Page 1

Stack Light

Bulletin 855T

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this publication, those responsible

for the application and use of this control equipment must satisfy themselves that all

necessary steps have been taken to assure that each application and use meets all performance

and safety requirements, including any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this guide are

intended solely for purposes of example. Since there are many variables and requirements

associated with any particular installation, Allen-Bradley does not assume responsibility or

liability (to include intellectual property liability) for actual use based upon the examples

shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application, Installation and Maintenance

of Solid-State Control (available from your local Allen-Bradley office), describes some important

differences between solid-state equipment and electromechanical devices that should be taken

into consideration when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part, without

written permission of Rockwell Automation, is prohibited.

Page 3

Throughout this manual we use notes to make you aware of safety considerations:

ATTENTION

Identifies information about practices or circumstances that can lead

to personal injury or death, property damage or economic loss

!

Attention statements help you to:

identify a hazard

avoid a hazard

recognize the consequences

IMPORTANT

Allen-Bradley is a trademark of Rockwell Automation

DeviceNet is a trademark of the Open DeviceNet Vendor Association (ODVA).

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within the European Union and

EEA regions. It has been designed and tested to meet the following directives.

Identifies information that is critical for successful application and

understanding of the product.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC Electromagnetic

Compatibility (EMC) by applying the following standards, in whole or in part, documented in

a technical construction file:

EN 50081-2 EMC — Generic Emission Standard, Part 2 — Industrial Environment

EN 50082-2 EMC — Generic Immunity Standard, Part 2 — Industrial Environment

This product is intended for use in an industrial environment.

Page 4

Low Voltage Directive

This product is not required to meet Council Directive 73/23/EEC Low Voltage, as it is

designed for use with a voltage rating below 50V for alternating current and below 75V for

direct current. The requirements of EN 60947-5-1:1997 Low-Voltage Switchgear and

Controlgear, Part 5 - Control Circuit Devices, have been applied.

Page 5

Table of Contents

Preface

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Contents of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

EDS Web Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Chapter 1 —

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Base Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Module Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Rotary Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

DeviceNet Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Typical DeviceNet Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

DeviceNet Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chapter 2 —

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Data Rate Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Node Address Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installing the Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Connection to the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Stack Light Parameter Configuration. . . . . . . . . . . . . . . . . . . . . . . . 2-3

Scanner Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Chapter 3 —

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

DeviceNet Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Equipment Needed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Setting the Rotary Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

DeviceNet Stack Light Base Dimensions . . . . . . . . . . . . . . . . . . . . 3-4

Mounting the DeviceNet Stack Light . . . . . . . . . . . . . . . . . . . . . . . 3-5

Overview of DeviceNet Stack Light

Quick Start

Installation and Mounting

Publication 855T-UM001C-EN-P May 2005

Page 6

Table of Contents

Chapter 4 —

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Parameter Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

I/O Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Resetting the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

DeviceNet Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Chapter 5 —

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Bulb Burnout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Chapter 6 —

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Sample Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Appendix A —

Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Special Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Operations

Troubleshooting and Maintenance

Off-Line Node Recovery

Specifications

Appendix B —

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Message Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Class Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Object Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Publication 855T-UM001C-EN-P May 2005

DeviceNet Information

Page 7

Preface

This manual gives an overview of the Bulletin 855T DeviceNet Stack Light and describes

how to configure, install, operate, and troubleshoot the device on the DeviceNet Network.

Intended Audience

This manual is for the individuals responsible for installing, mounting, and operating the

855T DeviceNet Stack Light in an industrial environment.

You should understand DeviceNet Network operations, including how slave devices

operate on the network and communicate with a DeviceNet Master.

Contents of Manual

This manual is organized as follows:

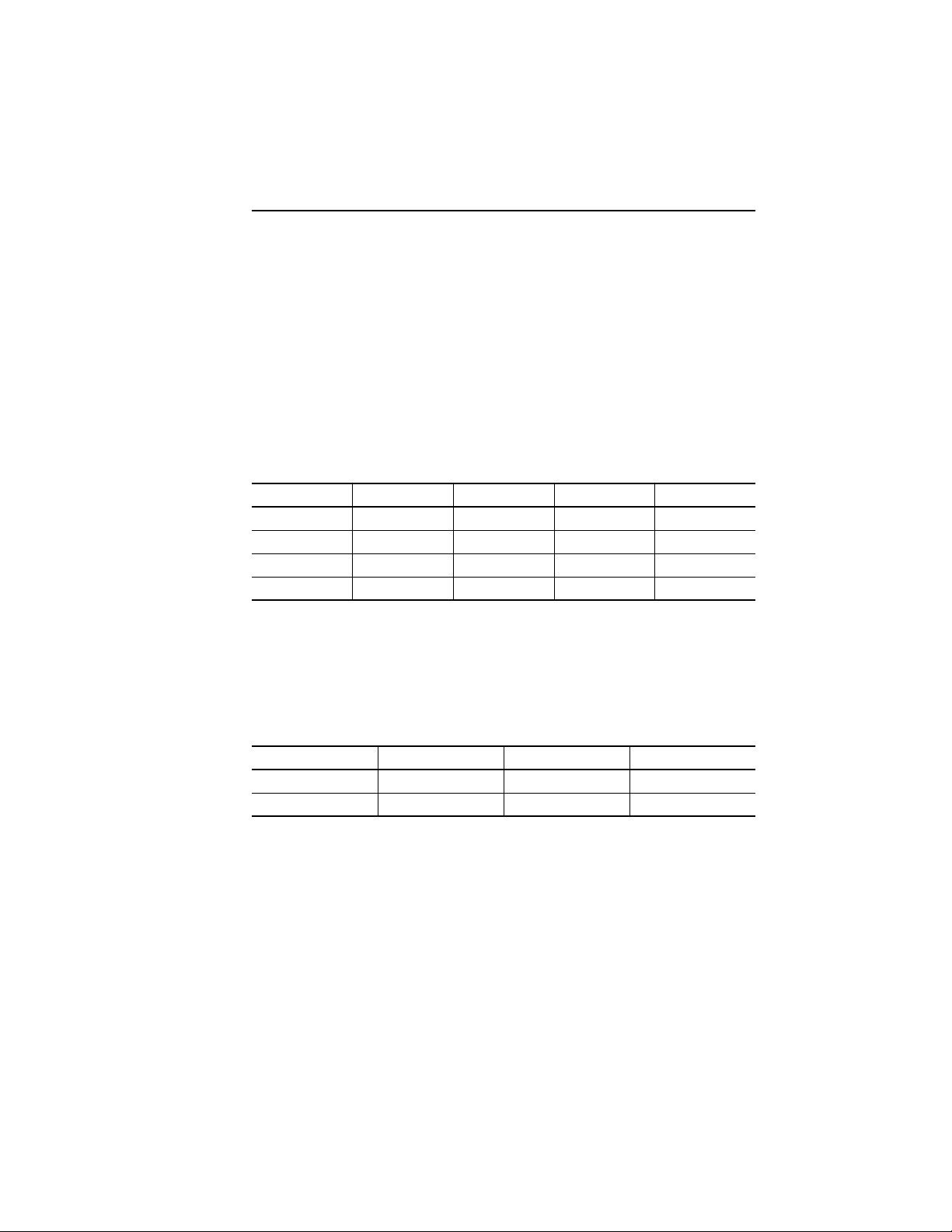

Table P.A

Chapter Title Description

— Preface Describes the purpose and contents of the manual,

1 Overview of DeviceNet Stack Light Provides an overview of the 855T DeviceNet Stack

2 Quick Start Describes how to get the DeviceNet Stack Light

3 Installation and Mounting Describes how to configure, mount, and install the

4 Operations Describes 855T DeviceNet Stack Light operations

5 Troubleshooting and Maintenance Provides information on how to troubleshoot and

A Specifications Provides 855T DeviceNet Stack Light specifications.

B DeviceNet Information Describes DeviceNet message types, class services,

and the intended audience.

Light and its features.

operating on the network.

855T DeviceNet Stack Light device on the

DeviceNet Network.

and other pertinent information.

maintain the device.

and object classes supported by the 855T

DeviceNet Stack Light.

.

Table P.B

Publication Title Publication No.

DeviceNet Media Design Installation Guide DNET-UM072*-EN-P

1756-DNB Scanner Module Configuration 1756-6.5.15

Publication 855T-UM001C-EN-P May 2005

Page 8

ii Preface

Related Publications

The following is a DeviceNet Network related publication:

DNET-UM072*-EN-P, DeviceNet Media Design Installation Guide

EDS Web Site

EDS files are available for downloading at: http://www.ab.com/networks/eds

Publication 855T-UM001C-EN-P May 2005

Page 9

Chapter

1

Overview of DeviceNet Stack Light

Chapter Objectives

This chapter provides an overview of the DeviceNet Stack Light and its features. It contains

the following sections:

Tabl e 1.A

Section Page Section Page

Description 1-1 DeviceNet Connection 1-3

Base Features 1-2 Typical DeviceNet Configuration 1-4

Module Positions 1-3 DeviceNet Components 1-5

Rotary Switches 1-3 Replacement Parts 1-5

Description

The 855T Control Tower Stack Light line offers DeviceNet Bases for applications where

network communication is desired. All of the functionality for the DeviceNet Interface is

contained within the mounting base. All light and sound modules for the 855T Control

Tow er Stack Light line are compatible with the standard bases, or with DeviceNet Bases.

The entire stack is powered from the DeviceNet Network. A separate power supply is not

required.

The 855T Control Tower Stack Light DeviceNet Bases allow up to five light modules, four

light modules plus a combination light and sound module, four light modules plus a

single-tone sound module, three light modules plus a dual-tone sound module, or three light

modules plus a dual-circuit light and sound module.

Publication 855T-UM001C-EN-P May 2005

Page 10

1-2 Overview of DeviceNet Stack Light

Summary of Features

Standard or assembled configurations

Surface mounting, pole mounting (10 cm or 25 cm), vertical mounting, and conduit

mounting available

Allows the use of up to five modules in one stack

NEMA Type 4/4X/13 environmental rating and IP65 environmental rating

Easy installation and startup

DeviceNet connectivity

Powered by DeviceNet connection (no power supply required)

Available with stranded wire, micro connector, or mini connector

DeviceNet Cable is pre-wired to all bases

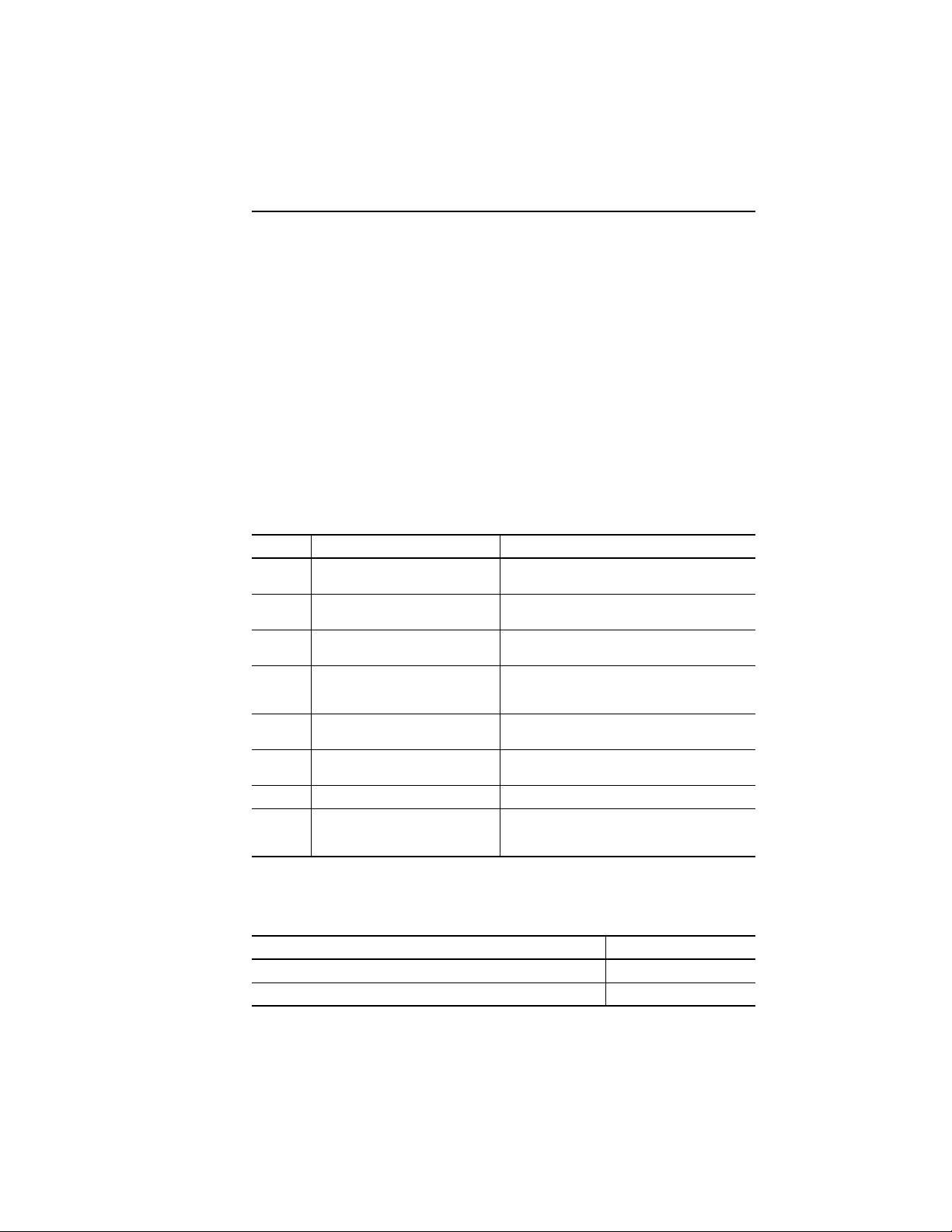

Base Features

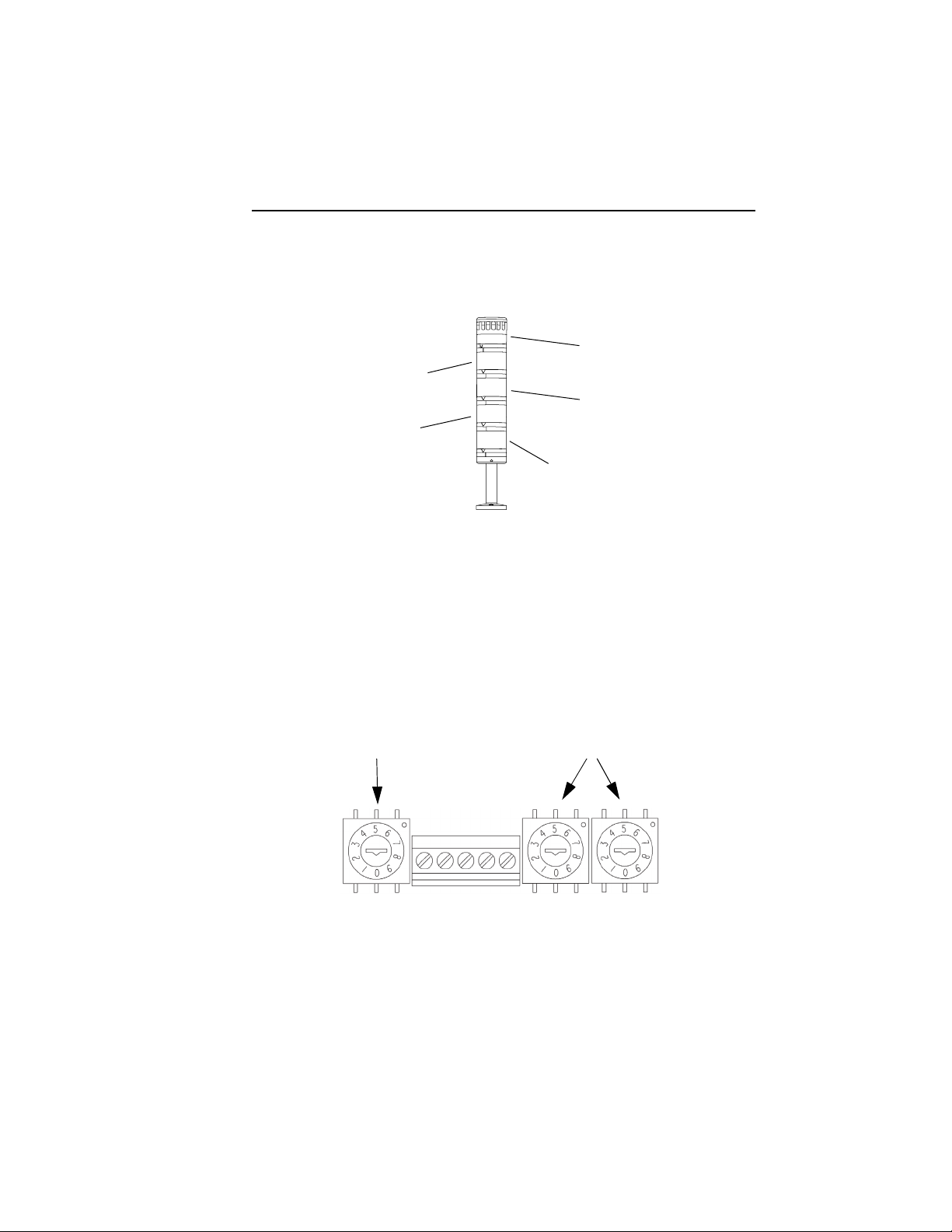

Figure 1.1

Rotary

Switches

855T

Base

Publication 855T-UM001C-EN-P May 2005

DeviceNet™

Connector

Page 11

Overview of DeviceNet Stack Light 1-3

Module Positions

Figure 1.2

5

4

3

2

1

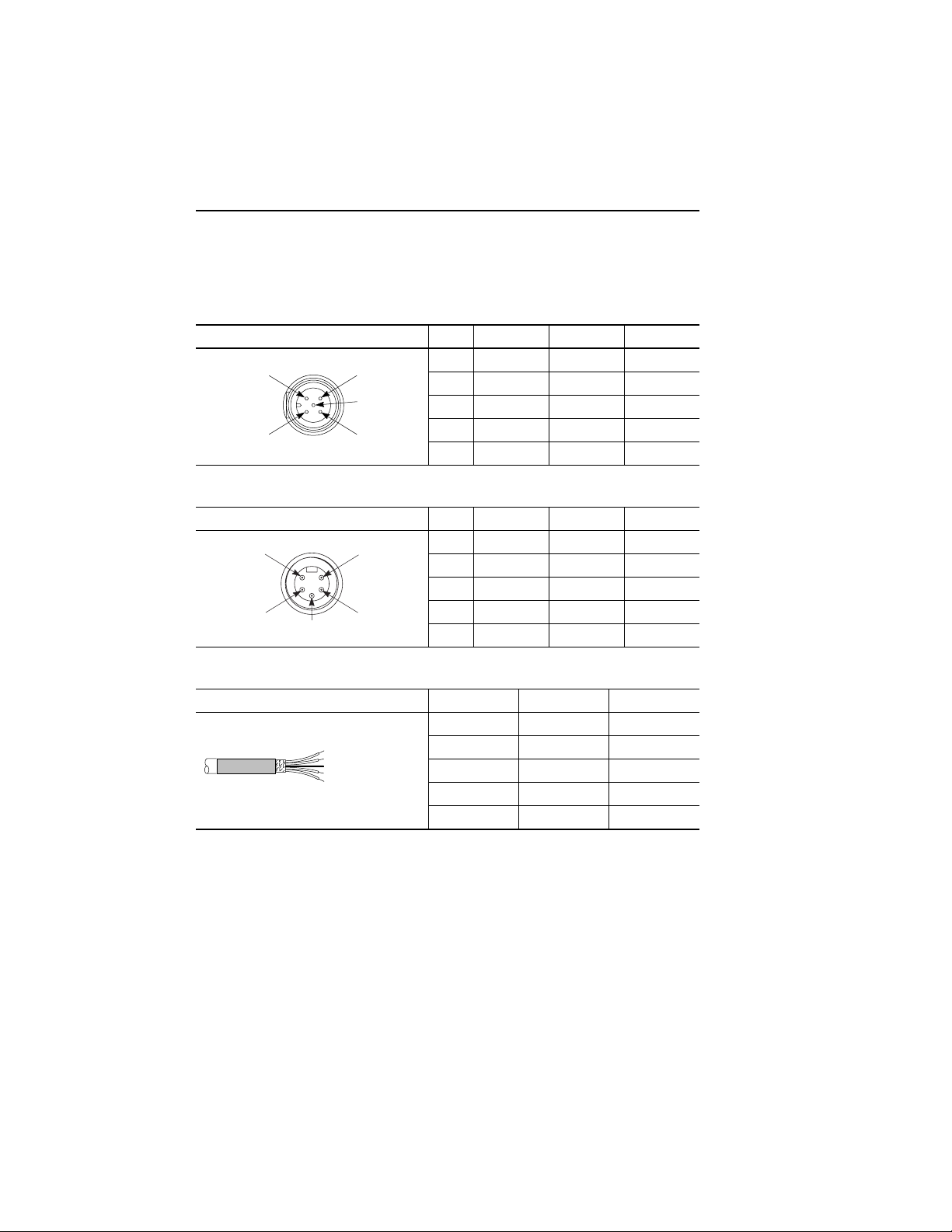

Rotary Switches

The DeviceNet Stack Light has three 10-position rotary switches for setting:

DeviceNet Data Rate

DeviceNet Node Address

The rotary switches are located on the circuit board on the top of the base. The switch

settings and functions are shown below.

Figure 1.3

Data Rate

Node Address

MSB

LSB

DeviceNet Connection

The DeviceNet Stack Light receives all power and communications through the DeviceNet

Cable. A separate power supply is not required. This is the only external connection to the

DeviceNet Stack Light.

Publication 855T-UM001C-EN-P May 2005

Page 12

1-4 Overview of DeviceNet Stack Light

The DeviceNet Stack Light connects to the DeviceNet Network using a cable with a micro

connector, a mini connector, or an open-style connector.

Table 1.B DeviceNet Micro Connector

Micro Connector Pin # Signal Function Color

1 DRAIN

2 RED

Table 1.C DeviceNet Mini Connector

Mini Connector Pin # Signal Function Color

1

2

3

4 WHITE

5 BLUE

3 BLACK

5

4

1 SHIELD SHIELD Uninsulated

2 VDC+ Power Supply Red

3 COM Common Black

4 CAN_H Signal High White

5 CAN_L Signal Low Blue

1 SHIELD SHIELD Uninsulated

2 VDC+ Power Supply Red

3 COM Common Black

4 CAN_H Signal High White

5 CAN_L Signal Low Blue

Table 1.D DeviceNet Open-Style Connector

Open-Style Connector Signal Function Color

COM Common Black

V-(black)

V+(red)

Drain Wire (bare)

CAN_H (white)

CAN_L (blue)

CAN_L Signal Low Blue

SHIELD Shield Uninsulated

CAN_H Signal High White

VDC+ Power Supply Red

Typical DeviceNet Configuration

A DeviceNet Network supports multiple Stack Light devices and allows them to

communicate with other network devices (up to 64).

The DeviceNet Stack Light operates on the network as a slave device. It does not initiate

communications except for a duplicate node address check on power-up. The master writes

data to, and receives data back from, the DeviceNet Stack Light.

The following DeviceNet configuration shows a variety of products operating as slaves to a

PLC-5 controller with a 1771-SDN DeviceNet Scanner Module.

Publication 855T-UM001C-EN-P May 2005

Page 13

Figure 1.4

Overview of DeviceNet Stack Light 1-5

DeviceNet™ Scanner Module

Block I/O

RediSTATION

PLC-5 Controller

Drive

DeviceNet™ Network

Sensor

SMC

Smart Motor Controller

Stack Light

DeviceNet Components

DeviceNet Cables and components are available from Allen-Bradley as separate cat. nos.

It is your responsibility to install and implement the DeviceNet Network and supported

devices according to the DeviceNet guidelines.

Replacement Parts

The DeviceNet Stack Light Bases and pre-assembled stacks come with all the parts required

to install and use the product. The installer needs only to supply the mounting hardware.

Replacement parts for 855T components (modules, replacement gaskets, and replacement

lamps) are available as separate cat. nos. Refer to the Signal Solutions Selection Guide

(Publication 855-SG001*-EN-P) or the Industrial Controls Catalog.

Publication 855T-UM001C-EN-P May 2005

Page 14

Chapter

2

Quick Start

Chapter Objectives

This chapter provides the necessary steps to get the DeviceNet Stack Light operating on the

network. It contains the following sections:

Table 2.A

Section Page Section Page

Data Rate Configuration 2-1 Connection to the Network 2-2

Node Address Configuration 2-2 Stack Light Parameter Configuration 2-3

Installing the Modules 2-2 — —

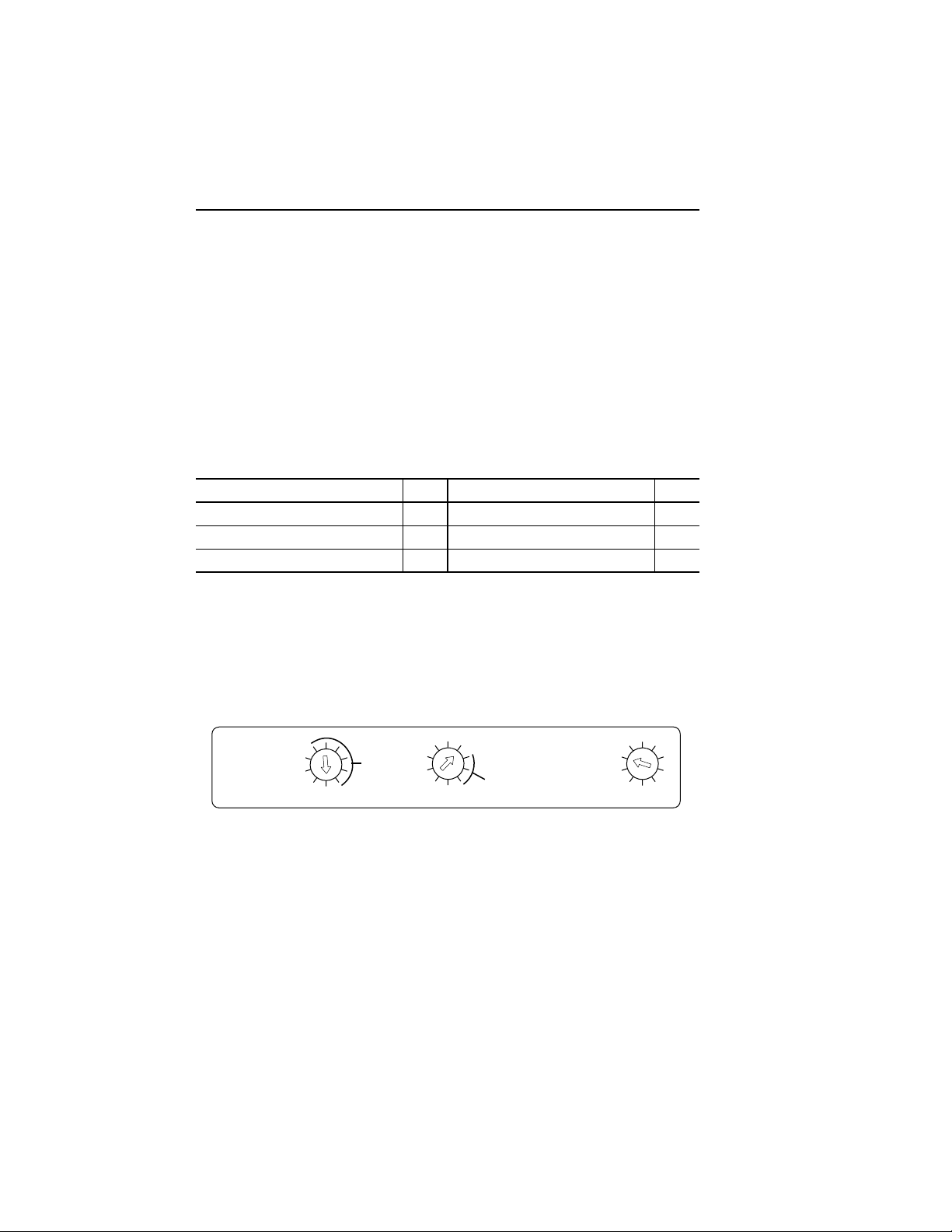

Data Rate Configuration

Rotary switch 3 (S3) sets the data rate at which the DeviceNet Stack Light communicates on

the DeviceNet Network. The factory default setting is 125 KB.

Figure 2.1

4

6

DATA

RATE

For more information on data rate configuration, refer to Chapter 3 — Installation and

Mounting (Setting the Data Rate).

Publication 855T-UM001C-EN-P May 2005

PGM

500K

250K

125K

NOT

USED

MSD

2

NODE ADDRESS

(00 – 63, PGM)

PGM

0

LSD

4

6

2

8

0

Page 15

Quick Start 2-2

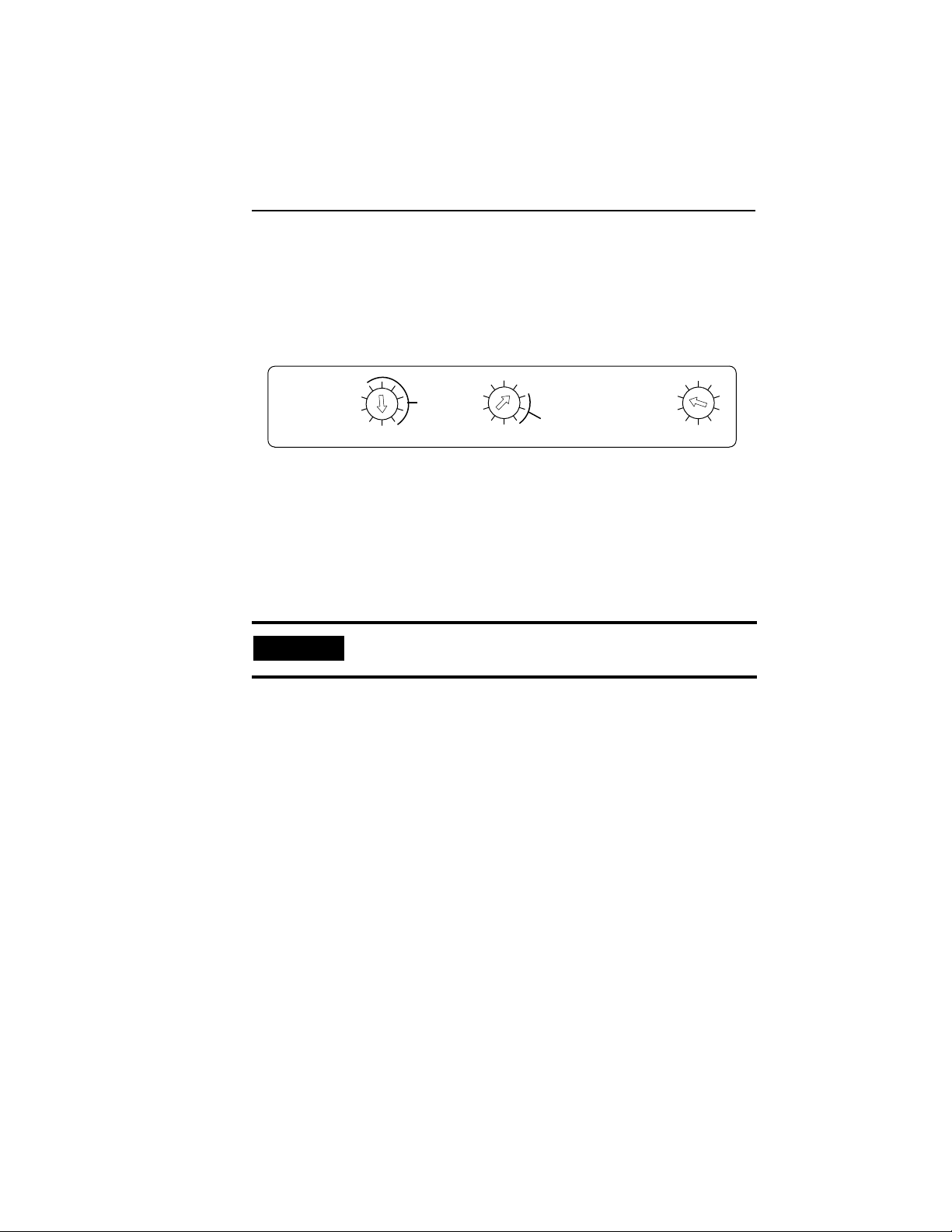

Node Address Configuration

Rotary switches 1 (S1) and 2 (S2) set the node address (0…63) of the stack light on the

DeviceNet Network. The factory default is 63.

Figure 2.2

4

6

DATA

RATE

For more information on node address configuration, refer to Chapter 3 — Installation and

Mounting (Setting the DeviceNet Node Address).

PGM

500K

250K

125K

NOT

USED

MSD

2

NODE ADDRESS

(00 – 63, PGM)

PGM

0

LSD

4

6

2

8

0

Installing the Modules

The stack light modules are installed to the base by placing a sealing o-ring between the base

and the module, lining up the arrow on the bottom of the module with the line on the top of

the prior module or base, and twisting the top module clockwise to lock them into place.

IMPORTANT

For more information on different modules, refer to the Signal Solutions Selection Guide

(Publication 855-SG001*-EN-P) or the Industrial Controls Catalog.

The DeviceNet Base is compatible with all 24V DC 855T modules.

Connection to the Network

Wire the DeviceNet Stack Light to an operating network. If the device is an 855T-DSxxxx,

the wires should be connected to a terminal block. If the device is an 855T-DMxxxx or

855T-DLxxxx, it will be connected with the quick disconnect connector. The device is fully

powered by the network, therefore it is important that the device is located near a power

supply.

For more information on system installation, refer to the DeviceNet Media Design Installation

Guide (Publication DNET-UM072*-EN-P).

Publication 855T-UM001C-EN-P May 2005

Page 16

2-3 Quick Start

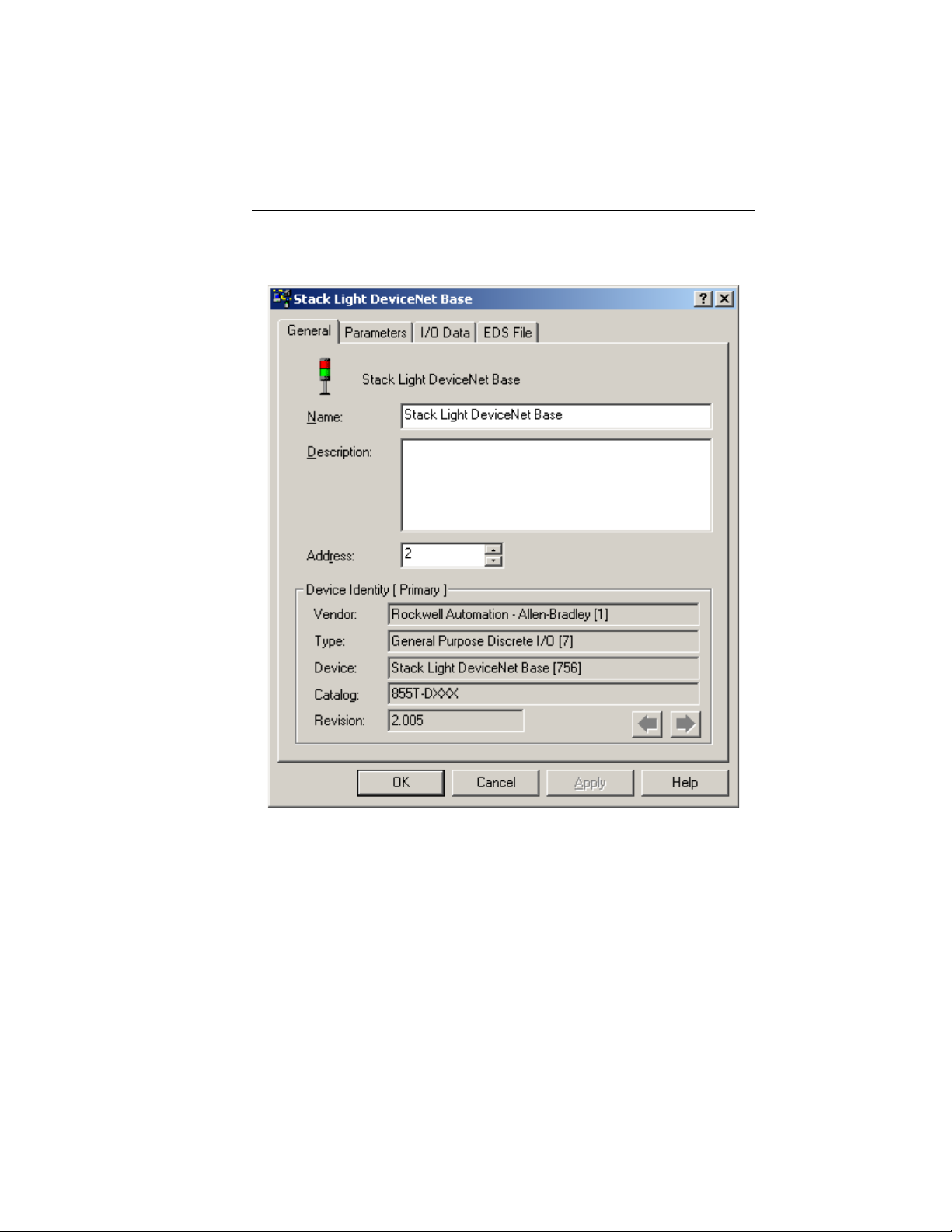

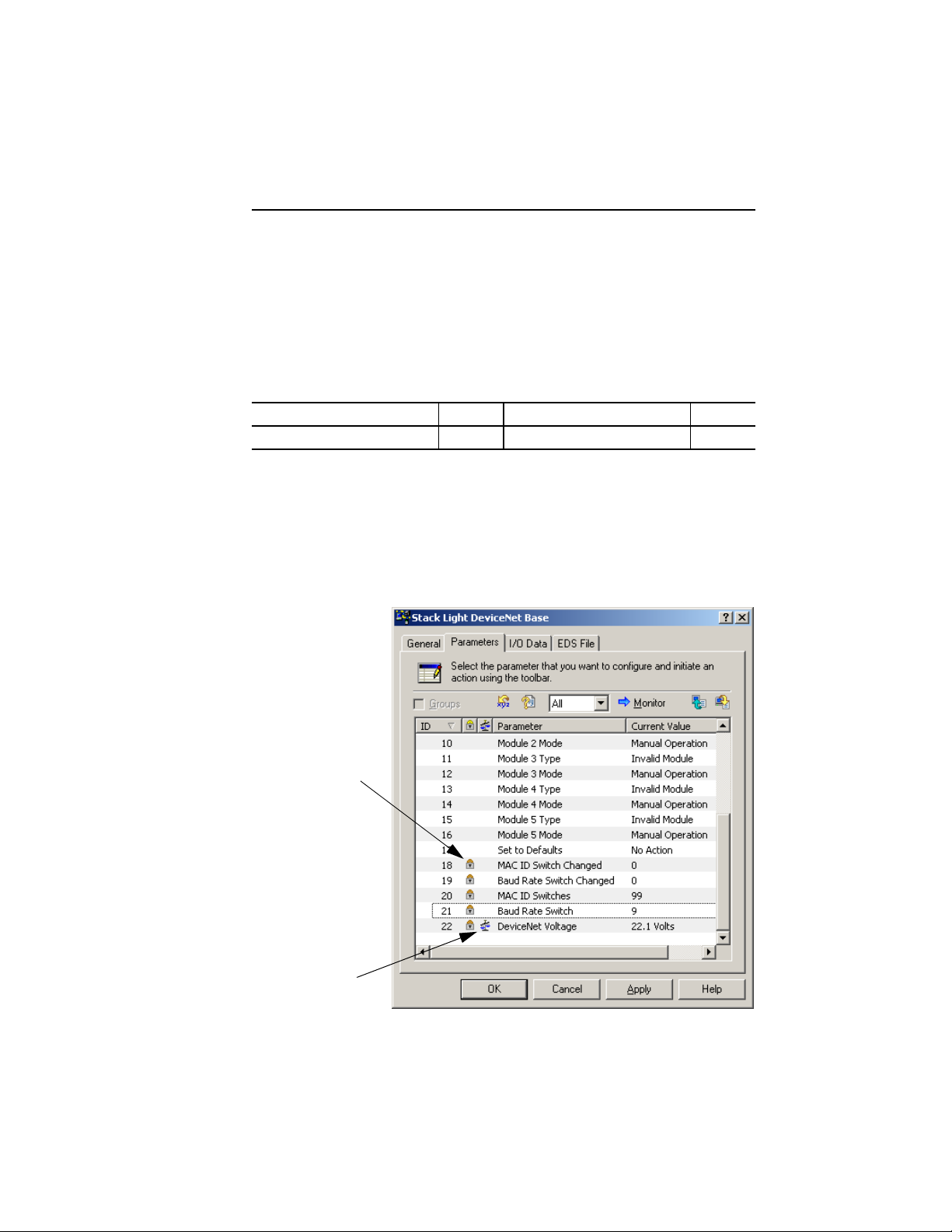

Stack Light Parameter Configuration

For proper operation, the parameters of the stack light must be configured. There are several

different parameters that can be configured, but the critical parameters are Module Type and

Module Mode. The parameters can be configured using RSNetWorx for DeviceNet.

Figure 2.3

To access the parameter configuration screen from the on-line view, double-click the stack

light icon.

Publication 855T-UM001C-EN-P May 2005

Page 17

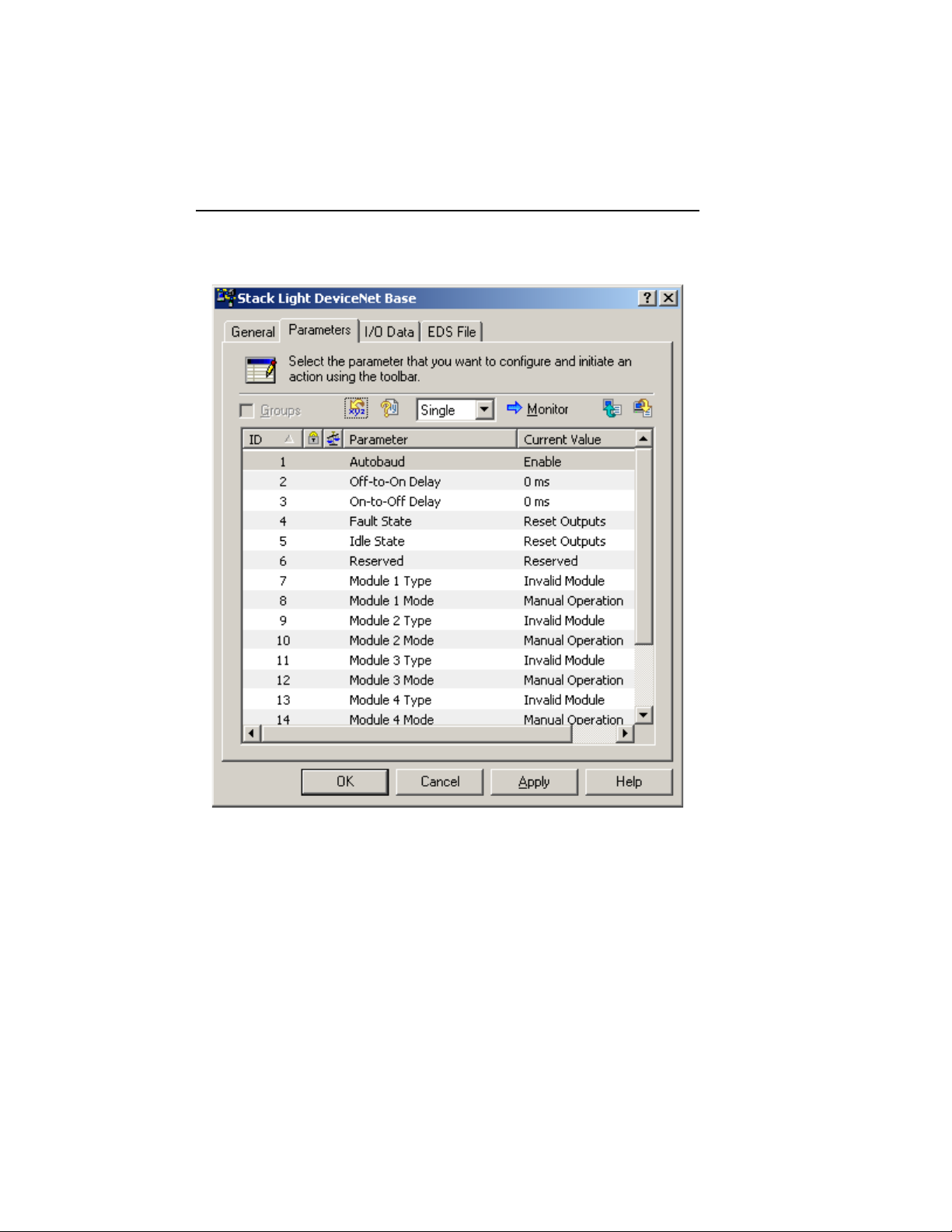

Figure 2.4

Quick Start 2-4

Select the Device Parameters tab.

Publication 855T-UM001C-EN-P May 2005

Page 18

2-5 Quick Start

Figure 2.5

The stack light will work without any parameter changes, but for flashing patterns and bulb

burnout detection, parameters must be changed. For more information on device

configuration, refer to Chapter 4 — Operations (Parameter Configuration) and RSNetWorx

for DeviceNet documentation.

Publication 855T-UM001C-EN-P May 2005

Page 19

Quick Start 2-6

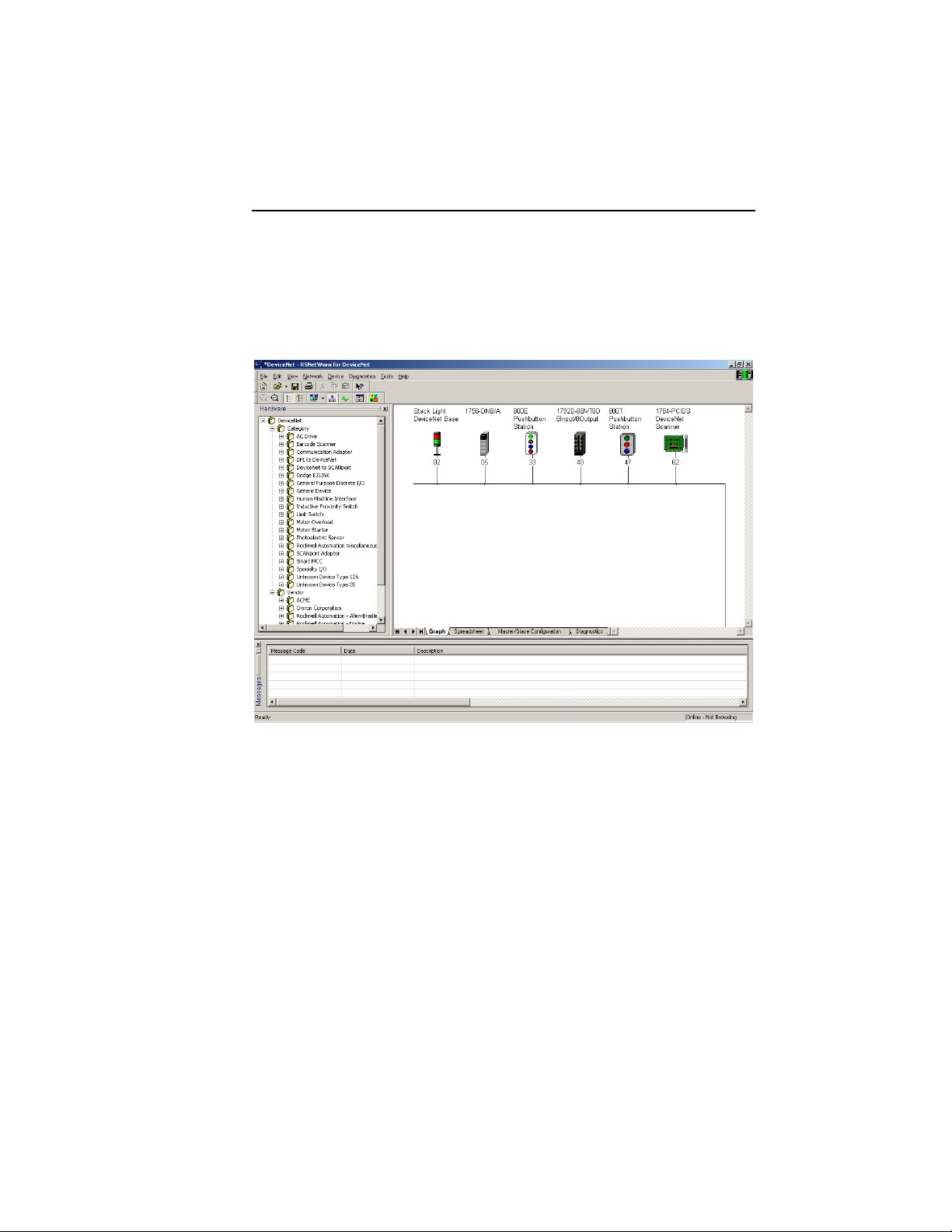

Scanner Configuration

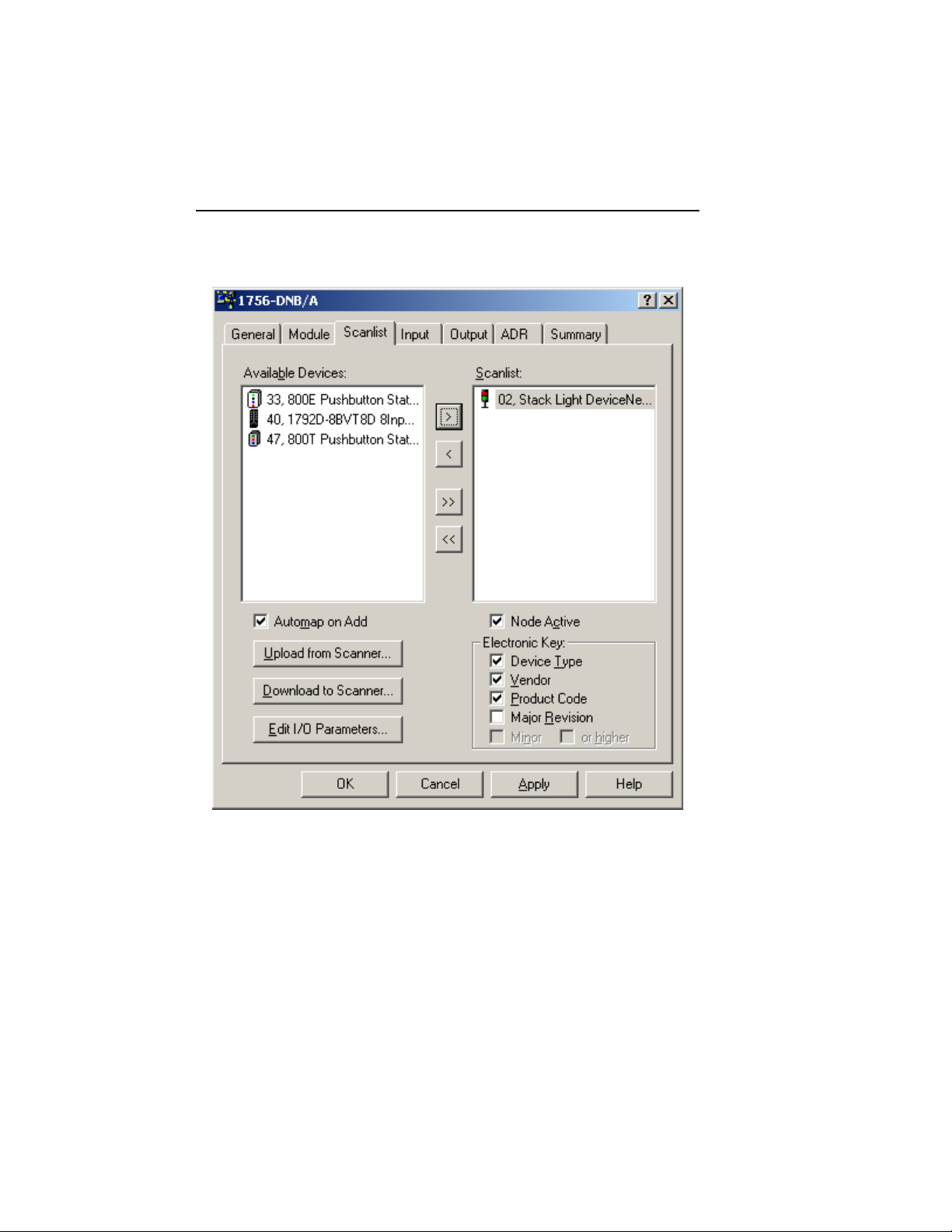

For proper operation, the scanner must be configured. The following graphics show the

configuration of a 1756-DNB from the RSNetWorx for DeviceNet software.

Figure 2.6

To access the Scanner Module Configuration screen from an on-line view, double-click the

1756-DNB scanner icon.

Publication 855T-UM001C-EN-P May 2005

Page 20

2-7 Quick Start

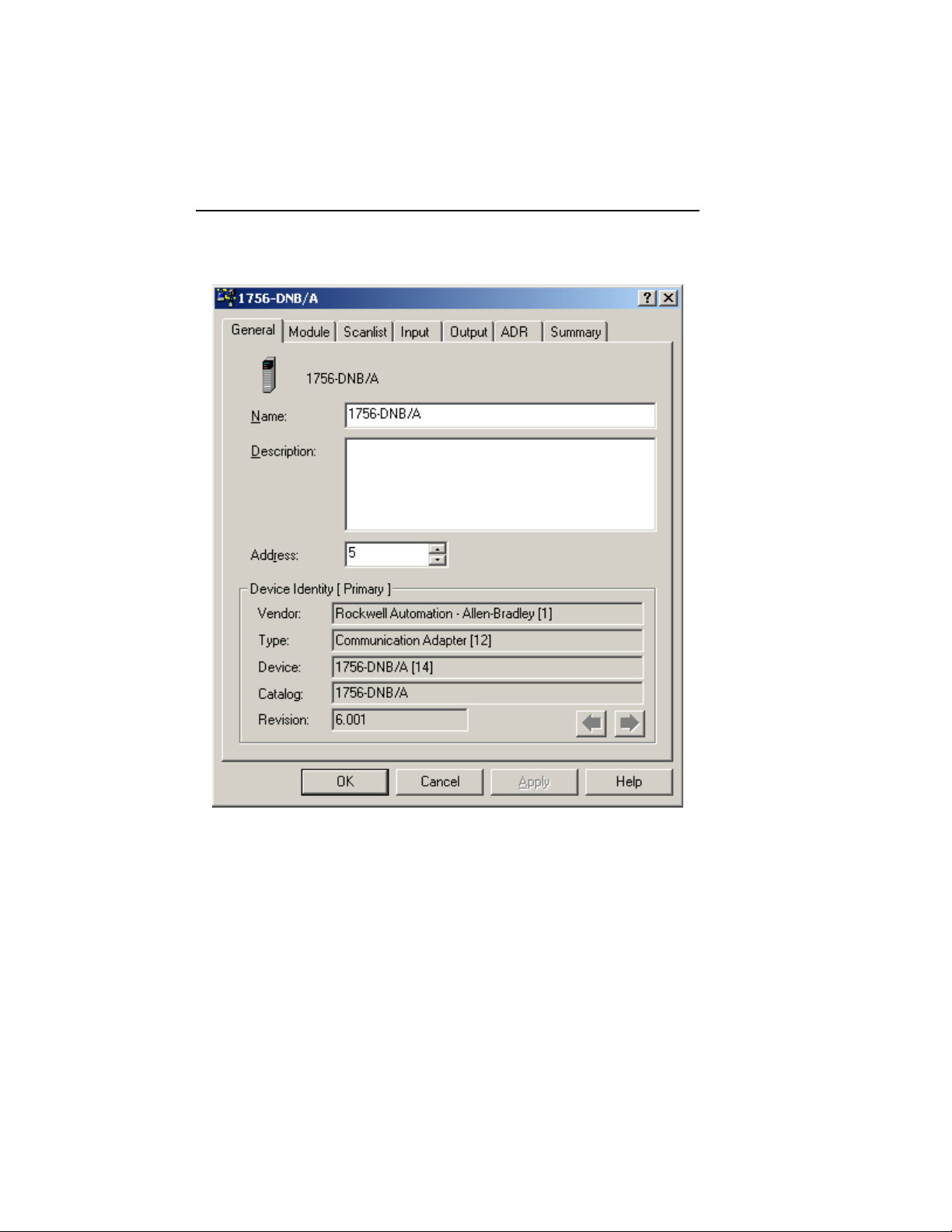

Figure 2.7

To access the Scanlist Editor, select the Scanlist tab.

Publication 855T-UM001C-EN-P May 2005

Page 21

Figure 2.8

Quick Start 2-8

Add Stack Light DeviceNet Base to the Scanlist. Select the device in the Available Devices

list. To have the software automatically assign I/O addresses, select the Automap on Add

selection box. Click the > button.

Publication 855T-UM001C-EN-P May 2005

Page 22

2-9 Quick Start

Figure 2.9

To view/edit I/O parameters, click Edit I/O Parameters.

Publication 855T-UM001C-EN-P May 2005

Page 23

Figure 2.10

Quick Start 2-10

To view/edit the mapping of the input data, click Cancel or OK to return to the Scanner

Module screen. Select the Input tab.

Publication 855T-UM001C-EN-P May 2005

Page 24

2-11 Quick Start

Figure 2.11

To view/edit the mapping of the output data, select the Output tab.

Publication 855T-UM001C-EN-P May 2005

Page 25

Figure 2.12

Quick Start 2-12

Publication 855T-UM001C-EN-P May 2005

Page 26

Chapter

3

Installation and Mounting

Chapter Objectives

This chapter describes how to install and mount a standard or custom DeviceNet Stack Light.

It contains the following sections:

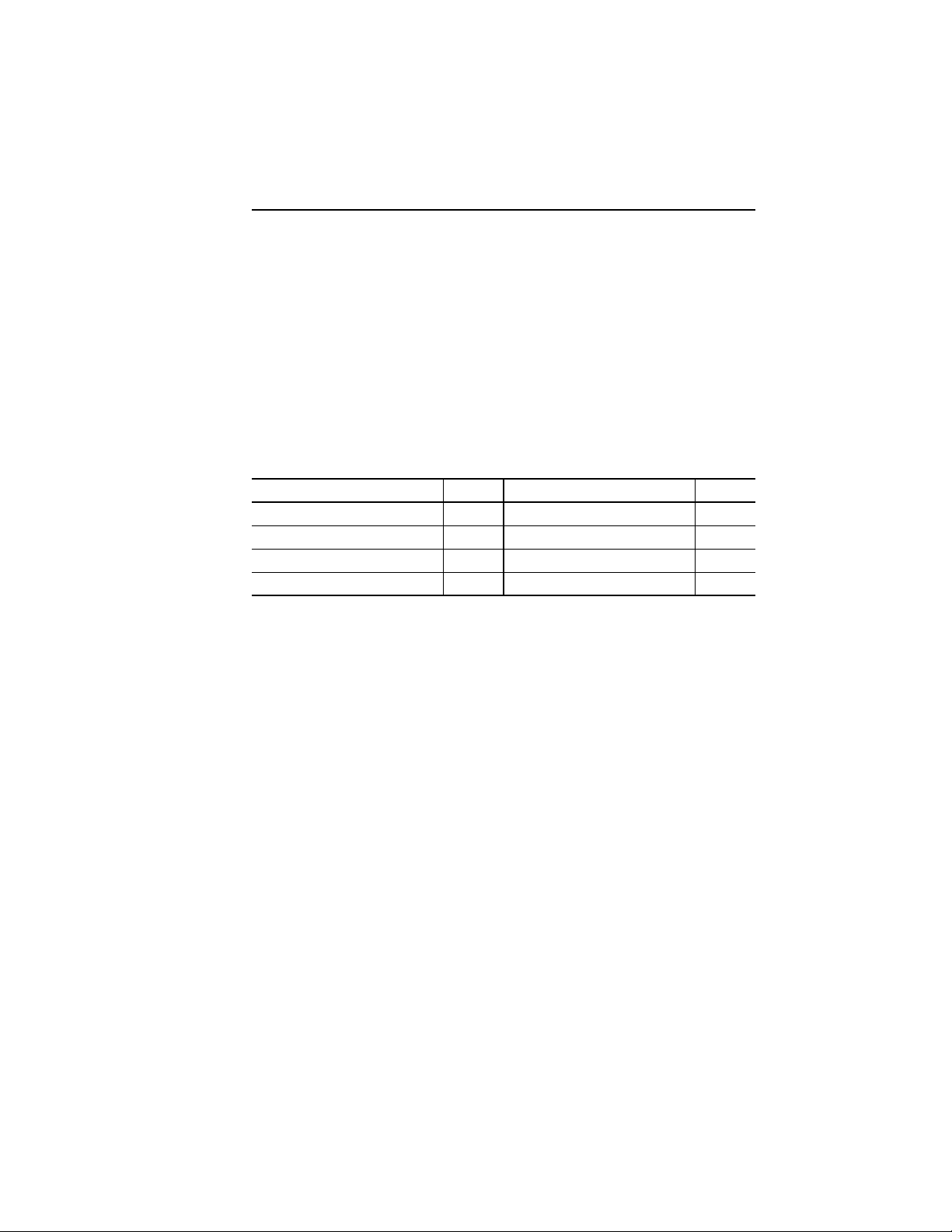

Table 3.A

Section Page Section Page

DeviceNet Guidelines 3-1 DeviceNet Stack Light Base Dimensions 3-4

Equipment Needed 3-1 Mounting the DeviceNet Stack Light 3-5

Setting the Rotary Switches 3-1 — —

DeviceNet Guidelines

It is your responsibility to install and implement the DeviceNet Network and supported

devices according to the DeviceNet guidelines.

Equipment Needed

Install the DeviceNet Stack Light using standard electrician’s tools:

Slotted screwdriver of standard and small sizes (one small screwdriver, required for

setting rotary switches, is included with the product)

Setting the Rotary Switches

The settings of the rotary switches on the circuit board determine:

DeviceNet Data Rate

DeviceNet Node Address

Publication 855T-UM001C-EN-P May 2005

Page 27

The location of the rotary switches is shown below.

Figure 3.1

Data

Rate

Installation and Mounting 3-2

Node

Address

S3

S2

S1

Network LED

Module LED

Setting the Data Rate

Rotary switch 3 (S3) sets the data rate at which the DeviceNet Stack Light communicates on

the DeviceNet Network. The factory default setting is 125 KB.

Figure 3.2

DATA

RATE

PGM

500K

250K

125K

NOT

USED

MSD

4

6

NODE ADDRESS

2

(00 – 63, PGM)

PGM

0

LSD

4

6

2

8

0

Publication 855T-UM001C-EN-P May 2005

Page 28

3-3 Installation and Mounting

The data rate determines the maximum length of the DeviceNet Cable.

Table 3.B

Position Data Rate Cable Length (Max.)

0 125 KB 500 m (1600 ft)

1 250 KB 200 m (600 ft)

2 500 KB 100 m (300 ft)

3 Autobaud See above, based on data rate of connected network

To set the DeviceNet data rate:

1. Refer to the table above to select the correct data rate.

2. If automatic baud rate selection is desired, set switch 3 (S3) in position 3. This

disables the switch and allows the device to sync to an operational network (if

Autobaud is disabled through parameter setup, this position is not valid).

Setting the DeviceNet Node Address

Rotary switches 1 (S1) and 2 (S2) set the node address (0…63) of the stack light on the

DeviceNet Network. The factory default is 63.

Figure 3.3

4

6

DATA

RATE

To set the DeviceNet node address:

1. Set Most Significant Digit (MSD) Switch, switch 2 (S2), to tens position. For example,

2. Set Least Significant Digit (LSD) Switch, switch 1 (S1), to ones position. For example,

3. If software programmability is desired, set the node address to 64 or greater. This

Publication 855T-UM001C-EN-P May 2005

PGM

500K

250K

125K

if the desired node address is 27, set switch 2 (S2) to 2.

if the desired node address is 27, set switch 1 (S1) to 7.

disables both switches and allows programming through the network. Software will

default to 63.

NOT

USED

MSD

2

NODE ADDRESS

(00 – 63, PGM)

PGM

0

LSD

4

2

0

6

8

Page 29

Installation and Mounting 3-4

DeviceNet Stack Light Base Dimensions

Figure 3.4 shows the dimensions of the Stack Light Bases. Dimensions in millimeters (inches).

Dimensions are not intended to be used for manufacturing purposes.

Figure 3.4 Stack Light Base Dimensions

20.8

(0.8)

124.5

(4.9)

4.5

(0.2)

69.0

(2.7)

PG16 or

1/2" NPT

Conduit Thread

65.3

(2.6)

5.2

(0.2)

30.0

(1.2)

40.3

(1.6)

45.0

(1.8)

Surface Mount Base

Vertical Mount Base

45.0

(1.8)

54.0

(2.1)

10 cm Pole Mount Base

54.0

(2.1)

54.0

(2.1)

54.0

(2.1)

274.5

(10.8)

70.0

(2.8)

(0.2)

70.0

(2.8)

5.0

5.0

(0.2)

Tube Mount Base

25 cm Pole Mount Base

Publication 855T-UM001C-EN-P May 2005

Page 30

3-5 Installation and Mounting

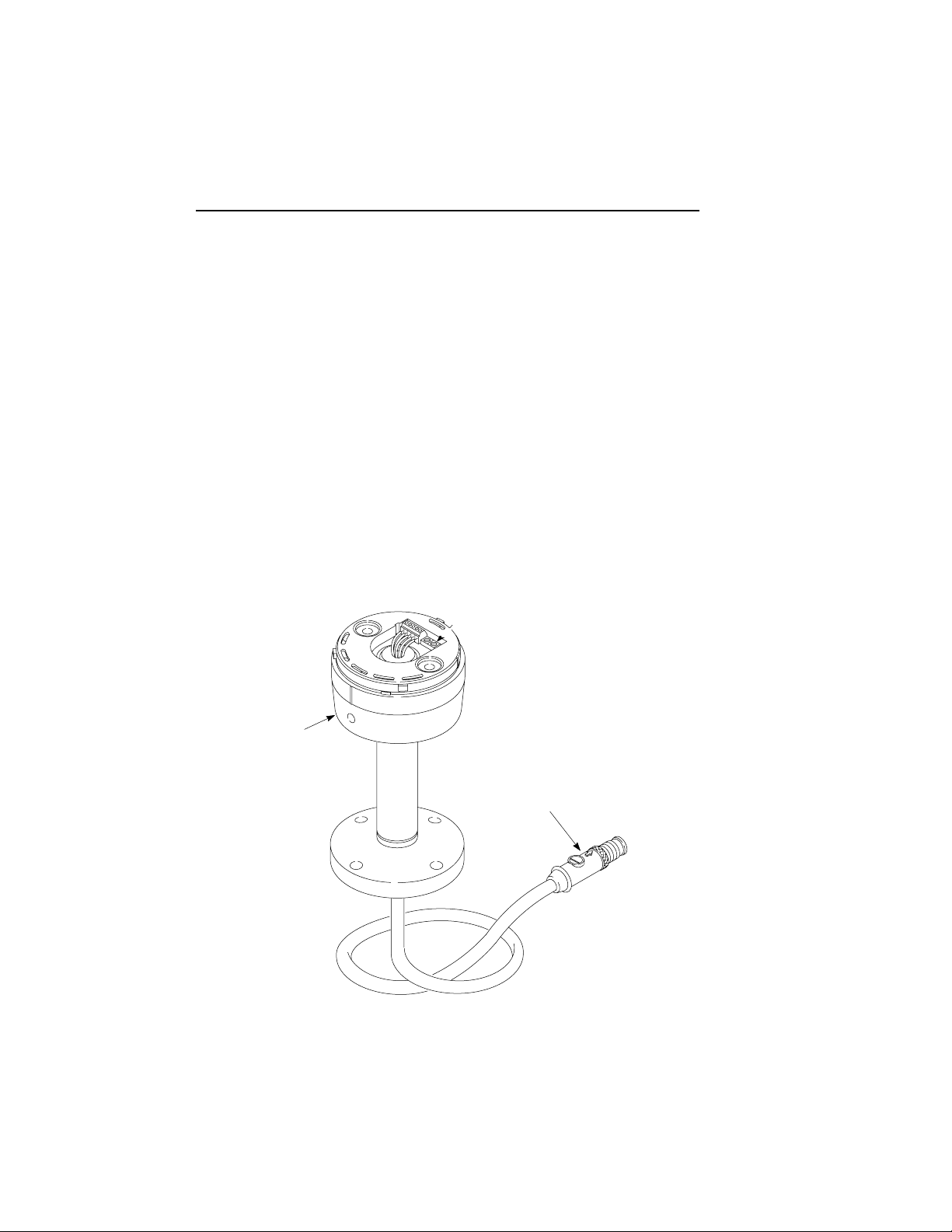

Mounting the DeviceNet Stack Light

Dimensions in millimeters (inches). Dimensions are not intended to be used for

manufacturing purposes.

Figure 3.5 Stack Light Mounting

45,0

(1 25/32)

Ø5,2

(13/64)

M5

(#10)

Ø10,0

(25/64)

Ø4,5

(11/64)

Ø11,5

(15/32)

M4

(#8)

M5

(#10)

mm

(in.)

45,0

(1 25/32)

2

3

855T - xTM

Publication 855T-UM001C-EN-P May 2005

38,0

(1 1/2)

89 N

(20 lb)

1

1,1 Nm

(10 lb-in.)

3 mm (M6 X 16)

Ø25,0

(63/64)

38,0

(1 1/2)

4

Page 31

Chapter

4

Operations

Chapter Objectives

This chapter contains the following sections:

Table 4.A

Section Page Section Page

Parameter Configuration 4-1 I/O Configuration 4-7

Parameter Configuration

There are 22 parameters available for monitoring in the Bulletin 855T DeviceNet Stack Light,

17 of which can be changed. Configuration of the parameters is accomplished through the

use of RSNetWorx for DeviceNet. The following illustration helps explain which parameters

are configurable and which are for monitoring.

Figure 4.1

The lock indicates this is

a read-only parameter

The scale indicates this

is a scaled value

Publication 855T-UM001C-EN-P May 2005

Page 32

4-2 Operations

The following tables give a brief explanation of the individual parameters and their uses:

Parameter 1 — Autobaud Enable

When enabled, the stack light automatically communicates at the network baud rate detected

at power-on. When disabled, the baud rate must be set correctly by the user during node

commissioning. This parameter’s setting takes effect after a module reset or at power-on.

Note: Only valid when rotary switch is set between 3…9. The default value is Enabled.

Table 4.B

Value Function Value Function

0 Enabled 1 Disabled

Parameter 2 — Off-to-On Delay

The Off-to-On delay determines the amount of time for which an input signal must be fully

present before the stack light updates the I/O. It is a means of filtering for noise on input

lines. The value must be set in units of microseconds. The default is set to 0 s to ensure

proper filtering on noisy lines, but it can be reduced depending on the application. (Not Used)

Table 4.C

Value (s) Function Value (s) Function

0 0 ms delay 8000 8 ms delay

2000 2 ms delay 16000 16 ms delay

4000 4 ms delay

Parameter 3 — On-to-Off Delay

The On-to-Off delay determines the amount of time for which an input signal must be fully

absent before the stack light updates the I/O. It is a means of filtering for noise on input lines.

The value must be set in units of microseconds. The default is set to 0 s to ensure proper

filtering on noisy lines, but it can be reduced depending on the application. (Not Used)

Table 4.D

Value (s) Function Value (s) Function

0 0 ms delay 8000 8 ms delay

2000 2 ms delay 16000 16 ms delay

4000 4 ms delay

Publication 855T-UM001C-EN-P May 2005

Page 33

Operations 4-3

Parameter 4 — Fault State

This parameter tells the stack light what to do with the output in the case of a fault state. If

“Go to Fault Value” is selected, the device refers to the Fault Value parameter to determine

the state. If “Hold Last State” is selected, the output stays in the last state. The default value is

0 — Go to Fault Value.

Table 4.E

Value Function Value Function

0 Go to Fault Value 1 Hold Last State

Parameter 5 — Idle State

This parameter tells the stack light what to do with the output in the case of an idle state (an

I/O connection exists, but the master is in program mode or idle state). If “Go to Idle Value”

is selected, the device refers to the Output Idle Value parameter to determine the state. If

“Hold Last State” is selected, the output stays in the last state. The default value is 0 — Go to

Idle Value.

Table 4.F

Value Function Value Function

0 Go to Idle Value 1 Hold Last State

Parameter 6 — Reserved

Reserved for future use.

Publication 855T-UM001C-EN-P May 2005

Page 34

4-4 Operations

Parameters 7, 9, 11, 13, 15 — Module Type

IMPORTANT

Although it is allowed, it is not recommended that strobe, sound, or

flashing modules be used with modes that flash.

In normal operation the device will permit configuration of each module type. The default

type is 8, Invalid Module.

Table 4.G Module Type

Type Module Type Module

0 Incandescent 5 Combination Strobe/Sound

1 LED 6 Single Tone Sound

2 Strobe 7 Dual Tone Sound

3 Combination Incandescent/Sound 8 Invalid Module

4 Combination LED/Sound — —

IMPORTANT

The module type list is abbreviated. If the module is a rotating, flashing,

or steady LED, then select the LED as the module type. If the module

type is a flashing incandescent, then select Incandescent as the module

type. The same logic applies to combination light/sound type modules.

Publication 855T-UM001C-EN-P May 2005

Page 35

Operations 4-5

Parameters 8, 10, 12, 14, 16 — Module Mode

Table 4.H Operating Modes

Mode Function

0Self Test

1 For Future Use

2 For Future Use

3 Follows Module status LED

4 Follows Network status LED

5 Manual Operation, controlled by network (PLC/PC)

6 For Future Use

7 For Future Use

8 IEC Fast Rate flash: 2 Hz, 50% duty cycle

9 For Future Use

10 For Future Use

11 IEC Slow Rate flash: 0.6 Hz, 50% duty cycle

12 For Future Use

13 For Future Use

14 Horn cycle: 30 s ON/10 s OFF

15 WALK: Sequence with other Mode 15 lights as: 1;2;3;4;5;1;2;…

16 STACK: Sequence with other Mode 16 lights as: 1;1&2;1&2&3;…;1&2&3&4&5;1

17 Binary count displayed on available Lamps

18 Odd/Even IEC Fast Rate Flash — All even number lights flash opposite all odd number lights.

19…255 Reserved

Parameter 17 — Set to Defaults

This parameter can be used to return the Bulletin 855T stack light to the “out of the box”

settings. This is the easiest way to clear an unwanted configuration. The default is No Action.

Table 4.I

Value Function Value Function

0 No Action 1 Reset

Publication 855T-UM001C-EN-P May 2005

Page 36

4-6 Operations

Parameter 18 — MAC ID Switch Changed

This is a read-only parameter used to determine whether the Node Address switches have

been changed since the last power up. If the switches have been changed this bit will be set.

The default is 0 — No Changes.

Table 4.J

Value Function Value Function

0 No changes 1 Switches have changed

Parameter 19 — Baud Rate Switch Changed

This is a read-only parameter used to determine whether the baud rate switch has been

changed since the last power up. If the switch has been changed this bit will be set. The

default is 0 — No Changes.

Table 4.K

Value Function Value Function

0 No changes 1 Switch has changed

Parameter 20 — MAC ID Switch Value

This is a read-only parameter used to identify the physical setting on the Node Address

switches. This is helpful because the enclosure does not need to be opened. The default is 99.

Table 4.L

Value Function

0…99 Value of switches

Parameter 21 — Baud Rate Switch Value

This is a read-only parameter used to identify the physical setting on the baud rate switch.

This is helpful because the enclosure does not need to be opened. The default is 9.

Table 4.M

Value Function

0…9 Value of switch

Publication 855T-UM001C-EN-P May 2005

Page 37

Operations 4-7

Parameter 22 — DeviceNet Voltage

This read only parameter is used for monitoring the DeviceNet voltage at the node. The

voltage reported via Parameter 22 may vary from actual voltage by up to 1V DC.

I/O Configuration

The I/O messaging is set up by the master device through client/server connections at

power-up. This device supports both Change-of-State (COS), cyclic, and Polled

I/O messaging connections. The default I/O size is one input byte and one output byte with

a polled I/O connection

The Output command is defined as follows:

Table 4.N Output Command Byte

Bit Number Function When = 1 Function When = 0

7——

6——

5——

4 Output 5 Execute Output 5 Idle

3 Output 4 Execute Output 4 Idle

2 Output 3 Execute Output 3 Idle

1 Output 2 Execute Output 2 Idle

0 Output 1 Execute Output 1 Idle

Table 4.O Input Byte

Bit Number Function When = 1 Function When = 0

7— —

6— —

5— —

4 Position 5 Idle, Not Present, or Burned Out Position 5 Normal

3 Position 4 Idle, Not Present, or Burned Out Position 4 Normal

2 Position 3 Idle, Not Present, or Burned Out Position 3 Normal

1 Position 2 Idle, Not Present, or Burned Out Position 2 Normal

0 Position 1 Idle, Not Present, or Burned Out Position 1 Normal

Publication 855T-UM001C-EN-P May 2005

Page 38

4-8 Operations

Error Mode

Errors are critical and non-critical.

Table 4.P

Error Type Description

Critical (non-recoverable) Failure of diagnostic tests during power-up/reset mode

Non-Critical (recoverable) Pilot lamp burned out/module missing (power must be cycled to reset Status

Refer to the troubleshooting chart in Chapter 5 for details on how to recover from an error.

Duplicate node address detected

Incorrect data rate

Byte once lamp is changed)

I/O connection timeout

Resetting the Device

To reset the 855T Control Tower Stack Light, you must cycle power to the unit or disconnect

the DeviceNet Cabling.

DeviceNet Operations

The Allen-Bradley 1747-SDN, 1771-SDN, and 1756-DNB DeviceNet Scanner Modules are

master devices on the DeviceNet Network. The 855T Control Tower Stack Light supports

the Master/Slave Connection Set for master/slave communications on the DeviceNet

Network.

To communicate with 855T Control Tower Stack Light, the DeviceNet Scanner Module must

be configured with the stack light:

Node Address

Input bytes (1)

Output bytes (1)

The DeviceNet Scanner Module:

connects to the 855T Control Tower Stack Light slave device.

performs appropriate connection configuration.

polls the 855T Control Tower Stack Light for I/O.

Publication 855T-UM001C-EN-P May 2005

Page 39

Chapter

Troubleshooting and Maintenance

Chapter Objectives

This chapter contains the following sections:

Table 5.A

Section Page Section Page

Preventive Maintenance 5-1 Troubleshooting 5-2

LED Indicators 5-2 Bulb Burnout 5-3

Preventive Maintenance

Prevent accumulation of dust and dirt by:

– keeping the base clean.

– keeping modules installed on base with o-rings.

Periodically check for loose connections.

5

ATTENTION

!

To avoid shock hazard, remove incoming power before checking

connections.

Publication 855T-UM001C-EN-P May 2005

Page 40

5-2 Troubleshooting and Maintenance

LED Indicators

LED indicators are provided in this design and can be mapped to modules. The functions are

defined below:

Table 5.B

Indication What To Do:

Module LED

Off No power applied to device

Green Device operating normally

Flashing Green Device needs commissioning due to configuration missing, incomplete, or incorrect

Flashing Red Recoverable fault

Red Unrecoverable fault may require device replacement

Flashing Red/Green Device is in self-test

Network LED

Off Device is not on-line

Green Device on-line and has connections in the established state

Flashing Green Device is on-line but has no connections in the established state

Flashing Red One or more I/O connections in timed-out state

Red Critical link failure - failed communication device. Device detected error that prevents it

Flashing Red/Green Communication faulted device - the device has detected a network access error and is

- Device has not completed dup_MAC_id test

- Device not powered - check module status indicator

from communicating on the network.

in communication faulted state. Device has received and accepted an identity

Communication Faulted Request - long protocol message.

Troubleshooting

The 855T Control Tower Stack Light goes through a power-up sequence when power is

cycled. It first goes through an internal memory check; if it passes this stage each of the

outputs is powered for 200 ms. If this does not occur, there is an internal fault with the device

or the modules are not connected properly. Check the modules for a good connection and

cycle power. If fault still exists, return the 855T Control Tower Stack Light for repair.

After power-up the device tries to connect to the network. The data rate is selected through a

rotary switch; if the data rate is incorrect the device will fault. Disconnect the device, change

the switch setting, and reapply power. If the data rate is unknown, Autobaud may be selected

and the device will select the correct data rate. (Note that this option can only be used with a

running network. It cannot be used for node commissioning.) (Autobaud will not work if it is

disabled through the parameter setup.)

Publication 855T-UM001C-EN-P May 2005

Page 41

Troubleshooting and Maintenance 5-3

Once the baud rate is set, the device issues a duplicate MAC ID check. If there is a duplicate

node on the network, the 855T Control Tower Stack Light will fault. Disconnect the device,

change the node address to an available one, and reapply power.

If the stack light or network resets when multiple outputs are turned on, it is likely due to

inadequate network power supply. This device has a high power consumption when used

with incandescent modules. Refer to the DeviceNet Media Design Installation Guide,

Publication DNET-UM072*-EN-P to make sure the power supply sizing and placement are

correct.

Bulb Burnout

Bulb Burnout is reflected in the Status Byte returned from the device. This feature only works

with incandescent modules or incandescent/sound combination modules. The current draw

of other module types is too low to sense correctly.

For burnout detection to work properly, the module type parameter must be configured by

the user. This can be done with the RSNetWorx for DeviceNet Software. If a module is

misconfigured, it may be reflected as a burnout in the Status Byte.

In order to clear the Status Byte, change the bulb and cycle power. If this does not clear the

fault, verify correct configuration of the module type parameter.

Publication 855T-UM001C-EN-P May 2005

Page 42

Chapter

6

Off-Line Node Recovery

Chapter Objectives

Table 6.A

Section Page Section Page

Overview 6-1 Sample Recovery 6-2

Overview

The Bulletin 855T Stack Light is equipped with a function known as Off-Line Node

Recovery. Off-Line Node Recovery is used mainly to commission a device on a network.

When a new product is put on the network, it is at a default address of Node 63. If multiple

units are placed on a network without first using node commissioning to change the node

address a duplicate MAC ID error occurs. This means that more than one device is located at

the same node address and only one of them is allowed online. Off-Line Node Recovery now

allows you to recover the faulted devices and change the node address. This is a powerful tool

because multiple nodes can be put on the network on installation and recovered one at a time

without having to continually reset the network. The following section will walk through a

sample recovery.

Note: If the MAC ID is set through the rotary switches, Off-Line Node Recovery will not be

able to recover the faulted device because it cannot change the node address.

Publication 855T-UM001C-EN-P May 2005

Page 43

Off-Line Node Recovery 6-2

Sample Recovery

This example has placed two Bulletin 855T Stack Lights on a network at the same node

address63.

From RSNetWorx, click the Single Pass Browse button. The following message will appear

in the message box at the bottom of the screen.

Figure 6.1

Select Faulted Address Recovery Wizard from the Tools menu.

Figure 6.2

Click the Next button.

Publication 855T-UM001C-EN-P May 2005

Page 44

6-3 Off-Line Node Recovery

Figure 6.3

If there are multiple faulted devices, they will show up in the list. Devices are identified by the

DeviceNet serial number that is unique to every product. The serial number for the Bulletin

855T Stack Light can be located on the nameplate or inside the product. Click the Next

button.

Publication 855T-UM001C-EN-P May 2005

Page 45

Figure 6.4

Off-Line Node Recovery 6-4

If there are multiple faulted units, you can verify which unit you are recovering by flashing the

Net Status LED. To do this click Flash LED. The LED will flash between red and green.

Click “00” under New Address to change the new address.

Publication 855T-UM001C-EN-P May 2005

Page 46

6-5 Off-Line Node Recovery

Figure 6.5

Change the address to the new address (for example, 22) and click Recover. Recovery is now

complete.

Publication 855T-UM001C-EN-P May 2005

Page 47

Off-Line Node Recovery 6-6

Figure 6.6

For more information on Off-Line Node Recovery refer to the RSNetWorx for DeviceNet

User Manual (Publication 1787-6.5.3).

Publication 855T-UM001C-EN-P May 2005

Page 48

Appendix

Specifications

Table A.1

Mechanical Ratings

Materials of Construction

Part Description Material Relative Thermal Index Flammability Rating

Bases, Cap Lexan 940 (polycarbonate),

Rubber Gaskets Perbunan NBR 70 (nitrile),

Rubber O-Ring HNBR 70 (nitrile),

Pole (for pole base) Aluminum — —

Plastic Washers Polypropylene — —

Strain Relief

Grommet

DeviceNet Cables Cable jacket is yellow CPR

Shock

Wave Shape 1/2 cycle sine wave

Duration 11 ms

Frequency Three times in each axis

Maximum

Allowable G Force

Vibration

Axis Definitions three mutually perpendicular axes

Frequency 5…2000 Hz

Duration 2 hrs each axis

Maximum

Allowable G Force

black, manufacturer GE

Plastics

Lexan 943 (polycarbonate),

gray, manufacturer GE

Plastics

manufacturer Freudenberg

manufacturer Angst + Pfister

Neoprene 50 Durometer,

manufacturer Kuehn Rubber

Corp.

chlorinated polyethylene,

molded connector is yellow

Santoprene

Operational

Non-operational

Operational

Non-operational

120C 94V-0

120C 94V-0

110C

max. use temperature

150C

max. use temperature

——

——

30 G

50 G

2.5 G

5G

—

—

A

Publication 855T-UM001C-EN-P May 2005

Page 49

Specifications A-2

Table A.1

Environmental Ratings

Ingress Ratings

Pole bases NEMA Type 4/13, IP65

All other NEMA Type 4/4X/13, IP65

Temperature Ratings

Operating Temperature –25…+70C

Storage Temperature –40…+85C

Relative Humidity (Non-Condensing) 0…95% humidity

Electrical Ratings

Supply Voltage The DeviceNet Base operates at 11…25V.

Power Consumption Maximum with five modules 36 W, 1.75 W in idle mode

Outputs (Modules) Up to five modules will be supported. The voltage

DeviceNet Connection Cables Three styles of DeviceNet connection cables will

Flash Upgrade Frequency Memory may be upgraded 100 times without

Communications

Data Rates 125 KB, 250 KB, and 500 KB

Distances

500 m (1600 ft) 125 KB

200 m (600 ft) 250 KB

100 m (300 ft) 500 KB

and current rating is 24V DC/300 mA maximum. All

standard 24V module types will be supported.

Refer to 855T catalog for module-specific

information.

be supported. A one meter micro-style connector, a

one meter mini-style connector, and a two meter

open-style cable will be supported. They will

consist of a 22 AWG drain wire, a 24 AWG twisted

pair for communications, and a 22 AWG twisted

pair for power. There is a 3 A maximum rating on

the power pair.

corruption of data.

Certifications

UL, CUL, and CE marked for all applicable directives. CE standards include EN55011,

EN50081-2, EN50082-2, and EN60947-5-1. This product is intended for use in an industrial

environment.

Special Notes

Refer to the Signaling Solutions Selection Guide (Publication 855-SG001*-EN-P) or the Industrial

Controls Catalog for module-specific information.

Publication 855T-UM001C-EN-P May 2005

Page 50

Appendix

B

DeviceNet Information

General Information

The 855T-Dxx (Multifunction I/O) device operates as a slave on the DeviceNet network.

The unit supports Explicit Messages and Polled I/O Messages of the predefined master/

slave connection set. It does not support the Explicit Unconnected Message Manager

(UCMM).

The device supports five discrete outputs, one for each possible stack position.

Message Types

As a group 2 slave device, the 855T-Dxx supports the following message types.

Table B.1 Supported Message Types

CAN Identifier Group 2 Message Type

10xxxxxx111 Duplicate MAC ID Check Messages

10xxxxxx110 Unconnected Explicit Request Messages

10xxxxxx101 Master I/O Poll Command Message

10xxxxxx100 Master Explicit Request Message

xxxxxx = Node Address

Class Services

As a group 2 slave device, the 855T-Dxx supports the following class services and instance

services.

Table B.2 Class Services

Service Code Service Name Service Code Service Name

14 (0x0E) Get Attribute Single 75 (0x4B) Allocate Group 2 Identifier Set

16 (0x10) Set Attribute Single 76 (0x4C) Release Group 2 Identifier Set

Publication 855T-UM001C-EN-P May 2005

Page 51

DeviceNet Information B-2

Object Classes

The 855T-Dxx device supports the following DeviceNet object classes.

Table B.3 Supported Objects

Class Object Class Object

01 (0x01) Identity 09 (0x09) Digital Output Point

02 (0x02) Message Router 15 (0x0f) Parameter

03 (0x03) DeviceNet 29 (0x1d) Discrete Input Group

04 (0x04) Assembly 30 (0x1e) Discrete Output Group

05 (0x05) Connection 43 (0x2b) Acknowledge Handler

08 (0x08) Digital Input Point 161 (0xa1) Non-Volatile Storage

Class Code 001 (0x01): Identity Object

The Identity Object is required on all devices and provides identification of and general

information about the device.

Class Attributes

None

Publication 855T-UM001C-EN-P May 2005

Page 52

B-3 DeviceNet Information

Instance Attributes

Table B.4

Attribute Access Name Type Value

1 Get Vendor UINT 1

2 Get Product Type UINT 7

3 Get Product Code UINT 756

4 Get Revision

5 Get Device Status UINT ➊

6 Get Serial Number UINT ➋

7 Get Product Name

➊ Device Status

bit 0 Owned 0 = not owned; 1 = owned (allocated)

bit 1 Reserved 0

bit 2 Configured 0

bit 3 Reserved 0

bit 4…7 Vendor-Specific 0

bit 8 Minor Cfg. Fault 0 = no fault; 1 = minor fault

bit 9 Minor Dev. Fault 0 = no fault; 1 = minor device fault

bit 10 Major Cfg. Fault 0 = no fault; 1 = major cfg. fault

bit 11 Major Dev. Fault 0 = no fault; 1 = major device fault

bit 12…15 Reserved 0

Major Revision

Minor Revision

Length

Name

STRUCT OF

USINT

USINT

Structure of:

USINT

STRING [Length]27“Tower Light I/O 2-in/5-out”

2

05

➋ Unique serial number

Common Services

Table B.5

Service Code Class Instance Service Name

05 (0x05) No Yes Reset

14 (0x0E) No Yes Get_Attribute_Single

Publication 855T-UM001C-EN-P May 2005

Page 53

DeviceNet Information B-4

Class Code 002 (0x02): Message Router Object

The Message Router Object provides a messaging connection point through which a client

may address a service to any object class or instance residing in the physical device.

Class Attributes

None

Instance Attributes

None

Common Services

None

Class Code 003 (0x03): DeviceNet Object

The DeviceNet Object is used to provide the configuration and status of a physical

attachment to DeviceNet. A product must support only one DeviceNet Object per physical

network attachment.

Class Attributes

Table B.6

Attribute Access Name Type Value

1 Get Revision UINT 2

Publication 855T-UM001C-EN-P May 2005

Page 54

B-5 DeviceNet Information

Instance Attributes

Table B.7

Attribute Access Name Type Value

1Get/SetMACID USINT➊

2 Get/Set Baud Rate USINT ➋

3 Get/Set Bus Off Interrupt BOOL ➌

4 Get/Set Bus Off Counter USINT ➍

5 Get Allocation Information

6 Get MAC ID Switch

7 Get Baud Rate Switch

8 Get MAC ID Switch Value USINT 0…99

9 Get Baud Rate Switch

100 (0x64) Get/Set Disable Autobaud BOOL ➏

Choice Byte

Master’s Node

Addr

Changed

Changed

Val ue

STRUCT of:

BYTE

USINT

BOOL 0 = No Change

BOOL 0 = No Change

USINT 0…9

➎

1 = Change since last Reset or

Power-Up

1 = Change since last Reset or

Power-Up

0…63 Hardware Set

64…99 Software Configurable

0…2 Hardware Set

3…9 Software Configurable

➊ The MACID is set using two BCD rotary switches located on the module top. Valid MACID addresses are

0…63 (0…3F Hex). Setting the switch address to a value greater than 63 will disable the switch and allow

software setting of the MACID. The software setting defaults to 63.

➋ The Baud Rate is set using a BCD rotary switch located on the module top. Valid Baud Rate settings are 0, 1,

and 2; these correspond to 125 KB/s, 250 KB/s, and 500 KB/s respectively. Setting the switch address to a

value of 3 will disable the switch and allow autobauding.

➌ Bus Off Interrupt (BOI) determines the action if a Bus Off state is encountered.

BOI Action BOI Action

0 Hold chip in OFF state (default) 1 If possible reset CAN chip

➍ Bus Off Counter will be forced to 0 whenever set regardless of the data value provided.

➎ Allocation_byte

bit 0 Explicit messaging bit 4 COS I/O

bit 1 Polled I/O bit 5 Cyclic I/O

bit 6 Acknowledge Suppression

➏ Disable Autobaud

0 Autobauding Enabled 1 Autobauding Disabled

Publication 855T-UM001C-EN-P May 2005

Page 55

DeviceNet Information B-6

Common Services

Table B.8

Service Code Class Instance Service Name

14 (0x0E) Yes Yes Get_Attribute_Single

16 (0x10) No Yes Set_Attribute_Single

75 (0x4B) No Yes Allocate_Master/Slave

76 (0x4C) No Yes Release_Master/Slave

Class Code 004 (0x04): Assembly Object

The Assembly Objects bind attributes of multiple objects to allow data to or from each object

to be sent or received over a single connection.

Class Attributes

Table B.9

Attribute Access Name Type Value

2 Get Max Class ID UINT 104 (0x68)

Instance Attributes

Table B.10 Assembly Object, Instance 100 Attributes

Attribute Access Name Type Value

3SetDataBYTE➊

Get State BYTE ➋

➊ The Assembly Data Byte consists of five bits, starting at bit 0. Each bit corresponds to a station position in

the stack. 1 = ON/ACTIVE.

➋ The Assembly Status Byte consists of five bits. Each of the lower five bits, starting at bit 0, corresponds to a

station position in the stack. 1 = Failed.

Publication 855T-UM001C-EN-P May 2005

Page 56

B-7 DeviceNet Information

Table B.11 Assembly Object, Instance 104 Attributes

Attribute Access Name Type Value

3Get/SetData

➊ The data for off_delay is time in microseconds, valid values: 0, 2000, 4000, 8000, 16000.

➋ The data for on_delay is time in microseconds, valid values: 0, 2000, 4000, 8000, 16000.

➌ Disable Autobaud: 0 = Enabled, 1 = Disabled

➍ Fault State: 0 = Reset Outputs, 1 = Hold Last State

➎ Idle State: 0 = Reset Outputs, 1 = Hold Last State

Off_delay

On_delay

Autobaud

DOG_Fault_State

DOG_Idle_State

STRUCT of:

UINT

UINT

BOOL

BOOL

BOOL

➊

➋

➌

➍

➎

Common Services

Table B.12

Service Code Class Instance Service Name

14 (0x0E) Yes Yes Get_Attribute_Single

16 (0x10) No Yes Set_Attribute_Single

Publication 855T-UM001C-EN-P May 2005

Page 57

DeviceNet Information B-8

Class Code 0x0005: Connection Object

No class attributes will be supported for the Connection Object.

Three instances of the Connection Object will be supported. Instance 1 will be the explicit

message connection, instance 2 will be the polled IO connection, and instance 4 will be the

COS/Cyclic IO connection.

Instance 1 is the Predefined Group 2 Connection Set Explicit Message Connection. The

following instance 1 attributes will be supported:

Table B.13

Attribute IDAccess

1 Get State USINT 0 = nonexistent

2 Get Instance Type USINT

3 Get Transport Class Trigger BYTE 0x83 — Server,

4 Get Produced Connection ID UINT 10xxxxxx011

5 Get Consumed Connection ID UINT 10xxxxxx100

6 Get Initial Comm. Characteristics BYTE 0x22

7 Get Produced Connection Size UINT 0x61

8 Get Consumed Connection Size UINT 0x61

9 Get/Set Expected Packet Rate UINT

12 (0C

13 (0D

14 (0E

15 (0F

16 (10

Rule

) Get Watchdog Action USINT 01 = auto delete

hex

) Get Produced Connection Path

hex

) Get Produced Connection Path EPATH Empty

hex

) Get Consumed Connection Path

hex

) Get Consumed Connection Path EPATH Empty

hex

Name Data Type Value

1 = configuring

3 = established

4 = timed out

0 = Explicit Message

Transport Class 3

xxxxxx = node address

xxxxxx = node address

In milliseconds

03 = deferred delete

Length

Length

UINT 0

UINT 0

Publication 855T-UM001C-EN-P May 2005

Page 58

B-9 DeviceNet Information

Instance 2 is the Predefined Group 2 Connection Set Polled I/O Message Connection. The

following instance 2 attributes will be supported:

Table B.14

Attribute IDAccess

Name Data Type Value

Rule

1 Get State USINT 0 = nonexistent

1 = configuring

3 = established

4 = timed out

2 Get Instance Type USINT

3 Get Transport Class Trigger USINT 0x82 — Server,

1 = I/O Connection

Transport Class 2

(If alloc_choice ! =

polled and ack

suppression is enabled

then value = 0x80)

4 Get Produced Connection ID UINT 01111xxxxxx

xxxxxx = node address

5 Get Consumed Connection ID UINT 10xxxxxx101

xxxxxx = node address

6 Get Initial Comm. Characteristics USINT 0x21

7 Get Produced Connection Size UINT 0…8

8 Get Consumed Connection Size UINT 0…8

9 Get Expected Packet Rate UINT

12 (0C

) Get/Set Watchdog Action USINT 0 = transition to timed

hex

In milliseconds

out

1 = auto delete

2 = auto reset

) Get Produced Connection Path

13 (0D

hex

14 (0E

) Get/Set Produced Connection Path — 20 04 24

hex

) Get Consumed Connection Path

15 (0F

hex

16 (10

) Get/Set Consumed Connection Path — 20 04 24

hex

) Get/Set Production Inhibit Time UINT —

17 (11

hex

Length

Length

UINT 6

(assy inst #) 30 03

UINT 6

(assy inst #) 30 03

Publication 855T-UM001C-EN-P May 2005

Page 59

DeviceNet Information B-10

Instance 4 is the Predefined Group 2 Connection Set Change of State/Cyclic I/O Message

Connection. The following instance 4 attributes will be supported:

Table B.15

Attribute IDAccess

Name Data Type Value

Rule

1 Get State USINT 0 = nonexistent

1 = configuring

3 = established

4 = timed out

2 Get Instance Type USINT

3 Get Transport Class Trigger USINT 0x00 (Cyclic,

1 = I/O Connection

unacknowledged)

0x03 (Cyclic,

acknowledged)

0x10 (COS,

unacknowledged)

0x13 (COS,

acknowledged)

4 Get Produced Connection ID UINT 01101xxxxxx

xxxxxx = node address

5 Get Consumed Connection ID UINT 10xxxxxx101

xxxxxx = node address

6 Get Initial Comm. Characteristics USINT 0x01 (acknowledged)

0x0F (unacknowledged)

7 Get Produced Connection Size UINT 0…8

8 Get Consumed Connection Size UINT 0…8

9 Get/Set Expected Packet Rate UINT

12 (0C

) Get Watchdog Action USINT 0 = transition to timed

hex

In milliseconds

out

1 = auto delete

2 = auto reset

) Get Produced Connection Path

13 (0D

hex

) Get Produced Connection Path — 20 04 24

14 (0E

hex

) Get Consumed Connection Path

15 (0F

hex

16 (10

) Get/Set Consumed Connection Path — 20 04 24

hex

) Get/Set Production Inhibit Time UINT In milliseconds

17 (11

hex

Length

Length

UINT 6

(assy inst #) 30 03

UINT 4 (acknowledged)

0 (unacknowledged)

(assy inst #) 30 03

Publication 855T-UM001C-EN-P May 2005

Page 60

B-11 DeviceNet Information

Instance 5 is the Group 1 Explicit Message Connection. The following instance 5 attributes

will be supported:

Table B.16

Attribute IDAccess

Name Data Type Value

Rule

1 Get State USINT 0 = nonexistent

1 = configuring

3 = established

4 = timed out

2 Get Instance Type USINT

3 Get Transport Class Trigger USINT 0x83 — Server,

4 Get Produced Connection ID UINT 0????xxxxxx

5 Get Consumed Connection ID UINT 0????xxxxxx

0 = Explicit Message

Transport Class 3

xxxxxx = node address

xxxxxx = node address

6 Get Initial Comm. Characteristics USINT 0x22

7 Get Produced Connection Size UINT 0x61

8 Get Consumed Connection Size UINT 0x61

9 Get/Set Expected Packet Rate UINT

12 (0C

) Get Watchdog Action USINT 01 = auto delete

hex

) Get Produced Connection Path

13 (0D

hex

14 (0E

) Get Produced Connection Path — Empty

hex

15 (0F

) Get Consumed Connection Path

hex

) Get Consumed Connection Path — Empty

16 (10

hex

Length

Length

UINT 0

UINT 0

In milliseconds

03 = deferred delete

Publication 855T-UM001C-EN-P May 2005

Page 61

DeviceNet Information B-12

Instance 6 and 7 are the Group 3 Explicit Message Connections. The following instance 6

and 7 attributes will be supported:

Table B.17

Attribute IDAccess

Name Data Type Value

Rule

1 Get State USINT 0 = nonexistent

1 = configuring

3 = established

4 = timed out

2 Get Instance Type USINT

3 Get Transport Class Trigger USINT 0x83 — Server,

4 Get Produced Connection ID UINT 11???xxxxxx

5 Get Consumed Connection ID UINT 11???xxxxxx

0 = Explicit Message

Transport Class 3

xxxxxx = node address

xxxxxx = node address

6 Get Initial Comm. Characteristics USINT 0x22

7 Get Produced Connection Size UINT 0x61

8 Get Consumed Connection Size UINT 0x61

9 Get/Set Expected Packet Rate UINT

12 (0C

) Get Watchdog Action USINT 01 = auto delete

hex

) Get Produced Connection Path

13 (0D

hex

14 (0E

) Get Produced Connection Path — Empty

hex

15 (0F

) Get Consumed Connection Path

hex

) Get Consumed Connection Path — Empty

16 (10

hex

Length

Length

UINT 0

UINT 0

In milliseconds

03 = deferred delete

The following common services will be implemented for the Connection Object.

Table B.18

Service Code Implemented for: Service Name

Class Instance

0x05 No Yes Reset

0x09 Yes Yes Delete

0x0E No Yes Get_Attribute_Single

0x10 No Yes Set_Attribute_Single

Publication 855T-UM001C-EN-P May 2005

Page 62

B-13 DeviceNet Information

Class Code 008 (0x08): Discrete Input Point Object

The Discrete Input Point (DIP) Object models discrete inputs in a product. You can use this

object in applications as simple as a toggle switch or as complex as a discrete I/O control

module. There is a separate instance for each discrete input available on the device.

Class Attributes

Table B.19

Attribute Access Name Type Value

1 Get Revision UINT 2

Instance Attributes

Table B.20

Attribute Access Name Type Value

3GetValueBOOL➊

4 Get Status BOOL 0

➊ State of the specific digital input.

Common Services

Table B.21

Service Code Class Instance Service Name

14 (0x0E) Yes Yes Get_Attribute_Single

Publication 855T-UM001C-EN-P May 2005

Page 63

DeviceNet Information B-14

Class Code 009 (0x09): Discrete Output Point Object

The Discrete Output Point (DOP) Object models discrete outputs in a product. You can use

this object in applications as simple as an actuator or as complex as a discrete I/O control

module. There is a separate instance for each discrete output available on the device.

Class Attributes

None

Instance Attributes

Table B.22

Attribute Access Name Type Value

3 Get/Set Value BOOL State of Output ➊

4 Get Status BOOL ➋

128 (0x80) Get/Set Mode BYTE —

129 (0x81) Get/Set Module_Type BYTE —

➊ Output ON or OFF

➋ 0 = OK

1 = Burnout, Module Not Present

Common Services

Table B.23

Service Code Class Instance Service Name

14 (0x0E) No Yes Get_Attribute_Single

16 (0x10) No Yes Set_Attribute_Single

Publication 855T-UM001C-EN-P May 2005

Page 64

B-15 DeviceNet Information

Class Code 015 (0x0F): Parameter Object

Use of the Parameter Object provides a known, public interface to a device’s configuration

data. In addition, this object also provides all the information necessary to define and

describe each of a device’s individual configuration parameters.

This object allows a device to fully identify a configurable parameter by supplying a full

description of the parameter, including minimum and maximum values and a human-readable

text string describing the parameter.

Class Attributes

Table B.24

Attribute Access Name Type Value

2 Get Maximum Instance UINT —

8 Get Parameter Class Descriptor WORD 9 ➊

9 Get Configuration Assembly Instance UINT —

➊ Parameter Class Descriptor Bit Values

Definition

0 Supports Parameter Instances

1 Supports Full Attributes

2 Must do non-volatile storage save command

3 Params are stored in non-volatile storage

Publication 855T-UM001C-EN-P May 2005

Page 65

DeviceNet Information B-16

Instance Attributes

Table B.25

Attribute Access Name Type Value

1 Get/Set Parameter_Value Specified in Data Type —

2 Get Link_Path_Size USINT 6

3 Get Link_Path Array of BYTE —

4 Get Descriptor WORD 0 ➊

5 Get Data_Type USINT —

6 Get Data_Size USINT —

➊ Semantics of Descriptor Instance Attribute

Bit Definition Meaning

0 Supports Settable Path Indicates that link path can be set.

1 Supports Enumerated

Strings

2 Supports Scaling Indicates that the scaling factor should be implemented to present the

3 Supports Scaling Links Indicates that the values for the scaling factor may be retrieved from

4 Read Only Parameter Indicates that the value attribute can only be read, and not set.

5 Monitor Parameter Indicates that the value attribute is updated in real time by the device.

6 Supports Extended

Precision Scaling

Indicates that enumerated strings are supported and can be read with

Get_Enum_String service.

value to the user in engineering units.

other parameters.

Indicates that the extended precision scaling factor should be

implemented to present the value to the user in engineering units.

Common Services

Table B.26

Service Code Class Instance Service Name

14 (0x0E) Yes Yes Get_Attribute_Single

16 (0x10) No Yes Set_Attribute_Single

Publication 855T-UM001C-EN-P May 2005

Page 66

B-17 DeviceNet Information

Class Code 029 (0x1D): Discrete Input Group Object

The Discrete Input Group (DIG) Object binds a group of discrete input points in a module.

All points bound to the group share all attributes contained in the group. If an attribute is

shared (points have the same attributes and the same attribute values) across more than one

Discrete Input Point (DIP), then that attribute can be contained in a Discrete Input Group. A

Discrete Input Point can be bound to more than one Discrete Input Group.

Class Attributes

None

Instance Attributes

Table B.27

Attribute Access Name Type Value

3 Get Number of Instances USINT 2

4 Get Binding Array of UINT 1,2

5 Get Status BOOL 0 = OK

6 Get/Set On-Delay UINT —

7 Get/Set Off-Delay UINT —

1 = Alarm

Common Services

Table B.28

Service Code Class Instance Service Name

14 (0x0E) No Yes Get_Attribute_Single

16 (0x10) No Yes Set_Attribute_Single

Publication 855T-UM001C-EN-P May 2005

Page 67

DeviceNet Information B-18

Class Code 030 (0x1E): Discrete Output Group Object

The Discrete Output Group (DOG) Object binds a group of discrete output points in a

module. All points bound to the group share all attributes contained in the group. If an

attribute is shared across more than one Discrete Output Point (DOP), then it can be

contained in a Discrete Output Group. A Discrete Output Point can also be bound to more

than one Discrete Output Group.

Class Attributes

None

Instance Attributes

Table B.29

Attribute Access Name Type Value

3 Get Number of Instances USINT 5

4 Get Binding Array of UINT 1,2,3,4,5

5 Get Status BOOL 0 = OK

6 Get/Set Command USINT Get = 0

7 Get/Set Fault State USINT — ➊

8 Get Fault Value USINT 0

9 Get/Set Idle State USINT — ➊

10 (0x0A) Get Idle Value USINT 0

1 = Alarm

Set = 1 to activate group

➊ 0 = Reset

1 = Hold Last State

Common Services

Table B.30

Service Code Class Instance Service Name

14 (0x0E) No Yes Get_Attribute_Single

16 (0x10) No Yes Set_Attribute_Single

Publication 855T-UM001C-EN-P May 2005

Page 68

B-19 DeviceNet Information

Class Code 043 (0x2B): Acknowledge Handler Object

The Acknowledge Handler Object is used to manage the reception of message

acknowledgements. This object communicates with a message producing Application Object

within a device. The Acknowledge Handler Object notifies the producing application of

acknowledge reception, acknowledge timeouts, and production retry limit.

Class Attributes

None

Instance Attributes

Table B.31

Attribute Access Name Type Value

1 Get/Set Acknowledge Timer UINT —

2 Get Retry Limit USINT —

3 Get COS Producing Connection Instance UINT 4

Common Services

Table B.32

Service Code Class Instance Service Name

14 (0x0E) No Yes Get_Attribute_Single

16 (0x10) No Yes Set_Attribute_Single

Publication 855T-UM001C-EN-P May 2005

Page 69

DeviceNet Information B-20

Class Code 0x00B4: DeviceNet Interface Object

This vendor-specific object will include no class attributes.

A single instance (instance 1) of the DeviceNet Interface Object will be supported. The

following instance attributes will be supported.

Table B.33

Attribute IDAccess

19 (13

30 (IE

Rule

) Get/Set Set To Defaults BOOL 0…1 0 0 = No action; 1 = Reset

hex

) Get DeviceNet Voltage UINT 0…287 0 DeviceNet voltage supplied

hex

Name Data

Ty pe

Min./

Max.

Default Description

to 855T Stack Light

The following common services will be implemented for the DeviceNet Interface Object.

Table B.34

Service Code Class Instance Service Name

0x0E No Yes Get_Attribute_Single

0x10 No Yes Set_Attribute_Single

Publication 855T-UM001C-EN-P May 2005

Page 70

B-21 DeviceNet Information

Notes

Publication 855T-UM001C-EN-P May 2005

Page 71

Page 72

Publication 855T-UM001C-EN-P May 2005 PN 40063-384-01(D)

Supersedes Publication 855T-UM001B-EN-P dated September 2000 Supersedes PN 40063-384-01(C)

© 2005 Rockwell International Corporation. Printed in the U.S.A.

Loading...

Loading...