Page 1

871F 2-wire AC/DC Proximity Sensors

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

Suitable for use in Class 1, Division 2,

Groups A, B, C, D or nonhazardous

locations only.

Explosion hazard: substitution of

components may impair suitability for

Class 1, Division 2.

Explosion hazard: Do not disconnect

equipment unless power has been

switched off or the area is known to be

nonhazardous.

WARNING

871F for Hazardous Locations

Models covered:

Conduit 1/2-14 NPT

871F-R50N80-T2

871F-K65N80-T2

Conduit PG13.5

871F-R50N80-Q2

871F-K65N80-Q2

Installation Instructions

General Specifications

Electrical

Load Current ≤ 100 mA

Minimum Load Current 5 mA

Leakage Current

Operating Voltage 20…250V AC/DC

Voltage Drop ≤ 10V

Repeatability ≤ 5%

Hysteresis ≤ 10% typical

False Pulse Protection Incorporated

Transient Noise Protection Incorporated

Short Circuit Protection Incorporated

Overload Protection Incorporated

Environmental

Certifications

Enclosure

Mechanical

Housing material

Connections Conduit Opening:1/2-14NPT thread, PG 13.5

LEDs Green: Power

Operating Temperature [C (F)] -25…+70° (-13…+158°)

Shock 30 g, 11 ms

Vibration 55 Hz, 1 mm amplitude, 3 planes

≤ 1.8 mA @ 24V

≤ 1.8 mA @ 120V

≤ 2.0 mA @ 250V

cULus Listed, and CE Marked for all

applicable all directives

NEMA 1, 2, 3, 4, 6, 6P, 12 and 13, IP67

(IEC529)

1200 psi (8270 kPa) washdown

Division 2 Class I: Groups A, B, C, D

®

Valox

thread

Orange: Output Energized

Page 2

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation NV, Pegasus Park, De Kleetlaan 12a, 1831 Diegem, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

Asia Pacic: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

www.rockwel lautomation.com

Wiring Diagram

T2 T3

Load

Note: Load can be switched to terminal 2.

LEDs

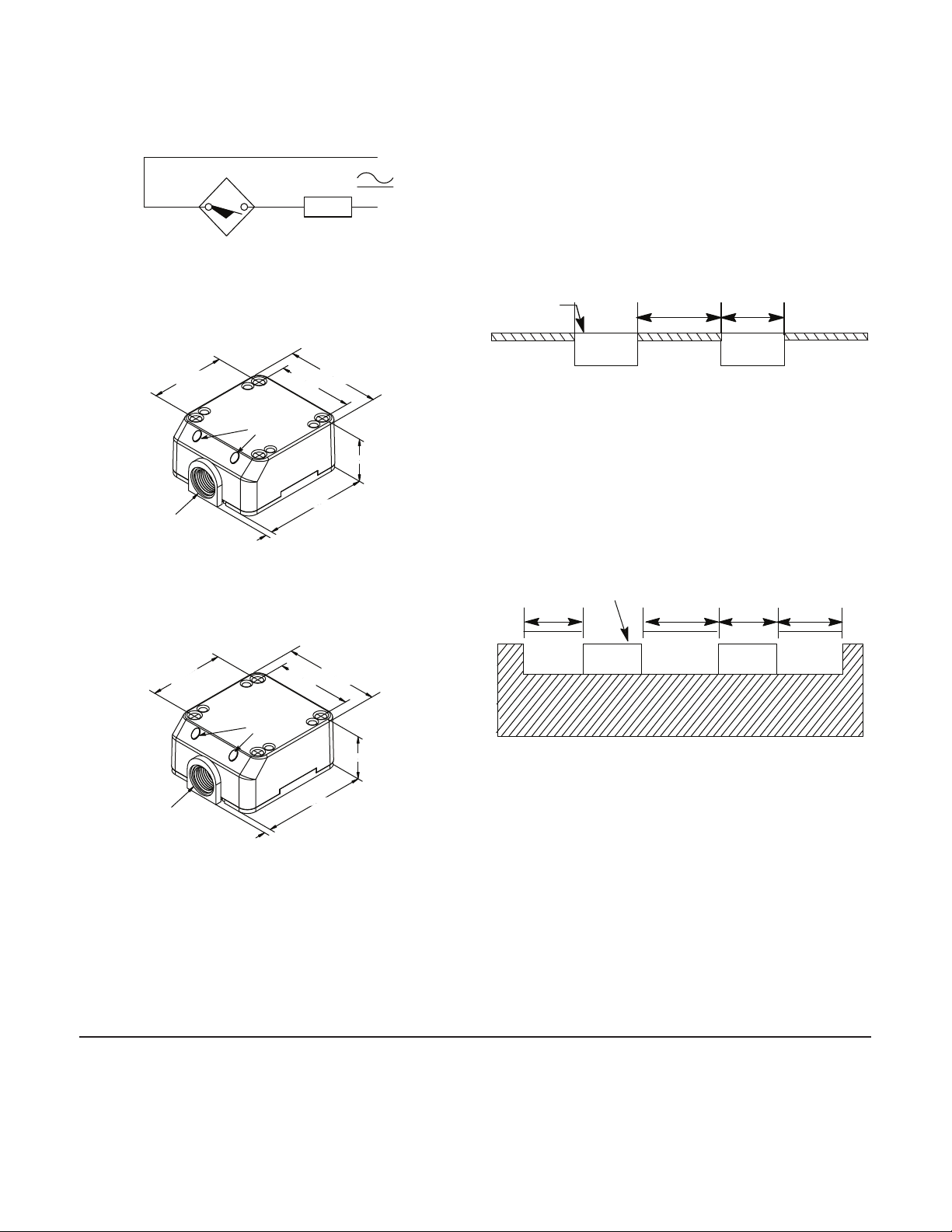

65.0

(2.56)

44.0 (1.57)

83.0

(3.27)

65.0

(2.56)

6.0

(0.24)

94.0 (3.70)

Conduit opening

1/2 inch internal

thread

LEDs

44.0 (1.57)

94.0 (3.70)

6.0

(0.24)

83.0

(3.27)

65.0

(2.56)

65.0

(2.56)

Conduit opening

PG13.5 internal

thread

Active Face

dd

Mounting Space

Conduit Style 1/2-14 NPT, PG13.5 Normally Open

Approximate Dimensions [mm (in.)]

Conduit Style 1/2-14 NPT

Spacing Between Shielded Sensors (flushmountable) and Nearby Metal Surfaces

Shielded proximity sensors allow the electro-magnetic field to be concentrated to the front of the

sensor face. Shielded construction allows the

proximity to be mounted flush in surrounding metal

without causing a false trigger.

Flat Pack Style (871F)

Spacing Between Unshielded Sensors (nonflushmountable) and Nearby Metal Surfaces

Longer sensing distances can be obtained by

using an unshielded sensor. Unshielded proximity

sensors require a metal-free zone around the

sensing face. Metal immediately opposite the

sensing face should be no closer than three times

the rated nominal sensing distance of the sensor.

Suggested mounting: M5 or SAE#10 cap screw should be

used with a split lock washer to install the unit.

Conduit Style PG13.5

Flat Pack Style (871F)

Active Face

d4d

dd

Copyright © 2012 Rockwell Automation, Inc. All Rights Reserved. PN-141168

10000243172 Ver 00

March 2012

Loading...

Loading...