Page 1

Enwatch

Installation Guide

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application, Installation and

Maintenance of Solid State Controls (Publication SGI-1.1 available from your local

Rockwell Automation sales office or online at http://www.ab.com/manuals/gi)

describes some important differences between solid state equipment and hard-wired

electromechanical devices. Because of this difference, and also because of the wide

variety of uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes.

Because of the many variables and requirements associated with any particular

installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of

information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written

permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual we use notes to make you aware of safety considerations.

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside the drive to alert

people that dangerous voltage may be present.

Labels may be located on or inside the drive to alert

people that surfaces may be dangerous temperatures.

Emonitor and Enwatch are registered trademarks and gSE and Spike Energy are a trademarks of Rockwell Automation, Inc..

All other trademarks are the property of their respective holders and are hereby acknowledged.

Page 3

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Table of Contents Chapter 1

Installing the Enwatch

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Analog Input Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Trigger Isolation Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Normal Operation versus Monitor Mode . . . . . . . . . . . . . . . . . . . . 9

Serial Port (RS-232) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Flash Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

On Board Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Setting Up an Enwatch Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Connecting Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connecting an ICP Accelerometer . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connecting a Coil-Based Velocity Sensor . . . . . . . . . . . . . . . . . . . 18

Connecting an Process DC Voltage Signal. . . . . . . . . . . . . . . . . . . 19

Connecting a Magnetic Hall Effect Sensor. . . . . . . . . . . . . . . . . . . 20

Enwatch Measurement Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Setting Up Sample Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . 25

Configuration of Emonitor with Enwatch . . . . . . . . . . . . . . . . . . . . . . 32

Table of Contents

Chapter 2

Specifications

Index

iii Publication GMSI10-UM031C-EN-E - July 2005

Power Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Temperature Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Page 4

Table of Contents iv

Publication GMSI10-UM031C-EN-E - July 2005

Page 5

Chapter

1

Installing the Enwatch

This manual introduces you to the Allen Bradley Enwatch® unit. The manual

is intended for anyone who installs, tests, or configures the Enwatch hardware.

It does not cover using the Enwatch unit to collect data. For information on

collecting data with the Enwatch unit, refer to the Online Applications Guide

provided with your Emonitor

®

online system.

Introduction

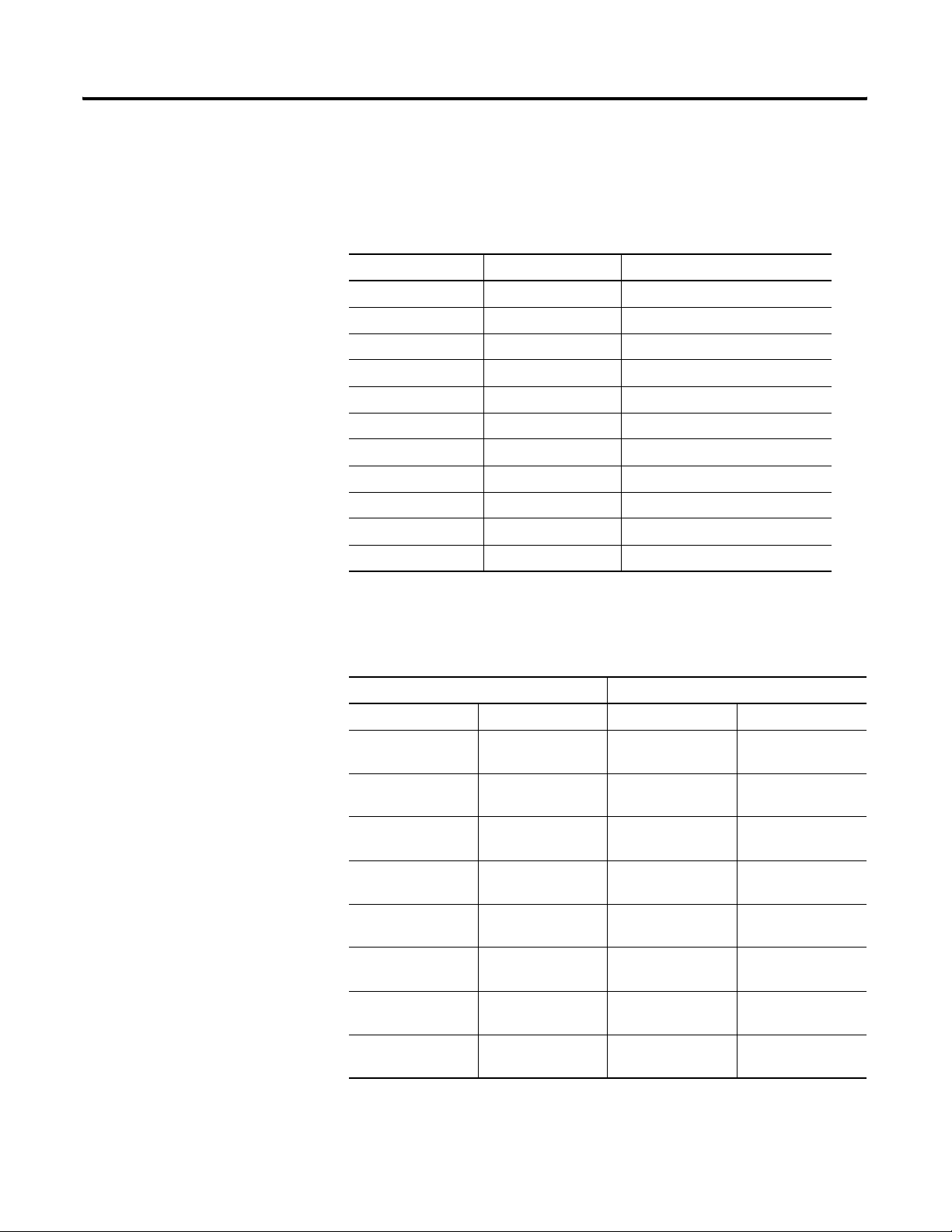

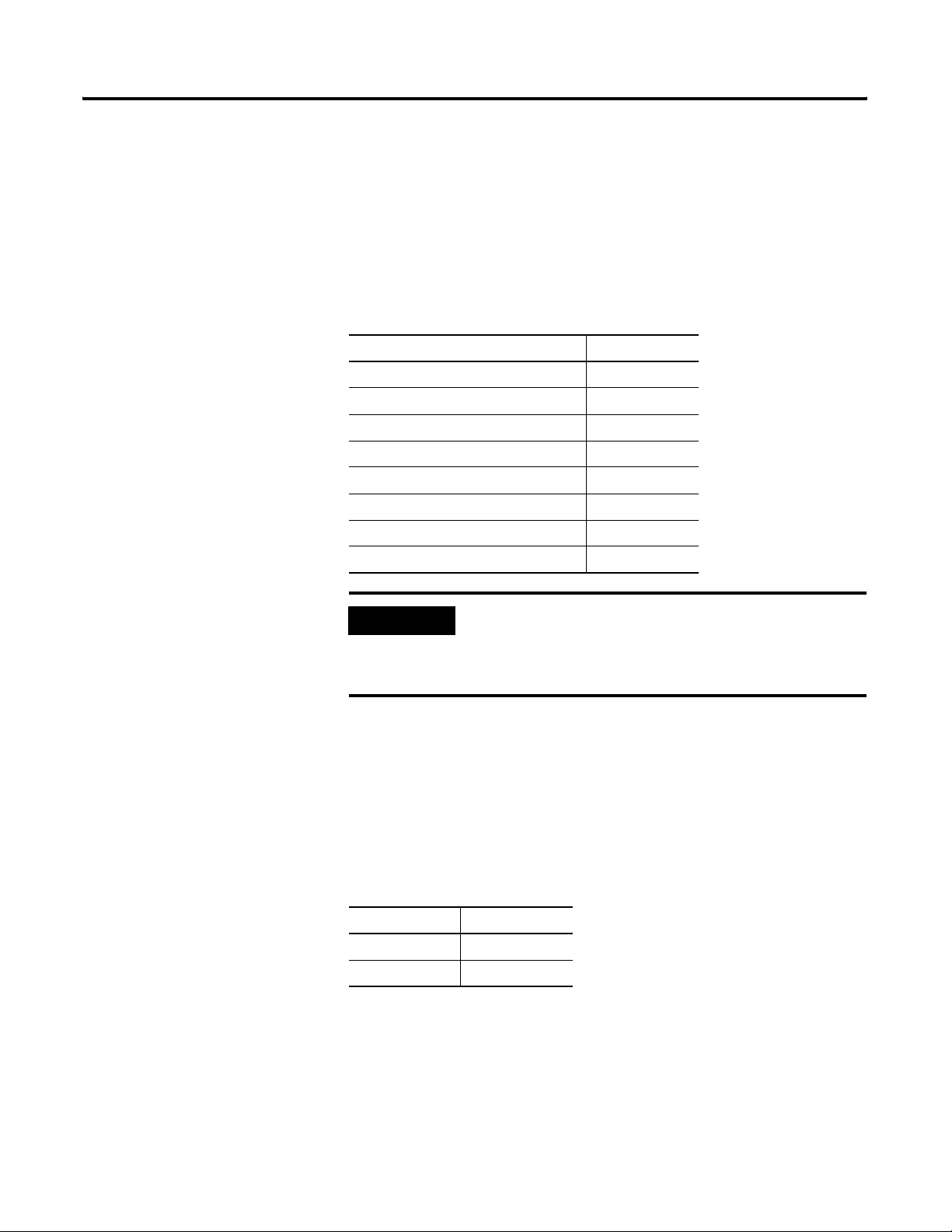

CHANNEL

ICP 1

ICP 2

ICP 16

External Trig. 1 - Event

External Trig. 4

Enwatch is a distributed network system providing 16 channels of analog

inputs together with 4 trigger channels. The unit includes signal conditioning

and analog to digital conversion. It allows you to connect 16 two-wire ICP or

other sensors into your Emonitor Online system. Each Enwatch unit is a

microprocessor-based system, complete with network controller that carries

out data acquisition tasks as directed by an Emonitor unload station. A typical

diagram for an Enwatch unit is shown in Figure 1.1, below.

Figure 1.1 Enwatch diagram

gSE

HP Filters

15:1

Bias Check

Multiplexer

4:1

Aux.

Intergrator

Programable

Gain

Select

Programable

Anti-Alias

Filter

A to D

Converter

Clock

Generator

Flash

SRAM

Watchdog

Microprocessor

RS-232

Ethernet

Controller

Power

Regulation

10Base-T

DC in

The Enwatch unit responds to all relevant network data exchanges as defined

by the Ethernet protocol using the UDP/IP standard. In addition, there is a

comprehensive on-board monitor program that can exercise all functions via

the on-board serial RS232 port.

1 Publication GMSI10-UM031C-EN-E - January 2009

Page 6

2 Installing the Enwatch

Installation

The Enwatch unit is easy to install. The enclosure is mounted using four

screws. Cables are terminated on removable screw terminal blocks, making

installation and service simple. Network cables are terminated on the board

using a a standard RJ-45 connector.

Each Enwatch board has four status LEDs to monitor system activity. In the

unlikely event of a system problem, a portable PC can be used to diagnose the

problem using the RS-232 serial interface on each Enwatch board.

Prior to installation, the only set-up required is to assign an IP address, Subnet

Mask, and Gateway IP address (if available) to the node. This must be a unique

address on the network. You assign the IP address by connecting a terminal

(or PC in terminal mode) to the on-board RS-232 port and using the on-board

monitor program. See “Setting Up an Enwatch Unit” on page 11 for more

information.

Electrical

The circuit board is a completely self-contained 16-channel analog input to

Ethernet interface, including power regulation and local communication

facilities. A block diagram of the board is shown in Figure 1.1 on page 1. Each

block of the diagram is described below.

• ICP interface - Each of the 16 channels has its own ICP interface that

is capable of powering a typical two-wire ICP transducer. The nominal

voltage is 24 V with a constant current of 3.6 mA. A typical transducer

has a bias voltage value of around 11 V, so that the system can

accommodate a full ±10V input range. The ICP interface can be

disabled for AC and DC coupling of voltage signals.

• Multiplexer - The multiplexer circuit selects one of the 16 input

channels under software control. All inputs are over-voltage and ESD

protected.

• High pass filters - Four software-programmable high-pass filters

(0.36 Hz, 2.67 Hz, 5.3 Hz, and 23.8 Hz) are available to remove

unwanted low frequency signals.

• Integrator - An on-board hardware integrator is available for getting a

velocity measurement from an accelerometer, as well as displacement

from a velocity sensor. The host software can perform a second level of

integration if required.

• Spike Energy™ function (gSE™) - gSE provides a conditioned

signal suitable for measurement of bearing condition.

• Anti-aliasing filter - This filter removes high-frequency components

from the incoming analog signal that might alias back into the sampled

signal, resulting in incorrect data in the spectrum. The filter has a very

high roll-off and removes all alias effects in standard sampling/spectral

analysis applications.

Publication GMSI10-UM031C-EN-E - January 2009

Page 7

Installing the Enwatch 3

• Analog-to-digital converter (ADC) - The ADC samples up to

51.2 kHz and has 16-bit resolution, providing a theoretical dynamic

range of 96 dB.

• Clock generator - The timer varies the sampling rate under

microprocessor control. Sampling can be synchronized to one of 4

external triggers (typically a once-per-rev TTL signal from a rotating

shaft). This system can also take a preprogrammed number of samples

per revolution. The external trigger acts as a tachometer to determine

shaft speed. Pre and post-trigger functions are available.

• Gain amplifier - The Enwatch unit automatically sets the input gain in

auto-range mode as each channel is selected by the multiplexer.

• Microprocessor subsystem - This comprises the microprocessor,

flash memory, and SRAM memory. The microprocessor controls the

Enwatch unit under instructions stored in the flash memory. The SRAM

memory acts as a temporary data storage area if buffering is required

before data is transferred over the network.

• Watchdog - The microprocessor subsystem incorporates a watchdog

facility that, if a power glitch or other external effect interrupts the

system, automatically resets without the need for user intervention.

• Ethernet controller/buffer memory/10Base-T - These functions

control data transfer over the Ethernet network. The system uses the

UDP/IP standard protocol and implements 10 Base-T as the physical

network layer.

• Power regulation - Input DC power is derived from an AC to DC

converter (not shown in Figure 1.1) and the Power Regulation function

provides the secondary DC voltages as required.

Rockwell Automation Support

Mechanical

The Enwatch unit is comprised of a single circuit board housed in a sealed (IP

66) enclosure. Each system has its own self-contained power supply, and

terminals for the input, power, tachometer, and network cables.

Rockwell Automation provides technical information on the Web to assist you

in using its products. At http://support.rockwellautomation.com

technical manuals, a knowledge base of FAQs, technical and application notes,

sample code and links to software service packs, and a MySupport feature that

you can customize to make the best use of these tools.

For an additional level of technical phone support for installation,

configuration, and troubleshooting, we offer TechConnect support programs.

For more information, contact your local distributor or Rockwell Automation

representative, or visit http://support.rockwellautomation.com

Publication GMSI10-UM031C-EN-E - January 2009

, you can find

.

Page 8

4 Installing the Enwatch

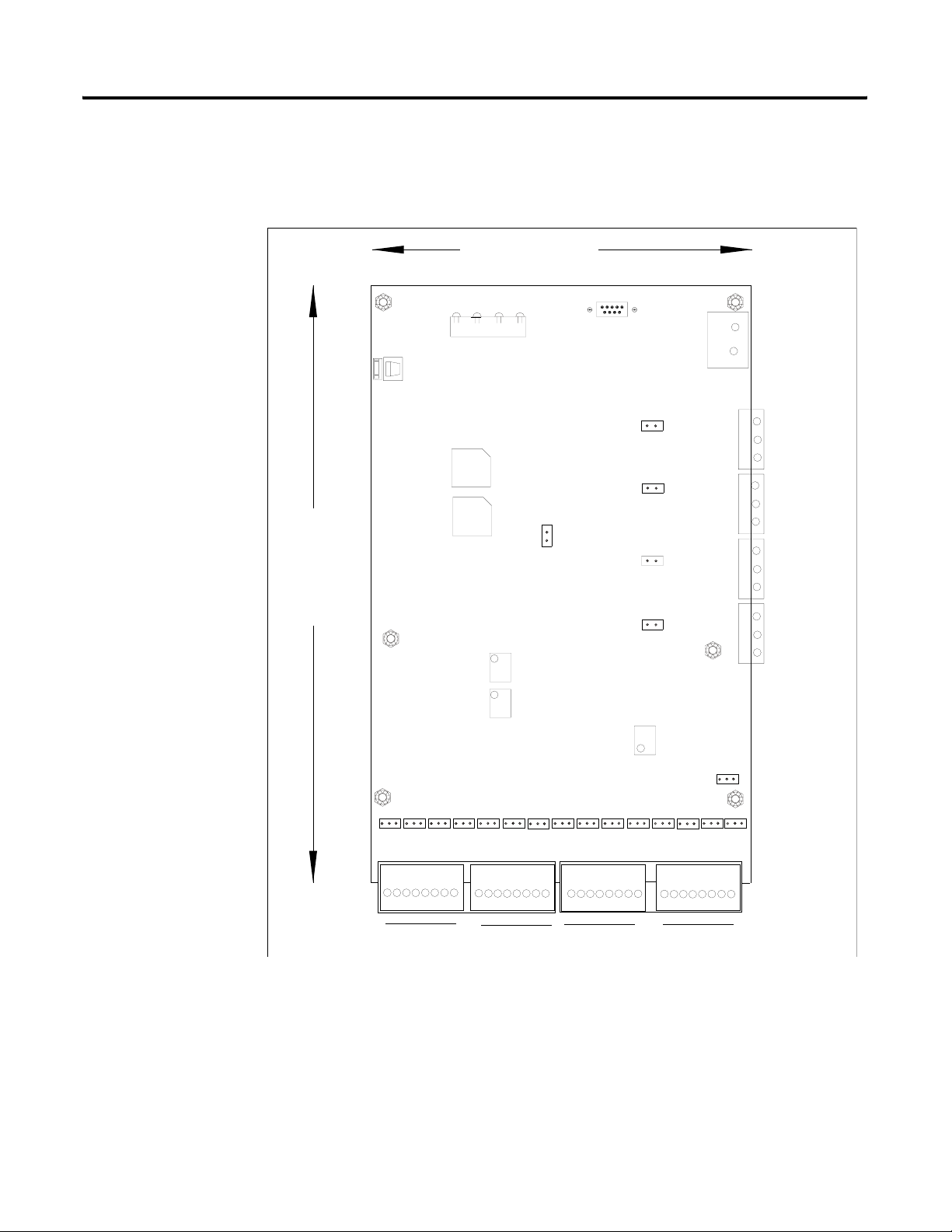

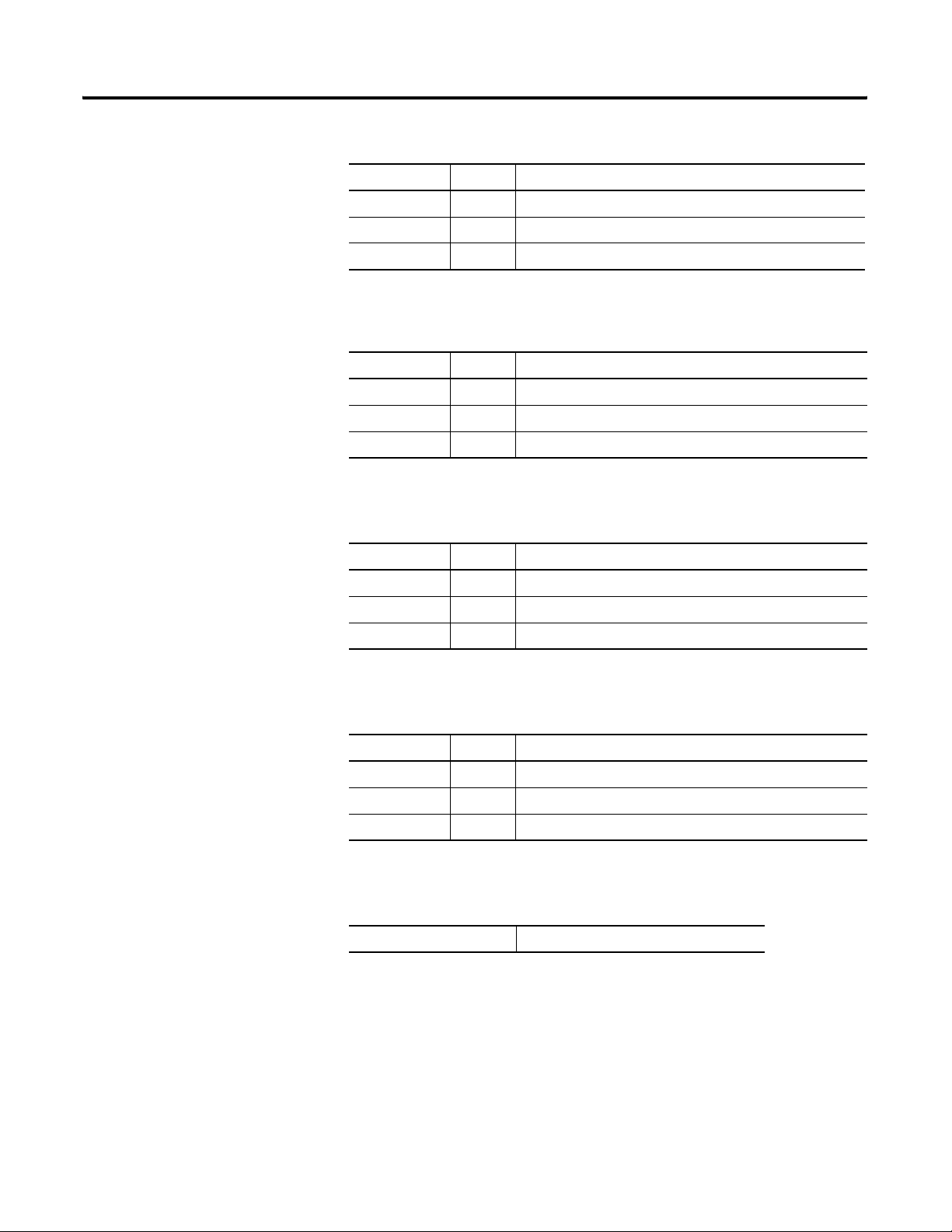

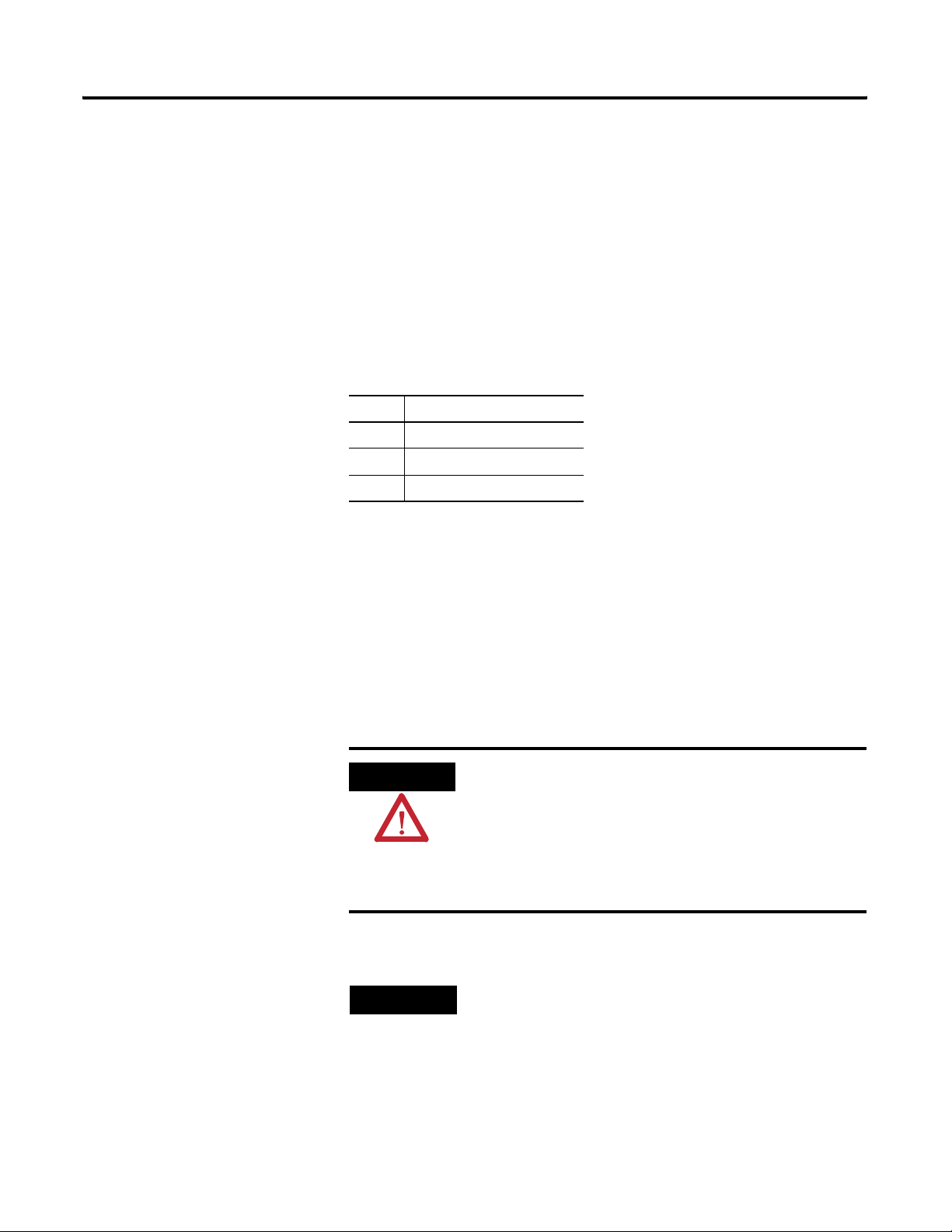

Electrical Connections

9.25"

(235 mm)

This section describes the electrical connections on the Enwatch board, shown

in Figure 1.2, below.

Figure 1.2 Enwatch electrical connections

6.75" (170 mm)

J11

JP 20

JP 19

JP 18

JP 17

J9

_

+

DC Power In

J6

J5

J4

J3

4

33

22

1

3

33

Ext. Trigger

22

Input Terminal

1

Block

33

2

22

1

1

33

22

1

J8

Status LED's

Network Input

RJ-45 Jack

RX LK OB

TX

U28

U20

Normal / Monitor

Mode Select

RS-232

DB-9 (female)

JP 21

RV2

RV3

Analog Input Configuration Jumpers

A - B A - B A - B A - B A - B A - B

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 9-10-11-12-13-14-15-16 1 - 2 - 3 - 4 - 5 - 6 - 7 - 8

A - B A - B A - B A - B A - B

A - B

J1

Input Connector Block

RV1

9-10-11-12-13-14-15-16

J2

A - B

A - B

A - B

A - B

Publication GMSI10-UM031C-EN-E - January 2009

Page 9

Installing the Enwatch 5

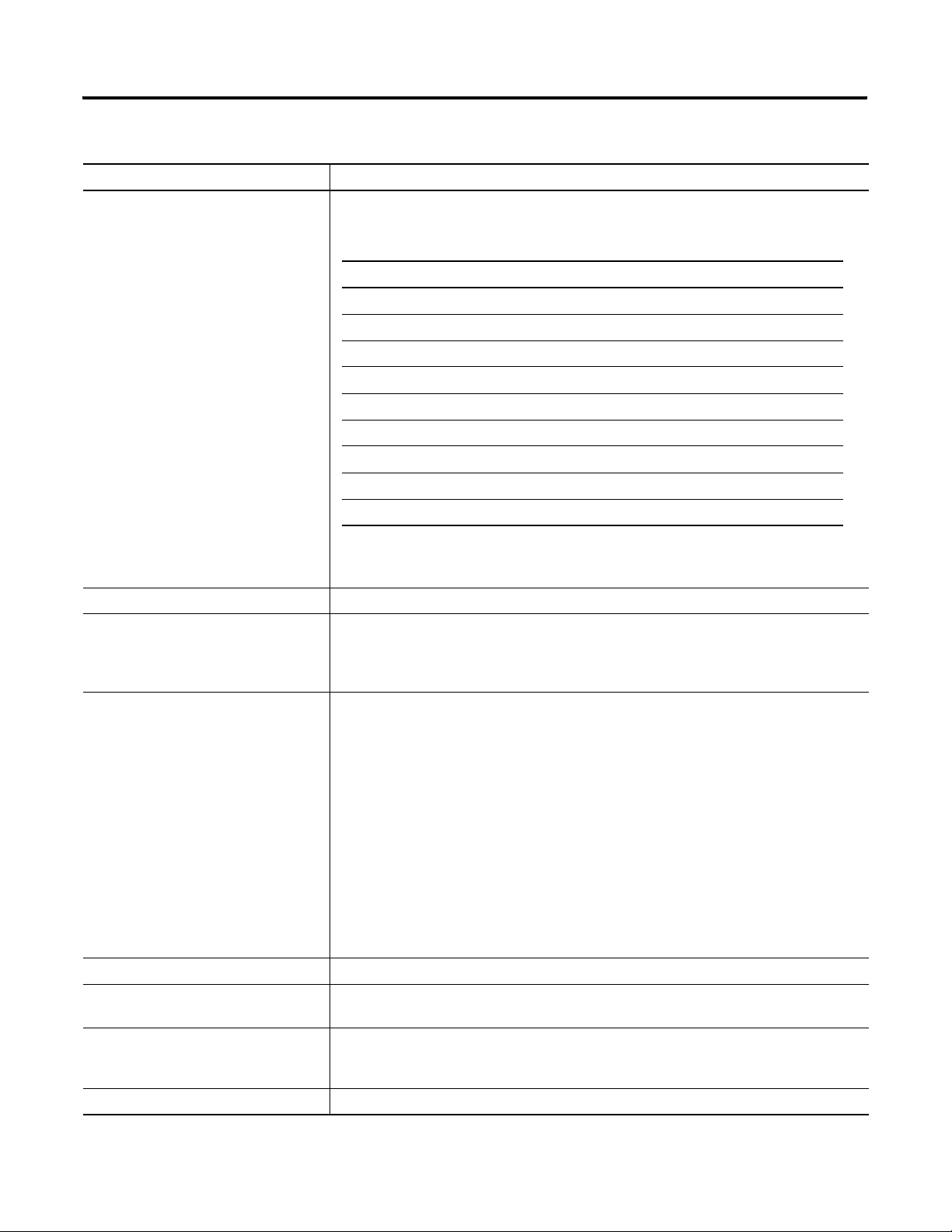

Connectors

The Enwatch unit has 11 connectors labeled J1 to J11 as shown in Table 1.1.

Table 1.1 Enwatch connectors

Connector No. of Pins Function

J1 16 Analog input channels 1–8

J2 16 Analog input channels 9–16

J3 3 External trigger 1 / event 1

J4 3 External trigger 2 / event 2

J5 3 External trigger 3

J6 3 External trigger 4

J7 5 Test points (service use only)

J8 8 Ethernet interface

J9 2 Supply voltage

J10 2 Spare

J11 9 Serial port (RS-232)

The location of the connectors is shown in Figure 1.2 on page 4. The pin

outputs are listed in the following tables.

Table 1.2 J1 and J2 pin outputs

J1: Analog Inputs 1-8 J2: Analog Inputs 9-16

Signal Pin No Signal Pin No.

CH 1 input

CH 1 ground

CH 2 input

CH 2 ground

CH 3 input

CH 3 ground

CH 4 input

CH 4 ground

CH 5 input

CH 5 ground

CH 6 input

CH 6 ground

CH 7 input

CH 7 ground

CH 8 input

CH 8 ground

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

CH 9 input

CH 9 ground

CH 10 input

CH 10 ground

CH 11 input

CH 11 ground

CH 12 input

CH 12 ground

CH 13 input

CH 13 ground

CH 14 input

CH 14 ground

CH 15 input

CH 15 ground

CH 16 input

CH 16 ground

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Publication GMSI10-UM031C-EN-E - January 2009

Page 10

6 Installing the Enwatch

Table 1.3 J3 External trigger pin outputs

Signal Pin No. Notes

Power supply 1 See note 1 on page 7.

Input 2 See note 2 on page 7.

Ground 3

Table 1.4 J4 External trigger pin outputs

Signal Pin No. Notes

Power supply 1 See note 1 on page 7.

Input 2 See note 2 on page 7.

Ground 3

Table 1.5 J5 External trigger pin outs

Signal Pin No. Notes

Power supply 1 See note 1 on page 7.

Input 2 See note 2 on page 7.

Ground 3

Table 1.6 J6 External trigger pin outputs

Signal Pin No. Notes

Power supply 1 See note 1 on page 7.

Input 2 See note 2 on page 7.

Ground 3

Table 1.7 J8 Ethernet connection pin outputs

Common RJ-45

Publication GMSI10-UM031C-EN-E - January 2009

Page 11

Installing the Enwatch 7

Table 1.8 J9 Supply voltage pin outputs

Signal Pin No.

Positive supply voltage +

Common -

Table 1.9 J10 pin outputs

Not user accessible

Table 1.10 J11 Serial port (RS-232) pin outputs

Signal Pin No. Notes

TXD 1 To connect to a host computer, use a

RXD 2

Ground 3

null modem 9-pin female to 9-pin

female cable.

Notes:

1. A supply voltage is available on pin 1 of the connector to power an

external trigger device. The voltage is equal to the voltage of the

incoming power supply to the board (on connector J9).

2. The external trigger is compatible with a CMOS/TTL logic level (5 V

logic). Alternatively, any voltage input in the range 5 to 24 V can be

accommodated. The trigger can be isolated or non-isolated.

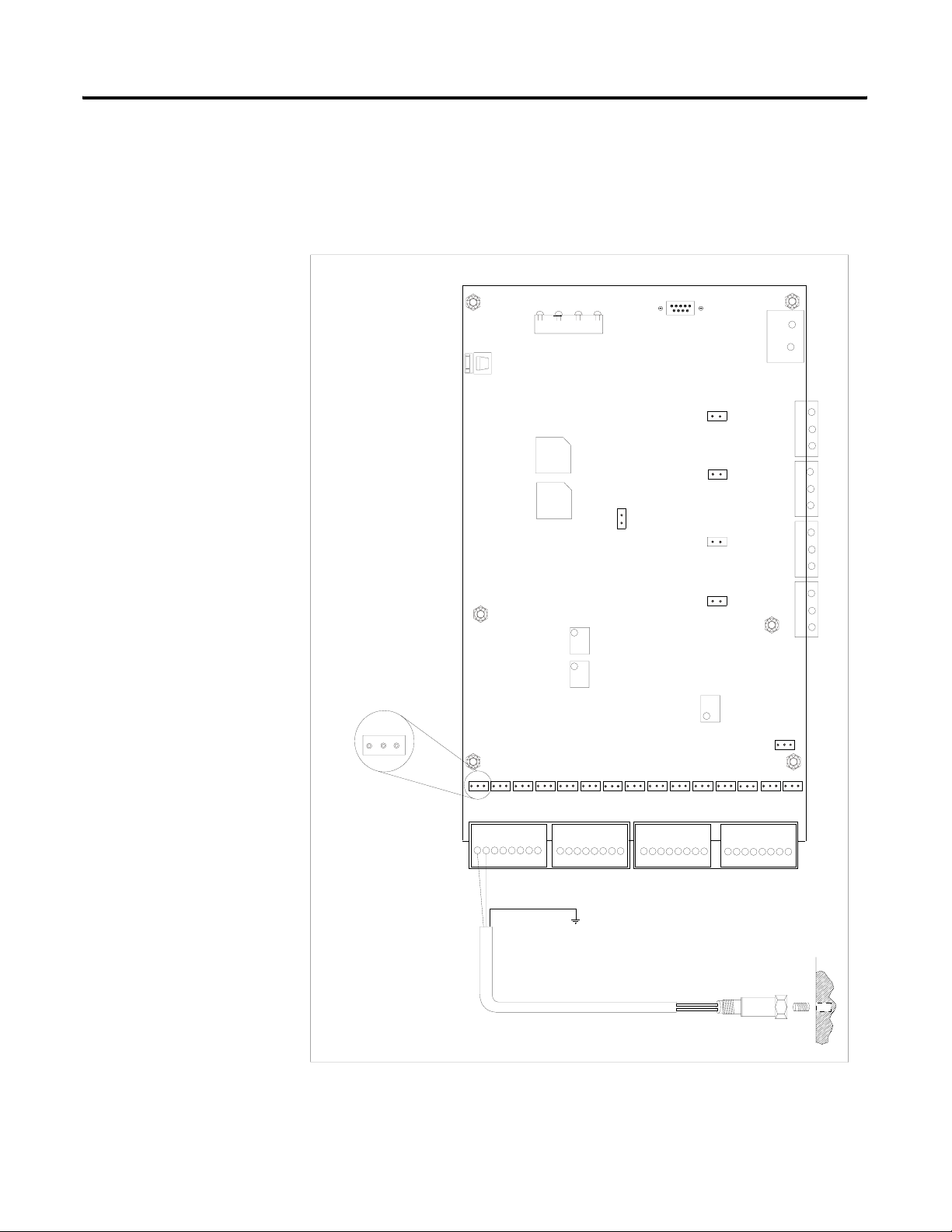

Analog Input Configuration

The 16 analog inputs provide you three options for signal coupling using a

3-way configurable jumper. The three positions are described in Table 1.11.

Table 1.11 Analog input options

Position Description

ICP Interface (nominal 24 V supply at 3.6 mA constant current for

transducer powering)

DC DC coupled

AC AC coupled

Publication GMSI10-UM031C-EN-E - January 2009

Page 12

8 Installing the Enwatch

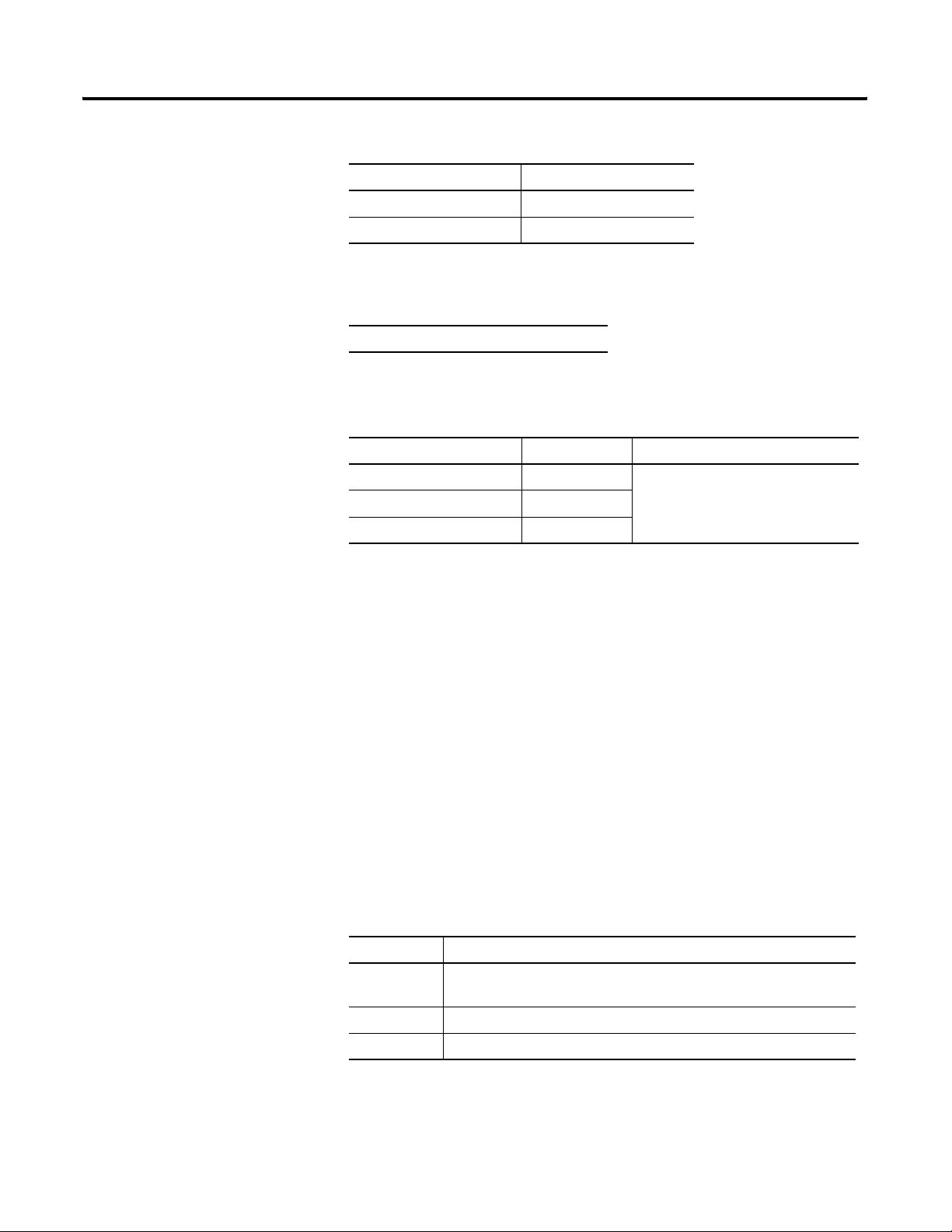

Each channel (16 total) has a 3-way header associated with it. These are labeled

with the channel number and “A” or “B.” The three jumper options are:

• Fitted to position xA

• Fitted to position xB

• Not fitted

where x is the channel number 1-16.

x B

Position Coupling

x A ICP

x B DC Coupled

Not Fitted AC Coupled

x A

IMPORTANT

The -3dB point of the high-pass coupling for the ICP

interface and AC Coupled configuration is 0.07 Hz.

LEDs

Four LEDs, as shown in Figure 1.2 on page 4, indicate the status of the

Ethernet communication. These illuminate as described in Table 1.12.

Table 1.12 LEDs

LED Description

OB The Enwatch unit is accessing LAN controller

LK Communication link is established between Enwatch unit and

network

RX Data is being received

TX Data is being transmitted

Publication GMSI10-UM031C-EN-E - January 2009

Page 13

Installing the Enwatch 9

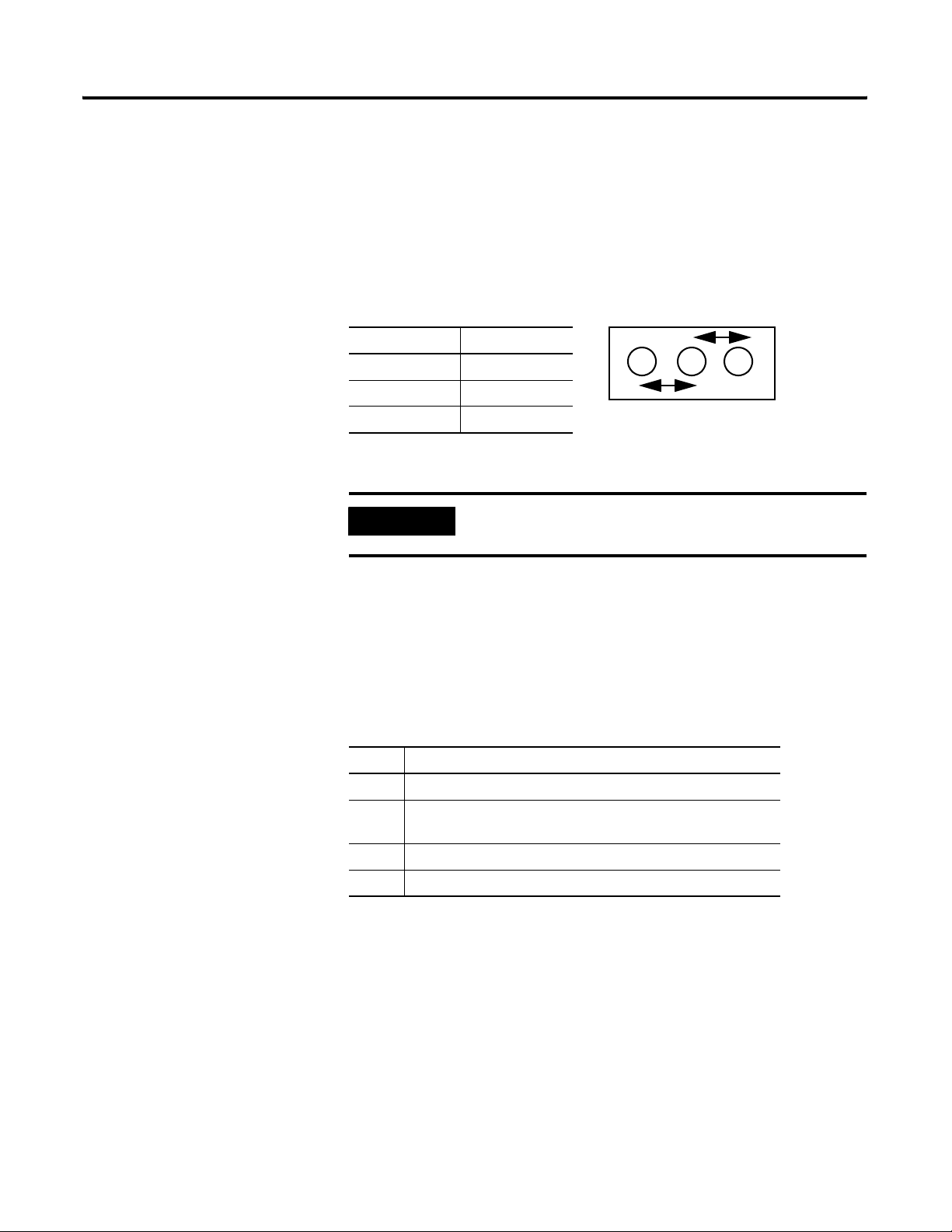

Trigger Isolation Jumpers

Four jumpers, JP17 to JP20, are sited on the board to enable the four trigger

inputs to be isolated or non-isolated. Non-isolated means the common of the

trigger input can be connected to the common of the Enwatch unit. With a

jumper removed, the trigger is isolated. Table 1.13 summarizes the jumper

positions.

Table 1.13 Jumper positions

Mode Jumper

External trigger 1 isolated JP17 Out

External trigger 1 non-isolated JP 17 In

External trigger 2 isolated JP18 Out

External trigger 2 non-isolated JP18 In

External trigger 3 isolated JP19 Out

External trigger 3 non-isolated JP19 In

External trigger 4 isolated JP20 Out

External trigger 4 non-isolated JP20 In

IMPORTANT

If an external sensor is to be used that is powered from pin

1 of J3, J4, J5 or J6, then the jumper corresponding to the

trigger channel must be inserted to provide a ground return

path for the sensor power.

Normal Operation versus Monitor Mode

The Enwatch unit incorporates an on-board monitor program for checking

the unit and modifying the system’s IP address. Inserting a jumper in JP21

enters into monitor mode.

Table 1.14 Normal vs. monitor mode

Mode Jumper J21

Normal Out

Monitor In

Publication GMSI10-UM031C-EN-E - January 2009

Page 14

10 Installing the Enwatch

Serial Port (RS-232)

An RS-232 compatible serial port is available on connector J11 for providing

local communication with the board (independent of the Ethernet network).

Only RXD and TXD lines are supported, and so a null modem cable must be

used. An on-board software monitor is provided to communicate through the

serial port.

If you do not use a 9-pin female to female null modem cable, the

recommended cable connection to a PC is shown in Table 1.15.

Table 1.15 J11 cable connections

J11 9-Pin D-Shell Connector

12

23

35

Supply Voltage

Incoming supply voltage to the power supply is 80 to 240 VAC / 50 or 60 Hz.

The power supply should be rated for a minimum of 1 A. If you have an

ISSUE F board, set the AC to DC power supply output voltage to 9 VDC. All

ISSUE G boards and higher, require a 24 VDC power supply. The power

supply that comes with the ISSUE G boards is pre set to 24 VDC and should

not be adjusted.

WARNING

TIP

Never attempt to connect the ISSUE F board to a 24V

power supply as doing this will damage the board. Always

ensure you have the proper power supply for the board

ISSUE you are using. The 24VDC power supply for ISSUE

G and higher boards has a yellow label that is marked

24VDC. The 12VDC power supply for ISSUE F boards

has a blue label that is marked 12VDC.

The ISSUE letter is located on the board. ISSUE F is

located at the bottom edge of the board near the J2

connector. See Figure 1.2 on page 4.

Publication GMSI10-UM031C-EN-E - January 2009

The ISSUE letter for ISSUE G and higher boards is

located in the upper left corner of the board, near the J8

connector.

Page 15

Installing the Enwatch 11

Flash Memory

If it is necessary to change the firmware, the flash memory is located in

position U20 and U28 (see Figure 1.2 on page 4). This flash memory is socket

mounted to allow you to change the EPROM. Make sure that the orientation

of the chip is correct when installing.

On Board Monitor

Setting Up an Enwatch Unit

When you insert a jumper into JP21, the Enwatch unit operates in its internal

monitor mode. This enables you to change the IP address as well as modify

other options. To invoke monitor mode, connect a terminal (or PC computer

in terminal mode) to the serial port and insert a jumper at position JP21.

Remove the power and then reconnect the power to reset the unit. A sign-on

message appears on the terminal together with a list of options (described in

“Setting Up an Enwatch Unit”, below).

To exit monitor mode, simply remove the jumper at position JP21, then

remove and reconnect the power to reset the unit.

Before installation, make sure you have plant specific IP network addresses

available for each Enwatch unit. For convenience write them down here.

IP Address 1: ____________________ IP Address 6: ____________________

IP Address 2: ____________________ IP Address 7: ____________________

IP Address 3: ____________________ IP Address 8: ____________________

IP Address 4: ____________________ IP Address 9: ____________________

IP Address 5: ____________________ IP Address 10: ___________________

You should also know the Subnet Mask and Gateway IP address (if available)

for each Enwatch unit.

1. Attach the Enwatch unit to the test computer via the RS-232 (serial)

port using a null modem cable.

2. Make sure the jumper in the middle of the Enwatch unit board is

inserted (JP21).

3. Start up any terminal program (Winterm, QVT/Term, Procomm,

etc.…) and set it up to communicate through the serial port at 9600

Baud, No parity, 8 data bits, and 1 stop bit.

Publication GMSI10-UM031C-EN-E - January 2009

Page 16

12 Installing the Enwatch

4. Turn on the Enwatch unit. It should display its configuration, then a

configuration menu in the terminal window.

---------- Start monitor com port: COM1 9600 N81

Intelligent Transducer Adapter Type 1) V 1.2

Copyright Icon Research Ltd 1998/99

Main Menu:

1 - Exercise Hardware Control

2 - Exercise Memory Devices

3 - Exercise Ethernet Controller

4 - Exercise Combined Sub-Systems

5 - Configure Adapter Settings

6 - Enter Download Mode

Make your selection (1-6) : 5

5. Select 5- Configure Adapter Settings.

Intelligent Transducer Adapter Type 1) V 1.2

Copyright Icon Research Ltd 1998/99

Configure Adapter Menu:

1 - Default Settings

2 - Assign Host MAC

3 - Assign Host IP

4 - Assign Host UDP Port

5 - Assign Subnet Mask

6 - Assign Gateway IP

7 - Assign Name

8 - Assign Network Option

9 - Assign Debug Level

ESC - Back to Main Menu

6. Select 2 - Assign Host MAC, and set it to the MAC address from the

board by pressing ESC.

Intelligent Transducer Adapter Type 1) V 1.2

Copyright Icon Research Ltd 1998/99

Configure Adapter Menu:

1 - Default Settings

2 - Assign Host MAC

3 - Assign Host IP

4 - Assign Host UDP Port

5 - Assign Subnet Mask

6 - Assign Gateway IP

7 - Assign Name

8 - Assign Network Option

9 - Assign Debug Level

ESC - Back to Main Menu

Make your selection (1-9) : 2

Assigning Host MAC

Current Host MAC : 00-50-C2-02-00-01

Enter New Address or ESC to abandon :

Aborted Input - Host MAC unchanged

Publication GMSI10-UM031C-EN-E - January 2009

Page 17

Installing the Enwatch 13

7. Select 3 - Assign Host IP, and set your Enwatch unit to one of your

plant specific IP addresses.

Intelligent Transducer Adapter Type 1) V 1.2

Copyright Icon Research Ltd 1998/99

Configure Adapter Menu:

1 - Default Settings

2 - Assign Host MAC

3 - Assign Host IP

4 - Assign Host UDP Port

5 - Assign Subnet Mask

6 - Assign Gateway IP

7 - Assign Name

8 - Assign Network Option

9 - Assign Debug Level

ESC - Back to Main Menu

Make your selection (1-9) : 3

Assigning Host IP

Current Host IP : 200.100.200.100

Enter New Address or ESC to abandon :

8. Select 4 - Assign Host UDP Port, and set it to 4242. This is the default

port number and cannot be any other number.

Intelligent Transducer Adapter Type 1) V 1.2

Copyright Icon Research Ltd 1998/99

Configure Adapter Menu:

1 - Default Settings

2 - Assign Host MAC

3 - Assign Host IP

4 - Assign Host UDP Port

5 - Assign Subnet Mask

6 - Assign Gateway IP

7 - Assign Name

8 - Assign Network Option

9 - Assign Debug Level

ESC - Back to Main Menu

Make your selection (1-9) : 4

Assigning Host UDP Port

Current Host UDP Port : 4242

Enter New Port or ESC to abandon :

Publication GMSI10-UM031C-EN-E - January 2009

Page 18

14 Installing the Enwatch

9. Select 5 - Assign Subnet Mask, and set it to the number obtained from

the IT department. Normally it is 255.255.255.000

Intelligent Transducer Adapter Type 1) V 1.2

Copyright Icon Research Ltd 1998/99

Configure Adapter Menu:

1 - Default Settings

2 - Assign Host MAC

3 - Assign Host IP

4 - Assign Host UDP Port

5 - Assign Subnet Mask

6 - Assign Gateway IP

7 - Assign Name

8 - Assign Network Option

9 - Assign Debug Level

ESC - Back to Main Menu

Make your selection (1-9) : 5

Assigning Subnet Mask

Current Subnet Mask : 255.255.255.000

Enter New Address or ESC to abandon :

10. Select 6 - Assign Gateway IP, and set it to the number obtained from

the IT department.

Intelligent Transducer Adapter Type 1) V 1.2

Copyright Icon Research Ltd 1998/99

Configure Adapter Menu:

1 - Default Settings

2 - Assign Host MAC

3 - Assign Host IP

4 - Assign Host UDP Port

5 - Assign Subnet Mask

6 - Assign Gateway IP

7 - Assign Name

8 - Assign Network Option

9 - Assign Debug Level

ESC - Back to Main Menu

Make your selection (1-9) : 6

Assigning Gateway IP

Current Gateway IP : 255.255.255.255

Enter New Address or ESC to abandon :

Publication GMSI10-UM031C-EN-E - January 2009

Page 19

Installing the Enwatch 15

11. Select 8 - Assign Network Option, and set it to the 10 Base T Port.

Intelligent Transducer Adapter Type 1) V 1.2

Copyright Icon Research Ltd 1998/99

Configure Adapter Menu:

1 - Default Settings

2 - Assign Host MAC

3 - Assign Host IP

4 - Assign Host UDP Port

5 - Assign Subnet Mask

6 - Assign Gateway IP

7 - Assign Name

8 - Assign Network Option

9 - Assign Debug Level

ESC - Back to Main Menu

Make your selection (1-9) : 8

Assigning Network Option

Currently using Ethernet 10 Base T Port

Network Options Available:

1 : Ethernet 10 Base T

2 : Ethernet 10 Base 2

Enter New Network or ESC to abandon :

12. Select 9 - Assign Debug Level, and set it to OFF unless you want to

see the debug messages from the Enwatch unit.

Intelligent Transducer Adapter Type 1) V 1.2

Copyright Icon Research Ltd 1998/99

Configure Adapter Menu:

1 - Default Settings

2 - Assign Host MAC

3 - Assign Host IP

4 - Assign Host UDP Port

5 - Assign Subnet Mask

6 - Assign Gateway IP

7 - Assign Name

8 - Assign Network Option

9 - Assign Debug Level

ESC - Back to Main Menu

Make your selection (1-9) : 9

Assigning Debug Level

Debug Options Available:

0 : Off

1 : Basic System Sampling & Message Processing

2 : (1) + Full Rx & Tx Message Display

3 : (2) + Interrupt Firing Notifications

Debug Level 1 Currently Set

Enter New Debug Level or ESC to abandon :

13. Shut down the Enwatch unit by removing the AC power, and turn it

back on. Look at the configuration settings and make sure the MAC and

IP address are correct.

Publication GMSI10-UM031C-EN-E - January 2009

Page 20

16 Installing the Enwatch

14. Shut down the Enwatch unit by removing the AC power, then remove

the jumper in the center of the board (JP21) and connect the board to

an active Ethernet connection. You do not have to disconnect the

RS-232 port.

15. Open a DOS prompt on a networked computer. Type ping, then a

space, and then the first IP address.

Connecting Transducers

EXAMPLE

16. You should get a return response from the Enwatch unit.

The following sections show how to connect transducers to the Enwatch

terminals.

ping 200.100.200.100

Publication GMSI10-UM031C-EN-E - January 2009

Page 21

Installing the Enwatch 17

Connecting an ICP Accelerometer

The following diagram shows the wiring from an ICP accelerometer to the

terminals of the Enwatch unit.

TYPICAL WIRING FOR ICP ACCELEROMETER

J11

JP 20

JP 19

JP 18

JP 17

J9

DC Power In

_

+

J6

33

4

22

1

J5

J4

J3

3

33

22

1

33

2

22

1

1

33

22

1

J8

Network Input

RJ-45 Jack

RX LK OB

TX

Status LED's

U28

U20

Normal / Monitor

Mode Select

RS-232

DB-9 (female)

JP 21

RV2

A - B

Jumper in xA position

for ICP Accelerometer

Terminal 1 - Signal

Terminal 2 - Ground

RV3

A - B A - B A - B A - B A - B A - B

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 9-10-11-12-13-14-15-16 1 - 2 - 3 - 4 - 5 - 6 - 7 - 8

A - B A - B A - B A - B A - B

A - B

Shield Ground

Pin A - Signal

Pin B - Ground

Cable shield not

connected at this end

RV1

9-10-11-12-13-14-15-16

A - B

A - B

A - B

A - B

Publication GMSI10-UM031C-EN-E - January 2009

Page 22

18 Installing the Enwatch

Connecting a Coil-Based Velocity Sensor

The following diagram shows the wiring from a coil-based velocity sensor to

the terminals of the Enwatch unit.

TYPICAL WIRING FOR COIL-BASED VELOCITY SENSOR

J11

JP 20

JP 19

JP 18

JP 17

J9

DC Power In

_

+

J6

33

4

22

1

J5

J4

J3

3

33

22

1

33

2

22

1

1

33

22

1

J8

Network Input

RJ-45 Jack

RX LK OB

TX

Status LED's

U28

U20

Normal / Monitor

Mode Select

RS-232

DB-9 (female)

JP 21

RV2

A - B

No Jumper for

Velocity Sensor

Terminal 1 - Signal

Terminal 2 - Ground

RV3

A - B A - B A - B A - B A - B A - B

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 9-10-11-12-13-14-15-16 1 - 2 - 3 - 4 - 5 - 6 - 7 - 8

A - B A - B A - B A - B A - B

A - B

Shield Ground

Pin A - Signal

Pin B - Ground

Cable shield not

connected at this end

RV1

9-10-11-12-13-14-15-16

A - B

A - B

A - B

A - B

Publication GMSI10-UM031C-EN-E - January 2009

Page 23

Installing the Enwatch 19

Connecting an Process DC Voltage Signal

The following diagram shows the wiring from a process DC voltage signal to

the terminals of the Enwatch unit.

TYPICAL WIRING FOR PROCESS DC VOLTAGE SIGNAL

J11

JP 20

JP 19

JP 18

JP 17

J9

DC Pow er In

_

+

J6

33

4

22

1

J5

J4

J3

3

33

22

1

33

2

22

1

1

33

22

1

J8

Network Input

RJ-45 Jack

RX LK OB

TX

Status LED's

U28

U20

Normal / Monitor

Mode Select

RS-232

DB-9 (female)

JP 21

RV2

A - B

Jumper in xB position

for DC Signal

Terminal 1 - Signal

Terminal 2 - Ground

RV3

A - B A - B A - B A - B A - B A - B

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 9-10-11-12-13-14-15-16 1 - 2 - 3 - 4 - 5 - 6 - 7 - 8

A - B A - B A - B A - B A - B

A - B

Shield Ground

Cable shield not

connected at this end

RV1

A - B

A - B

9-10-11-12-13-14-15-16

Process DC

Source

A - B

A - B

Publication GMSI10-UM031C-EN-E - January 2009

Page 24

20 Installing the Enwatch

Connecting a Magnetic Hall Effect Sensor

The following diagram shows the external trigger wiring from a magnetic Hall

effect sensor (magnetic interrupter) to the terminals of the Enwatch unit.

TYPICAL WIRING FOR MAGNETIC HALL EFFECT SENSOR

J8

Network Input

RJ-45 Jack

RX LK OB

TX

Status LED's

U28

U20

Normal / Monitor

Mode Select

JP 21

RV2

RS-232

DB-9 (female)

J11

JP 20

JP 19

JP 18

JP 17

J9

DC Power In

_

+

4

J6

33

22

1

3

J5

33

22

1

2

J4

33

22

1

1

J3

Ground

33

Input

22

Power

1

A - B A - B A - B A - B A - B A - B

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 9-10-11-12-13-14-15-16 1 - 2 - 3 - 4 - 5 - 6 - 7 - 8

IMPORTANT

RV3

RV1

A - B

A - B A - B A - B A - B A - B

A - B

9-10-11-12-13-14-15-16

A - B

A - B

A - B

If an external sensor is to be used that is powered from pin

1 of J3, J4, J5 or J6, then the jumper corresponding to the

trigger channel must be inserted to provide a ground return

path for the sensor power. See “Trigger Isolation Jumpers”

on page 9.

Publication GMSI10-UM031C-EN-E - January 2009

Page 25

Installing the Enwatch 21

Enwatch Measurement

This section lists the measurement capabilities of the Enwatch unit.

Capabilities

Table 1.16 Enwatch measurement capabilities

Product Feature Capability

Signal Control Raw input signal

Integrated input signal via HP filter

Hp filter input signal

gSE 200 Hz input signal

gSE 5000 Hz input signal

Bias Voltage

Combining measurements in the Enwatch

driver

How does the Enwatch driver choose the

high pass filter?

The Enwatch driver can combine measurements at the same location in Emonitor. The

following items must to be the same to combine measurements.

Signal route control (Integrate/non integrate/gSE/Raw)

Tachometer on/off

gSE time constant

Sample rate/maximum frequency

Phase lock loop

Number of averages

Measurement filter

Number of lines

X=2 x FMAX/lines

If X > 5.3 then set to 23.8

else if X > 2.67 set to 5.3

else if X > 0.36 set to 2.67

else if the Smart HP filter is on in Emonitor, then set to 2.67, otherwise set to 0.36

Note: The Smart HP filter in Emonitor does not use 0.36Hz HP filter.

Trigger usage Sample on trigger (the first version of Enwatch always uses this option)

Sample on post-trigger

Sample on pre-trigger

Tachometer usage Use tachometer for PLL (phase loop locked)

Autorange Always on, maximum input ±10 V

Integrator reset control Reset before first sampling of a measurement

Publication GMSI10-UM031C-EN-E - January 2009

Page 26

22 Installing the Enwatch

Table 1.16 Enwatch measurement capabilities

Product Feature Capability

Sampling rate 64 to 51200 Hz by 1

FMAX Sampling Rate FMAX Sampling Rate

25 64 2000 5120

50 128 3200 8192

100 256 4000 10240

200 512 5000 12800

400 1024 6400 16384

500 1280 8000 20480

800 2048 10000 25600

1000 2560 16000 40960

1600 4096 20000 51200

Number of synchronous time averages 1, 2, 4, 8, 32 ... 32768

Sample length Multiple of 256 bytes, maximum sample 32768 bytes if no trigger, 16384 bytes with

pre-trigger (not used in first version of Enwatch)

Filter settling time HP 0.36 Hz 18 seconds

HP 2.67 Hz 3 seconds

HP 5.3 Hz 1.2 seconds

HP 23.8 Hz 0.3 seconds

Integrator HP 0.36 Hz 25 seconds

Integrator HP 2.67 Hz 8 seconds

Integrator HP 5.3 Hz 1.5 seconds

Integrator HP 23.8 Hz 0.8 seconds

gSE 200 Hz 88 milliseconds

gSE 5 kHz 2 milliseconds

Core 0.7 seconds

Time constant of 0.03 seconds 300 milliseconds

Time constant of 0.006 seconds 60 milliseconds

Time constant of 0.0012 seconds 12 milliseconds

Time constant of 0.00024 seconds 3 milliseconds

Trigger delay 0-32768 samples. Emonitor always uses 0.

Trigger channel 1-4 channels, TTL input 5-20 V

Maximum combined trigger current (channels 1-4), not to exceed 100mA.

Gain control X1, X10, X100, X1000, X5, X50, X500, X5000

Download X1 always. The Enwatch unit autoranges and returns back the current gain for

rescaling.

Anti-Alias filter 20 kHz, 2 kHz, 500 Hz, 100 Hz. This is read only. The Enwatch unit selects the proper filter.

Publication GMSI10-UM031C-EN-E - January 2009

Page 27

Table 1.16 Enwatch measurement capabilities

Product Feature Capability

gSE time constant 0.03, 0.006, 0.0012, 0.00024 seconds, the default is 0.03 seconds

if FMAX > 350Hz set to 0.00024 seconds

else if FMAX > 150 Hz set to 0.0012 seconds

else if FMAX > 37.5 Hz set to 0.006 seconds

If the measurement is overall only (no spectrum) then set to 0.03 seconds.

Integrator One level of hardware integration

The hardware has a gain factor of:

2.67/f for the 0.36 Hz and the 2.67 Hz filter ranges (INTHI = 0)

38.9/f for the 5.3 Hz and 23.7 Hz filter ranges (INTHI = 1)

To convert from g->ips:

Velocity (ips peak) = [integrator output (volts peak)] x [1 / (gain factor)] x [accel scale factor

(g peak / mv peak)] x [61.24 / frequency]

Sample sequence allowed 4096 - one sample sequence uses one configuration table

Configuration tables 128 - one measurement point uses one table so total will be 128 points

Storage overhead 18 bytes per allocation

Flash memory lifetime 100,000 writes

Installing the Enwatch 23

Total available memory 640 Kilobytes

HOST software support (Emonitor) Window types: Hanning, Hamming, Rectangular, Kaiser Bessel, Flattop

Number of lines 100, 200, 400, 800, 1600, 3200

Number of averages 1-99

Bias voltage reading When you define a process measurement of DC in Emonitor, the Enwatch unit reads the

transducer bias voltage.

24V means open circuit, 10V is OK.

Publication GMSI10-UM031C-EN-E - January 2009

Page 28

24 Installing the Enwatch

Table 1.16 Enwatch measurement capabilities

Product Feature Capability

Maximum number of averages that can

be supported

Number of samples required: Lines x 2.56 + lines x 2.56(#avg -1) x (1 -%overlap)

Max number of samples per configuration: 32768

Max number of averages = ((32768 / (lines x 2.56)) - 1) / (1 -%overlap) + 1)

The following table shows the maximum number of averages versus the number of lines and

percent overlap for non-trigger point.

Max samples-non trigger points 32768

#lines 0 0.25 0.5 0.75

100 128 170 255 509

200 64 85 127 253

400 32 42 63 125

800 16 21 31 61

1600 8 10 15 29

3200 4 5 7 13

6400 2 2 3 5

12800 1 1 1 1

% overlapping % overlapping % overlapping % overlapping

The following table shows the maximum number of averages versus the number of lines and

percent overlap for pre-trigger point.

Max samples-trigger points 16384

% overlapping % overlapping % overlapping % overlapping

#lines 0 0.25 0.5 0.75

100 64 85 127 253

200 32 42 63 125

400 16 21 31 61

800 8 10 15 29

1600 4 5 7 13

3200 2 2 3 5

6400 1 1 1 1

12800 - - - -

Signal detection RMS, Peak, Peak-Peak

Configuration downloading Route mode configuration downloads to Flash memory

Live mode configuration downloads to RAM

Note: You can reduce number of average or increase percent overlap to reduce amount of

memory used.

Publication GMSI10-UM031C-EN-E - January 2009

Page 29

Installing the Enwatch 25

Setting Up Sample Measurements

This section gives examples of setting up measurement definitions in

Emonitor.

DC or other Numeric measurements

Suppose you have a transducer with an output of -2 V to 2 V and a linear scale

from -10° F to 100° F. How do you set up the transducer in Emonitor?

If the volts reading is R, then the data stored in Emonitor is:

(R / calibration + DC offset)

Input range volts: (X, Y)

Scale value: (A, B) volts

Data in Emonitor = (R - X) x ((B-A) / (Y-X)) + A

Calibration value in transducer setup: [(Y-X) x 1000mv / eu]/(B-A)

DC Offset in transducer setup: A - (B-A) x X / (Y-X)

EXAMPLE

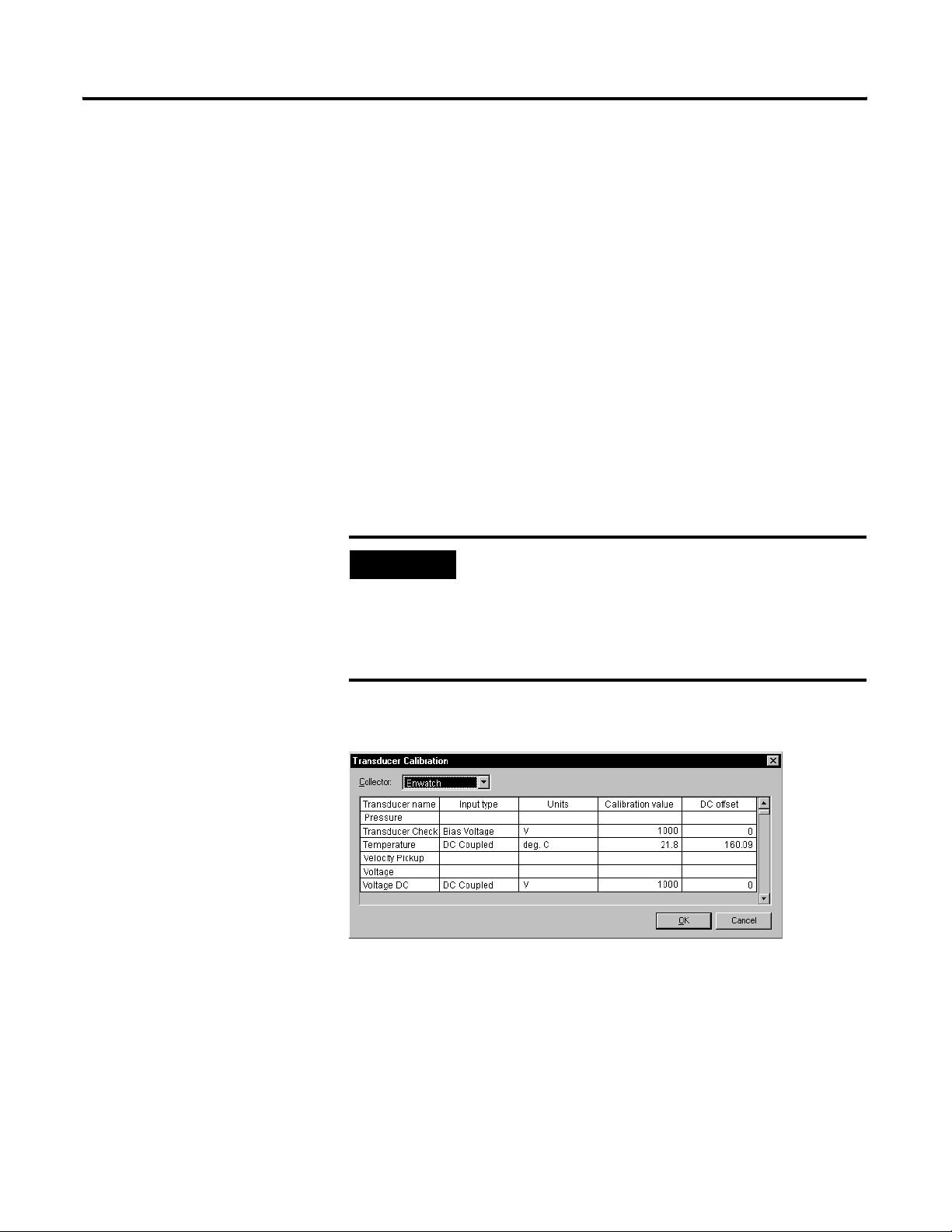

In Emonitor, select Setup>Calibration and set up the calibration for the

Temperature transducer.

Input range: (-1.31 V, +0.87 V)

Scale value: (100° F, 200° F)

Calibration: [(0.87 - (-1.31)) x 1000] / (200 - 100) = 21.8

Offset: 100 - (200 - 100) x (-1.31) / (0.87-(-1.31)) = 160.09

Input type should be DC coupled and the jumper setting

on board needs to be set as DC couple as well.

Publication GMSI10-UM031C-EN-E - January 2009

Page 30

26 Installing the Enwatch

Then select Setup>Transducer to select the “Temperature” transducer in the

collection specification.

In Emonitor, define a numeric measurement definition with the temperature

units and the “Temperature” collection specification.

Transducer bias reading

Enwatch can take transducer bias readings; however, this is not a transducer

check function that detects transducer failure before taking data. The bias

reading is an independent reading with a different signal path on the Enwatch

board.

First in Emonitor, select Setup>Transducer to define a new transducer

name, for example, “Transducer Check.”

Publication GMSI10-UM031C-EN-E - January 2009

Page 31

Installing the Enwatch 27

Then select Setup>Calibration to select “Bias Voltage” as the input type for

this transducer. The calibration should set to 1000 and the offset to 0.

Then select Setup>Collection to define a new collection specification. Select

“Transducer Check” as the transducer.

In Emonitor, define a numeric measurement definition with Vdc units and the

“Transducer Bias” collection specification.

Publication GMSI10-UM031C-EN-E - January 2009

Page 32

28 Installing the Enwatch

Saving the machine speed with a spectrum

In the Hardware Setup program, when adding or editing an Enwatch unit,

click the Trigger Channel tab.

The Timeout is defined in seconds (the default is 5 seconds). The Number of

pulse per rev default is 1 pulse per revolution. Click the Channel tab and

assign the correct Trigger channel to the vibration channel. This example

uses trigger channel 1 for the measurement on input channel 1.

Publication GMSI10-UM031C-EN-E - January 2009

When the Enwatch unit collects data for channel 1, the unit checks trigger

channel 1 to get the machine speed reading. The speed reading comes back

with time waveform data and gets stored into the database with the vibration

data.

Page 33

Installing the Enwatch 29

Magnitude and phase reading

A magnitude/phase reading is similar to any other data collector in Emonitor.

You set up an overall measurement, using the “Mag & Phase” collection

specification. Then select “1st Order” as the measurement filter (or any other

desired order).

Validating Enwatch measurements

In the Hardware Setup program, when adding or editing an Enwatch unit, you

can set up a validation function to allow the driver to check the channel’s data

before updating the database. This function can be used to filter unwanted

data when the machine is not running, or when some other parameter is not

within the correct bounds.

Click the Channel tab, then double-click in the Val id ate column to set up the

validation parameters.

Publication GMSI10-UM031C-EN-E - January 2009

Page 34

30 Installing the Enwatch

You can reference any channel and there is no order you need to follow.

Order normalized measurements

You enable order normalized measurements in the collection specification. In

Emonitor, select Setup>Collection. Then either edit an existing collection

specification or create a new one. Make sure the Order normalization

checkbox is selected. The Enwatch unit then finds the machine speed and

Publication GMSI10-UM031C-EN-E - January 2009

Page 35

Installing the Enwatch 31

applies it to the number of orders to select the proper sampling rate before

collecting data.

IMPORTANT

You must also define a trigger channel for the Enwatch

channel so that the Enwatch unit can find the machine

speed.

How are DSP functions handled in the Enwatch driver?

The Enwatch unit only takes time domain data and returns that data to the

host software. All DSP functions are done by the host driver. In this way, the

firmware can focus on data collection speed. Since Enwatch does not handle

calculating the average time waveform, the host driver software must tell the

Enwatch unit to collect a time waveform of sufficient length in order to

calculate the average.

Publication GMSI10-UM031C-EN-E - January 2009

Page 36

32 Installing the Enwatch

Limitation on number of points in Enwatch

The Enwatch unit has 640 K bytes memory for data storage. If you attempt to

collect data on more points than can fit in memory, the unit returns an error

message. The message appears in the Unload Station Manager window (refer

to the Online Applications Guide for more on the Unload Station Manager). The

Enwatch driver can combine measurements in some cases (see “Combining

measurements in the Enwatch driver” on page 21).

If a route has 5 points per channel and 400 lines, 4 averages, no overlap

averaging:

Bytes required: 5 points x 16 channels x 1024 bin x 2 byte/bin x 4 averages =

655360 bytes

If a route has 2 points per channel and 800 lines, 4 averages, no overlap

averaging:

Bytes required: 2 points x 16 channels x 2048 bin x 2 byte/bin x 4 averages =

524288 bytes

Configuration of Emonitor with Enwatch

To best use the 640K memory, try to use overlap averaging. For examples, see

“Maximum number of averages that can be supported” on page 24.

The Enwatch unit is specially designed to operate over an Ethernet

connection. Each Enwatch unit has a unique IP address that can be changed

through the RS232 port inside the unit. Ideally, one Enwatch unload station

can serve an unlimited number of Enwatch units. However, to improve unload

speed, multiple Enwatch unload stations are suggested.

Each Enwatch unit has 16 vibration channels and 4 tachometer channels. In

addition, the Allen Bradley Enlive software (live mode analysis) can be used to

“lock onto” one channel at a time. During live mode analysis, regularly

scheduled unload continues to unload whatever data is in the Enwatch unit

buffers before entering live mode analysis. The Enlive software has a default

timeout of 30 minutes to prevent an extended break in unloading scheduled

data.

For more information on setting up an Enwatch unit in an Emonitor system,

refer to the Online Applications Guide provided with your Emonitor online

system.

Publication GMSI10-UM031C-EN-E - January 2009

Page 37

Chapter

Specifications

This chapter lists the technical specifications for the Enwatch unit.

Enwatch Technical Specifications

Product Feature Specification

Inputs

Number of Channels

16 vibration and 4 tachometer

(synchronizer)

2

Voltage Protection

Input Impedance

Ranges

ICP Interface

Coupling

PGA Gains

Anti-Alias Filter

High Pass Filters

Channel Cross-Talk

Protects against over-voltage (channel

auto-switch off)

2000 V ESD protection

1 MOhm

±10 mV to ±10 V, 7 ranges (software

selectable)

3.6 mA @ 24 VDC, configurable per channel

AC/DC (numeric measurements),

configurable per channel

DC offset removal by optional use of

channel 16

Specified in Chapter 1

Compound analog filter with roll-off better

than 20th order filter; cut-off frequency

related to sample rate.

4th order with corner frequencies 0.36,

2.67, 5.3, and 23.8 Hz

-80 dB

Amplitude Accuracy

Phase Accuracy

Harmonic Distortions

Integration

Acquisition Modes

33 Publication GMSI10-UM031C-EN-E - July 2009

±2% typical in pass-band

±3%

-70 dB (typical)

One 2-stage with ideal stop-band edge at

0.36 Hz

Mode 1: Timed pickup

Mode 2: Data Ready flag

Mode 3: Data broadcast

Page 38

34 Specifications

Enwatch Technical Specifications

Product Feature Specification

Spike Energy Measurement

gSE Filters High pass at 200 Hz & 5 kHz 2nd order

Trigger

TTL Isolated or Non-Isolated, or any voltage

Types

up to +24 V

Maximum combined current for all

channels, not to exceed 100mA

Processing

Outputs

Machine Speed Range

Time to Lock

Averaging

Tachometer Information

Trigger Delays

Time Domain ADC

Sampling Rate

Dynamic Range

Block Lengths

Overall Units

Status

1 to 60,000 RPM

2 revolutions

1, 2, 4, ... 32,000 averages, programmable

RPM using trigger input

Post-trigger delays up to 32,768 samples

Pre-trigger delays up to 16,384 samples

(not used with Emonitor)

16 bit

64 Hz to 51.2 kHz

96 dB (theoretical)

256, 512, 1024, 2048, 4096, or 8192 with

averaging

up to 16,384 without averaging

Acceleration, velocity, or displacement

(double integration in one level hardware &

one level software), and Spike Energy data

LEDs indicate system functions

Publication GMSI10-UM031C-EN-E - July 2009

Storage

Mechanical

Environmental

Power

Interface Port

Memory Buffer

Power Fail Handling

Protection NEMA 4, IP66

Temperature -20 to 70° C

Power Supply

Power Consumption

RS-232C, 9600 baud for diagnostics

640 Kilobytes

Hardware checks for node power and

isolates node with no power

85 to 260 VAC

12 W maximum to board, using 3.6 mA ICP

current sources

Page 39

Enwatch Technical Specifications

Product Feature Specification

Communications

Network

Ethernet

Specifications 35

Medium

Connectors

Speed

Isolation

10BASE-T

Weidmuller terminal blocks

10 Mbits/sec

1000 Vrms

Publication GMSI10-UM031C-EN-E - July 2009

Page 40

36 Specifications

Publication GMSI10-UM031C-EN-E - July 2009

Page 41

Index

Numerics

10 Base T 3, 15

A

AC coupling 7

ADC 3

address

Enwatch IP

HOST IP 13

HOST MAC 12

HOST UDP 13

IP network 11

analog inputs

1–16

AC coupling 7

DC coupling 7

DC voltage signal 19

ICP transducer 7, 17

jumpers 7

velocity sensor 18

analog-to-digital converter 3

anti-aliasing filter 2, 22, 33

11

5

B

Base 3

bias, transducer 2, 23

block diagram 1

block diagram component description 2

board diagram 4

C

clock generator 3

CMOS/TTL 7

coil-based velocity sensor

See velocity sensor

collection specification

configuration with Emonitor 32

26, 27, 29, 30

configuring Enwatch 11

connections

DC voltage signal

Ethernet 6

Hall effect sensor 20

ICP transducer 17

serial port 7

supply voltage 7

velocity sensor 18

connectors

J10

7

J11 10

J1–J11 5

J1–J2 5

J3–J6 6

J8 6

J9 7

19

D

data storage 32

DC coupling 7

DC measurements 25

DC voltage signal

19

jumper

wiring 19

diagrams

block diagram

board 4

DC voltage signal 19

Hall effect sensor 20

ICP transducer wiring 17

velocity sensor wiring 18

DSP functions and Enwatch driver 31

1

E

electrical components 2

electrical connections 4

enclosure 3

Publication GMSI10-UM031C-EN-E - July 2009

Page 42

38 Index

Ethernet

communication LEDs

connection 6

controller/buffer memory 3

external trigger

channels 1–4

CMOS/TTL 7

isolation 9

jumpers 9

wiring 20

6

F

filters

1st order

anti-aliasing 2, 22, 33

gSE 34

high pass 2, 21, 33

settling time 22

Smart HP filter 21

firmware 11

flash memory 11

29

G

gain amplifier 3

gSE filter 34

gSE function 2

8

J

J10 7

J11 10

J11 serial port (RS-232) 7

J1–J11 5

J1–J2 analog inputs 5

J3–J6 external trigger 6

J8 Ethernet connection 6

J9 supply voltage 7

JP17–JP20 9

JP21 9, 11

jumpers

analog inputs

DC voltage signal 19

external trigger 9

ICP transducer 17

JP17–JP20 9

JP21 9, 11

on-board monitor program 9, 11

velocity sensor 18

7

L

LEDs

See light emitting diodes

light emitting diodes

limitations on number of points 32

8

H

Hall effect sensor wiring 20

high pass filter 21, 33

high pass filters 2

HOST IP address 13

HOST MAC address 12

HOST UDP address 13

I

ICP interface 2

ICP transducer

jumper

17

wiring 17

installation 11

installation overview 2

integrator 2

introduction 1

IP network addresses 11

isolating external trigger 9

M

machine speed measurements 28

magnitude and phase measurements 29

measurement capabilities 21

mechanical components 3

memory limitations 32

microprocessor subsystem 3

multiplexer 2

N

network option, assigning 15

O

on-board monitor program

configuring Enwatch

jumpers 9, 11

starting 11

order normalized measurements 30

11

Publication GMSI10-UM031C-EN-E - July 2009

Page 43

Index 39

P

ping 16

power regulation 3

process measurements 25

process signal

See DC voltage signal

R

RS-232 port 7, 10

S

serial port 7, 10

Smart HP filter 21

specifications, measurement 21

specifications, technical 33

Spike Energy function 2

storage, data 32

supply voltage 7, 10

T

tachometer input

See external trigger

technical specifications

temperature measurements 25

33

terminal program 11

transducer bias 2

transducer bias measurements 23, 26

TTL 7

U

U20 11

U28 11

V

validating measurements 29

velocity sensor

jumper

18

wiring 18

W

watchdog 3

wiring

DC voltage signal

external trigger 20

Hall effect sensor 20

ICP transducer 17

velocity sensor 18

19

Publication GMSI10-UM031C-EN-E - July 2009

Page 44

Power Ratings

120mA minimum, 280mA maximum / 24Vdc

Temperature Ratings

-10C to +70C

Publication GMSI10-UM031C-EN-E - July 2009 40 Part Number 44887-PUB

Supersedes Publication 44887 Rev. 2 - January 20 09 Copyright © 2009 Rockwell Automation, In c. All rights reserved. Printed in the U.S.A.

Loading...

Loading...