Page 1

8720MC Regenerative

Power Supply

Installation Manual

Page 2

Page 3

Important User Information

Because of the variety of uses for the products described in this publication,

those responsible for the application and use of this control equipment must

satisfy themselves that all necessary steps have been taken to assure that each

application and use meets all performance and safety requirements, including

any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this

guide are intended solely for purposes of example. Since there are many

variables and requirements associated with any particular installation,

Allen-Bradley does not assume responsibility or liability (to include

intellectual property liability) for actual use based upon the examples shown

in this publication.

Allen-Bradley publication SGI-1.1, Safety Guideline for the Application,

Installation and Maintenance of Solid-State Control (avialable from your

local Allen-Bradley office), describes some inportant differences between

solid-state equipment and electromechanical devices that should be taken

into consideration when applying products such as those described in this

publication.

Reproduction of the contents of this copyrighted publication, in whole or

part, without written permission of Rockwell Automation, is prohibited.

ATTENTION: Identifies information about practices

!

or circumstances that can lead to personal injury or death,

property damage, or economic loss.

Attention help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important:

Identifies information that is especially important for successful

application and understanding of the product.

Page 4

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within the

European Union and EEA regions. It has been designed and tested to meet

the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following standards,

in whole or in part, documented in a technical construction file:

• EN 50081-2 EMC - Generic Emission Standard, Part 2 Industrial Environment

• EN 50082-2-EMC - Generic Immunity Standard, Part 2 Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage, by

applying the safety requirements of EN 61131-2 Programmable Controllers,

Part 2 - Equipment Requirements and Tests. For specific information

required by EN 61131-2, see the appropriate sections in this publication, as

well as the Allen-Bradley pulbication Industrial Automation Wiring and

Grounding Guidelines For Noise Immunity, publication 1770-4.1.

This equipment is classified as open equipment and must be mounted in an

enclosure during operation to provide safety protection.

Page 5

Table of Contents

Contents of This

Manual

About 8720MC-RSP

Regenerative Power

Supply

Chapter 1

Introduction .................................................................................. 1-1

Finding Information ...................................................................... 1-1

Assumptions About the Audience................................................ 1-2

Notes on Handling the 8720MC-RPS Regenerative Power

Supply .......................................................................................... 1-3

Chapter 2

Model Numbers of the 8720MC-RPS Regenerative Power

Supply and its Accessories.......................................................... 2-1

Power Rating................................................................................ 2-2

Appearance of the 8720MC-RPS Regenerative Power Supply.. 2-2

Appearance of Model 8720MC-RPS027 and

8720MC-RPS065 ................................................................... 2-2

Appearance of Model 8720MC-RPS190................................ 2-4

Main Components and Locations ................................................ 2-5

Terminal Blocks on the Main Circuit ............................................ 2-10

Main Power Terminal Block (TB1) for Model 8720MC-

RPS027 and 8720MC-RPS065.............................................. 2-12

Control Power Terminal Block (TB2) for Model 8720MC-

RPS027 and 8720MC-RPS065.............................................. 2-12

Mainl Power Terminal Bar for Model 8720MC-RPS190 ........ 2-13

Control Power Terminal Block (TB2) and Control Terminal

Block (TB4) for Model 8720MC-RPS190 ............................... 2-13

Regulator Board ........................................................................... 2-14

Jumpers and Switches ........................................................... 2-15

Sequence Signal Terminal Block (TB3)................................. 2-17

Installation

Wiring

Chapter 3

Installation Site............................................................................. 3-1

Environmental Conditions to be Met ...................................... 3-1

Required Total Area ............................................................... 3-2

Recommended Air Flow Clearance ....................................... 3-7

Notes on Installation .................................................................... 3-7

Chapter 4

Recommended Wire Sizes .......................................................... 4-1

Recommended Wire Sizes for Power Wiring to the Main

Power Terminal Block (TB1) and the Main Power Terminal

Bars ........................................................................................ 4-2

Recommended Wire Sizes for Power Wiring to the Control

Power Terminal Block (TB2) and the Control Terminal

Block (TB4)............................................................................. 4-2

AC Input Power Wiring fot Model 8720MC-RPS027 and

8720MC-RPS065 ......................................................................... 4-3

When Model 8720MC-RPS027 or 8720MC-RPS065 is

operated in the Power Regeneration Mode only ................... 4-7

When Model 8720MC-RPS027 and 8720MC-RPS065 are

adapted to Capacitors having large capacity......................... 4-9

Installing Circuit Breaker ........................................................ 4-11

Page 6

ii

Table of Contents

Installing Main Magnetic Contactor........................................ 4-11

Installing Reactor.................................................................... 4-12

Installing Varistor.................................................................... 4-13

Installing Harmonic Filter........................................................ 4-14

Installing Input Fuses ............................................................. 4-14

Installing Line Filters .............................................................. 4-14

Bus Bar and Output Fuses..................................................... 4-15

AC Input Power Wiring for Model 8720MC-RPS190................... 4-16

When Model 8720MC-RPS190 is operated in the Power

Regeneration Mode only ........................................................ 4-22

When Model 8720MC-RPS190 is adapted to Capacitors

having large capacity ............................................................. 4-24

Installing Circuit Breaker - 8720MCRPS190.......................... 4-26

Installing ACL Unit (Reactor Assembly) - 8720MC-

RPS190 .................................................................................. 4-26

Installing Fuses - 8720MC-RPS190....................................... 4-27

Installing 8720MC-EF190-VB EMC Filter Unit....................... 4-28

Installing DC Bus Power Output Wiring - All RPS units .............. 4-29

Grounding the 8720MC-RPS Regenerative Power Supply......... 4-29

Wiring To Comply with EMC........................................................ 4-30

Sequence Signal Wiring............................................................... 4-32

Sequence Signal Wiring ......................................................... 4-32

Operation Timing of Sequence Control Signals .................... 4-33

Installing Ribbon Cables .............................................................. 4-36

Notes on Wiring............................................................................ 4-37

Start and Adjustment

Operation Panel

Parameters

Chapter 5

Checking before Powering up the 8720MC-RPS Regenerative

Power Supply .................................................................................. 5-1

Verifying the Installation ............................................................ 5-1

Verifying the Rating of the 8720MC-RPS Regenerative

Power Supply ............................................................................ 5-2

Verifying Wiring ......................................................................... 5-2

Powering up the 8720MC-RPS Regenerative Power Supply ........ 5-2

Operating the 8720MC-RPS Regenerative Power Supply............. 5-3

Chapter 6

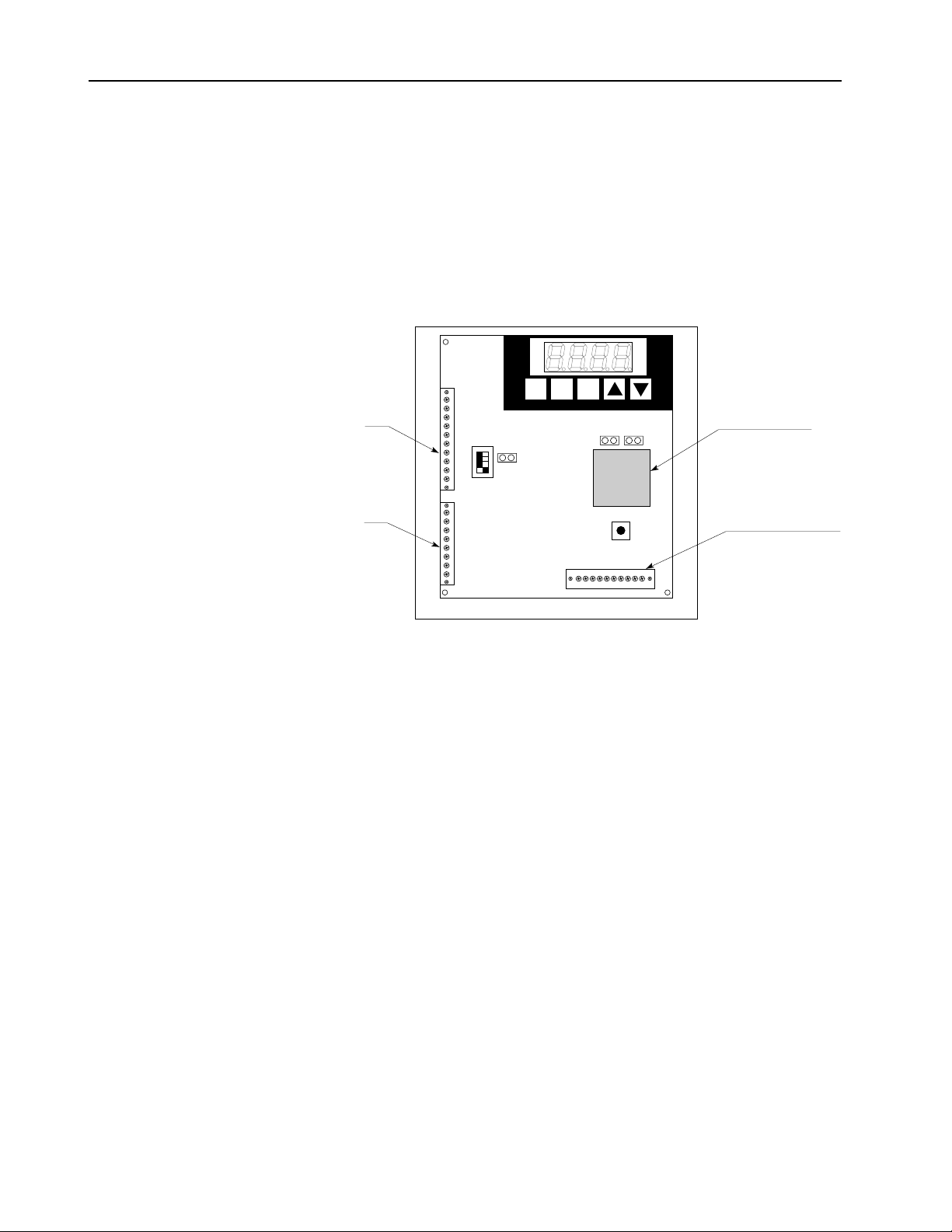

Configuration of the Operation Panel ............................................. 6-1

Operation Modes............................................................................. 6-1

Monitor Mode............................................................................. 6-2

Program Mode........................................................................... 6-3

Display............................................................................................. 6-3

Keypad ............................................................................................ 6-4

Status LEDs .................................................................................... 6-5

Chapter 7

Parameter Types............................................................................. 7-1

Protecting Parameters with Password............................................ 7-3

Displaying and Changing Parameter Values.................................. 7-3

User Parameters ............................................................................. 7-3

Factory Parameters ........................................................................ 7-5

Page 7

Table of Contents

iii

Error Codes and

Warning Buzzer

Inspecting Trouble

and Recovering

Special Replacement

Parts

Outline Drawings of

the Peripheral Devices

Chapter 8

Contents of Error Codes and Recovering ...................................... 8-2

Accessing and Clearing the Entries in the Error Log ..................... 8-5

Recovering from Fatal Error ........................................................... 8-6

Warning Buzzer............................................................................... 8-6

Chapter 9

Safety Precautions .......................................................................... 9-1

Preliminary Review ......................................................................... 9-2

Troubleshooting Flow Charts.......................................................... 9-2

8720MC-RPS Regenerative Power Supply Does Not Run ...... 9-2

DC Bus Voltage Does Not Go Up ............................................. 9-3

Chapter 10

Chapter 11

Outline Drawings of the Reactors................................................... 11-1

Outline Drawing of the Varistors..................................................... 11-3

Outline Drawing of the Harmonic Filters......................................... 11-4

Outline Drawing of the Line Filters ................................................. 11-5

8720MC-EF190-VB EMC Filter Unit for Model 8720MC-RPS190BM

and 8720MC-RPS190BS ................................................................ 11-7

Technical Specifications

Default Parameter Settings

Control Block Diagram

Appendix A

Appendix B

Appendix C

Page 8

iv

Table of Contents

End of Table of Contents

Page 9

Contents of This Manual

Chapter

1

Introduction

Finding Information

The 8720MC-RPS Regenerative Power Supply Bidirectional

Converter is a sinusoidal PWM converter which can control

increase of DC bus voltage and perform continuous power

generation.

The 8720MC-RPS Regenerative Power Supply, therefore, can be

used as power supply unit for various drives and inverter units.

This instruction manual covers the 8720MC-RPS Regenerative

Power Supply for 380-460 VAC, and describes the hardware

and the start-up and programming procedure for the 8720MC-RPS

Regenerative Power Supply. Read and understand this manual

before proceeding.

All the following units are UL/C-UL listed:

8720MC-RPS027BM,

8720MC-RPS065BM and 8720MC-RPS065BS,

8720MC-RPS190BM and 8720MC-RPS190BS

Also, the Declaration of Conformity with the requirement for CE

Mark was already issued for all the units.

The 8720MC-RPS Regenerative Power Supply is a bidirectional

converter with the following features:

• Use of chopper type voltage increasing method with sinusoidal

pulse-width-modulated (PWM) waveform control.

• Programmable DC bus voltage.

• Continuous power regeneration.

• Attenuation of the higher order harmonics in the line current.

• Safety interlocks and protection.

This manual describes the details of the 8720MC-RPS Regenerative

Power Supply in order to provide the user with a complete

understanding of the installation, wiring, operation and adjustment

of the product. As an aid in finding information in this manual,

each chapter is briefly described below:

• Chapter 1: Contents of This Manual

Provides situation for acquiring UL Marks and CE

Marks for the 8720MC-RPS Regenerative Power

Supply and information on how this manual is

organized and where to find additional

information.

Page 10

1-2

Contents of This Manual

• Chapter 2: About 8720MC-RPS Regenerative Power Supply

Identifies components of the 8720MC-RPS

Regenerative Power Supply, shows their locations,

and describes the main components.

• Chapter 3: Installation

Describes how to mount the 8720MC-RPS

Regenerative Power Supply properly.

• Chapter 4: Wiring

Describes how to properly wire and connect the

8720MC-RPS Regenerative Power Supply.

• Chapter 5: Start and Adjustment

Provides information on how to perform a final

check before power is applied, and instructions on

basic operation.

• Chapter 6: Operation Panel

Describes the composition and contents of the

operation panel.

• Chapter 7: Parameters

Provides detailed description of each parameter.

• Chapter 8: Error Codes and Warning Buzzer

Describes contents of error codes and how to

correct problems.

• Chapter 9: Inspecting Trouble and Recovering

Describes how to inspect and troubleshoot the

8720MC-RPS Regenerative Power Supply.

• Chapter 10: Special Replacement Parts

Provides a list of required replacement parts.

• Chapter 11: Outline Drawings of the Peripheral Devices

Provides outline dimensions of converters,

reactors, varistors, harmonic filters and line filters.

• Appendix A: Technical Specifications

Lists specifications of the 8720MC-RPS

Regenerative Power Supply in table form.

• Appendix B: Default Parameter Settings

Provides the default values of the parameters in

table form.

• Appendix C: Control Block Diagram

Provides a control block diagram.

Assumptions About the Audience

This manual is intended for electrical personnel familiar with the

operation of this equipment and the hazards involved.

Page 11

Contents of This Manual

1-3

Notes on Handling the

8720MC-RPS Regenerative

Power Supply

The following three labels are put on the 8720MC-RPS

Regenerative Power Supply, advising the user of the notes on

handling the unit. Read and understand the contents before using

the unit.

!

PWR

CAUTION!

WHEN YOU APPL Y POWER

AGAIN, VERIFY THAT

THIS LAMP "PWR" IS

TURNED OFF.

ME-B6013

!

DANGER

RISK OF ELECTRICAL SHOCK. DISCONNECT INPUT

POWER BEFORE SERVICING EQUIPMENT.

ME-B6015

CAUTION !

THIS EQUIPMENT MUST BE MOUNTED IN A SUITABLE

UL RECOGNIZED ENCLOSURE OR NEMA ENCLOSURE.

USE COPPER 60/75 DEGREE C WIRE ONLY.

Page 12

1-4

Contents of This Manual

End of Chapter

Page 13

Chapter

About 8720MC-RPS Regenerative Power Supply

This chapter describes model numbers, major components, their

locations, and terminal blocks of 8720MC-RPS Regenerative Power

Supply.

2

Model Numbers of the 8720MCRPS Regenerative Power

Supply and its Accessories

For operation of the 8720MC-RPS Regenerative Power Supply, a

line reactor is required for each incoming phase as well as a

varistor, a harmonic filter and a contactor. The following figure

shows the model numbers of the 8720MC-RPS Regenerative Power

Supply and its accessories.

Regenerative Power Supply

8720MC-RPSxxxvm-opt

BASE CATALOG NUMBER - CONVERTER

REGENERATIVE POWER SUPPLY SIZE

027 = 27 amp

065 = 65 amp

190 = 190 amp

INPUT VOLTAGE

B = 380 TO 460 VAC

TYPE

M = master

S = slave

See Note 1

Note 1: Blank includes the 8720MC - RPS only as a spare part.

HV2 option includes the 8720MC - RPS as well as 8720MC-HF-B2 harmonic

filter and 8720MC-VA-B varistor. HV2 option, however, is applied only to

8720MC-RPS027 and 8720MC-RPS065.

Line Reactor

8720MC-LRxx-ayyyb

Inductance as % Voltage Drop

03 = 3%

05 = 5%

10 = 10%

14 = 14%

Enclosure

blank = open

A = NEMA type 1

Current Rating

032 = 32 Amp

048 = 48 Amp

062 = 60 Amp

070 = 80 Amp

100 = 100 Amp

Voltage

B = 380 to 460 VAC

Voltage

B2 = 380 to 460 VAC

Voltage

B = 380 to 460 VAC

Current Rating

190 = 190 Amp

Voltage

B = 380 to 460 VAC

Harmonic Filter

8720MC-HF-b

Varistor

8720MC-VA-b

EMC Filter Unit

8720MC-EFxxx-Vb

Page 14

2-2

REGENERATIVE POWER SUPPLY

MC

READY

FAULT

PROGRAM

kW

About 8720MC-RPS Regenerative Power Supply

Power Rating

Appearance of the 8720MCRPS Regenerative Power

Supply

Power rating of 8720MC-RPS Regenerative Power Supply depends

on the number of units connected in parallel as shown in the table

below. Up to three units can be connected.

Table 2.1

Kind, Connection and Power Ratings

Kind of Unit

15 kW

37 kW

Connection

Single Unit

Single Unit

Two paralleled units

Model Number

8720MC-RPS027BM x 1

8720MC-RPS065BM x 1

8720MC-RPS065BM +

Power Rating

15 kW

37 kW

75 kW

8720MC-RPS065BS x 1

Three paralleled units

8720MC-RPS065BM +

110 kW

8720MC-RPS065BS x 2

125 kW

Single Unit

Two paralleled units

8720MC-RPS190BM x 1

8720MC-RPS190BM +

125 kW

250 kW

8720MC-RPS190BS x 1

Three paralleled units

8720MC-RPS190BM +

375 kW

8720MC-RPS190BS x 2

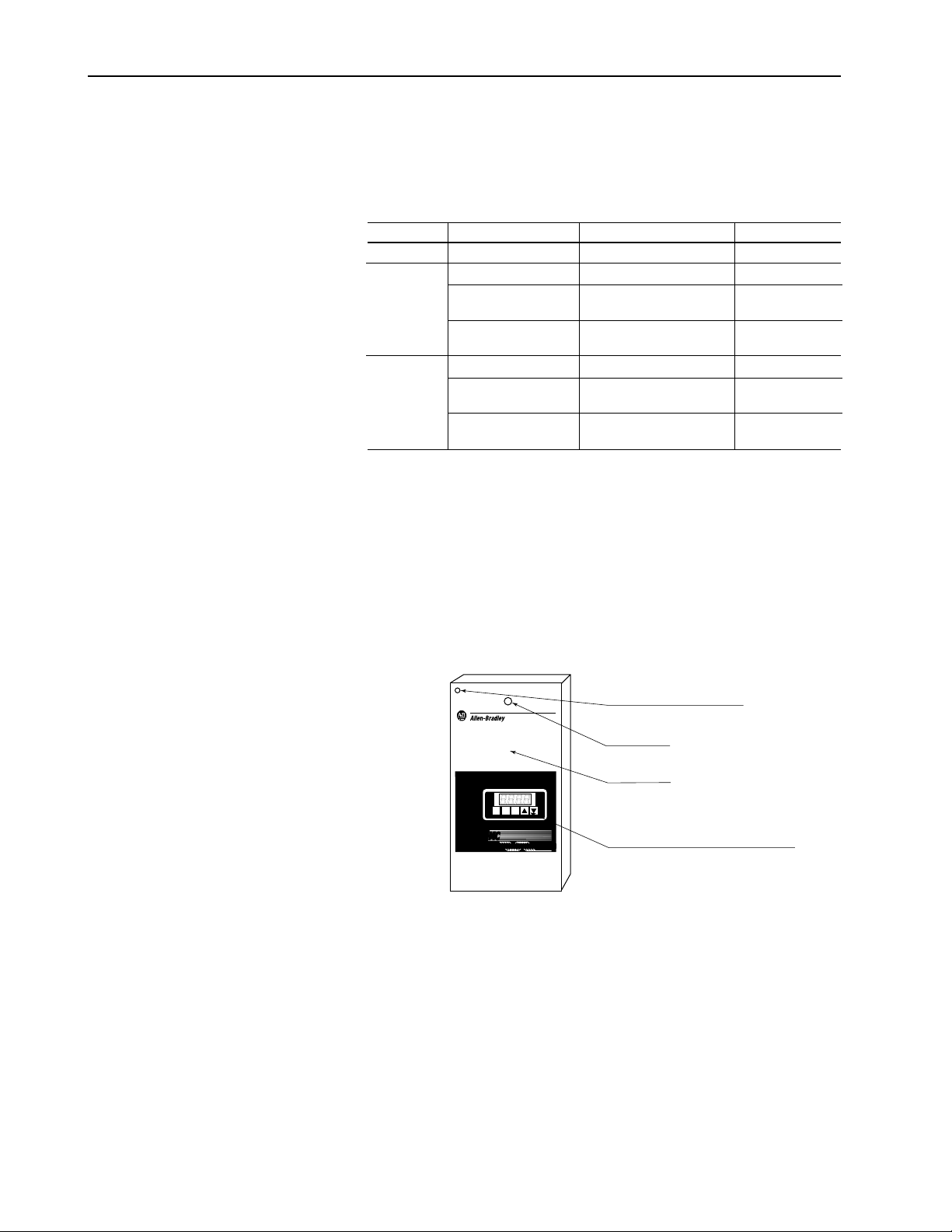

Appearance of Model 8720MC-RPS027 and 8720MC-RPS065

The figure below shows the front view of the 8720MC-RPS027 and

8720MC-RPS065 covered by the front cover.

The operation panel (only for master unit) and the power lamp can

be seen through the front cover. All the terminals blocks to

connect wiring are covered by the front cover.

Unit Front View

Hole for Cover Fixing Screw <1

Power Lamp

Front Cover

8720

READY

FAULT

PROGRAM

M

A

V

kW

ENT

PRG

RST

C

E

G

E

R

Y

L

P

P

S

U

R

W

E

P

O

IV

E

T

A

R

E

N

Operation Panel (only for Master Unit)

1> Model 8720MC-RPS027 has the cover fixing screw

at the right upper corner instead of the left upper corner.

Page 15

About 8720MC-RPS Regenerative Power Supply

READY

FAULT

PROGRAM

kW

POWER

Control Power Terminal Block (TB2)

Unit After Removing Regulator Board

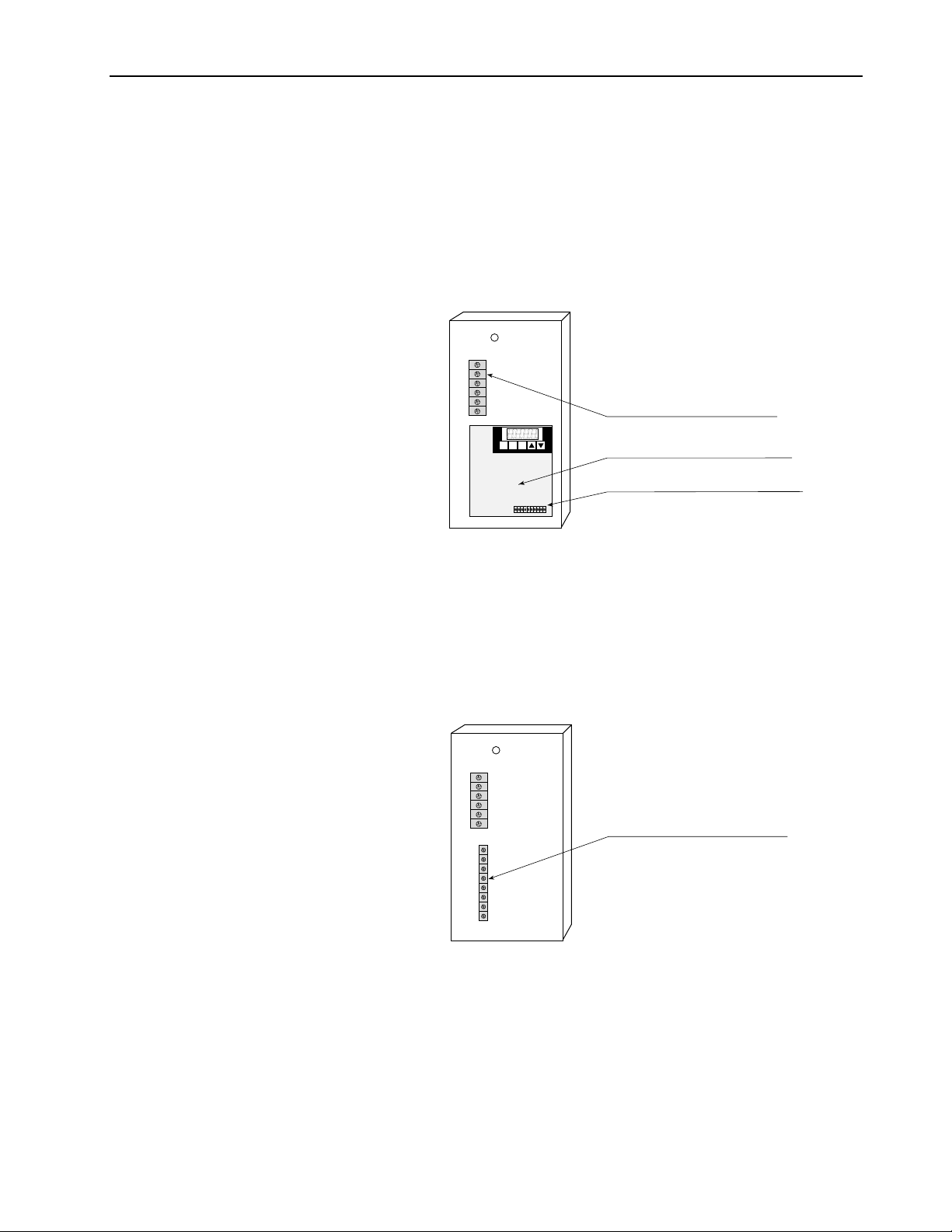

When the front cover is removed from the 8720MC-RPS027 and

8720MC-RPS065 , the main power terminal block (TB1) and the

Regulator Board (only for master unit) will appear as shown in the

following figure. To remove the front cover, first remove the screw

at the upper left corner of the unit, and then lift up the cover. Note,

however, that Model 8720MC-RPS027 has the cover fixing screw

at the upper right corner instead of the upper left corner. Do not

drop the screw from the cover.

Unit After Removing Front Cover

POWER

Main Power Terminal Block (TB1)

READY

FAULT

PROGRAM

A

V

kW

ENT

PRG

RST

Regulator Board (only for Master Unit)

Sequence Signal Terminal Block (TB3)

2-3

The control power terminal block (TB2) for Model 8720MCRPS027 and 8720MC-RPS065 will be disclosed as shown in the

figure below, when the Regulator Board is opened to the left hand

side by removing the two fixing screws on the right hand side of the

bracket supporting the Regulator Board.

Page 16

2-4

REGENERATIVE POWER SUPPLY

8720

MC

About 8720MC-RPS Regenerative Power Supply

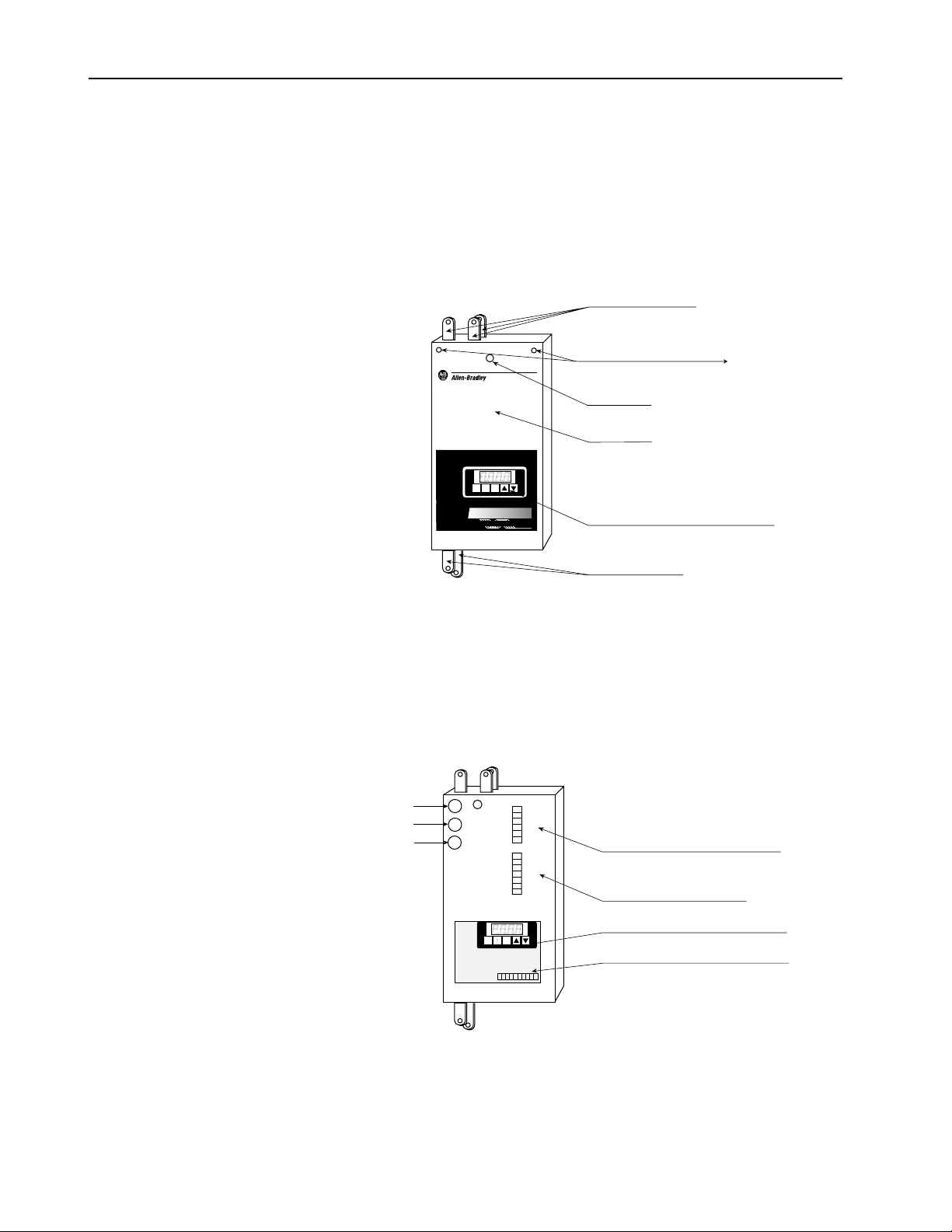

Appearance of Model 8720MC-RPS190

The figure below shows the front view of the 8720MC-RPS190

covered by the front cover.

This unit has the main power terminals L1 to L3 at the top of the

unit, and DC bus terminals P and N at the bottom of the unit.

L2

L3

L1

Main Power Terminals

Unit Front View

Hole for Cover Fixing Screw

Power Lamp

Front Cover

READY

FAULT

PROGRAM kW

M

8720

PN

A

V

ENT

PRG

RST

C

E

G

E

R

Y

L

P

P

S

U

R

W

E

P

O

IV

E

T

A

R

E

N

Operation Panel (only for Master Unit)

DC Bus Terminals

When the front cover is removed from the 8720MC-RPS190

Regenerative Power Supply, the Control Power Terminal Block

(TB2), the Control Terminal Block (TB4), the Regulator Board

(only for master unit) and Sequence Signal Terminal Block (TB3)

will appear as shown in the following figure.

Fuse1

Fuse2

Fuse3

READY

FAULT

PROGRAM kW

ENT

PRG

RST

L

L

L

PR1

PR2

PR3

+24V3

0V3

SENS

+24V2

0V2

MC1

MC2

Unit After Removing Front Cover

1AUX

2AUX

3AUX

Control Power Terminak Block (TB2)

Control Terminal Block (TB4)

A

V

Regulator Board (only for Master Unit)

Sequence Signal Terminal Block (TB3)

Page 17

About 8720MC-RPS Regenerative Power Supply

2-5

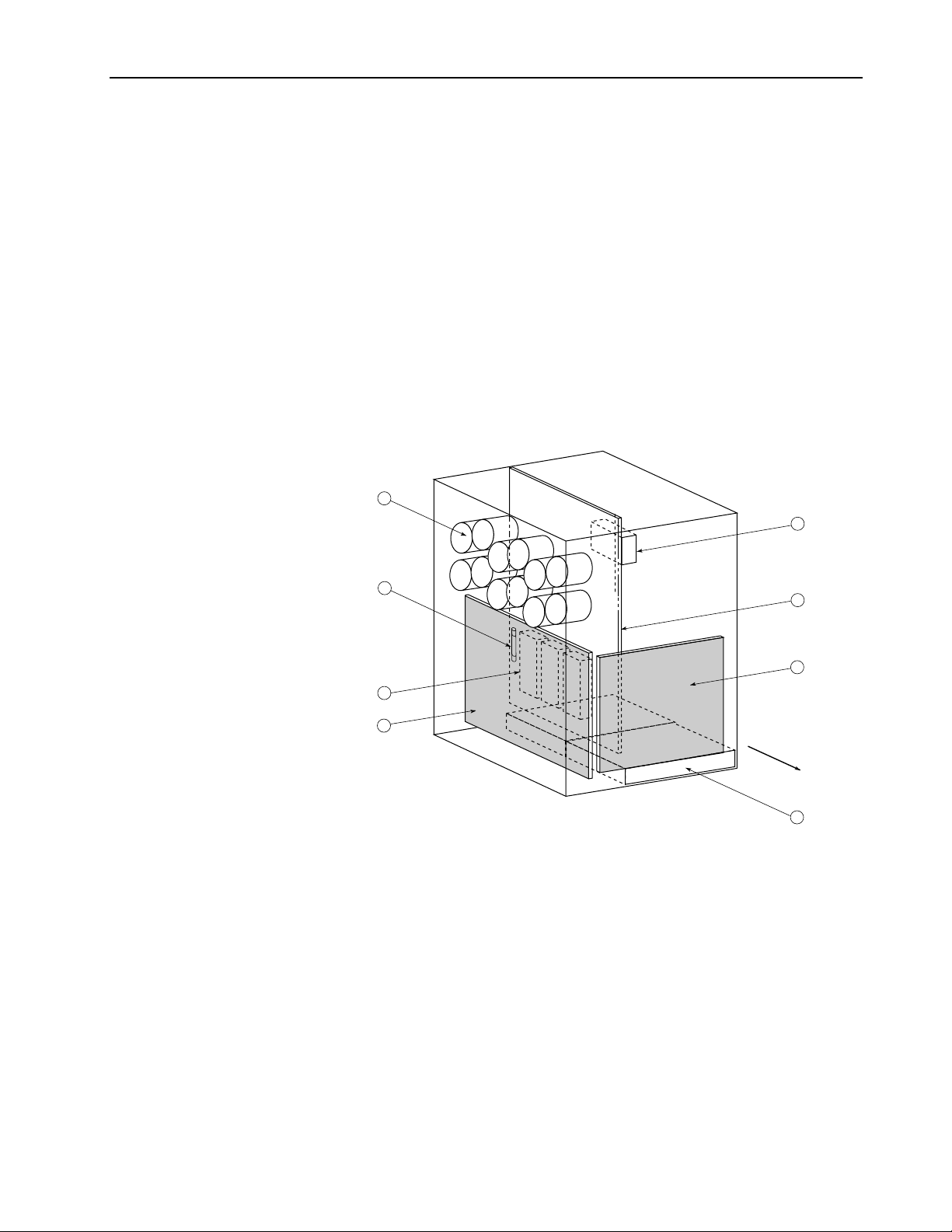

Main Components and Locations

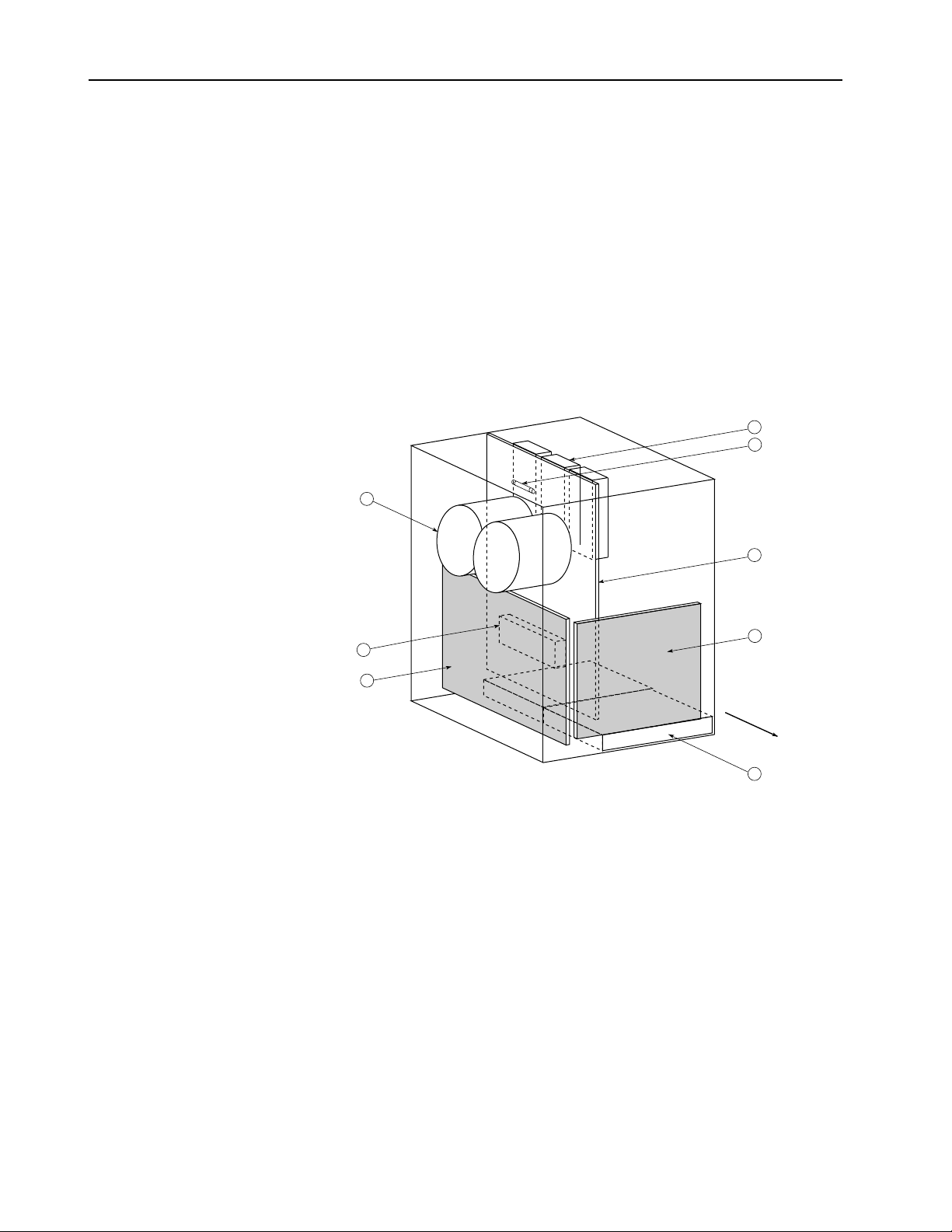

Model 8720MC-RPS027BM has the following main components.

The identification numbers provided correspond to the numbers

used in the following figure. The main components are included in

the special replacement part list shown in Chapter 10.

1. Regulator Board (BDSR) (only master unit has a Regulator

Board, not on slave unit)

2. Power Interface Board (PIFS)

3. Driver Board (RCPB)

4. Bus Capacitors

5. Cooling Fan

6. Power Modules

7. Fuse-1

8. Precharge/Discharge Resistor

The following figure shows the locations of the main components

of Model 8720MC2-RPS027BM.

4

8

7

6

2

3

1

Unit Front Side

5

Page 18

2-6

About 8720MC-RPS Regenerative Power Supply

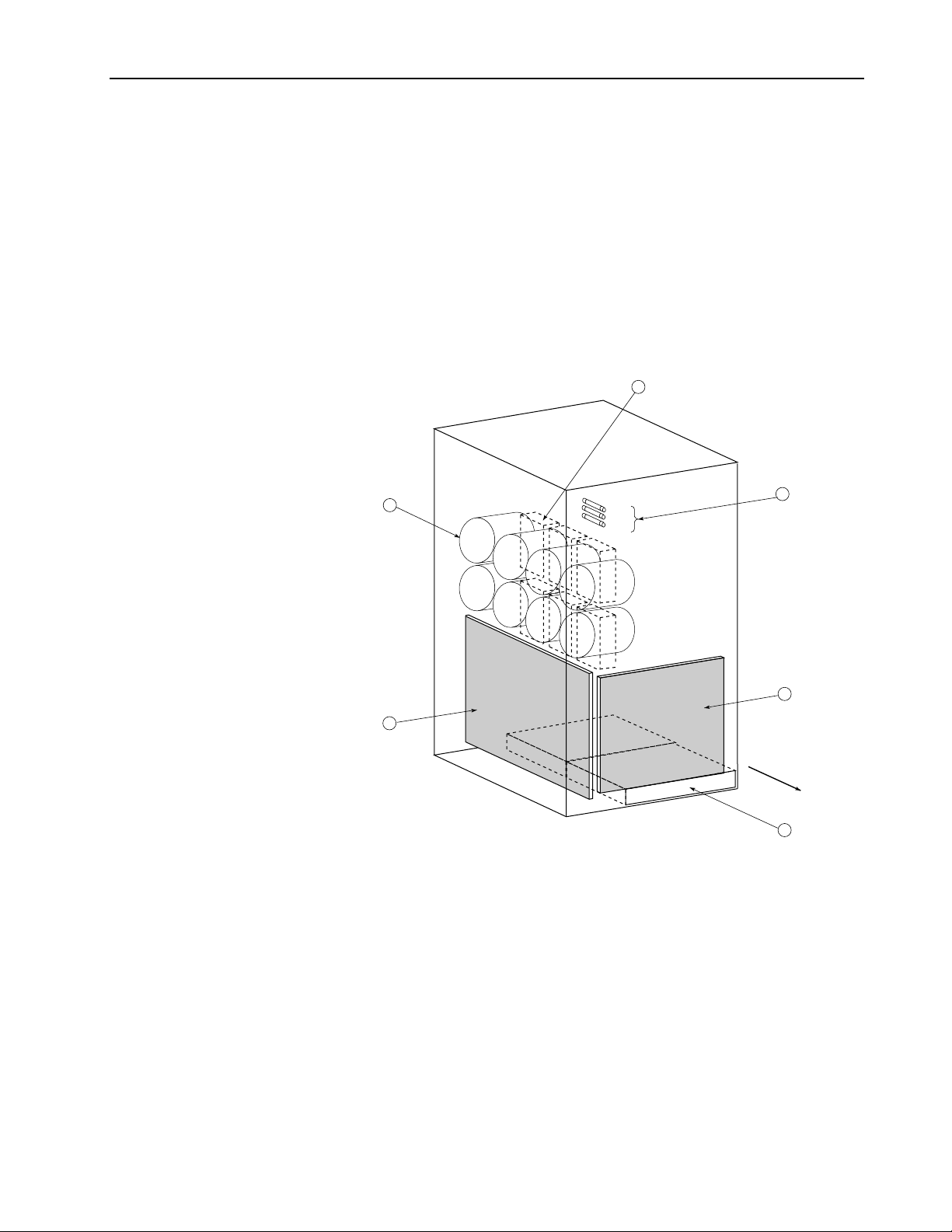

Model 8720MC-RPS065BM and 8720MC-RPS065BS have the

following main components.

1. Regulator Board (BDSR) (only master unit has a Regulator

Board, not on slave unit)

2. Power Interface Board (PIFS)

3. Driver Board (RCPB)

4. Bus Capacitors

5. Cooling Fan

6. Power Modules

7. Fuse-1

8. Precharge/Discharge Resistor

The following figure shows the locations of main components of

Model 8720MC-RPS065BM and 8720MC-RPS065BS.

6

7

4

3

8

2

1

Unit Front Side

5

Page 19

About 8720MC-RPS Regenerative Power Supply

Model 8720MC-RPS190BM and 8720MC-RPS190BS have the

following main components.

1. Regulator Board (BDSR) (only master unit has a Regulator

Board, not on slave unit)

2. Power Interface Board (PIFS)

3. Bus Capacitors

4. Cooling Fan

5. Power Modules

6. Fuses 1, 2, 3

The following figure shows the locations of main components of

Model 8720MC-RPS190BM and 8720MC-RPS190BS.

5

2-7

3

2

FU1

FU2

FU3

6

1

Unit Front Side

4

Page 20

2-8

READY

FAULT

PROGRAMkWkW

About 8720MC-RPS Regenerative Power Supply

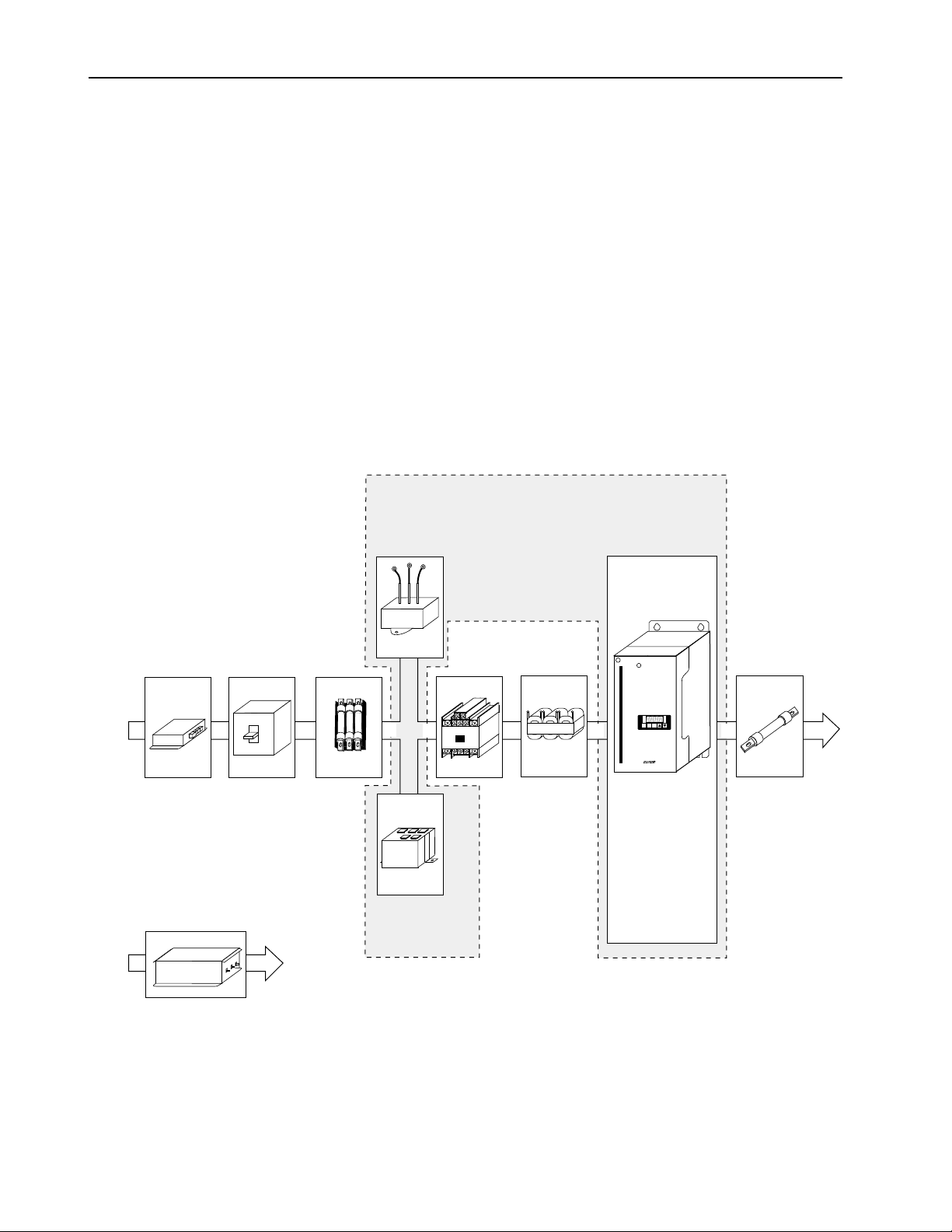

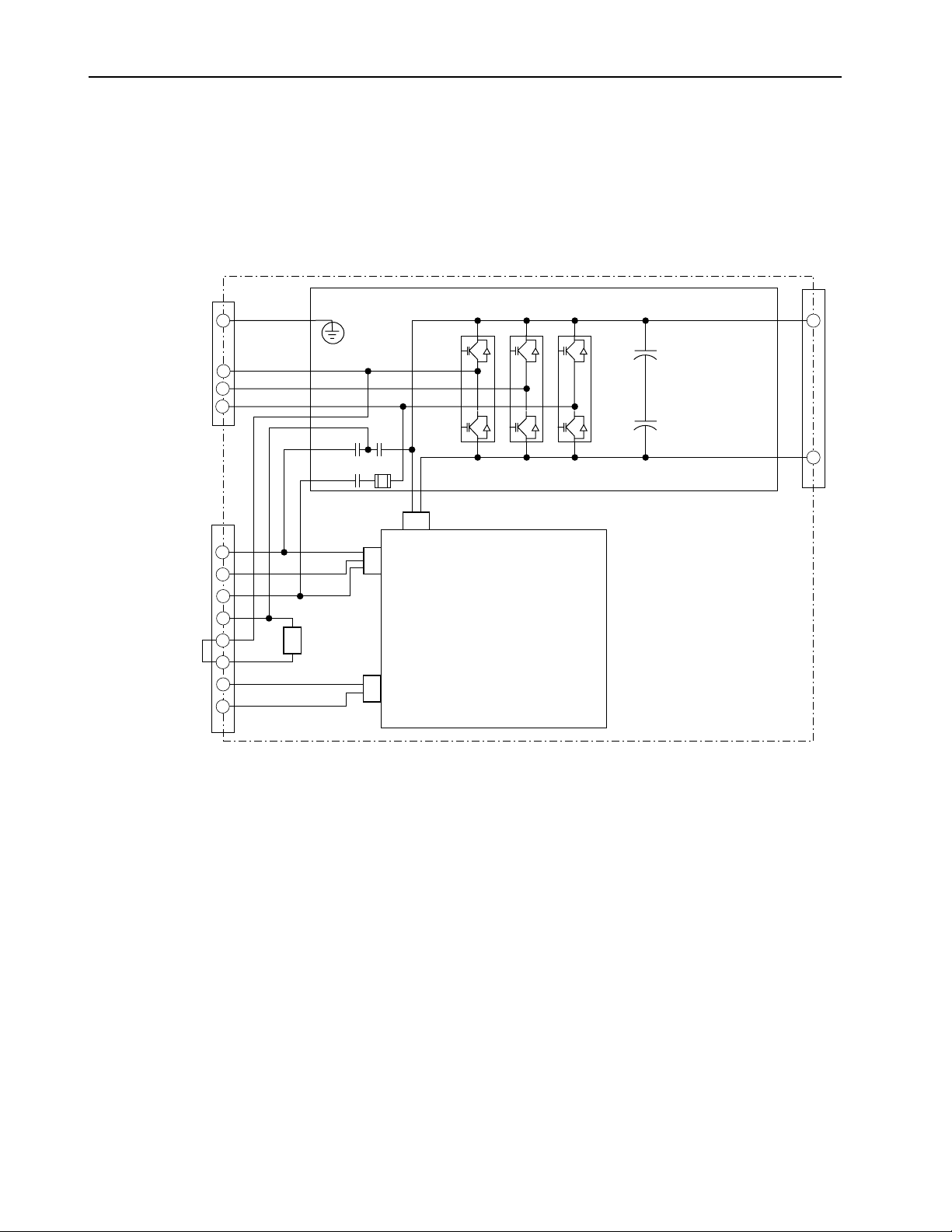

Model 8720MC-RPS027 and 8720MC-RPS065 are composed of the

following components.

1) 8720MC-RPS

2) Line filter for main circuit*

3) Line filter for sequence power*

4) Circuit breaker

5) AC input fuse

6) DC output fuse

7) Varistor

8) Harmonic filter

9) Main magnetic contactor

10) Reactor

* Not necessary when compliance with CE mark is not required.

The following figure shows system configuration of 8720MCRPS027 and 8720MC-RPS065.

8720MC-RPSxxxvm-HV2

2) Line Filter for

Main Circuit

*

3) Line Filter for

Sequence Power

4) Circuit

Breaker

*

5) AC

Input Fuse

7) Varistor

8720MC-VA-B

9) Main

Magnetic

Contactor

8) Harmonic Filter

8720MC-HF-B2

10)

Reactor

8720MC-LR

1) 8720MC-RPS

POWER

ss

4000

Synchronous Rectifier

A

READY

FAULT

V

PROGRAM

ENT

PRG

RST

6)DC Output

Fuse

Page 21

READY

FAUL

PROGRAM

kW

About 8720MC-RPS Regenerative Power Supply

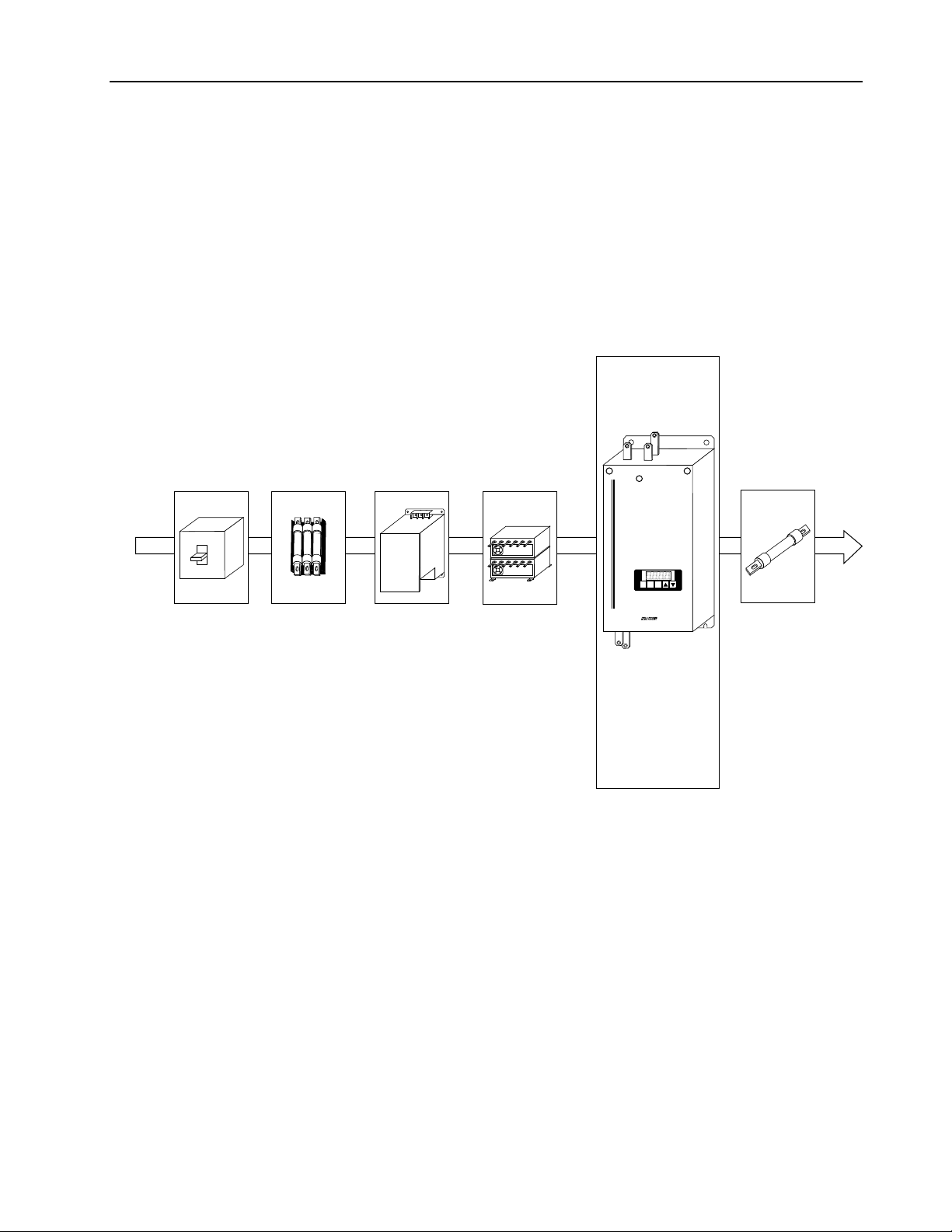

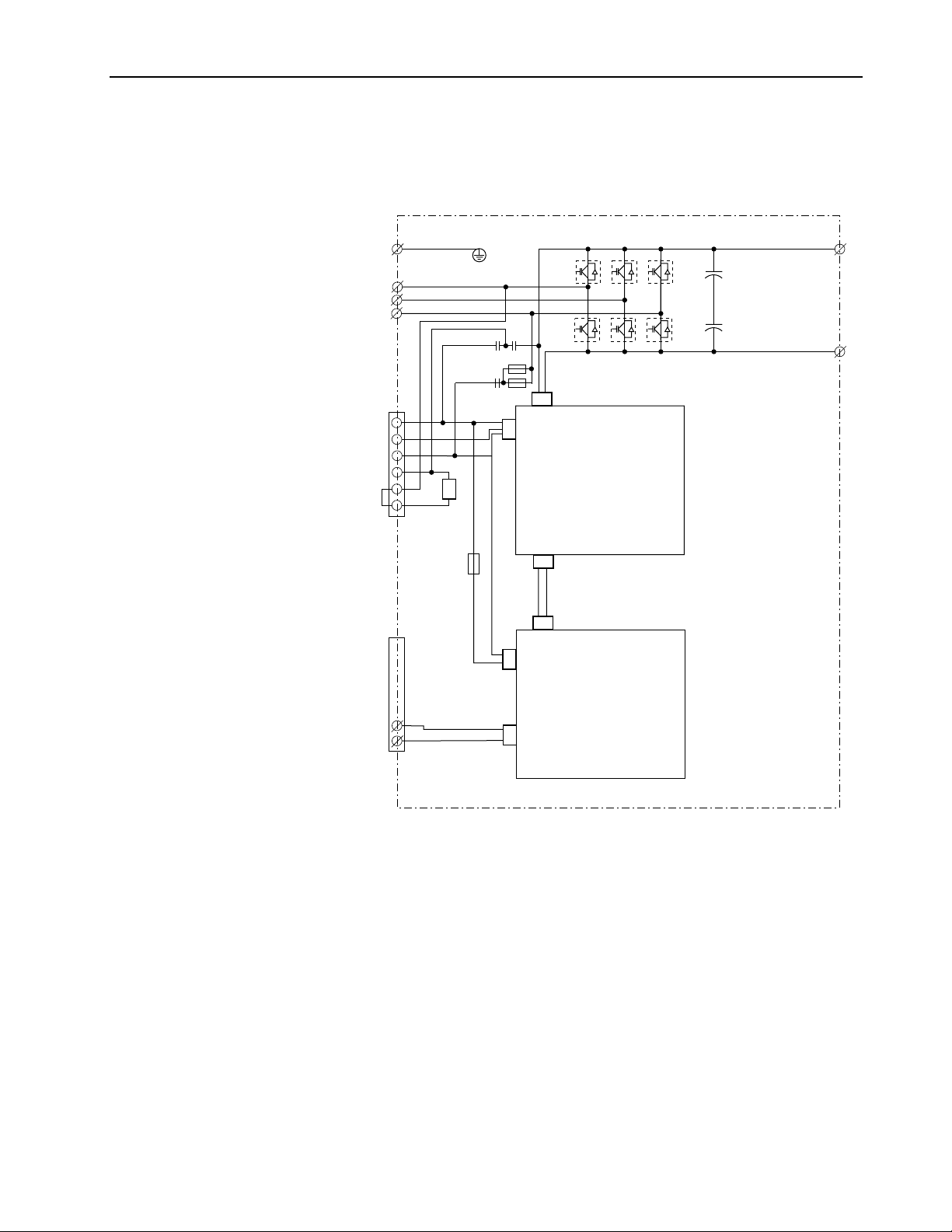

Model 8720MC-RPS190 is composed of the following components.

1) 8720MC-RPS

2) Circuit breaker

3) AC input fuse

4) DC output fuse

5) EMC filter unit

6) ACL unit

The following figure shows system configuration of Model

8720MC-RPS190.

1) 8720MC-RPS

2-9

2) Circuit

Breaker

3) AC Input

Fuse

5) EMC

Filter Unit

8720MC-EF

6) ACL Unit

8720MC-LR

POWER

ss

4000

Synchronous Rectifier

A

READY

FAUL

T

V

PROGRAM

kW

ENT

PRG

RST

For more information, refer to Chapter 4 of this manual.

4) DC Output

Fuse

Page 22

2-10

About 8720MC-RPS Regenerative Power Supply

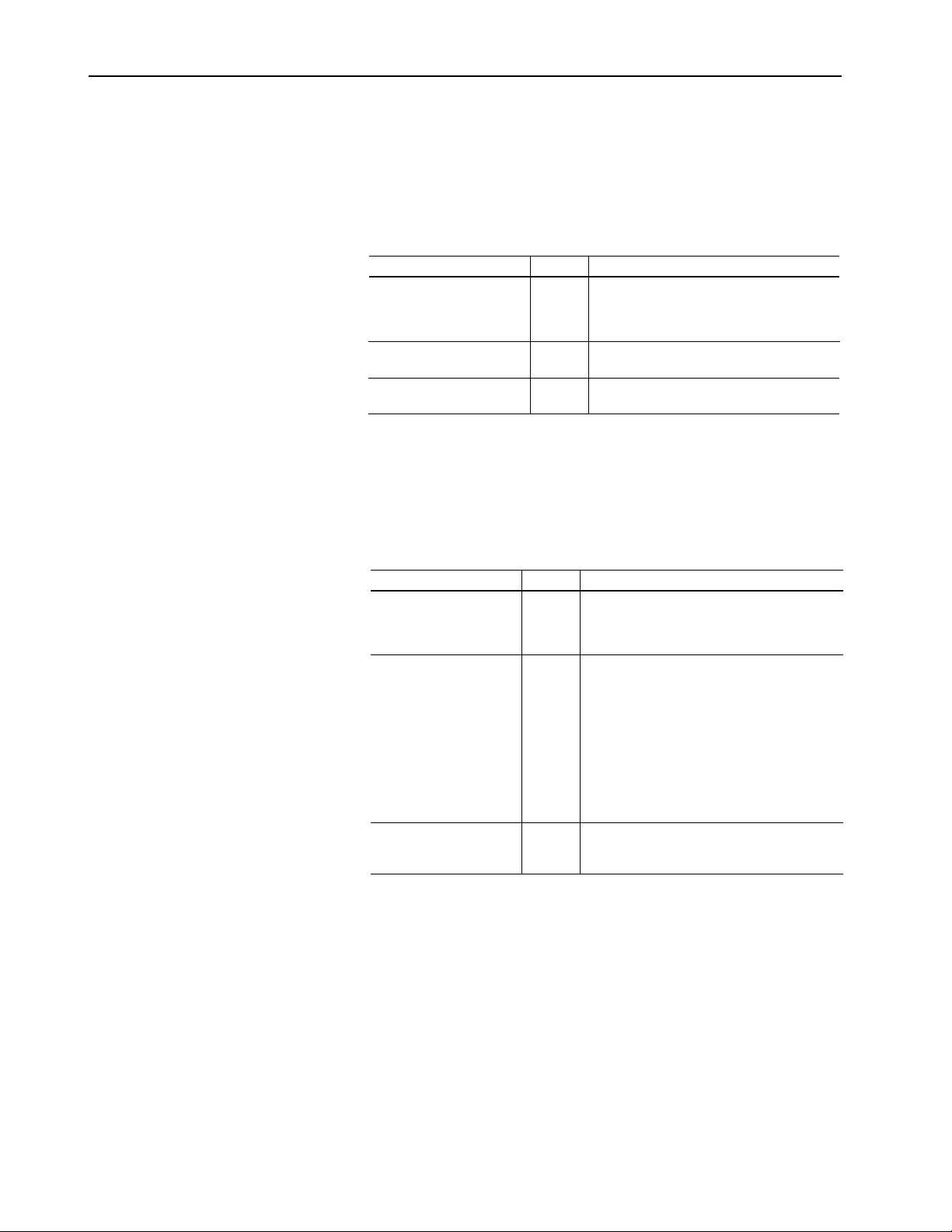

Terminal Blocks on the Main Circuit

This section provides the main circuit block diagram and the

description of the main power terminal block (TB1) and the control

power terminal block (TB2). The main circuit block diagram for

Model 8720MC-RPS027BM, 8720MC-RPS065BM and 8720MCRPS065BS is shown in Figure 2.1.

Figure 2.1

Terminal Blocks on the Main Circuit for RPS027 and RPS065 units

TB1

G

L

1

L

2

L

3

PR

PR FUSE1

TB2

L

1AUX

L

2AUX

L

3AUX

PR1

PR2

PR3

MC1

MC2

Precharge/

Discharge

Resistor

TB1

P

+

+

DIS

N

Driver Board RCPB

CN17

CN16

CN5

Power Interface Board PIFS

1> The G terminal for Model 8720MC-RPS027 is located on the front surface of the chassis.

Page 23

About 8720MC-RPS Regenerative Power Supply

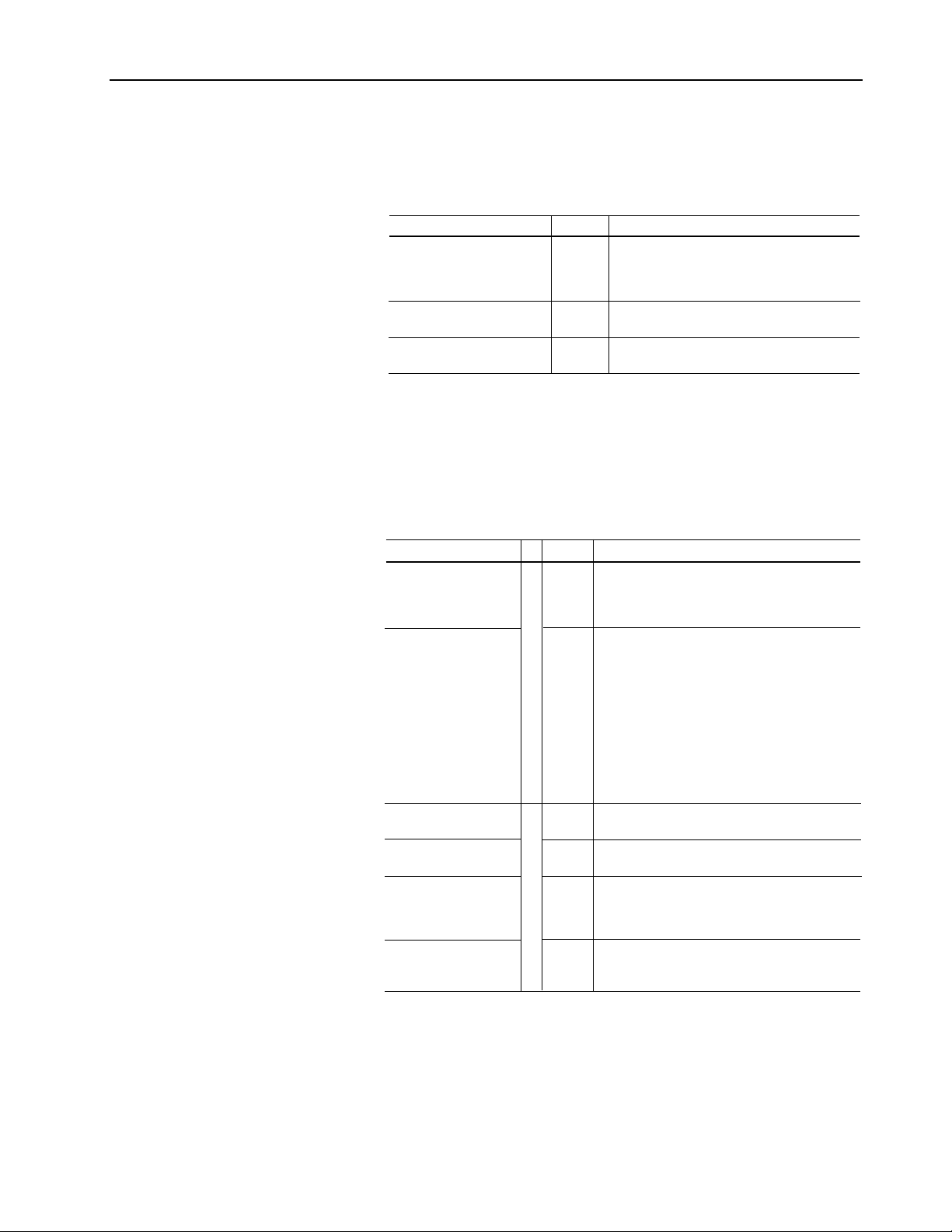

Figure 2.2 shows the main circuit block diagram for Model

8720MC-RPS190BM and 8720MC-RPS190BS.

Figure 2.2

Terminal Blocks on the Main Circuit for RPS190 unit

2-11

L

L

L

1AUX

2AUX

3AUX

PR1

PR2

PR3

G

L

1

L

2

L

3

TB2

TB4

Precharge/

Discharge

Resistor

Fuse 3

PR

PR

DIS

Fuse 2

Fuse 1

CN17

CN16

Power Interface Board PIFS

CN5

CN5

CN16

BDI

BDI

P

N

MC1

MC2

CN20

APS

Page 24

2-12

About 8720MC-RPS Regenerative Power Supply

Main Power Terminal Block (TB1) for Model 8720MC-RPS027 and 8720MC-RPS065

The table below provides the information of the terminals on use of

the terminals on the main power terminal block (TB1) for Model

8720MC-RPS027 and 8720MC-RPS065.

Terminal Name

Main Power

Terminals

DC Bus Terminals

Grounding Terminal

Symbol

, L2, L

L

1

P, N

G

Description

To connect three-phase AC input power to

3

the main circuit.

For 460 V unit: 380 to 460 VAC +10%,

-15%, 50/60 Hz +/-5%

To connect the 8720MC-RPS Regenerative

Power Supply to load equipment.

To ground the 8720MC-RPS Regenerative

Power Supply.

Control Power Terminal Block (TB2) for Model 8720MC-RPS027 and 8720MC-RPS065

The table below describes the terminals on the control power

terminal block (TB2) for Model 8720MC-RPS027 and

8720MC-RPS065.

Terminal Name

Control Power Terminals

Terminals to Connect

Precharge/Discharge

Resistor

Control Terminals for

Main Magnetic Contactor

Symbol

L

1AUX

,

L

2AUX

,

L

3AUX

PR1,

PR2,

PR3

MC1,

MC2

Description

To connect three-phase AC input power to the

control circuit.

For 460 V unit: 380 to 460 VAC +10%, -15%,

50/60 Hz +/-5%

To connect precharge/discharge resistor.

When the built-in resistor is used:

Jumper between PR2 and PR3, and open

PR1.

When an external resistor is used:

Connect the resistor between PR1 and

PR2, and open PR3.

When the unit is connected for power

regeneration mode only:

Open all the terminals PR1, PR2 and

PR3.

To be used as the control terminals for the

main magnetic contactor (rated for 250 VAC/

1 Amp or 30 VDC/1 Amp).

Page 25

About 8720MC-RPS Regenerative Power Supply

2-13

Main Power Terminal Bar for Model 8720MC-RPS190

The table below describes the terminals on the main power terminal

bar for Model 8720MC-RPS190.

Terminal Name

Main Power

Terminals

DC Bus Terminals

Grounding Terminal

Symbol

, L2, L

L

1

P, N

G

Description

To connect three-phase AC input power to

3

the main circuit.

For 460 V unit: 380 to 460 VAC +10%,

-15%, 50/60 Hz +/-5%

To connect the 8720MC-RPS Regenerative

Power Supply to load equipment.

To ground the 8720MC-RPS Regenerative

Power Supply.

Control Power Terminal Block (TB2) and Control Terminal Block (TB4) for Model 8720MC-RPS190

The table below describes the terminals on the control power

terminal block (TB2) and the terminals on the control terminal

block (TB4) for Model 8720MC-RPS190.

T

B

2

T

B

4

Symbol

L

1AUX

,

L

2AUX

,

L

3AUX

PR1,

PR2,

PR3

+24V3

0V3

SENS

+24V2

0V2

MC1

MC2

Description

To connect three-phase AC input power to the

control circuit.

For 460 V unit: 380 to 460 VAC +10%, -15%,

50/60 Hz +/-5%

To connect precharge/discharge resistor.

When the built-in resistor is used:

Jumper between PR2 and PR3, and open

PR1.

When an external resistor is used:

Connect the resistor between PR1 and

PR2, and open PR3.

When the unit is connected for power

regeneration mode only:

Open all the terminals PR1, PR2 and

PR3.

To supply AC power to the fan for the AC reactor

unit through the EM4000 EMC filter unit.

To enter fault signal of the fan for the AC reactor

unit.

To supply power to the main magnetic contactor

and the fan for the cabinet fan through the

8720MC-EF190 EMC filter unit.

To be used as the control terminals for the main

magnetic contactor.

Terminal Name

Control Power

Terminal

Terminals to Connect

Precharge/Discharge

Resistor

AC Reactor Fan

Power Terminals

Terminals for Fan Fault

Signal

Power Terminals for

Main Magnetic

Contactor MC

and Optional Fan

Control Terminaks for

Main Magnetic

Contactor

Page 26

2-14

READY

FAULT

PROGRAM

kW

About 8720MC-RPS Regenerative Power Supply

Regulator Board

The Regulator Board exists only on master unit. The slave unit for

parallel connection has no Regulator Board and is controlled by the

microprocessor of the Regulator Board on the master unit.

The 8720MC-RPS Regenerative Power Supply regulation is

performed by a microprocessor on the Regulator Board. The figure

below shows the locations of the main components on the Regulator

Board. The operation of the 8720MC-RPS Regenerative Power

Supply is adjusted by the parameters set by the keypad.

CN2

CN1

SW7

JP2

READY

FAULT

PROGRAM

RST

PRG

ENT

JP1 JP3

SW6

A

V

kW

Microprocessor

Sequence Signal

Terminal Block (TB3)

• PWM Gating Signals

Based on the output of the current/voltage control loop, the

Regulator Board sends PWM gating signals through the Power

Interface Board to the Power Modules (transistors), producing a

pulse-width-modulated (PWM) waveform.

• Sequence Output Signals

Sequence output signals are provided from the sequence signal

terminal block (TB3) of the Regulator Board to indicate the unit

status .

• Four-character Display and Six LEDs

A four-character seven-segment LED display is used to monitor

values, parameter numbers, parameter values, and error codes.

Six LEDs show the display mode of the operation panel and the

units of the monitored values.

Page 27

About 8720MC-RPS Regenerative Power Supply

Jumpers and Switches

ATTENTION: Only qualified electrical personnel

!

!

!

familiar with the construction and operation of this

equipment and the hazards involved should set

jumpers and switches. Read and understand this

manual in its entirety before proceeding. Failure to

observe this precaution could result in severe bodily

injury or loss of life.

ATTENTION: Do not press the reset button switch

(SW6) during operation. Also, do not alter the setting

of any jumpers and switches during operation.

Failure to observe this precaution could result in

destruction of the equipment, severe bodily injury or

loss of life.

ATTENTION: Do not alter the settings of any

jumpers not described in this manual. Failure to

observe this precaution could result in damage to, or

destruction of, the equipment.

2-15

The jumpers JP1 to JP3 and the switches SW6 and SW7 are set

before shipment from factory. If you need to change the jumpers

and/or switch settings, read and understand the following

description of these jumpers and switches before proceeding.

• Jumper JP1 to Enable Operation

Short this jumper to start switching operation of transistors of

the 8720MC-RPS Regenerative Power Supply when the RUN

sequence input is enabled. This jumper should always be kept

closed.

• Jumper JP2 to Enable Inspection Mode

Keep this jumper open always.

• Reset Switch SW6

Pressing this switch resets the CPU.

Important:

• Switch SW7 to Enable Base Block

This switch is used to stop switching of transistors that produce

PWM waveform by interrupting the base signal from the Power

Modules. To interrupt the base signal, turn the switch to the

OFF side.

As shown in the figure below, SW7 consists of four switches,

and SW7-1 to SW7-3 can be allocated to the master unit and

slave units 1 and 2. In the case of a master with paralleled slave

units, it is possible to interrupt the base signal of each unit by

turning the corresponding switch to the OFF side. SW7-4 must

always be kept to the OFF side.

Do not press the reset switch SW6 during operation.

Page 28

2-16

About 8720MC-RPS Regenerative Power Supply

When two units are connected in parallel, turn the switches

SW7-1 and SW7-2 to the ON side, and when three units are

connected in parallel, turn the switches SW7-1 through SW7-3

to the ON side.

Slave Unit 2

Slave Unit 1

Master Unit

SW7-4

SW7-3

SW7-2

SW7-1

ON

ENABLE BASE BLOCK

OFF

Keep SW7-4 always to the OFF side.

When the switch is turned to the OFF side, the base signal is

interrupted, and the unit will be in the OFF condition.

When the switch is turned to the ON side, the base signal is

kept ON, and PWM switching will continue.

Page 29

About 8720MC-RPS Regenerative Power Supply

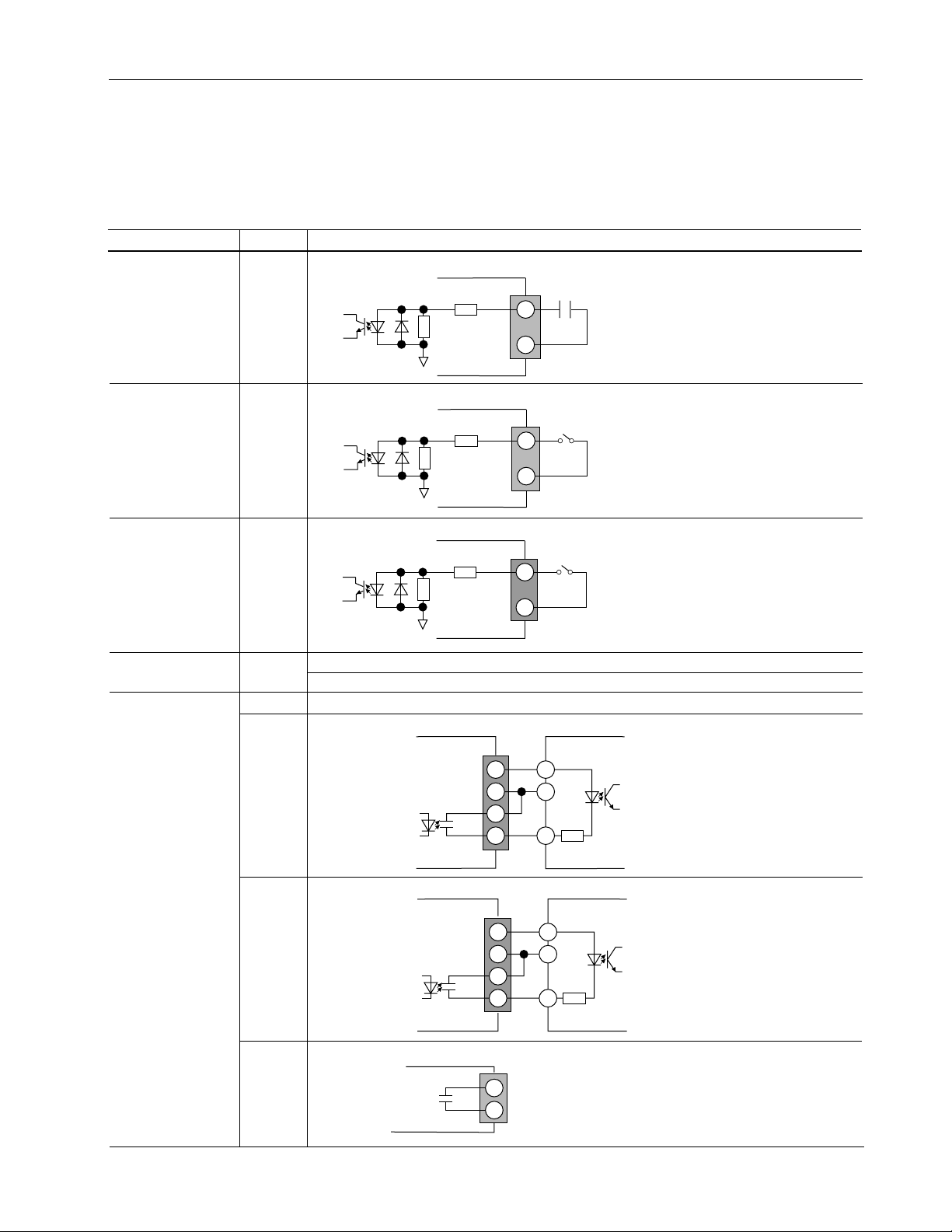

Sequence Signal Terminal Block (TB3)

As shown in the figure in page 2-14, there is a sequence signal

terminal block (TB3) on the Regulator Board. The following table

provides the information on each terminal of TB3.

2-17

Name of Terminal

Sequence Input

Signals

Power for

Sequence Signals

Sequence Output

Signals

Symbol

MC

RST

PWR

0 V

24 V

COM

IP

RDY

Description

Enter the supplemental contact signal (normally open contact) of the main magnetic contactor.*

4.7K

MC

1K

24V

8720MC-RPS

The reset signal (+24 VDC) is used to reset fault. Close this reset signal as required.*

4.7K

RST

1K

24V

8720MC-RPS

Enter the RUN signal (+24 VDC)*.

4.7K

PWR

1K

24V

8720MC-RPS

0 V of +24 VDC power.

+24 VDC power (rating : 24 VDC/0.2 Amps).

Common for IP and RDY signals.

This is a contact signal that is turned ON during instantaneous power loss (contact rating : 30 VDC/

50 mA).

24V

0V

COM

IP

8720MC-RPS

This is a contact signal that is turned ON while the unit is ready for operation (contact rating : 30 VDC/

50 mA).

24V

0V

COM

RDY

8720MC-RPS

MC

+VC

0VC

IP

4.64K

+VC

0VC

RDY

4.64K

* Because driving current of sequence input signals

is 5mA and below, use a contact of which

minimum applicable load is 5mA and below.

* Because driving current of sequence input signals

is 5mA and below, use a contact of which

minimum applicable load is 5mA and below.

* Because driving current of sequence input signals

is 5mA and below, use a contact of which

minimum applicable load is 5mA and below.

Load

Load

FR, FR

This is a contact signal that opens while fault occurs (contact rating : 250 VAC/1 Amp or 30 VDC/

1 Amp).

8720MC-RPS

FR

FR

Page 30

2-18

About 8720MC-RPS Regenerative Power Supply

End of Chapter

Page 31

Chapter

Installation

This chapter shows how to mount the 8720MC-RPS Regenerative

Power Supply properly, and provides information on the items to be

checked.

3

Installation Site

ATTENTION:

!

!

It is important to properly plan before installing the 8720MC-RPS

Regenerative Power Supply to ensure that the environment and

operating conditions of the units are satisfactory. Read this section

before continuing with the unit installation.

familiar with the construction and operation of this

equipment and the hazards involved should install,

adjust, operate, or service this equipment. Read and

understand this manual in its entirety before

proceeding. Failure to observe this precaution could

result in destruction of the equipment, severe bodily

injury, or loss of life.

ATTENTION:

with all applicable local, national and international

codes. Failure to observe this precaution could result

in damage to, or destruction of, the equipment.

Only qualified electrical personnel

The user is responsible for conforming

Environmental Conditions to be Met

The Declaration of Conformity with the requirements for CE Mark

was issued for the following units, and these units must be used in

cabinet.

8720MC-RPS027BM,

8720MC-RPS065BM, 8720MC-RPS065BS,

8720MC-RPS190BM and 8720MC-RPS190BS

Also, before deciding on an installation site, consider the following

guidelines:

• Verify that the units can be kept clean, cool and dry.

• Be sure that the units are always away from oil, metal powder,

other airborne contaminants, and direct sunlight.

• Check that the units will not be exposed to excessive vibration

and noise, and that they will not be close to instruments

sensitive to electrical noise.

• The area chosen should allow the space required for proper air

flow as defined in the following.

Page 32

3-2

Installation

• Check that the temperatures within the vicinity of the units are

between -10 to 50 degree C (14 to 122 degree F). In case of

8720MC-RPS190, however, the ambient temperature must be

between -10 to 40 degree C (14 to 104 degree F).

• Check that the relative humidity is between 5 and 95% without

condensation.

• Do not install the units above 1,000 meters (3,300 feet) without

derating output power. For every 300 meters (1,000 feet) above

1,000 meters (3,300 feet), derate the output power 4%. When

you need to install the units above 1,500 meters (5,000 feet),

contact The Allen-Bradley Company.

In case of Model 8720MC-RPS190BM and 8720MC-RPS190BS,

it is possible to ship the units from the factory after mounting each

of these units in a cabinet together with the required peripheral

devices and installing wiring in the cabinet. When the user

purchases from The Allen-Bradley Company the units mounted in

the cabinet, the above-mentioned guidelines should be considered

for selection of the installation site.

Required Total Area

Overall unit dimensions are shown in Figures 3.1 and 3.2. Figure

3.1 illustrates the dimensions of Model 8720MC-RPS027 and

8720MC-RPS065 units, and Figure 3.2 shows the outline

dimensions of 8720MC-RPS190 unit. Also as an aid in calculating

the required total area, Figures 3.3 and 3.4 show the required

distance between two adjacent units in case of two or three

paralleled units of Model 8720MC-RPS027 and 8720MC-RPS065,

and Figures 3.5 and 3.6 show the required distance between two

adjacent units in case of two or three paralleled units of Model

8720MC-RPS190 unit installed in a cabinet provided by the user.

Page 33

Installation

REGENERATIVE POWER SUPPLY

MC

READY

FAULT

PROGRAM

3-3

Figure 3.1

Overall Dimensions of a Single Unit of Model 8720MC-RPS027 and 8720MC-RPS065

Units

H dia.

G dia.

8720

READY

FAULT

PROGRAM

MC

R

C

A

V

kW

ENT

PRG

RST

P

P

S

U

R

W

E

P

IV

O

T

E

A

R

E

N

E

G

E

E

K

F

B

D

LY

Model

8720MC-

RPS065

8720MC-

RPS027

A

179.4

(7.06)

167

(6.57)

H

C

A

B

395

(15.6)

320

(12.6)

C

127

(5.0)

120

(4.72)

E

D

333.2

(131.2)

260

(10.24)

F

E

10

(0.39)

10

(0.39)

F

30

(1.2)

30

(1.2)

G

18

(0.71)

17

(0.67)

H

9

(0.35)

8.2

(0.32)

K

9

(0.35)

8

(0.31)

L

L

318.3

(12.53)

310

(12.20)

Unit: Millimeter (Inch)

Page 34

3-4

REGENERATIVE POWER SUPPLY

8720

MC

READY

FAUL

PROGRAM

kW

Installation

Figure 3.2

Overall Dimensions of a Single Unit of Model 8720MC-RPS190 Unit

20 (0.79)

639.5 (25.18)

566.5 (22.30)

(2.34)

30

(1.2)

59.5

(2.3)

L

2

58

READY

FAUL

T

PROGRAM

RST

8720

125

(4.92)

L1, L

PRG

MC

E

R

ENT

G

N

E

M10

T

A

R

E

3

A

V

kW

IV

P

E

O

W

10 (0.39) dia.

20 (0.79) dia.

Y

L

P

P

S

U

R

E

40 (1.6)

13 (0.5)

14 (0.6)

503 (19.8)

550 (21.7)

573 (22.6)

110 (4.3) 110 (4.3)

L

1

86 (3.4)

L

2

L

3

33

(1.3)

20 (08)

P

N

30

(1.2)

(2.34)

59.5

E

125 (4.9)

242 (9.6)

M8

10

(0.4)

30 (1.2)

10 (0.4)

435 (17.1)

P

N

45

(1.8)

(3.3)

Unit: Millimeters (Inch)

E

83

Page 35

Installation

REGENERATIVE POWER SUPPLY

MC

REGENERATIVE POWER SUPPLY

MC

REGENERATIVE POWER SUPPLY

MC

Max. 250 (9.8)

Unit: Millimeter (Inch)

R

E

G

E

N

E

R

A

T

IV

E

P

O

W

E

R

S

U

P

P

L

Y

REGENERATIVE POWER SUPPLY

87208720

MC

RST

PRG

ENT

READYREADY

FAULTFAULT

PROGRAMPROGRAM kWkW

V

A

R

E

G

E

N

E

R

A

T

IV

E

P

O

W

E

R

S

U

P

P

L

Y

REGENERATIVE POWER SUPPLY

87208720

MC

Note: In case two units of Model 8720MC-RPS027 or 8720MC-RPS065 unit are installed in parallel,

the master unit must be on the right hand side as shown in the above.

Figure 3.3

Required Distance between Units in Case of Two Paralleled Units of

Model 8720MC-RPS027 or 8720MC-RPS065 Units

3-5

Figure 3.4

Required Distance between Units in Case of Three Paralleled Units of

Model 8720MC-RPS027 or 8720MC-RPS065 Units

READY

FAULT

PROGRAM kW

PRG

RST

MC

8720

IV

T

A

R

E

N

E

G

E

R

Y

L

P

P

S

U

R

W

P

E

O

E

Max. 250 (9.8)

8720

MC

E

R

Y

L

P

P

S

U

R

W

P

E

IV

T

O

E

A

R

E

N

E

G

Max. 250 (9.8)

8720

MC

E

R

N

E

G

A

V

ENT

Y

L

P

P

S

U

R

W

P

E

IV

T

O

E

A

R

E

Note: In case three units of Model 8720MC-RPS027 or 8720MC-RPS065 unit are installed in parallel,

the master unit must be installed at the rightmost end as shown in the above.

Unit: Millimeter (Inch)

Page 36

3-6

REGENERATIVE POWER SUPPLY

8720

MC

READY

FAUL

PROGRAM

kW

REGENERATIVE POWER SUPPLY

8720

MC

REGENERATIVE POWER SUPPLY

8720

MC

READY

FAUL

PROGRAM

kW

REGENERATIVE POWER SUPPLY

8720

MC

REGENERATIVE POWER SUPPLY

8720

MC

Installation

Figure 3.5

Required Distance between Units in Case of Two Paralleled Units of

Model 8720MC-RPS190 Unit

POWER POWER

8720

READY

PROGRAM

C

M

R

Y

L

P

P

S

W

U

R

IV

P

T

E

E

O

A

R

E

N

E

G

E

8720

Max. 620 (24.4)

A

FAUL

T

V

kW

ENT

PRG

RST

C

M

R

Y

L

P

P

S

W

U

R

IV

P

T

E

E

O

A

R

E

N

E

G

E

Unit: Millimeters (inch)

Note: In case two units of Model 8720MC-RPS190 unit are installed in parallel, the master unit

must be installed on the right hand side as shown in the above.

Figure 3.6

Required Distance between Units in Case of Three Paralleled Units of

Model 8720MC-RPS190 Unit

POWER

POWER POWER

READY

A

FAUL

T

V

kW

ENT

PRG

RST

C

M

R

Y

L

P

P

S

W

U

R

IV

P

T

E

E

O

A

R

E

N

E

G

E

Unit: Millimeters (inch)

8720

PROGRAM

C

M

E

R

IV

T

E

A

R

E

N

E

G

Y

L

P

P

S

W

U

R

P

E

O

Max. 620 (24.4)

C

M

8720

E

R

Y

L

P

P

S

W

U

R

IV

P

T

E

E

O

A

R

E

N

E

G

Max. 620 (24.4)

8720

Note: In case three units of Model 8720MC-RPS190 unit are installed in parallel, the master unit must

be installed at the rightmost end as shown in the above.

Page 37

REGENERATIVE POWER SUPPLY

MC

PROGRAM

Installation

Recommended Air Flow Clearance

Be sure that there is adequate clearance for air ventilation around

the 8720MC-RPS Regenerative Power Supply. Cooling air flows

from the bottom to the top of the units. For best cooling effect, do

not mount the 8720MC-RPS Regenerative Power Supply directly

above each other. The figure below shows recommended air flow

clearance.

Exhaust

150

(5.9)

3-7

150

(5.9)

Notes on Installation

8720

READY

FAULT

PROGRAM

MC

150

(5.9)

A

V

kW

ENT

PRG

RST

Y

L

P

P

W

IV

R SU

P

T

E

E

O

A

R

E

N

E

G

E

R

150

(5.9)

Intake

Unit: Millimeter (Inch)

When mounting the 8720MC-RPS Regenerative Power Supply, pay

attention to the following:

• Mount the units vertically.

• When two or three units of 8720MC-RPS Regenerative Power

Supply are installed in parallel, install the master unit at the

rightmost end viewed from the front side.

• Be sure that the ambient temperatures surrounding the units is

between -10 to 50 degree C (14 to 122 dgree F). In case of

Model 8720MC-RPS190BM and 8720MC-RPS190BS units, the

ambient temperature is -10 to 40 degree C (14 to 104 degree F).

To cool down the temperature in the cabinet, provide sufficient

space to allow adequate air flow over the components. If

necessary, add circulating fans to assure good convective heat

transfer.

• Do not mount any devices behind the units. This area must be

kept clear of all power wiring (control power wiring, main

power supply wiring and DC bus power wiring).

Page 38

3-8

Installation

• Do not expose the units to excessive electrical noise. If it is not

avoidable to install the 8720MC-RPS Regenerative Power

Supply close to a noise source or to use the units in environment

where noise trouble is expected, take sufficient noise

suppression measures.

Page 39

Chapter

Wiring

This chapter provides instructions on how to properly wire the

8720MC-RPS Regenerative Power Supply units. It also provides

information on the selection of the circuit breaker, the main

magnetic contactor, reactor, and the harmonic filter, etc.

4

ATTENTION:

!

!

!

!

familiar with the construction and operation of this

equipment and the hazards involved should install,

adjust, operate, or service this equipment. Read and

understand this manual in its entirety before

proceeding. Failure to observe this precaution could

result in destruction of the equipment, severe bodily

injury or loss of life.

ATTENTION:

with all the applicable codes. Wiring practices,

grounding, disconnects, and overcurrent protection

are of particular importance. Failure to observe this

precaution could result in severe bodily injury or loss

of life.

ATTENTION:

continuity checks in the equipment. Use higher range

of a circuit tester for this purpose. Failure to observe

this precaution could result in damage to, or

destruction of, the equipment.

ATTENTION:

with all applicable local, national and international

codes. Failure to observe this precaution could result

in damage to, or destruction of, the equipment.

Only qualified electrical personnel

The user is responsible for conforming

Do not use a megger to perform

The user is responsible for conforming

Recommended Wire Sizes

This section shows the recommended wire sizes for the wires to be

used in cabinet. Select the wire sizes in consideration of the

following:

• Applicable local, national and international codes.

• Temperature increase and voltage drop due to type of wires,

wiring method, wiring distance, etc.

Page 40

4-2

Wiring

Recommended Wire Sizes for Power Wiring to the Main Power Terminal Block (TB1) and the Main Power Terminal Bars

Table 4.1 to 4.3 show the recommended wire sizes for power wiring

to the main power terminal block (TB1) and the Main Power

Terminal Bars. Table 4.1 shows the wire sizes for Model 8720MCRPS027 unit, Table 4.2 shows the wire sizes for Model 8720MCRPS065 unit, and Table 4.3 shows the wire sizes for Model

8720MC-RPS190 unit. The wire sizes shown assume full utilization

of the rated capacity of the RPS unit.

Table 4.1

Recommended Maximum Wire Sizes for Model 8720MC-RPS027 Unit

Name of Terminal

Main Terminals (Input)

DC Bus Terminals (Output)

Grounding Terminal (Earth)

Symbol

L1, L2, L

P, N

G

Screw Size

3

M5

M5

M5

Size of Wire AWG/mm

#10 / 5.5 mm

#10 / 5.5 mm

#10 / 5.5 mm

Table 4.2

Recommended Maximum Wire Sizes for Model 8720MC-RPS065 Unit

Name of Terminal

Main Terminals (Input)

DC Bus Terminals (Output)

Grounding Terminal (Earth)

Symbol

L1, L2, L

P, N

G

Screw Size

3

M6

M6

M6

Size of Wire AWG/mm

#4 / 22 mm

#4 / 22 mm

#5 / 22 mm

2

2

2

2

2

2

2

2

Table 4.3

Recommended Maximum Wire Sizes for Model 8720MC-RPS190 Unit

Name of Terminal

Main Power Supply

Terminals

Symbol

L1, L2, L

Screw Size

M10

3

Size of Wire AWG/mm

Larger than 38

mm2 - 2 in parallel

2

Attached Lugs

JST, R38-10

(M10) (6 Pieces)

(1)

(AWG #2 - 2 in

parallel)

DC Bus Terminals

Grounding Terminal

(1)

UL-listed wires must be lugged by attached lugs.

JST is Japan Solderless Terminal Co.

P, N

G

M10

M8

Larger than 100mm

(AWG #4/0)

Larger than 38mm

(AWG #2)

2

JST, R100-10

(M10) (2 Pieces)

2

JST, R38-8 (M10)

(1 Piece)

Recommended Wire Sizes for Power Wiring to the Control Power Terminal Block (TB2) and the Control Terminal Block (TB4)

Table 4.4 shows the recommended wire sizes for power wiring to

the control power terminal block (TB2) and the control terminal

block (TB4).

Table 4.4

Recommended Wire Sizes for Power Wiring to the Control Power Terminals

and the control terminal block (TB4)

Name of Terminal

Main Terminals (Input)

DC Bus Terminals (Output)

Grounding Terminal (Earth)

Symbol

L

, L

2AUX

, L

1AUX

PR1, PR2, PR3

MC1, MC2

3AUX

Size of Wire

2

3.5 mm

(AWG #12)

3.5 mm2 (AWG #12)

2.0 mm2 (AWG #14)

Page 41

Wiring

4-3

AC Input Power Wiring for Model 8720MC-RPS027 and 8720MC-RPS065

ATTENTION:

!

!

!

Regenerative Power Supply units using high speed

switching elements generates noise regarding

emission due to noise generated during switching.

To avoid influence of such noise, it is very important

to use as thick and short grounding wire as possible.

ATTENTION:

disconnecting device, a main magnetic contactor and

an AC reactor in the AC input power line. When

8720MC-RPS027 and 8720MC-RPS065 must

conform with the requirements of CE Mark, install a

line filter in the AC input power line. Failure to

observe these precautions could result in damage to,

or destruction of, the equipment.

ATTENTION:

is connected to AC input power line of 8720MC-RPS

Regenerative Power Supply unit, large distortion may

be produced in the AC input power voltage and the

8720MC-RPS Regenerative Power Supply may not

operate normally. Remove such large distortion from

the AC input power voltage.

Equipment as the 8720MC-RPS

It is required to install a power

When a thyristor or similar equipment

The capacity (rating) of the 8720MC-RPS Regenerative Power

Supply depends on the number of units connected in parallel, i.e.,

single unit, two paralleled units, or three paralleled units. The

relation between the number of paralleled units and the unit

capacity is shown in Table 2.1.

Figure 4.1 to 4.3 show typical connection of AC input power wiring

for Model 8720MC-RPS027 and 8720MC-RPS065 units. Figure

4.1 shows AC input power wiring for the single unit, and Figures

4.2 and 4.3 show AC input wiring for parallel connection of two

units and three units respectively. Install appropriate reactors,

magnetic contactors, disconnects, line filters, etc. at the positions

shown in these figures.

The phases of the AC input power to the main power supply

terminals L1, L2 and L3 must be same as the phases of the control

power to the control power terminals L

case of paralleled units, the phases of the control power L

and L

master unit.

for the slave unit(s) must also be same as those for the

3AUX

1AUX

, L

2AUX

, and L

3AUX

1AUX

. In

, L

2AUX

,

Page 42

4-4

Wiring

Line Filter <5

380 to

460 VAC

for AC Input

Power

100 to 115 VAC

200 to 230 VAC

Circuit

Breaker <4

(CB)

or

Fuse <4

for

Power

Supply

Single-phase

Line Filter <5

ATTENTION:

!

to the 8720MC-RPS Regenerative Power Supply when

connecting multiple units in parallel. The phases of AC

Special caution must be paid to wiring

input power to the main power supply terminals (L1, L

and L3) and to the control power terminals (L

L

2AUX

, and L

) and the polarity of DC bus output (P

3AUX

and N) of all the connected units must be the same.

Failure to observe this precaution could result in

destruction of the equipment, severe bodily injury or

loss of life.

Figure 4.1

Typical Connection of AC Input Power Wiring for Single Unit of

Model 8720MC-RPS027 and 8720MC-RPS065

8720MC-RPS

Regenerative

Power Supply

Unit

L

1

L

2

L

3

L

1AUX

L

2AUX

L

3AUX

PR1

PR2

PR3

MC1

MC2

P

N

G

PWR

MC

24V

Terminal Block for Main

Power Supply (TB1)

Protection Fuse <2

Terminal Block for

Sequence Signals (TB3)

RUN On/Off

MC

Varistor

Harmonic

Filter

E

<8, 9

MC

Main

Magnetic

Contactor

(MC)

Reactor <11

<1

Terminal Block for

Control Power (TB2)

,

1AUX

Terminals P and N <6

of Load Equipment

<10

2

1> The phases of the AC input power to the main supply terminals L1, L2 and L3 must be same as those of the control power

to the control power terminals L

2> It is recommended to install the DC bus protection fuses on the both lines to the terminals P and N to prevent ground fault,

when more than one drive is connected to the 8720MC-RPS Regenerative Power Supply.

3> Turn ON the switch SW7-1 on the Regulator Board without fail.

4> Both a three-phase circuit breaker and fuses are not required. Check your local code to determine if fuses should be

used instead of a circuit breaker.

5> When the 8720MC-RPS Regenerative Power Supply must conform with the requirements of CE Mark, install a line filter in

the AC input power line and a single-phase line filter in the power supply line to the main magnetic contactor.

6> The length of the DC bus wiring runs should not exceed 2 meters. It is also recommended to use twisted shielded cable.

7> The length of the wiring in the cabinet must be as short as possible.

8> The length of the wiring from the E terminal of the Harmonic Filter to the Grounding Terminal must be as short as possible.

9> The physical location of the Harmonic Filter and Varistor relative to the Contactor and Line Reactor is important.

Connect these devices in the relative positions shown in this illustration.

10> Because driving current of sequence input signals is 5mA and below, use a contact of which minimum applicable load is 5mA and below.

11> Use the reactor in maximum surrounding air temperature of 55 degree C (131 degree F) and below.

1AUX

, L

2AUX

and L

3AUX

.

Page 43

380 to

460 VAC

Line Filter <6

for AC

Input

Power

Circuit

Breaker <4

(CB2)

Fuse <4

for

Power

Supply

Wiring

Figure 4.2

Typical Connection of AC Input Power Wiring for Two Paralleled Units of

Model 8720MC-RPS027 and 8720MC-RPS065

8720MC-RPS

Regenerative Power

Varistor

Main

Magnetic

Contactor

(MC2)

Reactor

(L2)

<12

Supply Unit 2

(Slave Unit)

L

L

L

P

1

N

2

G

3

Protection

Fuse <2

Terminals

P and N

of Load

Equipment

4-5

<7

100 to

115 VAC

or

200 to

230 VAC

Single-phase

Line Filter <6

Line Filter <6

for AC

Input

Power

CB2

Circuit

Breaker <4

(CB1)

Fuse <4

for

Power

Supply

<9, 10

MC2

<9, 10

MC1

Harmonic

Filter

E

Varistor

Harmonic

Filter

E

MC2

Main

Magnetic

Contactor

(MC1)

<12

Reactor

(L1)

<1

MC1

L

1AUX

L

2AUX

L

3AUX

PR1

PR2

PR3

MC1

MC2

8720MC-RPS

Regenerative Power

Supply Unit 1

(Master Unit)

1

2

3

1AUX

2AUX

3AUX

P

N

G

L

L

L

L

L

L

PR1

PR2

PWR

PR3

MC

MC1

24V

MC2

Protection

Fuse <2

RUN On/Off

MC1

MC2

<5, 11

CB2

1> The phases of the AC input power to the main supply terminals L

L

, L

2AUX

and L

1AUX

2> It is recommended to install the DC bus protection fuses on the both lines to the terminals P and N to prevent ground fault, when more

. The phases of the control power L

3AUX

1AUX

, L2 and L

1

, L

must be same as those of the control power to the control power terminals

3

2AUX

and L

for the slave unit(s) must also be same as those for the master unit.

3AUX

than one drive is connected to the 8720MC-RPS Regenerative Power Supply.

3> Turn ON the switches SW7-1 and SW7-2 on the Regulator Board without fail.

4> Both a three-phase circuit breaker and fuses are not required. Check your local code to determine if fuses should be used instead of a circuit breaker.

5> The slave circuit breaker must be provided with an auxiliary contact as a safety interlock to the master. Use fuses with a slightly higher current rating

if your local code requires them.

6> When the 8720MC-RPS Regenerative Power Supply must comform with the requirements of CE Mark, install a line filter in the AC input power line and

a single-phase line filter in the power supply line to the main magnetic contactor.

7> The length of the DC bus wiring runs should not exceed 2 meters. It is also recommended to use Bus bar for the common bus sized to 1.75 times the total

continuous current output of the RPS units.

8> The length of the wiring in the cabinet must be as short as possible.

9> The length of the wiring from the E terminal of the Harmonic Filter to the Grounding Terminal must be as short as possible.

10> The physical location of the Harmonic Filter and Varistor relative to the Contactor and Line Reactor is important. Connect these devices in the relative positions

shown in this illustration.

11> Because driving current of sequence input signals is 5mA and below, use a contact of which minimum applicable load is 5mA and below.

12> Use the reactor in maximum surrounding air temperature of 55 degree C (131 degree F) and below.

Page 44

4-6

Wiring

Figure 4.3

Typical Connection of AC Input Power Wiring for Three Paralleled Units of

Model 8720MC-RPS027 and 8720MC-RPS065

8720MC-RPS

Regenerative Power

Supply Unit 3

(Slave Unit 2)

Protection

1

N

L

2

G

L

3

L

1AUX

L

2AUX

L

3AUX

PR1

PR2

PR3

MC1

MC2

8720MC-RPS

Regenerative Power

Supply Unit 2

(Slave Unit 1)

Protection

Fuse <2

P

L

1

N

L

2

G

L

3

L

1AUX

L

2AUX

L

3AUX

PR1

PR2

PR3

MC1

MC2

8720MC-RPS

Regenerative Power

Supply Unit 1

(Master Unit)

Protection

Fuse <2

P

L

1

N

L

2

G

L

3

<1

L

1AUX

L

2AUX

L

3AUX

PR1

PR2

PR3

MC1

MC2

must be same as those of the control power to the control power terminals

3

and L

for the slave unit(s) must also be same as those for the master unit.

AUX

3

PWR

MC

24V

RUN On/Off

MC1

MC2

MC3

CB2

Terminals P and N

of Load Equipment

CB3

Fuse <2

P

L

<7

<5, 11

Filter

Filter

E

E

Main

Magnetic

Contactor

(MC3)

MC3

Main

Magnetic

Contactor

(MC2)

Main

Magnetic

Contactor

(MC1)

Reactor

(L3)

Reactor

(L2)

Reactor

(L1)

<12

<12

<12

100 to 115 VAC

or

200 to 230 VAC

380 to

460 VAC

Single-phase

Line Filter

<6

Line Filter <6

for AC

Input

Power

Line Filter <6

for AC

Input

Power

Line Filter <6

for AC

Input

Power

Fuse <4

Circuit

Breaker <4

(CB3)

Breaker <4

Breaker <4

for

Power

Supply

CB3

Fuse <4

Circuit

(CB2)

for

Power

Supply

CB2 MC2

Fuse <4

Circuit

for

Power

(CB1)

Supply

Varistor

Harmonic

<9, 10

MC3

Varistor

Harmonic

<9, 10

MC2

Varistor

MC1

<9, 10

Harmonic

Filter

E

MC1

1> The phases of the AC input power to the main supply terminals L1, L2 and L

L

, L

2AUX

and L

1AUX

2> It is recommended to install the DC bus protection fuses on the both lines to the terminals P and N to prevent ground fault, when more

. The phases of the control power L

AUX

3

1AUX

, L

2AUX

than one drive is connected to the 8720MC-RPS Regenerative Power Supply.

3> Turn ON the switches SW7-1, SW7-2 and SW7-3 on the Regulator Board without fail.

4> Both a three-phase circuit breaker and fuses are not required. Check your local code to determine if fuses should be used instead of a circuit breaker.

5> The slave circuit breaker must be provided with an auxiliary contact as a safety interlock to the master. Use fuses with a slightly higher current rating

if your local code requires them.

6> When the 8720MC-RPS Regenerative Power Supply must comform with the requirements of CE Mark, install a line filter in the AC input power line and

a single-phase line filter in the power supply line to the main magnetic contactor.

7> The length of the DC bus wiring runs should not exceed 2 meters. It is also recommended to use Bus bar for the common bus sized to 1.75 times the total

continuous current output of the RPS units.

8> The length of the wiring in the cabinet must be as short as possible.

9> The length of the wiring from the E terminal of the Harmonic Filter to the Grounding Terminal must be as short as possible.

10> The physical location of the Harmonic Filter and Varistor relative to the Contactor and Line Reactor is important. Connect these devices in the relative positions

shown in this illustration.

11> Because driving current of sequence input signals is 5mA and below, use a contact of which minimum applicable load is 5mA and below.

12> Use the reactor in maximum surrounding air temperature of 55 degree C (131 degree F) and below.

Page 45

Wiring

4-7

When Model 8720MC-RPS027 or 8720MC-RPS065 is operated in the Power Regeneration Mode only

Figure 4.4

Wiring Model 8720MC-RPS027 or 8720MC-RPS065 Unit

Used as a Converter for the Power Regeneration Mode Only

8720MC-RPS027

and

8720MC-RPS065

Line Filter for

AC Input Power

Circuit

Breaker

(CB1)

100 to 115 VAC

or

200 to 230 VAC

Circuit

Breaker

(CB2)

Fuse

Single Phase

Line Filter

Varistor

Harmonic

Filter

E

<2

MC1

Main

Magnetic

Contactor

(MC1)

<7

<6

(Load Equipment)

Reactor

8720MC-RPS

Regenerative Power

Supply Unit

(Dedicated for Power

<9

Regeneration Mode)

Reactor

<1

Inverter

L

1

L

2

L

3

READY

L

1

L

2

L

3

L

1AUX

L

2AUX

L

3AUX

PR1

PR2

PR3

MC1

MC2

PWR

MC

24V

U

V

W

P

N

G

P

N

G

Protection Fuse <2

RUN On/Off

MC1

To AC Motor

READY

<8

1> The phases of the AC input power to the main supply terminals L

to the control power terminals L

2> It is recommended to install the DC bus protection fuses on the both lines to the terminals P and N to prevent ground fault,

when plural number of load equipment is connected to the 8720MC-RPS Regenerative Power Supply.

3> Turn ON the switch SW7-1 on the Regulator Board without fail.

4> Wiring to be taken into cabinet must be as short as possible.

5> This connection is only used with AC input drives.

6> The length of the wiring from the E terminal of the Harmonic Filter to the Grounding Terminal must be as short as possible.

7> The physical location of the Harmonic Filter and Varistor relative to the Contactor and Line Reactor is important.

Connect these devices in the relative positions shown in this illustration.

8> Because driving current of sequence input signals is 5mA and below, use a contact of which minimum applicable load is 5mA and below.

9> Use the reactor in maximum surrounding air temperature of 55 degree C (131 degree F) and below.

1AUX

, L

2AUX

and L

3AUX

.

, L2 and L3 must be same as those of the control power

1

It is possible to select the 8720MC-RPS units depending on the

regenerative power when only regenerated power of the unit

integrating converter and inverter is used. In this case, however,

the following cautions must be observed. Figure 4.4 shows wiring

of the 8720MC-RPS027 or 8720MC-RPS065 unit used as a

converter for the power regeneration mode only.

Page 46

4-8

Wiring

• Rating of regenerative power of the 8720MC-RPS is less than

rated power both in the instantaneous rating and continuous

rating.

• When rectifier portion of inverter is composed of thyristor, CR

snubber circuit between anode and cathode of thyristor may

become overloaded. Therefore, treating time for regenerative

power must be within 5 seconds for 3 minutes. Because the

current "ICR" flowing through CR snubber circuit in the power