Page 1

R

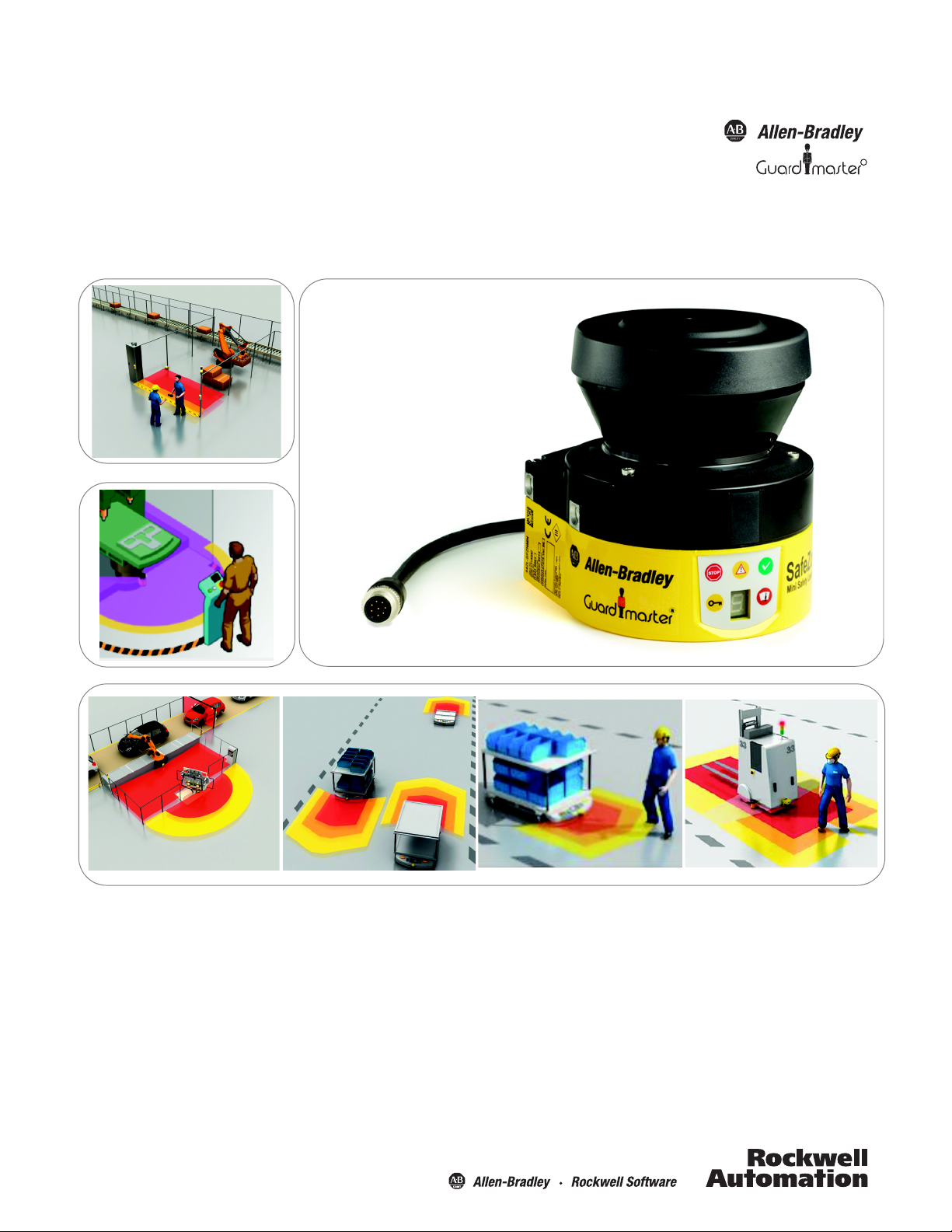

SafeZone Mini

Safety Laser Scanner

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this publication, those responsible for the

application and use of this control equipment must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance and safety requirements, including

any applicable laws, regulations, codes and standards.

Reproduction of the contents of this copyrighted publication, in whole or part, without written permission

of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety considerations:

The illustrations, charts, sample programs and layout examples shown in the guide are intended solely for

purposes of example. Since there are many variables and requirements associated with any particular

installation, Rockwell Automation does not assume responsibility or liability (to include intellectual property

liability) for actual use based upon the examples shown in this publication.

Rockwell Automation publication SGI-1.1, Safety Guidelines for the Application, Installation and

Maintenance of Solid-State Control (available from your local Rockwell Automation sales oce), describes

some important dierences between solid-state equipment and electromechanical devices that should be

taken into consideration when applying products such as those described in this publication.

It is recommended that you save this user manual for future use.

Identies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identies information that is critical for successful application and understanding of

the product.

Identies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss. Attentions help you identify a

hazard, avoid a hazard, and recognize the consequences.

SHOCK HAZARD

Labels may be on or inside the equipment (for example, drive or motor) to alert people

that dangerous voltage may be present.

BURN HAZARD

Labels may be on or inside the equipment (for example, drive or motor) to alert people

that surfaces may reach dangerous temperatures.

WARNING

IMPORTANT

ATTENTION

Page 3

Contents

Contents

About this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Chapter 1

Function of this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Depth of information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Abbreviations used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

On safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Chapter 2

Qualified safety personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Applications of the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Correct use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General safety notes and protective measures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Environmental protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Separation of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Applicable directives and standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Chapter 3

Special features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Principle of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Field set comprising of protective field and warning field(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

SafeZone Mini . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Device components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Status indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

LEDs and seven-segment display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Configurable functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Chapter 4

System parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Application name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Name of the scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

User data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Display direction of the seven-segment display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Basic response time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Maximum protective field range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Universal I/O connections of the SafeZone Mini. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

OSSDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Internal OSSDs of the SafeZone Mini . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

External device monitoring (EDM) SafeZone Mini . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Restart of the SafeZone Mini. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Field sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Configuring the protective field and warning field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Protective field or warning field suggested by the safety laser scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Using the contour as a reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Monitoring cases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Multiple sampling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Stand-by mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Chapter 5

Stationary application in horizontal operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Protective field size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Stationary vertical operaton for access protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Minimum distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Stationary vertical operation for hazardous point protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Rockwell Automation Publication 10000337275 Ver 01—October 2014 1

Page 4

Contents

Minimum distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Mobile applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Mounting (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Chapter 5

Protective field length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Protective field width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Height of the scan plane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Methods of preventing unprotected areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Near range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Mounting steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Direct mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Mounting with mounting kit 1a or 1b . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Mounting with mounting kit 2 and 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Information label Important information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Using multiple SafeZone Mini safet y laser scanners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Electrical installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Chapter 6

System connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Round plug connector SafeZone Mini. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Configuration connection M8 × 4 (serial interface). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Application examples and connection diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . Chapter 7

Stationary applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Applications with one monitored area (SafeZone Mini) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Mobile applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Vehicle monitoring for unidirectional travel (SafeZone Mini) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Connection diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

SafeZone Mini with restart interlock and external device monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

SafeZone Mini in combination with a UE10 safety relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Protective field switching using a Flexi Classic safety controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Chapter 8

Default delivery status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Preparation of the configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Chapter 9

Initial commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Power-up sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Test notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Pre-commissioning tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Regular inspection of the protective device by qualified safety personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Daily testing of the protective device by a specialist or authorized personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Maintenance and care. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Chapter 10

Cleaning optics cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Replacing the optics cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Chapter 11

In the event of faults or errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Rockwell Automation support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Error and status indications on the LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Error and status indications on the seven-segment display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

The lock-out operational status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Extended diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Technical specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Chapter 12

OSSD response times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Timing behavior of the OSSDs of the SafeZone Mini . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Data sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Dimensional drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

2 Rockwell Automation Publication 10000337275 Ver 01—October 2014

Page 5

Contents

SafeZone Mini . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Mounting kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Scan plane origin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Chapter 13

Items supplied SafeZone Mini . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Accessories/spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Mounting kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Annex. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Chapter 14

EC declaration of conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Checklist for the manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

List of tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

List of illustrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Rockwell Automation Publication 10000337275 Ver 01—October 2014 3

Page 6

Chapter 1 About this document

Chapter 1

About this document

Please read this chapter carefully before working with this documentation and the SafeZone Mini.

Function of this document

Target group

Scope

Depth of information

These operating instructions are designed to address the technical personnel of the machine manufacturer or the machine

operator in regards to correct mounting, electrical installation, commissioning, operation and maintenance of the

SafeZone Mini safety laser scanner.

These operating instructions do not provide instructions for operating the machine, the system or the vehicle on which the

safety laser scanner is, or will be, integrated. Information on this is to be found in the appropriate operating instructions

for the machine, the system or the vehicle.

These operating instructions are addressed to planning engineers, machine designers and the operators of machines and

systems which are to be protected by one or several SafeZone Mini safety laser scanners. They also address people who

integrate the SafeZone Mini into a machine, a system or a vehicle, initialize its use, or who are in charge of servicing and

maintaining the device.

These operating instructions are original operating instructions.

These operating instructions are only applicable to the SafeZone Mini safety laser scanner with the following entry on the

type label in the field Operating Instructions (Pub. No. 10000337275).

For the configuration and diagnostics of these devices you require the SCD (version 3.0 or higher) programming software.

To determine the software version, select the Module Info… option in the Help menu.

These operating instructions contain information on the SafeZone Mini safety laser scanner. They have the following parts:

• Mounting • Fault diagnosis and troubleshooting

• Electrical installation • Catalog numbers

• Commissioning and configuration • Accessories

• Care and maintenance • Conformity and approval

Planning and using protective devices such as the SafeZone Mini also require specific technical skills which are not detailed

in this documentation.

General information on accident prevention using opto-elect ronic protective devices can be found in the competence

brochure “Guidelines Safe Machinery.”

When operating the SafeZone Mini, the national, local and statutory rules and regulations must be observed.

Please refer also to the Rockwell Automation home page on the Internet at www.rockwellautomation.com.

Note:

Here you will find information on:

• Application examples

• A list of frequently asked questions regarding the SafeZone Mini

• These operating instructions in different languages for viewing and printing

Abbreviations used

Automated Guided Vehicle

AGV

American National Standards Institute

ANSI

American Wire Gauge = standardization and classification of wires and cables by type, diameter etc.

AWG

External device monitoring

EDM

Electromagnetic compatibility

EMC

4 Rockwell Automation Publication 10000337275 Ver 01—October 2014

Page 7

Chapter 1 About this document

.

.

Electrostatic discharge

ESD

Electro-sensitive protective equipment

ESPE

Fail-safe programmable logic controller

FPLC

Output signal switching device = signal output of the protective device that is used to stop the dangerous movement

OSSD

Robotic Industries Association

RIA

Symbols used

SCD software

Recommendation

Note

.

.

,

,

Take actio n…

Warning!

Rockwell Automation Safety Configuration and Diagnostic Software (SCD software) = software for configuration and

diagnostics on the SafeZone Mini

Recommendations are designed to give you some assistance in your decision-making process with respect to a certain

function or a technical measure.

Refer to notes for special features of the device.

Display indicators show the status of the sevensegment display on the SafeZone Mini:

Constant indication of characters, e.g. 8

Flashing indication of characters, e.g. 8

Alternating indication of characters, e.g. L and 2

LED symbols describe the status of an LED:

The “OSSDs in the OFF state” LED is illuminated continuously.

The “Error/contamination” LED is flashing.

The “Warning field interrupted” LED is off.

Instructions for taking ac tion are shown by an arrow. Read carefully and follow the instructions for action.

A warning indicates an actual or potential risk or health hazard. Observation and implementation of the warning will

protect you from accidents.

Read carefully and follow the warning notices!

Information is displayed in the software indicating to you which settings you can make in the SCD software (Safety

Configuration and Diagnostic Software).

The term “dangerous state”

The dangerous state (standard term) of the machine is always shown in the drawings and diagrams of this document as a

movement of a machine part. In practical operation, there may be a number of different dangerous states:

• Machine movements

• Vehicle movements

• Electrical conductors

• Visible or invisible radiation

• Combination of several risks and hazards

Rockwell Automation Publication 10000337275 Ver 01—October 2014 5

Page 8

Chapter 2 On safety

Chapter 2

On safety

This chapter deals with your own safety and the safety of the system operators.

Please read this chapter carefully before working with the SafeZone Mini or with the machine protected by the

SafeZone Mini.

Qualified safety personnel

Applications of the device

The SafeZone Mini safety laser scanner must be installed, connected, commissioned and serviced only by qualified safety

personnel. Qualified safety personnel are defined as persons who:

• Due to their specialist training and experience have adequate knowledge of the power-driven equipment to be

checked,

• Have been instructed by the responsible machine owner in the operation of the machine and the current valid safety

guidelines,

• Are sufficiently familiar with the applicable official health and safety regulations, directives and generally recognized

engineering practice (e.g. DIN standards, VDE stipulations, engineering regulations from other EC member states) that

they can assess the work safety aspec ts of the power-driven equipment, and

• Have access to these operating instructions and have read them.

As a rule these are qualified safety personnel from the ESPE manufacturer or also those persons who have been

appropriately trained at the ESPE manufacturer, are primarily involved in checking ESPE and are allocated the task by the

organization operating the ESPE.

The SafeZone Mini safety laser scanner is used to protect persons and systems. It is intended to be used to monitor

hazardous areas indoors.

• It is not allowed to use the SafeZone Mini outdoors.

• The SafeZone Mini cannot provide protection from parts thrown out of the machine or emitted radiation.

• The SafeZone Mini complies with the requirements in the standard on the radiated emissions as defined for class A

(industrial application); the SafeZone Mini is therefore only suitable for use in an industrial environment.

• The device is a type 3 ESPE as defined by EN 614961 and CLC/TS 614963 and is therefore allowed for use with

category 3 PL d controls as per EN ISO 138491 or SIL2 as per IEC 61508.

• The SafeZone Mini is suitable for:

– Hazardous area protection

– Hazardous point protection

– Access protection

– Vehicle protection (electrically powered industrial trucks)

Depending on the application, other protective devices and measures may be required in addition to the safety laser

Note

scanner.

Correct use

6 Rockwell Automation Publication 10000337275 Ver 01—October 2014

The SafeZone Mini safety laser scanner must be used only as defined in Chapter 2, “Applications of the device” on page 6. It

must be used only by qualified personnel and only on the machine where it has been installed and initialized by qualified

safety personnel in accordance with these operating instructions. It is only permitted to be used on machines on which the

dangerous state can be stopped immediately by the SafeZone Mini and/or it is possible to prevent the machine being

placed in operation.

If the device is used for any other purposes or modified in any way — also during mounting and installation — any

Note

warranty claim against Rockwell Automation shall become void.

Page 9

General safety notes and

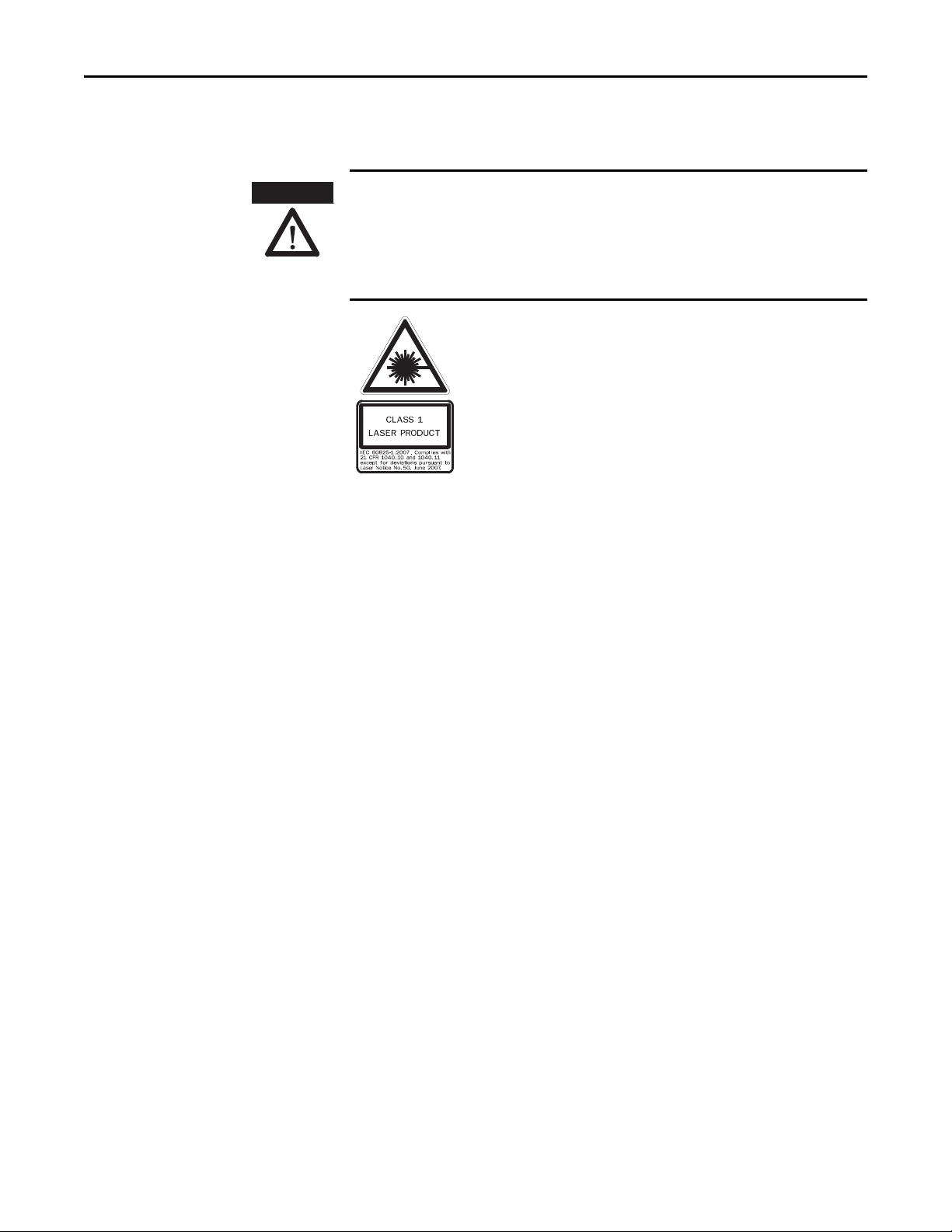

ATTENTION

The SafeZone Mini safety laser scanner is of laser safety class 1. Additional

measures for screening the laser radiation are not necessary (eye safe).

protective measures

Chapter 2 On safety

Pay attention to the safety notes!

Please observe the following items in order to ensure the correct use of the SafeZone Mini safety laser scanner.

Repair only by authorized persons!

The improper repair of the protective device can result in the loss of the protective function. The protective device is only

allowed to be repaired by the manufacturer or persons authorized by the manufacturer.

• This device meets the norms: IEC 608251 as well as CDRH 21 CFR 1040.10 and 1040.11; excluded are deviations due to

Laser Notice No. 50, dated 24.06.2007. In the standards CDRH 21CFR 1040.10 and 1040.11 the following note is

required: “Caution — use of controls, adjustments or performance of procedures other than those herein specified

may result in hazardous radiation exposure!”

• During the mounting, installation and usage of the SafeZone Mini, observe the standards and directives applicable in

your country. You will find an overview of the most important regulations in Chapter 2, “Applicable directives and

standards” on page 8.

• The national/international rules and regulations apply to the installation, commissioning, use and periodic technical

inspections of the SafeZone Mini safety laser scanner, in particular…

– Machinery Directive 2006/42/EC

– Work Equipment Directive 2009/104/EC

– The work safety regulations/safety rules

– Other relevant health and safety regulations

• Manufacturers and operators of the machine on which the SafeZone Mini is used are responsible for obtaining and

observing all applicable safety regulations and rules.

• The notes, in particular the test notes (see Chapter 9, “Commissioning” on page 47) in these operating instructions

(e.g. on use, mounting, installation or integration into the machine control) must be observed.

• Changes to the configuration of the devices can degrade the protective function. After every change to the

configuration you must therefore check the effectiveness of the protective device. The person who makes the change

is also responsible for the correct protective function of the device. When making configuration changes, please

always use the password hierarchy provided by Rockwell Automation to ensure that only authorized persons make

changes to the configuration.

• The tests must be carried out by qualified safety personnel or specially qualified and authorized personnel and must

be recorded and doc umented to ensure that the te sts can be reconstructed and retraced at any time.

• The operating instructions must be made available to the operator of the machine where the SafeZone Mini is used.

The machine operator is to be instructed in the use of the device by qualified safety personnel and must be instructed

to read the operating instructions.

• To meet the requirements of the relevant product standards (e.g. EN 614961), the external voltage supply for the

devices must be able to bridge a brief mains failure of 20 ms. Power supplies according to EN 602041 satisfy this

requirement. Suitable power supplies are available as accessories from Rockwell Automation.

Enclosed with these operating instructions is a checklist for checking by the manufacturer and OEM (see Chapter 14,

“Checklist for the manufacturer” on page 70). Use this checklist when checking the system that is protected with the

SafeZone Mini.

Environmental protection

The SafeZone Mini safety laser scanner is constructed in such a way that it adversely affects the environment as little as

possible and uses only a minimum of power and natural resources.

At work, always act in an environmentally responsible manner.

Rockwell Automation Publication 10000337275 Ver 01—October 2014 7

Page 10

Chapter 2 On safety

ATTENTION

Disposal

Unusable or irreparable devices should always be disposed as per the applicable national regulations on waste disposal

(e.g. European waste code 16 02 14).

• Information on the individual materials in the SafeZone Mini is given in Chapter 12 “Technical specifications” on page

Note

55.

Separation of materials

Only qualified safety personnel are allowed to separate materials!

Caution is required when dismantling devices. There is a risk of injuries.

Before you send the devices for appropriate recycling, it is necessary to separate the different materials in the SafeZone

Mini.

Separate the housing from the rest of the parts (in particular the circuit boards).

Send the separated parts for recycling as appropriate (see Tab. 1).

Table 1: Overview on

disposal by components

Applicable directives and

standards

Components Disposal

Product

Housing Metal recycling (aluminium)

Motor bracket Metal recycling (zinc die-cast housing)

Optics cover Plastic recycling

Circuit boards, cables, connectors and electrical

connecting pieces

Pack aging

Cardboard, paper Paper/cardboard recycling

Polyethylene packaging Plastic recycling

The most important directives and standards, valid for the use of opto-elec tronic protective devices in Europe, are listed

below. Further regulations may be of importance to you, depending on the application. You can obtain further

information of machine-specific standards from national institutions (e.g. DIN, BSI, AFNOR etc.), the authorities or your

trade association.

If you operate the machine or vehicle in a country outside the European Union, please contact the manufacturer of the

system and the local authorities and obtain information on the regulations and standards applicable there.

Electronic recycling

Application and installation of protective devices

Machinery Directive 2006/42/EC, e.g.:

• Safety of machinery — Basic concepts, general principles for design (EN ISO 12100)

• Industrial automation systems — Safety of integrated manufacturing systems — Basic requirements (ISO 11161)

• Safety of machinery — Electrical equipment of machines — Part 1: General requirements (EN 602041)

• Safety of machinery — safety distances to prevent hazard zones being reached by the upper and lower limbs

(EN ISO 13857)

• Safety requirements for robots (EN ISO 102181)

• Safety of industrial trucks. Driverless trucks and their systems (EN 1525)

• Safety of machinery — The positioning of protective equipment in respect of approach speeds of parts of the human

body (EN ISO 13855)

• Safety of machinery — Principles for risk assessment (EN ISO 141211)

• Safety of machinery — Safety-related parts of control systems — Part 1: General principles for design

(EN ISO 138491) as well as part 2: Validation (EN ISO 138492)

• Safety of machinery — elec tro-sensitive protective equipment — Part 1: General requirements (EN 614961) as well

as part 3: Special requirements for AOPDDR (CLC/TS 614963)

• Safety of machinery — Application of protective equipment to detect the presence of persons (IEC/TS 62046)

8 Rockwell Automation Publication 10000337275 Ver 01—October 2014

Page 11

Chapter 2 On safety

Regional standards, for example:

• Performance Criteria for Safeguarding (ANSI B11.19)

• Machine tools for manufacturing systems/cells (ANSI B11.20)

• Safety requirements for Industrial Robots and Robot Systems (ANSI/RIA R15.06)

• Safety Standard for guided industrial vehicles and automated functions of named industrial vehicles (ANSI B56.5)

To some extent these standards require the protective device to have the safety level “Control reliable.” The SafeZone

Note

Mini safety laser scanner meets this requirement.

Rockwell Automation Publication 10000337275 Ver 01—October 2014 9

Page 12

Chapter 3 Product description

SafeZone Mini

Send pulses

Receive pulses

Send pulses

Receive pulses

Chapter 3

Product description

This chapter provides information on the special features and proper ties of the SafeZone Mini safety laser scanner. It

describes the construction and the operating principle of the device.

Special features

Function

• Small design

• 270° scan area

• Increased dust and particle tolerance due to light saturation and particle algorithms

• With scanning ranges of two or three meters maximum protective field radii)

• Configuration using PC or notebook with Rockwell Automation SCD software

• Field sets comprising of one protective field and up to two warning fields

• Contour monitoring of the protective field if only one warning field is used

• Only standalone operation

• One field set

• One monitoring case

• Integrated external device monitoring (EDM)

• Integrated restart interlock/restart interlock delay for which the parameters can be set

• Two universal I/O connections

The SafeZone Mini safety laser scanner operates correctly as a protective device only if the following conditions are met:

• The control of the machine, system or vehicle must be electrical.

• It must be possible to transfer the dangerous machine, system or vehicle state to a safe state using the OSSDs on the

SafeZone Mini at any time, i.e. before a person has reached the hazardous point or hazardous area.

Or:

It must be possible to transfer the dangerous state of the machine, the system, or the vehicle to a safe state at any time

using the OSSDs on a safety controller connected to the SafeZone Mini.

• The SafeZone Mini must be mounted and configured such that it detects objects as they enter the hazardous area (see

Chapter 5, “Mounting” on page 35 and Chapter 9, “Commissioning” on page 47).

• The safety laser scanner’s optical path must always remain clear and is not allowed to be covered by transparent

objects such as protective windows, Plexiglas, lenses etc. The safety laser scanner’s protective function can only be

ensured if the contamination measurement function is not bypassed by such measures.

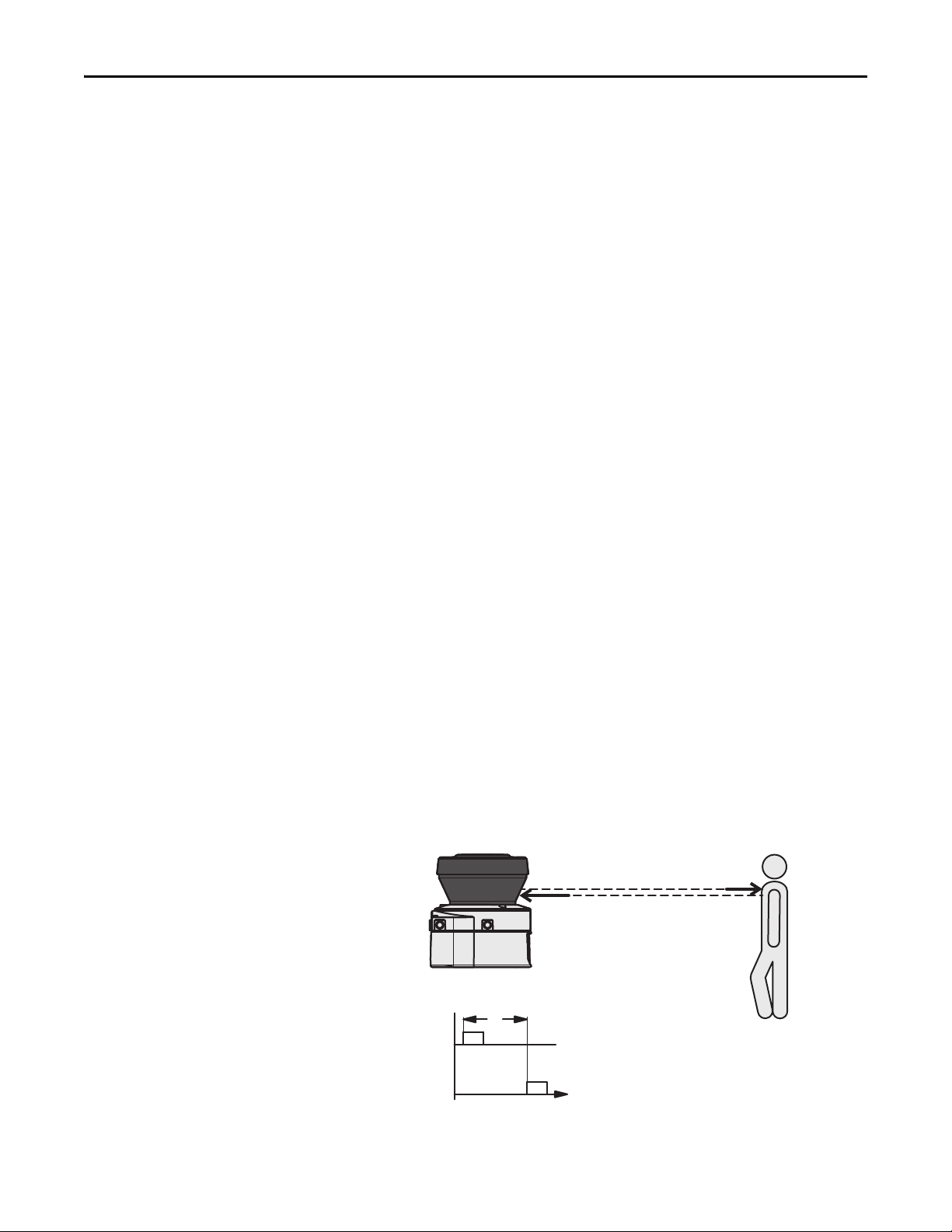

Principle of operation

The SafeZone Mini is an optical sensor that scans its surroundings in two dimensions using infrared laser beams. It is used

to monitor hazardous areas on machines or vehicles.

Fig. 1: Principle of operation,

time-of-flight measurement

by the SafeZone Mini

10 Rockwell Automation Publication 10000337275 Ver 01—October 2014

Page 13

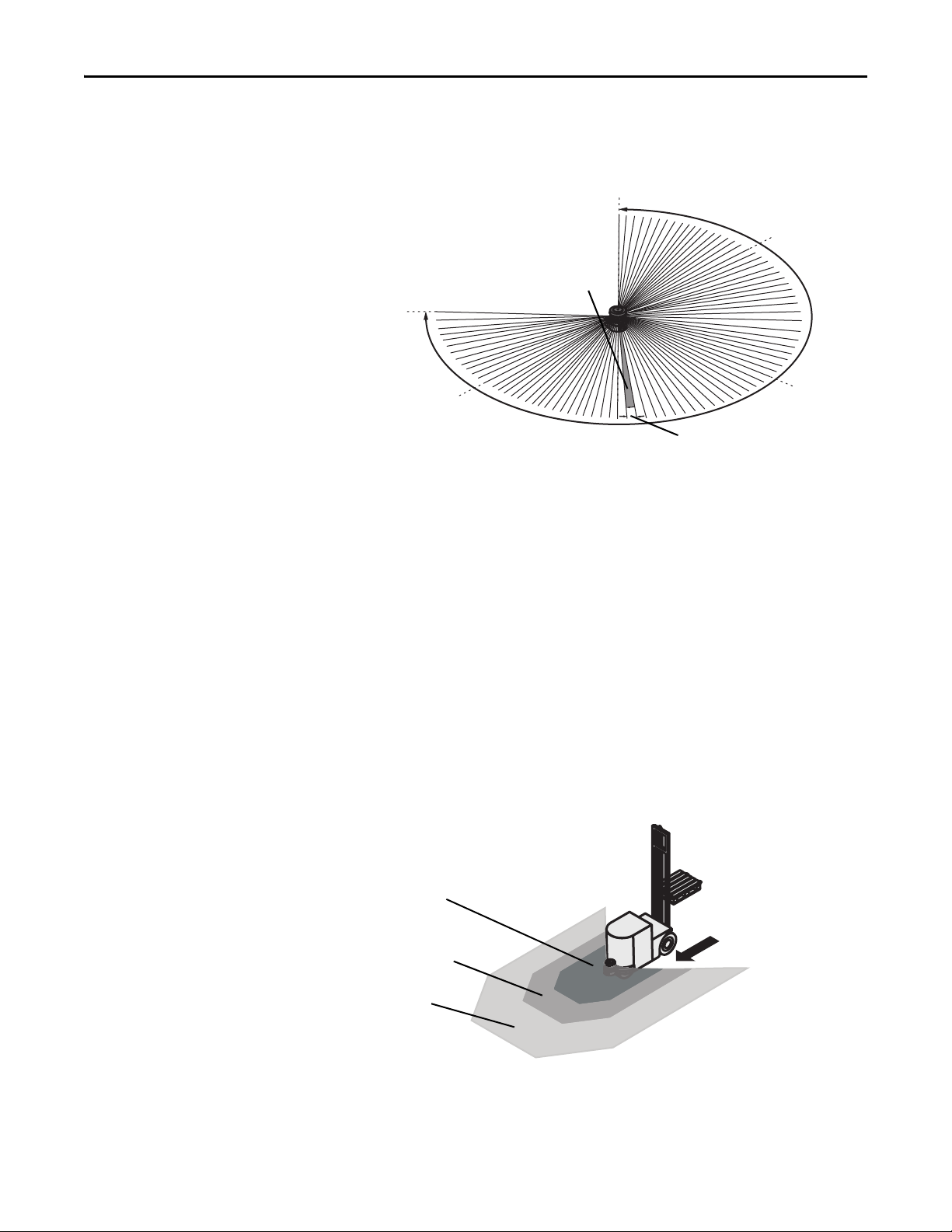

Fig. 2: Principle of operation,

225°

-45°

90°

0°

180°

Protective fie ld

Warn ing f ield 1

Warning field 2

rotation of the

SafeZone Mini

Chapter 3 Product description

The SafeZone Mini works on the principle of time-of-flight measurement. It sends out very short pulses of infrared light

(send pulses). At the same time an “electronic stopwatch” is started. When the light hits an object, it is reflected and

received by the safety laser scanner (receive pulses). From the time between sending and reception (t) the SafeZone

Mini calculates the distance to the object.

In the SafeZone Mini there is also a mirror rotating at constant speed that deflects the light pulses such that they cover an

arc of 270°. In this way an object can be detected in the protective field within 270°. The first beam of a scan starts at –45°

relative to the back of the safety laser scanner.

The SafeZone Mini sends a pulse of light with an angular resolution of 0.5° . As a result resolutions between 30 mm

(1.18 in.) and 70 mm (2.76 in.) can be achieved

.

Due to its active scanning principle, the SafeZone Mini does not require receivers or reflectors. This has the following

advantages:

• Your installation effort is lower.

• You can easily adapt the monitored area to the hazardous area on a machine.

• In comparison with contact sensors, electro-sensitive scanning is nearly wear-free.

Field set comprising protective field and warning field(s)

Protective fields and warning fields form the so-called field set. You can configure these field sets with the aid of the SCD

software. The fields can be configured as circular, rectangular or of arbitrary shape. If the area to be monitored changes,

then you can re -configure the SafeZone Mini in software without additional mounting effort.

You can configure field sets comprising one protective field and one or two warning fields.

The SafeZone Mini secures the hazardous area on a machine or vehicle. As soon as the safety laser scanner detects an

object in the protective field, it switches the OSSDs to the OFF state and thus initiates the shutdown of the machine or stop

of the vehicle.

Fig. 3: Field set with one

protective field and

two warning fields

You can define the warning fields such that the safety laser scanner detects an object before the actual hazardous area.

Warning field 1 can be used in particular fo r vehicle protection to detect an object even before the actual hazardous area

and to slowly retard the movement of the vehicle or bring it to a standstill. In this way the wear on the brakes on an AGV

can be reduced. Warning field 2 can also be used to trigger a warning signal.

Rockwell Automation Publication 10000337275 Ver 01—October 2014 11

Page 14

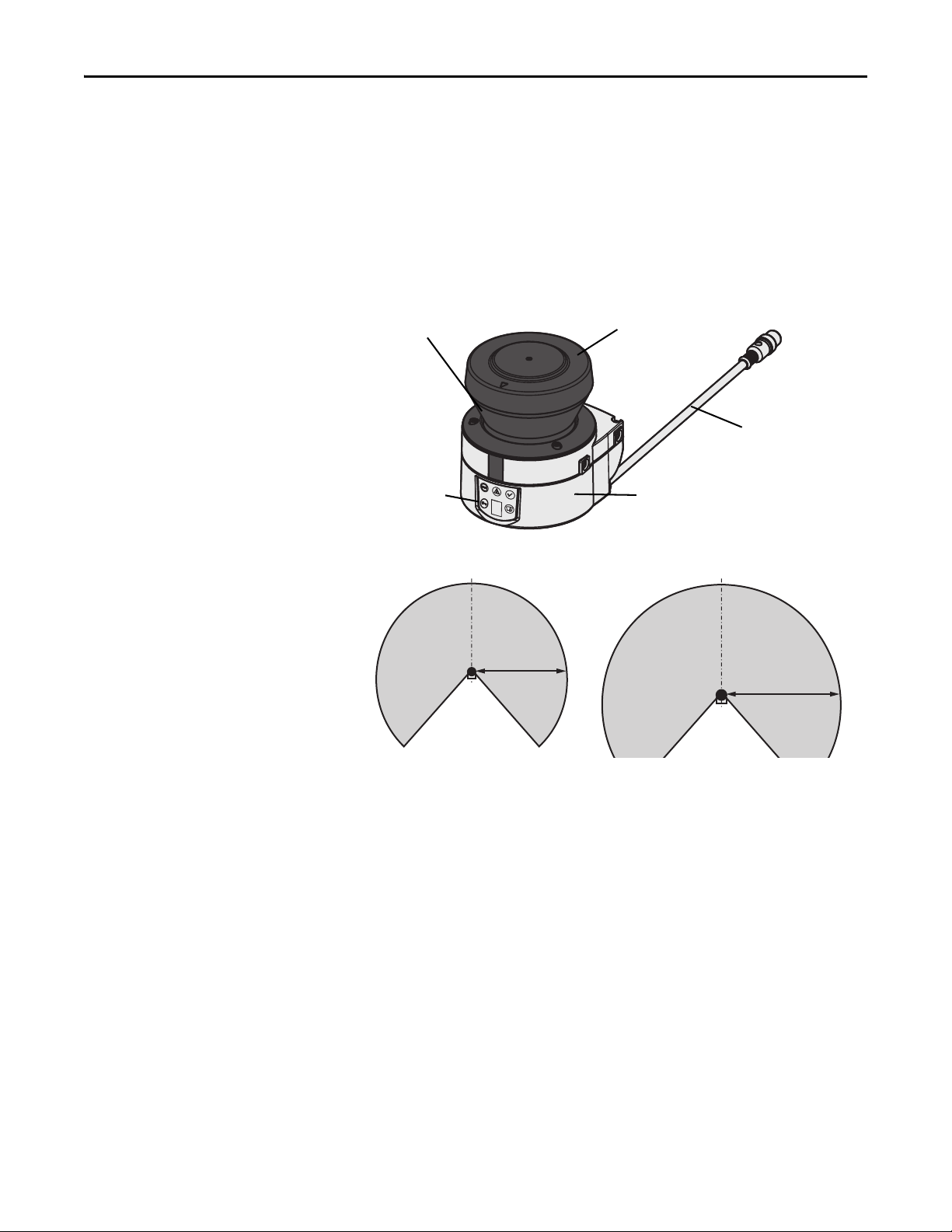

Chapter 3 Product description

Window for light output

LEDs and sevensegment display

Optics cover

Sensor

Round plug

connector

Connecting cable

Max. 2 m

(6.6 ft)

Max. 3 m

(9.84 ft)

A warning field on the SafeZone Mini is not allowed to be used for tasks related to the protection of people.

Note

Contour monitoring

In addition to the protective field, the SafeZone Mini can also monitor a contour (e.g. the floor in vertical applications).

SafeZone Mini

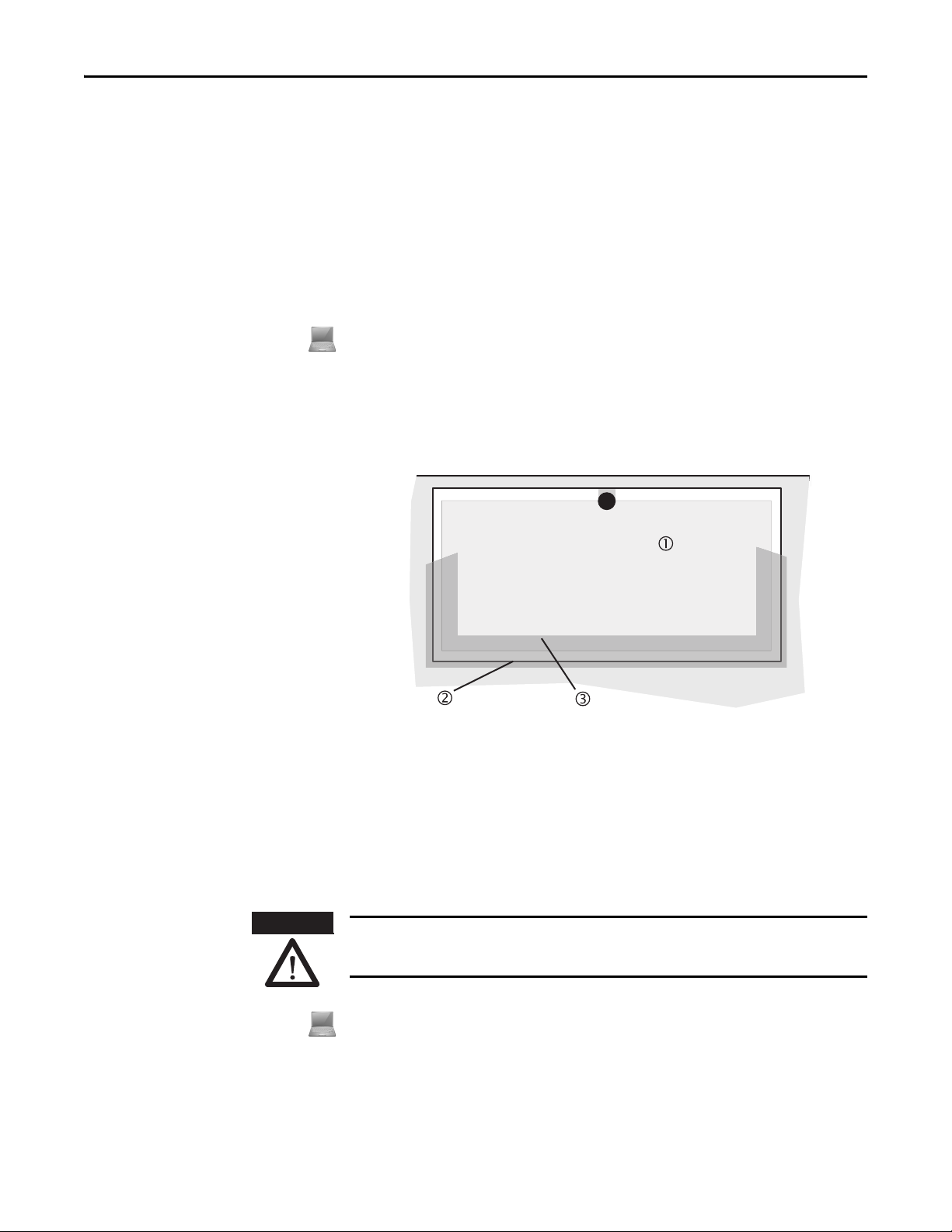

Device components

The SafeZone Mini safety laser scanner comprises three components:

• The sensor with the opto-electronic detection system, the LEDs, the sevensegment display and the connecting cable

with the electrical connections

• The optics cover with the window for the light output

Fig. 4: Device components

Fig. 5: Protective Field Range

12 Rockwell Automation Publication 10000337275 Ver 01—October 2014

Page 15

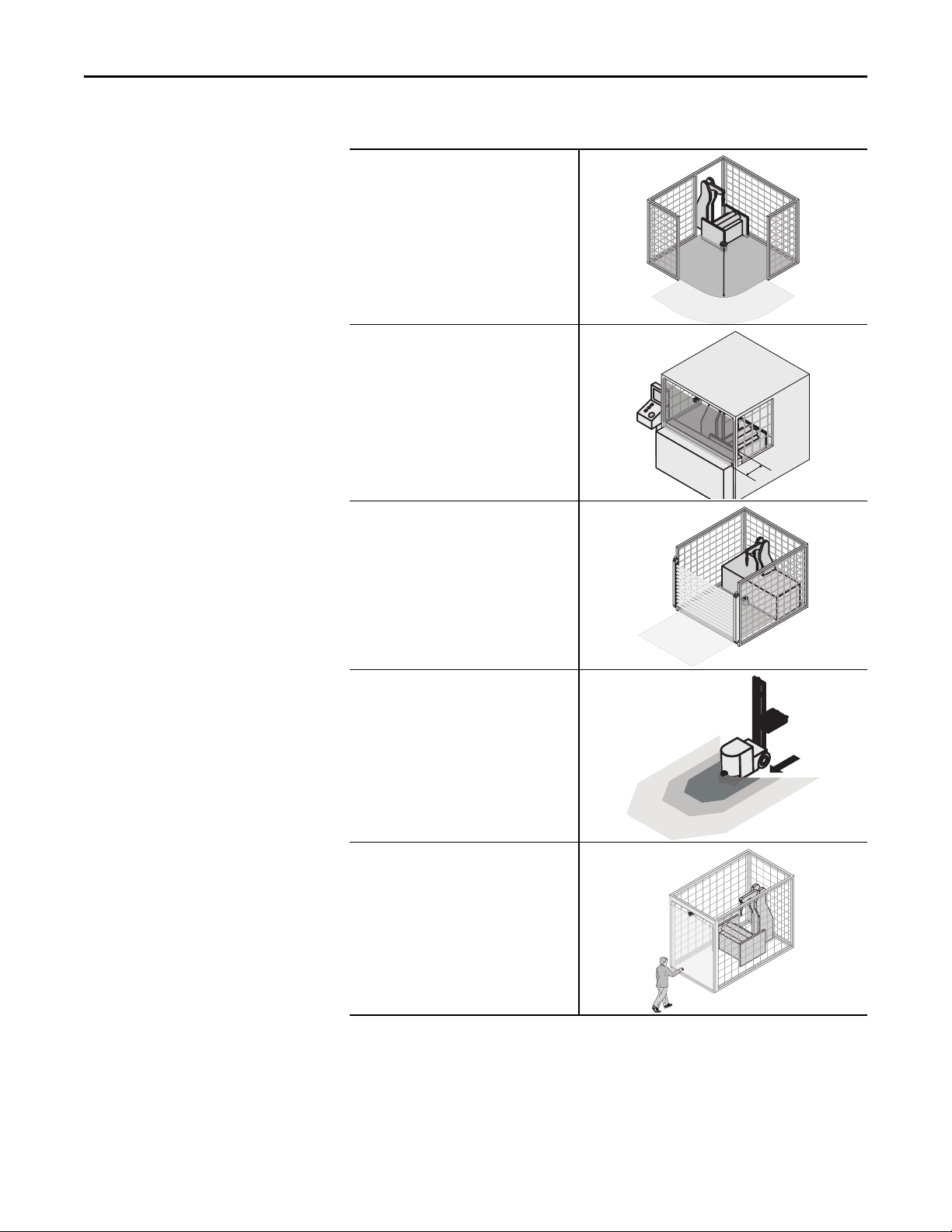

Applications

Chapter 3 Product description

Table 2: Possible applications for the

SafeZone Mini

SafeZone Mini:

Hazardous area protection on an insertion station

SafeZone Mini:

Hazardous point protection on an insertion station

SafeZone Mini:

Presence detection for a safety light curtain

SafeZone Mini:

Protection of an automated guided vehicle (AGV) for

one velocity

Access protection for high areas of access

Rockwell Automation Publication 10000337275 Ver 01—October 2014 13

Page 16

Chapter 3 Product description

Status indicators

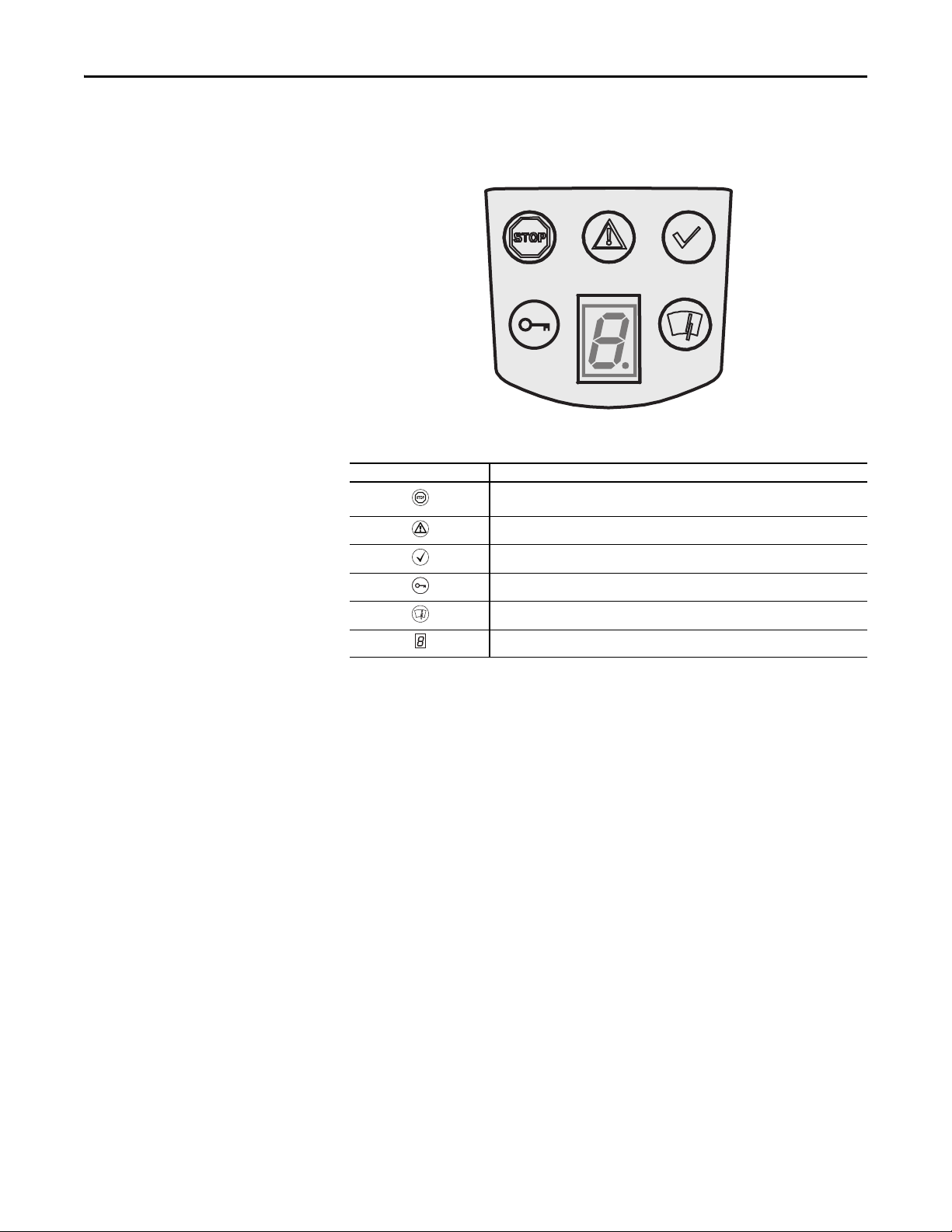

Fig. 6: Status indicators on the

Table 3: Status indicators on the

SafeZone Mini

SafeZone Mini

LEDs and sevensegment display

The LEDs and the sevensegment display indicate the operational status of the SafeZone Mini. They are on the front face of

the safety laser scanner.

The symbols have the following meaning:

Symbol SafeZone Mini

OSSDs in the OFF state (e.g. in case of object in the protective field, monitored contour

changed, reset required, lockout)

Warning field interrupted (object in one of the warning fields)

OSSDs in the ON state (no object in protective field)

Reset required

Optics cover contaminated

.

You will find detailed information in Chapter 11, “Error and status indications on the LEDs” on page 52 and in “Error and

Note

status indications on the sevensegment display” on page 52).

Sevensegment display for the indication of the status and errors

14 Rockwell Automation Publication 10000337275 Ver 01—October 2014

Page 17

Configurable functions

Chapter 4 Configurable functions

Chapter 4

System parameters

Recommendation

A name can be assigned to the application configured as well as to the safety laser scanner(s). The names are saved in the

devices after the configuration is transferred. The name chosen may be, for example, the identifier for the vehicle, system

or the machine.

You enter the application name and the names of the safety laser scanners used in the SCD software.

Application name

Enter a name for your application. You can enter a name with a maximum of 16 characters.

If you assign unique application names, you may “reserve” the devices for certain duties. A machine maintenance person

comparing exchanged devices with the configuration data saved in the SCD software will be notified that the application

name does not match. He may then exchange these devices for those with the correct application name.

Name of the scanner

Enter a device name for each of the safety laser scanners in the system. You can enter names with a maximum of eight

characters.

Use meaningful names, e.g. “front” and “rear” for vehicle monitoring. Unique device names make the subsequent

configuration steps easier (for example on allocating the control inputs or the OSSDs).

User data

You can enter your name in the field Name of the user. You can enter a name with a maximum of 22 characters. This is

then added to the configuration protocol and in the diagnostics report.

Display direction of the sevensegment display

The depiction of numbers on the sevensegment display can be rotated by 180° with the aid of the SCD software. This is

useful, for example, when the SafeZone Mini must be rotated by 180° owing to the specific assembly.

If you rotate the numbers of the sevensegment display, the point in the sevensegment display goes out.

How to determine the display direction of the sevensegment display:

Under sevensegment display, activate the Rotated by 180° option. After the configuration draft has been

transferred to the SafeZone Mini, the numbers of the sevensegment display are rotated by 180°.

Rockwell Automation Publication 10000337275 Ver 01—October 2014 15

Page 18

Chapter 4 Configurable function s

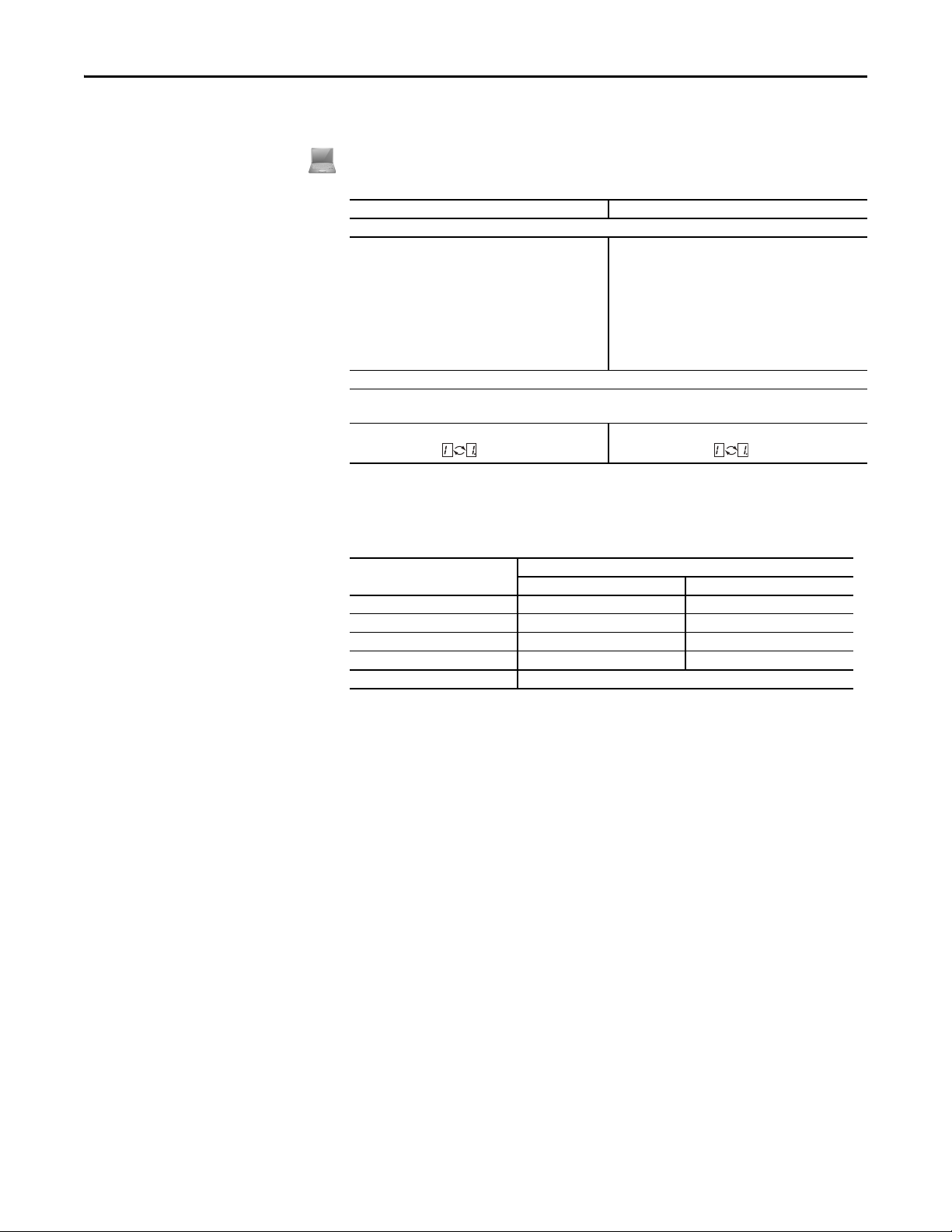

Application

With the help of the SCD software you can configure the SafeZone Mini for the required application. Depending on

whether you select a stationar y or a mobile application, different configuration options are available:

Table 4: Comparison of mobile and

stationary applications

Table 5: Maximum protective field

range at different resolutions

Mobile applications [mm (in.)] Stationary applications [mm (in.)]

Resolution

• 30 (1.2) (hand detection with smaller protective field

size)

• 40 (1.6) (hand detection with larger protective field

size)

• 50 (2.0) (leg detection with smaller protective field

size)

• 70 (2.8) (leg detection with larger protective field

size)

Manipulation prevention

The safety laser scanner checks whether in any 90° segment all measured values correspond to the maximum distance

value that can be measured.

If this is the case, the SafeZone Mini shuts down after

2hours and signals .

• 30 (1.2) (hand detection with smaller protective field

size)

• 40 (1.6) (hand detection with larger protective field

size)

• 50 (2.0) (leg detection with smaller protective field

size)

• 70 (2.8) (leg detection with larger protective field size)

• 150 (5.9) (whole body detection)

If this the case, the SafeZone Mini shuts down after

5seconds and signals .

Resolution

The maximum protective field range depends on the configured resolution. The following table shows the related

maximum protective field range at the resolutions that can be set:

Configured resolution [mm (in.)] Maximum protective field range [m (ft)]

2 m 3 m

30 (1.2) – (hand detection) 1.25 (4.1) 1.25 (4.1)

40 (1.6) – (hand detection) 1.60 (5.2) 1.60 (5.2)

50 (2.0) – (leg detection) 2.00 (6.6) 2.10 (6.89)

70 (2.8) – (leg detection) 2.00 (6.6) 3.00 (9.84)

150 (5.9) (whole body detection) 3.00 (9.84)

The warning field can be configured to up to 8 m (26.25 ft) for all resolutions. The detection capability within the warning

Note

field is dependent on the remission of the objects to be detected (see Chapter 12, “Technical Specifications” on page 55).

Basic response time

The basic response time of the SafeZone Mini is 80 ms.

You may need to add supplements to the basic response time due to multiple sampling (see Chapter 12, “OSSD response

Note

times” on page 55).

Maximum protective field range

Depending on the configured resolution used (see Chapter 4, “Resolution” on page 16), the maximum protective field

range of the safety laser scanner is shown in the SCD software.

The maximum protective field range of the SafeZone Mini must be sufficient to cover the calculated protective field size

Note

including the necessary supplements (see Chapter 5, “Protective field size” on page 25).

In mobile applications a resolution of only 70 mm (2.8 in.) is required for leg detection.

Radial distance to the safety scanner.

16 Rockwell Automation Publication 10000337275 Ver 01—October 2014

Page 19

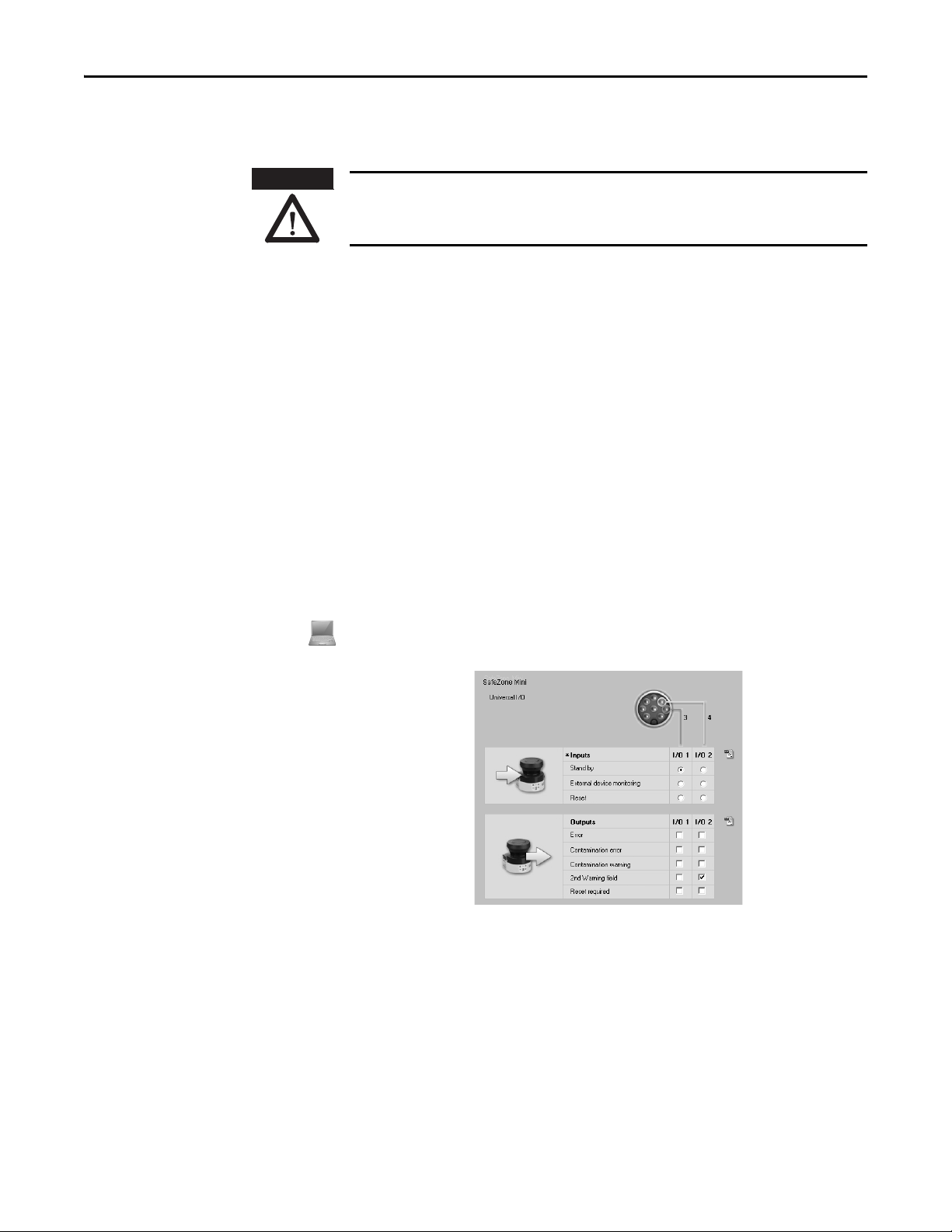

Universal I/O connections of

the SafeZone Mini

Chapter 4 Configurable functions

ATTENTION

Note

You are not allowed to use the universal I/O connections for safety-relevant functions!

You are only allowed to use the universal I/O connections for signaling. You must never use the signals for controlling the

application or for safety-relevant func tions.

The SafeZone Mini has two universal I/O connections (see Chapter 6, “Round plug connector SafeZone Mini” on page 40).

You can configure these two connections for the following functions:

• Inactive (factory default setting)

As inputs (it is only possible to select one function per universal I/O connection):

• Stand-by

• External device monitoring (EDM) (see page 18)

• Resetting the restart interlock (see page 18)

As outputs (it is possible to select several functions per universal I/O connection, these functions are linked

together using an OR operator):

• Device error

• Contamination error

• Contamination warning

• Second warning field

• Reset required

Other functions that can be configured are dependent on the configuration of the universal I/O connections. For example,

you can only realize a restart interlock if you configure one of the universal I/Os as an input for resetting the restart

interlock.

The universal I/O connections are configured in the SCD software in the Universal I/O area. Fig. 7 shows a configuration

example.

Fig. 7: Configuration example

universal I/O connections of the

SafeZone Mini

Recommendation

Stand-by

If, in mobile applications, vehicles are not moved for a time, the OSSDs can be switched to the OFF state and the laser on

the SafeZone Mini can be switched off. In this way the power consumption of the device is reduced.

Use this function if, e.g. you use several vehicles and do not move them for a time.

The SafeZone Mini remains in the stand-by mode as long as the related input information is present.

Rockwell Automation Publication 10000337275 Ver 01—October 2014 17

Page 20

Chapter 4 Configurable function s

.

OSSDs

Tab le 6 : Beh avi or o f th e

SafeZone Mini on a

contactor malfunction

Note

Internal OSSDs of the SafeZone Mini

If there is an object in the protective field, the internal OSSDs on the SafeZone Mini always switch. This can not be

configured differently in the SCD software.

External device monitoring (EDM) SafeZone Mini

The EDM checks if the contactors actually de-energize when the protective device is tripped. If you activate external device

monitoring, then the SafeZone Mini checks the contactors after each interruption of the protective field and prior to the

machine restart. The EDM can so identify if one of the contactors has welded, for instance. In this case the external device

monitoring places the system in a safe operational state and the OSSDs are not switched back to the ON state.

The table shows how the SafeZone Mini reacts if the external device monitoring detects a contactor malfunction:

Without internal restart interlock

or

with restart delay

With restart interlock

You can configure the external device monitoring in the SCD software.

You will find examples on the connection of the external device monitoring in Chapter 7, “Connection diagrams” on

page43.

• The system locks completely (lock-out).

• The error message 8 appears in the sevensegment display.

• The SafeZone Mini switches its OSSDs to the OFF state.

• The LED is illuminated.

• The error message e appears in the sevensegment display.

Restart of the SafeZone

Mini Standard

ATTENTION

You can configure the restart behavior of the SafeZone Mini as follows:

• Without restart interlock

• With restart delay

• With restart interlock

You can configure the type of restart in the SCD software.

It is imperative that you configure the SafeZone Mini or the application with restart interlock if the

protective field can be left to approach the hazardous point or if a person cannot be detected by the

SafeZone Mini at every point in the hazardous area!

During the assessment, pay attention to whether the protective field can be left in the direction of the hazardous point, to

areas that are unprotected due to the mounting and the unprotected near range of the SafeZone Mini (see Chapter 5,

“Methods of preventing unprotected areas” on page 33).

Configuration of the SafeZone Mini without restart interlock

After the OSSDs on the SafeZone Mini have been switched to the OFF state due to an object in the protective field, the

OSSDs are re-enabled again immediately when there is no longer an object in the active protective field.

This configuration is only allowed …

• If an external restart interlock is realized on the machine controller

or

• If the protective field cannot be left in the direction of the hazardous point and if people can be detected by the

SafeZone Mini at every point in the hazardous area!

Restart delay for mobile applications

In mobile applications you can configure a restart delay from 2 to 60 seconds on the SafeZone Mini. The OSSDs on the

SafeZone Mini change to the ON state if there is no object in the protective field for the duration given.

This configuration is only allowed if the protective field cannot be left in the direction of the hazardous point and if a

person can be detected at every point in the hazardous area by the SafeZone Mini!

18 Rockwell Automation Publication 10000337275 Ver 01—October 2014

Page 21

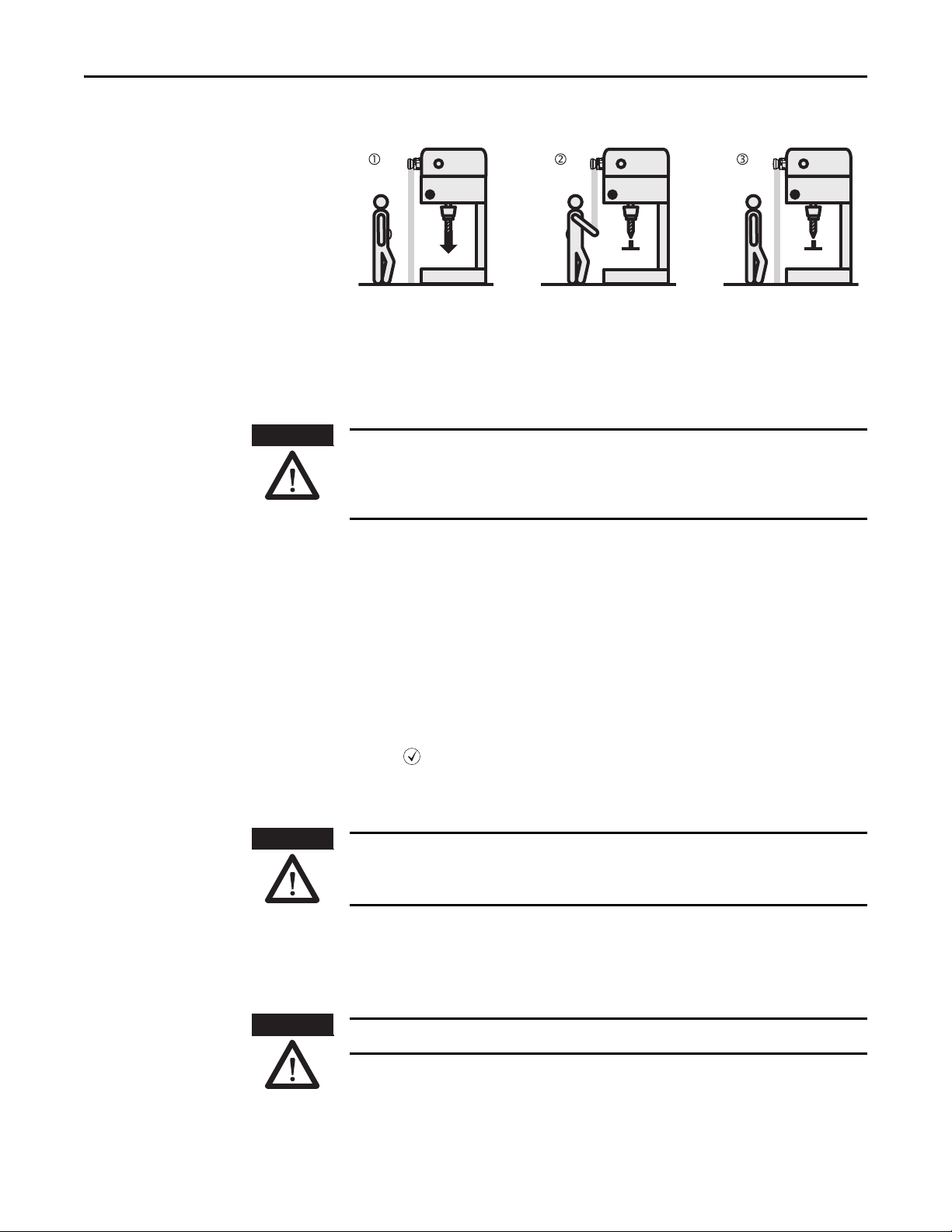

Fig. 8: Schematic outline of the

operation with restart interlock

Note

Chapter 4 Configurable functions

Configuration of the SafeZone Mini with restart interlock

Do not confuse the restart interlock with the star ting interlock on the machine. The starting interlock prevents the

machine starting after switching on. The restart interlock prevents the machine starting again after an error or a

protective field infringement.

The OSSDs on the SafeZone Mini change to the OFF state to initiate a machine or vehicle stop as soon as there is an

object in the protective field . They do not change to the ON state , even if there is no longer an object in the

protective field. The OSSDs only change to the ON state if the operator operates the control switch for restart or reset.

ATTENTION

Notes

Note

ATTENTION

Place the control switch for restart or reset outside the hazardous area in a place where it can clearly be

seen from the hazardous area!

Place the control switch for restart or reset outside the hazardous area such that it cannot be operated by a person in the

hazardous area. Ensure that the person who operates the control switch has a full view of the hazardous area.

• You will find examples on the connection of the internal restart interlock in Chapter 7, “Connection diagrams” on

page 43.

• If you do not use the internal restart interlock, then do not configure any of the universal I/Os as an input for

resetting (see Chapter 4, “Universal I/O connections of the SafeZone Mini” on page 17).

Reset

The reset function is often also called “preparation for restart.” In these operating instructions the term reset is used.

If you want to activate the restart interlock on the SafeZone Mini (internal) and also a restart interlock on the machine

(external), then each restart interlock has its own control switch.

After operating the control switch for the internal restart interlock (with protective field unoccupied) …

• The SafeZone Mini switches its OSSDs to the ON state.

• The LED on the SafeZone Mini illuminates green.

The external restart interlock prevents the machine from restarting. After resetting the SafeZone Mini the operator must

press the control switch to restart the machine controller.

Ensure that the correct sequence is followed!

The controller must be realized such that the machine only restarts if the SafeZone Mini is first reset and then the control

switch for restarting the machine controller is operated.

ATTENTION

Reset signals

If the SafeZone Mini safety laser scanner is operated using the “With restart interlock” function, then after a protective

field infringement and the subsequent clearing of the protective field, it requests a reset signal from the control system

(reset required).

The reset signal must be safety-related (single failure proof)!

Rockwell Automation Publication 10000337275 Ver 01—October 2014 19

Page 22

Chapter 4 Configurable function s

Field sets

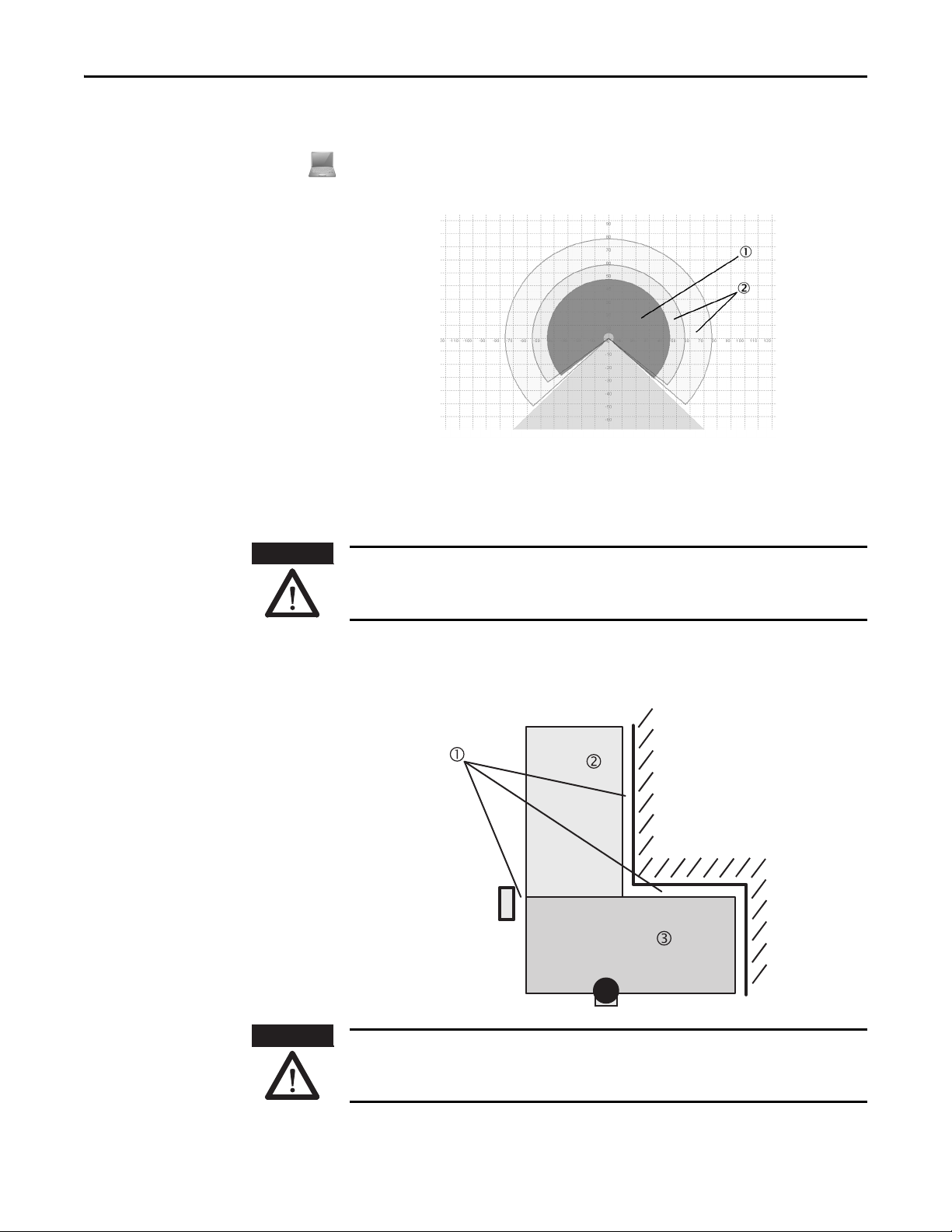

Fig. 9: Creating a field set in the SCD software

Note

ATTENTION

Configuring the protective field and warning field

With the aid of the SCD software you can configure the field set, which comprises a protective field and two warning

fields . During this process you configure the shape and size of the protective and warning fields. You can realize any

field shape required.

The area to be monitored is scanned radially by the SafeZone Mini. The SafeZone Mini cannot see through objects during

this process. The area behind objects that are in the area to be monitored (pillars, grilles, etc.) can thus not be monitored.

Protective fields and warning field can cover up an angle of up to 270° and have different radial scanning ranges

depending on the resolution configured (see Chapter 4, “Resolution” on page 16).

Check the protec tive fields configured!

Prior to commissioning the machine or vehicle, check the configuration of the protective fields using the instructions in

Chapter 9, “Commissioning” on page 47 and using the “Checklist” on page 70.

Note

Fig. 10: Configuring protective

field and warning field

ATTENTION

If the protective field or the warning fields stretch as far as a wall or another object (pillar, neighboring machine,

shelf), there should be a distance of 100 mm (3.94 in.) between the protective field or warning field and the object to

prevent false triggering .

Secure unprotected areas!

If it is possible to access a narrow strip between the protective field and a wall or another object, you must protect this

strip using additional measures (e.g. fence or floor protection).

20 Rockwell Automation Publication 10000337275 Ver 01—October 2014

Page 23

Fig. 11: Reading the protective field

Chapter 4 Configurable functions

Protective field or warning field suggested by the safety laser scanner

The SCD software can suggest the protective field or warning field in the field set editor. The safety laser scanner scans the

visible surrounding contour several times. From the data obtained the SCD software suggests the contour and size of the

field. The following figure shows an example for the reading of a protective field:

In those places at which the surrounding contour is smaller than the maximum protective field range (e.g. at ), the

protective field corresponds to the surrounding contour.

Note

ATTENTION

Fig. 12: Schematic diagram of

contour as reference

The measuring error tolerances for the SafeZone Mini are automatically subtracted from the protective field size. As a

result the protective field is slightly smaller than the surface covered .

In those places where the surrounding contour is larger than the protective field range , the protective field corresponds

to the possible scanning range.

Check the protective field suggested by the SCD software

The protective field suggested by the SCD software is not a replacement for the calculation of the minimum distance.

Calculate the minimum distance and check the effectiveness of the protective fields prior to commissioning the

application!

Pay attention to the descriptions in Chapter 5, “Mounting” on page 24, the notes in Chapter 9, “Commissioning” on page

47 and the “Checklist” on page 70.

Using the contour as a reference

In addition to the protective field, the SafeZone Mini can also monitor a contour (e.g. the floor in vertical applications).

For contour monitoring you define a contour segment . The contour segment comprises a positive and a negative

tolerance band.

Rockwell Automation Publication 10000337275 Ver 01—October 2014 21

Page 24

Chapter 4 Configurable function s

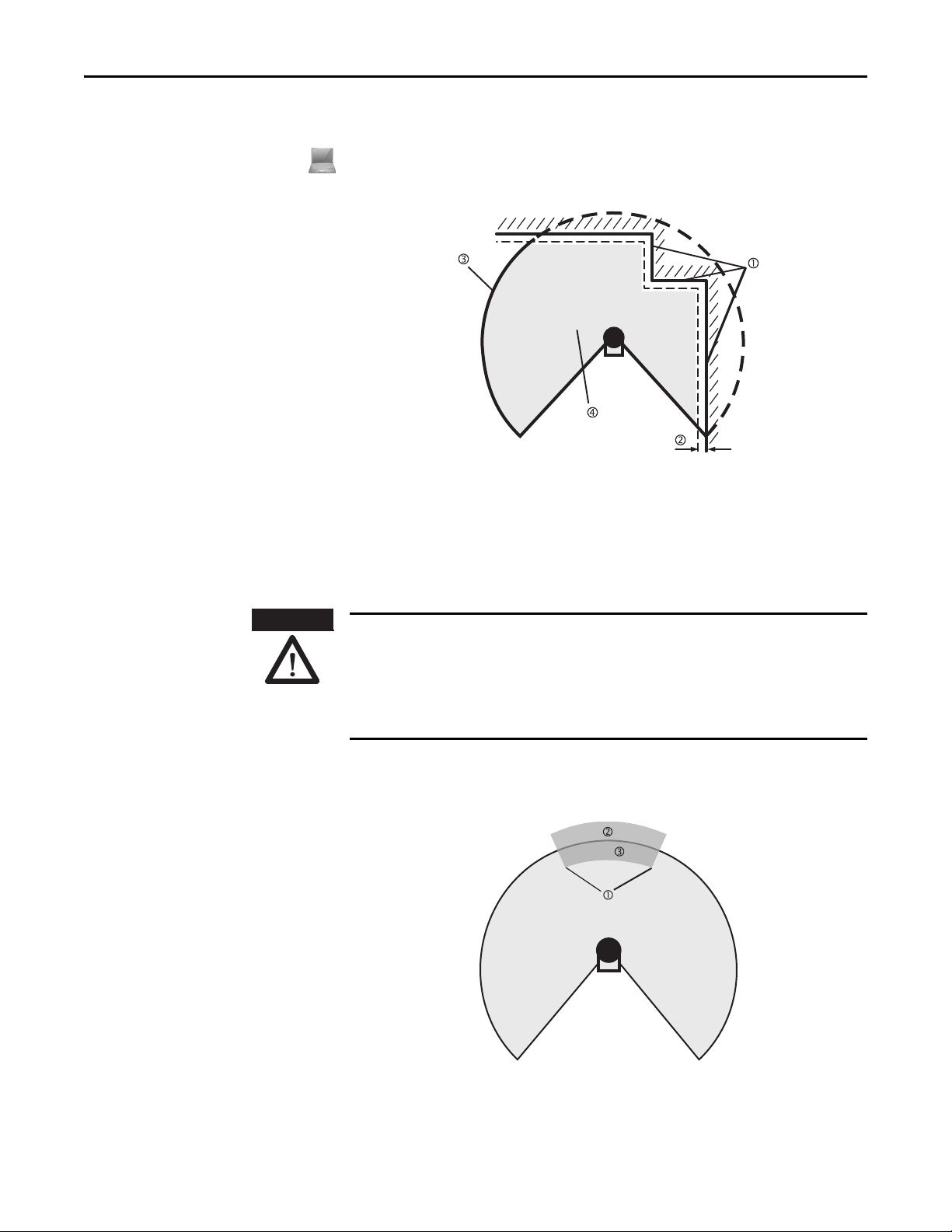

Fig. 13: Contour as reference for

Contours of the machine opening

Notes

vertical operation

Protective field

Contour segment

The OSSDs on the SafeZone Mini change to the OFF state or the SafeZone Mini Remote signals if…

• There is an object in the protective field.

• The monitored surrounding contour is no longer in the tolerance band (e.g. if the position of the SafeZone Mini is

changed).

• You can define any number of contour segments.

• The contour segments must not be narrower than the configured resolution.

• At the points where a contour has been configured as a reference you cannot define warning fields. If, for example, you

use the floor as a reference for access protection, you cannot configure a warning field there. However, you can, e.g.,

configure a warning field to the left and right of the contour segment to control a warning signal on approach from the

side.

• The contour as reference function and the warning field 2 function are mutually exclusive.

You define the contour as a reference in the SCD software field set editor.

Vertical operation

In vertical operation (for access protection and hazardous point protection) according to CLC/TS 614963 you must always

configure the protective fields used with the contour as reference function.

Recommendation

Monitoring cases

ATTENTION

22 Rockwell Automation Publication 10000337275 Ver 01—October 2014

Use lateral, vertical boundaries of the opening (e.g. door frame) and the floor as reference. If in this case the position of the

SafeZone Mini is changed in one or more planes, the distance to the reference changes and the SafeZone Mini switches its

OSSDs to the OFF state.

The SafeZone Mini supports a configuration with monitoring cases.

Ensure for each monitoring case that the minimum distance to the hazardous area is maintained!

See Chapter 5, “Mounting” on page 24.

You can configure the monitoring cases in the SCD software.

Each monitoring case includes …

• The input conditions, the so-called control signals, that control the activation of the monitoring case.

• A field set, comprising of protective field and warning field or fields.

• The multiple sampling for the field set.

Monitoring cases can be switched with the following input information:

• Static information

Page 25

Chapter 4 Configurable functions

Multiple sampling

If multiple sampling is set, an objec t must be scanned several times before the SafeZone Mini switches its OSSDs to the OFF

state. In this way you can reduce the probability that insects, welding sparks or other particles result in the shutdown of

the system.

If a multiple sampling of three is configured, for instance, an object must be detected in the protective field three times in

succession before the SafeZone Mini switches the OSSDs to the OFF state.

ATTENTION

Table 7: Recommended

multiple sampling

Recommendation

The total response time is increased by the multiple sampling!

With a multiple sampling greater than two, note that you must add a supplement to the basic response time (see Chapter

12, “OSSD response times” on page 55)!

On the SafeZone Mini, a multiple sampling of two is the minimum setting. You can set the multiple sampling to up to 16

with the aid of the SCD software. The supplement to the basic response time resulting from your setting is displayed in the

SCD software.

Application Recommended multiple sampling

Stationary under clean ambient conditions 2 times

Vertical applications 2 times

Mobile 4 times

Stationary under dusty ambient conditions 8 times

Using multiple sampling you can increase the availability of a system.

You can configure the multiple sampling in the SCD software. You can set individual multiple sampling for each

monitoring case.

Stand-by mode

If, in mobile applications, vehicles are not moved for a time (e.g. for battery charging), the OSSDs can be switched to the

OFF state and the laser on the SafeZone Mini can be switched off. In this way the power consumption of the device is

reduced.

In this way you also prevent the safety laser scanners from optically interfering with each other and entering an error

condition.

The function can be realized with the aid of the stand-by mode.

In order to switch to the stand-by mode, on the SafeZone Mini one universal I/O connection must be configured as stand-

by input. (see Chapter 4, “Universal I/O connections of the SafeZone Mini” on page 17).

A monitoring case is not occupied by the stand-by mode.

Note

Rockwell Automation Publication 10000337275 Ver 01—October 2014 23

Page 26

Chapter 5 Mounting

Mounting

This chapter describes the preparation and completion of the mounting of the SafeZone Mini safety laser scanner.

Mounting requires four steps:

• Definition of the application and the necessary mounting location for the safety laser scanner

• Calculation of the protective field sizes and minimum distances (see EN ISO 13855)

• Mounting the safety laser scanner with or without mounting kits

No protective function without sufficient minimum distance!

Only if you configure the protective field such that there is an adequate minimum distance to the hazardous area, is

protection by the SafeZone Mini ensured.

Mount the SafeZone Mini in a dry place and protect the device from dirt and damage.

Notes

Avoid the installation of the SafeZone Mini in the vicinity of strong electric fields. These can, e.g., be produced by

welding cables, induction cables in the immediate vicinity and also by mobile telephones operated nearby.

Ensure that there are no obstacles in the area to be monitored in the field of view of the S afeZone Mini that could cause

interference or shadowing. Such shadowed areas cannot be monitored by the SafeZone Mini. If there are unavoidable

shadowed areas, check whether there is a risk. Take additional safety precautions as necessary.

Keep the area to be monitored free of smoke, fog, steam or other forms of air impurities. There must not be any

condensation on the optics cover. Otherwise the function of the SafeZone Mini may be impaired and incorrect

switching may occur.

Avoid placing highly reflective objects in the scan plane of the SafeZone Mini. Examples: Retroreflectors can affec t the

measurement results of the SafeZone Mini. Highly reflective objects within the protective field can blank a part of the

area to be monitored in certain circumstances.

Mount the SafeZone Mini such that it is not saturated by incident sunlight. Do not position stroboscopic and

fluorescent lights or other strong light sources directly in the scan plane as these may affect the SafeZone Mini in

specific circumstances.

Mark the protective field on the floor, if this is reasonable for the application (see EN 614961 in Chapter 7).

Chapter 5

Stationary application in

horizontal operation

Fig. 14: Horizontal stationary application

The following steps are necessary after mounting:

• Completing the electrical connections (Chapter 6, “Electrical installation”)

• Configuration of the protective field (Chapter 8, “Configuration”)

• Commissioning and checking of the installation (Chapter 9, “Commissioning”)

• Checking the function and safe shutdown (Chapter 9, “Test notes”)

This type of protective device is suitable for machines and systems on which, e.g. a hazardous area is not completely

enclosed by a guard.

24 Rockwell Automation Publication 10000337275 Ver 01—October 2014

Page 27

Chapter 5 Mounting

Dangerous state

K x (1

M

+ 1s)

2

G

+ 2R + O

S

For a horizontal stationary application determine …

• The protective field size to observe the necessary minimum distance.

• The height of the scan plane.

• The restart behavior.

• Measures to protect any areas not covered by the SafeZone Mini.

Once you have defined the protective field size, mark the boundaries of the protective field on the floor. In this way you

Note

will make the protective field boundaries visible for the operator and ease subsequent testing of the protective function.

Protective field size

The protective field must be so configured that a minimum distance (S) to the hazardous area is maintained. This safety

distance ensures that the hazardous point can only be reached after the dangerous state of the machine has been

completely stopped.

You can operate the SafeZone Mini in stationary horizontal operation with 30, 40, 50, or 70 mm (1.2, 1.6, 2.0, or 2.8 in.)

Note

resolution. The maximum protective field range for the SafeZone Mini is given by the resolution.

ATTENTION

Fig. 15: Minimum distance S

Ensure that a human leg can be detected with 70 mm (2.8 in.)resolution!

As per EN ISO 13855, mount the scan planes for horizontal stationary applications with 70 mm (2.8 in.) resolution at least

300 mm (11.8 in.) above the floor (see “Height of the scan plane at 70 mm resolution” on page 33).

The minimum distance S depends on:

• Approach speed of the body or parts of the body

• Stopping/run-down time of the machine or system

(The stopping/run-down time is shown in the machine documentation or must be determined by taking a

measurement.)

• Response time of the SafeZone Mini

• Supplements for general measurement errors and any measurement errors related to reflection

• Supplement for prevention of reaching over

• Height of the scan plane

• Possibly the time for switching between the monitoring cases

How to calculate the minimum distance S (see EN ISO 13855):

First, calculate S using the following formula:

S=(K×(T

+ TS)) + ZG + ZR + C

M

Where …

K = Approach speed (1600 mm/s (63 in./s), defined in EN ISO 13855)

T

= Stopping/run-down time of the machine or system

M

T

= Response time of the SafeZone Mini and the downstream controller

S

Z

= General safety supplement of the SafeZone Mini = 100mm (3.94 in.)

G

Z

= Supplement for measurement error related to reflection

R

C = Supplement for prevention of reaching over

Rockwell Automation Publication 10000337275 Ver 01—October 2014 25

Page 28

Chapter 5 Mounting

C = 1200 (47.2) C = 850 (33.5) C = 850 (33.5)