Page 1

User Manual

PUBLICATION FTEM-UM002A-EN-P – JANUARY 2014

INTEGRATED PRODUCTION & PERFORMANCE SUITE

Asset Management

Page 2

FactoryTalk EnergyMetrix Software

Contact Rockwell Customer Support Telephone — 1.440.646.3434

Online Support — http://www.rockwellautomation.com/support/

Copyright Notice © 2014 Rockwell Automation Technologies, Inc. All rights reserved. Printed in USA.

This document and any accompanying Rockwell Software products are copyrighted by Rockwell

Automation Technologies, Inc. Any reproduction and/or distribution without prior written consent from

Rockwell Automation Technologies, Inc. is stri ctly prohibited. Please refer to the license agreement for

details.

Trademark Notices Allen-Bradley, ControlLogix, eProcedure, FactoryTalk, Rockwell Automation, Rockwell Software,

RSLinx, RSView, RSLinx Classic, RSLogix 5, RSLogix 500, RSLogix 5000, RSNetworx for

ControlNet, RSNetworx for DeviceNet, RSPower32, RSSql, RSView32, INTERCHANGE, PLC, PLC-2,

PLC-3, PLC-5, Data Highway Plus, DH+, ControlLogix, MicroLogix, PLC-5/20E, PLC-5/40E, PLC-5/

80E, SLC, and SLC 500 are trademarks of Rockwell Automation, Inc.

Other Trademarks Trademarks not belonging to Rockwell Automation are property of their respective companies.

Warranty This product is warranted in accordance with the product license. The product’s performance may be

affected by system configuration, the application being performed, operator control, maintenance, and

other related factors. Rockwell Automation is not responsible for these intervening factors. The

instructions in this document do not cover all the details or variations in the equipment, procedure, or

process described, nor do they provide directions for meeting every possible contingency during

installation, operation, or maintenance. This product’s implementation may vary among users.

This document is current as of the time of release of the product; however, the accompanying software

may have changed since the release. Rockwell Automation, Inc. reserves the right to change any

information contained in this document or the software at anytime without prior noti ce. It is your

responsibility to obtain the most current information available from Rockwell when installing or using

this product.

Publication Number: FTEM-UM002A-EN-P January, 2014

2

Page 3

CONTENTS

Chapter 1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

FactoryTalk EnergyMetrix Software Components . . . . . . . . . . . . . . . . . . . . 9

Chapter 2 FactoryTalk EnergyMetrix Web Interface Tour . . . . . . . . . . . . . . . . . . . 15

System Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Meters Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Reports Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Custom Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Chapter 3 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Contents of Installation DVD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Client Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Server Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Client Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Installation (64-bit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Installation (32-bit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Activate FactoryTalk EnergyMetrix Software . . . . . . . . . . . . . . . . . . . . . . 47

Chapter 4 Set up Your System Architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Set up a New Group or Domain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Roles and Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Overview of Privileges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Set up Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Set up a Meter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Set up a Meter Tag. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Automatic Data Repopulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Chapter 5 Visualize Energy Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

View a Trend Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

View a Calendar trend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

3

Page 4

FactoryTalk EnergyMetrix Software

Set up a Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Run Reports Automatically. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Set up a Billing Rate Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Set-up Alarming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Chapter 6 How to Set up a Personalized Start Page . . . . . . . . . . . . . . . . . . . . . . 151

Selections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

My Start Page Custom Pages Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

My Start Page Meters Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

My Start Page Reports Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Chapter 7 RT (Real Time) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Client Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Overview of the RT User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

PM5000 Device Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

PM5000 Device Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Chapter 8 ChartsPlus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

ChartsPlus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Client Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Start ChartsPlus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Create a New Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Set up a ChartsPlus Trend Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Set up an Overlay Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Change Appearance of Charts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

How to use X-Y Charting and Targeting . . . . . . . . . . . . . . . . . . . . . . . . 198

Chapter 9 ReportsPlus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Efficiency Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Electrical Summary Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Load Factor Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Power Factor Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Multi-purpose Reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Create an MPR Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Configure an MPR Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Populate the MPR with Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

4

Page 5

Contents

Configure the Report Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Add a Report Object to the MPR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Run the MPR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Selecting Groups and Meters in the MPR. . . . . . . . . . . . . . . . . . . . . . . . 226

Use the MPR for Cost Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

The MPR Object Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Sample MPR Scripts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

How to Administer FactoryTalk EnergyMetrix Software . . . . . . . . . . . . . . 285

Configure Program Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Release Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

RSLinx Classic Software on 64-bit Server Tips . . . . . . . . . . . . . . . . . . . . 294

Fiscal Calendars. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Contacting Rockwell Automation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

More Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

5

Page 6

FactoryTalk EnergyMetrix Software

Notes:

6

Page 7

Overview

Features and Benefits

C

HAPTER

1

FactoryTalk® EnergyMetrix softwear is a modular, scalable, web-enabled, client/server

energy information, and management application. It connects energy-related data sources

to a Microsoft SQL database and presents energy information in ways that enable you to

monitor and manage your energy use to maximize the value of your enterprise.

TM

FactoryTalk EnergyMetrix is built by using Microsoft.NET

technology, ensuring the

highest level of quality, reliability and compatibility now and in the future.

FactoryT alk EnergyMetrix is sophisticated web-enabled ener gy management software that

puts critical energy information at your desktop. The FactoryTalk EnergyMetrix Software

Suite combines data communication, client-server applications, and Microsoft’ s

advanced.NET web technology to provide you with a complete energy manageme nt

solution. FactoryTalk EnergyMetrix captures, analyzes, stores, and shares energy data

across your entire enterprise. Using a simple web browser, your energy information can

now be available on your company’s LAN or WAN, presenting you with the knowledge

necessary to optimize your energy consumption. The net result- improved productivity

and lower energy costs.

FactoryTalk EnergyMetrix software helps managers and engineers solve the ever

growing energy related challenges. With FactoryTalk EnergyMetrix software, you can do

the following:

Correlate energy costs to production costs

Provide accurate cost accounting based on consumption

Generate energy reports and charts for a process, a department, a facility or an

enterprise

Optimize energy procurement and negotiate better rates

Make decisions on electrical capacity

Avoid unscheduled shutdowns

Procure and analyze energy information with minimum capital investment

Provide energy data into FactoryTalk VantagePoint for integrating with other

enterprise data sources

7

Page 8

FactoryTalk EnergyMetrix Software

FactoryTalk EnergyMetrix software helps you connect to metering points right from

your desktop PC.

Connect to Allen-Bradley power monitors and other devices through RSLinx Classic

Lite: RS232, RS-485, Ethernet, DeviceNet, RIO pass-thru (RSLinx Classic Lite is

included).

Connects to FactoryTalk Live Data server on an Ethernet network.

Connect to third party meters and controllers through OPC; more than ten meters

requires the FTEMOPC option.

RSLinx Classic (OEM, Pro or Gateway) OPC supports native Logix tag addressing.

FactoryTalk EnergyMetrix software provides easy and flexible configuration.

Configure Electricity, gas, water, and steam meters or any energy or production

related inputs.

Configure Manual Meters for manual data entry.

Configure user defined data sources such as PLC-5, SLC 500 or OPC servers.

Set up a meaningful system architecture with the ability to do the following:

Name devices

Name groups and domains

Manage access by users through security

Create sub-groups

Share meters among multiple groups for cost allocation

Set-up and change meter configuration values remotely.

Multi-level password protection and privileges.

FactoryTalk EnergyMetrix software is a powerful load profiling, cost allocation, and

billing analysis tool.

Log usage, cost and power quality data

V iew any parameter in real time

Create historical trend reports and charts

View historical trending of individual meters and groups and save tabular data for

further processing and analysis

Establish consumption baseline

Create custom rate plans by using the rate plan menu and line item scripting with user

defined time of use periods

Assign rate plans to meters or groups of meters

Import and export rate schedules in XML format

8

Page 9

1 • Overview

Create and print daily or monthly cost and billing reports by:

Meter

Business group

Department

Site

Create energy budgets and forecasts

Compare and contrast alternative utility rates; do ‘what-if’ for other rate structures

Print and store all reports and charts

FactoryTalk EnergyMetrix software is a sophisticated power quality analysis tool

Overlay waveforms to correlate phase to phase relationships

Plot Transients, Surges, and Sags on ITI (CBEMA Curves)

Display Harmonics. THD, K-factor, Crest Factor, and Vector Diagrams

Generate Power Quality charts and reports

PowerQuality data is automatically logged in FactoryT alk Ener gyMetrix software and

then it clears the queue

FactoryTalk EnergyMetrix software generates alarms

Triggered by

System anomalies

Power quality event

User predefined conditions

Workstation alarms

E-mail alarms

FactoryTalk EnergyMetrix Software Components

This section describes the components of the software.

License Options

FactoryTalk EnergyMetrix software is a scalable, modular software application. Its

components and capabilities are determined by the licenses purchased and installed by the

user. Licenses are installed by means of FactoryTalk Activation.

The table below shows the component type and, if applicable, the number of meters

supported. There is no limit on the number of users. It is the customer's responsibility to

observe the requirements of software licenses.

The Manager license is required for use of the software, and includes 10 meters which can

be any combination of RSLinx software and 3rd-party OPC meters. Additional meter

licenses can be purchased in 10-, 50, 100- and 500- meter sets. The FTEMOPC 3rd-party

OPC option enables 3rd-party OPC connectivity to all licensed meters.

9

Page 10

FactoryTalk EnergyMetrix Software

If you are upgrading from an existing installation of RSEnergyMetrix software, your

existing licenses are supported, including existing meter counts.

FactoryTalk EnergyMetrix software only supports FactoryTalk Activation. If you plan

to upgrade from an installation of RSEnergyMetrix that uses EVRSI Master Disk

activation, please contact Rockwell Automation customer service to convert to FT

Activation.

Component Type Maximum Meter Count

FTEM Manager, includes 10 RSLinx or OPC meters 10

FTEM10 10-meter option, RSLinx 10

FTEM50 50-meter option, RSLinx 50

FTEM100 100-meter option, RSLinx 100

FTEM500 500-meter option, RSLinx 500

FTEMOPC 3rd-party OPC client for all licensed meters N/A

FTEMRT Real Time option N/A

FTEMRPT ReportsPlus option N/A

FTEMCHT ChartsPlus option N/A

Microsoft SQL Server bundle - 1 client license option N/A

Microsoft SQL Server bundle - processor license option N/A

Contact your Rockwell Automation representative for information on the meter and option

packages listed above.

Manager

Manager is the core data logging and reporting engine. Use Manager to organize your

enterprise's energy architecture, connect to up to ten Allen-Bradley or 3rd party power

monitors and programmable controllers, log energy data and view energy information.

Manager can report your energy usage by department or cost center, display load and

demand profiles, and correlate energy costs per unit of manufacturing out put. It includes a

flexible energy rate schedule that enables you to replicate utility bills or generate internal

energy billing.

Microsoft Internet Explorer browser is used to access and configure Manager. FactoryTalk

EnergyMetrix Manager is a required component.

RT (RealTime)

Use FactoryTalk EnergyMetrix RT (RealTime) to configure Allen-Bradley power

monitors and display their real-time data and power quality information. RT is a Click

Once software application installed with FactoryTalk EnergyMetrix software that requires

a separate activation. Once activated, RT device configuration and device viewer links

become operational from device setup pages and the RT device viewer links becomes

operational meter pages.

10

Page 11

1 • Overview

Use Microsoft Internet Explorer to interact with RT.

R T complements Manager's data logging, cost allocation, profiling and reporting functions

by allowing you to configure power monitors and to vi ew, print, and save data from power

monitors. With RT, you can:

Download and upload power monitor configurations and save the configurations to

the database

V iew and print all of the real-time parameters in power monitor

Manually capture oscillographs and view, print and save automatically captured

oscillographs

View, save, and print all of the data logs in the power monitor

ChartsPlus

ChartsPlus is an optional package that offers extensive custom charting capabilities.

ChartsPlus is a Microsoft ClickOnce application that downloads and runs on the client

computer. Its look and feel is that of a traditional Windows application rather than a web

application. ChartsPlus is included in FactoryTalk EnergyMetrix software and requires a

separate activation.

ChartsPlus provides you with the ability to create customized graphical views of your

energy data. Some of the possibilities include:

Enhanced Trend

Plots up to 8 variables with a lot of flexibility. Different time ranges can be selected for

each variable and you can select various summary methods for each variable (for example,

you can plot the average Monday for one variable vs. a specific Monday for the same

variable or another variable). Also, the chart control itself has many built-in functions

such as zoom, scroll, print, export, and user customization.

X-Y Trend

Plots one dependent variable against up to 3 independent variables, plots a linear least

squares regression line along with targeting and CUSUM analysis.

Enhanced Calendar Trend

Same as standard Calendar Trend but can overlay different months and multiple variables.

Load Factor Chart

Plots a trend of load factor over a one-month period as well as daily min, max, and average

demand.

11

Page 12

FactoryTalk EnergyMetrix Software

Overlay Chart

Graphically displays a tag value with user-definable overlays.

ReportsPlus

ReportsPlus provides you a package of enhanced reports in addition to the standard reports

included in Manager.

ReportsPlus reports are set up and viewed in the same way as standard Manager reports

and can be configured to automatically run on a schedule and optionally send the report

output to one or more email addresses.

ReportsPlus reports can be identified by their distinctive icon in the report list. You can

choose the report output type among PDF (the default), Microsoft Excel, HTML, Rich

Text Format (RTF), or Tagged Image File Format (TIFF).

ChartsPlus is best viewed with a Windows appearance scheme

with standard sized fonts. Windows appearance schemes wi th

large or extra large fonts may distort the appearance of

ChartsPlus.

12

The additional reports included in ReportsPlus include:

Multi-purpose Report

The Multi-purpose Report (MPR) supports a free-form type of report output that is driven

by script code stored in a Multi-Purpose Report Script.

Efficiency Report

The purpose of this report is to give you information on the ‘energy efficiency’ of part or

all of your process, plant or enterprise. You will be able to define an efficiency equation

and then execute the equation over a period of time and a group of meters. Examples of

how this report can be used are:

Calculating efficiency of a boiler system based on BTU of gas consumed versus steam

produced

Calculating production efficiency of a batch manufacturing line by calculating tons of

product versus energy consumed

Page 13

1 • Overview

The efficiency report will calculate not only average efficiency over the selected time

range, but also snapshots of the efficiency during the range at user-specified intervals.

Report output will be graphical and tabular, with a graph of efficiency versus time. The

efficiency report is based on a simple Rate Schedule script.

Load Factor Report

The Load Factor report lists minimum, average and peak real power demand, load factor

and time of peak demand. You can select Meters to include in the report, as well as the

report date range and calculation intervals. The report output contains a tabular report and

a graphical chart.

Power Factor Report

The Power Factor report lists real energy net, reactive energy net, and power factor (which

is calculated from the real energy and reactive energy values) for selected meters for a

selected date range divided into specified calculation intervals (hours, days, or months).

Report output is tabular with a chart of power factor on the first page.

For this report to function, the selected meters or groups must be logging Real Energy Net

and Reactive Energy Net.

Electrical Summary Report

The Electrical Summary report lists various electrical summary values for selected meters

for the selected date and time period. These summaries are:

Total Energy kWh, kVARh and kVAh

Average Demand for kW, kVAR and kVA

Load Factor for kW and kVA

Min and Max values for kW, kVAR, kVA and Power Factor and the date/time they

occurred along with the coincident values for the other parameters.

The selected meters must be logging the relevant data in order for it to show up on the

report (for example, if Real Power Demand is not logged then there will be no kW figures

on the report). Power Factor is calculated from any two of the other three parameters (kW,

kVAR, kVA).

FTEMOPC 3rd party Connectivity Option

FactoryTalk EnergyMetrix OPC enables Manager to collect data from third-party energy

data sources through an OPC server that you provide. FTEMOPC enables OPC client

support for all licensed meters.

The FTEMOPC option alone does not enable operation of FactoryTalk EnergyMetrix

software. A Manager license must be installed. For more information about 3rd

party OPC drivers, follow the Rockwell Software Preferred Server Program

link.

Internet

13

Page 14

FactoryTalk EnergyMetrix Software

Notes:

14

Page 15

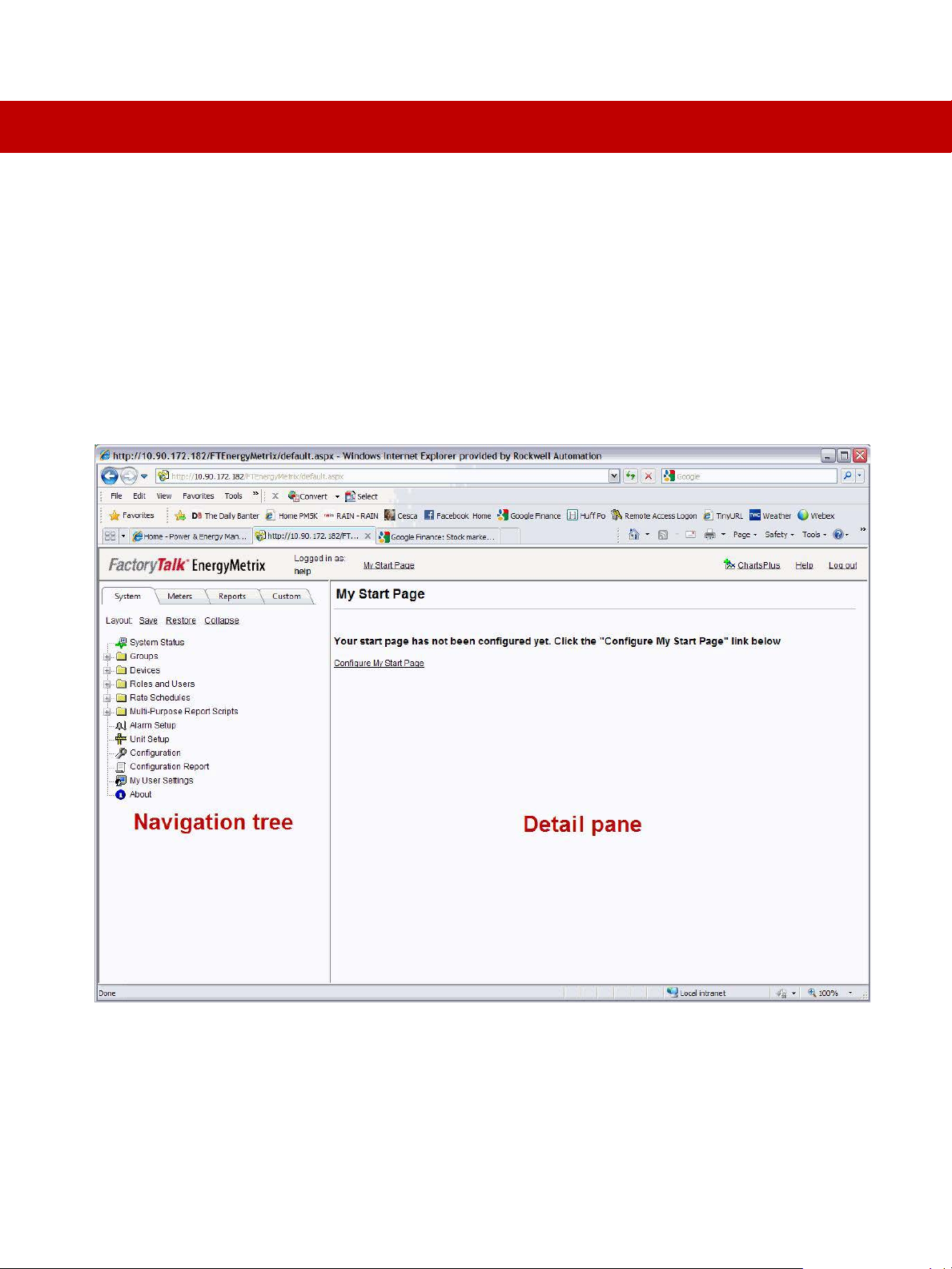

FactoryTalk EnergyMetrix Web Interface Tour

To access the FactoryTalk EnergyMetrix web page, browse to the following address:

http://<FactoryTalk EnergyMetrix server machine name or IP address>/

FTEnergyMetrix

After you log in, the client desktop appears. On the left is the navigation tree. On the right

is the detail pane.

C

HAPTER

2

15

Page 16

FactoryTalk EnergyMetrix Software

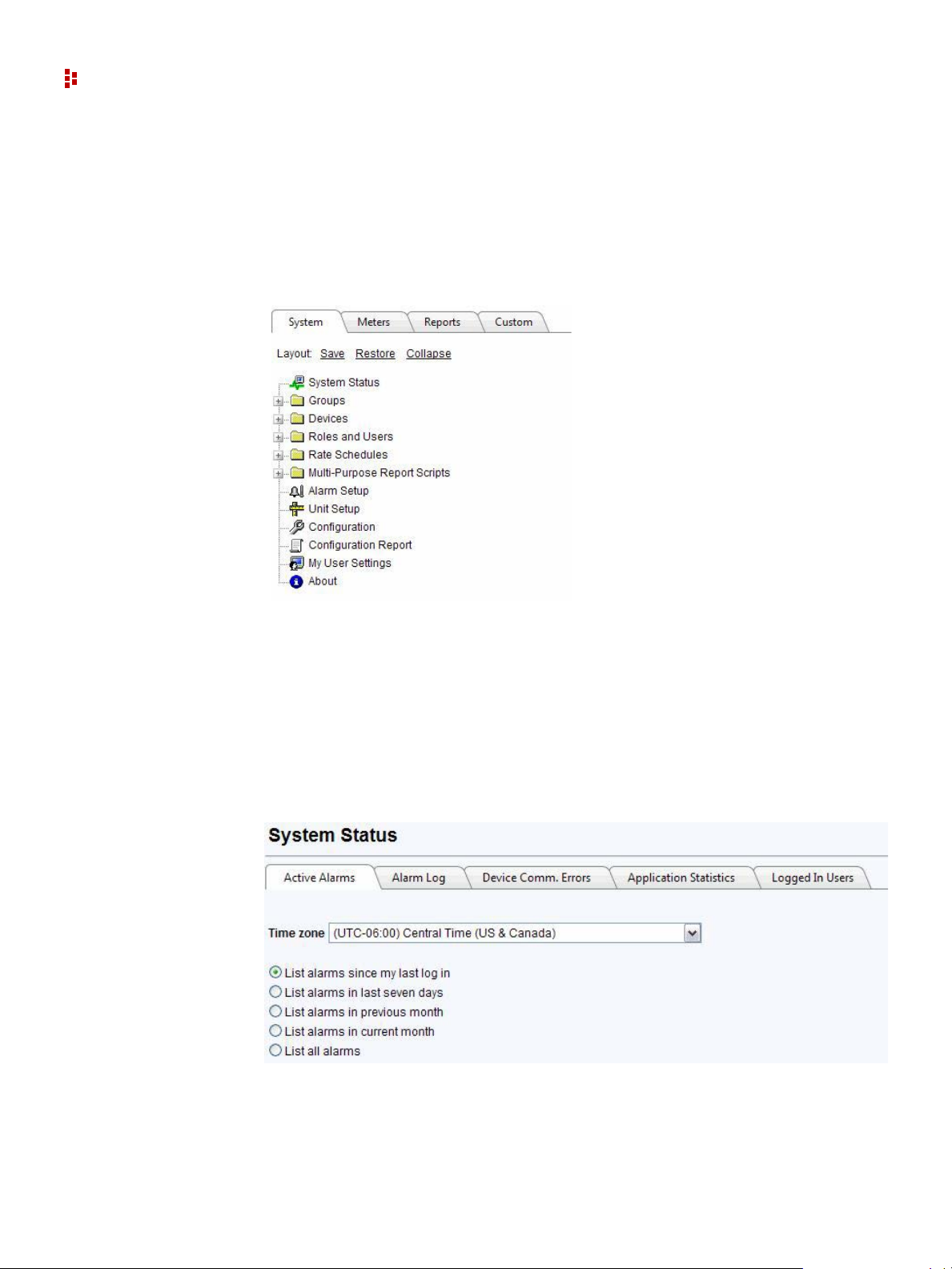

System Tab

The System tab in the navigation tree contains a number of folders and links that provide

access to setup items such as Devices, Groups, security settings (Roles and Users), Rate

Schedules, and Multi-Purpose Report Scripts, as well as links to the System Status, My

User Settings, Unit Setup, Configuration, System Configuration Report, and About pages.

System Status

Click the System Status link in the System tab to view alarms, device communication

status and other system-level information.

Alarms

The alarms tab provides a view of active and logged alarms. You can select the time range

of alarms to view by selecting a radio button.

16

Page 17

2 • FactoryTalk EnergyMetrix Web Interface Tour

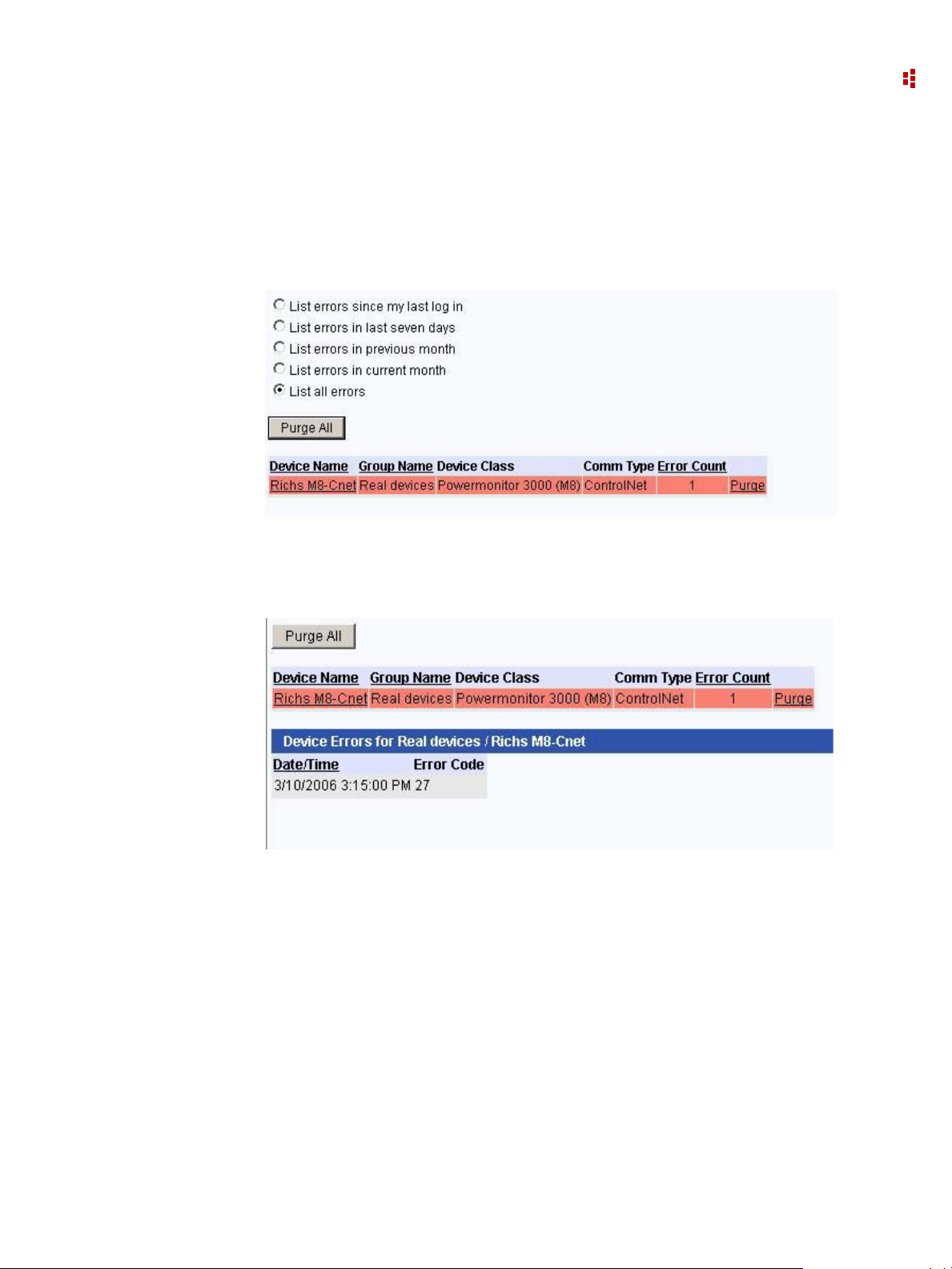

Device Communication Errors

This screen displays by default a list of device communication errors since your last login.

You can also select other error ranges.

For example, let's look at all errors:

Click on a Device Name link to expand to a detailed list of communication errors

associated with the Device.

You can purge errors for individual devices or click the Purge All button and confirm to

purge errors associated with all Devices.

Application Statistics

This tab provides information on the current number of system users and when the system

was last restarted among other information.

17

Page 18

FactoryTalk EnergyMetrix Software

User Monitor

This tab shows a list of users that are currently logged in to the system.

Groups

Click the Group link in the System tab to view the groups that have been set up. A Group

is a named collection of Devices and Meters that represents a subdivision of your

enterprise such as a department, division or process. Groups contain Meters, which can be

shared between Groups.

A Domain is a Group that is assigned Roles and Users. Rate Schedules and reports can

also be assigned to Domains. Users assigned to a Domain can only access objects assigned

to that specific Domain. This feature permits an administrator to allow certain users access

to only parts of the system he or she chooses.

Groups and Domains can be nested to any depth.

You must set up at least one Group or Domain before you can set-up Devices and

Meters.

Devices

Devices are physical entities that FactoryTalk EnergyMetrix software communicates with

over a network. Click the links listed below for information on specific device types.

Setting up a Device in FactoryT alk EnergyMetrix software establishes communication and

creates database definitions for the device, and enables device configuration and data

monitoring by using the optional FactoryTalk EnergyMetrix RT package.

Ethernet, ControlNet, serial, and DeviceNet devices can be directly connected provided

that the FactoryTalk EnergyMetrix server is also on the network through an appropriate

network interface and you have configured the appropriate RSLinx Classic direct device

drivers. Devices routed through a ControlLogix gateway or RSLinx Classic gateway are

also considered directly connected devices.

Devices can also be set up in a parent/child, or pass-thru configuration. Remote I/O

devices must be set up as children of a parent device such as a programmable controller.

DeviceNet devices can also be used as ‘Child’ devices.

18

Page 19

2 • FactoryTalk EnergyMetrix Web Interface Tour

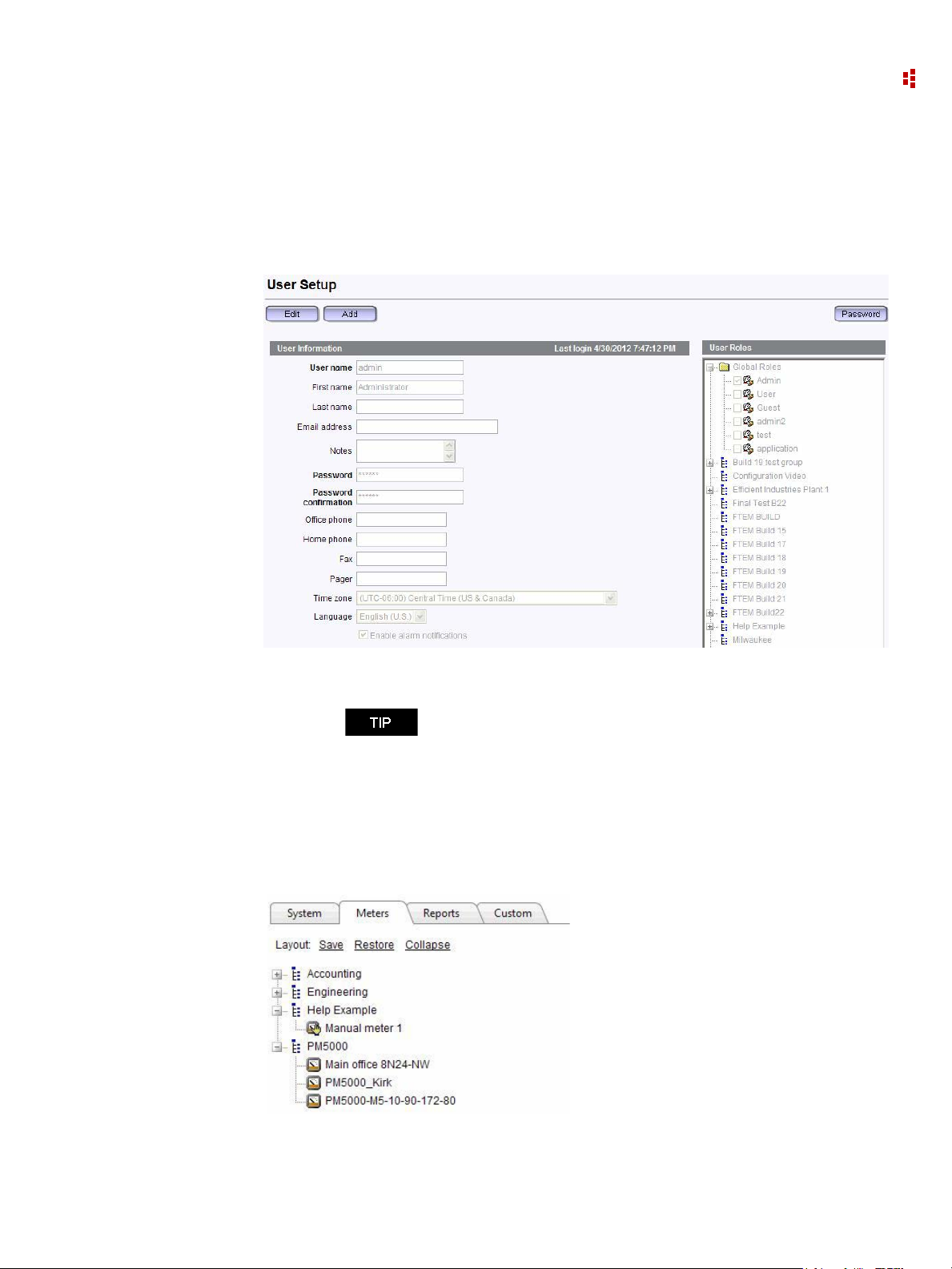

Roles and Users

Access to the application and its functions is controlled by means of Roles and Users.

A role is a named collection of privileges assigned to various users to manage security.

Roles can be global or domain specific.

A User is a named set of security credentials (user name and password) that permit an

individual to access the privileges defined in the Role assigned to the User. More than one

Role can be assigned to a User.

Roles and Users can be assigned Global scope where they are permitted access to all

domains, groups, devices, meters, reports and custom pages.

Alternately , Roles and Users can be assigned Domain-specific scope in which they permit

access to an individual domain and its sub-groups, devices, meters and reports, as well as

other Global objects such as reports, custom pages and rate schedules.

The default Roles are Admin, User, and Guest, with default user logins admin/admin,

user/user and guest/guest respectively.

Changing the default password on the Admin default user is

highly recommended to prevent inadvertent changes to the

database.

T o configure Roles and Users, navigate to the Roles and Users subfolder under the System

folder in the navigation tree.

To utilize Active Directory / LDAP (Lightweight Directory Access Protocol), simply

create a User name in the format DomainName\UserName used to log in to Windows.

The password fields and password button are displayed for Active Directory users,

however, the password entered into the user setup will only be used if the user cannot be

authenticated with the Active Directory server. When the user is authenticated against the

Active Directory server, the Windows password is stored in the database to keep the

passwords synchronized.

Rate Schedules

Rate schedules define the content and format of billing reports. You can use billing reports

for the following:

Shadow billing - replicating the monthly bill from your energy provider

Cost allocation - reporting the real cost of energy for each process or cost center in

your enterprise

Tenant billing - generating energy bills for use of your manufacturing or commercial

facilities by others

What-if analysis - Comparing costs of energy from different energy providers for the

same usage

Rate schedules can have global scope or be assigned to a domain. Global rate schedules

can be used in all domains. Domain rate schedules apply to only a single domain.

19

Page 20

FactoryTalk EnergyMetrix Software

The rate schedule model is designed to be very flexible so you can accommodate a wide

variety of utility tariffs.

Multi-purpose Report Scripts

The Multi-purpose Report (MPR) is a free-form report driven by script code stored in a

Multi-purpose Report Script. The MPR is part of the ReportsPlus Reports

A MPR Script defines what a MPR contains and what it looks like. A MPR script is

conceptually similar to a rate schedule. Like a rate schedule, an MPR script is combined

with selected meters or groups to form a specific report instance. This allows a script to be

reused for different meters and groups.

MPR scripts are listed in a new sub-tree under the System tab and can be Global or

assigned to a domain.

MPR scripts contain Visual Basic for .NET scripting that utilizes the MPR object model to

select and format the content of the report.

MPR users are assumed to be familiar with FactoryTalk EnergyMetrix, in particular with

its reporting and rate schedule functionality, and the Visual Basic for .NET scripting

language.

option.

You can select one or more of the following elements, or objects, when configuring an

MPR. Each provides a different way to view your energy, cost and production data.

Grid

A Grid displays data in tabular format. The MPR script contains code that creates a Grid,

specifies the number, width and heading text of columns, and populates the rows of the

grid with data.

Bar Chart

A Bar Chart displays a bar graph of data. The MPR script contains code that creates a bar

chart, defines the x and y axes and selects the data to be displayed in one or more data

series.

Tre nd C ha r t

A Trend Chart displays a line graph of data. The MPR script contains code that creates a

trend chart, defines the x and y axes and selects the data to be displayed in one or more

data series.

Bar chart series can be mixed with trend chart series in the same

chart. Charts may have multiple Y axes.

Pie Chart

20

A Pie Chart displays a series of data as wedges of different sizes in a pie-shaped graphic.

The MPR script contains code that creates a Pie Chart and populates it with data.

Page 21

2 • FactoryTalk EnergyMetrix Web Interface Tour

Rich Text Box

The Rich T ext Box provides a way to place text on a MPR. The MPR script contains code

that creates the Rich Text Box and controls its location, size, content and formatting.

Page Header and Footer

The page header contains identifying elements such as the report title, the report headings

from the Group setup, the report time range and time zone, and a user-selectable graphic

element.

The page footer contains the report page number and the date and time the report was

printed.

MPR script code controls the header graphic element selection and the visibility or the

header and footer.

Intervals

Intervals provide an easy way for MPR script code to process data in intervals specified by

the user when they run a Multi-Purpose Report. Interval types are Day, Week, Month.

Enable Intervals by selecting the Use Intervals checkbox on the MPR script setup screen.

Excel

The Excel report object moves the report output and formatting from the MPR script into

Excel. Since the report output is now Excel all of the functionality of Excel is now

available to the report.

21

Page 22

FactoryTalk EnergyMetrix Software

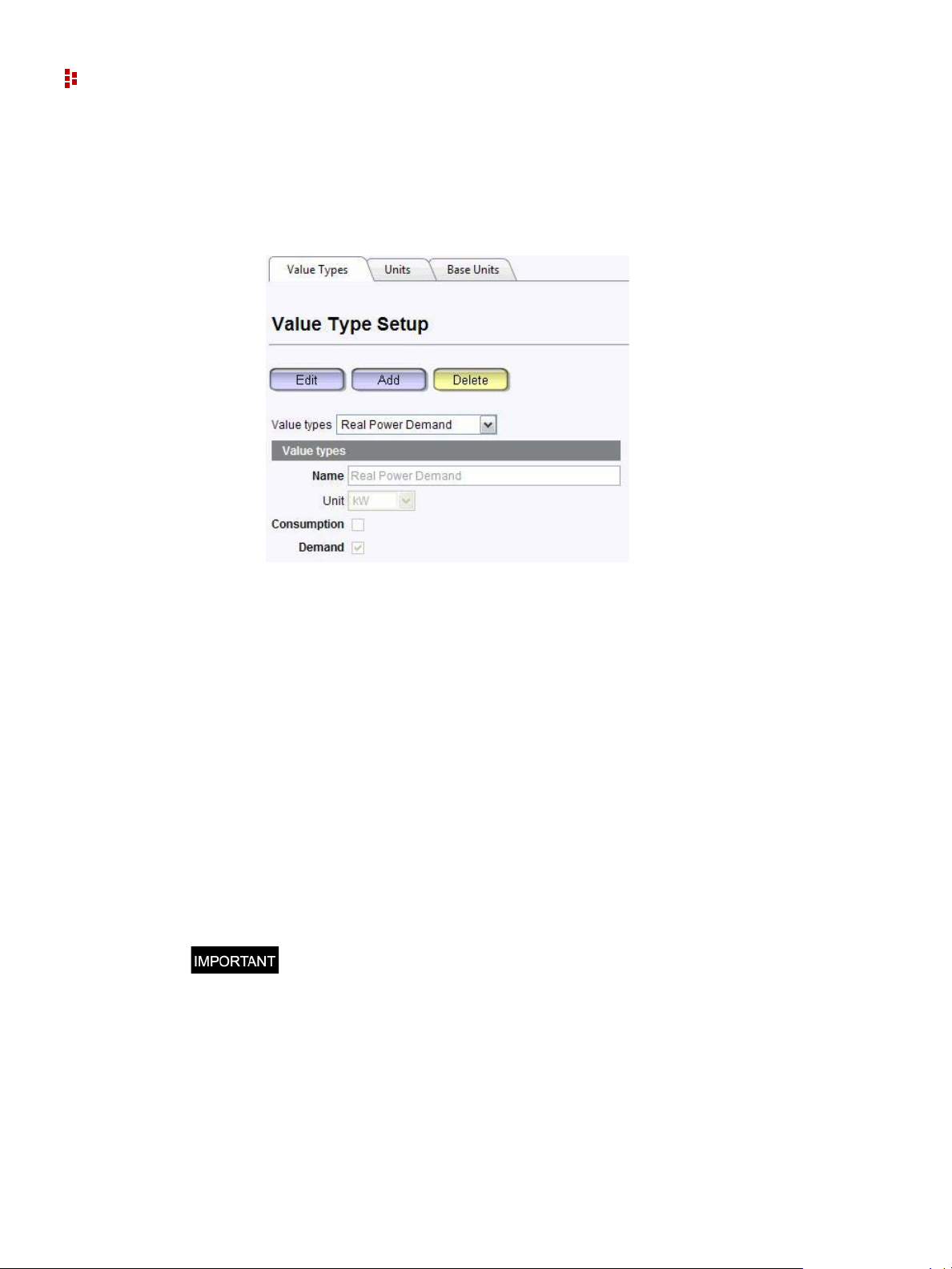

Unit Setup

The Unit Setup screen provides menus that let you add, delete, and edit Value Types, Base

Units, and Units.

The FactoryTalk EnergyMetrix collection of base units includes many that are commonly

uses in energy management applications. The default collection of units is based on the

base units and includes a scaling factor which relates it to the base unit. For example, VA

(volt-amperes) is a Base unit, and kVA (kilo-volt-amperes) is a Unit, with a scaling factor

of 0.001.

Value types are used by the reporting and billing functions to aggregate values of a

specific type in one or more meters or groups. The default collection of value types in

FactoryTalk EnergyMetrix software represents the most commonly used electrical energy

management parameters. Value types can be set up as Consumption or Demand.

Consumption value types are treated as accumulated values of energy or process output,

for example, real energy net. Demand value types are treated as 'rate' values such as real

power demand.

To add, edit or delete a Unit, Base Unit, or Value Type navigate to the System tab, Unit

Setup screen. Select the appropriate tab and enter the values you desire in the menu fields.

Exercise care not to delete a unit, base unit, or value type that is associated with

tags that exist in the database or unpredictable results may occur.

22

Page 23

2 • FactoryTalk EnergyMetrix Web Interface Tour

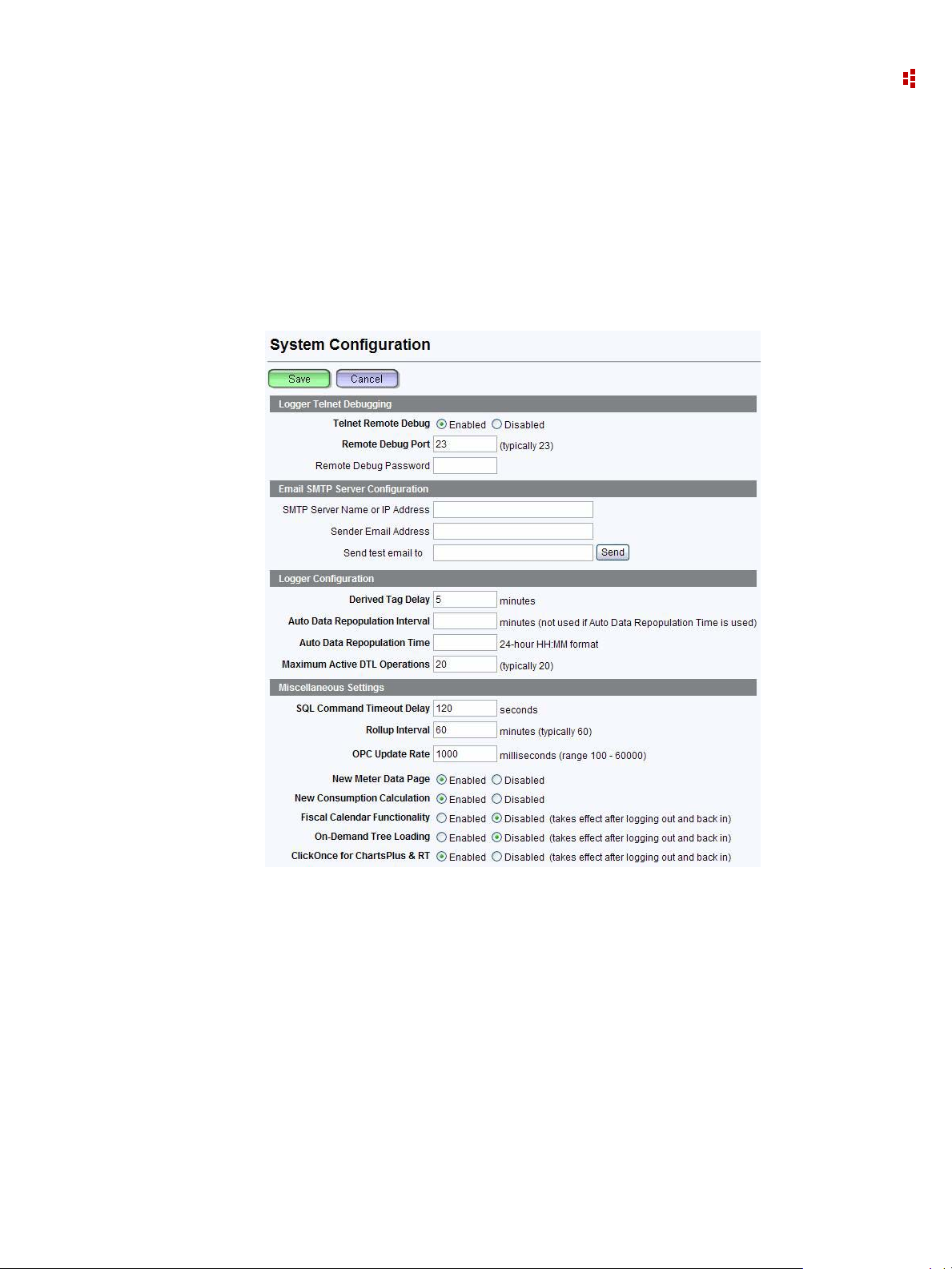

System Configuration

The Configuration page under the System tab provides a means for setting a variety of

program options.

To access the Configuration page, select the System tab and then select the Configuration

item in the navigation tree. Click the Edit button to change settings. You must have Edit

System Configurations privileges to make changes.

Logger Telnet Debugging

Telnet debugger, enabled or disabled (default)

Remote debug port, any unused port ID, default 23

Remote debug password, default "".

Email SMTP Server Configuration

FactoryTalk EnergyMetrix software sends email alarms and reports via a SMTP server

configured by using this page.

SMTP (Simple Mail Transport Protocol) server name or IP address

Sender email address (does not need to be an actual email address)

Test email button - sends a test message to the email address entered in the address

field when the Send button is clicked

23

Page 24

FactoryTalk EnergyMetrix Software

Logger Configuration

Derived tag delay - specifies how long after meter data is polled that derived tags are

calculated. Default is 5 minutes

Maximum active DTL operations - specifies the maximum concurrent messages with

RSLinx Classic and hence devices. Range is 1 to 35. Default is 20. It is unlikely that

you will need to adjust this setting

Miscellaneous Settings

SQL command timeout delay - default 120 seconds.

Roll-up interval - specifies how often tags are refreshed from roll-up servers, default

60 minutes.

OPC update rate - specifies how often the connection to OPC servers is refreshed.

New meter data page - Enabled by default, selects the paged meter data display page

New consumption calculation - provides more accurate consumption reporting in the

case of data logging anomalies such as unexpected zero values and resets.Enabled by

default.

Fiscal Calendar Functionality - permits the creation and use of fiscal periods for

reporting. Disabled by default.

On-demand tree loading - If on-demand tree loading is enabled, nodes are loaded only

when a user expands them. If disabled, the entire tree refreshes at a time.

ClickOnce for ChartsPlus and RT - Enabled by default, sets up RT and ChartsPlus as

ClickOnce applications.

System Configuration Report

The system configuration report may be found on the System tab. This report can be

configured to document the configuration of any or all of the objects listed in the report

setup page. In addition, you may select all groups or an individual group / domain and its

subgroups. Groups are limited to those accessible to your login role.

24

Page 25

2 • FactoryTalk EnergyMetrix Web Interface Tour

My User Settings

This screen shows the user settings of the currently logged-in user . A user can change their

personal password here. It also lets a user change other user settings, provided that the role

associated with the currently logged-in user has the privilege to edit users.

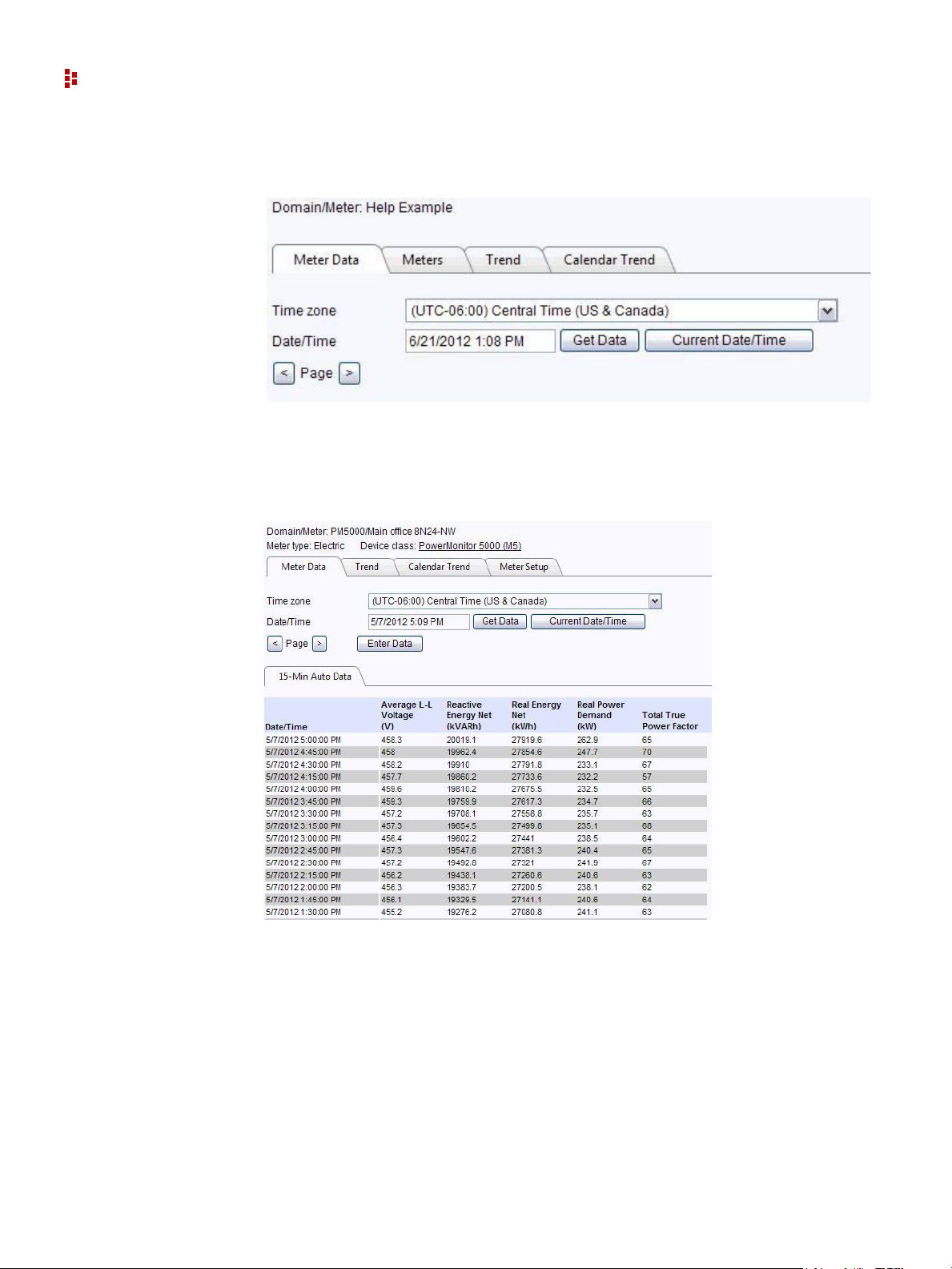

Meters Tab

The Meters tab in the navigation tree contains folders that organize the Meters into groups

and domains.

If you wish to receive alarm notifications by email, be sure to

check the Enable alarm notifications checkbox on this page.

25

Page 26

FactoryTalk EnergyMetrix Software

Selecting the Meters tab does not change the detail pane content. Select a Group or

Domain to view aggregated information from the Meters the group contains.

When you first select a Meter, the Meter Data ta b is selected. This screen lets you view the

logged meter data. The display is arranged by log rate. The user time zone is selected by

default. Controls allow you to select the desired date, scroll up and down through the data,

and page backward and forward through the meter data.

26

When you select a Group under the Meters tab, an aggregated view of the data of the

meters in the group is shown. Data is aggregated based on value type. If data is missing

from one or more meters for a particular time, no aggregated value appears in the Group

display.

The Get Data button refreshes the current page of meter data. The Current Date/Time

button selects the current time and refreshes the meter data display.

Page 27

2 • FactoryTalk EnergyMetrix Web Interface Tour

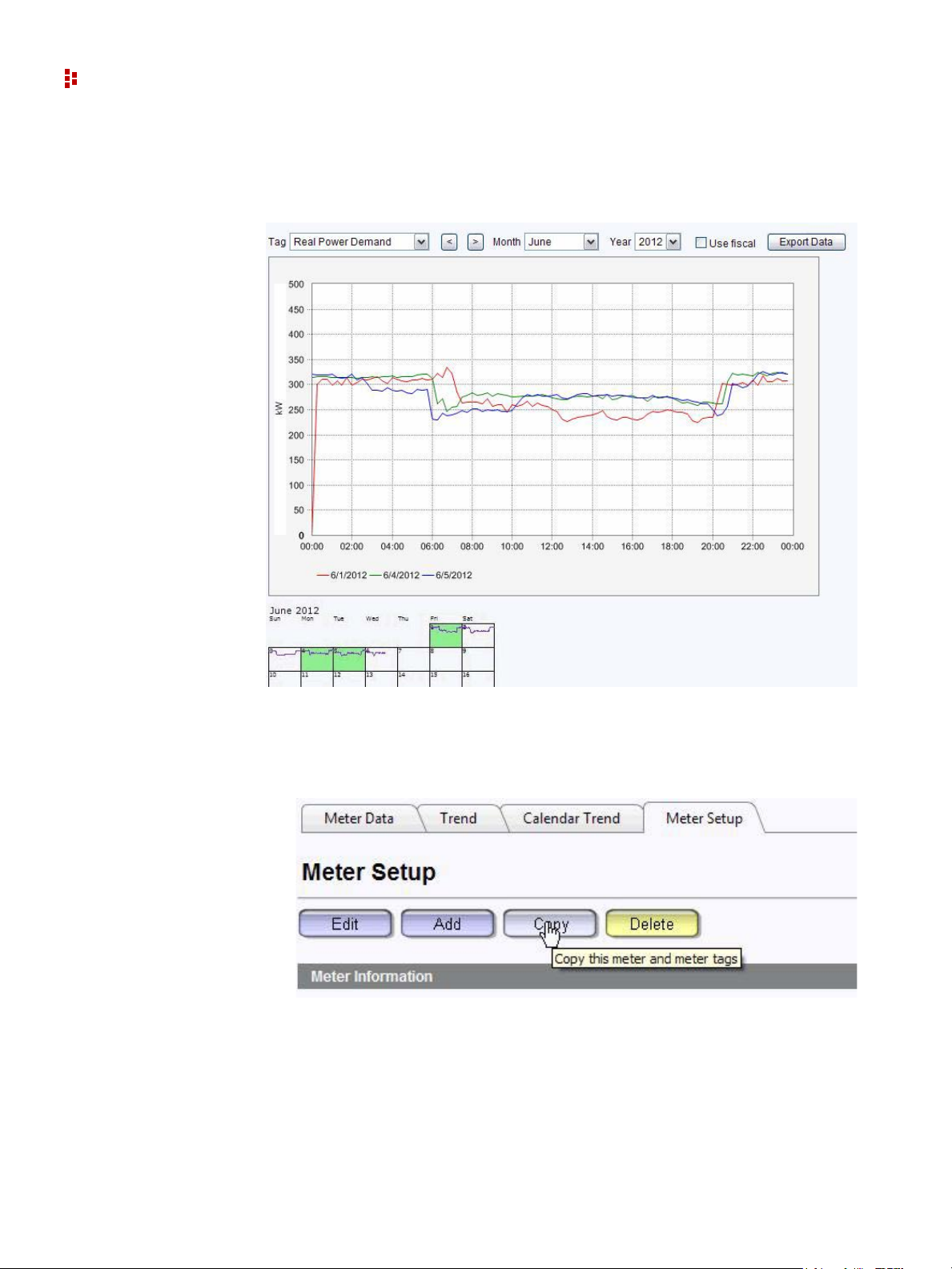

The Meter trend display lets you select and view tags as their values vary by time. You can

select up to five tags from one or more meters. Each pen can be individually selected to b e

displayed as a line chart or bar chart. The user time zone is selected by default. You can

select a different time zone for the trend and the start and end dates from the calendars. Or,

enter start and end dates into the date fields and click the Go button. One day is the

minimum trend period. If you select an end date earlier than the start date, the system will

adjust the start date, and vice versa.

The calendar trend display shows how the value of a meter tag or value type you select

varies over a full month. You can select the meter tag to display from the pull-down menu.

The calendar trend is available for individual meters and for groups by using aggregated

data.

27

Page 28

FactoryTalk EnergyMetrix Software

To zoom in to a day, click on the day in the calendar. You can overlay days by selecting

additional days from the small calendar under the zoomed display.

Meter Setup

The meter setup screen provides tools to allow you to create, modify, and delete Meters,

add and modify meter tags, and set up alarms.

28

Page 29

Reports Tab

Standard reporting converts the energy and production data logged in the database into

information you can use to manage your business, improve efficiency and reduce costs.

Standard reports can be run on demand, automatically on a configurable schedule , or

event-driven in response to an alarm condition.

Consumption Reports

Reports consumption values (for example kWH and kVARh) for selected meters or groups

for a specified date/time range. The consumption report aggregates data from each

selected meter based on consumption value types, that is, value types with the

Consumption flag selected. The report comprises one line item per meter with totals by

group. The group and meter names are listed in the left hand column and a colum n i s

added for each consumption value type that exists in the selected meters. If more than

three consumption value types exist the line items may be truncated.

Demand Analysis Reports

Reports kW demand values for selected meters or groups for a specified date/time range.

Reports ‘worst case scenario’ peak demand that would have occurred if each meter or

group's peak demand had occurred in the same demand interval. The demand analysis

report selects from each selected group or meter value types with the Demand flag

selected. The report is organized in groups by value type, for example, kVA or kW.

2 • FactoryTalk EnergyMetrix Web Interface Tour

Billing Reports

Runs billing reports for selected groups or meters for a specified date/time range. The

report outputs a list of line items and a total charge amount. Each line item consists of a

description, quantity, rate and charge. Billing reports select value types and calculate the

report line items based on Rate Schedules

currency symbols and numeric formatting based on the Windows regional setting that is

selected in the rate schedule.

that you configure. The billing report displays

Cost Allocation Reports

Runs a report that lists each meter's contribution to the total energy cost, based on a Rate

Schedules that you configure. Cost Allocation reports are generated in Microsoft Excel

output format.

29

Page 30

FactoryTalk EnergyMetrix Software

Power Quality Reports

Runs a report that combines a graph and a grid display of power quality (sag and swell)

events. The power quality report can only be used with Allen-Bradley PowerMonitor 3000

M6 and M8 models with their sag and swell setpoints configured. The Enable PQ events

logging flag must be selected in the Device setup page. With this flag set, FactoryTalk

EnergyMetrix periodically reads the power monitor event log and stores sag and swell

events in the database. Each sag and swell record lists the time, duration and maximum

deviation of the sag or swell. The power quality report displays the events logged during

the selected report interval on a ITI/CBEMA chart and in a grid (tabular) listing.

Pareto Chart Report

Runs a report on consumption values of a selection of meters or groups. The Pareto chart

displays each meter or group's consumption as a bar chart, with the bars arranged in order

of decreasing consumption. A line chart indicating the cumulative consumption of the

groups or meters, starting at zero and ending with 100%, is overlaid against the bar chart.

The Pareto chart report help identify the areas in your facility that use the most energy.

ReportsPlus Reports

ReportsPlus reports are available as part of the ReportsPlus option.

Automatically Run Reports

The reports listed above can be set up to run automatically, either on a schedule or in

response to an alarm.

System Configuration Report

This report can be configured to document the configuration of the FactoryTalk

EnergyMetrix project.

ReportsPlus Reports

ReportsPlus provides you a package of additional reports that are set up and viewed in the

same way as standard reports. Like standard reports, ReportsPlus reports can be

configured to automatically run on a schedule and optionally send the report output to one

or more email addresses. ReportsPlus reports can be identified by a distinctive icon in the

report list.

Multi-purpose Report

The Multi-purpose Report (MPR) supports a free-form type of report output that is driven

by script code stored in a Multi-purpose Report Script.

Efficiency Report

30

The purpose of this report is to give you information on the ‘energy efficiency’ of part or

all of your process, plant or enterprise. You will be able to define an efficiency equation

and then execute the equation over a period of time and a group of meters.

Page 31

2 • FactoryTalk EnergyMetrix Web Interface Tour

Load Factor Report

The Load Factor report lists minimum, average and peak real power demand, load factor

and time of peak demand. You can select Meters to include in the report, as well as the

report date range and calculation intervals. The report output contains a tabular report and

a graphical chart.

Power Factor Report

The Power Factor report lists real energy net, reactive energy net, and power factor (which

is calculated from the real energy and reactive energy values) for selected meters for a

selected date range divided into specified calculation intervals (hours, days, or months).

Report output is tabular with a chart of power factor on the first page.

Electrical Summary Report

The Electrical Summary report lists various electrical summary values for selected meters

for the selected date and time period, including Total Energy kWh, kVARh and kVAh,

Average Demand for kW, kVAR and kVA, Load Factor for kW and kVA, and Min and

Max values for kW, kVAR, kVA and Power Factor and the date/time they occurred along

with the coincident values for the other parameters.

Custom Tab

The Custom tab contains links to web pages or graphics that you select by using the

Manage custom pages link. Custom pages can be configured in one of two ways:

Upload a file which is then stored in the database

A URL that opens a web page

31

Page 32

FactoryTalk EnergyMetrix Software

Notes:

32

Page 33

Installation

Contents of Installation DVD

The installation DVD contains the following required components:

FactoryTalk EnergyMetrix 2.10.00

FactoryTalk Activation Manager v 3.60.00 (CPR9 SR6)

FactoryTalk Services Platform v 2.60.00 (CPR9 SR6)

RSLinx Classic Lite v 3.60 (CPR 9 SR6)

Microsoft .NET Framework 3.5 SP1

And the following optional components and resources:

RSLinx Enterprise 5.60.00 (CPR9 SR6)

Adobe Acrobat Reader 10

FactoryTalk EnergyMetrix User Manual

FactoryTalk EnergyMetrix Help

C

HAPTER

3

The CD also includes the following applications, which are not accessible from the autorun menu but may be browsed:

Internet Explorer WebControls 1.0

Client Requirements

Client requirements for compatibility with FactoryTalk EnergyMetrix:

Microsoft Windows XP Professional, Vista Professional, Windows 7 (Windows 2000

is not supported)

Internet Explorer 7, 8, 9 or 10

Adobe Acrobat Reader 7.0 or later is required to view reports

Microsoft .NET Framework 3.5 SP1 is required to use RT and Charts Plus options.

.NET Framework 3.5 SP1 is included on the installation DVD or may be downloaded

at no charge from Microsoft.

Your client workstation must also be permitted Intranet, Internet or dial-in access to the

FactoryTalk EnergyMetrix server. Contact your IT support personnel for assistance.

Server Requirements

Your browser should be set to check for newer versions of stored pages

automatically, not every visit to the page.

We recommend, but do not require, that you install FactoryTalk EnergyMetrix software

on a dedicated server with a local installation of Microsoft SQL Server.

33

Page 34

FactoryTalk EnergyMetrix Software

Server Software Requirements for Installing FactoryTalk EnergyMetrix

Windows 2003 Server or Windows 2008 Server, Application Server role. For 64-bit

operating systems, RSLinx Classic version 2.60 (CPR9 SR6) or later must be

installed. Windows 2000 Server is not supported.

Microsoft SQL Server 2005 or 2008, installed with mixed-mode authentication

(Windows and SQL). TCP/IP access must be enabled. A system administrator SQL

login must be used for the FactoryTalk EnergyMetrix installation.

You must have machine administrator privileges to install FactoryTalk EnergyMetrix.

Hardware Requirements

These are the hardware requirements that you need to use FactoryTalk EnergyMetrix

software.

Definitions

The following rules of thumb are offered as a starting point for determining server sizing

for FactoryTalk EnergyMetrix. Other factors will affect the required size of a server. A

higher number of tags being logged, a faster log rate, a larger number of users and a lar ger

number of reports being run will require a more powerful server than the guidelines

specify.

A low-end server has up to 8 meters and logs up to 40 meter tags at a minimum 15

minute log rate

A mid-range server has up to 64 meters and logs up to 320 meter tags at a minimum

15 minute log rate

A high-end server has more than 64 meters and logs more than 500 meter tags at a

minimum 15 minute log rate

Database Size Guidelines

FactoryTalk EnergyMetrix writes 16 bytes of data to the database for each meter tag

logged. Over time, the database can grow to become quite large. Some examples include

the following:

A low-end server, logging 40 meter tags at 15 minute intervals, will grow the database

at a rate of 2.56 KB per hour or 22 MB per year.

A mid-level server, logging 320 meter tags at 15 minute intervals, will grow the

database at a rate of 20.5 KB per hour, or 180 MB per year.

A high-end server, logging 1000 meter tags at 15 minute intervals, will grow the

database at a rate of 240 KB per hour, or 2.1 GB per year.

Consider these guidelines when determining hard disk requirements for a server as well as

database maintenance schedules.

Recommendations

34

These are general guidelines. FactoryT alk EnergyMetrix software is capable of running on

a variety of hardware platforms. The main scalability issue is related to processing of

logged data (for example, report generation, trending). CPU speed, number of CPUs,

RAM, and RAID 5 for the database files are the main scalability factors (in that order). All

hardware platforms require the following:

Page 35

Processor, RAM and hard drive as noted below

DVD drive

One or more Ethernet network ports

Internet access

Monitor, keyboard, pointing device (mouse)

Low-end Server

Single 2 GHz Pentium 4

1…2 GB RAM

80 GB hard disk

Mid-range Server

2 or 4 CPU 2 GHz Pentium 4 or better

2…4 GB RAM

160 GB hard disk (with separate disks for operating system and log files and

RAID 5 for main database files preferred)

3 • Installation

35

Page 36

FactoryTalk EnergyMetrix Software

High-end Server

High-end server requirements are very dependent upon the user's application

Client Requirements

The following are the client requirements for compatibility with

FactoryTalk EnergyMetrix software:

Microsoft Windows XP Professional, Vista Professional, Windows 7 (Windows 2000

is not supported) operating system.

Internet Explorer 7, 8, 9, or 10 web browser.

Adobe Acrobat Reader 7.0 software or later is required to view reports.

Microsoft .NET Framework 3.5 SP1 is required to use RT and Charts Plus options.

.NET Framework 3.5 SP1 is included on the installation DVD or can be downloaded

at no charge from Microsoft.

Your client workstation must also be permitted Intranet, Internet or dial-in access to the

FactoryTalk EnergyMetrix server. Contact your IT support personnel for assistance.

requirements. Please contact Rockwell Automation for assistance in specifying

hardware for a high-end server.

Your browser should be set to check for newer versions of stored pages automatically,

not every visit to the page.

36

Page 37

Installation (64-bit)

Perform the following steps while logged in as a Machine Administrator.

Configure Windows 2008 Server

Start with a clean Windows Server 2008 R2 SP1.

1. If it hasn’t launched automatically, launch Server Manager.

Wait until Server Manager has finished collecting data.

2. Right-click Roles and select Add Roles.

3. Click Next on Before You Begin page.

3 • Installation

4. Select Application Server.

5. Click Add Required Features.

6. Click Next.

7. Click Next.

8. Click Web Services (IIS) Support.

9. Click Add Required Role Services.

10. Click Next.

37

Page 38

FactoryTalk EnergyMetrix Software

11. Click Next.

12. Scroll down in the Role Services window and then select IIS 6 Management

Compatibility

13. Click Next

14. Click Install

15. Wait while installation proceeds

16. Click Close when done

We recommend that you disable Internet Explorer Enhanced

Security Configuration.

17. To do this, locate the Configure IE ESC link in the Security section In the Server

Manager.

18. Click the link, turn off IE ESC for Administrators, and then click OK.

38

Page 39

3 • Installation

Install SQL Server 2008 R2

Microsoft SQL Server 2008 R2 must be installed on the local server even if the

FactoryTalk EnergyMetrix database is to be hosted on another machine.

1. Insert disk into CD/DVD drive.

2. If necessary, run SETUP.EXE and click Yes to allow SQL Server 2008 R2 to install

on the computer.

3. Review the documentation in the SQL Server Installation Center window.

4. Install the upgrade advisor if desired.

5. Click the Installation link in the menu.

6. Click the New installation or add features to an existing installation link.

7. Enter the product key and then click Next.

8. Accept the license terms and click Next

9. On the Setup Support Files page, click Install.

10. Wait while installation proceeds.

11. Make note of any issues or warnings listed in the Setup Support Rules page and take

action as needed.

12. Click Next.

13. Select SQL Server Feature Installation.

14. Select the features shown as selected in the screen capture below.

39

Page 40

FactoryTalk EnergyMetrix Software

15. Click Next.

16. Click Next.

17. Leave the Default instance selected, click Next.

18. On the Disk Space Requirements page, click Next.

19. On the Service Account dialog box, Click Use the same account for all SQL Server

services.

20. Select NT AUTHORITY\SYSTEM in the dialog box and then click OK.

21. Click Next.

22. On the Database Engine Configuration page, select Mixed Mode.

23. Enter a password.

Record the password in a safe location. You will need to enter it when you install

FactoryTalk EnergyMetrix.

24. Click Add Current User.

Add additional users as administrators as desired.

25. Click Next.

26. Click Next.

27. Click Install.

28. Wait until installation completes.

29. Click Close.

30. Close the SQL Server Installation Center window.

31. Remove the SQL Server 2008 R2 installation DVD.

In SQL Server 2008 R2, TCP/IP network access is enabled by default.

40

Page 41

Enable 32-bit Applications

1. Using Internet Information Services (IIS) Manager -> Application Pools ->

DefautlAppPool -> Advanced Settings, set Enable 32-Bit Applications to True.

2. Click OK.

3 • Installation

Install FactoryTalk EnergyMetrix Software Version 2.10.00

1. Insert the FactoryTalk EnergyMetrix installation DVD into the CD/DVD drive.

If needed, browse the DVD and launch Autorun.exe to access the

installation menu. Perform the following steps from the

installation menu.

2. If needed, install Adobe Acrobat Reader (required for viewing reports on the server).

a. Click the Adobe Acrobat Reader link under Install Optional Software.

b. Select all defaults for a typical installation.

3. Install FactoryTalk Activation Manager.

a. Click the FactoryTalk Activation Manager link under Install Required Software.

b. Click Continue on the InstallShield Wizard screen.

c. When prompted, select No to installing the HASP USB dongle drivers.

d. Wait while prerequisite packages are installed.

e. On the FactoryTalk Activation Manager InstallShield Wizard, click Next.

f. Accept the terms of the license agreement, click Next.

g. Click Install.

41

Page 42

FactoryTalk EnergyMetrix Software

h. When prompted, reboot the server.

9. Install RSLinx Classic Lite software version 3.60 (CPR 9 SR6).

a. From the FactoryTalk EnergyMetri x installation menu, click RSLinx Lite 2. 57.00.

b. Complete the steps to install RSLinx Classic Lite.

c. After installation, RSLinx Classic starts as an application.

Do not install Microsoft .NET Framework 3.5 SP1 on Windows Server 2008 R2 SP1. It

is already installed with the operating system

FactoryTalk EnergyMetrix does not require the installation of Internet Explorer

WebControls 1.0.

4. Install FactoryT alk EnergyMetrix.

a. From the FactoryTalk EnergyMetrix installation menu, click FactoryTalk

Refer to the RSLinx application notes section below for tips on using RSLinx

Classic on Windows 2008 Server R2.

EnergyMetrix 2.10.00.

b. Locate the InstallShield Wizard.

It may be behind other windows on the desktop, click Next.

c. Click Yes to accept the EULA.

d. Enter the customer information, click Next.

e. Click Next.

f. Click Next.

g. Presuming a local installation of the SQL database, enter the server SQL login

username and password that you entered in step 2.v previously.

If the SQL server is hosted on a remote machine, enter the database server name

and SQL authentication credentials. Click Next.

h. Click Next.

i. Wait while FactoryTalk EnergyMetrix software is installed.

j. When complete, click Finish to reboot the server.

11. Install activations by using the FactoryTalk Activation Manager.

12. Add local machine user IIS_IUSRS with read and modify rights to the C:\Program

Files (x86)\Rockwell Software\FTEnergyMetrix\ChartFXNet folder.

13. Open Internet Explorer.

42

a. Browse to http://localhost/ftenergymetrix

.

b. Log in with username admin and password admin.

Page 43

3 • Installation

The RT and ChartsPlus options do not require specific security

configuration in FactoryTalk EnergyMetrix software. They run as

Microsoft ClickOnce applications by default. You will need to

grant permission for the options to run, but only one time on

each computer.

When you set up Devices such as power monitors and PLCs in

FactoryTalk EnergyMetrix software, you will need to access

RSLinx Classic software running on the server to configure

drivers and network addresses of devices. You access the RSLinx

Classic user interface to perform tasks such as configur e drivers,

monitor devices in RSWho, and set up OPC topics.

43

Page 44

FactoryTalk EnergyMetrix Software

Installation (32-bit)

See Installation (64-bit) on page 37 for instructions to install FactoryTalk

EnergyMetrix software on a 64-bit operating system.

Pre-installation Checks

1. Check out the server for required customer-provided software:

Windows 2003 R2 Server , set up in the Application Server role. ASPNET must be

SQL 2005 or 2008 Server, installed and set up for mixed mode authentication

If the SQL database server is hosted on a remote server, you must download from

installed. Active Server Pages must be enabled in Internet Information Services.

Network COM+ Access must be enabled. The server can not be set up as a

Domain Server. FactoryTalk EnergyMetrix software installation on

Windows 2000 Server is no longer supported.

(SQL Server and Windows). TCP/IP access must be enabled.

Microsoft (if necessary) and install Microsoft SQL Server 2005 or 2008 Express

Edition on the FactoryTalk EnergyMetrix server. This installs the osql.exe

application FactoryTalk EnergyMetrix software uses to connect to the remote

database.

IIS 6, 7, or 7.5 installed and enabled to run.

2. You must use a machine administrator login in Windows and have full administrator

rights for SQL.

3. Ping all Ethernet devices (meters and/or controllers) the customer wishes to connect

to.

Correct communication to any meters that don't respond.

Verify communication with Allen-Bradley Ethernet power monitors via their

built-in web page.

Installation

1. Verify the Application Server role configuration in the host Windows Server

operating system.

These are the minimum required components:

ASPNET

COM+ Services

Internet Information Services (IIS), all options

Make any necessary changes before proceeding with the installation.

44

Page 45

3 • Installation

2. If not already installed, install Microsoft SQL Server 2005 or 2008 (NOT included in

FactoryTalk EnergyMetrix base software but 2008 is available as a bundled option).

SQL Server must be set up with mixed-mode authentication (Windows and SQL

Server). You can make this selection during initial installation or by using Enterprise

Manager and editing the server properties, security tab after installation. We

recommend that you do not use the default system administrator login (username =

‘sa’, password = “”) due to known security issues. Record the system administrator

login credentials as you will be prompted to enter them when you install

FactoryTalk EnergyMetrix software. The same SQL database login will be required

when the software is upgraded to a new version eventually.

If the SQL Server is to be hosted on another computer, download (if needed) and

install SQL Server 2005 or 2008 Express Edition on the FactoryTalk EnergyMetrix

server at this time.

3. Using Internet Information Services manager, verify that ASP.NET version 2.0 is

selected in the default web page properties.

If it is not, select ASP.NET version 2.0 and run IISRESET before installing the

software.

4. Insert the FactoryTalk EnergyMetrix software installation DVD into the server’s

DVD drive.

If auto-run is enabled, the installation menu will launch. If not enabled, browse to and

launch autorun.exe in the root folder of the DVD.

The installation menu provides a link to the FactoryTalk

EnergyMetrix online Help.

5. From the installation menu, install the Factory Talk Activation Manager.

This step is recommended but not required when upgrading an

existing installation.

6. Install RSLinx Classic Lite software version 3.60 (CPR 9 SR6).

This step is recommended but not required when upgrading an

existing installation on a 32-bit Windows Server 2003 operating

system.

7. Install Microsoft .NET Framework version 3.5 SP1.

8. If not already installed, install Adobe Acrobat Reader.

9. Install FactoryT alk EnergyMetrix software:

a. Accept the license agreement and enter the serial number of the Manager software

when prompted.

b. When prompted, enter the computer name or IP address of the SQL Server (the

default is (local) for a SQL server hosted on the FactoryTalk EnergyMetrix

server).

45

Page 46

FactoryTalk EnergyMetrix Software

c. Accept the remaining prompts. The installation will proceed.

d. When prompted, reboot the server to complete the installation.

5. After the server restarts, log in as an administrator, and then open the Windows

Control Panel > Administrative Tools > Computer Management > Local Users and

Groups.

a. Select Users and right-click the ASPNET user name option.

b. Select Properties and select the Member Of tab.

c. If Administrators does not appear in the list, then click Add, and then click

d. Click Find Now.

e. Select Administrators and click OK.

f. When finished, reset IIS (Start > Run > ‘iisreset’> OK).

Then, enter the SQL system administrator account login credentials.

During the installation, the FactoryTalk EnergyMetrix SQL database is created,

populated with stock values and updated to the current version.

Advanced.

7. Install activations for Manager and all purchased options by using the Factory talk

Activation Manager.

8. Launch Internet Explorer on the server.

9. Enter the server url (universal resource locator) into the Internet Explorer address

field:

http://localhost/ftenergymetrix

To use FactoryTalk EnergyMetrix software from a client

workstation, substitute the FactoryTalk EnergyMetrix server

name or IP address for ‘localhost’ in the url.

10. When the login screen appears, log in by using the default login credentials.

If any errors are displayed when you try to log in or once you have logged in, please

refer to Troubleshooting

on page 303.

46

Page 47

Activate FactoryTalk EnergyMetrix Software

FactoryTalk EnergyMetrix software is one software product. The Manager and Options

are enabled by installing activations. For example, one activation enables Manager,

another enables the Real Time (RT) option, and one enables the ChartsPlus option.

It is the customer's responsibility to observe the requirements of all software

licenses.

FactoryT alk Ener gyMetrix software may be optionally purchased bundled with Microsoft

SQL Server 2008 R2 Standard Edition Runtime Database licenses. SQL Server bundles

are offered with a processor license (unlimited clients) or a single-client server license (1

client).

Any number of users may access the FactoryTalk EnergyMetrix server through its web

interface.

FactoryTalk EnergyMetrix software requires at minimum the activation for Manager

for operation. Without a Manager activation, the software will not permit users to

log in.

3 • Installation

The basic Manager software includes a license for 10 meters. You can increase the meter

limit on your server at any time by purchasing and installing additional meter licenses in

10, 50, 100, and 500-meter increments.

You can also add options such as RT, FTEMOPC, ChartsPlus, and ReportsPlus in the

same manner. Check with your local Rockwell Automation representative for option

pricing and availability.

FactoryTalk EnergyMetrix software uses FactoryTalk Activation. If you are a new user,

you will need to activate your software by using FactoryTalk Activation because

FactoryTalk EnergyMetrix software no longer ships with physical ‘master disks’ for

activating the base software and options.

If you are upgrading from RSEnergyMetrix software activated with EvRSI activation,

please contact your local Rockwell Automation Sales office or Technical Support for

information to migrate your activations to FactoryTalk activations.

For Rockwell Automation Technical Support in the U.S., call 1 (440) 646-3434. Outside

the U.S., see http://www.rockwellautomation.com/locations/

.

When you log in to the FactoryTalk EnergyMetrix web page, the software checks for the

activation file. If the system fails to detect the activation file, an error is displayed and

logged to FactoryTalk Diagnostics. For more information, refer to the online help included

with the FactoryTalk Manager software.

47

Page 48

FactoryTalk EnergyMetrix Software

How to Activate Your Software

To activate FactoryTalk EnergyMetrix software, perform the following steps.

1. Install the FactoryTalk Manager software available from the Optional Steps screen of

the Install program.

2. Once FactoryTalk Manager is installed, click Start > Programs > Rockwell Software >

FactoryTalk Activation > FactoryTalk Manager to launch the FactoryTalk Manager.

3. Click Get Activations.

4. Follow the instructions to select an activation method, enter activation information,

validate the activation and download the activation to your computer.

5. Refer to the Activation Manager Help topics for additional information.

FactoryT alk EnergyMetrix software does not provide a grace period. The software will not

permit users to log in if a valid activation is not available.

A Host ID is an internal code that uniquely identifies a hardware device. FactoryTalk

Activation uses the Host ID to ‘lock’ each software activation file to a specific hardware

device.

To prevent activations from failing unexpectedly at runtime, do not lock activations to

virtual network adapters, such as those used for virtual private networks (VPN) or virtual

machines. Instead, lock activations to the Host IDs of fixed devices such as hardware

network adapters or hard disk serial numbers. If you need help determining which network

adapters are virtual adapters, contact your Information Technology department.

For help at any point, click the Help link on FactoryTalk Manager software, or click the

Help link on the Rockwell Software Activation website:

https://activate.rockwellautomation.com/

.

For Rockwell Automation Technical Support in the U.S., call 1 (440) 646-3434. Outside

the U.S., see http://www.rockwellautomation.com/locations/

.

48

Page 49

Set up Your System Architecture

We suggest that you set up a system configuration that helps you visualize and understand

the energy use patterns of your plant or enterprise.

A project is organized in a familiar tree-structured fashion. The user constructs a tree made

up of domains and groups in a hierarchy. A typical and popular way to organize a project

tree is shown below.

C

HAPTER

4

At the ‘root’ of the tree is a top-level domain that represents a plant named ‘Efficient

Industries Plant 1’. Under the top-level domain are two sub-domains, ‘Accounting’ and

‘Engineering’. These are set up to address two groups of system users, those interested in

energy usage by department or process (Accounting), and those interested in usage by

utility type (Engineering).

Before we move on, let’s define some terms.

A Group, shown as a folder in the tree, is simply a collection of Devices and Meters

(we’ll define these a little later).

A Domain is a special group with security assigned. Domains also may contain

Devices, Meters, and other objects, such as Reports, Rate Schedules, and Multipurpose Report Scripts.

The main reason you would create a Domain rather than a Group is to control user access

to the meters and other objects in the group.

There is a lot of flexibility in setting up the project structure. For instance, a corporate user

with multiple locations can create a top-level domain for corporate, and sub-domains for

each plant. The security configuration might permit plant users access only to the plant

domains, while corporate users would have access to the corporate domain and all subdomains.

49

Page 50

FactoryTalk EnergyMetrix Software

You can assign a number of mete rs to a Group or domain, which represents a department,

division, or process. Meters can be assigned to multiple groups and domains, letting you

create different views of meter data. Groups and domains can be nested.

A user will encounter the project tree in several places as he or she navigates around the

web interface.

In the System tab, the entire tree is found in the Groups folder. This is where you build

the tree by adding groups and domains. This is the only place the tree can be edited.

Also in the System tab, a copy of the complete tree (domains and groups) is found in

the Devices folder. This is where you create and maintain Devices.

A copy of the tree that includes only Domains is found in the Roles and Users, Rate

Schedules, and Multi-purpose Report Script folders in the System tab.

The Meters tab is arranged with a complete copy of the tree.

The Reports and Custom tabs are organized with copies of the tree with only

Domains.

The tree is refreshed whenever a user clicks the Save button in

an object that resides in the tree, raising a database change

event. For instance, it refreshes when a Device, Meter, Group,

Rate Schedule, or Report is saved. The tree does not refresh

when a Meter Tag is saved.

Before you try to set up Devices and Meters, you must create at

least one Domain. Although roles, users, reports, rate schedules,

and multi-purpose report scripts may be global in scope,

devices, and meters must be assigned to groups.

Set up a New Group or Domain

1. Select up the System tab in the navigation tree.

2. Click on the Groups folder in the tree.

50

Page 51

3. Click Add.

4 • Set up Your System Architecture

4. Enter the appropriate information into the data fields.

Parent group - if this is a subgroup, type in the name of its parent group.

This group is a domain checkbox - check if this group is to be a domain that

Roles, Meters and Reports can be assigned to.

Name - type in a name for this group.

Notes - enter any additional information you desire in the Notes field.

Default log rate - enter the interval in minutes that you want to log data from your

meters. The default rate for the group can be adjusted for individual meters.

Reports title - Type in the first and second line of the report title that will be used

for all meters in this group.

5. Click Add.

Your new group now appears in the Groups folder in the System tree.

51

Page 52

FactoryTalk EnergyMetrix Software

Name Fields

Name fields can be up to 50 characters in length, except Rate Schedule names can be any