Page 1

Installation Instructions

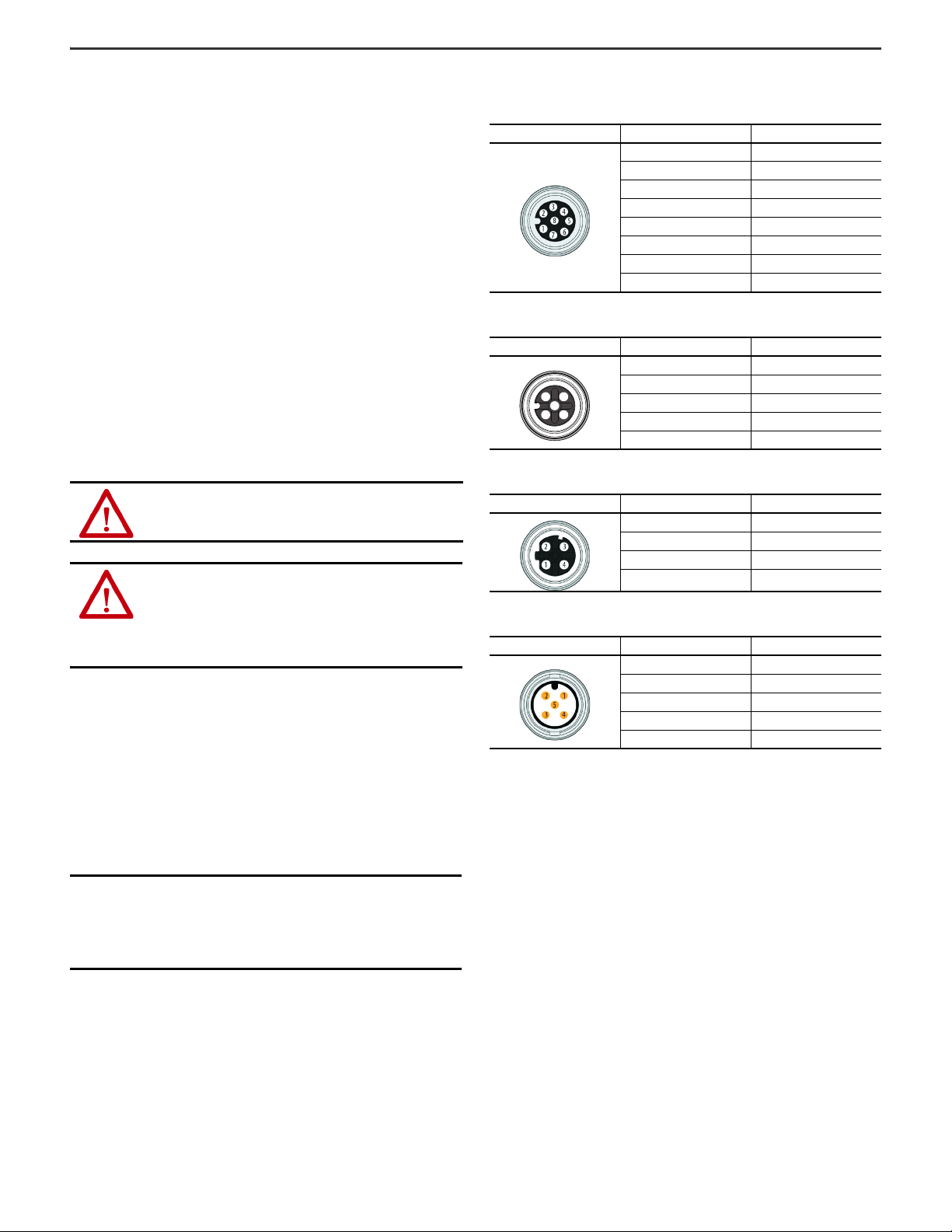

M12 8-pin

Female

M12 5-pin

Female

M12 5-pin

Male

M12 4-Pin

Female D-Code

(Network)

Network Indicator

Module Indicator

Link Indicators

Receiver Indicators

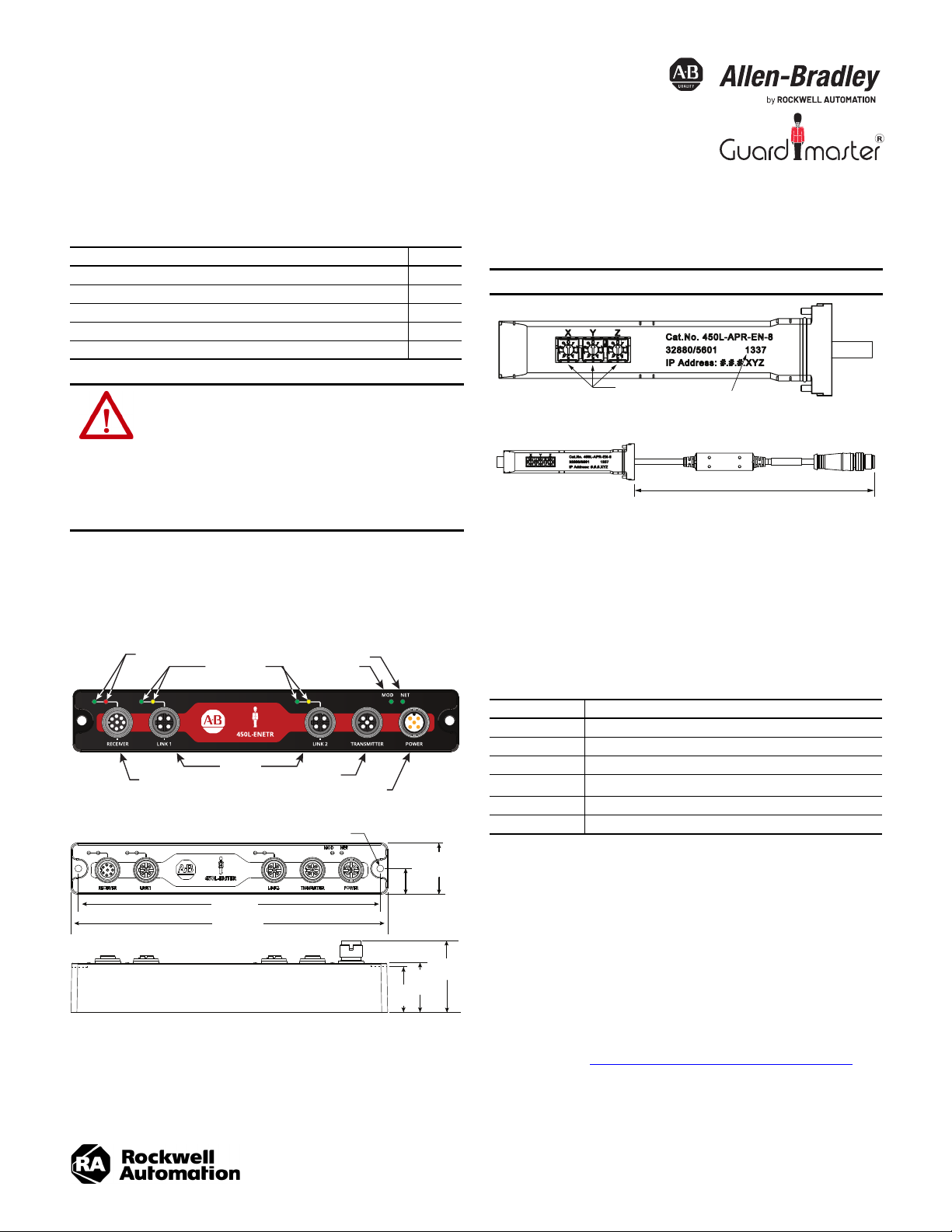

Front View

Side View

27.23

(1.07)

37.91

(1.49)

23.1

(0.91)

26.1

(1.03)

160.5 (6.32)

168.61 (6.63)

13.615

(0.535)

M3 (#8)

Dimensions in mm (in.)

Dimensions in mm (in.)

IP Address Switches

Mfg Datecode YYWW

Original Instructions

GuardShield Safety Light Curtain EtherNet/IP Network Interface

Catalog Number 450L-ENETR

Top ic Pa ge

Product Overview and Dimensions 1

Install the Network Interface 1

Reset to Factory Default and Protection Mode 2

Status Indicators 3

Specifications 3

ATTENTION: You must familiarize yourself with installation

and wiring instructions and requirements of all applicable

codes, laws, and standards. In accordance with applicable

codes of practice, suitably trained personnel are required to

install, adjust, put into service, use, assemble, disassemble,

and/or maintain this equipment. If this equipment is used in

a manner that is not specified by the manufacturer, the

protection that is provided by the equipment can be

impaired.

Module is designed to meet IEC 61496.

450L-APR-EN-8 Plug-in Module

IMPORTANT

The plug-in module is purchased separately.

205 (8)

Product Overview and Dimensions

450L-ENETR Network Interface

Install the Network Interface

This section contains installation-related information.

Assign IP Address

The 450L-ENETR network interface must be assigned a fixed (static) IP address to

maintain continued communication with the network. The IP address is set on the

450L-APR-EN-8 plug-in module.

Valu e Des cripti on

000 Clear explicit protected mode

001…254 Private address (#.#.#.XYZ)

888 Factory reset

900

999 DHCP

All others Do not use

(1) When explicit protection mode is set, explicit messages that affect the operation of the device are

blocked. Examples of blocked messages are changes to the IP address, reset of the module, and

update of the firmware. Explicit messages can still fetch diagnostic information.

Set explicit protected mode

There are four ways of assigning a fixed IP address:

• Use the XYZ rotary switches to set a 'Private' IP address.

• Use the Rockwell Automation BootP/DHCP tool, version 2.3 or later,

which ships with Studio 5000® software (RSLogix 5000® software).

• Use RSLinx® software.

• Have your network administrator configure the ENETR network

interface via the network DHCP server.

If the 450L-ENETR network interface is replaced, use the BOOTP/DHCP tool to

assign the IP address to the MAC ID of the new network interface.

Perform the steps in Reset to Factory Default and Protection Mode

before you change the IP address from a private address to a non-private address

or vice versa.

(1)

on page 2

Page 2

GuardShield Safety Light Curtain EtherNet/IP Network Interface Installation Instructions

1

2

3

4

5

Reset to Factory Default and Protection Mode

At any time, the 450L-ENETR network interface can be set to the factory default or

the protection mode can be set/cleared by following these steps:

1. Turn off power to the 450L-ENETR network interface.

2. Remove the 450L-APR-EN-8 plug-in module from the receiver stick.

3. Set the XYZ rotary switches on the 450L-APR-EN-8 plug-in module:

• 888 to reset to factory default

• 900 to set explicit protection mode

• 000 to clear explicit protection mode

4. Insert the 450L-APR-EN-8 plug-in module into the receiver stick.

5. Apply 24V DC to the 450L-ENETR network interface.

6. Wait at least 5 seconds. After 5 seconds, the MOD indicator blinks red. All

other indicators are OFF.

7. Remove power from the 450L-ENETR network interface.

8. Remove the 450L-APR-EN-8 plug-in module from the receiver stick.

9. Assign the new IP address by setting the XYZ rotary switches.

10. Insert the 450L-APR-EN-8 plug-in module into the receiver stick.

11. Apply 24V to the 450L-ENETR network interface.

Wire the Module

WAR N IN G : Disconnect power to the system before you attempt

installation or device wiring.

ATTENTION:

• Calculate the maximum current in each power and common

wire.

• Observe all electrical codes that dictate the maximum

current allowable for each wire size.

• Current above the maximum ratings can cause wiring to

overheat, which can cause damage.

• For the receiver cable, the maximum cable length is 2 m (6.6 ft).

• Do not run signal or communications wiring and power wiring in the

same conduit. Route wires with different signal characteristics by

separate paths.

• Separate wiring by signal type. Bundle wiring with similar electrical

characteristics together.

• Label wiring to all devices in the system. Use tape, shrink-tubing, or

other means to label wires. Also use colored insulation to identify wires

based on signal characteristics. For example, you can use blue for DC

wiring and red for AC wiring.

• Use the M12 protective cap (two provided) to maintain IP65 seal and help

protect unused ports.

Pinouts

Table 1 - Receiver (Female)

Pin Description

1Comm Rx

2+24V DC

3 Functional Earth, FE

4Comm Tx

5 14V from light curtain

6NC

70V (GND)

8 Safety interrupt

Table 2 - Transmitter (Female)

Pin Description

1+24V DC

2NC

30V (GND)

4NC

5 Functional Earth, FE

Table 3 - Link (Female)

Pin Description

1Tx Data+

2Rx Data+

3Tx-

4Rx-

Table 4 - Power Connector (Male)

Pin Description

1+24V DC

2NC

30V (GND)

4NC

5 Functional Earth, FE

IMPORTANT

Fault exclusions for conductors and wiring must

follow the requirements of EN ISO 13849-2 Table D.3

and D.4.

A fault exclusion can reduce the overall safety

rating of the related safety function to a maximum

of PLd per EN ISO 13849-1.

2 Rockwell Automation Publication 450L-IN008A-EN-P - August 2020

Page 3

GuardShield Safety Light Curtain EtherNet/IP Network Interface Installation Instructions

Status Indicators Specifications

Indicator Status Description

Off Module is not powered

Alternate flashing (red-green) Module is not configured

Module is configured, but not in

run mode

Module is powered, configured, and

operating correctly (run mode)

Flash update in progress.

(configuration mode)

Unrecoverable fault detected

(critical fault mode)

The module does not have an IP address

and is operating in DHCP mode

The module has an IP address, but no

CIP connections are established

The module has an IP address and CIP

connections (any transport class)

are established

An exclusive owner connection has

timed out

Module status

(MS)

EtherNet/IP™

Network

Status

Flashing green

Steady green

Flashing red

Steady red

Off

Flashing green

Steady green

Flashing red

Off No link/no activity

LINK1 or

LINK2 Status

Steady green Link

Flashing amber Port activity

Green Communication OK

450L-RX

Status

Flashing red Light curtain is in lockout state

Red No communication

Table 5 - General Specifications

Attribute Value

Communication power

supply voltage

Communication

current consumption

Communication rate EtherNet/IP 10/100 Mbps

Internet Protocol IPv4 Addressing

CIP Sync CIP sync/IEEE 1588 end-to-end transparent clock supported

CIP (safety) standards

24.0V DC±15% [Class 2 PELV]

340 mA/24V

IEC 61784-3-2: Functional safety fieldbusses - Additional specifications for CPF 2

regarding the following standards:

• IEC 61158-1: Overview and guidance for the IEC 61158 and IEC 61784 series

• IEC 61158-3-2: Data-link layer service definition - Type 2 elements

• IEC 61158-4-2: Data-link layer protocol specification - Type 2 elements

• IEC 61158-5-2: Application layer service definition - Type 2 elements

• IEC 61158-6-2: Application layer protocol specification - Type 2 elements

Table 6 - Environmental Specifications

Attribute Value

Operating temperature -10…+55 °C (14…131 °F)

Storage temperature -25…+75 °C (-13…+167 °F)

Relative humidity Up to 95% (noncondensing)

Enclosure type rating

Vibration 10...55 Hz with amplitude of 0.35 mm (0.01 in)

Shock, operating 1000 shocks with 10 g (0.35 oz) and 16 ms pulse duration

Emissions CISPR 11 Group 1, Class A

ESD Immunity

Radiated RF immunity

EFT Immunity

Surge transient

immunity

Conducted RF

Immunity

• IP20 (unplugged)

• IP65 (plugged)

IEC 61000-4-2 and 61496-1 section 4.3.2

• Normal Operation: 6 kV contact discharge, 8 kV air discharge

• No Dangerous Fail: 8 kV contact discharge, 15 kV air discharge

IEC 61000-4-3:

• 10.0V/m (80 MHz…1 GHz)

•3.0V/m (1.4…2 GHz)

• 3.0 V/m (2.0…2.7 GHz)

IEC 61000-4-4, section 5 and IEC61000-6-7 and 61496-1 section 4.3.2

• Normal Operation: ±1 kV

• No Dangerous Fail: ±2 kV and severity level 3

IEC 61000-4-5, section 5 and 61000-6-7 and 61496-1 section 4.3.2

• Normal operation: ±1 kV (Line to GND)

• No dangerous failure: ±2 kV and severity level 3

IEC 61000-4-6, section 5 and 61000-6-7

Table 7 - Certifications (when product is marked)

Attribute Value

c-UL-us UL Listed Industrial Control Equipment, certified for US and Canada.

European Union compliant with applicable directives:

CE

RCM

EtherNet/IP ODVA conformance tested to EtherNet/IP specifications

KC

(1) For declarations of conformity, certificates, and other certification details,

see rok.auto/certifications

•2014/30/EU EMC Directive

• 2006/42/EC Machinery Directive

• 2011/65/EU RoHS Directive (RoHS)

Australian Radiocommunications Act, compliant with:

• AS/NZS CISPR 11; Industrial Emissions

Korean Registration of Broadcasting and Communications Equipment,

compliant with:

• Article 58-2 of Radio Waves Act, Clause 3

.

(1)

Rockwell Automation Publication 450L-IN008A-EN-P - August 2020 3

Page 4

Waste Electrical and Electronic Equipment (WEEE)

At the end of life, this equipment should be collected separately from any unsorted municipal waste.

Rockwell Automation maintains current product environmental information on its website at rok.auto/pec.

Your comments help us serve your documentation needs better. If you have any suggestions on how to improve our content, complete the form at rok.auto/docfeedback.

For technical support, visit rok.auto/support.

Rockwell Otomasyon Ticaret A.Ş. Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenkÖy, İstanbul, Tel: +90 (216) 5698400 EEE YÖnetmeliğine Uygundur

Allen-Bradley, expanding human possibility, Guardmaster, GuardShield, Rockwell Automation, RSLinx, RSLogix 5000, Studi o 5000 are trademarks of

Rockwell Automation, Inc.

EtherNet/IP is a trademark of ODVA, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 450L-IN008A-EN-P - August 2020 | Supersedes Publication XXXX-X.X.X-Month Year

Copyright © 2020 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

PN-529486

DIR 10005641605 Ver 01

Loading...

Loading...