping it. However, if the

configuration is running and is not enabled for online edits,

the wizard will prompt you to stop the configuration. If you do

not stop the configuration, the Time- Series Data Collection

Wizard cannot make changes to the configuration, and the

wizard will close automatically.

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 27

NOTE

The FactoryTalk Transaction Manager Live Data Migration Tool

allows you to convert configurations with non-FactoryTalk data

points into FactoryTalk data points. For additional information

about editing a running configuration and using the FactoryTalk

Transaction Manager Live Data Migration Tool, see the “Online

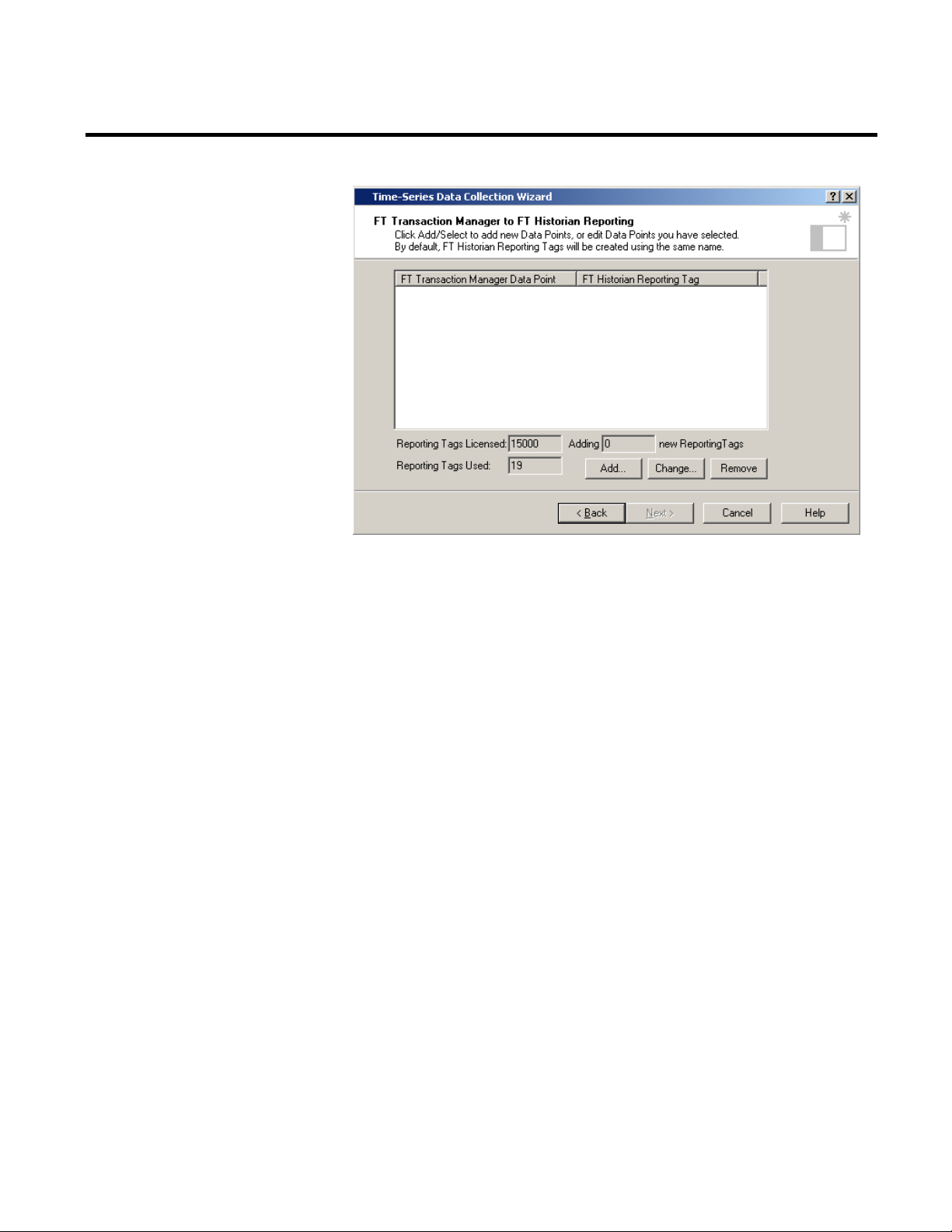

Next you’ll see the FactoryTalk Transaction Manager to

FactoryTalk Historian Classic Reporting dialog. This dialog enables

you to select the FactoryTalk Transaction Manager data points from

which FactoryTalk Historian Classic will be collecting data and

enables you to specify the FactoryTalk Historian Classic reporting

tags to which the data will be logged.

Page 28

Chapter 3 Collecting FactoryTalk Historian Classic Data

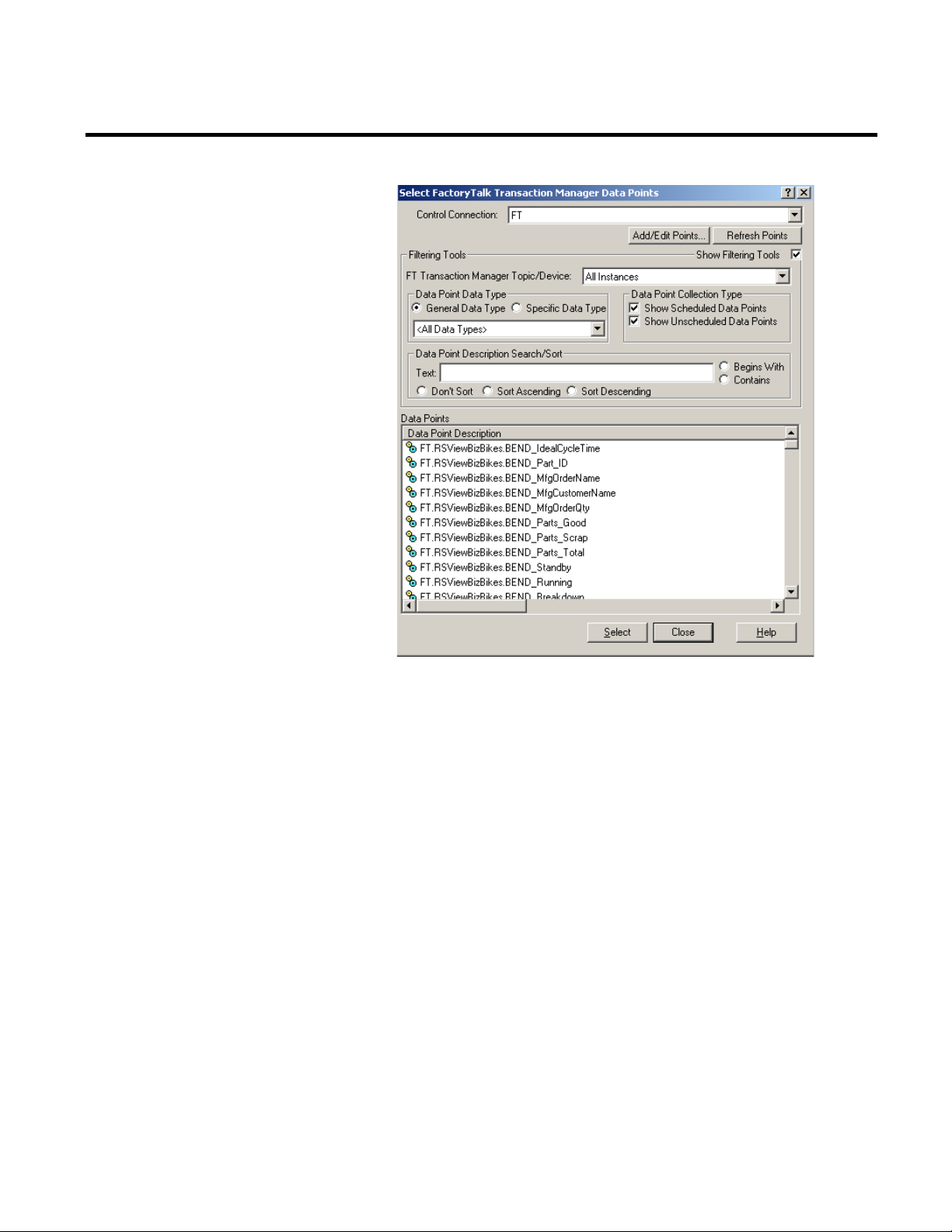

1. To select the data points from which data will be collected,

click the Add button. The Select FactoryTalk Transaction

Manager Data Points dialog that is displayed lists the data

points that exist in the FactoryTalk Transaction Manager

configuration. The top of the dialog is simply a set of tools that

you can use to filter the data point list.

28 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Page 29

Collecting FactoryTalk Historian Classic Data Chapter 3

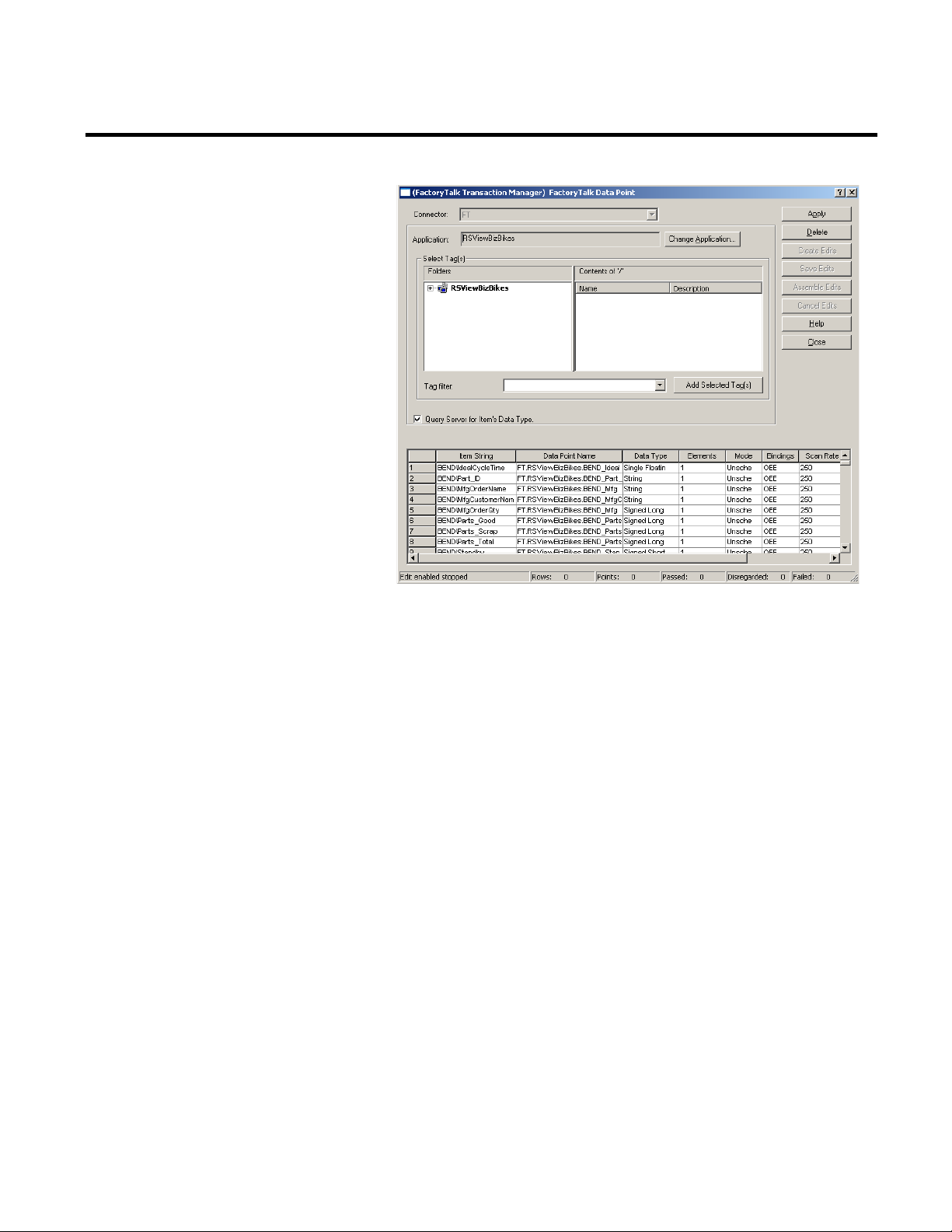

2. To add new data points to the FactoryTalk Transaction

Manager configuration, click the Add/Edit Points button to

display the (FactoryTalk Transaction Manager) FactoryTalk

Data Point dialog box.

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 29

Page 30

Chapter 3 Collecting FactoryTalk Historian Classic Data

This dialog may look different depending on the type of

control connector that you selected. This dialog allows you to

add data points to the Control Connector and set their

properties.

3. If you were creating new tags from a running FactoryTalk

Transaction Manager configuration, you would select them by

selecting a category of tags from the Folders tree, selecting the

actual tags from the Contents of ‘/” list, clicking the Add

Selected Tag(s) button, and clicking the Apply button. For

now, click Close to exit the dialog and return to the Select

FactoryTalk Transaction Manager Data Points dialog.

4. Highlight the data points for which you want to collect data.

For this tutorial, select the BEND_Breakdown data point

(unscheduled) and the BEND_BreakdownCode data point

(scheduled). Click Select to return to the From FactoryTalk

Transaction Manager to FactoryTalk Historian Classic

Reporting Tags step of the Time-Series Data Collection

Wizard.

30 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Page 31

Collecting FactoryTalk Historian Classic Data Chapter 3

Step 4: Configure Collection Parameters

The selected data points have been added to the list of data

points for which you will be creating transactions. Since we are

collecting data from newly selected data points, the

FactoryTalk Historian Classic Reporting Tag column does not

yet contain reporting tag names that will be associated with the

values when they are stored in the database.

5. You can associate each data point with an existing reporting

tag or you can have the application create a new reporting tag

for you. To associate an existing reporting tag with a data

point, you would select the data point from the list and click

the Change button to display the Select FactoryTalk Historian

Classic Reporting Tag dialog. You would then select the

reporting tag with which you want to associate the selected

data point and click OK to close the dialog. This approach is

useful if you have a data point/reporting tag association that

you want to change. For this tutorial, accept the reporting tag

names that the application generates by clicking Next.

The next step in the process is to assign collection parameters to the

selected data points. If you have selected data points that are

configured as scheduled, the FactoryTalk Transaction Manager

Scheduled Transaction dialog box will display. If you have selected

data points that are configured as unscheduled, the FactoryTalk

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 31

Page 32

Chapter 3 Collecting FactoryTalk Historian Classic Data

Transaction Manager Unscheduled Transaction dialog box will

display. If you have selected both scheduled and unscheduled data

points, the FactoryTalk Transaction Manager Scheduled

Transaction dialog box and the FactoryTalk Transaction Manager

Unscheduled Transaction dialog boxes will both be displayed.

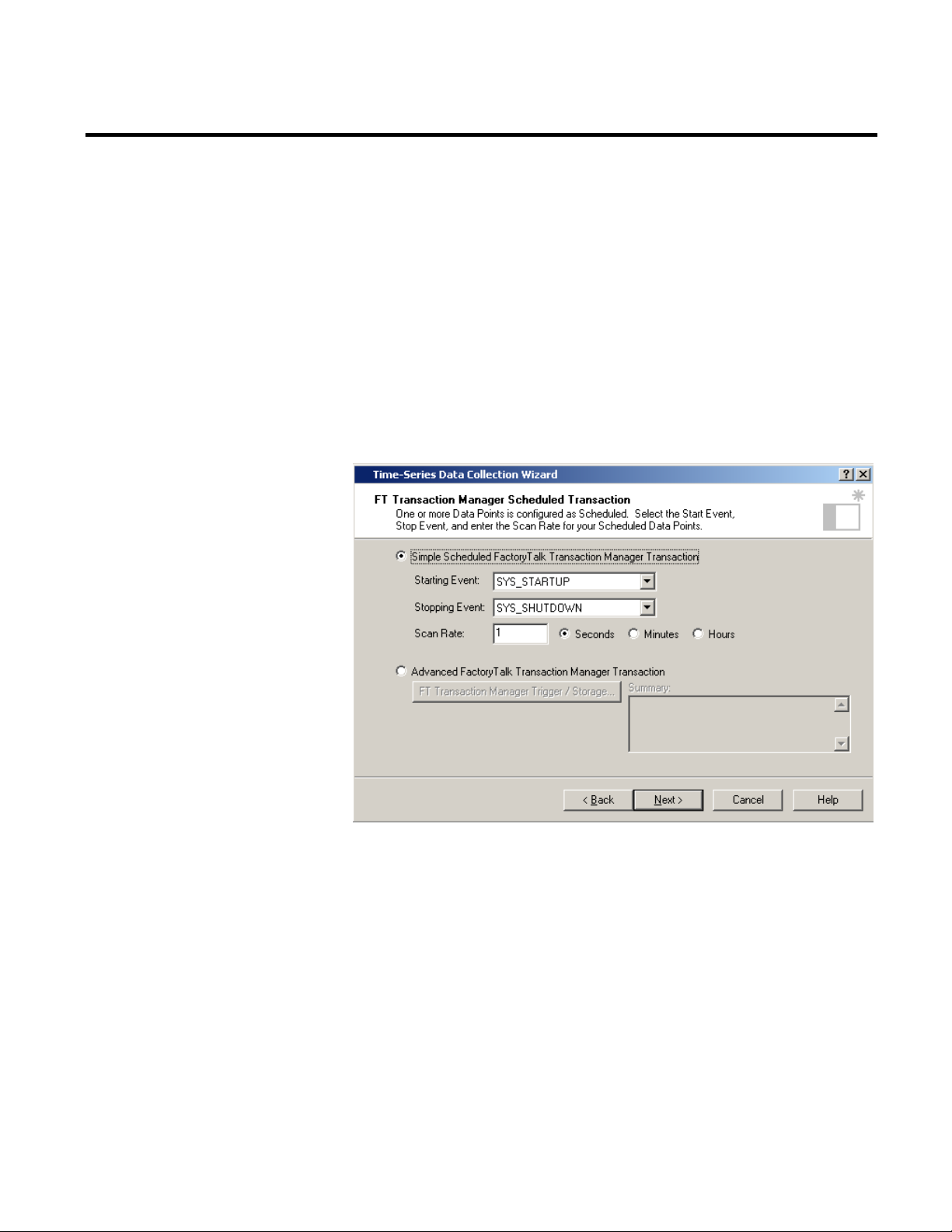

Scheduled transactions. Use the FactoryTalk Transaction Manager

Scheduled Transaction dialog box to indicate how often to poll the

control system and log the data to the RSBizWare database (e.g.,

once every 15 seconds).

1. The Simple Scheduled FactoryTalk Transaction Manager

Transaction option is useful if you want to trigger the

transaction on simple scheduled events such as system start up

or system shut down. If you want to set more sophisticated

triggers for the transaction, select the Advanced FactoryTalk

Transaction Manager Transaction option. For this tutorial,

accept the default Simple Scheduled FactoryTalk Transaction

Manager Transaction option and the default Starting Event

(SYS_STARTUP) and Stopping Event

(SYS_SHUTDOWN).

32 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Page 33

Collecting FactoryTalk Historian Classic Data Chapter 3

2. Set the scan rate to 15 seconds. This means we will be

collecting data every 15 seconds between the time the

configuration is started and the time the configuration is

stopped.

3. Click Next to continue.

Unscheduled transactions. Unscheduled transactions are triggered

by a change in the value of the data point that is being logged. The

FactoryTalk Transaction Manager Unscheduled Transaction dialog

box allows you to trigger the transaction when the data point value

goes high, low, or on any change in the data point value.

1. For our example, accept the default On Change option. This

option means that any time our data point value changes, a

value will be logged to the database.

2. Select the Specify Minimum Collection Frequency (MCF)

check box to create a scheduled transaction that will be paired

with your unscheduled transaction. The values from both

transactions will be logged to the same field in the database.

The data from the scheduled transaction will create a

“heartbeat” that will allow us to determine that the

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 33

Page 34

Chapter 3 Collecting FactoryTalk Historian Classic Data

Step 5: Configure Transaction Settings

3. Enter 15 in the Collect Value Every box and accept the default

4. Click Next to continue.

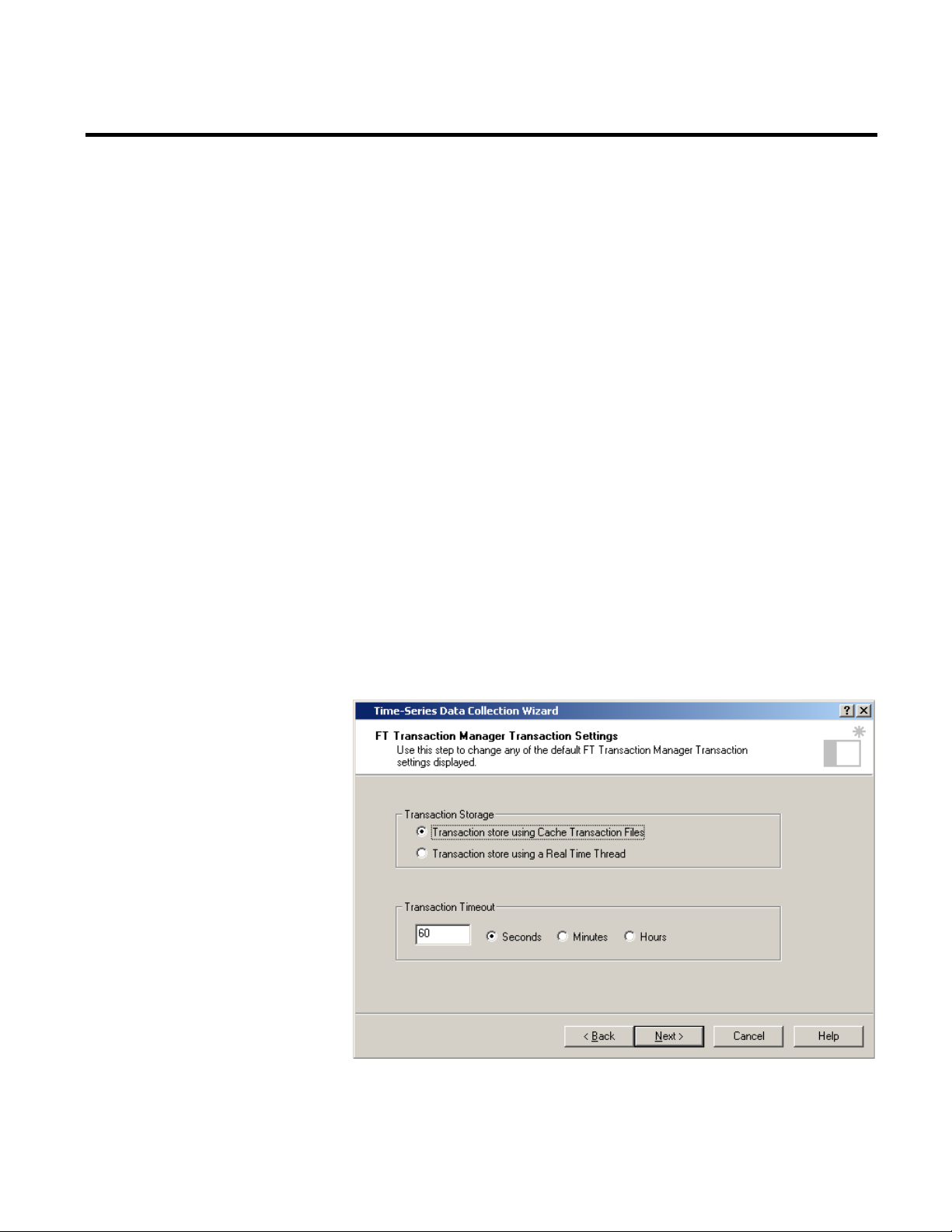

The FactoryTalk Transaction Manager Transaction Settings dialog

box enables you to specify how the transaction data will be stored in

the database and to specify how long FactoryTalk Transaction

Manager will wait for the transaction to complete before logging an

error.

configuration is still running even if our unscheduled

transaction has not been logged for a while. If you do not use a

minimum collection frequency and your unscheduled

transaction has not been logged for a while (this is called a

deadband), it may be difficult to determine if the FactoryTalk

Transaction Manager configuration is still running.

For additional information on setting a minimum collection

frequency, see the “Deadbanding” topic in the online help.

Seconds option. This will cause the application to collect a

“heartbeat” value every 15 seconds.

34 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Page 35

Collecting FactoryTalk Historian Classic Data Chapter 3

1. The Transaction Storage options allow you to specify how the

data will be stored to the database.

• Cache Transaction File—The FactoryTalk Transaction

Manager will write data values to a file for a specified period

of time or a specified number of transactions. When the file

reaches the specified limit, the Enterprise Connector reads

and processes the records in the file. The Cache

Transaction File option is most appropriate for transactions

that will be logged very often, such as a Scheduled data

point that will be collected every 10 seconds or less.

• Real Time Thread—The FactoryTalk Transaction

Manager will send a message to the Enterprise Connector

for each transaction as it is processed. The Real Time

• Thread option is most appropriate for transactions that will

not be logged very often; for example, an unscheduled data

point that triggers a transaction when its

• The value changes and where the value of that data point

changes infrequently.

Accept the default Cache Transaction File option.

2. The Transaction Timeout fields allow you to control how long

FactoryTalk Transaction Manager will wait for the transaction

to complete before logging an error. The transaction timeout

should be set slightly higher than the length of time it will take

for the data points to be collected, or be set to the length of

time after which the transaction is no longer valid. For

example, if a transaction should complete in 5 seconds but

might take as long as 7 seconds and still be acceptable, you

should set the transaction timeout to 8 seconds. If the

transaction goes past 8 seconds, the transaction will fail, and an

error will be logged.

Accept the default value of 60 seconds.

• Click Next to continue.

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 35

Page 36

Chapter 3 Collecting FactoryTalk Historian Classic Data

configuration that you stopped in the first step of the wizard, the

begin to collect data and log it to the RSBizWare database.

Step 6: Create Transactions

Organize FactoryTalk Historian Classic Reporting Tags

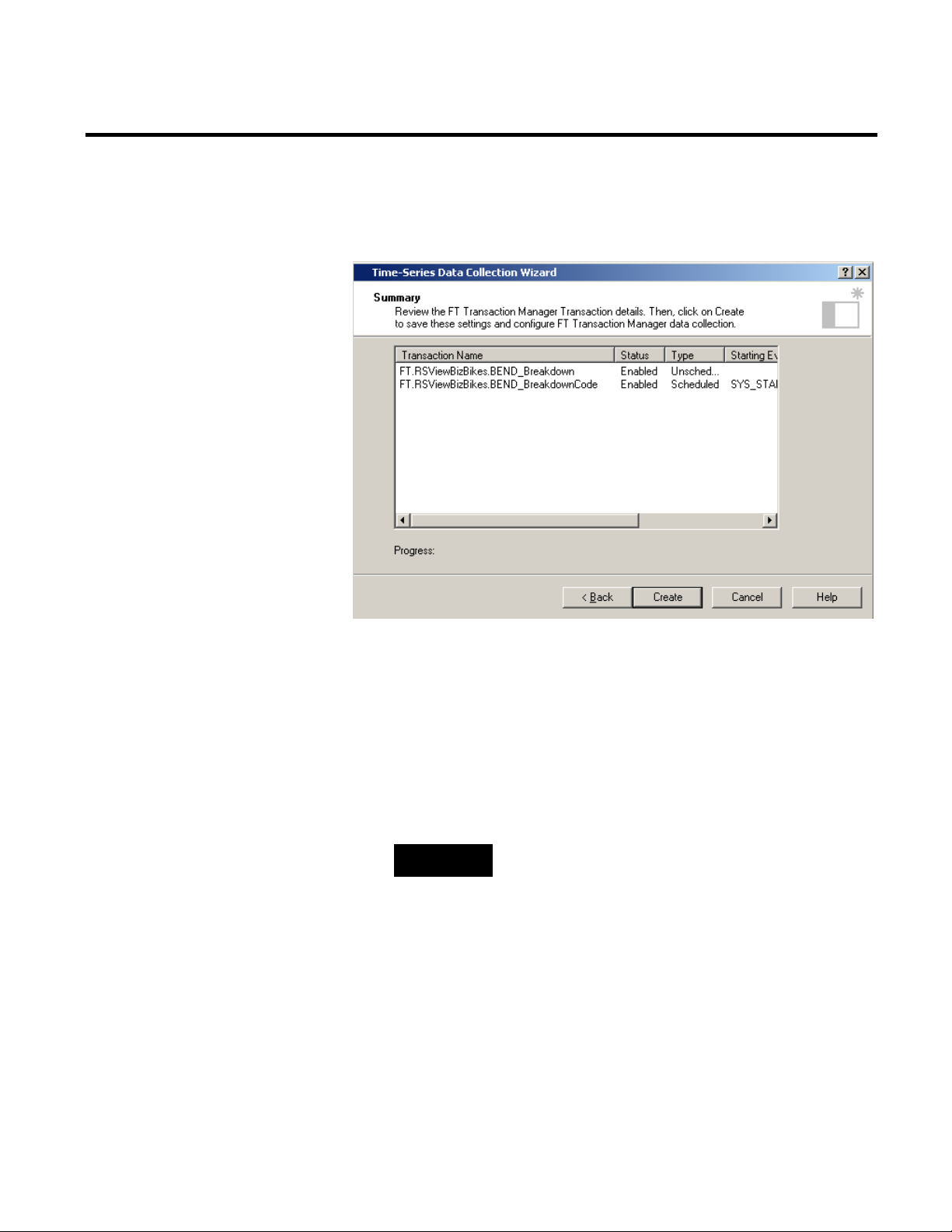

The Summary dialog box gives you a chance to review the

transactions that will be created.

1. If the transactions are correct, click Create.

2. The Results panel displays errors and warnings that occurred

during the generation of FactoryTalk Transaction Manager

transactions, if any. If the creation of transactions results in

errors or warnings, double-click the entries in the summary list

for more information about what went wrong, where the fault

occurred, and the severity of the error.

NOTE

If the configuration that you are working with was a running

wizard will prompt you to restart the configuration. After the

configuration is started, FactoryTalk Transaction Manager will

3. Click Finish to close the wizard.

As you configure FactoryTalk Historian Classic data collection for

your organization, you most likely will have a large number of

reporting tags to which you are collecting data and from which you

36 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Page 37

Collecting FactoryTalk Historian Classic Data Chapter 3

will be creating reports; therefore, it is a good idea to organize your

reporting tags.

NOTE

To manage time-series reporting tags, you must be granted the Manage

Reporting Tags privilege by your RSBizWare administrator.

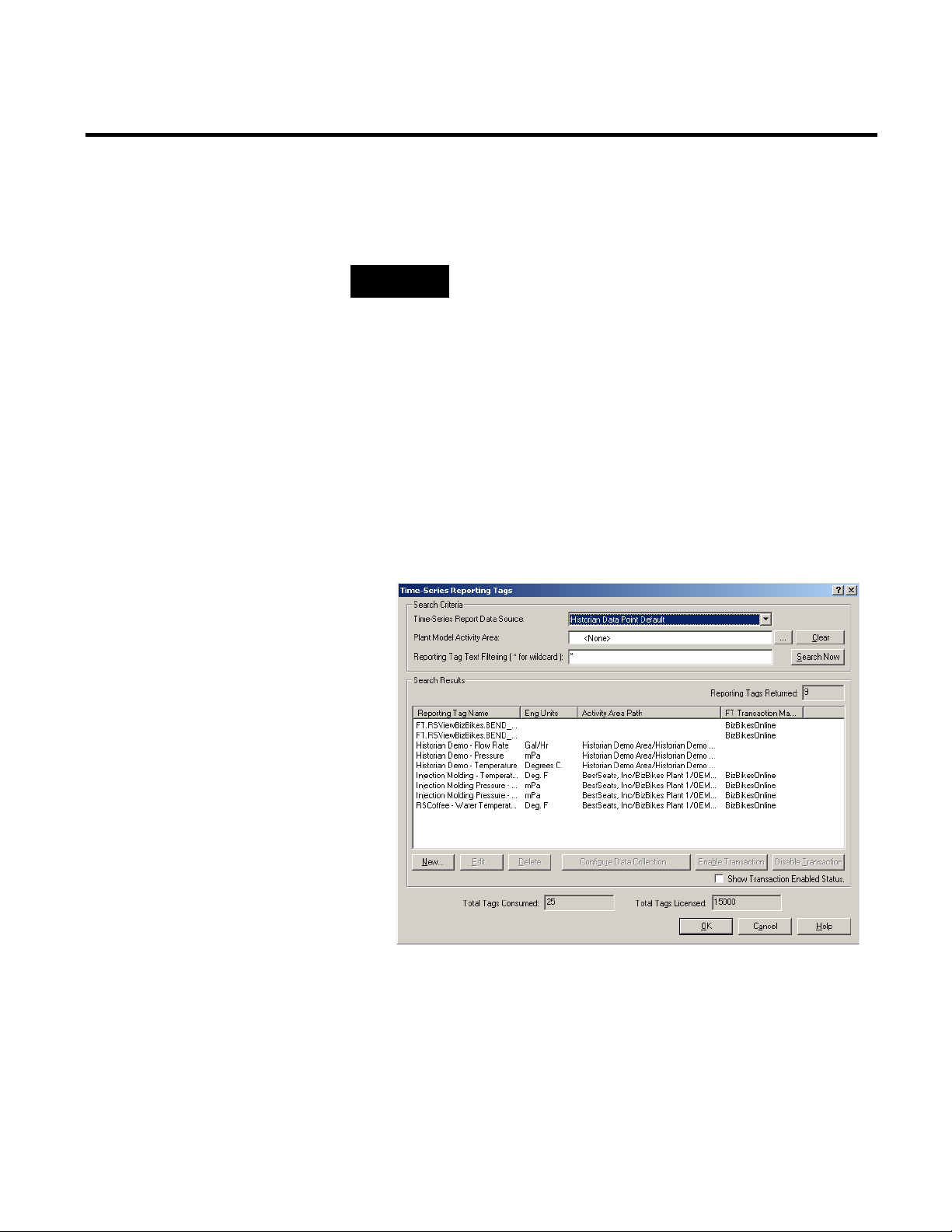

1. From the main menu, select Tools > FactoryTalk Historian

Classic > Manage Time-Series Reporting Tags to display the

Time-Series Reporting Tags dialog. This dialog is the starting

point for administering and managing reporting tags.

2. Select the time-series report data source that contains the

reporting tags that you want to modify or organize. To view

the reporting tags that we just created, select the Historian

Data Point Default report data source. The Search Results list

at the bottom of the dialog is refreshed to show the reporting

tags in the selected report data source.

3. When the Search Results list contains too many entries for you

to easily locate the reporting tags that you want to manage, use

the Plant Model Activity Area control, the Reporting Tag

Text Filtering control, or both to narrow the search results.

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 37

Page 38

Chapter 3 Collecting FactoryTalk Historian Classic Data

To perform an activity area search, click to the right of

the Plant Model Activity Area box. Use the Plant Model

Browser dialog that is displayed to select the activity area that

you want to search. Click OK to return to the Time-Series

Reporting Tags dialog. The Search Results list is refreshed to

show the reporting tags in the report data source that are

associated with the selected activity area. Our reporting tags

have not yet been associated with an activity area, so a search

by activity area would not return the reporting tags that we

created in the previous tutorial. So click the Clear button if

you selected an area in the Plant Model Browser dialog.

To perform a string search on the names of the reporting tags

in the selected report data source, enter the text that you want

to search for (using an “*” to represent a wild card character)

and click Search Now. Reporting tags that match the search

string are displayed in the list at the bottom of the dialog. For

example, a string search for *BEND* would return the

reporting tags that we created in the previous tutorial.

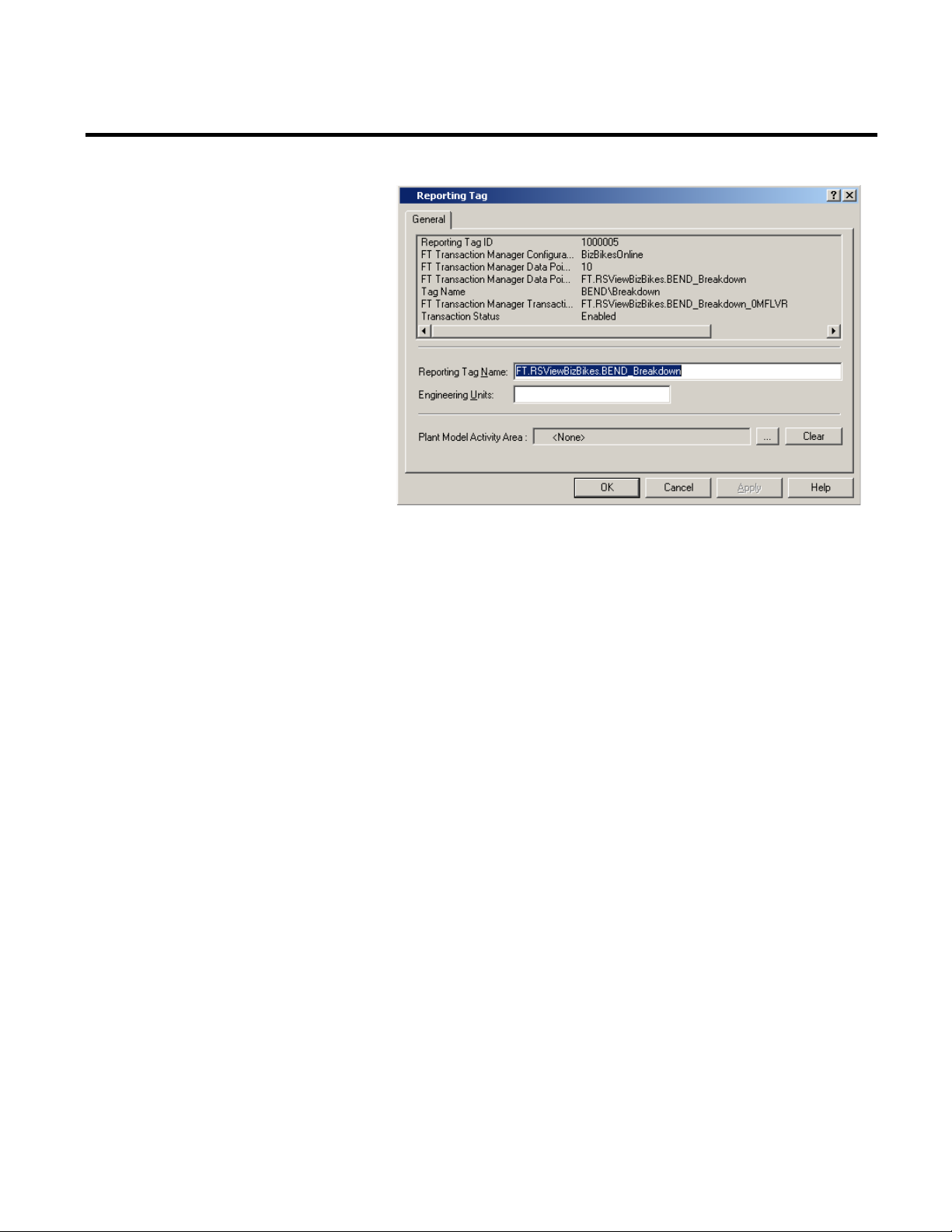

4. Select the BEND_Breakdown reporting tag from the list and

click Edit to display the Reporting Tag dialog box. Use it to

edit the name of the reporting tag, provide the engineering

units, and associate the reporting tag with an activity area in

the plant model.

38 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Page 39

Collecting FactoryTalk Historian Classic Data Chapter 3

Start Data Collection

5. Click OK to save your changes and return to the Time-Series

Reporting Tags dialog.

6. Click OK to close the Time-Series Reporting Tags dialog.

After you have finished configuring the performance parameters,

and enabled data collection for the activity areas that use a particular

FactoryTalk Transaction Manager configuration, you need to start

the FactoryTalk Transaction Manager configuration to begin the

data collection.

To start the data collection:

1. On the Tools menu, click FactoryTalk Transaction

Manager > Manage FactoryTalk Transaction Manager

Configurations.

The FactoryTalk Transaction Manager Configurations

dialog box appears.

It lists the FactoryTalk Transaction Manager configurations

that have been imported, and the applications to which they

apply. In the dialog box, you can evaluate the running status of

FactoryTalk Transaction Manager configurations that are

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 39

Page 40

Chapter 3 Collecting FactoryTalk Historian Classic Data

2. Select a FactoryTalk Transaction Manager configuration, and

collecting data from the control system, as well as start, stop, or

restart the configurations.

then click Start.

The configuration is started. The green traffic light icon (

)

indicates that the configuration is running and collecting data

from the control system.

40 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Page 41

Create a New RSBizWare Report

Chapter 4

Analyzing FactoryTalk Historian Classic Data

FactoryTalk Historian Classic provides a graphical environment in

which to analyze manufacturing process data. This chapter will help

report designers understand how to use FactoryTalk Historian

Classic to create and view RSBizWare reports containing time-series

charts; bar, pie, and line charts; and tables. We will discuss the parts

of a report, look at the sample reports that can be installed with the

software, create a report based on the sample data, and discuss the

creation of more complex reports. FactoryTalk Historian Classic

must be set up by the RSBizWare administrator before you can start

to create reports using real data.

In RSBizWare, a report is a complete, formatted document that is

made up of one or more report objects that have been placed in an

HTML document along with text, graphics, and hyperlinks. A

report, saved as an .htm file, is created and edited using the

Configuration Console with a FactoryTalk Metrics Author license.

RSBizWare reports can also be edited using Web-authoring tools

such as Microsoft FrontPage.

An RSBizWare report object shows the data from a database table

or view in a meaningful graphic or tabular presentation. The report

object defines how the data is to be shown to the user. It defines

both the visual representation of the data (e.g., pie chart, bar chart,

table) as well as the data sorting and summarization.

The data for the report object comes from an RSBizWare report

data source. A report data source is a connection to a table or view

within the RSBizWare database or an external database.

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 41

Page 42

Chapter 4 Analyzing FactoryTalk Historian Classic Data

Insert Text, Pictures, and Hyperlinks

The data in the report object may be restricted by a query (a filter),

made up of one or more search criteria, that determine which

records from the report data source will be shown. The use of a filter

is optional.

To create a new, blank report:

1. Open the Configuration Console.

2. On the File menu, click New Report.

To add a title, a picture, and a hyperlink:

A blank report page appears.

1. Click the report area, and type a title for your report, e.g.,

Company Web Page

.

My

Select the title, and then, on the Report Formatting toolbar,

change the title font to Arial, and the font size to 18.

2. On the Formatting Toolbar, click

to align the text to

the center of the page.

3. Click next to the title (its selection is canceled), and then press

Enter.

4. Right-click the report area, and then click Insert Image.

42 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

The Picture dialog box appears.

5. Next to the Picture Source box, click Browse to select the

picture that you want to add to the report.

6. In the Alternate Text box, type a description of the image.

Page 43

Analyzing FactoryTalk Historian Classic Data Chapter 4

The alternate text appears as a tooltip when you point to the

image.

7. Under Layout and Spacing, set the display properties of the

picture.

8. Click OK.

The logo appears under the title.

9. Click the image, and then on the Insert menu click

Hyperlink.

The Hyperlink dialog box appears.

10. In the URL box, type the address of the page which will open

when you click the image.

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 43

Page 44

Chapter 4 Analyzing FactoryTalk Historian Classic Data

. Then, repeat step 10.

report, report objects, and filters that are used on the report.

Save the Report

11. Click OK.

TIP

You can also add a hyperlink to a text. To do so, select the text,

and then, on the Reports Insertable Items toolbar, click

12. On the Report Formatting toolbar, click to see, how

the report will look like as a web page.

When you point to the image, the alternative text will appear.

44 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

NOTE

To edit the report, report objects, and filters, you need to have

the Author license and the appropriate object permissions for the

13. On the Report Formatting toolbar, click to go back to

editing your report.

RSBizWare reports are saved as HTML documents on the

Information Services Manager computer to which your

Configuration Console is connected. They appear in the Report

Explorer tree.

Page 45

Analyzing FactoryTalk Historian Classic Data Chapter 4

Add a Saved Report Object to Your Report

To save the report:

1. On the File menu, click Save Report As.

The Save Report As dialog box appears.

2. In the Report Name box, type a name for your report file.

In this example, the name is

My Company Report.

3. Click Save.

The report appears in the Report Explorer tree.

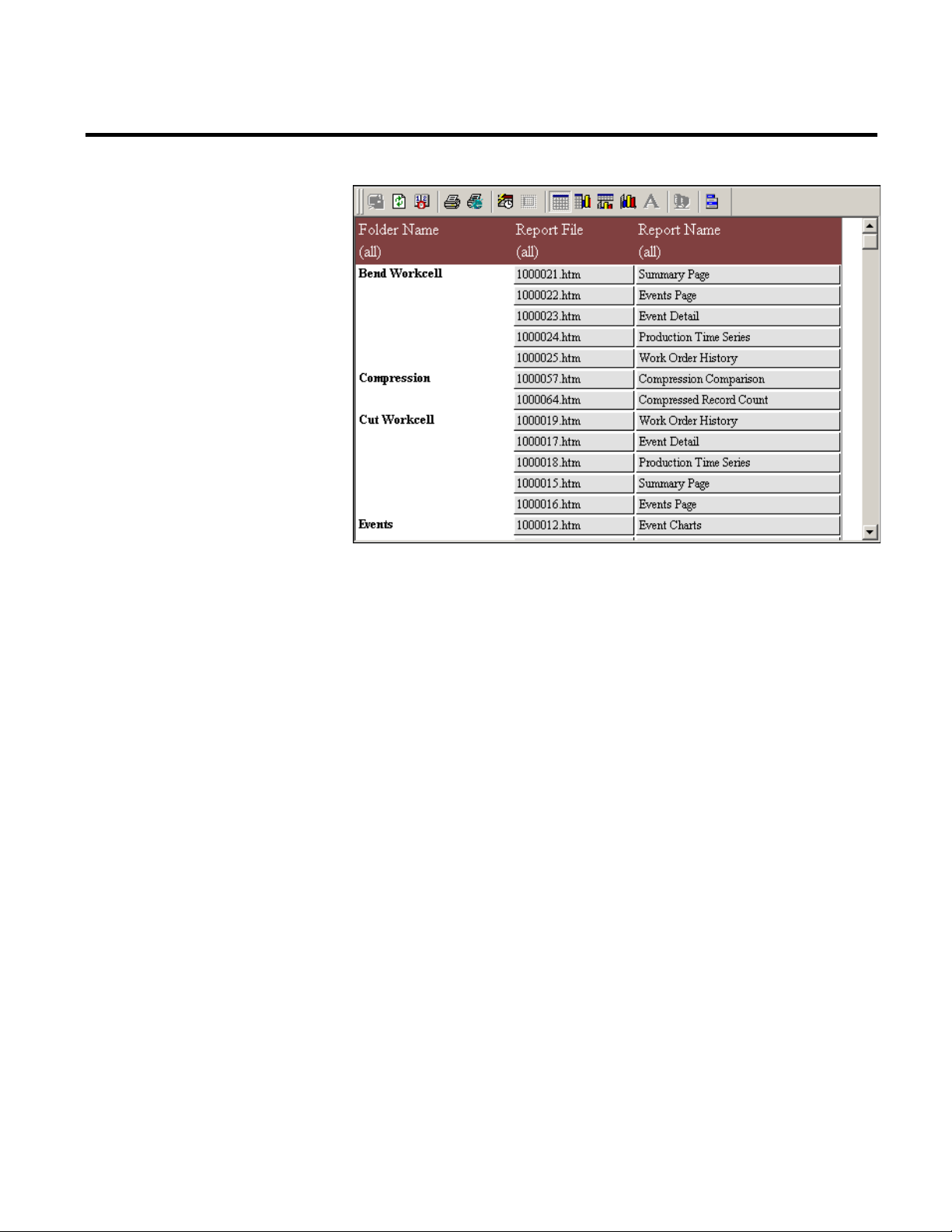

The Configuration Console allows you to view report objects that

other users have created and to add them to your report. For this

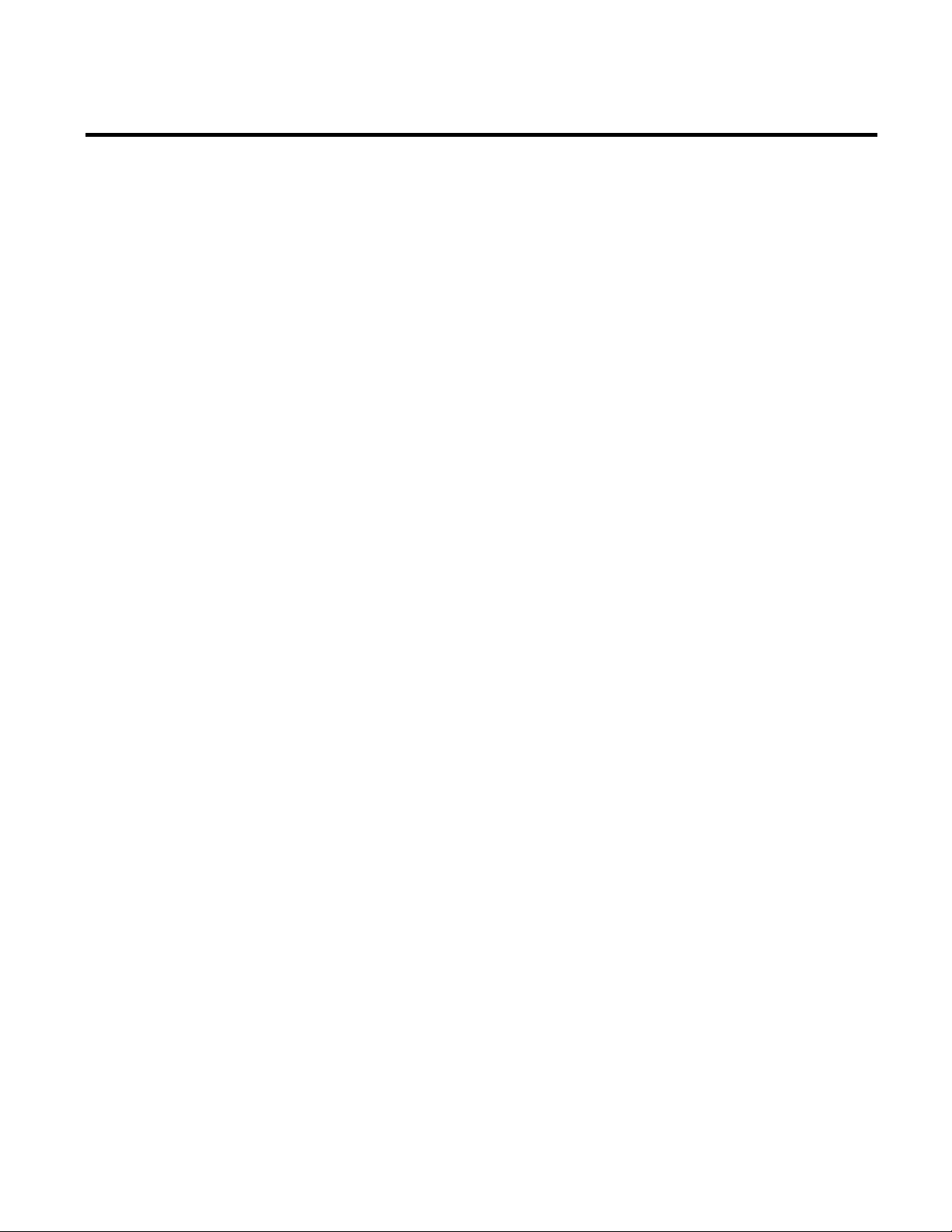

tutorial, we will add a saved report object that was created when the

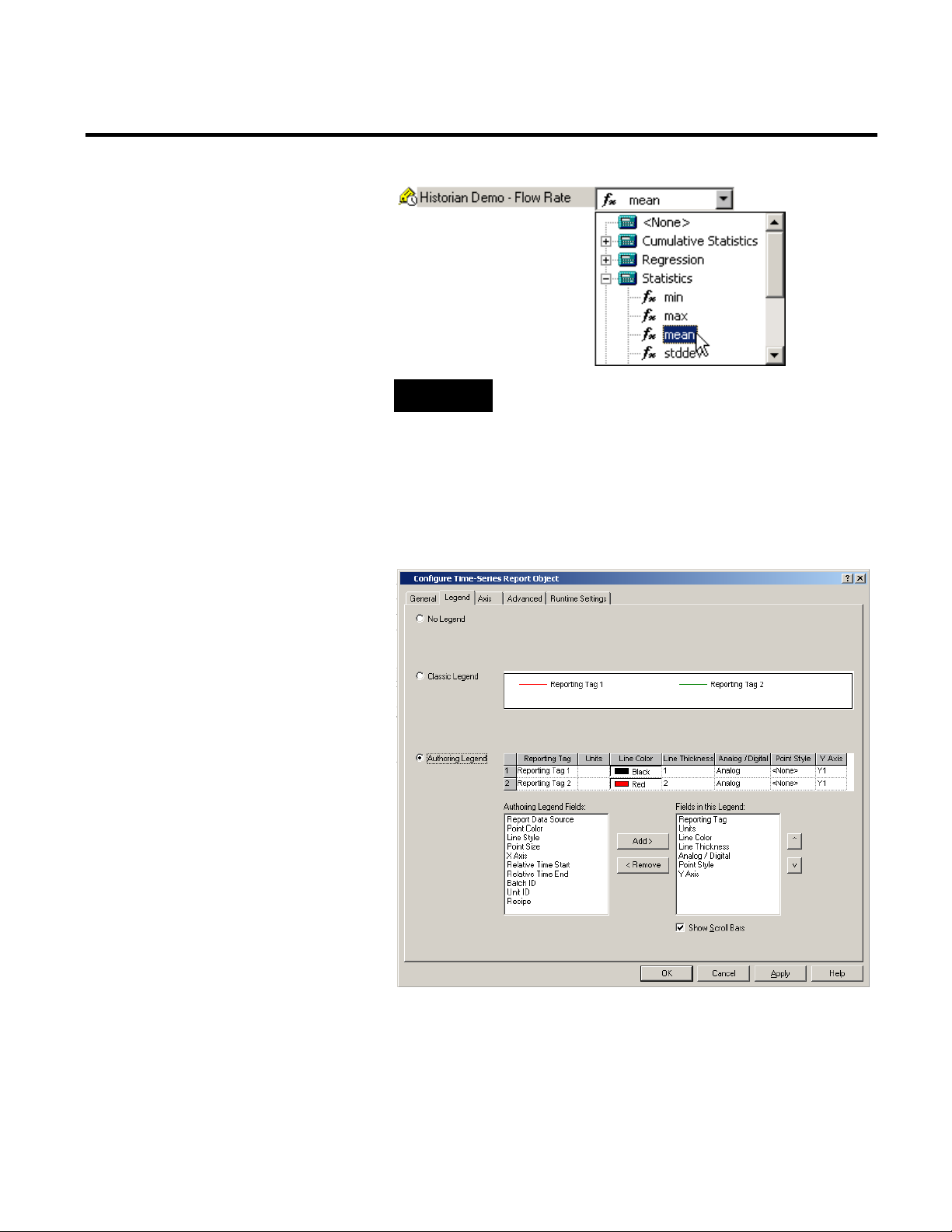

sample data was loaded.

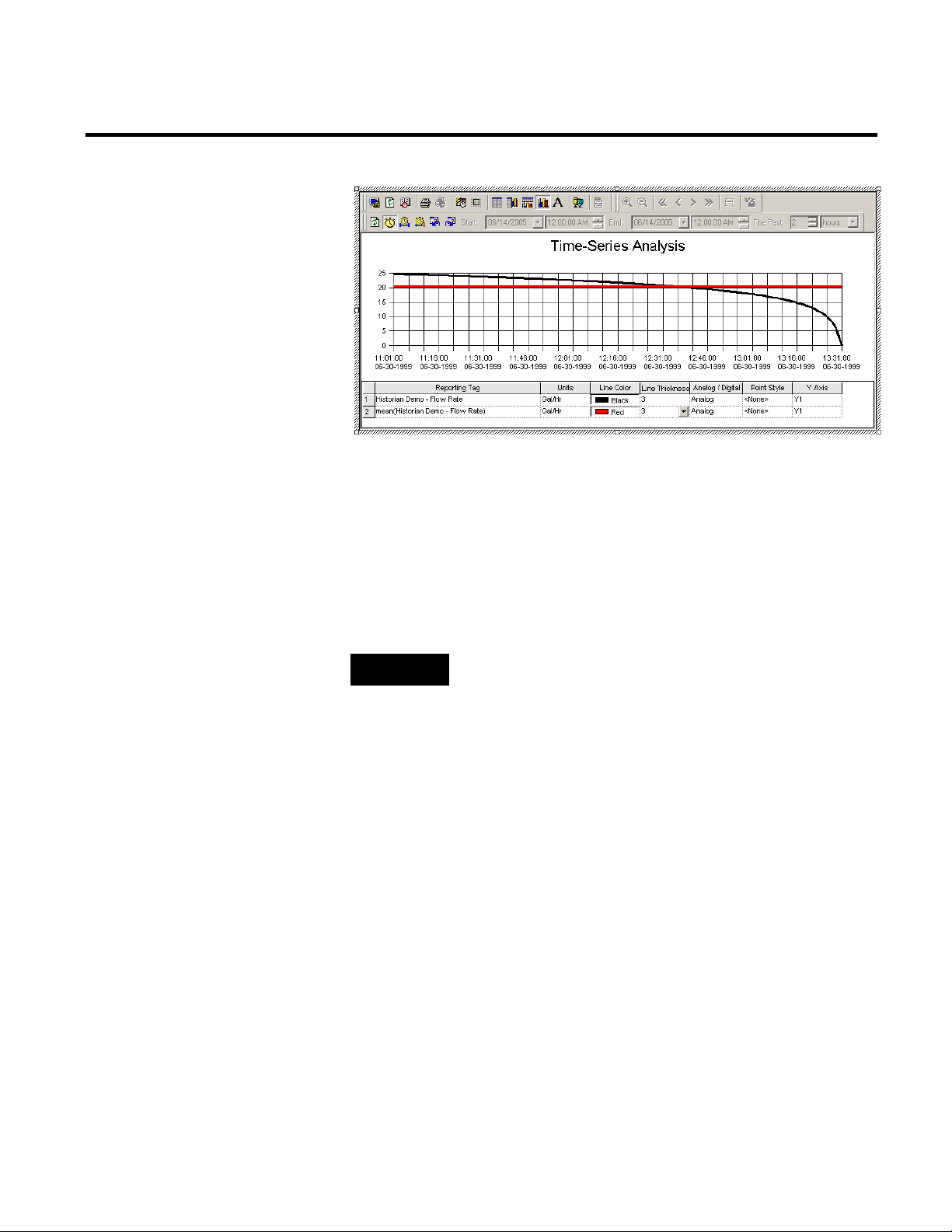

1. With the report open in the work area, place your cursor in the

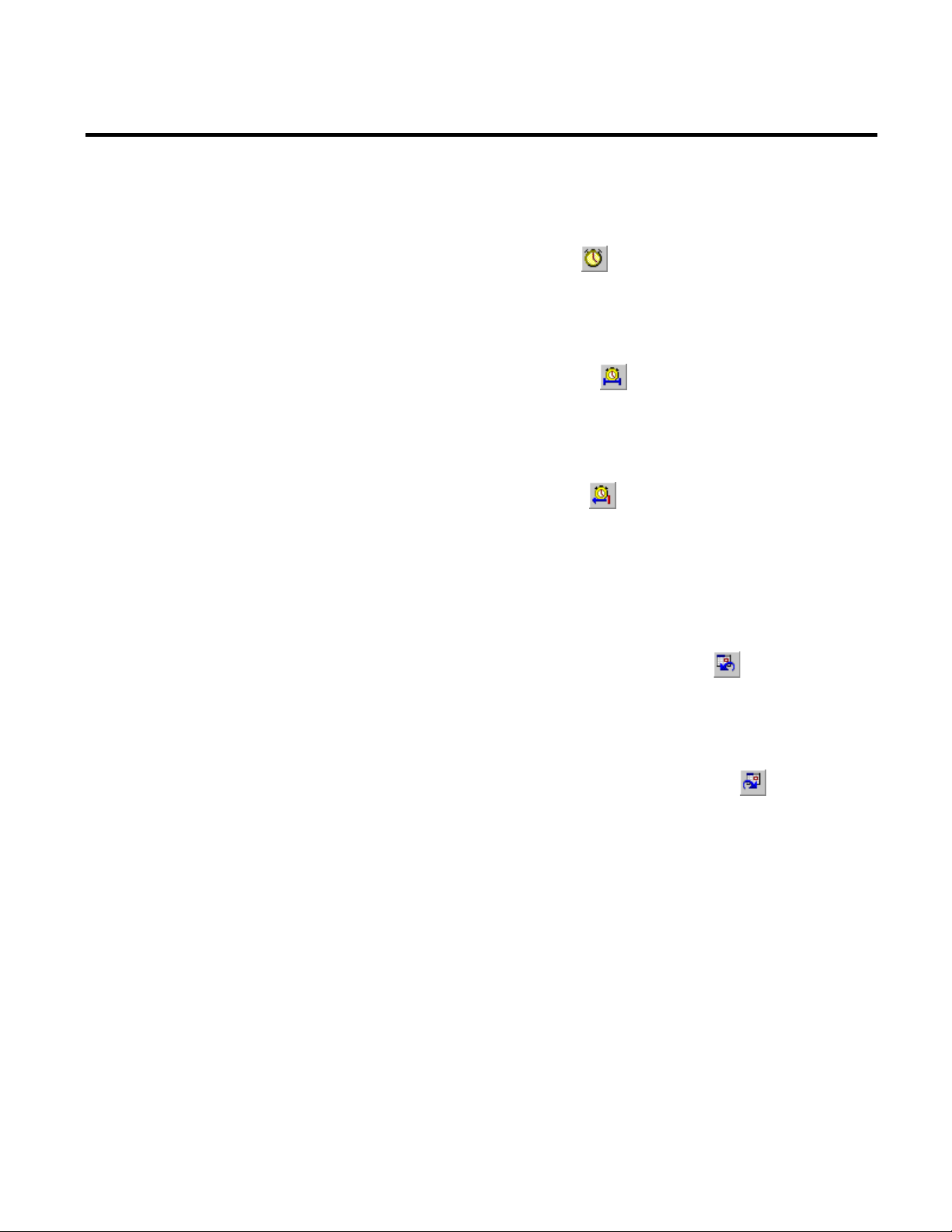

report where you want the report object to appear.

2. On the main menu, select Insert > Existing RSBizWare

Report Object. The following message appears.

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 45

Each report object on a report can connect to a different

Information Services Manager in your organization.

Therefore, before you continue, you must identify the server to

which this report object will connect.

Page 46

Chapter 4 Analyzing FactoryTalk Historian Classic Data

granted permissions.

the selected report data source

3. Use this dialog box to select the report object that you want to

Click Yes to accept the default user name and server.

Click No to connect to a different server and display the login

dialog box where you provide the credentials and the server

that you want to use to author the report object.

For this tutorial, click Yes to accept the default user name and

server. The RSBizWare Report Object Properties dialog box

appears.

insert in your report.

46 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Item Description

Report Data Source The list of report data sources from which the data will be

shown in the report object and to which you have been

Report Object The list of available report objects, grouped by the report

data source from which they get their data. When you

select a report data source, the list of report objects is

refreshed to show only the report objects that are based on

Page 47

Filter

The list of available filtering criteria.

Sources, Report Objects and Filters dialog box.

Select the check box near the toolbar name which you want

been created.

Item Description

Analyzing FactoryTalk Historian Classic Data Chapter 4

Manage Report

The button for displaying the Configure Report Data

Objects

Select Which

Toolbars to Show

options

to display on the report. The check boxes allow you to add

toolbars to the report object. The end users of your report

will use these toolbars to adjust the report object to suit

their needs.

The following toolbars can be selected:

• General

• Time Selection

• Status Bar

• Report Data Source

• Report Object

• Filter

4. From the Report Data Source list, select FactoryTalk

Metrics Workcell History. This is the data that will be shown

in the report object.

5. From the Report Object list, select Workcell History.

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 47

6. For this example, we will not select a filter, so leave the filter

list blank.

NOTE

Filters are grouped by the report data source for which they have

7. Select the Status Bar check box. This will cause a status bar to

display at the bottom of the report object. Because each report

object on a report can connect to a different server, the status

bar will indicate the user and server to which the report object

is connected at run time.

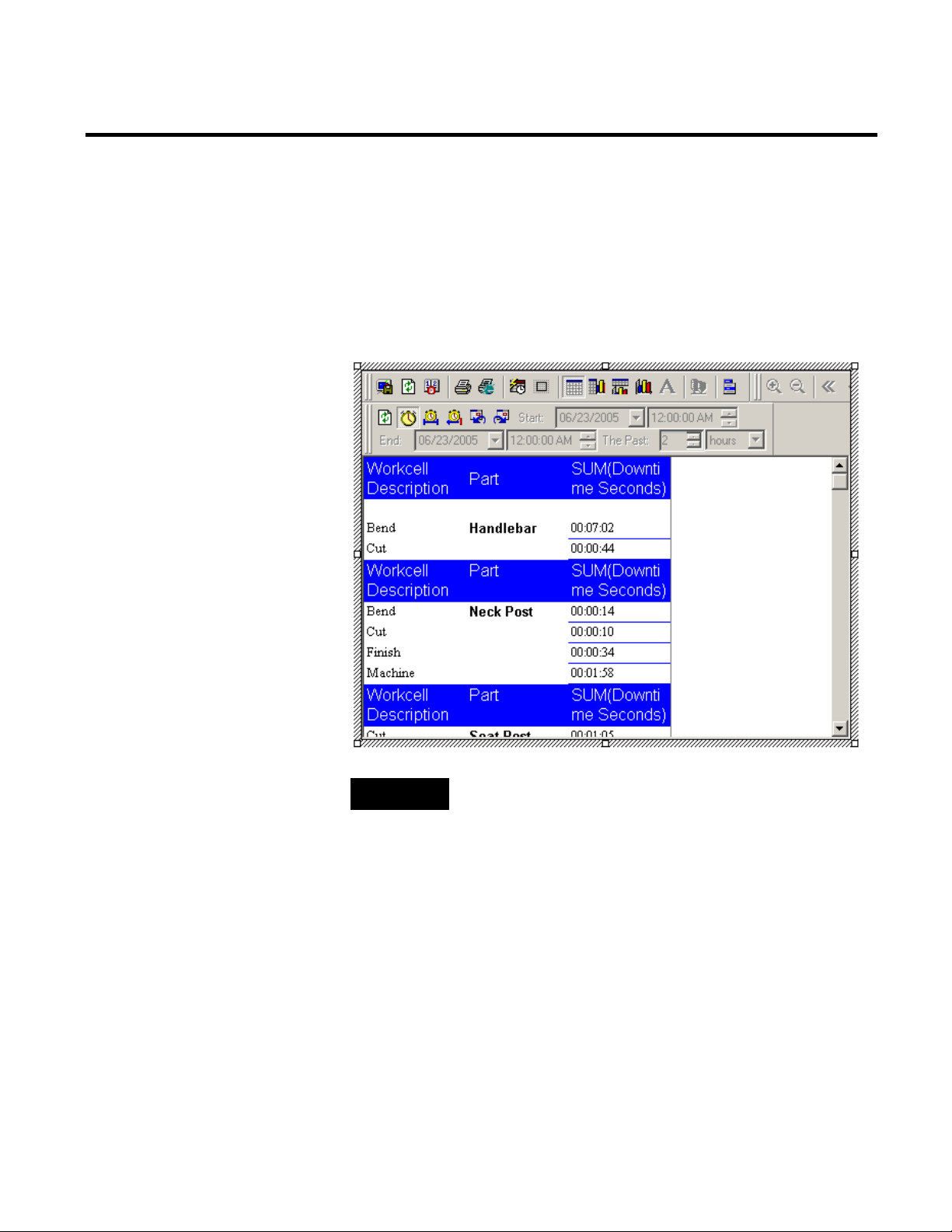

8. Click OK to add the report object to the report. The report

object is shown as a simple box outline.

9. Double-click inside the box outline to see the table, and click

Refresh. To populate the report object with data, click the

Refresh button. Your report object should look similar to the

following:

Page 48

Chapter 4 Analyzing FactoryTalk Historian Classic Data

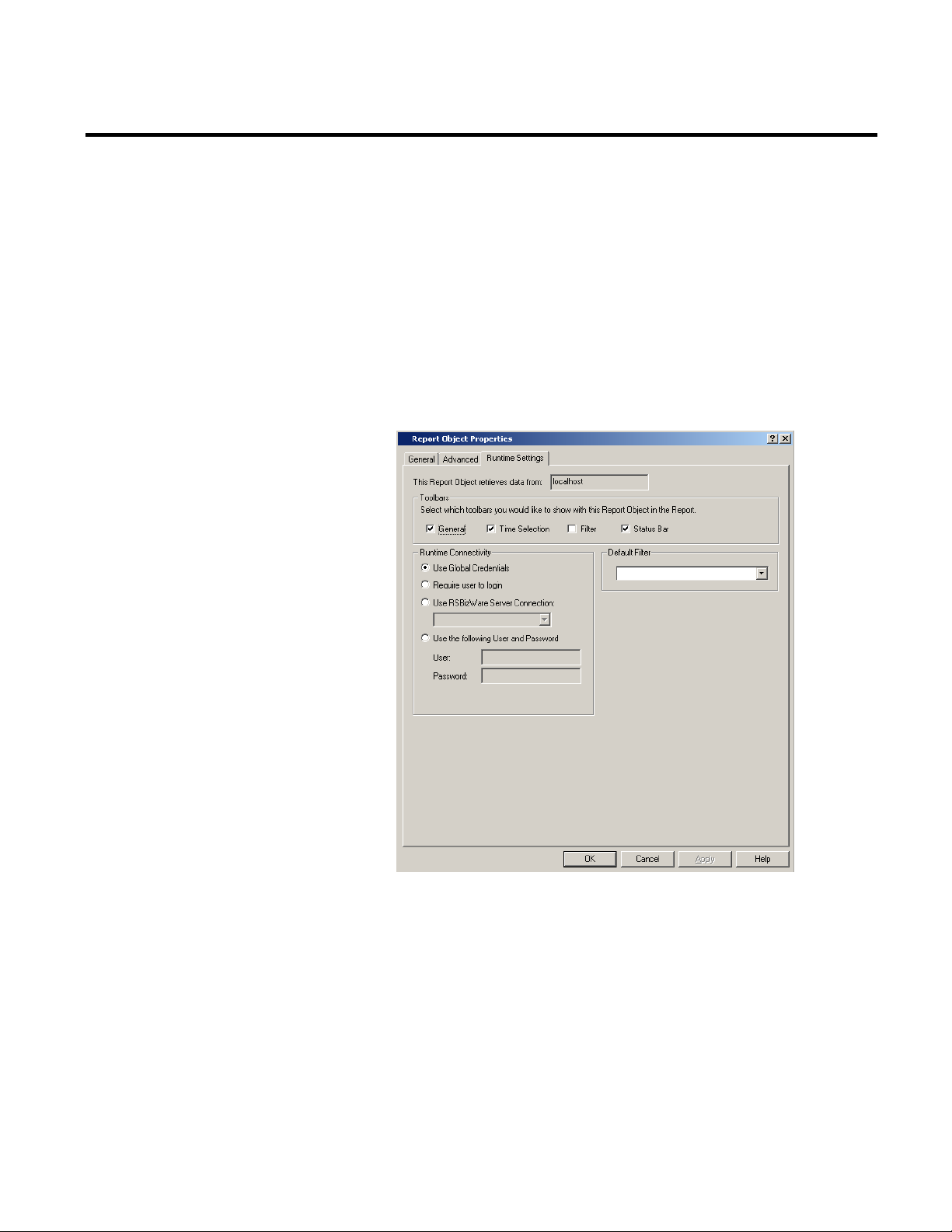

Configure the Report Object To Use Global Credentials

At run time, the RSBizWare report objects on your report will

attempt to connect to an Information Services Manager to access the

production data necessary to draw the chart, bar graph, etc. The

connectivity settings for each report object specify how they will

connect to the Information Services Manager. When the report user

attempts to view an RSBizWare report that contains multiple report

objects with different connectivity settings, the report users may be

required to log on multiple times before they can see the report.

To avoid repetitive logons on a report, you can set your report

objects to use Global Credentials. Global Credentials use a session

logon to connect to a report object. With a session logon, the user is

prompted for user name and password once for each server that is

encountered. After the user’s credentials (user, password) have been

specified for a server, those credentials are available to any

subsequent report object that is running on that client computer, is

using the Use Global Credentials option, and is attempting to

connect to the same server. The session logon that is established will

remain active until the user specifically logs off, the credentials

expire, or the client computer is rebooted.

48 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Page 49

Analyzing FactoryTalk Historian Classic Data Chapter 4

To enable a report object to make use of a session logon, the report

object must be configured to use Global Credentials.

To configure a report object to use Global Credentials:

1. Click the FactoryTalk Metrics Workcell History report object,

and on the main menu, select View > Properties. The Report

Object Properties dialog box appears.

2. Click the Runtime Settings tab.

The Runtime Settings tab enables you to specify how the user

will connect to the server that you selected when you inserted

the report object. When you are configuring the server

connection settings for a report object, you have the following

options:

• Use Global Credentials

This is the default option. Select this option if you want to

use a session logon to connect to this report object.

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 49

Page 50

Chapter 4 Analyzing FactoryTalk Historian Classic Data

and filter or they will not be able to see the report object.

place of RSBizWare Server Connection objects.

• Require user to login

Select this option if you want to require the users to provide

their user name and password to access this report object.

More than one report object on a report with this option

selected will require the user to log on multiple times.

NOTE

Remember that any users who will be viewing the report

must have access to the report data source, report object,

• Use RSBizWare Server Connection

Select this option if you want to specify the RSBizWare

Server Connection that this report object will use when the

user views the report at run time. You will only be able to

select from Server Connection objects that are configured

to use the same RSBizWare server that you selected when

you added this report object to the report.

NOTE

This option is provided for backwards compatibility only.

It is recommended that you use Global Credentials in

• Use the following User and Password

Select this option if you want to specify at design time the

user name and password that the report object will use

when the user attempts to view the report object at run

time. The advantage of choosing this option is that the user

will not have to login to view the data.

50 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

Page 51

Analyzing FactoryTalk Historian Classic Data Chapter 4

RSAssetSecurity documentation.

Create a New Chart

NOTES

By selecting this option, you are granting the specified

user’s application privileges to the runtime user for this

report object. Because the Save Report Object Contents

to File, Add Time-Series Comment, and Edit/Delete

Time-Series Comment application privileges allow action

on report objects, it is important to consider whether the

specified user has these privileges and whether you want

the runtime user to have these privileges.

If you use this option across many report objects and the

security policy for the user is very strict (that is, the

password must be changed frequently), you will need to

change the password setting separately for each report

object. Consider using a less strict security policy (such as

never requiring the password to be changed) for this

user. For more information on security policy, consult the

For this tutorial, make sure the Use Global Credentials

option is selected.

3. Click OK to close the dialog box and save your changes.

You will be adding more report objects to this report. If you want

the rest of the report objects on this report to use Global

Credentials, you will need to specify this option for each report

object when you insert the report object.

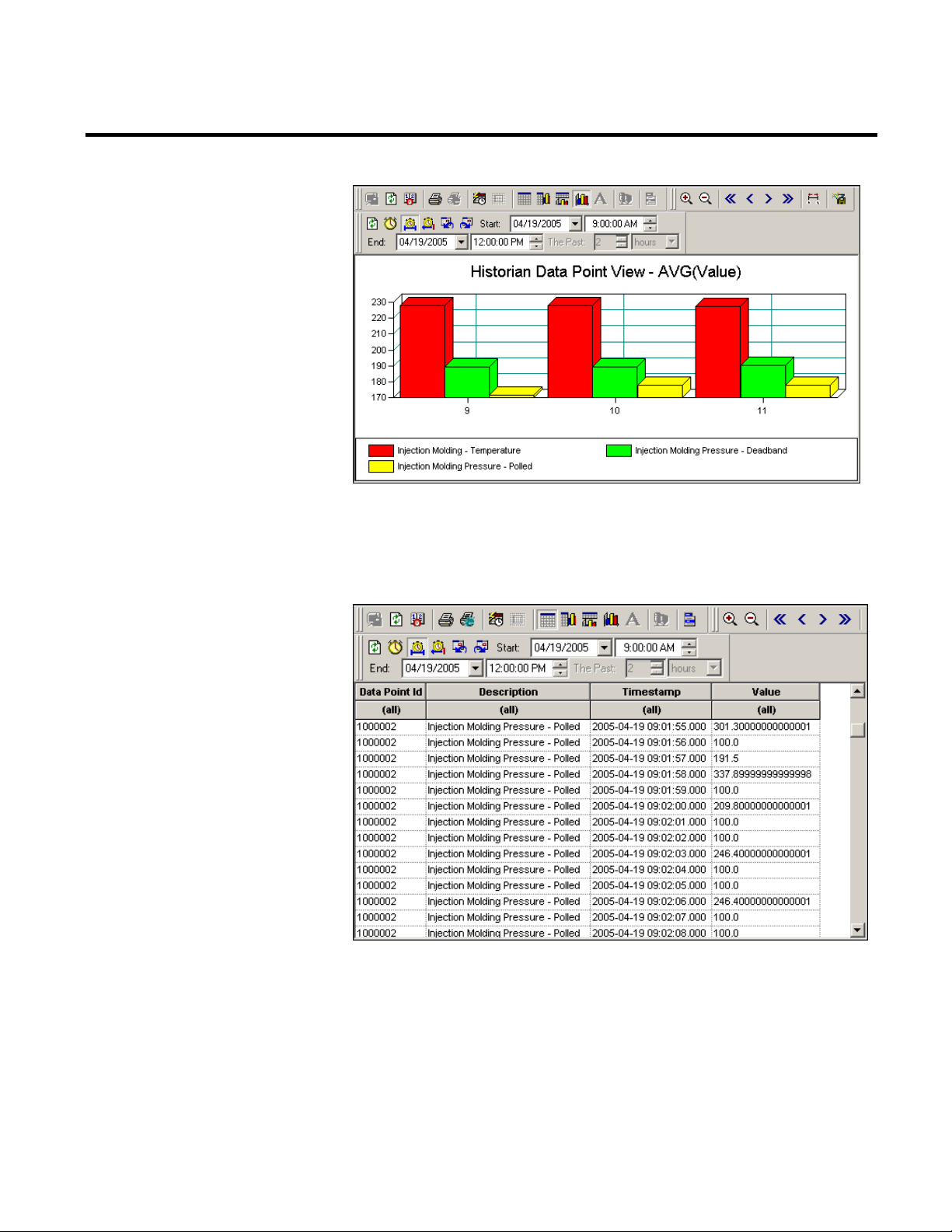

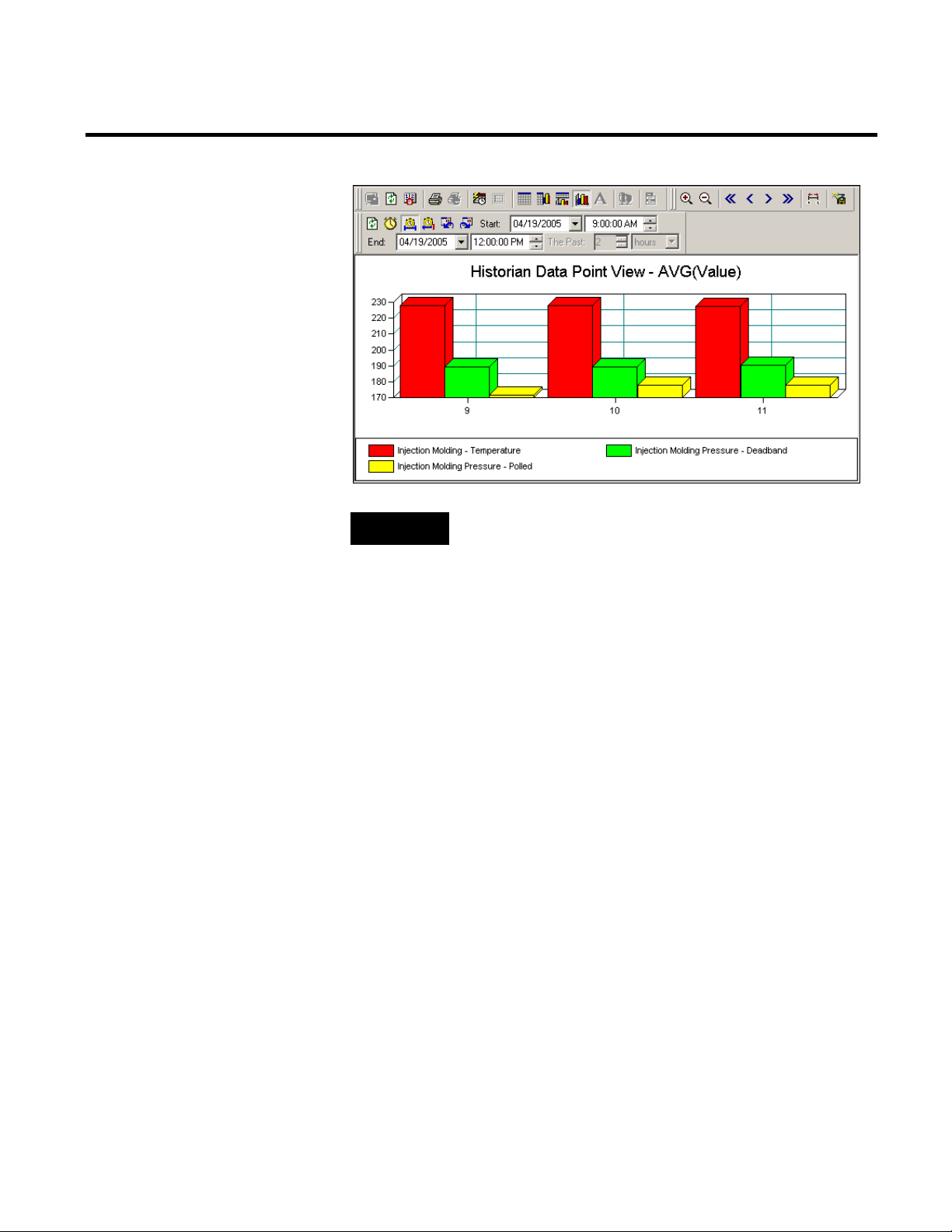

An important feature of the Configuration Console is the ability to

create bar, pie, and line charts from data stored in a report data

source. The purpose of this tutorial is to walk you through the steps

that are necessary to create a chart with the New Chart Wizard. For

this tutorial, you will use the Historian Data Point View report data

source to create a chart showing the average running time per hour

for work cells. This tutorial will also demonstrate how to create a

prompt-at-runtime filter so that the end-user of the report can

choose the work cells that will be charted. Your chart will look

similar to the one shown below.

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 51

Page 52

Chapter 4 Analyzing FactoryTalk Historian Classic Data

Step 1: Plan the Chart

The following table shows a representation of the data we will be

charting.

52 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

We will be creating a chart with a bar for each data point; therefore,

the Description field is the series. Notice that one column in our

table (Description) contains all of the data point descriptions, and

the data for the data points is organized in rows. Each row contains

the data value (Value) and the time stamp (TimeStamp) for each

Page 53

Analyzing FactoryTalk Historian Classic Data Chapter 4

Step 2: Select the Data On Which To Report

Step 3: Choose a Chart Type

Step 4: Describe the Data

data point. This will be important to remember when we are using

the New Chart Wizard.

Place your cursor where you want the chart to appear in the report

and select Insert >Chart to display the authoring user name and

server prompt. Click Yes to accept the default user name and server.

The New Chart Wizard will display. This wizard will lead you

through the process of creating a new chart for your RSBizWare

report.

The first step in the New Chart Wizard is to select the report data

source containing the data that we want to chart. The Report Data

Source list contains the report data sources for which you have the

appropriate permissions. Select Historian Data Point View from

the list and click Next to continue.

Next, we you need to specify the type of chart that you want to

create. The vertical bar chart is the default. Click Next to accept the

default and continue.

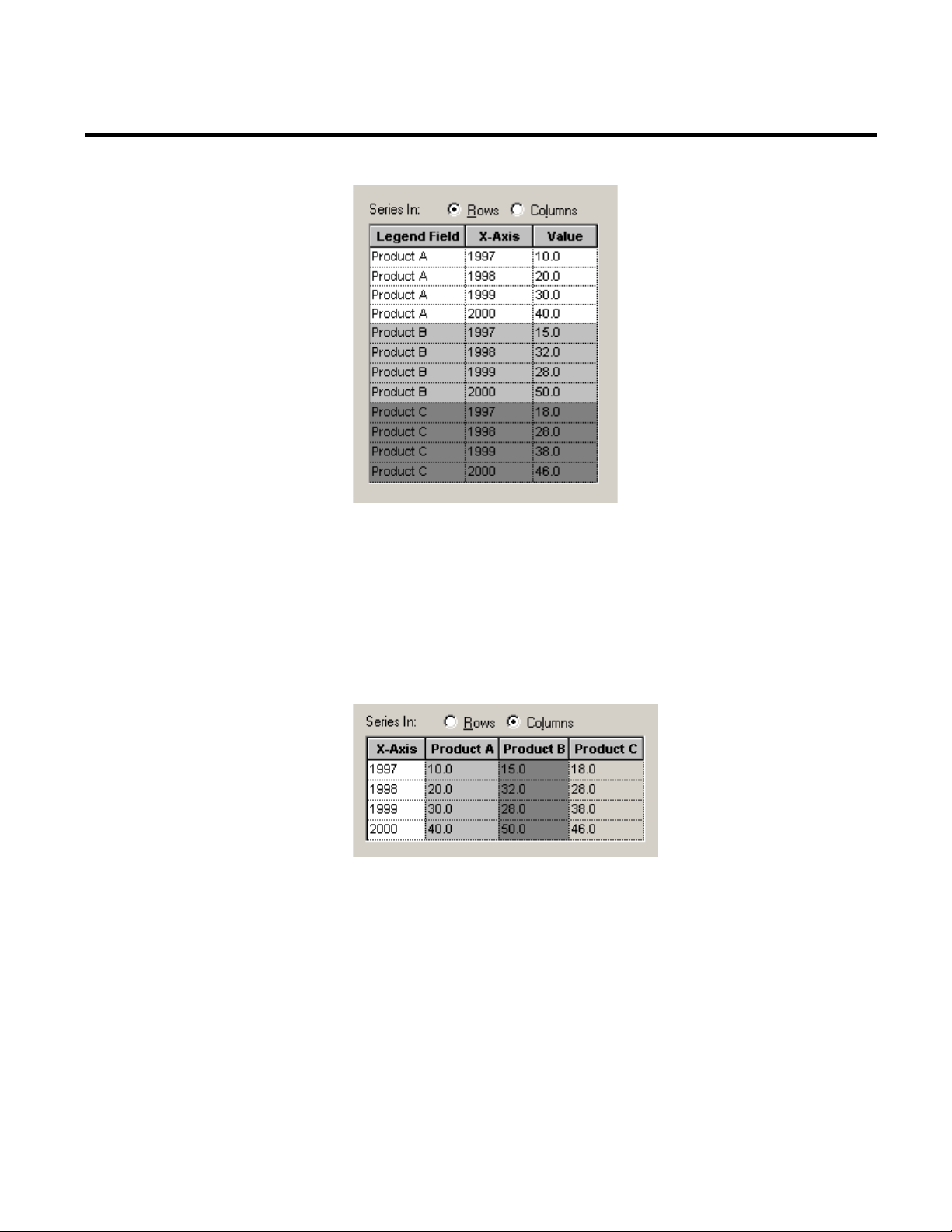

In the data configuration step, you need to describe the data to the

Chart Wizard. Recall that the data table data is organized in rows for

each work cell (series). This corresponds to the example table shown

in the Chart Wizard for the Rows option.

Rockwell Automation Publication HIST-UM001K-EN-E-June 2014 53

Page 54

Chapter 4 Analyzing FactoryTalk Historian Classic Data

Step 5: Select Summary or Detail

If the data points ID or descriptions If the series values (work cell

descriptions) were in the column headers of the table and the

Running Seconds values for each work cell were listed in the column

for that work cell, this would be an example of a table where the

series is in columns. For this type of table, you would select the

Columns option.

54 Rockwell Automation Publication HIST-UM001K-EN-E-June 2014

However, since you have determined that the data is in rows, make

sure the Rows option is selected and click Next to continue.